Jet GH-1440ZX, GH-1460ZX, GH-1440ZX-EVS, GH-1660ZX, GH-1840ZX Operating Instructions Manual

...

Operating Instructions

ZX Series Lathes

Models GH-1440ZX/1440ZX-EVS/1460ZX

GH-1640ZX/1660ZX

GH-1840ZX/1860ZX/1880ZX

GH-2280ZX

WMH TOO L GR OU P, Inc.

427 New Sanford Road

LaVergne, TN 37086 Part No. M-321910

Ph.: 800-274-6848 Revision H 05/09

www.jettools.com Copyright © 2009 WM H Tool Group, Inc.

Warranty and Service

WMH Tool Group, Inc., warrants every product it sells. If one of our tools needs service or repair, one of our

Authorized Service Centers located throughout the United States can give you quick service. In most cases, any of

these WMH Tool Group Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

perform routine maintenance and major repair on your JET

your area call 1-800-274-6848.

MORE INFORMATION

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product information, check

with your local WMH Tool Group distributor, or visit jettools.com.

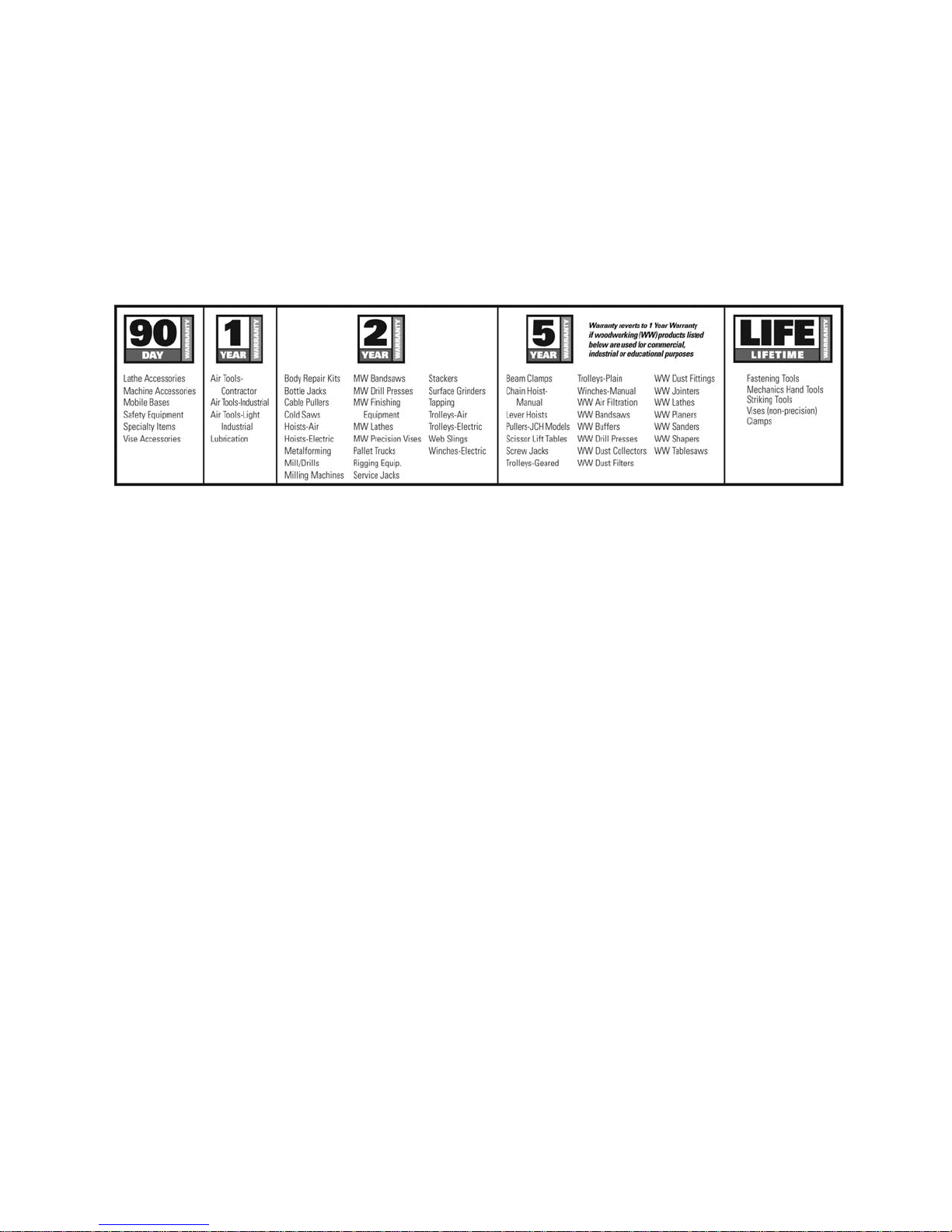

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS C OVERE D?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR

EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND

FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED

WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WMH TOOL GROUP, INC., SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR

PROPERTY, OR FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM

THE USE OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU.

WMH Tool Group sells through distributors only. The specifications in WMH catalogs are given as general information

and are not binding. Members of WMH Tool Group reserve the right to effect at any tim e, without prior notice, those

alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever.

® branded products are not sold in Canada by WMH Tool Group.

JET

® t ools. For the name of an Authorized Service Center in

2

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warning ................................................................................................................................................... 4

Specifications – 14” Lathes ...................................................................................................................... 6

Specifications – 16” Lathes ...................................................................................................................... 7

Specifications – 18” Lathes ...................................................................................................................... 8

Specifications – 22” Lathes ...................................................................................................................... 9

Unpac king ............................................................................................................................................. 10

Contents of the Shipping Container .................................................................................................... 10

Uncrating and Cleanup .......................................................................................................................... 11

Chuck Preparation (Three Jaw) .......................................................................................................... 11

Lubrication ......................................................................................................................................... 12

Coolant Prepar ation ........................................................................................................................... 13

Electri c al Connec tions ........................................................................................................................... 13

Conversion to 460 Volt Operation ....................................................................................................... 14

General Description ............................................................................................................................... 14

Lathe Bed .......................................................................................................................................... 14

Headstock .......................................................................................................................................... 14

Carriage ............................................................................................................................................. 15

Four Way Tool Post ........................................................................................................................... 15

Apron ................................................................................................................................................. 15

Tailsto ck ............................................................................................................................................ 1 5

Leadscrew and Feed Rod .................................................................................................................. 15

Feed Gearbox .................................................................................................................................... 15

Steady Rest ....................................................................................................................................... 15

Follow Rest ........................................................................................................................................ 16

Controls ................................................................................................................................................. 16

Operation .............................................................................................................................................. 1 9

Feed and Thread Selection ................................................................................................................ 19

Thread Cutting ................................................................................................................................... 19

Gib Adjustments................................................................................................................................. 1 9

Tailsto ck O ff- Se t ................................................................................................................................ 1 9

Removing Gap Section ...................................................................................................................... 20

Installing Removable Gap Section ...................................................................................................... 20

Belt Replacem ent and Adjustment...................................................................................................... 20

Aligning Tailstock to Headstock .......................................................................................................... 20

3

Warning

1. Read and understand the ent ire owners manual before attempting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or remov ed.

4. This lathe is designed and int ended for use by properly trained and experienc ed personnel only. If

you are not f amiliar wit h the pr oper and saf e operat ion of a lathe, do not use until proper t rai ning and

knowledge have been obtained.

5. Do not use this lathe f or other than its i ntended use. If used for other purposes, W MH Tool Group

disclaim s any real or i mplied warrant y and h olds itsel f harml ess from any injury t hat may r esult f rom

that use.

6. Always wear approv ed safety glasses/fac e shields whil e using this lat he. Everyday eyeglasses only

have impact resistant lenses; they are not saf ety glasses.

7. Before operating t his lat he, rem ove tie, r ings, watches and other j ewelr y, and r oll sleev es up past the

elbows. Remove all loose clothing and confine long hair . Non-slip f ootwear or anti - skid floor stri ps are

recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during ext ended periods of operation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some exampl es

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other masonry products.

• Arsenic and chromium from chemically treated lum ber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of dr ugs, alcohol or any medication.

11. Make certain the switch is in the OFF position before connecting the m achi ne to t he power supply .

12. Make certain the machine is properly grounded.

13. Make all machine adjustments or maintenance with t he machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replac e the guards immediately.

16. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

17. P rovide for adequate space surrounding work area and non-glare, overhead lighting.

18. K eep the floor around the m achi ne clean and free of scrap material, oil and grease.

19. K eep visitors a safe di st anc e from the work area. Keep children away.

20. Make your workshop chil d pr oof with padlocks, master switc hes or by removing starter keys.

4

21. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

22. M aintain a balanc ed stance at all t imes so that you d o not fall or lean against mov ing parts. Do not

overreach or use exc essive force to perform any machine operation. Never force the cutt ing action.

23. Use the ri ght t ool at the cor rect speed and f eed rate. Do not for ce a tool or attachm ent to do a j ob for

which it was not designed. T he ri ght tool will do the job better and safer.

24. Use rec om mended accessories; i mproper accessories may be hazardous.

25. Maintain tools with care. Keep cutting tools sharp and clean for the best and safest performance.

Follow instructions for lubricating and changing accessories.

26. Do not attempt to adjust or remov e tools during operation.

27. Tur n off the machi ne and disconnect f rom power bef ore cleani ng. Use a brush to remove shavi ngs or

debris — do not use your hands.

28. Do not stand on the machine. S eri ous injury could occur if the machine tips over.

29. Never leave the m ac hine r unning unattended. Turn the power off and do not l eav e the mac hine until it

comes to a complete stop.

30. Remove loose item s and unnecessary work pieces from the area before starting the machine.

Familiariz e you rself with the following safety notices used in this manual :

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

The following specificati ons were current at the time this manual was published, but becau se of our poli cy

of continuous improvement, WMH Tool Group, Inc. reserv es the r ight to change specifications at any time

and without pri or notice, without incurri ng obligations.

Specifications – 14” Lathes

Model Number ......................................... GH-1440ZX ............. GH-1440ZX-EVS ....................GH-1460ZX

Stock Number................................................. 321910 ............................ 321900 .......................... 321920

Capacities:

Swing over Bed (in.) ...............................................14 .................................... 14 .................................. 14

Swing over Cross Slide (in.) ............................... 7-5/8 ................................ 7-5/8 .............................. 7 -5/8

Swing Through Gap (in.) ...................................23-5/8 .............................. 23-5/8 ............................ 23-5 /8

Length of Gap (in.) ............................................12-1/4 .............................. 1 2-1/4 ............................ 12-1/4

Distance between Centers (in.) ...............................40 .................................... 40 .................................. 60

Headstock:

Spindle Bore (in.) ............................................... 3-1/8 ................................ 3-1/8 .............................. 3- 1/8

Spindle Mount .................................................... D1-8 ................................ D1-8 ...............................D1-8

Spindle Taper with Sleeve ....................... MT-7(MT-5) ..................... MT-7(MT-5) ....................MT-7(MT-5)

Number of Spindl e Speeds .....................................12 .................................... 1 2 .................................. 12

Range of Spindle Speeds (RPM ) ............... 42 to 1800 ........................40 to 2000 ...................... 42 to 1800

Gearbox:

Number of Longitudinal and Cross Feeds .............1 22 .................................. 122 ................................ 122

Range of Longitudinal Feeds (in./rev .) 0.0015 to 0.0913 .......... 0.0015 to 0.0913 ............ 0.0015 to 0.0913

Range of Cross Feeds (in. /rev.) ....... 0.0006 to 0.0365 .............. 0.0006 to 0.0365 ............ 0.0006 to 0.0365

Number of Inch Threads .........................................61 .................................... 61 .................................. 61

Range of Inch Threads (in.) ....................... 1-5/8 to 72 ....................... 1-5/8 to 72 ..................... 1-5/8 to 72

Number of Metric Threads ......................................24 .................................... 24 .................................. 24

Range of Metric Threads (mm) ................... 0.05 to 20 .........................0.05 to 20 ....................... 0.05 to 20

Compound and Carriage:

Maximum Tool Size (in.) ..................................... 1 x 1 ................................ 1 x 1 ...............................1 x 1

Maximum Compound Slide Travel (in.) .............. 5-1/8 ................................ 5-1 /8 .............................. 5-1/8

Maximum Cross Slide Travel (in.) ............................ 9 ...................................... 9 .................................... 9

Carriage Tr av el (i n.) ................................................35 .................................... 35 .................................. 55

Tailstock:

Tailstock Spindle Travel (in.) .................................... 5 ...................................... 5 .................................... 5

Tailstock Taper .................................................. MT-4 ................................ MT-4 .............................. MT-4

Steady Rest Capaci ty (in.) ........................ 1/2 to 3-1/2 ...................... 1/2 to 3-1/2 .................... 1/2 to 3-1/2

