Invacare MK5 EX, MK5 TT-EX Service Manual

Service Manual

MK

™

EX

™

5

™

MK

TT-EX

5

Electronics

and

™

DEALER: Keep this manual. The

procedures in this manual MUST be

performed by a qualified technician.

For more information regarding Invacare

products, parts, and services, please visit

www.invacare.com

WARNING

A QUALIFIED TECHNICIAN MUST PERFORM THE INITIAL SET UP

OF THIS WHEELCHAIR. ALSO, A QUALIFIED TECHNICIAN MUST

PERFORM ALL PROCEDURES IN THE SERVICE MANUAL.

WHEELCHAIR USERS: DO NOT SERVICE OR OPERATE THIS

EQUIPMENT WITHOUT FIRST READING AND UNDERSTANDING

(1) THE OWNER’S OPERATOR AND MAINTENANCE MANUAL

AND (2) THE SEATING SYSTEM’S MANUAL (IF APPLICABLE). IF

YOU ARE UNABLE TO UNDERSTAND THE WARNINGS,

CAUTIONS, AND INSTRUCTIONS, CONTACT INVACARE

TECHNICAL SUPPORT BEFORE ATTEMPTING TO SERVICE OR

OPERATE THIS EQUIPMENT - OTHERWISE INJURY OR DAMAGE

MAY RESULT.

DEALERS AND QUALIFIED TECHNICIANS: DO NOT SERVICE OR

OPERATE THIS EQUIPMENT WITHOUT FIRST READING AND

UNDERSTANDING (1) THE OWNER’S OPERATOR AND

MAINTENANCE MANUAL, (2) THE SERVICE MANUAL (IF

APPLICABLE) AND (3) THE SEATING SYSTEM’S MANUAL (IF

APPLICABLE). IF YOU ARE UNABLE TO UNDERSTAND THE

WARNINGS, CAUTIONS AND INSTRUCTIONS, CONTACT

INVACARE TECHNICAL SUPPORT BEFORE ATTEMPTING TO

SERVICE OR OPERATE THIS EQUIPMENT - OTHERWISE, INJURY

OR DAMAGE MAY RESULT.

NOTE: This manual is also available in French Canadian (Part Number 1123834).

NOTE: Updated versions of this manual are available on www.invacare.com.

™

MK

EX™ and MK

5

™

TT-EX™ Electronics 2 Part No 1114808

5

TABLE OF CONTENTS

TABLE OF CONTENTS

SPECIAL NOTES ................................................................................ 7

SECTION 1—EMI INFORMATION ....................................................... 8

SECTION 2—TROUBLESHOOTING .................................................... 10

All Power Wheelchairs ...........................................................................................................................10

Wheelchairs With Powered Seating Systems....................................................................................11

Formula™TRE only.............................................................................................................................12

SECTION 3—JOYSTICK DESCRIPTIONS ............................................. 14

Joystick Overview.....................................................................................................................................14

DPJ Joystick Switches and Indicators ...................................................................................................14

Power/Drive Select Toggle Switch ..................................................................................................14

Selecting the Drive Mode .............................................................................................................14

Turning the Wheelchair Off ........................................................................................................14

Speed Control Knob ...........................................................................................................................15

Mode (On/Off) Switch........................................................................................................................15

Battery Gauge Display (BGD)...........................................................................................................15

MPJ Joystick Switches and Indicators...................................................................................................15

Power/Drive Select Toggle Switch ..................................................................................................16

Selecting the Drive Mode .............................................................................................................16

Turning the Wheelchair Off ........................................................................................................16

Speed Control Knob ...........................................................................................................................16

LCD Display ..........................................................................................................................................16

Remote On/Off Input..........................................................................................................................17

SECTION 4—REMOTE PROGRAMMER .............................................. 18

Overview....................................................................................................................................................18

Remote Programmer Terminology ......................................................................................................18

Function..................................................................................................................................................18

Value .......................................................................................................................................................19

Standard Program (Preset Programs) .............................................................................................19

User Memory Values...........................................................................................................................19

Description Of Remote Programmer Keys .......................................................................................19

SECTION 5—PERFORMANCE ADJUSTMENTS .................................... 20

Speed and Response Screen ..................................................................................................................20

Advanced Menu.........................................................................................................................................20

Performance Menu...................................................................................................................................20

Making Performance Adjustments........................................................................................................21

Performance Menu Description............................................................................................................24

SECTION 6—STANDARD VALUE SETTINGS ...................................... 32

Standard Value Settings...........................................................................................................................32

Part No 3 Manual Title

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION 7—CALIBRATION OF THE CONTROL MODULE ................... 33

When to Calibrate the Control Module.............................................................................................33

What Functions Can Be Calibrated .....................................................................................................33

Calibrating the Control Module............................................................................................................33

SECTION 8—CURRENT STATUS DISPLAY ......................................... 37

SECTION 9—DIAGNOSTIC CODES .................................................... 38

What Are Diagnostics Codes? ..............................................................................................................38

MK5 EX Controller Diagnostic Codes ...............................................................................................38

MK5 TT-EX Controller Diagnostic Codes ........................................................................................39

SECTION 10—OPTIONS ................................................................... 42

Display Unit................................................................................................................................................42

Drive Select and On/Off Switch.......................................................................................................42

Selecting the Drive Mode .............................................................................................................42

LCD Display ..........................................................................................................................................43

Remote On/Off ....................................................................................................................................43

Special Purpose Indicators .................................................................................................................43

MK5 PSR/PSF Joysticks............................................................................................................................44

Joystick Overview................................................................................................................................44

Power/Drive Select Toggle Switch ..................................................................................................45

Selecting the Drive Mode .............................................................................................................46

Turning the Wheelchair Off ........................................................................................................46

Speed Control Knob ...........................................................................................................................46

Battery Gauge Display (BGD)...........................................................................................................46

Mode and Level Indicators.................................................................................................................46

1558M4 Compact Joystick......................................................................................................................47

1500M4 Rim Head Control ...................................................................................................................48

1812M4 Dual Proportional Joystick .....................................................................................................48

1554M5 or 1554M4 Sip & Puff Switch Input ......................................................................................49

Driver Control Input Connector.....................................................................................................49

Proportional Attendant Connector.................................................................................................50

Sip and Puff (Pneumatic Switch) Input.............................................................................................50

Mounting Precautions and Maintenance.........................................................................................50

Selecting the Driver Input Type .......................................................................................................50

Calibrating the Sip & Puff Pressures ................................................................................................51

PACM5 Proportional Attendant Control...........................................................................................52

Override and Speed Control Knob.................................................................................................52

1552M Attendant Control .....................................................................................................................53

On/Off Toggle Switch .........................................................................................................................53

Four Directional Switch......................................................................................................................53

Manual Title 4 Part No

TABLE OF CONTENTS

TABLE OF CONTENTS

1556m Heavy Duty Joystick...................................................................................................................53

Using the Heavy Duty Joystick..........................................................................................................54

AUX12 Eight Output Electronic Communications Module ...........................................................54

AUX34 Ten Output Electronic Communications Module.............................................................55

ECU1 and ECU2 .......................................................................................................................................55

ECU3 and ECU4 .......................................................................................................................................55

Connector Description...........................................................................................................................55

MK5 Tilt, Recline and Elevate Control Module (TRECM)..............................................................56

Programming the TRECM..................................................................................................................57

TRECM Performance Adjust Menu Description ....................................................................57

TRECM Standard Programs Menu Description ......................................................................58

TRECM Actuator Selection Menu Description .......................................................................58

TRECM Current Status Menu Description ..............................................................................59

MK5 Tilt and Recline Control Module (TRCM) ...............................................................................60

Programming the TRCM ....................................................................................................................60

TRCM Performance Adjust Menu Description .......................................................................61

TRCM Standard Programs Menu Description ........................................................................62

TRCM Actuator Selection Menu Description .........................................................................63

TRCM Current Status Menu Description ................................................................................63

MK5 Two Actuator Controller (TAC) ...............................................................................................64

Programming the TAC .......................................................................................................................65

TAC System Type Menu Description .......................................................................................66

TAC Performance Adjust Menu Description ..........................................................................66

TAC Actuator Selection Menu Description ............................................................................67

TAC Current Status Menu Description ...................................................................................67

MK5 Single Actuator Control (SAC)...................................................................................................67

Lockout ..................................................................................................................................................68

Slow.........................................................................................................................................................68

SECTION 11—CALIBRATING POTENTIOMETERS .............................. 69

Preparing to Calibrate Potentiometers...............................................................................................69

Potentiometer Calibration for 2GTR Systems..................................................................................69

Tilt Angle Potentiometer Calibration .............................................................................................69

Recline Angle Potentiometer Calibration ......................................................................................70

Potentiometer Calibration for 2GT Systems.....................................................................................71

Tilt Angle Potentiometer Calibration .............................................................................................71

Potentiometer Calibration for 2GR Systems.....................................................................................72

Recline Angle Potentiometer Calibration ......................................................................................72

SECTION 12—CONNECTOR DESCRIPTIONS ...................................... 73

Driver Control Input Connector (1554M4 or 1554M5) ................................................................73

Part No 5 Manual Title

Environmental Control Outputs - ECU 1, 2, 3 and 4......................................................................73

Emergency Stop/Reset Switch ...............................................................................................................74

Emergency Stop/Reset Input..................................................................................................................74

15-pin D-Subminiature on Control Module.......................................................................................75

5-Pin Connector on Control Module..................................................................................................75

Battery Connector - Anderson SB50 ..................................................................................................75

MI and M2 Motor Connectors..............................................................................................................75

4-Pin (MK5 EX) ....................................................................................................................................75

13-Pin D-Sub (MK5 TT EX)...............................................................................................................76

5-Pin Connector on Control Module..................................................................................................76

PTO/Charge Input (MK5 EX)................................................................................................................76

Remote On/Off Input On MPJ or Display unit..................................................................................76

SECTION 13—CURRENT ROLLBACK ................................................ 77

What Is Current Rollback?.....................................................................................................................77

What Increases the Likelihood of Current Rollback?......................................................................77

Weight....................................................................................................................................................77

Rolling Resistance ................................................................................................................................77

Terrain Angle ........................................................................................................................................77

Speed.......................................................................................................................................................77

How to Solve It? .......................................................................................................................................78

Electronic Adjustments.......................................................................................................................78

Drive Motors ........................................................................................................................................78

Common Mistakes ...................................................................................................................................78

SECTION 14—APPENDIX ................................................................ 79

Special Purpose Indicator Description for LCD Display.................................................................79

LIMITED WARRANTY ..................................................................... 80

Manual Title 6 Part No

SPECIAL NOTES

SPECIAL NOTES

WARNING/CAUTION notices as used in this manual apply to hazards or unsafe

practices which could result in personal injury or property damage.

NOTICE

THE INFORMATION CONTAINED IN THIS DOCUMENT IS SUBJECT TO

CHANGE WITHOUT NOTICE.

