Owners

Manual

FOR POTABLEWATER

HEATING ONLY

NOT SUITABLE FOR

SPACEHEATING

NOT FOR USE IN

MOBILE HOMES

Model No.

153.337113

153.337162

153.337213

153.337262

153.337362

153.337413

153.337462

153.337513

153.337562

153.337613

153.337662

153.337762

153.337862

153.337960

CauUon:

Read and Follow

All Safety Rules and

Operating Instructions

Before First Use of

This Product.

50 Gal. Short High Altitude

50 Gal. Short

40 Gal. Short High Altitude,

40 Gal. Short

30 Gal.

40 Gal. High Altitude

40 Gal.

50 Gal. High Altitude

50 Gal.

65 Gal, High Altitude

65 Gal.

50 Gal. High Recovery

65 Gal. High Recovery

40 Ga!.(LP.)

POWER MISERTM9

GAS WATER H EATER

• Safety Instructions • Care and Maintenance

• Installation • Troubleshooting

• Operation • Parts List

For Your Safety

AN ODORANT IS ADDED TO THE GAS USED BY THIS

WATER HEATER

WARNING: If the information in these instructions are not fol-

lowed exactly, a .fire or explosion may result, causing property

damage, personal ,nlury or death.

-Do not store or use gasoline or other flammable vapors and liq-

uids in the vicinity of t_is or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electr,'cal switch; do not use any phone in your

building. . .

Immediately call your I_as supp.her from a ne,ghbor's phone.

i Follow gas suppliers instructions.

If you can not reach your gassuppl,er, call the fire department.

-Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

Improper installatmn, adlus_on , service or maintenance I

can cause DEATH, SERIOUS BODILY INJURY, OR PROPERTY DAM- I

AGE. Refer to this manual for assistance or consult the local Sears I

Service Center or gas utility for further reformation. J

the

AWARNING

• .

]

Savethis Manual for Future Reference.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Flammable vapors may be drawn by air currents from other areas

of the structure to this appliance.

&WARNING t

AWARNING

READ THE GENERAL SAFETY SECTION BEGINNING ON INSIDE

COVER AND THEN THIS ENTIRE MANUAL BEFORE INSTALLING

OR OPERATING THIS WATER HEATER•

Safety Precautions

AWARNING

Improper installation, adjustment, alteration, service or I

maintenance can cause DEATH, SERIOUS BODILY

INJURY, OR PROPERTY DAMAGE. Refer to this manu-

al for assistance or consult your local Sears Service

Center for further information. I

AWARNING

WATER HEATERS EQUIPPED FOR ONE TYPE GAS

ONLY: This water heater is equipped for one type gas

only. Check the model rating plate near the gas control

valve for the correct gas. DO NOT USE THIS WATER

HEATER WITH ANY GAS OTHER THAN THE ONE

SHOWN ON THE MODEL RATING PLATE. Failure to

usethe €orrect gascan cause problems which can result in

DEATH, SERIOUS BODILY INJURY, OR PROPERTY

DAMAGE. If you have any questions or doubts consult

your gassupplier or local utility.

4WARNING

INSTALLATIONS IN AREAS WHERE FLAMMABLE LIQ-

UIDS (VAPORS) ARE LIKELY TO BE PRESENT OR

STORED (GARAGES, STORAGE, AHD UTILITY AREAS,

ETC): Flammable liquids (such as gasoline, solvents,

propane (LP) or butane, etc.), all of which emit flammable

vapors, may be improperly stored or used in such areas.

The gas water heater pilot tightor main burner can ignite

such vapors. The resulting flashback and fire can cause

death or serious burns to anyone in the area, _ well as

property d_magn, i

If installation in such areas isyour only option, then the

installation must be accomplished in a way that the pilot

flame and main burner flame are elevated from the floor

at least 18 inches. While this may reduce the chancesof

!flammable vapors from a floor spill being ignited, gasoline

iand other flammable substancesshould never be stored or

used in the same room or erda containing a gas water

heater or other open flame or spark producingappliance.

NOTE: Flammable vapors may be drawn by air currents

from other areas of the structure to the appliance.

AWARNING

If this water heater will be used in beauty shops, barber

shops, cleaning establishments, or self-service laundries

with dry cleaning equipment, it is imperative that the

water heater or water heaters be installed so that €om-

bustion and ventilation air be taken from outside these

areas, Refer to the "Facts to Consider About the

Location" section of this manual and also the latest edi-

tion of the National Fuel Gas Code, ANSI Z223.1, also

referred to as NFPA 54 for specifics provided concernin

air required,

I A WARNING . I

A fire can start if combustible materials such as cloth,ng,

cleaning ma_, or flamm_de liquids are placed againstI

or next to the water heater. [

AWARNING

At the time of manufacture this water heater was provid-

ed with a combination temperature-pressures relief valve

certified by a nationally recognized testing laboratory

that maintains periodic inspection of production of listed

equipment or materials, as meeting the requirements

for Relief Valves and Automatvc Gas Shutoff Devices for

Hot Water Supply Systems, and the latest edition of

ANSI Z21.22 and the code requirements of ASHE. If

replaced, the valve must meat the requirements of local

codes, but not lessthan a combination temperature and

pressure relief valve certified as meeting the require-

ments for Relief Valves and Automatic Gas Shutoff

Devices for Hot Water Supply Systems, ANSI Z21.22 by

a nationally recognized testing laboratory that maintains

periodic inspection of production of listed equipment or

materials.

The valve must be marked with a maximum set pressure

not to exceed the marked hydrostatic working pressure

of the water heater (I 50 IbsJsq. in.) and a discharge

capacity not less than the water heater input rate as

shown on the model rating plate. (Electric heaters -

watts divided by 1000 x 3415 equal BTU/Hr. rate.)

[Your local jurisdictional authority, while mandating the

use of a temperature-pressora relief valve complying

with ANSI Z21.22 and ASME, may require a valve model

different from the one furnished with the water heater.

Compliance with such local requirements must be satis-

fied by the installer or end user of the water heater with

a locally prescribed temperature-pressure relief valve

installed in the designated opening in the water heater in

place of the factory furnishedvalve.

For safe operation of the water heater, the relief valve

must not be removed from it's designated opening or

plugged.

Tho temperatere-pressore relief valve must be installed

directly into the fitting of the water heater designated

for the relief valve. Position the valve downwlu_l and pro-

vide tubing so that any discharge will exit only within 6 i

inches above, or at any distance below the structural

floor. Be certain that no contact is made with any live

electrical part. The discharge opening must not be

blocked or reduced in size under any circumstances.

Excessivelength, over 30 feet, or use of more than four

elbows can cause restriction and reduce the discharge

capacity ofthe valve.

No valve or other ebstxuction is to be placed between

the relief valve and the tank. Do not connect tubing

ditec_ to discharge drain unlessa 6" air gap isprovided.

To prevent bodily injury, hazard to life, or property dam-

age, tho relief valve must be allowed to discharge water

in quantities should circumstances demand. If the dis-

charge pipe is not connected to a drain or other suitable

means, the water flow may cause property damage.

The Discharge Pipe:

• Must not be smaller in size than the outlet pipe size of

the valve, or have any reduclng couplings or other

restrictions.

Must not be plugged or blocked.

Must be of"material listed fur hot water distribution.

Must be installed so as to allow complete drainage of

both the temperature-pressure relief valve, and the

dischargel_e,

Must terminate at an adequate drain,

Host not have any valve between the relief valve and

tank.

Safety Precautions

_,WARNING

A gaswater heater cannot operate properly without the

correct amount of air for combustion. Do not install in a

confined area such a closet, unless you provide air as

shown inthe "Facts to Consider About the Location" sec-

tion. Never obstruct the flow ofventilation air. If you have

any doubts or questions at all, call your gas company.

Failure to provide the proper amount of combustion air

can result in a fire or explosion and can CAUSE DEATH,

SERIOUS BODILY INJURY,OR PROPERTY DAMAGE.

AWARNING

HOTTER WATER CAN SCALD: Water heaters are

intended to produce hot water. Water heated to a tern-

perature which willsa_ clotheswashing, disk washing,

and other sanitizing needs can scald and permanently

injure you upon €ontac_ Some people ace more likely to

be permanently injured by hot water than other_ These

include the elderly,children, the infiPm,or physicailyimen-

tally handicapped.If anyone usinghot water in your home

fits into one of these groupsor if there Is a local code or

state Ilw requiring a certain temperature water at the hot

water tap, then you must take specialprecautions, In addi-

tion to usingthe lowest possible temperature setting that i

satisfiesyour hot water needs, a means suchas a mixing I

valve, shouldbe used at the hot water tapsused by these

people or at the water heater. Mixing valvesare available

at plumbing supply or hardware stores. Follow manufac-

turers instructions for installation of the valves. Before

changingthe fa_)ry setting on the thermostat, read the

'_l'emperature Regulation" sectionin this manual.

A,WARNING

Soot build-up Indicates a problem that requires correc-

tion before further use, Turn "OFF" gas to water heater

and leave "OFF" until repairs are made, because failure

to correct the causeof the sooting can result in s fire or

Iexplosion causing DEATH, SERIOUS BODILY INJURY,

OR PROPERTY DAMAGE.

_WARNING

This water heater must not be installed directly on car-

Feting. Cerpe_ag must be protected by a metal or wood

panel beneath the appliance extending beyond the full

width and depth of the appliance by at least 3 inches

(76.2mm) in any direction, or iftbe appliance is installed

in analcove or c oset, the entire floor must be coveredby

the panel. Failure to heed this warning may result in a

Ere hazard.

AWARNING

VENT DAMPERS - Any vent damper, whether it is operat-

ed thermally or otherwise must be removed if Its use

inhibitsproper drafting of the water heater.

Thermally Operated Vent Dampers: Gas-fired water

heaters having thermal efficiency in excess of 80% may

*roduce a relatively low flue gastemperature. Such tem-

peratures may not be high enough to properly open ther-

mally operated vent dampers. This would causespillageof

flue gasesand may causecarbon monoxide poisoning.

Vent dampers must bear evidence of certification ascom-

plying with the latest edition of American National

Standard ANSI Z21.68(ANSI Z21.66 & 67, respectively,

cover electrically and mechanically actuated vent

I

dampers). Before installation of any vent damper, consult

your local Sears Service Center or the gas utility for fur-

ther nformat on.

AWARNING

•The appliance and its Individual shutoff valve must be dis.

connected from the gall supply piping systemduring any

pressure testing of the gas system at test pressures In

excessof '/2pound per square inch (3.$kPa).

•The appliancemust be isolatedfrom the gassupplypip-

ing system by closing its individual manual shutoffvalve

during any pressuretesting of the gas supply pipingsys-

tem at test pressures equal or lessthan '/2pound per

square Inch (3.SkPa).