Follow Rest Capacit y (i n.) ............................... 3/8 to 7 ............................ 3/8 to 7 .......................... 3/8 to 7

Width of Bed (in.) ..............................................13-3/8 .............................. 13-3/8 ............................ 13-3/8

Overall Dimensions(in.)(LxWxH) . 97-1/2 x 40 x 46-7/8 ......... 97-1/2 x 40 x 46-7/8 ..... 116-1/2 x 40 x 46-7/8

Motor .................................... 7-1/2HP,3Ph,230/460V* ... 7-1/2HP,3Ph,230/460V* . 7-1/2HP,3Ph,230/460V*

Approximate Net Weight (lbs.) ............................ 5187

................................ 5187 .............................. 5380

*pre-wired 230V

6

Specifications – 16” Lathes

Model Number .......................................................................GH-1640ZX ...............................GH-1660ZX

Stock Number.............................................................................. 321930 ..................................... 321940

Capacities:

Swing over Bed (in.) ............................................................................ 16 ............................................. 16

Swing over Cross Slide (in.) ................................................................. 10 ............................................. 10

Swing Through Gap (in.) ................................................................ 25-7/8 ....................................... 25- 7/8

Length of Gap (in.) ......................................................................... 12-1/4 ....................................... 12-1 /4

Distance between Centers (in.) ............................................................ 40 ............................................. 60

Headstock:

Spindle Bore (in.) ............................................................................. 3 - 1 /8 ......................................... 3-1/8

Spindle Mount ..................................................................................D1-8 ..........................................D1-8

Spindle Taper with Sleeve .....................................................MT-7(MT-5 ) ...............................MT-7(MT-5 )

Number of Spindl e Speeds .................................................................. 12 ............................................. 12

Range of Spindle Speeds (RPM ) ............................................. 25 to 1800 ................................. 25 to 1800

Gearbox:

Number of Longitudinal and Cross Feeds .......................................... 1 22 ........................................... 12 2

Range of Longitudinal Feeds (in./rev .) ........................... 0.0015 to 0.0913 ....................... 0.0015 to 0.0913

Range of Cross Feeds (in. /rev.) ..................................... 0.0006 to 0. 0365 ....................... 0.0006 to 0.0365

Number of Inch Threads ...................................................................... 61 ............................................. 61

Range of Inch Threads (in.) .................................................... 1-5/8 to 72 ................................ 1-5/8 to 72

Number of Metric Threads ................................................................... 24 ............................................. 24

Range of Metric Threads (mm) ................................................. 0.05 to 20 .................................. 0.05 to 20

Compound and Carriage:

Maximum Tool Size (in.) ...................................................................1 x 1 ..........................................1 x 1

Maximum Compound Slide Travel (in.) ............................................ 5- 1/8 ......................................... 5-1/8

Maximum Cross Slide Travel (in.) .......................................................... 9 ............................................... 9

Carriage Tr av el (i n.) ............................................................................. 35 ............................................. 55

Tailstock:

Tailstock Spindle Travel (in.) .................................................................. 5 ............................................... 5

Tailstock Taper ................................................................................ MT-4 ......................................... MT-4

Steady Rest Capaci ty (in.) ..................................................... 1/2 to 3-1/2 ............................... 1/2 to 3-1/2

Follow Rest Capacit y (i n.) ............................................................ 3/8 to 7 ..................................... 3/8 to 7

Width of Bed (in.) ........................................................................... 13-3/8 ....................................... 13-3/8

Overall Dimensions (in.)(LxWxH) .................................... 97-1/2 x 40 x 48 ...................... 116-1/2 x 40 x 48

Motor ................................................................ 7-1/2HP, 3Ph, 230/460V* .......... 7-1/2 HP, 3Ph, 230/460V*

Approximate Net Weight (lbs.) ......................................................... 5475 ......................................... 5795

*pre-wired 230V

7

Specifications – 18” Lathes

Model Number .................................................... GH-1840ZX ............... GH-1860ZX ...............GH-1880ZX

Stock Number............................................................ 321950 ...................... 321960 ..................... 321970

Capacities:

Swing over Bed (in.) ......................................................... 18 .............................. 18 ............................. 18

Swing over Cross Slide (in.) .............................................. 11 .............................. 11 ............................. 11

Swing Through Gap (in.) ............................................. 27-1/2 ........................ 27-1/2 ....................... 27-1 /2

Length of Gap (in.) ...................................................... 12-1/4 ........................ 12-1/4 ....................... 12-1/4

Distance between Centers (in.) ......................................... 40 .............................. 60 ............................. 8 0

Headstock:

Spindle Bore (in.) .......................................................... 3-1/8 .......................... 3-1/8 ......................... 3-1/8

Spindle Mount ............................................................... D1-8 .......................... D1-8 ..........................D1-8

Spindle Taper with Sleeve .................................. MT-7(MT-5) ............... MT-7(MT-5) ...............MT-7(MT-5)

Number of Spindl e Speeds ............................................... 12 .............................. 12 ............................. 12

Range of Spindle Speeds (RPM ) .......................... 25 to 1800 ................. 25 to 1800 ................. 25 to 1800

Gearbox:

Number of Longitudinal and Cross Feeds ....................... 1 2 2 ............................ 122 ........................... 12 2

Range of Longitudinal Feeds (in./rev .) ........ 0.0015 to 0.0913 ........ 0. 0015 to 0.0913 ....... 0.0015 to 0.0913

Range of Cross Feeds (in. /rev.) .................. 0.0006 to 0. 0365 ........ 0.0006 to 0.0365 ....... 0.0006 to 0.0365

Number of Inch Threads ................................................... 61 .............................. 61 ............................. 61

Range of Inch Threads (in.) .................................. 1-5/8 to 72 ................. 1-5/8 to 72 ................ 1-5/8 to 72

Number of Metric Threads ................................................ 24 .............................. 24 ............................. 24

Range of Metric Threads (mm) .............................. 0.05 to 20 .................. 0.05 to 20 .................. 0.05 t o 20

Compound and Carriage:

Maximum Tool Size (in.) ................................................ 1 x 1 .......................... 1 x 1 ..........................1 x 1

Maximum Compound Slide Travel (in.) ......................... 5-1/8 .......................... 5-1/8 ......................... 5-1/8

Maximum Cross Slide Travel (in.) ....................................... 9 ................................ 9 ............................... 9

Carriage Tr av el (i n.) .......................................................... 35 .............................. 55 ............................. 75

Tailstock:

Tailstock Spindle Travel (in.) ............................................... 5 ................................ 5 ............................... 5

Tailstock Taper ............................................................. MT-5 .......................... MT-5 ......................... MT-5

Steady Rest Capaci ty (in.) ................................... 1/2 to 3-1/2 ................ 1/2 to 3-1/2 ............... 1/2 to 3-1/2

Follow Rest Capacit y (i n.) .......................................... 3/8 to 7 ...................... 3/8 to 7 ..................... 3/8 to 7

Width of Bed (in.) ........................................................ 13-3/8 ........................ 13-3/8 ....................... 13-3/8

Overall Dimensions (in.)(LxWxH) ............... 97-1/2x40x48-7/8 ..... 116-1/2x40x48-7/8 ....

Motor ............................................................... 7-1/2HP, 3Ph ............. 7-1/2HP, 3Ph ............ 7-1/2HP, 3Ph

............................................................................. 230/460V* ................. 230/460V* ................. 230/460V*

Approximate Net Weight (lbs.) .......................................5980 .......................... 6245 ......................... 6590

136-1/8x40x48-7/8

*pre-wired 230V

8

Specifications – 22” Lathes

Model Number .........................................................................................................................GH-2280ZX

Stock Number................................................................................................................................ 321980

Capacities:

Swing over Bed (in.) .............................................................................................................................. 2 2

Swing over Cross Slide (in.) ................................................................................................................... 11

Swing Through Gap (in.) .................................................................................................................. 27-1/2

Length of Gap (in.) ........................................................................................................................... 12-1/4

Distance between Centers (in.) .............................................................................................................. 80

Headstock:

Spindle Bore (in.) ............................................................................................................................... 3-1/8

Spindle Mount ....................................................................................................................................D1-8

Spindle Taper with Sleeve .......................................................................................................MT-7(MT-5)

Number of Spindl e Speeds .................................................................................................................... 12

Range of Spindle Speeds (RPM ) ............................................................................................... 25 to 1800

Gearbox:

Number of Longitudinal and Cross Feeds ............................................................................................ 1 22

Range of Longitudinal Feeds (in./rev .) ............................................................................. 0.0015 to 0.0913

Range of Cross Feeds (in. /rev.) ....................................................................................... 0.0006 to 0.0365

Number of Inch Threads ........................................................................................................................ 61

Range of Inch Threads (in.) ...................................................................................................... 1-5/8 to 72

Number of Metric Threads ..................................................................................................................... 24

Range of Metric Threads (mm) ................................................................................................... 0.05 to 20

Compound and Carriage:

Maximum Tool Size (in.) .....................................................................................................................1 x 1

Maximum Compound Slide Travel (in.) .............................................................................................. 5- 1/8

Maximum Cross Slide Travel (in.) ............................................................................................................ 9

Carriage Tr av el (i n.) ............................................................................................................................... 75

Tailstock:

Tailstock Spindle Travel (in.) .................................................................................................................... 5

Tailstock Taper .................................................................................................................................. MT-5

Steady Rest Capaci ty (in.) ....................................................................................................... 1/2 to 3-1/2

Follow Rest Capacit y (i n.) .............................................................................................................. 3/8 to 7

Width of Bed (in.) ............................................................................................................................. 13-3/8

Overall Dimensions (in.)(LxWxH) .............................................................................. 136-1/8 x 40 x 48-7/8

Motor .......................................................................................... 10HP, 3PH, 230V/460V (pre- wir ed 230V )

Approximate Net Weight (lbs.) ........................................................................................................... 7400

9

Unpacking

Open shipping cont ainer and check f or shipping

damage. Report any damage immediately to

your distributor and shipping agent. Do not

discard any shipping material until the Lathe is

assembled and running properly.

Compare the c ontent s of y our cont ainer wit h t he

following parts list to make sure all parts are

intact. Mi ssing parts, if any, should be reported

to your distributor. Read the instruction manual

thoroughly for assembly, maintenance and

safety instructions.

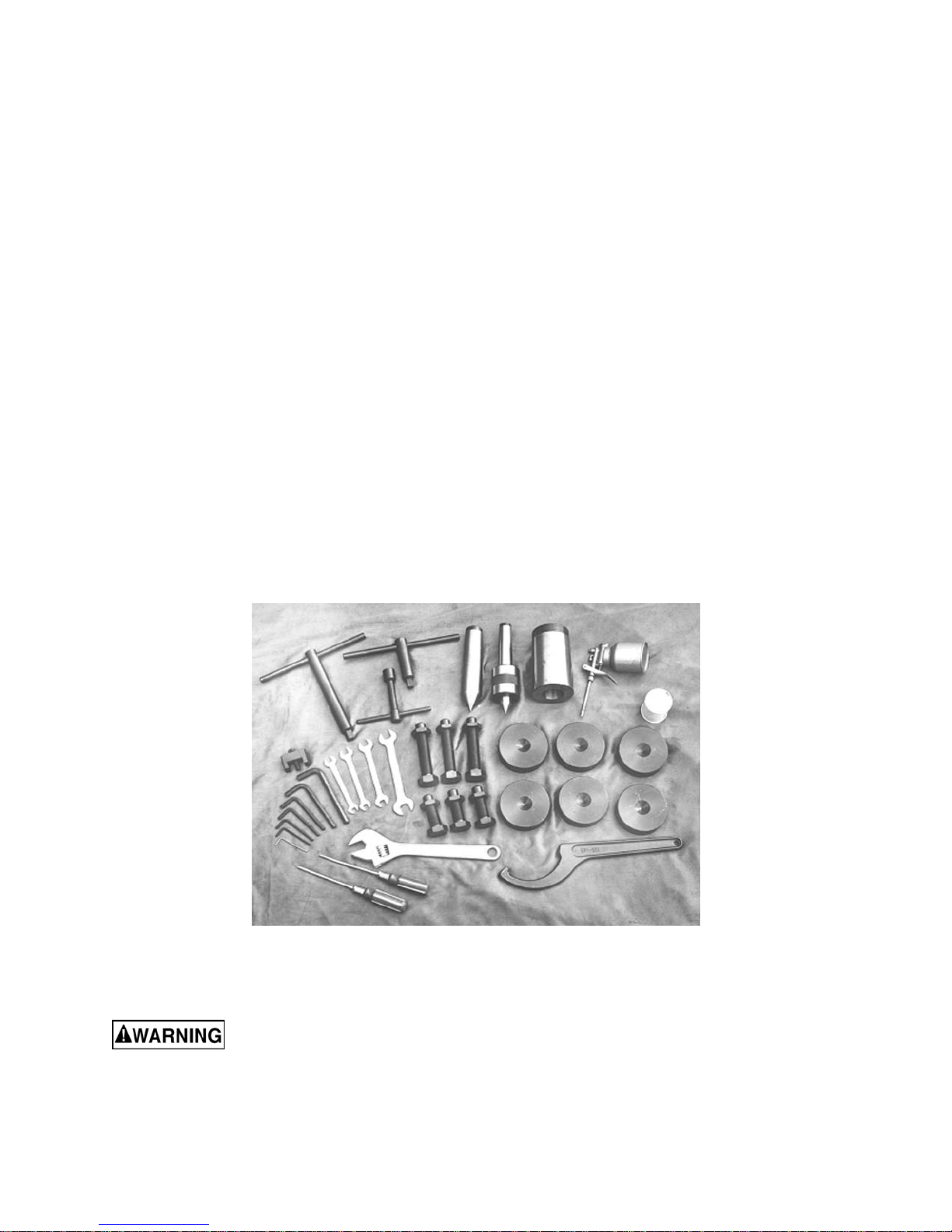

Contents of the Shipping Container

1 Lathe

1 Steady Rest (mount ed on Lathe)

1 Follow Rest (mounted on Lathe)

1 10” Three Jaw Chuck (mount ed on Lathe)

