JLG G6-42A Operator Manual

OWNER/OPERATOR MANUAL

CORPORATE OFFICE

JLG INDUSTRIES, INC.

1 JLG DRIVE

McConnellsburg, PA

17233-9533

USA

Telephone: (717) 485-5161

Fax: (717) 485-6417

GRADALL DIVISION

JLG INDUSTRIES, INC.

406 Mill Avenue S.W.

New Philadelphia, OH

44663

USA

Telephone: (330) 339-2211

Fax: (330) 339-8458

®

®

Form #20036

®

G6-42A

9147-4003

June 2003

Starting Serial No.

0190001 thru 0190457

& 0160000022 thru Current

Original Issue 3/01

Revised Issue 6/03

®

A Company

®

material handler

G6-42A MATERIAL HANDLER

OWNER/OPERATOR MANUAL

COVERING OPERATION & PERIODIC MAINTENANCE

KEEP OPERATOR AND SAFETY MANUALS IN CAB

Part No. 9147-4003

Revised 6-13-03

Form No. 20036

COVERS MATERIAL HANDLER G6-42A

STARTING SERIAL NUMBER

0190001 thru 0190457 & 0160000022 thru Current

IMPORTANT!

Read and understand this Manual and the Gradall Material

Handler Safety Manual before starting, operating or

performing maintenance procedures on this machine.

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123

4

1234567890123456789012345678901212345678901234567890123456789012123456

1

23456789012345678901234567890121234567890123456789012345678901212345

6

1

23456789012345678901234567890121234567890123456789012345678901212345

6

1

23456789012345678901234567890121234567890123456789012345678901212345

6

1

23456789012345678901234567890121234567890123456789012345678901212345

6

1

23456789012345678901234567890121234567890123456789012345678901212345

6

1

23456789012345678901234567890121234567890123456789012345678901212345

6

1234567890123456789012345678901212345678901234567890123456789012123456

IMPORTANT SAFETY NOTICE

Safe operation depends on reliable equipment and proper operating procedures. Performing

the checks and services described in this Manual will help keep your GRADALL Material

Handler in reliable condition. Following recommended operating procedures can help you

avoid accidents. Because some procedures may be new to even the experienced operator,

we require that this Manual be read, understood and complied with by all who operate

this machine.

Strict attention to and compliance with instructions provided in this Manual, the GRADALL

Material Handler Safety Manual, as well as instructional decals and plates affixed to the

machine will help prevent injuries to personnel and damage to the equipment. The

information provided herein is not intended to cover all situations; it is impossible to

anticipate and evaluate all possible applications and methods of operation for this

equipment.

This Manual covers recommended operating procedures and basic maintenance checks

and services for the Material Handler. Detailed maintenance information is available in

the appropriate Service Manual.

Any procedure not specifically recommended by GRADALL must be thoroughly evaluated

from the standpoint of safety before it is placed in practice. If you are not sure,

contact your GRADALL Material Handler Distributor before operating.

Use only GRADALL authorized parts. The use of counterfeit parts may cause premature

failure which could lead to injuries and/or machine damage.

Do not modify this machine without written

permission from GRADALL. Use only genuine

GRADALL replacement parts.

OTHER NOTICES

GRADALL retains all proprietary rights to the information contained in this Manual.

GRADALL reserves the right to change specifications without notice.

Gradall is a registered trademark for Hydraulic Excavators, Hydraulic Material Handlers

and Attachments manufactured by The Gradall Company.

Form No. 20036 • G6-42A Owner/Operator Manual

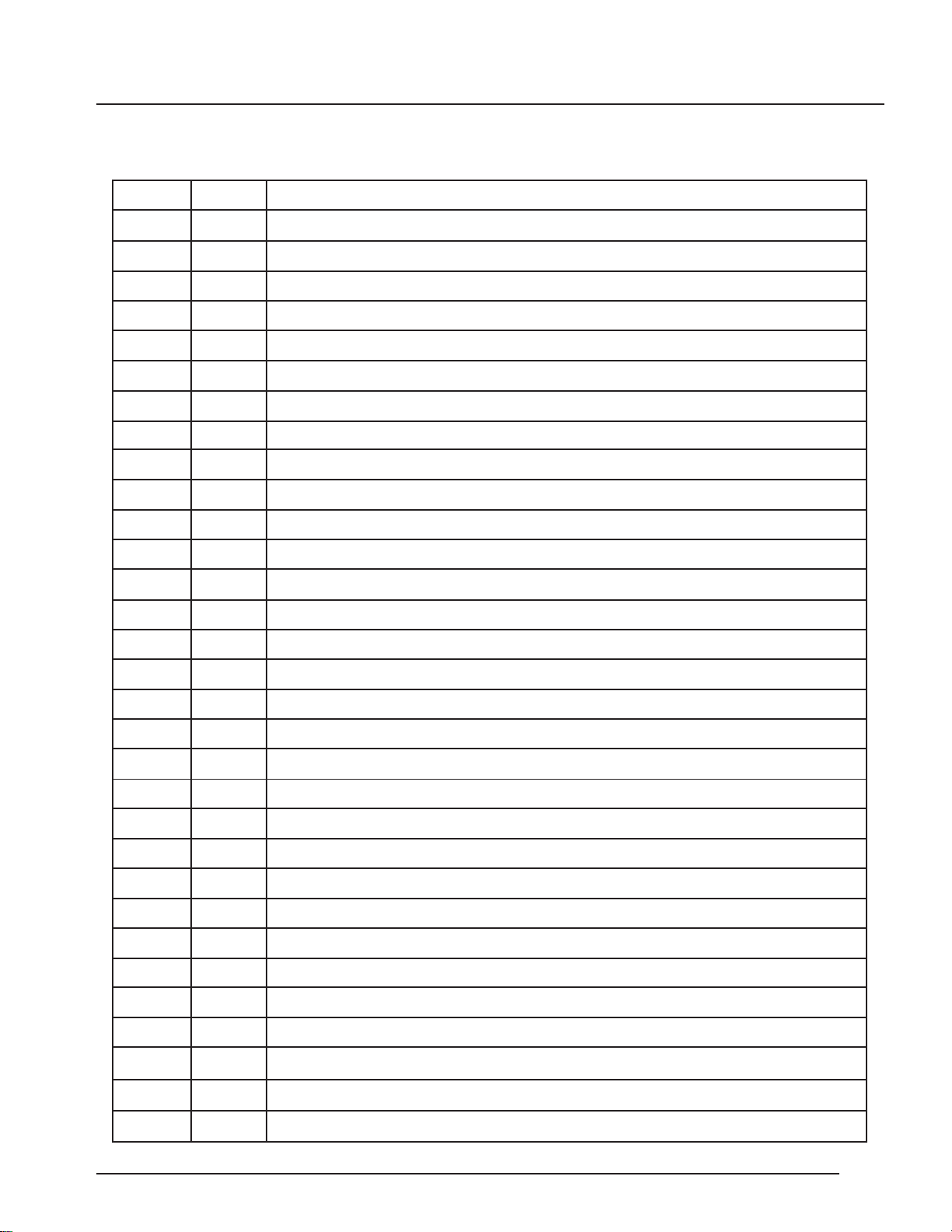

REVISIONS

This page is provided so you may determine that this Manual is complete and current with respect to Gradall

Engineering Specifications.

Page Date Revision

17.1 7-22-02 Added an additional lubrication notice.

Cover 6-13-03 Revised Notes & Serial Numbers.

Intro Revised Operator Qualification section.

2.0 Revised all.

2.1 Revised all.

2.2 Replaced 9140-3525 Decal with 9150-3102 Decal.

2.3 Replaced 9147-3123 Decal with 9147-3217 Decal; added 9141-3061 Decal &

P/N’s to Angus Palm Decal.

2.4 Revised locations on 9108-3492, 9114-3288, 9114-3284, 9114-3281 &

9114-3285 Decals.

2.5 Revised location on 9114-3282 Decal.

3.0 Revised Operator’s Cab section & Figure 3-1.

3.1 Revised Warning.

3.2 Revised Service Brake description.

6.0 Revised Cold-Weather Starting Aid section.

7.0 Revised Service Brake section.

8.0 Revised Precaution & Parking Procedure sections.

12.2 Revised Load Center section; Removed Figure.

12.3 Changed Figure 12-5 to 12-4.

12.4 Changed Figure 12-6 to 12-5.

13.1 Revised Attachment Operation section.

13.8 Revised Personnel Work Platform section.

14.0 Revised Step 4; Added Figure 14-1.

16.0 Revised Moving Short Distances section.

16.1 Added Carraro Axle to title; changed all chock references to block.

16.2 Added Page for Dana Axle.

17.0 Added Figure 17-1.

17.1 Revised Art.

17.3 Changed Carraro Axle Values & Added Dana Axle Values.

TABLE OF CONTENTS

IMPORTANT SAFETY NOTICE ..................................................... inside front cover

TABLE OF CONTENTS

INTRODUCTION

General

Operator Qualifications

Orientation

Related Manuals & Decals

Models Covered

Serial Number Location

SAFETY HIGHLIGHTS ............................................................... 1.0

DECALS ................................................................................. 2.0

Decals

OPERATORS CAB..................................................................... 3.0

Cab

Control & Instrument Identification

CHECKS & SERVICES BEFORE STARTING ENGINE ........................ 4.0

WARM-UP & OPERATIONAL CHECKS ........................................... 5.0

ENGINE OPERATION ................................................................ 6.0

Starting the Engine

Cold-Weather Starting Aids

Battery-Boosted Starting

Normal Engine Operation

Stopping the Engine

BRAKE SYSTEM ....................................................................... 7.0

General

Service Brake

Park Brake

PARKING THE HANDLER ........................................................... 8.0

STEERING SYSTEM .................................................................. 9.0

DRIVE TRAIN .......................................................................... 10.0

LEVELING THE HANDLER ......................................................... 11.0

OPERATING PROCEDURE & TECHNIQUES .................................. 12.0

Hydraulic Controls

Rated Capacity Chart

ATTACHMENTS ........................................................................ 13.0

Approved Attachments

Non-Approved Attachments

Carriage/Fork Capacities

Other Attachment Capacities

Attachment Installation

Attachment Operation

OBTAINING HYDRAULIC OIL SAMPLE FOR ANALYSIS .................... 14.0

LOADING & SECURING FOR TRANSPORT .................................... 15.0

MOVING HANDLER IN EMERGENCY ............................................ 16.0

Moving Short Distances

Moving Longer Distances

MAINTENANCE SECTION .......................................................... 17.0

Nomenclature

Lubrication and Maintenance

Recommended Lubricants & Capacities

Torque Chart

Boom

INSPECTION AND MAINTENANCE LOG ....................................... 18.0

HAND SIGNALS ....................................................................... inside back cover

Form No. 20036 • G6-42A Owner/Operator Manual

General

This Manual provides important information regarding safe operating and

maintenance requirements for GRADALL Material Handlers. Refer to front cover

for specific model and serial number range.

