Invacare PHOENIX PLUS Service Manual

PHOENIX PLUS

SERVICE GUIDE

PART NO: 1420254

INTRODUCTION

1) This manual provides basic details to enable the PHOENIX Wheelchair to be

maintained. It is not intended to be a comprehensive maintenance guide/policy, but is

intended for use by competent personnel to enable the chair to adequately maintained.

2) The manual includes detailing assemblies that are maintainable and the relevant

procedures.

3) The Wheelchair is manufactured by:

INVACARE Ltd

South Road

Bridgend Industrial Estate

Bridgend

Mid-Glamorgan

CF31 3PY

SALES TEL NO: 01656 647327 TECHNICAL SERVICE TEL NO: 01656 753337

FAX NO: 01656 649016 FAX NO: 01656 753299

4) For TECHNICAL ADVICE, repairs, servicing, contact Technical Services.

For SPARE PARTS orders contact Sales.

5) Quote the following details at all times:

5.1 Part Number

5.2 Description

5.3 Quantity required

5.4 Serial Number

5.5 Chair Type

POLICY

INVACARE Ltd repair is as follows:

Repairs to ANY component other than those detailed in this manual are not covered. Repairs

to ANY tube metal work is not generally permitted without express permission of INVACARE

Ltd. ALL fasteners i.e. bolts, Nyloc nuts, and any fastener showing damage MUST be

renewed.

In the event of repairing a crash damaged Vehicle we strongly advise you contact INVACARE

TECHNICAL SERVICES DEPARTMENT before proceeding with repairs.

Failure to comply with the above absolves INVACARE Ltd of liability.

Note: Certain components will require removal to carry out maintenance. With the exception

of fasteners, those components should be refitted.

CONTENTS

Page

- Armrests 1

- Upholstery and Back Seat Cloth 2

- Castor Wheel & Fork 3

- Rear Wheel & Tyres 6

- Footrest 8

- Mechanical Brake 9

- Batteries & Charger 10

- Motor Assembly 13

- Gearbox Assembly 15

- Controller with Integral Joystick Remote (DL. 40) 17

- What to do in the event of a fault 18

- Troubleshooting 19

- Diagnostics 19

- Frame & Chassis 22

TOOLS REQUIRED

THE FOLLOWING LIST DETAILS THE BASIC TOOLS REQUIRED TO CARRY OUT THE

MAINTENANCE GIVEN IN THE FOLLOWING CHAPTERS.

2 - Open End Spanner (13mm)

1 - Open End Spanner (11mm)

2 - Open End Spanner (10mm)

1 - Open End Spanner (8mm)

1 - 1/4" BSW Open End Spanner

1 - Combination Spanner (19mm)

1 - Socket / Wrench (Shallow) (19mm)

1 - Phillips Screwdriver (No 1)

1 - Flat Bladed Screwdriver (No 1)

1 - Nylon Mallet

1 - Torque Wrench

1 - Allen Key - (6mm)

1 - Allen Key - (5mm)

1 - Allen Key - (3mm)

1 - Allen Key - (4mm)

