Invacare LiNX Service Manual

Invacare®LiNX

enControlsSystem

ServiceManual

DEALER:Keepthismanual.

TheproceduresinthismanualMUSTbeperformedbyaqualied

technician.

©2017InvacareCorporation

Allrightsreserved.Republication,duplicationormodicationinwholeorinpartisprohibitedwithoutpriorwritten

permissionfromInvacare.Trademarksareidentiedby™and®.AlltrademarksareownedbyorlicensedtoInvacare

Corporationoritssubsidiariesunlessotherwisenoted.

Invacarereservestherighttoalterproductspecicationswithoutfurthernotice.

Contents

1General.........................................4

1.1Aboutthismanual..............................4

1.2Symbolsinthismanual..........................4

1.3Generalinformation............................4

1.4Imagesinthismanual...........................4

2Safety..........................................5

2.1Safetyinformation..............................5

2.2Safetynotesontheelectricalsystem................5

3Assembly........................................6

3.1Tighteningtorques.............................6

3.2Imperialtometricconversionchart.................6

3.3Overviewcomponents...........................7

3.4Powermodulemounting.........................10

3.5Mountingpositionsonwheelchairs.................11

3.6Portpin-outs..................................11

3.7Portcongurations(Factoryset-up).................12

3.7.1PortcongurationsforsystemswithDLX-REM2xx

(EU-VersionwithModuliteseat)................12

3.7.2Portcongurationfornon-expandablesystems(US

version)..................................13

3.7.3PortcongurationforsystemswithDLX-REM400

andDLX-REM500(withUltraLowMaxxseat)......14

3.7.4Portcongurationsforfunctionkeys..............15

3.8Wiringdiagrams...............................16

3.9Mountingtheprimaryremotes....................26

3.9.1MountingDLX-REM1XXandDLX-REM2XXfor

Modulite.................................26

3.9.2MountingDLX-REM2XXforUltraLowMaxx........27

3.9.3MountingtheDLX -REM400....................29

3.9.4MountingtheDLX -REM500....................30

3.10Mountingthesecondaryremotes.................31

3.10.1MountingtheDLX -ACU200....................31

3.10.2MountingtheDLX -CR400.....................32

3.10.3MountingtheDLX -REM050....................33

3.11MountingtheASLcomponents...................33

3.11.1MountingtheCompactSingleSwitchJoystick......33

3.11.2MountingtheMicroExtremityControlJoystick.....35

3.11.3MountingthePediatricCompactJoystick.........36

3.11.4Mountingtheeclipsetraywithproximity

sensors...................................38

3.12Mountingthe10wayswitch.....................38

3.12.1Mountingthe10wayswitchforModulite........38

3.12.2Mountingthe10wayswitchforUltraLow

Maxx....................................39

4OverviewLiNXAccesstools..........................40

4.1TheLiNXAccessKey............................40

4.1.1RenameLiNXAccessKey(onlypossiblewithLiNX

AccessPCtool).............................40

4.2OverviewFunctions.............................41

4.2.1OverviewUserPreferences.....................42

5Suggestedprogrammingprocedure....................45

5.1Step1–Power-uptest..........................45

5.2Step2–Checkmotororientation..................45

5.3Step3–Setloadcompensation...................45

5.3.1CalibratingAdaptiveLoadCompensation(iOS

tool).....................................46

5.3.2CalibratingAdaptiveLoadCompensation(PC

tool).....................................46

5.4Step4–Adjustspeedsettings.....................47

5.5Step5–Adjustaccelerationsettings................48

6UsingtheLiNXAccessiOStool........................50

6.1Navigationbar.................................50

6.1.1Applicationmenu............................50

6.1.2Changingtheprogramname...................50

6.2Homescreen..................................52

6.3Connectioncontextactions.......................52

6.3.1Connecttodevicescreen......................52

6.3.2Readingaprogramfromthewheelchair...........52

6.3.3Selectingawheelchairconguration..............52

6.3.4Modifyingaprogram.........................53

6.3.5Writingaprogramtothewheelchair.............53

6.3.6Savingprograms............................54

6.3.7Upgradingrmware..........................54

6.3.8StoringtheLAKcerticate.....................55

6.4Filecontextactions.............................55

6.4.1Loadfromlescreen.........................55

6.4.2Openingles...............................56

6.4.3Deletingles...............................56

6.4.4E-mailingles..............................56

7ModifyingwheelchaircongurationwithiOStool.........58

7.1Proleandfunctionactions.......................58

7.2Modifyingfunctionandprolenames...............60

7.3Modifyingdriveparametersgraphically..............61

7.4Modifyingdriveparametersnumerically..............62

7.5Modifyingseatingparameters.....................62

7.6JoystickSwitchThreshold........................64

7.7Adjustquadrantoperation........................65

7.7.1Adjustdrivedirections........................65

7.8Enableindirectnavigation........................66

7.9Installing/Settingupalternativeinputs..............67

7.10SipandPuffinstallation.........................67

7.10.1SipandPuffcalibration......................68

8UsingtheLiNXAccessPCtool........................71

8.1Installingthesoftware...........................71

8.1.1UsingBluetoothonacomputer.................72

8.2Layoutoverview...............................72

8.3Concepts.....................................73

8.4Checkingandgettingthelatestversion..............73

8.5Connectioncontextactions.......................74

8.5.1Connecting/DisconnectingtheLiNXAccessPC

tool.....................................74

8.5.2Writeaprogramtoawheelchair................74

8.5.3Readaprogramfromawheelchair...............74

8.5.4Saveaprogramasale.......................75

8.5.5StoringtheLAKcerticate.....................75

8.5.6Managechaircongurations....................75

8.6Filecontextactions.............................76

8.6.1Open/Closeale............................76

8.6.2Removealefromlist........................76

8.6.3Writingbundlelestoachair..................76

9ModifyingwheelchaircongurationwithPCtool..........77

9.1Proleandfunctionactions.......................77

9.2Modifyingfunctionandprolenames...............78

9.3Modifyingdriveparameters.......................78

9.4Modifyingseatingparameters.....................78

9.5JoystickSwitchThreshold........................80

9.6Settingupasystemforlatcheddriving..............81

9.7Adjustquadrantoperation........................82

9.7.1Adjustdrivedirections........................83

9.8Enableindirectnavigation........................84

9.9Programmingexternalswitches....................85

9.10Programmingmultipurposebuttons................86

9.11Installing/Settingupalternativeinputs.............87

9.12SipandPuffinstallation.........................88

9.12.1SipandPuffcalibration......................88

10Diagnostics......................................91

10.1ViewingSystemSummary.......................91

10.2ViewingActiveErrors...........................91

10.3ViewingChairStatistics.........................91

10.4Viewingreal-timediagnostics.....................93

10.5Clearingtheeventlog..........................93

Invacare®LiNX

1General

1.1Aboutthismanual

Thisservicemanualcontainsinformationaboutassembly ,

adjustmentandadvancedmaintenanceoftheproduct.In

ordertoensuresafetywhenhandlingtheproduct,readthe

manualcarefullyandfollowthesafetyinstructions.

Forpre-saleanduserinformation,pleaseseetheuser

manual.FindtheusermanualonInvacare’swebsiteor

contactyourInvacarerepresentative(seeaddressesatthe

endofthismanual).

1.2Symbolsinthismanual

Inthismanual,hazardstatementsareindicatedbysymbols.

Thesymbolsareaccompaniedbyasignalwordthatindicates

theseverityoftherisk.

WARNING

Indicatesahazardoussituationthatcouldresult

inseriousinjuryordeathifitisnotavoided.

CAUTION

Indicatesahazardoussituationthatcouldresult

inminororslightinjuryifitisnotavoided.

IMPORTANT

Indicatesahazardoussituationthatcouldresult

indamagetopropertyifitisnotavoided.

Givesusefultips,recommendationsand

informationforefcient,trouble-freeuse.

Thissymbolidentiesalistofvarioustools,

componentsanditemswhichyouwillneedin

ordertocarryoutcertainwork.

•Itisimperativethatyouobservesafetyinformation.

•Informationaboutoperationoraboutgeneral

maintenanceandcareworkonthemobilitydevice

shouldbetakenfromServicemanual.

•Y oucanndinformationaboutorderingsparepartsin

thesparepartscatalogue.

•SparepartsMUSTmatchoriginalInvacareparts.Only

usesparepartswhichhavebeenapprovedbyInvacare.

•Wereservetherighttomakeanyalterationsonthe

groundsoftechnicalimprovements.

•Formoreinformationabouttheproduct,forexample

productsafetynoticesandproductrecalls,contactyour

localInvacarerepresentative.Foraddressandwebsite

seebackpageofthismanual.

•Themobilitydevicemayonlybemaintainedand

overhauledbyqualiedpersonnel.

•Theminimumrequirementforservicetechniciansis

suitabletraining,suchasinthecycleororthopedic

mechanicselds,orsufcientlylong-termjob

experience.

–Experienceintheuseofelectricalmeasuring

equipment(multimeters)isalsoarequirement.

–SpecialInvacaretrainingisrecommended.

•Alterationstothemobilitydevicewhichoccurasaresult

ofincorrectlyorimproperlyexecutedmaintenanceor

overhaulworkleadtotheexclusionofallliabilityon

thesideofINVACARE.

•IfyouhaveanyproblemsorquestionscontactInvacare

Service.

1.4Imagesinthismanual

Thedetailedimagesinthismanualaregivenmarksto

identifyvariouscomponents.Componentmarksintextand

operationalinstructionsalwaysrelatetotheimagedirectly

above.

1.3Generalinformation

•Serviceandmaintenanceworkmustbecarriedout

takingthisservicemanualintoaccount.

4

1605129-C

Safety

2Safety

2.1Safetyinformation

WARNING!

Theproceduresinthisservicemanual,mustbe

performedbyaspecializeddealerorqualied

servicetechnician.

–Donothandlethisproductoranyavailable

optionalequipmentwithoutrstcompletely

readingandunderstandingtheseinstructions

andanyadditionalinstructionalmaterialsuch

asusermanuals,installationmanualsor

instructionsheetssuppliedwiththisproduct

oroptionalequipment.

Theinformationcontainedinthisdocumentissubject

tochangewithoutnotice.

2.2Safetynotesontheelectricalsystem

WARNING!

Fireandburnhazardduetoelectricalshorts

–Themobilitydevicemustbecompletely

switchedoffbeforeremovalofvoltage-carrying

components.T odothis,removethebatteries.

Forinformationaboutremovingthebatteries,

refertotheservicemanualoftheparticular

wheelchair.

–Avoidshort-circuitingthecontactswhen

carryingoutmeasurementsonvoltage-carrying

components.

WARNING!

Riskofinjuryordamageduetoelectricalshorts

Connectorpinsoncablesconnectedtothepower

modulecanstillbeliveevenwhenthesystem

isoff.

–Cableswithlivepinsshouldbeconnected,

restrainedorcovered(withnon-conductive

materials)sothattheyarenotexposedto

humancontactormaterialsthatcouldcause

electricalshorts.

–Whencableswithlivepinshavetobe

disconnected,forexample,whenremovingthe

buscablefromtheremoteforsafetyreasons,

makesuretorestrainorcoverthepins(with

non-conductivematerials).

Tomaximizeperformance,minimizeEMCemissions,

maximizeEMCandESDimmunity,andtokeepthecabling

ofthewheelchairsafeandtidy,observethefollowing

guidelines:

•Allwiringshouldcomplywiththerequirementsof

ISO7176-14.

•Keepallcablesasshortaspossible.

•AllcablesusedshouldberesistanttoretoVW-1(UL

1581)orsimilar.

•Avoidwireloops,especiallyloopsofsinglewiresinstead

ofwirepairs.

•Trytorunwiresinpairsorbunches.Forexample,run

thebattery'spositiveandnegativewirestogether,and

themotor'spositiveandnegativewirestogether.Bind

wirestogetherandxthemtothechassis.

•Donotroutethecables(includingthemotorcable)

nearthemotorcase,wherepossible.

•Makesurethatallvehiclesub-frames,particularlythe

motorsandcontrollercase,areelectricallyconnected.

•Donotusethevehicleframeastheearthreturn.Any

electricallow-resistanceconnectiontotheframeisa

safetyriskandisnotallowedbyinternationalsafety

standards.

•T ominimizeelectromagneticemissionsbythemotor

brushes,itmaybenecessarytotcapacitorsbetween

thebrushholdersandthemotorcase.Makesurethat

theleadsarekeptasshortaspossible.Asuitable

capacitoris4n7,2kVCeramic.

•Forbestelectricalperformance,thewiresizemustbe

aslargeaspossible,butnolargerthanwhatthecrimp

intheconnectorcanwithstand.Alwaysusethecorrect

toolforcrimping.

•Recommendedminimumwiresizesareshowninthe

wiringsections.

•Forlow-currentsignals,donotusewiresizessmaller

than0.5mm

2

/20AWG,becausesmallerwiresare

physicallynotstrongenoughforthisapplication.

•Thetypeofcableusedmustbeappropriateforthe

mechanicalandenvironmentalabuseitislikelyto

encounter .

•Donotusedamagedorabusedcables.Adamaged

cablecanpotentiallyproducelocalizedheat,sparksor

arcing,andassuchitcancauseare.

•Protectallcablesagainstpossiblecontactwith

ammablematerial.

•Ifanextensionloomistted,mountitwiththefemale

connectorfacinghorizontalordownwards,andprotect

itfromdirectsplashing.Iftheextensionloomisto

beusedforfrequentdisconnection,mountthefemale

connectorsothatitfacesdownwards.

Riskofdamagetotheconnectorpins

Ifyoutouchtheconnectorpins,theycanbecome

dirtyortheycanbedamagedbyelectrostatic

discharge.

–Donottouchtheconnectorpins.

1605129-C5

Invacare®LiNX

3Assembly

3.1Tighteningtorques

CAUTION!

Riskofdamagetomobilitydevicedueto

improperlytightenedscrews,nutsorplastic

connections.

–Alwaystightenscrews,nutsetc.tothestated

tighteningtorque.

–Onlytightenscrewsornutswhicharenotlisted

herengertight.

Thetighteningtorquesstatedinthefollowinglistarebased

onthethreaddiameterforthenutsandboltsforwhichno

specicvalueshavebeendetermined.Allvaluesassume

dryandde-greasedthreads.

ThreadTighteningtorquein

Nm±10%

M43Nm

M5

M610Nm

M825Nm

M1049Nm

M1280Nm

M14120Nm

M16180Nm

3.2Imperialtometricconversionchart

Youcanusethischartasanorientationtondtheright

toolsize.