REPAIR OR SERVICE WARNING

Setup of the Electronic Controller is to be performed ONLY by individuals certified

by Invacare. The adjustments of the controller may affect other activities of the

wheelchair. Damage to the equipment could occur under these circumstances. If

uncertified individuals perform any work on these units, the warranty is void.

OPERATION WARNING

Performance adjustments should only be made by professionals of the health care

field or persons fully conversant with this process and the driver's capabilities. Incorrect settings could cause injury to the driver, bystanders, damage to the chair and

surrounding property. After the wheelchair has been setup, check to make sure that

the wheelchair performs to the specifications entered in the setup procedure. If the

wheelchair does NOT perform to specifications, turn the wheelchair OFF immediately and re-enter setup specifications. Repeat this procedure until the wheelchair

performs to specifications.

Part No 1114808 7 MK

™

EX™ and MK

5

™

TT-EX™ Electronics

5

SECTION 1—EMI INFORMATION

SECTION 1—EMI INFORMATION

WARNING

CAUTION: IT IS VERY IMPORTANT THAT YOU READ THIS INFORMATION

REGARDING THE POSSIBLE EFFECTS OF ELECTROMAGNETIC

INTERFERENCE ON YOUR POWERED WHEELCHAIR.

Electromagnetic Interference (EMI) From Radio Wave Sources

Powered wheelchairs and motorized scooters (in this text, both will be referred to

as powered wheelchairs) may be susceptible to electromagnetic interference (EMI),

which is interfering electromagnetic energy (EM) emitted from sources such as

radio stations, TV stations, amateur radio (HAM) transmitters, two way radios, and

cellular phones. The interference (from radio wave sources) can cause the powered

wheelchair to release its brakes, move by itself, or move in unintended directions. It

can also permanently damage the powered wheelchair's control system. The

intensity of the interfering EM energy can be measured in volts per meter (V/m).

Each powered wheelchair can resist EMI up to a certain intensity. This is called its

"immunity level." The higher the immunity level, the greater the protection. At this

time, current technology is capable of achieving at least a 20 V/m immunity level,

which would provide useful protection from the more common sources of radiated

EMI.

There are a number of sources of relatively intense electromagnetic fields in the

everyday environment. Some of these sources are obvious and easy to avoid.

Others are not apparent and exposure is unavoidable. However, we believe that by

following the warnings listed below, your risk to EMI will be minimized.

The sources of radiated EMI can be broadly classified into three types:

1) Hand-held Portable transceivers (transmitters-receivers with the antenna

mounted directly on the transmitting unit. Examples include: citizens band (CB)

radios, "walkie talkie", security, fire and police transceivers, cellular telephones,

and other personal communication devices).

NOTE: Some cellular telephones and similar devices transmit signals while they are ON,

even when not being used.

2) Medium-range mobile transceivers, such as those used in police cars, fire trucks,

ambulances and taxis. These usually have the antenna mounted on the outside of

the vehicle; and

3) Long-range transmitters and transceivers, such as commercial broadcast

transmitters (radio and TV broadcast antenna towers) and amateur (HAM)

radios.

NOTE: Other types of hand-held devices, such as cordless phones, laptop computers,

AM/FM radios, TV sets, CD players, cassette players, and small appliances, such as electric shavers and hair dryers, so far as we know, are not likely to cause EMI problems to

your powered wheelchair.

™

MK

EX™ and MK

5

™

TT-EX™ Electronics 8 Part No 1114808

5

SECTION 1—EMI INFORMATION

WARNING

Powered Wheelchair Electromagnetic Interference (EMI)

Because EM energy rapidly becomes more intense as one moves closer to the

transmitting antenna (source), the EM fields from hand-held radio wave sources

(transceivers) are of special concern. It is possible to unintentionally bring high

levels of EM energy very close to the powered wheelchair's control system while

using these devices. This can affect powered wheelchair movement and braking.

Therefore, the warnings listed below are recommended to prevent possible

interference with the control system of the powered wheelchair.

Electromagnetic interference (EMI) from sources such as radio and TV stations,

amateur radio (HAM) transmitters, two-way radios, and cellular phones can affect

powered wheelchairs and motorized scooters.

FOLLOWING THE WARNINGS LISTED BELOW SHOULD REDUCE THE

CHANCE OF UNINTENDED BRAKE RELEASE OR POWERED WHEELCHAIR

MOVEMENT WHICH COULD RESULT IN SERIOUS INJURY.

1) Do not operate hand-held transceivers (transmitters receivers), such as citizens

band (CB) radios, or turn ON personal communication devices, such as cellular

phones, while the powered wheelchair is turned ON;

2) Be aware of nearby transmitters, such as radio or TV stations, and try to avoid

coming close to them;

3) If unintended movement or brake release occurs, turn the powered wheelchair

OFF as soon as it is safe;

4) Be aware that adding accessories or components, or modifying the powered

wheelchair, may make it more susceptible to EMI (NOTE: There is no easy way

to evaluate their effect on the overall immunity of the powered wheelchair); and

5) Report all incidents of unintended movement or brake release to the powered

wheelchair manufacturer, and note whether there is a source of EMI nearby.

Important Information

1) 20 volts per meter (V/m) is a generally achievable and useful immunity level

against EMI (as of May 1994) (the higher the level, the greater the protection);

2) The immunity level of the product is unknown.

Modification of any kind to the electronics of this wheelchair as manufactured by

Invacare may adversely affect the RFI immunity levels.

Part No 1114808 9 MK

™

EX™ and MK

5

™

TT-EX™ Electronics

5

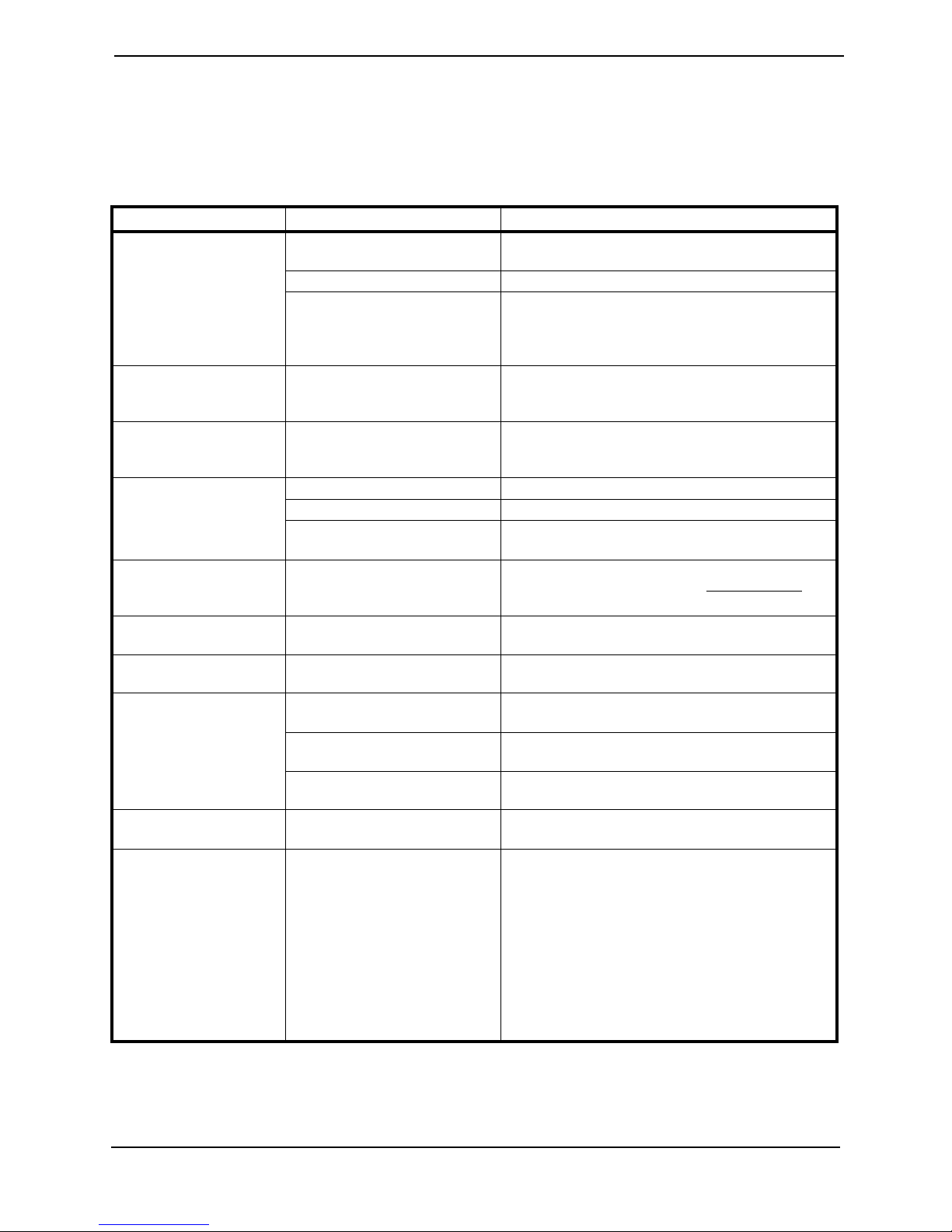

SECTION 2—TROUBLESHOOTING

SECTION 2—TROUBLESHOOTING

All Power Wheelchairs

SYMPTOM PROBABLE CAUSE SOLUTIONS

Error Code:

E9 or E10 - MPJ joystick

3 flashes - DPJ joystick

Error Code:

E28 - MPJ joystick

5 flashes - DPJ joystick

Error Code:

E14 - MPJ joystick

5 flashes - DPJ joystick

Joystick erratic or does

not respond as desired.

Wheelchair veers to the

left or right when driving

on level surface.

No LED’s on joystick. Joystick connection to controller

Corroded wiring or

connections.

Wheelchair does not

respond to commands.

Power indicator off - even

after recharging.

Wheelchair slows or

stops while driving AND

one (1) of the following

occurs:

DPJ Joystick - ORANGE

LED flashes

Motor lock levers disengaged. Engage motor lock levers. Refer to the wheelchair

Owner’s Manual for more information.

Bad motor connection. Check all motor connections.

Bad brake coil. Ohm out motors. Check brushes and replace if

necessary. Replace motors if high reading is present.

Normal reading is 0-5 Ohms (4 Pole only). Calibrate

GB motors. Refer to wheelchair Service Manual.

Battery charger connected. Unplug battery charger from the wheelchair. Refer

to the wheelchair Owner’s Manual for information

about the battery charger.

Batteries need to be charged. Charge batteries. Refer to the wheelchair Owner’s

Manual for charging instructions.

Damaged motor coupling. Contact Dealer/Invacare for Service.

Electrical malfunction. Contact Dealer/Invacare for Service.

Controller programmed

improperly.

