Juki LBH-781, LBH-782, LBH-783, LBH-784 Instruction Manual

BE078130B0A

MODEL

LBH-781-782-783-784

Before

operating

your

JUKI

Lock

stitch

Machine,

please

read

this

In

struction

Book

carefully

in

order

to

operite

it in

the

correct

and

efficient

HIGH

SPEED

SINGLE

NEEDLE

LOCKSTITCH

STRIAGHX

BUTTON

HOLING

SEWING

MACHINE

Instruction

Book

CAUTION

IN

OPERATION

SPECIFICATIONS

1.

The

machine

should

rotate

counterclockwise

as

observed

from

the

pulley.

Take

care

not

to

rotate

the

machine in

the

opposite

direction.

2. Never start the machine before filling the machine base

with

lubricating

oil.

3.

Remove

the

bobbin

case

and

the

needle

thread

from

the

machine before performing

the

trial

operation.

4. Clean up

the

sewing'

hook

and

the

bobbin

thread

trimmer

every

day

after

sewing

work.

Also

check

the

level

of

the

lubricating

oil.

Application

Sewing

speed

Buttonhole

length

Bar-tack

width

Needle

Presser

lift

Lubricating oil

1.

MOTOR

PULLEY

AND

V

BELT

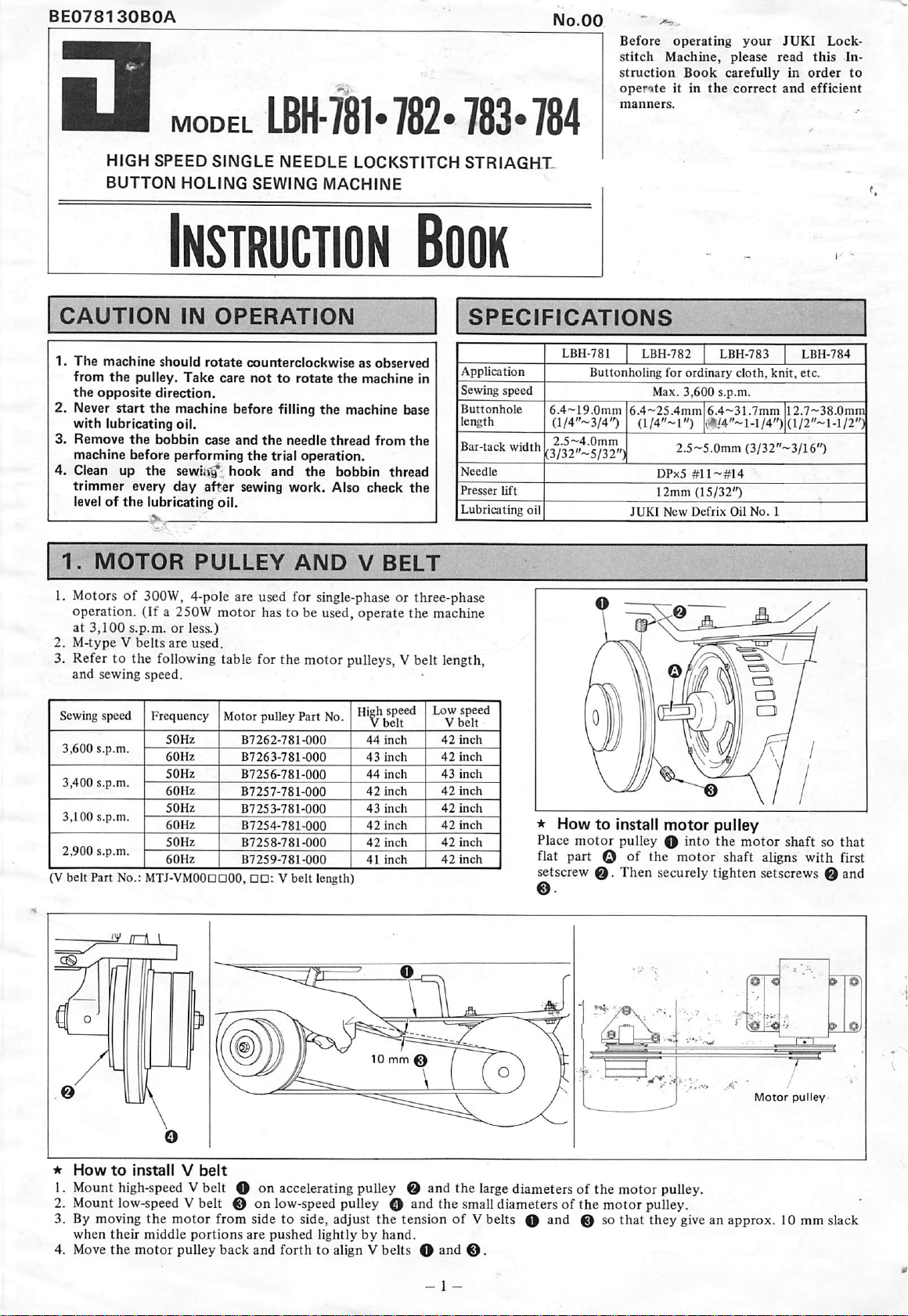

1. Motors

of

300W, 4-pole are used for single-phase or three-phase

operation.

(If

a 250W

motor

has to be used, operate the machine

at

3,100

s.p.m.

or

less.)

2.

M-type

V

belts

are

used.

3. Refer to the following table for the motor pulleys, V belt length,

and

sewing speed.

Sewing speed

Frequency

Motor