IMPERIALMETRIC

inch

5/64

3/32

7/64

1/8

9/64

5/32

11/64

3/16

13/64

7/32

15/64

1/4

17/64

9/32

mm

1.9844

2.3813

2.7781

3.1750

3.5719

3.9688

4.3656

4.7625

5.1594

5.5563

5.9531

6.3500

6.7469

7.1438

6Nm

IMPERIALMETRIC

inch

19/64

5/16

21/64

11/32

23/64

3/8

25/64

13/32

27/64

7/16

29/64

15/32

31/64

1/2

33/64

17/32

35/64

9/16

37/64

19/32

39/64

5/8

41/64

21/32

43/64

11/16

45/64

23/32

47/64

3/4

49/64

25/32

51/64

13/16

53/64

27/32

55/64

7/8

mm

7.5406

7.9375

8.3344

8.7313

9.1281

9.5250

9.9219

10.3188

10.7156

11.1125

11.5094

11.9063

12.3031

12.7000

13.0969

13.4938

13.8906

14.2875

14.6844

15.0813

15.4781

15.8750

16.2719

16.6688

17.0656

17.4625

17.8594

18.2563

18.6531

19.0500

19.4469

19.8438

20.2406

20.6375

21.0344

21.4313

21.8281

22.2250

61605129-C

Assembly

3.3Overviewcomponents

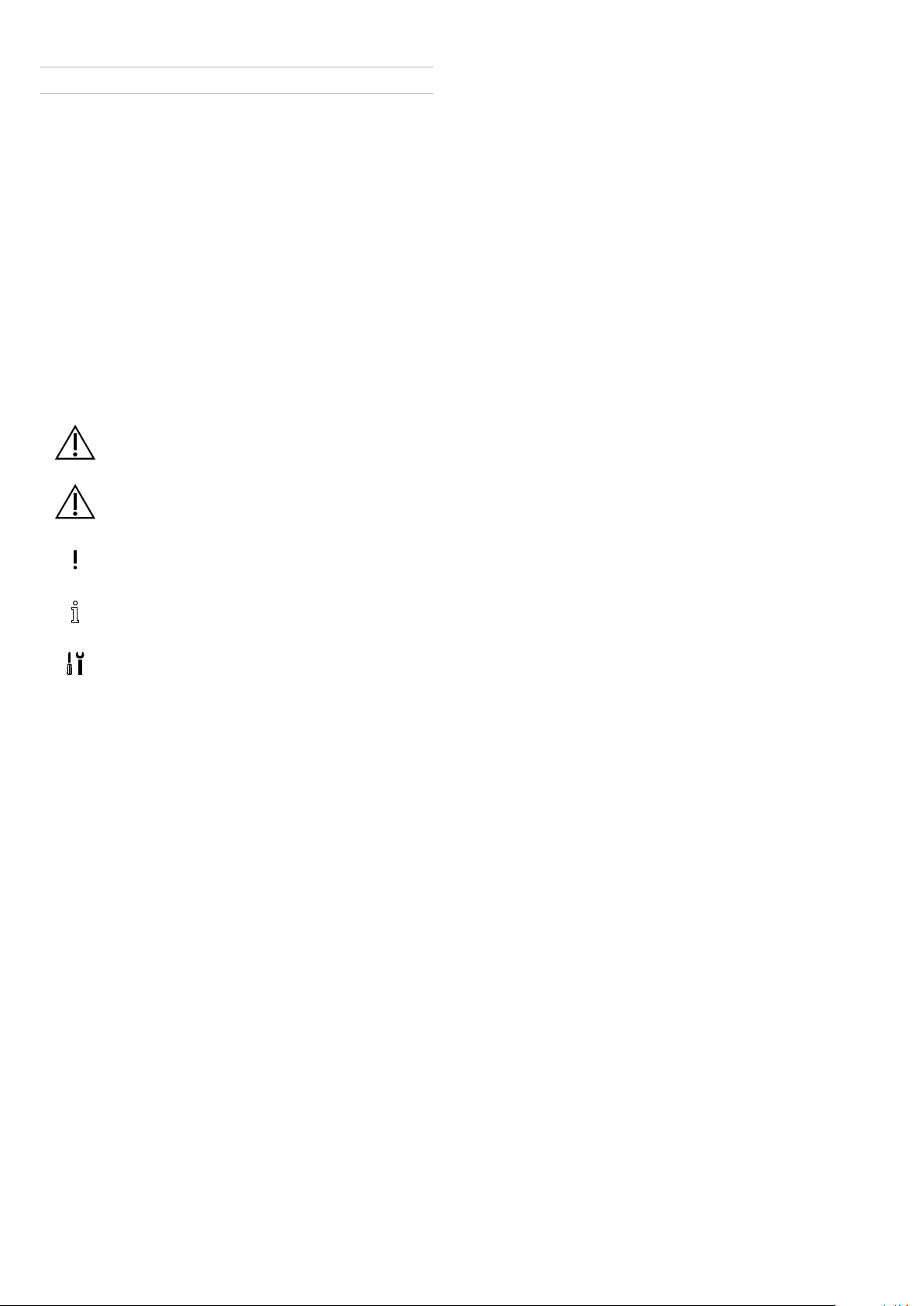

Remotemodules

DLX-REM110

•Drivefunction

DLX-REM210

•Drivefunction

•Poweredseating

function

Uptotwoactuators

Remotemodules

DLX-REM400

•T ouchscreeninterface

tofacilitate:

–Multipledrive

functions

–Multiplepowered

seatingfunctions

Twoormore

actuators

–Lightingfunction

•Multipurposebuttons

•3.5mmjacksockets

DLX-REM500

•T ouchscreeninterface

tofacilitate:

–Multipledrive

functions

–Multiplepowered

seatingfunctions

Twoormore

actuators

–Lightingfunction

•Multipurposebuttons

•3.5mmjacksockets

DLX-REM211

•Drivefunction

•Poweredseating

function

Twoormoreactuators

DLX-REM215

•Drivefunction

•Poweredseating

function

Uptotwoactuators

•Lightingfunction

DLX-REM216

•Drivefunction

•Poweredseating

function

Twoormoreactuators

•Lightingfunction

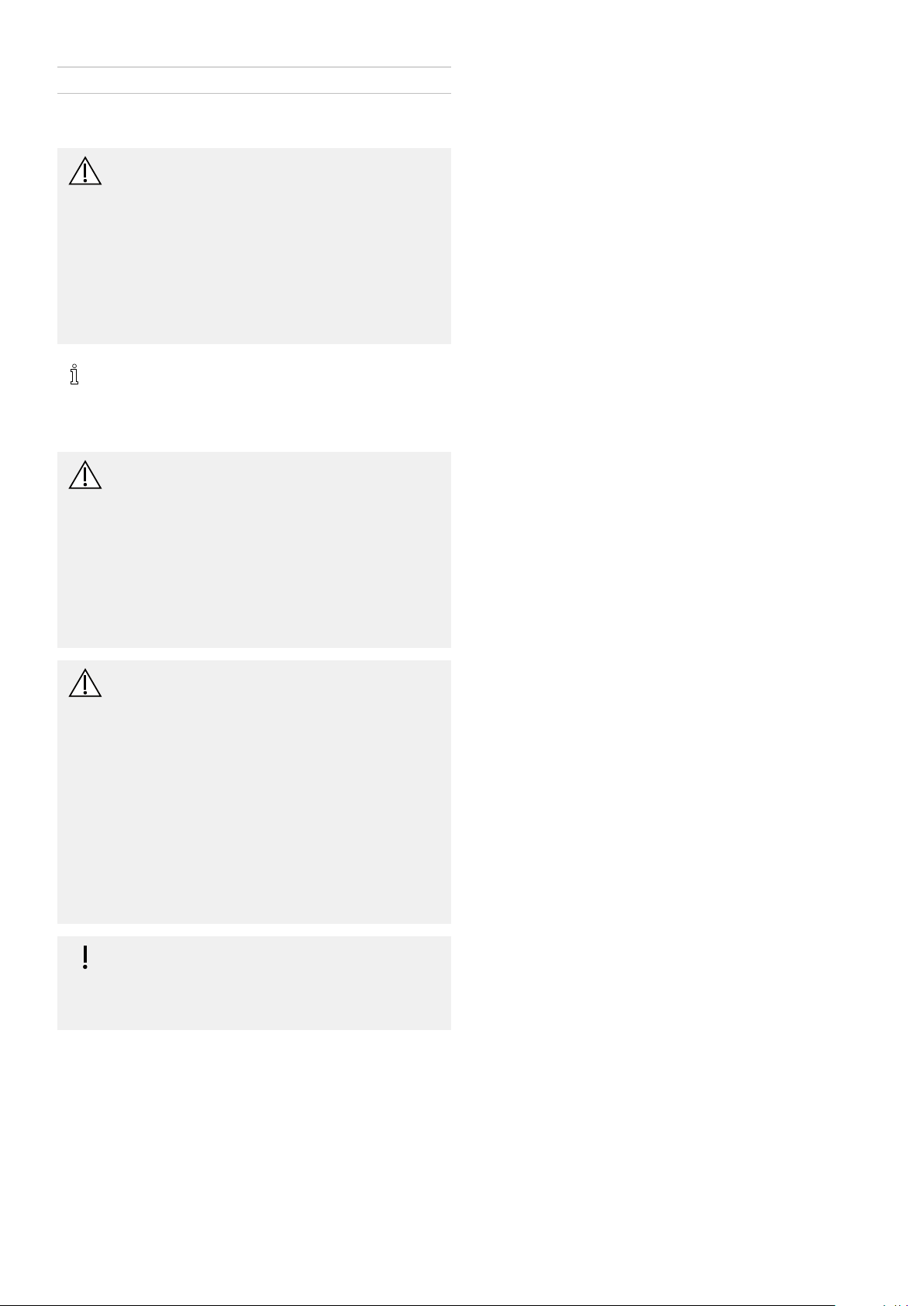

Secondaryremotemodules

DLX-CR400

CompactRemote

•On/Offbutton

•Menubutton

•Displayfordrive,

seatingand

connectivityfunctions

DLX-CR400LF

CompactRemoteLowForce

•Ascompactremote

•Withlowforcejoystick

DLX-ACU200

AttendantControlUnit

•On/Offrespectively

Selectbutton

•Menubutton

•Displayfordriveand

seatingfunctionsand

"who'sincharge"

indication

DLX-REM050

•Attendantcontrolunit

withdrivefunction

1605129-C

7

Invacare®LiNX

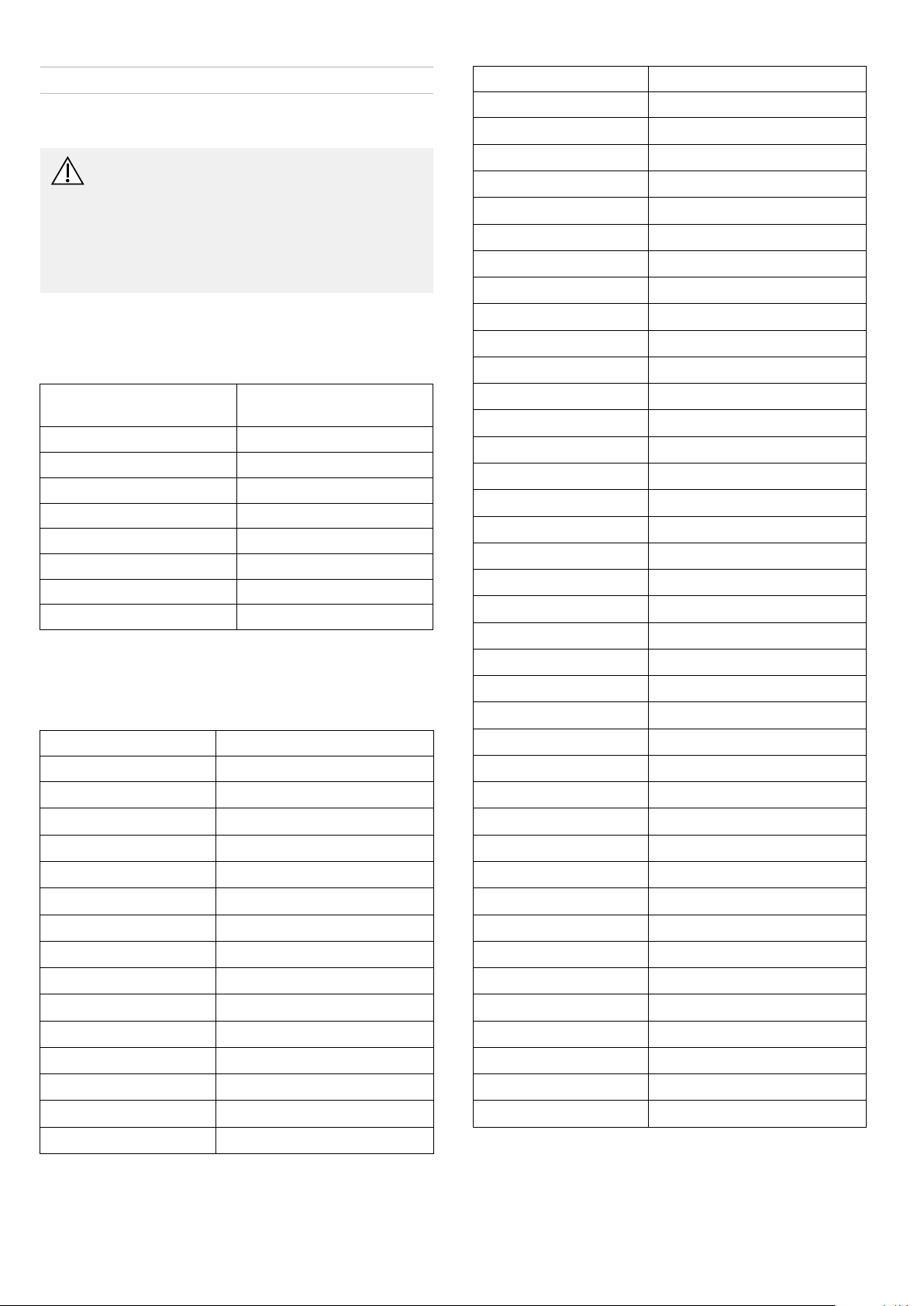

ASLcomponents

ASL138

ExtremityControlJoystick

ASL133

CompactSingleSwitch

Joystick

ASL130

MicroExtremityControl

Joystick

ASL132

CompactJoystick

ASL109

SipandPuffHeadArray

ASL104/ASL104P

HeadArray

ASLcomponents

ASL106

FourSwitchProximityArray

ASL504

RemoteStopSwitch

WirelessAccessoriesfor

ATOM:

