Invacare Dragon, Tiger Service Manual

Invacare® Dragon

Invacare® Tiger

SERVICE INSTRUCTIONS

These instructions contain information on:

Inspection work

Repair work

Issue: 21/04/10

Mobitec Mobilitätshilfen GmbH

Herzog Odilostrasse 101

A-5310 Mondsee

Austria

: +43 6232 55 35 0

Fax: +43 6232 55 35 4

@: office@mobitec-austria.com

@: austria@invacare.com

WWW: www.mobitec-austria.com

Invacare® n.v.

Autobaan 22

B-8210 Loppem (Brugge)

Belgium

: +32 (0)50 83 10 10

Fax: +32 (0)50 83 10 11

@: belgium@invacare.com

WWW: www.invacare.be

Mobitec Rehab AG

Benkenstraße 260

CH-4108 Witterswil

Switzerland

: +41 (0)61 48 77 08 0

Fax: +41 (0)61 48 77 08 1

@: office@mobitec-rehab.ch

@: switzerland@invacare.com

WWW: www.mobitec-rehab.ch

Invacare Aquatec

Alemannenstraße 10

88316 Isny

Deutschland

+49 (0)75 62 7 00 0

Fax +49 (0)75 62 7 00 66

@: info@invacare-aquatec.com

WWW: www.invacare-aquatec.de

Invacare® A/S

Sdr. Ringvej 37

DK-2605 Brøndby

Danmark

(Kundeservice): +45 (0)36 90 00 00

Fax (Kundeservice): +45 (0)36 90 00 01

@: denmark@invacare.com

WWW: www.invacare.dk

Invacare® SA

c/ Areny, s/n

Polígon Industrial de Celrà

E-17460 Celrà (Girona)

ESPAÑA

: +34 (0)972 49 32 00

Fax: +34 (0)972 49 32 20

@: contactsp@invacare.com

WWW: www.invacare.es

Invacare® Poirier SAS

Route de St Roch

F-37230 Fondettes

France

: +33 (0)247 62 64 66

Fax: +33 (0)247 42 12 24

@: contactfr@invacare.com

WWW: www.invacare.fr

Invacare® Ltd

Pencoed Technology Park

Pencoed

Bridgend CF35 5HZ

United Kingdom

(Customer Service): +44 (0)1656 776 222

Fax (Customer Service): +44 (0)1656 776 220

@: uk@invacare.com

@: eire@invacare.com

WWW: www.invacare.co.uk

2

Invacare Mecc San s.r.l.

Via Dei Pini, 62

I - 36016 Thiene (VI)

ITALIA

: +39 0445 38 00 59

Fax: +39 0445 38 00 34

@: italia@invacare.com

WWW: www.invacare.it

Invacare Ireland Ltd.

Unit 5 Seatown Business Campus

Seatown Rd, Swords

County Dublin

Ireland

: +353 18 10 70 84

Fax: +353 18 10 70 85

@: eire@invacare.com

WWW: www.invacare.ie

Invacare® AS

Grensesvingen 9

Postboks 6230

Etterstad

N-0603 Oslo

Norge

(Kundeservice): +47 (0)22 57 95 00

Fax (Kundeservice): +47 (0)22 57 95 01

@: norway@invacare.com

WWW: www.invacare.no

Invacare® B.V.

Celsiusstraat 46

NL-6716 BZ Ede

Nederland

: +31 (0)318 69 57 57

Fax: +31 (0)318 69 57 58

@: nederland@invacare.com

WWW: www.invacare.nl

Invacare Portugal, Lda

Rua Estrada Velha, 949

P-4465-784 Leça do Balio

Portugal

: +351 225 1059 46

: +351 225 1059 47

Fax: +351 225 1057 39

@: portugal@invacare.com

WWW: www.invacare.pt

3

Återförsäljare:

Invacare® AB

Fagerstagatan 9

S-163 91 Spånga

Sverige

Tillverkare:

Invacare® Deutschland GmbH

Kleiststraße 49

D-32457 Porta Westfalica

Deutschland

(Kundtjänst): +46 (0)8 761 70 90

Fax (Kundtjänst): +46 (0)8 761 81 08

@: sweden@invacare.com

@: finland@invacare.com

WWW: www.invacare.se

MÖLNDAL

: +46 (0)31 86 36 00

Fax: +46 (0)31 86 36 06

@: ginvacare@invacare.com

LANDSKRONA

: +46 (0)418 285 40

Fax: +46 (0)418 180 89

@: linvacare@invacare.com

OSKARSHAMN

: +46 (0)491 101 40

Fax: +46 (0)491 101 80

@: oinvacare@invacare.com

4

Table of Contents

Chapter Page

TABLE OF CONTENTS 5

1 INTRODUCTION 7

1.1 General information 7

1.2 Notes on transport 7

1.3 Definition and representation of information and safety information in this manual 8

1.4 Hazard symbols and symbols used 9

1.5 Images in this manual 10

2 SAFETY AND FITTING INSTRUCTIONS 11

2.1 Before any inspection or repair work 11

2.2 Personal safety equipment 11

2.3 General safety information and information about fitting / removal 11

3 TIGHTENING TORQUES 13

4 ARRANGEMENT OF THE ASSEMBLY GROUPS AND COMPONENTS 14

5 SERVICE PLAN (1X ANNUALLY) 15

6 OPERATIONAL FAULTS 17

6.1 Operational faults on a wheelchair fitted with Shark electronics 17

6.1.1 Diagnosis of actuation disorders 17

6.1.2 Shark error codes and diagnostic codes 19

6.2 Troubleshooting the Tornado with ACS 21

6.2.1 Diagnosing driving faults 21

6.2.2 Diagnosing problems with electric actuators 23

6.2.3 REM24 Error Codes and Diagnostic Codes 24

7 REPAIR WORK 26

7.1 General warning information on installation work 26

7.2 Replacing the motor 26

5

7.3 Replacing the Shark Electronics 31

7.4 Updating the driving program 33

7.5 Changing the batteries 34

7.5.1 Removing the batteries 35

7.5.2 How to handle damaged batteries correctly 36

7.6 Checking and replacing the main fuse 37

7.7 Checking the cables 39

7.8 Replacing the Shark Remote 41

7.9 Replacing the ACS Remote 43

7.10 Replacing the steering head bearings on the steering wheels 45

7.11 Repairing a flat tyre 47

7.11.1 Repairing the flat tyre (pneumatic tyre equipment type 12½ x 2¼") 47

7.11.2 Repairing a flat tyre (pneumatic tyre equipment type 220/120 x 50) 48

7.12 Replacing a drive wheel 50

7.13 Adjusting the seat angle/seat height 51

7.13.1 Adjustment tables 53

7.14 Replacing the safety belt 56

7.15 Testing an actuator motor 56

6

1 Introduction

1.1 General information

• Service and maintenance work must be carried out taking this service manual into account.

• It is imperative that you observe safety information.

• Information about operation or about general maintenance and care work on the mobility aid

should be taken from the operating manual.

• You can find information about ordering spare parts in the spare parts catalogue.

• Only use original Invacare® spare parts. The guarantee will become invalid if other spare

parts are used!

• We reserve the right to make any alterations on the grounds of technical improvements.

• The mobility aid may only be maintained and overhauled by qualified personnel.

• The minimum requirement for service technicians is suitable training, such as in the cycle or

orthopaedic mechanics fields, or sufficiently long-term job experience.

- Experience in the use of electrical measuring equipment (multimeters) is also a requirement.

- Special Invacare® training is recommended.

• Alterations to the mobility aid which occur as a result of incorrectly or improperly executed

maintenance or overhaul work lead to the exclusion of all liability on the side of INVACARE.

• If you have any problems or questions please contact Invacare® Service.

1.2 Notes on transport

• If the mobility aid has to be shipped back to the manufacturer for major repairs, you should

always use the original packaging for transport.

• Please attach a precise description of the fault.

7

1.3 Definition and representation of information and safety

information in this manual

Different types of information and signal words are used throughout this manual.

HAZARD!

The signal word "HAZARD!" refers to immediate hazards.

• The following lines in italics refer to actions which serve to avoid such hazards.

WARNING!

The signal word "WARNING!" refers to possibly-occurring hazards which can lead to

death or serious injuries if they are not avoided.

• The following lines in italics refer to actions which serve to avoid such hazards.

ATTENTION!

The signal word "ATTENTION!" refers to possibly-occurring hazards which can lead to

minor injuries and/or material damage if they are not avoided.

• The following lines in italics refer to actions which serve to avoid such hazards.

CAUTION!

The signal word "CAUTION!" refers to hazards which could lead to material damage if

they are not avoided.

• The following lines in italics refer to actions which serve to avoid such hazards.

Note

The signal word "Note" is used to denote general information which simplifies the handling of

your product and refers to special functions.

8

1.4 Hazard symbols and symbols used

Different types of hazard symbols and symbols are used throughout this manual.

General hazards

This symbol warns you of general hazards!

• Always follow the instructions to avoid injury to the user or damage to the product!

BURN HAZARD!

This symbol warns you of the danger of chemical burns, for example due to the discharge

of battery acids!

• Always follow the instructions to avoid injury to the user or damage to the product!

DANGER OF CRUSHING!