If you have any questions regarding the material handler, contact your GRADALL

Material Handler Distributor.

Operator Qualifications

Operators of the material handler must be in good physical and mental condition,

have normal reflexes and reaction time, good vision and depth perception and

normal hearing. He must not be using medication which could impair abilities

nor be under the influence of alcohol or any other intoxicant during the work

shift.

The operator should possess a valid, applicable driver’s license and must have

completed a training course for this type of material handling equipment.

In addition, the operator must read/view, understand and comply with

instructions contained in the following material furnished with the material

handler:

• This Owner/Operator Manual

• GRADALL Material Handler Safety Manual

• All instructional decals and plates

• Any optional equipment instructions furnished

The operator must also read, understand and comply with all applicable Employer,

Industry and Governmental rules, standards and regulations.

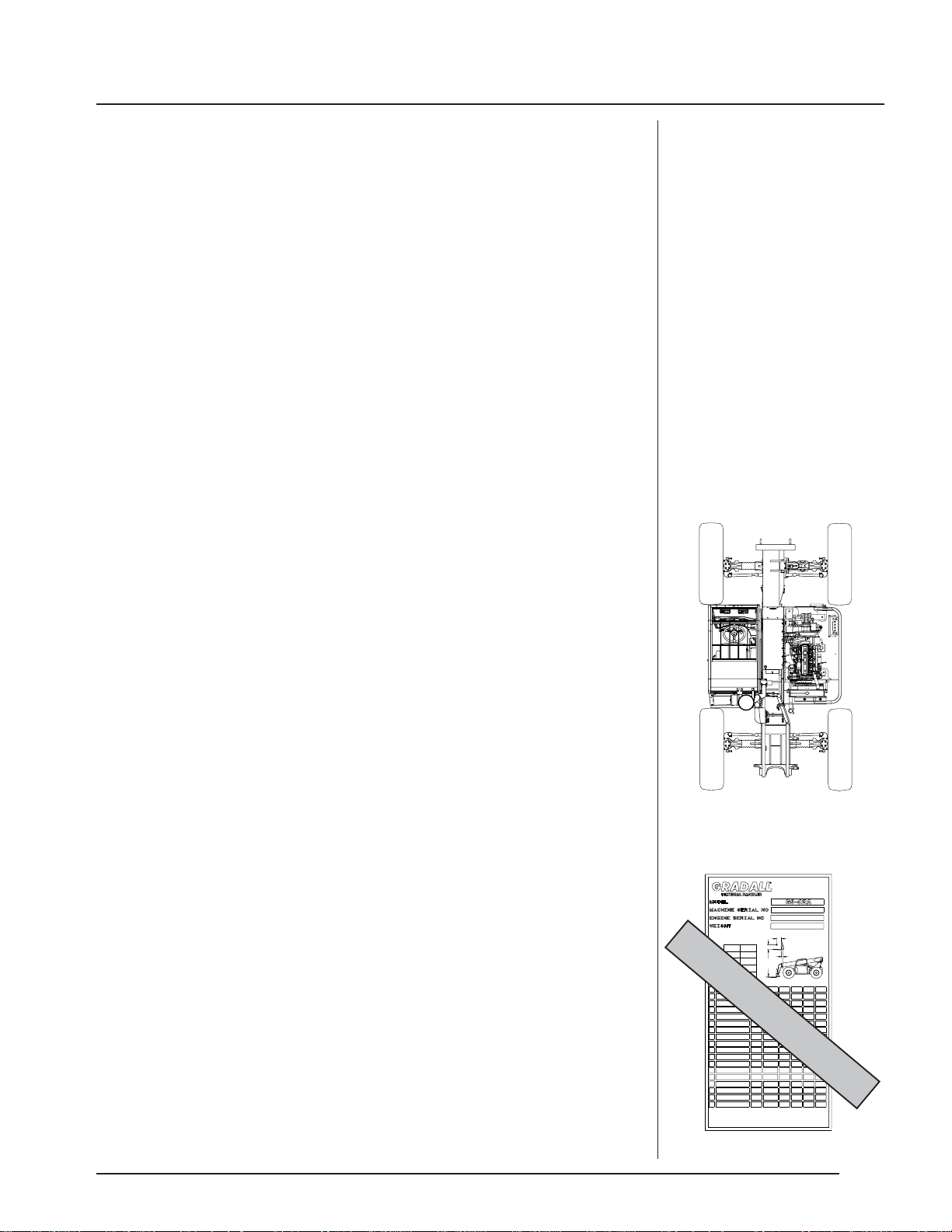

Orientation

When used to describe the location of components in the material handler, the

directions “front’”, “rear”, “right” and “left” relate to the orientation of a person

sitting in the operator’s seat. (See figure I-1)

Related Manuals & Decals

Separate publications are furnished with the material handler to provide

information concerning safety, replacement parts, maintenance procedures,

theory of operation and vendor components. Replacement manuals, decals and

instruction plates can be ordered from your GRADALL Material Handler Distributor.

Models Covered

This Manual covers basic information for Gradall Material Handlers. Detailed

information for each particular machine is in the maintenance section in the

back of this manual. Be certain to refer to proper information for your unit

and the optional equipment furnished on your machine.

Serial Number Location

Specify Model Number and Serial Number when ordering parts and when

discussing specific applications and procedures with your Distributor. The model/

serial number plate is located inside the operator’s cab, right wall.

(See figure I-2)

NOTE!

“Material handler” and handler

are used interchangeably

throughout this Manual.

Though no offense or

discrimination is intended, only

the masculine pronouns will be

used throughout the remainder

of this Manual.

NOTE!

REAR

FRONT

RIGHT

LEFT

Figure I-1

Figure I-2

INTRODUCTION

24"

24"

406 MILL AVE. S.W., NEW PHILADELPHIA, OHIO 44663

GRADALL IS A REGISTERED TRADEMARK FOR

HYDRAULIC EQUIPMENT BUILT BY THE

GRADALL CO. MANUFACTURED IN THE U.S.A.

AS RELEASED FROM FACTORY THIS TRUCK MEETS THE DESIGN SPECIFICATIONS

ESTABLISHED IN AMERICAN NATIONAL STANDARDS FOR POWERED INDUSTRIAL

TRUCKS PART III ASME B56.6b-1998.

CAP#

X1000

A

B

42'

6.6

1.0

CAPACITY WITH STANDARD

48" & 72" CARRIAGE.

(WITHOUT

ATTACHMENTS)

4.6'

B

C

A

D

20,650

20,460

24"

24"

42' 24"

C

D

ATTACHMENT

TRUCK &

ATTACHMENT

WEIGHT

24"

DCBA

6.6

20,180

CAP#

1000

9147-3131 (B)

42' 24" 24"

6.6

20,290

6.6

42' 24" 24"

24"24"42'

6.6

48" CARRIAGE

P/N 9140-5073 *

72" CARRIAGE

P/N 9140-5074 *

SHIPPED

WITH

48" SLOPE PILER

P/N 9140-5101 *

72" SLOPE PILER

P/N 9140-5079 *

2.0' 26.9'

2.0'

2.0'

2.7'

2.7'

FORKS RATED LESS THAN THE ATTACHMENT CAPACITY SHOWN ABOVE DECREASE

CAPACITY OF ATTACHMENT TO THAT OF FORKS. FORKS RATED MORE THAN

ATTACHMENT CAPACITY DO NOT INCREASE ATTACHMENT CAPACITY.

*WEIGHTS ARE BASED ON USING 2 X 4 X 48" FORKS (APPROX. 268# PER PAIR)

**BUCKET DIMENSIONS (A & D) REFER TO BUCKET LIP HEIGHT.

***TRUSS BOOM & WINCH DIMENSIONS (A & D) REFER TO HOOK CENTER.

****WEIGHT IS BASED ON SP'L SWING MAST FORKS (APPROX. 230# PER PAIR)

*****PLATFORM DIMENSIONS (A & D) REFER TO CENTER OF FLOOR.

19430 LBS

SAMPLE ONLY

In the U.S.A., the operator

must have completed a training

course meeting the OSHA

Powered Industrial Truck

Operator Training

Requirements (CFR 1910.178)

NOTE!

Read and understand all manuals and instructional material listed on cover, inside

front cover and introduction page of this Manual before starting, operating or

performing maintenance procedures on this equipment.

Regardless of previous experience operating similar equipment, the operator

must be given sufficient opportunity to practice with the handler in a safe, open

area (not hazardous to people or property) to gain operating skills and the

proper “feel” for controls and operating clearances required for safe, efficient

operation.

GRADALL Material Handlers are equipped with a right-side rearview mirror. This

mirror is intended as an operator’s aid and does not replace the requirement for

line-of-sight. Certain job site and machine conditions may require use of a signal

person to help the operator when picking, placing or transporting a load. Never

operate the handler until you know pick-up point, line of travel and landing point

are clear. Always be aware that objects in mirror are closer than they appear.

Safety Precautions

Make sure all DANGER, WARNING, CAUTION and INSTRUCTIONAL DECALS

are in place and can be read. Clean or replace decals as required.

Ensure handler is on a firm, level surface before lifting or placing load. Have

surface leveled if necessary. Unit can tip over if load is raised with handler

on a soft or uneven surface.

