Jose Antonio design and fabrication of 2 stroke workshop

UNIVERSIDADE DA BEIRA INTERIOR

Engenharia

Design and Fabrication of a small SI Two-Stroke

Engine

Murphy 1.0

(versão final após defesa)

José António Pacheco Nunes da Rocha

Dissertação para obtenção do Grau de Mestre em

Engenharia Aeronáutica

(Ciclo de estudos integrado)

Orientador: Prof. Doutor Francisco Miguel Ribeiro Proença Brójo

Covilhã, abril de 2020

Design and Fabrication of a small SI Two-Stroke Engine

ii

Design and Fabrication of a small SI Two-Stroke Engine

Acknowledgements

First and foremost I want to thank both my parents, Ana Pacheco and Belmiro Rocha, without

the two of them I wouldn’t even be here to begin this dissertation. I’m eternally grateful to you

both for everything, you were my safe harbor, my anchors. Thank you.

I also want to express my deep gratitude to Professor Francisco Miguel Ribeiro Proença Brójo,

who was my supervisor in this project. Without his guidance, this work would not have been

possible. I’m forever thankfull for all the patience and for the knowledge passed onto me, as

well as for all the countless hours spent helping me in the experimental part of this dissertation

and for the constant motivation and optimism that helped me continue this work when things

were going south.

A special thanks to DCA’s technician and operational assistant, Mr. Rui Manuel Tomé Paulo, for

teaching me most of what I know about working with tools as well as for all the help and companionship.

There are several people who made an impact in this dissertation and to whom I’m very grateful,

to some of them I hereby present my gratitude:

To Mr. João Antunes for all the help with the assembling of the ECU electronics and for the

availability to help me in the experimental part of this work; To Professor Abílio Manuel Pereira

da Silva for allowing me to use the electric oven from his laboratory; To Alexandro Nunes for

all the time spent helping me in the experimental part of this dissertation and for the words of

advice; To Pedro Alves for the disponibility in printing the 3D models that were crucial; To Professor Miguel Ângelo Rodrigues Silvestre for having supplied old pistons and crankcases for the

foundry process; To Professor Bruno Jorge Ferreira Ribeiro for having supplied an old cylinder

block for the foundry process;

And lastly but not least, to all my friends and family who supported me, put up with me and

made this journey a fantastic one from which I will always look back with a tender heart.

iii

Design and Fabrication of a small SI Two-Stroke Engine

iv

Design and Fabrication of a small SI Two-Stroke Engine

Resumo

Motores de combustão interna (ICEs, Internal combustion engines) desempenham um papel importante na sociedade atual e vão continuar a fazê-lo pelo futuro próximo. Mesmo com todos os

desenvolvimentos e progressos que têm sido feitos em motores elétricos, ainda falta percorrer

um longo caminho até que estes consigam substituir o papel dos ICEs, se é que o farão. É então

desta forma importante continuar o desenvolvimento de ICEs, caso contrário, poderá não se

descobrir vantagens adicionais que os ICEs ainda tenham para oferecer.

Esta dissertação foi feita com intuito de avaliar a possibilidade de fazer o design e fabricar um

cilindro e uma cabeça de cilindro para um motor a dois tempos na universidade. Este trabalho

vai então consistir num projecto conceptual sobre o design e a fabricação de um cilindro e uma

cabeça para um motor a dois tempos controlado pelo pistão (Piston-ported) e acendido a faísca.

Como os motores normalmente têm algum tipo de nome/referência, o protótipo desenhado e

fabricado foi chamado de “Murphy 1.0”.

Primeiramente, foi feito um estudo teórico sobre motores de combustão interna, mais especificamente sobre motores a dois tempos acendidos por faísca, e com a informação reunida o

protótipo foi desenhado em CATIA V5. Para fabricar o “Murphy 1.0” foi estabelecido um processo de fabrico que consegue ser reproduzido na universidade para obter peças de fundição

com precisão e detalhe considerável. A maioria dos componentes práticos necessários para a

fabricação e para o funcionamento do motor também foram fabricados na universidade e vão

ser apresentados ao longo deste documento.

Foram enfrentados vários problemas durantea componente experimental desta tese e os maiores

irão ser apresentados ao longo deste documento. Um exemplo destes problemas foi o facto de

que o motor foi idealizado e desenhado para funcionar com um carburador e um pequeno sistema

de igniçao por descarga capacitiva (CDI, capacitator discharge ignition) mas devido a problemas

que ocorreram, ambos tiveram que ser substituídos. Foi então feita a cablagem e a instalação

de uma centralina (Microsquirt V2) com os sensores/atuadores necessários para permitir o controlo da ignição e injeção do combustível eletronicamente.

Infelizmente, não foi possível conseguir que o “Murphy 1.0” ligasse. As possíveis razões para

tal vão ser apresentadas e explicadas nos capítulos finais mas a razão que estava a impedir

com certeza o funcionamento do protótipo era a falta de compressão no cilindro. Esta baixa

compressão era proveniente de fugas na junta da cabeça com o cilindro. Devido ao prazo de

entrega definido para esta dissertação, não foi possível encontrar uma solução para este problema a tempo. As tentativas feitas para tal, vão ser explicadas também no fim deste documento.