•WirelessMouse

EmulatorASL558

•WirelessTripleSwitch

ReceiverASL557-3

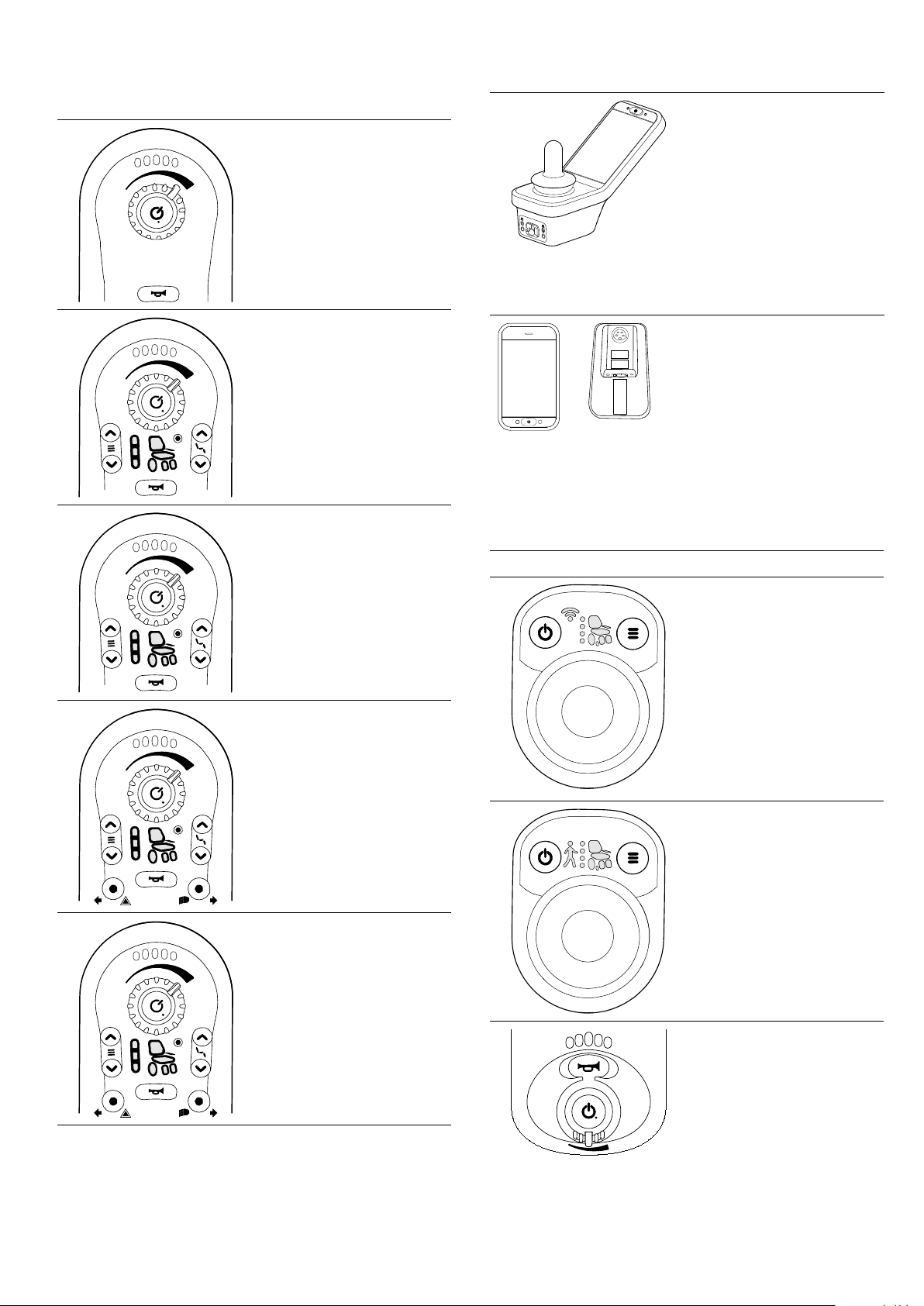

Powermodules

DLX-PM60

•63Amaximumcurrent

•2xbussockets

•DynamicLoad

Compensation

•AdaptiveLoad

Compensation

•Utilityport

•Real-timeclock

DLX-PM75

•78Amaximumcurrent

•2xbussockets

•DynamicLoad

Compensation

•AdaptiveLoad

Compensation

•Utilityport

•Real-timeclock

DLX-PM120

•120Amaximum

current

•2xbussockets

•DynamicLoad

Compensation

•AdaptiveLoad

Compensation

•Utilityport

•Real-timeclock

81605129-C

Assembly

Powermodules

DLX-PM75AL

•78Amaximumcurrent

•2xbussockets

•DynamicLoad

Compensation

•AdaptiveLoad

Compensation

•Utilityport

•2xactuators

•3xlights

•Real-timeclock

DLX-PM120AL

•120Amaximum

current

•2xbussockets

•DynamicLoad

Compensation

•AdaptiveLoad

Compensation

•Utilityport

•2xactuators

•3xlights

•Real-timeclock

LiNXseatingmodulesandinterfaces

DLX-ACT200

•2xactuatorchannels

•2xbusports

•1x6–pingeneral

purposeinput(GPI)

port

•ModulestatusLED

•Actuatorpower

providedthroughthe

bus

DLX-ACT400

•4xactuatorchannels

•2xbusports

•1x6–pingeneral

purposeinput(GPI)

port

•ModulestatusLED

•Actuatorpower

providedthroughthe

bus

GLM-CONX4

4–wayconnector

•Expansionblockto

connecttoadditional,

multiplemodulesina

LiNXsystem

LiNXseatingmodulesandinterfaces

DLX-IN500

Inputmodule

•DB9connectorfor

proportionaland

switchedinputs

•12V(200mA)power

supply

•Sipandpuffnozzle

•Jackinput(stereo)

•2xLiNXbusconnector

•Activityindicator

displayinginput

demands

Buscable;lengthfrom300

upto2500mm

Extensionloom;length640

and900mm

Poweredseatingaccessories

ASL300

Eggswitch

•Momentaryswitch

•Normallyopen

•Monojack

Stereobuttonswitch

•2switches

•Stereojack

Stereotoggleswitch

•T oggleswitch

•Normallyopen

•Stereojack

4–waybuttonswitch

•4switches

•DB9connector

4–waytoggleswitch

•4toggledirections

•DB9connector

1605129-C9

Invacare®LiNX

Poweredseatingaccessories

10wayswitch

•Hardware-onlymodule

thatprovidessimple,

directaccessto

poweredseating

functions

DLX-FKEY01

•Forsystemswithone

physicalactuator

•Poweredseating

controlthroughegg

switch,stereobutton

switchorstereotoggle

switch

DLX-FKEY02

•Forsystemswithtwoor

morephysicalactuators

•Poweredseating

controlthrough4–way

buttonswitchor4–way

toggleswitch

Correctmounting

DLX-GYR100

LiNXG-Tracmodule

•stabilizeswheelchair’s

drivingbehavior

DLX-USB02

LiNXUSBcharger

•2USBchargerports

•1Achargingcurrent

perport

•Protectiverubber

bungs

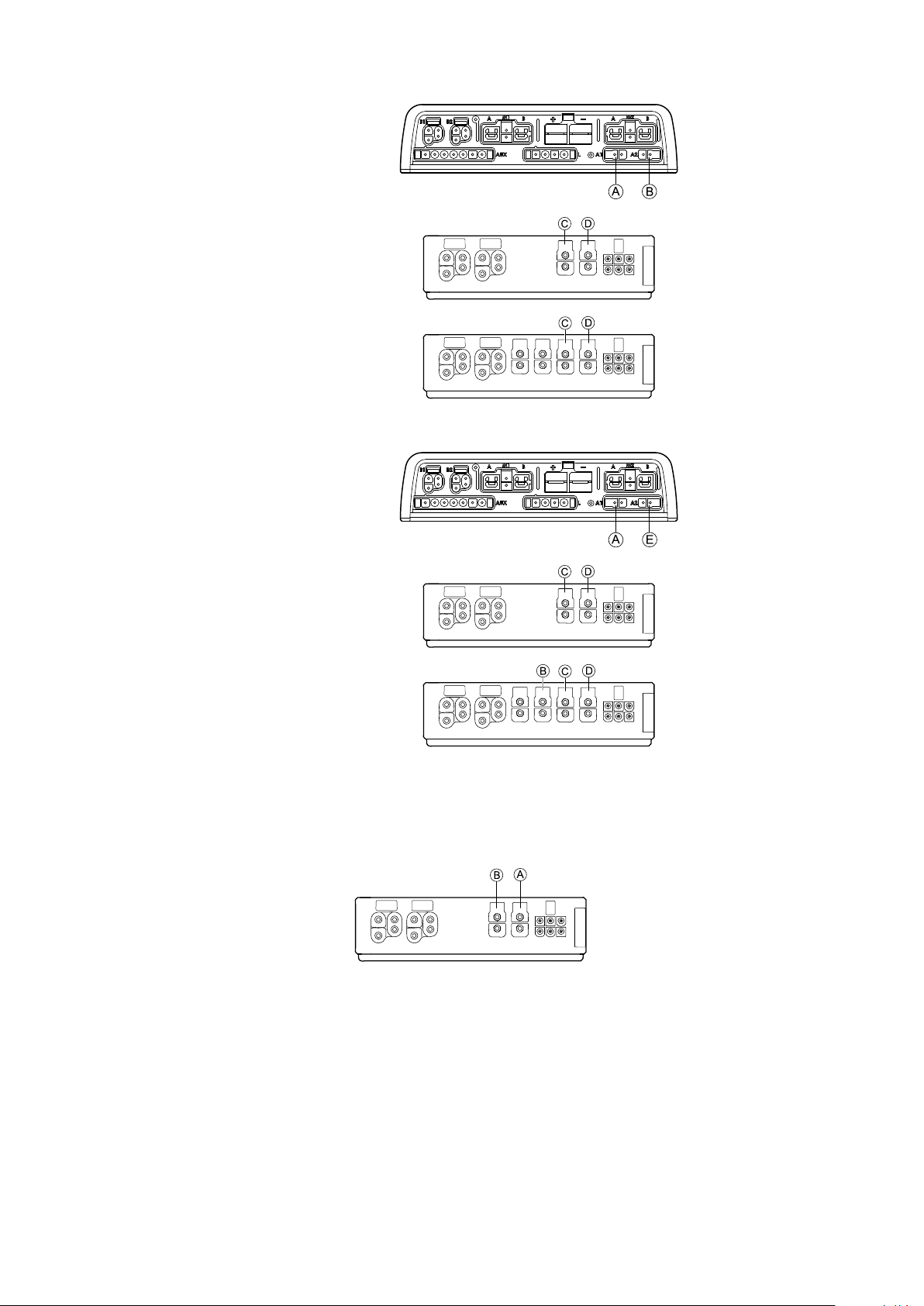

3.4Powermodulemounting

Themountingorientationofthepowermodulethatis

speciedbyInvacareperwheelchairmodelmustbekept.

Dimensionsofthepowermodules

DLX-PM60,DLX-PM75,DLX-PM120

Rear

A

Connectors

B

Top

C

Base

D

Thepowermodulescanbeplacedonitssideoratanangle.

Whenplacingthepowermodulesatanangle,ensurethat

theconnectorsBfacingdownwards,sothattheconnector

recesseswillnotcollectorretainforeignmatterorliquids.

Incorrectmounting

DLX-PM75AL,DLX-PM120AL

101605129-C

Assembly

Rear

A

Connectors

B

Top

C

Base

D

Testing

TheLiNXsystemmustbefullytestedafterallmodulesand

cableshavebeeninstalled.

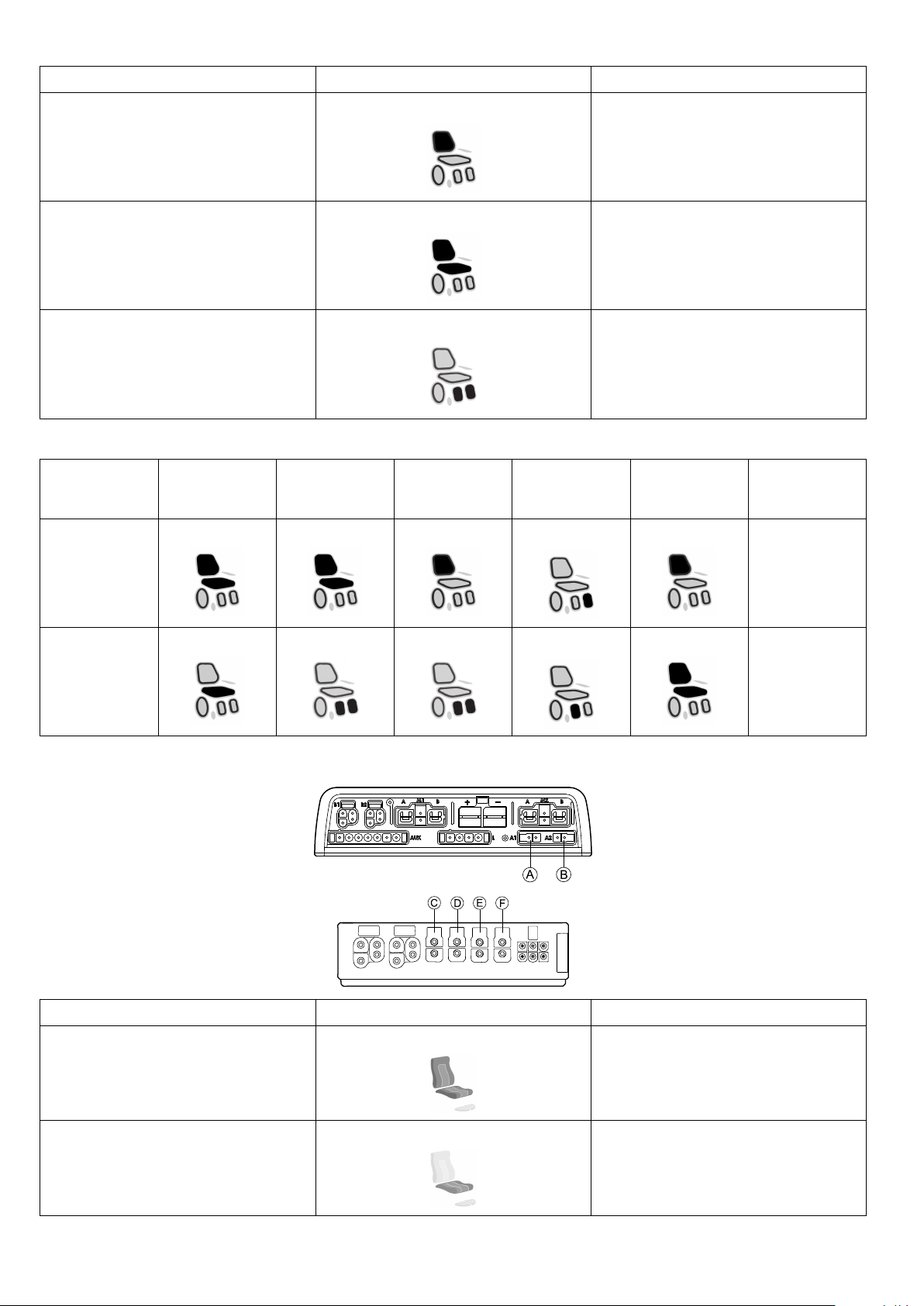

3.5Mountingpositionsonwheelchairs

ThepositionsofthepowermodulesAandDLX-ACT200/400Bdependingonwheelchairmodeland—congurationare

showninthetablebelow.Forfurtherinformationaboutaccesstothecomponents,refertotheServicemanualof

theparticularwheelchairmodel.