When traveling at high rates of speed, use two wheel front steer mode and

slow the machine prior to turning.

Do not change steer mode while the machine is traveling. Change the

steer mode only when machine is stopped.

Always look in the direction of travel. Reduce speed and be especially careful

when traveling in reverse and/or turning. Bring the machine to a complete

stop before changing the direction of travel.

Travel in reverse only at slow rates of speed.

When turning, the forks on the four wheel steer machine sweep through an arc

beyond the turn radius of the tires. Maintain adequate clearance between

the forks/load and other objects.

If load or conditions obstruct view, use a signal person when lifting, carrying

or placing a load.

Loose clothing can get caught in moving machinery and can also cause accidental

actuation of controls. Dress properly for the job.

Be alert to any unusual response to controls. If unusual response is noticed,

position handler in a safe area, lower forks to ground, apply parking brake, stop

engine and remove key from ignition switch. Tag steering wheel to forbid

operation and notify maintenance personnel.

Keep hands, gloves, shoes, control knobs and pedals clean. Slippery controls

can cause accidents. Keep a firm grip on the steering wheel when traveling.

Load capacities are based on load center being within .6m (24 inches)

from front vertical face of forks.

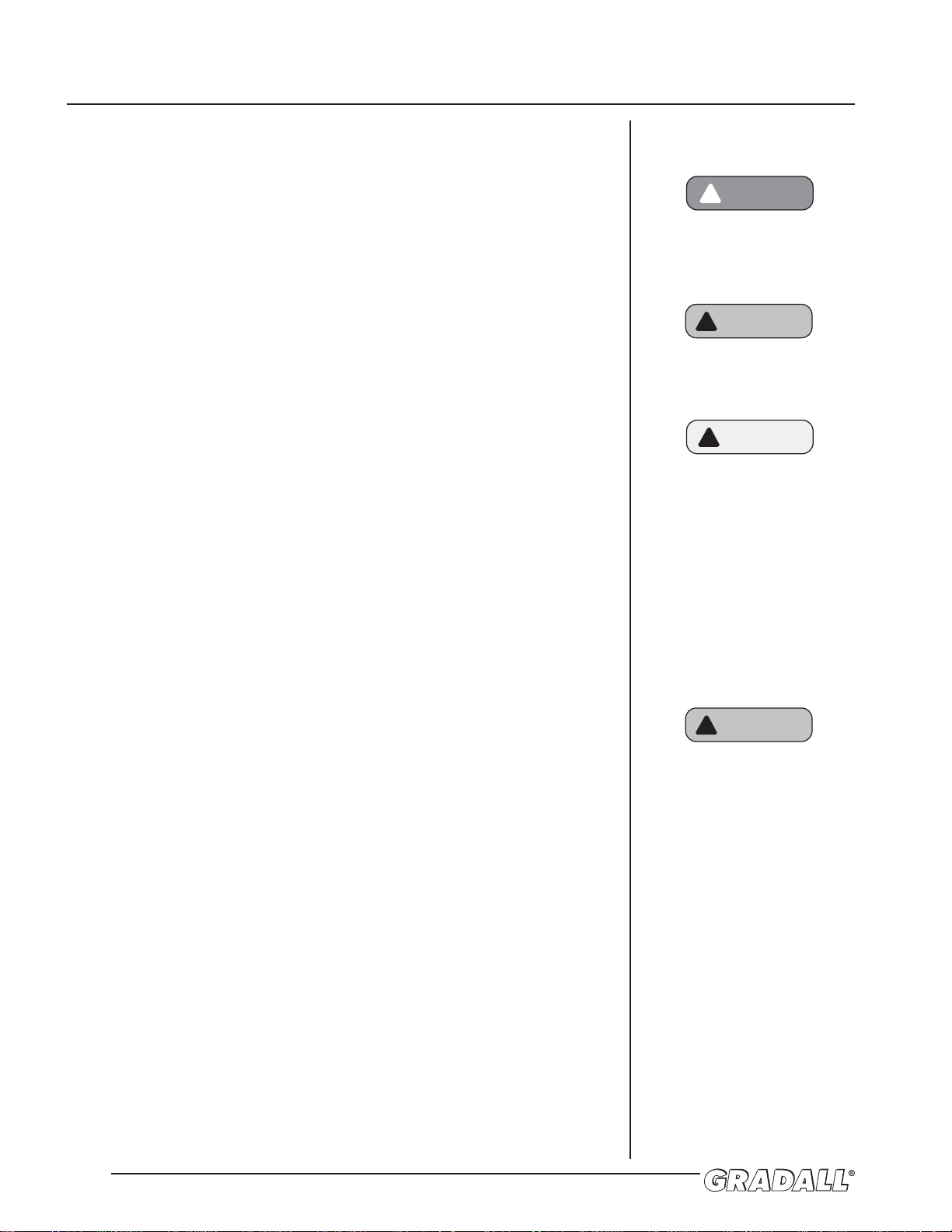

This symbol indicates a hazard

which may result in injury or

damage to equipment or property

if proper precautions are not

taken.

This symbol indicates a hazard

which could result in death or

serious injury if proper

precautions are not taken.

This symbol indicates an

extreme hazard which will result

in high probability of death or

serious injury if proper

precautions are not taken.

WATCH FOR THESE SYMBOLS ;

THEY CALL YOUR ATTENTION

TO SAFETY NOTICES.

SAFETY HIGHLIGHTS

1.0

Operator must be seated with

seat belt fastened, transmission

control lever in “Neutral”

position, parking brake applied

and all hydraulic controls in

“Neutral” before starting engine.

DANGER

!

WARNING

!

CAUTION

!

WARNING

!

Form No. 20036 • G6-42A Owner/Operator Manual

1.1

Release trapped pressure before disconnecting, opening or removing any

hydraulic component.

Keep all windows and mirror(s) clean. Adjust mirror(s) as

required for maximum

visibility, before and during opera

tion.

Do not increase engine speed with the transmission in forward or reverse

and the service brake pedal depressed in an attempt to get quicker hydraulic

performance. This could cause unexpected machine movement.

After bringing the material handler to a stop using the service brake, place

the directional control lever in neutral, and set the park brake prior to lifting

a load.

Allow the handler to slow down, or use the service brakes prior to down-shifting.

Do not downshift more than one gear at a time.

When traveling on downhill slopes, downshift to a lower gear and use the service

brake as necessary to maintain a slow speed. Do not shift into neutral and

coast downhill.

Never permit diesel engine to run out of fuel. Doing so can cause severe

engine damage.

DO NOT burn or drill holes in forks. Modifying any part of machine or

attachment affects it’s capacity and/or stability of machine.

Keep head, arms, hands, legs and all other body parts inside the operator’s cab

at all times.

DO NOT approach power lines, overhead or underground cables or other

power sources with any part of your material handler or load unless all

local, state/provincial and federal regulations have been met and the

appropriate utility company’s hotline has been contacted to de-energize

the lines.

Whenever leaving the cab, perform standard shut-down procedure:

Standard Shut-Down Procedure

Position the handler in a safe location, lower forks to ground, apply park

brake, move all controls to

“Neutral”, allow engine to run at low idle for 3 to 5

minutes.

Stop engine and remove ignition key. Chock wheels.

Contact The Gradall Company prior

to welding on machine.

WARNING

!

1.2

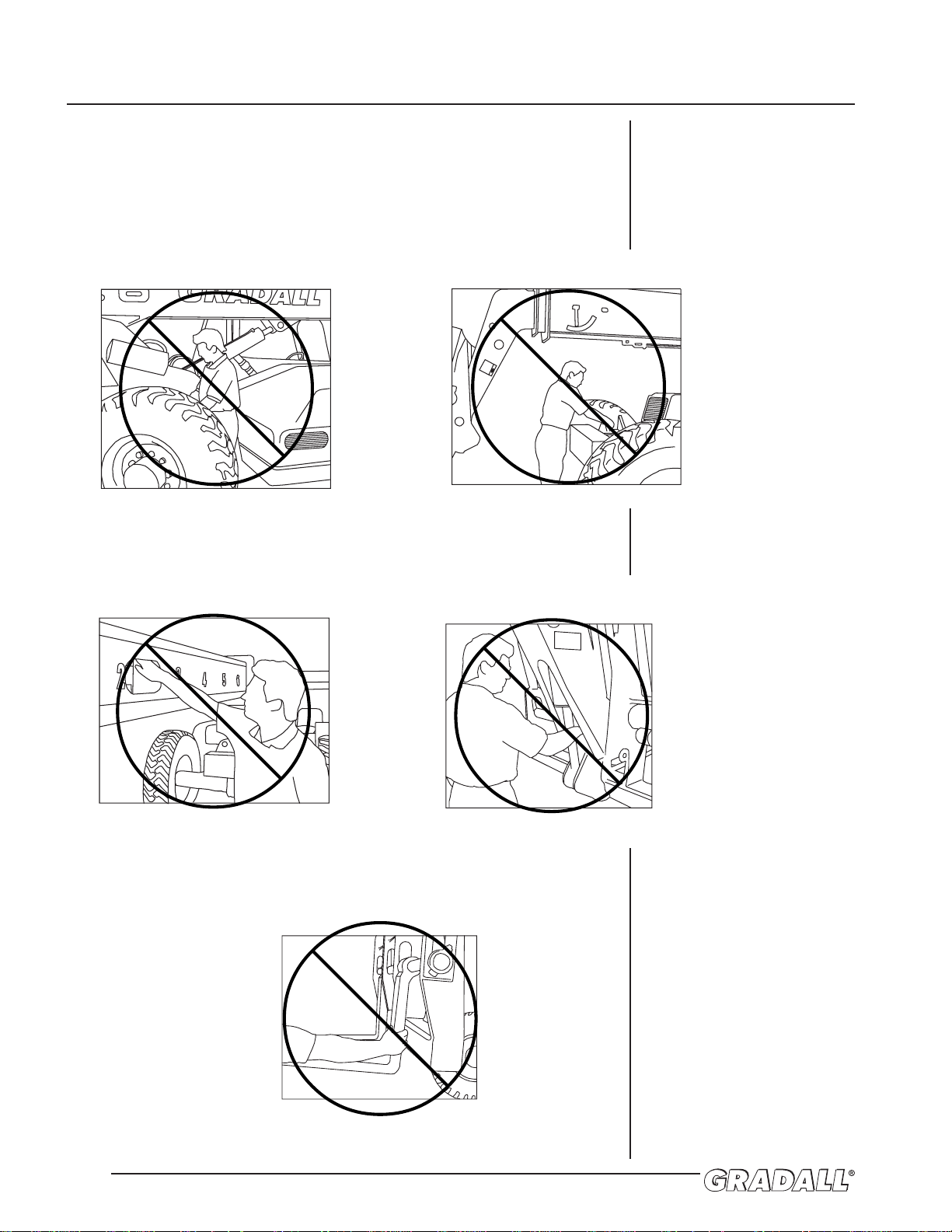

Pinch Points

Stay clear of pinch points and rotating parts on the material handler.