pulley Part No.

3,600

s.p.m.

B7262-781-000

B7263-781-000

3,400

s.p.m.

B725

6-781-000

B7257-781-000

B725

3-781-000

High speed

Vbelt

44

inch

43

inch

44

inch

42

inch

43

inch

Low

speed

Vbelt

42

inch

42

inch

43

inch

42

inch

42

inch

LBH-781

LBH-782 LBH-783 LBH-784

Buttonholing

for

ordinary

cloth,

knit,

etc.

Max.

3,600

s.p.m.

6.4~19.0mni

6.4~25.4mm

6.4~31.7mm

12.7~38.0m

(l/4"~3/4")

(1/4"~1")

,i®/4"-l-l/4")

(l/2"-I-l/2

mrATn''\

-S.Omin

(3/32"~3/l

6")

DPx5

#11~#14

12mm

{15/32")

JUKI

New

Defrix

Oil

No.

1

i

3,100

s.p.m.

B7254-781-000

42

inch

2,900

s.p.m.

B7258-781-000

B7259-781-000

42

inch

42

inch

42

inch

* How

to

install

motor

pulley

Place

motor

pulley 0

into

the

motor

shaft so

that

flat part © of the

motor

shaft aligns with first

setscrew o

Then

securely

tighten

setscrews

0

and

41

inch

(V

belt

Part No.: MTJ-VMOODDOO, V

belt

length)

*

How

to

install

V

belt

1. Mount high-speed V belt O oti accelerating pulley 0 and the large diameters of the motor pulley.

2. Mount low-speed V belt 0 on low-speed pulley 0 and the smalldiameters of the motor pulley.

3. By moving

the

motor

from

side to side, adjust

the

tension

of

V belts 0 and 0 so

that

they

give an approx. 10 mm slack

when

their

middle

portions

are

pushed

lightly

by

hand.

4. Move

the

motor

pulley

back

and

forth

to align V belts 0 and

0.