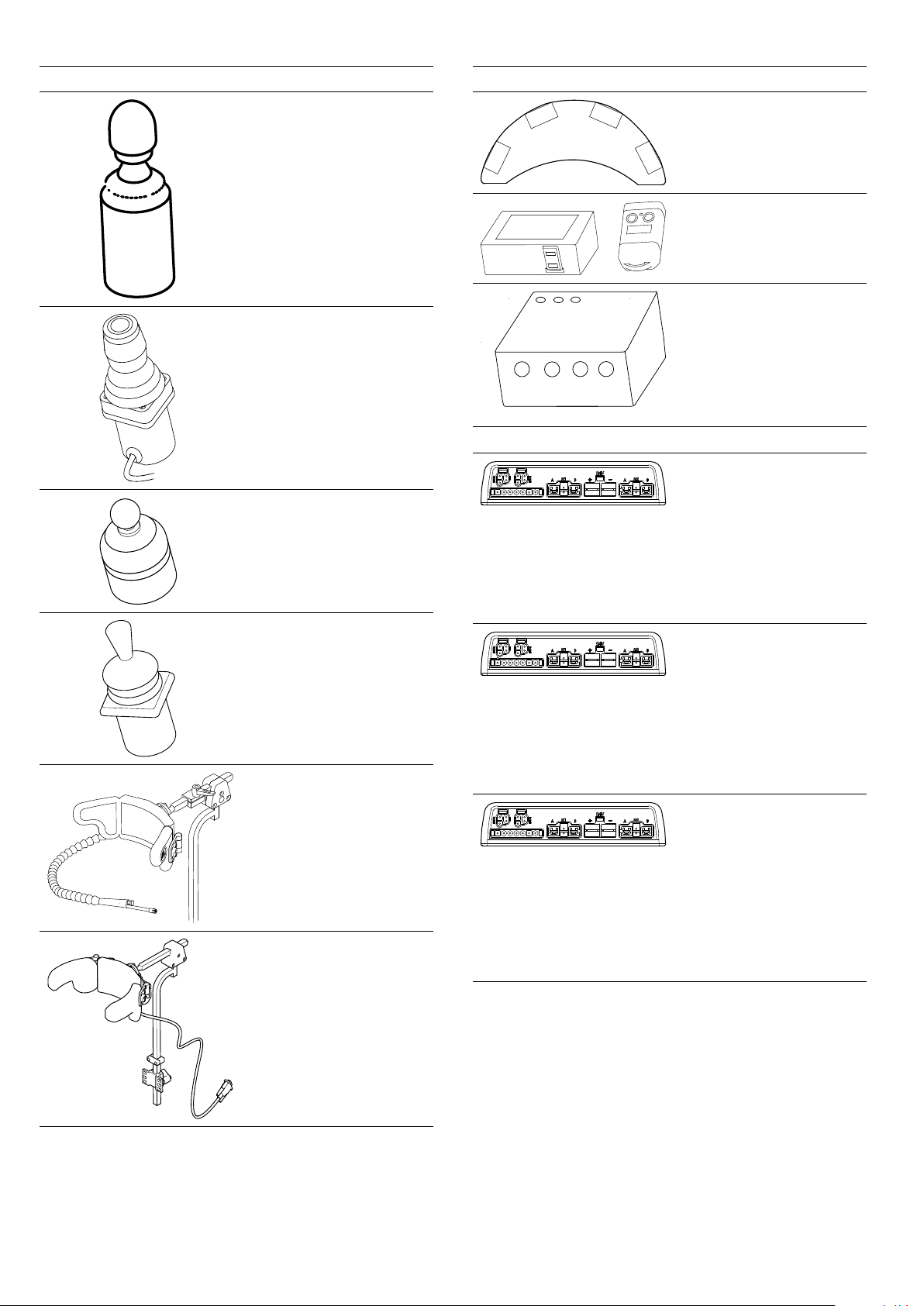

RearWheelDriveCenterWheelDrive

Fox

Kite,KiteHD

TDXSP2,TDXSP2narrow

base,TDXSP2widebasewith

Moduliteseat

TDXSP2narrowbaseand

TDXSP2widebasewithUltra

LowMaxxseat

Bora/SpectraXTR,Spectra

XTRHDw/olifter/tiltmodule

Bora/SpectraXTR,Spectra

XTRHDwlifter/tiltmodule

4

Storm

,Storm

4

Storm

1

4

X-plore,

1

Max

noDLX-ACT200/400onStorm

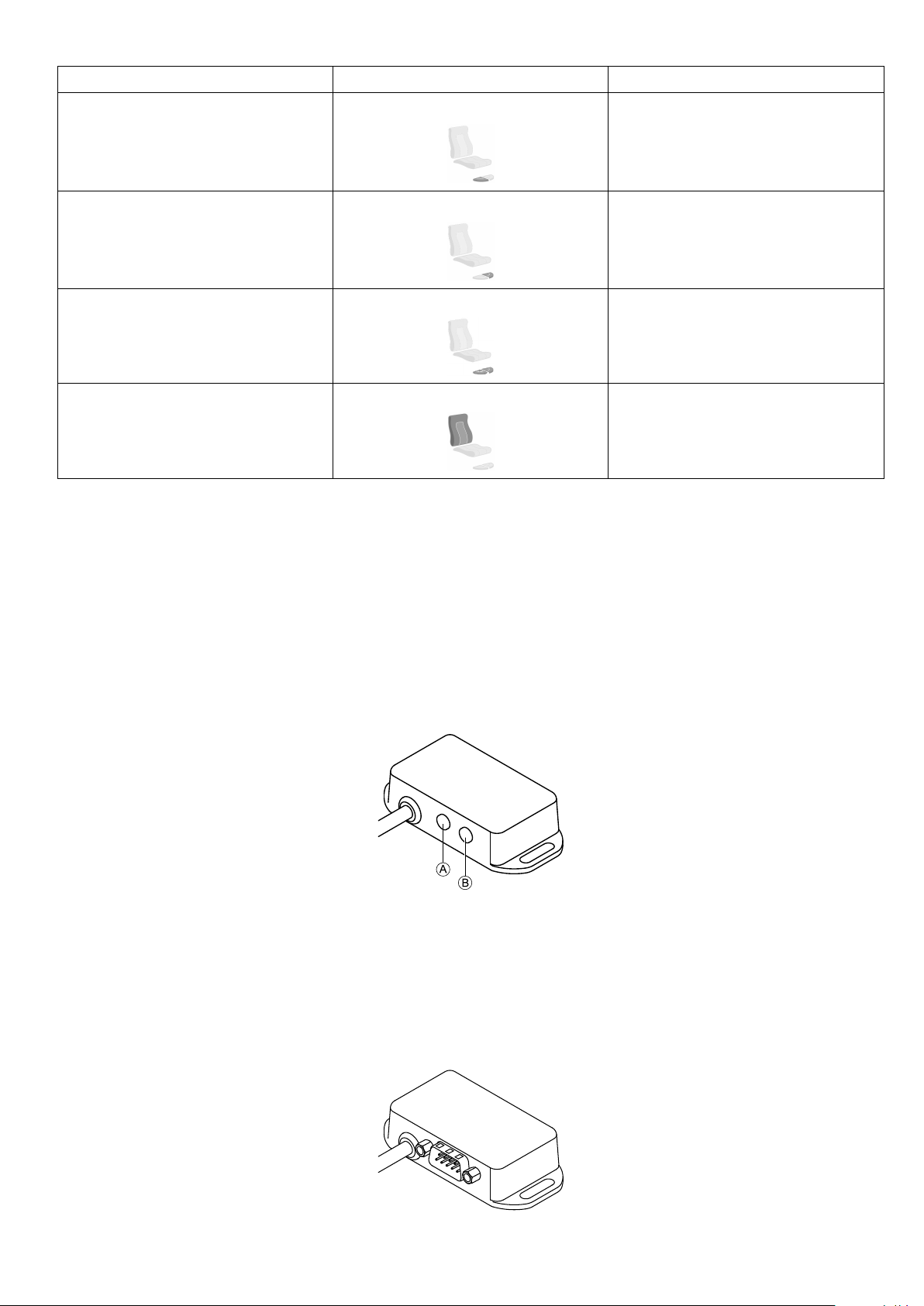

3.6Portpin-outs

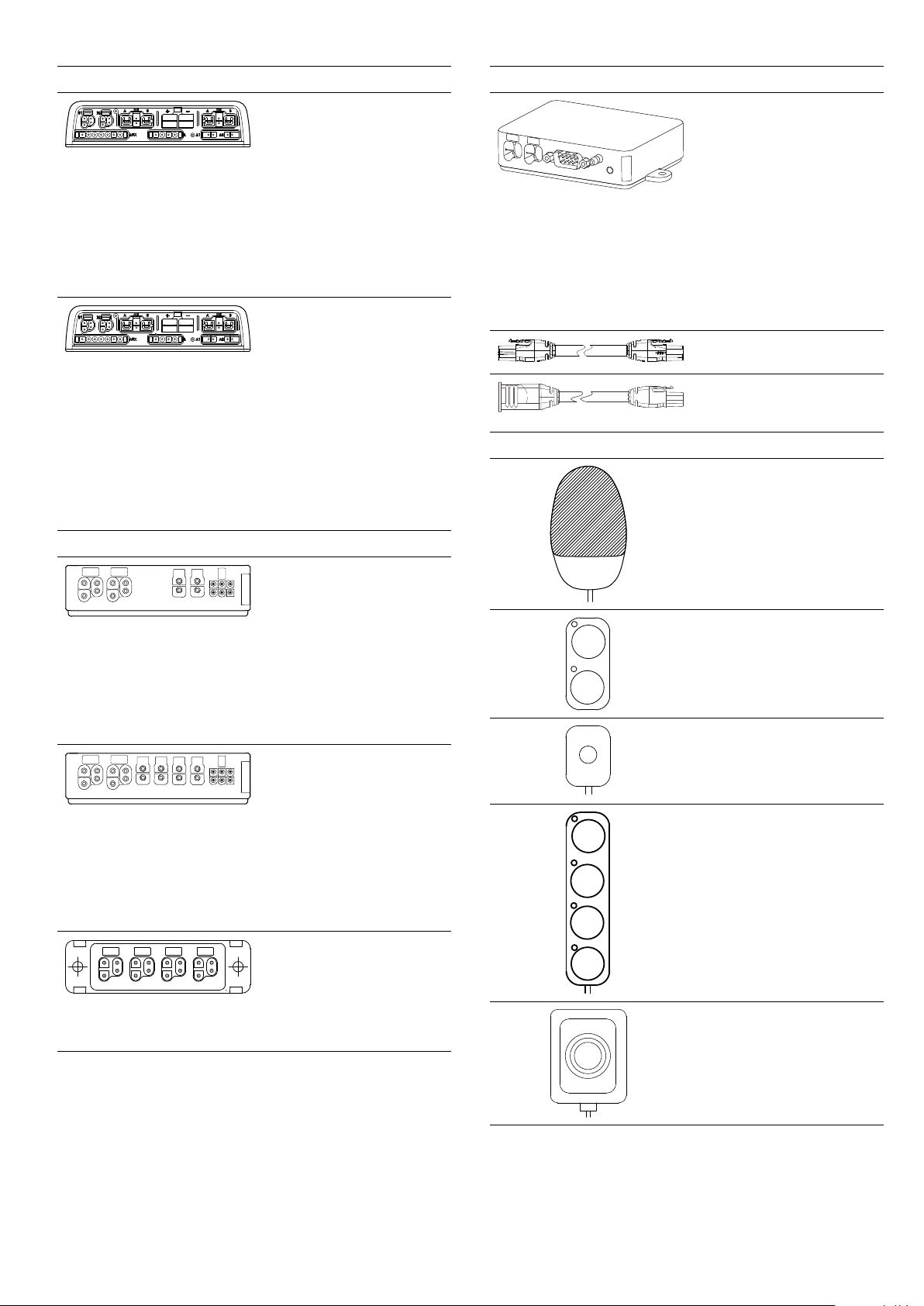

DLX-PM60,DLX-PM75,DLX-PM120

4

Max

LiNXcommunicationbus

A

B

Motor/parkbrakeportM1

Batteryport

C

D

Motor/parkbrakeportM2

Utilityport

E

1605129-C

11

Invacare®LiNX

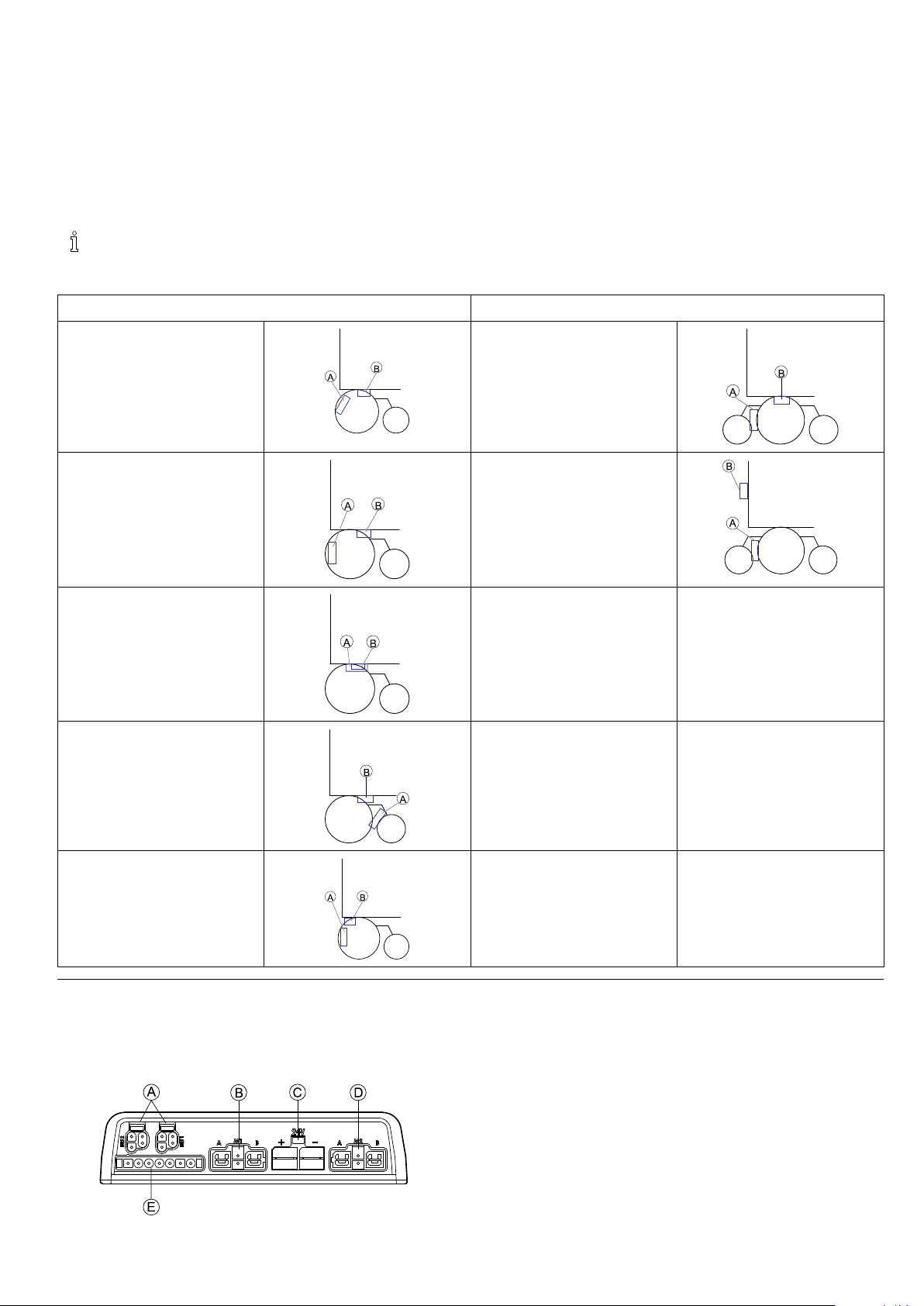

DLX-PM75AL,DLX-PM120AL

3.7Portcongurations(Factoryset-up)

Actuatorports,propertiesandbehaviorperactuatorare

denedbyInvacare.Youcanchangespeed,directionand

operationmode.Thisisdoneindifferentmenus,referto

7.5Modifyingseatingparameters,page62.

Seatingmotion

Theseatingmovementiscalledseatingmotion.Theseating

motiondenestheicondisplayedontheuserinterface,

LiNXcommunicationbus

A

B

Motor/parkbrakeportM1

Batteryport

C

D

Motor/parkbrakeportM2

Actuatorports

E

Lightingport

F

Utilityport

G

overallspeed,theindividualactuatorsandtheirspeeds.A

seatingmotioncancontroloneormoreactuators.Thereare

sixseatingmotionsdenedinthefactoryset-up.

Seatingfunction

Theseatingfunctionistheuserinputanddeneshowthe

motionisoperated.

