Invacare Twister, Twister-Junior Service Manual

Invacare® TWISTER

TWISTER-JUNIOR

SERVICE MANUAL

These instructions contain information

about:

Troubleshooting

Testing of Components

Repair

Edition: 10.2001

Twister/Twister Junior Service Manual

General information

These repair instructions contains all the information necessary for maintenance and overhaul

of both wheelchairs.

• Work which only applies to the Twister Junior is noted in the text.

• All maintenance and overhaul work must be carried out in accordance with these repair

instructions.

• Please observe all safety instructions.

• Information about operation or about general maintenance and care work should be taken

from the corresponding wheelchair Operating Manual.

• You can find information about complete replacement of the Twister Junior seating system in

the Twister Junior assembly instructions.

• You can find information about ordering spare parts in the spare parts catalogue.

• We reserve the right to make any alterations on the grounds of technical improvements.

• The wheelchair may only be maintained and overhauled by qualified personnel.

• The minimum requirement for service technicians is relevant training, such as in the cycle

or orthopaedic mechanics fields, or suitably long-term job experience.

Experience and knowledge of electrical measuring devices (Multimeter) is also a

requirement.

• If you have any problems or questions please contact INVACARE SERVICE:

Central office: Tel. +49 5731-754-0

Fax +49 5731-754-111

Service dept.: Tel. +49 5731-7545-(70-80)

Fax +49 5731-7542-(08-16)

Address: Invacare Deutschland GmbH

Dehmer Str. 66

32549 Bad Oeynhausen

PO Box: Invacare Deutschland GmbH

Postfach 60 01 06

32 527 Bad Oeynhausen

• Alterations to the wheelchair which occur as a result of incorrectly or improperly executed

maintenance or overhaul work lead to the exclusion of all liability on the side of INVACARE.

Twister / Twister Junior Service Manual

Issued: 21.01.02 Page 3

Notes on transport

• If the wheelchair has to be shipped back to the manufacturer for major repairs, you should

always use the original packaging for transport.

• You should also include as accurate a fault description as possible.

The following symbols are used in these repair instructions:

Note:

This symbol identifies general information which indicates special points or simplifications in

dismantling / reassembly.

Caution:

It is imperative that you observe any >safety instructions< identified with this symbol