42

inch

i

Motor

pulley

From the library of: Superior Sewing Machine & Supply LLC

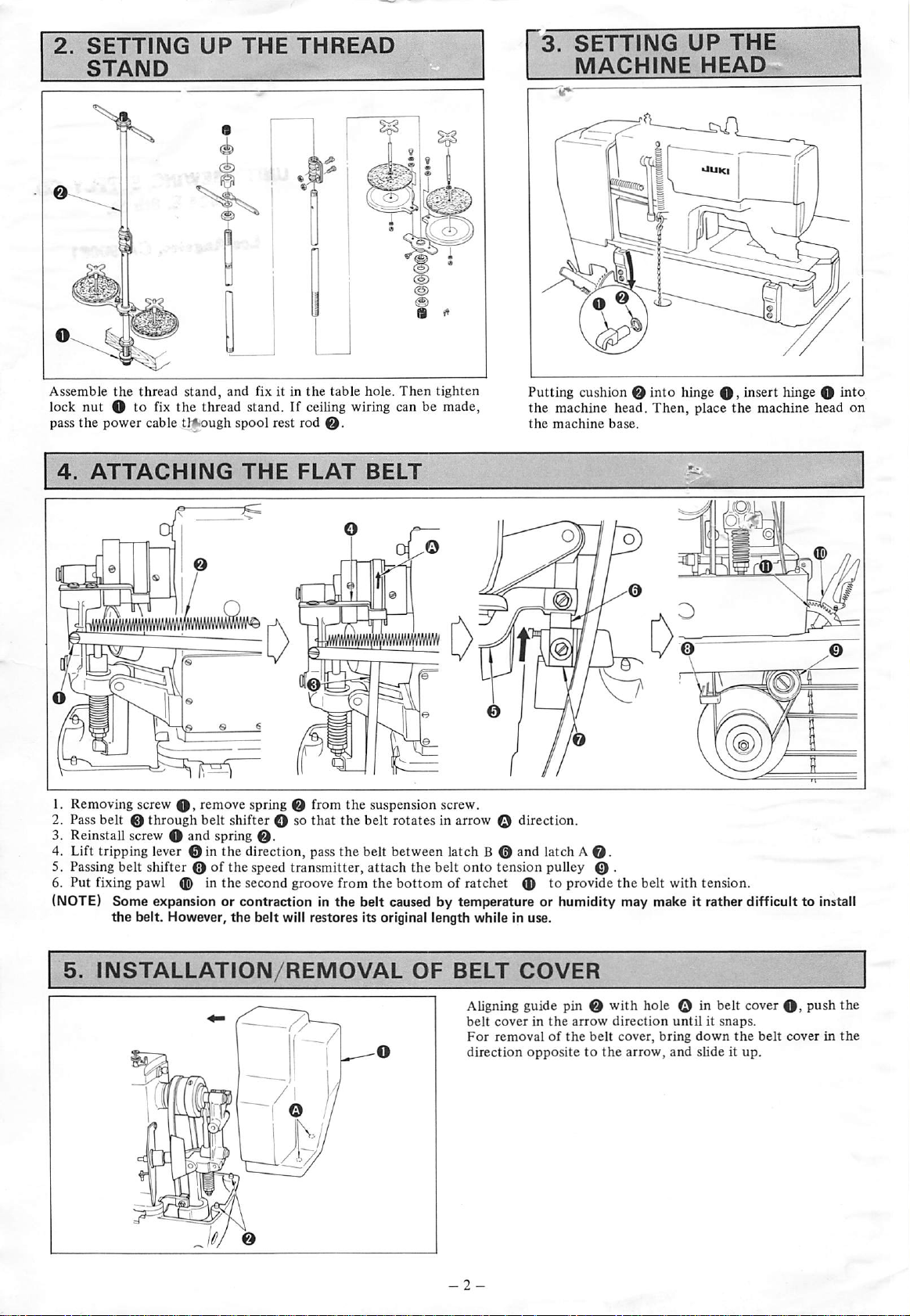

2.

SETTING

UP

THE

THREAD

STAND

3.

SETTING

UP

THE

MACHINE

HEAD

Assemble

the

thread

stand,

and

fix it in

the

table

hole.