The“AL”powermodulesthatfeatureactuatorsand

lights,havetwoactuatorports.Ifrequired,thesystemis

completedwiththeDLX-ACT200orDLX-ACT400,basedon

theconguration.Thefollowingchaptersdetailtheport

set-uppermodule/conguration.

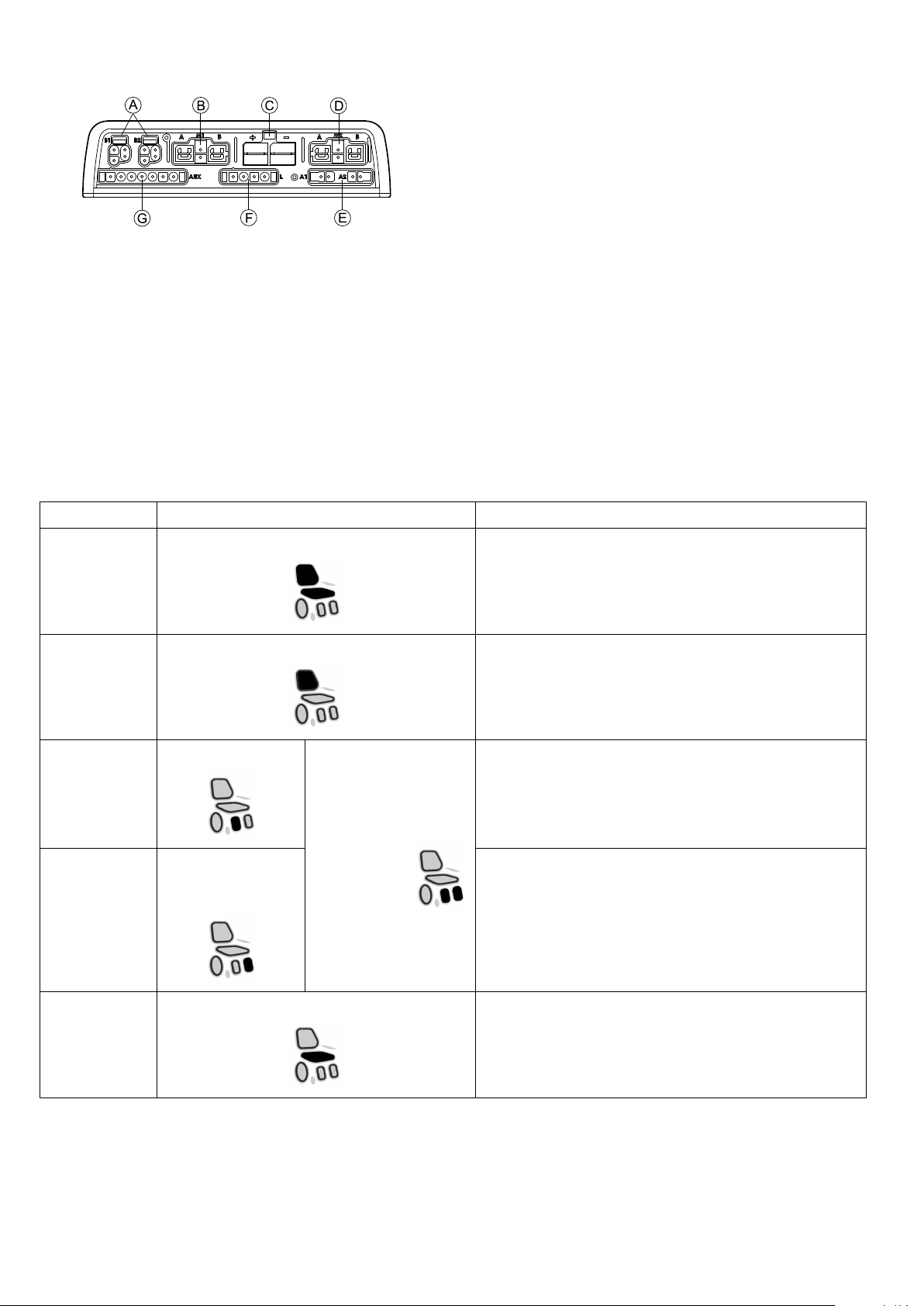

3.7.1PortcongurationsforsystemswithDLX-REM2xx(EU-VersionwithModuliteseat)

Channel

A

Seatingmotion(Icon)Seatingfunction(Operation)

Tilt

ProportionalFWD/REV

B

C

Recline

Rightleg

ProportionalFWD/REV

ProportionalFWD/REV

Bothlegs

D

Leftleg/

ProportionalFWD/REV

Center-mounted

legrest

E

Lifter

ProportionalFWD/REV

12

1605129-C

Portcongurationwithoutlifter

Powermodule

DLX-ACT200

DLX-ACT400

Portcongurationwithlifer

Powermodule

Assembly

DLX-ACT200

DLX-ACT400

3.7.2Portcongurationfornon-expandablesystems(USversion)

Non-expandablesystemsarettedwithexternalswitchesandafunctionkey ,tocontrolthepoweredseatingfunctions.For

moreinformationaboutfunctionkeys,refertochapter3.7.4Portcongurationsforfunctionkeys,page15.

Singleactuatorsystems

1605129-C13

Invacare®LiNX

Channel

A

B

B

Twoactuatorsystems

Channel

A

Seatingmotion(Icon)Seatingfunction(Operation)

Reclineonly

Tiltonly

LNXonly

Seatingmotion

(Icon)

Seatingmotion

(Icon)

Seatingmotion

(Icon)

Seatingmotion

(Icon)

ProportionalFWD/REV

ProportionalFWD/REV

ProportionalFWD/REV

Seatingmotion

(Icon)

Seating

function

(Operation)

Tilt

TiltReclineLeftlegReclineProportional

FWD/REV

B

Lifter

LNXLNX

RightlegTiltProportional

3.7.3PortcongurationforsystemswithDLX-REM400andDLX-REM500(withUltraLowMaxxseat)

Channel

A

Seatingmotion(Icon)Seatingfunction(Operation)

Tilt

ProportionalFWD/REV

FWD/REV

B

14

Lifter

ProportionalFWD/REV

1605129-C

Assembly

Channel

C

D

E

F

3.7.4Portcongurationsforfunctionkeys

Seatingmotion(Icon)Seatingfunction(Operation)

Legrestright

Legrestleft

LNX

Recline

ProportionalFWD/REV

ProportionalFWD/REV

ProportionalFWD/REV

ProportionalFWD/REV

Ifthesystemisttedwithanexternalswitch,tocontrolthepoweredseatingfunctions(excepta10wayswitch),afunctionkey

isrequiredtointerfacetheswitches.Therearefourdifferentcongurationsoffunctionkeys.Thetypeoffunctionkeydetermines

thebehaviorofthesysteminregardstothecontrolofactuators.

Type1:SingleActuatorSystem(SAS)

Thisfunctionkeyisforsystemswithonephysicalactuator.Itisavailableintwodifferentcongurations:

•FKEY01:actuatorcontrolthroughswitchesonly

•FKEY01TDC:actuatorcontrolthroughswitchesandjoystick

IndependentoftypeFKEY01orFKEY01TDCtheexternalswitchestocontrolthepoweredseatingfunctions,mustbeplugged

intotheJacksockets,seetablebelow.

A

B

Monojacktoconnecteggswitch

Stereojacktoconnectstereobuttonswitchorstereotoggleswitch

Type2:Multi-ActuatorSystem(MAC)

Thisfunctionkeyisforsystemswithtwoormorephysicalactuators.Itisavailableintwodifferentcongurations:

•FKEY02:actuatorcontrolthroughswitchesonly

•FKEY02TDC:actuatorcontrolthroughswitchesandjoystick

1605129-C15

Invacare®LiNX

IndependentoftypeFKEY02orFKEY02TDCthe4–waybuttonswitchorthe4–waytoggleswitchmustbepluggedintothe

DB9socket.

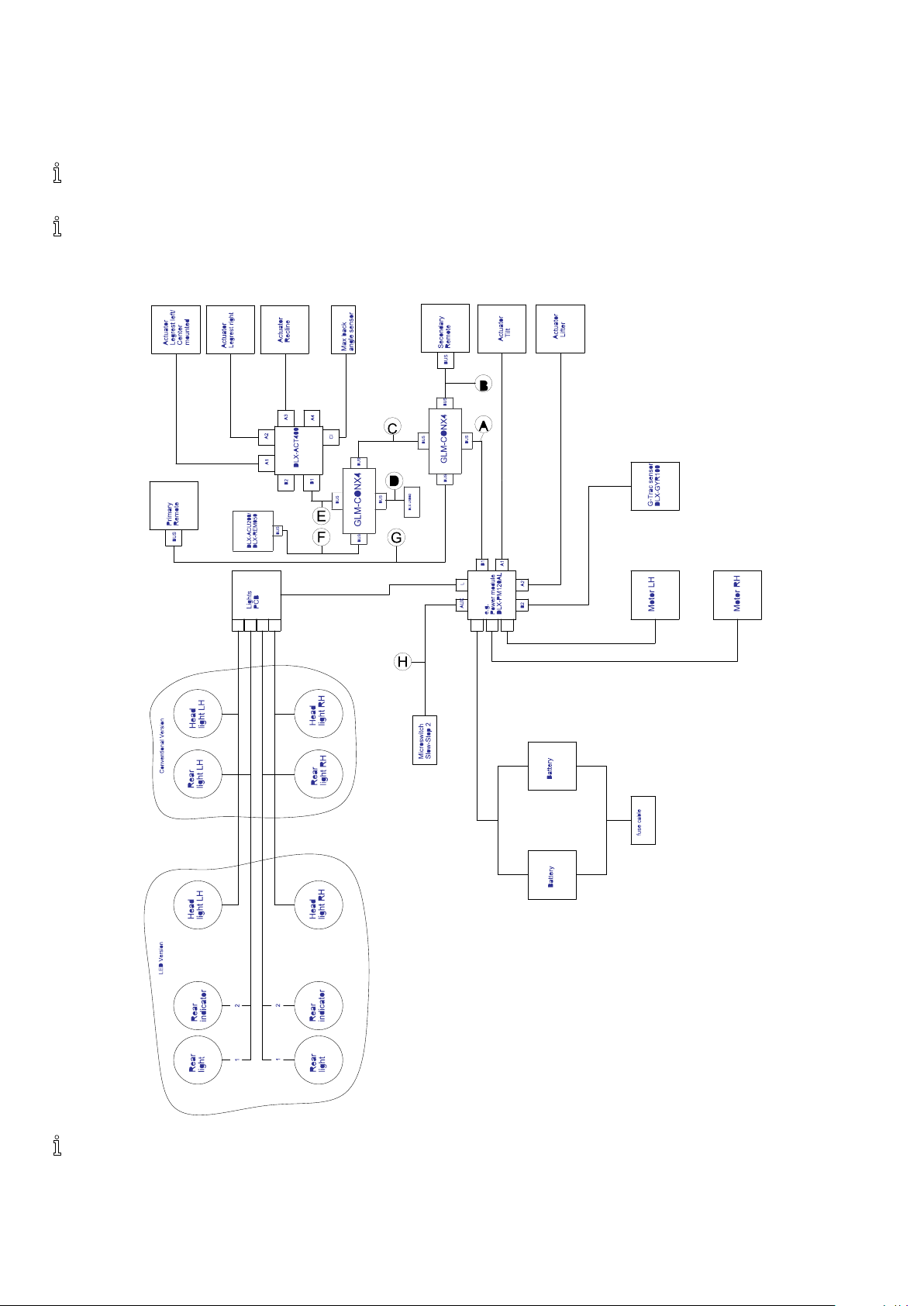

3.8Wiringdiagrams

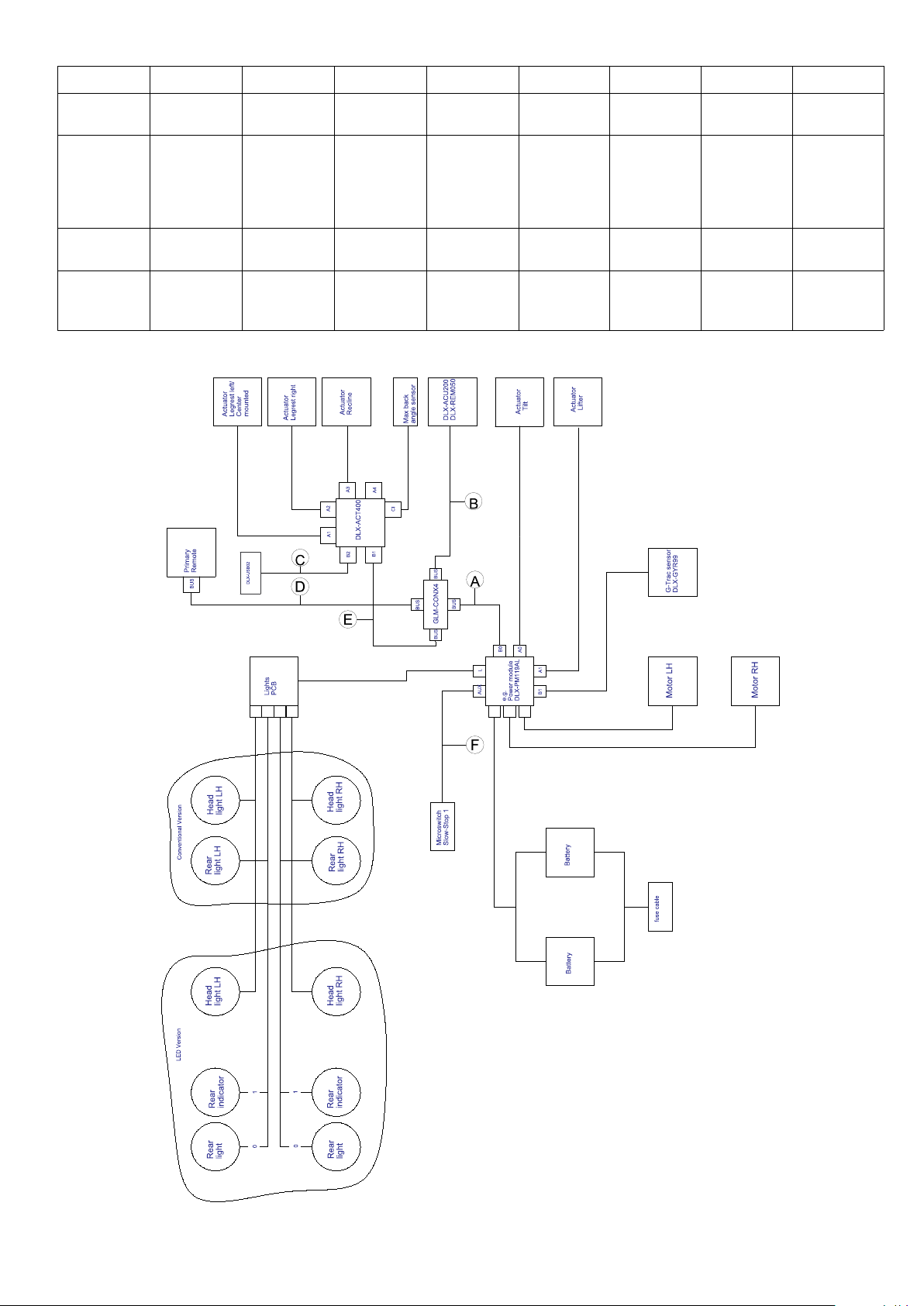

Thefollowingdiagramsshowthewiringforawheelchairinacomplexcongurationincludingmultipleactuators,

lightsandattendantcontrolunit.