Joystick needs to be calibrated. Calibrate joystick with programmer. If this does not

unplugged or damaged.

Possible water, salt, or urine

damage.

Poor battery terminal

connection.

Bad joystick connection. Check all joystick connections. Refer to wheelchair

Bad wiring harness connection

or blown fuse.

Electrical malfunction. Contact Dealer/Invacare for Service.

Current rollback. Wheelchair

has been driving under a heavy

load for an extended period of

time.

Contact Dealer/Invacare to have controller

reprogrammed.

work, replace joystick. Refer to Joystick Throw

page 25 for calibration information.

Check all joystick connections. Refer to wheelchair

Owner’s Manual. If damage is found, replace joystick.

Replace wiring harness. Refer to wheelchair

Owner’s Manual.

Have clean terminals. Refer to wheelchair Owner’s

Manual.

Owner’s Manual.

Replace wiring harness. Refer to wheelchair

Owner’s Manual.

Adjust driving parameters to match driving

environment.

Allow time for the electronics to cool down (Light

Duty Use).

on

MPJ Joystick “HOT” or “SLOW” is

displayed

™

MK

EX™ and MK

5

™

TT-EX™ Electronics 10 Part No 1114808

5

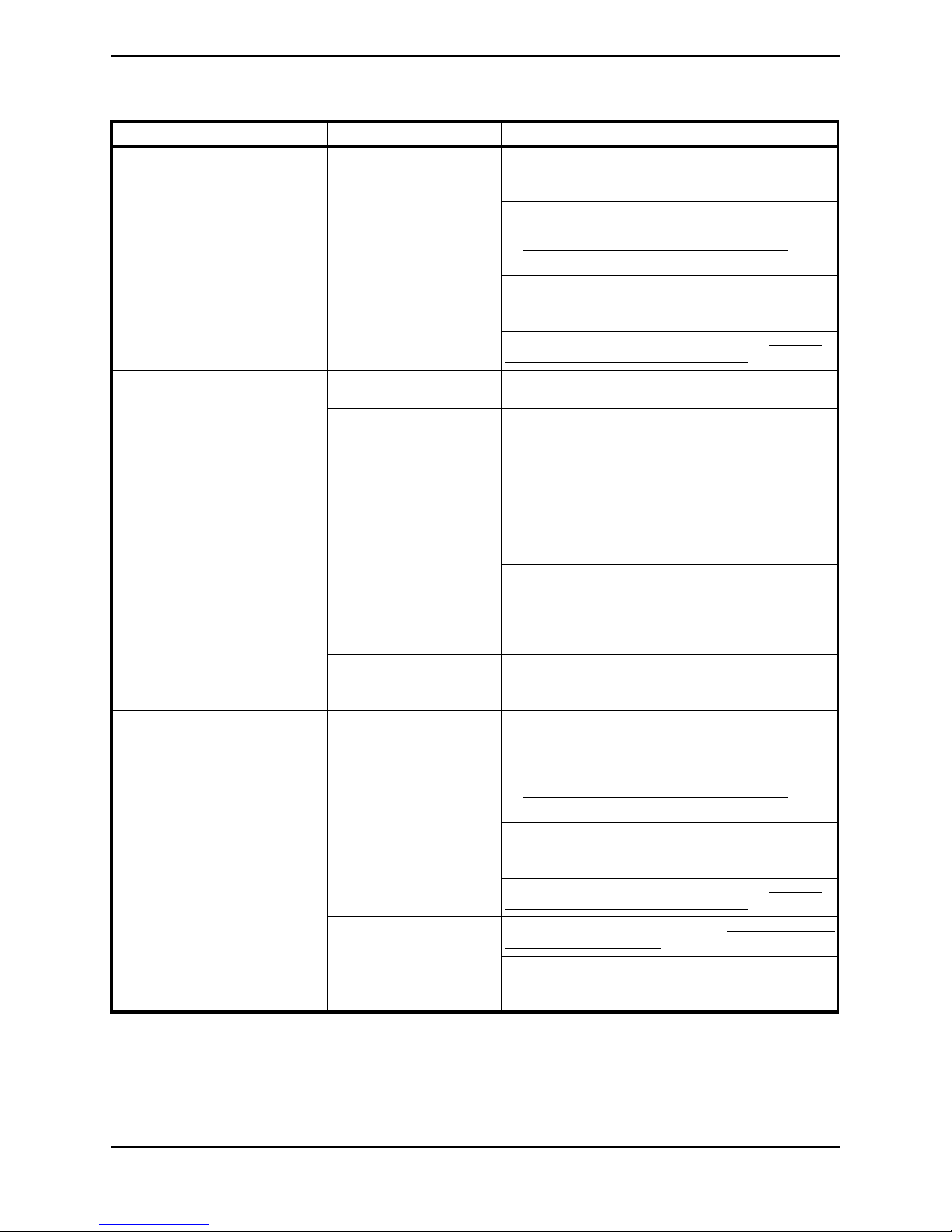

SECTION 2—TROUBLESHOOTING

Wheelchairs With Powered Seating Systems

SYMPTOM PROBABLE CAUSE SOLUTIONS

Wheelchair Power ON but does

not drive.

Seating system not functioning or

working intermittently.

Error Code:

E28 - MPJ joystick

or

5 flashes - DPJ joystick

System tilted, reclined or

elevated beyond drive

lock-out angle (20°).

Return to neutral position (upright and completely

lowered). Refer to the seating system Owner’s

Manual for seating system operating instructions.

Use the programmer to check the Current Status

Menu, particularly the drive lock-out setting. Refer

to TRECM Current Status Menu Description

page 59.

To adjust drive lock-out angle, Refer to the Formula

TRE setup instructions, part number 1125061 for

drive lock-out adjustment instructions.

To turn drive lock-out on or off, refer to TRECM

Performance Adjust Menu Description on page 57.

Low batteries. Charge batteries. Refer to the seating system

Owner’s Manual.

Faulty electrical

Check all connections.

connection.

Blown fuse. Replace wiring harness. Refer to the seating system

Owner’s Manual.

Seat has been driven

under a heavy load for an

extended period of time.

Open Motor

connection/Motor locks

Allow time for the electronics to cool down (Light

Duty Use). Leave power on, and do not activate

powered seating functions for at least 3 minutes.

Check all motor connectors.

Make sure motor locks are engaged.

disengaged.

Malfunctioning seating

Replace seating system controller. Contact Invacare.

system controller

(TRECM, SAC-E, or ESC).

Bad user switch. Use the programmer to check the TRECM Current

Status Menu for switch status. Refer to TRECM

Current Status Menu Description on page 59.

System tilted, reclined or

elevated beyond drive

lock-out angle (20°).

Return to neutral position (upright and completely

lowered). Refer to seating system Owner’s Manual.

Use the programmer to check the Current Status

Menu, particularly the drive lock-out setting. Refer

to TRECM Current Status Menu Description

page 59.

To adjust drive lock-out angle, Refer to the Formula

TRE setup instructions, part number 1125061 for

drive lock-out adjustment instructions.

To turn drive lock-out on or off, refer to TRECM

Performance Adjust Menu Description on page 57.

Bad limit switch, limit

switch out of position or

limit switch missing.

Check limit switch setting. Refer to TRECM Current

Status Menu Description on page 59.

Refer to the Formula TRE setup instructions, part

number 1125061 for limit switch adjustment

instructions.

on

on

Part No 1114808 11 MK

™

EX™ and MK

5

™

TT-EX™ Electronics

5

SECTION 2—TROUBLESHOOTING

SYMPTOM PROBABLE CAUSE SOLUTIONS

Wheelchair slows or stops while

driving AND one (1) of the

following occurs:

DPJ Joystick - ORANGE LED

flashes

MPJ Joystick “SLOW” is displayed

Wheelchair drives at full speed

when seat is elevated.

Wheelchair will not drive when

seat is elevated.

Programmer does not work or

gives “communication error”

Elevating seat is elevated.

The elevating seat is

equipped with a speed

reduction safety

mechanism. While the

seat is in an elevated

position, the safety feature

slows the speed of the

wheelchair by 80%.

Faulty electrical

connection.

Malfunctioning seating

system controller

(TRECM, SAC-E, or ESC).

If not an Elevate Only

system, the seat may be

tilted or reclined beyond

the drive lock-out angle

(20°).

System tilted, reclined or

elevated beyond drive

lock-out angle (20°).

Return the seat to its lowest position. Refer to the

seating system Owner’s Manual.

Check all connectors.

Check for error codes. Refer to Options

on page 42

for the correct performance adjustment menu

descriptions. Replace seating system controller, if

necessary. Contact Invacare.

Return to neutral position (upright and completely

lowered). Refer to seating system Owner’s Manual.

Use the programmer to check the Current Status

Menu, particularly the drive lock-out setting. Refer

to TRECM Current Status Menu Description

on

page 59.

To adjust drive lock-out angle, Refer to the Formula

TRE setup instructions, part number 1125061 for

drive lock-out adjustment instructions.

To turn drive lock-out on or off, refer to TRECM

Performance Adjust Menu Description on page 57.

Return to neutral position (upright and completely

lowered). Refer to seating system Owner’s Manual.

Use the programmer to check the Current Status

Menu, particularly the drive lock-out setting. Refer

to TRECM Current Status Menu Description

on

page 59.

To adjust drive lock-out angle, Refer to the Formula

TRE setup instructions, part number 1125061 for

drive lock-out adjustment instructions.

To turn drive lock-out on or off, refer to TRECM

Performance Adjust Menu Description on page 57.

Formula™TRE only

SYMPTOM PROBABLE CAUSE SOLUTIONS

One or more functions do

not stop at the desired

position.

Incorrect switch response. Programming error or bad

™

MK

EX™ and MK

5

™

5

Limit switch not adjusted

properly.

switch.

TT-EX™ Electronics 12 Part No 1114808

Check limit switch setting. Refer to TRECM Current

Status Menu Description on page 59.

Refer to the Formula TRE setup instructions, part number

1125061 for limit switch adjustment instructions.

Use the programmer to verify TRECM programming. Save

the proper standard program to reset switch functions.

Refer to TRECM Standard Programs Menu Description

on

page 58.

SECTION 2—TROUBLESHOOTING

SYMPTOM PROBABLE CAUSE SOLUTIONS

Drive lock-out will not

engage.

Actuator speed too slow. Low battery voltage. Recharge batteries. Refer to the seating system Owner’s

Actuator speed too fast. Programming error. Check TRECM programming to confirm the speed setting

Functions respond to

switch command, but do

not operate through the

driver control.

Functions will only operate

in one direction

Programming error. Use the programmer to verify the drive lock-out setting in

the Current Status Menu. Refer to TRECM Current Status

Menu Description on page 59.

To adjust drive lock-out angle, Refer to the Formula TRE

setup instructions, part number 1125061 for drive

lock-out adjustment instructions.