Twister/Twister Junior Service Manual

Page 4 Issued:21.01.02

Contents

1 SAFETY AND ASSEMBLY INSTRUCTIONS 19

1.1 Before any inspection or repair work 19

1.2 During dismantling/reassembly 20

1.3 Before operation / after completion of work: 20

2 TOOL LIST 21

3 LAYOUT OF MODULES, COMPONENTS AND DISPLAYS AND

CONTROLS 22

4 ELECTRONIC CONTROL COMPONENTS (ACS) 26

4.1 General 26

4.2 Module connection cables 28

4.3 Sensors 28

4.4 Status displays 28

5 MODULE COMPOSITION 30

5.1 Wheelchair fittings: without lighting system, without actuators 30

5.2 Wheelchair fittings: with 24 V lighting system, without actuators 31

5.3 Wheelchair fittings: without lighting, with actuators 32

5.4 Wheelchair fittings: with 24 V lighting, with actuators 33

5.5 Wheelchair fittings: with 12 V lighting (TÜV Version), without actuators 34

5.6 Wheelchair fittings: with 12 V lighting (TÜV Version), with actuators 35

5.7 Wheelchair fittings: with electrically adjustable RECARO seat 36

6 INSPECTION PLAN 37

7 OPERATIONAL FAULTS 41

7.1 General 41

7.2 Fault causes 41

8 ERROR MESSAGE AT JOYSTICK BOX 44

8.1 Joystick box error codes 44

Twister / Twister Junior Service Manual

Issued: 21.01.02 Page 5

9 INSPECTION AND REPAIR WORK TO STANDARD SEATING

SYSTEMS 46

9.1 Armrests and side panels 46

9.1.1 Disassembly of armrests and side panels 47

9.1.2 Reassembly of armrests and side panels 47

9.2 Standard legrests without angle-adjustable footplate 48

9.2.1 Disassembly of legrests 49

9.2.2 Reassembly of legrests 49

9.3 Standard legrests with angle-adjustable footplate 50

9.3.1 Disassembly of legrests 51

9.3.2 Reassembly of legrests 51

9.4 Legrest, manually height-adjustable 52

9.4.1 Disassembly of legrests 54

9.4.2 Reassembly of legrests 54

9.5 Legrests, electrically height-adjustable 55

9.5.1 Disassembly of legrests 57

9.5.2 Reassembly of legrests 57

9.6 Legrest with one-piece footplate 58

9.6.1 Disassembly of legrests 59

9.6.2 Reassembly of legrests 59

9.7 Legrests with one-piece footplate for shorter lower legs 60

9.7.1 Disassembly of legrests 62

9.7.2 Reassembly of legrests 62

9.8 Legrests 73° and 90° 63

9.8.1 Disassembly of legrests 64

9.8.2 Reassembly of legrests 64

9.9 Headrest 65

9.9.1 Disassembly of headrest 66

9.9.2 Reassembly of headrest 66

9.10 Backrest anatomic element in standard, pin dot- and Dutch version 67

9.10.1 Disassembly of backrest element 68

9.10.2 Reassembly of the backrest elements 68

9.11 Backrest element, electrically adjustable, in standard and comfort version. 69

9.11.1 Disassembly of backrest element 71

9.11.2 Reassembly of the backrest elements 71

9.12 Backrest element, manually adjustable, in standard and comfort version 72

9.12.1 Disassembly of backrest element 73

9.12.2 Reassembly of the backrest elements 74

9.13 Expansion wedge 75

9.13.1 Disassembly of expansion wedge 75

9.13.2 Reassembly of the expansion wedge 75

10 TESTING AND REPAIR WORKS ON RECARO SEATING SYSTEM 76

10.1 General 76

Twister/Twister Junior Service Manual

Page 6 Issued:21.01.02

10.2 Headrest, safety belt and push handle 76

10.2.1 Disassembly of the headrest, the safety belt and the push handle 77

10.2.2 Disassembly of the headrest, the safety belt and the push handle 77

10.3 Armrests and side panels 78

10.3.1 Disassembly of armrests and side panels 79

10.3.2 Reassembly of armrests and side panels 79

10.4 Seating module and Frame 80

10.4.1 Disassembly of legrests 82

10.4.2 Reassembly of legrests 82

10.4.3 Disassembly of seat tilt adjustment 83

10.4.4 Reassembly of the seat tilt adjustment 83

10.4.5 Disassembly of the seating module and the seat frame 83

10.4.6 Reassembly of the seating module and the seat frame 83

11 TESTING AND REPAIR WORKS ON RECARO SEATING SYSTEM 84

11.1 General 84

11.2 Twister Junior headrest 85

11.2.1 Disassembly of headrest 86

11.2.2 Reassembly of headrest 86

11.3 Twister Junior backrest trunk supports 87

11.3.1 Disassembly of backrest trunk supports 88

11.3.2 Reassembly of backrest trunk supports 88

11.4 Electrical backrest adjustment, Twister Junior 89

11.4.1 Disassembly of actuator motor 90

11.4.2 Reassembly of actuator motor 90

11.5 Manual backrest adjustment, Twister Junior 91

11.5.1 Disassembly of backrest adjustment 92

11.5.2 Reassembly of backrest adjustment 92

11.6 Twister Junior armrests 93

11.6.1 Disassembly of armrests 95

11.6.2 Reassembly of armrests 95

11.7 Twister Junior backrest unit 96

11.7.1 Disassembly of the backrest unit 97

11.7.2 Reassembly of backrest unit 97

11.8 Expanding wedge for Twister Junior 98

11.8.1 Disassembly of the expanding wedge 98

11.8.2 Reassembly of expanding wedge 98

11.9 Twister Junior seating unit 100

11.9.1 Removal of seat unit 101

11.9.2 Reassembly of the seat unit 101

11.10 Footplate for Twister Junior 102

11.10.1 Disassembly of the footplate 103

11.10.2 Reassembly of footplate 103

11.11 Legrest upper part for Twister Junior 104

11.11.1 Disassembly of legrest upper parts 106

11.11.2 Reassembly of legrest upper parts 106

Twister / Twister Junior Service Manual

Issued: 21.01.02 Page 7

11.12 Legrest attachment for Twister Junior 107

11.12.1 Disassembly of legrest attachments 108

11.12.2 Reassembly of legrest attachments 108

11.13 Chin control and switch joystick for Twister Junior 109

11.13.1 Disassembly of the chin control and switch joystick 110

11.13.2 Reassembly of the chin control and switch joystick 110

12 TESTING AND REPAIR WORKS ON CHASSIS 111

12.1 Steering wheel suspension and steering wheels 8" x 2" 111

12.1.1 Disassembly of the steering wheel suspension and steering wheels 112

12.1.2 Reassembly of the steering wheel suspension and steering wheels 112

12.2 Splash protection for modules 113

12.2.1 Disassembly of "Standard" splash protection 113

12.2.2 Reassembly of "Standard" splash protection 113

