Invacare TDXSPBASE, TDXSP, TDXSP-GT, TDXSP-MCG-GT, TDXSP-CG Service Manual

...

Service Manual

®

TDX

SP

Wheelchair Base

DEALER: Keep this manual. The

procedures in this manual MUST be

performed by a qualified technician.

For more information regarding

Invacare products, parts, and services,

please visit www.invacare.com

REFERENCE DOCUMENTS

DANGER

Risk of Death, Serious Injury or Damage

Improper use of this product may cause injury or damage.

If you are unable to understand the warnings, cautions or instructions, contact a health care

professional or dealer before attempting to use this equipment.

- DO NOT use this product or any available optional equipment without first completely reading and

understanding these instructions and any additional instructional material such as user manuals,

service manuals or instruction sheets supplied with this product or optional equipment.

Continued use of the wheelchair with damaged parts could lead to the wheelchair malfunctioning

causing injury to the user and/or caregiver.

- Check all wheelchair components and carton for damage and test components before use. In case

of damage or if the wheelchair is not working properly, contact a qualified technician or Invacare for

repair.

WARNING

Risk of Injury, Damage or Death

Improper setup, service, adjustment or programming may cause injury, damage or death.

– Qualified technician MUST setup, service and program the wheelchair.

– DO NOT allow non-qualified individuals to perform any work or adjustments on the wheelchair.

– DO NOT setup or service the wheelchair while occupied except for programming or unless

otherwise noted.

– Turn off power BEFORE adjusting or servicing the wheelchair. Note that some safety features will

be disabled.

– Ensure all hardware is securely tightened after setup, service or adjustments.

– Warranty is void if non-qualified individuals perform any work on this product.

DANGER

Risk of Death or Serious Injury

Not wearing your seat positioning strap could result in death or serious injury.

ALWAYS wear your seat positioning strap. Your seat positioning strap helps reduce the

possibility of a fall from the wheelchair. The seat positioning strap is a positioning belt only. It is

not designed for use as a safety device withstanding high stress loads such as auto or aircraft

safety belts. If signs of wear appear, seat positioning strap MUST be replaced IMMEDIATELY.

REFERENCE DOCUMENTS

Refer to the table below for part numbers of additional documents which are referenced in this manual.

MANUAL PART NUMBER

MK6i™ Electronics Field Reference Guide 1141471

Adjustable ASBA user manual 1143196

Adjustable ASBA Service Manual 1143238

NOTE: Updated versions of this manual are available on www.invacare.com

TDX® SP 2 Part No 1143209

TABLE OF CONTENTS

TABLE OF CONTENTS

REFERENCE DOCUMENTS ................................................................................. 2

SPECIAL NOTES ................................................................................................ 6

LABEL LOCATIONS ........................................................................................... 8

All Wheelchairs ......................................................................................................................................................................8

Wheelchairs with TRRO................................................................................................................................................... 10

Wheelchairs without TRRO............................................................................................................................................. 10

SPECIFICATIONS ............................................................................................ 11

TDX SP.................................................................................................................................................................................. 11

SECTION 1—GENERAL GUIDELINES ................................................................. 13

General .................................................................................................................................................................................. 13

Accessories........................................................................................................................................................................... 13

Replacement Parts ..............................................................................................................................................................13

Repair or Service Information.......................................................................................................................................... 14

Stability Lock ........................................................................................................................................................................15

Operating Information ....................................................................................................................................................... 16

Electrical ................................................................................................................................................................................ 17

SECTION 2—ELECTROMAGNETIC COMPATIBILITY (EMC) INFORMATION ......... 19

SECTION 3—SAFETY INSPECTION/TROUBLESHOOTING .................................... 21

Safety Inspection Checklists.............................................................................................................................................. 21

Troubleshooting - Mechanical.......................................................................................................................................... 22

Troubleshooting - Electrical.............................................................................................................................................. 22

Troubleshooting - Motor/Gearbox/Brake..................................................................................................................... 27

Troubleshooting - Battery................................................................................................................................................. 29

Troubleshooting - Battery Charger ................................................................................................................................ 29

Checking Battery Charge Level .......................................................................................................................................30

Field Load Test .................................................................................................................................................................... 31

4-Pole Motor Brush Inspection and/or Replacement................................................................................................. 32

Electro-Mechanical Parking Brake Testing .................................................................................................................... 33

Part No 1143209 3 TDX® SP

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION 4—WHEELS AND WHEEL LOCKS ......................................................... 34

Removing/Installing the SSD Motor Drive Wheel/Wheel Hub................................................................................ 34

Removing/Installing the Inside Rim and Pneumatic Tire............................................................................................. 34

Replacing the Front/Rear Casters ................................................................................................................................... 35

Adjusting Caster Fork Assemblies ..................................................................................................................................36

Removing/Installing the Caster Fork Assemblies......................................................................................................... 36

Installing the Wheel Locks - SSD 4-pole Motor .......................................................................................................... 37

Installing the Wheel Lock Bracket - SSD 4-pole Motor............................................................................................. 38

SECTION 5—MOTORS ...................................................................................... 39

Removing/Installing the SSD Motor/Gearbox Assembly............................................................................................ 39

Replacing the SSD Motor or Gearbox Only................................................................................................................. 40

Aligning the SSD Motor to the Gearbox....................................................................................................................... 41

Installing the SSD Brake Lever ......................................................................................................................................... 41

Installing the SSD Motor Push/Drive Label ................................................................................................................... 41

SECTION 6—SIDE FRAME ................................................................................ 42

Removing/Installing The Walking Beam Assembly ...................................................................................................... 42

Removing/Installing the Head Tube ................................................................................................................................ 44

Removing/Installing the Lower Pivot Link .....................................................................................................................44

Removing/Installing The Locking-Gas Cylinder Assembly......................................................................................... 45

Removing/Installing the Fender Assembly ..................................................................................................................... 47

Removing/Installing the Front Bumpers......................................................................................................................... 47

SECTION 7—REAR FRAME .............................................................................. 48

Removing/Installing the Rear Suspension Assembly.................................................................................................... 48

Removing/Installing the Rear Springs.............................................................................................................................. 50

Replacing the Elevator Bolt............................................................................................................................................... 51

Disassembling/Assembling the Rear Suspension Frame ............................................................................................. 51

Stability Lock Inspection/Adjustment .............................................................................................................................52

Adjusting the Stability Lock Setting................................................................................................................................. 53

Checking Stability Lock Function..................................................................................................................................... 53

Check Actuator Function.................................................................................................................................................. 54

TDX® SP 4 Part No 1143209

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION 8—BASE FRAME ............................................................................... 55

Removing/Installing Seat..................................................................................................................................................... 55

Adjusting Seat Angle (Non TRRO Wheelchairs Only) .............................................................................................. 56

Checking Formula CG Seating System Mounting Position........................................................................................ 57

Adjusting the Formula CG Seating System Mounting Position................................................................................. 58

Removing/Installing the Wheelchair Shrouds ............................................................................................................... 60

SECTION 9— BATTERIES ................................................................................. 62

Using the Proper Batteries ............................................................................................................................................... 63

Replacing Batteries.............................................................................................................................................................. 65

Cleaning Battery Terminals............................................................................................................................................... 67

Removing/Installing the Batteries From/Into the Wheelchair................................................................................... 67

Removing/Installing the Battery Tray.............................................................................................................................. 70

When to Charge Batteries................................................................................................................................................ 71

Charging Batteries............................................................................................................................................................... 72

SECTION 10—ELECTRONICS ............................................................................ 74

Controller Calibration ....................................................................................................................................................... 74

Removing/Installing the Controller ................................................................................................................................. 74

Preparing MK6i Joystick For Use..................................................................................................................................... 75

Removing/Installing/Repositioning MK6i Joystick......................................................................................................... 76

Wire Routing........................................................................................................................................................................ 77

SECTION 11—TRANSPORT IN VEHICLES .......................................................... 78

About Transport Ready Packages ................................................................................................................................... 78

Wheelchair Transport Brackets (TRBKTS) .................................................................................................................. 79

Transport Ready Option (TRRO)................................................................................................................................... 79

Compliance Information.................................................................................................................................................... 80

Securing the Wheelchair to the Vehicle........................................................................................................................ 81

Securing the Occupant....................................................................................................................................................... 82

LIMITED WARRANTY ..................................................................................... 88

Part No 1143209 5 TDX® SP

SPECIAL NOTES

SPECIAL NOTES

Signal words are used in this manual and apply to hazards or unsafe practices which could result in personal injury or

property damage. See the information below for definitions of the signal words.

SIGNAL WORD MEANING

Danger indicates an imminently hazardous situation which, if not avoided, will result in death or

DANGER

WARNING

CAUTION

IMPORTANT Indicates a hazardous situation that could result in damage to property if it is not avoided.

NOTE: Gives useful tips, recommendations and information for efficient, trouble-free use.

NOTE: THE INFORMATION CONTAINED IN THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE.

NOTE: As a manufacturer of wheelchairs, Invacare endeavors to supply a wide variety of wheelchairs to meet many needs of the end

user. However, final selection of the type of wheelchair to be used by an individual rests solely with the user and his/her healthcare

professional capable of making such a selection. Invacare highly recommends working with a qualified rehab technology provider, such

as an ATP (Assistive Technology Professional).

serious injury.

Warning indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Caution indicates a potentially hazardous situation which, if not avoided, may result in property

damage, minor injury or both.

NOTICE

NOTE: As of January, 1 2017, Transport Ready Option (TRRO) has been discontinued on this product. Please

contact your dealer or Invacare for legacy information or to answer questions regarding TRRO.

As of this date, the Department of Transportation has not approved any tie-down systems for

transportation of a user while in a wheelchair, in a moving vehicle of any type. It is Invacare’s

position that users of wheelchairs should be transferred into appropriate seating in vehicles for

transportation and use be made of the restraints made available by the auto industry. Invacare

cannot and does not recommend any wheelchair transportation systems.