Then

tighten

lock

nut

O to fix

the

thread stand. If ceiling wiring can be made,

pass

the

power

cable tl*iOugh

spool

rest

rod

0.

Putting cushion 0 into hinge

0,

insert hinge O into

the

machine

head.

Then,

place

the

machine

head

on

the

machine

base.

4.

ATTACHING

THE

FLAT

BELT

i

•iiiiiiiiliii'iiiiii

1. Removing screw

0,

remove spring 0 from

the

suspension screw.

2. Pass belt 0 through belt shifter 0 so that the belt rotates in arrow o direction.

3. Reinstall screw 0 and spring

0.

4. Lift tripping lever 0 in the direction, pass the belt between latch B 0 and latch A

0.

5. Passing

belt

shifter 0 of

the

speed

transmitter,

attach

the

belt

onto

tension pulley 0 .

6.

Put

fixing pawl 0 in

the

second

groove

from

the

bottom

of

ratchet

0

to

provide

the

belt

with

tension.

(NOTE) Some expansion or contraction In

the

belt caused by temperature or humidity may make It rather difficult to Install

the

belt. However,

the

belt

will restores its original length while In use.

5.

INSTALLATION/REMOVAL

OF

BELT

COVER

Aligning guide pin 0

with

hole 0 in belt cover

0,

push

the

belt

cover

in

the

arrow

direction

until

it

snaps.

For

removal

of

the

belt

cover,

bring

down

the

belt

cover

in

the

direction

opposite

to

the

arrow,

and

slide

it

up.