_,WARNING

BEFORE LIGHTING [PROPANE (L.P.) GAS WATER

HEATERS): Propane (L.R) gas is heavier than air. Should

there be a leak In the system, the gas will settle near the

ground. Basements, crawl spaces, skirted areas under

mobile homes (even when ventilated), closets and areas

below ground levelwill serve as pockets fur the accumula-

tion of this gas. Before attempting to light or relight the

water heater's pilot or turning on a nearby electrical light

switch, be absolutely sure there is no accumulated gas In

the aceL Search for odor of gasby sniffingat ground level

in the vicinity of the appliance. If odor is detected, follow

steps indicated at "For Your Safety" on the cover page of

this manualthen leavethe premises.

AWARNING

Chemical vapor corrosion of the flue and vent system

may occur if air fur combustion contains certain chemical

vapors.Spraycan propellants, cleaning solvents,refrigera-

tor and air conditioner refrigerants, swimming pool

chemicals, calcium and sodium chloride, waxes, bleach,

and process chemicals are typical compounds which are

potentially corrosive.

I _,WARNING

Obstructedor deterioratedvent systems maypresenta

serioushealthriskor asphyxiation.

Safety Precautions continuedon page4.

3

Safety Precautions

I A,WARNING J

The water heater with draft hood installed must be prop-[

erly vented to a chimney which terminates outdoors.]

Never operate the water heater unlessit is vented to the]

outdoors and has adequate air supply to avoid risks of[

Improper operation, explosionor asphyxiation. [

AWARNING

Minimum clearancesbetween the water heater end com-

bustiblecon_ction am I" at the sidesand rear, 4" at the

front, and 6 from the vent pipe. Clearence from the top

of the jacket is 18" on most models. Note that a lesser

dimension may be allowed on some models. Refer to the

label on the water heater adjacent to the gascontrol valve

for all clearances.

I &WARNING I

Do not use this _opllence if any part of It hasbeen under I

water, immediately call a Sears Service Technician to I

inspect the appliance andto replace the gas control or any J

part of the burner system which hasbeen under water. I

&WARNING

HYDROGEN GAS: Hydrogengas canbe producedIn a hot

water system that hasnot been used for a long period of

time (generally two weeks or more). Hydrogen gas is

exVemelyfl_mma_e _d mq_s_e. Topreventthe pem-

bility of injury under these conditions, we recommend the

hot water faucet be opened for several minutes at the

kitchen sink before any electrical appliances which

connected to the hot water system are used (suchas a dis-

hwasher or washingmachine). If hydrogen gasis present,

there will probably be an unusual sound similar to air

escaping through the pipe as the hot water faucet Is

opened. There must be no smoklnfl or open R_umenear

the faucetat the time It is open.

ACAUTION

WATER HEATERS EVENTUALLY LEAK: Installation of

t_ water heater must be accomplishedin such a manner

that Iftho tank or any connectionsshouldleak, the flow of

water will not causedamage to the structure. When such

locations cannot be avoided, a suitable drain pan should

be instal ed under the water heater. Drain pans are wall.

at ynor load Sun s_re. Such a drain pan must be

not greater than 1½ Inchesdeep, havea minimum length

and width of at least 2 Inches greater than the water

heater dimensions and must be piped to an adequate

drain. The pan must not restrict combustion air flow,

Under no clrcumstencesis the manufectumr or Sears to

be held liable for any water damage in connection with

this water heater.

AWARNING

INSULATING JACKETS: When installing an external

water heater insulationjacket on a p.s water heater:

• DO NOT cover the temperature-pressure relief valve.

• DO NOT put Insulation over any part of the top of the

gaswater heater.

• DO NOT put insulation overthe gascontrol wive or gas

control valve/burner coverpor any accessareas to the

burner.

• DO NOT let insulation around the gaswater heater to

get within 8 inches of the floor (air must get to the

burner).

• DO NOT cover or remove operating Instructions. and

safety related warning labels and materials affixedto tee

water heater.

Failure to heedthis will result In the pesslbility of a fire or

explosion.

4

Table of Contents

Safety Precautions ............................................................................................................................................2_

Table of Contents ................................................................................................................................................5

Customer

Product

T'_ ol_14e

Kesponslbllltles .......................................................................................................................6

_ o/,b .

_pecmcauons ..................................................................................................................................6

Materials and Basic Tools Needed ....................................................................i..........................7

Materials Needed ...................................................................................................................................................................... 7

Basic Tools ................................................................................................................................................................................ 7

Installation Instructions ........................................................................................................................8-16

Removing the Old Water Heater ............................................................................................................................................... 8

Facts to Consider About the Location ....................................................................................................................................... 9

Combustion Air and Ventilation for Appliances in Unconfined Spaces ................................................................................... 10

Combustion Air and Ventilation for Appliances in Confined Spaces ....................................................................................... 10

Water Piping ........................................................................................................................................................................... 11

Temperature-Pressure Relief Valve ........................................................................................................................................... 12

Filling the Water Heater ....................... ;.................................................................................................................................. 13

Venting .............................................................................................................................................................................. 13-14

Gas Piping ......................................................................................................................................................................... 14-15

Installation Checklist .............................................................................................................................................................. 16

_""t)peratmgInstructions .........................................................................................................................17-19

Eighting .........Z. ................................................................................................................................................................ 17-18

Temperature Regulation .......................................................................................................................................................... 19

Serviceand

Tank (Sediment) Cleaning_....................................................................................................................... 20

Venting System Inspection ...................................................................................................................................................... 20

Burner Inspection ................................................................................................................................................................... 20

Burner Cleaning ..................................................................................................................................................................... 20

L.E Gas Control Valve & Burner Assembly Replacement Information .................................................................................... 21

Draining ................................................................................................................................................................................. 21

Temperature-Pressure Relief Valve Operat on .............................................................................. 21

Drain Valve Washer Replacement ........................................................................................................................................... 22

Housekeeping ......................................................................................................................................................................... 22

Service .................................................................................................................................................................................... 22

ACtlustment ......................................................................................................................20-22

"_ -" -"lroubleshootlng Guide ........................................................................................................................23-25

Start Up Conditions ...............................................................................................................................................................v 23

Condensation ........................................................................................................................................................................ 23

Smoke/Odor ......................................................................................................................................................................... 23

Thermal Expansion ............................................................................................................................................................... 23

Strange Sounds ...................................................................................................................................................................... 23

Operational Conditions .......................................................................................................................................................... 24

Smelly Water ......................................................................................................................................................................... 24

Air in Hot Water Faucets ...................................................................................................................................................... 24

High Temperature Shut Off System ...................................................................................................................................... 24

Not Enough or No Hot Water .............................................................................................................................................. 24

Water is too Hot ................................................................................................................................................................... 24

Leakage Checkpoints .............................................................................................................................................................. 25

Parts Order List...............................................................................................................................................28-35

Customer Responsibilities

Thank You _or purchasinga Sears water heater.

Properly installed and maintained, it should give you years of

trouble free service. If you should decide that you want the new

water heater professionally installed by Sears call the local Sears

Service Center or any Sears store. They will arrange for prompt,

quality installation by Sears authorized contractors.

Abbreviations Found In This Instruction Manual

I.A,S. - International Approval Services, A Division of CSA

A.N.S.I, - American National Standards Institute

N.EEA. - National FirePrevention Association

AWARNING

This gas-fired water heater is design certified by the

International Approval Services, A Division of CSA under

American National Standard/C$A Standard for Gas Water

Heaters AN$ Z21.10.1 • CSA 4.1 (latest edition). The

installation must conform with this manual, Local Codes

and with the latest edition of the National Fuel Gas Code,

ANSI Z223.1.

This publication is available from y_ur local government or

public library, gas company, or by writing NFPA.

Batterymarch Park, Quincy, MA 02269.

• Read the _Safety Precautions" section, pages 2 through 4 of

this,manual first and then the entire manual carefiflly. If you

dont follow the safety rules, the water heater will not operate

properly. It could cause DEATH, SERIOUS BODILY

INJURY AND/OR PROPERTY DAMAGE.

This manual contains instructions for the installation,opera-

tion, and maintenance of the gas-fired water heater. It also

contains warningsthrough out the manual that youmust read

and be awareoffAll warnings andall instructionsareessential

to the proper operation of the water heater and your safety.

Sincewe cannot put everythingon the first few pages,READ

THE ENTIRE MANUAL BEFORE ATTEMPTING TO

INSTALLOR OPERATETHEWATERHEATER.

• The installation must conform with the instructions in this

manual; gas company rules; and Local Codes, or in the

absenceofLocalCodes,with the latestedition ofthe National

FuelGas code, ANSI Z223.1, also referredto as NFPA 54.

This publication is available from your local governmentor

public library or gas company or by writing NFPA,

BattcrymarchPark,Quincy,MA02269.

• If a_er reading this manualyou haveany questions ordo not

understand any portion of the instructions, call the Sears

ServiceCenter.

• _y plan the placewhere you are going to put the water

heater. Correct combustion, vent action, and ventpipe instal-

htion are very importan_ in preventing dear from possible

cathon monoxidepoisoningand fires.

Examinethe locationto ensure the water heatercomplies with

the _Facrsto Consider About the Location"section in this

manual.

• For California installation this water heater must be braced,

anchored, or strapped to avoid failing or moving during an

earthquake. See instructionsfor correct installation proce-

dures.Instructions may be obtained from your local dealer,

wholesaler,public utilities or California Office of the State

Architect,400 P Street,Sacramento, CA 95814.