• TRBKTS includes four factory-installed wheelchair transport brackets. TRBKTS has not been

crash-tested in accordance with WC 19. Use these transport brackets only to secure an unoccupied

wheelchair during transport.

• TRRO includes four factory-installed transport brackets and a wheelchair anchored pelvic belt.

TRRO has been crash-tested in accordance with ANSI/RESNA WC Vol 1 Section 19 Frontal Impact

Test requirements for wheelchairs with a 168 lb crash dummy, which corresponds to a person with

a weight of 114 to 209 lbs.

WARNING

Improper installation or service may result in injury, damage or death.

- Transport ready packages are not retrofittable to existing models and are not field serviceable.

- DO NOT over tighten hardware.

NOTE: Refer to Transport in Vehicles on page 78 for more information about transporting the wheelchair.

NOTE: Wheelchairs with TRRO or TRBKTS Only - Battery retention brackets MUST be installed at all times.

TDX® SP 6 Part No 1143209

SPECIAL NOTES

The drive behavior initially experienced by the user may be different from other wheelchairs previously used. This power

wheelchair has Invacare’s SureStep® technology, a feature that provides the wheelchair with optimum traction and stability

when driving forward over transitions and thresholds. The following warnings apply specifically to the SureStep feature:

WARNING!

Risk of Injury, Damage or Death

Loss of traction or stability on inclines/grades or ramps may cause injury, damage or death.

Lighter weight users may be at an increased risk. Surfaces that may be wet, icy, oily, slippery,

painted, treated wood, rotten wood, rusted metal or other similar surfaces or materials may also

increase risk.

– DO NOT use on inclines or ramps where surface is uncertain or compromised.

– DO NOT use on inclines greater than nine (9) degrees.

– DO NOT operate the seating system while the wheelchair is moving. Stop before operating

seating system.

– DO NOT operate the seating system while on an incline. Operation on an incline may result in

increased instability.

– To determine and establish your particular safety limits, practice use of this product on various

sloping surfaces in the presence of a qualified healthcare provider before attempting active use of

this wheelchair.

– DO NOT use on inclines where line of sight is impaired.

– Travel at a reduced, constant speed and DO NOT make sudden stops or direction changes.

Release the joystick and allow the wheelchair to come to a full stop before changing directions.

Traveling at high speeds reduces traction and increases stopping distance.

– DO NOT drive in an elevated position while on an incline.

– DO NOT leave elevating legrests in the fully extended position when proceeding down

inclines/grades.

– DO NOT leave an unoccupied wheelchair unattended on inclines or ramps.

Part No 1143209 7 TDX® SP

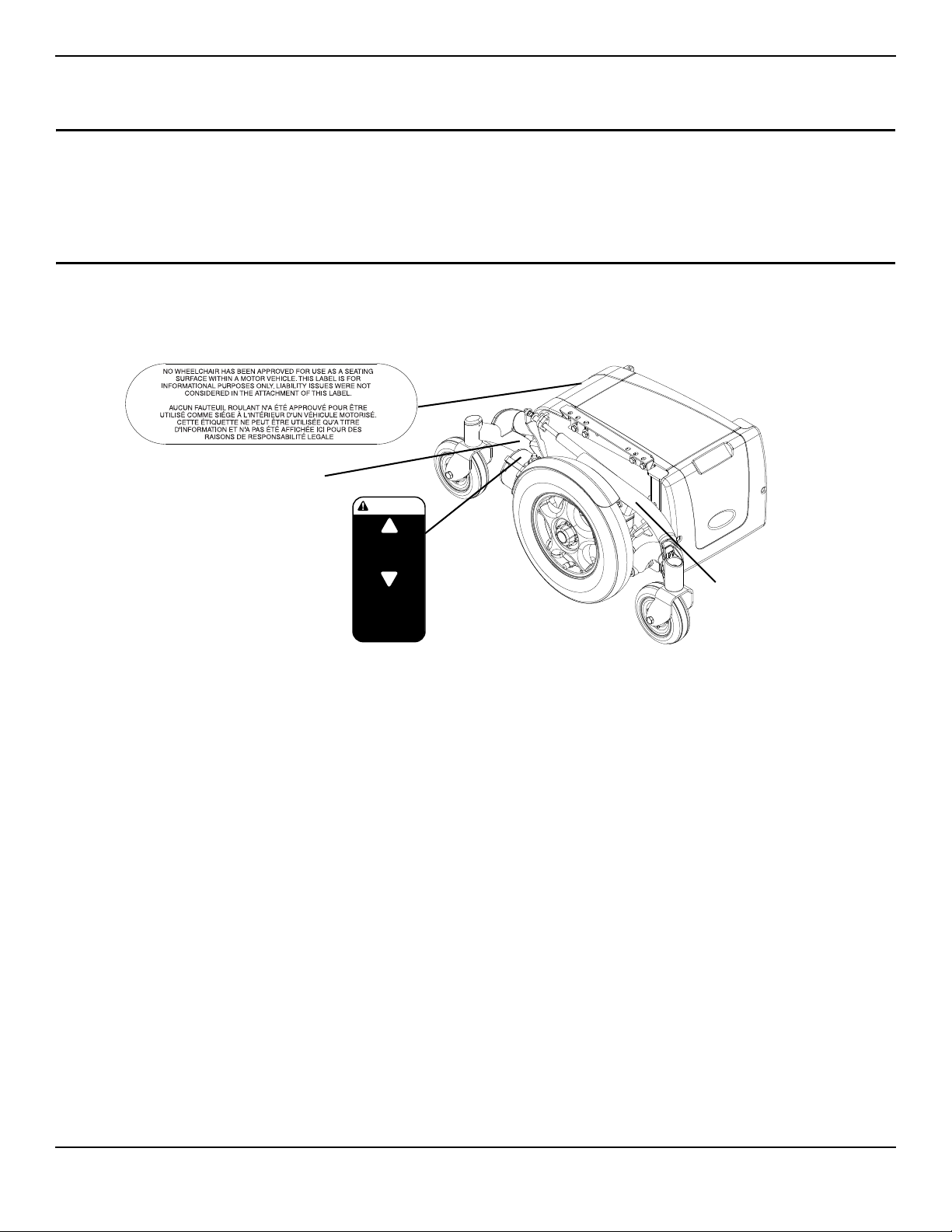

LABEL LOCATIONS

Serial Number Label is

located on the right side

rear swingarm.

Weight Capacity

Label located here

(Base Only)

P/N 1118367

Rev A - 3/03

DRIVE

PUSH

CAUTION

Ensure both clutches

are fully engaged

before driving chair

Located on each

4-pole motor

LABEL LOCATIONS

DANGER

Risk of Injury, Damage or Death

Missing or damaged labels may contribute to injury damage or death.

- Ensure labels are present and legible.

NOTE: Labels are subject to change without notice.

All Wheelchairs

TDX® SP 8 Part No 1143209

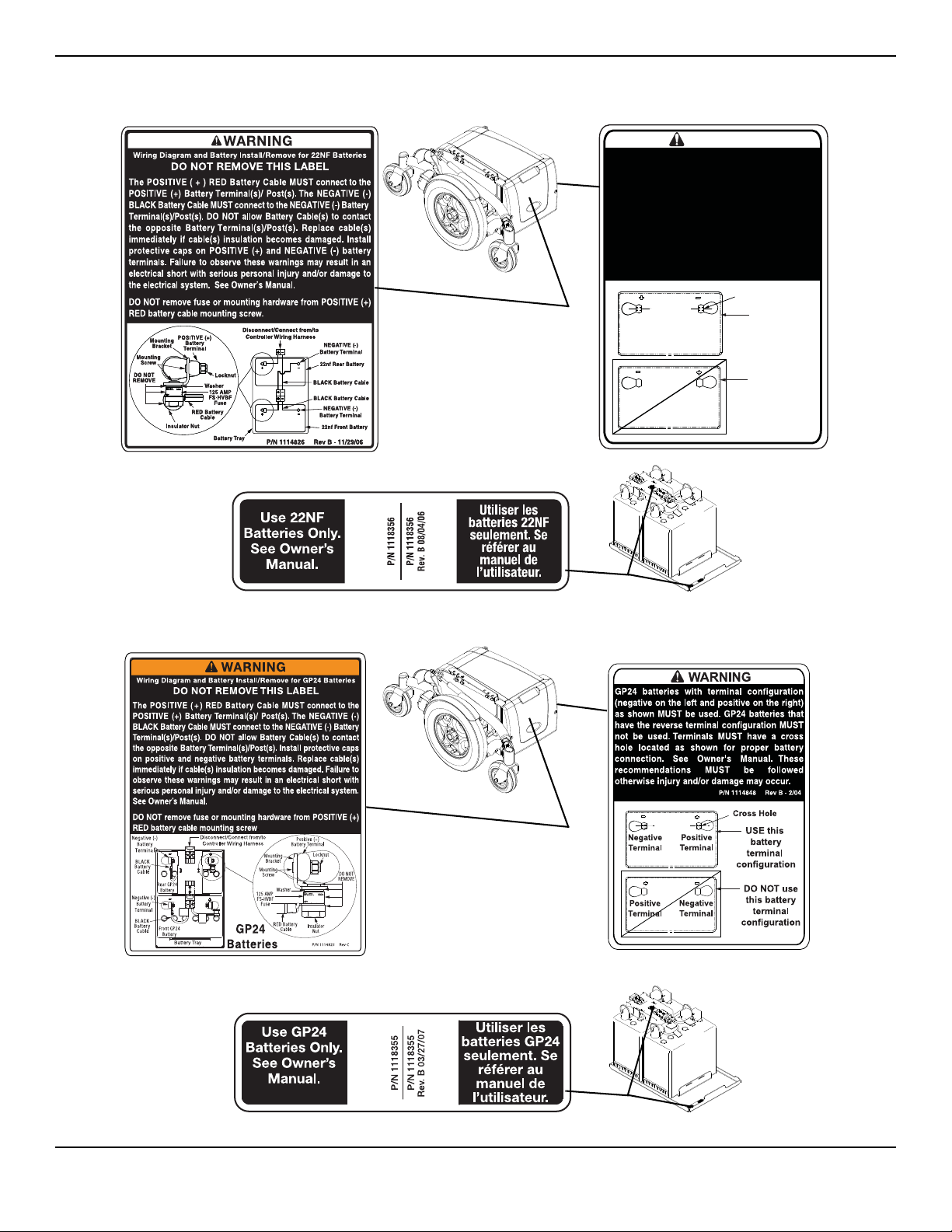

Wheelchairs with 22NF Batteries

WARNING

USE this

battery

terminal

configuration

Positive

Terminal

Negative

Terminal

Positive

Terminal

Negative

Terminal

P/N 1114847 Rev B - 2/04

Cross Hole

DO NOT use

this battery

terminal

configuration

22NF batteries with terminal configuration

(positive on the left and negative on the right)

as shown MUST be used. 22NF batteries that

have the reverse terminal configuration MUST

not be used. Terminals MUST have a cross

hole located as shown for proper battery

connection. See Owner's Manual. These

recommendations MUST be followed

otherwise injury and/or damage may occur.