This symbol warns you of crushing hazards due to inattentive working with heavy

components.

• Always follow the instructions to avoid injury to the user or damage to the product!

EXPLOSION HAZARD!

This symbol warns you of an explosion hazard, which can be caused by excessive tyre

pressure in a pneumatic tyre.

• Always follow the instructions to avoid injury to the user or damage to the product!

Wear safety shoes

The symbol refers to the requirement for wearing safety shoes.

• Wear standardised safety shoes during all work.

Wear eye protection

This symbol refers to the requirement for wearing eye protection, for example when

working with batteries.

• Wear eye protection when this symbol is shown.

Wear safety gloves

This symbol refers to the requirement for wearing safety gloves, for example when

working with batteries.

• Wear safety gloves when this symbol is shown.

Note

This symbol identifies general information which is intended to simplify working with your product

and which refers to special functions.

Requirements:

• This symbol identifies a list of various tools, components and items which you will need in

order to carry out certain work. Please do not attempt to carry out the work if you do not

have the listed tools available.

Always dispose used or damaged batteries correctly

The symbol refers to information for the correct disposal of used or damaged batteries.

9

1.5 Images in this manual

The detailed images in this manual are given digits to identify various components. Component

numbers in text and operational instructions always relate to the image directly above.

10

2 Safety and fitting instructions

These safety instructions are intended to prevent accidents at work, and it is imperative that they

are observed.

2.1 Before any inspection or repair work

• Read and observe this repair manual and the associated operating manual!

• Observe the minimum requirements for carrying out the work (see chapter entitled „General

information)!

2.2 Personal safety equipment

Safety shoes

The mobility device, and some of its components, are very heavy. These parts can result

in injuries to the feet if they are allowed to drop.

• Wear standardised safety shoes during all work.

Eye protection

It is possible that battery acid can be discharged when working on defective batteries or

when handling batteries improperly.

• Always wear eye protection when working on any defective or possibly defective batteries.

Safety gloves

It is possible that battery acid can be discharged when working on defective batteries or

when handling batteries improperly.

• Always wear acid-proof safety gloves when working on any defective or possibly defective

batteries.

2.3 General safety information and information about fitting / removal

WARNING: Danger of crushing!

Various components such as the drive unit, batteries, seat etc are very heavy. This results

in injury hazards to your hands!

• Please note the high weight of some components! This applies especially to the removal of

drive units, batteries and the seat.

WARNING!

Injury hazard if the vehicle starts moving unintentionally during repair work!

• Switch the power supply off (ON/OFF key)!

• Engage the drive!

• Before raising the vehicle, secure the wheels by blocking them with wedges!

ATTENTION!

Fire and burn hazard due to electrical short-circuit!

• The mobility device must be completely switched off before removal of voltage-carrying

components! To do this, remove the batteries.

• Avoid short-circuiting the contacts when carrying out measurements on voltage-carrying

components!

11

ATTENTION!

Injury hazard and danger of damage to vehicle due to improper or incomplete

maintenance work!

• Use only undamaged tools in good condition.

• Some moving parts are mounted in sockets with PTFE coating (Teflon™). Never grease

these sockets!

• Never use "normal" nuts instead of self-locking nuts.

• Always use correctly-dimensioned washers and spacers

• When reassembling, always replace any cable ties which were cut during dismantling.

• After completing your work / before renewed start-up of the mobility device, check all

connections for tight fitting.

• After completing your work / before renewed start-up of the mobility device, check all parts for

correct locking.

• Only operate the vehicle with the approved tyre pressures (see technical data).

• Check all electrical components for correct function. Please note that incorrect polarity can

result in damage to the electronics.

• Always carry out a trial run at the end of your work.

Note

Mark all current settings for the mobility aid (seat, armrests, backrest etc.), and the associated

cable connecting plugs, before dismantling. This makes reassembly easier.

All plugs are fitted with mechanical safety devices which prevent release of the connecting plugs

during operation. To release the connecting plugs the safety devices must be pressed in. When

reassembling ensure that these safety devices are correctly engaged.

WARNING!

Any changes to the drive program can affect the driving characteristics and the tipping

stability of the vehicle!

• Changes to the drive program may only be carried out by trained Invacare® specialist

dealers!

• Invacare® supplies all mobility aids with a standard drive program ex-works. Invacare® can

only give a warranty for safe vehicle driving behaviour - especially tipping stability - for this

standard drive program!

