Jet MBS-1323EVS-H, MBS-1323EVS-H-4, 413412, 413415 Operating Instructions Manual

Operating Instructions and Parts Manual

Dual Mitering EVS Band Saw

Models MBS-1323EVS-H, MBS-1323EVS-H-4

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-413412

Ph.: 800-274-6848 Edition 5 04/2018

www.jettools.com Copyright © 2018 JET

1

1.0 IMPORTANT SAFETY

INSTRUCTIONS

WARNING – To reduce risk of injury:

1. Read and understand the entire owner's

manual before attempting assembly or

operation.

2. Read and understand the warnings posted on

the machine and in this manual. Failure to

comply with all of these warnings may cause

serious injury.

3. Replace the warning labels if they become

obscured or removed.

4. This band saw is designed and intended for use

by properly trained and experienced personnel

only. If you are not familiar with the proper and

safe operation of a band saw, do not use until

proper training and knowledge have been

obtained.

5. Do not use this band saw for other than its

intended use. If used for other purposes, JET

disclaims any real or implied warranty and holds

itself harmless from any injury that may result

from that use.

6. Always wear ANSI Z87.1 approved safety

glasses or face shield while using this band

saw. (Everyday eyeglasses only have impact

resistant lenses; they are not safety glasses.)

7. Before operating this machine, remove tie,

rings, watches and other jewelry, and roll

sleeves up past the elbows. Do not wear loose

clothing. Confine long hair. Non-slip footwear or

anti-skid floor strips are recommended. Do not

wear gloves.

8. Wear ear protectors (plugs or muffs) if noise

exceeds safe levels.

9. CALIFORNIA PROPOSITION 65 WARNING:

This product contains chemicals known to the

State of California to cause cancer, or birth

defects or other reproductive harm.

10. This product, when used for welding, cutting, or

working with metal, produces fumes, gases, or

dusts which contain chemicals known to the

State of California to cause birth defects and, in

some cases, cancer. (California Health and

Safety Code Section 25249.5 et seq.)

11. Make certain the switch is in the OFF position

before connecting the machine to the power

supply.

12. Make certain the machine is properly grounded.

13. Make all machine adjustments or maintenance

with the machine unplugged from the power

source.

14. Remove adjusting keys and wrenches. Form a

habit of checking to see that keys and adjusting

wrenches are removed from the machine

before turning it on.

15. Keep safety guards in place at all times when

the machine is in use. If removed for

maintenance purposes, use extreme caution

and replace the guards immediately after

completion of maintenance.

16. Check damaged parts. Before further use of the

machine, a guard or other part that is damaged

should be carefully checked to determine that it

will operate properly and perform its intended

function. Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting and any other conditions that may

affect its operation. A guard or other part that is

damaged should be properly repaired or

replaced.

17. Provide for adequate space surrounding work

area and non-glare, overhead lighting.

18. Keep the floor around the machine clean and

free of scrap material, oil and grease.

19. Keep visitors a safe distance from the work

area. Keep children away.

20. Make your workshop child proof with padlocks,

master switches or by removing starter keys.

21. Give your work undivided attention. Looking

around, carrying on a conversation and “horseplay” are careless acts that can result in serious

injury.

22. Maintain a balanced stance at all times so that

you do not fall into the blade or other moving

parts. Do not overreach or use excessive force

to perform any machine operation.

23. Use the right tool at the correct speed and feed

rate. Do not force a tool or attachment to do a

job for which it was not designed. The right tool

will do the job better and more safely.

24. Use recommended accessories; improper

accessories may be hazardous.

25. Maintain tools with care. Keep saw blades

sharp and clean for the best and safest

performance. Follow instructions for lubricating

and changing accessories.

26. Maintain proper adjustment of blade tension,

blade guides and thrust bearings.

27. Turn off the machine before cleaning. Use a

brush to remove chips or debris — do not use

your hands.

2

28. Do not stand on the machine. Serious injury

could occur if the machine tips over.

29. Never leave the machine running unattended.

Turn the power off and do not leave the

machine until it comes to a complete stop.

30. Remove loose items and unnecessary work

pieces from the area before starting the

machine.

31. Never hand hold the material. Always use the

vise and clamp it securely.

32. Be sure that blade is not in contact with

workpiece when motor is started. Allow motor to

come up to speed before bringing blade into

contact with workpiece.

