John Deere 750J Specifications

|

|

|

1 4 5 – 2 0 0 |

N E T |

H O R S E P O W E R |

J DOZERS

750J | 850J

750J

145 hp Standard, LT

155 hp LGP

32,585 lb. Standard

34,395 lb. LT

36,725 lb. LGP

22-, 24-, 28-, and 34-in. grousers 128-, 130-, and 156-in. blades

Simply advanced.

Built with the same kind of forward thinking as our first hydrostatic dozer more than 30 years ago, 750J and 850J Dozers continue to define the way earthwork gets done. Their unique state- of-the-art Total Machine Control (TMC) enables

an operator to customize machine operation and response to personal preferences. Coupled with an uncommonly smooth full-featured hydrostatic drivetrain, the John Deere J-Series Dozers deliver unsurpassed power, control, and results. Again.

PAGES

2–3

850J

185 hp Standard, LT, WT, WLT

200 hp LGP

40,165 lb. Standard

43,015 lb. LT

41,285 lb. WT

44,225 lb. WLT

45,375 lb. LGP

22-, 24-, 30-, and 36-in. grousers 128-, 140-, 146-, 152-,

158-, and 168-in. blades

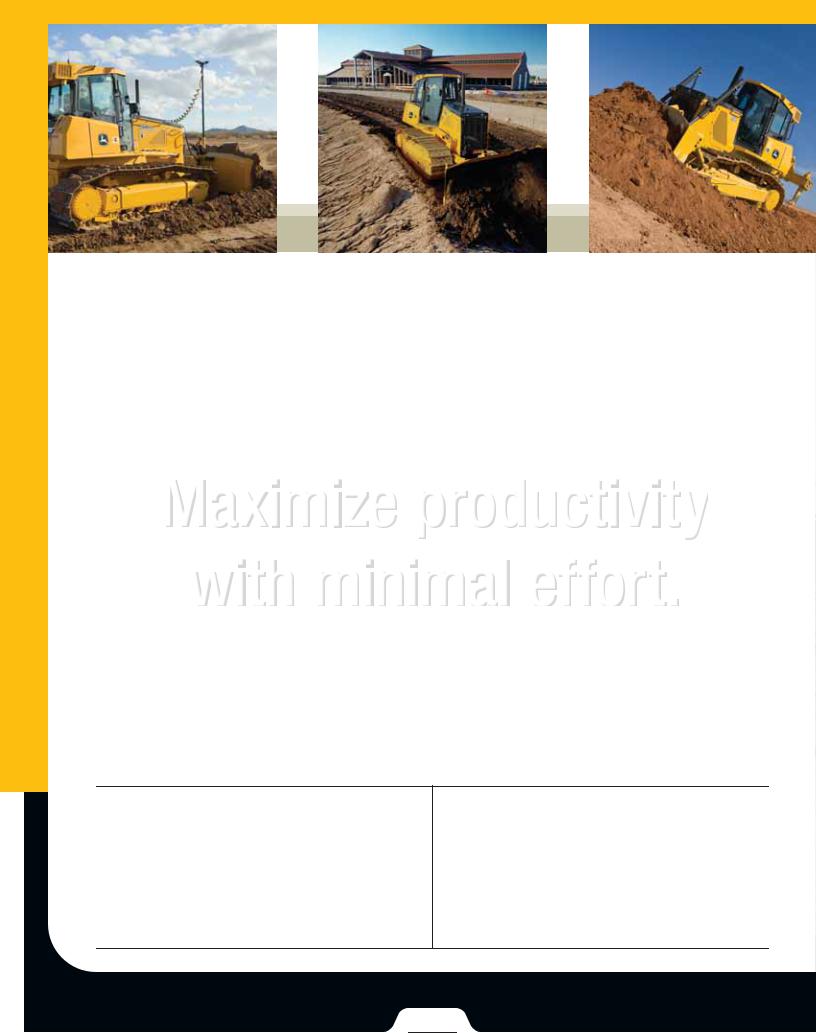

Power turns, power management, infinite speed control –– we introduced them all more than 30 years ago. And today’s 750J and 850J are loaded with even more productivityand uptime-boosting enhancements.

Eleven track frames, four mainframes, and a variety of blades let you choose the right crawler configuration for your kind of work.

Tier 3-certified John Deere diesels deliver power without compromise in

all conditions.

Deere’s unique Total Machine Control lets an operator customize the crawler’s operational characteristics and response, and even records machine usage.