Sem primeiro resolver o problema relativo à compressão, a metodologia seguida para dimensionar as janelas (ports) não pode ser avaliada adequadamente. Foi desta forma inconclusivo

se o motor iria funcionar caso o problema da compressão não persistisse. Ao longo deste documento, todas as escolhas não só relativamente ao design mas também ao processo de fabrico

usado, serão explicadas para permitir uma replicação do trabalho atual ou uma adaptação.

v

Design and Fabrication of a small SI Two-Stroke Engine

Palavras-chave

Design; Fabricação; Motor dois tempos; Motores de combustão interna; Ignição por faísca; Centralina; Fundição.

vi

Design and Fabrication of a small SI Two-Stroke Engine

Abstract

Internal combustion engines (ICEs) perform an important role in today’s society and will keep

doing so in the foreseeable future. Even with all the technological development regarding electric motors, there is still a long way to go before they can substitute ICEs, if they ever do. It is

therefore important that the development of ICEs continues, otherwise, the potential further

advantages that ICEs can offer will not be realized.

This dissertation was done to assess the possibility of designing and fabricating a two-stroke

engine cylinder and cylinder head in the university. This work will then consist of a conceptual

project regarding the design and fabrication of a piston-ported two-stroke SI engine cylinder and

cylinder head. As engines typically have some sort of name/reference, the prototype designed

was named “Murphy 1.0”.

Firstly, a theoretical study about internal combustion engines, more specifically two-strokes SI

engines, was done and then with the information gathered, a prototype was drawn in CATIA V5.

To fabricate the “Murphy 1.0” prototype it was established a fabrication process that can be

achieved at the university to obtain cast-pieces with considerable accuracy and detail. All the

practical components necessary for the fabrication and for the start up of the engine were also

made at the university and will be presented throughout this document.

Several adversities were faced in the experimental component and the major ones will be presented in this document. For instance, the design was made idealizing the usage of a carburetor

and a CDI ignition system for small engines but due to experimental problems, both had to be

changed. It was then done the wiring harness to an ECU (Microsquirt V2) and afterward, the

required sensors/actuators were installed to both the ECU and to the engine to permit the electronical control of the ignition and fuel injection.

Unfortunately, it was not possible to get “Murphy 1.0” to start up. The possible reasons for

such will be presented and explained in the final chapters but the reason that was most likely

impeding the prototype from working was the lack of compression in the cylinder. This lack of

compression was prevenient from a leak in the cylinder head gasket. Due to the deadline set

for this dissertation, it was not possible to find a solution to fix this in time. The attempts made

to solve this problem in the available time will also be explained at the end of this document.

Without first solving the problem regarding compression, the methodology followed to design

the ports cannot be properly assessed. It was therefore not conclusive if the designed engine

could or could not work. Throughout this document, all the choices and steps made will be

explained, not only regarding the engine design but also the fabrication methods used so that a

replication, or an adaption, of this work can be made.

vii

Design and Fabrication of a small SI Two-Stroke Engine

Keywords

Design; Fabrication; Two-Stroke; Internal Combustion Engine; Spark-Ignition; ECU; Metal-casting.

viii

Design and Fabrication of a small SI Two-Stroke Engine

Contents

1 Motivation and Objectives 1

1.1 Motivation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Dissertation outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Bibliographic Review 5

2.1 Historical context of piston engines . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.1 Two-stroke engines history . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Two-stroke engine classification . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Spark-Ignition Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.1 Two-stroke Engine Components . . . . . . . . . . . . . . . . . . . . . . 7

2.3.2 Two-Stroke Cycle and Timing Diagram . . . . . . . . . . . . . . . . . . . 8

2.3.3 Scavenging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.4 Port Shapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.5 Combustion Chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3.6 Cylinder Liner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.7 Otto Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4 Ignition Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4.1 Magneto Ignition System . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4.2 Battery Ignition System . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4.3 Eletronic Ignition System . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.4.4 Spark-plug and Ignition Advance . . . . . . . . . . . . . . . . . . . . . . 19

2.5 Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5.1 Mixture Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5.1.1 Carburetor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5.1.2 Fuel Injection . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.6 Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.6.1 Types of cooling systems . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.7 Performance Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.7.1 Basic Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.7.1.1 Power and Torque . . . . . . . . . . . . . . . . . . . . . . . . 25

2.7.1.2 Compression Ratio . . . . . . . . . . . . . . . . . . . . . . . . 25

2.7.1.3 Crankcase Compression Ratio . . . . . . . . . . . . . . . . . . . 25

2.7.1.4 Swept Volume . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.7.1.5 Mean Effective Pressure . . . . . . . . . . . . . . . . . . . . . 26

2.7.1.6 Mean piston speed . . . . . . . . . . . . . . . . . . . . . . . . 27

2.7.1.7 Specific fuel consumption . . . . . . . . . . . . . . . . . . . . 27

2.7.1.8 Specific power output . . . . . . . . . . . . . . . . . . . . . . 27

2.7.1.9 Air-fuel ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.7.1.10 Heating value of the fuel . . . . . . . . . . . . . . . . . . . . . 28

2.7.2 Efficiencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.7.2.1 Indicated Thermal Efficiency . . . . . . . . . . . . . . . . . . . 28

2.7.2.2 Brake Thermal Efficiency . . . . . . . . . . . . . . . . . . . . . 29

ix

Design and Fabrication of a small SI Two-Stroke Engine

2.7.2.3 Mechanical Efficiency . . . . . . . . . . . . . . . . . . . . . . . 29

2.7.2.4 Volumetric Efficiency . . . . . . . . . . . . . . . . . . . . . . . 29

2.7.2.5 Relative Efficiency . . . . . . . . . . . . . . . . . . . . . . . . 29

2.7.3 Filling efficiencies of two-stroke engines . . . . . . . . . . . . . . . . . 29

2.7.3.1 Scavenge Ratio and Delivery Ratio . . . . . . . . . . . . . . . . 30

2.7.3.2 Scavenging Efficiency . . . . . . . . . . . . . . . . . . . . . . . 30

2.7.3.3 Trapping Efficiency . . . . . . . . . . . . . . . . . . . . . . . . 30

2.7.3.4 Charging Efficiency . . . . . . . . . . . . . . . . . . . . . . . . 31

3 Methodology 33

3.1 Conception (3D Modeling) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.2 Fabrication Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3 Cylinder and Cylinder Head dimensioning . . . . . . . . . . . . . . . . . . . . . 35

