KEYENCE XG-8000 User Manual

1

Multi Camera High Performance Machine

Vision System

XG-8000 Series

Controller Instruction Manual

Read this manual thoroughly before using the XG-8000 Series.

Always keep this manual in a safe place for future reference.

This manual describes the hardware information. Read this manual

thoroughly to understand the performance and functions of the “Multi

Camera High Performance Machine Vision System XG-8000 Series”

in order to maximize the performance of the system.

• This manual covers the XG-8000 Series. All references, unless

otherwise noted, pertain to the XG-8000(P)/8002(P)/8500(P)/

8502(P)/8700(P)/8702(P)/8800(P)/8802(P)/8500L(P)/8502L(P)/

8700L(P)/8702L(P)/8800L(P)/8802L(P). Except when indicated

otherwise, the explanations will use the XG-8700 as the standard.

For more details on the differences between the models, see

“Main Specifications” (page 9).

• Always keep this manual in a safe place for future reference.

• Ensure that the manual is passed to the end user in case of

transfer of the unit.

Trademarks

• “SD Memory Card” is a registered trademark of the SD

association.

• Other company names and product names are registered

trademarks or trademarks of their respective companies.The TM

mark and ® mark are omitted in this manual.

Concerning the Library and Program

libjpeg

Copyright ©1991-2010, Thomas G. Lane.

This software is based in part on the work of the Independent JPEG

Group.

The equipment and accessories listed below are included in the

package when shipped. Upon opening the carton, check that you

have received all of the equipment and accessories listed below.

Standard Package

• Controller Unit x 1

(XG-8000(P)/8002(P)/8500(P)/8502(P)/

8700(P)/8702(P)/8800(P)/8802(P)/

8500L(P)/8502L(P)/8700L(P)/8702L(P)/

8800L(P)/8802L(P), whichever is

appropriate)

•SD card

(XG-8000(P)/8002(P)/8500(P)/8502(P)/

8500L(P)/8502L(P): OP-87133(512MB),

XG-8700(P)/8702(P)/8800(P)/8802(P)/

8700L(P)/8702L(P)/8800L(P)/8802L(P):

CA-SD1G (1GB)) x 1

(already installed in the SD card slot (lower) of the controller)

• Controller instruction manual (This manual: one part Japanese,

one part English)

• Terminal block sticker package x 1

• Ferrite core for RS-422 use x 1 (only for the XG-8500L(P)/

8502L(P)/8700L(P)/8702L(P)/8800L(P)/8802L(P))

Introduction

Package Contents

96M13087

2

Symbols

The following warning symbols are used to ensure safety and to prevent

human injury and/or damage to property when using the system.

Warning

Indicates that the operator is at risk of physical injury if the system is

improperly operated or this precaution is not followed.

Caution

Indicates that property could be damaged (product malfunction, etc.)

if the system is improperly operated or this precaution is not

followed.

Indicates important operating procedures that could be easily

overlooked.

It indicates tips for better understanding or useful information.

General Cautions

• Before starting work or before starting the system, confirm that all

the functions of the system are working properly.

• If any KEYENCE product fails, take full safety measures to prevent

damage before using the system again.

• If the system is used beyond published specifications or if the

system is modified, the functions and performance cannot be

guaranteed.

• Please note that when the system is used in combination with

other instruments, its functions and performance may be

degraded.

• Do not use this product for the purpose to protect a human body

or a part of human body.

• This product is not intended for use as explosion-proof product.

Do not use this product in hazardous location and/or potentially

explosive atmosphere.

• Do not subject this unit or connected devices to a sudden change

of temperature, as condensation may occur.

Warning

General

• Do not use with any power voltage other than 24 V DC. Doing so

may cause fire, electric shock, or product malfunction.

• Do not disassemble or modify this unit. Doing so may cause fire or

electric shock.

Operating environment and conditions

• To use the system properly and safely, avoid installing this unit in

the following locations: Doing so may cause fire, electric shock, or

product malfunction.

– Locations that contain moisture or dust, or that are poorly

ventilated.

– Locations where the system is exposed to direct sunlight or

temperature increases.

– Locations where there are flammable or corrosive gases.

– Locations where the unit may be directly subjected to vibration

or impact.

–

Locations where water, oil or chemicals may splash onto the unit.

– Locations where static electricity occurs.

• Keep this unit and cables away from high-tension cables or power

lines. Otherwise, noise may cause malfunction or accidents.