Standard equipped with JDLink™ Ultimate, you have 24/7 anywhere access to your dozer’s location, utilization, dashboard alerts, fuel consumption, diagnostic codes, and hours. Plus geofencing, curfew, and numerous other capabilities.

Best-in-class service access, same-side daily servicing, and extended engine, hydraulic, and transmission oil and filter service intervals help keep downtime to a minimum.

Equipped with optional Integrated Grade Control (IGC), adding your preferred grade-control system is “plug-and-play” easy.

Independent track control speeds up or slows down each side – for smooth, full-power turns. An automatic 10-percent power boost helps carry more material in a turn.

No need to cross-steer or ride a brake. These dozers steer the same and maintain their preset speed whether working on level ground or a 2-to-1 slope.

Maximize productivity

with minimal effort.

with minimal effort.

All dozers move the earth. But if you want one that does more with a lot less effort, you’ll choose a John Deere J-Series. State-of-the-art electronic controls put you in complete command of a whole arsenal of hydrostatic advantages, including power turns, counterrotation, and

infi nitely variable travel speeds. What’s more, Total Machine Control lets an operator customize decelerator mode and response, forward/reverse ground-speed ranges, steering modulation, and forward/reverse speed ratios. Nothing else even comes close.

PAGES

4–5

Low-effort controls command the blade and a full-featured hydrostatic drivetrain, ensuring predictable response at all times in all conditions.

Simply set the maximum desired ground speed and the powermanagement system automatically maintains peak engine rpm and power efficiency without stalling or shifting.

Infinitely variable range to 6.8 mph gives total flexibility to match ground speed to the load. Travel can also be varied to fit specific applications, terrain, or operating preferences — and even limited to maximize undercarriage life.

Purpose-built mainframes for power-angle-tilt and outsidemount blades allow optimized component placement for uncompromised grading ability.

Fully modulated drivetrain ensures smooth starts and direction changes, while virtually eliminating jerky or abrupt movements.

Counterrotation is a productivity-boosting feature that enables an operator to overcome heavy corner loads and quickly reposition the blade on the go. Provides space-saving spot turns, too.

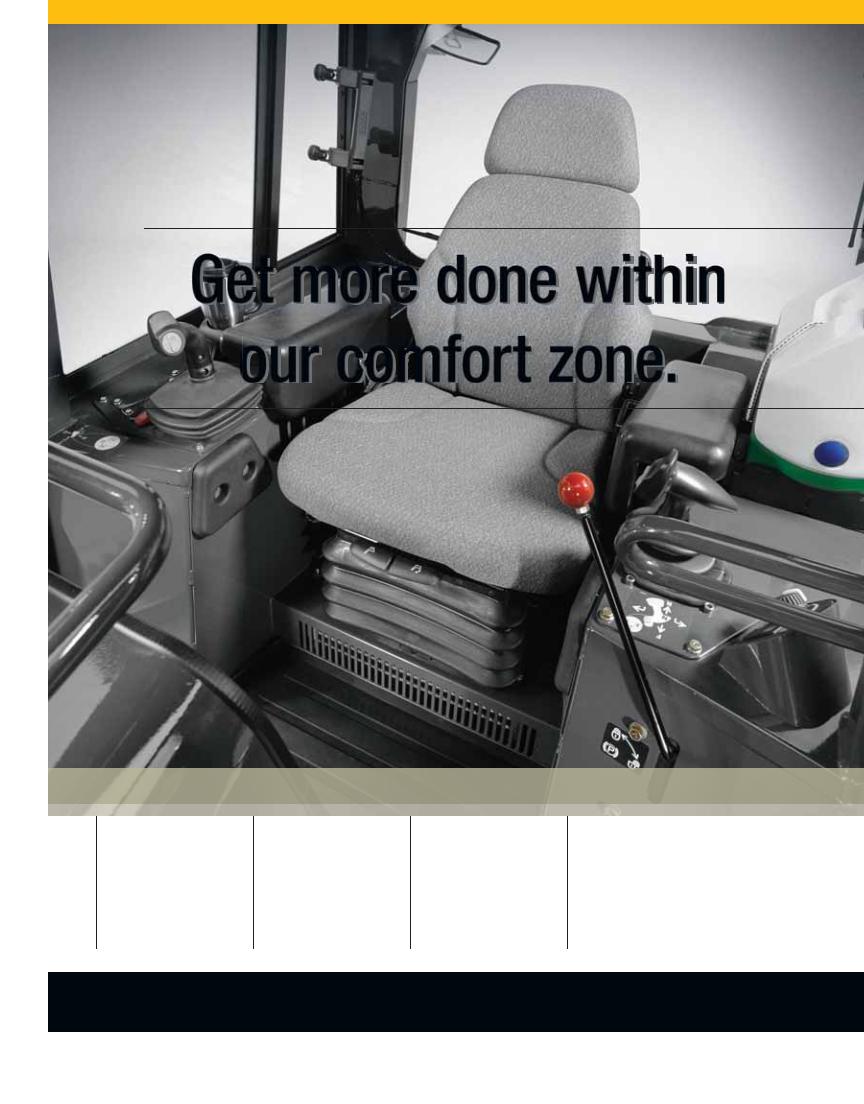

Get more done within our comfort zone.