3.3.1 Ports size and timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.3.2 Combustion Chamber (Squish Band) . . . . . . . . . . . . . . . . . . . . 38

3.4 Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4 Practical Case 41

4.1 Existing Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.1.1 Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.1.2 Connecting Rod and Crankshaft . . . . . . . . . . . . . . . . . . . . . . 42

4.1.3 Crankcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.2 Results from the dimensioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.2.1 Cylinder and Cylinder-head . . . . . . . . . . . . . . . . . . . . . . . . 43

4.2.2 Combustion Chamber (Squish Band) . . . . . . . . . . . . . . . . . . . . 44

4.2.3 Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.2.4 Air-fins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.3 Draw of the components - Murphy 1.0 . . . . . . . . . . . . . . . . . . . . . . . 47

4.4 Fabrication of the components . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.4.1 Furnace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.4.2 Detailed explanation of the fabrication process . . . . . . . . . . . . . . 54

4.4.3 Foundry attempts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.4.4 Machining and final adjustments . . . . . . . . . . . . . . . . . . . . . . 65

4.5 Murphy 1.0, engine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5 Results and Discussion 69

5.1 Assembly, preliminary tests and required alterations . . . . . . . . . . . . . . . 69

5.1.1 Engine assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.1.2 Load cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.1.3 Test stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.1.4 Propeller and adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.1.5 Ignition system and Mixture Preparation . . . . . . . . . . . . . . . . . . 72

5.1.6 Alterations required to the ignition system and mixture preparation . . . 73

5.1.6.1 Ignition module replacement . . . . . . . . . . . . . . . . . . . 73

5.1.6.2 TunerStudio basic configurations for ignition control . . . . . . . 74

5.1.6.3 Troubleshoot to start the engine - Carburetor and Electronic ignition 75

5.1.6.4 Substitution of the carburetor system for fuel injection . . . . . 75

5.1.6.5 TunerStudio configurations for fuel injection . . . . . . . . . . . 75

x

Design and Fabrication of a small SI Two-Stroke Engine

5.1.7 Troubleshooting to start the engine - Fuel Injection and Electronic ignition 76

5.1.8 Alterations to the cylinder liner . . . . . . . . . . . . . . . . . . . . . . 77

5.2 Final attempts to start up the engine . . . . . . . . . . . . . . . . . . . . . . . 78

5.3 Results and discussion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6 Final Considerations and Future Works 81

6.1 Final considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.2 Future works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Bibliography 85

Appendixes 89

xi

Design and Fabrication of a small SI Two-Stroke Engine

xii

Design and Fabrication of a small SI Two-Stroke Engine

List of Figures

2.1 Exploded view of a simple two-stroke engine [3] . . . . . . . . . . . . . . . . . 8

2.2 Timing Diagram of a typical two-stroke engine [2] . . . . . . . . . . . . . . . . 9

2.3 Different scavenging arrangements as well as the corresponding port geometry

for a two-stroke engine. (a) Cross-scavenging; (b) loop scavenging; (c) Schnurle

loop scavenging; (d) uniflow scavenging with poppet exhaust valves; (e) uniflow

scavenging with opposed pistons. [2] . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Typical port shapes [8] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 Intake port shapes [6] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6 Exhaust port widening [6] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7 Transfer ducts performance comparison [6] . . . . . . . . . . . . . . . . . . . . 13

2.8 Angled port vs straight port[6] . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.9 Combustion chamber with centrally located spark-plug with the use of a squish

band [6] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.10 Side located combustion chamber[6] . . . . . . . . . . . . . . . . . . . . . . . 15

2.11 Conical combustion chamber[6] . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.12 Actual P-V diagram of a two-stroke SI engine [12] . . . . . . . . . . . . . . . . . 16

2.13 Magneto Ignition System [13] . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.14 Battery Ignition System [14] . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.15 Eletronic Ignition System [15] . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.16 Conventional spark-plug [1] . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.17 Carburetor Schematics [1] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.18 Liquid-cooled engine [12] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.19 Air-cooled engine [12] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.20 Geometry of cylinder, piston, connecting rod, and crankshaft where B=bore, L=stroke,

l=connecting road length, a=crank radius, θ=crank angle [1] . . . . . . . . . . . 26

3.1 Flowchart of the fabrication process . . . . . . . . . . . . . . . . . . . . . . . 34

3.2 Flowchart of the dimensioning process . . . . . . . . . . . . . . . . . . . . . . 35

3.3 Flowchart of the dimensioning of the ports . . . . . . . . . . . . . . . . . . . . 37

3.4 Ports height in the cylinder [6] . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.5 Flowchart of the process used to design the combustion chamber . . . . . . . . 39

4.1 Piston used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.2 Crankshaft and Connecting rod . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.3 Crankcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.4 Existing components assembled . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.5 Minimum distance recommended between the exhaust and transfer ports [6] . . 46

4.6 Visual representation of how the exhaust flange should be designed [9] . . . . . 46

4.7 Isometric view of the cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.8 Exhaust side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.9 Intake side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.10 Top view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.11 Bottom view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.12 Transfer port inside view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

xiii

Design and Fabrication of a small SI Two-Stroke Engine

4.13 Exhaust port inside view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.14 Intake port inside view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.15 Isometric view of the cylinder head . . . . . . . . . . . . . . . . . . . . . . . . 51

