JLG T500J Service Manual

Service & Maintenance Manual

Model

T500J

3121200

January 9, 2013

INTRODUCTION

SECTION A. INTRODUCTION - MAINTENANCE SAFETY

PRECAUTIONS

A GENERAL |

C MAINTENANCE |

This section contains the general safety precautions which must be observed during maintenance of the aerial platform. It is of utmost importance that maintenance personnel pay strict attention to these warnings and precautions to avoid possible injury to themselves or others, or damage to the equipment. A maintenance program must be followed to ensure that the machine is safe to operate.

MODIFICATION OR ALTERATION OF AN AERIAL WORK PLATFORM SHALL BE MADE ONLY WITH WRITTEN PERMISSION FROM THE MANUFACTURER.

The specific precautions to be observed during maintenance are inserted at the appropriate point in the manual. These precautions are, for the most part, those that apply when servicing hydraulic and larger machine component parts.

Your safety, and that of others, is the first consideration when engaging in the maintenance of equipment. Always be conscious of weight. Never attempt to move heavy parts without the aid of a mechanical device. Do not allow heavy objects to rest in an unstable position. When raising a portion of the equipment, ensure that adequate support is provided.

SINCE THE MACHINE MANUFACTURER HAS NO DIRECT CONTROL OVER THE FIELD INSPECTION AND MAINTENANCE, SAFETY IN THIS AREA RESPONSIBILITY OF THE OWNER/OPERATOR.

B HYDRAULIC SYSTEM SAFETY

It should be noted that the machines hydraulic systems operate at extremely high potentially dangerous pressures. Every effort should be made to relieve any system pressure prior to disconnecting or removing any portion of the system.

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN THIS SECTION COULD RESULT IN MACHINE DAMAGE, PERSONNEL INJURY OR DEATH AND IS A SAFETY VIOLATION.

•ENSURE REPLACEMENT PARTS OR COMPONENTS ARE IDENTICAL OR EQUIVALENT TO ORIGINAL PARTS OR COMPONENTS.

•NO SMOKING IS MANDATORY. NEVER REFUEL DURING ELECTRICAL STORMS. ENSURE THAT FUEL CAP IS CLOSED AND SECURE AT ALL OTHER TIMES.

•REMOVE ALL RINGS, WATCHES AND JEWELRY WHEN PERFORMING ANY MAINTENANCE.

•DO NOT WEAR LONG HAIR UNRESTRAINED, OR LOOSE-FITTING CLOTHING AND NECKTIES WHICH ARE APT TO BECOME CAUGHT ON OR ENTANGLED IN EQUIPMENT.

•OBSERVE AND OBEY ALL WARNINGS AND CAUTIONS ON MACHINE AND IN SERVICEMANUAL.

•KEEP OIL, GREASE, WATER, ETC. WIPED FROM STANDING SURFACES AND HAND HOLDS.

•USE CAUTION WHEN CHECKING A HOT, PRESSURIZED COOLANT SYSTEM.

•NEVER WORK UNDER AN ELEVATED BOOM UNTIL BOOM HAS BEEN SAFELY RESTRAINED FROM ANY MOVEMENT BY BLOCKING OR OVERHEAD SLING, OR BOOM SAFETY PROP HAS BEEN ENGAGED.

•BEFORE MAKING ADJUSTMENTS, LUBRICATING OR PERFORMING ANY OTHER MAINTENANCE, SHUT OFF ALL POWER CONTROLS.

•BATTERY SHOULD ALWAYS BE DISCONNECTEDDURING REPLACEMENT OF ELECTRICAL COMPONENTS.

•KEEP ALL SUPPORT EQUIPMENT AND ATTACHMENTS STOWED IN THEIR PROPER PLACE.

•USE ONLY APPROVED, NONFLAMMABLE CLEANING SOLVENTS.

3121200 |

– JLG Lift – |

A-1 |

INTRODUCTION

|

REVISON LOG |

Original Issue |

- January 15, 2005 |

Revised |

- July 15, 2005 |

Revised |

- August 26, 2005 |

Revised |

- December 12, 2005 |

Revised |

- February 24, 2006 |

Revised |

- May 1, 2007 |

Revised |

- September 28, 2011 |

Revised |

- January 9, 2013 |

A-2 |

– JLG Lift – |

3121200 |

TABLE OF CONTENTS

SECTION NO. |

TITLE |

PAGE NO. |

SECTION A - INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

A General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

B Hydraulic System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

C Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

SECTION 1 - SPECIFICATIONS

1.1 Operating Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 Electric Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.4 Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.5 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.6 Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.7 Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.8 Major Component Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.9 Pressure Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.10 Operator Maintenance & Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

SECTION 2 - GENERAL

2.1 Machine Preparation, Inspection, and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Preparation, Inspection, and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Pre-Start Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Pre-Delivery Inspection and Frequent Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Annual Machine Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Service and Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Safety and Workmanship . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Cleanliness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Components Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Component Disassembly and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Pressure-Fit Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Bearings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Bolt Usage and Torque Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Hydraulic Lines and Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Lubrication and Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 Lubrication and Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Changing Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 Cylinder Drift Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Platform Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Cylinder Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