1 - Knife

1 - Pressure Gauge

2 - Tyre Levers

1 - Pump

1 - Drift

1 - Vice

1 - Talcum Powder

1 - Valve Remover

1 - Multi-Meter

1 - Soldering Iron

1 - Pin Hammer

1 - Punch

1 - Pair Pliers

1 - Battery Discharge Tester

1 - HHP - Programmer

NOTE: THE ABOVE LIST IS NOT EXHAUSTIVE

1

Phoenix

11/01

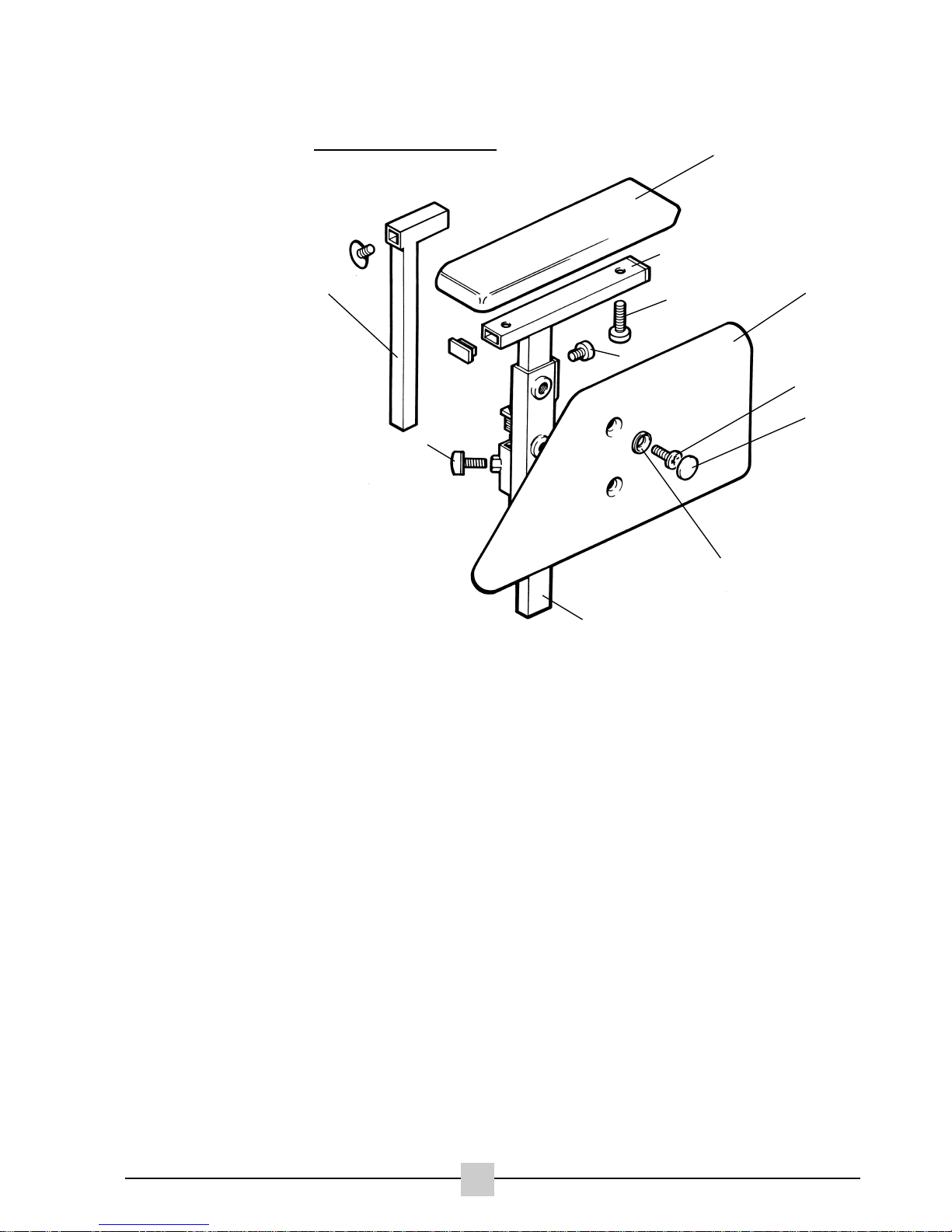

ARM REST

PARTS:

1. Armrest Pad Bracket

2. Hand Knob

3. Armrest Bracket

4. Arm Upright Assembly

5. Washer

6. Cap

7. Screw

8. Skirt Guard

9. Screw (Allen)

10. Armpad Fixing Screws

11. Armrest Pad

Tools Required:

No1 Phillips Screwdriver

Flat Headed Screwdriver

6mm Allen Key

INTRODUCTION

STEP 1

Check that the skirtguard is fixed and not physically damaged. If the panel is loose retighten the fixing screw, install a new panel if necessary.

STEP 2

Check for armpad wear or damage. Replace if necessary.