12.2.3 Disassembly of the "Lifter" spray protection 113

12.2.4 Reassembly of "Lifter" splash protection 113

12.3 Drive wheels, tyres and wheel hubs 114

12.3.1 Disassembly of drive wheels and tyres 115

12.3.2 Reassembly of drive wheels and tyres 116

12.3.3 Dismounting of the wheel hubs 116

12.3.4 Reassembly of the wheel hubs 116

12.4 Drive unit complete 117

12.4.1 Dismounting the drive unit 121

12.4.2 Mounting the drive unit 121

12.5 Disengaging mechanism 122

12.5.1 Performance test of the disengaging mechanism 122

12.5.2 Adjusting the disengaging mechanism 123

12.5.3 Replacing the Star lock caps 123

12.6 Anti-tip mechanism 124

12.6.1 Disassembly of the anti-tip mechanism 124

12.6.2 Disassembly of the anti-tip mechanism 124

12.6.3 Disassembly of the anti-tip mechanism 124

13 CHANGES, TESTING AND REPAIR WORKS ON LIFTER UNIT 125

13.1 Changing the vehicle from front wheel to rear wheel drive 125

13.1.1 Converting the standard vehicle(without lifter) 125

13.1.2 Conversion of a vehicle with lifter 126

13.2 Conversion of the vehicle from rear wheel to front wheel drive 128

13.2.1 Converting the standard vehicle(without lifter) 128

13.2.2 Conversion of vehicle with lifter 129

13.3 Retrofitting the lifter module to current safety standards 131

13.3.1 Instructions for retrofitting the lifter module: 131

13.3.2 Final inspection 132

14 TESTING AND REPAIR WORKS ON POWER SUPPLY 133

14.1 Testing battery voltage and charge testing 133

14.1.1 "Testing the individual voltage of the batteries" 133

14.1.2 Checking total voltage of the batteries in non-operative state and under load 134

Twister/Twister Junior Service Manual

Page 8 Issued:21.01.02

14.2 30 Ah battery unit. 135

14.2.1 Disassembly of battery unit 136

14.2.2 Reassembly of the battery unit 136

14.3 40 Ah battery unit. 137

14.3.1 Disassembly of battery unit 138

14.3.2 Reassembly of the battery unit 138

14.4 Charge batteries. 139

14.4.1 General 139

14.4.2 Checks before charging 139

14.4.3 Charging procedure 140

14.4.4 Charging of fully discharged batteries 140

14.4.5 Performance test 141

15 TESTING AND REPAIR WORKS ON LIGHTING SYSTEM 142

15.1 Fault causes 142

15.2 Check lighting system 143

15.3 Disassemble / check headlight 144

15.3.1 Disassembly of headlights 144

15.3.2 Checking the headlights 144

15.3.3 Reassembly of headlights 145

15.4 Disassembling / checking rear lights 146

15.4.1 Disassembling rear lamps 146

15.4.2 Checking the rear lights 146

15.4.3 Reassembly of rear lights 146

15.5 Disassemble / check direction indicators 147

15.5.1 Disassembly of direction indicators 147

15.5.2 Checking the direction indicators 148

15.5.3 Reassembly of the direction indicators 148

15.6 Disassembling headlight / direction indicator unit completely 149

15.6.1 Disassembling the headlight 149

15.6.2 Reassembly of the headlight 149

15.6.3 Disassembly of the direction indicators 150

15.6.4 Reassembly of the direction indicators 150

15.6.5 Disassembly of the bulb holder 150

15.6.6 Reassembly of the bulb holder 150

15.7 Disassembling rear light and direction indicator unit completely 151

15.7.1 Disassembly of the rear light 151

15.7.2 Reassembly of the rear light 151

16 TESTING AND REPAIR WORK ON THE DRIVE UNIT 152

16.1 General 152

16.2 Performance check 152

16.3 Checking and replacing carbon brushes 152

16.3.1 Removing carbon brushes 153

16.3.2 Check carbon brushes 153

16.3.3 Refitting carbon brushes 153

Twister / Twister Junior Service Manual

Issued: 21.01.02 Page 9

16.4 Testing motor, magnetic brake and freewheel switch 154

16.4.1 Testing preparations / replacement of drive motors 154

16.4.2 Testing drive motor 154

16.4.3 Checking the magnetic brake 155

16.4.4 Checking the freewheel switch 155

17 TESTING AND REPAIR WORK ON THE ACTUATOR MOTORS 156

17.1 General 156

17.2 Checking the actuator motors 156

17.2.1 Visual inspection of the plug contacts: 156

17.2.2 Continuity check: 156

17.2.3 Performance test: 157

17.3 Replacing the actuator motors for the legrests 158

17.3.1 Disassembly 158

17.3.2 Reassembly 158

17.4 Replacing the seat adjustment actuator motor (without lifter module) 159

17.4.1 Disassembly 159

17.4.2 Reassembly 159

17.5 Replacement of seat adjustment (with lifter module) 160

17.5.1 Disassembly (Twister) 160

17.5.2 Reassembly (Twister) 160

17.5.3 Disassembly (Twister Junior) 160

17.5.4 Reassembly (Twister Junior) 160

17.6 Replacing actuator of automatic seat back adjustment or support tube for

manual seat back adjustment. 161

17.6.1 Disassembly 161

17.6.2 161

18 TESTING THE DRIVING ELECTRONICS 162

18.1 Overview of the electronic module and cable 162

18.2 Testing joystick boxes 164

18.2.1 Check power supply to joystick box 164

18.3 - Check power module. 166

18.3.1 Status display 166

18.3.2 Check power supply to power module. 167

Remove the battery cable plug from the power module. 167

18.4 Checking lighting modules or combined lighting / actuator module 168

18.4.1 Status display 168

18.4.2 Preparations for testing 168

18.4.3 Check the power supply from the power module to the lighting module 24V Æ 12V,

or to the lighting / actuator module 169

18.5 Testing additional power supply of lighting module 24V Æ 12V (TÜV version) 170

18.5.1 Preparations for testing 170

18.5.2 Test 170

18.6 Check the voltage converter for the Recaro seat 171

18.6.1 Preparations for testing 171

18.6.2 Checking voltage at Recaro seat voltage converter 171

Twister/Twister Junior Service Manual

Page 10 Issued:21.01.02

19 TESTING THE DRIVING ELECTRONICS 172

19.1 Standard joystick box 172

19.1.1 Disassembly of the standard joystick box 173

19.1.2 Reassembly of the standard joystick box 173

19.1.3 Disassembly joystick box support tube and joystick box attachment 173