3121200 |

– JLG Lift – |

i |

TABLE OF CONTENTS

SECTION NO. |

TITLE |

PAGE NO. |

2.5 Pins and Composite Bearing Repair Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5 2.6 Welding on JLG Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6 Do the Following When Welding on JLG Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6 Do NOT Do the Following When Welding on JLG Equipment . . . . . . . . . . . . . . . . . . . . . . . 2-6

SECTION 3 - CHASSIS & TURNTABLE

3.1 Breaking-in a New Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1 Retighten Lug Nuts at First 10, 25 & 50 Miles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 Adjust Brake Shoes at First 200 Miles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 Synchronizing the Brake Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Trailer inspection and Service Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1 Fasteners and Frame Members . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 Brake Shoes and Drums . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 Manually Adjusting Brake Shoes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Electric Brakes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2 Brake Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 Brake Cleaning and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 Shoes and Linings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.4 Hydraulic (Surge) Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2 Self Adjusting Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3 Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3 General Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.5 Hubs, Drums, Wheel Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4 Hub Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4 Brake Drum Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4 Bearing Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4 Bearing Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5 Seal Inspection and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5 Bearing Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.6 Tires & Wheels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7 Tire Inflation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7 Tire Wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7 Tire Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7 Wheel and Tire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8 Wheel Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8 Lug Nuts (Bolts). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.7 Hydraulic brake Coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10 Bleeding the Brake System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11 Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11 Backing Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13 Extended Storage Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13 Proper Towing Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.8 Combination Coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14 Bleeding the Brake System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14 General Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14 Servicing the Emergency Lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

ii |

– JLG Lift – |

3121200 |

TABLE OF CONTENTS

SECTION NO. |

TITLE |

PAGE NO. |

3.9 Hitch Coupler & Axle (CE Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17 Ball Coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17 Coupling Head Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19 Damper Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20 Brake Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21 Adjustment and Readjustment of the Overrun Braking System . . . . . . . . . . . . . . . . . . . . . . 3-24 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

3.10 Coupler Assembly (S/N 0030002099 to Present). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27 Engaging Manual Lockout Lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27 Servicing the Breakaway Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27 Actuator Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29 Coupler Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

3.11 Trailer Jack (Solid wheels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

3.12 Swing Motor (Prior to S/N 0030000960) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31 Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32 Shaft Timing Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

3.13 Swing Motor (S/N 0030001050 to Present) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-36 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36 Disassembly and inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43 One Piece Stator Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

3.14 Swing Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-51 Turntable Bearing Mounting Bolt Condition Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51 Wear Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53 Swing Bearing Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53 Swing Bearing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-54 Swing Bearing Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

3.15 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-56 Throttle & Choke Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56 Fuel Valve Lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56 Checking RPM Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56 Choke Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58 Checking Oil Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

3.16 Outrigger cylinder and Stabilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-60 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-60 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

3.17 Outrigger Limit SwitchEs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-63 Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-63 3.18 Procedure For Retracting Outriggers Using Service Harness (Optional) . . . . . . . . . . . . . . . . . . .3-63

3.19 Leveling, Tilt sensor calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-64 When Machine Is on a Firm Level Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-64 Setup When Machine Is Not on Firm Level Surface and Adjustment Procedure: . . . . . . . . 3-65

3121200 |

– JLG Lift – |

iii |

TABLE OF CONTENTS

SECTION NO. |

TITLE |

PAGE NO. |

3.20 Drive & Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-66

Drive & Set Interlocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-67

3.21 Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-71

Disassembly and inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-71

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-78

One Piece Stator Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-85

3.22 Batteries (Electric Machines) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-86

Quarterly Battery Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-86

3.23 Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-90

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-90

Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-90

Transformer Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-90

Printed Circuit Board Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-91

Shunt Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-91

Interlock Relay Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-91

SCR Rectifier Replacement (Either Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-91

AC Circuit Breaker Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-92

DC Circuit Breaker Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-92

3.24 Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-95

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-95

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-95

Battery Charger Fault Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-95

SECTION 4 - BOOM & PLATFORM

4.1 Boom and Cylinder AssemblY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Main Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.3 Master Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.4 Slave Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.5 Jib Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.6 Boom Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Boom Elevation Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

iv |

– JLG Lift – |

3121200 |

TABLE OF CONTENTS

SECTION NO. |

TITLE |

PAGE NO. |

SECTION 5 - HYDRAULICS |

|

|

5.1 Lubricating O-Rings in the Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Cup and Brush. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Dip Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Spray Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Brush-on Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2 Cylinder Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.3 Pressure Setting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

Main Relief . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Telescope In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Telescope Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Platform Level Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Platform Level Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Swing Right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Swing Left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Outrigger Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.4 Hydraulic Oil Fill at Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

5.5 Hydraulic Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

5.6 Hydraulic Filter and Breather . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

SECTION 6 - JLG CONTROL SYSTEM

6.1 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-1 |

6.2 |

To Connect the JLG Control System Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-2 |

6.3 |

Using the Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-2 |

6.4 |

Changing the Access Level of the Hand Held Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-3 |

6.5 |

Adjusting Parameters Using the Hand Held Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-4 |