From the library of: Superior Sewing Machine & Supply LLC

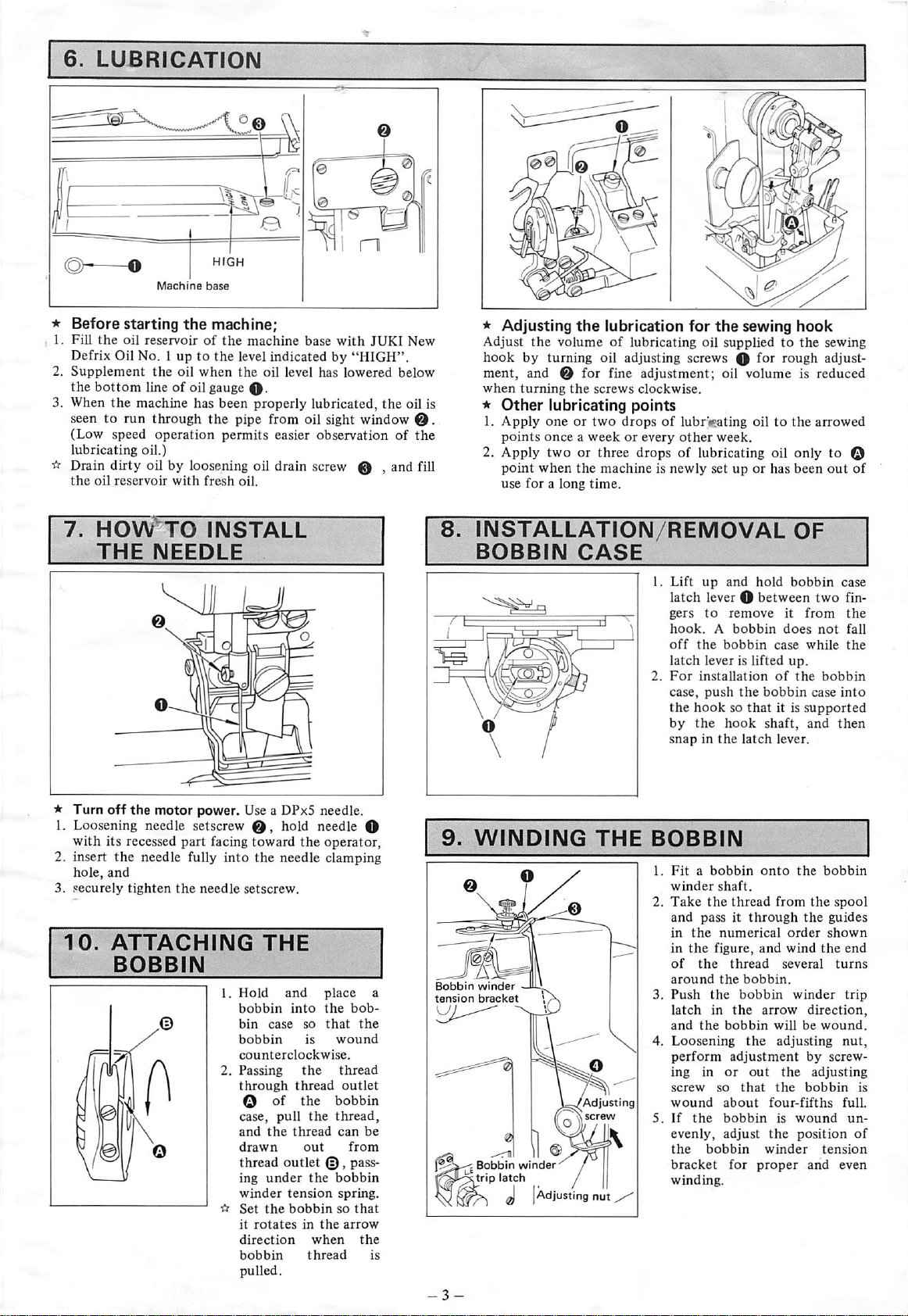

6.

LUBRICATION

★

Before

Starting

the

machine;

1.

Fill

the

oil

reservoir

of

the

machine

base

with

JUKI

New

Defrix Oil No. I up to the level indicated by

"HIGH",

2.

Supplement

the

oil

when

the

oil

level has

lowered

below

the

bottom

line of oil gauge

0.

3. When

the

machine has been properly lubricated,

the

oil is

seen to

run

through

the

pipe from oil sight window

O.

(Low

speed

operation

permits

easier

observation

of

the

lubricating

oil.)

Drain dirty oil by loosening oil drain screw 0 , and fill

the

oil

reservoir

with

fresh

oil.

7.

HOW^TO

INSTALL

THE

NEEDLE

*

Adjusting

the

lubrication

for

the

sewing

hook

Adjust

the

volume

of

lubricating

oil supplied

to

the

sewing

hook

by turning oil adjusting screws O for rough adjust

ment, and 0 for fine adjustment; oil volume is reduced

when

turning

the

screws

clockwise.

*

Other

lubricating

points

1.

Apply

one

or

two

drops

of

lubr'ijating oil

to

the

arrowed

points

once

a

week

or

every

other

week.

2.

Apply

two

or

three

drops of lubricating oil

only

to O

point

when

the

machine

is

newly

set

up

or

has

been

out

of

use

for

a

long

time.

INSTALLATION/REMOVAL

OF

BOBBIN

CASE

1.

Lift

up

and

hold

bobbin

case

latch

lever O

between

two

fin

gers

to

remove

it

from

the

hook.

A

bobbin

does

not

fall

off

the

bobbin

case

while

the

latch

lever is lifted

up.

2.

For

installation

of

the

bobbin

case,

push

the

bobbin

case

into

the

hook

so

that

it is

supported

by

the

hook

shaft,

and

then

snap

in

the

latch

lever.

★

Turn

off

the

motor

power.

Use a

DPx5

needle.

1. Loosening needle setscrew hold needle O

with

its recessed

part

facing

toward

the

operator,

2.

insert

the

needle

fully

into

the

needle

clamping

hole,

and

3.

securely

tighten

the

needle

setscrew.

9.

WINDING

THE

BOBBIN

10.