4.16 Top view cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.17 Bottom view cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.18 Front view cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.19 Side view cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.20 Furnace built with the original cover . . . . . . . . . . . . . . . . . . . . . . . 53

4.21 Furnace with the plaster cover . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.22 Propane burner built . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.23 Crucible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.24 Test pieces in PLA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.25 Test piece in ABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.26 Molds of the test pieces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.27 Results from the test pieces . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.28 3D print of the first cylinder head attempt . . . . . . . . . . . . . . . . . . . . 58

4.29 Mold of the first cylinder head attempt . . . . . . . . . . . . . . . . . . . . . . 58

4.30 Results from the first cylinder head attempt . . . . . . . . . . . . . . . . . . . 58

4.31 3D print of the second cylinder head attempt . . . . . . . . . . . . . . . . . . . 59

4.32 Results from the second cylinder head attempt . . . . . . . . . . . . . . . . . . 59

4.33 3D print of the third cylinder head attempt . . . . . . . . . . . . . . . . . . . . 59

4.34 Gating system used for this attempt . . . . . . . . . . . . . . . . . . . . . . . . 60

4.35 Restuls from the third cylinder head attempt . . . . . . . . . . . . . . . . . . . 60

4.36 3D print of the fourth cylinder head attempt . . . . . . . . . . . . . . . . . . . 61

4.37 Results from the fourth cylinder head attempt . . . . . . . . . . . . . . . . . . 61

4.38 Third attempt cylinder head after being machined . . . . . . . . . . . . . . . . 61

4.39 3D print of the first cylinder attempt . . . . . . . . . . . . . . . . . . . . . . . 62

4.40 Mold of the first cylinder attempt after the burnout schedule . . . . . . . . . . 62

4.41 3D print of the second cylinder attempt . . . . . . . . . . . . . . . . . . . . . . 63

4.42 Gating system used for the second cylinder attempt . . . . . . . . . . . . . . . 63

4.43 Results from the second cylinder attempt after being machined . . . . . . . . . 63

4.44 3D print of the third cylinder attempt . . . . . . . . . . . . . . . . . . . . . . . 64

4.45 Results from the third cylinder attempt after the foundry . . . . . . . . . . . . 64

4.46 Final cylinder after the J.B. Weld was applied and after the machining . . . . . . 65

4.47 Steel liner built . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.48 Cylinder after the liner was inserted . . . . . . . . . . . . . . . . . . . . . . . 66

4.49 Cylinder with the steel liner, final result . . . . . . . . . . . . . . . . . . . . . 67

4.50 Cylinder head, final result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.51 Copper head gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.52 Cylinder to crankcase paper gasket . . . . . . . . . . . . . . . . . . . . . . . . 68

5.1 Connections made between the Arduino Nano, load cell and HX711 amplifier.

Taken from [26] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.2 Representative diagram of the test stand, taken from [28] . . . . . . . . . . . . 70

5.3 Adapter built for the propeller . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.4 Pegasus DC-CDI ignition system [29] . . . . . . . . . . . . . . . . . . . . . . . . 72

5.5 Test Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

xiv

Design and Fabrication of a small SI Two-Stroke Engine

5.6 50 cc Carburetor used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.7 MicroSquirt V2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.8 Cast-iron liner built . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.9 Cylinder with the cast-iron liner, final result . . . . . . . . . . . . . . . . . . . 78

A.1 ABS burnout schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

A.2 PLA burnout schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

B.1 ”Idealised cylinder head” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

B.2 ”Final design cylinder head” . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

B.3 ”Idealised Cylinder design” . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

B.4 ”Final Cylinder design” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

B.5 ”Ports dimensions” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

C.1 Timing diagram of the engine designed . . . . . . . . . . . . . . . . . . . . . . 95

F.1 Representative CATIA V5 design of the support platform built in previous projects.

Taken from [26] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

F.2 Detailed view of the modification made to the test stand . . . . . . . . . . . . . 98

F.3 Detailed view of the engines backside . . . . . . . . . . . . . . . . . . . . . . . 99

F.4 Engine assembled to the test stand . . . . . . . . . . . . . . . . . . . . . . . . 99

F.5 Plastic cone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

F.6 Adapter for the drill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

F.7 Aluminum disc used to connect the cone to the propeller . . . . . . . . . . . . . 100

F.8 Propeller assembled with the adaptor and the cone . . . . . . . . . . . . . . . . 100

F.9 Ignition module and ignition coil assembled to the test stand . . . . . . . . . . . 100

F.10 Detailed view of the hall sensor . . . . . . . . . . . . . . . . . . . . . . . . . . 101

F.11 Adapter built to install the exhaust . . . . . . . . . . . . . . . . . . . . . . . . 101

F.12 Exhaust installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

F.13 Adapter built for the intake . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

F.14 Engine with the carburetor installed . . . . . . . . . . . . . . . . . . . . . . . 102

F.15 Engine with the fuel injection system installed, final assembly . . . . . . . . . . 102

G.1 Adapter designed to install the propeller . . . . . . . . . . . . . . . . . . . . . 103

H.1 Wiring harness diagram, taken from [32] . . . . . . . . . . . . . . . . . . . . . 104

I.1 TunerStudio basic ignition configuration . . . . . . . . . . . . . . . . . . . . . . 105

I.2 TunerStudio basic configuration for fuel injection . . . . . . . . . . . . . . . . . 106

I.3 Table VE generated with recourse to TunerStudio MS . . . . . . . . . . . . . . . 107

K.1 The efficiency of straight fins of rectangular, triangular and parabolic profiles.