• Bundle cables with a spiral tubing material. Direct bundling will

concentrate the cable load on the bindings, which can result in

cable damage or short circuit.

• This unit and optional devices are precision components. Do not

subject them to vibration or impact.

Measures to be taken when an abnormality occurs

In the following cases, turn the power OFF immediately. Using the

unit in an abnormal condition may cause fire, electric shock, or

product malfunction. Contact your local KEYENCE office for repair.

• If water or debris enters the system

• If the system is dropped or the case is damaged

• If smoke or a burning smell emits from the system

Caution

Usage

• Before making any connections/disconnections, be sure to turn off

the power of this unit and connected devices. Failure to do so may

result in malfunction of the system or connected devices.

• Do not turn the power off while you are programming. Otherwise,

all or part of the program settings may be lost.

• Do not block the ventilation holes. Otherwise, the inside

temperature may rise and malfunction may occur.

• Do not allow an excessive amount of sunlight or bright indoor light

to enter the camera for a long period of time. Doing so may cause

damage to the imaging area inside the camera.

• Do not use the controller, cameras, and options in any

combination other than that specified by Keyence. Doing so may

cause failure or malfunction.

Note

Maintenance

• Do not clean with benzene, thinner, or alcohol.

• Doing so may cause discoloration or deformation of the unit. If the

unit has any dirt on it, wipe it off with a cloth moistened with a mild

detergent, then wipe with a dry cloth.

CE Marking

KEYENCE evaluates compliance with the requirements of the EC

directive according to how products fulfill the below conditions.

KEYENCE has confirmed that the XG-8000 Series meets these

requirements. When the XG-8000 Series is used in EU nations, take

note of the following precautions.

EMC Directive (2004/108/EC)

• Applicable Standard EMI: EN61326-1, Class A

EMS: EN61326-1

• Use cables shorter than 30 m to connect the controller unit and its

external devices.

• When connecting a CC-Link unit CA-NCL10E, attach a ferrite core

(OP-84364, optional) within 300 mm on the CA-CNL10E side of

the CC-Link dedicated cable.

• When using the RS-422, attach the included ferrite core

(ZCAT2035-9030A) within 300 mm on the controller side of the

cable.

• When the XG-8800/8802/8800L/8802L is connected with 5 or

more Ultra-compact cameras (XG-S035C/S035M or XG-S200C/

S200M), attach a ferrite core (OP-87476, optional) to the all

cables from the camera control units to the CCD within 100 mm

on the camera control unit side.

However, these precautions do not guarantee that the customer’s

entire machinery installation is compliant with the EMC Directive.

The customer is responsible for determining the compliance of the

overall machinery installation.