19.1.4 Reassembly joystick box stay bar and joystick box attachment 173

19.1.5 Disassembly of the joystick box holder (hinged) 174

19.1.6 Reassembly of the joystick box holder (hinged) 174

19.1.7 Disassembly of the joystick box holder for attendant 174

19.1.8 Reassembly of the joystick box holder for attendant 174

19.2 Joystick box for attendant 175

19.2.1 Disassembly of joystick box 176

19.2.2 Reassembly of the joystick box 176

19.2.3 Disassembly of the joystick box holder 176

19.2.4 Reassembly of joystick box holder 176

19.3 Table control / central control 177

19.3.1 disassembly of joystick box 178

19.3.2 Reassembly of joystick box 178

19.3.3 Disassembly of central control support 178

19.3.4 Reassembly of central control support 178

19.3.5 Disassembly of table plate and support 179

19.3.6 Reassembly of table plate and support 179

19.4 Chin control, manually / electrically swivelling in horizontal direction 180

19.4.1 Disassembly of control 182

19.4.2 Reassembling the control 182

19.4.3 Disassembly of the motor 183

19.4.4 Reassembly of the motor 183

19.4.5 Disassembly of the switchbox 183

19.4.6 Reassembly of the switchbox 183

19.4.7 Disassembly of support, complete 183

19.4.8 Reassembly of support, complete 183

19.5 Chin control, electrically swivelling in vertical direction 184

19.5.1 Disassembly of control 185

19.5.2 Reassembling the control 185

19.5.3 Disassembly of the motor 185

19.5.4 Reassembly of the motor 185

19.5.5 Disassembly of the switchbox 186

19.5.6 Reassembly of the switchbox 186

19.5.7 Disassembly of support, complete 186

19.5.8 Reassembly of support, complete 186

19.6 Power module 187

19.6.1 Preparation 187

19.6.2 Removal of power module 187

19.6.3 Fitting the power module 187

19.7 Lighting and actuator module (Clam), lighting module and lighting module with

voltage converter 188

19.7.1 General 188

19.7.2 Removal of module 189

19.7.3 Refitting the module 189

20 CHECKING CABLES, PLUGS AND SENSORS 190

20.1 General 190

Twister / Twister Junior Service Manual

Issued: 21.01.02 Page 11

20.2 Test procedure 190

20.2.1 Checking plugs and cables 190

20.2.2 Checking the sensors 191

21 WHEELCHAIR PROGRAMMING 192

21.1 General 192

21.2 Programming on the PC 193

21.3 Programming with the programming device 194

22 STORING THE WHEELCHAIR 195

1 SAFETY AND ASSEMBLY INSTRUCTIONS 19

1.1 Before any inspection or repair work 19

1.2 During dismantling/reassembly 20

1.3 Before operation / after completion of work: 20

2 TOOL LIST 21

3 LAYOUT OF MODULES, COMPONENTS AND DISPLAYS AND

CONTROLS 22

4 ELECTRONIC CONTROL COMPONENTS (ACS) 26

4.1 General 26

4.2 Module connection cables 28

4.3 Sensors 28

4.4 Status displays 28

5 MODULE COMPOSITION 30

5.1 Wheelchair fittings: without lighting system, without actuators 30

5.2 Wheelchair fittings: with 24 V lighting system, without actuators 31

5.3 Wheelchair fittings: without lighting, with actuators 32

5.4 Wheelchair fittings: with 24 V lighting, with actuators 33

5.5 Wheelchair fittings: with 12 V lighting (TÜV Version), without actuators 34

5.6 Wheelchair fittings: with 12 V lighting (TÜV Version), with actuators 35

5.7 Wheelchair fittings: with electrically adjustable RECARO seat 36

Twister/Twister Junior Service Manual

Page 12 Issued:21.01.02

6 INSPECTION PLAN 37

7 OPERATIONAL FAULTS 41

7.1 General 41

7.2 Fault causes 41

8 ERROR MESSAGE AT JOYSTICK BOX 44

8.1 Joystick box error codes 44

9 INSPECTION AND REPAIR WORK TO STANDARD SEATING

SYSTEMS 46

9.1 Armrests and side panels 46

9.1.1 Disassembly of armrests and side panels 47

9.1.2 Reassembly of armrests and side panels 47

9.2 Standard legrests without angle-adjustable footplate 48

9.2.1 Disassembly of legrests 49

9.2.2 Reassembly of legrests 49

9.3 Standard legrests with angle-adjustable footplate 50

9.3.1 Disassembly of legrests 51

9.3.2 Reassembly of legrests 51

9.4 Legrest, manually height-adjustable 52

9.4.1 Disassembly of legrests 54

9.4.2 Reassembly of legrests 54

9.5 Legrests, electrically height-adjustable 55

9.5.1 Disassembly of legrests 57

9.5.2 Reassembly of legrests 57

9.6 Legrest with one-piece footplate 58

9.6.1 Disassembly of legrests 59

9.6.2 Reassembly of legrests 59

9.7 Legrests with one-piece footplate for shorter lower legs 60

9.7.1 Disassembly of legrests 62

9.7.2 Reassembly of legrests 62

9.8 Legrests 73° and 90° 63

9.8.1 Disassembly of legrests 64

9.8.2 Reassembly of legrests 64

9.9 Headrest 65

9.9.1 Disassembly of headrest 66

9.9.2 Reassembly of headrest 66

9.10 Backrest anatomic element in standard, pin dot- and Dutch version 67

9.10.1 Disassembly of backrest element 68

9.10.2 Reassembly of the backrest elements 68

9.11 Backrest element, electrically adjustable, in standard and comfort version. 69

9.11.1 Disassembly of backrest element 71

9.11.2 Reassembly of the backrest elements 71

Twister / Twister Junior Service Manual

Issued: 21.01.02 Page 13

9.12 Backrest element, manually adjustable, in standard and comfort version 72

9.12.1 Disassembly of backrest element 73

9.12.2 Reassembly of the backrest elements 74

9.13 Expansion wedge 75

9.13.1 Disassembly of expansion wedge 75

9.13.2 Reassembly of the expansion wedge 75

10 TESTING AND REPAIR WORKS ON RECARO SEATING SYSTEM 76

10.1 General 76

10.2 Headrest, safety belt and push handle 76

10.2.1 Disassembly of the headrest, the safety belt and the push handle 77

10.2.2 Disassembly of the headrest, the safety belt and the push handle 77

10.3 Armrests and side panels 78

10.3.1 Disassembly of armrests and side panels 79

10.3.2 Reassembly of armrests and side panels 79

10.4 Seating module and Frame 80

10.4.1 Disassembly of legrests 82

10.4.2 Reassembly of legrests 82

10.4.3 Disassembly of seat tilt adjustment 83

10.4.4 Reassembly of the seat tilt adjustment 83