STEP 3

Check for corrosion or paint damage to the bracketry and replace affected parts where

necessary.

DISMANTLING

STEP 1

Remove the handknob by rotating it anti-clockwise. Pull out the arm assembly.

STEP 2

Remove the two armpad fixing screws under the armpad and remove the armpad.

STEP 3

Remove the allen screw and pull out the armpad bracket.

STEP 4

Carefully remove the 2 caps with a flat headed screwdriver, remove the 2 phillips screws and

remove the skirtguard. Take care not to loosen the washers.

To re-assemble reverse step 4 to 1 taking care not to over tighten the fixing screws as this

could cause burrs and split the plastic washer.

3

10

1

9

8

7

6

5

4

11

2

1

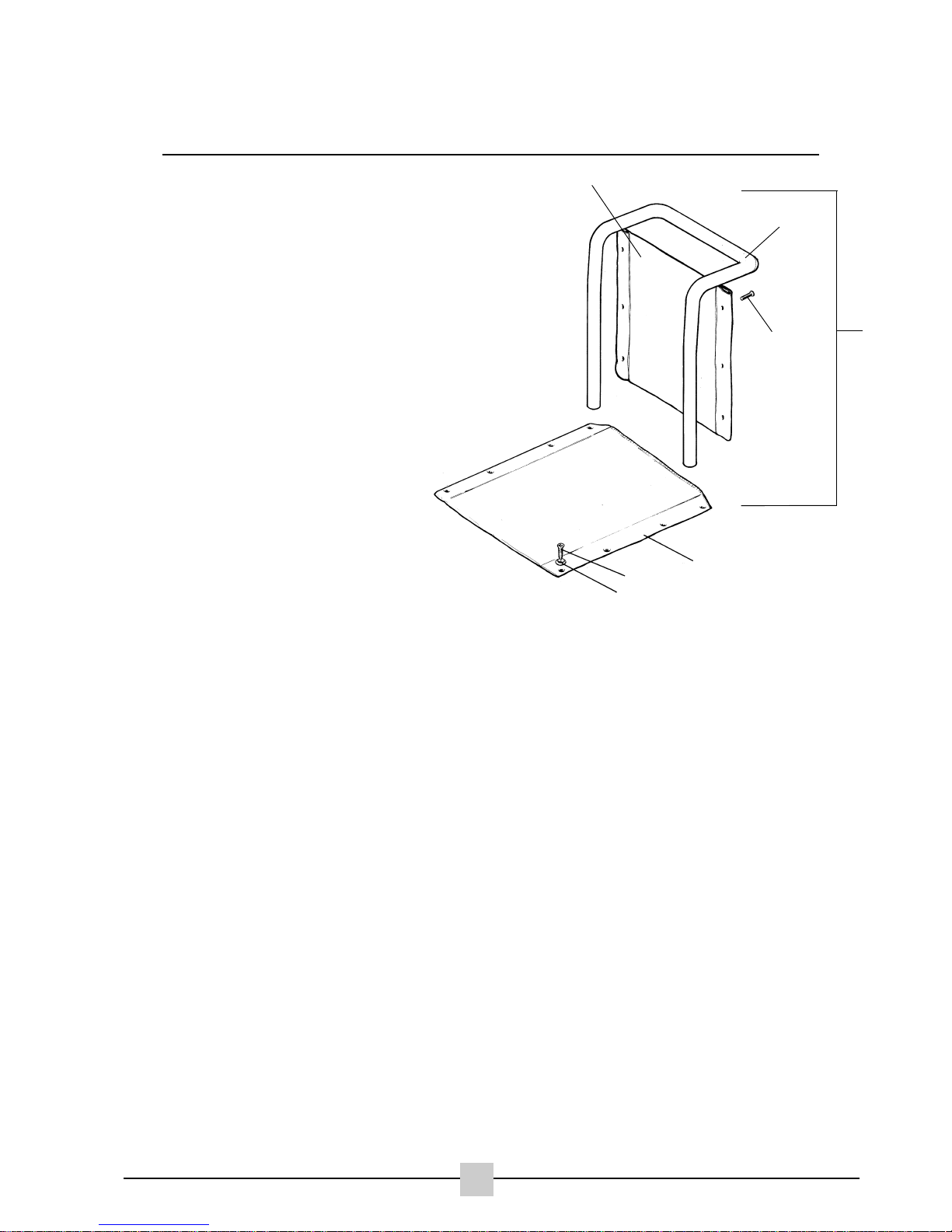

UPHOLSTERY AND BACK/SEAT CLOTH

PARTS:

1. One Piece Backrest Complete

2. One Piece Backpost

3. Taptite Screw

4. Upholstery Washer

5. Seat Upholstery

6. 40cm High Back Upholstery

Tools Required:

No1 Phillips Screwdriver

INTRODUCTION

STEP 1

Check that the upholstery does not sag and is not unevenly stretched, torn or excessively

worn, paying attention to the adjustment features within the tension adjustable back

upholstery.

STEP 2

Check that all stitches are in good condition.

STEP 3

Check that all screws and washers are tight and free of sharp edges and burrs.

DISMANTLING

STEP 1

Remove all fixing screws and detach upholstery from tubework.

To re-assemble reverse above procedure ensuring that the fixing holes in the upholstery and

tubes are properly aligned.

NOTE:

TAKE CARE NOT TO OVER TIGHTEN SCREWS AS THIS MIGHT CAUSE BURRS.