33. Avoid contact with coolant, especially guarding

your eyes.

35. Do not remove jammed pieces until blade has

stopped.

36. Don’t use in dangerous environment. Don’t use

power tools in damp or wet location, or expose

them to rain. Keep work area well lighted.

37. Use proper extension cord. Make sure your

extension cord is in good condition. When using

an extension cord, be sure to use one heavy

enough to carry the current your product will

draw. An undersized cord will cause a drop in

line voltage resulting in loss of power and

overheating. Table 2 (sect. 6.3) shows correct

size to use depending on cord length and

nameplate ampere rating. If in doubt, use the

next heavier gage. The smaller the gage

number, the heavier the cord.

34. Never reach around or over saw blade during

operation. Keep hands and fingers away from

blade area.

Familiarize yourself with the following safety notices used in this manual:

machine damage.

injury.

This means that if precautions are not heeded, it may result in minor injury and/or possible

This means that if precautions are not heeded, it may result in serious, or possibly even fatal,

3

2.0 Table of contents

Section Page

1.0 IMPORTANT SAFETY INSTRUCTIONS ....................................................................................................... 2

2.0 Table of contents ............................................................................................................................................ 4

3.0 About this manual .......................................................................................................................................... 5

4.0 Specifications ................................................................................................................................................. 6

5.0 Setup and assembly ....................................................................................................................................... 8

5.1 Shipping contents ....................................................................................................................................... 8

5.2 Unpacking and cleanup .............................................................................................................................. 8

5.3 Installation .................................................................................................................................................. 8

6.0 Electrical connections .................................................................................................................................... 8

6.1 GROUNDING INSTRUCTIONS ................................................................................................................. 8

6.2 Extension cords .......................................................................................................................................... 9

7.0 Adjustments ................................................................................................................................................... 9

7.1 Blade installation and removal ................................................................................................................... 9

7.2 Guide post adjustment ............................................................................................................................... 9

7.3 Blade guide adjustment .............................................................................................................................. 9

7.4 Blade tension and tracking ....................................................................................................................... 10

7.5 Belt tension ............................................................................................................................................... 11

7.6 Vise adjustment ........................................................................................................................................ 11

7.7 Bow swivel adjustment ............................................................................................................................. 12

7.8 Material stop ............................................................................................................................................. 12

7.9 Coolant flow .............................................................................................................................................. 12

8.0 Control panel ................................................................................................................................................ 12

9.0 Operation ..................................................................................................................................................... 13

9.1 Automatic shut-off .................................................................................................................................... 13

9.2 Auxiliary coolant hose .............................................................................................................................. 13

9.3 Prior to Operation ..................................................................................................................................... 13

9.4 General operating procedure ................................................................................................................... 13

9.5 Evaluating cutting efficiency ..................................................................................................................... 14

9.6 Blade selection ......................................................................................................................................... 14

9.7 Blade break-in procedures ....................................................................................................................... 14

10.0 User-maintenance ...................................................................................................................................... 15

10.1 General cleaning .................................................................................................................................... 15

10.2 Lubrication .............................................................................................................................................. 15

10.3 Belt replacement .................................................................................................................................... 15

10.4 Additional servicing ................................................................................................................................ 15

11.0 Optional accessory ..................................................................................................................................... 15

12.0 Troubleshooting MBS-1323EVS-H Band Saw ........................................................................................... 16

13.0 Replacement Parts ..................................................................................................................................... 17

13.1.1 MBS-1323EVS-H Bow Assembly – Exploded View ............................................................................ 18

13.1.2 MBS-1323EVS-H Bow Assembly – Parts List ..................................................................................... 19

13.2.1 MBS-1323EVS-H Base Assembly – Exploded View ........................................................................... 22

13.2.2 MBS-1323EVS-H Base Assembly – Parts List .................................................................................... 23

13.3.1 MBS-1323EVS-H Electrical Box Assembly – Exploded View ............................................................. 25

13.3.2 MBS-1323EVS-H Electrical Box Assembly – Parts List ...................................................................... 25

14.0 Electrical Connections for MBS-1323EVS-H ............................................................................................. 26

14.1 230V Only ............................................................................................................................................... 26

14.2 460V Only ............................................................................................................................................... 27

15.0 Warranty and service ................................................................................................................................. 28

4

3.0 About this manual

This manual is provided by JET, covering the safe operation and maintenance procedures for a JET Model MBS1323EVS-H Mitering Band Saw. This manual contains instructions on installation, safety precautions, general

operating procedures, maintenance instructions and parts breakdown. Your machine has been designed and

constructed to provide consistent, long-term operation if used in accordance with the instructions as set forth in

this document.