Generous hydraulic flow and precise metering ensure powerful and quick blade response, while providing a natural “feel” that will enhance any operator’s grading skills. A thumb-actuated switch provides low-effort angle control.

Retractable seat belt, slip-resistant floor mat, convenient grab bars, neutral-start lever, and automatic park brake help keep the operator out of harm’s way.

Deluxe suspension armchair won’t cramp your operator’s style. Seven-way adjustable seat provides plenty of legroom and daylong comfort. Armand footrests also adjust.

Ergonomically correct joystick |

Convenient 12-volt port pro- |

provides intuitive, low-effort |

vides power for accessories |

control of steering, forward/ |

such as cell phones. |

reverse travel, and ground speed. |

|

It’s detented so it doesn’t require |

|

an operator’s constant touch or |

|

attention, and employs a thumb- |

|

actuated travel-speed switch. |

|

|

Cab-forward design positions the operator for a more stable ride and a commanding view behind, below, and beyond the blade. Side and rear visibility is equally unobstructed.

Monitor keeps a vigilant watch on vital machine functions with warnings you can see and hear.

PAGES

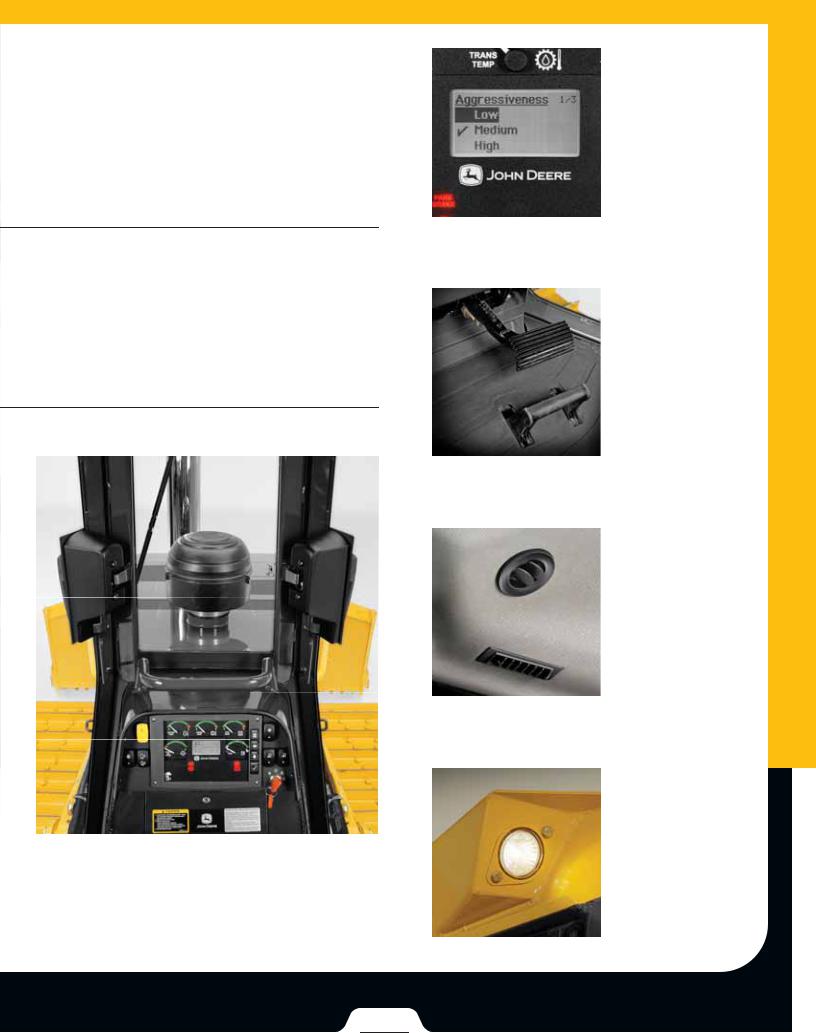

Exclusive TMC lets you customize decelerator mode and response, forward/ reverse ground-speed ranges, steering modulation, FNR shift rate, and forward/ reverse speed ratios, for unsurpassed one-of-a-kind control.