Toidentifytherequiredcablelength,seetablesbelowormeasurethecableafterremovingit.

WiringforcongurationsofModuliteseatwithlifter,tilt,recline,poweredelevatinglegrests,lights,attendantcontrolunit,

secondaryremote,DLX-ACT400andUSBcharger

Cablelengthmayvarydependingonmountingpositionsofprimaryandsecondaryremotesandof4–wayconnector

GLM-CONX4.

161605129-C

Assembly

Model

Kite

Spectra

XTR

A

A A

•2500

mm

•1700

2

HD,

mm

B

B B

•1500

mm

•1700

mm

C

C C

•300

mm

•300

mm

D

D D

•700

mm

•700

mm

E

E E

•700

mm

•700

mm

F

F F

•1500

mm

•1200

mm

G

G G

•1700

H

H H

•700

mm

•1500

•700

mm

Bora/SpectraXTR

Standard

TDXSP2•1500

4

Storm

,

4

Storm

mm

•1500

mm

•1200

mm

•1200

mm

•300

mm

•300

mm

•300

mm

•500

mm

•700

mm

•300

mm

•1000

mm

•1200

mm

•1200

•300

mm

•1500

•300

mm

X-plore

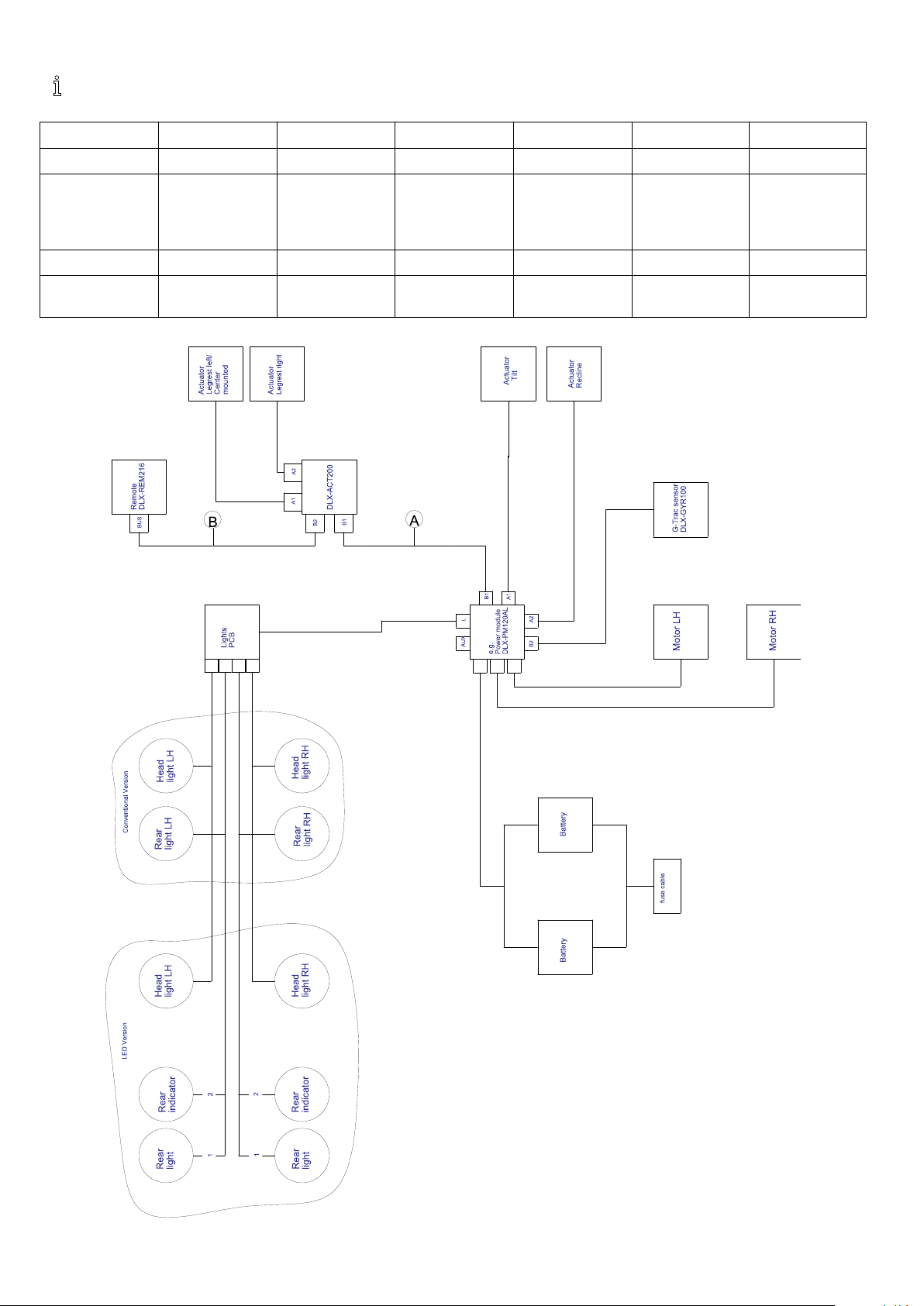

WiringforcongurationsofModuliteseatwithlifter,tilt,recline,poweredelevatinglegrests,lights,attendantcontrol

unit,DLX-ACT400andUSBcharger

mm

mm

mm

mm

1605129-C

17

Invacare®LiNX

Cablelengthmayvarydependingonmountingpositionsofprimaryandsecondaryremotesandof4–wayconnector

GLM-CONX4.

Model

Kite

Spectra

XTR

A

A A

B

B B

•2500mm•1500mm•700mm•1700mm•700mm•700mm

•1700mm•1200mm•700mm•1500mm•700mm•700mm

2

HD,

C

C C

D

D D

E

E E

F

F F

Bora/Spectra

XTRStandard

TDXSP2•1500mm•1000mm•300mm•1500mm•700mm•300mm

4

Storm

,Storm

4

•1500mm•1200mm•500mm•1500mm•300mm•300mm

X-plore

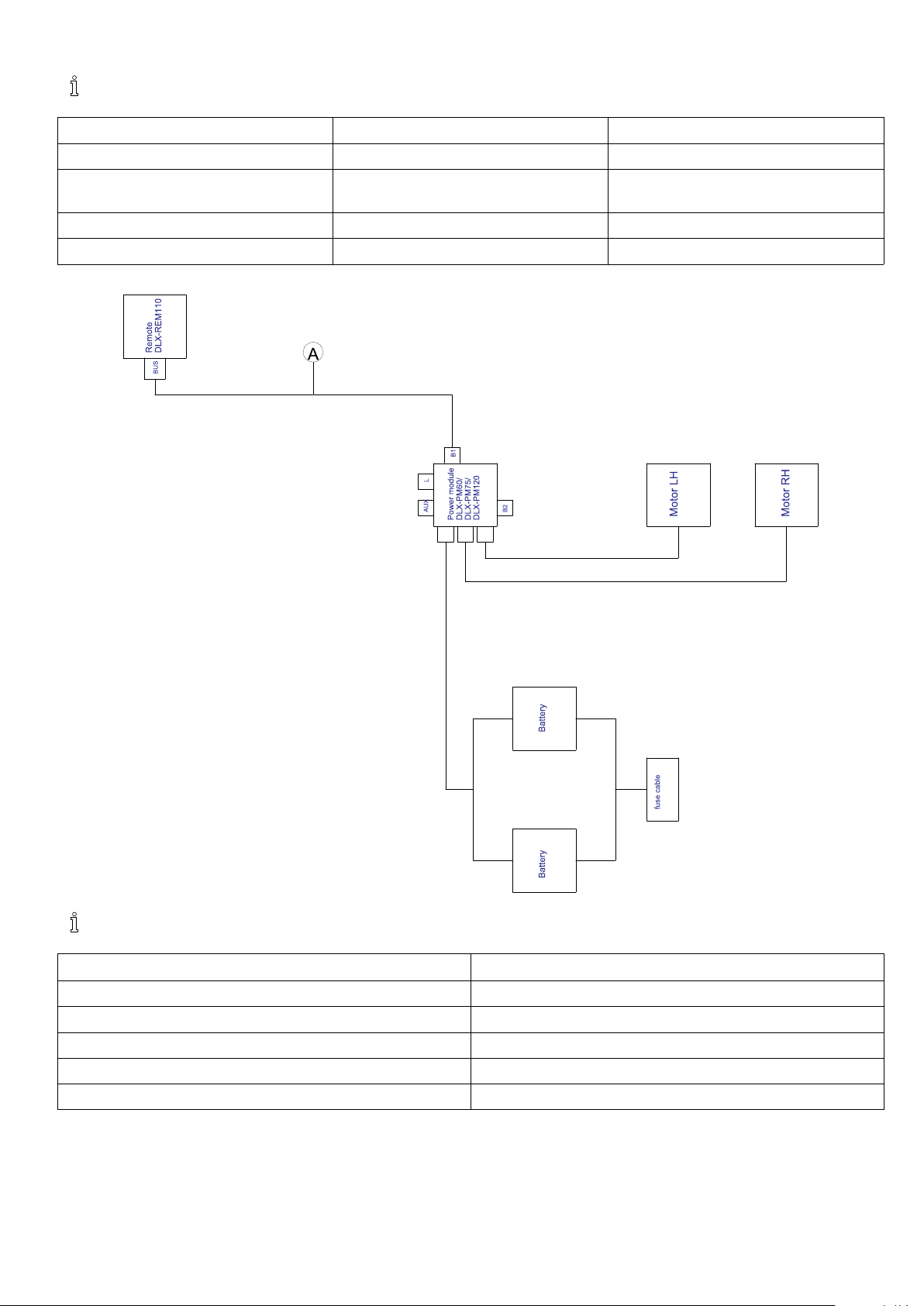

WiringforcongurationsofModuliteseatwithtilt,recline,poweredelevatinglegrests,lightsandDLX-ACT200

181605129-C

Cablelengthmayvarydependingonmountingpositionsofprimaryandsecondaryremotes.

Assembly

Model

Kite

SpectraXTR

2

HD,Bora/SpectraXTR

A

A A

B

B B

•1500mm•1500mm

•1500mm•1500mm

Standard

TDXSP2•1700mm•1000mm

4

Storm

,Storm

4

X-plore

•1200mm•1500mm

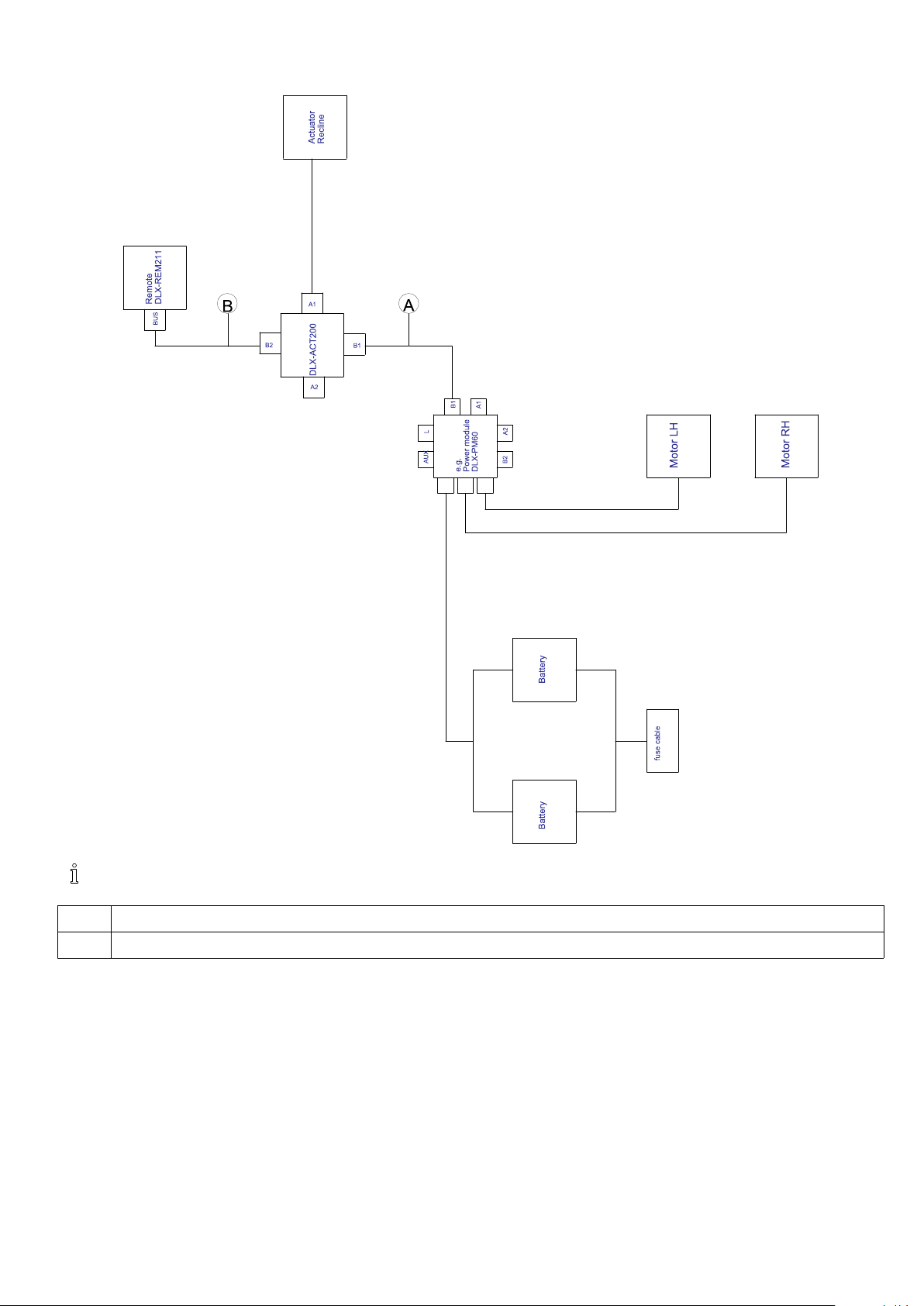

WiringforDriveonlycongurationofModuliteseat

Cablelengthmayvarydependingonmountingpositionsofprimaryremote.