10.4.5 Disassembly of the seating module and the seat frame 83

10.4.6 Reassembly of the seating module and the seat frame 83

11 TESTING AND REPAIR WORKS ON RECARO SEATING SYSTEM 84

11.1 General 84

11.2 Twister Junior headrest 85

11.2.1 Disassembly of headrest 86

11.2.2 Reassembly of headrest 86

11.3 Twister Junior backrest trunk supports 87

11.3.1 Disassembly of backrest trunk supports 88

11.3.2 Reassembly of backrest trunk supports 88

11.4 Electrical backrest adjustment, Twister Junior 89

11.4.1 Disassembly of actuator motor 90

11.4.2 Reassembly of actuator motor 90

11.5 Manual backrest adjustment, Twister Junior 91

11.5.1 Disassembly of backrest adjustment 92

11.5.2 Reassembly of backrest adjustment 92

11.6 Twister Junior armrests 93

11.6.1 Disassembly of armrests 95

11.6.2 Reassembly of armrests 95

11.7 Twister Junior backrest unit 96

11.7.1 Disassembly of the backrest unit 97

11.7.2 Reassembly of backrest unit 97

11.8 Expanding wedge for Twister Junior 98

11.8.1 Disassembly of the expanding wedge 98

11.8.2 Reassembly of expanding wedge 98

Twister/Twister Junior Service Manual

Page 14 Issued:21.01.02

11.9 Twister Junior seating unit 100

11.9.1 Removal of seat unit 101

11.9.2 Reassembly of the seat unit 101

11.10 Footplate for Twister Junior 102

11.10.1 Disassembly of the footplate 103

11.10.2 Reassembly of footplate 103

11.11 Legrest upper part for Twister Junior 104

11.11.1 Disassembly of legrest upper parts 106

11.11.2 Reassembly of legrest upper parts 106

11.12 Legrest attachment for Twister Junior 107

11.12.1 Disassembly of legrest attachments 108

11.12.2 Reassembly of legrest attachments 108

11.13 Chin control and switch joystick for Twister Junior 109

11.13.1 Disassembly of the chin control and switch joystick 110

11.13.2 Reassembly of the chin control and switch joystick 110

12 TESTING AND REPAIR WORKS ON CHASSIS 111

12.1 Steering wheel suspension and steering wheels 8" x 2" 111

12.1.1 Disassembly of the steering wheel suspension and steering wheels 112

12.1.2 Reassembly of the steering wheel suspension and steering wheels 112

12.2 Splash protection for modules 113

12.2.1 Disassembly of "Standard" splash protection 113

12.2.2 Reassembly of "Standard" splash protection 113

12.2.3 Disassembly of the "Lifter" spray protection 113

12.2.4 Reassembly of "Lifter" splash protection 113

12.3 Drive wheels, tyres and wheel hubs 114

12.3.1 Disassembly of drive wheels and tyres 115

12.3.2 Reassembly of drive wheels and tyres 116

12.3.3 Dismounting of the wheel hubs 116

12.3.4 Reassembly of the wheel hubs 116

12.4 Drive unit complete 117

12.4.1 Dismounting the drive unit 121

12.4.2 Mounting the drive unit 121

12.5 Disengaging mechanism 122

12.5.1 Performance test of the disengaging mechanism 122

12.5.2 Adjusting the disengaging mechanism 123

12.5.3 Replacing the Star lock caps 123

12.6 Anti-tip mechanism 124

12.6.1 Disassembly of the anti-tip mechanism 124

12.6.2 Disassembly of the anti-tip mechanism 124

12.6.3 Disassembly of the anti-tip mechanism 124

13 CHANGES, TESTING AND REPAIR WORKS ON LIFTER UNIT 125

13.1 Changing the vehicle from front wheel to rear wheel drive 125

13.1.1 Converting the standard vehicle(without lifter) 125

13.1.2 Conversion of a vehicle with lifter 126

13.2 Conversion of the vehicle from rear wheel to front wheel drive 128

Twister / Twister Junior Service Manual

Issued: 21.01.02 Page 15

13.2.1

Converting the standard vehicle(without lifter) 128

13.2.2 Conversion of vehicle with lifter 129

13.3 Retrofitting the lifter module to current safety standards 131

13.3.1 Instructions for retrofitting the lifter module: 131

13.3.2 Final inspection 132

14 TESTING AND REPAIR WORKS ON POWER SUPPLY 133

14.1 Testing battery voltage and charge testing 133

14.1.1 "Testing the individual voltage of the batteries" 133

14.1.2 Checking total voltage of the batteries in non-operative state and under load 134

14.2 30 Ah battery unit. 135

14.2.1 Disassembly of battery unit 136

14.2.2 Reassembly of the battery unit 136

14.3 40 Ah battery unit. 137

14.3.1 Disassembly of battery unit 138

14.3.2 Reassembly of the battery unit 138

14.4 Charge batteries. 139

14.4.1 General 139

14.4.2 Checks before charging 139

14.4.3 Charging procedure 140

14.4.4 Charging of fully discharged batteries 140

14.4.5 Performance test 141

15 TESTING AND REPAIR WORKS ON LIGHTING SYSTEM 142

15.1 Fault causes 142

15.2 Check lighting system 143

15.3 Disassemble / check headlight 144

15.3.1 Disassembly of headlights 144

15.3.2 Checking the headlights 144

15.3.3 Reassembly of headlights 145

15.4 Disassembling / checking rear lights 146

15.4.1 Disassembling rear lamps 146

15.4.2 Checking the rear lights 146

15.4.3 Reassembly of rear lights 146

15.5 Disassemble / check direction indicators 147

15.5.1 Disassembly of direction indicators 147

15.5.2 Checking the direction indicators 148

15.5.3 Reassembly of the direction indicators 148

15.6 Disassembling headlight / direction indicator unit completely 149

15.6.1 Disassembling the headlight 149

15.6.2 Reassembly of the headlight 149

15.6.3 Disassembly of the direction indicators 150

15.6.4 Reassembly of the direction indicators 150

15.6.5 Disassembly of the bulb holder 150

15.6.6 Reassembly of the bulb holder 150

15.7 Disassembling rear light and direction indicator unit completely 151

15.7.1 Disassembly of the rear light 151

Twister/Twister Junior Service Manual

Page 16 Issued:21.01.02

15.7.2

Reassembly of the rear light 151

16 TESTING AND REPAIR WORK ON THE DRIVE UNIT 152

16.1 General 152

16.2 Performance check 152

16.3 Checking and replacing carbon brushes 152

16.3.1 Removing carbon brushes 153

16.3.2 Check carbon brushes 153

16.3.3 Refitting carbon brushes 153

16.4 Testing motor, magnetic brake and freewheel switch 154