Safety Precautions

Note

Reference

Precautions on Regulations and Standards

3

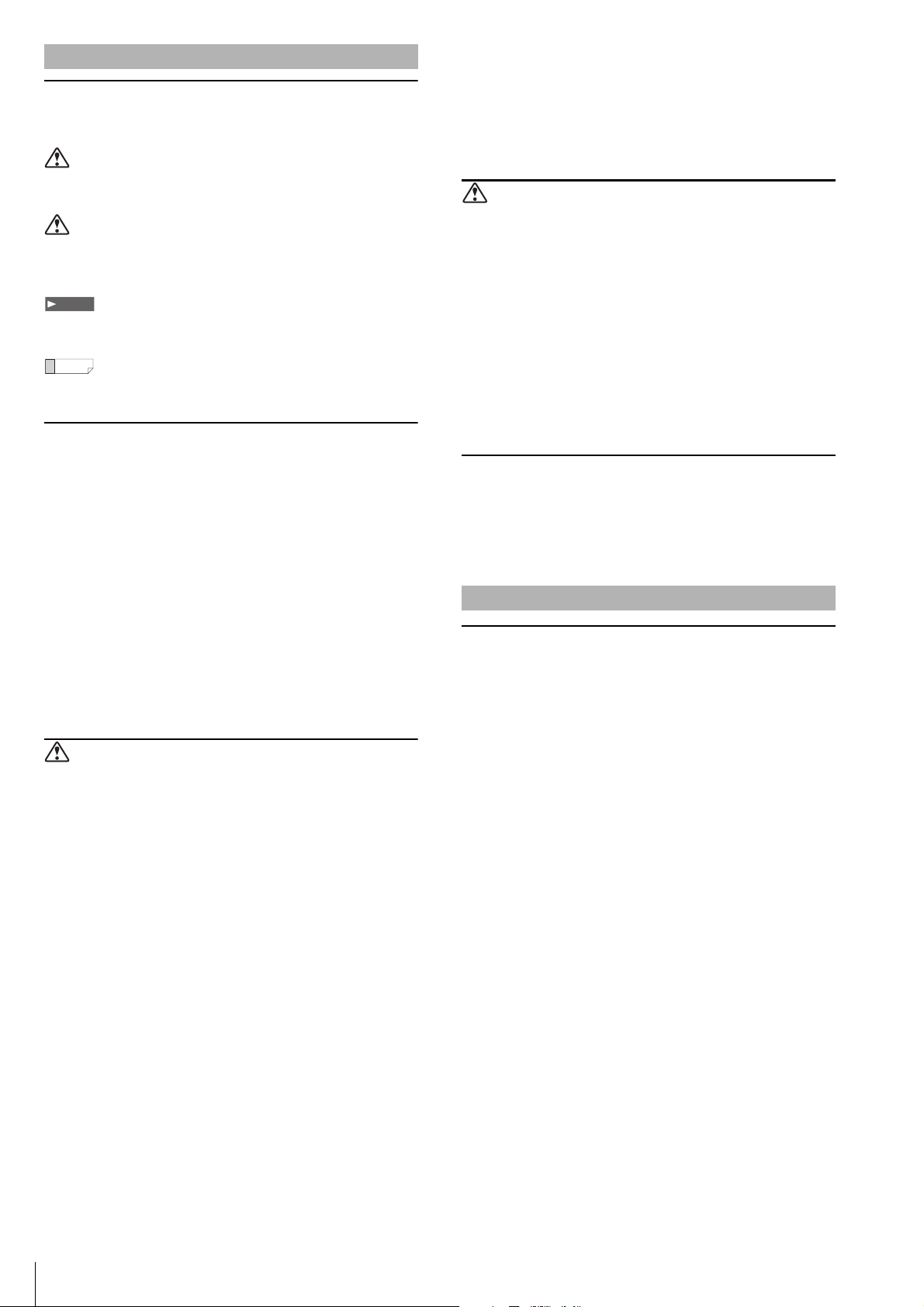

XG-8700/8702/8500/8502/8000/8002

XG-8700L/8702L/8500L/8502L

XG-8800/8002/8800L/8802L

1 Parallel I/O connector

Use to connect the parallel input/output signals.

2 SD2 slot (upper), SD1 slot (lower)

Insert an SD card.

The lower slot (SD1) holds the included SD Card (CA-SD1G: 1GB,

or OP-87133: 512MB) as SD Card 1.

SD Card 1 must be inserted while the device is operating.

3 Camera Slot

Connect the camera input unit.

• The Camera Input Unit (CA-EC80: Area Scan Camera, or

CA-EC80L: Line Scan Camera) is connected to the slot at the

time of shipping.

• The XG-8800(P)/8802(P)/8800L(P)/8802L(P) have 3 free slots.

The user can add camera input units according to need.

• Camera input unit CA-EC80HX cannot be used with the XG-8800L(P).

Camera input unit CA-EC80HX/CA-EC80L/XG-EC80L cannot be used with

the XG-8800(P).

• If the firmware of the camera input unit is old, an error message will be

displayed at the startup of the device (Ver.5.0.0020 or later). In this case,

execute an update with the latest firmware with the camera input unit

attached.

4 CONSOLE (Modular) connector

Use to connect to the console (OP-84231/OP-84236, optional) or to

the console connector cable (OP-87260: 3 m/OP-87261: 10 m,

optional).

5 MONITOR (RGB output) terminal

Use to connect to an Analog RGB Monitor.

• When using a commercially available Analog RGB Monitor other than the

SVGA (800 x 600 pixels), or XGA (1024 x 768 pixels), due to the

specifications of the Monitor, the image quality may become worse or the

screen may not display correctly (recommended monitor: CA-MP120T/

CA-MP120/CA-MP81).

• When a program setting where XGA output is set is used in the main unit,

always connect a monitor that supports the XGA. When using a monitor

that supports the SVGA only, the screen may not display correctly.

6 CAMERA 2 connector (only when CA-EC80/XG-EC80

installed)

Connect Camera 2. When the XG-EC80HX/CA-EC80L/XG-EC80L

is installed only Camera 1 is connected.

7 USB connector

Use to connect to the USB cable.

8 Expansion unit connector 1 (right side)

Use to connect the camera expansion unit CA-E800/XG-E800.

9 CAMERA 1 connector

Use to connect to the camera 1.