To turn drive lock-out on or off, refer to TRECM

Performance Adjust Menu Description on page 57.

TRECM failure. Check all connections to TRECM.

Check limit switch setting. Refer to the Formula TRE

setup instructions, part number 1125061 for limit switch

adjustment instructions.

MK5 controller failure. Replace MK5 controller. Refer to the Service Manual for

the wheelchair.

Drive lock-out turned off

for that particular drive.

Turn on drive lock-out for the desired drive using your

programmer. Refer to TRECM Performance Adjust Menu

Description on page 57.

Limit switch not adjusted

properly.

Check limit switch setting. Refer to TRECM Current

Status Menu Description on page 59.

Refer to the Formula TRE setup instructions, part number

1125061 for limit switch adjustment instructions.

Manual.

Programming speed set

too low.

Check TRECM programming to confirm the speed setting

for the desired actuator. Refer to TRECM Performance

Adjust Menu Description on page 57.

for the desired actuator. Refer to TRECM Performance

Adjust Menu Description on page 57.

Programming error Check the Tilt/Recline setting and make sure it is adjusted

to the correct operating mode in the appropriate drive.

Incorrect or

malfunctioning driver

Refer to TILT/RECLINE

Replace driver control. Refer to wheelchair Service

Manual.

on page 30.

control

Improperly wired actuator

Check actuator wiring.

motor leads.

Limit switches not

adjusted properly.

Check limit switches for damage. If damaged replace them.

Contact Invacare.

Check limit switch setting. Refer to TRECM Current

Status Menu Description on page 59.

Refer to the Formula TRE setup instructions, part number

1125061 for limit switch adjustment instructions.

Part No 1114808 13 MK

™

EX™ and MK

5

™

TT-EX™ Electronics

5

SECTION 3—JOYSTICK DESCRIPTIONS

SECTION 3—JOYSTICK

DESCRIPTIONS

Joystick Overview

There are two (2) standard joysticks which make up the MK5 system. The two (2) joystick

types are the DPJ™ and MPJ™. The joysticks differ in user controls, switches, number of

programmable drives and performance adjustments. The joysticks provide proportional

drive control of speed and direction.

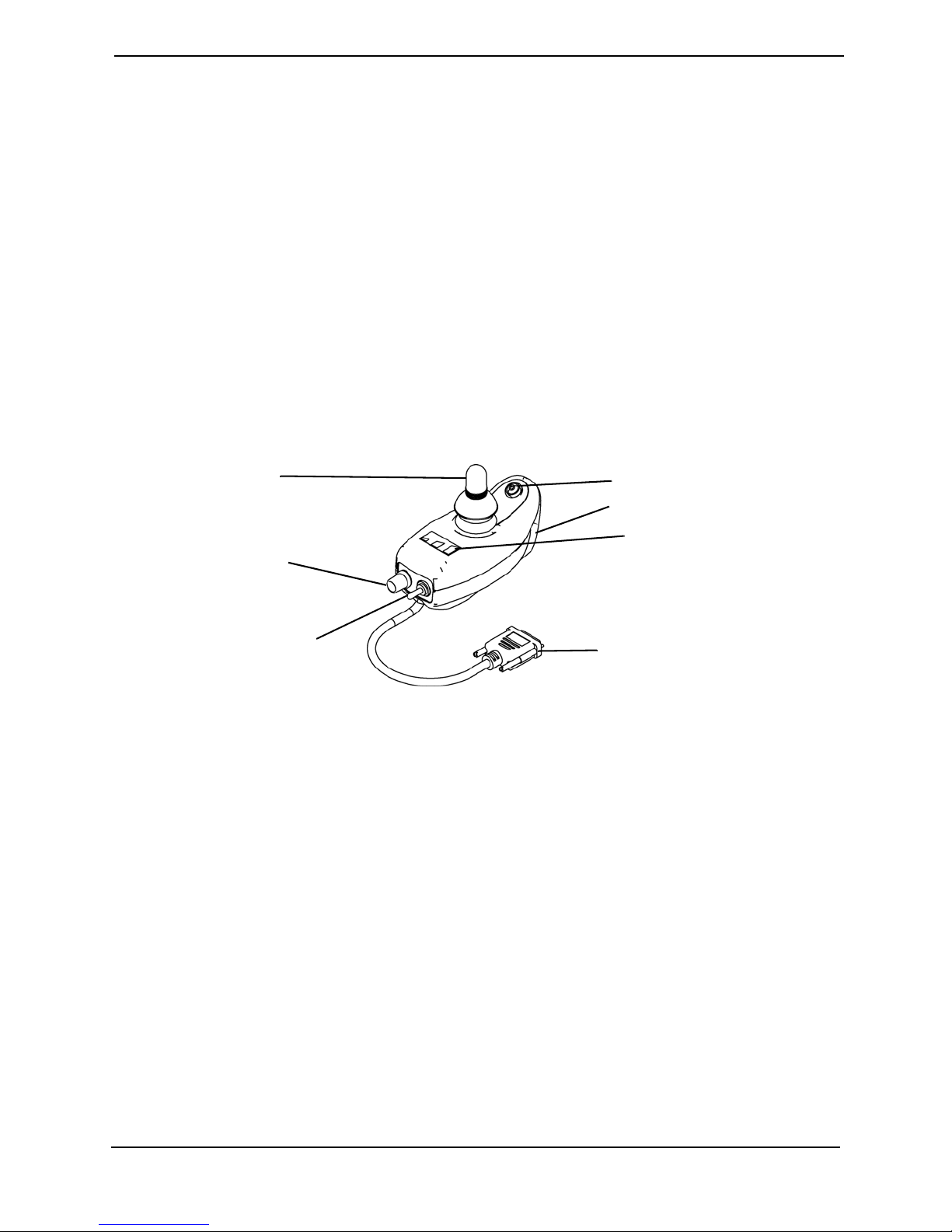

DPJ Joystick Switches and Indicators

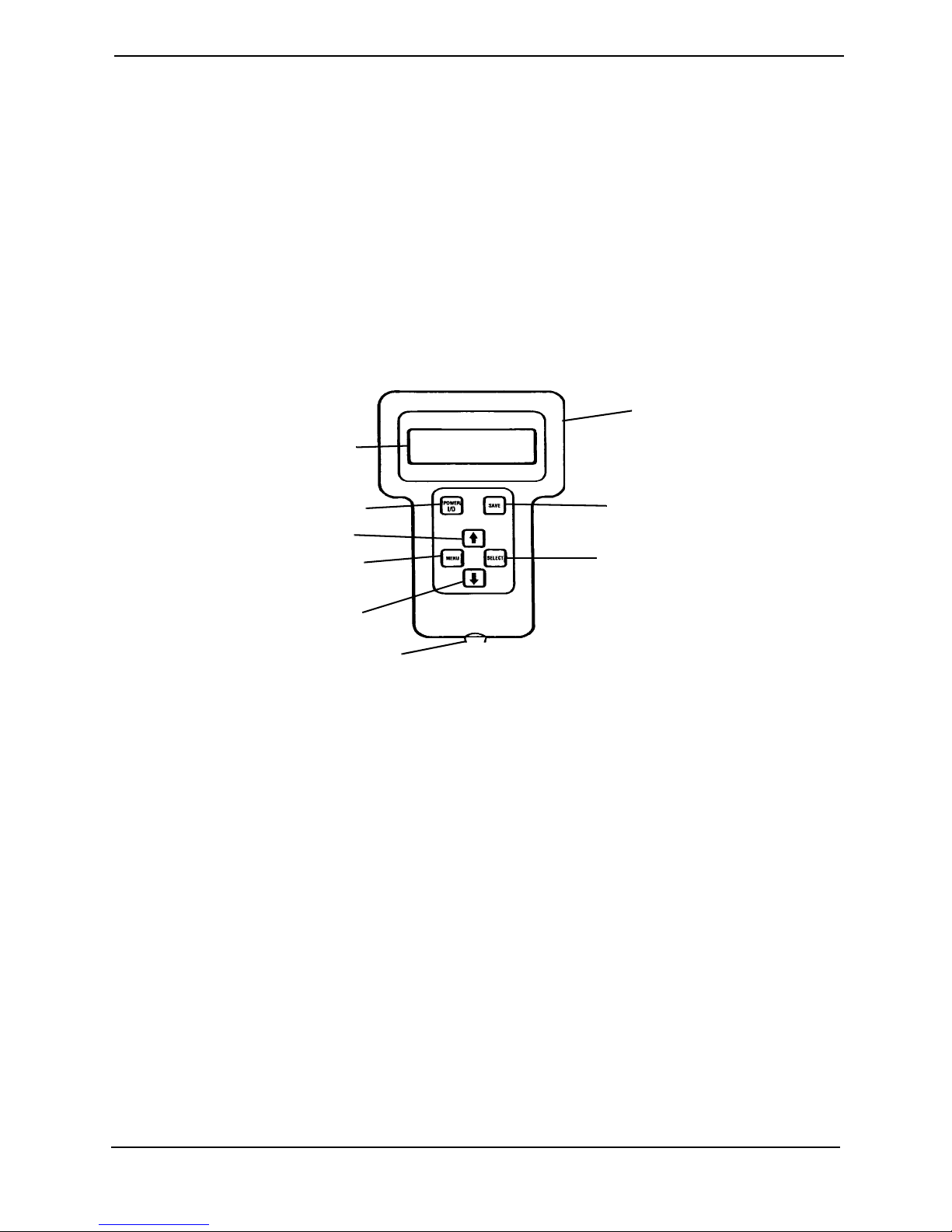

NOTE: For this procedure, refer to FIGURE 3.1.

Joystick

Speed Control Knob

Power/Drive Select Toggle

Switch

Mode Switch

Charger/Programming Port

Battery Gauge Display

To Controller

FIGURE 3.1 DPJ Joystick Switches and Indicators

Power/Drive Select Toggle Switch

The three (3) position power/drive select toggle switch is located at the back of the joystick

housing. This switch allows the operator to select the type of operation or performance

which best suits a particular control need or situation and turn the wheelchair off. The

DRIVE 1 program uses performance values which are independent of those used for the

DRIVE 2 program. For example, an operator may have a control need for spasticity in the

morning and a very different need in the afternoon. DRIVE 1 can be programmed for

higher speeds and quicker response while DRIVE 2 can be programmed for slower

speeds and less responsiveness or vise versa.

Selecting the Drive Mode

1. To select DRIVE 1 mode, move the toggle UP.

2. To select DRIVE 2 mode, move the toggle to the MIDDLE position.

Turning the Wheelchair Off

1. To turn the wheelchair off, move the toggle DOWN.

™

MK

EX™ and MK

5

™

TT-EX™ Electronics 14 Part No 1114808

5

SECTION 3—JOYSTICK DESCRIPTIONS

Speed Control Knob

The speed control knob is located at the back of the joystick housing.

