Invacare TDX-SP, TDX-SP N Service Manual

Invacare ® TDX-SP / TDX-SP N

SERVICE MANUAL

Edition: 01.02.2013

SERVICE MANUAL

These instructions contain information about:

Testing work

Repair Instructions

This manual is part of the instructions for use.

Service addresses

Invacare

®

- TDX-SP / TDX-SP N

Invacare Austria GmbH

Herzog Odilostrasse 101

A-5310 Mondsee

Austria

Invacare n.v.

Autobaan 22

B-8210 Loppem (Brugge)

Belgium

Invacare AG

Benkenstraße 260

CH-4108 Witterswil

Switzerland

Invacare Aquatec GmbH

Alemannenstraße 10

88316 Isny

Deutschland

Invacare A/S

Sdr. Ringvej 37

DK-2605 Brøndby

Danmark

(: +43 6232 5 53 50

Fax: +43 6232 5 53 54

@: info@invacare-austria.com

WWW: www.invacare.at

(: +32 (0)50 83 10 10

Fax: +32 (0)50 83 10 11

@: belgium@invacare.com

WWW: www.invacare.be

(: +41 (0)61487 70 80

Fax: +41 (0)61487 70 81

@: switzerland@invacare.com

WWW: www.invacare.ch

( +49 (0)7562 70 00

Fax +49 (0)7562 7 00 66

@: info@invacare-aquatec.com

WWW: www.invacare-aquatec.de

( (Kundeservice): +45 (0)36 90 00 00

Fax (Kundeservice): +45 (0)36 90 00 01

@: denmark@invacare.com

WWW: www.invacare.dk

Invacare® SA

c/ Areny s/n

Polígon Industrial de Celrà

E-17460 Celrà (Girona)

ESPAÑA

Invacare® Poirier SAS

Route de St Roch

F-37230 Fondettes

France

Invacare® Ltd

Pencoed Technology Park

Pencoed

Bridgend CF35 5HZ

United Kingdom

Invacare Mecc San s.r.l .

Via dei Pini, 62

I - 36016 Thiene (VI)

Italia

2

(: +34 (0)972 49 32 00

Fax: +34 (0)972 49 32 20

@: contactsp@invacare.com

WWW: www.invacare.es

(: +33 (0)247 62 64 66

Fax: +33 (0)247 42 12 24

@: contactfr@invacare.com

WWW: www.invacare.fr

( (Customer services ): +44 (0)1656 77 62 22

Fax (Customer services): +44 (0)1656 77 62 20

@: uk@invacare.com

WWW: www.invacare.co.uk

(: +39 0445 38 00 59

Fax: +39 0445 38 00 34

@: italia@invacare.com

WWW: www.invacare.it

Invacare ® - TDX-SP / TDX-SP N

SERVICE MANUAL

Invacare Ireland Ltd.

Unit 5 Seatown Business Cam pus

Seatown Rd, Swords

County Dublin

Ireland

Invacare® AS

Grensesvingen 9

Postboks 6230

Etterstad

N-0603 Oslo

Norge

Invacare® B.V.

Celsiusstraat 46

NL-6716 BZ Ede

Nederland

Invacare Lda

Rua Estrada Velha, 949

P-4465-784 Leça do Balio

Portugal

(: +353 18 10 70 84

Fax: +353 18 10 70 85

@: ireland@invacare.com

WWW: www.invacare.ie

( (Kundeservice): +47 (0)22 57 95 00

Fax (Kundeservice): +47 (0)22 57 95 01

@: norway@invacare.com

@: island@invacare.com

WWW: www.invacare.no

(: +31 (0)318 69 57 57

Fax: +31 (0)318 69 57 58

@: nederland@invacare.com

@: csede@invacare.com

WWW: www.invacare.nl

(: +351 225 10 59 46

(: +351 225 10 59 47

Fax: +351 225 10 57 39

@: portugal@invacare.com

WWW: www.invacare.pt

Eastern

european

countries

Återförsäljare:

Invacare® AB

Fagerstagatan 9

S-163 91 Spånga

Sverige

Tillverkare:

Invacare® Deutschland GmbH

Kleiststraße 49

D-32457 Porta Westfal i ca

Deutschland

European Distributor

Organisation (EDO)

Kleiststraße 49

D-32457 Porta Westfal i ca

Deutschland

( (Kundtjänst): +46 (0)8 761 70 90

Fax (Kundtjänst): +46 (0)8 761 81 08

@: sweden@invacare.com

@: finland@invacare.com

WWW: www.invacare.se

MÖLNDAL

(: +46 (0)31 86 36 00

Fax: +46 (0)31 86 36 06

@: ginvacare@invacare.com

LANDSKRONA

(: +46 (0)418 2 85 40

Fax: +46 (0)418 1 80 89

@: linvacare@invacare.com

OSKARSHAMN

(: +46 (0)491 1 01 40

Fax: +46 (0)491 1 01 80

@: oinvacare@invacare.com

( +49 (0)5731 75 45 40

Fax +49 (0)5731 75 45 41

@: edo@invacare.com

WWW: www.invacare.de

3

SERVICE MANUAL

Invacare

®

- TDX-SP / TDX-SP N

Contents

Chapter Page

1 Introduction 7

1.1 General information .................................................................................................................. 7

1.2 Notes on transport .................................................................................................................... 7

1.3 Definition and representation of information and safety information in this manual ........ 8

1.4 Hazard symbols and symbols used ......................................................................................... 9

1.5 Images in this manual ............................................................................................................. 10

2 Safety and fitting instruct ions 11

2.1 Before any inspe ction or repair work .................................................................................... 11

2.2 Personal safety equipment ..................................................................................................... 11

2.3 General safety information and information about fitting / removal .................................. 11

3 Tightening torques 13

4 Layout of components and componentry 14

4.1 Overview ................................................................................................................................... 14

4.2 Electronic modules.................................................................................................................. 16

4.2.1 ACS 2 electronic module .............................................................................................. 18

4.2.2 ACS 2 PMA90L electronic module................................................................................ 18

4.2.3 Shark electronic module ............................................................................................... 18

4.2.3.1 Shark with DCI 12-pole ............................................................................................ 18

4.2.4 ACT actuator module .................................................................................................... 18

4.2.4.1 ACT 2 actuator module ............................................................................................ 19

4.2.4.2 ACT 4 actuator module ............................................................................................ 19

4.2.5 Lighting PCB ................................................................................................................. 19

5 Service plan (1x annually) 20

6 Operational f a ults 23

6.1 Drive fault diagnosis ............................................................................................................... 24

6.2 REM remotes: Error code s and diagnostic codes ............................................................... 28

6.3 Shark II remote: Error codes and diagnostic codes ............................................................ 30

6.4 Diagnosis of charging device faults ...................................................................................... 31

7 Test procedures 32

7.1 Testing the motor .................................................................................................................... 32

7.2 Testing the electro-mechanical parking brake ..................................................................... 33

8 Repair work 35

8.1 Covers without lifter ................................................................................................................ 35

8.1.1 Opening the front panel ................................................................................................ 35

8.1.2 Opening the rear cover panel ....................................................................................... 36

8.1.2.1 Rear cover without an operating hours counter ....................................................... 36

8.1.2.2 Rear cover with an operating hours counter ............................................................ 37

8.1.3 Opening the top cover panel ......................................................................................... 38

8.1.4 Replacing the splash guard .......................................................................................... 39

8.2 Electronic module.................................................................................................................... 40

8.2.1 Replacing the remote .................................................................................................... 40

8.2.2 Replacing the electronic module ................................................................................... 40

8.2.3 Replacing the G-Trac sensor ........................................................................................ 44

8.2.4 Replacing the operating hours counter / connecting cable ........................................... 45

8.2.5 Drive program selection after component replacement ................................................ 48

8.2.5.1 Profile selection with remote REM A or REM B ....................................................... 48

8.2.5.2 Profile selection with remote REM 550 .................................................................... 49

4

Invacare ® - TDX-SP / TDX-SP N

SERVICE MANUAL

Updating the driving program ................................................................................................ 50

8.3

8.4 Batteries, cables & battery charger ....................................................................................... 51

8.4.1 Making the batteries accessible .................................................................................... 51

8.4.2 Replacing batteries (Standard TDX SP) ....................................................................... 53

8.4.3 Replacing batteries / replacing battery cables (TDX-SP N) .......................................... 55

8.4.4 Correct handling of damaged batteries ......................................................................... 57

8.4.5 Checking and replacing the main fuse (Standard TDX-SP) ......................................... 58

8.4.6 Replacing the main fuse (TDX-SP N) ........................................................................... 59

8.4.7 Checking the cable ....................................................................................................... 60

8.4.8 Cable routing ................................................................................................................. 62

8.5 Battery carrier .......................................................................................................................... 63

8.6 Replacing the battery case ..................................................................................................... 64

8.7 Lighting unit ............................................................................................................................. 65

8.7.1 Replacing the front bulb ................................................................................................ 65

8.7.2 Replacing the front headlight complete ........................................................................ 66

8.7.3 Replacing the front bulbholder ...................................................................................... 68

8.7.4 Replacing the rear bulb ................................................................................................. 69

8.7.5 Replacing the rear light complete ................................................................................. 70

8.7.6 Replacing the rear bulbholder ....................................................................................... 71

8.8 Wheel forks front/rear ............................................................................................................. 72

8.8.1 Replacing the wheel fork............................................................................................... 72

8.8.2 Adjusting the wheel fork ................................................................................................ 74

8.8.3 Replacing the wheels on double-sided wheel forks ...................................................... 75

8.9 Drive wheels ............................................................................................................................. 76

8.9.1 Replacing the drive wheel ............................................................................................. 76

8.9.2 Replacing the tyre or inner tube .................................................................................... 77

8.9.2.1 Replacing pneumatic tyres ...................................................................................... 77

8.9.2.2 Replacing puncture-protected tyres ......................................................................... 79

8.9.2.3 Replacing puncture-proof tyres ................................................................................ 81

8.9.3 Replacing the drive wheel hub (Standard motor).......................................................... 82

8.9.4 Replacing the drive wheel hub (SSD motor) ................................................................. 83

8.10 Rear wheel suspension ........................................................................................................... 84

8.10.1 Removing the rear wheel suspension ........................................................................... 84

8.10.2 Removing the rear wheel suspension – alternative method ......................................... 86

8.10.3 Refitting the rear wheel suspension .............................................................................. 88

8.10.4 Refitting the rear wheel suspension – alternative method ............................................ 89

8.11 Rear springs ............................................................................................................................. 91

8.11.1 Removing the rear springs ............................................................................................ 91

8.11.2 Refitting the rear springs ............................................................................................... 93

8.12 Bottom walking beam ............................................................................................................. 95

8.13 Top walking beam ................................................................................................................... 96

8.13.1 Removing the top walking beam ................................................................................... 96

8.13.2 Refitting the top walking beam ...................................................................................... 98

8.14 Drive unit ................................................................................................................................ 100

8.14.1 Replacing the motor/transmission unit (Standard motor) ........................................... 100

8.14.2 Replacing the motor/transmission unit (SSD motor) .................................................. 102

8.14.3 Replacing or rotating the motor / gearbox unit sealing ring (SSD motor) ................... 104

8.14.4 Replacing the motor/transmission clutch (Standard Motor) ........................................ 106

8.14.5 Replacing the motor/transmission clutch (SSD Motor) ............................................... 108

8.14.6 Replacing the carbon brushes (SSD motor) ............................................................... 110

8.14.7 Replacing the carbon brushes (Standard motor) ........................................................ 112

8.15 Replacing the rubber bu m p er .............................................................................................. 114

8.16 Castor housing front ............................................................................................................. 115

8.17 Replacing tilt module / lifter module .................................................................................... 116

8.17.1 Replacing the tilt module (max. > 30°) (without a lifter) .............................................. 116

8.17.1.1 Replacing the tilt module microswitch.................................................................... 118

8.17.1.2 Replacing the tilt module angular sensor ............................................................... 120

8.17.2 Replacing the tilt module (max. < 30°) (without a lifter) .............................................. 121

8.17.3 Replacing the lifter / tilt module ................................................................................... 124

5

SERVICE MANUAL

Invacare

®

- TDX-SP / TDX-SP N

8.17.4 Replacing the tilt actuator ........................................................................................... 128

8.17.5 Replacing the lifter actuator ........................................................................................ 130

8.17.5.1 Method 1 - Removing the lifter actuator when the lifter is raised ........................... 130

8.17.5.2 Method 2 - Removing the lifter actuator when the lifter is lowered ........................ 132

8.18 Seat support ........................................................................................................................... 136

8.19 Centre-mounted legrest (e lectric & manual) ....................................................................... 138

8.19.1 Replacing the manually operated centre-mounted legrest ......................................... 138

8.19.2 Replacing the electrically operated centre-mounted legrest ....................................... 139

8.19.3 Replacing an electric legrest actuator ......................................................................... 141

8.19.4 Replacing the calf plate on the centre-mounted legrest (electric & manual) .............. 143

8.19.5 Replacing the foot plate on the centre-mounted legrest (electric & manual) .............. 144

8.20 Anti-tip system ....................................................................................................................... 145

8.20.1 Removing the gas cylinder .......................................................................................... 145

8.20.2 Repairing the gas cylinder .......................................................................................... 148

8.20.2.1 Replacing the guide block fixing or clamping support ........................................... 148

8.20.2.2 Replacing the guide bush ...................................................................................... 149

8.20.2.3 Replacing the gas cylinder ..................................................................................... 149

8.20.3 Refitting the gas cylinder ............................................................................................. 150

8.20.4 Replacing the setting screw ........................................................................................ 152

8.20.5 Adjusting the setting screw ......................................................................................... 155

9 Installing accessories 156

9.1 Replacing the safety belt ...................................................................................................... 156

9.2 Further accessories ............................................................................................................... 156

6

Invacare ® - TDX-SP / TDX-SP N

1 Introduction

1.1 General information

● Service and maintenance work must be carried out taking this service manual into account.