10 RS-232C Port 2

Connect the RS-232C Cable for the Touch Panel (OP-87258: 3 m/

OP-87259: 10 m, optional) or a commercially available RS-232C

Cable (D-sub9 Pin female).

11 RS-232C Port 1

Connect the RS-232C Communication Cable (OP-26487: 2.5 m,

optional) or the RS-232C Modular Cable for the Touch Panel

(OP-87264: 3 m/OP-87265: 10 m, optional).

For the default settings of the RS-232C Port: Port 1 is for data output and

command control, and Port 2 is for CA Series Touch Panel use. Concerning

changes in the settings refer to the XG-8000 Series User’s Manual.

12 Ethernet connector

Use to connect the Ethernet cable.

13 OUT1/IN1 Connector (Terminal Block 1)

Use the signal Input/Output (OUT1/IN1).

14 Power Source/Grounding Terminal

Connect the power supply (24 VDC) and the grounding wire.

15 Expansion unit connector 2 (left side)

Use to connect the illumination expansion unit CA-DC30E/DC21E or

CC-Link unit CA-NCL10E.

• The CA-DC30E cannot be connected to the XG-8800(P) or XG-8800L(P).

• When the illumination expansion unit CA-DC20E is connected, flash control

is limited to FLASH1-4.

16 IN2/OUT2 Connector

(Terminal Block 2, XG-8500L(P)/8502L(P)/8700L(P)/8702L(P)/

8800(P)/8802(P)/8800L(P)/8802L(P) only)

Use for the Input/Output signal (IN2/OUT2).

Identifying Controls and Connectors

1

2

4

3

5

6

7

8

9

10

11

12

13

14

15

16

3

Note

Note

Note

Reference

Note

4

Install the controller unit to DIN rail, or use the holes on the bottom of

the controller to secure it with screws.

• Do not install the XG in a location with lots of dust or water vapor. The XG

does not have a mechanism to protect the XG from dust or water. Dust or

water entering the controller can cause damage to the XG.

• Turn off the power to the controller when connecting or removing an

expansion unit, a cable, or a terminal block. Connecting or removing the

camera expansion unit, the cable, or the terminal block while the power is

being supplied may damage the controller or peripheral devices.

• When an expansion unit is not connected, place the connector protection

cover back on the controller. Using the controller with the connector

exposed may cause damage to the controller.