ATTACHING

THE

BOBBIN

1.

Hold

and

place

a

bobbin

into

the

bob

bin

case

so

that

the

bobbin

is

wound

counterclockwise.

2.

Passing

the

thread

through

thread

outlet

O of

the

bobbin

case,

pull

the

thread,

and

the

thread

can

be

drawn

out

from

thread

outlet

0,

pass

ing

under

the

bobbin

winder

tension

spring.

^

Set

the

bobbin

so

that

it

rotates

in

the

arrow

direction

when

the

bobbin

thread

is

pulled.

Bobbin

winder

-

tension

bracket

Adjusting

!

screw

-^1

11

Bobbin

winder

/

trip latch /

X J I

Adjusting

nut

1.

Fit

a

bobbin

onto

the

bobbin

winder

shaft.

2.

Take

the

thread

from

the

spool

and

pass

it

through

the

guides

in

the

numerical

order

shown

in

the

figure,

and

wind

the

end

of

the

thread

several

turns

around

the

bobbin.

3.

Push

the

bobbin

winder

trip

latch

in

the

arrow

direction,

and

the

bobbin

will

be

wound.

4.

Loosening

the

adjusting

nut,

perform

adjustment

by

screw

ing

in

or

out

the

adjusting

screw

so

that

the

bobbin

is

wound

about

four-fifths

full.

5.

If

the

bobbin

is

wound

un

evenly,

adjust

the

position

of

the

bobbin

winder

tension

bracket

for

proper

and

even

winding.

