ISSI IS93C46-3P, IS93C46-3GRI, IS93C46-3GR, IS93C46-3GI, IS93C46-3PI Datasheet

...

IS93C46-3 |

ISSI® |

1,024-BIT SERIAL ELECTRICALLY ERASABLE PROM

MARCH 2001

FEATURES

•State-of-the-art architecture

—Non-volatile data storage

—Low voltage operation: 3.0V (Vcc = 2.7V to 6.0V)

—Full TTL compatible inputs and outputs

—Auto increment for efficient data dump

•Low voltage read operation

—Down to 2.7V

•Hardware and software write protection

—Defaults to write-disabled state at power-up

—Software instructions for write-enable/disable

•Advanced low voltage CMOS E2PROM technology

•Versatile, easy-to-use Interface

—Self-timed programming cycle

—Automatic erase-before-write

—Programming status indicator

—Word and chip erasable

—Stop SK anytime for power savings

•Durable and reliable

—10-year data retention after 100K write cycles

—100,000 write cycles

—Unlimited read cycles

OVERVIEW

The IS93C46-3 is a low cost 1,024-bit, non-volatile, serial E2PROM. It is fabricated using ISSI’s advanced CMOS E2PROM technology. The IS93C46-3 provides efficient non-volatile read/write memory arranged as 64 registers of 16 bits each. Seven 9-bit instructions control the operation of the device, which includes read, write, and mode enable functions. The data out pin (DOUT) indicates the status of the device during in the self-timed nonvolatile programming cycle.

The self-timed write cycle includes an automatic erase- before-write capability. To protect against inadvertent writes, the WRITE instruction is accepted only while the chip is in the write enabled state. Data is written in 16 bits per write instruction into the selected register. If Chip Select (CS) is brought HIGH after initiation of the write

cycle, the Data Output (DOUT) pin will indicate the READY/ BUSY status of the chip.

APPLICATIONS

The IS93C46-3 is ideal for high-volume applications requiring low power and low density storage. This device uses a low cost, space saving 8-pin package. Candidate applications include robotics, alarm devices, electronic locks, meters and instrumentation settings.

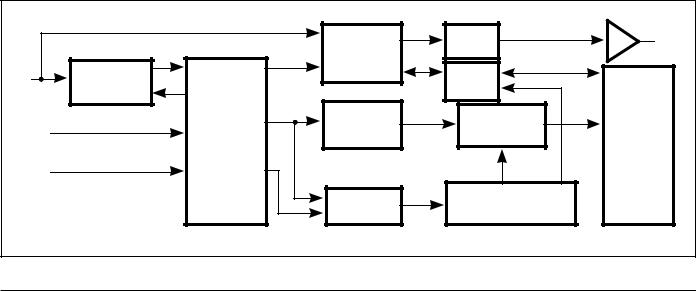

FUNCTIONAL BLOCK DIAGRAM

|

|

DATA |

DUMMY |

DOUT |

|

|

BIT |

||

|

|

REGISTER |

|

|

|

|

|

|

|

|

INSTRUCTION |

(16 BITS) |

|

|

DIN |

|

R/W |

|

|

REGISTER |

|

|

||

|

(9 BITS) |

|

AMPS |

|

|

|

|

|

|

|

INSTRUCTION |

ADDRESS |

1 OF 64 |

EEPROM |

CS |

DECODE, |

REGISTER |

DECODER |

ARRAY |

|

CONTROL, |

|

|

(64 X 16) |

|

AND |

|

|

|

|

|

|

|

|

SK |

CLOCK |

|

|

|

GENERATION |

|

|

|

|

|

|

|

|

|

|

|

WRITE |

HIGH VOLTAGE |

|

|

|

ENABLE |

GENERATOR |

|

ISSI reserves the right to make changes to its products at any time without notice in order to improve design and supply the best possible product. We assume no responsibility for any errors which may appear in this publication. © Copyright 2001, Integrated Silicon Solution, Inc.