6.6 |

Machine Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-5 |

6.7 |

System Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-9 |

|

Platform Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-9 |

|

Ground Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-11 |

6.8 |

User Fault Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-12 |

6.9 |

Machine Orientation When Setting Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-23 |

|

Test Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-23 |

3121200 |

– JLG Lift – |

v |

TABLE OF CONTENTS

SECTION NO. |

TITLE |

PAGE NO. |

SECTION 7 - BASIC ELECTRICAL INFORMATION & SCHEMATICS

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1 7.2 Multimeter Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 Backprobing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 Min/Max . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 Voltage Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 Resistance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 Continuity Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 Current Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.3 Checking Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3 Basic Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3 Limit Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3 Automatic Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4 Switch Wiring - Low Side, High Side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.4 Applying Silicone Dielectric Compound to Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . .7-4 7.5 AMP Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5 Applying Silicone Dielectric Compound to AMP Connectors. . . . . . . . . . . . . . . . . . . . . . . . 7-5 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5 Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7 Wedge Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7 Service - Voltage Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.6 Deutsch Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9 DT/DTP Series Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9 DT/DTP Series Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9 HD30/HDP20 Series Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10 HD30/HDP20 Series Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

vi |

– JLG Lift – |

3121200 |

LIST OF FIGURES

FIGURE NO. |

TITLE |

PAGE NO. |

1-1. Operator Maintenance & Lubrication Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4 1-2. Torque Chart (SAE Fasteners - Sheet 1 of 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7 1-3. Torque Chart (SAE Fasteners - Sheet 2 of 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8 1-4. Torque Chart (SAE Fasteners - Sheet 3 of 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9 1-5. Torque Chart (SAE Fasteners - Sheet 4 of 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10 1-6. Torque Chart (METRIC Fasteners - Sheet 5 of 7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11 1-7. Torque Chart (METRIC Fasteners - Sheet 6 of 7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12 1-8. Torque Chart (METRIC Fasteners - Sheet 7 of 7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13 3-1. Electric Brake Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2 3-2. Hydraulic Brake Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3 3-3. Hub and Brake Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6 3-4. Spare Tire (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9 3-5. Hydraulic Brake Coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15 3-6. Combination Coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16 3-7. Brake Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22 3-8. Overrun Brake System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24 3-9. Coupler Assembly - S/N 0030002099 to Present . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28 3-10. Seal Orientation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32 3-11. Notch Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33 3-12. Timing Mark. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34 3-13. Swing Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35 3-14. Swing Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-37 3-15. Swing Bolt Feeler Gauge Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-51 3-16. Swing Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-52 3-17. Swing Bearing Tolerance Measuring Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-53 3-18. Swing Bearing Torque Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-55 3-19. Engine Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-59 3-20. Outrigger Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-62 3-21. Drive and Set - Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-68 3-22. Drive and Set - Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-69 3-23. Drive and Set Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-70 3-24. Swing Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-72 3-25. Battery and Contactor Installation - Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-87 3-25. Battery and Contactor Installation - Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-88 3-25. Battery Cable Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-89 3-26. Battery Charger Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-93 3-27. Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-94 4-1. Boom and Cylinders Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10 5-1. Level Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4 5-2. Lift Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5 5-3. Master Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6 5-4. Outrigger Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7 5-5. Telescope Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8 5-6. Jib Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9 5-7. Hydraulic Test Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12 5-8. Control Valve Torque Values - Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14 5-8. Control Valve Torque Values - Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15 5-8. Drive Directional Valve Identification - Drive & Set Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16 5-9. Drive Directional Valve Torque Values - Drive & Set Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17 5-10. Drive Enable Valve Identification - Drive & Set Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18 5-11. Hydraulic Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19 6-1. Hand Held Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1 6-2. Analyzer Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6 6-3. Analyzer Flow Chart - Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7 6-4. Analyzer Flow Chart - Personalties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8 6-5. System Test Flow Chart - Platform Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10 6-6. System Test Flow Chart - Ground Station Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

3121200 |

– JLG Lift – |

vii |

LIST OF FIGURES

FIGURE NO. |

TITLE |

PAGE NO. |

6-7. Ground Module - Sheet 1 of 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14 6-8. Ground Module - Sheet 2 of 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15 6-9. Ground Module - Sheet 3 of 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16 6-10. Ground Module - Sheet 4 of 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17 6-11. Ground Module - Sheet 5 of 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18 7-1. Voltage Measurement (DC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1 7-2. Resistance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2 7-3. Continuity Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2 7-4. Current Measurement (DC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3 7-5. Connector Assembly Figure 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5 7-6. AMP Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5 7-7. Connector Assembly Figure 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6 7-8. Connector Assembly Figure 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6 7-9. Connector Assembly Figure 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6 7-10. Connector Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7 7-11. Connector Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8 7-12. DT/DTP Contact Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9 7-13. DT/DTP Contact Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9 7-14. HD/HDP Contact Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10 7-15. HD/HDP Locking Contacts Into Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10 7-16. HD/HDP Contact Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10 7-17. HD/HDP Unlocking Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10 7-18. Chassis Wiring Harness and Connectors - Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12 7-19. Chassis Wiring Harness and Connectors - Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-13 7-20. Controller and Valve Body Connector Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-14 7-21. Electrical Schematic (Boom Operations) - Sheet 1 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-18 7-22. Electrical Schematic (Boom Operations) - Sheet 2 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-19 7-23. Electrical Schematic (Trailer) - Sheet 1 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-20 7-24. Electrical Schematic (Trailer) - Sheet 2 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-21 7-25. Electrical Schematic (Trailer) - Sheet 3 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-22 7-26. Hydraulic Schematic - Electric Machines - Sheet 1 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-24 7-27. Hydraulic Schematic - Electric Machines - Sheet 2 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-25 7-28. Hydraulic Schematic - Gas Machines - Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-26 7-29. Hydraulic Schematic - Gas Machines - Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-27 7-30. Hydraulic Schematic - Drive Option (Gas) - Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-28 7-31. Hydraulic Schematic - Drive Option (Gas) - Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-29 7-32. Hydraulic Schematic - Drive Option (Electric) - Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-30 7-33. Hydraulic Schematic - Drive Option (Electric) - Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-31

viii |

– JLG Lift – |

3121200 |

LIST OF TABLES

TABLE NO. |

TITLE |

PAGE NO. |

1-1 Operating & Towing Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1-2 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1-3 Electric Power Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1-4 Tire Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1-5 Battery Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-6 Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-7 Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-8 Mobilfluid 424 Specs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-9 Component Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-10 Pressure Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-11 Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