Getting caught in a pinch point or a moving part can cause serious

injury or death. Before performing any maintenance on machine, follow

the “STANDARD SHUT-DOWN PROCEDURE” on page 1.1.

Front & Rear Steering Axles

Boom

Boom Holes Attachment Tilt Cylinder

Carriage Forks

Form No. 20036 • G6-42A Owner/Operator Manual

THIS PAGE INTENTIONALLY LEFT BLANK.

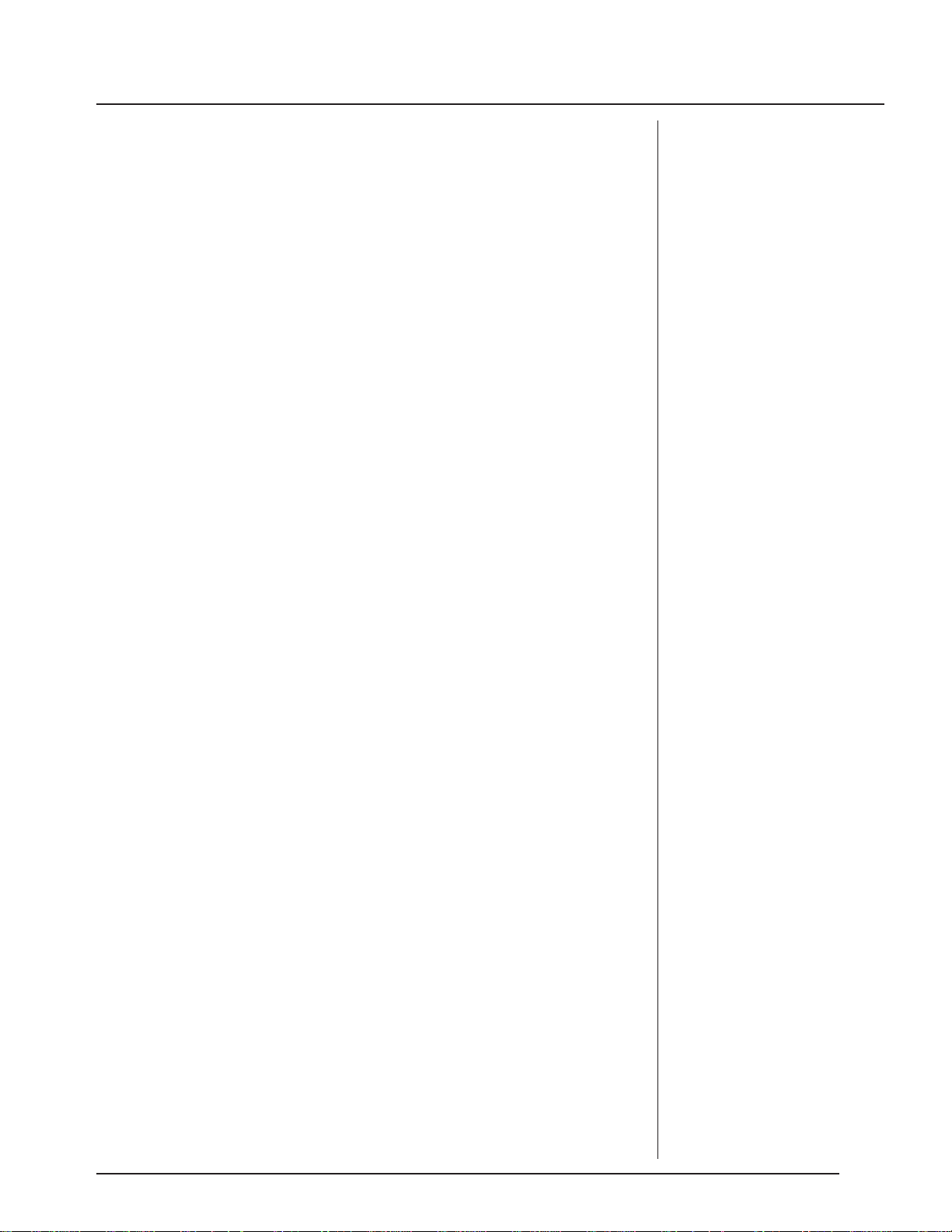

DECAL LOCATIONS

2.0

1 9114-3282 Warning Decal, Pinch P oint

2 9114-3280 Warning Decal, Exhaust System

3 9140-3569 Oil Level Decal

4 9114-3288 Hydraulic Oil Decal

5 9132-3030 Warning Decal, Capacity Chart

6 9055-3027 Warning Decal, Lifting P ersonnel

7 8060-3022 Danger Decal, High V oltage

8 7733-3027 Made in USA Decal

9 9114-3283 Warning Decal, No Riders

10 9114-3286 Warning Decal, Diesel Fuel

11 9108-3492 Oil Warning Decal

12 9055-3028 Warning Decal, Safe Operation

13 9147-3131 Serial No. & Attaching Plate

14 9150-3102 Boom Operation Decal

15 9147-3217 Service Instruction Plate

16 9140-3618 Load Chart Cover

17 9147-3139 Carriage Chart

18 9147-3162 G6-42A Capacity Chart

19 9141-3061 Ignition Decal,

(S/N 0160001283 thru Current)

1

2

3

4

1

5

6

7

1

8

10

9

1

11

5

12 13

14

15

17

16

18

19

WORK PLATFORM

6 FT. MAST

9140-3618

48" & 72"

CARRAIGE

100° SWING

CARRIAGE

B

B

9114-3283

NO RIDERS PERMITTED ON HANDLER.

OPERATOR ONLY IN MACHINE

WHILE RUNNING.

RIDERS COULD FALL OFF MACHINE

CAUSING SERIOUS INJURY OR DEATH.

9114-3286

DIESEL FUEL IS FLAMMABLE

EXTINGUISH ALL OPEN FLAME AND

SMOKING MATERIALS WHEN REFUELING

INJURY OR DEATH COULD RESULT

FROM FIRE.

9114-3282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

CAUSE SERIOUS INJURY OR DEATH.

DO NOT GO NEAR LEAKS

10814B

* High pressure oil easily punctures skin causing serious injury, gangrene or death.

* If injured, seek emergency medical help. Immediate surgery is required to remove oil.

* Do not use finger or skin to check for leaks.

* Lower load or relieve hydraulic pressure before loosening fittings.

9114-3282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

CAUSE SERIOUS INJURY OR DEATH.

A

A

9114-3282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

CAUSE SERIOUS INJURY OR DEATH.

9114-3280

EXHAUST SYSTEMS CAN BE HOT.

KEEP AWAY FROM EXHAUST SYSTEM WHEN HOT.

HOT EXHAUST COMPONENTS CAN CAUSE

SEVERE BURNS.

ADD

FULL

9140-3569

CHECK OIL LEVEL WITH

HANDLER LEVEL AND ALL

CYLINDERS RETRACTED.

2.5 GALLON BETWEEN

ADD AND FULL MARKS

HYDRAULIC

OIL LEVEL

HYDRAULIC SYSTEM

Genuine Parts

9114-3282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

CAUSE SERIOUS INJURY OR DEATH.

VIEW B-B

9132-3030

NEVER OPERATE MACHINE WITHOUT

CONSULTING PROPER CAPACITY CHART FOR THE

CARRIAGE/FORK COMBINATION BEING USED.

9055-3027 REV. A

READ AND UNDERSTAND THE FOLLOWING PRIOR TO LIFTING PERSONNEL.

WHEN LIFTING PERSONNEL USE ONLY A GRADALL MANUFACTURED PERSONNEL WORK PLATFORM.

DO NOT DRIVE MACHINE WITH PERSONNEL IN PLATFORM.

WHEN PERSONNEL ARE IN PLATFORM REMAIN SEATED IN CAB WITH PERSONNEL

IN DIRECT LINE OF SIGHT.

OPERATE CONTROLS LIGHTLY AND CAUTIOUSLY WHEN LIFTING PERSONNEL.

READ AND UNDERSTAND PERSONNEL WORK PLATFORM USER'S MANUAL BEFORE LIFTING PERSONNEL.

DO NOT USE PERSONNEL WORK PLATFORM WITHOUT THE PROPER GRADALL MATERIAL

HANDLER/PERSONNEL WORK PLATFORM CAPACITY CHART DISPLAYED IN CAB.

FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY OR DEATH.

8060-3022

AVOID HIGH VOLTAGE LINES.

IT IS UNLAWFUL TO PLACE

ANY PART OF THIS MACHINE

OR LOAD WITHIN 10 FEET

OF HIGH VOLTAGE LINES

UP TO 50,000 VOLTS.

DEATH OR INJURY MAY

RESULT FROM CONTACTING

ELECTRIC LINES.