If there are questions or comments, please contact your local supplier or JET. JET c an also be reached at our

web site: www.jettools.com.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual before attempting assembly or

operation! Failure to comply may cause serious injury!

Register your product using the mail-in card provided, or register online: http://www.jettools.c om/us/en/serviceand-support/warranty/registration/

5

4.0 Specifications

Table 1

Model number MBS-1323EVS-H MBS-1323EVS-H-4

Stock number – saw only

Motor and Electricals

Motor type Totally enclosed, fan cooled, induction

Horsepower 3 HP (2.25 kW)

Motor phase 3

Motor voltage 230 V 460 V

Cycle 60Hz

Listed FLA (full load amps) 8.2 4.1

Motor speed 1720 RPM

Power transfer Dual belt

Inverter B-type, 3HP 3PH 230V B-type, 3HP 3PH 460V

Power cord 2.0mm x 4C, 600V

Power plug n/a

Hydraulic pump 1/4HP, 230/460V, 3PH, 60Hz, 1.34/0.67A, 4P

Coolant pump 1/8HP, 220/440V, 3PH, 60Hz, 0.2/0.1A, 2850/3400min

Recommended circuit size 1 20 A

Sound emission without load 2 75 Db at 3 ft. from machine

Capacities

Maximum cutting capacity 12 x 23-1/2 in. (305 x 597 mm)

Bow swivel -45, +60 deg.

Maximum vise opening 600 mm

Blade speeds variable within 50 – 297 SFPM

Coolant tank capacity (approx.) 23L (5.2 gal.)

Gearbox oil capacity (approx.) 1 L (1 qt.)

90° 13 in. (330mm)

Round

+ 60° 11 in. (279mm)

- 45° 13 in. (330mm)

Cutting Capacity

Tubing or Solid

Square

90° 13 in. (330mm)

+ 60° 11 in. (279mm)

- 45° 13 in. (330mm)

90° 12 x 23-1/2 in. (305 x 597mm)

Rectangle

+ 60° 7 x 12 in. (178 x 305mm)

- 45° 8 x 16 in. (203 x 406.4 mm)

Main materials

Stand Welded steel plate

Bow Steel

Blade wheels Cast iron

Dimensions

Provided blade (4/6T) HSS, 1-1/4 x 0.043 x 172 in. (34 x 1.1 x 4365mm)

Table height from floor 700 mm

Table size 440 x 195 mm

Assembled dimensions (approx.) 88 x 55 x 51 in. (40 x 25 x 23 mm)

Shipping dimensions (approx.) 90 x 58 x 60 in. (41 x 26 x 27 mm)

Weights

Net (approx.) 1826 lbs (628.3 kg)

Shipping (approx.) 2090 lbs (948 kg)

413412 413415

6

1

subject to local and national electrical codes

2

The specified values are emission levels and are not necessarily to be seen as safe operating levels. As workplace

conditions vary, this information is intended to allow the user to make a better estimation of the hazards and risks

involved only.

L = length, W = width, H = height n/a = not applicable

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without

incurring obligations.

7

Read and understand all

assembly instructions before attempting

assembly. Failure to comply may cause serious

injury.

5.0 Setup and assembly

Disconnect band saw from

power during setup.

5.1 Shipping contents

5. Adjust leveling screws until machine is level in

both directions and tighten nuts against the

base flanges.

6. Install material stop into front hole in table, as

shown in Figure 7-9.

7. Fill coolant reservoir with 15L (4 gal.) of

appropriate coolant, by pouring it through the

filter screen atop the pan.

8. Install splash plate over lip of base and below

cutting area. This deflects coolant and chips

down into the base.

1 Band saw

1 Splash plate

1 Tool box containing:

6 Leveling pads

1 Set of open-end wrenches

1 Set of hex wrenches

1 Cross-point screwdriver

1 Adjustable wrench, 12 in.

6 Hex cap bolts, 1/2-20 x 2in.

6 Hex nuts, 1/2in.

5.2 Unpacking and cleanup

1. Finish uncrating saw and inspect for damage.

Should any have occurred, contact your local

distributor. Do not discard any packing material

until saw is set up and running properly.