Model

Kite

SpectraXTR

2

HD,Bora/SpectraXTRStandard

A

A A

•2000mm

•2000mm

TDXSP2•1500mm

4

Storm

,Storm

Fox

1605129-C19

4

X-plore

•2000mm

•300mm+640mmextensionloom

Invacare®LiNX

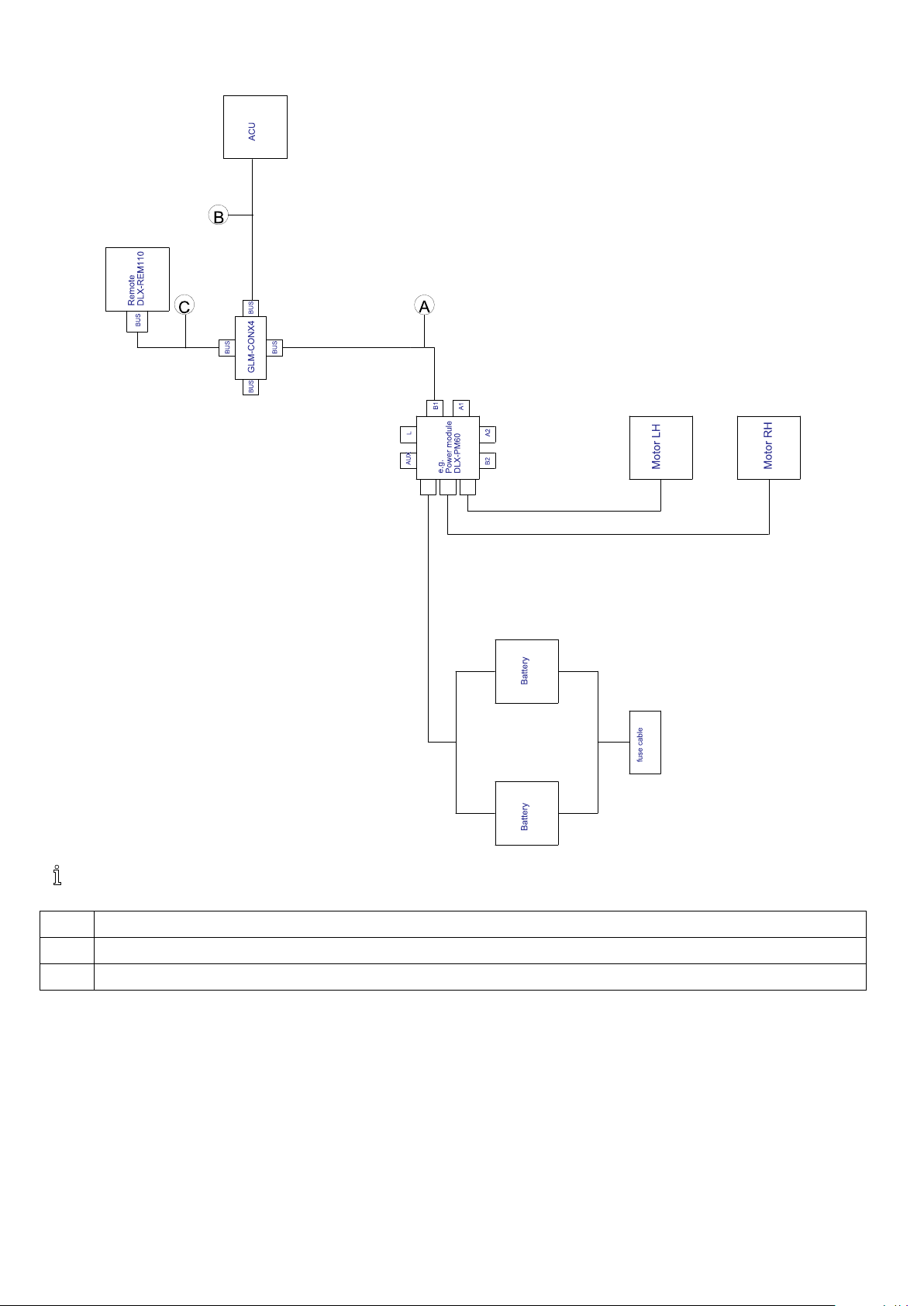

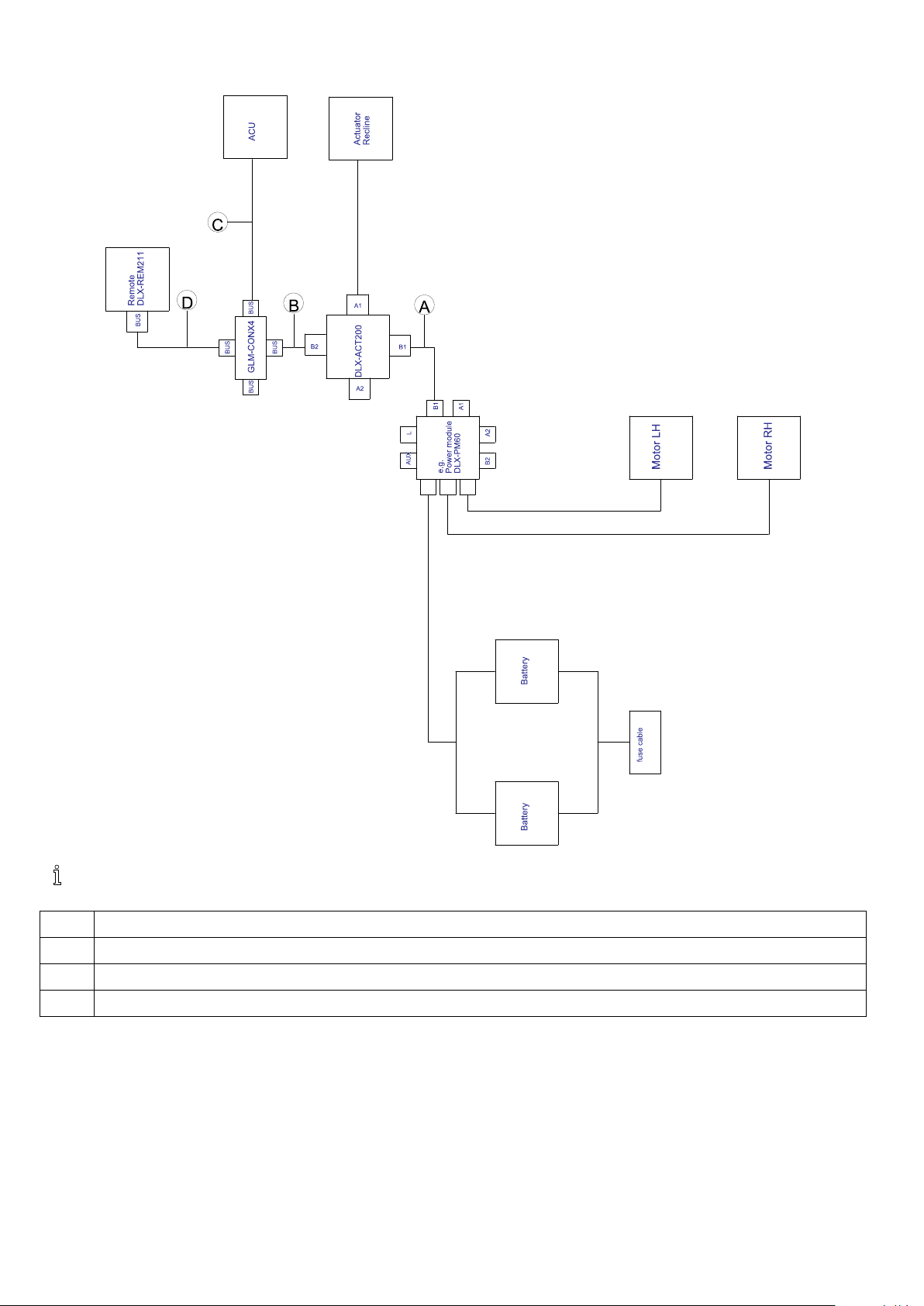

WiringforFoxwithModuliteDriveonlywithACU

Cablelengthmayvarydependingonmountingpositionsofprimaryandsecondaryremotesandof4–wayconnector

GLM-CONX4.

A

B

C

201605129-C

•1000mm

•1200mm

•1000mm

WiringforFoxwithModuliteReclineonly

Assembly

Cablelengthmayvarydependingonmountingpositionsofprimaryremote.

A

B

1605129-C

•1000mm

•1000mm

21

Invacare®LiNX

WiringforFoxwithModuliteReclineonlyandACU

Cablelengthmayvarydependingonmountingpositionsofprimaryandsecondaryremotesandof4–wayconnector

GLM-CONX4.

A

B

C

D

22

•1000mm

•300mm

•1200mm

•1000mm

1605129-C

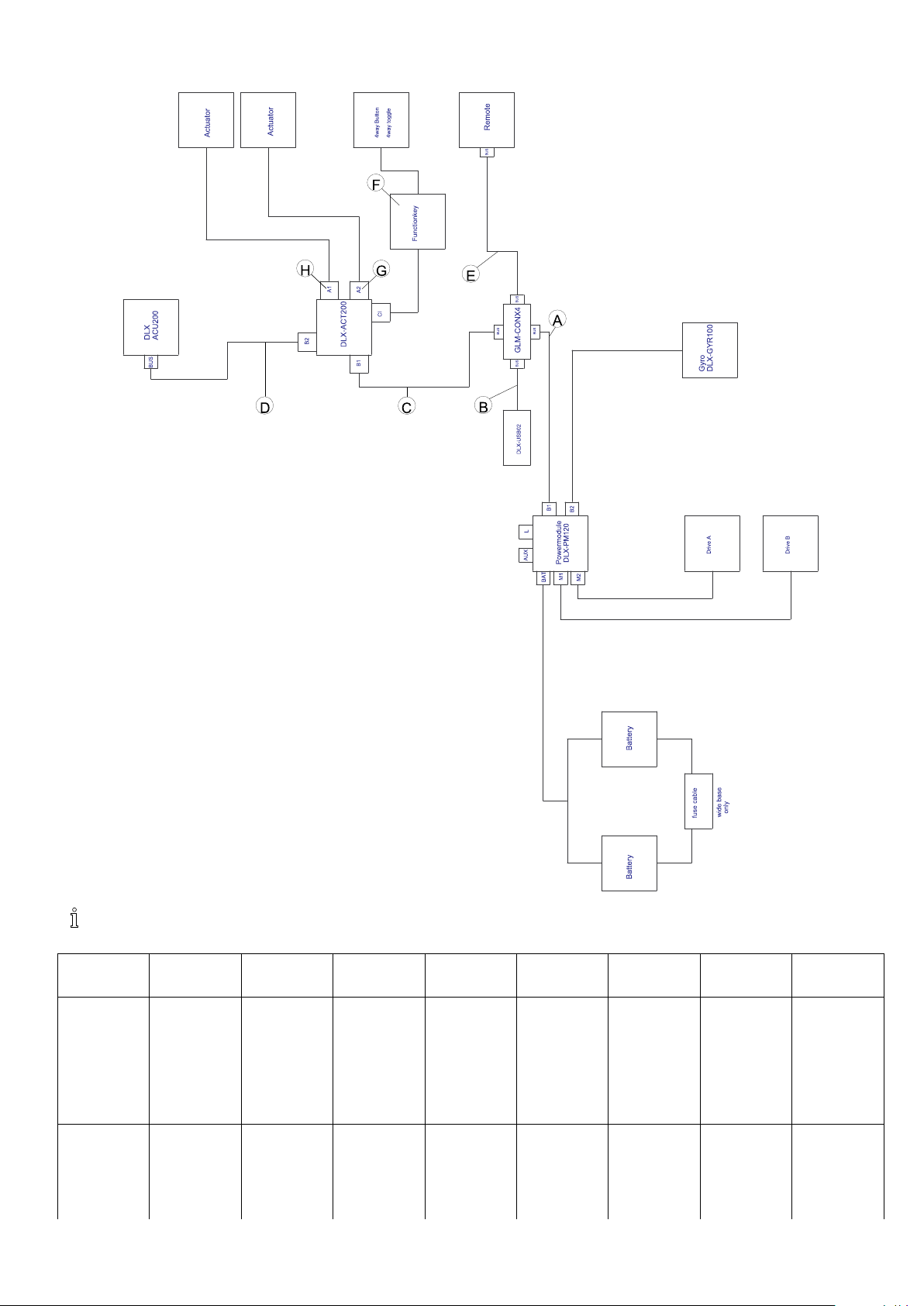

WiringforNonexpandablesystemswithUltraLowMaxxseat(USonly)

Assembly

Cablelengthmayvarydependingonmountingpositionsofprimaryandsecondaryremotesandof4–wayconnector

GLM-CONX4.

Congura-

A

A A

B

B B

C

C C

D

D D

E

E E

F

F F

G

G G

H

H H

tion

Reclineonly

•1200

mm

•300

mm

•700

mm

•300

mm

•1500

mm

•Functionkey

•not

used

•Recline

connected

FKEY01/FKEY01

TDC

Tilt/Recline

•1200

mm

•300

mm

•700

mm

•300

mm

•1500

mm

•Functionkey

•Tilt

connected

•Recline

connected

FKEY02/F-

1605129-C23

Invacare®LiNX

Conguration

LNXonly

Tiltonly

Duallegs

Recline/LNX

Tilt/LNX

Tilt/Lifter

A

A A

B

B B

C

C C

D

D D

E

E E

F

F F

G

G G

H

H H

KEY02

TDC

•1200

mm

•300

mm

•1200

mm

•300

mm

•1500

mm

•Functionkey

•LNX

connected

•not

used

FKEY01/FKEY01

TDC

•1200

mm

•300

mm

•1200

mm

•300

mm

•1500

mm

•Functionkey

•Tilt

connected

•not

used

FKEY01/FKEY01

TDC

•1200

mm

•300

mm

•1200

mm

•300

mm

•1500

mm

•Functionkey

FKEY-

•Legrest

right

connected

•Legrest

left

connected

02/FKEY02

TDC

•1200

mm

•300

mm

•1200

mm

•300

mm

•1500

mm

•Functionkey

•LNX

connected

•Recline

connected

FKEY02/FKEY02

TDC

•1200

mm

•300

mm

•1200

mm

•300

mm

•1500

mm

•Functionkey

•LNX

connected

•Tilt

connected

FKEY02/FKEY02

TDC

•1200

mm

•300

mm

•1200

mm

•300

mm

•1500

mm

•Functionkey

•Lifter

•Tilt

connected

con-

nected

FKEY02/FKEY02

TDC

24

1605129-C

WiringforcongurationswithUltraLowMaxxseat

Assembly

Cablelengthmayvarydependingonmountingpositionsofprimaryandsecondaryremotesandof4–wayconnector

GLM-CONX4.

Dependingonconguration,theEggswitchASL300canbeconnectedtotheprimaryremote.