2-1 Inspection and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2-2 Cylinder Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2-3 Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

3-1 Tire Wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3-2 Wheel Torque Chart - ANSI, ANSI Export, CSA, Aus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3-3 Wheel Torque Chart - CE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3-4 Surge Brake Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3-5 Malfunctions and Remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

3-25 Battery Charger Fault Codes (Delta-Q). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-95

5-1 Control Valve Torque Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

5-2 Control Valve Torque Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

6-1 User Fault Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

6-2 Machine Model Adjustments and Speeds - ANSI & CSA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

6-3 Machine Model Adjustments and Speeds - CE Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

6-4 Machine Configuration Programming Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-24

6-5 Help Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

7-1 Connector Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-15

3121200 |

– JLG Lift – |

ix |

LIST OF TABLES

TABLE NO. |

TITLE |

PAGE NO. |

This page left blank intentionally.

x |

– JLG Lift – |

3121200 |

SECTION 1 - SPECIFICATIONS

SECTION 1. SPECIFICATIONS

1.1OPERATING SPECIFICATIONS

Table 1-1. Operating & Towing Specifications

Tongue Weight (ANSI): |

350 lbs.(154 kg) |

|

|

|

|

Maximum Allowable Tow Speed: |

65 mph |

|

(Do NOT exceed legal speed limit) |

(105 kph) |

|

|

|

|

Maximum Work Load (Capacity) |

440 lbs. |

|

w/Rotator |

(200 kg) |

|

|

|

|

Maximum Work Load (Capacity) |

500 lbs. |

|

w/o Rotator |

(230 kg) |

|

|

|

|

Maximum Work Load (Capacity) |

320 lbs. |

|

w/Rotator & Panel Tray |

(145 kg) |

|

|

|

|

Maximum Work Load (Capacity) |

350 lbs. |

|

w/o Rotator & w/Panel Tray |

(158 kg) |

|

|

|

|

Material Hook Capacity (Optional) |

500 lbs.(230 kg) |

|

|

|

|

Accessory Tray Capacity |

250 lbs.*(114 kg) |

|

|

|

|

Panel Tray Capacity (w/Rotator) |

70 lbs. (32 kg) |

|

|

|

|

Panel Tray Capacity (w/o Rotator) |

100 lbs.(45 kg) |

|

|

|

|

Swing |

410° non-continuous |

|

|

|

|

Max.Vertical Platform Height (Unrestricted) |

50 ft. (15.2 m) |

|

|

|

|

Vertical Reach (unrestricted) |

50 ft. (15.2 m) |

|

|

|

|

Horizontal Reach |

|

|

(from centerline of machine) |

31 ft. (9.45 m) |

|

(from outrigger pad edge) |

25 ft. (7.62 m) |

|

|

|

|

Up and Over Clearance |

18 ft. (5.49 m) |

|

|

|

|

Maximum Outrigger Load |

2660 (1206.5 kg) |

|

|

|

|

Maximum Ground Bearing Pressure |

30.7 psi (2.15 kg/cm2) |

|

Maximum Travel Gradeability - ANSI, CSA, |

20% |

|

AUS |

||

|

||

|

|

|

Maximum Travel Gradeability - CE |

15% |

|

|

|

|

Maximum Sideslope - ANSI, CSA, AUS |

11° |

|

|

|

|

Maximum Sideslope - CE |

8.5° |

|

|

|

|

Max. Hydraulic System Pressure |

2950 psi (203 Bar) |

|

|

|

|

Maximum Operating Wind Speed |

28 mph (12.5 m/s) |

|

|

|

|

Maximum Horizontal Manual Force |

90 lb. force (400 N) |

|

|

|

|

Electrical System Voltage - Electric Machine |

24 Volts |

|

|

|

|

Electrical System Voltage - Gas Machine |

12 Volts |

|

|

|

|

Gross Machine Weight (Platform Empty) |

4750 lbs. (2155 kg) |

|

ANSI Machines/CSA/AUS |

||

|

||

|

|

|

Gross Machine Weight (Platform Empty) |

5776 lbs. (2620 kg) |

|

CE Machines |

||

|

* DO NOT exceed axle rating or GVW rating.