2. Remove all bolts attaching machine to shipping

pallet. (The wood support beam can be

removed after machine has been connected to

power and the bow raised.)

3. Clean all rust protected surfaces with a cleanerdegreaser or kerosene to remove protective

coating. Do not use gasoline, paint thinner,

mineral spirits, etc. These may damage painted

surfaces.

4. Lubricate all slideways with SAE 10W oil.

5. Compare contents of shipping carton with the

contents list in this manual. Report shortages, if

any, to your distributor.

5.3 Installation

1. The band saw should be located on a solid and

level foundation, preferably concrete. Allow

room for bow swiveling, servicing and for

moving large stock around the machine.

2. Use lifting straps that are isolated from the band

saw’s finished surfaces and knobs, to move

machine to desired location. Position straps

under secure areas; do not strap bow or vise

assembly.

3. Install leveling bolts/nuts/pads, and the leveling

feet as desired, through the base flanges.

4. Place a level on the table surface and check

side-to-side and front-to-back.

6.0 Electrical connections

Electrical connections must be

made by a qualified electrician in compliance

with all relevant codes. This machine must be

properly grounded to help prevent electrical

shock and possible fatal injury.

The MBS-1323EVS-H Horizontal Band Saw is wired

for 3-phase, 230V; the MBS-1323EVS-H-4 is wired

for 3-phase 460V. The machine is not provided with

an electrical plug; you may either attach a proper

UL/CSA-listed plug, or “hardwire” the machine

directly to a service panel.

It is recommended that the band saw be connected

to a dedicated 20 amp circuit with circuit breaker or

time-delay fuse marked “D”. Local codes take

precedence over recommendations.

Before connecting to power source, be sure switch

is in off position.

6.1 GROUNDING INSTRUCTIONS

This tool must be grounded. In the event of a

malfunction or breakdown, grounding provides a

path of least resistance for electric current to reduce

the risk of electric shock. This tool is equipped with

an electric cord having an equipment-grounding

conductor. If a plug is used, it must be plugged into

a matching outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipment-grounding

conductor to a live terminal.

Check with a qualified

electrician or service personnel if the grounding

instructions are not completely understood, or if

in doubt as to whether the tool is properly

grounded. Failure to comply may cause ser ious

or fatal injury.

8

If hardwired:

Permanently connected tools: This tool should be

connected to a grounded metal permanent wiring

system; or to a system having an equipmentgrounding conductor. Make sure a disconnect is

available for the operator. During hard-wiring of the

machine, make sure the fuses have been removed

or the breakers have been tripped in the circuit to

which the drill press will be connected. ALWAYS

FOLLOW PROPER LOCK-OUT/TAG-OUT PROCEDURES.

6.2 Extension cords

The use of extension cords is discouraged; try to

position equipment within reach of the power

source. If an extension cord becomes necessary, be

sure it is heavy enough to carry the current your

product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and

overheating.