12

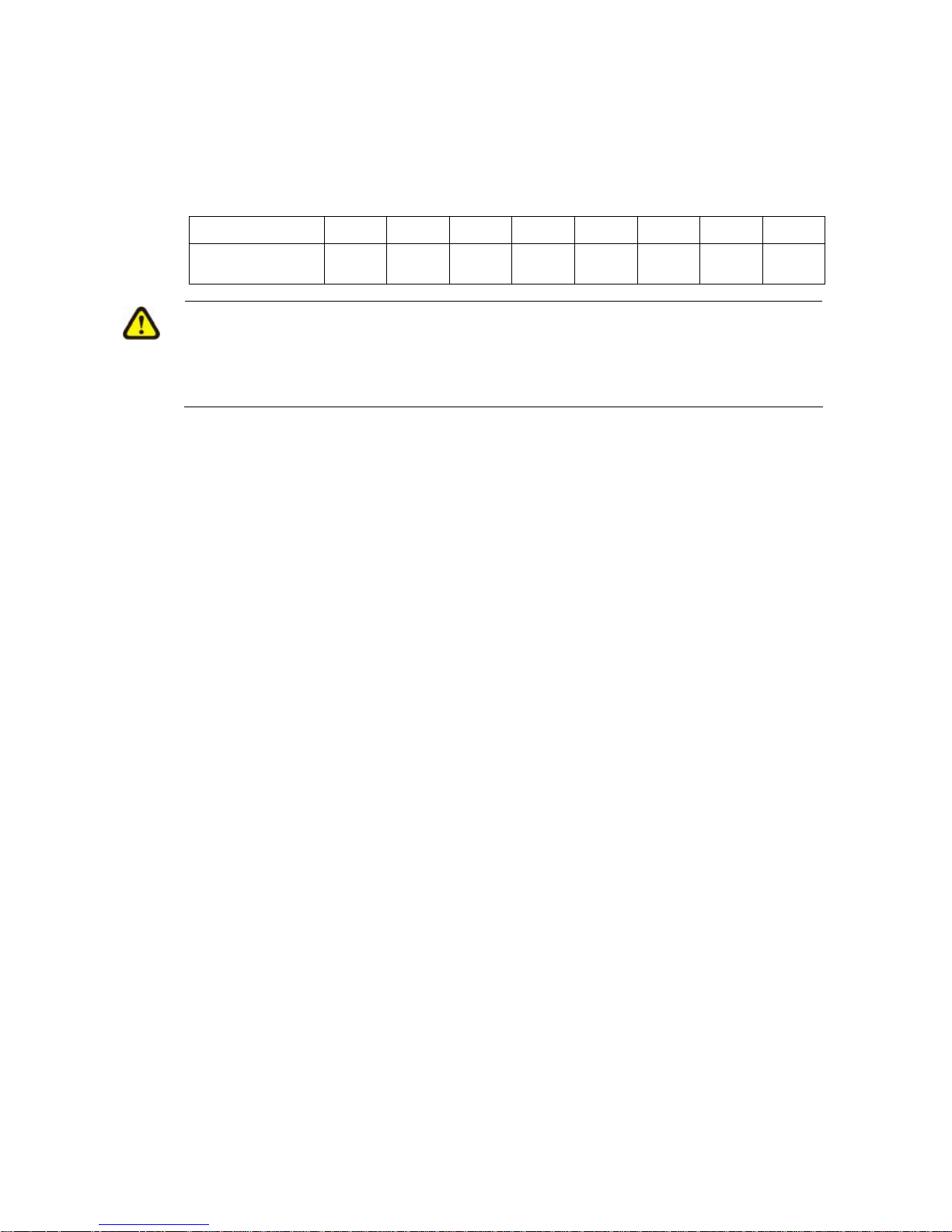

3 Tightening torques

The tightening torques stated in the following list are based on the thread diameter for the nuts and

bolts for which no specific values have been determined. All values assume dry and de-greased

threads.

Thread

M4 M5 M6 M8 M10 M12 M14 M16

Tightening torque

in Nm ±10%

3 Nm 6 Nm 10 Nm 25 Nm 49 Nm 80 Nm 120 Nm 180 Nm

CAUTION!

Damage can be caused to the mobility device due to improperly tightened screws, nuts or

plastic connections.

• Always tighten screws, nuts etc to the stated tightening torque.

• Only tighten screws or nuts which are not listed here fingertight.