LABEL LOCATIONS

Wheelchairs with GP24 Batteries

Part No 1143209 9 TDX® SP

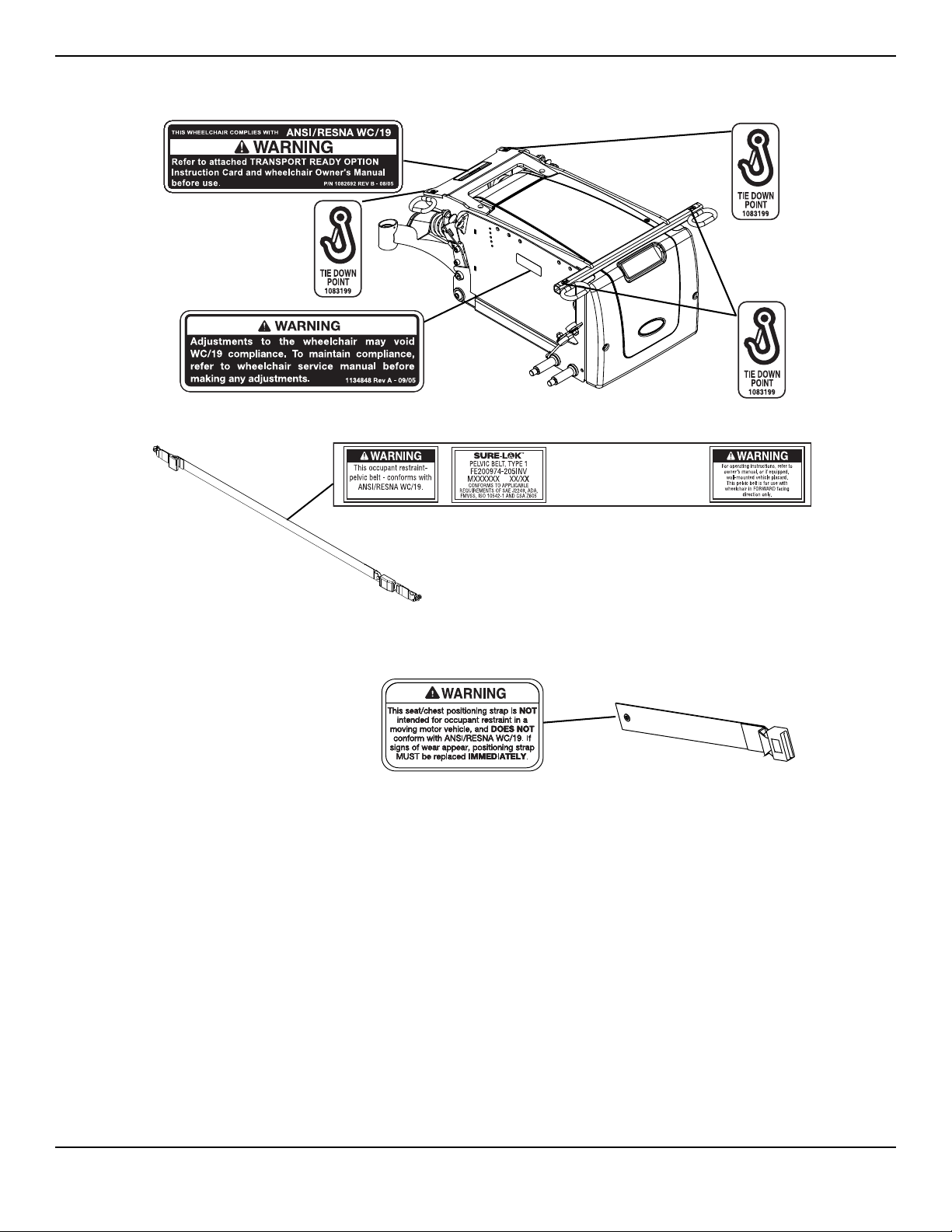

LABEL LOCATIONS

NOTE: Also on opposite side.

NOTE: Auto style seat positioning strap

shown. This label is also on the airline

style seat positioning strap.

Wheelchairs with TRRO

Wheelchairs without TRRO

TDX® SP 10 Part No 1143209

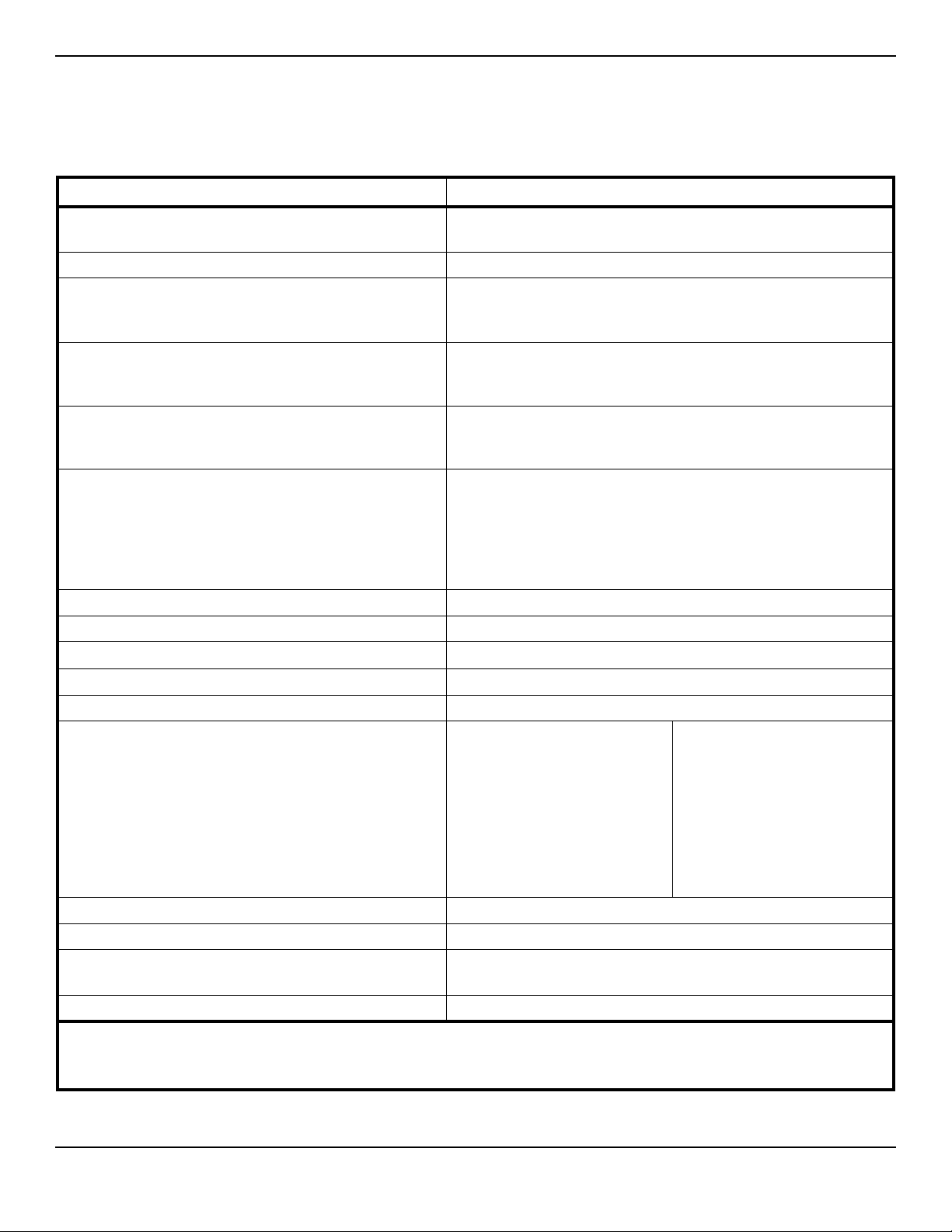

SPECIFICATIONS

SPECIFICATIONS

TDX SP

TDX SP

MODELS: TDXSPBASE, TDXSP, TDXSP-CG, TDXSP-MCG, TDXSP-CG-GT,

TDXSP-GT, TDXSP-MCG-GT

BASE LENGTH (WITHOUT FRONT RIGGINGS): 35.25 inches

OVERALL WIDTH OF BASE

(WITHOUT JOYSTICK): 24 inches (With two 22NF Batteries)

25.5 - inches (With two GP 24 Batteries or three 22NF Batteries)

OVERALL HEIGHT

WITH ASBA SEAT:

WITH FORMULA CG TILT ONLY:

OVERALL LENGTH

WITH CENTER MOUNT FRONT RIGGING:

WITHOUT FRONT RIGGINGS:

WEIGHT (BASE ONLY)

WITHOUT 22NF BATTERIES:

WITH TWO 22NF BATTERIES:

WITHOUT GP24 BATTERIES:

WITH TWO GP24 BATTERIES:

WITH TRANSPORT READY OPTION:

MOTOR: 4 Pole

35.5 to 39.5 inches

36.5 to 40.5 inches

42.9 inches @ 0°

35.25 inches

123 lbs

221 lbs

158 lbs

260 lbs

Add 10 lbs

DRIVE AXLE: Non-adjustable

*DRIVE WHEELS/TIRES: 14 x 3-inch Foam Filled or Pneumatic (Standard)

*CASTERS: 6 x 2-inch, Semi-pneumatic with Precision Sealed Bearings

CASTER FORKS: Two side fork

BATTERY REQUIREMENTS

NUMBER OF BATTERIES NEEDED:

MANUFACTURER:

MODEL:

VOLTAGE:

CAPACITY (AMP-HOURS) FOR 5 HOUR RATING:

NOTE: Only sealed non-spillable batteries that meet DOT

CFR 173.159 (d), IATA Packing Instructions 806, and IATA

Provision A67 shall be installed in this wheelchair.