From the library of: Superior Sewing Machine & Supply LLC

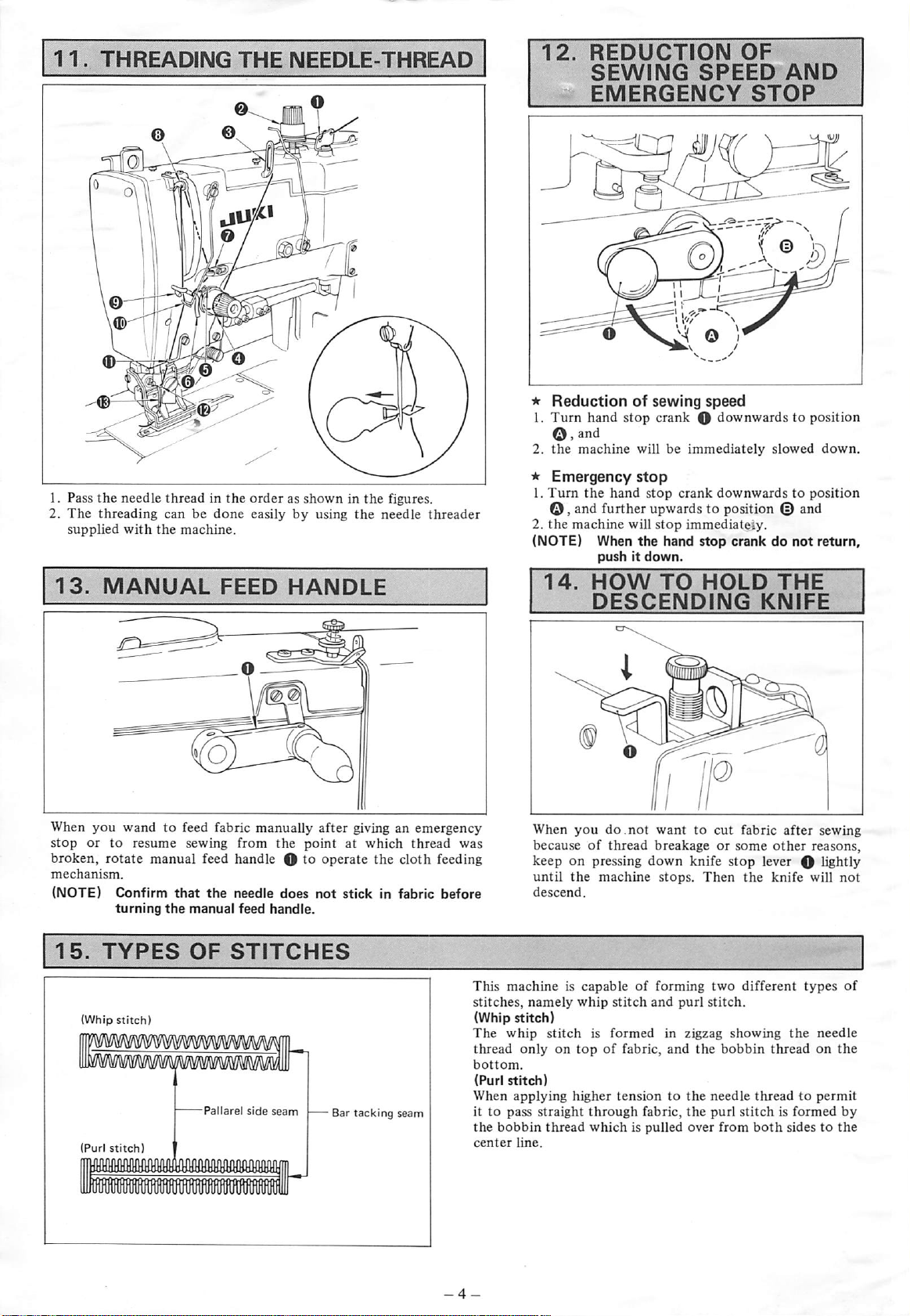

12.

REDUCTION

OF

SEWING

SPEED

AND

EMERGENCY

STOP

11.

THREADING

THE

NEEDLE-THREAD

r©/.

--

1. Pass

the

needle

thread

in

the

order

as

shown

in

the

figures.

2.

The

threading

can

be

done

easily

by

using

the

needle

threader

supplied

with

the

machine.

•k

Reduction

of

sewing

speed

1.

Turn

hand

stop

crank

O

downwards

to

position

O,

and

2.

the

machine

will

be

immediately

slowed

down.

★

Emergency

stop

1.

Turn

the

hand

stop

crank

downwards

to

position

o , and further upwards to position © and

2.

the

machine

will

stop

immediately.

(NOTE) When

the

hand

stop

crank

do

not

return,

push

It

down.

13.

MANUAL

FEED

HANDLE

14.

HOW

TO

HOLD

THE

DESCENDIIMG

KNIFE

m

When

you

wand

to

feed fabric

manually

after

giving an

emergency

stop

or

to

resume

sewing

from

the

point

at

which

thread

was

broken,

rotate

manual

feed handle O to operate

the

cloth

feeding

mechanism.

(NOTE)

Confirm

that

the

needle

does

not

stick

in

fabric

before

turning

the

manual

feed

handle.

When

you

do ,

not

want

to

cut

fabric

after

sewing

because

of

thread

breakage

or

some

other

reasons,

keep

on

pressing

down

knife

stop

lever O lightly

until

the

machine

stops.

Then

the

knife

will

not

descend.

15.

TYPES

OF

STITCHES

(Whip

stitch)

mmwmmimmimMimm

Pallarel side seam Bar tacking seam

(Purl

stitch)

This

machine

is

capable

of

forming

two

different

types

of

stitches,

namely

whip

stitch

and

purl

stitch.

(Whip stitch)

The

whip

stitch

is

formed

in

zigzag

showing

the

needle

thread

only

on

top

of

fabric,

and

the

bobbin

thread

on

the

bottom.

(Purl

stitch)

When

applying

higher

tension

to

the

needle

thread

to

permit

it

to

pass

straight

through

fabric,

the

purl

stitch

is

formed

by

the

bobbin

thread

which

is

pulled

over

from

both

sides

to

the

center

line.

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...