VIEW A-A

Figure 2-1

Form No. 20036 • G6-42A Owner/Operator Manual

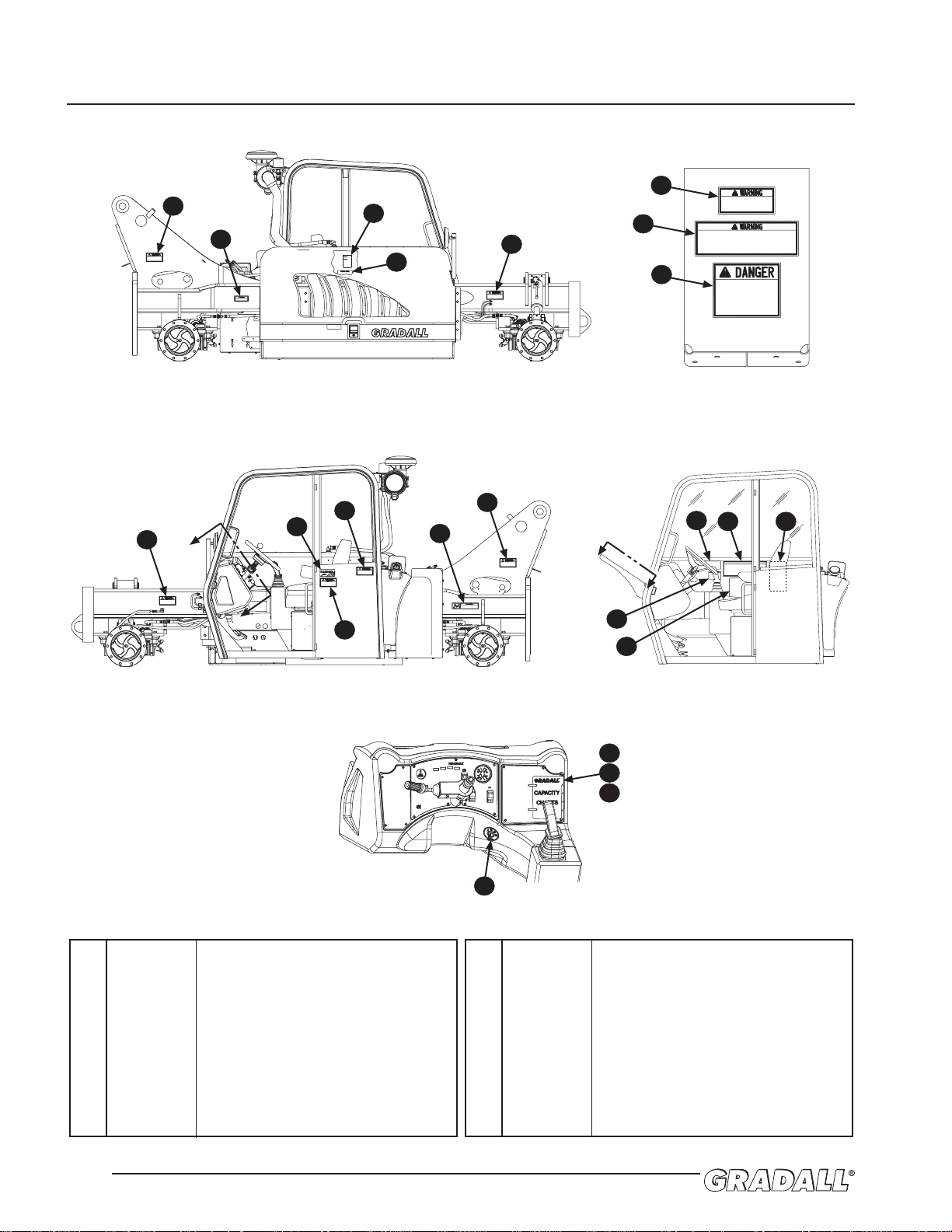

2.1

20 8060-3026 Caution Decal, Cooling System

21 9114-3281 Warning Decal, Moving Parts

22 9114-3284 Warning Decal, Battery

23 9114-3285 Instruction Decal, Jump Start

24 9140-3573 Hydraulic Fluid Decal

25 9147-3133 G6-42A Decal

26 9147-3132 Gradall Decal

27 9114-3290 Warning Decal, Attachment

28 9100-3031 Boom Angle Decal

29 8060-3037 Warning Decal, Pinch Point

30 9055-3026 Warning Decal, Lifting P ersonnel

31 9100-3016 “1” Decal

32 9100-3018 “2” Decal

33 9112-3042 “3” Decal

34 9100-3020 “4” Decal

35 9112-3044 “5” Decal

36 9116-3077 “6” Decal

C

C

D

27

1

28

29

25

26

D

31

32

33

34

35

36

29

VIEW C-C

30

VIEW D-D

29

80

6

0

-

3

0

2

6

C

O

O

L

I

N

G

S

Y

S

T

E

M

I

S

P

R

E

S

S

U

R

I

Z

E

D

.

R

E

M

O

V

E

C

A

P

S

L

O

W

L

Y

.

H

O

T

F

L

U

I

D

C

A

N

C

A

U

S

E

B

U

R

N

S

.

9

1

1

4

-

3

2

8

1

S

T

A

Y

C

L

E

A

R

O

F

M

O

V

I

N

G

P

A

R

T

S

W

H

I

L

E

E

N

G

I

N

E

I

S

R

U

N

N

I

N

G

.

M

O

V

I

N

G

P

A

R

T

S

C

A

N

C

A

U

S

E

S

E

R

I

O

U

S

I

N

J

U

R

Y

.

23

22

21

20

24

Figure 2-2

9150-3102 REV. -

DECALS

2.2

9132-3030

NEVER OPERATE MACHINE WITHOUT

CONSULTING PROPER CAPACITY CHART FOR THE

CARRIAGE/FORK COMBINATION BEING USED.

R

9140-3618

FRONT

GENERAL

NOTES

9140-3618

LEVEL GRADALL HANDLER BEFORE LIFTING ABOVE 4 FT.

USE CAPACITY CHART FOR SPECIFIC ATTACHMENT ON MACHINE.

FOR OTHER ATTACHMENTS CONSULT A GRADALL DEALER

FOR LOAD RATINGS NOT LISTED.

USE LARGEST NUMBER VISIBLE FROM THE CAB TO

DETERMINE BOOM EXTENSION.

MATCH WITH BOOM ANGLE TO DETERMINE ALLOWABLE LOAD.

FIGURES SHOWN ARE STACKING CAPACITY TRUCK LEVEL.

RATED LIFTING CAPACITIES SHOWN ARE WITH MACHINE ON A FIRM,

LEVEL SURFACE WITH UNDAMAGED, PROPERLY INFLATED TIRES.

MACHINE SPECIFICATIONS AND STABILITY ARE BASED ON RATED LIFT

CAPACITIES AT SPECIFIC BOOM ANGLES AND BOOM LENGTHS.

IF SPECIFICATIONS ARE CRITICAL, THE PROPOSED APPLICATION

SHOULD BE DISCUSSED WITH YOUR DEALER.

DO NOT EXCEED RATED LIFT CAPACITY LOADS, AS UNSTABLE AND

DANGEROUS MACHINE CONDITIONS WILL RESULT.

DO NOT TIP THE MACHINE FORWARD TO DETERMINE ALLOWABLE LOAD.

CERTAIN CARRIAGE/FORK COMBINATIONS MAY CAUSE HANDLER TO TIP

WITHOUT LOAD WHEN EXTENDED INTO "NO OPERATION" ZONE AS NOTED

ON CAPACITY CHART.

CAPACITY LIMITS FOR THIS UNIT ARE BASED IN

ACCORDANCE WITH STANDARDS LISTED ON SERIAL

NUMBER PLATE.

BACK

SAMPLE ONLY - USE CHART IN CAB

Located on dashboard

P/N 9140-3618

Located on dashboard

P/N 9147-3139

Located on right cab wall

P/N 9055-3028

Located on right cab wall

P/N 9150-3102

Located on right cab wall

and cab fender

P/N 9132-3030

8. ON INCLINES, TRAVEL WITH LOAD UP-GRADE.

9. DO NOT USE BOOM AS WALKWAY.

10. USE TWO HANDS WHEN CLIMBING ON MACHINE.

1. ONLY TRAINED AND AUTHORIZED PERSONNEL MAY

OPERATE THIS MACHINE.

2. BEFORE OPERATING, READ AND UNDERSTAND ALL CAPACITY

CHARTS, OPERATOR MANUALS AND SAFETY MANUALS. IF

MANUALS ARE NOT AVAILABLE, CONSULT AN AUTHORIZED

GRADALL DEALER. UNDERSTAND ALL CONTROLS IN CAB AND

CHECK FOR PROPER OPERATION. CLEAR LOOSE OBJECTS

OFF MACHINE AND SOUND HORN BEFORE STARTING ENGINE.

3. OPERATOR MUST BE SEATED WITH SEAT BELT FASTENED.

ASSURE FORWARD/REVERSE LEVER IS IN NEUTRAL,PARK

BRAKE APPLIED AND ALL HYDRAULIC CONTROLS ARE IN

NEUTRAL BEFORE IGNITION SWITCH IS TURNED ON.

4. DO NOT OPERATE MACHINE WITHOUT PROPER CAPACITY

CHART IN PLACE.

5. BEFORE MOVING, BE SURE OF A CLEAR PATH AND SOUND

HORN. WATCH FOR PEDESTRIANS AND OBSTRUCTIONS.

CHECK OVERHEAD AND SIDE CLEARANCES. ALWAYS LOOK

IN DIRECTION OF TRAVEL.

6. START, TURN, AND BRAKE SMOOTHLY. REDUCE TRAVEL

SPEEDS FOR TURNS, SLIPPERY, OR UNEVEN SURFACES.

AVOID RUNNING OVER LOOSE OBJECTS OR HOLES IN THE

ROADWAY SURFACE.

7. WHEN TRAVELING WITH LOAD, FULLY RETRACT BOOM AND

PLACE FORKS IN CARRY POSITION (APPROX.12" ABOVE

GROUND). TILT CARRIAGE BACK SLIGHTLY TO CRADLE

LOAD. USE EXTREME CAUTION WHEN TURNING.