● It is imperative that you observe safety information.

● Information about operation or about general maintenance and care work on the mobility aid

should be taken from the operating manual.

● You can find information about ordering spare parts in the spare parts catalogue.

● Only use original Invacare® spare parts. The guarantee will become invalid if other spare parts

are used!

● We reserve the right to make any alterations on the grounds of technical improvements.

● The mobility aid may only be maintained and overhauled by qualified personnel.

● The minimum requirement for service technicians is suitable training, such as in the cycle or

orthopaedic mechanics fields, or sufficiently long-term job experience.

- Experience in the use of electrical measuring equipment (multimeters) is also a requirement.

- Special Invacare® training is recommended.

SERVICE MANUAL

● Alterations to the mobility aid which occur as a result of incorrectly or improperly executed

maintenance or overhaul work lead to the exclusion of all liability on the side of INVACARE.

● If you have any problems or questions please contact Invacare® Service.

1.2 Notes on transport

● If the mobility aid has to be shipped back to the manufacturer for major repairs, you should

always use the original packaging for transport.

● Please attach a precise description of the fault.

7

SERVICE MANUAL

to hazards which could lead to ma terial damage if they

Invacare

®

- TDX-SP / TDX-SP N

1.3 Definition and re presentation of inf ormation and safet y information in t his manual

Different types of information and signal words are used throughout this manual.

HAZARD!

The signal word "HAZ ARD!" refers to immediate hazards.

● The following lines in italics refer to actions which serve to avoid such hazards.

WARNING!

The signal word "WARNING!" refers to possibly-occurring hazards which can lead to

death or serious inj u ries if they are not avoided.

● The following lines in italics refer to actions which serve to avoid such hazards.

ATTENTION!

The signal word " ATTENTION!" refers to possibly-occur ring hazards which can lead to

minor injuries and/o r material damage if they are not avoided.

● The following lines in italics refer to actions which serve to avoid such hazards.

CAUTION!

The signal word "CAUTION!" refers

are not avoided.

● The following lines in italics refer to actions which serve to avoid such hazards.

Note

The signal word "Note" is used to denote general information which simplifies the handling of

your product and refers to special functions.

8

Invacare ® - TDX-SP / TDX-SP N

1.4 Hazard symbols and symbols used

Different types of hazard symbols and symbols are used throughout this manual.

General hazards

This symbol warns you of general hazards!

● Always follow the instructions to avoid injury to the user or damage to the product!

BURN HAZARD!

This symbol warns you of the danger of chemical burns, for example due to the discharge

of battery acids!

● Always follow the instructions to avoid injury to the user or damage to the product!

DANGER OF CRUSHING!

This symbol warns you of c rushing hazards due to inattentive working with heavy

components.

● Always follow the instructions to avoid injury to the user or damage to the product!

EXPLOSION HAZARD!

This symbol warns you of an explosion hazard, which can be caused by excessive tyre

pressure in a pneumatic tyre.

● Always follow the instructions to avoid injury to the user or damage to the product!

Wear safety shoes

The symbol refers to the requirement for wearing safety shoes.

● Wear standardised safety shoes during all work.

Wear eye protection

This symbol refers to th e requirement for wearing eye protection, for example when

working with batteries.

● Wear eye protection when this symbol is shown.

Wear safety gloves

This symbol refers to th e requirement for wearing safety gloves, for example when

working with batteries.

● Wear safety gloves when this symbol is shown.

Note

This symbol identifies general information which is intended to simplify working with your product

and which refers to special functions.

Requirements:

● This symbol identifies a list of various tools, components and items which you will need in

order to carry out certain work. Please do not attempt to carry out the work if you do not have

the listed tools available.

Always dispose used or damaged batteries correctly

The symbol refers to information for the correct disposal of used or damaged batteries.

SERVICE MANUAL

9

SERVICE MANUAL

1.5 Images in this manual

The detailed images in this manual are given digits to identify various components. Component

numbers in text and operational instructions always relate to the image directly above.

Invacare

®

- TDX-SP / TDX-SP N

10

Invacare ® - TDX-SP / TDX-SP N

SERVICE MANUAL

2 Safety and fitting instructions

These safety instructions are intended to prevent accidents at work, and it is imperative that they

are observed.

2.1 Before any inspection or repa ir wor k

● Read and observe this repair manual and the associated operating manual!

● Observe the minimum requirements for carrying out the work (see chapter entitled „General

information)!

2.2 Personal safety equipment

Safety shoes

The mobility device, and some of its components, are very heavy. These parts can result

in injuries to the feet i f th ey are allowed to drop.

● Wear standardised safety shoes during all work.

Eye protection

It is possible that batte ry acid can be discharged when working on defective batteries or

when handling batteries improperly.

● Always wear eye protection when working on any defective or possibly defective batteries.

Safety gloves

It is possible that batte ry acid can be discharged when working on defective batteries or

when handling batteries improperly.

● Always wear acid-proof safety gloves when working on any defective or possibly defective

batteries.

2.3 General safety information and informati on a bout f itting / removal

WARNING: Danger of crushing!

Various components such as the drive unit, batteries, seat etc are very heavy. This results

in injury hazards to your hands!

● Please note the high weight of some components! This applies especially to the removal of

drive units, batteries and the seat.

WARNING!

Injury hazard if the vehicle starts moving unintentionally during repair work!

● Switch the power supply off (ON/OFF key)!

● Engage the drive!

● Before raising the vehicle, secure the wheels by blocking them with wedges!

ATTENTION!

Fire and burn hazard due to electrical short-circuit!

● The mobility device must be completely switched off before removal of voltage-carrying

components! To do this, remove the batteries.

● Avoid short-circuiting the contacts when carrying out measurements on voltage-carrying

components!

11

SERVICE MANUAL

● Allow the motors to cool down before commencing work on them.

reassembling ensure that these safety devices are correctly engaged.

CAUTION!

Danger of burns from hot surfaces on the motor!

ATTENTION!

Injury hazard and danger of damage to vehicle due to improper or incomplete

maintenance work!

● Use only undamaged tools in good condition.

● Some moving parts are mounted in sockets with PTFE coating (Teflon™). Never grease these

sockets!

● Never use "normal" nuts instead of self-locking nuts.

● Always use correctly-dimensioned washers and spacers

● When reassembling, always replace any cable ties which were cut during dismantling.

● After completing your work / before renewed start-up of the mobility device, check all

connections for tight fitting.

● After completing your work / before renewed start-up of the mobility device, check all parts for

correct locking.

● Only operate the vehicle with the approved tyre pressures (see technical data).

● Check all electrical components for correct function. Please note that incorrect polarity can

result in damage to the electronics.

● Always carry out a trial run at the end of your work.

CAUTION!

Danger of injury an d d amage to property, if the maxim u m speed reduction on a

wheelchair with a lifter does not function correctly!

The wheelchair’s control uni t m u st reduce the maximum possible sp eed as soon as the

lifter is raised.

● Test the maximum speed reduction for correct function after any maintenance work or

modifications to the wheelchair.

Note

Mark all current settings for the mobility aid (seat, armrests, backrest etc.), and the associated

cable connecting plugs, before dismantling. This makes reassembly easier.

All plugs are fitted with mechanical safety devices which prevent release of the connecting plugs

during operation. To release the connecting plugs the safety devices must be pressed in. When

Invacare

®

- TDX-SP / TDX-SP N

WARNING!

Any changes to the drive program can affect the driving characteristics and the tipping

stability of the vehicle!

● Changes to the drive program may only be carried out by trained Invacare® specialist

dealers!

● Invacare® supplies all mobility aids with a standard drive program ex-works. Invacare® can

only give a warranty for safe vehicle driving behaviour - especially tipping stability - for this

standard drive program!

12

Invacare ® - TDX-SP / TDX-SP N

3 Tightening torques

The tightening torques stated in the following list are based on the thread diameter for the nuts and

bolts for which no specific values have been determined. All values assume dry and de-greased

threads.

SERVICE MANUAL

Thread

Tightening torque

in Nm ±10%

M4 M5 M6 M8 M10 M12 M14 M16

3 Nm 6 Nm 10 Nm 25 Nm 49 Nm 80 Nm 120 Nm 180 Nm

CAUTION!

Damage can be caused to the mobility device due to improperl y tightened screws, nuts or

plastic connections.

● Always tighten screws, nuts etc to the stated tightening torque.

● Only tighten screws or nuts which are not listed here fingertight.

13

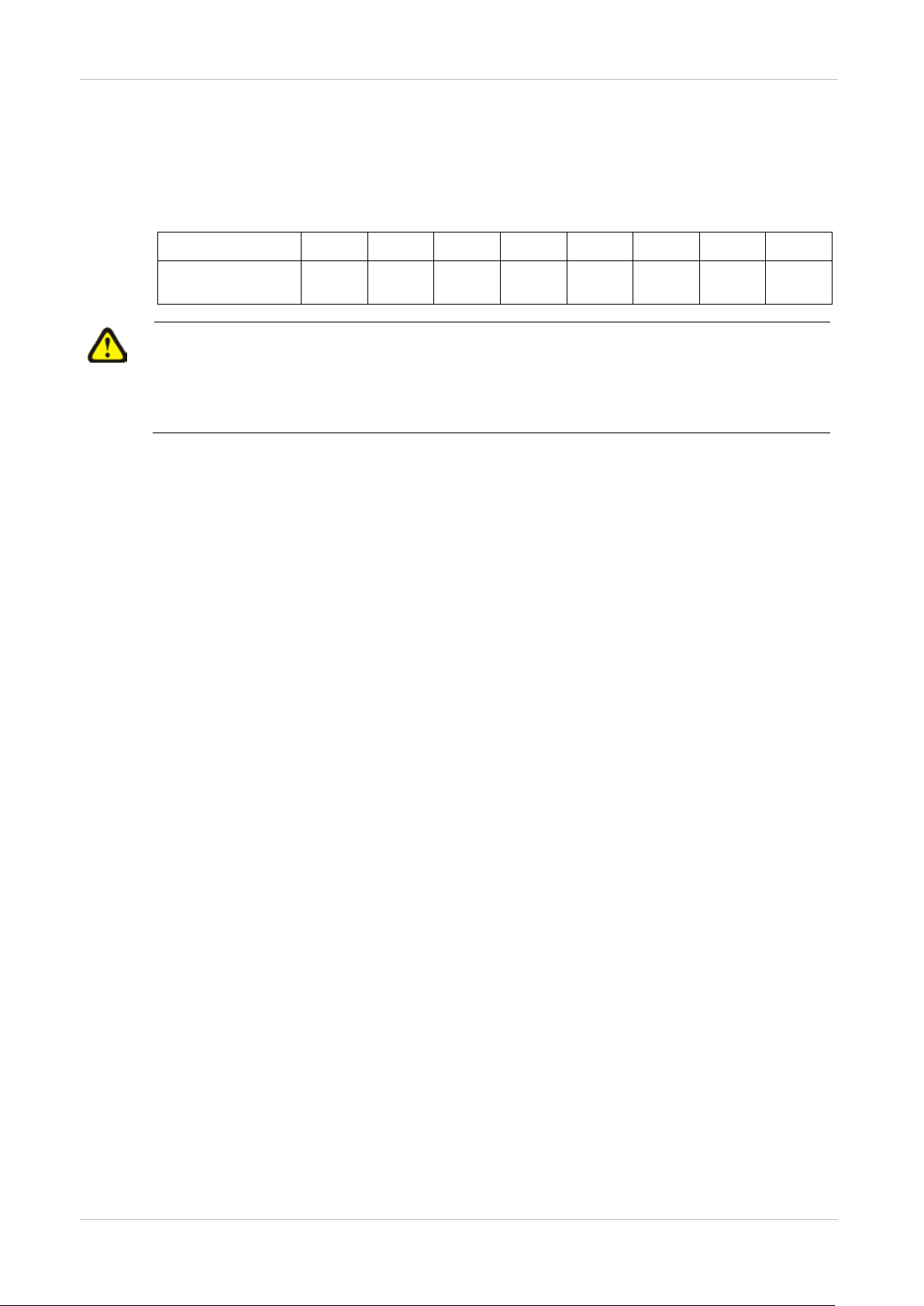

SERVICE MANUAL

At rear underneath seat:

In rear cover:

Invacare

4 Layout of components and componentry

4.1 Overview

Electronic modules

The electronic modules are located

underneath the rear cover panel (1).

