Invacare HomeFillII AW Service Manual

Service Manual

0434

HomeFill® II AW

Compressor

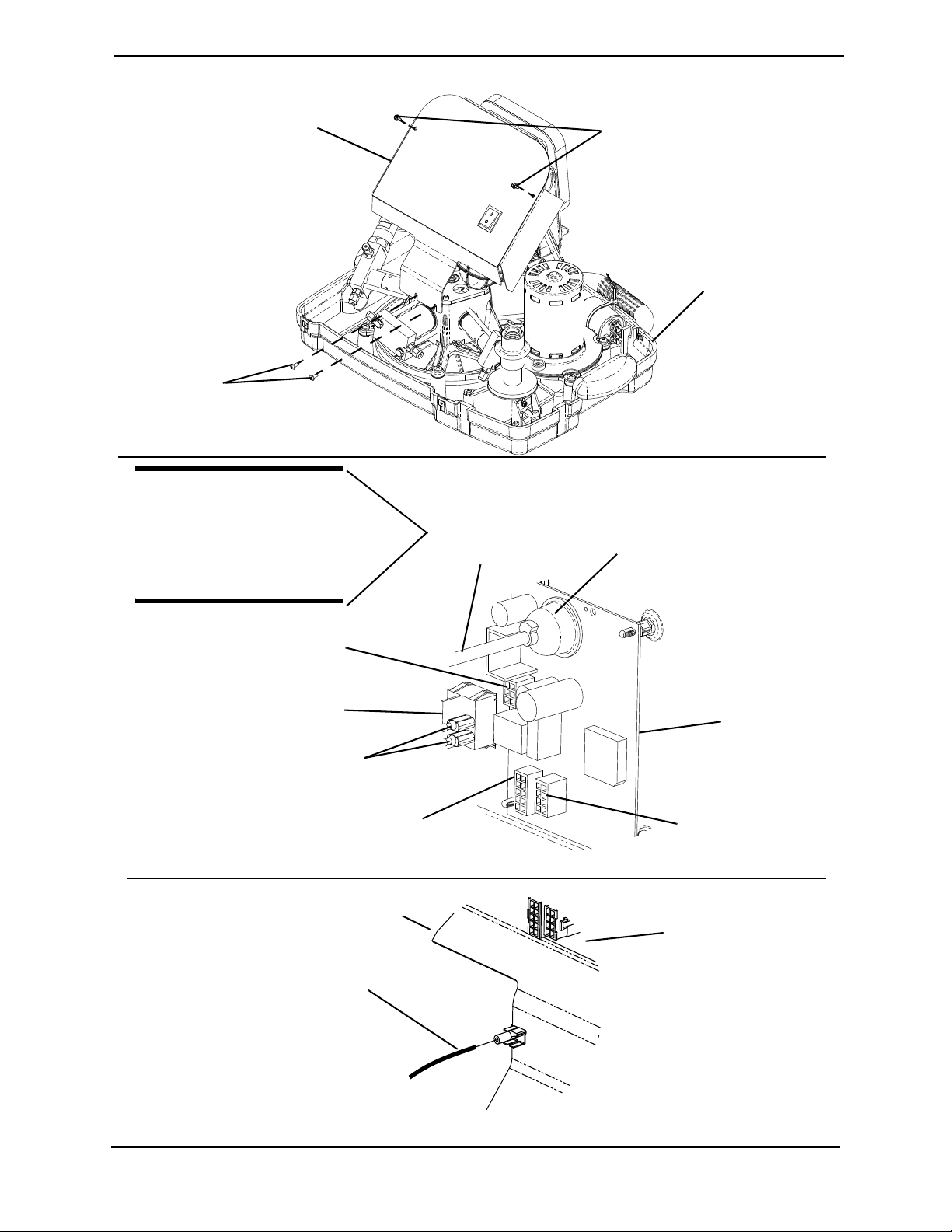

NOTE: Compressor shown without cylinder attached.

DEALER: Keep this manual. The

procedures in this manual MUST be

performed by a qualified technician.

For more information regarding

Invacare products, parts, and services,

please visit www.invacare.com

REFERENCE DOCUMENTS

DANGER

Risk Of Death, Injury, Or Damage

Improper use of the product may cause death, injury or damage. This

manual contains important information for the safe operation and use

of this product.

- DO NOT use this product or any available optional equipment without

first completely reading and understanding these instructions and any

additional instructional material such as user manuals, service manuals

or instruction sheets supplied with this product or optional equipment.

- If you are unable to understand the warnings, cautions or instructions,

contact a healthcare professional, dealer or technical personnel before

attempting to use this equipment.

- THE PROCEDURES IN THIS SERVICE MANUAL MUST BE

PERFORMED BY A QUALIFIED TECHNICIAN.

REFERENCE DOCUMENTS

Refer to the following table for part numbers of additional documents which are

referenced in this manual.

MANUAL PART NUMBER LANGUAGES*

HomeFill AW Compressor User Manual 1116444 English

1145804 Northern

1145805 Southern

1145806 Scandinavian

®

Platinum

Platinum Concentrator Service Manual 1118396 English

Perfecto

™ AW & VAW Concentrator User Manual 1163145 Northern

2

Concentrator User Manual

1134866 English

1141491 Northern

1141492 Southern

1141493 Scandinavian

1163146 Southern

1163147 Scandinavian

1160877 English

Perfecto

Concentrator Service Manual 1154245 English

2

*NOTE: Northern languages include English, Czech, French, German, Italian and Polish.

Southern languages include English, Dutch, French, Greek, Italian, Portuguese and Spanish.

Scandinavian languages include English, Danish, Finnish, Norwegian and Swedish.

HomeFill® II AW Compressor 2 Part No 1154316

TABLE OF CONTENTS

TABLE OF CONTENTS

REFERENCE DOCUMENTS ................................................................. 2

SPECIAL NOTES ................................................................................ 6

TECHNICAL DATA ........................................................................... 7

LABEL LOCATIONS ........................................................................... 8

GENERAL ....................................................................................... 10

Symbols.................................................................................................................................................................................. 10

Symbols in the Manual ........................................................................................................................10

Symbols on the Product .....................................................................................................................10

Intended Use........................................................................................................................................................................ 11

SECTION 1: GENERAL GUIDELINES .................................................. 13

Operating Information......................................................................................................................................................13

Handling................................................................................................................................................................................. 14

EMC Information................................................................................................................................................................ 15

SECTION 2: CONCENTRATOR VERIFICATION AND

MAINTENANCE ............................................................................. 16

Performance Verification.................................................................................................................................................16

Connecting the Compressor to the Concentrator................................................................................................ 17

SECTION 3: CHECKLIST AND CYLINDER INSPECTION ...................... 18

Compressor Operation Checklist................................................................................................................................ 18

Cylinder Prefill Inspection................................................................................................................................................ 18

Hydrostatic Testing Date...................................................................................................................19

External Examination ..........................................................................................................................19

SECTION 4: COMPRESSOR OPERATION ........................................... 20

Connecting/Disconnecting Cylinder to/from Compressor..................................................................................20

Connecting the Cylinder to the Compressor...............................................................................20

Disconnecting Cylinder From Compressor ..................................................................................22

Turning the Compressor On and Off......................................................................................................................... 23

SECTION 5: CABINET ASSEMBLY .................................................... 25

Removing/Installing the Cabinet .................................................................................................................................... 25

Removing ...............................................................................................................................................25

Installing..................................................................................................................................................25

Removing/Installing the Cabinet Filter Grid............................................................................................................... 26

Removing ...............................................................................................................................................26

Installing..................................................................................................................................................26

Replacing Non-Skid Adhesive Back Pad...................................................................................................................... 27

Replacing Foam Gasket....................................................................................................................................................27

Part No 1154316 3 HomeFill® II AW Compressor

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION 6: PANEL ASSEMBLY ........................................................ 28

Replacing Exhaust Fan.......................................................................................................................................................28

Removing/Installing Control Panel................................................................................................................................29

Installing................................................................................................................................................................................. 29

Testing/Replacing the Power Switch............................................................................................................................ 31

Replacing Circuit Board ................................................................................................................................................... 32

Replacing Accumulator Assembly.................................................................................................................................33

SECTION 7: BASE COMPONENTS ..................................................... 34

Replacing the Fuse.............................................................................................................................................................. 34

Removing/Installing the Power Inlet............................................................................................................................. 35

Removing ...............................................................................................................................................35

Installing..................................................................................................................................................35

Replacing Hour Meter......................................................................................................................................................36

Replacing O2 Inlet Connector/Inlet Connector Dust Cap...................................................................................36

Replacing Transformer.....................................................................................................................................................37

Testing/Replacing Capacitor ........................................................................................................................................... 38

Testing ....................................................................................................................................................38

Replacing Capacitor.............................................................................................................................39

Removing Connector Fillport Dust Cover and Lanyard - Units Manufactured

Before 10/03/2005............................................................................................................................................................. 40

Removing ...............................................................................................................................................40

Removing/Installing Connector Fillport Dust Cover and Lanyard - Units Manufactured

After 10/02/2005................................................................................................................................................................ 41

Replacing the High Pressure Switch.............................................................................................................................42

Replacing Burst Disk Fitting............................................................................................................................................ 42

SECTION 8: BASE REPLACEMENT .................................................... 44

Disassembly.......................................................................................................................................................................... 44

Reassembly...........................................................................................................................................................................50

SECTION 9: MOTOR REPLACEMENT ................................................ 52

Disassembly...........................................................................................................................................52

Reassembly ............................................................................................................................................57

SECTION 10: COMPRESSOR REPLACEMENT ..................................... 59

HomeFill Units Manufactured Before 8/1/05 ............................................................................................................ 59

Disassembly...........................................................................................................................................59

Assembly of New Motor/Pump Assembly .....................................................................................64

Reassembly ............................................................................................................................................66

HomeFill Units Manufactured After 8/1/05............................................................................................................... 68

Disassembly of HomeFill Units.........................................................................................................68

Reassembly of HomeFill Units ..........................................................................................................73

HomeFill® II AW Compressor 4 Part No 1154316

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION 11: TIMING BELT REPLACEMENT ...................................... 75

Disassembly.......................................................................................................................................................................... 75

Reassembly...........................................................................................................................................................................80

SECTION 12: WIRING ASSEMBLIES ................................................... 81

Replacing Wiring Assemblies.......................................................................................................................................... 81

Full View of Wiring Harnesses .........................................................................................................81

Replacing Transformer Assembly.....................................................................................................81

Replacing Bleed Resistor Assemblies ..............................................................................................82

Replacing HFII Assembly Wire Harness.........................................................................................83

SECTION 13: TROUBLESHOOTING/CYLINDER FILL TIMES .................. 85

Indicator Light Explanation.............................................................................................................................................. 85

Troubleshooting .................................................................................................................................................................85

Cylinder Fill Times............................................................................................................................................................. 87

Leak Test............................................................................................................................................................................... 87

Cylinder Fill Test ................................................................................................................................................................88

HomeFill 2000 psi Switch/P.C.B. Shut Down Test.................................................................................................. 92

SECTION 14: MAINTENANCE .......................................................... 94

Wear and Tear.................................................................................................................................................................... 94

Service Life............................................................................................................................................................................ 94

Cleaning/Replacing the Cabinet Filter..........................................................................................................................95

Cleaning Cabinet ................................................................................................................................................................ 95

Verification Process - Invacare HomeFill Compressor..........................................................................................96

Function Test.......................................................................................................................................................................97

Verification Process - Invacare HomeFill Cylinder.................................................................................................. 98

Function Test.......................................................................................................................................................................99

SECTION 15: AFTER USE ............................................................... 100

Disposal...............................................................................................................................................................................100

CUSTOMER SERVICE AND WARRANTY INFORMATION ................. 103

Part No 1154316 5 HomeFill® II AW Compressor

SPECIAL NOTES

SPECIAL NOTES

DANGER

Risk Of Death, Injury Or Damage From Fire

Textiles, oil or petroleum substances, grease, greasy substances and other

combustibles are easily ignited and burn with great intensity in oxygen enriched air

and when in contact with oxygen under pressure. To avoid fire, death, injury or

damage:

- DO NOT SMOKE while using this device.