1. Turn the knob clockwise to increase the maximum speed of the wheelchair.

2. Turn the knob counterclockwise to decrease the maximum speed of the wheelchair.

Mode (On/Off) Switch

The mode (on/off) switch is a push button switch located at the front of the joystick. When

an optional actuator control [Single Actuator control, (SAC), Two Actuator Control (TAC)

or Tilt and Recline Control Module (TRCM)] is present, pushing the switch will change

the controller mode to control the optional actuators through the joystick. The mode

switch LED indicator will be ON. Push the switch again to return to normal joystick

driving. The mode switch LED indicator will be off.

Battery Gauge Display (BGD)

Located at the rear of the joystick housing, the BGD provides information on the

remaining charge in the batteries. At full charge, all six (6) segments of the bar graph are

lit. As the battery discharges, the farthest right (GREEN) segment will go out until only

the red bar is lit. At this level, the last red bar will start to flash on and off to indicate that

the user should charge the batteries as soon as possible.

The BGD also serves as a system diagnostic device when a fault is detected by the control

module. A specific number of flashes (up to eight (8) flashes) of the two (2) RED bars

separated by a pause will indicate the type of fault detected. A chart of the diagnostic

indications is given in Diagnostic Codes on page 38.

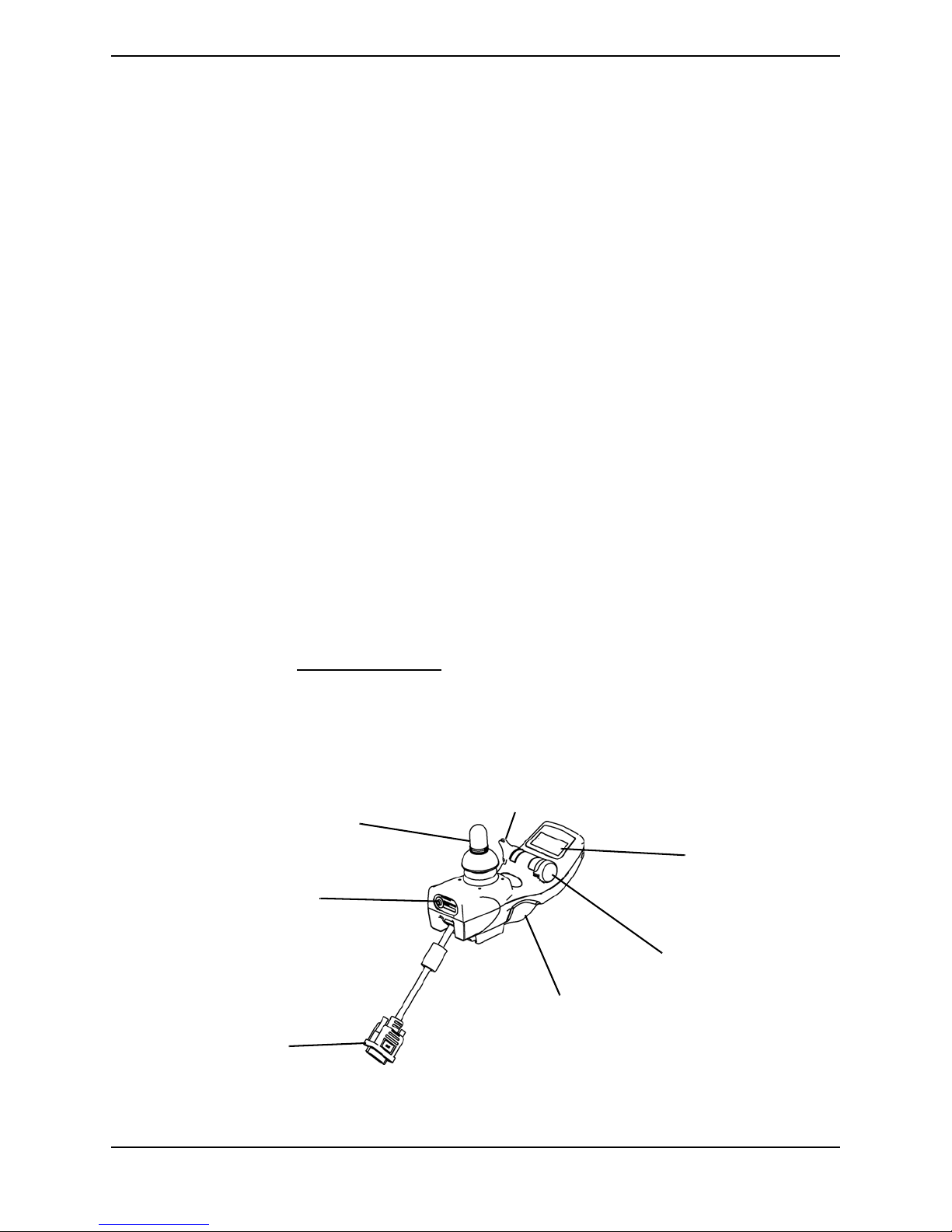

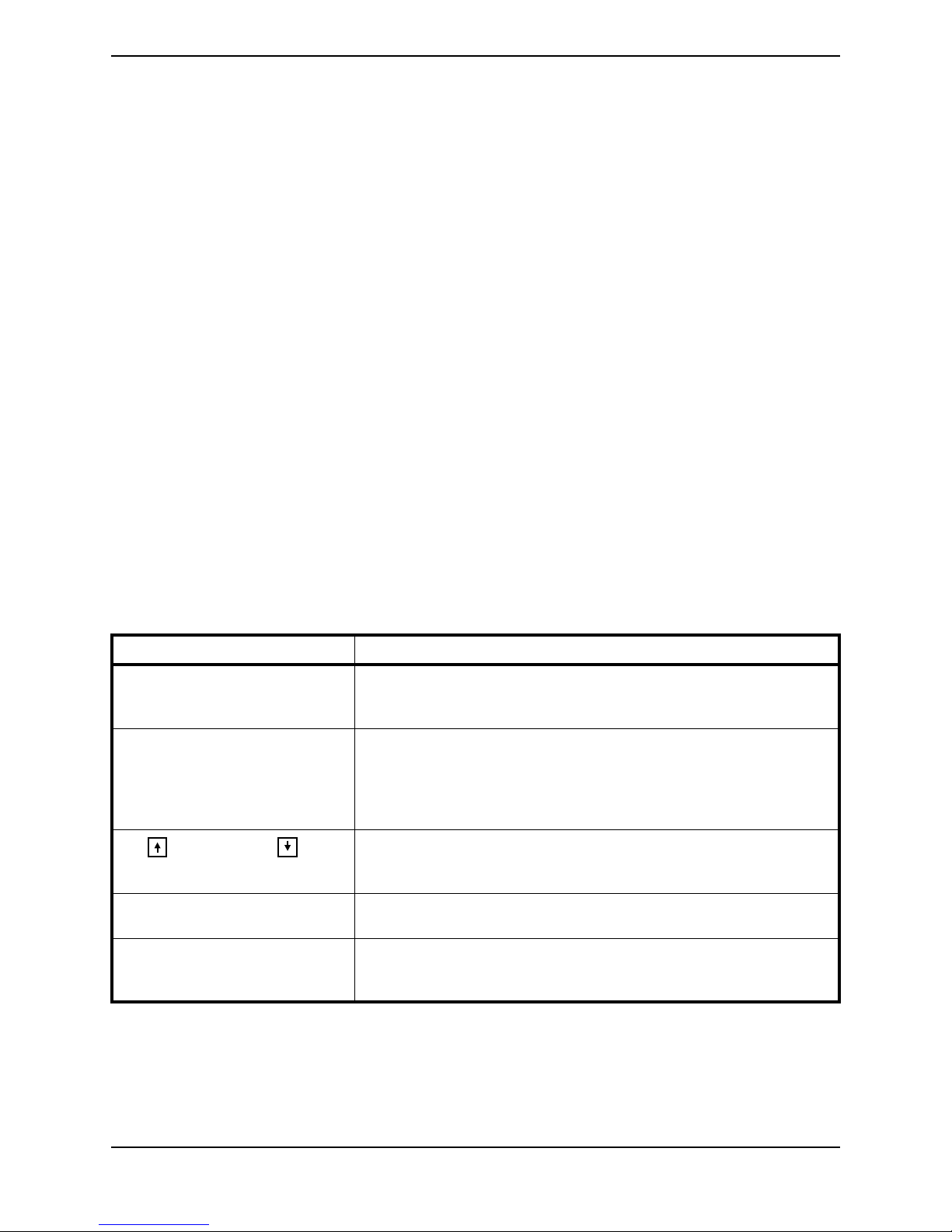

MPJ Joystick Switches and Indicators

NOTE: For this procedure, refer to FIGURE 3.2, unless otherwise indicated.

Power/Drive Select Toggle Switch

Joystick

LCD

Remote On/Off

Input

Speed Control Knob

Charger/Programming Input

To Controller

FIGURE 3.2 MPJ Joystick Switches and Indicators

Part No 1114808 15 MK

™

EX™ and MK

5

™

TT-EX™ Electronics

5

SECTION 3—JOYSTICK DESCRIPTIONS

Power/Drive Select Toggle Switch

A three (3) position power/drive select toggle switch is located on the side of the joystick

housing. The DRIVE SELECT position is momentary.

This switch allows the operator to select the type of operation or performance which best

suits a particular control need or situation. The DRIVE 1 program uses performance

values which are independent of those used for the DRIVE 2 or 3 or 4 program. As an

example, an operator may have a control need for spasticity in the morning and a very

different need in the afternoon. DRIVE 1 can be programmed for higher speeds and

quicker response while DRIVE 2 can be programmed for slower speeds and less

responsiveness. The remaining drive programs could also be used for indoor and outdoor

versions of DRIVE 1 and DRIVE 2. Finally, when a powered seating system is installed,

one of the remaining drives may be used to control the tilt, recline and/or elevate

functions.

Selecting the Drive Mode

1. Move the toggle UP and release. DRIVE 1 will appear on LCD.

2. Move the toggle UP and release again. DRIVE 2 will appear on LCD.

3. Move the toggle UP and release again. DRIVE 3 will appear on LCD.

4. Move the toggle UP and release again. DRIVE 4 will appear on LCD.

5. Move the toggle UP and release one more time to select DRIVE 1.

Turning the Wheelchair Off

1. Move the toggle BACK to turn the wheelchair off.

Speed Control Knob

The speed control knob is located on the side of the joystick housing.

1. Rotate the knob forward to increase the speed of the wheelchair to the programmed

max speed (FIGURE 3.2).