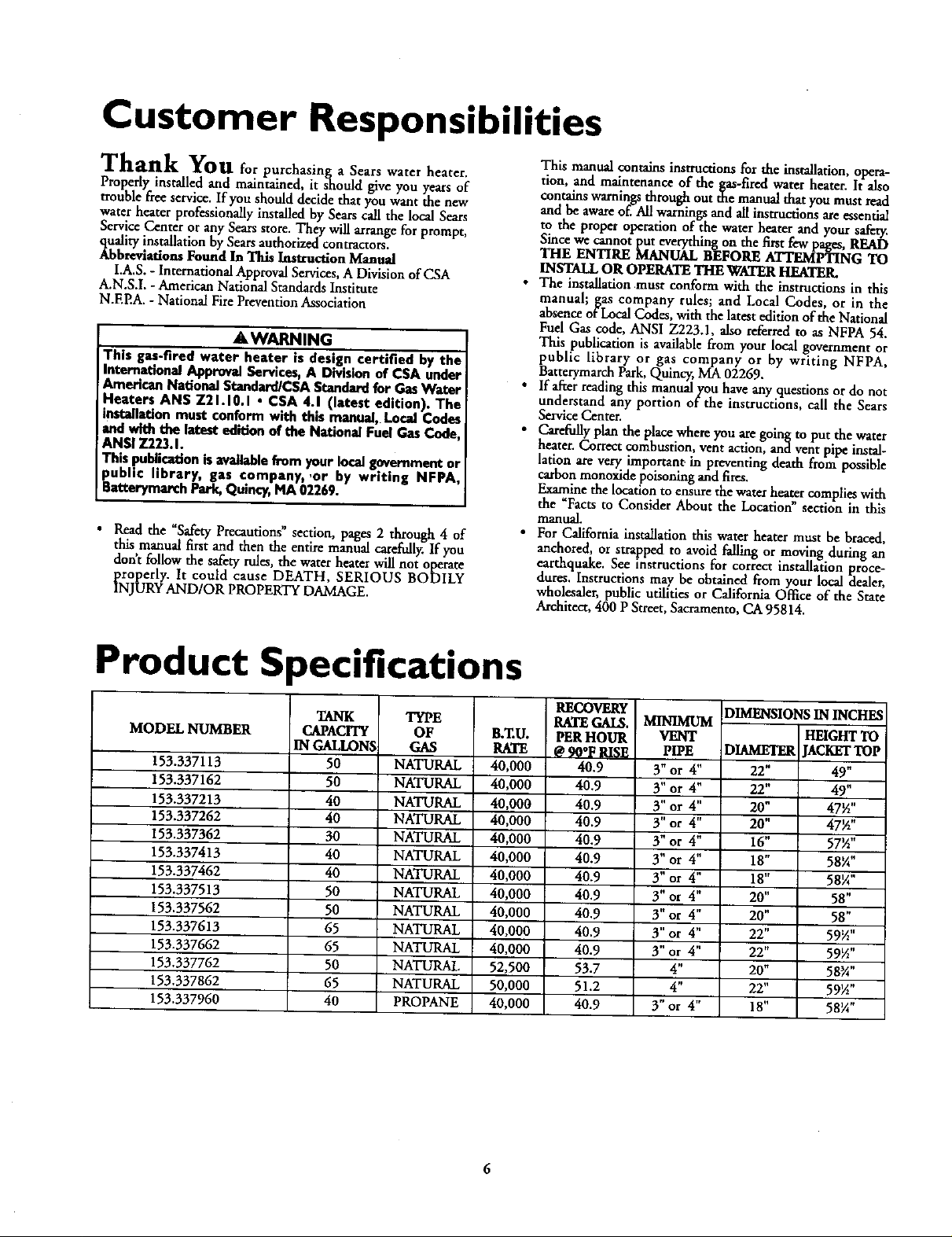

Product Specifications

MODEL NUMBER

153.337113

153.337162

153.337213

153.337262

153.337362

153.337413

153.337462

153.337513

153.337562

153.337613

153.337662

153.337762

153.337862

153.337960

TANK

CAPACITY

IN GALLONS

50

50

40

40

30

40

40

50

50

65

65

50

65

40

TYPE

OF

GAS

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

PROPANE

B,ZU.

RATE

40,000

40,000

40,000

40,000

40,000

40,000

40,000

40,000

40,000

40.000

40,000

52,500

50,000

40,000

RECOVEI_

RATE GAI&

PER HOUR

@9O°F8II;!_

40.9

40.9

40.9

40.9

40.9

40.9

40.9

40.9

40.9

40.9

40.9

53.7

51.2

40.9

MINIMUM

VENT

PIPE

3" or 4"

3"or 4"

3" or 4"

3"or 4"

3" or 4"

3" or 4"

3" or 4"

3" or 4"

3" or 4"

3"or 4"

3"or 4"

4"

4"

3"or 4"

DIMENSIONSIN INCHES

HEIGHTTO

)IAMETER JACKETTOP

22" 49"

22" 49"

20" 47½"

20" 47½"

16" 57½"

18" 58_A"

lg" 5glA"

20" 58"

20" 58"

22" 59½"

22" 59½"

20" 58_A"

22" 59½"

18" 58¼"

Materials and Basic Tools Needed

Materials Needed

To simplify the installation Sears has available the installation

_lsartsshown below.Youmay ormaynot needall of thesemateri-

, depending-onyour type of installation.

WATER HEATER HEAT

TRAPS HELP REDUCE

NEAT LOSS DUE TO

THERMAL SYPHONING

EXPANSION TANKS

FOR THERMAL

EXPANSION CONDI-

TIONS AVAILABLE IN

2 GALLON AND $

GALLON CAPACITY

THROUGN LOCAL

SEARS STORE OR

SERVICE CENTERS

VENT PIPE

WATER NEATER INSTAL-

LATION KIT WITH FLEXI-

BLE CONNECTORS FOR

314" OR 112" THREADED

OR COPPER PLUMBING

@

VENT ELBOW

FLEXIBLE WATER

HEATER GAS CON-

HECTOR WITN

FITTINGS

/ \

WATER HEATER STAND 24"x24"xl 8"

FOR USE WITH WATER HEATERS

INSTALLED IN RESIDENTIAL

GARAGES HAVING A DIAMETER 24"

OR LESS AND A RATED CAPACITY 7S

GALLONS OR LESS

DRAIN PANS AVAILABLE IN 20"

DIAMETER FOR WATER HEATERS

HAVING A DIAMETER 18" OR LESS

AND AVAILABLE IN 28" DIAMETER

FOR WATER HEATERS HAVING A

DIAMETER 26" OR LESS

Basic Tools

You may or may not need all of these tools, depending on your

type of installation. These tools can be purchased at your local

Scrags store,

• Pipe Wrenches (2) 14"

• Screwdriver

• Tin Snips

• 6 Foot Tape of Folding Rule

• Garden Hose

• Drill

• Pipe dope or Teflon Tape

GARDEN HOSE 6 FOOT TAPE

SLOT-HEAD SCREWDRIVER

PHILLIPS SCREWDRIVER

ROLL OF TEFLON TAPE

(USE ONLY ON WATER

CONNECTIONS)

PIPE DOPE (SQUEEZE TUBE)

USE FOR WATER AND

_AS CONNECTIONS)

PiPE

WRENCH

TIN SNIPS

ADDITIONAL TOOLS NEEDED

WHEN SWEAT SOLDERING

• Tubing Cutters or Hacksaw

• Propane Torch

• Sof_ Solder

• Solder Flux

• Emery Cloth

• Wire Brushes

HACKSAW

$14" WIRE BRUSH

C>--'"

ROLL OF LEAD FREE

ROLL OF EMERY

I/2" WIRE BRUSH

PROPANE

TORCH

SOFT SOLDER

CLOTH SOLDER FLUX TUBING

CUTTER

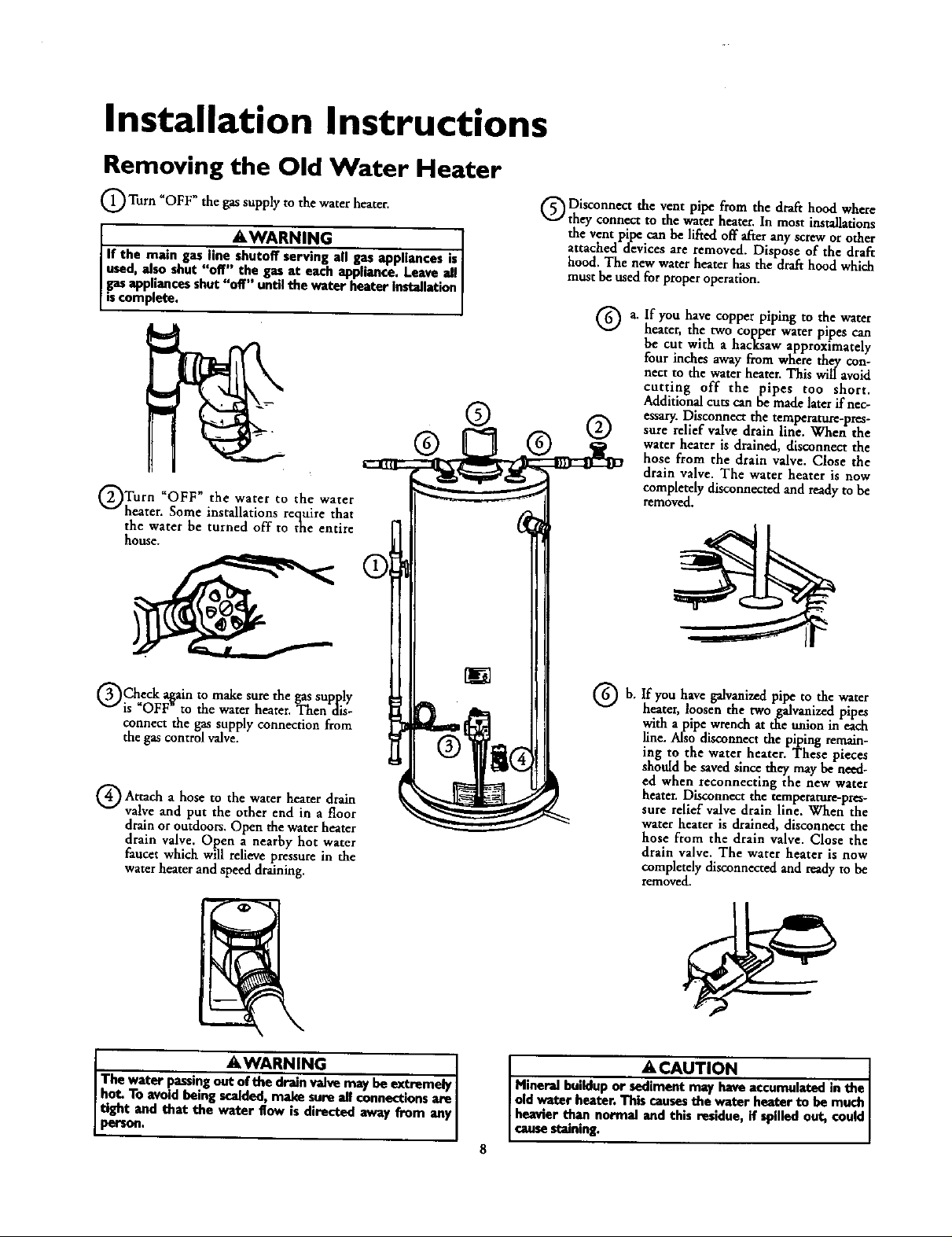

Installation Instructions

Removing the Old Water Heater

_OFF"the the heater,

Turn gassupply to water

l AWARN,N I

If the main gasline--all gasappliancesis

used, _lso shut'doff'"the gasat eachappliance. Leaveall

gasappliancesshut"off'" untilthe waterheaterinstallation

iscomplete.

@@ @ @

Turn _OFF" the water to the water

heater. Some installations require that

the water be turned off to the entire

house.