1 12” Four Jaw Chuck

1 Face Plate (12” Fac e Pl ate f or 14” & 16”

lathes; 16” F ac e Plate for 18” & 22” lathes)

1 Tool Box containing:

1 Open End Wrench Set

1 Hex Wrench Set

1 Morse Reduction Sleeve

1 Center

6 Leveling Bolts with Hex Nuts

6 Leveling Pads

1 Flat Blade Scr ewdriver

1 Cross Point Screwdriver

1 Chuck Wrench

1 Tool Post Wrench

1 Cam Wrench

1 Adjustable Wrench

1 Round Nut Wrench

1 Oil Gun

1 Cross Feed Handle (not shown)

2 Shear Pins (not shown)

1 Gap Bridge Pin Driver

1 Live Center (MT 4 for 14” & 16” lathes;

MT5 for 18” & 22” lathes)

1 Operating Instructions Manual

1 Parts List Manual

1 Test Record

1 Warranty Card

Read and understand the entire contents of this manual before attempting set-up

or operation! Failure t o co mply may cause serious injury.

contents of Tool Box

10

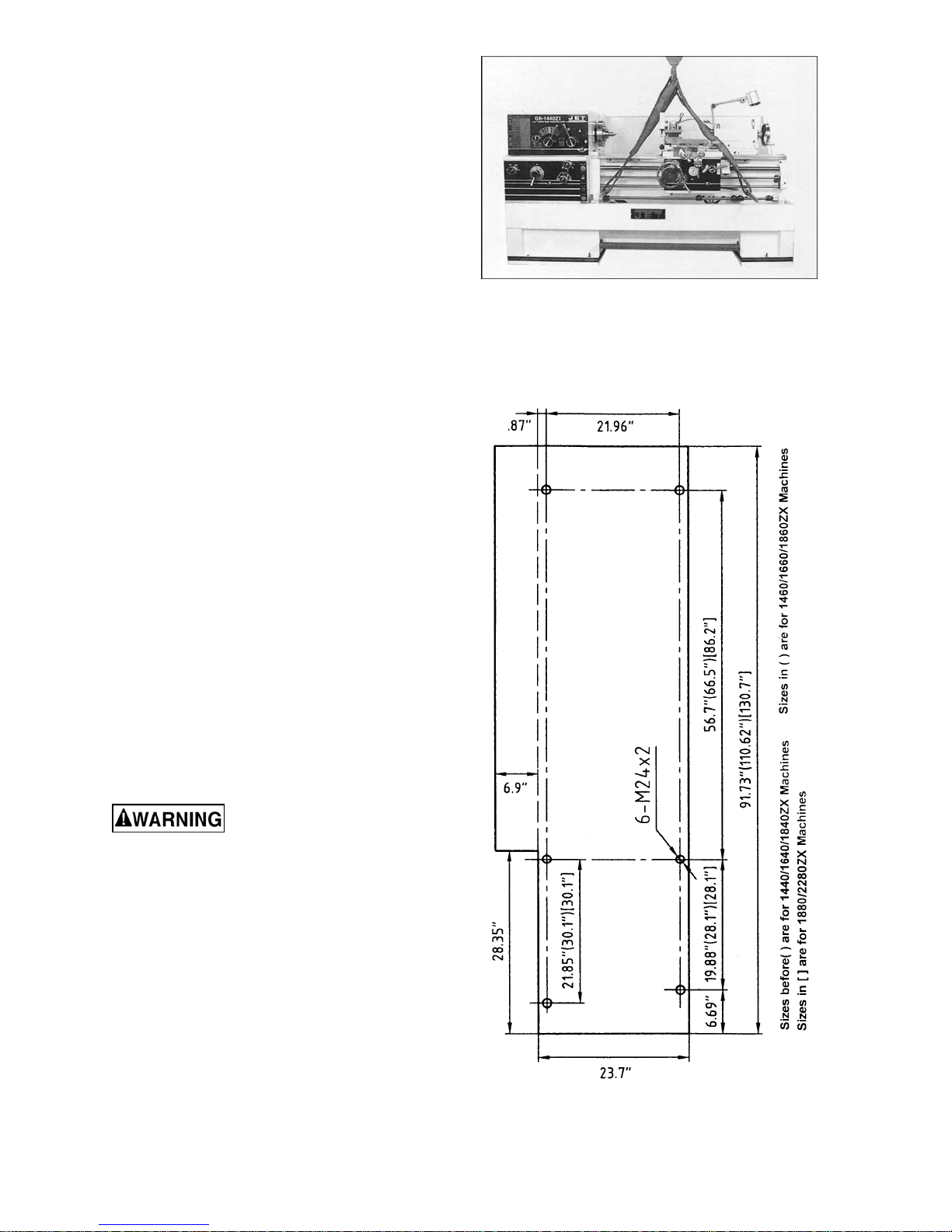

Uncrating and Cleanup

1. Finish removing the wooden crate from

around the lathe.

2. Unbolt the lathe from the shipping crate

bottom.

3. Choose a location f or the lathe that is dry,

has good light ing, and has enough room t o

allow servicing the lathe on all four sides.

4. Sling t he lathe as shown i n Figure 1, using

steel rods or pipes of sufficient strength

inserted through the holes in the bed

casting. Do not lift lathe by the spindle.

With adequate lifting equipment, slowly

raise the lat he off the shipping cr ate bot tom .

Make sure lathe is balanc ed before moving.

5. To avoid twisting the bed, the lathe’s

location must be absolutely flat and level.

Check for a level condition using a

machinist’s precision level on the bedways

both front to back and side to side. The

leveling pads included in the tool box and

the leveling screws in the lathe base will

help you to reach a level condition. The

lathe must be level to be accurate.

Figure 1

6. Clean all rust protected surfaces using a

mild commer cial solvent , kerosene or di esel

fuel. Do not use paint thinner, gasoline, or

lacquer thi nner. These will dam age painted

surfaces. Cov er all cleaned surf aces with a

light film of 2 0W machine oil .

7. Open the end gear cover. Clean all

components of the end gear assembly and

coat all gears with a heavy, non-slinging

grease. Close the end gear cover.

Chuck Preparation (Three Jaw)

Read and understand all

directions for chuck preparation. Failure to

comply may cause serious injury and/or

damage to the lath e.

NOTE: Before removing the chuck from the

spindle, place a flat piece of wood (plywood,

etc.) across the bedways under the chuck to

prevent damage to the bedways should the

chuck fall from your hands.

To remove the chuck:

1. Support the chuck while turning six

camlocks 1/4 t urn countercl ockwise with the

chuck wrench fr om the tool box.

2. Carefully remove t he chuck from the spindl e

and place on an adequate work surface.

Figure 2

11

3. Inspect the cam lock studs. Make sure they

have not become crac ked or broken during

transit. Clean all parts thoroughly with

solvent. Also clean the spindle and

camlocks.

4. Cover all chuck jaws and scroll inside the

chuck with #2 li thium tube grease. Cov er the

spindle, camlocks, and chuck body with a

light film of 2 0W oil.