Taken from [23] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

L.1 Existing components assembled, 3D model . . . . . . . . . . . . . . . . . . . . 110

L.2 All the components assembled, 3D model . . . . . . . . . . . . . . . . . . . . . 110

xv

Design and Fabrication of a small SI Two-Stroke Engine

xvi

Design and Fabrication of a small SI Two-Stroke Engine

List of Tables

4.1 Murphy 1.0 basic engine data . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

J.1 Heating values for common fuels [19] . . . . . . . . . . . . . . . . . . . . . . . 108

K.1 Expected Indicated Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

K.2 Expected Brake Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

K.3 Reboring allowance for IC engine cylinder, taken from [21] . . . . . . . . . . . . 109

xvii

Design and Fabrication of a small SI Two-Stroke Engine

xviii

Design and Fabrication of a small SI Two-Stroke Engine

Nomenclature

A Cross section area of the cylinder

A

fin

A

unfin

B Bore

C Reboring allowance

C

R

C

Rcc

h Convective heat transfer coefficient

L Stroke

m

ar

m

as

m

dref

m

ex

m

sref

m

tas

m

tr

˙m

a

˙m

f

N Rotational velocity

N

C

N

fin

n

R

P Power

P

max

˙

Q

fin

˙

Q

total

˙

Q

unfin

sfc Specific fuel consumption

T Torque

T

b

T

∞

t Time

th

c

th

c,empirical

th

ch

V

c

V

cc

V

d

η

bth

η

fin

η

ith

η

m

η

re

η

ve

Area of one fin

Area of cylinder where there are no fins

Compression ratio

Crankcase compression ratio

Mass of unburned mixture from the previous cycle

Mass of fresh charge supplied per cycle

Necessary mass to fill the swept volume

Mass of the exhaust gasses

Necessary mass to fill the entire cylinder volume

Mass of fresh charge that is trapped in the cylinder

Total mass of the charge that is trapped in the cylinder

Air mass flowrate

Fuel mass flowrate

Number of cylinders

Number of fins

Number of crank revolutions for each power stroke per cylinder

Maximum gas pressure inside the cylinder

Heat dissipation rate from the fins

Total heat rate dissipation

Heat dissipation rate from the unfinned area of the cylinder

Temperature of the engine

Temperature of the air flowing through the fins

Cylinder wall thickness

Empirical cylinder wall thickness

Cyliner head thickness

Clearance volume

Volume of the crankcase at bottom dead center

Swept volume

Brake thermal efficiency

Fins efficiency

Indicated thermal efficiency

Mechanical efficiency

Relative efficiency

Volumetric efficiency

xix

Design and Fabrication of a small SI Two-Stroke Engine

ρ

a

σ

c

Inlet air density

Allowable tensile stress

xx

Design and Fabrication of a small SI Two-Stroke Engine

List of Acronyms

ABS Acrylonitrile Butadiene Styrene

BDC Bottom Dead Center

BMEP Brake mean effective pressure

CDI Capacitive discharge ignition

CE Charging Efficiency

CI Compression Ignition

CAD Computer Aided Design and drafting

CATIA Computer Aided Three-Dimensional Interactive Application

DE Delivery Ratio

DCA Department of Aerospace Sciences

DC Direct Current

EMF Electomotive Force

ECU Electronic Control Unit

EFI Electronic fuel injection

FMEP Friction mean effective pressure

IMEP Indicated mean effective pressure

MAP Manifold absolute pressure

MEP Mean effective pressure

MPS Mean piston speed

PLX-DAQ Parallax Data Acquisition Tool

PETG Polyethylene terephthalate glycol

PLA Polylactic acid

RC Radio controlled

SE Scavenge efficiency

SR Scavenge ratio

SI Spark Ignition

TDC Top Dead center

TE Trapping efficiency

UBI University of Beira Interior

VE Volumetric efficiency

xxi

Design and Fabrication of a small SI Two-Stroke Engine

xxii

Design and Fabrication of a small SI Two-Stroke Engine

Chapter 1

Motivation and Objectives

1.1 Motivation

For this thesis, it was chosen a subject that would allow acquiring a more profound and deep

knowledge about propulsion, more specifically engine design and its fabrication. Even though

the technological developments in electric motors has been increasing and now being a possible

substitute for combustion engines, there is still a long way to go. In several applications, combustion engines are still a better choice. Combustion engines have been used in the aeronautical

industry for a very long time now, but piston engines are now mainly used in light aircraft and

RC model airplanes. It is, however, within the branch of ultralight aircraft that two-stroke

engines stand out above four-strokes. The majority of ultralights produced in the recent past

years have been powered by two-stroke engines and good reasons exist as to why. For instance,

they require fewer parts and less moving ones too, being, therefore, lighter and mechanically

simpler; have a superior power to weight ratio; are simpler and cheaper to maintain and build.

It is also of interest to point out that two-stroke engines may be making a comeback, a huge

amount of research is currently being made in two-stroke engines by companies like KTM and

Honda. Formula 1 Chief Technical Officer (Pat Symonds) has recently stated that the future

of F1 may reside in two-stroke engines, and changes may happen as soon as 2025. If such big

developments are being made in two-stroke engines and are now even being considered for the

future of F1 and MotoGP, it could only further enhance its potential in light aviation.