Disconnect the vent pipe from the drafthood where

they connect to the waterhearer.In most installations

the ventpipe canbe lifted off afterany screworother

attached devicesare removed, Dispose of the draft

hood. The new water heater has the drafthood which

mustbe usedfor properoperation.

a. If you have copper piping to the water

heater, the two copper water pipes can

be cut with a hacksaw approximately

four inches awayfrom where they con-

nect to the water heater. This will avoid

cutting off the pipes too short.

Additionalcuts can bemadelaterif nec-

essary.Disconnectthe temperature-pres-

sure relief valvedrainline. When the

water heater is drained,disconnect the

hose from the drain valve. Close the

drain valve. The water heater is now

completelydisconnectedandreadyto be

removed.

Check a_ainto make sure thegassupply

is OFF to the water heater. Then dis-

connect the gassupply connection from

the gascontrol valve.

a to water

Attach hose the heater drain

valve and put the other end in a floor

drainoroutdoors.Open the waterheater

drain valve. Open a nearby hot water

faucet which willrelievepressure in the

waterheater and speed draining.

I AWARNING

The water passingout--valve may be extremely

hot. To avoid being scalded,make sure all connectionsare I

i_.d that the water flow is directed away from any I

If you have galvanized pipe to the water

b,

heater, loosen the two galvanized pipes

with a pipe wrench at the anion in each

line. Also disconnect the piping remain-

lug to the water heater. These pieces

should be saved since they may be need-

ed when reconnecting the new water

heater. Disconnect the temperature-pres-

sure relief valve drain llne. When the

water heater is drained, disconnect the

hose from the drain valve. Close the

drain valve, The water heater is now

completely disconnected and ready to be

removed.

ACAUTION I

Mineral buildup or sediment may have accumulated in the

old water heater. Thiscausesthe water heater to be much

heavier than normal and this residue, if spilledout, could

causestaining.

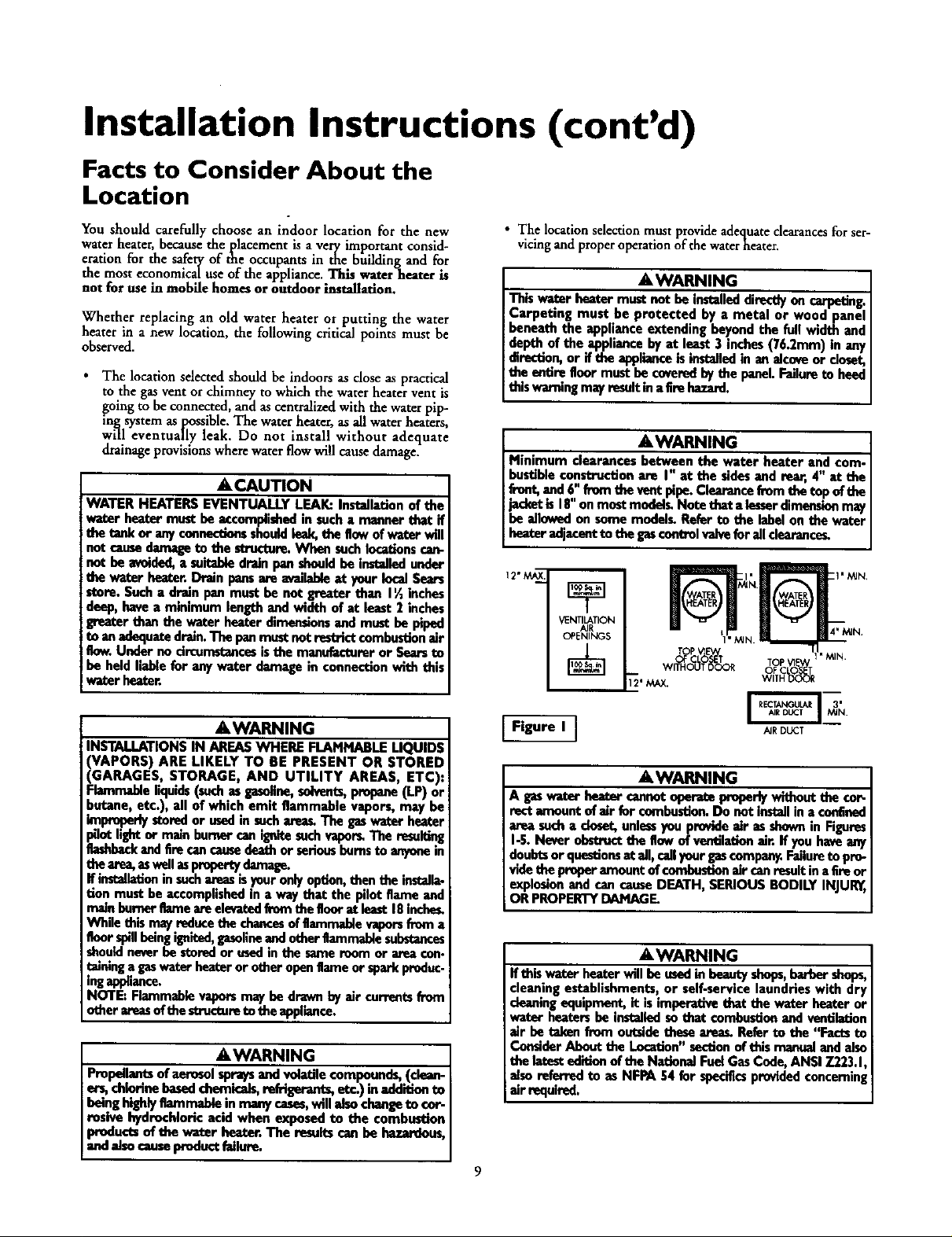

Installation Instructions (cont'd)

Facts to Consider About the

Location

You should carefully choose an indoor location for the new

water heater, because the placement is a very important consid-

eration for the safety of the occupants in the building and for

the most economical use of the appliance. This water heater is

not for use in mobile homes or outdoor installation.

Whether replacing an old water heater or putting the water

heater in a new location, the following critical points must be

observed.

• The location selected should be indoors as close as practical

to the gas vent or chimney to which the water heater vent is

going to be connected, and as centralized with the water pip-

in._ system as possible. The water heater, as all water heaters

will eventually leak. Do not install without adequate

drainage provisions where water flow will cause damage.

&CAUTION

WATER HEATERS EVENTUALLY LEAK: Installation of the

water heater must be accomplisbedin sucha manner that if

the tank or anyconnectionsshouldleak,the flowof water will

notcausedan_ge to the structure.Wben suchIocatfonscan-

not be avoided, a soitalde drain panshouldbe installedunder

the water buater. Drain pansm_eavailableat your local Sears

store. Such a drain pan must be lootgreater than I _ inches

deep, have a minimum lengthand width of at least 2 inches

greater than the water heater dimensionsand must be piped

ito anadequatedrain.The panmust notrestrict combustionair

iBow.Under no circumstancesis the manufactureror Searsto

! be held liablefor any water damage in connectionwith this

!water heater.

• The location selection must provide adequate clearances for ser-

vicing and proper operation of the waterheater.

AWARNING

This water heater must loot be installeddin_y on carpeting.

Carpeting must be protected by a metal or wood panel

beneath the appliance extending beyond the full width and

depth of the appliance by at least 3 inches (76.2mm) in any

direction,or if the applianceis installedin an alcoveor deset,

the entire floormust be coveredby the panel.Failureto heed

this warningmayresultin a firehazard.

AWARNING

Minimum clearances between the water heater and com-

bustibleconstruction are I" at the sidesand rear, 4" at the

front,and6" frem the vant pipe.Clearancefrom the top of the

jacketis I8" onmostmodelg Note that a lesserdimensionmay

be allowedon some modelg Refer to the labelon the water

heater adjacantto the gascnotrelvaivefor all dearance_

12"M__

VENTILATION

TOPP V_E'V,/

OF CLOSET TOP VI_

WITHOUT DOOR V_OIFT_ _d_

AWARNING

INSTALLATIONS IN AREAS WHERE FLAMMABLE LIQUIDS

VAPORS) ARE LIKELY TO BE PRESENT OR STORED

GARAGES, STORAGE, AND UTILITY AREAS ETC):

qammable iquids(suchasgasoline,solvents,propane(LP)or

butane, etc.), all of which emit flammable vapors, may be

improperlystoredor usedin suchare_ The gaswater heater

_ot light or main burner camignitesuch vaporLThe resul_ng

flashbackandfire cancausedeathorseriousbumsto anyonein

the area,eswellm pmportydamage.

If installat_ninsuchareasisyouronly option,then the installa-

tion must beaccomplishedin a way that the pilot flame and

mainbureor flameareeleva_._lfrem the goor at least18inches.

While this mayreducethe chancesof flammablevaporsfrom a

floor spillbeingigeited, gasolineand otherflammablesubstances

shouldneverbe storedorusedin the sameroom or area con.

talningagaswater heateror other openflameor sparkproduc.

ingappliance.

NOTE: Flammablevaporsmay be drawn by air currentsfrom

other areasof thestructureto the appliance.

AWARNING

Propellantsof aerosol spraysand vohLtilecompounds,(clean-

er_ chlorine basedchemicals,rofrigeran_, etc.) in addition to

beinghighlyflammable inmanycases,will also changeto cor-

rosive hydrochloric acid when exposed to the combustion

products of the wator beator. The resultscan be hazardous,

andalsocauseproductfailure.

Figure I ]

AIRDUCT

AWARNING

Ages wat_ bea_r cannotaperato preperlywithout the co_

rectamount of air for combustler_Do not installin a confined

area sucha closet,unle_ you provideair as shownin Figures

I-5. Never obstruct_ flow of ventilationair. If you haveany

doubtsor questionsat all, callyour gascompany.Failureto pro-

videthe proper amountof combustionair canresultin aEreor

explosionand cancauseDEATH, SERIOUS BODILY INJUI_,

OR PROPERTYDAMAGE.

AWARNING

If this water heater will be usedin beautyshops,barbershops,

cleaningestablishments, or self-service laundries with dry

cleaningequipment, it isimperative that the water heater or

water heatersbe installed sothat combustionand ventilation

air be taken from outsidethese areas, Refer to the "Facts to

ConsiderAbout the Location"sectionof this manualand also

the latestedition of the NationalFuel GasCode, ANSI 7.223.1,

alsoreferred to as NFPA 54 for specificsprovidedconcerning

air e_luired.

9

Installation Instructions (cont'd)

Combustion Air and Ventilation

for Appliances Located in

Unconfined Spaces

Unconfined Spac¢ is a space whosevolume is not less than 50

cubic feet per 1,000 Btu per hour of the aggregateinputrating

of all appliancesinstalhd in that space. Roomscommunicating

directlywith the space in which the appliances are installed,

through openings not furnished with doors, are considereda

partofthe unconfinedspace

In unconfined spacesin buildings, infiltrationmay be adequate

to provide air for combustion, ventilationand dilution of flue

gases.However,in buildings of tight construction (for example,

weatherstripping,heavilyinsulated, caulked, vaporbarrier,etc.),

additional air may need to be provided using the methods

describedin Combustion Air and Ventilation for Appliances

Locatedin Confined Spaces,b.