The electronic modules used are

described in Chapter 4.2.

®

- TDX-SP / TDX-SP N

(1) – Operating hours counter (optional)

14

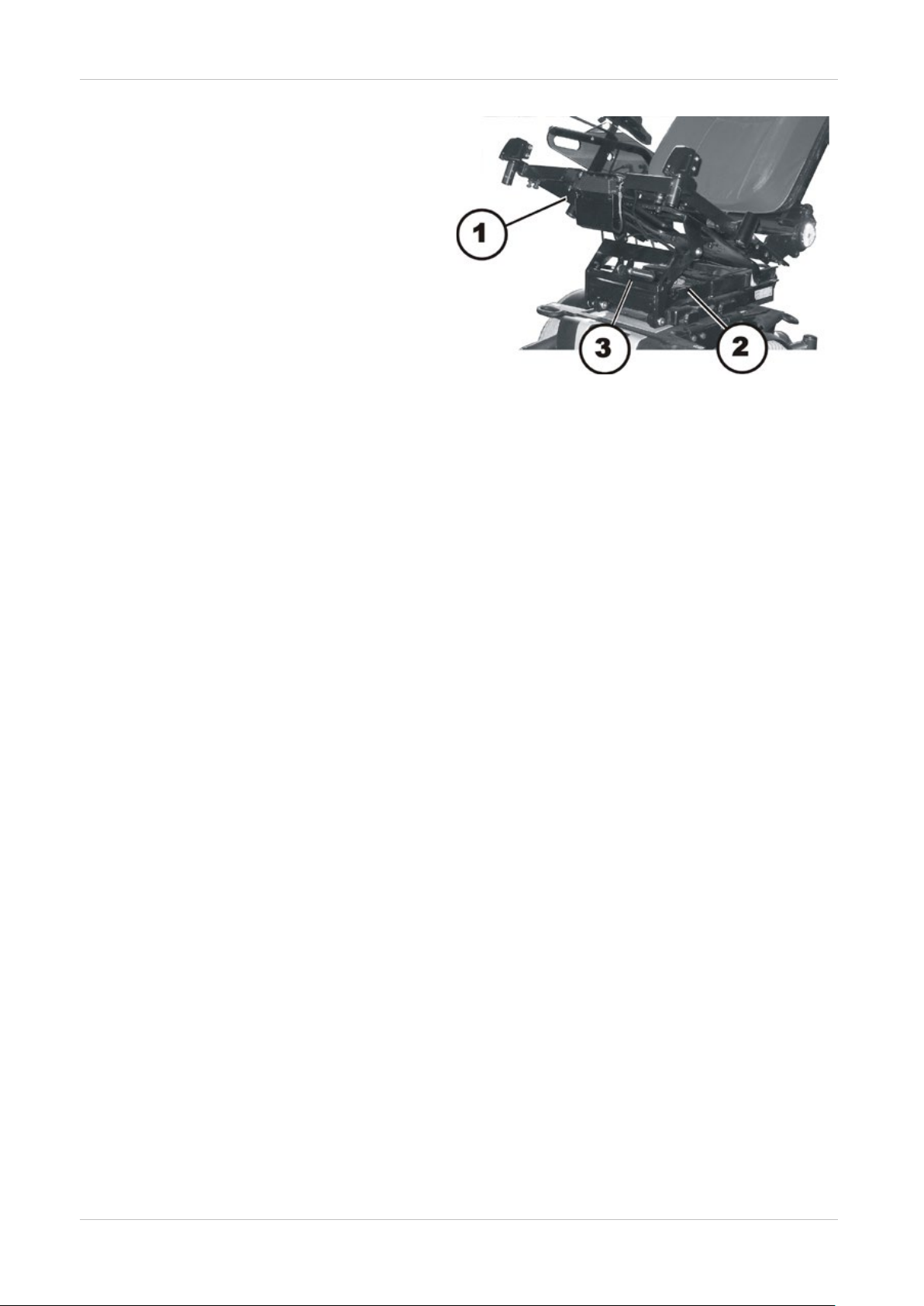

Invacare ® - TDX-SP / TDX-SP N

At the front, underneath the seat:

(1) – actuator module (optional)

(2) – lifter actuator (optional)

(3) – tilt actuator (optional)

SERVICE MANUAL

15

SERVICE MANUAL

ACS 2

REM 24

Shark

Shark II remote

ACT actuator

The actuator module

Lighting PCB

The lighting PCB is

4.2 Electronic modules

A variety of electronic modules can be fitted to the mobility aid.

Before you connect any mobility aid components such as adjusting motors/actuators or motors to

the electronic modules, you should first ensure that you know exactly which electronic module has

been fitted. Please refer to the following table for an overview.

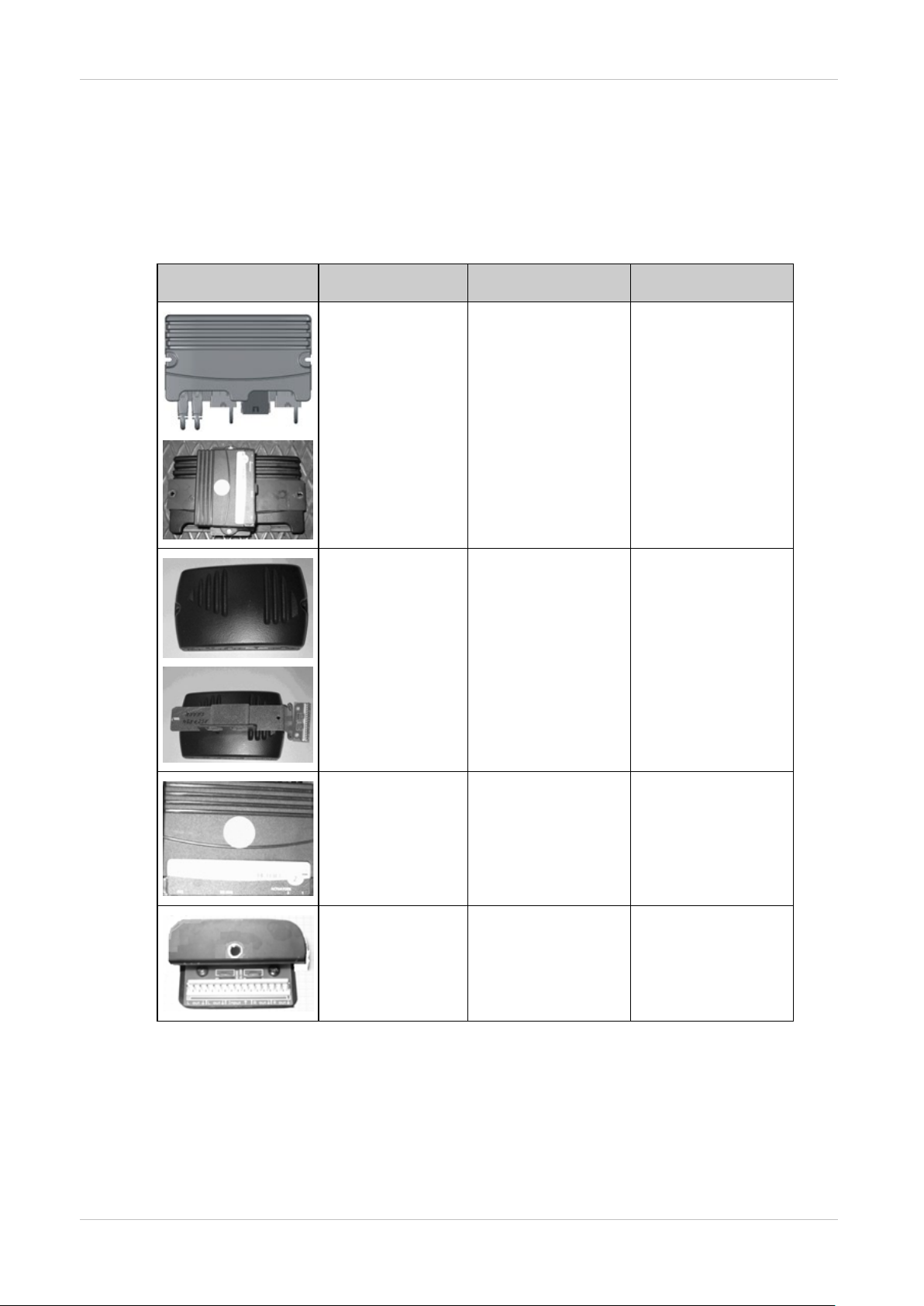

Electronic module Designation Joystick boxes Notes

Invacare

®

- TDX-SP / TDX-SP N

ACS 2 PMA90L

ACS 2 ACT

actuator module

Shark with lighting

PCB

REM A

REM B

REM 550

The actuator module

is optional.

The lighting PCB is

optional.

16

module

is optional.

optional.

Invacare ® - TDX-SP / TDX-SP N

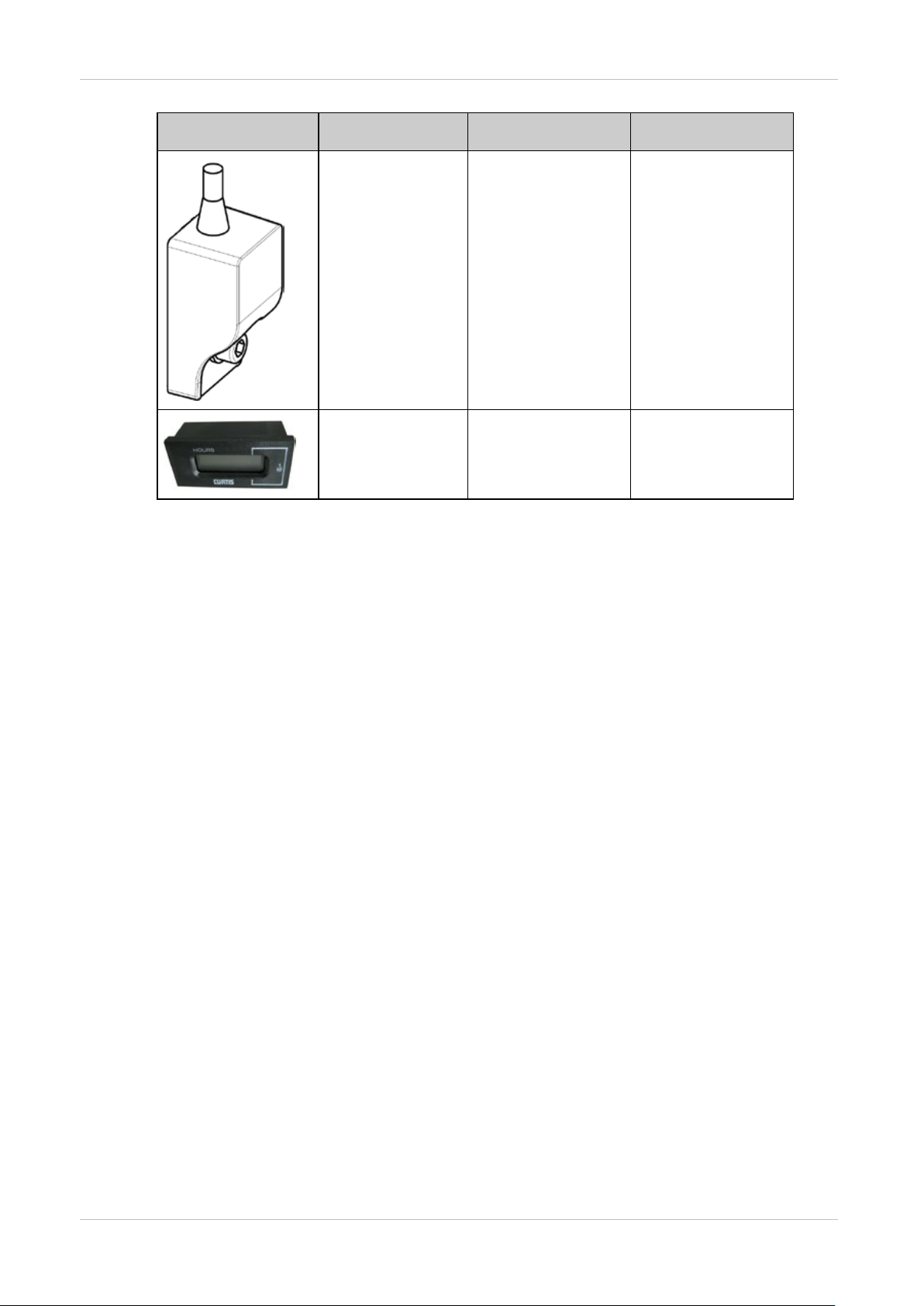

G-Trac sensor

The G-Trac sensor is

Operating hours

The operating hours

Electronic module Designation Joystick boxes Notes

SERVICE MANUAL

optional

counter

counter is optional.