5. Lift the chuck up to the spindle nose and

press onto the spindle. Tighten in place by

turning the camlocks 1/4 turn cl oc k wise. The

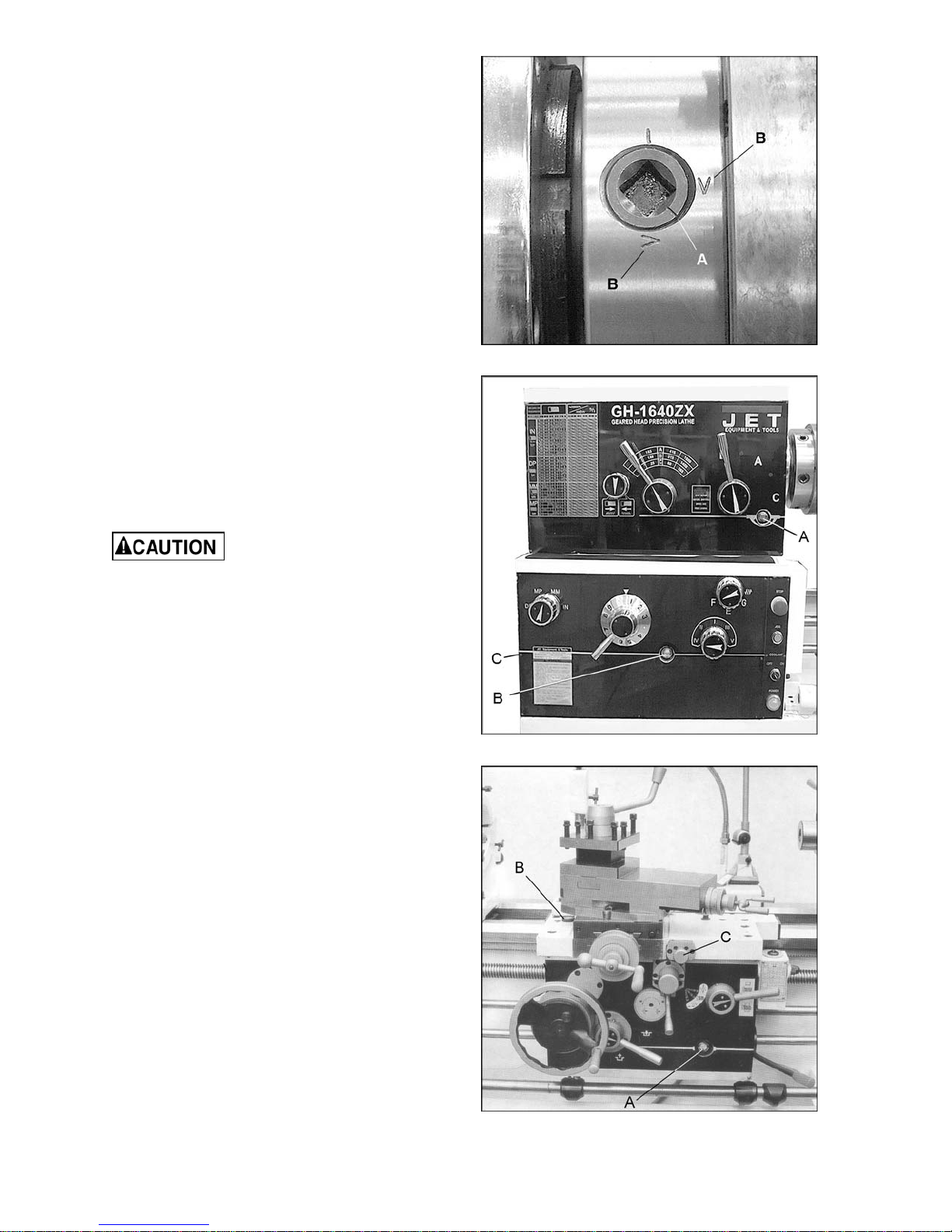

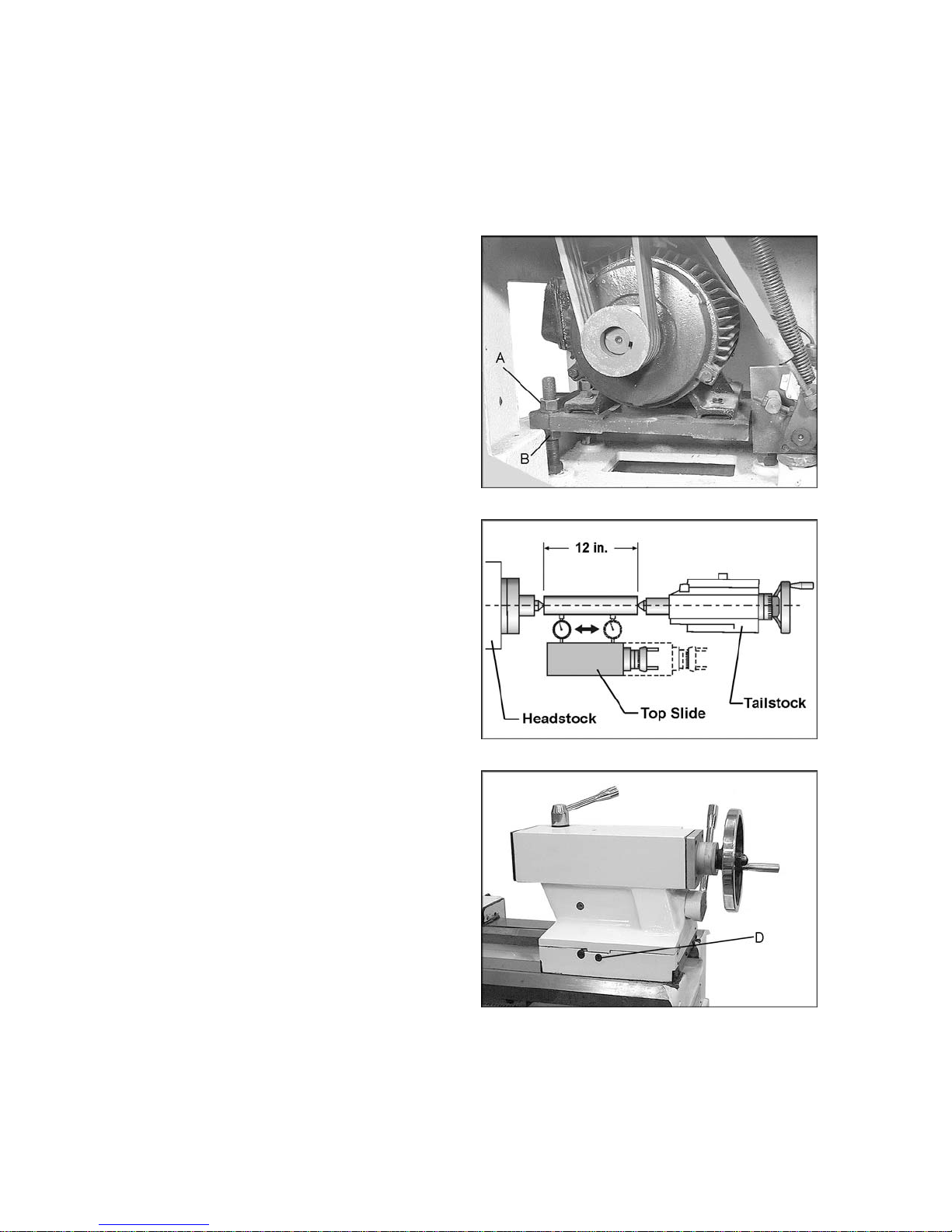

index mark (A, Figure 3) on the camlock

should be between the t wo indicator ar rows

when tight ( B, Fi gure 3). If the i ndex m ark is

not between the two arrows, remove the

chuck and adjust the camlock studs by

either turning out one full turn (if cams will

not engage) or turning in one full turn (if

cams turn beyond indic ator marks.)

6. Install chuck and tighten in place.

Lubrication

Figure 3

L athe must be serviced at all

lubrication points and all reservoi rs filled to

operating level before the lathe is put into

service. Failure to comply may cause serious

damage to the lath e.

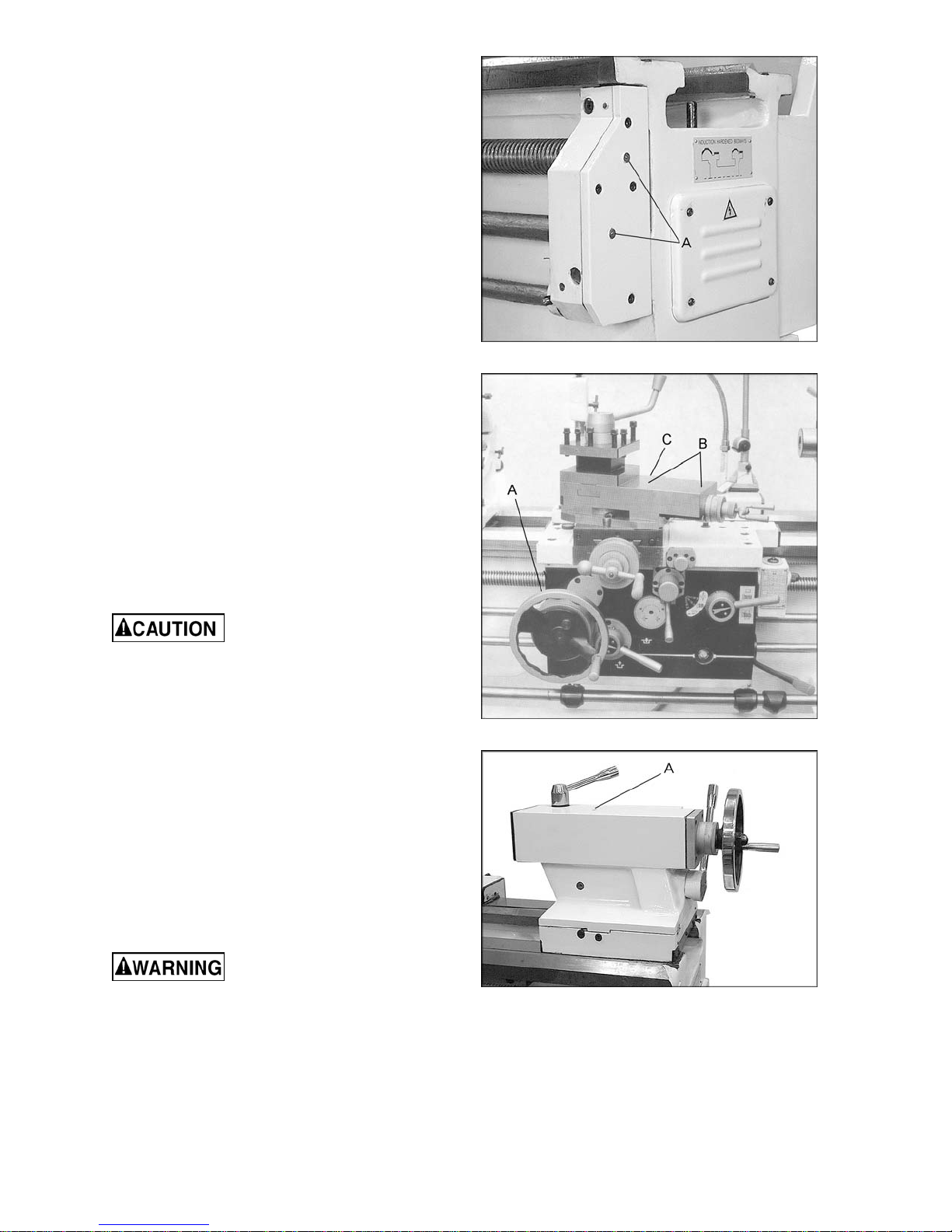

1. Headstock – Oil must be up to indicator

mark in oil sight gl ass (A, Figure 4). Top off

with Mobil DTE® Oil Heav y Medium. Fill by

removing the pl ug on top of the headstock.

To drain, remove drain pl ug on the left si de

of the headstock at the lower rear corner.

Drain oil com pletely and clean out all met al

shavings. Refill after the first month of

operation. Then change the oil in the

headstock every two months.

2. Gearbox – Oil must be up to indi cator mark

in oil sight gl ass (B, Figure 4). Top off with

Mobil DTE® Oil Heavy Medium. To add oil

to the gearbox, remove two screws on the

top cover and remove cover. To drain,

remove drain plug (C, Figure 4) on the left

side of the gearbox. Drain oil completely

and refill after the first three months of

operation. Then change oil in the gearbox

every six mont hs.

Figure 4

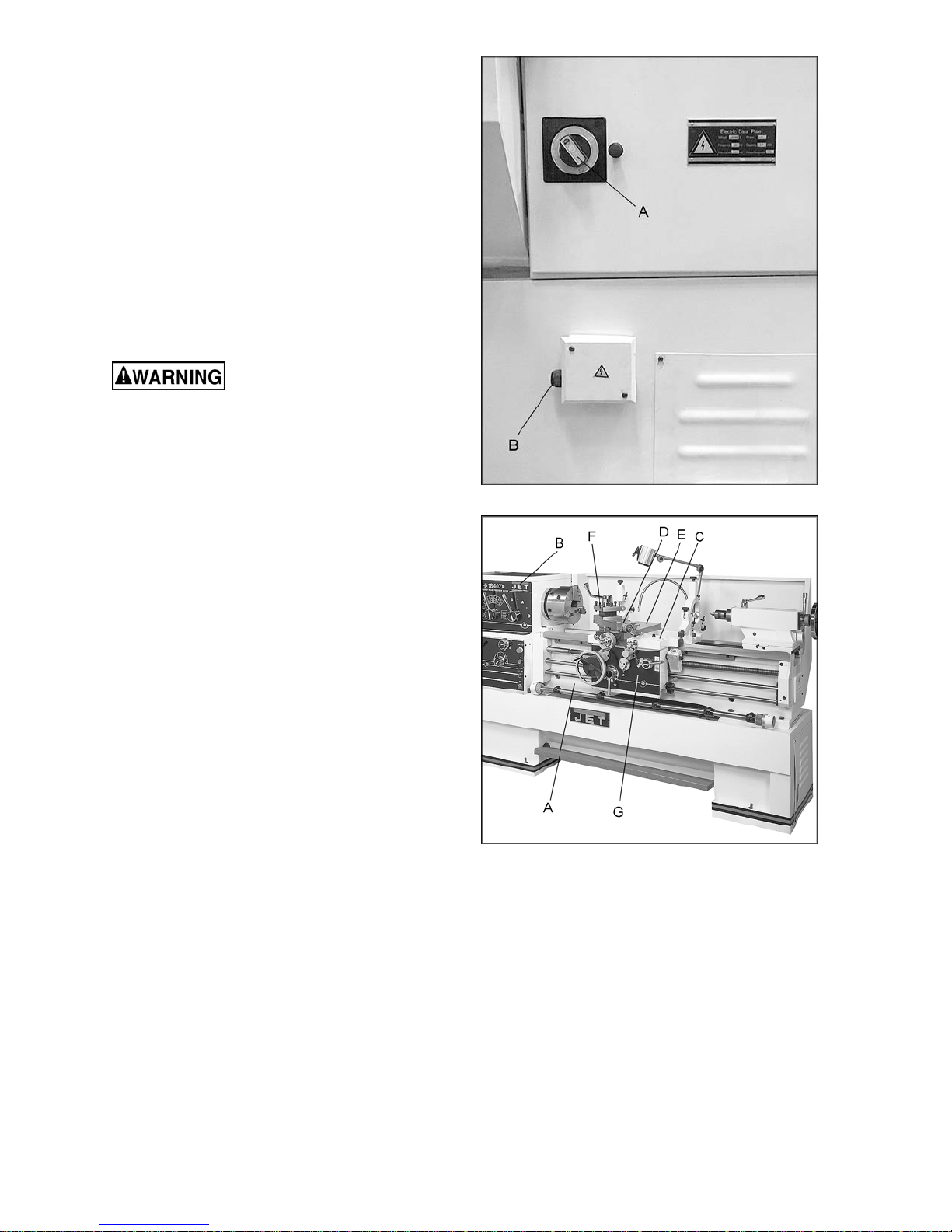

3. Apron – Oil must be between indicator

marks in the oil sight glass (A, Figure 5).

Top off with Mobil DTE ® Oil Heavy Medium.

Remove oil plug (B, Figure 5) to fill. To

drain, remove drain plug on bottom of

apron.

Figure 5

12

Drain oil completely and refill after the first

three mont hs of operati on. Then, c hange oil

in the apron annually. Pull knob (C, Figure

5) on the one-shot lube sy stem and hol d for

several seconds t o allow oil to fill the pump.

When the knob is released, oil will flow

through various oil lines to lubricate the

ways and cross slide surface. Perform this

twice dail y or as needed. When t he oil l evel

is below the indicator mark, oil must be

added.

4. Leadscrew and Feed Rod – Lubricate two

ball oilers on the right side bracket (A,

Figure 6) with 30W machine oil daily.

5. Saddle – Daily lubri cate ball oiler (A, Figure

7) on handwheel shaft with M obil DTE® Oil

Heavy Medium.

6. Compound Rest – Daily lubricate two ball

oilers (B, Fi gur e 7) on top of compound slide

with Mobil DTE® Oil Heavy Medi um.

7. Cross Slide – Dail y lubricate one ball oiler

(C, Figure 7) with Mobil DTE® Oil Heavy

Medium.