Combustion Air and Ventilation

for Appliances Located in

Confined Spaces

Confined Spacc is a spacewhose volumeis less than 50 cubic

feet per 1,000 Btu per hour of the aggregateinput ratingof all

appliancesinstalled inthat space.

a. ALL AIR FROM INSIDE BUILDINGS:

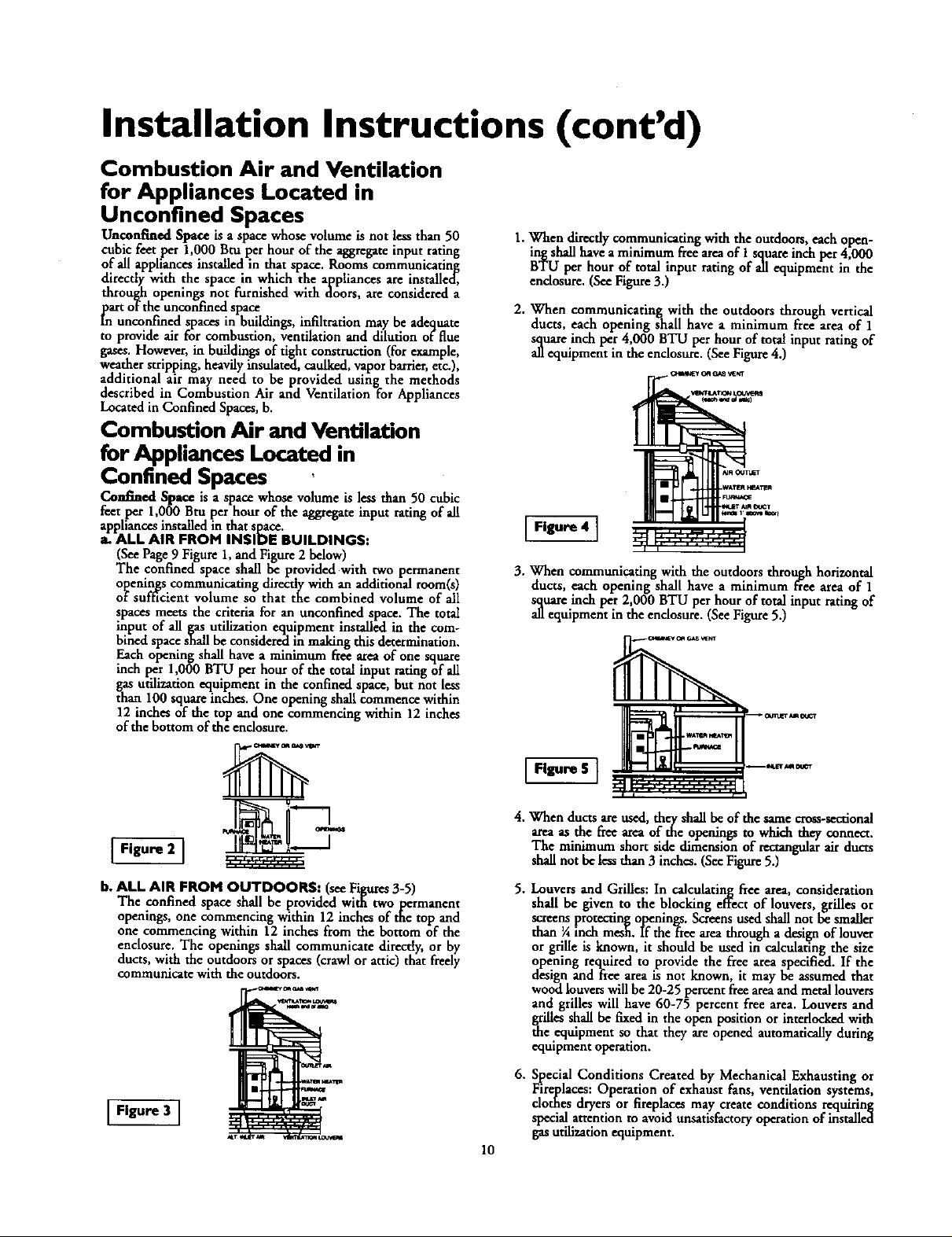

(SeePage9 Figure1,and Figure2 below)

The confined space shall be provided with two permanent

openingscommunicating directlywith an additional room(s)

of sufficient volume so that the combined volume of all

spacesmeets the criteria for an unconfined space. The total

input of all gas utilization equipment installed in the com-

bined spaceshallbe considered inmaking this determination.

Eachopeningshall have a minimum free area of one square

inch per 1,000 BTU per hour of the total inputratingofafi

gasutilization equipment in the confined space, but not less

than 100 squareinches. One openingshall commencewithin

12 inches of the top and onecommencing within 12 inches

of the bottom of the enclosure.

1.When direcdycommunicating with the outdoors,each open-

ing shallhaveaminimumflee areaof I squareinch per 4,000

BTU per hour of total input raring of all equipment in the

enclosure.(SeeFigure3.)

2. When communicatingwith the outdoors through vertical

ducts, each opening shall have a minimum free area of 1

sc!uareinch per 4,000 BTU per hour of total input ratingof

all equipment in the enclosure.(SeeFigure4.)

Figure 4 ]

3. When communicating with the outdoors through horizontal

ducts, each opening shall have a minimum free area of 1

square inch per 2,000 BTU per hour of total input rating of

all equipment in the endosure. (SeeFigure5.)

I Figure 2 ]

b. ALL AIR FROM OUTDOORS: (seeFigures3-5)

The confined space shall be provided with two permanent

openings,one commencing within 12 inchesof tee top and

one commencing within 12 inches from the bottom of the

enclosure. The openings shall communicate directly,or by

ducts,with the outdoorsor spaces (crawlorattic) that freely

communicatewiththe outdoors.

I Figure 3 ]

[el,-- ....

4.When ductsare used, they shallbe ofthe same cross-sectional

areaas the free area of the openingsto which they connect.

The minimum short side dimensionof rectangularair ducts

shallnot be lessthan 3 inches.(SeeFigure5.)

5. Louversand Grilles: In calculating free area, consideration

shall be given to the blocking effect of louvers, grillesor

screensprotecting openings.Screensused shall not be smaller

than ¼inch mesh.If the_ee area through a desi_ of louver

orgrilleis known, it should be used in calculating the size

opening recLuiredto provide the free area specified. If the

designand free area is not known, it may be assumed that

woodlouverswillbe20-25 percent freeareaand metallouvers

and grilleswill have 60-75 percent free area. Louversand

grillesshall be fixedin the open position orinterlocked with

the .equipment so.that they are openedautomaticallyduring

equipmentoperation.

6. Special Conditions Created by Mechanical Exhaustingor

Fireplaces:Operation of exhaust fans,ventilationsystems,

clothesdryersor fireplacesmay create conditions requiring

specialattention to avoid unsatisfactoryoperationof installed

gasutilizationequipment.

1o

_i " ....... Ii f I

Installation Instructions (cont'd)

Water Piping

AWARNING

HOVrERWATERCANSCALD:.Waterheatersareintendedto

producehot_ Waterheatedto a temperaturewhichwill

satisfyclotheswashing,dishwashing,andothersanitizingneeds

_n sealdandpmnanentlyInjureyouuponcontoc_Somepe_

piem_emore Wadyto be pem_nen_ injured byhot w_er _

others.TheseI_fude t_ elde_ ddldren, the k_irm,orp_sk_

ly/mentallyhandicapped.Ifanyoneusinghot waterinyourhome

Etsintooneofthese gruupsor ifthere isa localcadeorstatolaw

requiringa certaintompeeature _ atthehot watortap,then

foumusttakespecialprecaudom.Inadditionto usingthelowest

)ossiblettmperatum set,rigthatsatisEesyourhotwaterneeds,

_meanssuchasa mixingvalve,shouldbeusedatthehotwater

tapsusedbythesepeopleorot the woterheater.Mixingvalves

aruwallableatplumbingsupl_yorhan_r_xestoreLFollowman-

ufacturersinstructionsfor installationof thevalves.Before

changingthe factory settingon the thermostat,read the

"TemperatureRegulation"sectioninthismanual.

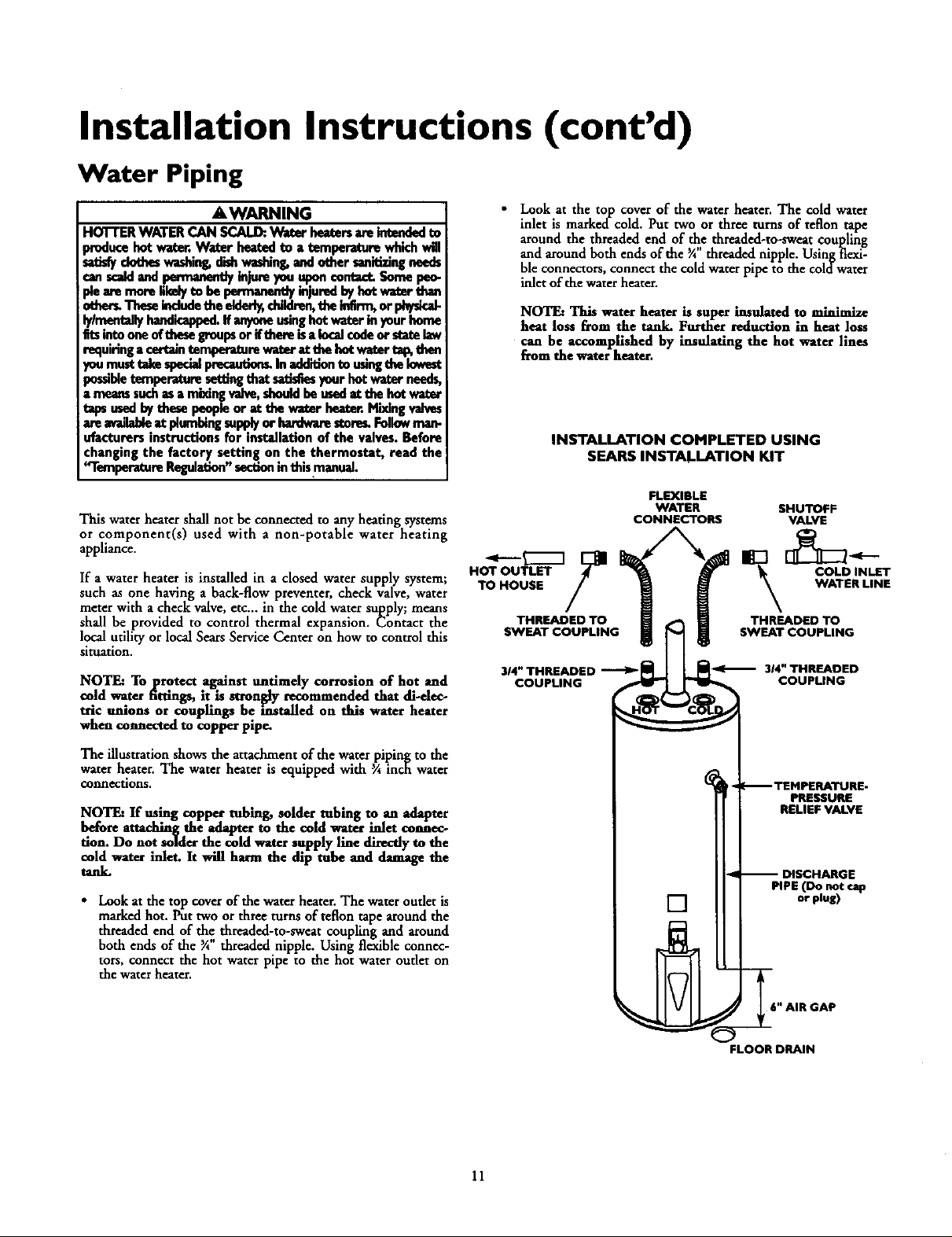

This waterheater shallnot be connected to any heating systems

or component(s) used with a non-potable water heating

appliance.