LCD Display

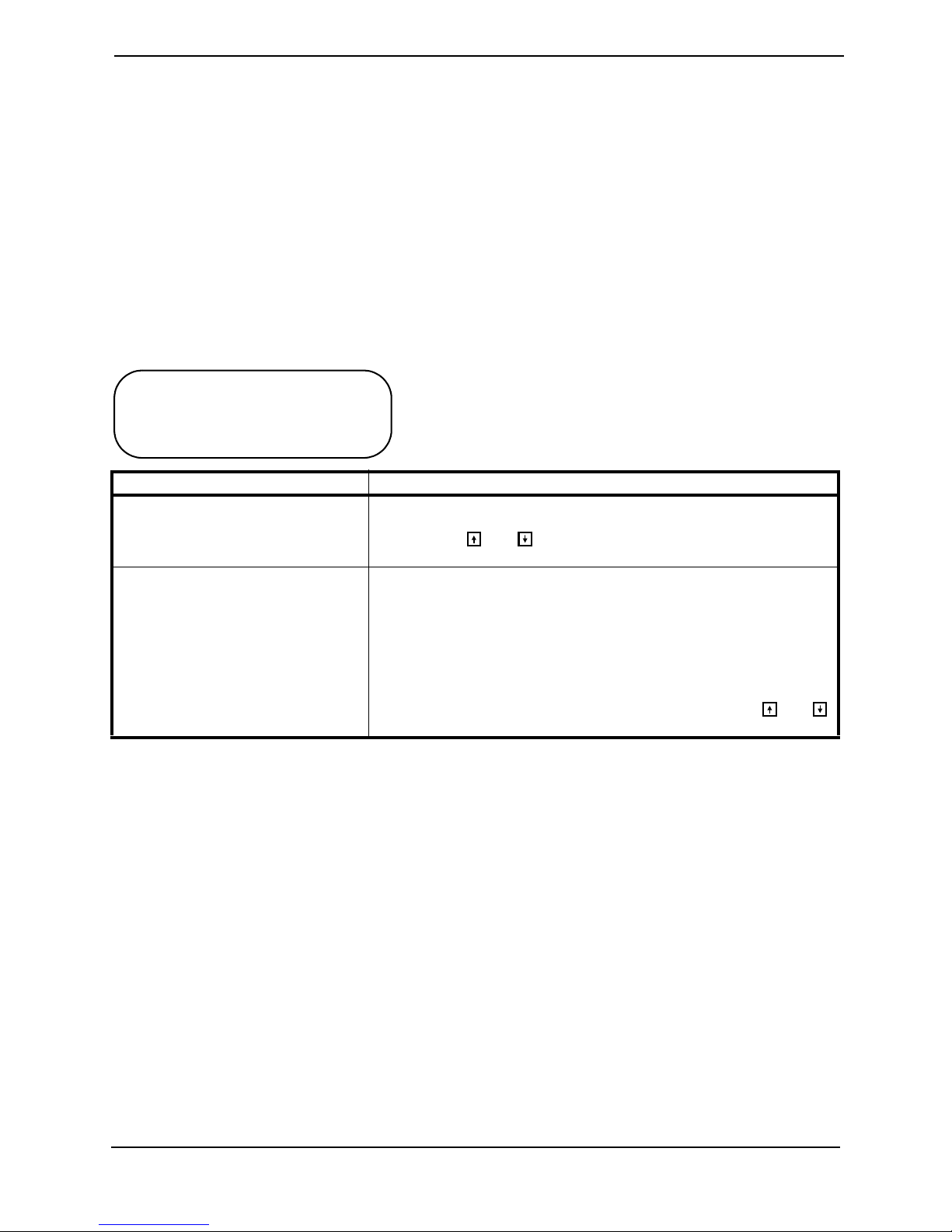

NOTE: For this procedure, refer to FIGURE 3.2 and FIGURE 3.3.

The LCD Display is located in front of the joystick and provides information on the status

of the wheelchair through a 2 line by 12 character length back lighted display. The LCD

display is readable in both bright sunlight and complete darkness (FIGURE 3.2).

During normal operation the active drive is displayed on the left half of the first line. The

left half of the second line displays the Battery Gauge Display (BGD). It provides

information on the remaining charge in the batteries. At full charge solid blocks fill in all

five segments between E (Empty) and F (Full). As the battery becomes discharged, the

furthest right segments will progressively disappear a half bar at a time until no segments

appear between E and F. At this level the word RECHARGE will appear on the second

line to indicate that the user should charge the batteries as soon as possible.

™

MK

EX™ and MK

5

™

TT-EX™ Electronics 16 Part No 1114808

5

SECTION 3—JOYSTICK DESCRIPTIONS

The right half of the display is the Information Center. The Information Center displays

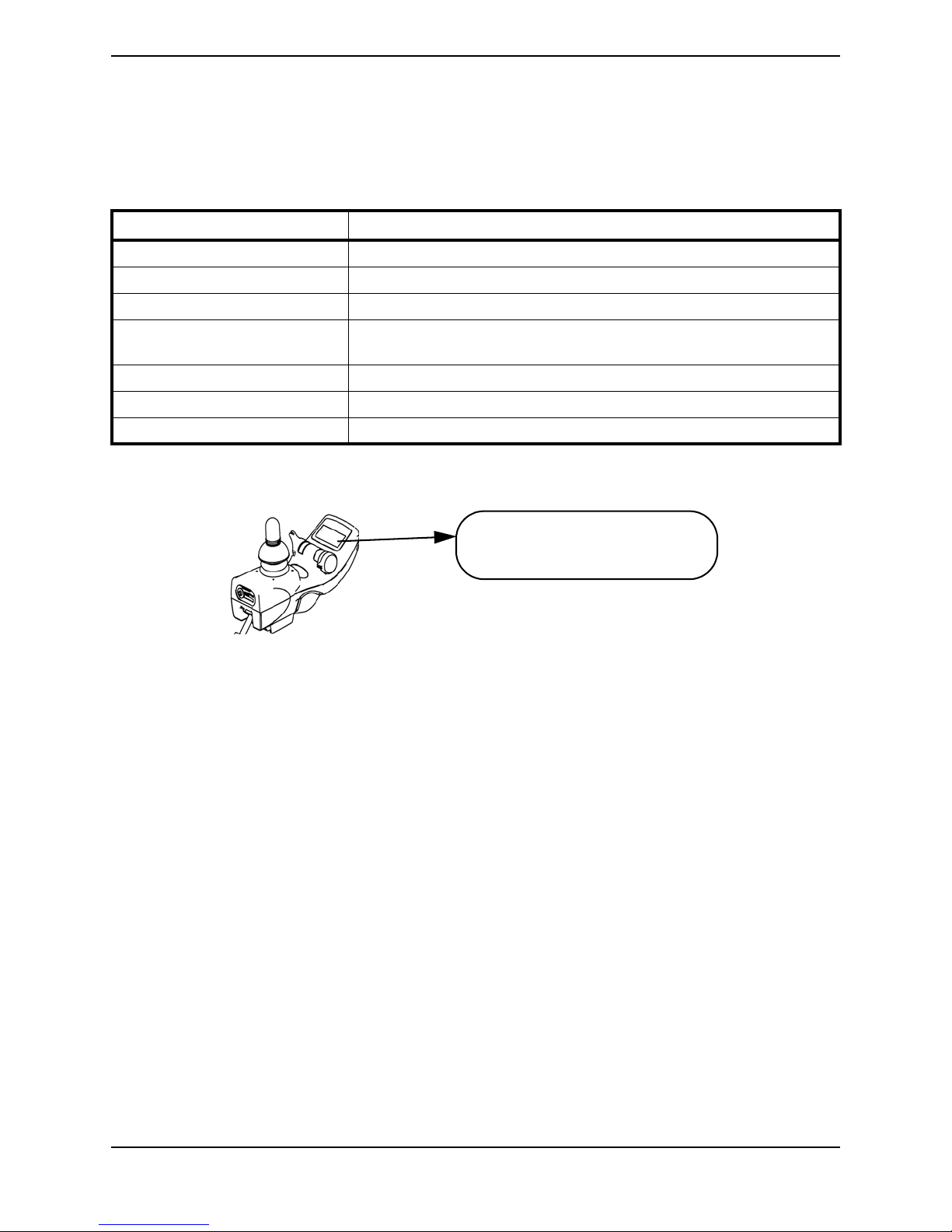

current data on the wheelchair. FIGURE 3.3 shows the factory default odometer display.

The top line shows the unit of measured MI (miles). The second line is the value, 0000

(total miles driven).

The Information Center can display:

ITEM DESCRIPTION

Speedometer Current Wheelchair Speed - MPH/KMH

Trip Odometer Distance traveled since the wheelchair was last powered ON

Odometer Total Distance Traveled (Factory Default) - MI/KM

Trip Amp-Hour meter Battery Capacity consumed since the wheelchair was last powered ON -

AH

Battery Volts Current Battery Voltage - VOLT

Battery Current Battery current being used - AMP

Load Test Results Current battery condition based on a load test - BATT

If a fault is detected, the cause of the fault will be scrolled across the second line of the

display.

DRIVE I MI

EF 0000

FIGURE 3.3 MPJ Joystick Switches and Indicators - LCD Display

Remote On/Off Input

The remote on/off input allows the power switch to be operated by an ability switch

(normally open momentary switch with mono plug). To use the remote on/off feature, the

Drive Select/On/Off switch must be in the ON position. Each activation of the ability

switch will alternately turn the joystick ON or OFF.