- DO NOT use near OPEN FLAME or IGNITION SOURCES.

- DO NOT use any lubricants on the compressor unless recommended by Invacare.

- NO SMOKING signs should be prominently displayed.

- Avoid creation of any spark near oxygen equipment. This includes sparks from

static electricity created by any type of friction.

- Keep all matches, lighted cigarettes, electronic cigarettes or other sources of

ignition out of the room in which this compressor is located and away from where

oxygen is being delivered.

- Keep the oxygen tubing, cord, and compressor out from under such items as

blankets, bed coverings, chair cushions, clothing, and away from heated or hot

surfaces including space heaters, stoves, and similar electrical appliances.

- DO NOT allow oil from your hands or other sources to come into contact with the

compressor coupling or cylinder fittings. These substances may become flammable

in the presence of oxygen and cause injury. Avoid touching the cylinder fitting

whenever possible. Example of items to avoid are hand creams or lotions, cooking

oils, suntan oils or sunblocks and similar oily products. If you use these types of

products Invacare suggests you wash your hands prior to using the HomeFill unit.

If the cylinder fitting should come in contact with such substances it should be

cleaned off with a damp cloth prior to connecting it to the compressor.

- NEVER oil or lubricate the compressor coupler or cylinder fittings. NEVER use any

penetrating oil or lubricant such as WD-40® or 3-in-1 Oil®. If connection difficulty

is experienced verify that the cylinder fitting is being inserted straight down into

the compressor coupler. If continued difficulty is experienced contact your supplier

for assistance.

ACCESSORIES WARNING

Risk of Serious Injury Or Damage

Use of non-Invacare accessories may result in serious injury or damage.

- Invacare products are specifically designed and manufactured for use in

conjunction with Invacare accessories. Accessories designed by other

manufacturers have not been tested by Invacare and are not recommended for use

with Invacare products.

- DO NOT use non-Invacare accessories.

- To obtain Invacare accessories, contact Invacare by phone or at www.invacare.com.

NOTE: The information contained in this document is subject to change without notice.

HomeFill® II AW Compressor 6 Part No 1154316

TECHNICAL DATA

SPECIFICATIONS

Regulatory Listings: EN/IEC 60601-1

EN/IEC 60601-1-2

Electrical Ratings: 230 V~, 1.0 A, 50 Hz

TECHNICAL DATA

Operating Environmental

Conditions:

Atmospheric Pressure: 700 to 1060 hPa

Storage and Transport:

Input Pressure Required:

Input Flow Required:

Input O2% Required:

Width:

Height:

Depth:

Weight:

Shipping Weight:

Max Applied Part

Temperature:

41 to 104° F (5 to 40° C) at 15 to 60% non-condensing humidity

-25 to 158° F (-23 to 70° C) at 15 to 95% non-condensing humidity

14 - 21 PSI (96.5-144.7 kPa)

2 L/min

>90% O

20 ¼ inches (51.44 cm)

15 inches (38.1 cm)

16 inches (40.64 cm)

33 lbs (14.97 kg)

39 lbs (17.69 kg)

122° F (50° C)