16.4.1 Testing preparations / replacement of drive motors 154

16.4.2 Testing drive motor 154

16.4.3 Checking the magnetic brake 155

16.4.4 Checking the freewheel switch 155

17 TESTING AND REPAIR WORK ON THE ACTUATOR MOTORS 156

17.1 General 156

17.2 Checking the actuator motors 156

17.2.1 Visual inspection of the plug contacts: 156

17.2.2 Continuity check: 156

17.2.3 Performance test: 157

17.3 Replacing the actuator motors for the legrests 158

17.3.1 Disassembly 158

17.3.2 Reassembly 158

17.4 Replacing the seat adjustment actuator motor (without lifter module) 159

17.4.1 Disassembly 159

17.4.2 Reassembly 159

17.5 Replacement of seat adjustment (with lifter module) 160

17.5.1 Disassembly (Twister) 160

17.5.2 Reassembly (Twister) 160

17.5.3 Disassembly (Twister Junior) 160

17.5.4 Reassembly (Twister Junior) 160

17.6 Replacing actuator of automatic seat back adjustment or support tube for

manual seat back adjustment. 161

17.6.1 Disassembly 161

17.6.2 161

18 TESTING THE DRIVING ELECTRONICS 162

18.1 Overview of the electronic module and cable 162

18.2 Testing joystick boxes 164

18.2.1 Check power supply to joystick box 164

18.3 - Check power module. 166

18.3.1 Status display 166

18.3.2 Check power supply to power module. 167

Remove the battery cable plug from the power module. 167

Twister / Twister Junior Service Manual

Issued: 21.01.02 Page 17

18.4 Checking lighting modules or combined lighting / actuator module 168

18.4.1 Status display 168

18.4.2 Preparations for testing 168

18.4.3 Check the power supply from the power module to the lighting module 24V Æ 12V,

or to the lighting / actuator module 169

18.5 Testing additional power supply of lighting module 24V Æ 12V (TÜV version) 170

18.5.1 Preparations for testing 170

18.5.2 Test 170

18.6 Check the voltage converter for the Recaro seat 171

18.6.1 Preparations for testing 171

18.6.2 Checking voltage at Recaro seat voltage converter 171

19 TESTING THE DRIVING ELECTRONICS 172

19.1 Standard joystick box 172

19.1.1 Disassembly of the standard joystick box 173

19.1.2 Reassembly of the standard joystick box 173

19.1.3 Disassembly joystick box support tube and joystick box attachment 173

19.1.4 Reassembly joystick box stay bar and joystick box attachment 173

19.1.5 Disassembly of the joystick box holder (hinged) 174

19.1.6 Reassembly of the joystick box holder (hinged) 174

19.1.7 Disassembly of the joystick box holder for attendant 174

19.1.8 Reassembly of the joystick box holder for attendant 174

19.2 Joystick box for attendant 175

19.2.1 Disassembly of joystick box 176

19.2.2 Reassembly of the joystick box 176

19.2.3 Disassembly of the joystick box holder 176

19.2.4 Reassembly of joystick box holder 176

19.3 Table control / central control 177

19.3.1 disassembly of joystick box 178

19.3.2 Reassembly of joystick box 178

19.3.3 Disassembly of central control support 178

19.3.4 Reassembly of central control support 178

19.3.5 Disassembly of table plate and support 179

19.3.6 Reassembly of table plate and support 179

19.4 Chin control, manually / electrically swivelling in horizontal direction 180

19.4.1 Disassembly of control 182

19.4.2 Reassembling the control 182

19.4.3 Disassembly of the motor 183

19.4.4 Reassembly of the motor 183

19.4.5 Disassembly of the switchbox 183

19.4.6 Reassembly of the switchbox 183

19.4.7 Disassembly of support, complete 183

19.4.8 Reassembly of support, complete 183

19.5 Chin control, electrically swivelling in vertical direction 184

19.5.1 Disassembly of control 185

19.5.2 Reassembling the control 185

19.5.3 Disassembly of the motor 185

19.5.4 Reassembly of the motor 185

19.5.5 Disassembly of the switchbox 186

19.5.6 Reassembly of the switchbox 186

19.5.7 Disassembly of support, complete 186

19.5.8 Reassembly of support, complete 186

Twister/Twister Junior Service Manual

Page 18 Issued:21.01.02

19.6 Power module 187

19.6.1 Preparation 187

19.6.2 Removal of power module 187

19.6.3 Fitting the power module 187

19.7 Lighting and actuator module (Clam), lighting module and lighting module with

voltage converter 188

19.7.1 General 188

19.7.2 Removal of module 189

19.7.3 Refitting the module 189

20 CHECKING CABLES, PLUGS AND SENSORS 190

20.1 General 190

20.2 Test procedure 190

20.2.1 Checking plugs and cables 190

20.2.2 Checking the sensors 191

21 WHEELCHAIR PROGRAMMING 192

21.1 General 192

21.2 Programming on the PC 193

21.3 Programming with the programming device 194

22 STORING THE WHEELCHAIR 195

Twister / Twister Junior Service Manual

Issued: 21.01.02 Page 19

1 Safety and assembly instructions

The safety instructions are intended as prevention of accidents at work and it is imperative that

they are observed.

1.1 Before any inspection or repair work

• Read and observe this repair manual and the associated operating manual.

• Observe the minimum requirements for carrying out the work. See the chapter entitled

“General

guidelines”.

Caution:

• Please note the high weight of some components. This applies especially to removal

of drive units and batteries.

• The wheelchair must be switched off before removal of voltage-carrying components.

To do this remove the battery.

• When making measurements on voltage-carrying components, avoid short-circuiting

the contacts.

Danger of fire and combustion !

• Use only undamaged tools in good condition.

Twister/Twister Junior Service Manual

Page 20 Issued:21.01.02

1.2 During dismantling/reassembly

• Mark all current settings for the wheelchair (seat, armrests, backrest etc.), and the cable

connecting plugs associated, before any removals. This makes reassembly easier.

Caution:

• Prop up the lifted wheelchair with appropriate supports before starting the

disassembly or assembly.