Integrated Silicon Solution, Inc. — 1-800-379-4774 |

1 |

Rev. G

04/26/01

IS93C46-3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ISSI® |

||||||

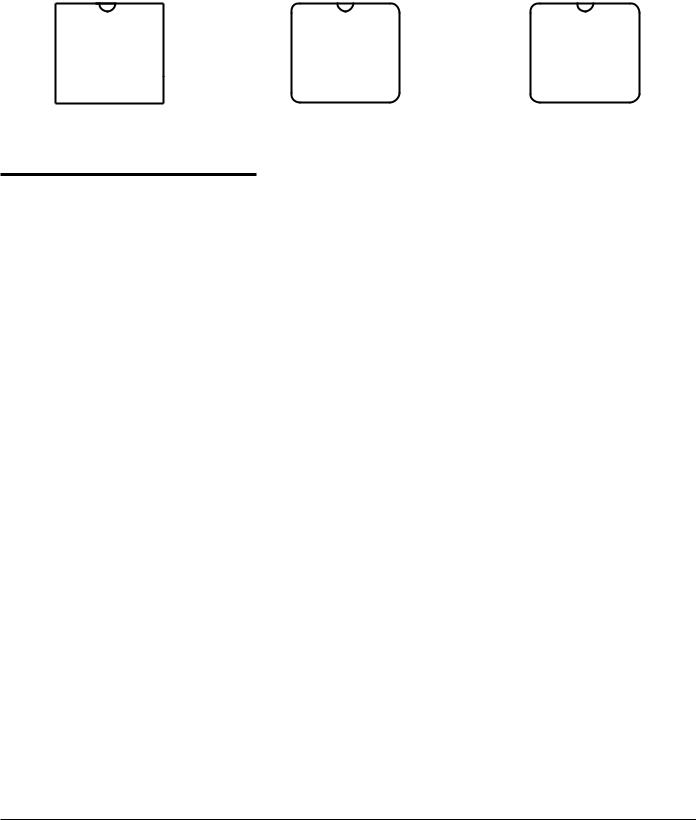

PIN CONFIGURATION |

|

|

PIN CONFIGURATION |

|

|

PIN CONFIGURATION |

|

|

|

||||||||||||

8-Pin DIP |

|

|

|

|

8-Pin JEDEC Small Outline “G” |

8-Pin JEDEC Small Outline “GR” |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CS |

|

1 |

8 |

|

VCC |

|

NC |

|

1 |

8 |

|

NC |

|

CS |

|

1 |

8 |

|

VCC |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

SK |

|

2 |

7 |

|

NC |

|

VCC |

|

2 |

7 |

|

GND |

|

SK |

|

|

7 |

|

NC |

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|||||||||||

DIN |

|

3 |

6 |

|

NC |

|

CS |

|

3 |

6 |

|

DOUT |

|

DIN |

|

|

6 |

|

NC |

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|||||||||||

DOUT |

|

4 |

5 |

|

GND |

|

SK |

|

4 |

5 |

|

DIN |

|

DOUT |

|

|

5 |

|

GND |

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PIN DESCRIPTIONS

CS |

Chip Select |

SK |

Serial Data Clock |

|

|

DIN |

Serial Data Input |

|

|

DOUT |

Serial Data Output |

|

|

NC |

Not Connected |

|

|

Vcc |

Power |

|

|

GND |

Ground |

|

|

ENDURANCE AND DATA RETENTION

The IS93C46-3 is designed for applications requiring up to 100,000 programming cycles (WRITE, WRALL, ERASE and ERAL). It provides 10 years of secure data retention, without power after the execution of 100,000 programming cycles.

DEVICE OPERATION

The IS93C46-3 is controlled by seven 9-bit instructions. Instructions are clocked in (serially) on the DIN pin. Each instruction begins with a logical “1” (the start bit). This is followed by the opcode (2 bits), the address field (6 bits), and data, if appropriate. The clock signal (SK) may be halted at any time and the IS93C46-3 will remain in its last state. This allows full static flexibility and maximum power conservation.

Read (READ)

The READ instruction is the only instruction that outputs serial data on the DOUT pin. After the read instruction and address have been decoded, data is transferred from the selected memory register into a 16-bit serial shift register. (Please note that one logical “0” bit precedes the actual 16-bit output data string.) The output on DOUT changes during the low-to-high transitions of SK (see Figure 3).

Low Voltage Read

The IS93C46-3 has been designed to ensure that data read operations are reliable in low voltage environments. The IS93C46-3 is guaranteed to provide accurate data during read operations with Vcc as low as 2.7V.