1605129-C25

Invacare®LiNX

Conguration

A

B

C

D

1

E

F

G

H

I

J

K

1

BusporteitherforDLX-CR400orforRemoteStopSwitch.Cannotbecombined.

wtilt,wrecline,w/o

lifter

wtilt,w/orecline,

w/olifter

•1200mm•1200mm•1500mm•1500mm

•1500mm•1700mm•1700mm•1700mm

•700mm•1200mm•700mm•1200mm

•300mm•300mm•300mm•300mm

•1700mm•1200mm•1200mm•1200mm

•300mm•300mm•300mm•300mm

•300mm•300mm•300mm•300mm

•300mm•300mm•300mm•300mm

•300mm•300mm•300mm•300mm

•300mm•300mm•300mm•300mm

•300mm•300mm•300mm•300mm

3.9Mountingtheprimaryremotes

Formoreinformationabouthowremoteholders

aremountedtothewheelchair ,refertotheservice

manualoftheseatingsystem.

wtilt,wrecline,w

lifter

Swingawayremoteholder

•4mmAllenkey

•3mmAllenkey

•8mmwrench

•10mmwrench

wtilt,w/orecline,w

lifter

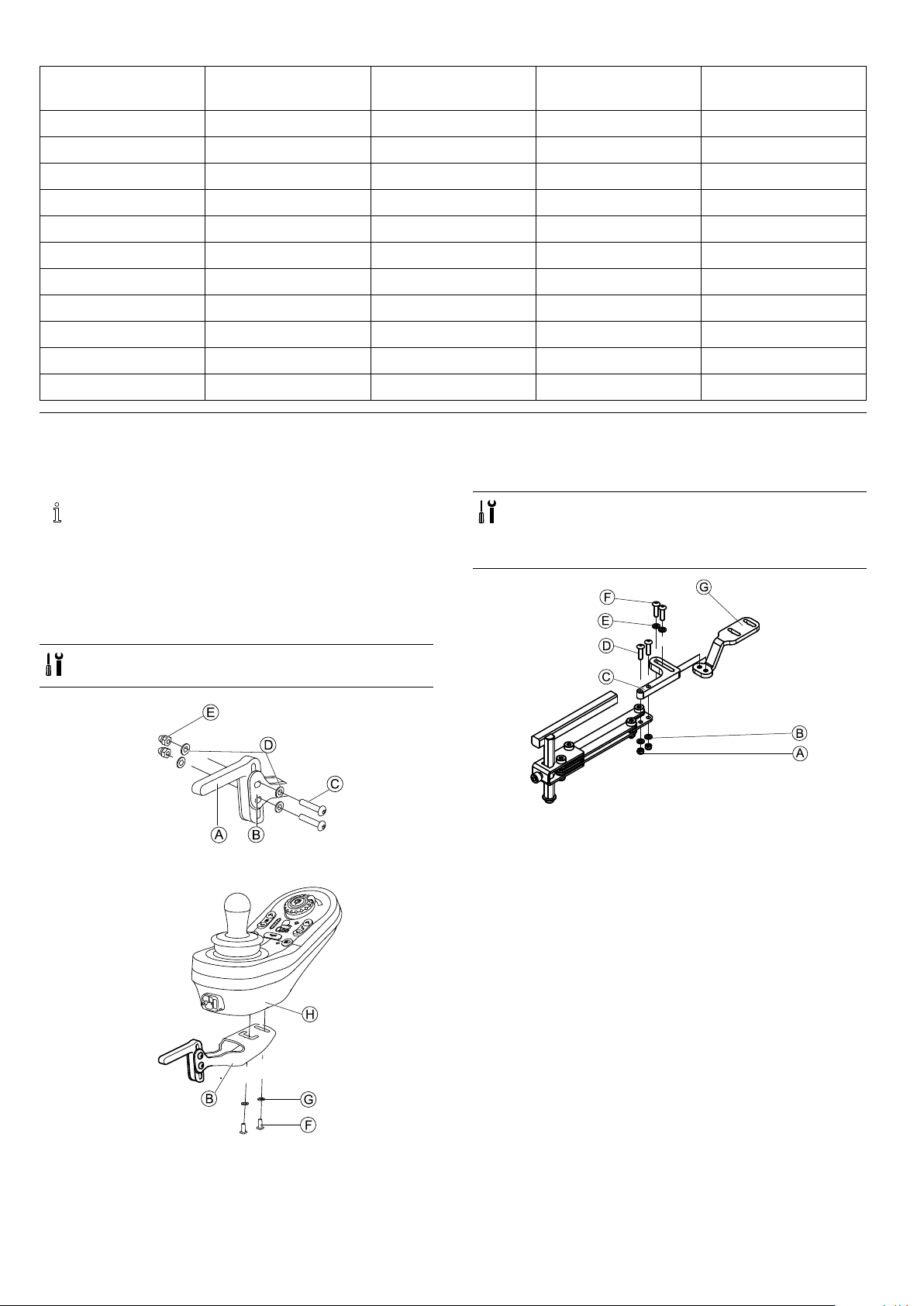

3.9.1MountingDLX-REM1XXandDLX-REM2XXfor Modulite

Standardremoteholder

•3mmAllenkey

•8mmwrench

1.

MountjoystickholderAtoremoteadapterBwith

screwsC,washersDandnutsE.

2.

1.PullscrewsDthroughbracketC,remoteholderand

washersB.

2.TightenscrewswithnutsA.

MountremoteHtoremoteadapterBwithscrewsF

andwashersG.

261605129-C

Assembly

3.PullscrewsFthroughwashersE,bracketCand

bracketGandtightenscrews.

4.

TightenremoteHwithscrewsJandwashersTto

bracketG.

Remoteholderforattendant

Theremoteisttedtothewheelchairusingabracketonthe

pushhandleorthepushbar.

•4mmAllenkey

•3mmAllenkey

1.PullscrewsAthroughwashersB,mountingplateC

andbottomsideofbracketD.

2.Tightenbottomsideofthebrackettopushbarwiththe

topsideofthebracketEandnutsF.

3.

FixremotetobracketIwithscrewsGandwashersH.

Formountingpositions,referto3.10.3Mountingthe

DLX-REM050,page33.

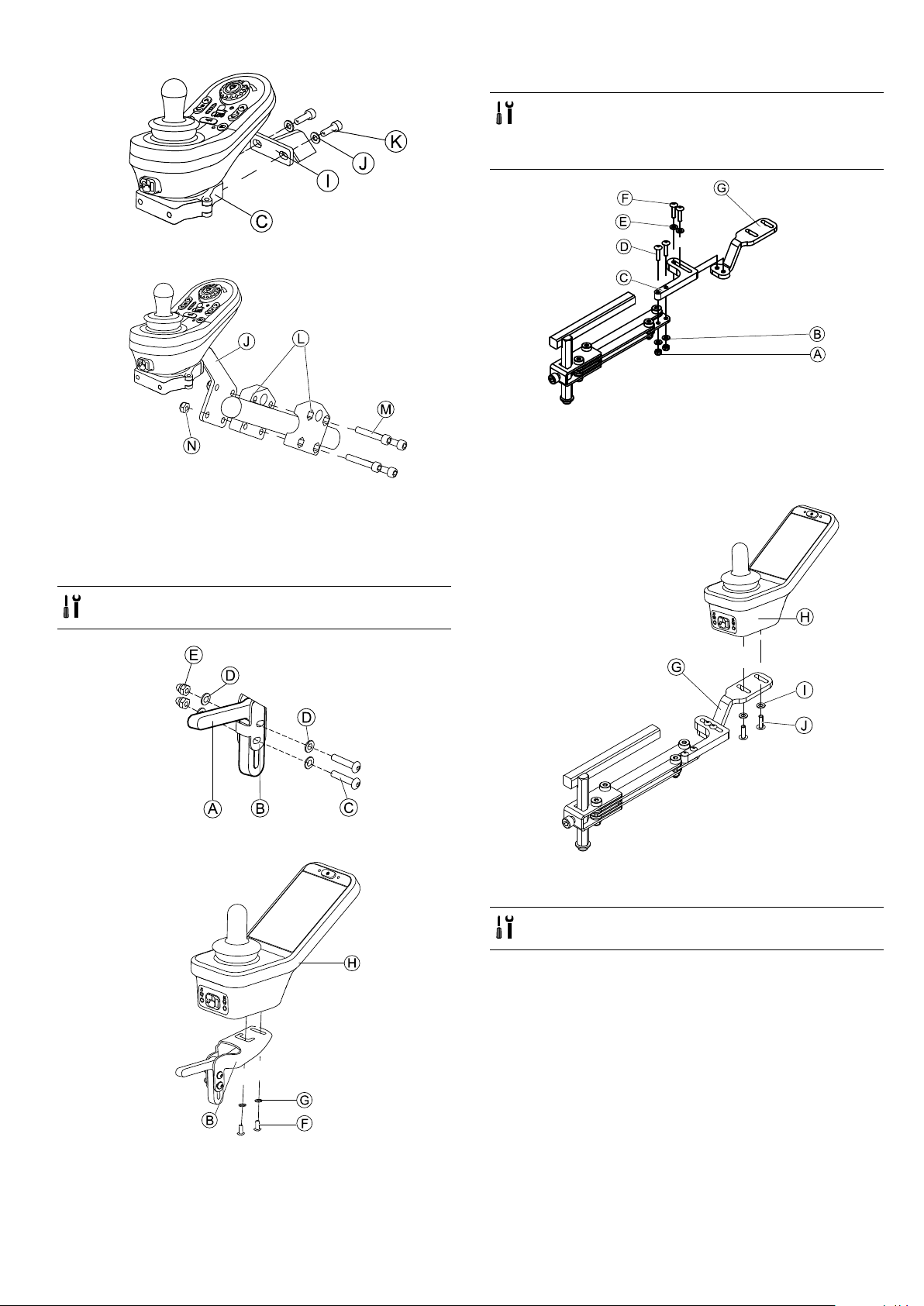

3.9.2MountingDLX-REM2XXforUltraLowMaxx

Standardremoteholder

•3mmAllenkey

•8mmwrench

1.

MountjoystickholderAtoremoteadapterBwith

screwsC,washersDandnutsE.

2.

MountremoteHtoremoteadapterBwithscrewsF

andwashersG.

Swingawayremoteholder

•3mmAllenkey

•4mmAllenkey

•8mmwrench

•10mmwrench

1605129-C

27

Invacare®LiNX

1.PullscrewsDthroughbracketC,remoteholderand

washersB.

2.TightenscrewswithnutsA.

3.PullscrewsFthroughwashersE,bracketCand

bracketGandtightenscrews.

4.

1.MountLiNXremoteadapterBwithscrewsAtoremote

C.

TheLiNXremoteadaptercanbeturned90°right

orleftformoreadjustmentoptions.

2.MountremotetoQuadLinkFwithscrewD,Nord-Lock

washerEandserratedlockwasherG.

TightenscrewDwithamaximumtorqueof25

Nm.

Remoteholderforattendant

Theremoteisttedtothewheelchairusingabracketonthe

pushhandleorthepushbar.

•3mmAllenkey

•5mmAllenkey

•8mmwrench

1.

TightenremoteHwithscrewsJandwashersTto

bracketG.

QuadLinkremoteholder

•3mmAllenkey

•5mmAllenkey

MountremoteAwithandsupportdrumBtoclampC

withscrewsEandwashersD.

2.

Riskofdamagetotheremote

Themaximumtorquetotightenthescrew

is1Nm.

–Donotexceedthisratingasitmaydamage

theremote.

FixsupportdrumBinclampCwithscrewF,washer

GandnutH.

281605129-C

Assembly

3.

AttachclampCtobracketIwithscrewsKand

washersJ.

4.

AttachbracketItogripperclampLwithscrewsM

andnutsN.

Swingawayremoteholder

•4mmAllenkey

•3mmAllenkey

•8mmwrench

•10mmwrench

1.PullscrewsDthroughbracketC,remoteholderand

washersB.

2.TightenscrewswithnutsA.

3.PullscrewsFthroughwashersE,bracketCand

bracketGandtightenscrews.

4.

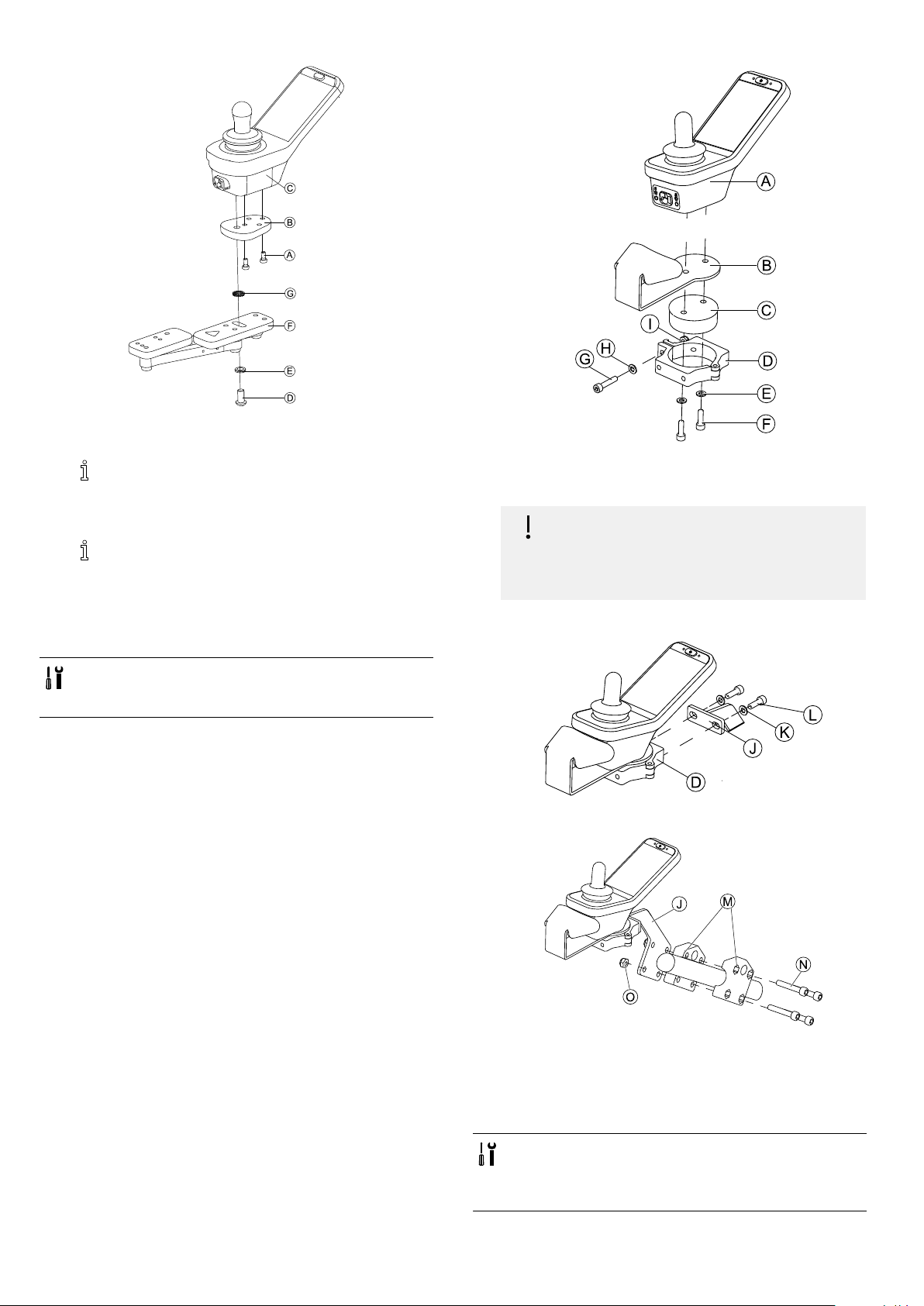

3.9.3MountingtheDLX-REM400

Standardremoteholder

•3mmAllenkey

•8mmwrench

1.

MountjoystickholderAtoremoteadapterBwith

screwsC,washersDandnutsE.

2.

TightenremotewithscrewsAtobracketG.

QuadLinkremoteholder

•3mmAllenkey

•5mmAllenkey

MountremoteHtoremoteadapterBwithscrewsF

andwashersG.

1605129-C29

Invacare®LiNX

1.MountLiNXremoteadapterBwithscrewsAtoremote

C.

TheLiNXremoteadaptercanbeturned90°right

orleftformoreadjustmentoptions.

2.MountremotetoQuadLinkFwithscrewD,Nord-Lock

washerEandserratedlockwasherG.

TightenscrewDwithamaximumtorqueof25

Nm.

Remoteholderforattendant

Theremoteisttedtothewheelchairusingabracketonthe

pushhandleorthepushbar.

•3mmAllenkey

•5mmAllenkey

•8mmwrench

1.

MountremoteAwithsupportBandsupportdrumC

toclampDwithscrewsFandwashersE.

2.

Riskofdamagetotheremote

Themaximumtorquetotightenthescrew

is1Nm.

–Donotexceedthisratingasitmaydamage

theremote.

FixsupportdrumCinclampDwithscrewG,washer

HandnutI.

3.

AttachclampDtobracketJwithscrewsLand

washersK.

4.

AttachbracketJtogripperclampMwithscrewsN

andnutsO.

3.9.4MountingtheDLX-REM500

Swingawayremoteholder

•3mmAllenkey

•4mmAllenkey

•Medium-strengththread-lockinguid,e.g.

Loctite243

301605129-C

Loading...

Loading...