2

Part No 1154316 7 HomeFill® II AW Compressor

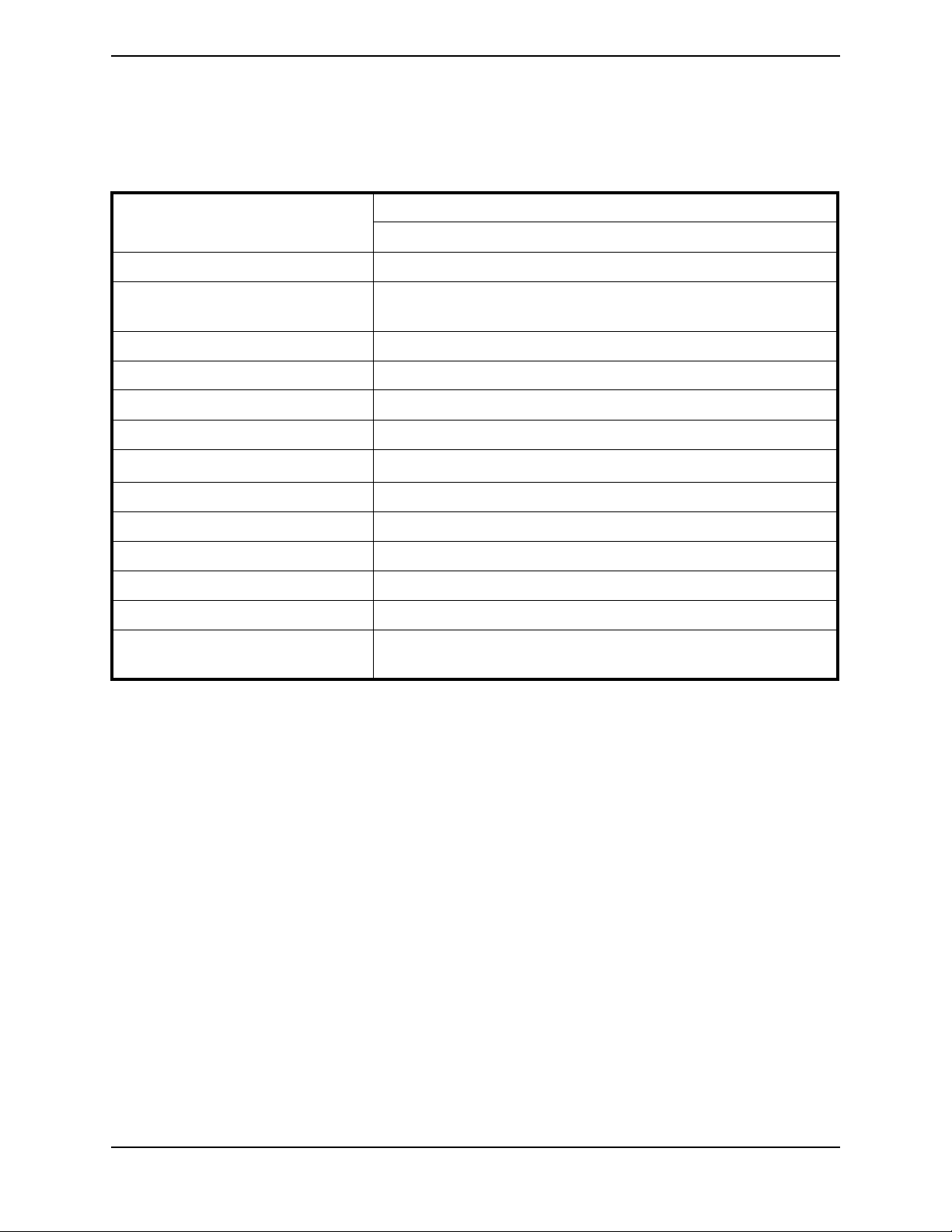

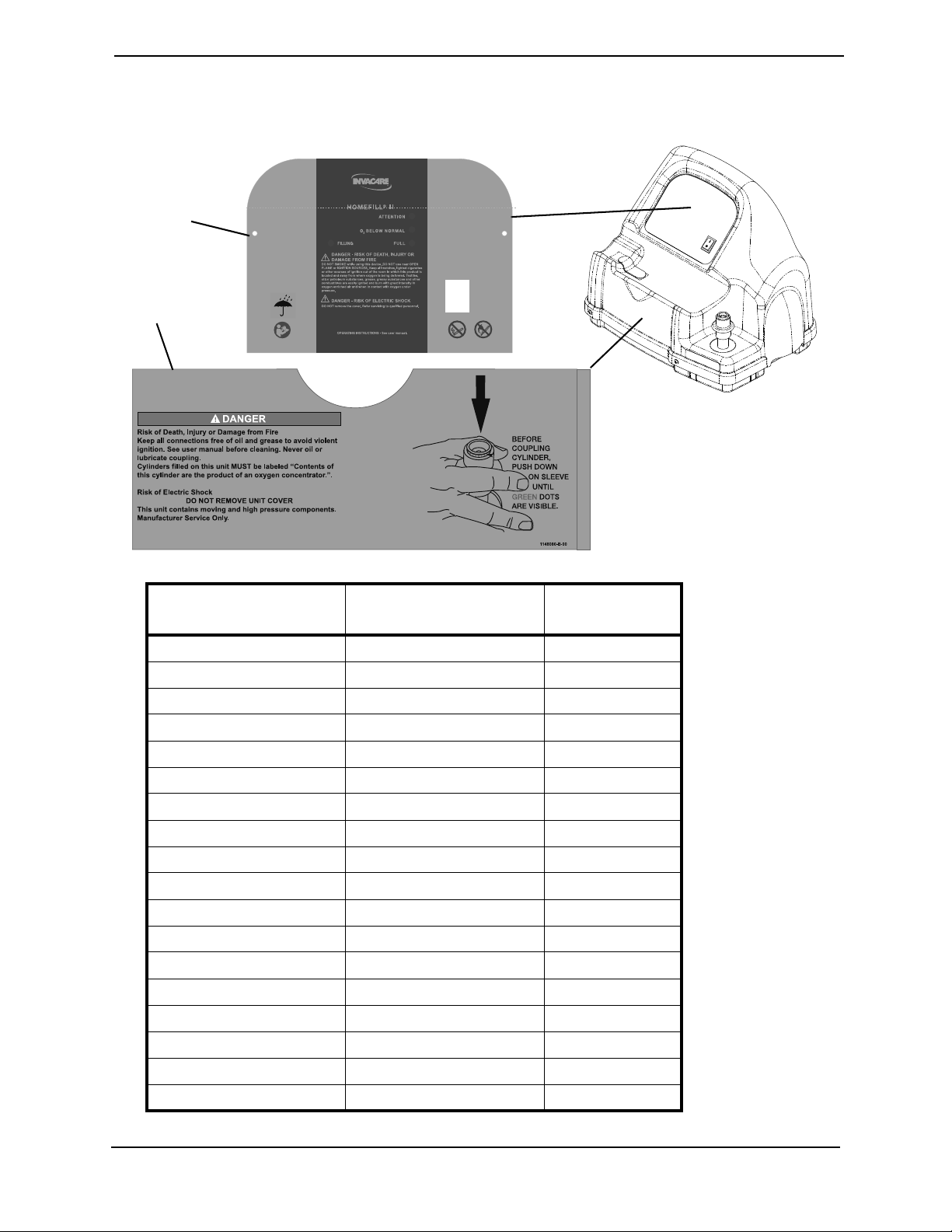

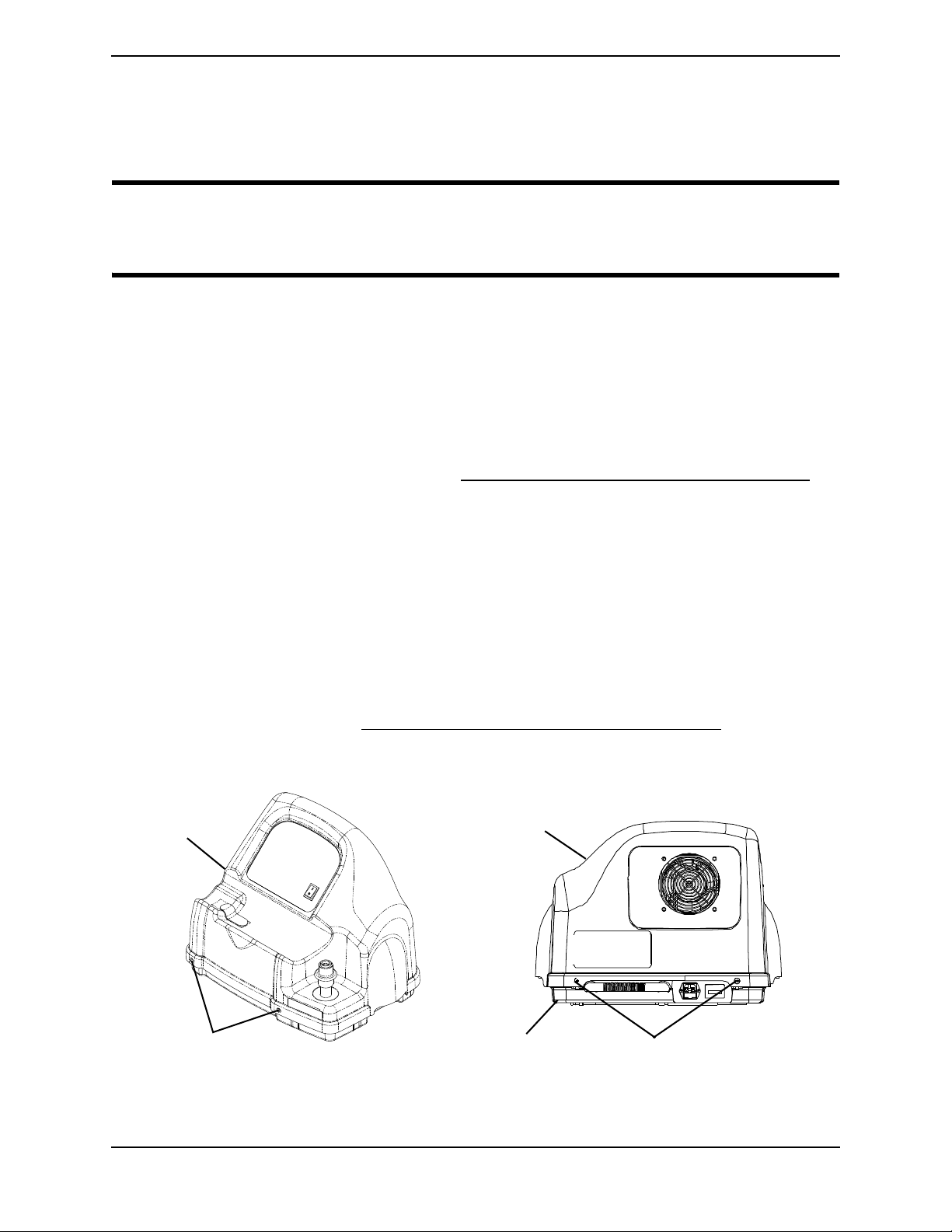

P/N 1145730-D-02

NOTE: Compressor

shown without

cylinder attached.

FRONT PANEL LABEL

A PART NUMBER

COMPOSITE LABEL B

PART NUMBER

LANGUAGE

1145730 1148080 English

1145734 1148081 Spanish

1145735 1148082 French

1145736 1148083 German

1145737 1148084 Portuguese

1145738 1148085 Norwegian

1145739 1148086 Finnish

1145740 1148087 Danish

1145741 1148088 Italian

1145742 1148089 Polish

1145743 1148090 Czech

1145744 1148091 Greek

1145745 1148092 Dutch

1145746 1148093 Swedish

1155844 1155847 Chinese

1163176 1163177 Estonian

1164884 1164885 Latvian

1167490 1167489 Lithuanian

A

B

LABEL LOCATIONS

LABEL LOCATIONS

HomeFill® II AW Compressor 8 Part No 1154316

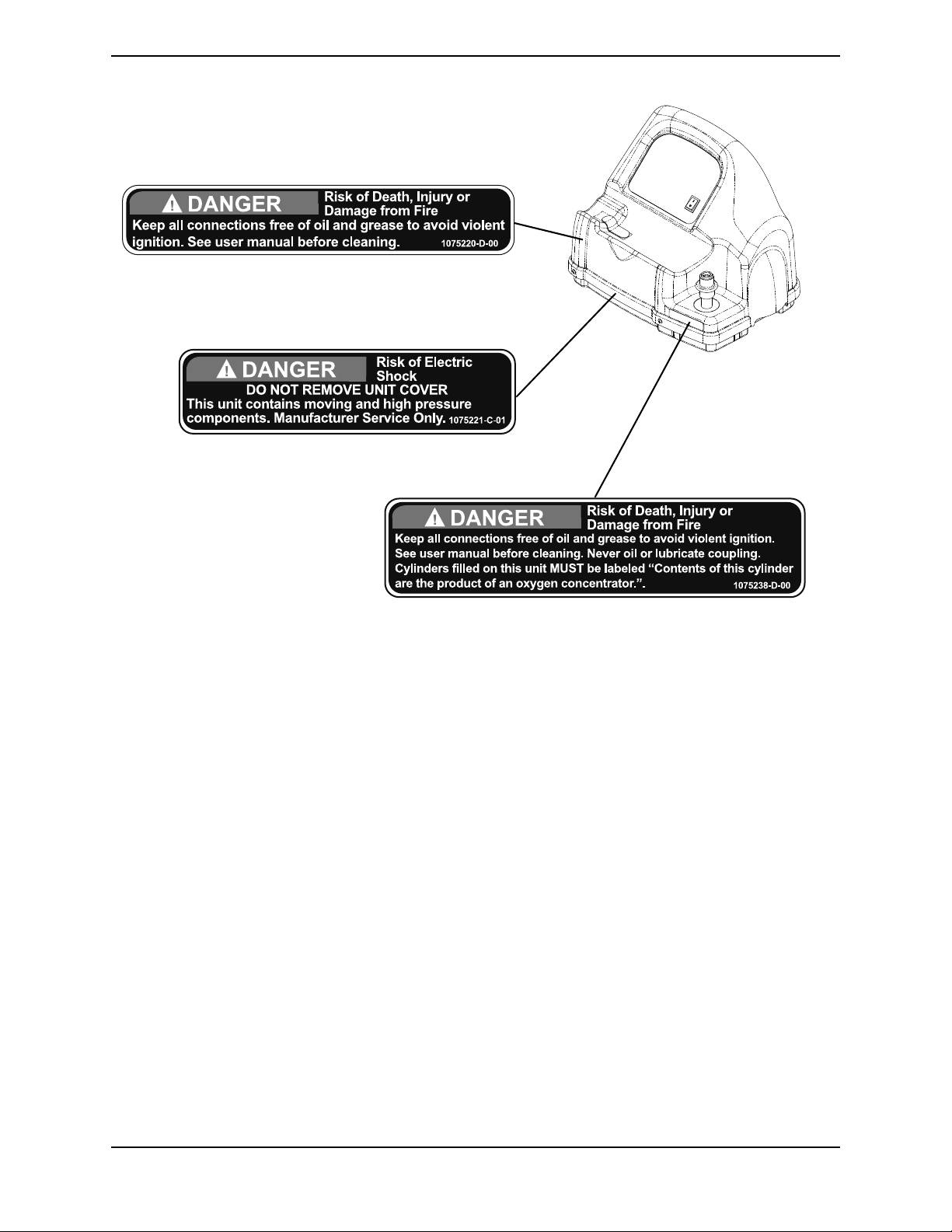

LABEL LOCATIONS

NOTE: Compressor shown without cylinder attached.

Part No 1154316 9 HomeFill® II AW Compressor

GENERAL

GENERAL

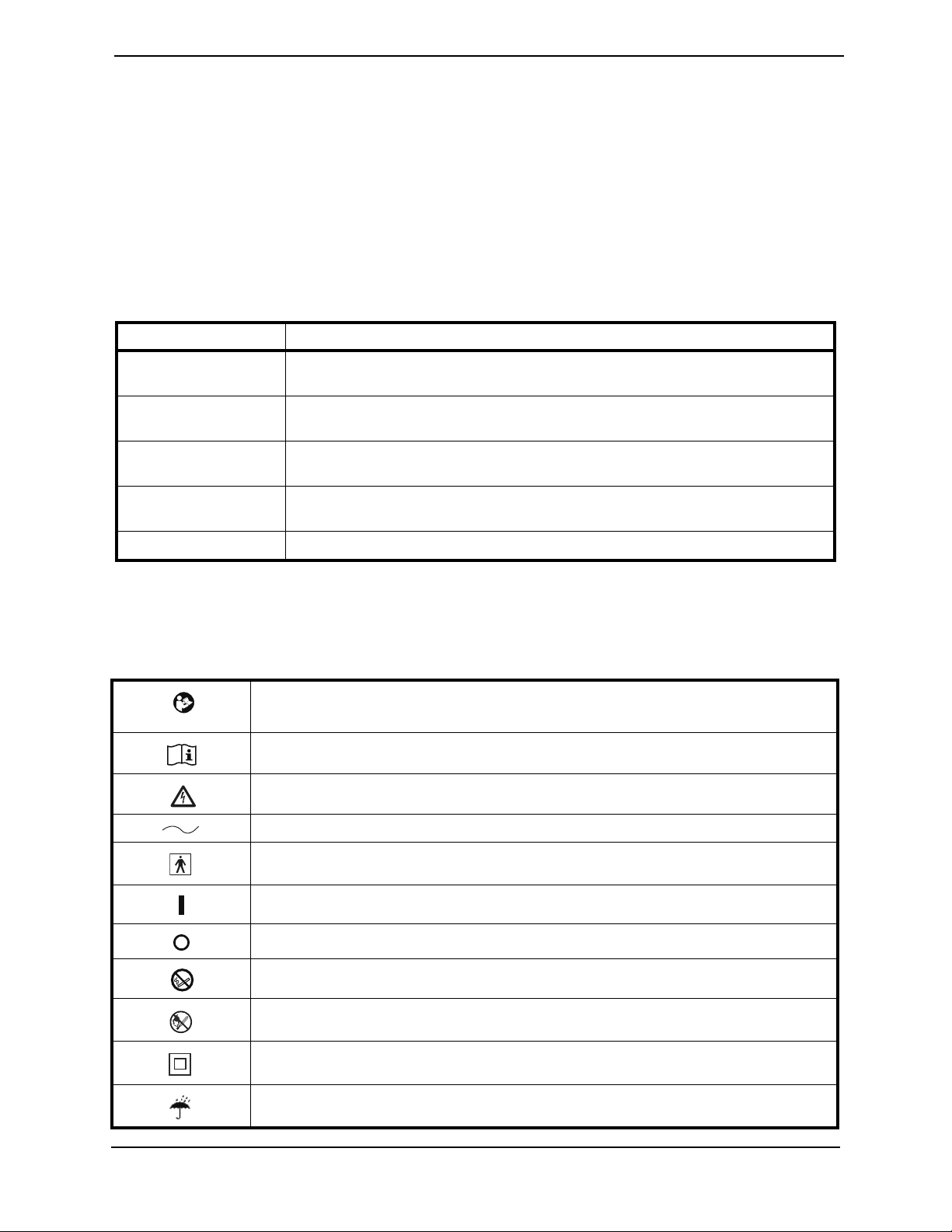

Symbols

Symbols in the Manual

Signal words are used in this manual and apply to hazards or unsafe practices which

could result in personal injury or property damage. Refer to the table below for

definitions of the signal words.