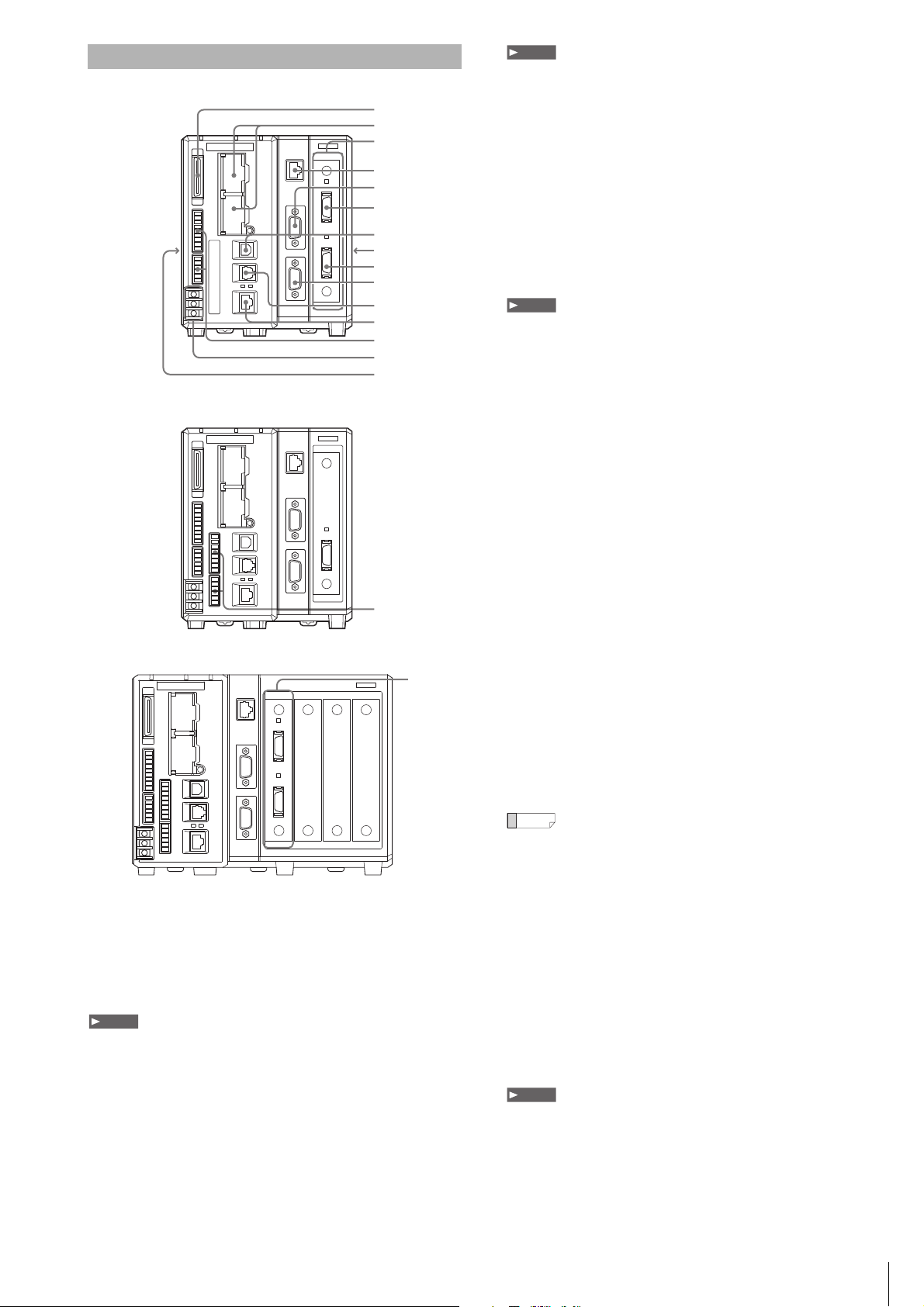

Caution on Direction of Controller Mounting

• Install the controller in the direction indicated by the circle as

shown below. Do not install the controller in any other direction.

• For ventilation, keep the space free of objects for 50 mm or more

above the controller and 50 mm or more for both sides. Keep the

space free of objects for 90 mm or more in the front of the

connector panel to connect the cables safely.

• When two or more controllers are installed side by side, keep the

space free of objects for 50 mm or more between controllers, and

50 mm or more on top of both controllers.

• Do not block the ventilation openings on the top and bottom of the

controller. If the vents are blocked, heat is accumulated inside the machine

and can cause system failure.

• If the temperature inside the control panel (temperature at the upper part of

the front surface of the controller) exceeds the rating, use forced air-cooling

or increase the free space around the system to improve ventilation until the

operating ambient temperature drops below the rating.