8. Tailstock – Daily lubricate one ball oiler (A,

Figure 8) on top of tailstock with Mobil

DTE® Oil Heavy Medium.

Coolant Preparation

Follow coolant manu-

facturer’s recommendations for use, care

and dispos a l.

1. Remove access cover on tailstock end at

the rear base of the lathe. Make sure

coolant pump has not shifted during

transport.

2. Pour four gallons (approximate) of coolant

mix into the chip pan.

Figure 6

Figure 7

3. After machine has been connected to

power, turn on coolant pump and check to

see that coolant is cycli ng pr oper ly.

4. Replace access cover .

Electrical Connections

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded while in

use to help protect the operator from

electrical sho ck and po ssib le fatal injury.

Figure 8

13

The main motor is rated at 7-1/2 HP (or 10HP

for model 2280ZX), 230/460V and comes from

the factor y prewired at 230V. Confirm that power

available at the lathe’s location is the same

rating as the lat he.

Power is connected properly when rotating the

forward-reverse knob (E, Figure 12) to the left

position causes the spindle to rotate

countercl ockwise as v i ewed from the t ail stock. If

the chuck rotates in the clockwise direction,

disconnect the lathe from the power source,

switch any two of the thr ee power lead s (not t he

green ground wire), and re-connect the lathe to

the power source.

Conversion to 460 Volt Operation

Disconnect machine from

power source. Failure to do so may cause

serious injury.

Mai n Mo tor : Change the wire s accordi ng to the

diagram on the outside of the motor junction

box.

Transformer: Open electrical panel on rear of

machine on the headstock side. Switch wire

from 230V termi nal to 460V termi nal as outli ned

on the transf ormer.

Figure 9

Coolant Pump: Open access panel on the base

at the tailstock end. Change wires in coolant

pump junction box according to diagram on the

outside of the junc tion box cover.

Main Power Switch (A, Figure 9): Turns power

to machine on and off.

Power Source Cabl e Receiver (B , Figure 9).

Make sure the lat he is properly grounded.

General Description

Lathe Bed

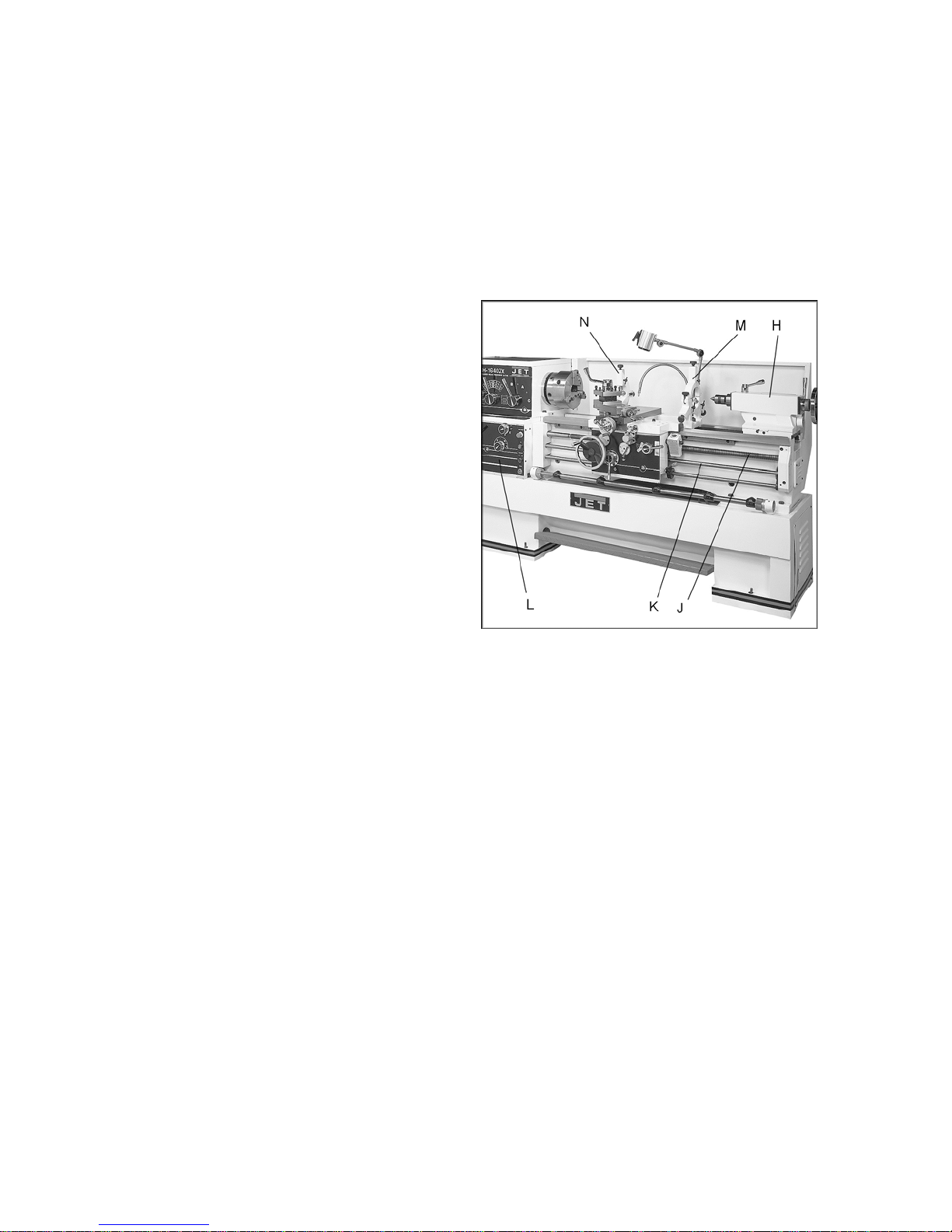

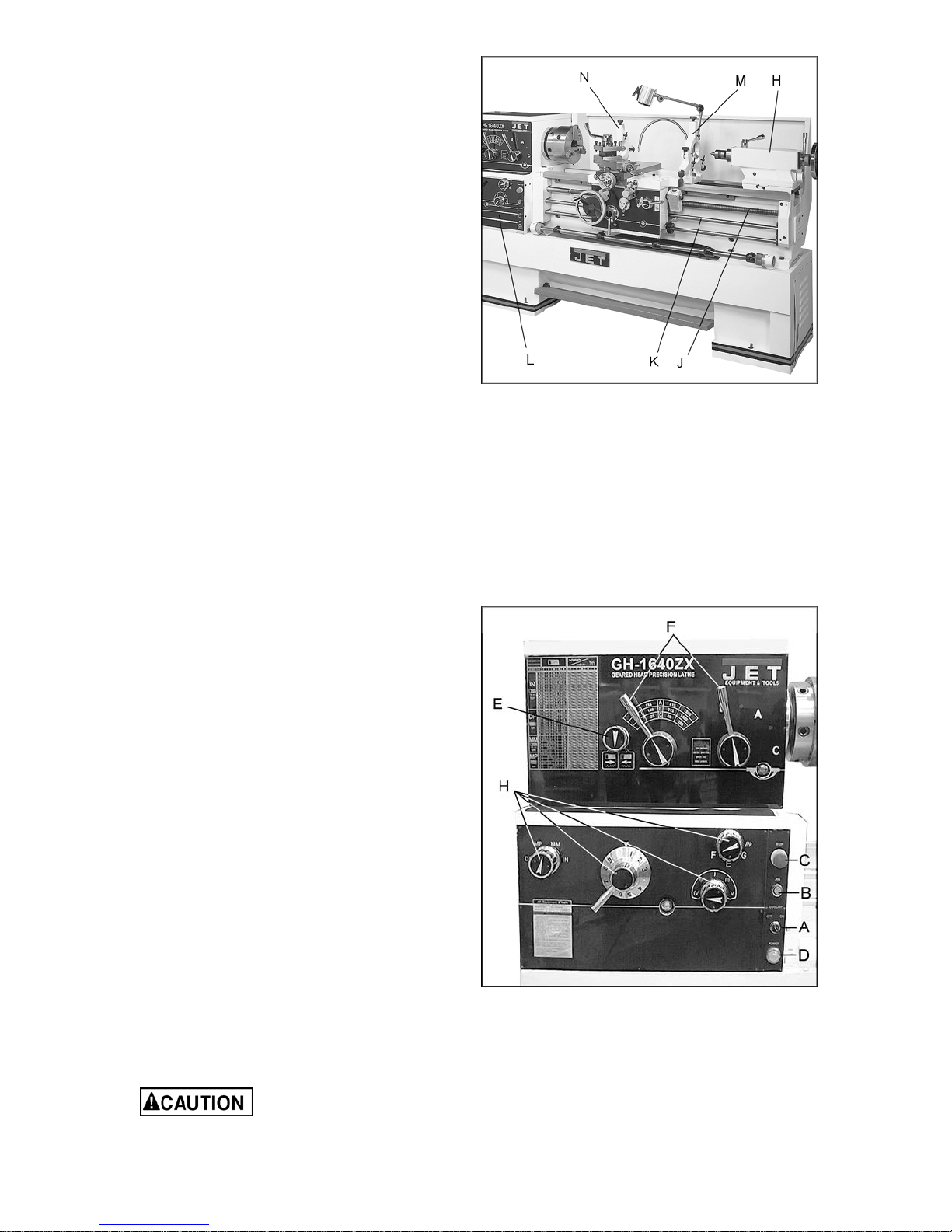

The lathe bed ( A , Fi gur e 10) is made of cast ir on

with low vibration and high rigidity. Two

precision ground v-slideways, reinforced by

induction hardening and grinding, are an

accurate guide for the carriage and headstock.

The main drive motor is mounted in the stand

below the the headstock.

Headstock

The headstock (B, Figure 10) is cast from high

grade, low vibr ation cast iron. It is bolted t o the

bed by four hex socket cap bolts. In the head,

the spindle i s mounted on precision t aper roller

bearings.

Figure 10

14

Carriage

The carriage (C, Figure 10) is made from high

quality cast ir on. The cross-slide (E, Figure 10)

is mounted on the carriage and moves on a

dovetail ed slide which can be adj usted for pl ay

by means of the gibs.

The compound sli de (D, Figure 10) which is Tslotted, and mounted on the cross slide (E,

Figure 10) c an be rotated 360°. The compound

slide and the cross slide travel in a dovetailed

slide and have adj ustable gibs.

Four Way Tool Post

The four way t ool post (F, Figure 10) is mounted

on the compound slide and allows a maximum

of four tools to be mounted at the same time.

Remember to use a mi nimum of two cl amping

screws when installing a cutting tool.

Apron

The apron (G, Figure 10) is mounted to the

carriage. Quick travel of the apron is

accomplished by m eans of a bed-mount ed rack

and pinion, operated by the handwheel on the

front of the apron.

Tailstock

The tailstock (H, Figure 11) slides on a v-way

and can be locked at any locati on by a clamping

lever. T he tail stock has a heavy duty qui ll wit h a

Morse Taper #4, or Morse Taper #5 (18” and

22” models).

Leadscrew and Feed Rod

The leadscrew (J, Figure 11) and feed rod (K,

Figure 11) are mounted on the front of the

machine bed. They are connected to the

gearbox at the left and are supported by

bearings on both ends. Both ar e equipped with

shear pins.

Feed Gearbox

The gearbox (L, Figure 11) is made from high

quality cast i ron and is mounted to t he left side

of the machine bed.

Figure 11

Steady Rest

The steady rest (M, Figure 11) serves as a

support for shaf ts on the free tailstoc k end. The

steady rest is mounted on the bedway and

secured fr om below with a bol t, nut and loc king

plate. The sliding fingers require continuous

lubrication at the contact points with the

workpiece to prevent them from premature

wear.

15

To set the steady rest:

1. Loosen three hex sock et cap screws.

2. Loosen knurled screw and open sliding

fingers until the steady rest can be moved

with its fingers around the workpiece.

Secure the steady rest in position.

3. Set the fingers snugly t o the workpiece and

secure by tightening three hex socket cap

screws. Fingers should be snug but not

overly tight. Lubricate sliding points with

lead-based grease.

Follow Rest

The traveling follow rest (N, Figure 11) is

mounted on the saddle and follows the

movement of the turning tool. Only two fingers

are required a s the pl ace of t he thi rd i s taken by

the turning tool. The follow rest is used for

turning operat ions on long, slender workpieces.

It prev ents the workpiece f rom fl exing under the

pressure of t he cutting tool.

The slidi ng fingers are set simi lar to the steady

rest, free of play, but not binding. Always

lubricate adequately with lead-based grease

before operating.