Part No 1114808 17 MK

™

EX™ and MK

5

™

TT-EX™ Electronics

5

SECTION 4—REMOTE PROGRAMMER

SECTION 4—REMOTE

PROGRAMMER

Overview

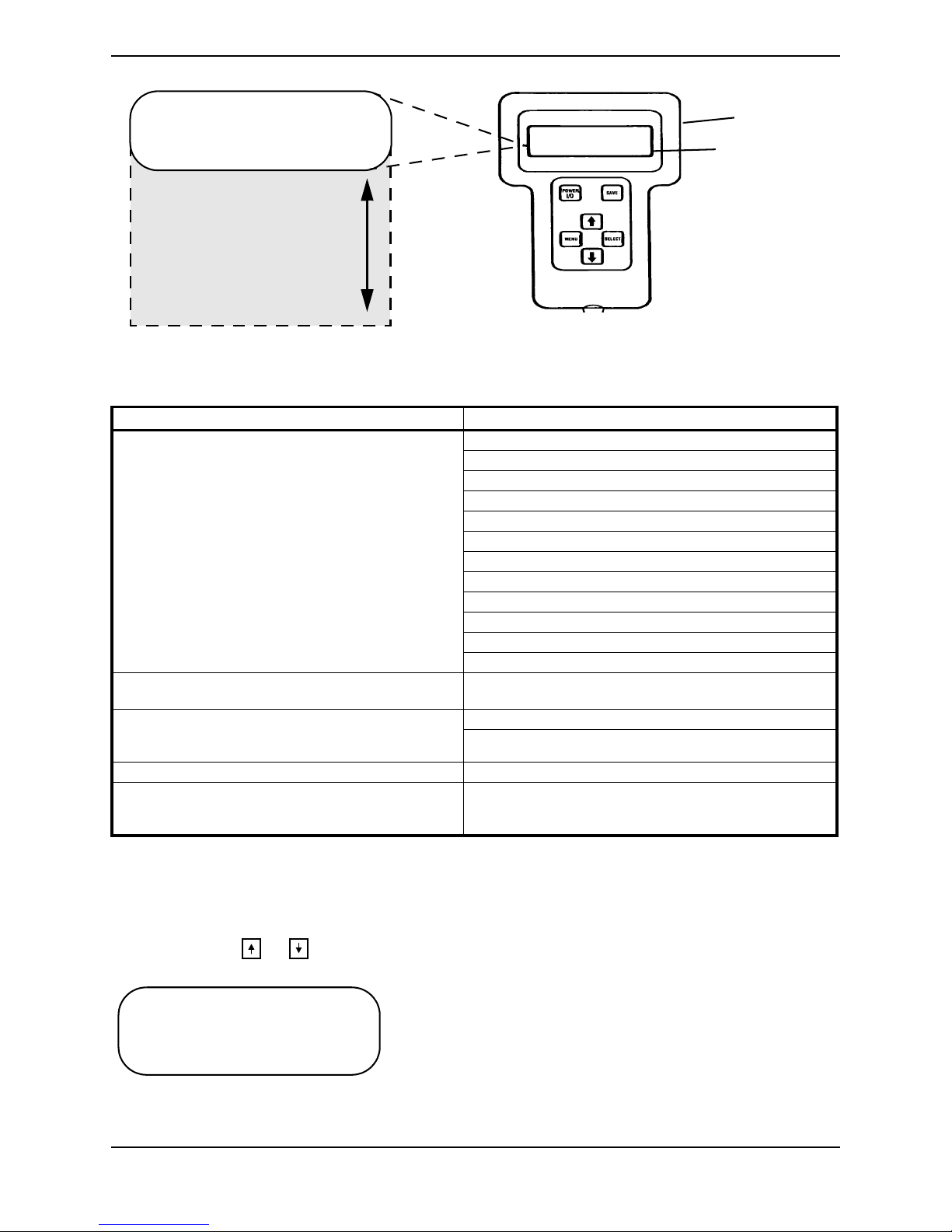

NOTE: For this procedure, refer to FIGURE 4.1.

The Remote Programmer is the information center of the control module. Through simple

key sequences, the Remote Programmer allows modification of the performance

characteristics, gives diagnostics information for trouble shooting and permits calibration

of the control module.

Remote Programmer

LCD Display

POWER Key

UP Key

MENU Key

DOWN Key

To Controller

SAVE Key

SELECT Key

FIGURE 4.1 Overview

Remote Programmer Terminology

Function

A function is a performance characteristic which can be adjusted or modified to improve

the operation of the wheelchair for a particular control need. Two (2) examples are:

The forward speed function may be adjusted to a higher or lower speed the same way as

you would adjust a trimpot in other controls.

Stand-by Mode Function may be turned ON or OFF the same as a switch would be used.

All functions are listed in a menu.

™

MK

EX™ and MK

5

™

TT-EX™ Electronics 18 Part No 1114808

5

SECTION 4—REMOTE PROGRAMMER

Value

Each function has a value. It is the degree or amount of the function which is used to

influence the overall wheelchair performance. Most values are numerical or in

percentages, for instance - high speed may be set to 75% of the wheelchair's maximum.

For others, the value is either ON or OFF, for example - Stand-by Mode. Changing a value

is called Adjustment.

Standard Program (Preset Programs)

The standard programs are fixed function values which are used as an initial set up point

from which individualization of the wheelchair performance can begin. Standard values

are NEVER altered or modified.

User Memory Values

The user memory values can only be changed through the Remote Programmer by first

modifying the temporary memory values and then by saving them in the user memory

where they become the user program. The Remote Programmer is activated by pressing

the POWER key when the wheelchair is in neutral. The wheelchair cannot be driven when

the LCD display is illuminated. The display will automatically turn itself OFF after 45

seconds if no keys are pressed. It can also be turned OFF by pressing the POWER key.

Description Of Remote Programmer Keys

KEY DESCRIPTION

POWER KEY The POWER key turns on and off the LCD display. Press the POWER key

once and the display will come ON. Press the POWER key again and the

display will turn OFF.

MENU KEY The MENU key returns the LCD display to the previous screen. If a func-

tion is being adjusted, pressing the MENU key returns the display to the

Performance Menu. Pressing the key again will cause the display to change

to the Main Menu.

UP AND DOWN

SELECT KEY The SELECT key chooses the item to which the selection arrow on the

SAVE KEY The SAVE key causes the Save screen to appear or causes the values that

KEYS

These keys are used to move the selection arrow on the LCD up and

down or adjust a value up or down. An adjusted value is not saved unless

the SAVE key is pressed.

LCD is pointing and displays the appropriate next screen.

have been modified in temporary memory to be permanently stored in the

driving program specified by the selection arrow.

Part No 1114808 19 MK

™

EX™ and MK

5

™

TT-EX™ Electronics

5

SECTION 5—PERFORMANCE ADJUSTMENTS

SECTION 5—PERFORMANCE

ADJUSTMENTS

Speed and Response Screen

The first display screen shown after powering on the Remote Programmer is the Speed

and Response screen.

The first line shows the current drive. The second line shows the forward speed. The third

line shows the responsiveness of the wheelchair to changes in drive commands. The

fourth line is the entry point to the Main Menu.

DRIVE 1

➜ SPEED 95%

RESPONSE 50%

ADVANCED MENU

MENU ITEM DESCRIPTION

SPEED Adjusts the speed of the wheelchair. It affects forward speed, turning speed

and reverse speed simultaneously and uniformly. The fastest speed setting is

100%. Use the and to increase or decrease the speed of the wheelchair.

RESPONSE Adjusts the responsiveness or quickness of the wheelchair to changes in

drive commands. It affects acceleration, turn acceleration, turn deceleration, braking, torque and turning speed. The value of the Response parameter is set to 50% whenever a Standard Program is selected. It is good

practice to first select a standard program that is close to the desired performance and then use Response to individualize the driving performance

to the user. The Response parameter will be ineffective in making large

changes in wheelchair responsiveness, e.g. changing a fast/responsive drive

into one suitable for users needing tremor dampening. Use the and

to increase or decrease the responsiveness of the wheelchair.

Advanced Menu

Allows entry into the Main Menu where the Performance Adjust menu, Standard

Programs menu, Calibrations menu and Current Status menu are displayed. Press the

SELECT key to display the Main Menu.

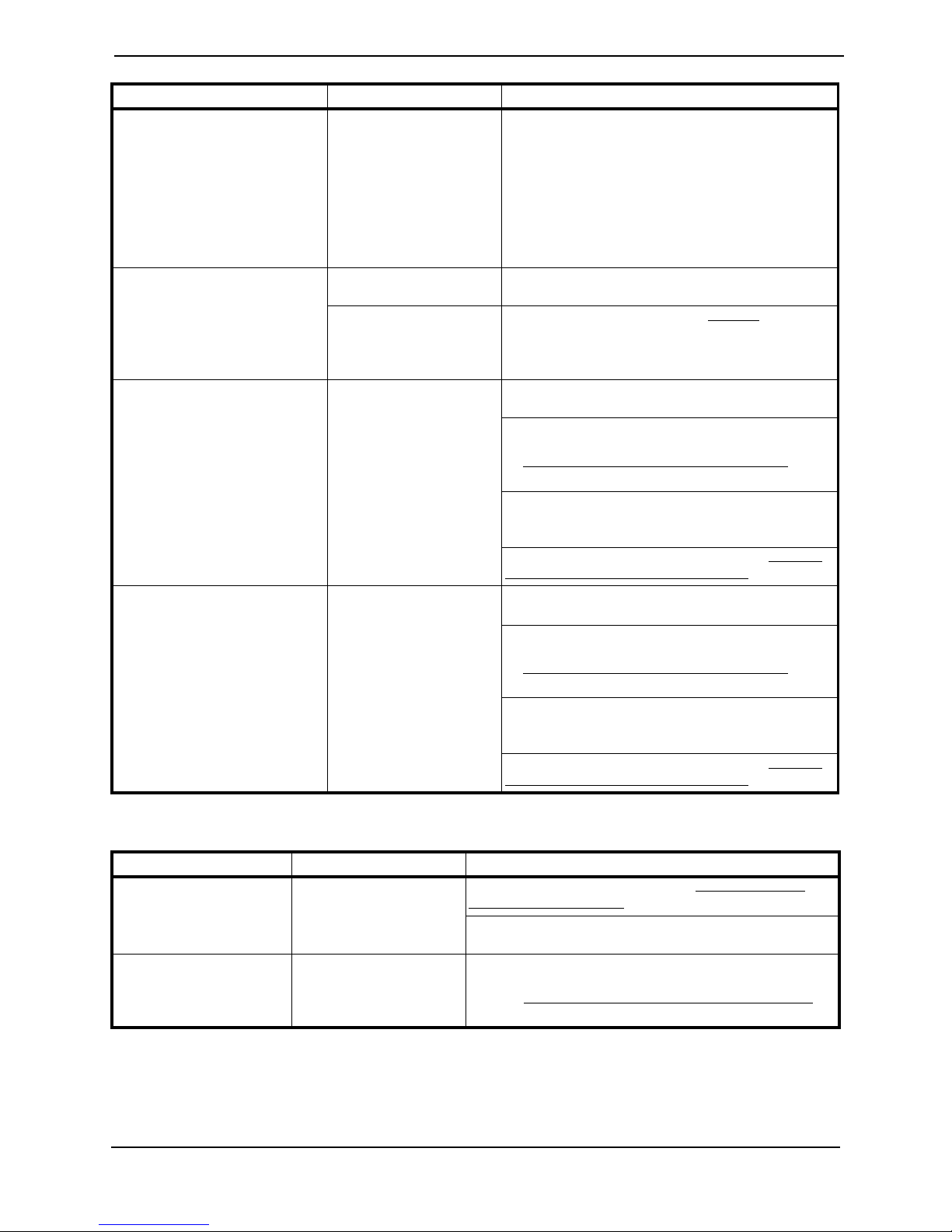

Performance Menu

NOTE: For this procedure, refer to FIGURE 5.1.