Signal Word Meaning

DANGER

WARNING

CAUTION

! IMPORTANT Indicates a hazardous situation that could result in damage to property if it is not

NOTE:

Danger indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

Warning indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

Caution indicates a potentially hazardous situation which, if not avoided, may result in

property damage or minor injury or both.

avoided.

Gives useful tips, recommendations and information for efficient, trouble-free use.

Symbols on the Product

The following symbols are found on the compressor, compressor packaging or the

oxygen cylinder.

Read the Manual (Compressor)

NOTE: The color of the symbol background is blue on product labels.

Read the Manual (Cylinder)

Electrical Hazard

Alternating Current

Type BF equipment - Applied Parts

Power switch “ON”

Power switch “OFF”

DO NOT smoke

No Open Flame

Class II, Double Insulation. Refer to Double Insulated Products in the Safety section of the manual.

Keep dry in transport or storage and during use

HomeFill® II AW Compressor 10 Part No 1154316

GENERAL

Fuse

Oxidizer

NOTE: The color of the symbol background is yellow on product labels.

Non-flammable gas, class 2 type (oxygen)

NOTE: The color of the symbol background is green on product labels.

Transport and Storage Temperature

Transport and Storage Humidity

Recycle this product. Refer to Disposal of Equipment and Accessories in the After Use section of the

manual.

This product complies with Directive 93/42/EEC concerning medical devices.

The launch date of this product is stated in the CE declaration of conformity.

European Representative

Manufacturer

Intended Use

WARNING

- The use of this device is limited to refilling a specific patient’s own oxygen cylinders.

The designated cylinders MUST be used ONLY by the specific oxygen patient and

are not to be distributed to any other individual for any purpose.

- No other use of this device is indicated.

WARNING

Risk of Death, Injury or Damage

The Invacare HomeFill compressor was designed to be used only with Invacare

oxygen concentrators. Use with other types of devices may cause injury, death or

property damage.

- DO NOT use the Invacare HomeFill compressor with anything other than an

Invacare oxygen concentrator.

- Use only with specially designed Invacare oxygen concentrators that are HomeFill

compatible.

Part No 1154316 11 HomeFill® II AW Compressor

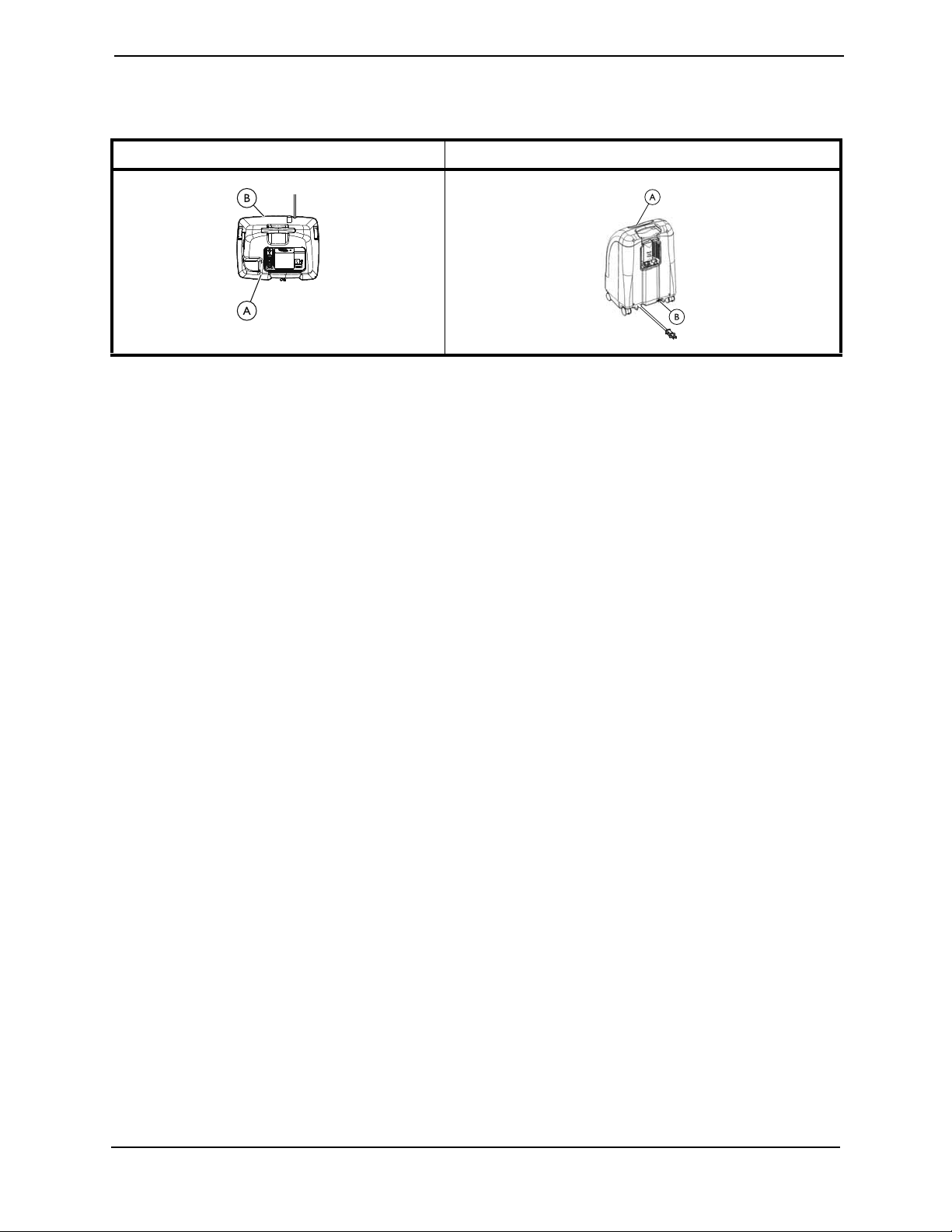

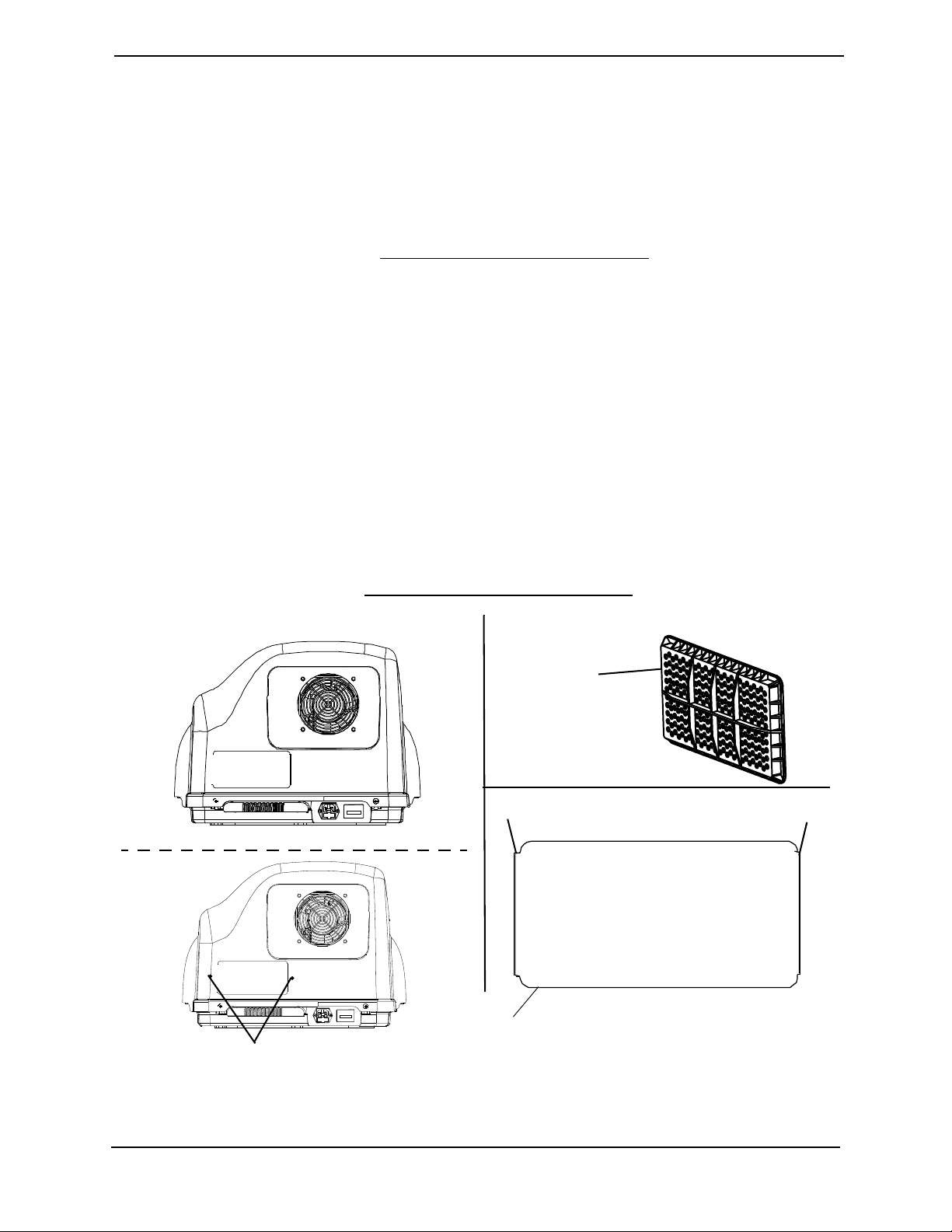

GENERAL

To determine if your oxygen concentrator is HomeFill compatible, examine the lower