1.2CAPACITIES

Table 1-2. Capacities

Fuel Tank |

1.6 Gal. (6.0 L) |

|

|

Hydraulic Tank |

|

Filling Volume |

6.9 Gallon (26.1 Liters) |

Usable Volume |

6.3 Gallon (23.8 Liters) |

|

|

1.3ELECTRIC POWER UNIT

Table 1-3. Electric Power Unit Specifications

|

|

@ 740PSI |

@1500PSI |

@ 3000PSI |

|

|

(51 Bar) |

(103 Bar) |

(207 Bar) |

|

|

|

|

|

Motor |

Power |

3.0 kW |

3.0 kW |

3.0 kW |

|

|

|

|

|

|

Voltage |

24 VDC |

24 VDC |

24 VDC |

|

|

|

|

|

|

Amperage |

90 |

140 |

230 |

|

|

|

|

|

|

Speed |

4000 rpm |

3600 rpm |

2900 rpm |

|

|

|

|

|

|

Short Term |

9 minutes |

6 minutes |

2 minutes |

|

Operation |

|

|

|

|

|

|

|

|

|

Intermittent |

28% |

19% |

10% |

|

Operation |

|

|

|

|

|

|

|

|

Pump |

Flow Rate |

3.0 gpm |

2.7 gpm |

2.2 gpm |

|

|

(11.3 lpm) |

(10.2 lpm) |

(8.3 lpm) |

|

|

|

|

|

|

Displacement |

|

0.192 cu.in. |

|

|

|

|

(3.15 cc) |

|

|

|

|

|

|

1.4TIRES

Table 1-4. Tire Specifications

|

(ANSI) |

(CE) |

Size |

225-75-R15 |

225/75-R16 |

|

|

|

Load Rating |

2540 lbs. @ 60 psi |

3195 lbs. @ 83 psi |

|

(1152 kg @ 414 kPa) |

(1449 kg @ 575 kPa) |

|

|

|

Ply Rating/Load Range |

6/D |

10/E |

|

|

|

Inflation Pressure |

65 psi (448 kPa) |

60 psi (414 kPa) |

|

|

|

Wheel Nut Torque |

221 ft. lbs. |

90-120 ft. lbs. |

|

(300 Nm) |

(122-164 Nm) |

|

|

|

3121200 |

– JLG Lift – |

1-1 |

SECTION 1 - SPECIFICATIONS

1.5ENGINE

Battery

Table 1-5. Battery Specifications

BCI Group Size |

51R |

|

|

Cranking Performance |

550 amps @ 32°F (0°C) |

|

450 amps @ 0°F (-18°C) |

|

|

Reserve Capacity |

80 minutes @ 32°F (0°C) |

|

|

1.6DIMENSIONAL DATA

Table 1-6. Dimensional Data

Overall Length |

|

Surge Brake, 2" ball |

26 ft 9.75 in (8.2 m) |

Electric Brake |

26 ft 8 in (8.1 m) |

Surge Brake Combination |

26 ft 10.25 in (8.2 m) |

|

|

Overall Height ANSI |

6 ft 7.25 in (2 m) |

|

|

Overall Height CE |

7 ft 0.5 in (2.1 m) |

|

|

Overall Width - (outriggers up) |

5ft 10.25 in (1.8 m) |

|

|

Overall Width (outriggers down - ANSI) |

12 ft 7.75 in (3.9 m) |

|

|

Overall Width (outriggers down - CE) |

13 ft 5.25 in (4.1 m) |

|

|

1.7 LUBRICATION

Hydraulic Oil

Table 1-7. Hydraulic Oil

Hydraulic System |

S.A.E. Viscosity |

|

Operating |

||

Grade |

||

Temperature Range |

||

|

||

|

|

|

+0° to + 180° F |

10W |

|

(-18° to +83° C) |

|

|

|

|

|

+0° to + 210° F |

10W-20, 10W30 |

|

(-18° to +99° C) |

|

|

|

|

|

+50° to + 210° F |

20W-20 |

|

(+10° to +99° C |

|

|

|

|

NOTE: Hydraulic oils must have anti-wear qualities at least to API Service Classification GL-3, and sufficient chemical stability for mobile hydraulic system service. JLG Industries recommends Mobilfluid 424 hydraulic oil, which has an SAE viscosity index of 152.

NOTE: When temperatures remain consistently below 20° F. (-7° C.), JLG Industries recommends the use of Mobil DTE13.

Aside from JLG recommendations, it is not advisable to mix oils of different brands or types, as they may not contain the same required additives or be of comparable viscosities. If use of hydraulic oil other than Mobilfluid 424 is desired, contact JLG Industries for proper recommendations.

Table 1-8. Mobilfluid 424 Specs

SAE Grade |

|

10W30 |

|

|

|

Gravity, API |

|

29.0 |

|

|

|

Density, Lb/Gal. 60°F |

|

7.35 |

|

|

|

Pour Point, Max |

|

-46°F (-43°C) |

|

|

|

Flash Point, Min. |

|

442°F (228°C) |

|

|

|

Viscosity |

|

|

Brookfield, cP at -18°C |

|

2700 |

|

|

|

at 40° C |

|

55 cSt |

|

|

|

at 100° C |

|

9.3 cSt |

|

|

|

Viscosity Index |

|

152 |

|

|

|

1-2 |

– JLG Lift – |

3121200 |

SECTION 1 - SPECIFICATIONS

1.8MAJOR COMPONENT WEIGHTS

Table 1-9. Component Weights

Component |

Pounds |

Kilograms |

|

|

|

Frame (bare) |

597 |

271 |

|

|

|

Frame - CE, Aus (bare) |

892 |

382 |

|

|

|

Turntable (bare) |

262 |

119 |

|

|

|

Booms & Cylinders Assy. |

1891 |

859 |

|

|

|

Main Boom |

957 |

435 |

|

|

|

Engine Assy. (Incl. Tray) |

116 |

53 |

|

|

|

Engine (bare) |

57 |

26 |

|

|

|

Axle |

221 |

100 |

|

|

|

1.9PRESSURE SETTINGS

Cold temperatures have a significant impact on pressure readings. JLG Industries Inc. recommends operating the machine until the hydraulic system has warmed to normal operating temperatures prior to checking pressures. JLG Industries Inc. also recommends the use of a calibrated gauge. Pressure readings are acceptable if they are within

± 5% of specified pressures.