Figure 11 (repeated)

Controls

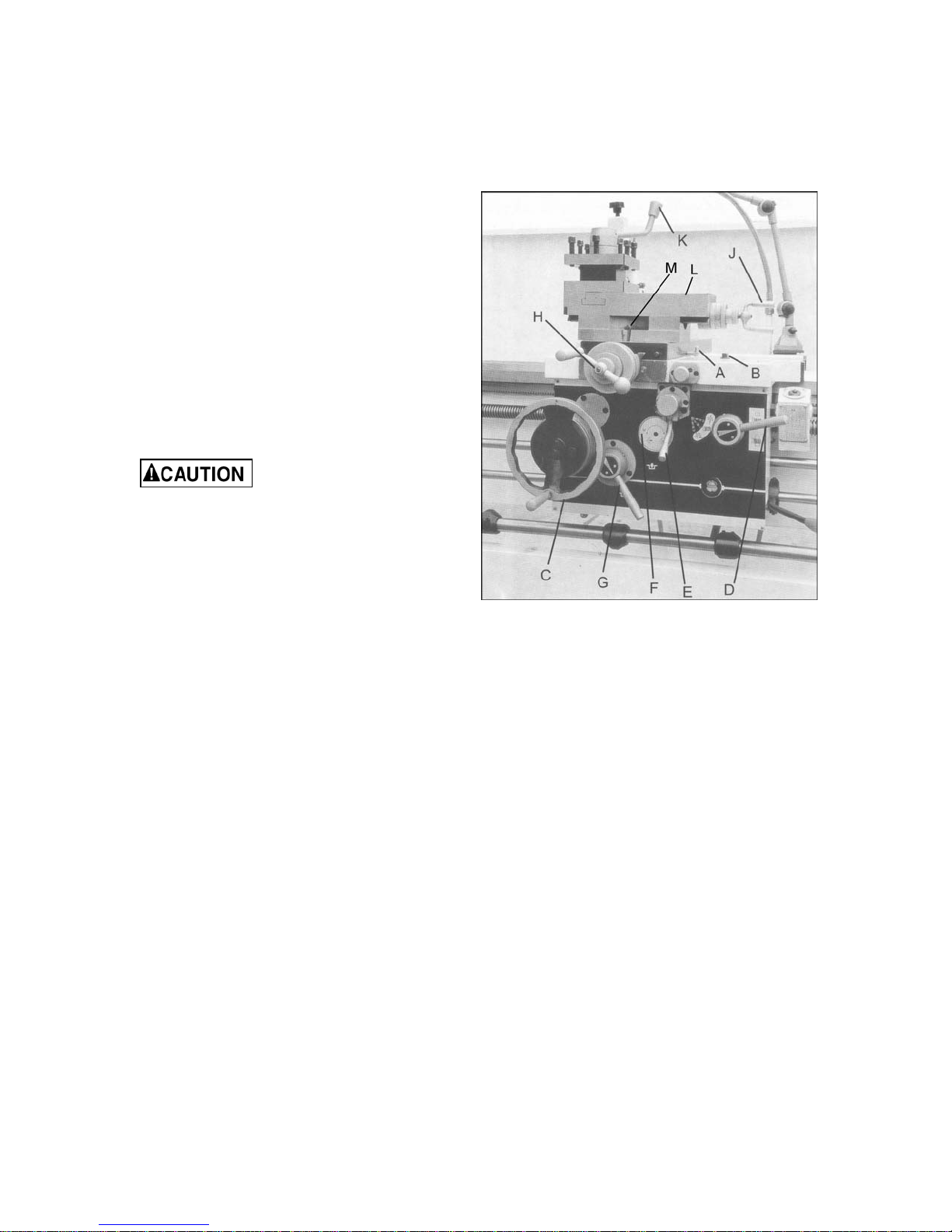

1. Control Panel: located on front of

headstock. [On EVS models, control panel

is located on a swivel post above the

headstock.]

• Coolant On-Off Switch (A, Figure 12)

turns coolant pum p on and off .

• Power Indicator Light (D, Figure 12) is lit

whenever lathe is receiving power.

• Emergency Stop Switch (C, Figure 12)

stops all machine functions (Caution:

Lathe will still have power). Twist

clockwise to re-set.

• Jog Switch (B, Figure 12). Quickly press

and release to rotate the spindle.

2. Headstock Gear Change Levers (F, Figure

12): Located on front of headstock. Move

levers left or right to desired spindle speed.

NOTE: The left handle is omitted on EVS

models.

3. Leadscrew/Feed Rod Directional Lever

(E, Figure 12): Located on front of

headstock at lower left. Changing knob

changes direction of feed.

Figure 12

Do not move knob while

machine is running.

16

4. Feed/Lead Selector Lever (H, Figure 12):

Located on f ront of headstock. Used when

setting up for thr eading or feeding.

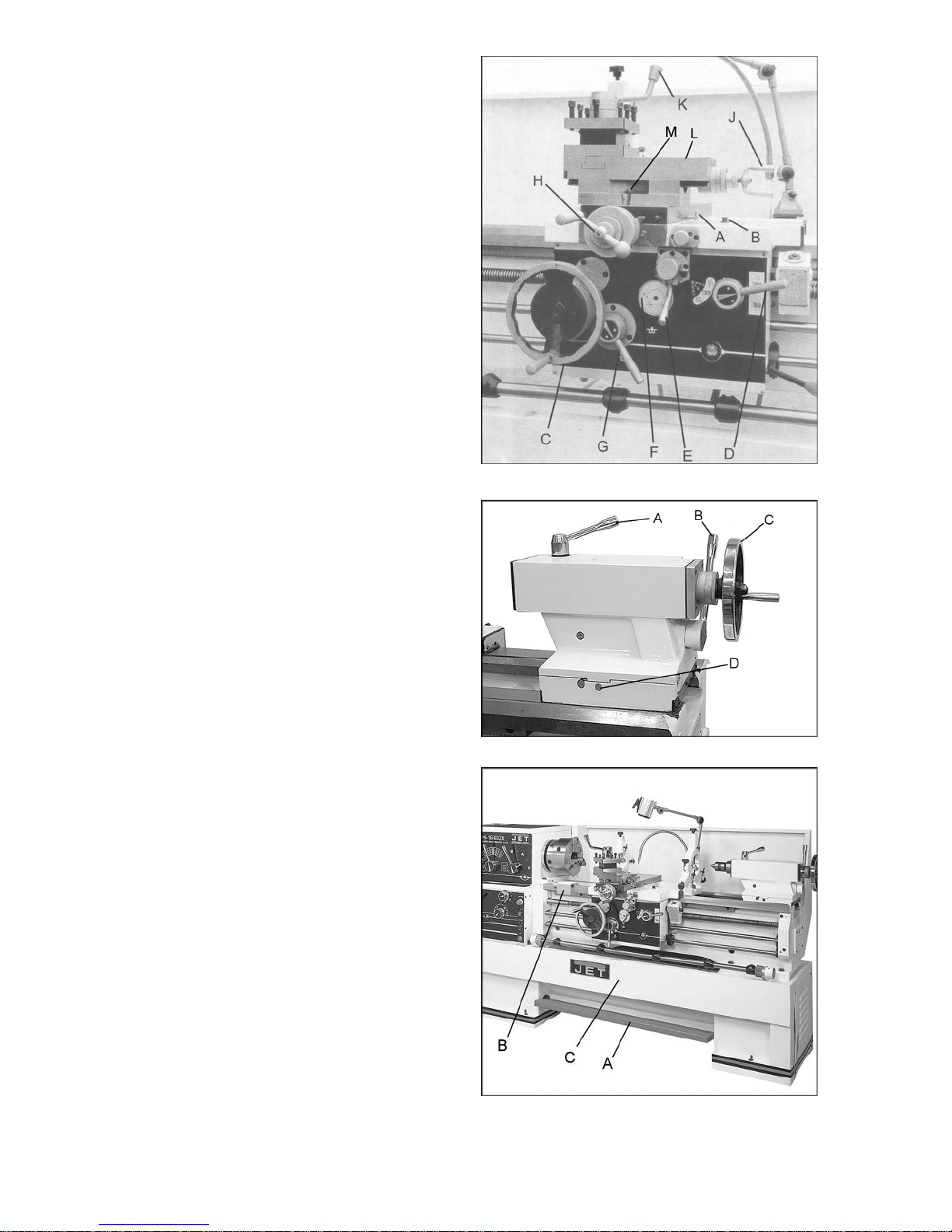

5. Compound Slide (L, Figure 13) is located

on top of t he cross slide and c an be rotated

360°. There are c alibrations in degrees (M,

Figure 13) below the rest to assist in

placement of the compound slide to the

desired angle.

6. Compound Lock (not shown): Lever

located on back of compound slide. Turn

clockwise to lock and counterclockwise to

unlock.

7. Cross Slide Lock (A, Figure 13): Lever

located on left side of cross slide. Turn

clockwise to lock and counterclockwise to

unlock.

8. Carriage Lock (B, Figure 13): Located on

top right of carriage. Turn clockwise to lock,

countercl oc k wise to unlock.

Carriage lock must be

loose before moving carriage or damage

to lathe may occur.

9. Longitudinal Traverse Handwheel (C,

Figure 13): Located on the apr on assembl y.

Rotate handwheel clockwise to move the

apron assembl y toward the tai lstock (right).

Rotate the wheel count erclockwise to move

the apron assembly toward headstock (left).

10. Longitudinal/Cross Feed Selector Lever

(E, Figure 13): Can be pushed to upper,

middle and lower three positions. Push the

lever up, cross feed is effected. Push the

lever down, longitudinal feed is effected.

When the lever is in the middle position,

screws can be cut by engaging the half nut.

11. Half Nut Lever (D, Figure 13): Located on

the front of the apron assembly. Used for

threading.

12. Feed Engage Lever (G, Figure 13):

Located in the f ront of the apron assem bly.

Pull lever up to engage. Push lev er down to

disengage.

13. Adjustable Feed Clutch (F, Figure 13):

When the machine is ov erloaded, it can sli p.

Then cutting rate must be reduced. Note:

This setting has been calibrated at the

factory and should not need adjustment. If

adjustment ever becomes necessary, f ollow

the diagram on the front of t he apr on.

14. Cross Traverse Handwheel (H, Figure 13):

Located above the apron assembly.

Clockwise rotation moves the cross slide

toward the rear of mac hine.

Figure 13

17

15. Compound Rest Traverse Handle (J,

Figure 13): Located on the end of the

compound slide. Rotate clockwise or

countercl oc k wise to posi tion.

16. Tool Post Cl amping Lever (K, Figure 13):

Located on top of the tool post. Rotate

countercl ockwise to l oosen and cloc kwise to

tighten.

17. Tailstock Quill Clamping Lever (A, Figure

14): Located on the tailstock. Rotate

clockwise to lock the sleeve. Rotate

countercl oc k wise to unlock.

18. Tailstock Clamping Lever (B, Figure 14):

Lift up t o lock. Push down to unloc k. If the

tailstock has a heavy load, tighten the

hexagon head at right side of the tailstock

for auxiliary l oc ki ng.

19. Tailstock Quill Traverse Handwheel (C,

Figure 14): Rotat e cl ockwise to advance t he

quill and count erclockwise to retract it.

20. Tailstock Off-Set Adjustment (D, Figure

14): Two hex socket cap screws locat ed on

the tailstock base are used to off-set the

tailstock for cutting tapers. Loosening one

screw while tightening the other will off-set

the tailstock . Do not clam p the tailstock loc k

handle when adjusting.

Figure 13 (repeated)

21. Foot Brake (A, Figure 15): The connect ing

rod mechanism is in the bed stand. The

braking device is in the pulley of the

headstock. P ress the pedal to stop all lathe

functions. ( Caution: Lathe still has power.)

22. Micro Carriage S top ( B, Fi gure 15): can be

used during manual feed oper ation. The dial

can be turned for fi ne tuning the position of

the stop. The micro carriage stop can be

moved along t he bed by loosening the t wo

socket head cap screws underneath the

stop.

23. Bed Cover (C, Figure 15): can be easily

removed to clean out the stand.