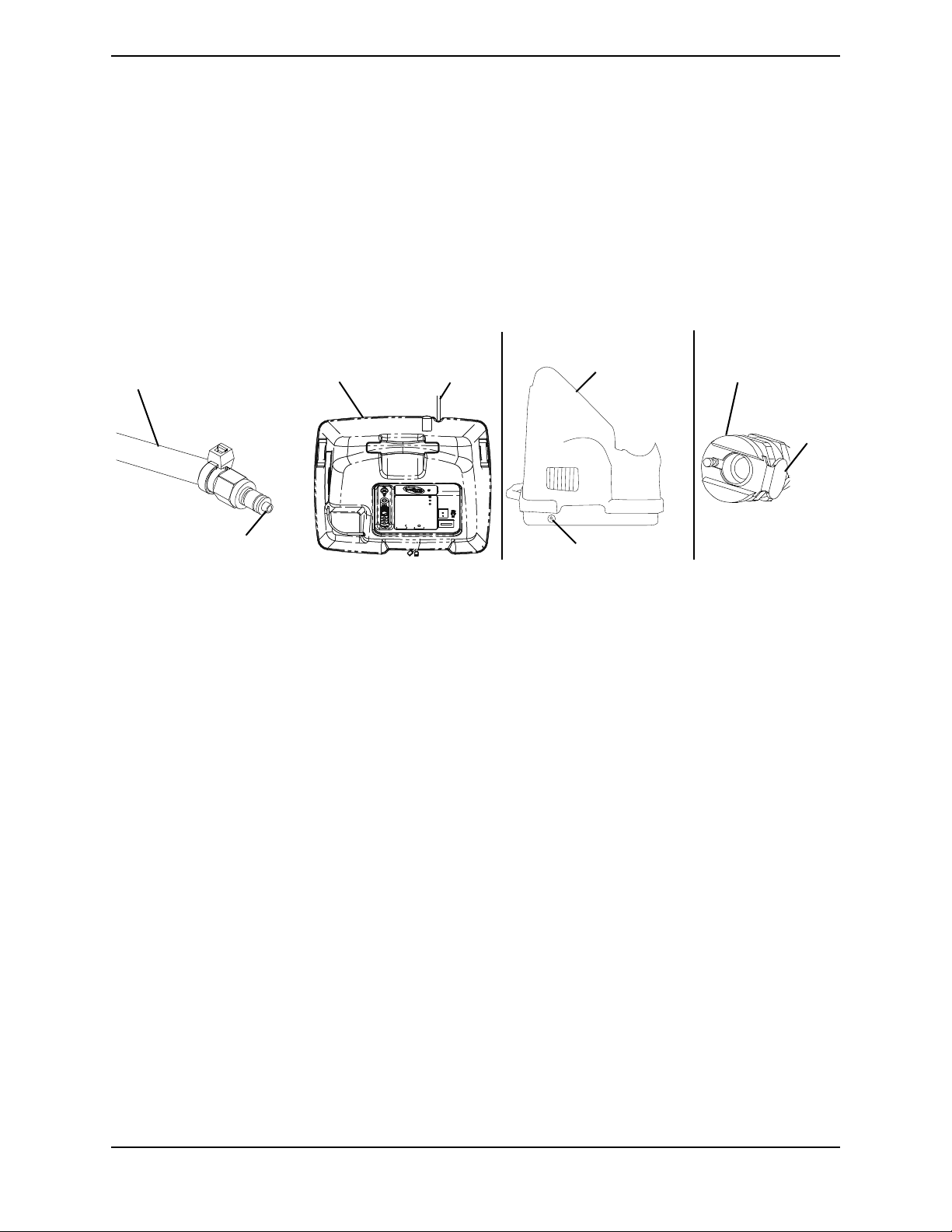

right corner of the rear of the oxygen concentrator A for an outlet fitting B.

Platinum - Top View Perfecto2 - Rear View

The intended use of an Invacare HomeFill compressor is an accessory device to an

Invacare oxygen concentrator that enables the patient to refill custom portable oxygen

cylinders for personal use.

This product is intended for single patient use in the indoor homecare environment only

and is not to be used for bulk cylinder refilling.

No specific product knowledge or training is required, other than what is contained in

this manual, to operate the product.

It is not intended for supplying oxygen therapy during refilling.

This product is intended to be used by or under adult supervision only after reading and

understanding the instructions and warnings of this user manual.

HomeFill® II AW Compressor 12 Part No 1154316

SECTION 1—GENERAL GUIDELINES

SECTION 1—GENERAL GUIDELINES

DANGER

Risk Of Death, Injury Or Damage

Improper use of the product may cause death, injury or damage. This section

contains important information for the safe operation and use of this product.

- In order to ensure the safe installation, assembly and operation of the HomeFill

Compressor these instructions MUST be followed.

CAUTION

Federal (statutory) law restricts this device to sale by or on the order of a medical

practitioner licensed by a governmental agency where he/she practices.

- ONLY a licensed medical practitioner may order the purchase or use of this device.

Operating Information

WARNING

Risk of Injury or Damage

The HomeFill is equipped with a high pressure relief valve to ensure the user’s

safety. When activated, this safety feature will make an extremely loud noise. To

avoid injury or damage:

- If this noise occurs, turn the unit Off. DO NOT use. Service unit before use. Refer

to Replacing Burst Disk Fitting on page 42.

If improperly positioned and secured, the power cord and interconnect hose can

cause injury due to tripping and falling. Product damage may also occur.

- The power cord and interconnect hose MUST be routed and secured properly.

- Avoid positioning power cords across areas of high traffic.

- Before moving or repositioning either the compressor or concentrator, ALWAYS

disconnect the AC power cords and the interconnect hose between the

compressor and concentrator.

Blocking the air flow into and out of the compressor may cause injury or damage.

- NEVER block the air openings of the product or place it on a soft surface, such as a

bed or couch, where the air opening may be blocked.

- Keep the openings free from lint, hair and similar foreign items.

- NEVER drop or insert any object into any opening.

A damaged product may malfunction and cause injury or damage. To avoid injury

or damage:

- DO NOT get the compressor wet.

- If the compressor is not working properly, if it has been dropped or damaged, or

submersed in water, a qualified technician MUST examine and repair the unit

BEFORE it is given to the user.

Part No 1154316 13 HomeFill® II AW Compressor

SECTION 1—GENERAL GUIDELINES

WARNING

Risk of Injury or Damage

- If any leakage of the oxygen cylinder is detected, DO NOT attempt to use the

cylinder. Turn the flow selector knob on the regulator to “Off”. If leakage persists,

place the cylinder outdoors and notify your Home Health Care Provider or Service

Representative of this condition.

Risk of Injury

- ALWAYS keep hands and fingers clear of moving parts to avoid injury.

Handling

WARNING

Risk of Fire

- DO NOT store filled cylinder assemblies near a furnace, hot water tank, in the

trunk of a car or other high temperature area. Storage in areas such as this can

result in bursting of the cylinder assembly or fire.

Risk of Injury or Damage

- NEVER transport a compressor with a cylinder connected to or stored on the

compressor. Otherwise, injury or damage can occur.

CAUTION

Risk of Injury or Damage

To reduce the risk of injury or damage from dropped or impacted cylinder

assemblies:

- Use two hands when handling/transporting oxygen cylinders.

- Only use Invacare Corporation carrying bag.

- DO NOT allow cylinder assemblies to tip or fall. DO NOT drop cylinder assemblies.

- Secure gas cylinders so they cannot fall.

- Ensure cylinder is always in upright position when not connected to the HomeFill

compressor.

- DO NOT allow cylinder to impact inanimate objects.

HomeFill® II AW Compressor 14 Part No 1154316

SECTION 1—GENERAL GUIDELINES

EMC Information

WARNING

Risk of Injury or Damage

To reduce the risk of injury or product damage from interference with wireless

equipment:

- Keep the compressor at least 9.8 ft (3.0 m) away from wireless communication

equipment such as wireless home network devices, mobile phones, cordless phones

and base stations, walkie-talkies, etc.

Medical Electrical Equipment needs to be installed and used according to the EMC

information in this manual.

This equipment has been tested and found to comply with EMC limits specified by IEC/

EN 60601-1-2 for Type BF equipment. These limits are determined to provide reasonable

protection against electromagnetic interference in a typical home healthcare

environment. This equipment is not intended for use in a professional healthcare

environment.

Portable and mobile RF communications equipment can affect the operation of this

equipment. The compressor may be stacked on top on an Invacare HomeFill compatible

oxygen concentrator during setup. The compressor operation should be observed to

verify normal cylinder filling in either situation.

Other devices may experience interference from even the low levels of electromagnetic

emissions permitted by the above standard. To determine if the emissions from the

compressor are causing the interference, turn the compressor Off. If the interference with

the other device operation stops, then the compressor is causing the interference. In such

rare cases, interference may be reduced or corrected by one of the following measures:

• Reposition, relocate, or increase the separation between the devices.

• Connect either line powered device to a different electrical power circuit.

Contact Invacare for any additional EMC information or EMC tables for the device

environment.

Part No 1154316 15 HomeFill® II AW Compressor

SECTION 2—CONCENTRATOR VERIFICATION AND MAINTENANCE

SECTION 2— CONCENTRATOR VERIFICATION

AND MAINTENANCE

Performance Verification

NOTE: A dedicated concentrator should be used to test HomeFill compressors.

NOTE: The test concentrator MUST have its performance verified and documented prior to

testing HomeFill compressors.

NOTE: All performance verification and maintenance performed on the test concentrator MUST

be documented on a log sheet that is attached to the concentrator.

1. Turn On the concentrator and set the flow rate to 5 L/min.

2. Allow the concentrator to warm up for a minimum of 30 minutes.

3. After the 30 minute warm-up, check the oxygen concentration using a calibrated

oxygen analyzer.

NOTE: The oxygen concentration reading MUST be above 90% at 5 L/min.

4. Provided the oxygen concentration is 90% or higher at 5 L/min., record the following

on the repair statement and on the test concentrator maintenance log:

A. Date of the performance test and when any service is performed.

B. Hour meter reading.

C. Oxygen concentration.

D. If service is performed, record all details of repair, including preventative

maintenance.

E. Record all parts replaced, and list all detailed performance results.

NOTE: A new entry MUST be made for each performance test, or when any service type items are

performed.

5. Turn the concentrator flow rate down to 2.5 L/min.

6. Connect the test concentrator to the HomeFill compressor to be tested. Refer to

Connecting the Compressor to the Concentrator on page 17.

7. Test the HomeFill compressor. Refer to Troubleshooting/Cylinder Fill Times on

page 85.