• Never use "normal" nuts instead of self-locking nuts.

• Never re-use self locking nuts, always replace with new.

• Always use correctly dimensioned washers or spacers.

Note:

• All plugs are fitted with mechanical safety devices which prevent release of

the connecting plugs during operation.

• To release the connecting plugs the safety devices must be pressed in.

• When reassembling ensure that these safety devices are correctly engaged.

• If the seating system is tipped forward for maintenance and service work,

it must be supported as necessary.

1.3 Before operation / after completion of work:

Caution:

• Check all fixings for tight fit.

• Check all parts for correct interlocking.

• Only operate wheelchair with correct tyre pressure (2.5 bar).

• As a last check always

carry out a trial run.

Twister / Twister Junior Service Manual

Issued: 21.01.02 Page 21

2 Tool list

You will need a standard tool set with at least the following:

• Open-end and ring spanner SW 6, 7, 8, 10, 11, 12, 13, 17, 19 (mm)

• Allen key 2.5, 3, 4, 5, 6, 8, 10 (mm)

• torque wrench (commercial)

• socket spanner set

• Screwdriver TX 40

• slot-headed screwdrivers (various)

• Phillips screwdriver No. 1, 2, 3

• oblique pliers

• flat-nosed pliers

• circle pliers

• pointed pliers

• plumber's wrench

• cable lug pliers

• wooden or plastic hammer

• tyre repair kit (commercial)

• tyre pressure indicator

• valve removal tool

• wheel bearing puller

• Multimeter with probes and various cable clips

• jump leads

• soldering iron 30 W

• hot-melt glue gun

• front wheel hub puller (available from INVACARE Service)

• circlip pliers for Star lock caps (commercial, e.g. Tigtemeyer)

For setting up the ACS Control there is need of:

• programming device Item No.: 6 001 450

• Software package Item No.: P10 076

(including interface cable and dongle)

Twister/Twister Junior Service Manual

Page 22 Issued:21.01.02

3 Layout of modules, components and displays and controls

The following illustrations show the general arrangement of the wheelchair's subassemblies,

components and control elements. The designations correspond to the component designations

in the spare parts catalogue.

The vehicles are available in different types, comprising the following main subassemblies:

• Chassis

• Seating system

• Power supply

• Drive control

• Lighting system

Note:

Depending on the type of wheelchair, the main subassemblies are equipped with

different subassemblies (legrests, control elements, seats, etc.).

1. Seat cushion

2. Side panel

upholstery

3. Backrest upholstery

4. Armrest

5. Side panel

6. Rear wheel

7. Battery

8. Front wheel

9. Footplates

10.Legrest

11. Standard joystick

box

Standard "Twister" configuration,

front wheel drive, without lighting with standard seat attachments,

standard seat, standard backrest and 65°/73° legrests, without

headrests.

1

1

2

3

4

5

6

7

7

8

9

1

Twister / Twister Junior Service Manual

Issued: 21.01.02 Page 23

1. . Recaro seat

cushion

2. Side panel

upholstery

3. . Recaro backrest

upholstery

4. Armrest

5. Side panel

6. . Rear wheel,

complete

7. Batteries

8. . Front wheel,

complete

9. Footplates

10.Legrest, complete

11.Calf support

12.Lifter

13.. Motor for seat tilt

14.Rear lights

15.Headlights

16. Direction indicators

"Twister" configuration, side view

with Recaro seat, lifter(raised), front wheel drive, lighting system,

electrical. Backrest adjustment, electrical seat tilt, height and tiltadjustable footrests, swivelling joystick box and calf support without

headrests.

1

2

3

4

5

6

12

7

8

9

10

11

11

13

14

15

16

Twister/Twister Junior Service Manual

Page 24 Issued:21.01.02

1. Seat cushion

2. Backrest upholstery

3. Armrest

4. Rear wheel

5. Battery

6. Front wheel

7. Footplates

8. Legrest

9. Standard joystick

box

10. Calf support

"Twister" configuration, front view

with KAB seat, front wheel drive, manually adjustable backrest,

manually adjustable seat tilting, height and tilt-adjustable footrests,

standard joystick box, calf support without headrests.

1

2

5

6

7

8

9

1

3

4

Twister / Twister Junior Service Manual

Issued: 21.01.02 Page 25

1. Seat cushion

2. Lateral trunk

support

3. Armrest with

upholstery

4. Backrest trunk

supports

5. Backrest upholstery

6. Headrest

7. Armrest with joystick

box

8. Rear lights and

direction indicators

9. Headlights and

direction indicators

10. Rear wheel

11. Front wheel

12. Battery

13. Footplate

14. Calf strap

15. Legrest

"Twister Junior" configuration with Junior seating system, rear

wheel drive, adjustable backrest, seat tilt, height and lean-adjustable

footplate, standard joystick box, calf strap and headrest:

1

2

4

3

6

7

8

10

11

12

13

14

15

5

9

Twister/Twister Junior Service Manual

Page 26 Issued:21.01.02

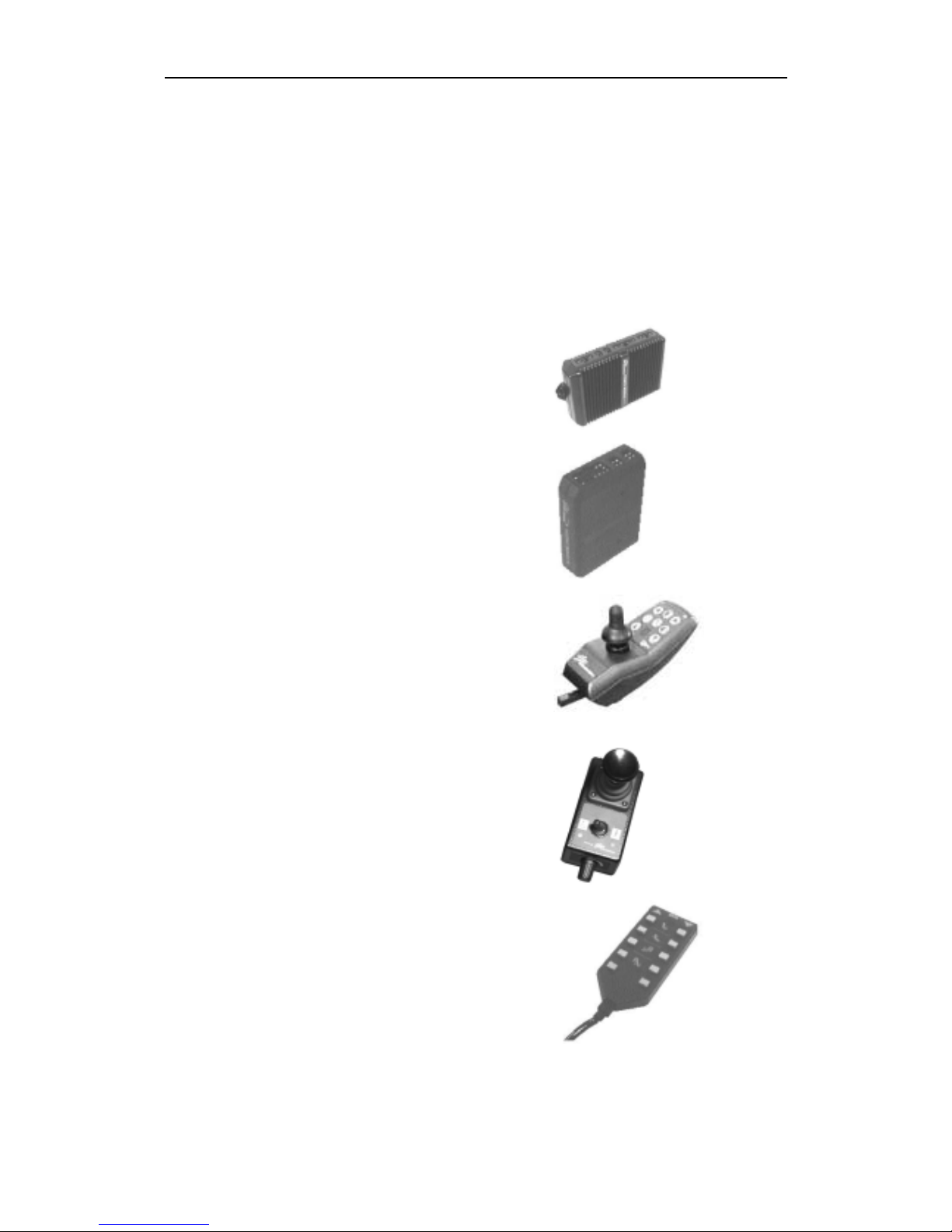

4 Electronic control components (ACS)

4.1 General

The wheelchair's electronic control ACS (Action Control System) is composed of individual

components (modules. According to type, the wheelchairs are equipped with different modules.

ACS Control module :

Module designation

(designation on module sticker)

Main module

(power module)

24 Volt lighting module lighting/actuator module

(combined lighting + actuator module)

Standard joystick box

(DX - REM 24)

joystick box for attendant

(DX - ACU 1AS)

Control unit for actuator motors

DX - ARC 5

Twister / Twister Junior Service Manual

Issued: 21.01.02 Page 27

Joystick box for table or central control

DX - REM 41 / REM 41 S

Chin control voltage converter

for Recaro seat

DX - ACC 1, or DC - DC converter

Standard joystick box for Twister Junior

(G - 80 - I)

Chin control and

switch joystick for Twister Junior

Apart from its controlling functions, the electronic control is in a position to perform the following

additional functions:

• Modules monitoring

• Actuator motor monitoring

• Drive system monitoring

• Fault diagnosis

Note:

The control unit for the Recaro seat's adjustment functions is integrated in the seat and

is not a part of the ACS.

Twister/Twister Junior Service Manual

Page 28 Issued:21.01.02

4.2 Module connection cables

The module connection cables are called

BUS cables. They are designed as fourconductor cables. Two conductors serve the

power supply and two the transfer of data.

Cable allocation

Power supply = black ground cable

red positive cable

Data transfer = yellow cable

(CAN high)

purple cable

(CAN low)

4.3 Sensors

The sensor unit consists of the sensor and a

magnet. If the magnet is closer than 1.5 cm

to the sensor tip, no electrical energy can

flow through the sensor.

In a vehicle with lifter, information is passed

using the sensor unit to the lifter positioning

control and the seat tilting.

4.4 Status displays

Status displays are LEDs that point to errors in the

wheelchair's electrical installation by means of blinking.

The following joystick boxes have a status display:

• joystick box (standard)

• chin control

• table and central control

The ON/OFF LED's are designed as status displays. The

causes of trouble are displayed by a blinking interval (blinking

code) of these LED's.

The remaining modules are also equipped with status

displays. A blinking of these displays points to a module

error.

Table central control

BUS cable

BUS

Sensor unit

Magnet Sensor

Twister / Twister Junior Service Manual

Issued: 21.01.02 Page 29

Note:

The ACS is equipped with an error memory, which can be evaluated by means of a

commercially available PC. Additionally required hardware and software can be

obtained from INVACARE Deutschland GmbH under Item No.: P10 076.

Chin control

Standard-joystick

Standard-joystick

box

Joystick box for attendant

Twister/Twister Junior Service Manual

Page 30 Issued:21.01.02

5 Module composition

The composition of modules depends on the type of wheelchair. The basic equipment consists

of the power module with its joystick box.

The joystick box can be used for any available module that is not older than the original joystick

box.

5.1 Wheelchair fittings: without lighting system, without actuators

Modules:

• Main module (power

module)

• Joystick box

Cables:

• BUS cable to joystick

box

• Battery cable

tojoystick box

Battery cable

Main

Loading...

Loading...