13

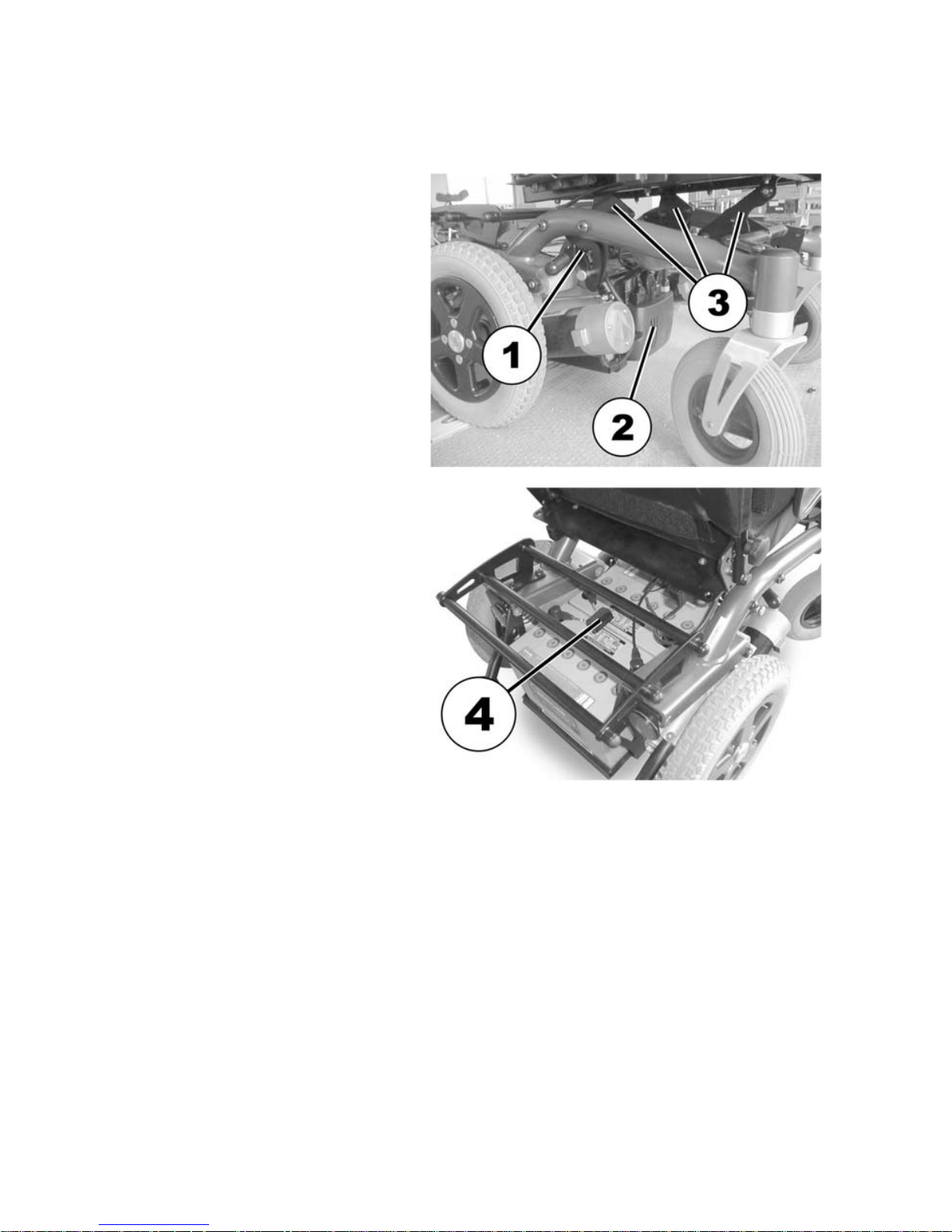

4 Arrangement of the assembly groups and components

Under the seat:

1) Decoupling mechanism

2) Power module

3) Perforated plates for adjusting

the seat height and seat angle

Under the battery cover

4) Main battery fuse

14

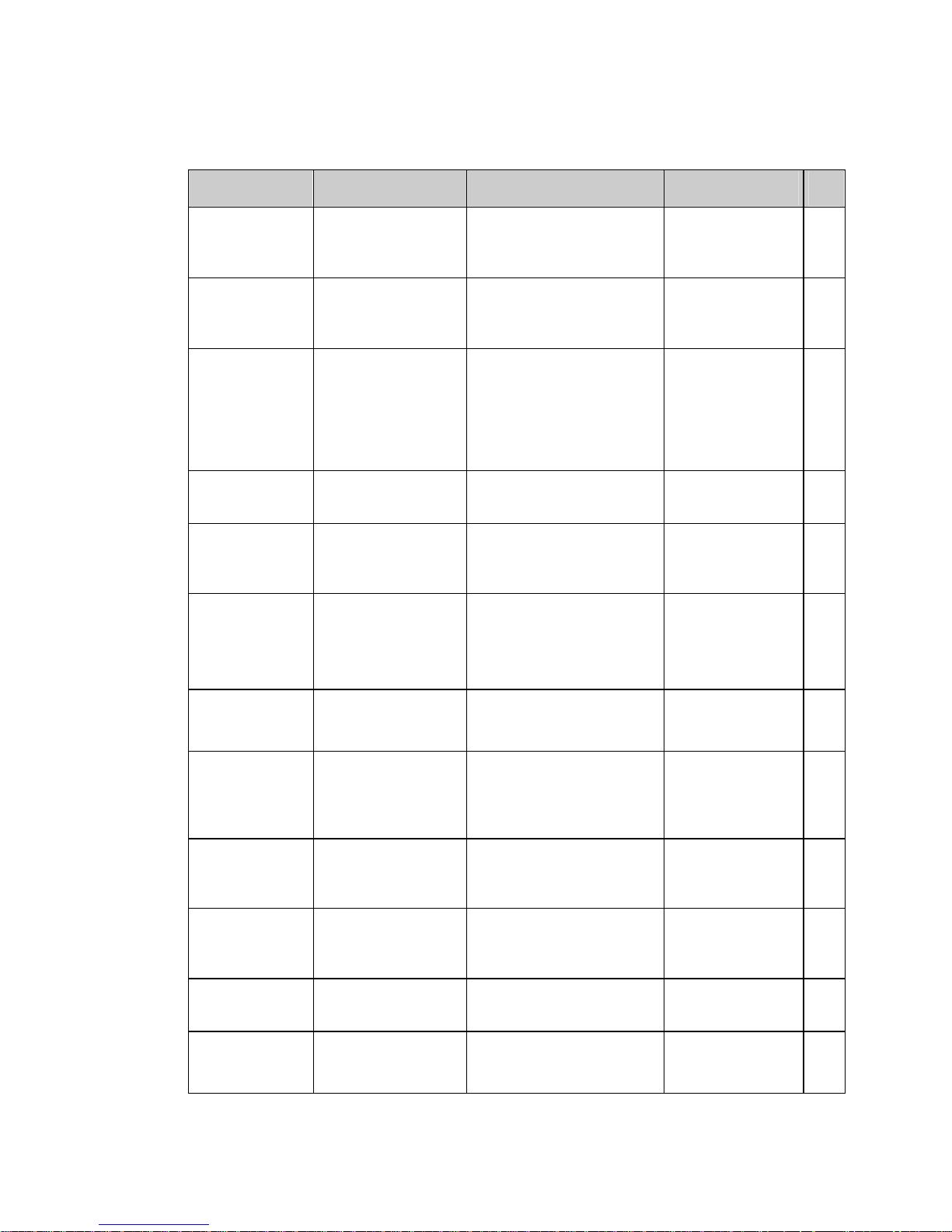

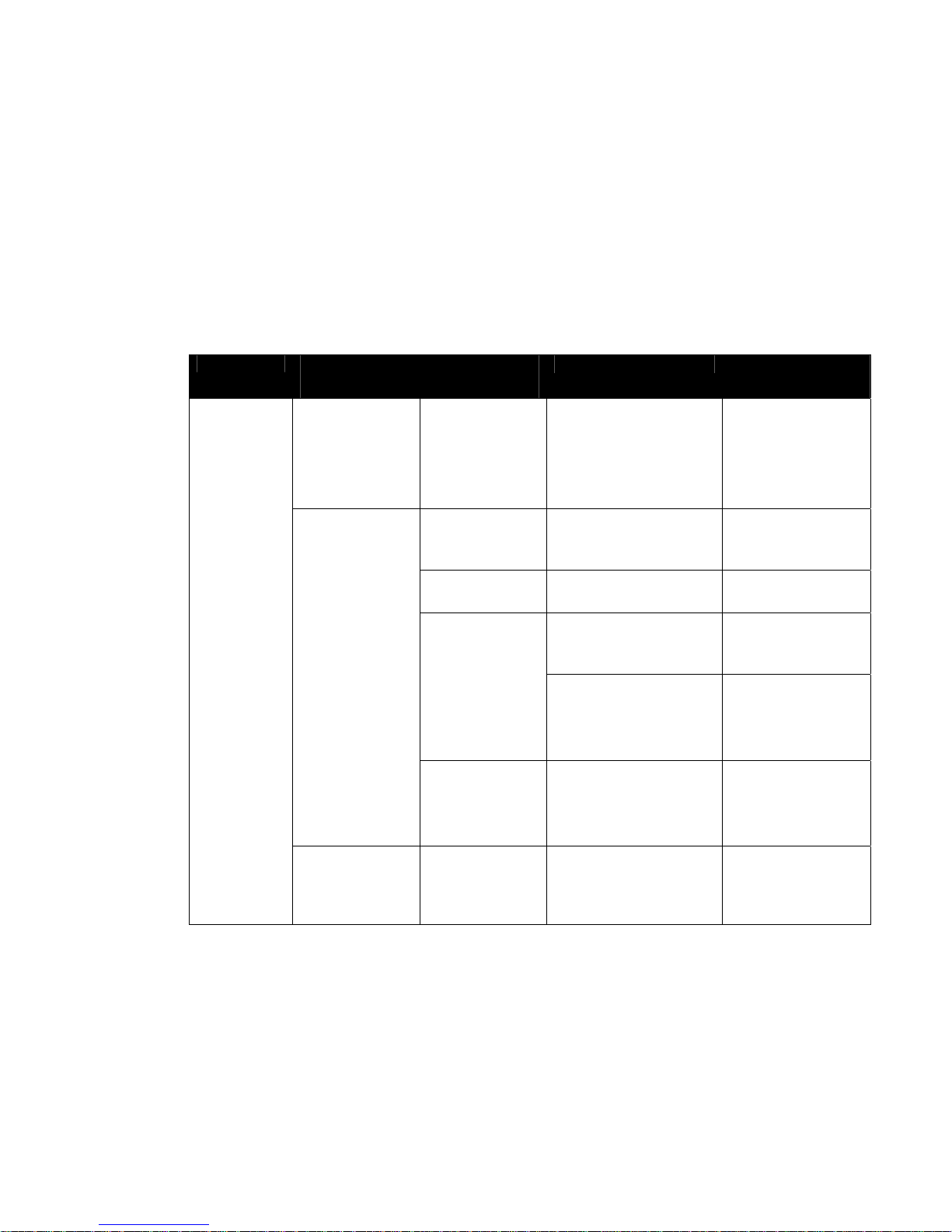

5 Service plan (1x annually)

Component Check Action Notes

Armrests and

side panels

• Armrest damage

and fastening

• Side panel

damage and fixing

• Tighten screws, replace

padding if damaged

• Tighten screws, replace

side panels if damaged

Seat unit / seat

angle

adjustment

• Cushion

• Check seat angle

adjustment

• Replace covers /

upholstery if damaged

• Replace parts if

damaged

Backrest unit

mechanical

Backrest unit

electrical (if

installed)

• Damage and

seams

• Fixing

• Check cabling

• Check function

• Replace parts if

damaged

• Tighten screws

• Replace cable or motor if

necessary

Frame (chassis)

/ battery box

• Check fixings,

welded seams and

battery box

• Tighten screws, replace

components

Wheel

suspension and

wheels

• Check drive

wheels for tight fit

and side play

• Adjust, replace wheel

hubs

See "

Replacing a

drive wheel

" on

page

50

• Check steering

wheels for tight fit,

float, side play and

correct torque (15

Nm +/- 1.5 Nm)

• Replace wheels, wheel

fork or wheel bearings

See "Replacing

the steering head

bearings on the

steering wheels

"

on page

45

• Pneumatic tyres (if

available)

• Repair or replace if

damaged

See "Repairing a

flat tyre

" on page

47

Drive units,

disengager

• Check functions in

drive and push

modes

• Check disengager

• Replace motor if

necessary

• Tighten screws / nuts,

adjust or replace if

necessary

Legrests

• Check welded

seams,

interlocking,

screws, footplates

• Tighten, replace if

necessary

Electrical

footrests (if

installed)

• Check cabling

• Check contacts

• Check functions

• Replace cable if

necessary

Lighting (if

installed)