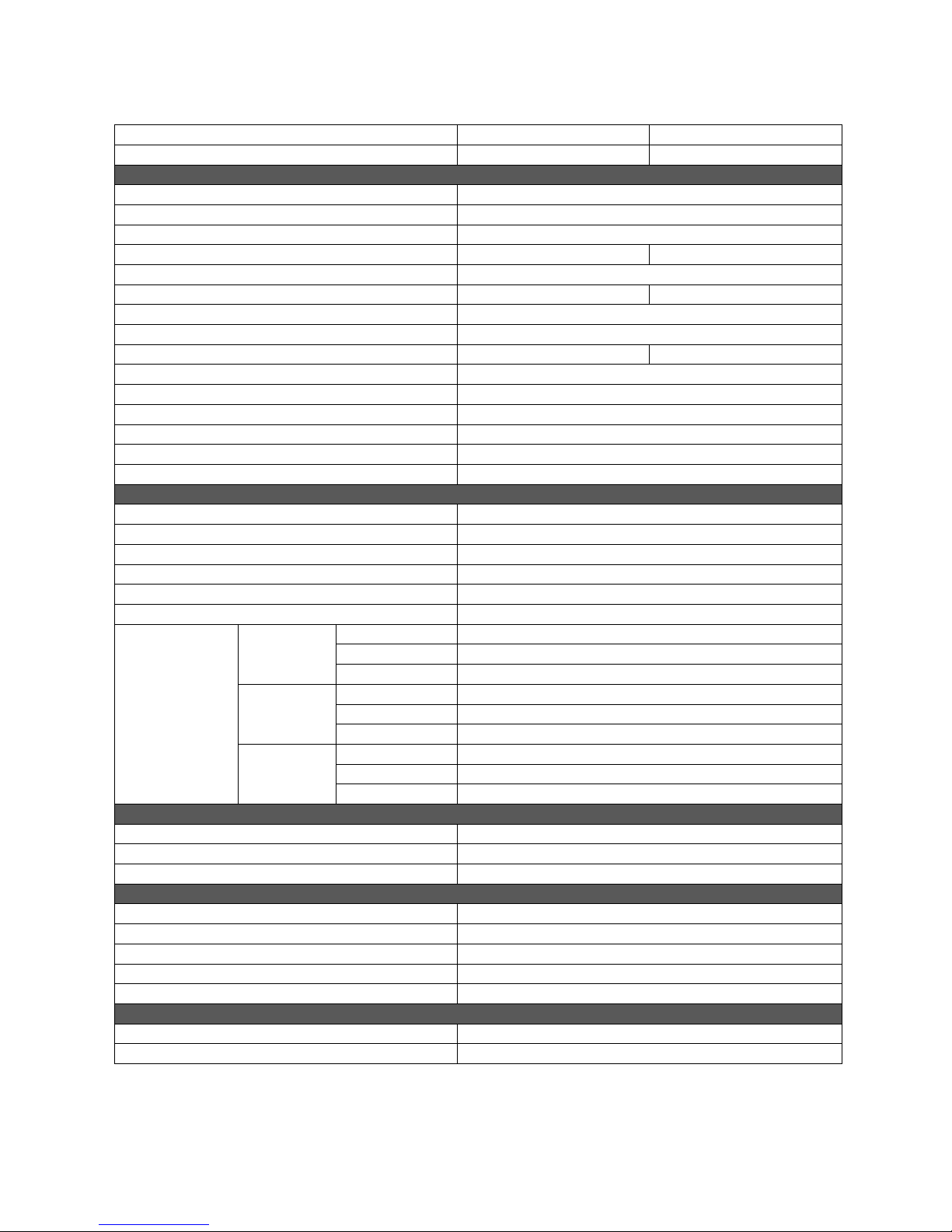

Table 2 shows recommended size to use depending

on cord length and nameplate ampere rating. If in

doubt, use the next heavier gauge. The smaller the

gauge number, the heavier the cord.