HomeFill® II AW Compressor 16 Part No 1154316

SECTION 2—CONCENTRATOR VERIFICATION AND MAINTENANCE

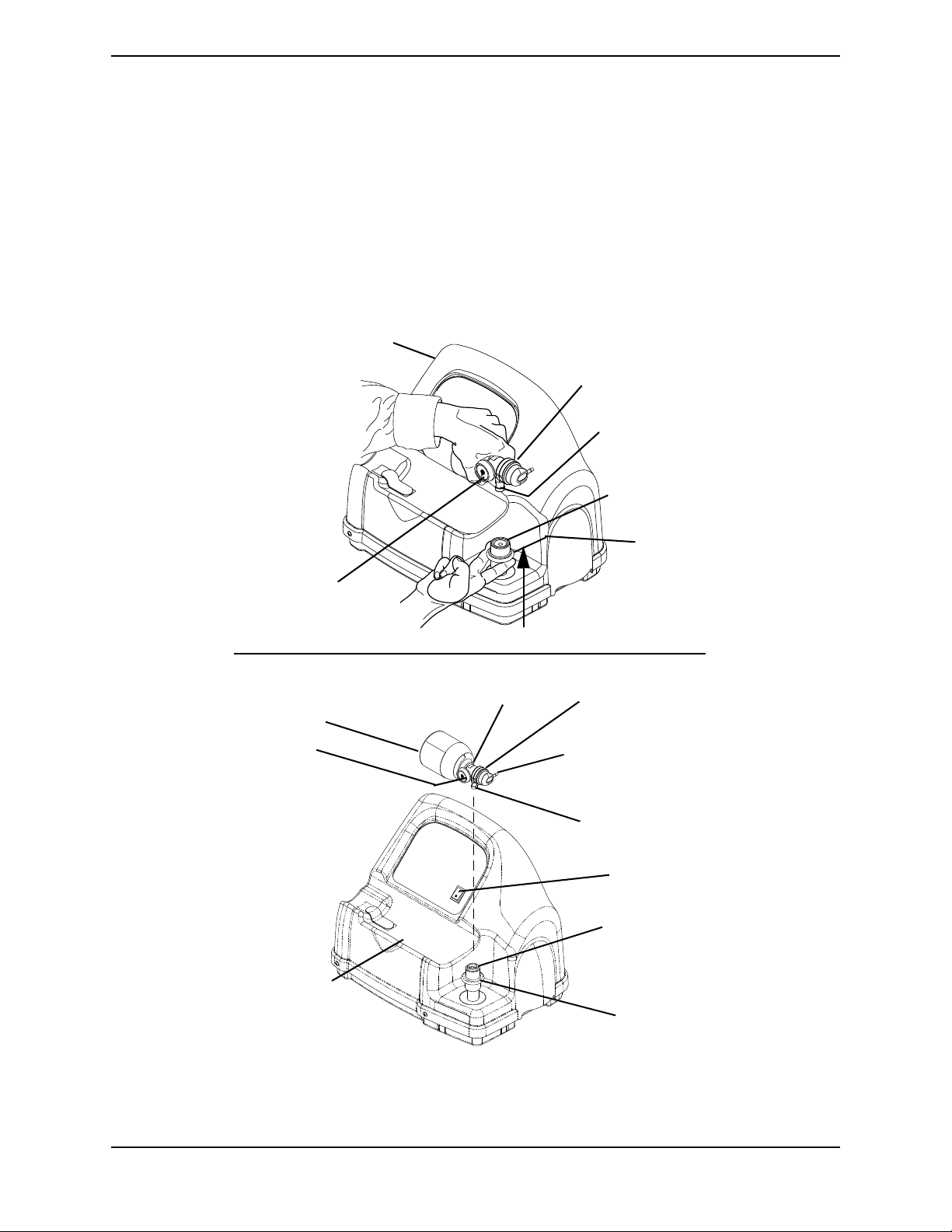

Insert End of

Interconnect Hose into

Inlet/Outlet Fitting

Inlet/Outlet Fitting

Metal

Tab

Interconnect

Hose (or

Coiled tubing)

Compressor

Inlet Fitting

Power

Cord

Outlet Fitting

CONCENTRATOR

TOP VIEW

DETAIL “A”

DETAIL “C”

DETAIL “B”

Connecting the Compressor to the Concentrator

NOTE: For this procedure, refer to FIGURE 2.1 on page 17.

1. Insert one end of the interconnect hose into the outlet fitting on the back of the

concentrator (Detail “A”).

2. Insert the opposite end of the interconnect hose into the inlet fitting on the side of the

compressor (Detail “B”).

NOTE: The metal tabs on the concentrator outlet fitting and the compressor inlet fitting will pop

out with an audible “click” when the end of the interconnect hose is properly installed (Detail “C”).

3. For models that DO NOT have coiled tubing, loop any excess interconnect hose and

secure to the back of the concentrator with the fastening straps.

FIGURE 2.1 Concentrator Verification and Maintenance

Part No 1154316 17 HomeFill® II AW Compressor

SECTION 3—CHECKLIST AND CYLINDER INSPECTION

SECTION 3—CHECKLIST AND CYLINDER

INSPECTION

Compressor Operation Checklist

Each time the HomeFill Compressor is used to fill a cylinder, complete the following

checklist:

❑ Ensure the concentrator has been on for at least 30 minutes. Refer to the concentrator

User Manual.

❑ Perform the prefill inspection on the cylinder.

❑ Connect the cylinder to the compressor.

❑ Turn the compressor On.

❑ Examine the indicator lights on the control panel.

❑ Disconnect and remove the full cylinder.

❑ Turn the compressor Off.

❑ If filling another cylinder, repeat this checklist.

Cylinder Prefill Inspection

WARNING

Use only cylinders that have the Invacare HomeFill II connection and the HomeFill

II label as shown in FIGURE 3.1 on page 18.

All cylinders MUST be inspected before attempting to fill. Otherwise, injury or

damage may occur.

NOTE: For this procedure, refer to FIGURE 3.1 on page 18.

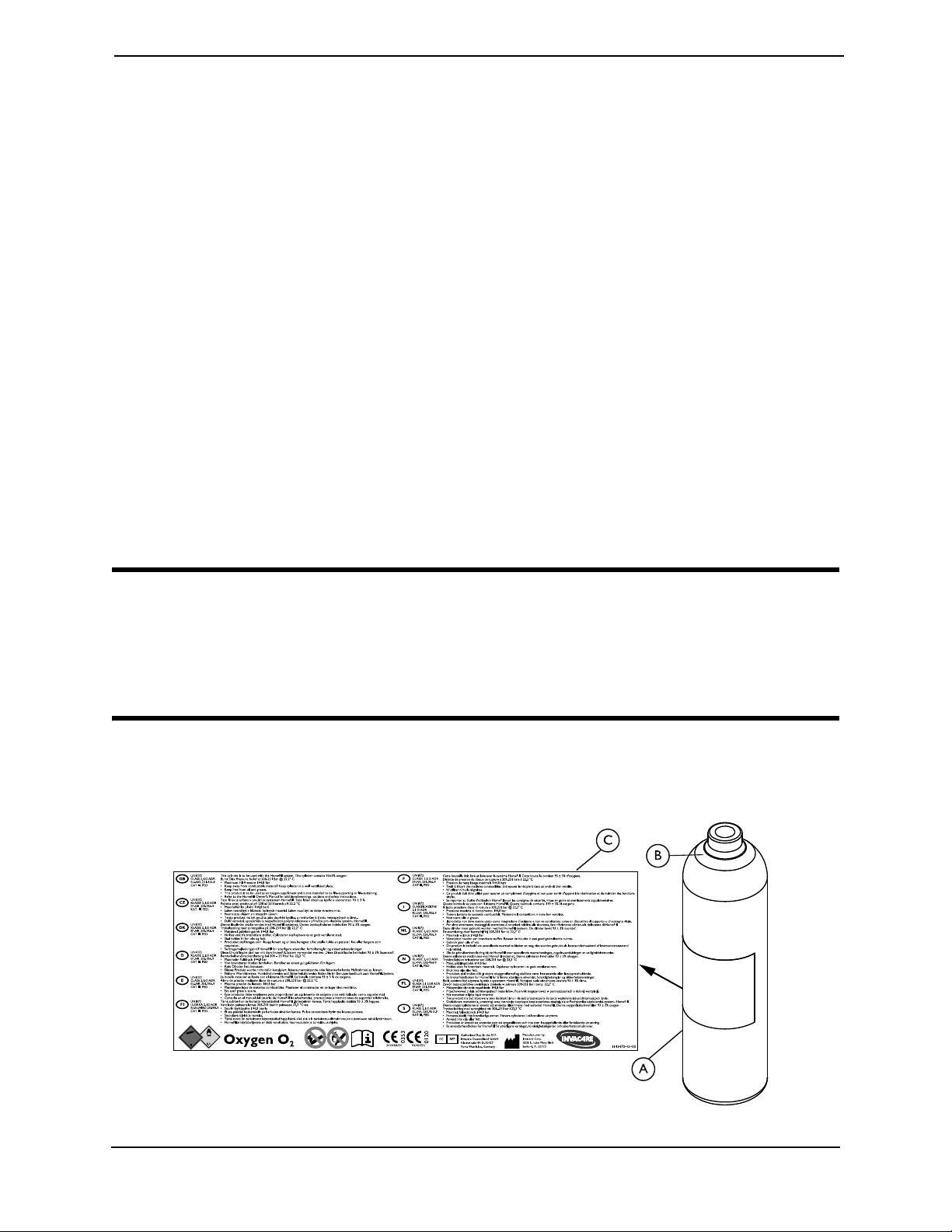

To identify a HomeFill II compatible cylinder A, look for a black stripe B on the top of the

cylinder and look for the HomeFill II label C.

FIGURE 3.1 Cylinder Prefill Inspection

HomeFill® II AW Compressor 18 Part No 1154316

SECTION 3—CHECKLIST AND CYLINDER INSPECTION

Hydrostatic Testing Date

Aluminum cylinders MUST undergo testing every ten years.

WARNING

Risk of Injury

To reduce the risk of injury:

- DO NOT fill cylinders that have not been tested in the past ten years. Otherwise,

serious personal injury may result. Contact your dealer/Home Care equipment

provider for replacement.

External Examination

1. Examine the outside of the cylinder for the following conditions, and replace the

cylinder if they exist:

• Dents or dings

• Arc burns

• Oil or grease

• Any other signs of damage that might cause a cylinder to be unacceptable or

unsafe for use.

2. Examine the cylinder for evidence of fire or thermal damage. Evidence includes

charring or blistering of the paint, or other protective coating or heat sensitive

indicator. If fire or thermal damage is found, replace the cylinder.