As two-strokes still play an important part in ultralight aviation and might even be making a

comeback, it was of the authors’ keen interest to deepen is knowledge in this kind of propulsion

system. This thesis will then focus on the conceptual project of a small, simple piston ported

two-stroke engine and its construction. It will regard all the steps, as well as the methodology

used, to design and fabricate a two-stroke engine cylinder and cylinder head. These were designed for a recovered piston with the corresponding crankcase, crankshaft and connecting rod.

The reasons why it was opted only to fabricate the cylinder and cylinder head are the reasons

that also justify why the majority of projects regarding engine design rarely go as far as into

building a prototype. The design of ICEs is mostly empirical and those who possess that information are usually corporations, whom for obvious reasons won’t share them with the public.

Consequently, not much empirical information regarding engine design can be freely accessed/found, which means that any attempt to build a prototype isn’t assured of success, given the

lack of solid empirical information to base the design at. Hence, having a company build the

designed prototype is extremely expensive and could prove ungrateful; and the remaining alternative which is to fabricate it oneself is a long and laborious process with even lower chances

of success.

It is, therefore, important as well as interesting to at least try and assess the possibilities of

designing and fabricating two-stroke engines in the university. If one proves to be successful,

1

Design and Fabrication of a small SI Two-Stroke Engine

it will permit the creation of empirical data from which conclusions can be drawn and future

works can take place with better and better results.

1.2 Objectives

This thesis main objective was to try and create a functional prototype with a simple design

that could be fabricated with the resources available at the university. This means that one of

the thesis main objectives was to try and replicate a fabrication method that can be used to

obtain a functional prototype. As no groundwork has been done at the university as for how to

fabricate a two-stroke engine with the resources there available, this project will serve as the

groundwork for future projects where the fabrication of an engine is intended through castings.

This goes as well to the empirical data regarding the design of a two-stroke engine. So this

thesis objectives can be listed as:

• Understand the functioning of two-stroke engines

• Dimension and design a cylinder and cylinder head

• Find a fabrication method that can be used and improve it as much as possible.

• Assemble the fabricated components with the existing ones.

• Check if the prototype is functional.

• Take basic performance parameters of the engine.

• Creation of empirical data in engine design for future works at the university.

1.3 Dissertation outline

This dissertation is divided into 6 main chapters, each dedicated to a different objective but all

dependent on one another. It follows the traditional format of a master thesis, being the first

chapter the current one which includes the motivation of this project as well as its objectives.

The second chapter is dedicated to the bibliographic review which contains the theoretical

content regarding the operation of two-stroke spark-ignition engines and some of the different

variations possible in its design. It will also be looked into the main different options for ignition

systems, mixture preparation methods as well as the performance parameters of spark-ignition

engines.

The third chapter is a description of the methodology followed for the fabrication and the dimensioning of the engine.

The fourth chapter describes all the choices made for the design of the engine such as the cylinder and cylinder head thicknesses and the dimensions of the ports. The process of fabrication

and machining are also explained in-depth with all the conclusions that were drawn from the

various attempts.

2

Design and Fabrication of a small SI Two-Stroke Engine

In the fifth chapter, the experimental components necessary for the test runs are presented in

detail as well as the troubleshooting done to try and start up the engine.

In the final chapter, are presented the conclusions obtained from the present dissertation and

possible future works to be done in this area.

3

Design and Fabrication of a small SI Two-Stroke Engine

4

Design and Fabrication of a small SI Two-Stroke Engine

Chapter 2

Bibliographic Review

2.1 Historical context of piston engines

Internal combustion engines date back to 1860 when J. J. E. Lenoir (1822-1900) [1] developed

an engine that burned a mixture of coal gas and air at atmospheric pressure. In this engine

there was no compression before combustion, the inflammable gas and air were drawn into the

cylinder and ignited by an electric spark. Later in that decade, 1867, Nicolaus A. Otto (1832-

1891) and Eugen Langen (1833-1895) introduced the atmospheric engine [1]. This engine was

more efficient than Lenoir’s engine and had half its fuel consumption [2]. In 1876, Otto came

up with the four-stroke cycle to overcome the engine’s shortcomings of low thermal efficiency

and excessive weight [1]. This was the discovery that permitted the internal combustion engine

industry to thrive. Soon after, the two-stroke cycle was developed by Dugald Clerk (1854-1913)

and James Robson (1833-1913), in England and Karl Benz (1844-1929), in Germany [1]. The

two-stroke cycle engine was lighter and with a higher power-to-weight ratio than the fourstroke. The next big development in internal combustion engines came in 1892, brought by

Rudolf Diesel (1858-1913) [1]. He purposed a new form of internal combustion engine. In this

new type of engine, the combustion occurred with the injection of liquid fuel into air heated

only by compression. Allowing this way, the creation of engines with the double of efficiency

when compared to other internal combustion engines. Based on what these men invented,

several improvements and variations have been made. And even now that over a century has

passed there is still room for improvement [1]. Engine manufactures, be them the Diesel type

or conventional spark-ignition type, continue to show improvements in their engines power,

efficiency, fuel consumption, reduced emissions among many others.

2.1.1 Two-stroke engines history

The first successful two-stroke cycle engine was developed by Dugald Clerk, a Scottish engineer,

by the end of the 19th century [3]. However, Clerks’ original design was not adaptable to small

engines. The crankcase-compression two-stroke engine, as we know, is credited to Joseph Day.

He named his original design the “Valveless air compressor”, which interestingly had two flap

valves, one in the inlet port and one in the piston crown, this because he still hadn’t come up

with the idea for transfer ports. It was one of his workmen, Frederick Cock, who made the modification which would allow the skirt of the piston to control the inlet port, creating this way the

classic piston port engine as we know [4]. Joseph Day ended up naming this new variation the

“valveless two-stroke engine”. This design used the crankcase compression for the induction

process, and the control of the timing and area of the exhaust, transfer and intake ports was

made by the piston [3]. It was Joseph Day simplification of the two-stroke engine concept that

made possible for the construction of small powerful two-stroke engines.