Ampere

Rating

More

Than

Not

More

Than

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12

Extension Cord Recommendations

Volts

240 50 100 200 300

AWG

Total length of

cord in feet

Not

Recommended

Table 2

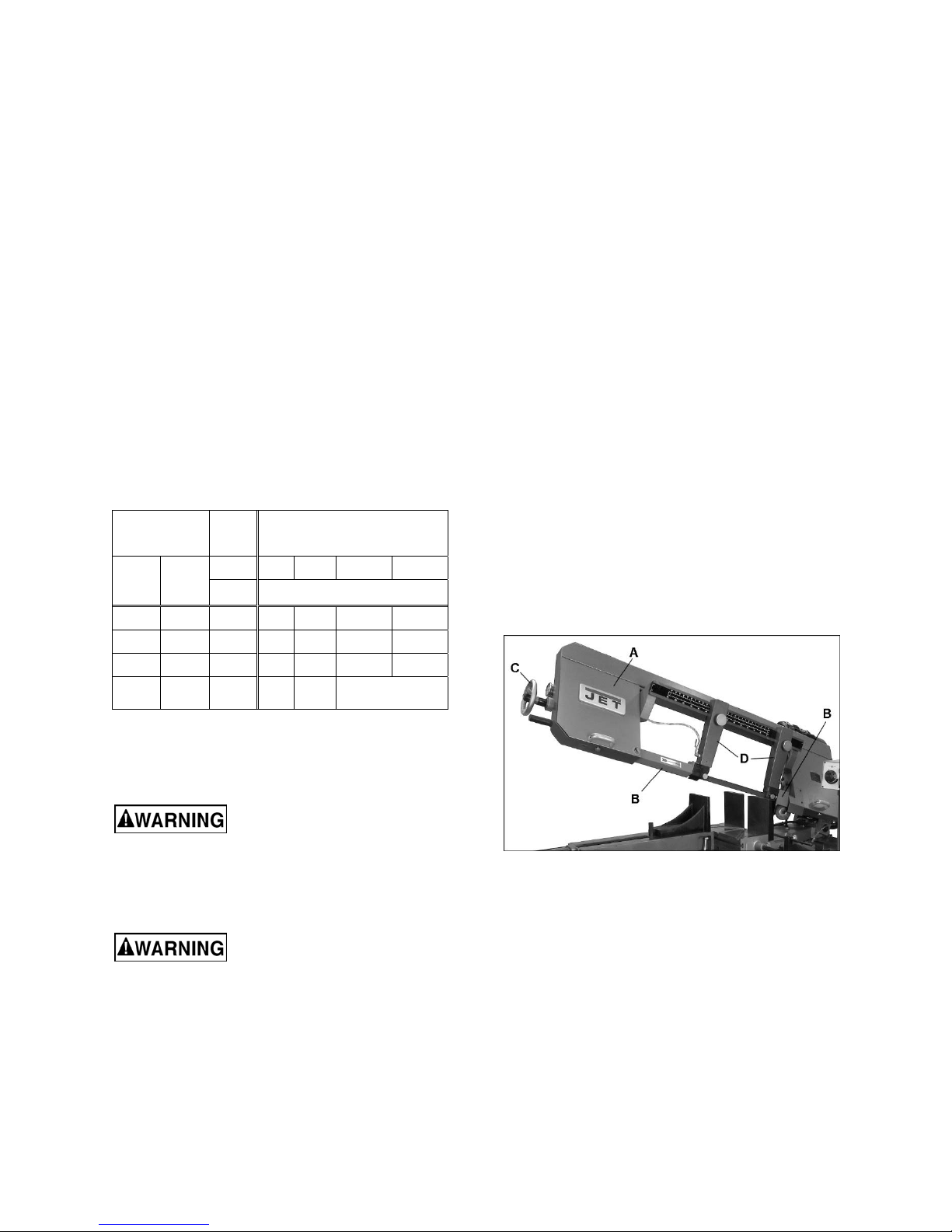

3. Open both wheel covers (A, Figure 7-1) and

clean out any swarf from wheel areas.

4. Remove red blade guards (B).

5. Back off the blade guides by loosening knob (H,

Figure 7-2). Back off the wire chip brush.

6. Release blade tension by turning blade tension

handwheel (C) counter-clockwise.

7. Remove blade from both wheels and out of

each blade guide.

8. Make sure teeth of new blade are pointing in

direction of travel. If necessary, turn blade

inside out.

9. Position new blade around wheels and through

upper slot. Slide it into blade guide bearings

with back edge of blade contacting backup

bearing. (see Figure 7-2). For further guide

bearing adjustment, see sect. 7.3

10. Lightly increase tension (C) and position blade

so it rests against shoulder of both wheels.

11. When blade is properly positioned, place full

tension upon it (see sect. 7.4.1).

12. Reinstall blade guards (B).

13. Adjust chip brush up against blade teeth.

14. Jog the start/stop buttons to ensure blade is

tracking properly. If tracking adjustment is

needed, see sect. 7.4.2.

15. Close wheel covers.

7.0 Adjustments

Disconnect machine from

power source before making adjustments,

unless indicated otherwise.

7.1 Blade installation and removal

Refer to Figure 7-1.

Always wear leather gloves

when handling blades to avoid injury.

A blade (1-1/4 in. W x 172 in. L) is pre-installed and

tensioned on saw. To replace blade:

1. Raise bow about 15-degrees and keep it in

raised position by turning feed rate control knob

clockwise all the way (see sect. 8.0).

2. Disconnect machine from power source.

Figure 7-1: blade changing

7.2 Guide post adjustment

The blade guide posts (D, Figure 7-1) must be set

to just clear the workpiece, but should not interfere

with workpiece or other saw components during

bow’s descent.

Loosen knobs and slide posts into position. Always

tighten knobs before operating machine.

7.3 Blade guide adjustment

The bearing and carbide guides come pre-adjusted

from the factory for the installed blade. If adjustment

is needed, or if a blade is replaced, follow the below

steps for left and right guides.

9

Loading...

Loading...