17

SERVICE MANUAL

Connections

2) & 3) Order number: 1552876

Connections

Connections

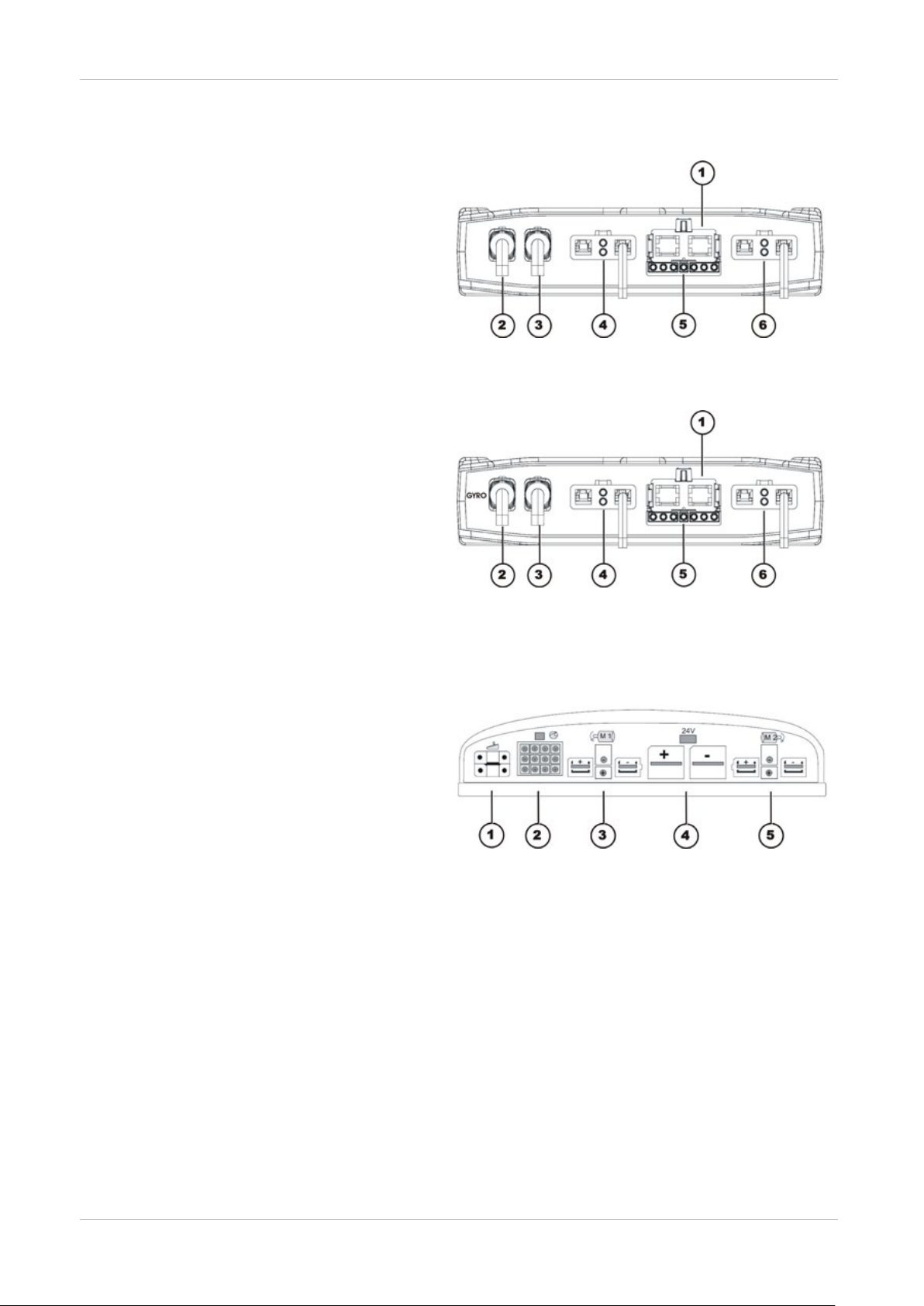

4.2.1 ACS 2 electronic module

1) Battery 24V

2) Bus cable (to remote or ACT)

3) Bus cable (to remote or ACT)

4) Motor M1

5) Light

6) Motor M2

Rubber stoppers for free slots

4.2.2 ACS 2 PMA90L electronic module

1) Battery 24V

2) Cable to G-Trac sensor (GYRO)

3) Bus cable (to remote or ACT)

4) Motor M1

5) Light

6) Motor M2

Invacare

®

- TDX-SP / TDX-SP N

4.2.3 Shark electronic module

4.2.3.1 Shark with DCI 12-pole

1) Cable to remote

2) DCI for actuators/lighting (12-pole)

3) Right-hand motor M1

4) Battery 24V

5) Left-hand motor M2

4.2.4 ACT actuator module

A range of adjusting motors, also known as actuators, can be fitted to the mobility aid. These

actuators are either connected directly to the electronic module or to a separate actuator module.

The actuator module is connected with the electronic module via a bus cable.

18

Invacare ® - TDX-SP / TDX-SP N

Connections

Connections

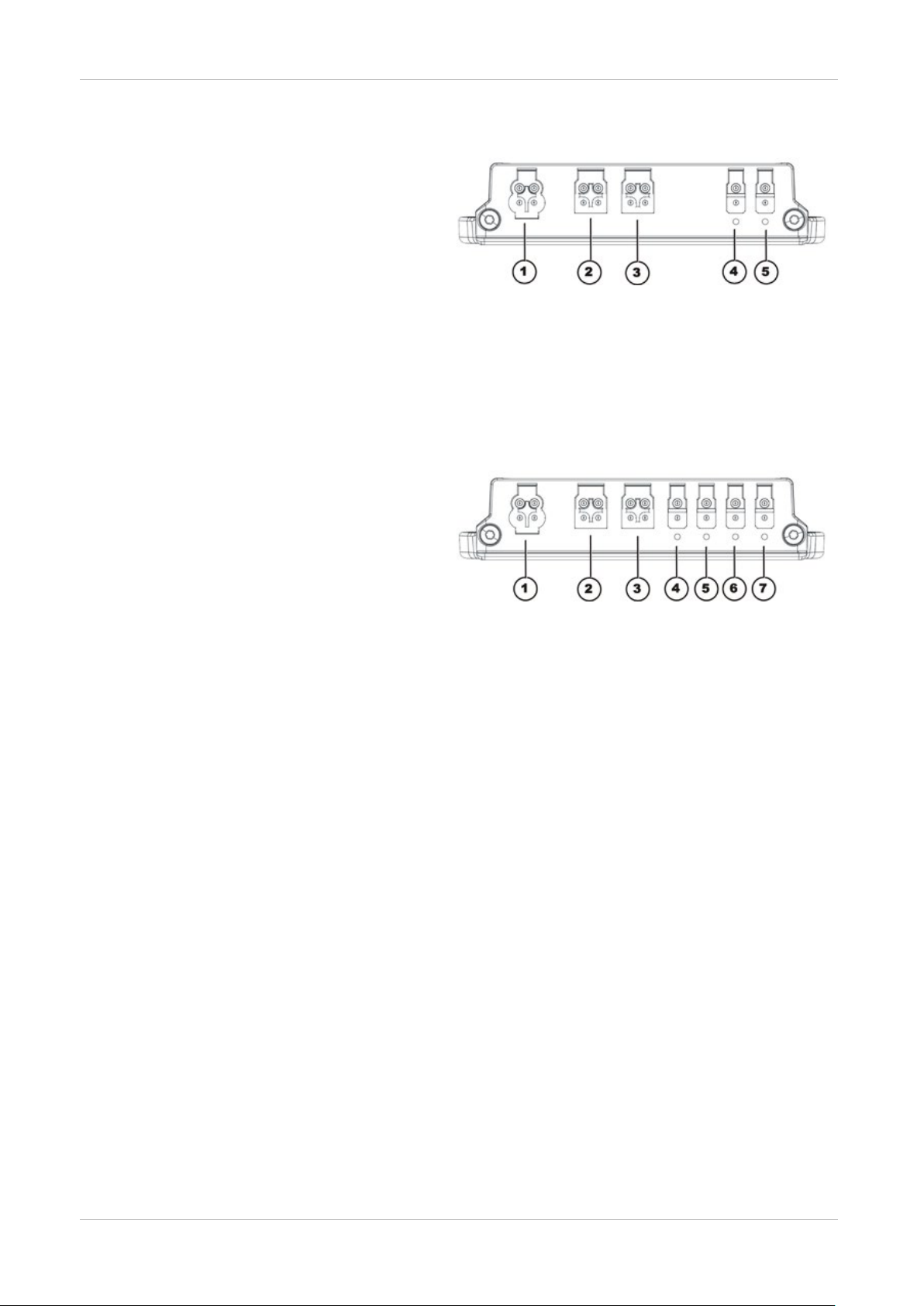

4.2.4.1 ACT 2 actuator module

1) ACI*

2) Bus cable (to remote or ACT)

3) Bus cable (to remote or ACT)

4) Adjusting motor/actuator - Channel 2

5) Adjusting motor/actuator - Channel 1

Rubber stoppers for free slots

1) Order number: 1555701

2) & 3) Order number: 1552876

4) & 5) Order number: 1555700

* The ACI connection is used for actuator limitation or speed reduction.

4.2.4.2 ACT 4 actuator module

1) ACI*

2) Bus cable (to remote or electronic

module)

3) Bus cable (to remote or electronic

module)

4) Actuator - Channel 4

5) Actuator - Channel 3

6) Actuator - Channel 2

7) Actuator - Channel 1

Rubber stoppers for free slots

1) Order number: 1555701

2) & 3) Order number: 1552876

4) to 7) Order number: 1555700

SERVICE MANUAL

* The ACI connection is used for actuator limitation or speed reduction.

4.2.5 Lighting PCB

The lighting PCB connections are printed directly on the circuit board.

19

SERVICE MANUAL

ü

5 Service plan (1x annually)

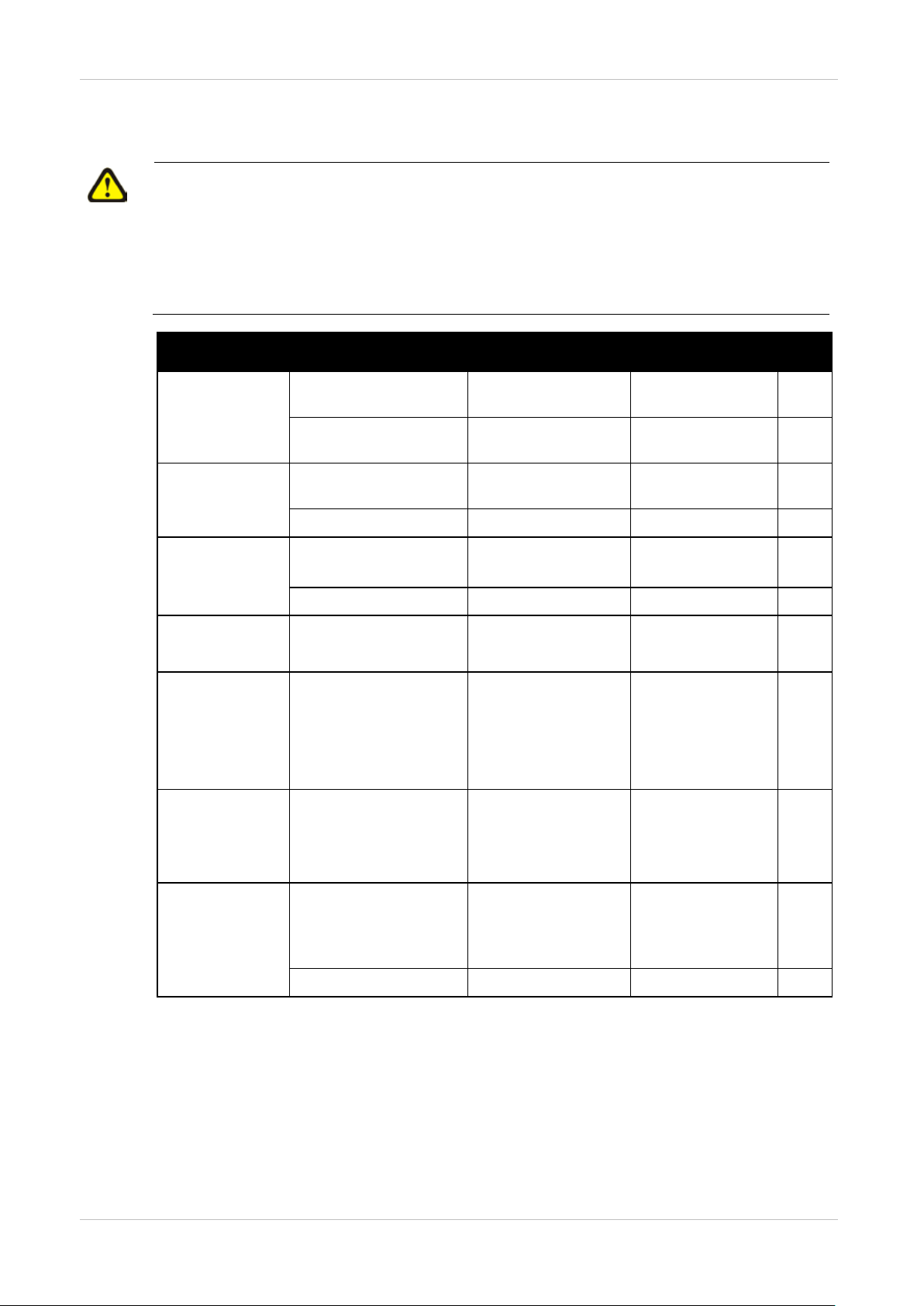

CAUTION!