Early applications of two-stroke engines were in motorcycles [3], and with time they became

mainly used when there is a necessity for a lightweight engine. This happened due to the leg-

5

Design and Fabrication of a small SI Two-Stroke Engine

islative pressure on exhaust emissions that some countries established, making manufacturers

swing to four-stroke engines in some applications. Two-strokes are still vastly used in motorcycles, handheld power tools, aircraft/car RC models as well as ultralight aircrafts among others.

Two-stroke engines usually have high fuel consumption’s but a huge amount of research is being

conducted in two-stroke engines by companies like KTM and Honda. Recent technological developments made with direct injection, supercharging, new ignition systems are permitting the

creation of new forms of two-stroke engines that are more efficient and Eco-friendly. Formula 1

Chief Technical Officer, Pat Symonds, has recently stated in the Motorsport Industry Association

conference that the future of F1 may reside in two-strokes and that he is looking forward to

it. He also stated that the opposed piston (two-stroke) is coming back and is already delivering

efficiencies superior to 50% in road car form. Basil von Rooyen in 2009/2012 has patented and

proved a new type of two-stroke engine, the Crankcase-Independent Two-Stroke (CITS) which

eliminates the traditional need to burn the two-stroke oil and dramatically reduce the exhaust

emissions. Two-stroke engines have enormous potential and only future research will tell how

their future will turn out.

2.2 Two-stroke engine classification

Two-stroke engines are classified, as well as other internal combustion engines, by several different parameters. Some of them are [2], [1]:

1. Type of ignition:

• Spark Ignition (SI): the combustion process is initiated by a spark from a spark plug.

• Compression Ignition (CI): the combustion process is initiated by the elevated temperature of the gas inside the cylinder (caused by the mechanical compression).

2. Working Cycle:

• Two-stroke cycle: A two-stroke cycle engine completes its cycle in two piston movements, one up and down, during only one crankshaft revolution.

• Four-stroke cycle: A four-stroke cycle experiences four piston movements to complete its cycle, in which two crankshaft revolutions occur.

3. Application: Automobile, locomotive, light aircraft, boats, power tools, among others.

4. Basic engine design:

• Reciprocating: also known as a piston engine, is an engine that has one or more

cylinders and uses the reciprocating motion of the pistons to cause the rotary motion

of the crankshaft. This type of engine can be subdivided by the arrangement of the

cylinders: in-line,V, radial, opposed.

• Rotary engine: is an engine whose radial cylinders rotate about a fixed crankshaft.

Rotary engines also include pistonless engines like the Wankel engine, which uses an

eccentric rotor to convert pressure into rotating motion.

5. Fuel used: gasoline, diesel, natural gas, ethanol, and others.

6. Combustion chamber design: Open chamber and divided chamber. Both of each type

have several designs.

6

Design and Fabrication of a small SI Two-Stroke Engine

7. Method of mixture preparation: the mixture preparation can be made through a carburetor, through fuel injection in the intake phase or through fuel injection into the engine

cylinder.

8. Cooling system: the engine can be air cooled, water cooled or even uncooled.

9. Port design and location: The location of the ports in the cylinder, can fall under the fol-

lowing categories: - Cross-scavenged porting, loop-scavenged porting, uniflow-scavenged.

From all these distinct parameters it’s possible to distinguish and classify an internal combustion

engine. The method of ignition, according to literature, is the principal classifying feature

[1], since from it come important characteristics such as the fuel to use, how the mixture

is going to be prepared, how the combustion chamber should be designed as well as other

classifications even though some fall into subcategories of the ones mentioned above. The

second most important classifying feature is the engines operating cycle. Two stroke engines

induction usually falls under three different categories. They can be piston ported, which is the

simplest and uses the piston to control the ports as it moves up and down, they can use reed

valves which is the most commonly used in high-performance two-stroke engines, and they can

also use rotary valves.

2.3 Spark-Ignition Engines

Spark-ignition engines are those whose combustion process initiates with recourse to a spark

plug, which will ignite the air-fuel mixture with a spark near the end of the compression stroke.

The necessary components in this type of engine to ignite the mixture are, an ignition coil as

the high-voltage source and a spark plug which delivers the spark in the combustion chamber

[5].