OPERATING TEMPERATURE

STORAGE TEMPERATURE

FOOTRESTS: Telescoping Front Rigging Supports,

SEAT TILT ANGLE ADJUSTMENT: Adjustable (0° to 10°)

NOTE: All dimensions are ± .50 inches unless otherwise indicated.

*NOTE: The size of tire is marked on the side wall of each drive tire. The caster tires do not have the tire size marked as the caster tires

are not serviceable. If new tire is needed, the entire caster wheel assembly MUST be replaced.

p/n M24SLDG batteries only

GP24

2

MK batteries

p/n M22NFSLDG batteries only

12

63

122 F (50 C) Maximum to -13 F (-25 C) Minimum

149 F (65 C) Maximum to -58 F (-40 C) Minimum

2-inch and 4-inch long Pivot Slide Tube

MK batteries

22NF

2

12

43.2

Part No 1143209 11 TDX® SP

SPECIFICATIONS

TDX SP

WEIGHT LIMITATION

WITH ASBA SEAT:

WITH FORMULA™ CG POWERED SEATING:

4 POLE

Up to 300 lbs

Up to 300 lbs

WARNING

Risk of Death or Serious Injury

Exceeding the weight capacity of the wheelchair/seating system could cause instability resulting

in death or serious injury.

– DO NOT exceed the weight capacity.

NOTE: Weight limitation is total weight (user weight plus any additional items that the user may require [back pack, etc.]). Example:

If weight limitation of the wheelchair is 300 lbs and additional items equal 25 lbs, subtract 25 lbs from 300 lbs this means the maximum

weight limitation of the user is 275 lbs.

NOTE: All dimensions are ± .50 inches unless otherwise indicated.

*NOTE: The size of tire is marked on the side wall of each drive tire. The caster tires do not have the tire size marked as the caster tires

are not serviceable. If new tire is needed, the entire caster wheel assembly MUST be replaced.

TDX® SP 12 Part No 1143209

SECTION 1—GENERAL GUIDELINES

SECTION 1—GENERAL GUIDELINES

NOTE: SECTION 1 - GENERAL GUIDELINES contains important information for the safe operation and use of this product.

General

DANGER

Risk of Death, Serious Injury or Damage

Improper use of this product may cause injury or damage.

If you are unable to understand the warnings, cautions or instructions, contact a health care

professional or dealer before attempting to use this equipment.

- DO NOT use this product or any available optional equipment without first completely reading

and understanding these instructions and any additional instructional material such as user

manuals, service manuals or instruction sheets supplied with this product or optional equipment.

Continued use of the wheelchair with damaged parts could lead to the wheelchair malfunctioning

causing injury to the user and/or caregiver.

- Check all wheelchair components and carton for damage and test components before use. In

case of damage or if the wheelchair is not working properly, contact a qualified technician or

Invacare for repair.

Accessories

WARNING

Risk of Serious Injury or Damage

Use of non-Invacare accessories may result in serious injury or damage.

Invacare products are specifically designed and manufactured for use in conjunction with

Invacare accessories. Accessories designed by other manufacturers have not been tested by

Invacare and are not recommended for use with Invacare products.

DO NOT use non-Invacare accessories.

To obtain Invacare accessories, contact Invacare by phone or at www.invacare.com.

Replacement Parts

DANGER

Risk of Death, Serious Injury or Damage

Use of incorrect or improper replacement (service) parts may cause death, serious injury, or

damage.

Replacement parts MUST match original Invacare parts.

ALWAYS provide the wheelchair serial number to assist in ordering the correct replacement

parts.

Part No 1143209 13 TDX® SP

SECTION 1—GENERAL GUIDELINES

Repair or Service Information

DANGER

Risk of Death, Serious Injury, or Damage

Continued use of the wheelchair that is not set to the correct specifications may cause erratic

behavior of the wheelchair resulting in death, serious injury, or damage.

Performance adjustments should only be made by professionals of the healthcare field or persons

fully conversant with this process and the driver's capabilities.

After the wheelchair has been set up/adjusted, check to make sure that the wheelchair performs

to the specifications entered during the set up procedure. If the wheelchair does not perform to

specifications, turn the wheelchair Off immediately and reenter set up specifications. Contact

Invacare, if wheelchair still does not perform to correct specifications.

WARNING

Risk of Death, Serious Injury, or Damage

Missing attaching hardware could cause instability resulting in death, serious injury or damage.

Ensure all attaching hardware is present and tightened securely.

WARNING

Risk of Serious Injury or Damage

Attaching hardware that is loosely secured could cause loss of stability resulting in serious injury

or damage

After ANY adjustments, repair or service and before use, make sure that all attaching hardware

is tightened securely.

DANGER

Risk of Death or Serious Injury

Electric shock can cause death or serious injury

To avoid electric shock, inspect plug and cord for cuts and/or frayed wires. Replace cut cords or

frayed wires immediately.

DANGER

Risk of Death, Serious Injury, or Damage

Corroded electrical components due to water and/or liquid exposure, or incontinent users can

result in death, serious injury, or damage.

– Minimize exposure of electrical components to water and/or liquids. Electrical components

damaged by corrosion MUST be replaced immediately.

– Wheelchairs that are used by incontinent users and/or are frequently exposed to water/liquids

may require replacement of electrical components more frequently.

TDX® SP 14 Part No 1143209

SECTION 1—GENERAL GUIDELINES

WARNING

Risk of Injury, Damage or Death

Malfunctioning or damaged joystick may cause unintended/erratic movement resulting in injury,

damage or death.

– Ensure the joystick is securely connected to controller.

– DO NOT use if joystick does not spring back to the neutral position or becomes sticky or

sluggish.

– DO NOT use if joystick boot is torn or damaged.

– DO NOT use with a broken or missing joystick knob.

– If unintended/erratic movement occurs, stop using the wheelchair immediately and contact a

qualified technician.

– Ensure control knobs are secure before using the wheelchair. Stop using the wheelchair

immediately and contact a qualified technician if control knobs are not secure.

G-Trac

WARNING

Risk of Serious Injury or Damage

Improperly connecting the motor leads to the controller may cause injury or damage.

WHEELCHAIRS WITH G-TRAC: Crossing the motor leads (for example: connecting the left

motor lead into the right motor connector on the controller) may result in unintended

movement.

DO NOT cross the motor leads when connecting the motors to the controller - otherwise injury

or damage may occur.

Stability Lock

DANGER

Risk of Death or Serious Injury

Not performing periodic maintenance on stability lock could result in death or serious injury.

ALWAYS perform the periodic maintenance to the stability lock listed in the inspection

checklist of this manual.

Part No 1143209 15 TDX® SP

SECTION 1—GENERAL GUIDELINES

Sip n’ Puff (Pneumatic) Controls

WARNING!

Risk of Injury or Damage

Improper mounting or maintenance of the Sip n’ Puff control including the mouthpiece and

breath tube may cause injury or damage.

Water inside the Sip n’ Puff interface module may cause damage to the unit.

Excessive saliva residue in the mouthpiece/straw can reduce performance.

Blockages, a clogged saliva trap or air leaks in the system may cause Sip N’ Puff not to function

properly.

– Ensure moving parts of the wheelchair, including the operation of powered seating, DO NOT

pinch or damage the Sip n’ Puff tubing.

– Saliva trap MUST be installed to reduce risk of water or saliva entering the Sip n’ Puff interface

module.

– Occasionally flush the mouthpiece to remove saliva residue.

– The mouthpiece/straw MUST be completely dry before installation.

– If Sip n’ Puff does not function properly, inspect system for blockages, clogged saliva trap or air

leaks.

– As necessary, replace mouthpiece, breath tube and saliva trap.

NOTE: Contact your Invacare dealer/provider for more information about maintaining and troubleshooting the Sip n’ Puff system.

Operating Information

WARNING

Risk of Minor to Serious Injury

Pinch points can cause minor to serious injury.

Be mindful of potential pinch points and use caution when using this product.

TDX® SP 16 Part No 1143209

SECTION 1—GENERAL GUIDELINES

WARNING

Risk of Injury, Damage or Death

Loss of traction or stability on inclines/grades or ramps may cause injury, damage or death.

Lighter weight users may be at an increased risk. Surfaces that may be wet, icy, oily, slippery,

painted, treated wood, rotten wood, rusted metal or other similar surfaces or materials may also

increase risk.

– DO NOT use on inclines or ramps where surface is uncertain or compromised.

– DO NOT use on inclines greater than nine (9) degrees.

– DO NOT operate the seating system while the wheelchair is moving. Stop before operating

seating system.

– DO NOT operate the seating system while on an incline. Operation on an incline may result in

increased instability.

– To determine and establish your particular safety limits, practice use of this product on various

sloping surfaces in the presence of a qualified healthcare provider before attempting active use of

this wheelchair.