• Check cabling

• Check function

• Replace bulbs or cables

if necessary

Batteries

• Check batteries

for damage

• Replace batteries if

necessary

See "Changing the

batteries

" on page

34

15

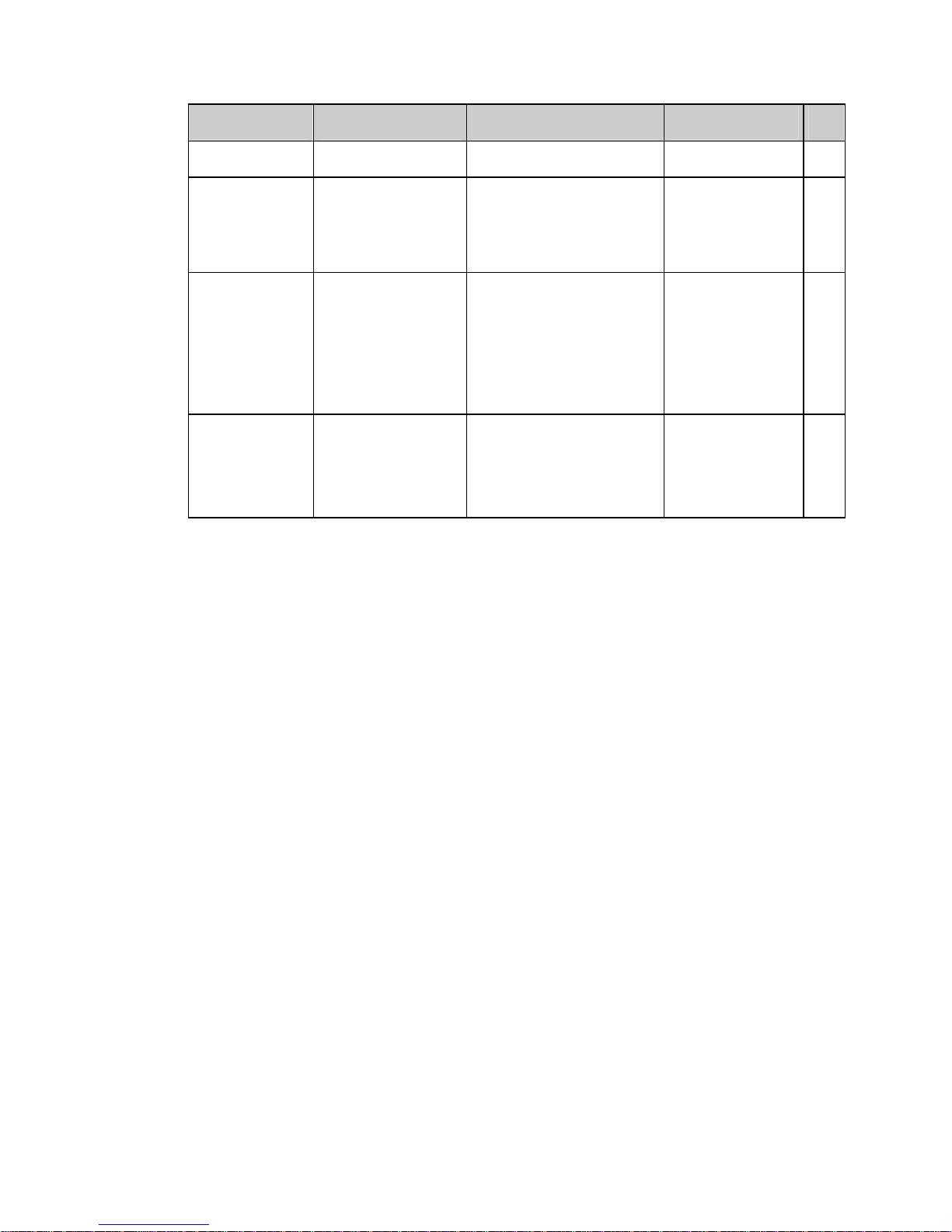

Component Check Action Notes

• Check battery

charge

• Charge batteries

See User Manual

• Check contacts

and terminals for

corrosion

• Clean contacts and

terminals

See "Changing the

batteries

" on page

34 for safety

information when

handling batteries

Remote /

electronics

• Remote,

status display

blinking

• Fixing

• Cable, connecting

plug

• Joystick function

• Power supply

• Evaluate flash code

• Tighten, replace

• Replace

• Replace joystick

• Replace cable, connector

plug or console

Driving

Programme

• Check the

programme

version of the

driving electronics.

Is there a newer

version available?

• Update the software.

See "Updating the

driving program

"

on page

33

16

6 Operational Faults

6.1 Operational faults on a wheelchair fitted with Shark electronics

Please proceed as follows in the event of operational faults:

• First of all analyse the possible cause of the disorder on the basis of the following tables.

• Check the status display on the remote. Analyse the flashing error code.

• Carry out the necessary checks and repairs as recommended in the following table.

6.1.1 Diagnosis of actuation disorders

PROBLEM

OTHER

SYMPTOMS

POSSIBLE

CAUSE

• SOLUTION

DOCUMENTATION

Wheelchair

will not start

up

Status display on

the remote

illuminated as

normal and does

not indicate a

disorder code

Actuation motors

may be

disengaged

• Clutch in actuation

motors

See operating

instructions

Status display on

the remote is not

illuminated

Batteries may be

faulty

• Replace the batteries

See "

Changing the

batteries

" on page

34

Batteries may be

almost empty

• Charge batteries

See User Manual

Power supply to

the remote may

be interrupted

• Check the main fuse

See "

Checking and

replacing the main

fuse

" on page 37

• Check the cable

between the

modules for any

loose connections or

damage

Siehe "

Checking

the cables

" on

page

39

Remote may be

faulty

• Change the remote

on the wheelchair to

be able to exclude

the remote being the

cause of the fault.

See "

Replacing the

Shark Remote

" on

page

41

Status display on

remote flashing

Various causes

• Analyse error code

See "

Shark error

codes and

diagnostic codes

"

on page

19

17

Loading...

Loading...