Danger of injury and damage to property, if the maximum speed reduction on a

wheelchair with a lifter does not function correctly!

The wheelchair’s control uni t m u st reduce the maximum possible sp eed as soon as the

lifter is raised.

● Test the maximum speed reduction for correct function after any maintenance work or

modifications to the wheelchair.

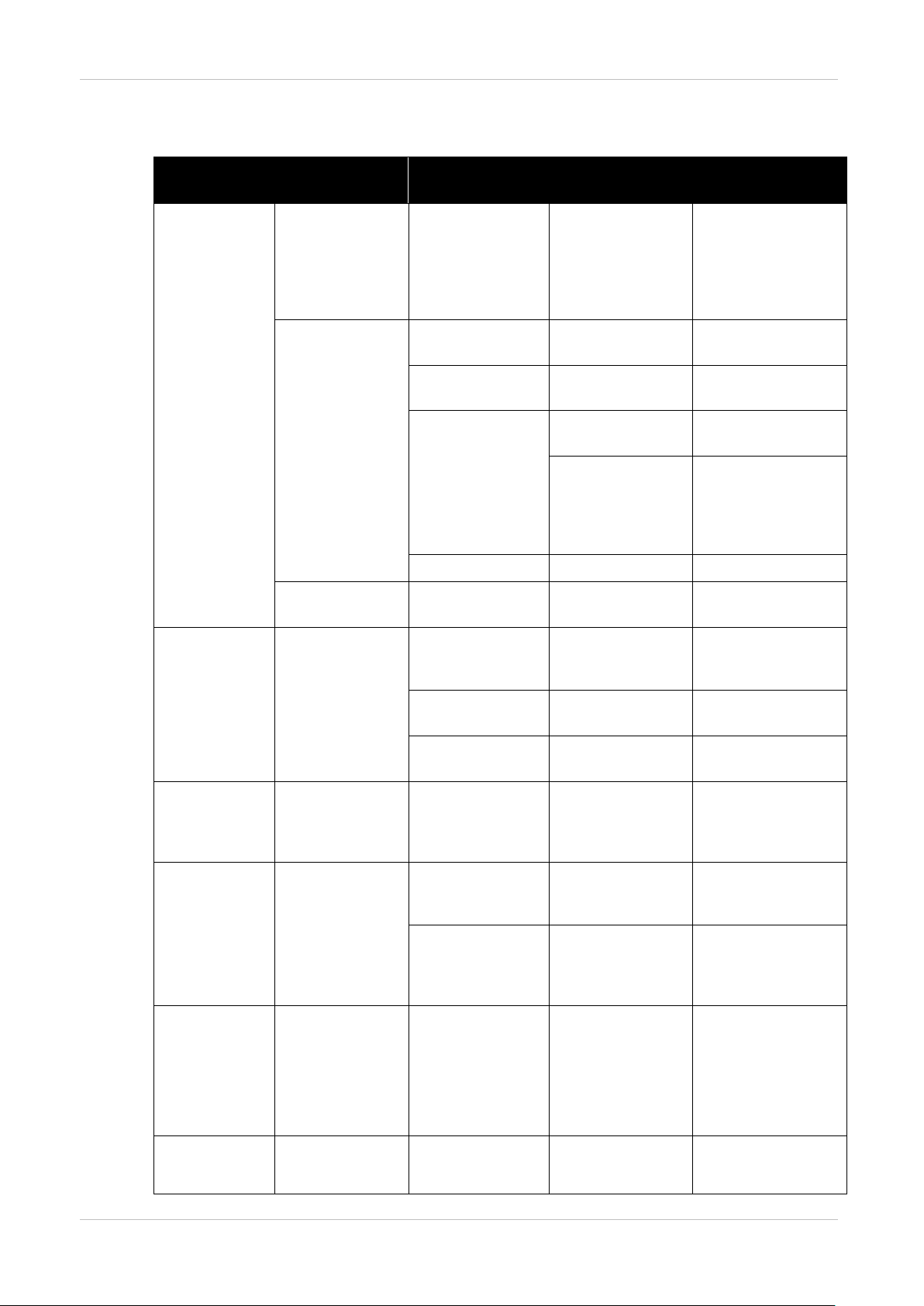

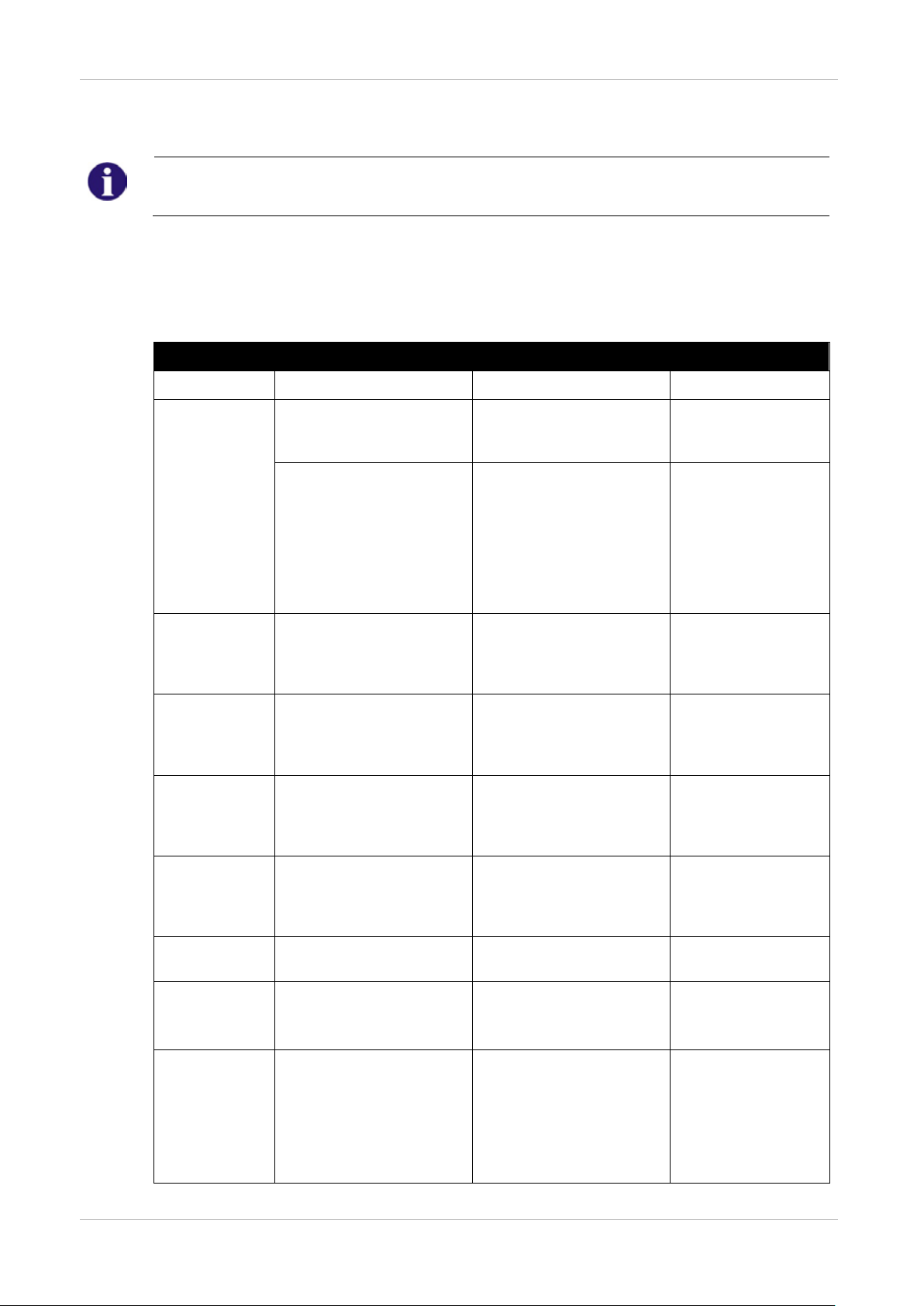

Component Check Remedy Notes

Invacare

®

- TDX-SP / TDX-SP N

Safety belt

Armrests

Side panels

Seat angle

adjustment

Power backrest

(if fitted)

Frames

(chassis) /

battery

mounting

Damage to safety belt Replace belt if

See chapter 9.1.

damaged.

Belt lock function Replace belt if

See chapter 9.1

damaged.

Damage to armrests Replace covering if

damaged

Armrest fixings Tighten screws

Damage to side panels Replace side panels if

damaged

Side panel fixings Tighten screws

Tight seating of SL

fuses

Damage to backrest

Seams

Fixing

Check cable

Check function

Check fixings, welded

seams and battery

mounting

Replace SL fuses if

necessary

Replace parts if

damaged

Tighten screws

Replace cable motor

if necessary

Tighten screws

Replace components

if necessary

Anti-tip system

Check gas cylinder Repair or replace if

See chapter 8.20

damaged

Replace gas cylinder

every 2 years!

Check adjustment Speed See chapter 8.20.5.