Table 1-10. Pressure Settings

Circuit |

PSI |

Bar |

|

|

|

Main Relief |

2950 |

203.5 |

|

|

|

Telescope In |

2850 |

196.5 |

|

|

|

Telescope Out |

2400 |

166 |

|

|

|

Platform Level Up |

2800 |

193 |

|

|

|

Platform Level Down |

2000 |

138 |

|

|

|

Swing Right |

600-800 |

41-55 |

|

|

|

Swing Left |

600-800 |

41-55 |

|

|

|

Outrigger Up |

2500 |

172.5 |

|

|

|

3121200 |

– JLG Lift – |

1-3 |

SECTION 1 - SPECIFICATIONS

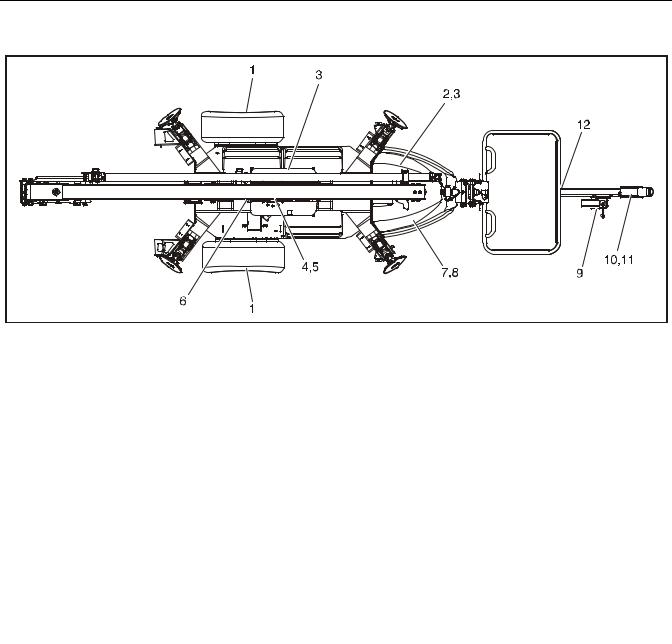

1. |

Wheel Bearings |

5. |

Swing Bearing Teeth |

9. |

Trailer Jack |

2. |

Hydraulic Oil |

6. |

Swing Drive |

10. |

Surge Brake |

3. |

Hydraulic Filter & Breather |

7. |

Engine |

11. |

Coupler & Hitch Ball |

4. |

Swing Bearing |

8. |

Fuel Tank |

12. |

Jockey Wheel Bearing |

Figure 1-1. Operator Maintenance & Lubrication Diagram

1.10OPERATOR MAINTENANCE & LUBRICATION

NOTE: Lubrication intervals are based on machine operation under normal conditions. For machines used in multi shift operations and/or exposed to hostile environments or conditions, lubrication frequencies must be increased accordingly.

|

Table 1-11.Lubrication Specifications |

|

|

|

|

KEY |

|

SPECIFICATIONS |

|

|

|

MPG |

|

Multipurpose Grease having a minimum dripping point of |

|

|

350 degrees F. Excellent water resistance and adhesive |

|

|

qualities; and being of extreme pressure type (Timken |

|

|

OK 40 pounds minimum). |

|

|

|

EPGL |

|

Extreme Pressure Gear Lube (oil) meeting API Service |

|

|

Classification GL-5 or Mil-Spec Mil-L-2105. |

|

|

|

HO |

|

Hydraulic Oil. API Service Classification GL-3, SAE |

|

|

10W-20, Viscosity Index 152, e.g. Mobilfluid 424. |

|

|

|

EO |

|

Engine (crankcase) Oil. Gas - API SF/SG class, MIL-L- |

|

|

2104. Diesel - API CC/CD class, MIL-L-2104B/MIL-L- |

|

|

2104C. |

|

|

|

OGL |

|

Open Gear Lubricant - Mobiltac 375 or equivalent. |

|

|

|

1. Wheel Bearings

Lube - MPG

Interval - every 12 months or 12,000 miles Comments - Refer to Section 3.5, Hubs, Drums, Wheel Bearings

1-4 |

– JLG Lift – |

3121200 |

SECTION 1 - SPECIFICATIONS

2. Hydraulic Oil

Lube Point(s) - Fill Cap Capacity - 4 gal. (15.1 L) Lube - HO

Interval - Check oil daily, change after, then every 1200 hours of operation.