11. USE ONLY A GRADALL MANUFACTURED PERSONNEL WORK

PLATFORM FOR LIFTING PERSONNEL. NO RIDERS ON MACHINE,

FORKS, LOAD, OR OTHER LIFTING ATTACHMENTS AT ANY

TIME. DO NOT USE PERSONNEL WORK PLATFORM WITHOUT THE

PROPER GRADALL MATERIAL HANDLER/PERSONNEL WORK

PLATFORM CAPACITY CHART DISPLAYED IN THE CAB. DO NOT

DRIVE MACHINE WITH PERSONNEL IN PLATFORM.

12. KEEP OTHERS AWAY FROM MACHINE WHILE OPERATING.

DO NOT STAND UNDER BOOM OR LOAD.

13. USE EXTREME CARE WHEN HANDLING LONG, HIGH, OR

WIDE LOADS. DO NOT HANDLE UNSTABLE OR LOOSELY

STACKED LOADS.

14. FORKS TO BE CENTERED UNDER LOAD AND SPACED APART

AS FAR AS POSSIBLE.

15. BEFORE ADJUSTING OR SERVICING, PLACE

FORWARD/REVERSE LEVER IN NEUTRAL, REST BOOM ON

GROUND OR SUPPORT, SET PARKING BRAKE, SHUT OFF

ENGINE AND CHOCK WHEELS.

16. BEFORE LEAVING MACHINE UNATTENDED, PLACE

FORWARD/REVERSE LEVER IN NEUTRAL, LOWER BOOM,

SET PARKING BRAKE,AND SHUT-OFF ENGINE. CHOCK

WHEELS IF MACHINE MUST PARK ON AN INCLINE.

17. LEVEL MACHINE BEFORE LIFTING ANY LOAD ABOVE 4

FEET. (IF EQUIPPED WITH FRAME LEVELING).

18. OPERATOR PROTECTION (SUCH AS HARD HATS, SAFETY

GLASSES, AND/OR HEARING PROTECTION) SHOULD BE

WORN WHEN JOB CONDITIONS WARRANT. ALWAYS USE

SEAT BELT.

19. IMPROPER USE OF MACHINE COULD RESULT IN MACHINE

TIPPING OVER. IF MACHINE STARTS TO TIP OVER, DO

NOT LEAVE OPERATORS SEAT. LEAN AWAY FROM TIP &

BRACE YOURSELF.

20. KEEP MIRROR(S) CLEAN AND PROPERLY ADJUSTED.

OBJECTS IN MIRROR ARE CLOSER THAN THEY APPEAR.

9055-3028 REV. A

FOR SAFE OPERATION OF MACHINE AND TO MINIMIZE RISK OF

SERIOUS INJURY, READ AND OBSERVE THE FOLLOWING:

48" & 72"

SLOPE PILER

9147-3139 (-)

BACK

DEDUCT 350 LBS

FROM ALL CAPACITIES

WHEN MACHINE IS

EQUIPPED WITH WINCH

MODEL

G6-42A

USE WITH: 9140-5101 48"

9140-5079 72"

SLOPE PILER CARRIAGE

RATED CAPACITY 2 FT. LOAD CENTER

600 LBS

2000 LBS

3000 LBS

4000 LBS

5000 LBS

6600 LBS

0'

4'

8'12'

16'

20'24'28'32'

-8'

-4'

0'

4'

8'

-9°

0°

10°

20°

12'

16'

20'

30°

24'

28'

32'

36'

40'

44'

48'

40°

50°

60°

70°

6

5

4

3

2

1

USE WITH:

9140-5073 48" CARRIAGE

9140-5074 72" CARRIAGE

9140-5024 WINCH (4,000 LB MAX. CAPACITY)

6600 LBS

6000 LBS

5000 LBS

4000 LBS

3000 LBS

2000 LBS

1000 LBS

9147-3139 (-)

FRONT

48" & 72"

CARRIAGES

MODEL

G6-42A

DEDUCT 350 LBS

FROM ALL CAPACITIES

WHEN MACHINE IS

EQUIPPED WITH WINCH

RATED CAPACITY 2 FT. LOAD CENTER

0°

10°

20°

30°

40°

50°

60°

70°

1

2

3

4

5

6

-9°

0'

-4'

-8'

4'

8'

12'

16'

20'

24'

28'

32'

36'

40'

44'

0'

4'

8' 12'

16'

20' 24' 28' 32'

48'

SAMPLE ONLY - USE CHART IN CAB

Form No. 20036 • G6-42A Owner/Operator Manual

24"

24"

406 MILL AVE. S.W., NEW PHILADELPHIA, OHIO 44663

GRADALL IS A REGISTERED TRADEMARK FOR

HYDRAULIC EQUIPMENT BUILT BY THE

GRADALL CO. MANUFACTURED IN THE U.S.A.

AS RELEASED FROM FACTORY THIS TRUCK MEETS THE DESIGN SPECIFICATIONS

ESTABLISHED IN AMERICAN NATIONAL STANDARDS FOR POWERED INDUSTRIAL

TRUCKS PART III ASME B56.6b-1998.

CAP#

X1000

A

B

42'

6.6

1.0

CAPACITY WITH STANDARD

48" & 72" CARRIAGE.

(WITHOUT

ATTACHMENTS)

4.6'

B

C

A

D

20,650

20,460

24"

24"

42' 24"

C

D

ATTACHMENT

TRUCK &

ATTACHMENT

WEIGHT

24"

DCBA

6.6

20,180

CAP#

1000

9147-3131 (B)

42' 24" 24"

6.6

20,290

6.6

42' 24" 24"

24"24"42'

6.6

48" CARRIAGE

P/N 9140-5073 *

72" CARRIAGE

P/N 9140-5074 *

SHIPPED

WITH

48" SLOPE PILER

P/N 9140-5101 *

72" SLOPE PILER

P/N 9140-5079 *

2.0' 26.9'

2.0'

2.0'

2.7'

2.7'

FORKS RATED LESS THAN THE ATTACHMENT CAPACITY SHOWN ABOVE DECREASE

CAPACITY OF ATTACHMENT TO THAT OF FORKS. FORKS RATED MORE THAN

ATTACHMENT CAPACITY DO NOT INCREASE ATTACHMENT CAPACITY.

*WEIGHTS ARE BASED ON USING 2 X 4 X 48" FORKS (APPROX. 268# PER PAIR)