3. Inspect the Invacare valve for the following and replace if found:

• Debris, oil or grease

• Noticeable signs of damage

• Signs of corrosion inside the valve

• Signs of excessive heat or fire damage

Part No 1154316 19 HomeFill® II AW Compressor

SECTION 4—COMPRESSOR OPERATION

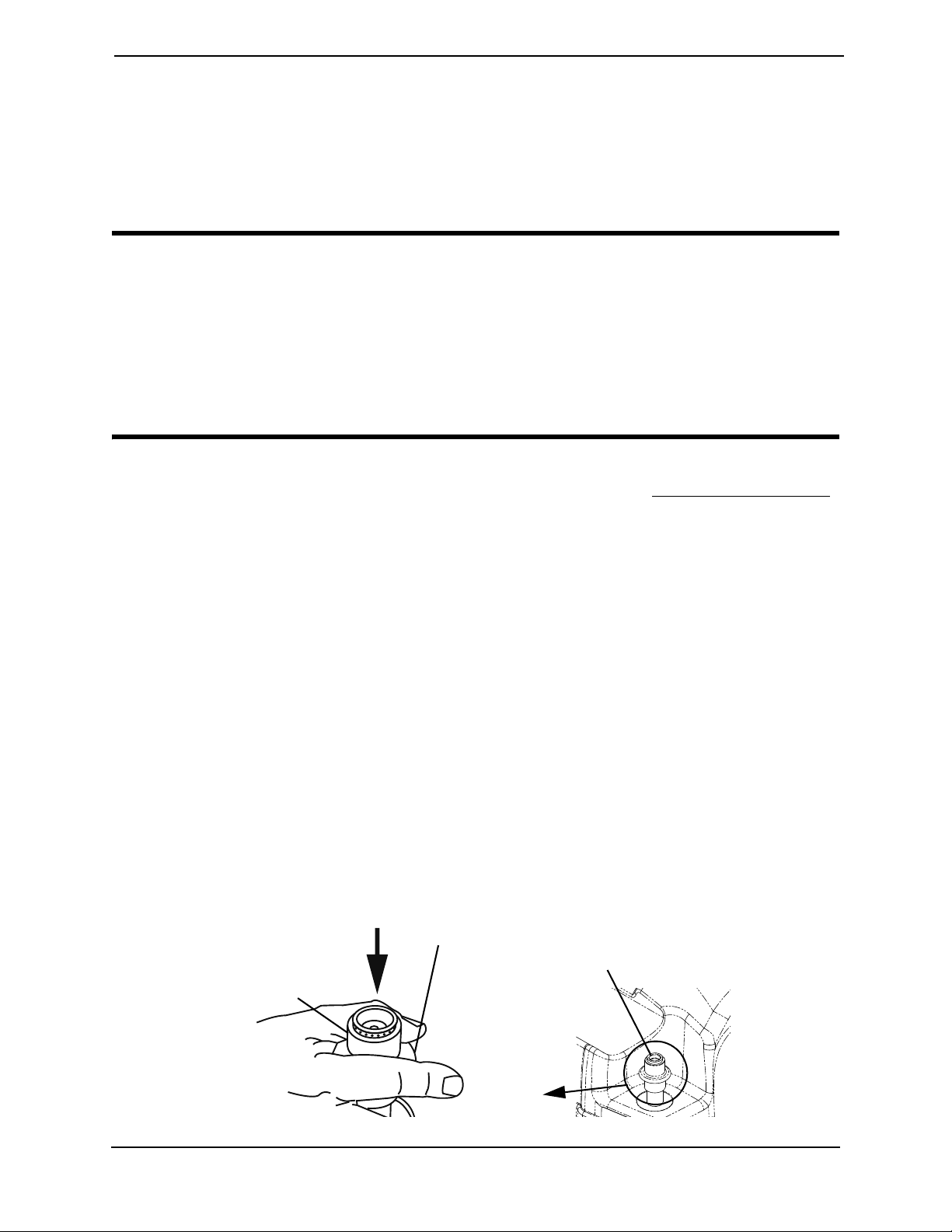

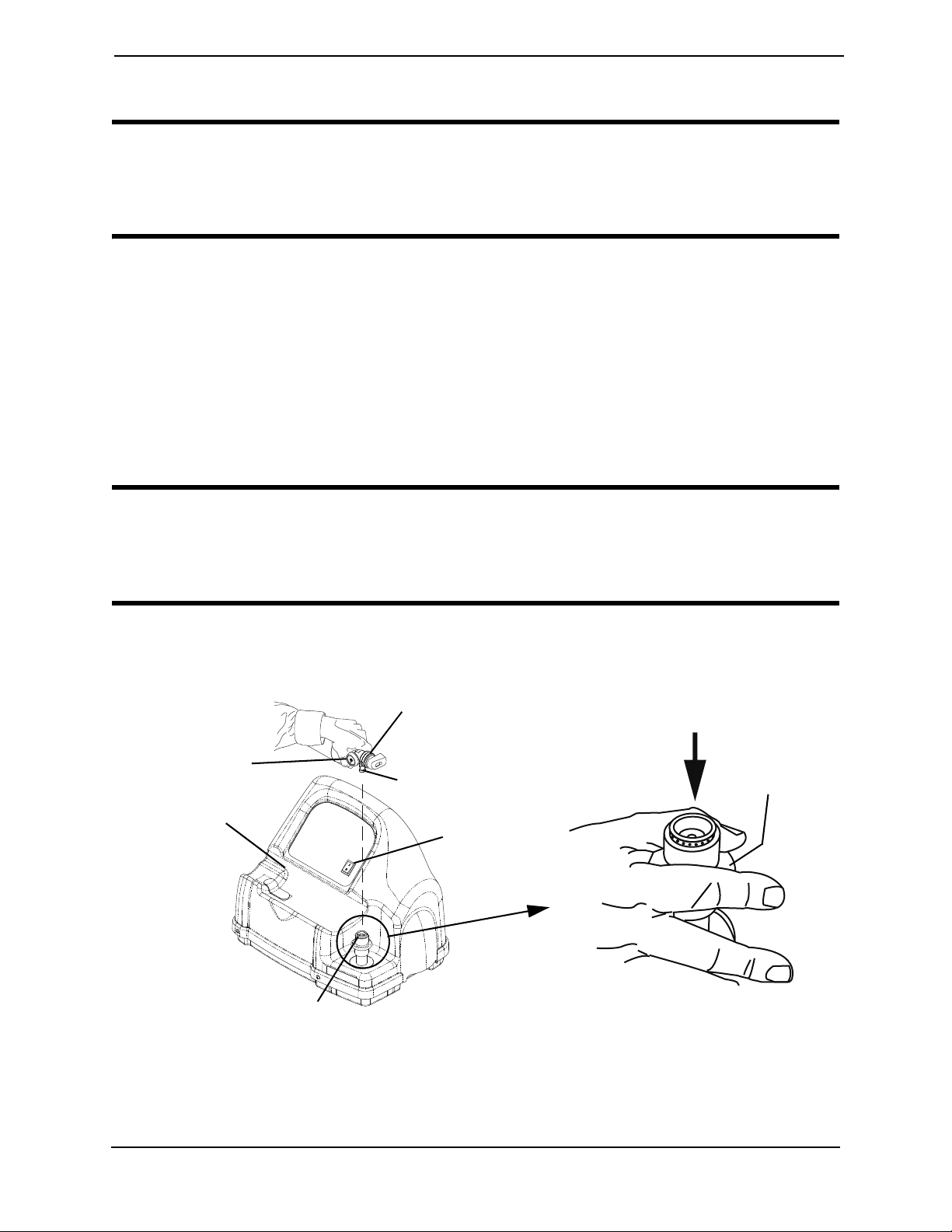

BEFORE

COUPLING

CYLINDER,

PUSH DOWN

ON SLEEVE

UNTIL

GREEN DOTS

Connector Fillport

Outer Ring (Sleeve)

PUSH

DOWN

GREEN Dots

SECTION 4—COMPRESSOR OPERATION

Connecting/Disconnecting Cylinder to/from Compressor

Connecting the Cylinder to the Compressor

WARNING

DO NOT modify any connections on the HomeFill compressor.

NEVER use tools of any kind to connect/disconnect the cylinder and the

compressor. Otherwise, severe injury and/or damage may occur.

DO NOT drop oxygen cylinders. Use two hands when handling/transporting oxygen

cylinders. Otherwise, injury or damage may occur.

DO NOT use a liquid leak detector to test for leaks.

NOTE: For this procedure, refer to FIGURE 4.1 on page 20 and FIGURE 4.2 on page 21.

1. Prior to each use, inspect product for visible damage. Refer to External Examination

on page 19. DO NOT use if any damage is found.

NOTE: If for any reason, any label becomes illegible or lost, contact your dealer/Home Care

equipment provider.

2. Examine the cylinder gauge. If the cylinder pressure is less than 1500 psig. (10342 kPa),

proceed to STEP 2.

NOTE: For location of the cylinder gauge, refer to the cylinder user manual. If the cylinder

pressure is greater than 1500 psig (10342 kPa), DO NOT attempt to top off the cylinder. It may

not fill. Bleed the cylinder or select another cylinder.

3. Set the regulator flow dial on the cylinder to Off (Detail “B” of FIGURE 4.2). Refer to

the cylinder user manual.

4. Remove the cylinder and connector fillport covers (if present).

NOTE: On older models, the green dots do not exist.

5. To reset the connector, momentarily push down on the outer ring (sleeve) of the

connector fillport until GREEN dots are visible (FIGURE 4.1).

NOTE: If the outer ring (sleeve) is in the up position (GREEN dots not visible), the connector

fillport will not be able to accept the cylinder fillport. Pushing down momentarily will reset the

connector fillport (GREEN dots visible) to accept the cylinder fillport.