3. Hydraulic Filter & Breather

4. Swing Bearing

Lube Point(s) - 1 Grease Fitting Capacity - As Required

Lube - MPG

Interval - Every month or 50 hours

Comments - Rotate the bearing back and forth

to ensure grease is distributed evenly the whole way around the bearing.

5.Swing Bearing Teeth

Lube Point(s) - Spray On Capacity - As Required Lube - OGL

Interval - Every month or 50 hours

Comments - More frequent lubrication intervals may be required.

6.Swing Drive

NOTE: The cap securing the filter must be torqued 154 to 170 ft.lbs. (209 to 230.5 Nm).

Interval - 100 hours

Comments - Change after the first 20 hours, then every 100 hours of operation.

Lube Point(s) - 2 Grease Fittings

Capacity - As Required

Lube - MPG

Interval - As Required

DO NOT OVERGREASE BEARINGS. OVERGREASING BEARINGS WILL RESULT IN BLOWING OUTER SEALS IN HOUSING.

3121200 |

– JLG Lift – |

1-5 |

SECTION 1 - SPECIFICATIONS

7. Engine

Capacity - See Engine Manual. Lube - EO, 10W30 API SJ

Interval - Check level daily; change per manufacturer’s engine manual.

Comments - Adjust final oil level by mark on dipstick 8. Fuel Tank

Capacity - 1.6 Gal. (6.0 L) Fuel - Gasoline

Interval - Check periodically during each shift 9. Trailer Jack

OIL

GREASE

Capacity - As necessary

Lube - MPG & EO

Interval - As necessary

10. Surge Brake

Lube Point(s) - Fill Cap

Capacity - No more than 1/2" (13 mm) from top of reservoir

Lube - DOT 3 or 4 Brake Fluid

Interval - Check before each tow. Flush the system yearly or when system is known to be contaminated

11. Coupler & Hitch Ball

Capacity - Coupler 2 Grease Fittings (CE Only); Hitch Ball

As necessary Lube - MPG

Interval - As necessary

12. Jockey Wheel Bearing (Drive and Set Option Only)

Lube Point(s) - 1 Grease Fittings

Capacity - As Required

Lube - MPG

Interval - As Required

1-6 |

– JLG Lift – |

3121200 |

SECTION 1 - SPECIFICATIONS

|

|

|

|

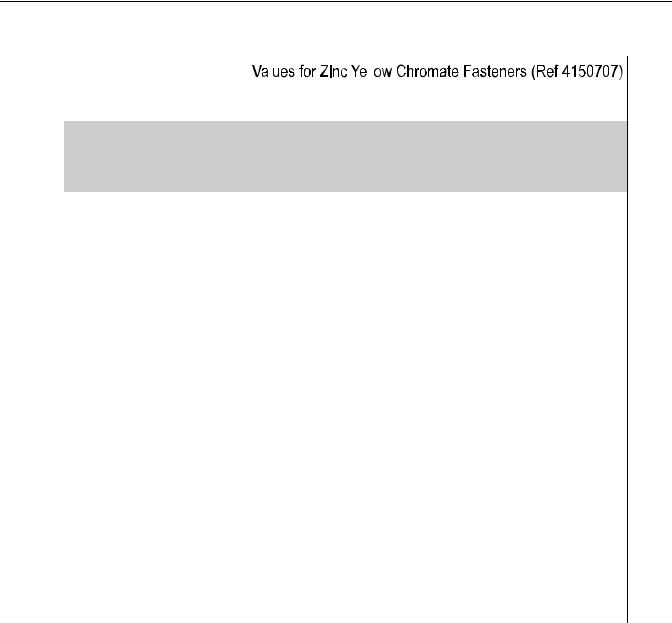

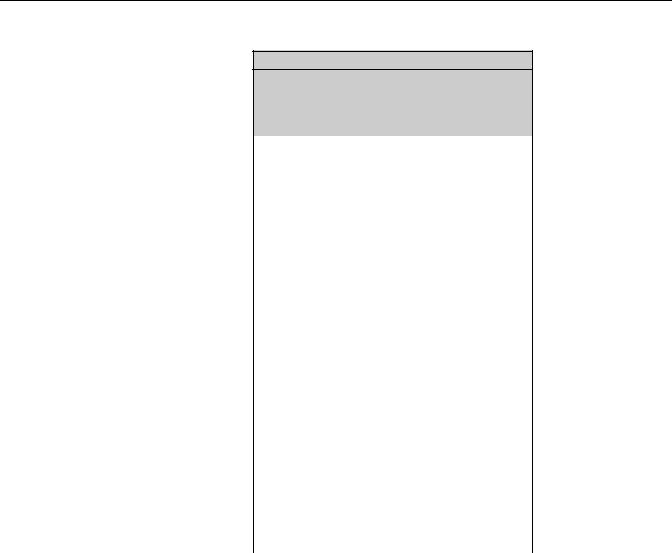

Values for Zinc Yellow Chromate Fasteners (Ref 4150707) |

|||||||||||||

|

|

|

|

|

|

SAE GRADE 5 BOLTS & GRADE 2 NUTS |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Torque |