– DO NOT use on inclines where line of sight is impaired.

– Travel at a reduced, constant speed and DO NOT make sudden stops or direction changes.

Release the joystick and allow the wheelchair to come to a full stop before changing directions.

Traveling at high speeds reduces traction and increases stopping distance.

– DO NOT drive in an elevated position while on an incline.

– DO NOT leave elevating legrests in the fully extended position when proceeding down

inclines/grades.

– DO NOT leave an unoccupied wheelchair unattended on inclines or ramps.

Electrical

Grounding Instructions

WARNING

Power wheelchairs are equipped with three-prong (grounding) plugs for protection against

possible shock hazards. Where a two-prong wall receptacle is encountered, it is the personal

responsibility and obligation of the customer to contact a qualified electrician and have the

two-prong replaced with a properly grounded three-prong wall receptacle in accordance with

the National Electrical code. If you must use an extension cord, use only a three-wire extension

cord having the same or higher electrical rating as the device being connected. DO NOT, under

any circumstances, cut or remove the round grounding prong from any plug used with or for

Invacare products. In addition, Invacare has placed RED warning tags on some equipment. DO

NOT remove these tags.

Part No 1143209 17 TDX® SP

SECTION 1—GENERAL GUIDELINES

DANGER

Risk of Death, Injury or Damage

Shock hazards and risk of fire exist due to use of improper extension cord and/or use of three

prong adapters.

– To avoid injury or product damage, when using an extension cord, use only a UL approved

three wire extension cord having at least 16 AWG (American Wire Gauge) wire and the same or

higher electrical rating as the device being connected.

– DO NOT use three prong to two prong adapters.

TDX® SP 18 Part No 1143209

SECTION 2—ELECTROMAGNETIC COMPATIBILITY (EMC) INFORMATION

SECTION 2—ELECTROMAGNETIC COMPATIBILITY

(EMC) INFORMATION

WARNING

CAUTION: IT IS VERY IMPORTANT THAT YOU READ THIS INFORMATION REGARDING

THE POSSIBLE EFFECTS OF ELECTROMAGNETIC INTERFERENCE ON YOUR POWERED

WHEELCHAIR.

Electromagnetic Interference (EMI) From Radio Wave Sources

Powered wheelchairs and motorized scooters (in this text, both will be referred to as powered

wheelchairs) may be susceptible to electromagnetic interference (EMI), which is interfering

electromagnetic energy (EM) emitted from sources such as radio stations, TV stations, amateur

radio (HAM) transmitters, two way radios, and cellular phones. The interference (from radio

wave sources) can cause the powered wheelchair to release its brakes, move by itself, or move in

unintended directions. It can also permanently damage the powered wheelchair's control

system. The intensity of the interfering EM energy can be measured in volts per metre (V/m).

Each powered wheelchair can resist EMI up to a certain intensity. This is called its "immunity

level." The higher the immunity level, the greater the protection. At this time, current

technology is capable of achieving at least a 20 V/m immunity level, which would provide useful

protection from the more common sources of radiated EMI.

There are a number of sources of relatively intense electromagnetic fields in the everyday

environment. Some of these sources are obvious and easy to avoid. Others are not apparent and

exposure is unavoidable. However, we believe that by following the warnings listed below, your

risk to EMI will be minimized.

The sources of radiated EMI can be broadly classified into three types:

1) Hand-held Portable transceivers (transmitters-receivers with the antenna mounted directly

on the transmitting unit. Examples include: citizens band (CB) radios, "walkie talkie",

security, fire and police transceivers, cellular telephones, and other personal communication

devices).

NOTE: Some cellular telephones and similar devices transmit signals while they are ON, even when not

being used.

2) Medium-range mobile transceivers, such as those used in police cars, fire trucks, ambulances

and taxis. These usually have the antenna mounted on the outside of the vehicle; and

3) Long-range transmitters and transceivers, such as commercial broadcast transmitters (radio

and TV broadcast antenna towers) and amateur (HAM) radios.

NOTE: Other types of hand-held devices, such as cordless phones, laptop computers, AM/FM radios,

TV sets, CD players, cassette players, and small appliances, such as electric shavers and hair dryers, so

far as we know, are not likely to cause EMI problems to your powered wheelchair.

Part No 1143209 19 TDX® SP

SECTION 2—ELECTROMAGNETIC COMPATIBILITY (EMC) INFORMATION

WARNING

Powered Wheelchair Electromagnetic Interference (EMI)

Because EM energy rapidly becomes more intense as one moves closer to the transmitting

antenna (source), the EM fields from hand-held radio wave sources (transceivers) are of special

concern. It is possible to unintentionally bring high levels of EM energy very close to the powered

wheelchair's control system while using these devices. This can affect powered wheelchair

movement and braking. Therefore, the warnings listed below are recommended to prevent

possible interference with the control system of the powered wheelchair.

Electromagnetic interference (EMI) from sources such as radio and TV stations, amateur radio

(HAM) transmitters, two-way radios, and cellular phones can affect powered wheelchairs and

motorized scooters. Also, the electronics used in our powered wheelchair can generate a low

level of electromagnetic interference, which however will remain within the tolerances

permitted by law.

FOLLOWING THE WARNINGS LISTED BELOW SHOULD REDUCE THE CHANCE OF

UNINTENDED BRAKE RELEASE OR POWERED WHEELCHAIR MOVEMENT WHICH

COULD RESULT IN SERIOUS INJURY.

1) Do not operate hand-held transceivers (transmitters receivers), such as citizens band (CB)

radios, or turn ON personal communication devices, such as cellular phones, while the

powered wheelchair is turned ON;

2) Be aware of nearby transmitters, such as radio or TV stations, and try to avoid coming close

to them;

3) If unintended movement or brake release occurs, turn the powered wheelchair OFF as soon

as it is safe;

4) Be aware that adding accessories or components, or modifying the powered wheelchair, may

make it more susceptible to EMI (NOTE: There is no easy way to evaluate their effect on the

overall immunity of the powered wheelchair); and

5) Report all incidents of unintended movement or brake release to the powered wheelchair

manufacturer, and note whether there is a source of EMI nearby.

Important Information

1) 20 volts per metre (V/m) is a generally achievable and useful immunity level against EMI (as of

May 1994) (the higher the level, the greater the protection);

2) This device has been tested to a radiated immunity level of 20 volts per meter.

3) The immunity level of the product is unknown.

Modification of any kind to the electronics of this wheelchair as manufactured by Invacare may

adversely affect the EMI immunity levels.

CAUTION

Risk of Injury or Damage

EMC interference affecting other products may result in injury or damage.

To avoid impacting the operation and function of other products:

- Products not specified by Invacare that may be used on or near the wheelchair may be

impacted by emissions from this product if they have a sensitivity level that is lower than the

recognized standard and provided by this wheelchair. Refer to the manufacturer specifications

for any electronic device BEFORE use near this product to determine its level of immunity and

potential risk.

TDX® SP 20 Part No 1143209

SECTION 3—SAFETY INSPECTION/TROUBLESHOOTING

SECTION 3—SAFETY INSPECTION/TROUBLESHOOTING

Safety Inspection Checklists

NOTE: Initial adjustments should be made to suit the end user's personal body structure needs and preference. After initial setup, perform these

procedures every time the wheelchair is serviced.

Inspect/Adjust Initially

DANGER

Risk of Injury, Damage or Death

Overinflation of tires may cause tires to explode.

—Inflate tire to the proper tire pressure (P.S.I./ kilopascals) listed on the side wall of the tire.

—Only use wheelchair with tires at proper tire pressure.

—The wheels and tires should be checked periodically for cracks and wear and should be

replaced if necessary.

❑ Ensure wheelchair rolls straight (no excessive drag or pull to one side).

❑ Inspect all fasteners.

❑ Inspect TRRO/TRBKTS fasteners and hardware.

❑ Ensure clothing guards are secure.

❑ Arms are secure but easy to release and adjustment levers engage properly.

❑ Adjustable height arms operate and lock securely.

❑ Upholstery has no rips.

❑ Armrest pad sits flush against arm tube.

❑ Axle nut and wheel mounting nuts are secure on drive wheels.

❑ No excessive side movement or binding when drive wheels are lifted and spun when disengaged (free-wheeling).

❑ Ensure that casters are free of debris.

❑ Wheels/casters have proper tension when wheels/casters are spun (when free-wheeling). Wheels/casters should come to a

gradual stop.

❑ Loosen/tighten caster locknut if wheel wobbles noticeably or binds to a stop.

❑ Ensure all caster/wheel/fork/headtube fasteners are secure and not damaged/missing.

❑ Wheel locks DO NOT interfere with tires when rolling.

❑ Wheel lock pivot point are free of wear and looseness.

❑ Wheel locks are easy to engage.

❑ Inspect tires for flat spots and wear.

❑ Check pneumatic tires for proper inflation.

❑ Check center mount front riggings for worn/frayed belts and/or loose fasteners. If found, replace these items.

❑ Check that all labels are present and legible. Replace if necessary.

❑ Inspect locking gas cylinders.

❑ Clean upholstery and armrests.

❑ Clean dirt and lint from axles.

❑ Clean dirt and lint from bearings.

❑ Inspect mechanical anti-dive for function.

❑ Inspect seat positioning strap for any signs of wear. Ensure buckle latches. Verify hardware that attaches strap to frame is

secure and undamaged. Replace if necessary.

❑ Inspect foam handgrips for damage. If damaged, have them replaced by a qualified technician.

❑ Inspect motor brushes and gearbox coupling.

❑ Inspect electrical components for signs of corrosion. Replace if corroded or damaged.

❑ For optimum performance, replace locking-gas cylinders every two years.

Part No 1143209 21 TDX® SP

SECTION 3—SAFETY INSPECTION/TROUBLESHOOTING

Troubleshooting - Mechanical

SOLUTIONS

TURN/

SLUGGISH

WHEELCHAIR

VEERS LEFT/RIGHT

X X X If pneumatic, check tires for correct and equal pressure.