Figure 14

Figure 15

18

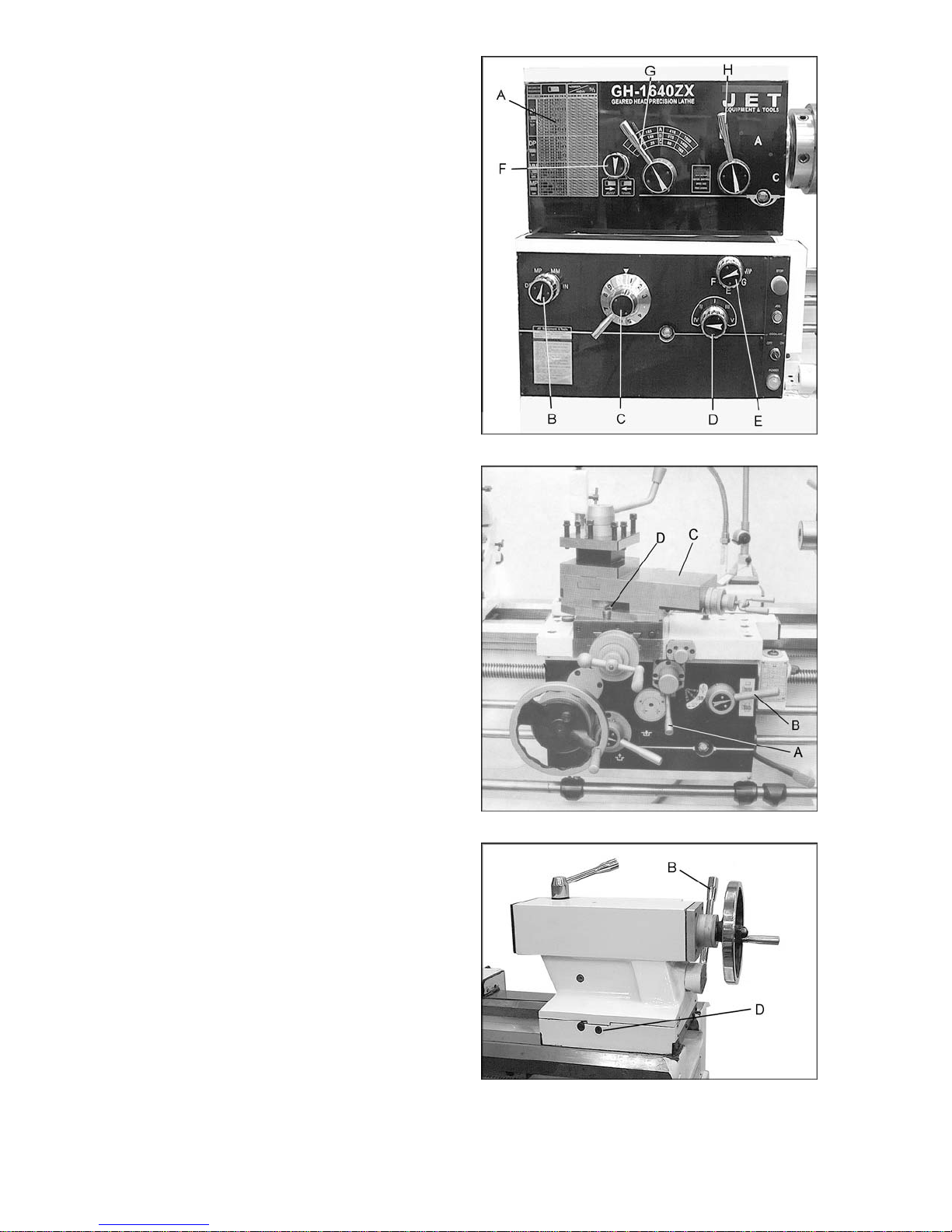

Operation

Feed and Thread Selection

1. Ref erence the feed and t hread chart on the

front of the headstock ( A, Figure 16).

2. Move lev ers and knobs (B/C/D/E, Figure 16)

to the appropri ate position according to t he

feed and thread chart.

Thread Cutting

1. Set forward/reverse lever (F, Figure 16) to

desired direction.

2. Set selector levers (G/H, Figure 16) to

desired R.P.M. [On EVS models, use lever

H and the v ariable speed dial on the swiv el

control panel to select speed.]

3. Select desired t hread using l evers (B/ C/ D/E,

Figure 16).

4. Set selector lever (A, Figure 17) to correct

position (neutral).

5. Engage the half nut lev er (B, Figure 17) .

Figure 16

6. Make a test cut with scrap material and

check results before cutting regular m aterial.

Gib Adjustments

After a period of time, some of the moving

components may need to be adjusted due to

wear.

Saddle

Turn gib screws on either si de of the saddle at

the rear to adjust t he dr ag on the saddle.

Cross Slide

Turn gib screws in the f r ont and rear of the gib

to adjust the dr ag of the cross slide.

Compound Slide

Turn gib screws to adjust the drag of the

compound slide.

Tailstock Off-Set

Follow the procedure below to off-set the

tailstock t o cut shall ow tapers:

1. Loosen tailstock in position by lowering

locking handl e (B, Figure 18) and loosening

hexagon head eccentric shaft at back of

tailstock.

Figure 17

2. Alternately l oosen and t i ghten f r ont and rear

screws (D, Fi gure 18). Note: Front screw is

shown.

Figure 18

19

Removing Gap Section

1. To remov e the gap section, rem ove four hex

socket cap screws, and two hex cap bolts.

2. Tighten the hex nuts on the tapered

alignment pins to loosen the pins. Once

loosened, they can be r em ov ed.

3. Gap section can now be removed.

Installing Removable Gap Section

1. Clean the bottom and the ends of the gap

section thoroughly.

2. Set gap section in plac e and align the ends.

3. Loosen the nuts on the locating pins and

push down through the gap into the lathe

bed.

4. Replace four hex socket cap screws and

tighten alt ernately until all are snug.

Belt Replacement and Adjustment

1. Disconnect machine from power source.

2. Open end gear cover, remove lower rear

cover and lower side cover. This will expose

the motor and v-belts.

Figure 19

3. Loosen upp er hex nut ( A, Figure 19). P lace

scrap piece of wood under motor to act as

lever. Lift motor up and bloc k tem por arily.

4. Remove belts. Install new belts onto pulleys.

5. Lift up on motor and remove temporary

blocking.

6. Tension belts by loosening lower nut (B,

Figure 19) and tightening upper nut (A,

Figure 19) unt il light f inger pressure cau ses

approxim ately 3/4” deflection on each belt.

7. Install covers and connect lathe to the

power source.

Aligning Tailstock to Headstock

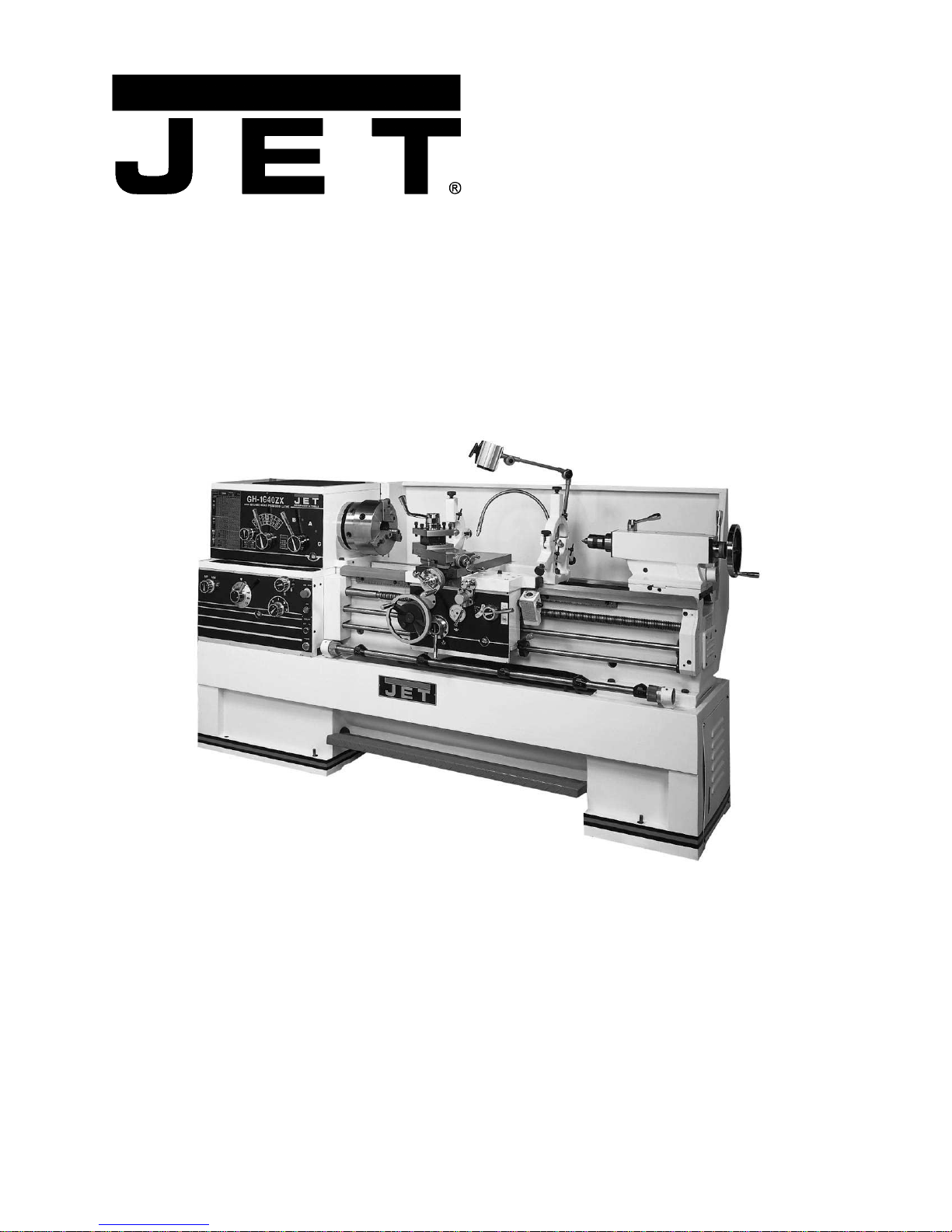

1. Fit a 12” ground steel bar bet ween centers

of the headstock and t ailstock (Figure 20).

2. Fit a dial indicator to the top slide and

traverse the cent er line of the bar.

3. If adjustment is needed, align the tailstock

using the off- set screws (D, Figure 21) until

the tailstoc k is ali gned.

Figure 20

Figure 21

20

Parts List

ZX Series Lathes

WALTER MEIER (Manufacturing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-321910-1

Ph.: 800-274-6848 Revision H1 08/2010

www.waltermeier.com Copyright © 2010 Walter Meier (Manufacturing) Inc.

Table of Con tents

Table of Contents .................................................................................................................................... 2

Stand Assembly ................................................................................................................................... 3-5

Brake Assembly ................................................................................................................................... 6-7

Bed Assembly .................................................................................................................................... 8-10

Headstock Assembly I ...................................................................................................................... 11-13

Headstock Assembly II ..................................................................................................................... 14-16

Headstock Assembly III .................................................................................................................... 17-18

Headstock Assembly IV .................................................................................................................... 19-20

Change Gear Box Assembly I ........................................................................................................... 21-22

Change Gear Box Assembly II .......................................................................................................... 23-24

Quick Change Gear B ox I ................................................................................................................. 25-27

Quick Change Gear B ox II ................................................................................................................ 28-29

Quick Change Gear B ox III ............................................................................................................... 30-31

Apron Assembly I ............................................................................................................................. 32-34

Apron Assembly II ............................................................................................................................ 35-37

Apron Assembly III ........................................................................................................................... 38-39

Carriage Assembl y ........................................................................................................................... 40-42

Micro Carri age Stop A ssembly ............................................................................................................... 43

Carriage Stop Assembly ................................................................................................................... 44-45

Four Way Tool Post .......................................................................................................................... 46-47

Tailstock Assembly I ......................................................................................................................... 48-49

Tailstock Assembly II ........................................................................................................................ 50-51