Each of the standard joysticks and optional joysticks/devices has its own performance

menu. Only the menu for the particular configuration of the joystick and options

connected to the control module appear on the performance menu. Common to all of the

MK5 control systems are the following:

™

MK

EX™ and MK

5

™

TT-EX™ Electronics 20 Part No 1114808

5

SECTION 5—PERFORMANCE ADJUSTMENTS

➜ SPEED

RESPONSE

FORWARD SPD

TURNING SPD

ACCELERATION

TURN ACCELERATION

TURN DECELERATION

BRAKING

REVERSE SPEED

TORQUE

POWER LEVEL

JOYSTICK THROW

Remote

Programmer

LCD Display

FIGURE 5.1 Performance Menu

The following menu items are added as shown in the chart below:

JOYSTICK/OPTIONAL DEVICE ADDITIONAL MENU ITEM

THE MPJ JOYSTICK

1500M4 RIM

1558M4 COMPACT JOYSTICK

NOTE: The entire menu can be customized and stored in

four drive programs (DRIVE 1 - 4)

1812M4 DUAL PROPORTIONAL CONTROL INPUT SELECT - determines which driver control device is

ENVIRONMENTAL CONTROLS

(ACCESSED THROUGH AUX12 AND

AUX34)

MK5 SINGLE ACTUATOR CONTROL (SAC) SAC - Single Actuator

MK5 TAC

MK5 TRCM

MK5 TRECM

MOM/LATCH

LATCHED TYPE

MOM REVERSE

STANDBY MODE

STANDBY SEL

STANDBY TIME

RIM CONTROL

REMOTE SEL

AUDIBLE IND - Not available with MPJ joysticks

DISPLAY SELECT

AXES SELECTION

NO DRIVING

active in each driving program

ECU 1, ECU 2

ECU 3, ECU 4

Tilt/Recline

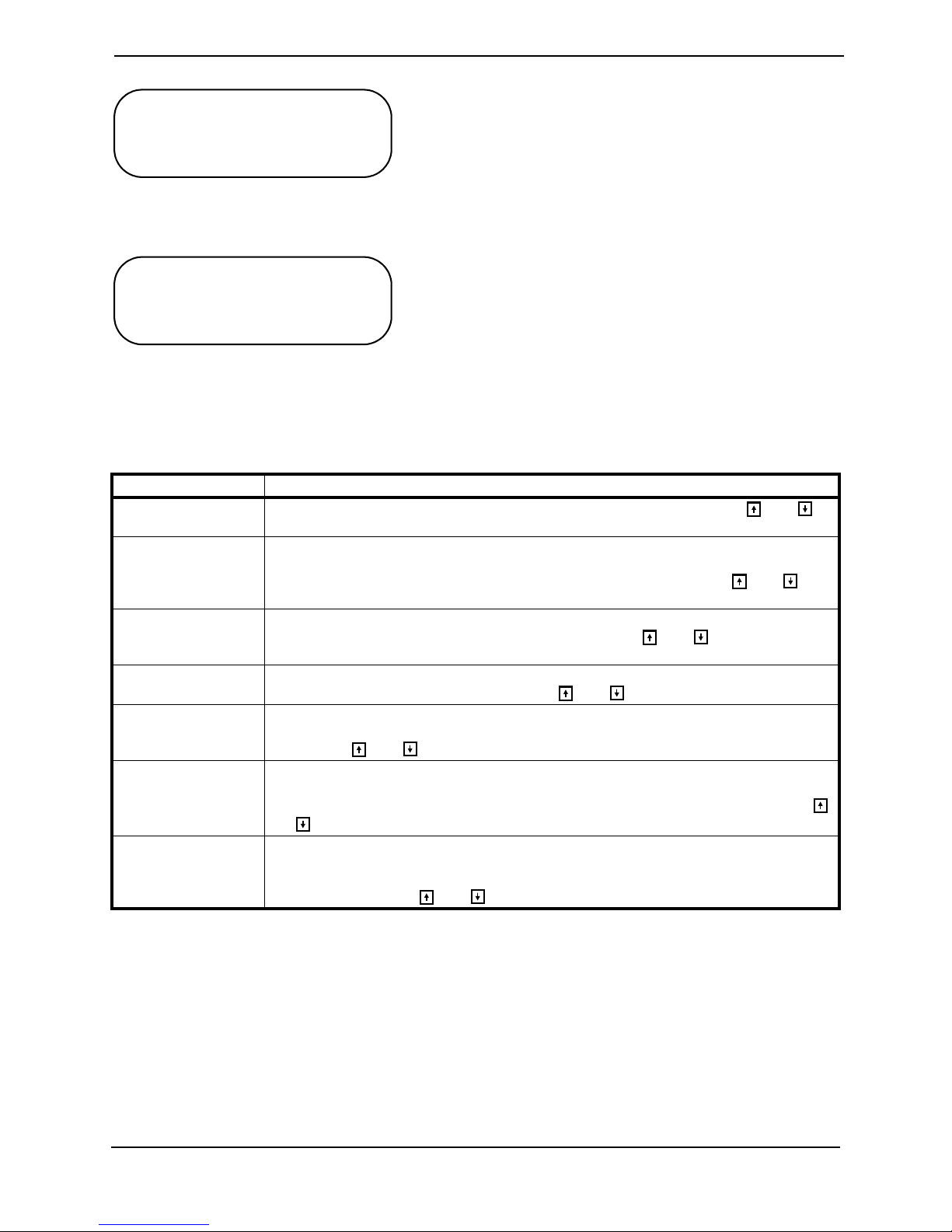

Making Performance Adjustments

The arrow to the left is the selection pointer. It can be moved up or down the main menu

by pressing the or key. The selection arrow points to PERFORMANCE ADJUST. To

select this activity press the SELECT key.

➜ PERFORMANCE ADJUST

STANDARD PROGRAMS

CALIBRATIONS

CURRENT STATUS

Part No 1114808 21 MK

™

EX™ and MK

5

™

TT-EX™ Electronics

5

SECTION 5—PERFORMANCE ADJUSTMENTS

The display screen will change to show the driving programs available for programming.

The DPJ joystick has only two driving programs, only DRIVE 1 and DRIVE 2 will be

shown. Use the key to move the selection arrow down to select drives displayed.

➜ DRIVE 1

DRIVE 2

DRIVE 3

DRIVE 4

Use the key to move the selection arrow down.

DRIVE 1

➜ DRIVE 2

DRIVE 3

DRIVE 4

To view the menu for DRIVE 2 press the SELECT key. The display screen changes to show

the first four performance functions and the programmed values for the functions. The

selection arrow points to the first function. Pressing the or key will move the

selection arrow up or down.

➜ FORWARD SPD 95%

TURNING SPD 50%

ACCELERATION 30%

TURN ACCELERATION35%

Move the selection arrow down to TURNING SPD by pressing the key.

FORWARD SPD 95%

➜ TURNING SPD 50%

ACCELERATION 30%

TURN ACCELERATION35%

Move the selection arrow down to ACCELERATION by pressing the key again.

FORWARD SPD 95%

TURNING SPD 50%

➜ ACCELERATION 30%

TURN ACCELERATION35%

Move the selection arrow to TURN ACCELERATION by pressing the key again.

FORWARD SPD 95%

TURNING SPD 50%

ACCELERATION 30%

➜ TURN ACCELERATION 35%

Pressing the key again leaves the selection arrow in the same place and the entire

performance menu shifts up one line. The selection arrow now points to BRAKING.

TURNING SPD 50%

ACCELERATION 30%

TURN ACCELERATION35%

➜ BRAKING 35%

™

MK

EX™ and MK

5

™

TT-EX™ Electronics 22 Part No 1114808

5

SECTION 5—PERFORMANCE ADJUSTMENTS

To change the programmed value for TURN ACCELERATION, press the key so the

selection arrow points to TURN ACCELERATION.

TURNING SPD 50%

ACCELERATION 30%

➜ TURN ACCELERATION 35%

BRAKING 35%

Press the SELECT key. The display screen changes to the adjustment screen. The top line

shows the function. The second line shows the value. At the bottom is a bar graph which

shows the relative position of the current value to the total adjustment range. Pressing the

or key will adjust the value.

TURN ACCELERATION

35%

MORE

LESS

Pressing the key causes the value to increase and the bar graph to move toward

MORE.

TURN ACCELERATION

70%

MORE

LESS

If another change is needed, press the MENU key to change the screen back to the

performance menu and move the selection arrow to a new function. To save this change,

press the SAVE key to show the first save screen. The select arrow points to DRIVE 2. (The

DPJ joystick will show only two drive programs.) To select the drive program to which

the changes just made will be stored use the or key to move the selection arrow to

point to the intended drive program.

SAVE TO DRIVE 1

➜ DRIVE 2

DRIVE 3

DRIVE 4

Press the key to move the selection arrow up to DRIVE 1.

SAVE TO ➜ DRIVE 1

DRIVE 2

DRIVE 3

DRIVE 4

To store the program into DRIVE 1, press the SAVE key again. The display screen changes

to show that the command is being executed.

SAVING CHANGES TO

DRIVE 1

When saving to the drive program is complete, the screen will change to display:

Part No 1114808 23 MK

™

EX™ and MK

5

™

TT-EX™ Electronics

5

SECTION 5—PERFORMANCE ADJUSTMENTS

SAVING CHANGES TO

DRIVE 1

CONTINUE? PRESS MENU

QUIT? PRESS POWER

Pressing the MENU key allows the adjustment sequence to be repeated for other drive

programs or the new program can be test driven by pressing the POWER key to turn OFF

the display screen (The wheelchair cannot be driven while the display screen is ON.).

➜ P E R F O R M A N C E A D J U S T

STANDARD PROGRAMS

CALIBRATIONS

CURRENT STATUS

Performance Menu Description

The performance adjustment menu is listed with its display mnemonic and a description

of its function.

MENU ITEM DESCRIPTION

FORWARD SPEED

TURNING SPEED Sets the TURNING SPEED as a percentage of the maximum forward speed. The turning

ACCELERATION ACCELERATION sets the time that it takes the wheelchair to accelerate to its maximum

TURN

ACCELERATION

BRAKING BRAKING sets the response time to slow or stop the wheelchair. 100% represents the max-

TORQUE Adjusts the stiffness of the response and tracking ability of the wheelchair to joystick com-

POWER LEVEL POWER LEVEL is an adjustment to the current limit of the control. Lower values reduce the

Sets the maximum forward speed. The fastest speed setting is 100%. Use the and

keys to change the value.

speed is independent of the forward speed setting so that the turning speed can be greater

than the forward speed. The fastest turning speed setting is 60%. Use the and keys

to change the value.

speed. A value of 100% is the quickest acceleration. Use the and keys to change the

values.

TURN ACCELERATION is the response time to start turn commands. A value of 100% is

the quickest response to turn commands. Use and keys to change the value.

imum braking capability of the system. This function is independent of the acceleration setting. Use the and keys to change the value.

mands. A 100% value is the maximum stiffness while a 0% value is the maximum softness.

The MK5 TT-EX True Track Feature is turned off when the value is set to 0%. Use the

and keys to change the value.

maximum pulling power and increase the range of the wheelchair. Reduced power should be

used for chairs operated very slowly or child-sized chairs. A value of 100% provides full

power output. Use the and keys to change the value.

™

MK

EX™ and MK

5

™

TT-EX™ Electronics 24 Part No 1114808

5

Loading...

Loading...