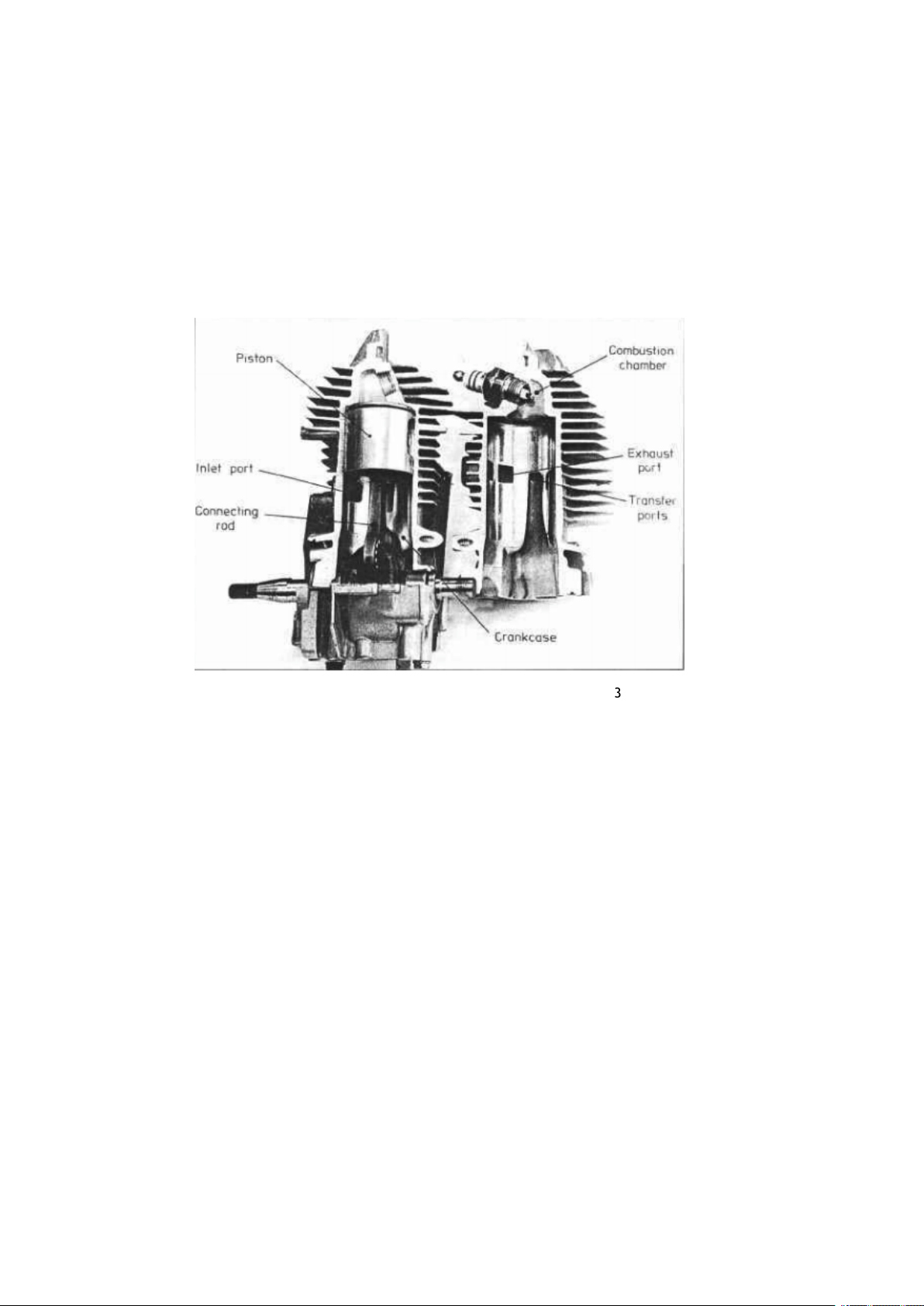

2.3.1 Two-stroke Engine Components

In a common two-stroke spark-ignition engine, the major components are listed below and can

be seen in figure 2.1:

• Piston: Usually made from aluminum alloys, it is located inside the cylinder and is responsible for transferring the force from the expanding gases to the crankshaft. This transfer

occurs from the up and down movement of the piston.

• Cylinder/Liner: Is a cylindrical vessel typically made of cast iron. It’s inside of the liner

that the piston moves.

• Block: It’s where the cylinder/s is placed and in small engines is usually made from aluminum alloys.

• Crankshaft: It’s a shaft that along with the connecting rod is responsible for converting the

reciprocating motion of the piston into a rotational one. The crankshaft has traditionally

been made with steel and forged [1].

• Connecting Rod: It’s a rod that connects the piston to the crankshaft. The connecting rod

is usually made of steel or an alloy forging, although in small engines sometimes aluminum

is used [1].

7

Design and Fabrication of a small SI Two-Stroke Engine

• Combustion Chamber: Located in the top of the cylinder and is where combustion occurs.

• Spark Plug: It’s the ignition source and is usually located in the combustion chamber, in a

zone out of reach of the piston.

• Ports: The intake port, responsible for allowing the new mixture of air-fuel inside the

crankcase; the transfer port, responsible for transferring the new mixture of air-fuel from

the crankcase into the cylinder; and the exhaust port, whose function is to allow the

burned mixture out of the cylinder.

Figure 2.1: Exploded view of a simple two-stroke engine [3]

2.3.2 Two-Stroke Cycle and Timing Diagram

In two-stroke cycle engines we obtain power after only one crankshaft revolution. This crankshaft

revolution requires two strokes of the piston, hence its name of two-stroke.

• In the first stroke (compression stroke), the piston goes up in the cylinder compressing the

fuel-air mixture trapped there. When the piston is reaching top dead center the mixture is

met by a spark plug that will ignite the compressed fuel. As the piston goes up the intake

port opens, allowing a new mixture of air-fuel to enter the crankcase.

• In the second stroke (Power stroke), the mixture that was ignited by the spark plug raises

the temperature and pressure in the cylinder which forces the piston down [2]. As the

piston goes down, the new fuel-air mixture is compressed in the crankcase and when the

piston is near the end of its stroke, the exhaust port opens allowing the burnt gases to

be expelled. Simultaneously to this, the transfer port opens and the previous compressed

charge in the crankcase expands into the cylinder. The process where the burnt gases are

expelled from the cylinder as the new mixture is forcing its way into the cylinder is called

‘scavenging’.

Another important concept to understand about engines who run on the two-stroke cycle is the

timing diagram. In figure 2.2 we can see a typical timing diagram for a piston-ported two-stroke

engine, and below an explanation of this diagram.

8

Loading...

Loading...