If a water heater is installed in a closed water supply system;

such as one having a back-flow preventer, check valve, water

meterwith a check valve,etc.., in the cold water supply; means

shall be provided to control thermal expansion. Contact the

local utility or localSearsServiceCenter on how to control this

situation.

NOTE: Toprotect against untimely corrosion of hot and

cold water fitthags,it is steon_iy recommended that all-elec-

tric unions or couplings be mstelled on this water heater

when connected to copperpipe.

• Look at the top cover of the waterheater. The cold water

inlet is markedcold. Put two or three turnsof teflon tape

around the threaded end of _e threaded-to-sweat coupling

and around both ends of the ¾ threaded nipple. Usingflexi-

ble connectors,connect the cold waterpipe to the coldwater

inlet of the waterheater.

NOTE: This water heater is super insulated to minimize

heat loss from the tank. Further reduction in heat loss

can be accomplished by insulating the hot water lines

from the water heater.

INSTALLATION COMPLETED USING

SEARS INSTALLATION KIT

FLEXIBLE

WATER SHUTOFF

CONNECTORS VALVE

HOT OUTLET COLD INLET

TO HOUSE WATER LINE

THREADED TO _ THREADED TO

314"THREADED _ _ 314"THREADED

COUPLING COUPLING

SWEAT COUPLING_ SWEAT COUPLING

The illustration shows the attachment of the water piping to the

water heater. The water heater is equipped with 3Ainch water

connections.

NOTE: If using copper tubing, solder tubing to an adapter

before auaching the adapter to the cold water inlet connec-

tion. Do not solder the cold water supply line directlyto the

cold water inlet. It will harm the dip tube and damage the

tank.

• Look at the top coverof the waterheater.The water oudet is

markedhot. Puttwo orthree turns of teflon tape around the

threaded end of the threaded-to-sweat coupling a-,xdaround

both ends of the _A"threaded nipple. Using flexible connec-

tors, connect the hot waterpipe to the hot water outlet on

the waterheater.

11

_ TEMPERATURE-

PRESSURE

RELIEF VALVE

-- DISCHARGE

PIPE (Do not cap

[]

,_ _6" AIR GAP

FLOOR DRAIN

or plug)

Installation Instructions (cont'd)

Temperature-Pressure Relief Valve

A, WARNING

At the time of manufacturethis water heater was provided

with acomb_nat;_nm_ratu_--,_ures relief valvecerti_d

by a nationally recognized testing laboratory that maintains

periodicinspectionof productionoflistedequipmentor mate-

rials, as meeting the requirements for Relief Valves and

AutomaticGasShutoffDevicesfor Hot Water SupplySystems,

and the latest edition of ANSI Z21.22 and the code require-

mentsof ASME. If replaced,thevalve must meat the require-

mentsof localcedes,butnot lessthan acombinationtempera.

ture andpressurerelief valvecertifiedasmeeting the _luire-

meritsfor ReliefValvesandAutomaticGasShutoffDevicesfor

Hot Water SupplySystems,AHSLZ2|.Z2 by anationallyrecog.

nizedtesting laboratorythat maintainsperiodicinspectionof

productionof llstedequipment or materials.

The valve mustbe made:d with a maximum set presserenot

to exceed the marked hydrostatic working pressureof the

water heater(I 50IbsJsq.in.) and a dischargecapacitynot less

than thewater heaterinput rateas,shownon the modelrating

plate. (Electric heaters • watts dividedby 1000x 3415 equal

BTU/I-Ir.rate.)

Yourlocaljurisdictionalauthority,whilemandatingtbe useof a

temperature-pressure reliefvalvecomp,Wyingwith ANSI 7.21.22

and ASME,may requirea valvemodeldifferentfrom the one

fomished withthe waterheater.

Compliancewith suchlocalrequirements must be satisfiedby

the installeror end userof the water heaterwitha locallypre-

scribedtemperature-pressure reliefvalveinstalledin the desig-

nateclopeninginthe water heater in placeof the factoryfur-

nishedvalve.

Forsafeoperationofthe water heate_,the relief valvemust not

bemrnovedfrom it'sdesignatedopeningor plugged.

The temperature-pressure reliefvalvemustbe installeddirectly

intothe fittingofthewaterheaterdesignatedforthe relief valve.

Pesltlenthevalvedownwerdandpravidetebing so that anydi_

chargewillexit only within 6 inchesabove,or at anydistance

below the structuralfloor.Be certainthat nocontactis made

with anyliveelectricalpart. Thedischa_eopeningmustnot be

Mocked or reduced insizeunderanycircumstances.Excessive

length, avev30 fa_€,er useofmere th_ fonr elbewscancause

restriction andreducethe dischargecapecityofthevalve.

No valveor other obstructionisto be placedbetweenthe relief

valveand the tank. Do nutconnecttubingdirectlyto discharge

drainunlessa6" airgapisprovided.Topreventbodilyinjury,haz-

ardtolife,or propertydamage,the relief valvemustbe allowed

todischargewater inquantitiesshouldcircumstancesdemand.If

the dischargepipeisnot connectedto adrain or othersuitable

means,the water flowmaycausepropertydamage.

The DischargePipe:

Must not be sm_ller in size than the outiot pipe size of the

valve,or haveanyreducingcouplingsor other restrictions.

Mustnot bepluggedor blocked.

Mustbeof material listedfor hot water distribution.

Mustbe installedso asto allow completedrainageof both

the temperature-pressure relief valve, and the discharge

pipe.

Mustterminateat an adequatedrain.

Mustnot haveanyvalvebetweenthe relief valveandtank.

A WARNING

The temperature-pressure relief valve must be manually

operated ot least on©ea year,Cantion shoukl be taken to

onsore that (I) no one isin front of or around the oudet of

the temperoture-peessurerefiofvalvedischargeline,and (2)

the water manually discharged will not cause any bodily

injury or property damage because the water may be

extremely hot.

If after manually operating the valve, it failsto completely

reset and continuesto releasewater_immediately dosethe

cold water inlet to the water heater, follow the draining

instructions, and replace the temperature-pressure relief

valvewlth a new ane.

-II--- q

HOT SHUTOFF COLD

FLOOR DRAIN

VALVE

PRESSURE

REUEF VALVE

PiPE

(Do not cap or plug)

6" AIR GAP

RELIEFVALVEOPENING

At sfiedineof manu_'mre,thiswaterheaterv_s edwisha €ombfoedontera-

;_-_u_ rd_ va_e_sted_sconing _'w_ _an_ for_ _ _d

automaticg)sshut-offd_ces forhotwatersupplysy_ems,ANSI7)1.22.Forsafo

opera_oeofshewaterheater,_be_ief vahemustn_ beremovedfromitsdesignated

pointofinstaria_onorplng_l.

relief_ complyingwithANSI7.21.22andASMF.mayrequireavahemodeldiffe_nt

fromtheonefurnishedwiththewaterhea_e_

ofC_iancewishsuchlocalrequirementsmustbesatisfiedby_e installerorenduser

waterheaterwi_haIo_11_prescribedter_erature-pr_sure_ief valveIn.ailed

inthedesignatedopeninginthewa_erbea_.

Seemanualbe_ding-"Temper_tur_PressureReliefValves"forinstalb_onant;mainte-

nanceofreliefvalve_dischargeline,andostlersafer/precauri_n_.

12

Installation Instructions (cont'd)

Filling the Water Heater

ACAUTION

Nev_ usethis water hex/;erunlessit iscompletelyfilled with ]

water.To praventdamagete the tank, the tank mu_ be filled]

with water. Water must flow from the hot water faucet

beforetumng 'ON gnsto the water heater,

To fill the water heater with water:

• Close the water heater drain valve by turning the handle to

the right (clockwise). The drain valve is on the lower front of

the water heater.

• Open the cold water supply valve to the water heater.

NOTE: The cold water supply valve must be left open

when the water heater is in use.

• To insure complete filling of the tank, allow air to exit by

opening the nearest hot water faucet. Allow water to run

until a constant flow is obtained. This will let air out of the

water heater and the piping.

• Check all new water piping for leaks. Repairas needed.

Venting

A WARNING

VENT DAMPERS. Any vent damper,whether it isoperated

thermaJlyor otherwisemustbe removedifitsuseinhibitsprop.

er drdCingof thewaterhe_er.

Thermally Operated Vent D_rnpers:Gas-firedwater heaters

havingthermal et_ency in excessof 80%may producea rela-

_vely lowfluegastemperature. Suchtemperaturesmaynot be

high enough to properly open thermally operated vent

danll_H,s.Thiswouldcausesptll_ offlue pses midmayQuse

carbonmonoxidepoisoning.

Ventdampersmustbear evidenceofcertificationascomplying

with the latest edition of American NationalStandard ANSI

7.21.68(ANSI Z21.6_ & 67, respectS, coverelec_;callyand

mechank:al_/ac_ vent dan_). Boforeim(:all,_ of any

ventdampe_consuityourlocalSearsServiceCenteror the gas

AWARNING

To insureproper venting of this gas-firedwater heater, the

correct ventpipe d'_-_er must beutilized,Anyadditionsor

deletlom of other ps appliancesona commonvent with this

water heater maqfadverselyofrectthe operation of the water

heater.Consultthe localSearsService Center or gasudllty if

anysuchchangesare planned.

