Jet AP-0, AP-1, AP-2 AP-3, AP-5 Operating Instructions Manual

GB - ENGLISH

Operating Instructions

Dear Customer,

Many thanks for the confidence you have shown in us with the purchase of your new JET-machine. This manual has been

prepared for the owner and operators of a JET AP-0, AP-1, AP-2 AP-3, AP-5 arbor press to promote safety during

installation, operation and maintenance procedures. Read this manual thoroughly and follow instructions carefully.

…Table of Contents

1. Declaration of conformity

2. Warranty

3. Safety

Authorized use

Safety notes

4. Machine specifications

Technical data

Machine description

5. Transport and Installation

Transport

Installation

Initial Lubrication

6. Machine operation

7. Adjustments

8. Maintenance

9. Environmental protection

1. Declaration of conformity

On our own responsibility we

hereby declare that this product

complies with the regulations*

listed on page 2. Designed in

consideration with the standards**.

2. Warranty

The Seller guarantees that the

supplied product is free from

material defects and

manufacturing faults. This

warranty does not cover any

defects which are caused, either

directly or indirectly, by incorrect

use, carelessness, accidental

damage, repair, inadequate

maintenance or cleaning and

normal wear and tear. Guarantee

and/or warranty claims must be

made within twelve months from

the date of purchase (date of

invoice). Any further claims shall

be excluded. This warranty

includes all guarantee obligations

of the Seller and replaces all

previous declarations and

agreements concerning warranties.

The warranty period is valid for

eight hours of daily use. If this is

exceeded, the warranty period

shall be reduced in proportion to

the excess use, but to no less than

three months.

Returning rejected goods requires

the prior express consent of the

Seller and is at the Buyer’s risk

and expense.

Further warranty details can be

found in the General Terms and

Conditions (GTC). The GTC can

be viewed at www.jettools.com or

can be sent by post upon request.

The Seller reserves the right to

make changes to the product and

accessories at any time.

3. Safety

3.1 Authorized use

The arbor press is designed for

pressing, broaching, bending and

straightening purposes only.

The proper use also includes

compliance with the operating and

maintenance instructions given in

this manual.

For machining, the workpiece must

allow to safely be loaded and

supported.

The machine must be operated

only by persons familiar with its

operation and maintenance and

who are familiar with its hazards.

The required minimum age must

be observed.

The machine must only be used in

a technically perfect condition.

When working on the machine, all

safety mechanisms and covers

must be mounted.

Any other use exceeds

authorization.

In the event of unauthorized use of

the machine, the manufacturer

renounces all liability and the

responsibility is transferred

exclusively to the operator.

3.2 Safety notes

Metal forming machines can be

dangerous if not used properly.

Read and understand the entire

instruction manual before

attempting assembly or operation.

Keep this operating instruction

close by the machine, protected

from dirt and humidity, and pass it

over to the new owner if you part

with the tool.

Install the machine so that there is

sufficient space for safe operation

and work piece handling.

Keep work area well lighted.

3

The arbor press is designed to

operate in closed rooms, and must

be bolted to a solid work bench or

table securely attached to the floor.

Keep the floor around the machine

clean and free of scrap material,

oil and grease.

Remove all loose clothing and

confine long hair.

Before operating the machine,

remove tie, rings, watches and

other jewellery.

Wear safety shoes; never wear

leisure shoes or sandals.

Sheet metal stock has sharp

edges.

WEAR GLOVES when handling

sharp edged work pieces.

WEAR SAFETY GLASSES.

KEEP HANDS AND FINGERS

clear of the pressing area in front

and rear of the ram.

Stay alert!

Give your work undivided

attention. Use common sense. Do

not operate the machine when you

are tired.

Keep an ergonomic body position.

Maintain a balanced stance at all

times.

Do not operate the machine under

the influence of drugs, alcohol or

any medication. Be aware that

medication can change your

behaviour.

Keep children and visitors a safe

distance from the work area.

Keep guards in place and in

working order.

Specifications regarding the

maximum pressing force must be

observed.

Do not overload the press by using

handle extensions (cheater bars)

Work must be mounted on the

press securely. Do not use the

press with work mounted at an

angle.

The press is designed for pressing,

broaching, bending and

straightening purposes only.

Always make sure the ram

contacts the workpiece squarely

before applying pressure.

Some parts may have a tendency

to pop out of the press or explode

under pressure. Protect yourselves

accordingly.

Support long work pieces with

helping roller stands.

Do not stand on the machine.

4. Machine specifications

4.1 Technical Data

AP-0:

Throat 85mm

Working height above table 100mm

Tons pressure 0,5t

Ram Bore Ø9,5mm

Basic size (LxWxH) 240x100x250mm

Weight 8,5kg

AP-1:

Throat 102mm

Working height above table 125mm

Tons pressure 1t

Ram Bore Ø9,5mm

Basic size (LxWxH) 275x125x305mm

Weight 10,5kg

AP-2:

Throat 145mm

Working height above table 145mm

Tons pressure 2t

Ram Bore Ø12,7mm

Basic size (LxWxH) 430x160x410mm

Weight 28kg

AP-3:

Throat 137mm

Working height above table 290mm

Tons pressure 3t

Ram Bore Ø12,7mm

Basic size (LxWxH) 460x215x550mm

Weight 45kg

AP-5:

Throat 216mm

Working height above table 460mm

Tons pressure 5t

Ram Bore Ø12,7mm

Basic size (LxWxH) 660x250x860mm

Weight 140kg

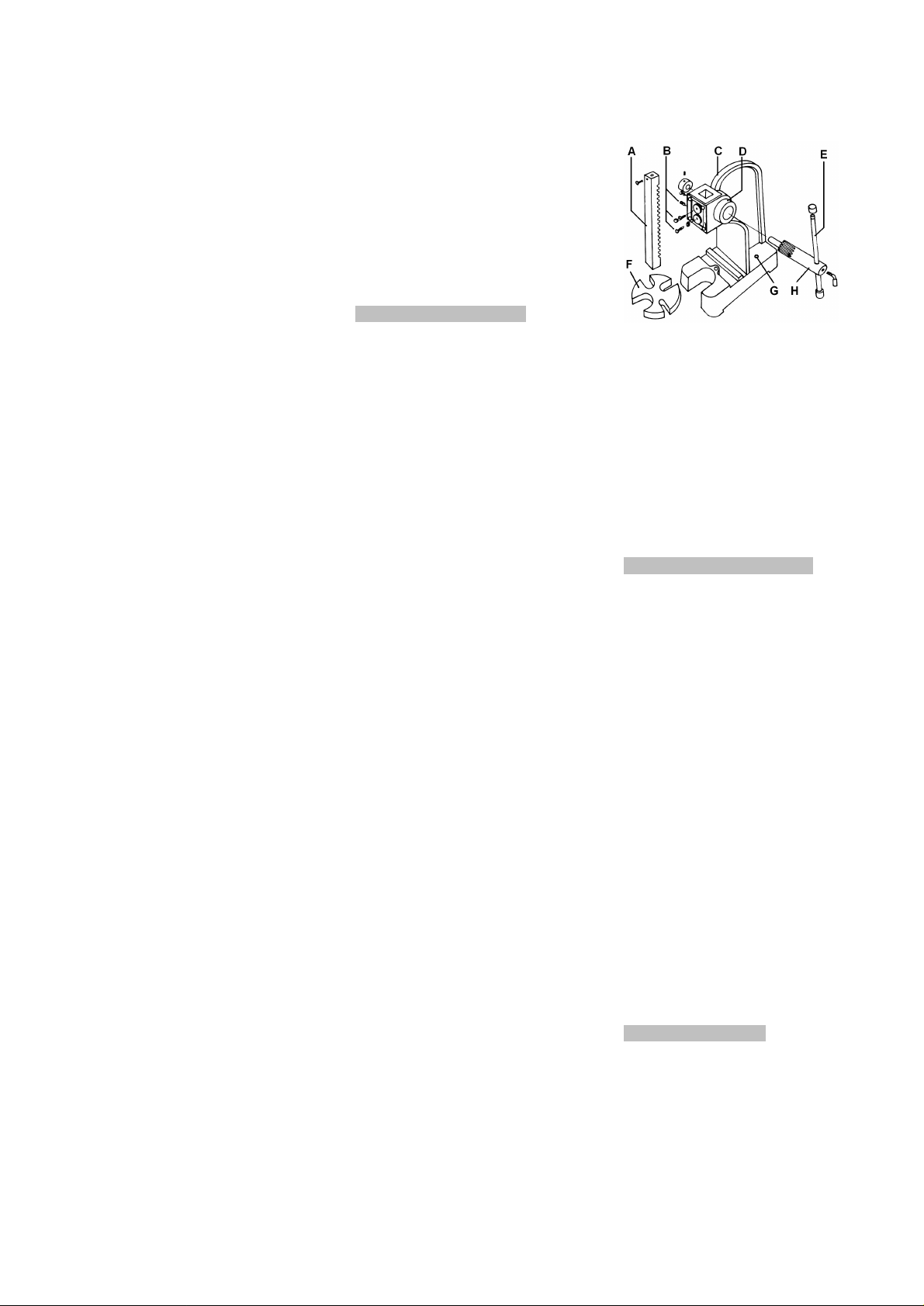

4.2 Machine Description

Fig 1

A…Ram

B….Ram guide adjust bolts

C….Arbour press body

D…Pinion oil hole

E…Press handle

F….Support plate

G….Bolt down holes

H….Pinion

5. Transport and installation

5.1 Transport

For transport use a forklift or hand

trolley. Make sure the machine

does not tip or fall off during

transport.

If you notice transport damage

while unpacking, notify your

supplier immediately. Do not

operate the machine!

Dispose of the packing in an

environmentally friendly manner.

Clean all rust protected surfaces

with petroleum, diesel oil or a mild

solvent.

Coat all machined surfaces with a

light coat of oil to inhibit rust.

5.2 Installation

The arbor press is designed to

operate in closed rooms, and must

be bolted to a solid work bench or

table securely attached to the floor.

5.3 Initial Lubrication

See chapter 8 for lubrication.

6. Machine operation

Specifications regarding the

maximum pressing force must be

observed.

Do not overload the press by using

handle extensions (cheater bars)

4

Work must be mounted on the

press securely. Do not use the

press with work mounted at an

angle.

The press is designed for pressing,

broaching, bending and

straightening purposes only.

Always make sure the ram

contacts the workpiece squarely

before applying pressure.

Some parts may have a tendency

to pop out of the press or explode

under pressure. Protect yourselves

accordingly.

KEEP HANDS AND FINGERS

clear of the pressing area in front

and rear of the ram.

WEAR SAFETY GLASSES.

Support long work pieces with

helping roller stands.

Sheet metal stock has sharp

edges.

WEAR GLOVES when handling

sharp edged work pieces.

7. Adjustments

If ram is loose and falls by itselves,

snug bolts (B). All four bolts should

be tensioned equally.

8. Maintenance

Lubrication:

The machine must be lubricated

every day of service.

Oil the pinion through the oil port

(D).

Grease ram rack (A).

Lubricate all slide and pivot points

of the machine.

Lightly oil the machined parts

when not in use to prevent rust.

9. Environmental protection

Protect the environment.

Your appliance contains valuable

materials which can be recovered

or recycled. Please leave it at a

specialized institution.

5

Loading...

Loading...