Automotive-style directional vents deliver effective airflow to keep the glass clear and the cab comfortable. Air conditioning is standard on all cabs. For ROPS-only

crawlers, an optional underseat heater helps warm the operator.

High-intensity halogen driving lights are standard. Or opt for the factoryinstalled 360-degree light package and extend your workday beyond normal daylight hours.

6–7

|

One-piece welded main- |

Individually replaceable wet- |

Sealed transmission connec- |

|

|

frame resists torsional |

sleeve cylinder liners provide |

tors prevent moisture and |

|

|

stress, absorbs shock loads, |

uniform engine cooling and |

contaminants from entering |

|

|

and delivers maximum |

long-term durability. |

terminals: gold pins resist |

|

|

strength while allowing easy |

|

corrosion for increased |

|

|

service access to major |

|

reliability. |

|

|

components. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

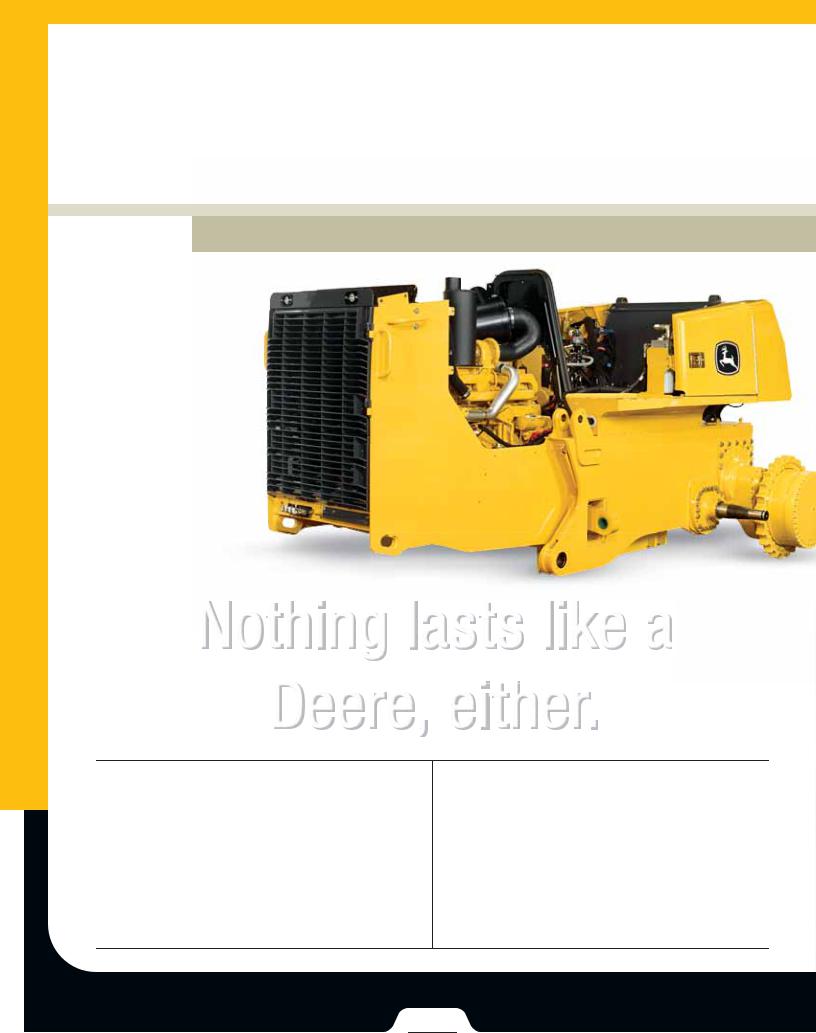

Designed and built with state-of-the-art tools and techniques by a quality-conscious workforce at our world-class facility in Dubuque, Iowa, the J-Series are loaded with uptime-boosting features. Enhancements include a variable-speed hydraulic-driven cooling system fan, gold-plated electrical connectors, and

extended service intervals. These, plus traditional Deere durability features such as one-piece unitized mainframes, Dura-Trax™ undercarriage, wet-sleeve engine liners, O-ring face-seal hose couplers, and isolated planetary final drives keep them keeping on. When you know how they’re built, you’ll run a Deere.

PAGES

8–9

Loading...

Loading...