**BUCKET DIMENSIONS (A & D) REFER TO BUCKET LIP HEIGHT.

***TRUSS BOOM & WINCH DIMENSIONS (A & D) REFER TO HOOK CENTER.

****WEIGHT IS BASED ON SP'L SWING MAST FORKS (APPROX. 230# PER PAIR)

*****PLATFORM DIMENSIONS (A & D) REFER TO CENTER OF FLOOR.

19430 LBS

SAMPLE ONLY - USE CHART IN CAB

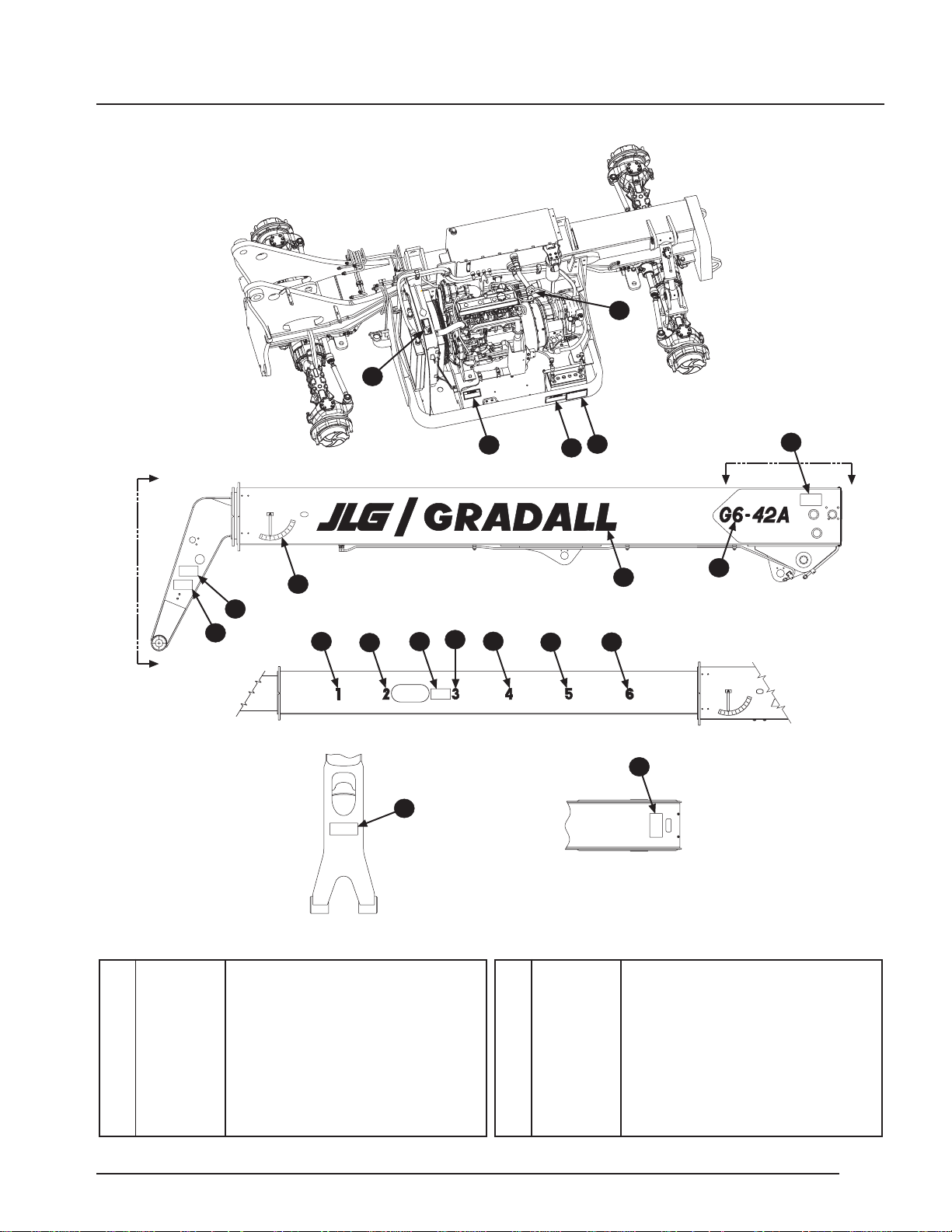

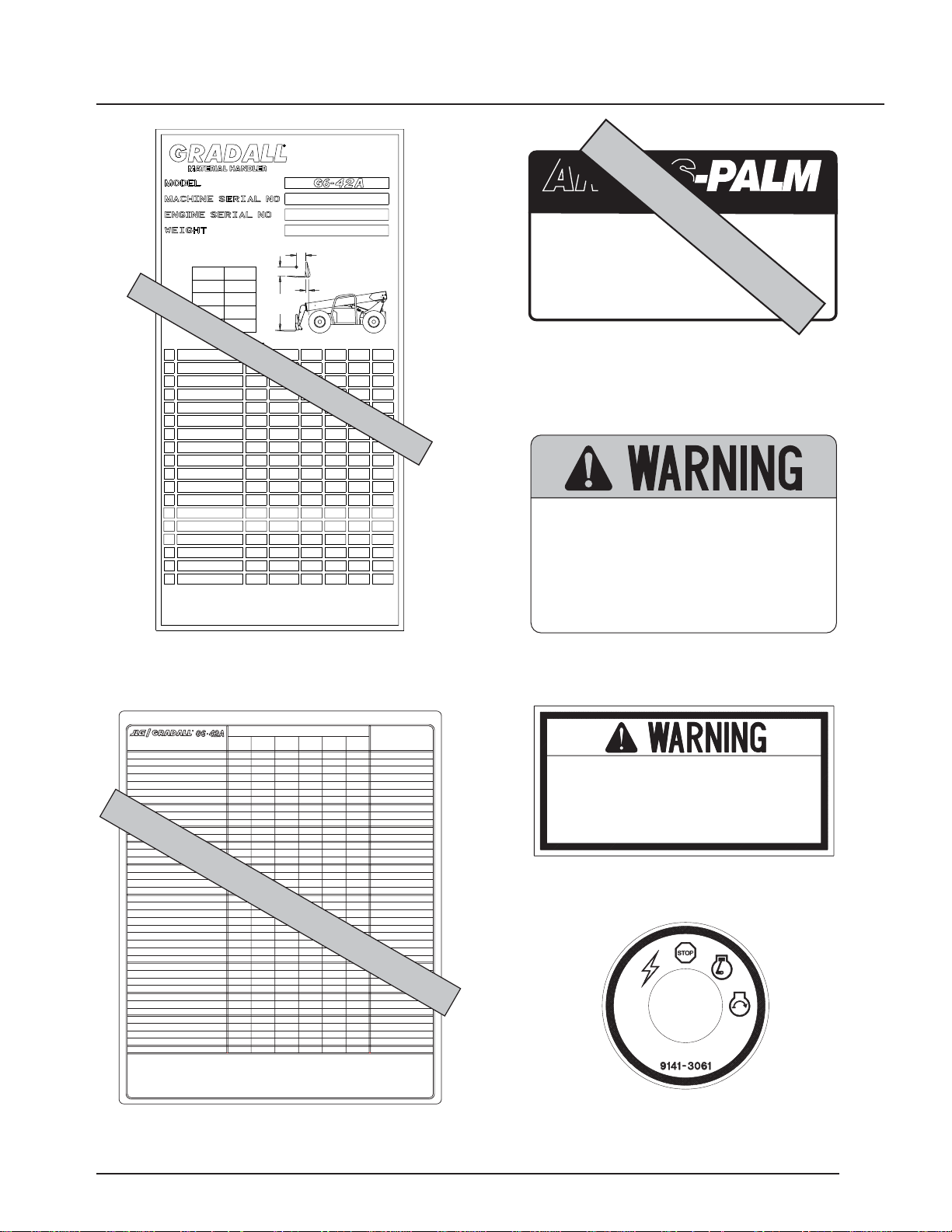

2.3

Located on right cab wall

P/N 9147-3131

Located on right cab wall

P/N 9147-3217

Located on left side, front cab plate

P/N 9116-4094

000850

THE PROTECTION OFFERED BY THIS

ROPS WILL BE IMPAIRED IF IT HAS BEEN

SUBJECTED TO ANY MODIFICATION,

STRUCTURAL DAMAGE, OR HAS BEEN

INVOLVED IN AN OVERTURN INCIDENT.

THIS ROPS MUST BE REPLACED AFTER

A ROLL-OVER. SEAT BELTS MUST BE

WORN WHILE OPERATING VEHICLE.

GRADALL MATER 06 / 9 / 10

MAX WEIGHT : 2150

MEETS SAE : J1040 MA

MEETS ISO : 3471 (94) / 3

MEETS ANSI : B56.6 - 8.16 / P

GRADALL : 9114-3261 SERIAL : 8

Box 61 SD 57201

SAMPLE ONLY

Located on back wall, behind

operator’s seat

P/N 9147-4483 (enclosed cab)

P/N 9147-4471 (open cab)

9114-3290

ATTACHMENT MUST BE SECURED TO MACHINE.

CHECK TO ASSURE QUICK SWITCH PLUNGER

PIN IS FULLY ENGAGED AND LOCKED AFTER

ATTACHMENT CHANGE.

IF PLUNGER PIN IS NOT FULLY ENGAGED

AND LOCKED ATTACHMENT MAY FALL OFF

CAUSING SERIOUS INJURY OR DEATH.

Located on boom head

P/N 9114-3290

Diesel Engine

SERVICE INTERVALS

LUBRICATION AND MAINTENANCE

MATERIAL HANDLER

9147-3217 REV(-)

Use this chart in conjunction with the "Lubrication & Maintenance" and "Recommended

Lubricants & Capacities" sections of the Owner/Operator Manual.

Service intervals may need to be more frequent than those shown depending upon

application severity. Consult your Gradall dealer for recommendations.

It is recommended that engine oil and filter, transmission lubricant and filter,

transfer case lubricant and axle lubricant be changed after first 100 hours on

new, or rebuilt units.

LUBRICANT TYPE

OR

SPECIFICATION

Air Cleaner Element

Fuel Filter

Engine Oil Filter

Engine Oil

Coolant

Diesel Fuel

YEARLY

OR

1500 HRS

6 MO.

OR

1000 HRS

3 MO.

OR

500 HRS

EVERY 5

WKS OR

250 HRS

WEEKLY

OR

50 HRS

DAILY

OR

10 HRS

Transmission

Lubricant

Filter

Transfer Case

Lubricant

Center Section

Axle Lubricant

Planetary Hubs

Filter

Lubricant

Hydraulic System

Breather/Filter

Grease Fittings

Axles (6 Pts. Ea.)

Boom Head Pivot (2 Pts.)

Boom Pivot (2 Pts.)

Extend Chain Sheave (1 Pt.)

Drive Shafts (1 Pt. Ea.)

Cylinder Pins(13 Pts.)

Quick Switch Pin (1 Pt.)

Retract Chain Sheave (1 Pt.)

Boom

Front Bottom Bearing Pads

All Other Bearing Pads

Extend/Retract Chains

Options And Attachments

Stabilizer Cylinder (3 Pts.)

Attachment Pivots And Pins

Tires

13.00-24 12 Ply

13.00R24 Radial

15.5-25 12 Ply

Lug Nut Torque

Torque

Check

Check

Check

Check

Check

Check

Check

Check

Check

Check

Check

Check

Check

Check

Grease

Grease

Grease

Grease

Grease

Grease

Grease

Grease

Grease

Grease

Grease

Grease

Change

Change

Change

Change

Change

Change

Change

Change

Change

Change

Change

Change

SAE 15W-40 CH/CI Oil

Ethylene Glycol

No. 2 Diesel Fuel

Mobil 424

Mobil 424

Mobil 424

Mobil 424

Mobil 424

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

See Manual

65 PSI (448 kPa)

70 PSI (483 kPa)

58 PSI (400 kPa)

350-400 Lb-Ft (475-540 Nm)

Fill

SAMPLE ONLY - USE CHART IN CAB

Located on dash

Starting S/N 0160001283

P/N 9141-3061

2.4

8060-3026

COOLING SYSTEM

IS PRESSURIZED.

REMOVE CAP SLOWLY.

HOT FLUID CAN

CAUSE BURNS.

R

For Mobil Product Information, Call 1-800-662-4525.

HYDRAULIC SYSTEM

FILL WITH TRACTOR HYDRAULIC FLUID

or equivalent.