Auto Increment Read Operations

In the interest of memory transfer operation applications, the IS93C46-3 has been designed to output a continuous stream of memory content in response to a single read operation instruction. To utilize this function, the system asserts a read instruction specifying a start location address. Once the 16 bits of the addressed word have been clocked out, the data in consecutively higher address locations (the address “000000” is assumed as the address of “111111") is output. The address will wrap around continuously with CS HIGH until the chip select (CS) control pin is brought LOW. This allows for single instruction data dumps to be executed with a minimum of firmware overhead.

Write Enable (WEN)

The write enable (WEN) instruction must be executed before any device programming (WRITE, WRALL, ERASE, and ERAL) can be done. When Vcc is applied, this device

2 Integrated Silicon Solution, Inc. — 1-800-379-4774

Rev. G

04/26/01

IS93C46-3 |

ISSI® |

powers up in the write disabled state. The device then remains in a write disabled state until a WEN instruction is executed. Thereafter, the device remains enabled until a WDS instruction is executed or until Vcc is removed. (NOTE: Neither the WEN nor the WDS instruction has any effect on the READ instruction.) (See Figure 4.)

Write (WRITE)

The WRITE instruction includes 16 bits of data to be written into the specified register. After the last data bit has been applied to DIN, and before the next rising edge of SK, CS must be brought LOW. The falling edge of CS initiates the self-timed programming cycle.

After a minimum wait of 250 ns (5V operation) from the falling edge of CS (tCS), if CS is brought HIGH, DOUT will indicate the READY/BUSY status of the chip: logical “0” means programming is still in progress; logical “1” means the selected register has been written, and the part is ready for another instruction (see Figure 5). (NOTE: The combination of CS HIGH, DIN HIGH and the rising edge of the SK clock, resets the READY/BUSY flag. Therefore, it is important if you want to access the READY/BUSY flag , not to reset it through this combination of control signals.) Before a WRITE instruction can be executed, the device must be write enabled (see WEN).

Write All (WRALL)

The write all (WRALL) instruction programs all registers with the data pattern specified in the instruction. While the WRALL instruction is being loaded, the address field

INSTRUCTION SET

becomes a sequence of “Don’t Care” bits (see Figure 6).

As with the WRITE instruction, if CS is brought HIGH after a minimum wait of 250 ns (tCS), the DOUT pin indicates the READY/BUSY status of the chip (see Figure 6).

Write Disable (WDS)

The write disable (WDS) instruction disables all programming capabilities. This protects the entire part against accidental modification of data until a WEN instruction is executed. (When Vcc is applied, this part powers up in the write disabled state.) To protect data, a WDS instruction should be executed upon completion of each programming operation. (NOTE: Neither the WEN nor the WDS instruction has any effect on the READ instruction.) (See Figure 7.)

Erase Register (ERASE)

After the erase instruction is entered, CS must be brought LOW. The falling edge of CS initiates the self-timed internal programming cycle. Bringing CS HIGH after a minimum of tCS, will cause DOUT to indicate the READ/BUSY status of the chip: a logical “0” indicates programming is still in progress; a logical “1” indicates the erase cycle is complete and the part is ready for another instruction (see Figure 8).

Erase All (ERAL)

Full chip erase is provided for ease of programming. Erasing the entire chip involves setting all bits in the entire memory array to a logical “1” (see Figure 9).

Instruction |

Start Bit |

OP Code |

Address |

Input Data |

READ |

1 |

10 |

(A5-A0) |

|

|

|

|

|

|

WEN |

1 |

00 |

11XXXX |

|

(Write Enable) |

|

|

|

|

|

|

|

|

|

WRITE |

1 |

01 |

(A5-A0) |

D15-D0(1) |

|

|

|

|

|

WRALL |

1 |

00 |

01XXXX |

D15-D0(1) |

(Write All Registers) |

|

|

|

|

|

|

|

|

|

WDS |

1 |

00 |

00XXXX |

|

(Write Disable) |

|

|

|

|

|

|

|

|

|

ERASE |

1 |

11 |

(A5-A0) |

|

|

|

|

|

|

ERAL |

1 |

00 |

10XXXX |

|

(Erase All Registers) |

|

|

|

|

|

|

|

|

|

Note: 1. If input data is not 16 bits exactly, the last 16 bits will be taken as input data (a word).

Integrated Silicon Solution, Inc. — 1-800-379-4774 |

3 |

Rev. G

04/26/01

Loading...

Loading...