20

Invacare ® - TDX-SP / TDX-SP N

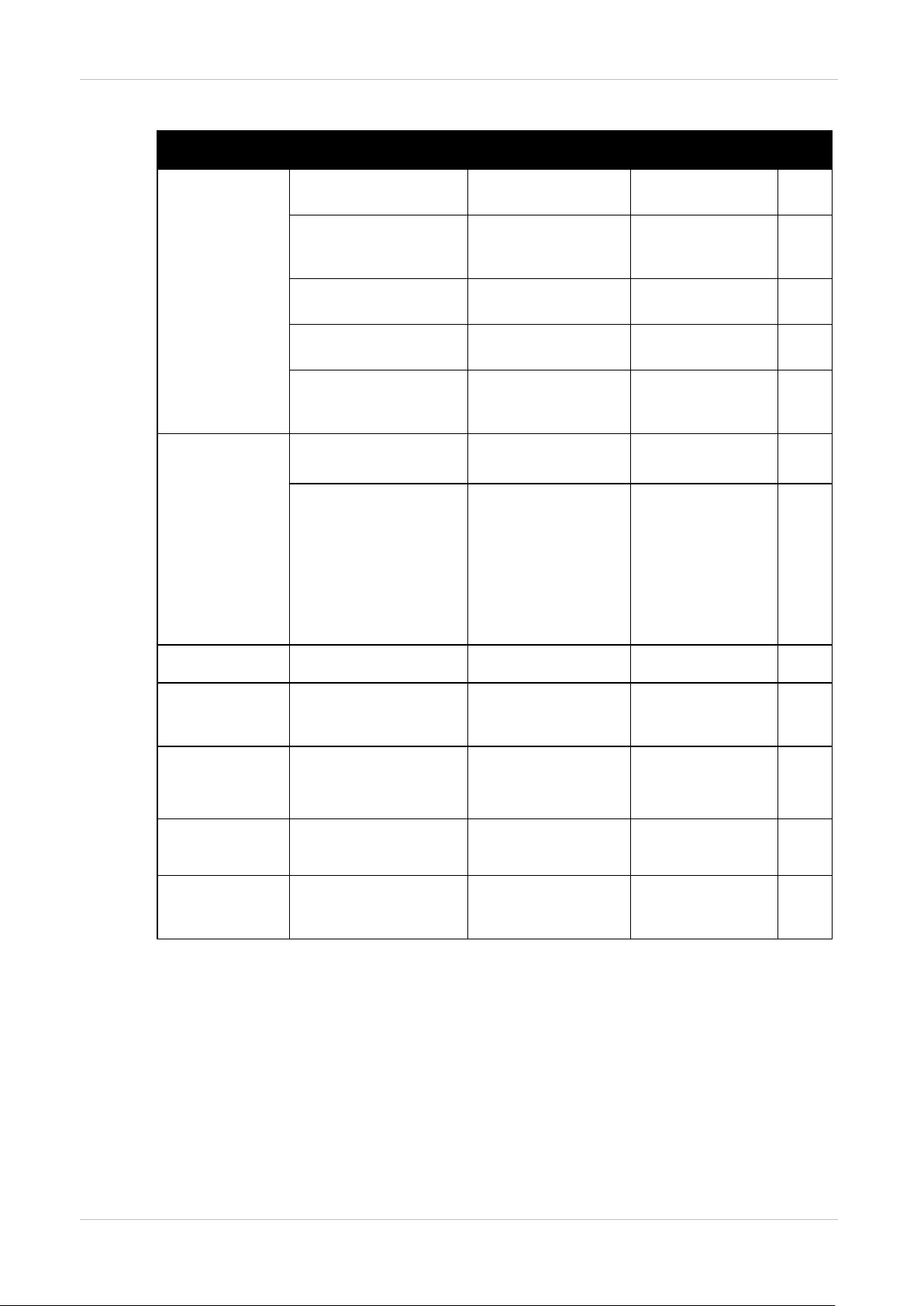

ü

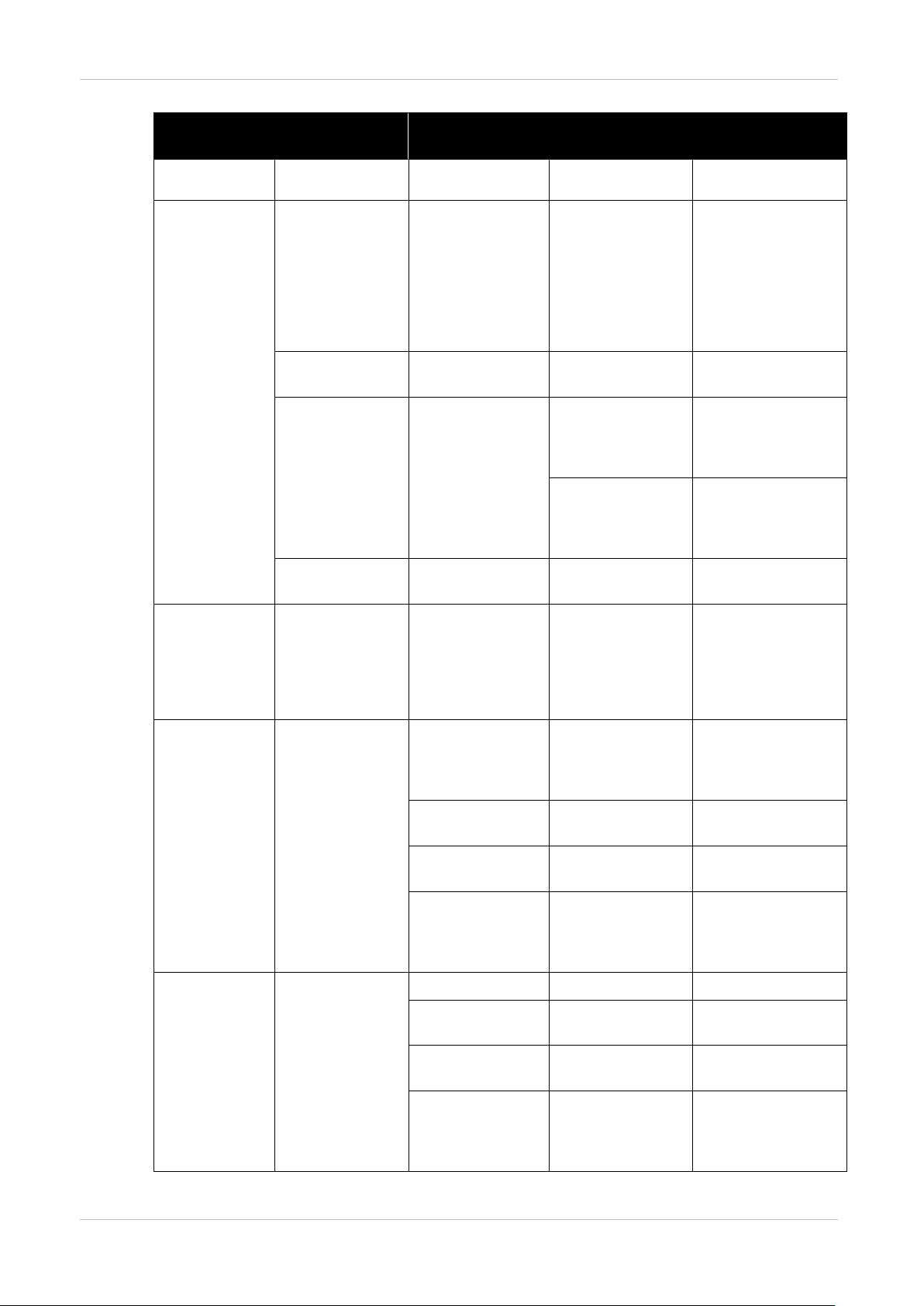

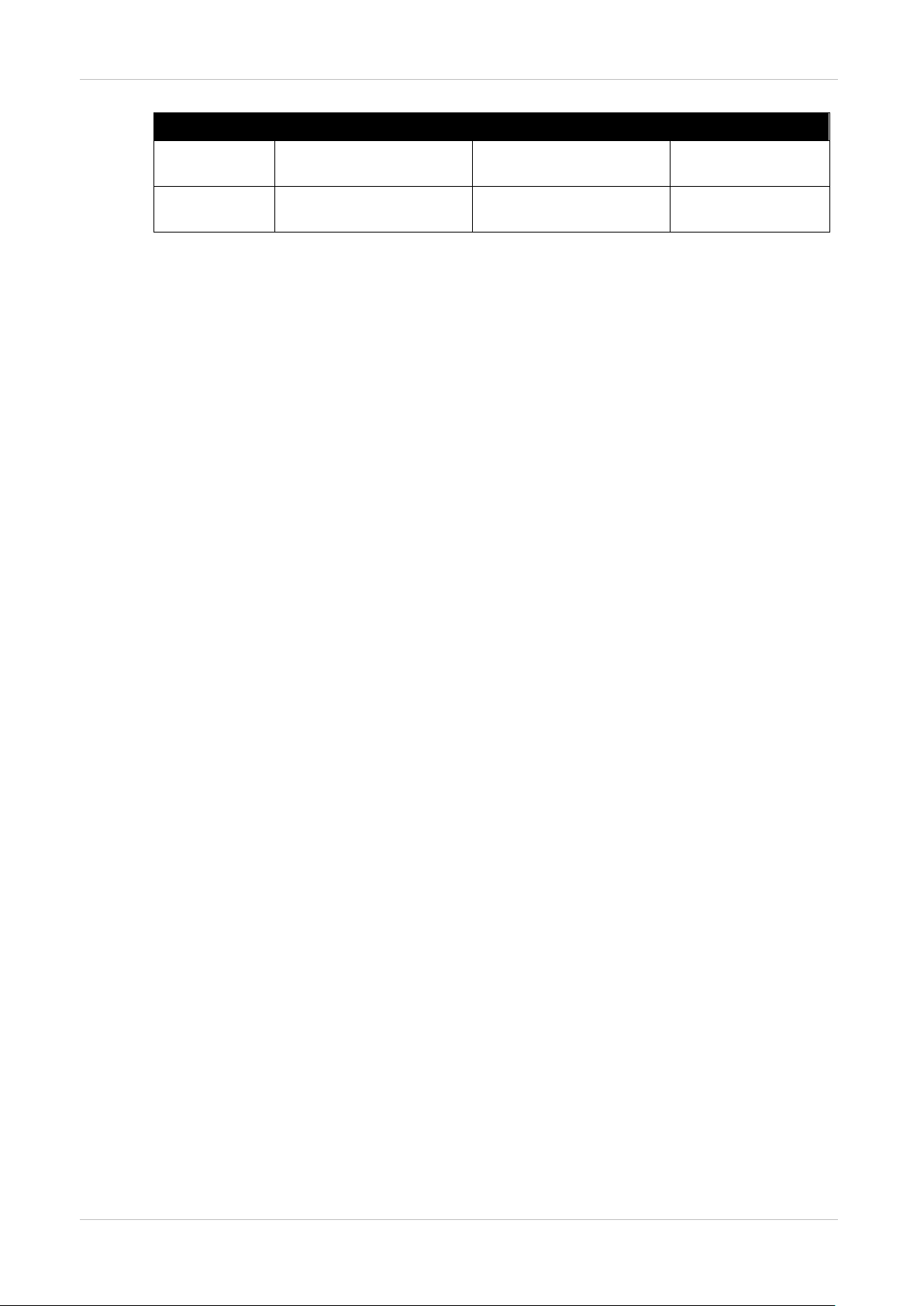

Component Check Remedy Notes

SERVICE MANUAL

Wheel

suspension and

wheels

Drive units,

clutch

mechanism

Check drive wheels for

tight fit and side play

Check steering wheels

for tight fit, float and

side play

Adjust, replace wheel

hubs

Replace wheels,

wheel fork or wheel

bearings

Tyres Repair or replace if

damaged

Check suspension Repair or replace if

damaged

Check straight running Replace wheels,

wheel fork or wheel

bearings

Motors

Check motors See chapter 7.

Check functions in drive

and push modes

Check clutch

mechanism

Check carbon

brushes, replace if

necessary

Replace motor if

necessary.

Tighten screws/nuts,

adjust or replace if

necessary

See chapters 8.9.1

and 8.9.3/8.9.4

See chapter 8.9

See chapter 8.9.2.

See chapter 8.11

See chapter 8.8.

See chapter 8.14

Brakes

Legrests

Power legrests

(if fitted)

Lighting (if

fitted)

Battery

mounting

Inspect motor brake Check motor brake See chapter 7.2.

Check welded seams,

interlocking, screws,

Tighten, replace if

necessary

footplates

Check cable

Check contacts

Replace cable if

necessary

check functions

Check cable

Check function

Check battery support

Replace lamp or

See chapter 8.7.