Forproper ventingin certain installations,a largerdiametervent

pipe may benecessary.Due to greatvariancesin installations,

unforeseeableby themanufacturerof the water heater,you must

consult your gas company to aid you in determining the proper

ventingfor yourwaterheaterfromthe venttablesinthelatestedi-

tion of the NationalFuelGas CodeANSIZ223.1, alsoreferredto

asNFPA 54.

Check the ventingsystemfor signsofobstructionor deterioration

and replaceifneeded.

Thecombustionand ventilationairflowmustnot beobstructed.

AWARNING

heaithriskor_.

• Place the draf_ hood legs in the receiving holes on the top of

the water heater. The legs will snap in the holes to give a tight

fit.

• 1

Phce the vent pipe over the drafthood. With the vent pipe in

position, drill a small hole through both the vent pipe and

draft hood. Secure them together with a sheet metal screw.

ORAFTHOOO41' IVeNT J

f SCR_ DRAFT HOOD

DRAFT H( OD_VEI_ITNTE_OUTDOORS,,N

AWARNING I

ThewaterhexterwlthdrafthoodInstalledmustbeproperlyI

ventedtoa chimneywhichterminatesoutdoors.Neveroper-I

atethe_ hext_runlessit isventecltothe outxJoorsandhas[

adequateairsupplyte avoidrisksof improperoperation,explo-

sionorasphyx_on.

AWARNING I

The _mt pipefrom the water heater mustbe no lessthan the I

diameter of the draft hood outlet on the water heater, and

_)o_S ope upward to the chmneyat east '/4nchper near

OR

13

Installation Instructions (cont'd)

Venting (cont'd)

Allventgasesmust be completelyvented to the outdoorsof the

structure (dwelling). Instal[only the draft hood provided with

the new water heater and no otherdrafthood.

Ventpipesmust besecured at eachjoint with sheet metal screws.

CHIMNEY

TO

RISE PFEc_NEAR I

!

VENT PIPE INSTALLATION

There must be a minimum of 6" dearance between single wall

vent pipe and any combustible maserial.Fill and seal any deat-

ancebetween single wall vent pipe*and combustible material

with mortarmix, cement, or other noncombustible substance.

Forotherthan singlewall, follow ventpipe manufacturer'sdear-

0axcespecifications.To insure a dgb-t fit of the vent pipe in a

brick chimney, seal around the vent pipe with mortar mix

cement.

AWARNING

Failureto havemqulrecl.,durances betweenventpipingand

combustible _ willremit Ina Emhazard.

Besureventpipeisproperlyamnoctodto preventnscapeof

dangemmIlueSasnswhich€ouldcausedead_asphln_o_

AWARNING ]

Gas Piping

AWARNING

Makesurethe gassuppliedisthe sametypelistedon the

modelns_ngpia_ The Inlntgaspressurenmstnnt exceed

10.S in. water column ('].61d_) for natuili gas or 13 in.

column(3.2kPa)forpropane(I.R) gas.The minimuminlet

gaspressurelistedon the modelredng plateisfor the pur-

pose04'inputadjustment.

AWARNING

Ifthegescona'olvaiveIssubjectedto pressuresexceeding½]

poundpersquareinch(3._la_a),the damageto thegascon-I

tmlvelvecouklrnsultinatimorexplosionfromleaidnggel J

AWARNING

] If themaingaslineshutoffservingallgasappliancesisused,]

Ialso tom "off" the ges et each appliance. Leaveall gas appii-J

I th" I

A gas line of su_cient size must be tun to the water heater.

Consult the latest edition of National Fuel Gas Code ANSI

Z223.1,alsoreferredto as NFPA54 and the gascompanyconcern-

ingpipesize.

There mustbe:

• A readilyaccessiblemanualshut off valvein the gassupplyline

servingthewaterheater,and

• A dripleg (sediment trap)aheadof the gascunt_rolvalveto hdp

preventdirt and foreign materialsfrom entering the gascontrol

valve.

• A flexiblegasconnector or a groundjoint union between the

shutoffvalveand controlvalveto permit servicingofthe unit.

AWARNING

Chemicalvaporcorrosionof the flueand vent systemmay

occurifair for combustioncontainscertainchemicalveporL

Spraycan pmpellonts,deaningsolvents,refrigeratorKtd air

conditionerrefrigerants,swimmingpoolchemicals,calcium

andsodiumddoride,waxe_bleach,andprocesschemlcalsare

typicalcompoundswhicharepotentially€orrnslve.

Be sure to check all the gas piping for leaks before lighting the

water heater. Use a soapy water solution, not a match or open

flame. Rinse offsoapy solution and wipe dry.

Standard Models are for imtattadon up to 3,300 feet above sea

level.

fl_h Altltud¢ Models are for insm]htion from 3,300 to 5,500

ahove sea levd.

If a standard toodd isinstalled above 3,300 feet or a high altitude

model is installed above 5,500 feet, the input rating must be

reduced at the rate of 4 percent for each 1,000 feet above sea level.

Contact your local Sears Service Center or gas udlity for further

information.

AWARNING

The applianceand its gasconnectionmustbe leaktested

befo_p_clagtheafCl_acemoperaUo_

14

Installation Instructions (cont'd)

AWARNING

• Theq3pliancerand_ individualshutoffvalsemasthediscon-

nectedfromthelas_3ply pipingI_-m duringmr¢prassure

testingof the gassystemat test pressuresinexcessof

. peundpersc_relech(3.SkP',).

Theapprmsemustbeiselatedfromthe_s supplypipinlsys-

ternbydosingitsindividualmanualshutoffvalveduringany

pressuretastingofthe gassupplypipingsystemat testpras-

suresequalorless_ _ poundpersquareinch(3.5kPa),

I &WARNING

Usepipejoint compoundor teflon tapemarkedasbeingJ

SEDIMENT TRAP

A sediment trap shall be installed as close to the inlet of the

waterheater as practicalat the time of waterheater installation.

The sediment trap shallbe eithera teefittingwith a cappednip-

ple in the bottom oudet or otherdevicerecognized asan effec-

fivesediment trap. Ira tee fitting is used, it shall be installedin

conformance with one of the methods of installation shown

below.

Connecting the gaspiping to the gascontrol valveof the water

heater canhe accomplishedby either ofthe twomethods shown.

GAS PIPING WITH

FLEXIBLE CONNECTOR

GROUND

CAP

LOOP

GAS

CONTROL

VALVE

GAS PIPING WITH ALL BLACK IRON

PIPE TO GAS CONTROL

AWARNING

ContaminentsIntheIpsrmesn_/came i_ oper_on

of the gas€ontrolvalvethat r,_/rasult intireor expleslen.

Be(oreIttKhleg thegasIleehesurethatangaspipeisdean

ontheimlde.To_ap anydirtor foreignmateslalInthe gas

supplyline, a drip leg (sometimes called a sediment trap)

must be incocperated in the piping.The drip leg must he

readilyaccessible.Installinaccordancewith the "Gas Piping,"

sectine.Refer to the letest ediUonof the National FuelGas

Code, ANSI 7.223.1,alse re_-md to as NFPA 54.

LJCAP

15

Installation Instructions (cont'd)

Installation Checklist

BEFORE LIGHTING THE PILOT:

• Check the gaslines for leaks.

a. Use a soapy water solution. DO NOT test for gas leaks

usingamatch or open flame.

b. Brushthe soapywater solution on all gaspipes, joints and

fittings.

c. Check for bubbling soap• This means you have a leak.

Turn OFF" gasand makethenecessaryrepairs.

d. Recheckfor leaks.

e. Rinse offsoapy solution and wipe dry.

• Isthe new temperature-pressurereliefvalveproperly installed

andpiped to art adequate d_in? See _Temperatttre-Pressure

ReliefValve"section•

• Are the cold and hot water lines connected to the water

heater correctly? See "Water Piping" instructions in the

_lnstallation Instructions _ section.

HOT

VENT PIPE TO

OUTDOORS

OR CHIMNEY

DRAFT HOOD

UNION

SHUTOFF VALVE

COLD

• Is the water heater completdy filled with water? See "Filling"

instructions in the Installation Instructions section.

• Will a water leak damage anything? See the "Facts to

Consider About the Location" section.

• Is there proper clearance between @e water heater and any-

thing that might catch fire? See the Facts to Consider About

the Location" section.

• Do you have adequate ventilation so that the water heater

will operate propetly? See Combustion Air and Ventilation

in the _Facts to Consider About the Location" section.

• Is the draft hood vent piping proper secured. See Ventmg_

instructions m the Installation Instructions section.

• Is there proper dearance betw_n the vent pipe and anything

that might catch on fire. See Venting instructions in the

'" ly ....

"Installation Instructions" section.

• Is the vent pipe properly sloped and does the vent terminate

outdoors? See "Venting" instructions in the "Installation

Instruct ons seCtiOn.

• Do you need to call your gascompany to check the gaspipe

and itshookup?

GAS SUPPLY

TEE

(Sediment

trap) PIPE CAP

DRAIN VALVE '

SHUTOFF VALVE

PRESSURE

REUEF VALVE

(Do not rap or plug)

i

6" AIR GAP

FLOORDRAIN

16

MODEL RATING PLATE

Operating Instructions

Lighting

A WARNING

BEFORE LIGHTING [PROPANE (L.P.) GAS WATER

HEATERS]:Propane(L.R) gasis heavierthan air.Shouldthere

be a leak in the system,the gaswill settle near the ground.

Basements,crawl spaces,skirted areas undermobile homes

(evenwhenventilated),closetsandareasbelowgroundlevelwill

serve as pockets for the accumulation of this gas. Before

attemptingto lightorrelightthewater heater'spilotor turning

ona nearbyelectricallight switch,be absolutelysurethere isno

accumulatedgasinthearea.Searchforodorof gasbysniffingat

groundlevelinthe vicinityofthe appliance.If odor isdetected

followstepsindicatedat"For YourSafety"onthe coverpageof

thismanualthen leavethe premises.

Lighting and operating instructions are located on front of the

water heater, above or to one side of the gas control valve.

_,WARNING

AN ODORANT ISADDED TO THE GAS USED

FOR YOUR SAFETY

IF YOU SMELL GAS:

• Do not try to lightanyappliance.

• DOnot touch anyelectricalswitch;donot useanyphone in

your building.

• Immediately callyour gassupplierfrom aneighbor's phone.

Follow the gassuppiier_instruedons.

• If you cannotreachyour gassupplier,call the fire depart-

merit.

BY THIS WATER HEATER.

Figure 6

Figure 7

AWARNING

DO NOT forcethe gescontrnlImob. Use only your hand to

pushit downto lightthe pilot, or to turn it to "ON", "OFF"

or "PILOT". Never use atool such as a lever,w_nch or pli-

ers. Do not hit or damage the knob. A darnagedImob may

resultin an explosionandsuHous injury.If you haveproblem

turningtheImob,callthe gassupplier immediately.