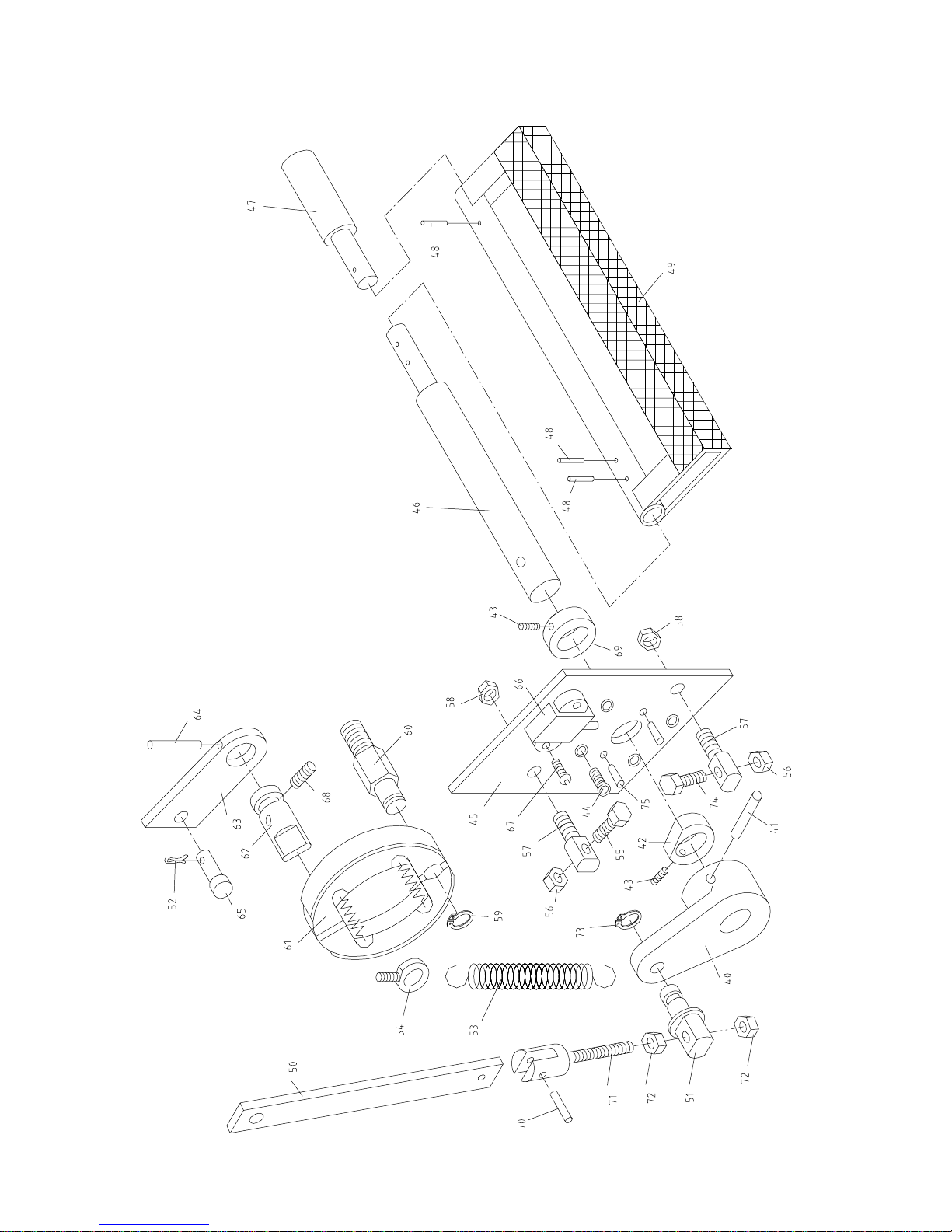

Steady Rest Assembly ...................................................................................................................... 52-53

Follow Rest Assembly ...................................................................................................................... 54-55

Coolant And Work Light Assembly .................................................................................................... 56-57

Other Parts ............................................................................................................................................ 58

Electrical Cabinet................................................................................................................................... 59

Wiring Diagram ...................................................................................................................................... 60

Rotary Switch Diagram .......................................................................................................................... 61

2

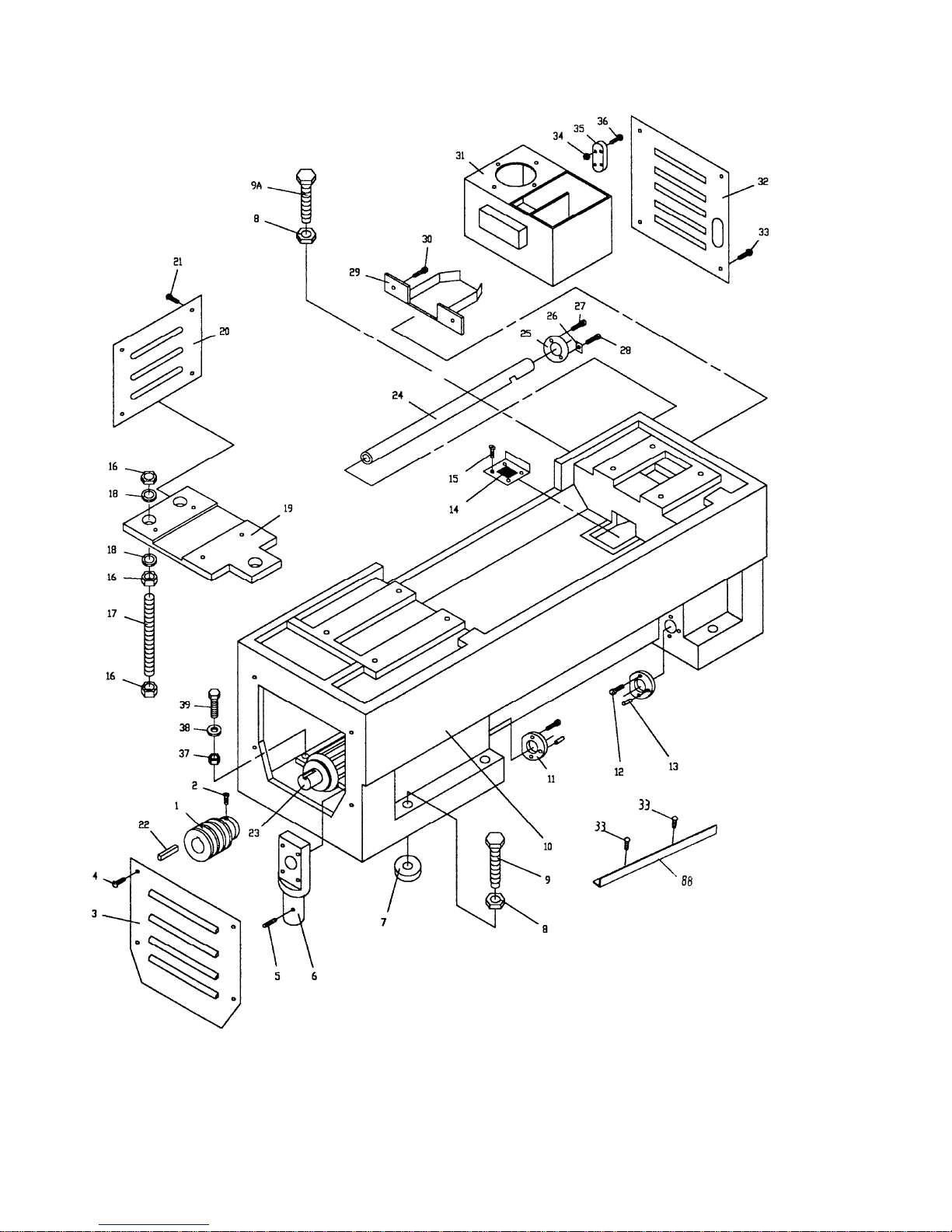

Stand Assembly

3

Stand Assembly

Index Part

No. No. Description Size Qty.

1 .......... ZX-01 101A ....................Pulley ................................................................................................... 1

............ GH2280ZX-01101 .........Pulley (for 2280ZX) ................................................................................ 1

2 .......... ZX-S2 ...........................Cylindrical End Set Screw ...................................M8x16 ........................ 1

3 .......... ZX-01734 ......................Cover .................................................................................................... 1

............ ML-2080-01701.............Cover (for 2280ZX) ................................................................................ 1

4 .......... ZX-S4 ...........................Cross Head Screw ..............................................M6x14 ........................ 4

5 .......... ZX-S2 ...........................Cylindrical End Set Screw ...................................M8x16 ........................ 1

6 .......... ZX-01701 ......................Pedal Rod Support ................................................................................ 1

............ ML-2080-01703.............Pedal Rod Support (for 2280ZX) ............................................................ 1

7 .......... ZX-01715 ......................Lining .................................................................................................... 6

8 .......... TS-1540231 ..................Hex Nut ..............................................................M24-2 ......................... 6

9 .......... ZX-01712 ......................Hex Cap Bolt ......................................................................................... 3

9A ....... ZX- 01713 ......................Hex Cap Bolt ......................................................................................... 3

10 ........ ZX-01102A ....................Bed Stand (for 40” models, serial # 010611ZX349 and lower) ................ 1

............ ZX-01 102AN .................New Bed Stand (for 40” models, serial # 010618Z X350 and hi gher ) ....... 1

............ ZX-01 102B ....................Bed Stand (for 60” models, serial # 010611ZX349 and lower) ................ 1

............ ZX-01 102BN .................New Bed Stand (for 60” models, serial # 010618ZX350 and higher) ...... 1

............ ZX-01 102C....................Bed Stand (for 1880ZX, serial # 010611ZX349 and lower) .................... 1

............ ZX-01 102CN .................New Bed Stand (for 1880ZX, serial # 010618ZX350 and higher ) ............ 1

............ GH2280ZX-01102 .........Bed Stand (for 2280ZX) ......................................................................... 1

11 ........ ZX-01703 ......................Fixed Support ........................................................................................ 2

12 ........ TS-150341 ....................Socket Head Cap Screw .....................................M6x14 ........................ 4

13 ........ ZX-S13 .........................Taper Pin ............................................................5x20 ........................... 2

14 ........ ZX-01705 ......................Water Leaking Chip Guard..................................................................... 1

15 ........ ZX-S15A .......................Cross Head Screw ..............................................M5x20 ........................ 4

16 ........ TS-1540121 ..................Hex Nut ..............................................................M20 ............................ 9

17 ........ ZX-01702 ......................Bolt........................................................................................................ 3

............ ML-2080-01704.............Bolt (for 2280ZX) ................................................................................... 3

18 ........ TS-1550111 ..................Fla t W a sher ........................................................M20 ............................ 6

19 ........ ZX-01122A ....................Motor Mounting Plate (for 14” models) ................................................... 1

............ ZX-01 122B ....................Motor Mounting Plate (for 16”/18” models) ............................................. 1

............ ML-2080-01122 .............Motor Mounting Plate (for 22” model) ) .................................................... 1

20 ........ ZX-01726 ......................Cover .................................................................................................... 1

............ GH2280ZX-01701 .........Cover .................................................................................................... 1

21 ........ ZX-S4 ...........................Cross Head Screw ..............................................M6x14 ........................ 4

22 ........ ZX-S22 .........................Key.....................................................................10x8x70 ..................... 1

23 ........ ZX-S23BC ....................Main Motor (for 22” model) .................................10 HP, 6P, 3Ph............ 1

............ ZX-S23A .......................Main Motor (for 14” models) ................................7.5HP, 4P, 3Ph............ 1

............ ZX-S23B .......................Main Motor (for 16”/18” models) ..........................7.5HP, 6P, 3Ph............ 1

24 ........ ZX-017609A..................Wire Conduit (for 1440/1640/1840Z X) .................................................... 1

............ ZX-017609B..................Wire Conduit (for 1460/1660/1860ZX) .................................................... 1

............ ZX-017609C .................Wire Conduit (for 1880/2280ZX) ............................................................ 1

25 ........ ZX-01708 ......................Wire Conduit Support ............................................................................ 1

26 ........ ZX-01706 ......................Locking Plate ......................................................................................... 1

27 ........ ZX-S27 .........................Cross Head Screw ..............................................M5x8 .......................... 2

28 ........ ZX-S15 .........................Cross Head Screw ..............................................M4x6 .......................... 1

29 ........ ZX-01711 ......................Water Reception Plate ........................................................................... 1

30 ........ ZX-S4 ...........................Cross Head Screw ..............................................M6x14 ........................ 2

31 ........ ZX-01510 ......................Coolant Tank ......................................................................................... 1

32 ........ ZX-01714 ......................Cover .................................................................................................... 1

............ ML-2080-01702.............Cover (for 2280ZX) ................................................................................ 1

33 ........ ZX-S4 ...........................Cross Head Screw ..............................................M6x14 ........................ 4

34 ........ ZX-S34 .........................Nut .....................................................................M3 .............................. 4

35 ........ ZX-S 35 .........................Co olant Indicator ................................................................................... 1

36 ........ ZX-S36 .........................Cross Head Screw ..............................................M3x20 ........................ 4

4

Index Part

No. No. Description Size Qty.

37 ........ TS-1540072 ..................Hex Nut ..............................................................M10 ............................ 4

38 ........ TS-1550071 ..................Fla t W a sher ........................................................M10 ............................ 4

39 ........ TS-1491041 ..................Hex Cap Bolt ......................................................M10x30 ...................... 4

80 ........ ZX-01716A ...................Stand Front Cover (for 1440/1640/1840ZX)............................................ 1

............ ZX-01716B ...................Stand Front Cover (for 1460/1660/1860ZX)............................................ 1

............ ZX-01716C ...................Stand Front Cov er (f or 1880/2280ZX) .................................................... 1

81 ........ ZX-01501 ......................Gasket................................................................................................... 1

82 ........ ZX-S82 .........................Hex Nut ..............................................................M5 .............................. 2

83 ........ ZX-01740 ......................Left Tra y ................................................................................................ 1

84 ........ ZX-01741 ......................Right Tr a y .............................................................................................. 1

85 ........ ZX-01511 ......................Gasket................................................................................................... 2

86 ........ ZX-S86 .........................Cross Head Screw ..............................................M5x16 ........................ 6

87 ........ ZX-01512 ......................Gasket................................................................................................... 1

88 ........ ZX-05753 ......................Extending Plate ..................................................................................... 1

............ JX21004 .......................Terminal Board (not shown) ................................................................... 1

............ 18301 ...........................Junction Box (not shown)....................................................................... 1

............ D97-4 ............................Plastic Fitting (not shown) ...................................................................... 1

5

Brake Assembly

6

Loading...

Loading...