X X X X Check for loose stem nuts/bolts.

X X Check that casters contact ground at the same time.

CASTERS

FLUTTER

PERFORMANCE

SQUEAKS AND

RATTLES

LOOSENESS

IN WHEELCHAIR

X X If pneumatic, check tires for correct and equal pressure.

WHEELS

WHEELCHAIR 3

Troubleshooting - Electrical

NOTE: For additional troubleshooting information and explanation of error codes, refer to the individual Electronics Manual supplied with

each wheelchair.

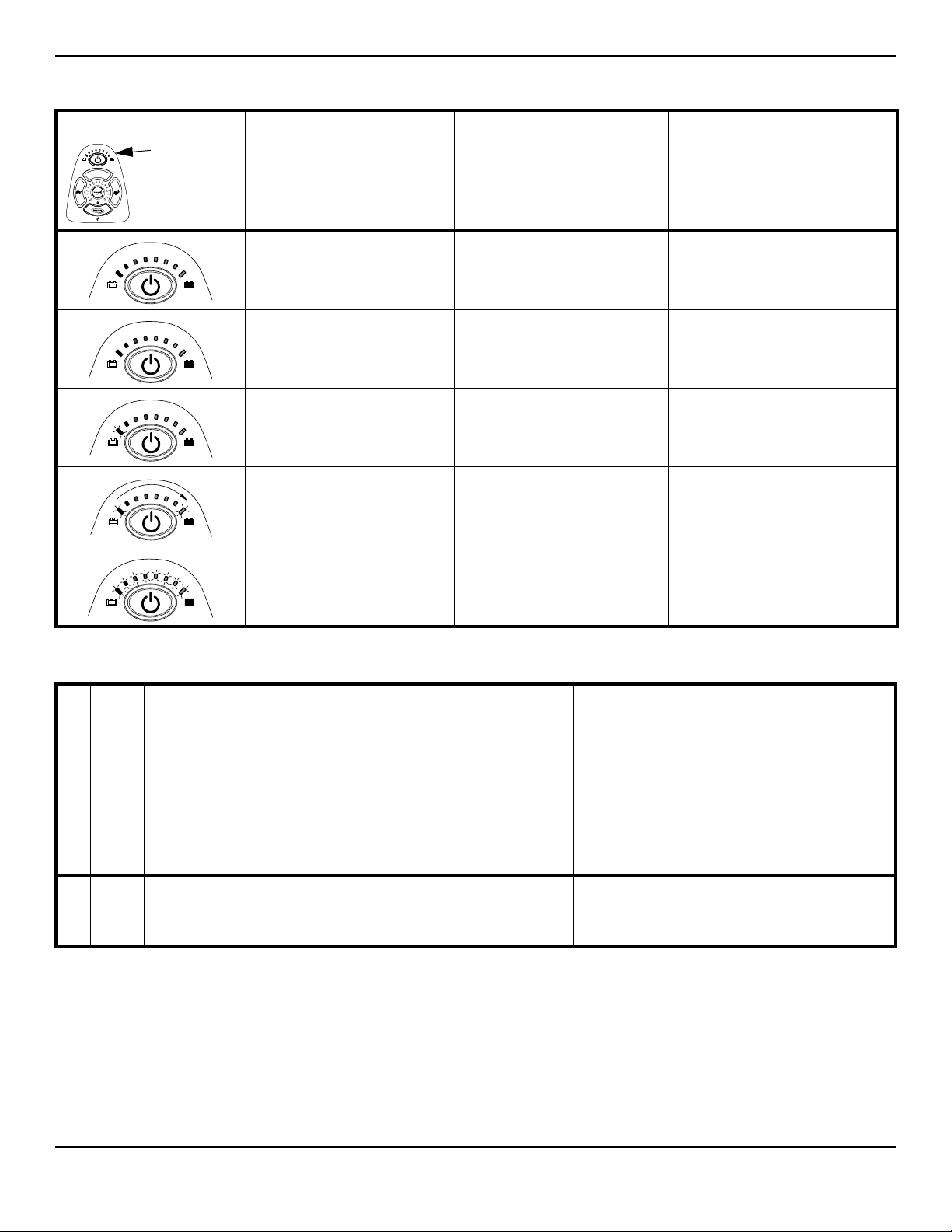

SPJ™+, SPJ+ w/PSS or SPJ+ w/ACC Joysticks

The joystick information gauge and the service indicator give indications of the type of fault or error detected by the control

module. When a fault is detected, the wheelchair may stop and not drive. The LEDs on the information gauge may flash in a

particular pattern or the service indicator light will flash. The number or type of flashes indicates the nature of the error. If multiple

errors are found, only the first error encountered by the control module will be displayed.

TDX® SP 22 Part No 1143209

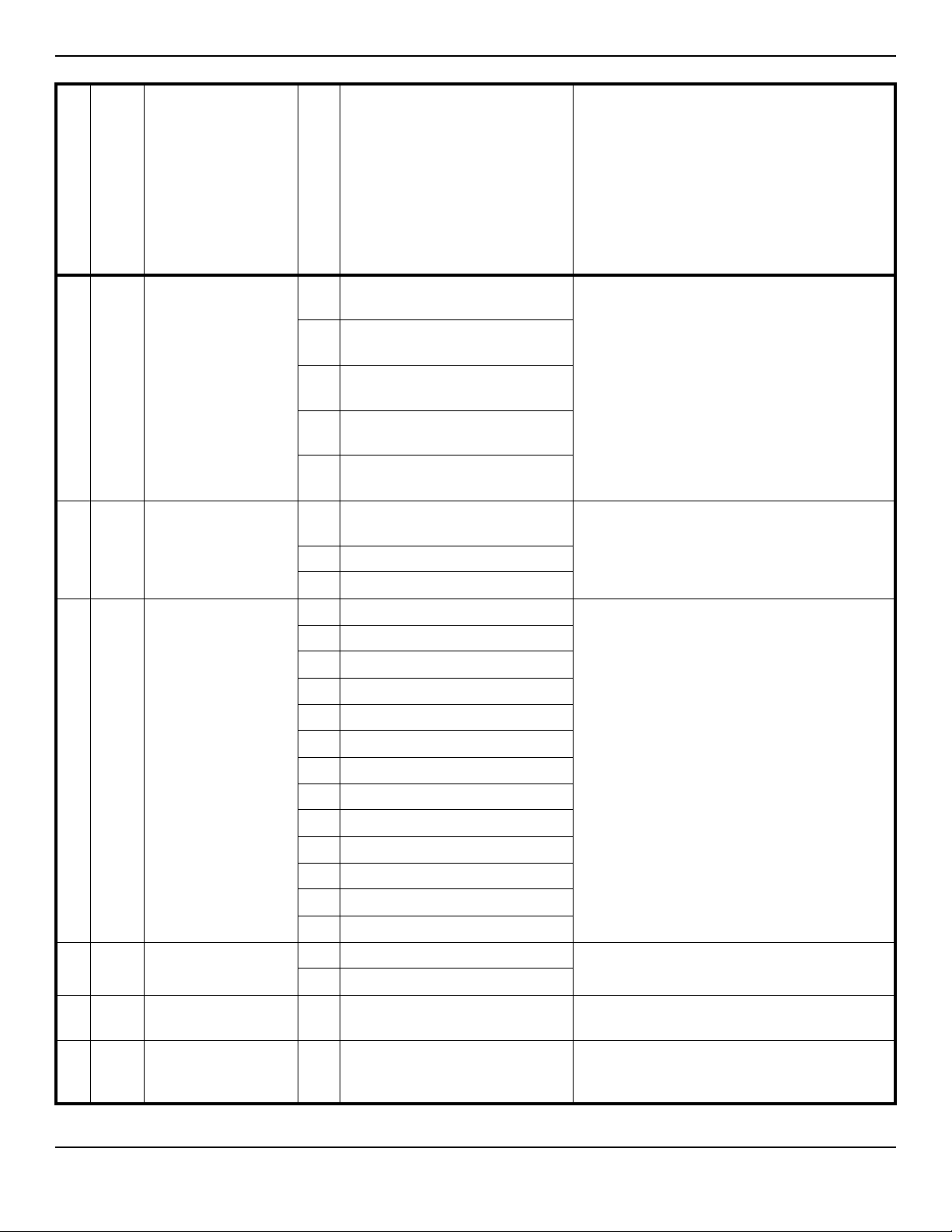

Information Gauge Display Diagnostics

Information

Gauge

Display

DISPLAY DESCRIPTION DEFINITION COMMENTS

All LEDs are off. Power is off.

All LEDs are on. Power is on. Fewer than three LEDs on implies

Left RED LED is flashing. Battery charge is low. The batteries should be charged

SECTION 3—SAFETY INSPECTION/TROUBLESHOOTING

reduced battery charge.

as soon as possible.

Left to Right “chase”

alternating with steady display.

All LEDs are flashing slowly. Joystick has detected Out- of-

Joystick is in programming,

inhibit and/or charging mode.

Neutral-at-Power-Up mode.

The steady LEDs indicate the

current state of the battery

charge.

Release the joystick to Neutral.

Service Indicator Light Diagnostics

POSSIBLE

ERROR CODE

DESCRIPTION

DIAGNOSTICS CODE

NUMBER OF FLASHES

1 E 01 User Fault 00 Stall Timeout or user error. Release joystick to neutral and try again.

2 E02 Battery Fault 00 Recharge batteries or replace. Check the batteries and cable. Try charging the

SUB CODE*

DETAILS OF

ERROR CODE

batteries. Batteries may require replacing.