9114-3288

Genuine Parts

9

1

4

0

-

3

5

7

3

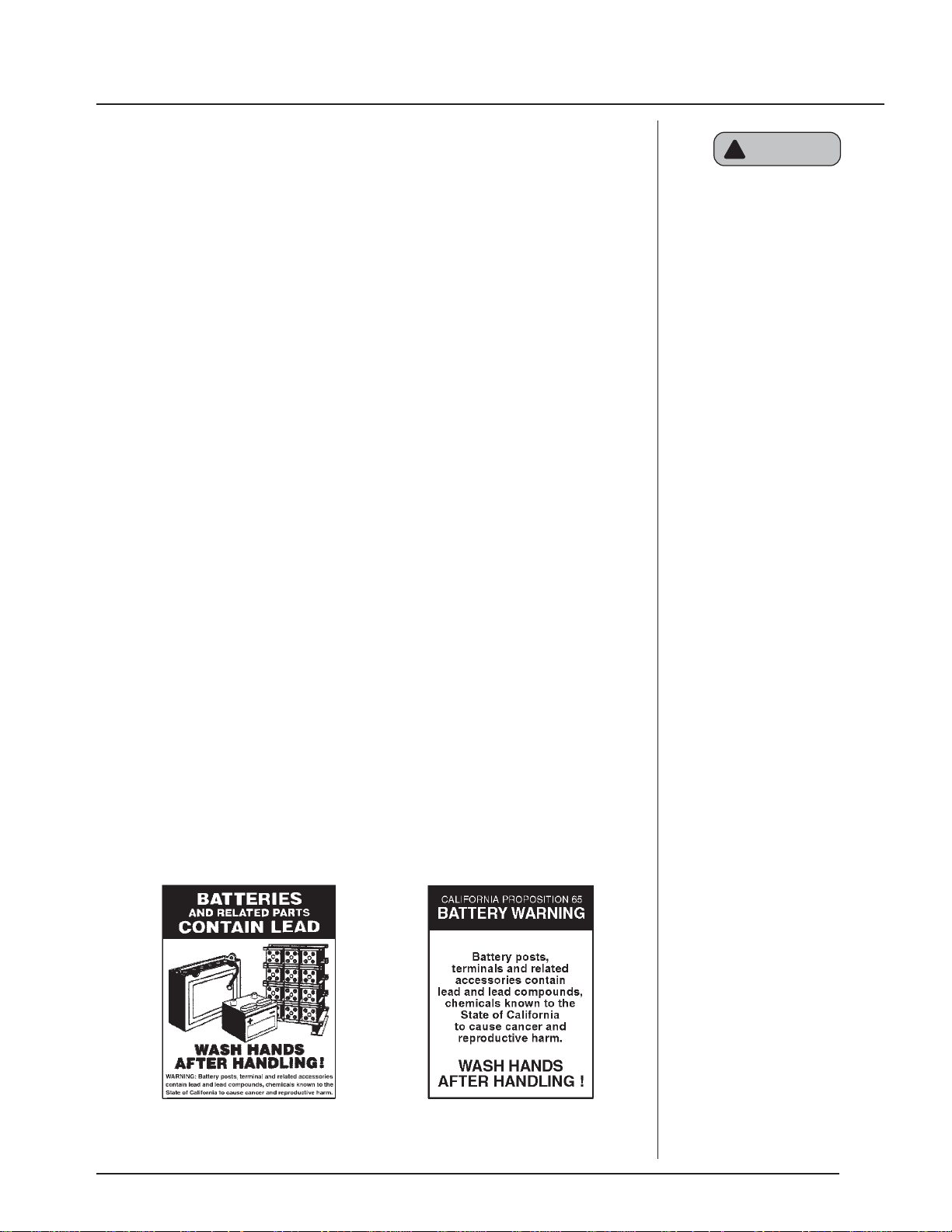

9114-3284

LEAD ACID BATTERIES PRODUCE FLAMABLE AND

EXPLOSIVE GASSES

WHEN CHECKING, TESTING, USING

BOOSTER BATTERY OR CHARGING BATTERIES:

* DO NOT USE SMOKING MATERIALS NEAR BATTERIES

* KEEP FLAMES AND SPARKS AWAY FROM BATTERIES

* WEAR SAFETY GLASSES

* ASSURE BATTERY IS NOT FROZEN AND ELECTROLYTE

IS AT PROPER LEVEL IN EACH CELL

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS INJURY OR DAMAGE TO THE

ELECTRICAL SYSTEM

9114-3285

WHEN JUMP STARTING MATERIAL HANDLER

* NEVER ALLOW VEHICLES TO TOUCH

* CONNECT THE POSITIVE (+) JUMPER CABLE TO

POSITIVE (+) POST OF DISCHARGED BATTERY

* CONNECT OPPOSITE END OF POSITIVE (+) JUMPER

CABLE TO POSITIVE (+) POST OF BOOSTER BATTERY

* CONNECT THE NEGATIVE (-) JUMPER CABLE TO

NEGATIVE (-) POST ON BOOSTER BATTERY

* CONNECT OPPOSITE END OF NEGATIVE (-) JUMPER

CABLE TO GROUND POINT ON MACHINE AWAY FROM

DISCHARGED BATTERY

* FOLLOW STANDARD STARTING PROCEDURES

* REMOVE CABLES IN REVERSE ORDER AFTER MACHINE

HAS STARTED

JUMP STARTING INSTRUCTIONS

9114-3281

STAY CLEAR OF MOVING PARTS

WHILE ENGINE IS RUNNING.

MOVING PARTS CAN CAUSE

SERIOUS INJURY.

Located on frame beside main control valve

P/N 9108-3492

Located on radiator

P/N 8060-3026

Located on hydraulic fill cap

P/N 9140-3573

Located on frame below engine cover

P/N 9114-3284

Located on frame below engine cover

P/N 9114-3285

Located on hydraulic reservoir

P/N 9114-3288

Located in engine compartment

P/N 9114-3281

DECALS

Form No. 20036 • G6-42A Owner/Operator Manual

2.5

8060-3022

AVOID HIGH VOLTAGE LINES.

IT IS UNLAWFUL TO PLACE

ANY PART OF THIS MACHINE

OR LOAD WITHIN 10 FEET

OF HIGH VOLTAGE LINES

UP TO 50,000 VOLTS.

DEATH OR INJURY MAY

RESULT FROM CONTACTING

ELECTRIC LINES.

ADD

CHECK OIL LEVEL WITH

HANDLER LEVEL AND ALL

CYLINDERS RETRACTED.

2.5 GALLON BETWEEN

ADD AND FULL MARKS

FULL

HYDRAULIC

OIL LEVEL

9140-3569

R

7733-3027

9114-3286

DIESEL FUEL IS FLAMMABLE

EXTINGUISH ALL OPEN FLAME AND

SMOKING MATERIALS WHEN REFUELING

INJURY OR DEATH COULD RESULT

FROM FIRE.

9114-3283

NO RIDERS PERMITTED ON HANDLER.

OPERATOR ONLY IN MACHINE

WHILE RUNNING.

RIDERS COULD FALL OFF MACHINE

CAUSING SERIOUS INJURY OR DEATH.

9114-3282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

CAUSE SERIOUS INJURY OR DEATH.

Located on cab fender

P/N 8060-3022

Located on hydraulic reservoir

P/N 9140-3569

Located on both sides of frame

near axles and boom head

P/N 9114-3282

Located on left cab wall

P/N 9114-3283

Located on left cab wall

P/N 7733-3027

Located on left cab wall

P/N 9114-3286

Located on mud guard

P/N 9055-3027

9055-3027 REV. A

READ AND UNDERSTAND THE FOLLOWING PRIOR TO LIFTING PERSONNEL.

WHEN LIFTING PERSONNEL USE ONLY A GRADALL MANUFACTURED PERSONNEL WORK PLATFORM.

DO NOT DRIVE MACHINE WITH PERSONNEL IN PLATFORM.

WHEN PERSONNEL ARE IN PLATFORM REMAIN SEATED IN CAB WITH PERSONNEL

IN DIRECT LINE OF SIGHT.

OPERATE CONTROLS LIGHTLY AND CAUTIOUSLY WHEN LIFTING PERSONNEL.

READ AND UNDERSTAND PERSONNEL WORK PLATFORM USER'S MANUAL BEFORE LIFTING PERSONNEL.

DO NOT USE PERSONNEL WORK PLATFORM WITHOUT THE PROPER GRADALL MATERIAL

HANDLER/PERSONNEL WORK PLATFORM CAPACITY CHART DISPLAYED IN CAB.

FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY OR DEATH.

2.6

9114-3280

EXHAUST SYSTEMS CAN BE HOT.

KEEP AWAY FROM EXHAUST SYSTEM WHEN HOT.

HOT EXHAUST COMPONENTS CAN CAUSE

SEVERE BURNS.

8060-3037-A

PINCH POINT

KEEP OUT

REACHING INTO BOOM

HOLES AND OTHER PINCH

POINTS CAN CAUSE

SERIOUS INJURY

OR DEATH.

Located on right rear frame

P/N 9114-3280

Located on left side of boom

P/N 9100-3031

Located on boom

P/N 8060-3037

406 MILL AVE. S.W. NEW PHILADELPHIA, OHIO MADE IN U. S. A.

THE CAPACITY OF FORKLIFT, ATTACHMENT AND FORK

COMBINATION MAY BE LESS THAN THE CAPACITY SHOWN

ON ATTACHMENT - CONSULT FORKLIFT NAMEPLATE

AND ALSO INSURE FORKS ARE OF PROPER SIZE.

9015-3001

ATTACHMENT

SERIAL NUMBER

WEIGHT

CAPACITY

HYD. PRESSURE

Located on attachment

P/N 9015-3001

Located on boom head & personnel

work platform

P/N 9055-3026

9055-3026 REV. A

READ AND UNDERSTAND THE FOLLOWING PRIOR TO LIFTING PERSONNEL.

WHEN LIFTING PERSONNEL USE ONLY A GRADALL MANUFACTURED

PERSONNEL WORK PLATFORM.

ALL PERSONNEL IN PLATFORM MUST WEAR A FULL BODY HARNESS WITH

LANYARD ATTACHED TO A DESIGNATED ANCHORAGE POINT.

READ AND UNDERSTAND PERSONNEL WORK PLATFORM USER'S MANUAL

BEFORE OCCUPYING PERSONNEL WORK PLATFORM.

FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY OR DEATH.

Located on Personnel

work platform

P/N 9055-3031

9055-3031 REV. A

MAXIMUM OCCUPANCY THREE (3) PEOPLE.

DO NOT USE PERSONNEL WORK PLATFORM

WITHOUT THE PROPER GRADALL MATERIAL

HANDLER/PERSONNEL WORK PLATFORM

CAPACITY CHART DISPLAYED IN CAB.

FAILURE TO COMPLY COULD RESULT IN

SERIOUS INJURY OR DEATH.

Located on work platform

P/N 9055-3032

ATTACH LANYARD HERE

9055-3032

Located on Personnel Work Platform

P/N 9055-3033

406 MILL AVE. S.W. NEW PHILADELPHIA, OHIO MADE IN U. S. A.

DO NOT USE PERSONNEL WORK PLATFORM WITHOUT THE

PROPER GRADALL MATERIAL HANDLER/PERSONNEL WORK

PLATFORM CAPACITY CHART DISPLAYED IN CAB.

9055-3033

ATTACHMENT

SERIAL NUMBER

WEIGHT

CAPACITY

HYD. PRESSURE

DECALS

Loading...

Loading...