CHECK FOR LEAKS

Be sure to check all your gas pipes for leaks before lighting your

water heater. Use a soapy water solution, not a match or open

flame. Check the factory gas fittings after pilot is lit and gas con-

trol knob is still in "PILOT" position. Then, check the fittings

when the main burner is turned "ON". Use a soapy water solu-

tion for this, too.

17

Figure 8

Figure 9

_INNER DOOR

OUTER

DOOR

Operating Instructions (cont'd)

Lighting label on the water heater as it appears above the thermostat

FOR YOUR SAFETY READ BEFORE LIGHTING

If you do not follow these instructions exactly, a fire or explosion

may resut caus ng property damage, personal injury or oss of I re.

A. Thisappliancehas a pilotwhichmustbelightedby

hand.Whenlightingthepilot,followtheseinstructions

exactly.

B.BEFORELIGHTINGsmellallaroundtheappliancearea

forgas. Besureto smellnext to thefloorbecause

somegasIsheavierthanairandwillsettleonthefloor,

WHATTODOIFYOUSMELLGAS

• Donottry tolightanyappliance.

• DOnottouchanyelectricswitch;do notuseany

phoneinyourbuilding.

• Immediatelycallyourgassupplierfroma neighbor's

phone,FollowthegassuppJier'sinstructions,

WARNING i

LIGHTING INSTRUCTIONS

1.STOP!Readthesafetyinformationaboveonthislabel.

2.Removeouterdoor.

3. Satthethermostatto lowestsetting,byturning the

watertemperaturedialclockwise,(( _,)to itslowest

temperaturesetting(witharrowondial)asshown.DO

NOTFORCE.

4,Turngascontrolknobclockwise_) to "OFF"posi-

tion.Knobcannotbeturnedfrom"PILOT"to"OFF"

unlessknob is depressedslightly.DO NOTFORCE.

(Figure6, page17)

5.Waitfive(5) minutesto clearoutanygas.Ifyouthan

smellgas,STOP!Follow"B" inthe safetyinformation

aboveonthislabel.If youdon'tsmellgas,go to the

nextstep.

6. Remove(or open)innerdoorlocatedbelowthegas

controlunit.

7.Findpilot-followmetaltubefromgascontrol.Thepilot

islocatedInfrontoftheburner.

PILOT BURNER _ I THERMOCOUPLE

8.IfyoUdon'tsmellgas,turnknobongascontrolcounter

clockwlse_,_' to "PILO'F"position.(Figure7,page17)

tLX_

• If youcannotreachyourgassupplier,callthefire

department.

C. Useonlyyour handtopushinortumthegascontrol

knob.Neverusetools.Iftheknobwillnot pushinor

turnbyhand,don'ttryto repairit,calla qualifiedser-

vicetechnician.Forceorattemptedrepatrmayresult

inafireorexplosion.

D.Donotusethisapplianceif anyparthasbeenunder

water,tmmedictelyca, a quaitfledservicetechnician

toinspecttheapplianceandtoreplaceanypartofthe

controlsystemandanygascontrolwhichhasbeen

underwater.

g. Pushin control knoball thewayandholddown.

Immediatelylightthepilotwitha match,Continueto

holdcoutmtknobin foraboutone(1)minutealter

thepilotIslit.Releaseknobanditwillpopbackup.

Pilotshouldremainlit.If it goesout,repeatsteps3

through8.

• it knobdoesnotpop upwhenreleased,stopand

immediatelycallyourservicetechnicianorgas

supp,m.

• If the pilotwill notstay lit afterseveraltries,

depR*ssandturnthegascontrolknobclockwise

i(_ _ to"OFF"ahdcallyourservicetechnician

orgassupplier.(Figure6,page17)

10.Replace(orclose)Innerdoor.Replaceouterdoorif

doordoesnotcovergascontrolon/offknobortam-

paratureadjustmentknob.(Figure9,page17)

11. Atarmslengthaway,turngascontrolknobcounter-

clockwise_ tothefull "ON"position.Wanting

do not use gas controlknob to regulate gas

flow.(Figure8,page17)

12.At armslengthaway,setthethermostatto desired

setting.Themark( • ) HOTindicativeof approximate

120°Fis preferredstartingpoint.Somelocallaws

mayrequirea lowerstartingpoint,If hotterwateris

desired,seeinstructionmanualand"warning"below.

13.ReplacetheouterdoorIf notreplacedinstep10.

I WARNING

Hotterwaterincreasestheriskofscaldinjury.Beforechangingtemperaturesettingseeinstructionmanual.

TO TURN OFF GAS TO APPLIANCE

1.Setthethermostatto lowestsettingbyturningthe

watertemperaturedialclockwise(F'_) to Its lowest

temperaturesetting(witharrowondial)asshown.DO

NOTFORCE,

2. Turngascontrolknobclockwise_') to "OFF"

position.Knobcannotbeturnedfrom"PILOT" to

"OFF"unlessknobis depressedslightly.DONOT

FORCE.

3.Replaceouterdoor(ifremoved).

18

Operating Instructions (cont'd)

Temperature Regulation

Due to the nature of the typical gas water heater, the water tem-

_oerature in certain situations may vary up to 30°F higher or

wet at the point of use such as, bathtubs, showers, sink, etc.

This means that when the temperature adjustment dial is set at

the mark approximating 120° F, the actual water temperature at

any hot water tap could be as high as 150°F or as low as 90°E

Any water heater's intended purpose is to heat water. Hot water

is needed for cleaning (bodies, dishes, clothing). Hot water will

present a scald hazard. Depending on the time element and the

people involved (normaladults, children, toddlers, elderly,

infirm, etc.) scalding may occur at different temperatures.

AWARNING

HOTTER WATER CAN SCALD: Water heatersare intendedto

prod.uco hotwater. Water heatedto a temperature whichwill

sa'dsfyclotheswashing_dishwashing,andother sanitizingneeds

canscald_ndpermanently injure youupon contact.Some peo-

ple aremore likelyto bepermanently inuredby hot water than

othem Theseindudethe elderly,children,the infirm,or physical-

lylmentallyhandicapped.If anyoneusinghotwater inyour home

fitsintooneofthesegroupsor ifthere isa localcodeor statelaw

requiringa certaintemperature waterat the hotwater tap,then

_mmusttakespecialprecautions.In additionto usingthe lowest

mssibletemperature settingthat satisfiesyourhot water needs,

Lmeanssuchasa mixingvalve,shouldbe usedat the hot water

tppsusedbythese peopleor at the water heater Mi_ingvalves

are availableat plumbingsupplyor hardwarestore_Followman-

ufacturers instructions for installation of the valves. Before

changing the factory setting on the thermostat, read the

'q'emperature Regulation"sectioninthismanual.

Turn the water temperature dial clockwise (ff"_) to decrease

the temperature, or counterclockwise (_",_) to increase the

temperature.

PILOT LIGHTING-Set here before attempting to light pilot.

• HOT-Is a thermostat setting of approximately

120°F,whichwillsupply hot waterat the

most economical temperatures. The

temperature adjustment knob can be

turned lowerthan "HOT"ifdesired.

A-Is a thermostat setting of approximately

130°E

B-Is a thermostat setting of approximately

140°F. This is the lowest setting for

supply of hot water to dishwashers.

AWARNING J

Neverallowsmallchildrento usea hotwater_ or todraw

thalrownbathwater,Neverleaveachildor handicappedper-I

sonunattendednabathtubor shower. I

The thermostat of this water heater has been factory set at its

lowest position, to reduce the risk of scald in ury. It is adjustable

and must be reset to the desired temperature setting. The mark

(•) HOT indicative of approximately 120°F is title preferred

stattin_ point. Some states have a requirement for a lower set-

ting. Iryou need hotter water, follow directions for temperature

adjustment, but beware of the warnings in this section.

C-Is a thermostat setting of approximately

150°E

VERY HOT-Is a thermostat setting of 160°F. It is

recommended that the dial be set lower

wheneverpossible.

NOTE: Water temperature range of 120°--140°F recom-

mended by mostdishwasher manufacturers.

AWARNING

Shouldoverheatingoccuror the gassupplyfailto shutoff,

turn"OFF" themanualgascontrolvalvetotheappliance.

19

Service and Adjustment

Tank (Sediment) Cleaning

Sediment build-up on the tank bottom may create varying

amounts of noise, and if left in the tank will causepremature

tank failure. In some waterareas, you may not be ableto drain

all sediment depositsby simply drainingthe tank. In thesecases

MagErad (part no. 23600) can be used to help remove the sedi-

ment deposits. This may be ordered from the Sears Service

Center. Forordering,referto the "Repair Parts"section.

Venting System Inspection

At least once a year a visual inspection should be made of the

venting system. You should look for:

• Obstructions which could cause improper venting. The com-

bustion and ventilation air flow must not be obstructed.

Damage or deterioration which could cause improper vent-

ing or leakage of combustion products.

Rusted flakes around top of water }_eater.

&WARNING

Chemical vapor corrosion of the flue and vent system may

,occur if air for combustion contains certain chemicalvapors.

! Spray can propellants,cleaningsolvents,refrigerator and air

conditioner refrigerants, swimming ponl chemica/s,calcium

andsodiumchloride,waxes,bleach,and processchemicalsare

typicaicompoundswh chare potentiallycorrosive.

AWARNING

Obstructedor deteriorated ventsystemsmay presenta serious

heaithriskorusphyxiation.

Burner Inspection

AWARNING I

Do ont usethisapldianceif anypert of it hasbeenander water. _

Immediately call a Sears Service Technicianto inspect the I

applianceand to replace the gas control or any part of the

burner systemwhchhasbeen underwat_

At least once a year a visual inspection should be made of the

main burner and pilot burner. The drawing is for your reference.

You should check for sooting which is not normal and will

impair proper combustion.

AWARNING J

Soot build-up indicates a problem that requires correction

beforefurther use.Turn "OFF" gasto water heater and leaveI

"OFF" until repairs are made, becausefailureto correct the

causeof the sootingcan result in a fire or explosioncausing

DEATH, SERIOUSBOD LY NJUI_, OR PROPERTYDAMAGE.

Burner Cleaning

AWARNING [

Be sure the vent piping is properly connected to prevent ]

escape of dangerous flue gosseswhich could cause deadly

asphyxation.

AWARNING I

If after inspection of the vent system you found sooting or I

deterioration, somethingiswrong. Call the localgas utilityto ]

correct the problem anddean or replace the flueand venting

beforeresumng operation ofthe water heater.

In the event your burner needs cleaning, use the following

instructions:

If inspection of the burner shows that cleaning is required, turn

the gas control knob dock'wise (ff"x) to the "OFF" position,

depressing slightly.

NOTE: The knob cannot be turned from "PILOT" to "OFF"