SOLUTION

Part No 1143209 23 TDX® SP

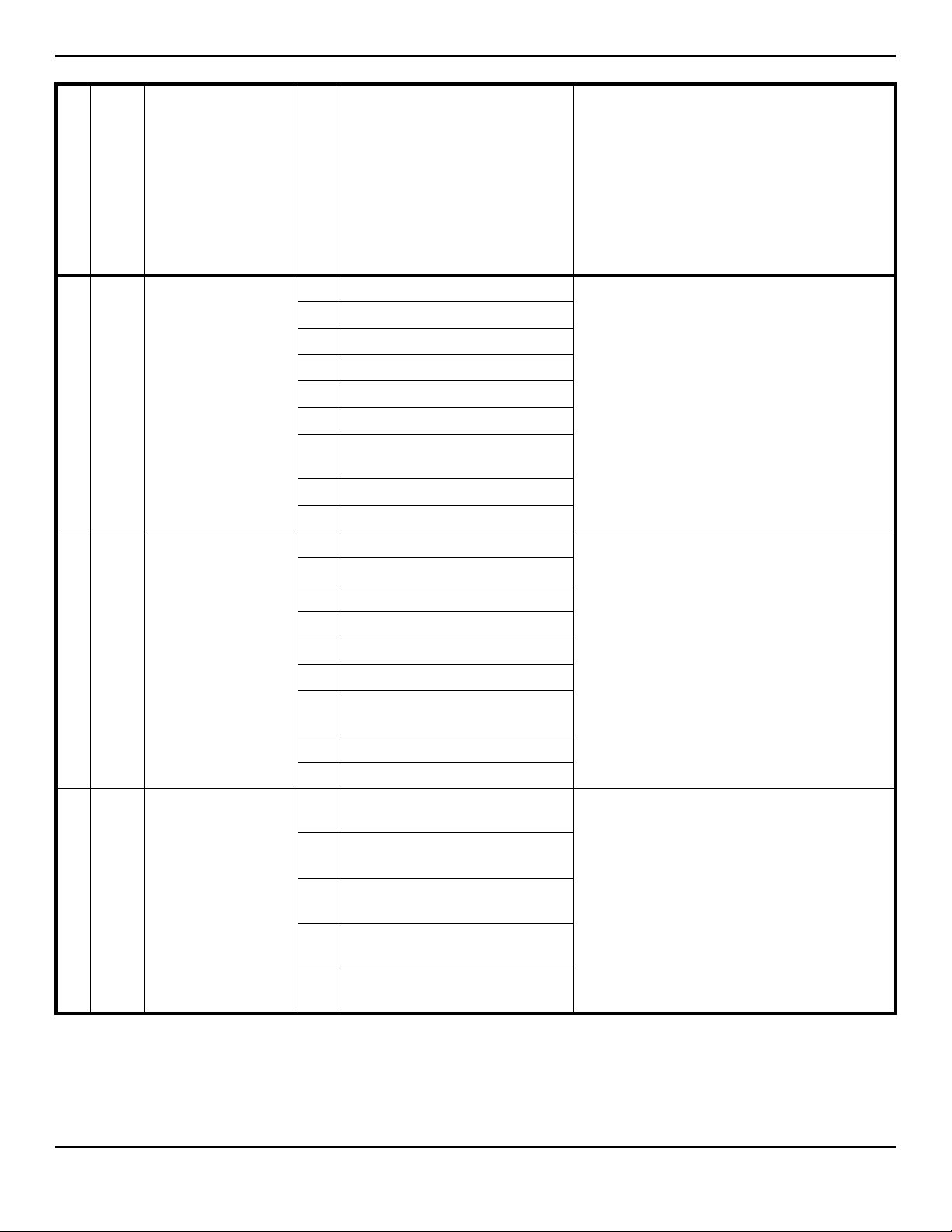

SECTION 3—SAFETY INSPECTION/TROUBLESHOOTING

POSSIBLE

ERROR CODE

DESCRIPTION

DIAGNOSTICS CODE

NUMBER OF FLASHES

3 E03 Left Motor Fault 00 Left Motor Short Circuit Check the left motor, connections and motor

SUB CODE*

01 Left Motor Open Circuit

02 Left Motor Connection Fault B-

03 Motor Terminal Connected to B+

04 Left Motor Voltage Fault

05 Left Motor Bridge Fault

06 Too Many Hardware Current

07 Current Offset Out of Range

08 Hardware Current Limit Fault

DETAILS OF

ERROR CODE

Limit Events

cable.

SOLUTION

4 E04 Right Motor Fault 00 Right Motor Short Circuit Check the right motor, connections and motor

01 Right Motor Open Circuit

02 Right Motor Connection Fault B-

03 Motor Terminal Connected to B+

04 Right Motor Voltage Fault

05 Right Motor Bridge Fault

06 Too Many Hardware Current

Limit Events

07 Current Offset Out of Range

08 Hardware Current Limit Fault

5 E05 Left Park Brake Fault 00 Left Park Brake Drive-Time Test

Failed

01 Left Park Brake Output Enabled

When Wheelchair Idle

02 Left Park Brake Output Did not

Enable When Entering Drive Mode

03 Left Park Brake fault during

power-up testing

04 Left park brake feedback low

during drive (park brake short)

cable.

Check the left park brake connections and cable.

TDX® SP 24 Part No 1143209

SECTION 3—SAFETY INSPECTION/TROUBLESHOOTING

ERROR CODE

DESCRIPTION

DIAGNOSTICS CODE

NUMBER OF FLASHES

6 E06 Right Park Brake Fault 00 Right Park Brake Drive-Time Test

7 E07 Remote Fault 00 Local SR Fault (CPU, EEPROM,

SUB CODE*

01 Right Park Brake Output Enabled

When Wheelchair Idle

02 Right Park Brake Output Did not

Enable When Entering Drive Mode

03 Right Park Brake fault during

power-up testing

04 Right park brake feedback low dur-

ing drive (park brake short)

DETAILS OF

ERROR CODE

Failed

etc.)

POSSIBLE

SOLUTION

Check the right park brake connections and

cable.

Check the communications bus, connections and

wiring. Replace the remote.

01 Joystick fault at the remote

02 Speed pot fault at the remote

8 E08 Controller Fault 00 Controller fault Check connections and wiring. Replace power

01 RAM fault

02 ROM fault

03 CPU fault

04 EEPROM fault

05 Watchdog fault

06 Stack fault

07 Software fault

08 Power-up testing fault

09 Relay fault or precharge fault

10 Bridge fault or disable all fault

11 Electronics fault: Thermistor

12 Calibration setting fault

9 E09 Communications Fault 00 Remote connection lost Check connections and wiring. Replace Bus

01 Low communication mode

10 E10 General Fault 00 General fault Check all connections and wiring. Contact

11 E11 Incompatible/incor-

rect Remote

00 Incompatible/incorrect Remote Wrong type of remote connected. Ensure the

module.

cable.

Invacare Technical Service.

branding of the joystick matches that of

controller unit.

Part No 1143209 25 TDX® SP

SECTION 3—SAFETY INSPECTION/TROUBLESHOOTING

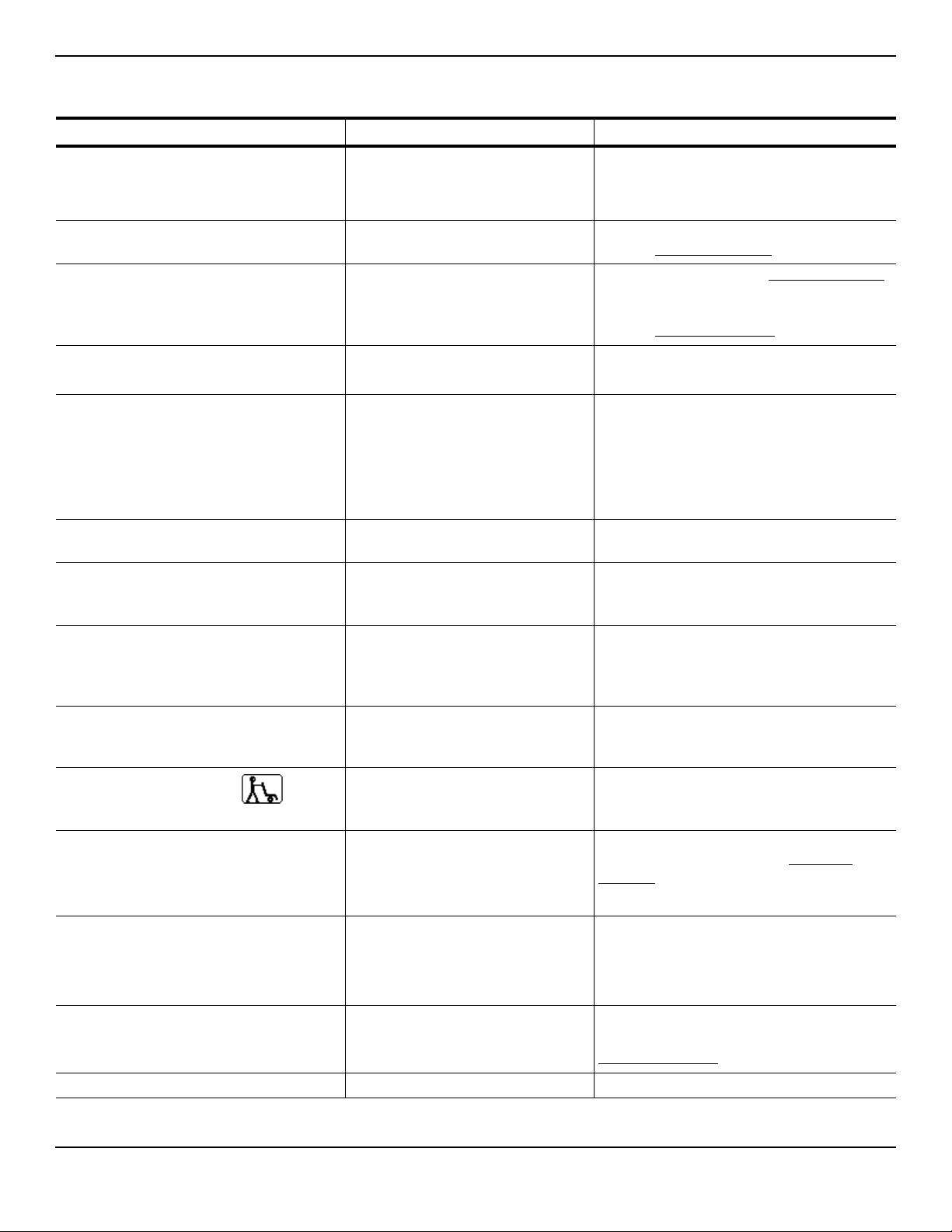

MPJ™+, PSR+, PSF+ Joysticks or Displays

SYMPTOM PROBABLE CAUSE SOLUTIONS

SPM L Park Brake Fault or

SPM R Park Brake Fault displays and

wheelchair does not drive.