|

Torque |

|

|||

|

|

|

Tensile |

|

Torque |

Torque |

|

(Loctite® 242TM or 271TM |

|

||||||||

Size |

TPI |

Bolt Dia |

Clamp Load |

|

|

TM |

or Vibra- |

||||||||||

Stress Area |

|

(Dry) |

Lubricated |

OR Vibra-TITE |

TM |

111 or |

(Loctite® 262 |

||||||||||

|

|

|

|

|

|

TITETM 131) |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

140) |

|

|

|

|

|

|

|

|

In |

Sq In |

LB |

IN-LB |

|

[N.m] |

IN-LB |

|

[N.m] |

IN-LB |

|

[N.m] |

IN-LB |

|

[N.m] |

|

4 |

40 |

0.1120 |

0.00604 |

380 |

8 |

|

0.9 |

6 |

|

0.7 |

|

|

|

|

|

|

|

|

48 |

0.1120 |

0.00661 |

420 |

9 |

|

1.0 |

7 |

|

0.8 |

|

|

|

|

|

|

|

6 |

32 |

0.1380 |

0.00909 |

580 |

16 |

|

1.8 |

12 |

|

1.4 |

|

|

|

|

|

|

|

|

40 |

0.1380 |

0.01015 |

610 |

18 |

|

2.0 |

13 |

|

1.5 |

|

|

|

|

|

|

|

8 |

32 |

0.1640 |

0.01400 |

900 |

30 |

|

3.4 |

22 |

|

2.5 |

|

|

|

|

|

|

|

|

36 |

0.1640 |

0.01474 |

940 |

31 |

|

3.5 |

23 |

|

2.6 |

|

|

|

|

|

|

|

10 |

24 |

0.1900 |

0.01750 |

1120 |

43 |

|

4.8 |

32 |

|

3.5 |

|

|

|

|

|

|

|

|

32 |

0.1900 |

0.02000 |

1285 |

49 |

|

5.5 |

36 |

|

4 |

|

|

|

|

|

|

|

1/4 |

20 |

0.2500 |

0.0318 |

2020 |

96 |

|

10.8 |

75 |

|

9 |

105 |

|

12 |

|

|

|

|

|

28 |

0.2500 |

0.0364 |

2320 |

120 |

|

13.5 |

86 |

|

10 |

135 |

|

15 |

|

|

|

|

|

|

In |

Sq In |

LB |

FT-LB |

|

[N.m] |

FT-LB |

|

[N.m] |

FT-LB |

|

[N.m] |

FT-LB |

|

[N.m] |

|

5/16 |

18 |

0.3125 |

0.0524 |

3340 |

17 |

|

23 |

13 |

|

18 |

19 |

|

26 |

16 |

|

22 |

|

|

24 |

0.3125 |

0.0580 |

3700 |

19 |

|

26 |

14 |

|

19 |

21 |

|

29 |

17 |

|

23 |

|

3/8 |

16 |

0.3750 |

0.0775 |

4940 |

30 |

|

41 |

23 |

|

31 |

35 |

|

48 |

28 |

|

38 |

|

|

24 |

0.3750 |

0.0878 |

5600 |

35 |

|

47 |

25 |

|

34 |

40 |

|

54 |

32 |

|

43 |

|

7/16 |

14 |

0.4375 |

0.1063 |

6800 |

50 |

|

68 |

35 |

|

47 |

55 |

|

75 |

45 |

|

61 |

|

|

20 |

0.4375 |

0.1187 |

7550 |

55 |

|

75 |

40 |

|

54 |

60 |

|

82 |

50 |

|

68 |

|

1/2 |

13 |

0.5000 |

0.1419 |

9050 |

75 |

|

102 |

55 |

|

75 |

85 |

|

116 |

68 |

|

92 |

|

|

20 |

0.5000 |

0.1599 |

10700 |

90 |

|

122 |

65 |

|

88 |

100 |

|

136 |

80 |

|

108 |

|

9/16 |

12 |

0.5625 |

0.1820 |

11600 |

110 |

|

149 |

80 |

|

108 |

120 |

|

163 |

98 |

|

133 |

|

|

18 |

0.5625 |

0.2030 |

12950 |

120 |

|

163 |

90 |

|

122 |

135 |

|

184 |

109 |

|

148 |

|

5/8 |

11 |

0.6250 |

0.2260 |

14400 |

150 |

|

203 |

110 |

|

149 |

165 |

|

224 |

135 |

|

183 |

|

|

18 |

0.6250 |

0.2560 |

16300 |

170 |

|

230 |

130 |

|

176 |

190 |

|

258 |

153 |

|

207 |

|

3/4 |

10 |

0.7500 |

0.3340 |

21300 |

260 |

|

353 |

200 |

|

271 |

285 |

|

388 |

240 |

|

325 |

|

|

16 |

0.7500 |

0.3730 |

23800 |

300 |

|

407 |

220 |

|

298 |

330 |

|

449 |

268 |

|

363 |

|

7/8 |

9 |

0.8750 |

0.4620 |

29400 |

430 |

|

583 |

320 |

|

434 |

475 |

|

646 |

386 |

|

523 |

|

|

14 |

0.8750 |

0.5090 |

32400 |

470 |

|

637 |

350 |

|

475 |

520 |

|

707 |

425 |

|

576 |

|

1 |

8 |

1.0000 |

0.6060 |

38600 |

640 |

|

868 |

480 |

|

651 |

675 |

|