2

Phoenix

11/01

3

2

6

5

3

4

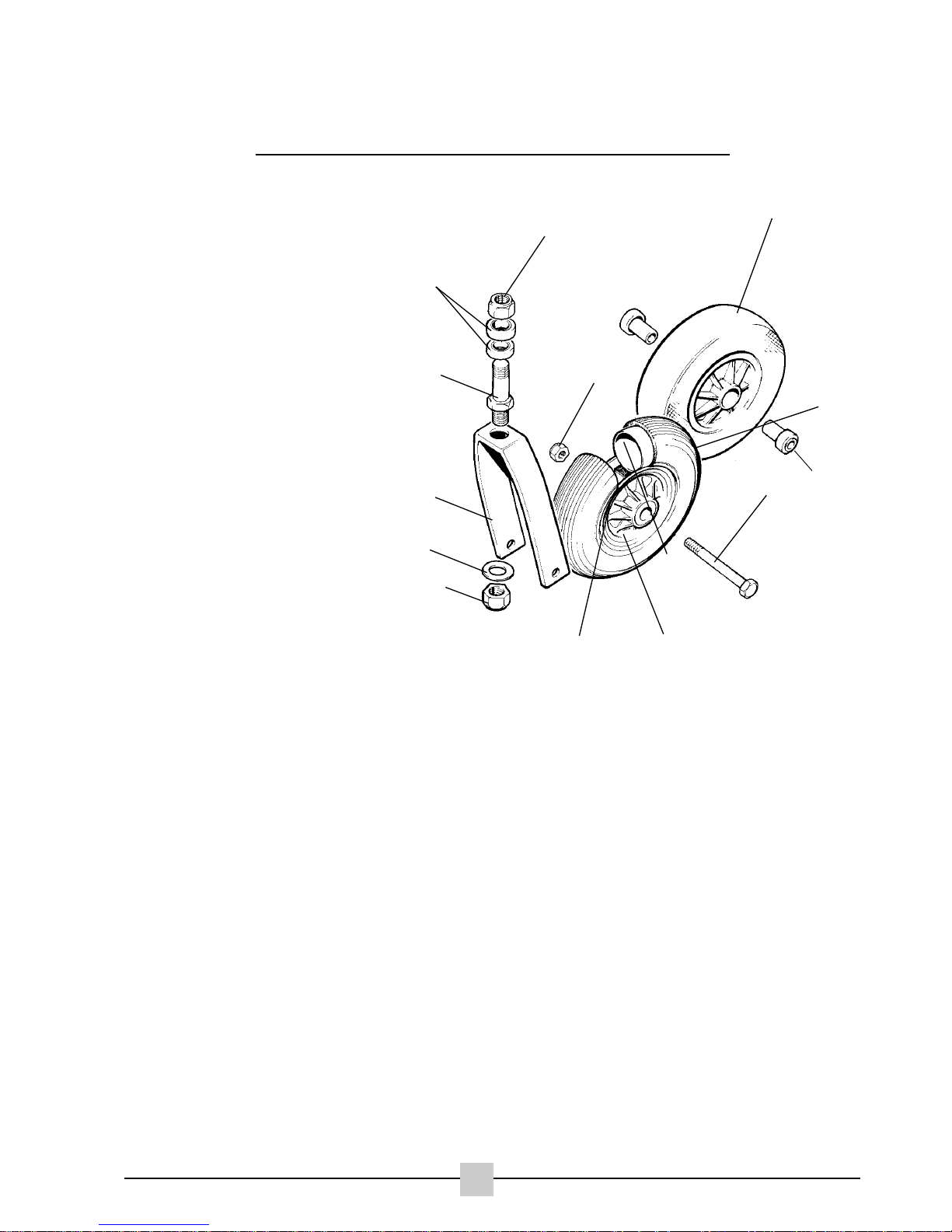

CASTOR WHEEL AND FORK

PARTS:

1. Castor fork

2. Washer

3. Nyloc Nut

4. Axle Bolt

5. Nyloc Nut

6. Pneumatic Castor

7. Bearing

8. Tyre

9. Inner Tube

10. Hub Centre

11. Castor Wheel

12. Fork Stem

13. Bearings

Tools Required:

19mm Socket Spanner x 2

Flat Bladed Screwdriver

Mallet

Pressure Gauge

Tyre Levers

Pump

Drift

INTRODUCTION

STEP 1

Check castor wheels are not buckled or physically damaged. Replace if required.

STEP 2

Check that the wheel bearings run freely without excessive play.

STEP 3

Check that the castor wheel and fork nuts are tight.

STEP 4

Check that the castor forks are bent or damaged.

STEP 5

Check the crown/castor fork bearings for wear and correct adjustment.

STEP 6

Check tyres for wear and correct inflation. Both wheels should show the same degree of wear

(see side of tyre pressure rating). For tyre fitment see rear tyre section.

3

Phoenix

11/01

1

2

3

3

4

5

8

9

10

11

12

13

6

7

CASTOR WHEEL AND FORK

DISMANTLING

STEP 1

Remove castor socket cap with flat bladed screw driver, hold the lower fork stem nut secure

with 19mm spanner and remove the upper fork stem nut.

STEP 2

Gently tap the threaded end to the fork stem with a mallet taking care not to damage the

threads. Remove the castor fork assemblies

STEP 3

Lever out the top fork bearings carefully, using the fork stem as a lever. Take care not to

damage the threads.

STEP 4

Remove the castor fork bearings using a drift and a mallet, tapping gently to avoid damaging

the castor socket and bearing.

STEP 5

To remove the castor wheels undo the axle nut with a 13mm spanner using a second

spanner at the other end of the axle to lock against rotation. Remove the axle bolt and

remove the wheel from the fork.

STEP 6

Remove the bearings by hand.

To reassemble reverse step 6 & 7, but adjust tightness of nut until the wheel runs freely to a

gradual halt.

a) If the wheel stops abruptly, loosen the castor axle nut.

b) If the wheel wobbles (sideplay), tighten the castor axle nut enough to allow free spinning

without sideplay.

TO RE-ASSEMBLE

STEP 1

Insert the fork stem bearings using a mallet and drift across the bearing to prevent damage.

STEP 2

Start at the bottom and place the threaded end of the fork stem through both bearings and in

the castor fork socket.

4

Phoenix

11/01

Loading...

Loading...