CHARGER PLUGGED IN displays. Battery charger connected (Error

SPM Battery Fault displays and the

wheelchair does not drive.

JOYSTICK TIMEOUT displays and the

wheelchair does not drive.

JS REV TOO LARGE

JS FWD TOO LARGE

JS LFT TOO LARGE or

Motor lock levers disengaged (Error

code E9 or E10).

code E28).

Batteries need to be charged (Error

code E14).

Joystick or input device is

disconnected (Error code 32).

The joystick or input device is sending

a value outside of the reverse,

forward, left or right limits (Error

codes E01, E02, E03 or E04).

Engage motor lock levers. Refer to user

manual shipped with wheelchair.

Unplug battery charger from the wheelchair.

Refer to Charging Batteries

Charge batteries. Refer to Charging Batteries

on page 72. If batteries fail to charge properly,

check battery charger or replace batteries.

Refer to Replacing Batteries

Turn off power, reconnect the joystick of

input device and turn power on.

Replace joystick or input device.

JS RGT TOO LARGE

displays and the wheelchair does not drive.

NEUTRAL TESTING displays. The joystick neutral test has failed

(Error code E18).

BAD JOYSTICK CAL VALUES displays

and the wheelchair does not drive.

SPM NOT CONNECTED

SPM Communications Fault displays and

the wheelchair drives slowly.

ATTENDANT ACTIVE and displays.

Batteries draw excessive current when

charging.

Battery indicator flashes the charge level is

low - immediately after recharge.

Battery indicator flashes the charge level is

low - too soon after being recharged.

Motor “chatters” or runs irregular. Electrical malfunction. Contact Invacare for service.

The joystick calibration values are

outside of the expected range (Error

code E19).

The MPJ or Display module is not

communicating with the control

module (Error code E200).

The controller has determined a fault

during a previous turn-off process

(Error code E41).

The Proportional or Digital Attendant

control is active and can be used to

drive the chair (Error code W05).

Battery failure.

Electrical malfunction.

Battery failure.

Malfunctioning battery charger.

Electrical malfunction.

Batteries not charged.

Weak batteries.

Release the joystick and try to get the joystick

back into the center-most position.

Recalibrate the joystick (joystick throw

procedure).

Check the connections between the joystick

or display and the controller. Turn the power

off and then back on. Replace the controller if

necessary.

Turn the wheelchair off and back on.

This is normal behavior.

Have batteries checked for shorted cell.

Replace if necessary. Refer to Replacing

Batteries on page 65.

Contact Invacare for service.

Check batteries for shorted cell. Replace if

necessary.

Replace charger.

Contact Invacare for service.

Have charger checked.

Replace batteries if necessary. Refer to

Replacing Batteries

on page 65.

on page 72.

on page 65.

TDX® SP 26 Part No 1143209

SECTION 3—SAFETY INSPECTION/TROUBLESHOOTING

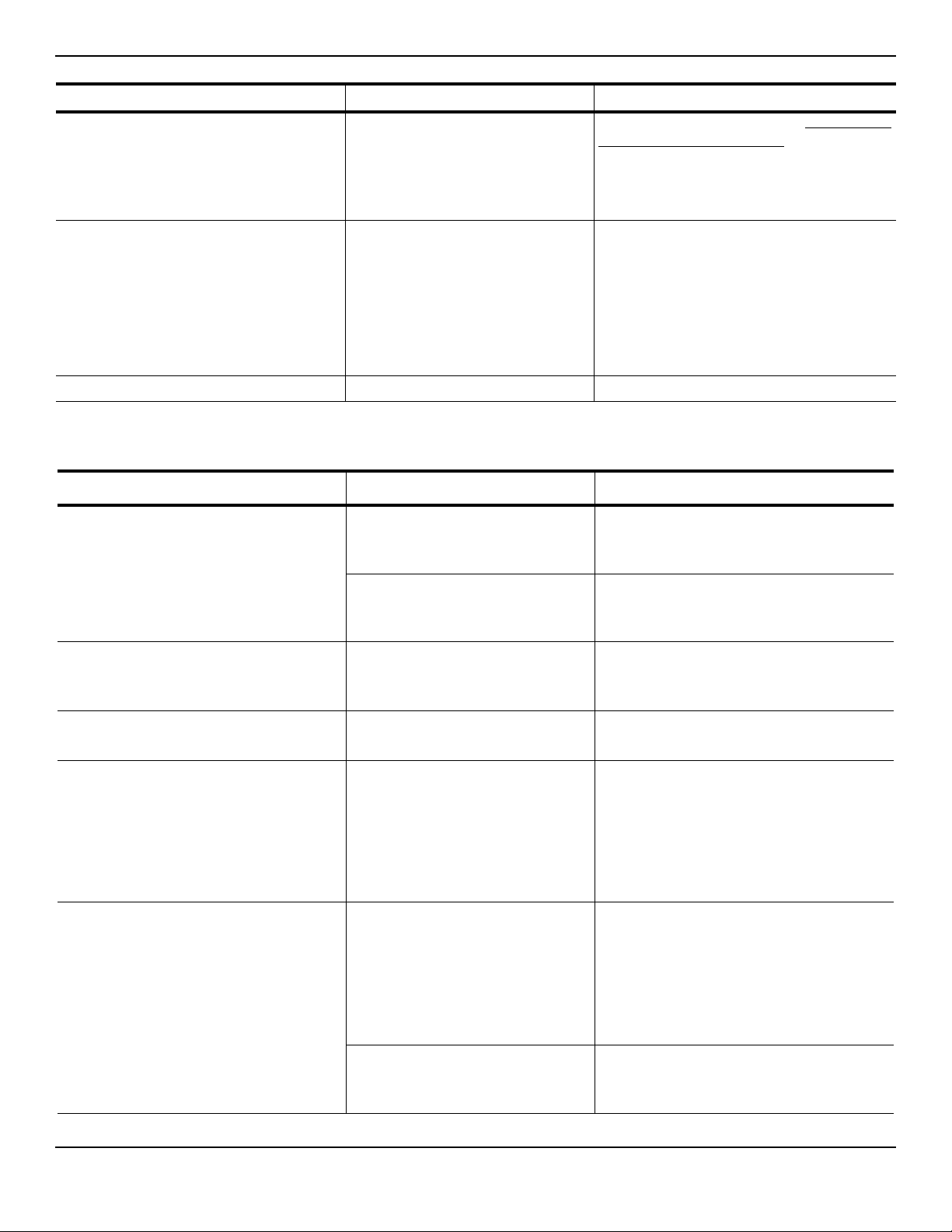

SYMPTOM PROBABLE CAUSE SOLUTIONS

Joystick erratic or does not respond as

desired.

Wheelchair does not respond to

commands.

Power indicator off - even after recharging. Electrical malfunction. Contact Invacare for service.

Damaged motor coupling.

Electrical malfunction.

Controller programmed improperly.

Joystick error. Calibrate joystick.

Inspect motor coupling. Refer to Replacing the

SSD Motor or Gearbox Only on page 40.

Contact Invacare for service.

Check programming. See electronics manual.

Check programming.

Check "INPUT TYPE": Programming Menu.

Check joystick throw: DIAGNOSTICS menu.

Re-Calibrate Joystick.

Check Drive Lock Out status.

Check motor brake engagement.

Try different Joystick.

Troubleshooting - Motor/Gearbox/Brake

SYMPTOM PROBABLE CAUSE SOLUTIONS

Motor makes a clicking noise.

Grinding noise or motor is locking up.

Motors stall and starts up again.

Wheelchair will not drive with power on

(E09 or E10).

Motor chatters or runs erratically, or only

one motor turns.

Bad gearbox, chipped or worn

gears.

bad bearings.

Raised commutator plate inside of

motor.

Bad gearbox.

Bad coupler between motor and

gearbox or bad bearings. Bad Gears.

Current Rollback. Stop driving the wheelchair and , with the

Check motor locks. Engage motor locks to drive wheelchair.

Damaged connector or worn

brushes.

Bad motor or gear box.

Commutator bars expanded.

Water or oil in motor.

Replace gearbox.

If bearings are bad, replace motor.

Ohm out motor and replace motor if high

reading is present. Normal reading is .5-5

Ohms.

Replace gearbox.

Replace coupler.

If bearings are bad, replace motor.

power on, let electronics cool.

Swap out motor leads. Using a programmer,

check for error codes.

NOTE: WHEELCHAIRS WITH G-TRAC

ONLY - Before swapping motor leads for

troubleshooting purposes, use the

programmer to turn off G-trac in all drives.

Ohm out motors. Check brushes and

replace brushes if necessary. Replace motor

if high reading is present. Normal reading is

.5-5 Ohms. 4 Pole ONLY.

Inspect commutator bars for expansion

from getting to hot. Replace motor.

Rotate gearbox by hand.

Controller malfunction. Check for error codes with programmer.

Refer to the MK6i Electronics Programming

Guide, part number 1141471.

Part No 1143209 27 TDX® SP

Loading...

Loading...