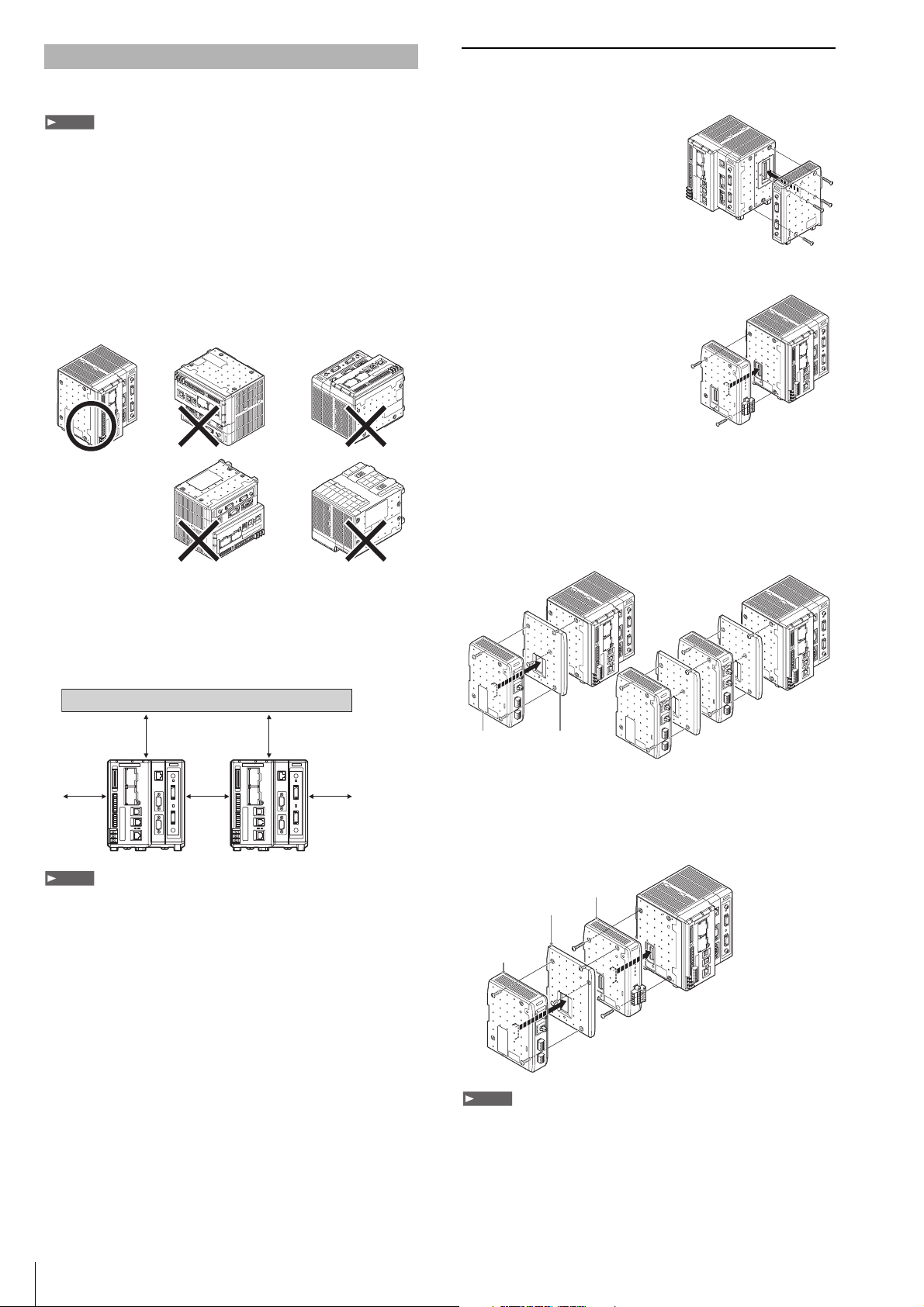

Installing the Expansion Unit

Installing the Camera Expansion Unit

(Excluding the XG-8800(P)/8802(P)/8800L(P)/8802L(P))

When connecting three or more

cameras, after connecting the optional

Camera Input Unit to the optional

Camera Expansion Unit CA-E800/

XG-E800, install to the controller.

After detaching the protection sticker

of connector 1 to the right side of the

main controller, install the Camera

Expansion Unit.

Installing the Communication Expansion Unit

The optional CC-Link expansion unit

CA-NCL10E is used when

communicating with CC-Link devices.

Remove the protective cover of

connector 2 from the left side of the

controller and install the CC-Link

expansion unit.

Installing the Illumination Expansion Unit

A combination of up to 4 CA-DC21E and CA-DC30E illumination

expansion units (sold separately) may be connected for control of up

to 8 individual lighting units. However, a maximum of 2 CA-DC30E

units may be connected for control of up to 4 individual lighting units.

Remove the protective cover of connector 2 from the left side of the

controller and install the illumination expansion unit as shown below.

When using the illumination expansion unit and CC-Link unit

simultaneously

Mount the CC-Link unit CA-NCL10E directly to the controller, then

mount the illumination expansion unit to the left side of the CC-Link

unit.

• Turn off the power to the controller when connecting or removing each

expansion unit. Connecting or removing the each expansion unit while the

power is being supplied may damage the controller or peripheral devices.

• When an expansion unit is not connected, place the connector protection

cover back on the controller. Using the controller with the connector

exposed may cause damage to the controller.

• It is necessary to mount the supplied attachments before mounting the

illumination expansion unit.

Installing the Controller Unit

Note

50 mm

50 mm 50 mm

50 mm

50 mm

Note

When connecting

multiple units

OUT

IN

PO

WER

LIGHT 2

4

3

2

1

LIGHT 1

4

3

2

1

OUT

IN

PO

WER

LIGHT 2

4

3

2

1

LIGHT 1

4

3

2

1

Attachment

(Supplied to

the illumination expansion unit)

Illumination

expansion unit

OUT

IN

PO

WER

LIGHT 2

4

3

2

1

LIGHT 1

4

3

2

1

OUT

IN

P

O

WER

LIGHT 2

4

3

2

1

LIGHT 1

4

3

2

1

Attachment (Supplied to

the illumination expansion unit)

Illumination

expansion unit

CC-Link unit

CA-NCL 10E

Note

Loading...

Loading...