cable if necessary

Replace if necessary

and mounting belts for

damage

21

SERVICE MANUAL

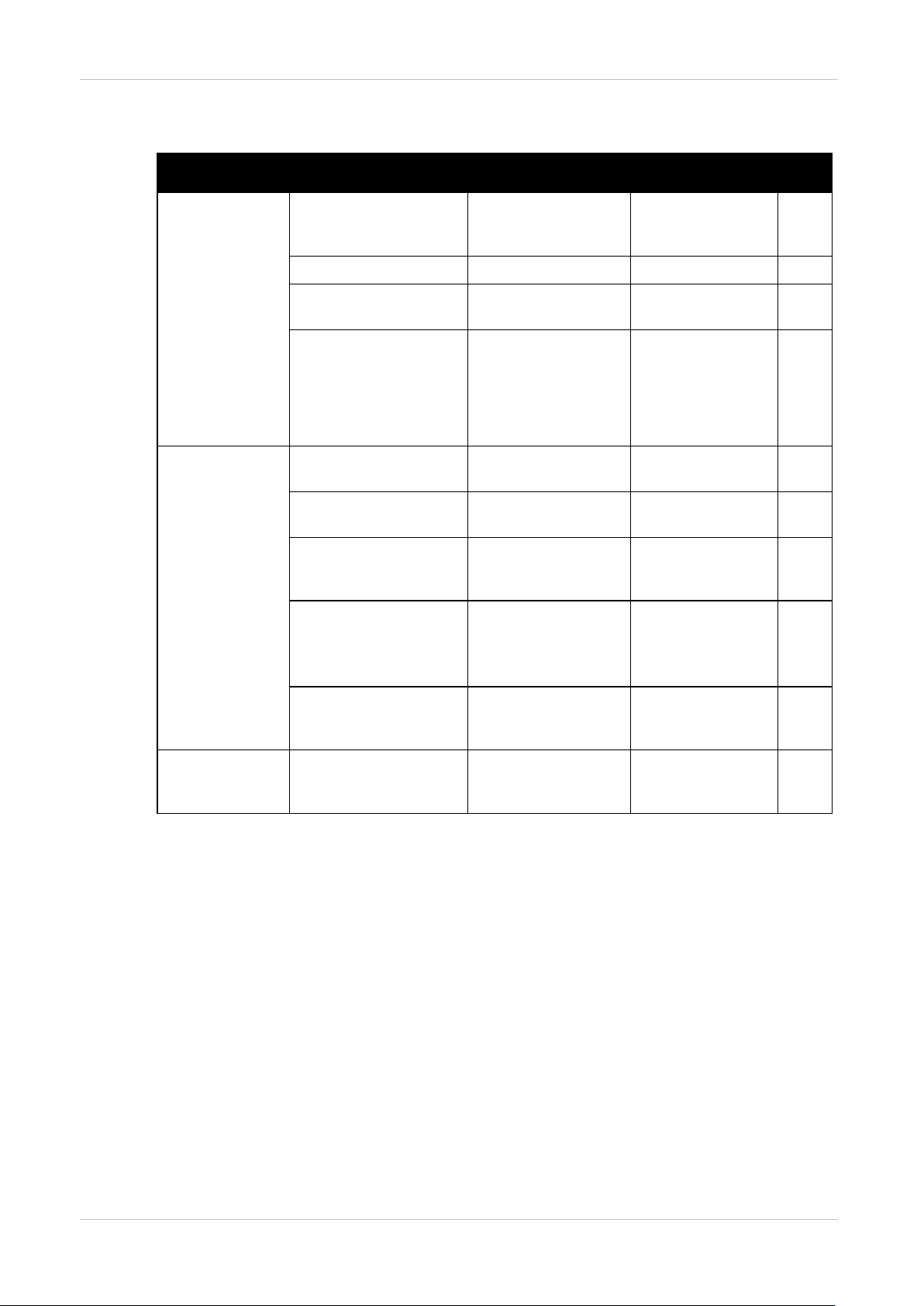

ü

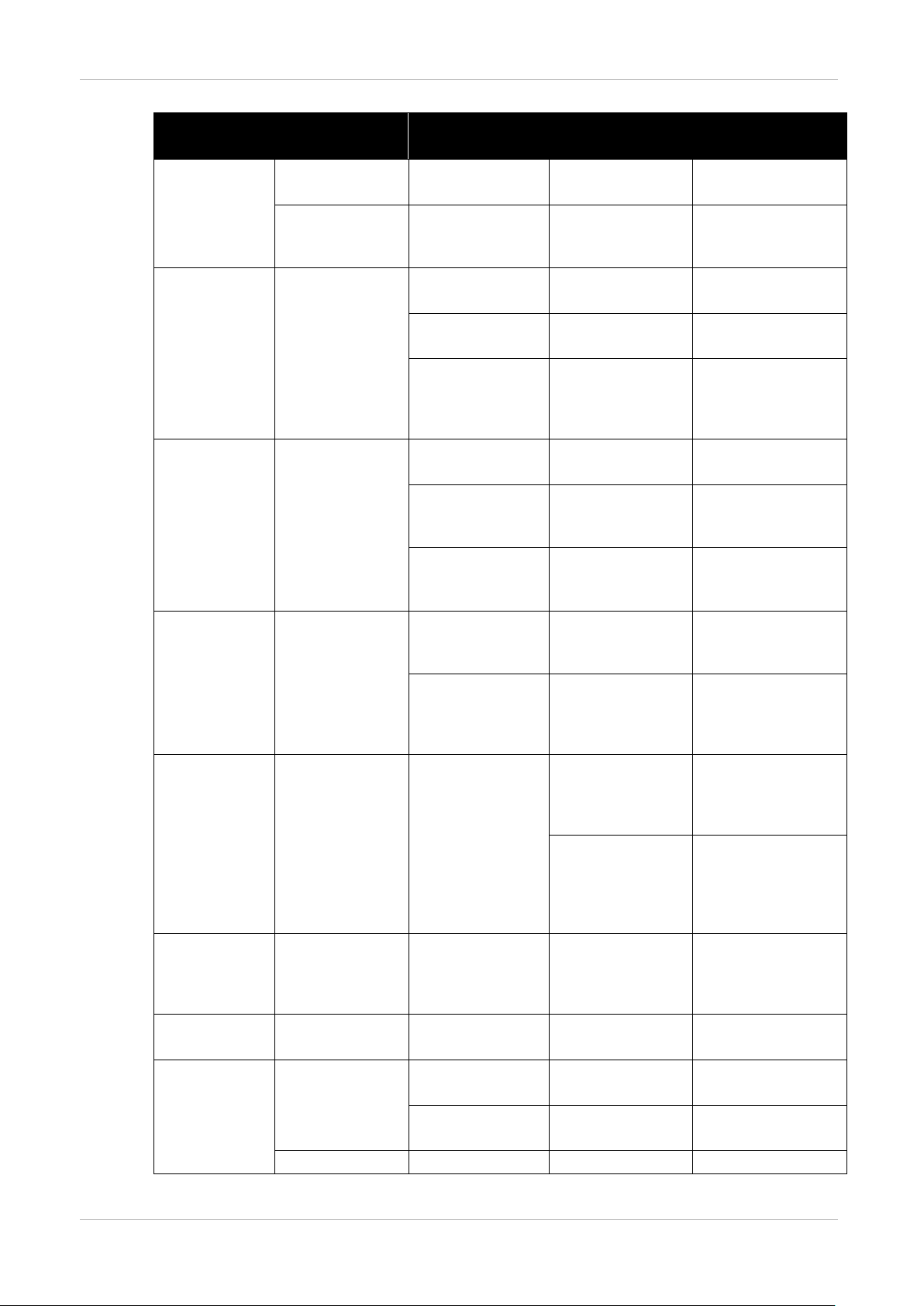

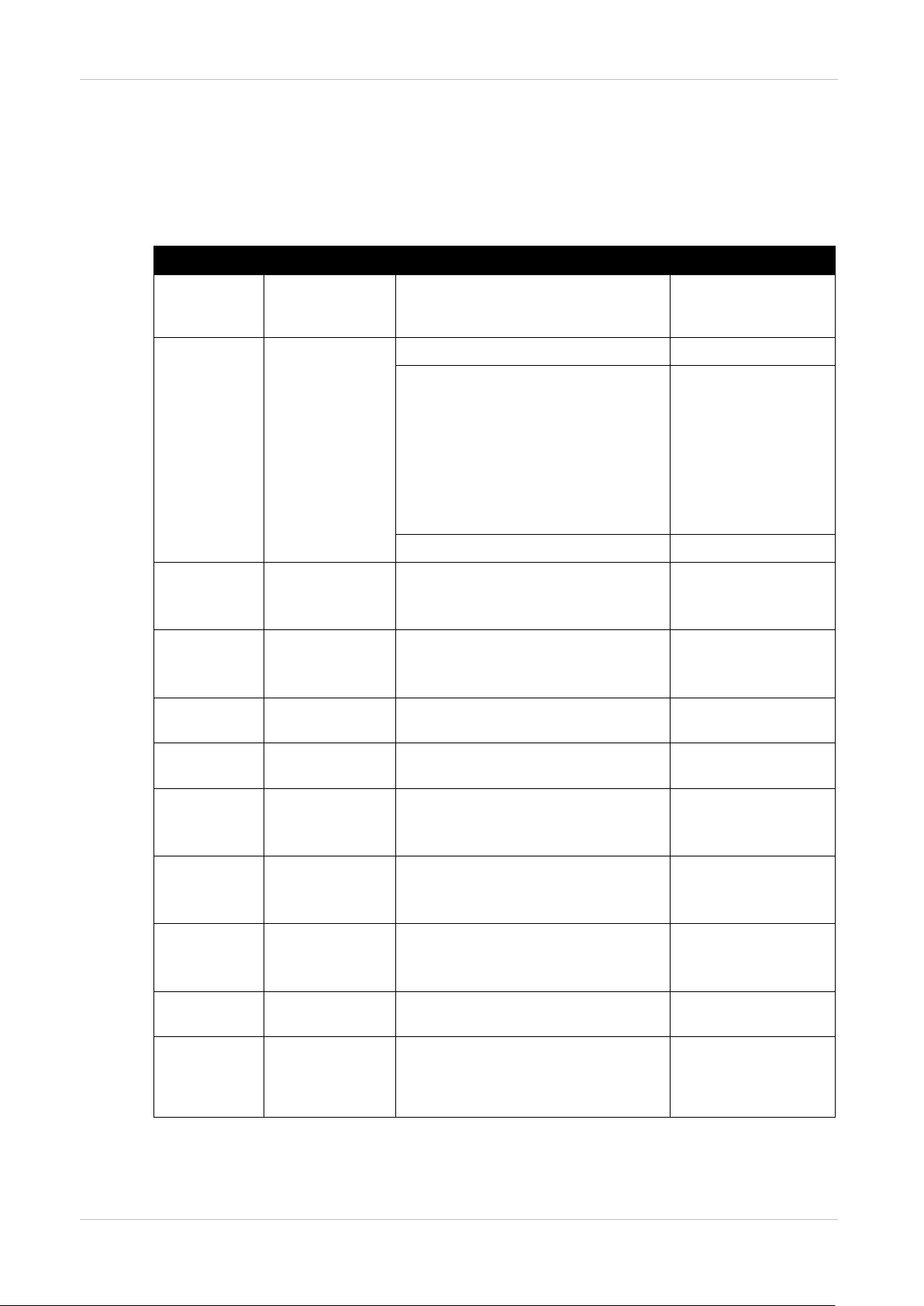

Component Check Remedy Notes

Invacare

®

- TDX-SP / TDX-SP N

Batteries

Remote /

electronic

module

Check batteries for

damage

Replace batteries if

necessary

See chapters

8.4.2/8.4.3 and

8.4.4

Check battery voltage Charge batteries

Check battery voltage Charge batteries See operating

manual

Check contacts and

terminals

Clean contacts and

terminals

Please refer to the

safety information

in Chapter

8.4.2/8.4.3 and

8.4.4 for handling

batteries

Remote, status display

blinking

Fixings Tighten fixings,

Evaluate error/blink

code

See chapter 6.

replace if necessary

Cables and connecting

plugs

Tighten cables and

connecting plugs,

replace if necessary

Drive lever function Replace drive lever if

necessary

Replace remote if

necessary

Power supply Tighten cables and

connecting plugs,

replace if necessary

Drive program

Check drive electronic

program version

Update software if

newer version

See chapter 8.3.

available.

22

Invacare ® - TDX-SP / TDX-SP N

You can obtain the original manuals from Invacare®.

6 Operational faults

The various electronic modules can be fitted in connection with differing remotes in the mobility aid.

Rectification of operational faults is dependent on the electronic module fitted.

The electronic modules used are described in Chapter 4.2.

Note

The tables for rectification of operational faults listed in the following chapters are only an excerpt

from the original manufacturer's manuals.

If you have problems with the mobility aid, please proceed as follows:

● First assess the possible cause of the problem using the following table.

● Check the remote status display. Evaluate the error code.

● Carry out the necessary checks and repairs as recommended in the following table.

SERVICE MANUAL

23

SERVICE MANUAL

None

electronic module

6.1 Drive fault diagnosis

Invacare

®

- TDX-SP / TDX-SP N

PROBLEM OTHER

SYMPTOMS

Mobility aid

will not start

The remote

status display

illuminates

normally and

displays blink

code 5/6.

Remote status

display does not

illuminate

Remote status

display blinking

POSSIBLE

SOLUTION DOCUMENTATION

CAUSE

Drive motors

disengaged

Batteries

defective

Completely

discharge battery

Power supply to

remote

interrupted

Engage drive

motors

See operating

manual

Replace batteries See chapter

8.4.2/8.4.3.

Pre-charge

batteries

Check master

fuse

Check cables

See operating

manual

See chapter

8.4.5/8.4.6.

See chapter 8.4.7.

between the

modules for loose

connections and

damage

Remote defective Replace remote See chapter 8.2.1.

Various causes Assess error code See chapter 6.2

and 6.3.

Mobility aid

judders in

drive mode

Mobility aid

pulls to left or

right

Error

message

does not go

out

Motors stop

and start

irregularly

Batteries

Replace batteries See chapter

defective

(unstable voltage)

Drive motor(s)

Replace motor(s) See chapter

defective

Replace carbon

brushes

None Drive motors

running

asymmetrically

Change

programming to

synchronise

motors.

None Bad connections Check all

connecting

cables.

Motor brake

defective

Measure internal

resistance of

brakes, replace

motor if defective.

None Voltage decline Stop journey and

allow electronic to

cool down.

8.4.2/8.4.3.

8.14.1/8.14.2.

See chapter

8.14.6/8.14.7.

See chapter 8.3.

See chapter 8.4.7.

See chapters 7.2

and 8.14.1/8.14.2

24

Motor runs

but loses

None

High motor

loading causes

Stop journey and

allow electronic to

Invacare ® - TDX-SP / TDX-SP N

power

to decrease

cool down.

PROBLEM OTHER

SYMPTOMS

POSSIBLE

SOLUTION DOCUMENTATION

SERVICE MANUAL

CAUSE

voltage

Motors stop

and do not

start again

Motors lose

power during

journey

None High motor

loading causes

electronic module

to decrease

voltage

Leave mobility aid

switched on and

allow electronic

module to work.

Charge batteries

overnight with

mobility aid

switched on.

None Fuse burnt out Check cabling

and replace fuse

None Motor defective Check carbon

brushes and

replace if

necessary

Measure internal

resistance of

motor, replace

motor if defective.

None Electronic module

defective

Replacing the

electronic module

None Bad connections Switch mobility aid

off, wait 10

seconds, switch

mobility aid on

again. Check all

cabling.

See chapters 8.4.7

and 8.4.5/8.4.6

See chapter

8.14.6/8.14.7.

See chapters 7.1

and 8.14.1/8.14.2

See chapter 8.2.2.

See chapter 8.4.7.

Motor judders

or runs

irregularly, or

only one

motor runs

Motors do not

run

None Carbon brushes

worn

Check carbon

brushes and

See chapter

8.14.6/8.14.7.

replace if

necessary

Clutch(es)

defective

Bearing defective Replacing the

Collector

defective

Replace clutch See chapter

8.14.4/8.14.5.

See chapter

motor

Measure internal

resistance of

8.14.1/8.14.2.

See chapters 7.1

and 8.14.1/8.14.2

motor, replace

motor if defective.

None Bad connections Check all cabling. See chapter 8.4.7.

Fuse burnt out Check cabling

and replace fuse

Batteries

Replace batteries See chapter

defective

Cabling to

check cabling See chapter 8.4.7.

See chapters 8.4.7

and 8.4.5/8.4.6

8.4.2/8.4.3.

electronic module

or joystick

defective

25

SERVICE MANUAL

LEDs blinking on

Charging unit

Replace charging

See charging unit

PROBLEM OTHER

SYMPTOMS

POSSIBLE

CAUSE

®

Invacare

- TDX-SP / TDX-SP N

SOLUTION DOCUMENTATION

Motor makes

clicking noise

Scraping

noise or

motor

blocked

Electronic module

defective

Corroded

contacts

Water, salt or

urine has

penetrated

None Clutch(es)

defective

Bearing defective Replacing the

Collector

defective

None Clutch(es)

defective

Bearing defective Replacing the

Transmission

defective

Replacing the

See chapter 8.2.2.

electronic module

Check cabling,

See chapter 8.4.7.

replace if

necessary.

Replace clutch See chapter

8.14.4/8.14.5.

See chapter

motor

Measure internal

resistance of

8.14.1/8.14.2.

See chapters 7.1

and 8.14.1/8.14.2

motor, replace

motor if defective.

Replace clutch See chapter

8.14.4/8.14.5.

See chapters

motor

8.14.1/8.14.2 and

8.14.4/8.14.5

Replace

transmission.

See chapters

8.14.1/8.14.2 and

8.14.4/8.14.5

Transmission

makes

clicking noise

Transmission

losing oil

Irregular

running

Parts lost

Batteries not

being

charged

None Transmission

defective

Replace

transmission.

Drive wheel loose Tighten drive

wheel, secure

bolts with Loctite if

necessary

None Sealing ring on

drive shaft

defective

Replace

transmission if

sealing ring

defective.

Check carbon

brushes for oil

wetting, replace

motor if brushes

wet

None Drive shaft

movable or bent

Check drive shaft,

replace

transmission if

defective.

None Parts lost Reattach parts

once found.

None Fuse burnt out,

cable defective

Batteries

Check cabling

and replace fuse

Replace batteries See chapter

defective

See chapters

8.14.1/8.14.2 and

8.14.4/8.14.5

See chapter

8.14.1/8.14.2.

See chapters

8.14.1/8.14.2 and

8.14.4/8.14.5

See chapters

8.14.1/8.14.2,

8.14.4/8.14.5 and

8.14.6/8.14.7

See chapters

8.14.1/8.14.2 and

8.14.4/8.14.5

See chapters 8.4.7

and 8.4.5/8.4.6

8.4.2/8.4.3.

26

Invacare ® - TDX-SP / TDX-SP N

charging unit

defective

unit

operating manual

period

slowly

PROBLEM OTHER

SYMPTOMS

POSSIBLE

SOLUTION DOCUMENTATION

SERVICE MANUAL

CAUSE

Short

charging

Mobility aid

runs too

Actuator does

not react

None One of the

batteries could be

Replace batteries See chapter

8.4.2/8.4.3.

defective

None Remote defective Replace remote See chapter 8.2.1.

Batteries

defective

Remote shows

blinking "E"

blink code 2

1

or

2

Lighting / actuator

module defective

Replace batteries See chapter

8.4.2/8.4.3.

Replace lighting /

See chapter 8.2.2.

actuator module

Status diode on

lighting/actuator

module does not

go out even if

the remote has

been switched

off or

disconnected

None Cable

disconnected or

damaged

Safeguard cable

connection,

replace cable if

See chapter 8.4.7.

necessary

Electrical

adjusting motor

Check adjusting

motor

defective

Remote defective Replace remote See chapter 8.2.1.

1 Only applies to remote SD24

2 All remotes except SD24

27

SERVICE MANUAL

connected to electronic modules DX, ACS or ACS 2.

nking. If the

Remove electronic modules

Invacare

®

6.2 REM remotes: Error codes and dia gnost ic codes

Note

The following table is applicable to remotes REM 24, REM A, REM B and REM 550, which are

The drive electronic can automatically rectify some faults. In this case the status display will stop

blinking. Switch the remote on and off again several times. Wait around 5 seconds each time

before switching the remote on again. If this does not rectify the fault, determine the cause using

the blink codes from the following table.

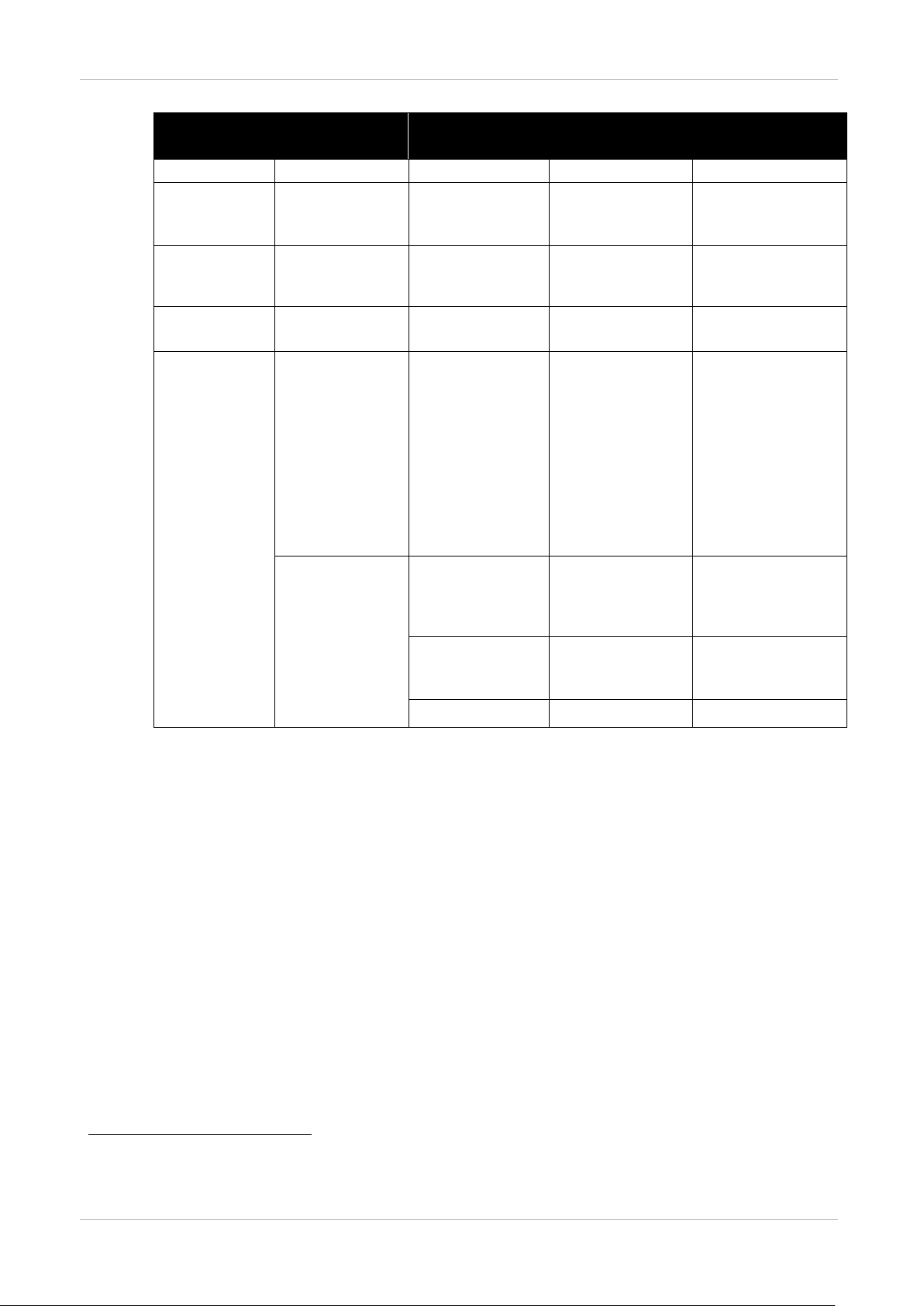

BLINK CODE POSSIBLE CAUSE SOLUTION DOCUMENTATION

- TDX-SP / TDX-SP N

1 x blink

2 x blink

3 x blink

4 x blink

5 x blink

Module defective Replace defective module See chapter 8.2.2.

Accessory error (e.g. short-

circuit in adjusting motor)

Check accessory

connections, check

See chapter 8.4.7.

accessory

Lifter too high or too low

(seat not at driving height)

If the lifter is raised, lower it

slowly until the status

See operating manual

display stops bli

lifter is too low, raise it

slowly until the status

display stops blinking. Only

drive when the seat is at

driving height.

Fault on left-hand motor

(M2). Connection

Check connection plug,

check motor

See chapters 8.4.7

and 7.1

loose/defective or motor

defective

Fault on right-hand motor

(M1). Connection

Check connection plug,

check motor

See chapters 8.4.7

and 7.1

loose/defective or motor

defective

Fault/brake fault on lefthand motor (M2).

Check connection plug,

check motor

See chapters 8.4.7

and 7.1

Connection loose/defective

or motor defective

6 x blink

Fault/brake fault on righthand motor (M19.

Connection loose/defective

or motor defective

7 x blink

Completely discharge

battery

8 x blink

9 or 10 x blink

Battery voltage too high Switch lighting to low

Faulty data transmission

between modules

28

Check connection plug,

check motor

Pre-charge battery

battery voltage

Check battery charger

except for the power

module and the remote.

Replace the modules one

after another in order to

ensure which was the one

causing the fault.

See chapters 8.4.7

and 7.1

See operating manual

See charging unit

operating manual

See chapter 8.2.2.

Invacare ® - TDX-SP / TDX-SP N

BLINK CODE POSSIBLE CAUSE SOLUTION DOCUMENTATION

SERVICE MANUAL

11 x blink

12 x blink

Drive motors overloaded /

overheated

Compatibility problems

Switch remote on and off /

-

wait if necessary

Remove incorrect module See chapter 8.2.2.

between modules

29

SERVICE MANUAL

Invacare

®

- TDX-SP / TDX-SP N

6.3 Shark II remote: Error code s a nd diagnostic codes

The drive electronic can automatically rectify some faults. In this case the status display will stop

blinking. Switch the remote on and off again several times. Wait around 5 seconds each time

before switching the remote on again. If this does not rectify the fault, determine the cause using

the following link codes:

BLINK CODE MEANING SOLUTION DOCUMENTATION

1

2

3

4

5

Operating error Set drive lever to neutral central

position (just release drive lever) and

switch on again

Battery error Check battery and mains cable See chapter 8.4.7.

Charge batteries.

see operating manual

If you switch the mobility aid off for a

few minutes, the batteries can often

charge themselves up enough to

enable a short journey. You should,

however, only use this solution in

emergency situations because it

results in excessive battery

discharging.

Replace batteries See chapter 8.4.2.

Fault on left-hand

motor (M2)

Check motor cable and connecting

plug.

See chapters 8.4.7

and 7.1

Check motor.

Fault on righthand motor (M1)

Check motor cable and connecting

plug.

See chapters 8.4.7

and 7.1

Check motor.

Fault at left-hand

(M2) motor brake

Check cable and plug. See chapters 8.4.7

and 7.2

6

7

Fault right-hand

(M1) motor brake

Error in Shark

remote

Check cable and plug. See chapters 8.4.7

and 7.2

Check bus cable in remote and

See chapter 8.2.1.

connecting plug.

Replace remote.

8

9

10

Error in Shark

electronic

module

Communication

error in Shark

system

Unknown error Check all cables and connecting

Check all the cables and plugs in the

Shark system.

Replace electronic module

Check all cables and connecting plugs

in the Shark system.

Replace remote.

See chapters 8.4.7

and 8.2.2

See chapters 8.4.7

and 8.2.1

See chapter 8.4.7.

plugs.

11

Incompatible

remote

The wrong remote has been

connected. Ensure that electronic

See chapters 8.2.1

and 8.2.2

module code and the remote code

match.

30

Loading...

Loading...