HomeFill® II AW Compressor 20 Part No 1154316

FIGURE 4.1 Resetting Connector Fillport

SECTION 4—COMPRESSOR OPERATION

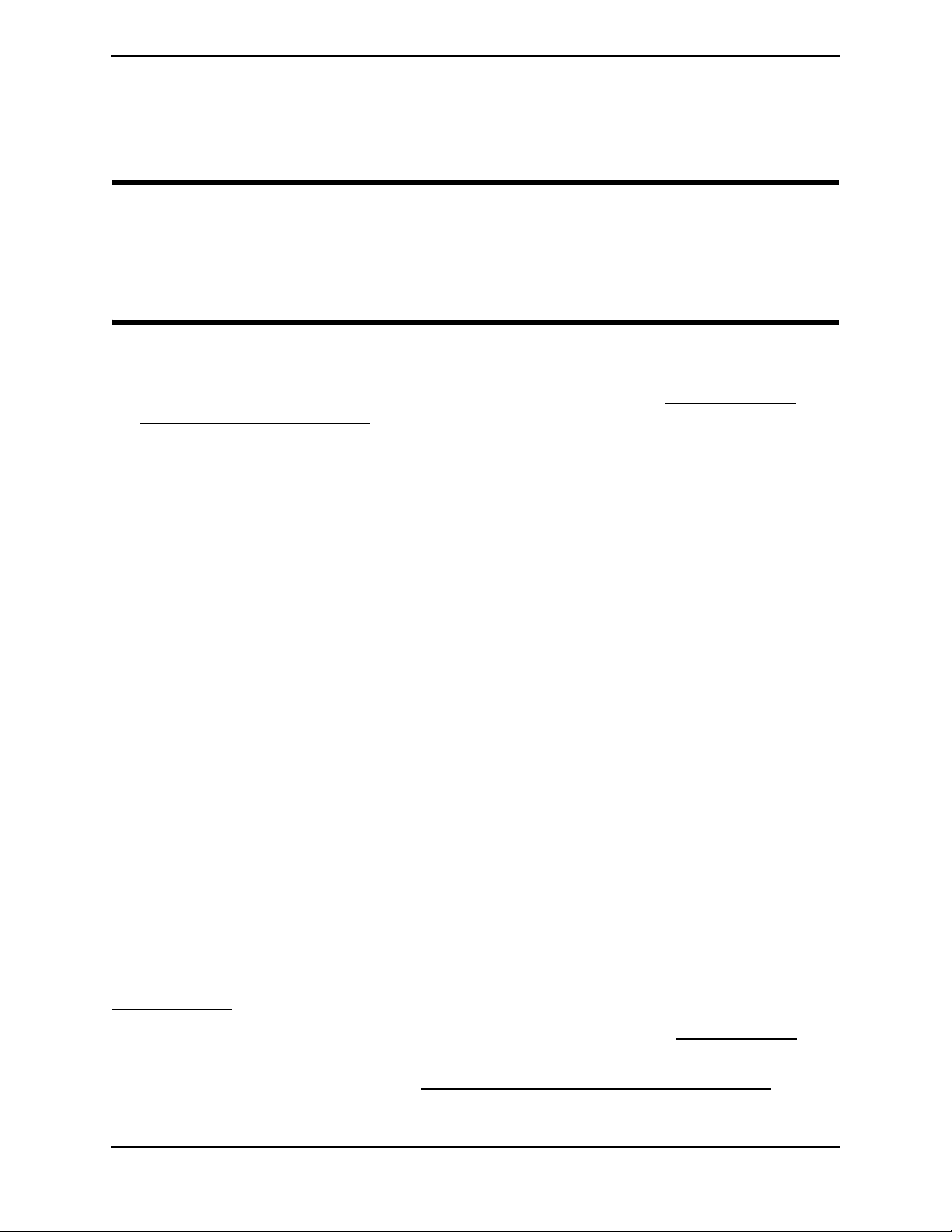

Cylinder/Regulator

Assembly

Compressor

Cylinder

Gauge

Cylinder

Fillport

Connector

Fillport

PULL UP

Cylinder

Compressor

Cradle

Cylinder

Gauge

Regulator

Flow Dial

Cylinder Fillport

Outer Ring

(Sleeve)

Connector

Fillport

NOTE: Fillport covers not shown for clarity.

Outlet (Cannula)

Connection

Power

Switch

Regulator

Outer Ring

(Sleeve)

DETAIL “A”

DETAIL “B”

6. Grasp the cylinder/regulator assembly in the area behind the cylinder gauge in

FIGURE 4.2 on page 21.

7. Position the cylinder in the compressor cradle (Detail “A” of FIGURE 4.2).

8. Align the cylinder fillport with the connector fillport (Detail “B” of FIGURE 4.2).

9. Pull up on the outer ring (sleeve) of the connector fillport while pushing down on the

cylinder/regulator assembly to couple the cylinder fillport into the connector fillport

(Detail “A” of FIGURE 4.2).

NOTE: The cylinder is properly connected when an audible “click” is heard.

FIGURE 4.2 Connecting the Cylinder to the Compressor

Part No 1154316 21 HomeFill® II AW Compressor

SECTION 4—COMPRESSOR OPERATION

Cylinder/Regulator

Assembly

Compressor

Cradle

Cylinder Gauge

Cylinder

Fillport

Connector Fillport

Outer Ring

(Sleeve)

PUSH DOWN

Power Switch

Disconnecting Cylinder From Compressor

WARNING

DO NOT modify any connections on the HomeFill compressor. NEVER use tools of

any kind to connect/disconnect the cylinder and the compressor. Otherwise, severe

injury and/or damage may occur.

NOTE: For this procedure, refer to FIGURE 4.3 on page 22.

1. Press the compressor power switch to the Off (O) position.

2. Grasp the cylinder/regulator assembly in the area behind the cylinder gauge.

3. With the other hand, grasp the outer ring (sleeve) of the connector fillport and push

down.

4. Lift up on the cylinder/regulator assembly to remove from the connector fillport.

5. When the cylinder fillport is disconnected from the connector fillport, release the

outer ring (sleeve) of the connector fillport and use two hands to remove the cylinder

from the compressor cradle.

WARNING

- The fillport cover on the connector fillport and the cylinder fillport MUST be

replaced after filling and whenever not in use. If either of the fillport covers are

missing replace these parts before using or returning to the user.

6. Place the fillport covers onto the connector and cylinder fillports.

NOTE: The fillport covers should be used whenever cylinders are not being filled.

FIGURE 4.3 Disconnecting Cylinder From Compressor

HomeFill® II AW Compressor 22 Part No 1154316

SECTION 4—COMPRESSOR OPERATION

Turning the Compressor On and Off

NOTE: For this procedure, refer to FIGURE 4.4 on page 24.

1. Make sure the concentrator is On and runs a minimum of 30 minutes.

CAUTION

The concentrator flow rate to the patient MUST be set at maximum: 2.5 L/min. or

less for Platinum 5, Platinum S, Perfecto2 and 5 L/min. for Platinum 9. Otherwise,

the oxygen level to the compressor will be <90% and the compressor will not fill the

cylinder.

2. Set the concentrator flow rate to the patient to 2.5 L/min. or less for Platinum 5,

Platinum S, Perfecto2 and 5 L/min. for Platinum 9.

3. Make sure the cylinder is connected to the compressor. Refer to Connecting the

Cylinder to the Compressor on page 20.

4. Push the power switch on the control panel to the On position.

5. Perform one of the following:

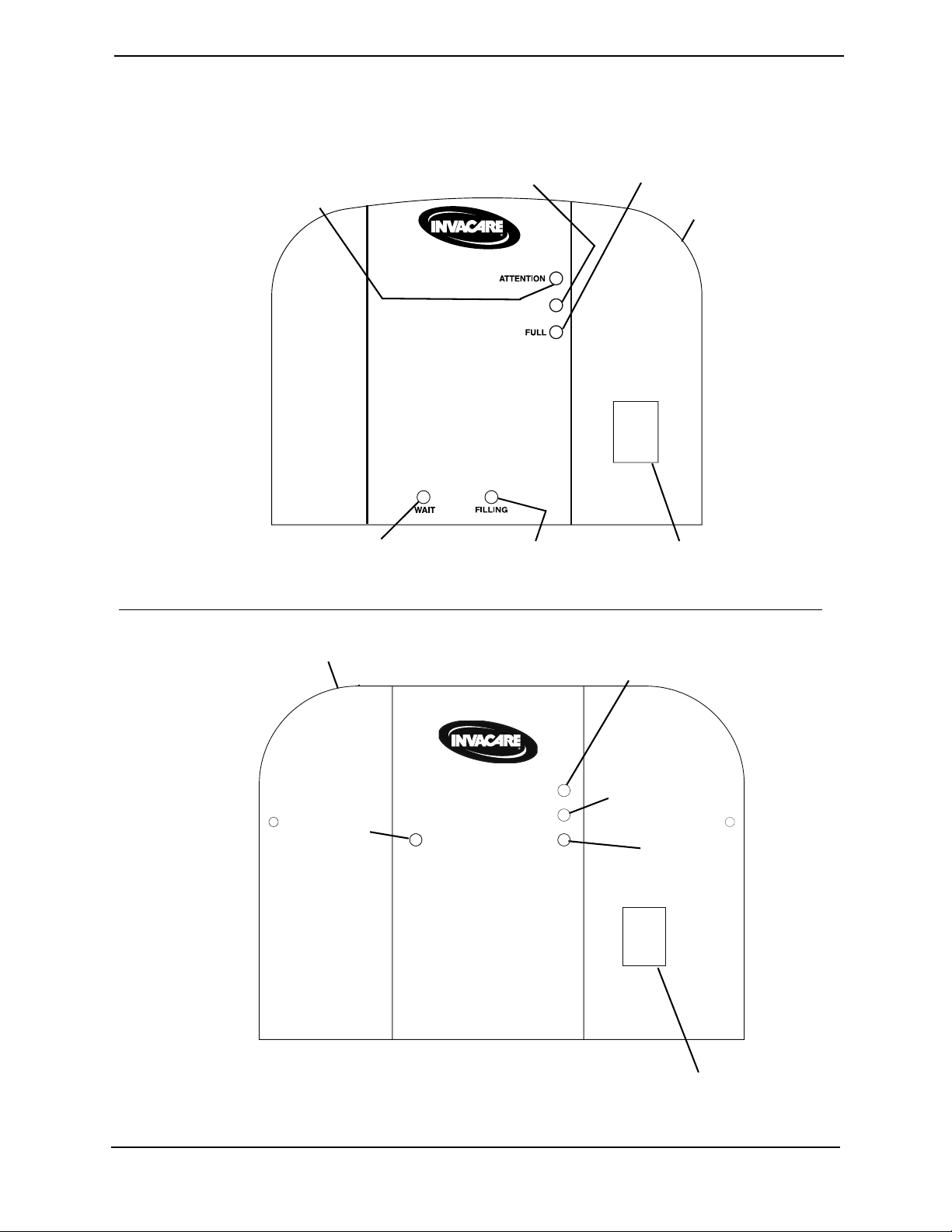

A. For HomeFill units manufactured before 02/02/06 - Examine the control panel. The

following sequence of events should occur:

• 0-3 minutes - The WAIT (YELLOW) light will be lit while the compressor

warms up.

•After three minutes - The FILLING (GREEN) light will be on while the cylinder

is filling.

•The FULL (GREEN) light will be on when the cylinder is finished filling. Proceed

to STEP 6.

B. For HomeFill units manufactured after 02/02/06 - Examine the control panel. The

following sequence of events should occur:

• 0-3 minutes - The O

Below Normal (YELLOW) light will be lit while the

2

compressor warms up.

• After three minutes - The FILLING (GREEN) light will be on while the cylinder

is filling.

• The FULL (GREEN) light will be on when the cylinder is finished filling.

Proceed to STEP 6.

NOTE: The O

BELOW NORMAL (YELLOW) light may come on if the oxygen level from the

2

concentrator has not yet reached or drops below 90%. The compressor will begin or resume filling

when the oxygen level reaches 90%. If light does not go Off within 10 minutes, refer to

Troubleshooting on page 85.

NOTE: If the ATTENTION (RED) light and audible alarm are on, refer to Troubleshooting

on

page 85.

6. Remove the full cylinder. Refer to Disconnecting Cylinder From Compressor on

page 22.

Part No 1154316 23 HomeFill® II AW Compressor

SECTION 4—COMPRESSOR OPERATION

USE NO OIL

I

O

O2 BELOW NORMAL

ATTENTION

(RED Light and

Audible Alarm)

O

2

BELOW

NORMAL

(YELLOW Light)

FULL

(GREEN Light)

Control

Panel

WAIT

(YELLOW Light)

FILLING

(GREEN Light)

Power Switch

For HomeFill units manufactured before 02/02/06

I

O

Attention (RED light and

Audible Alarm)

O

2

below normal

(YELLOW light)

Full

(GREEN Light)

Control Panel

Power Switch

Filling

(GREEN

Light)

ATTENTION

O2 BELOW NORMAL

FULL

FILLING

For HomeFill units manufactured after 02/02/06

FIGURE 4.4 Turning the Compressor On and Off

HomeFill® II AW Compressor 24 Part No 1154316

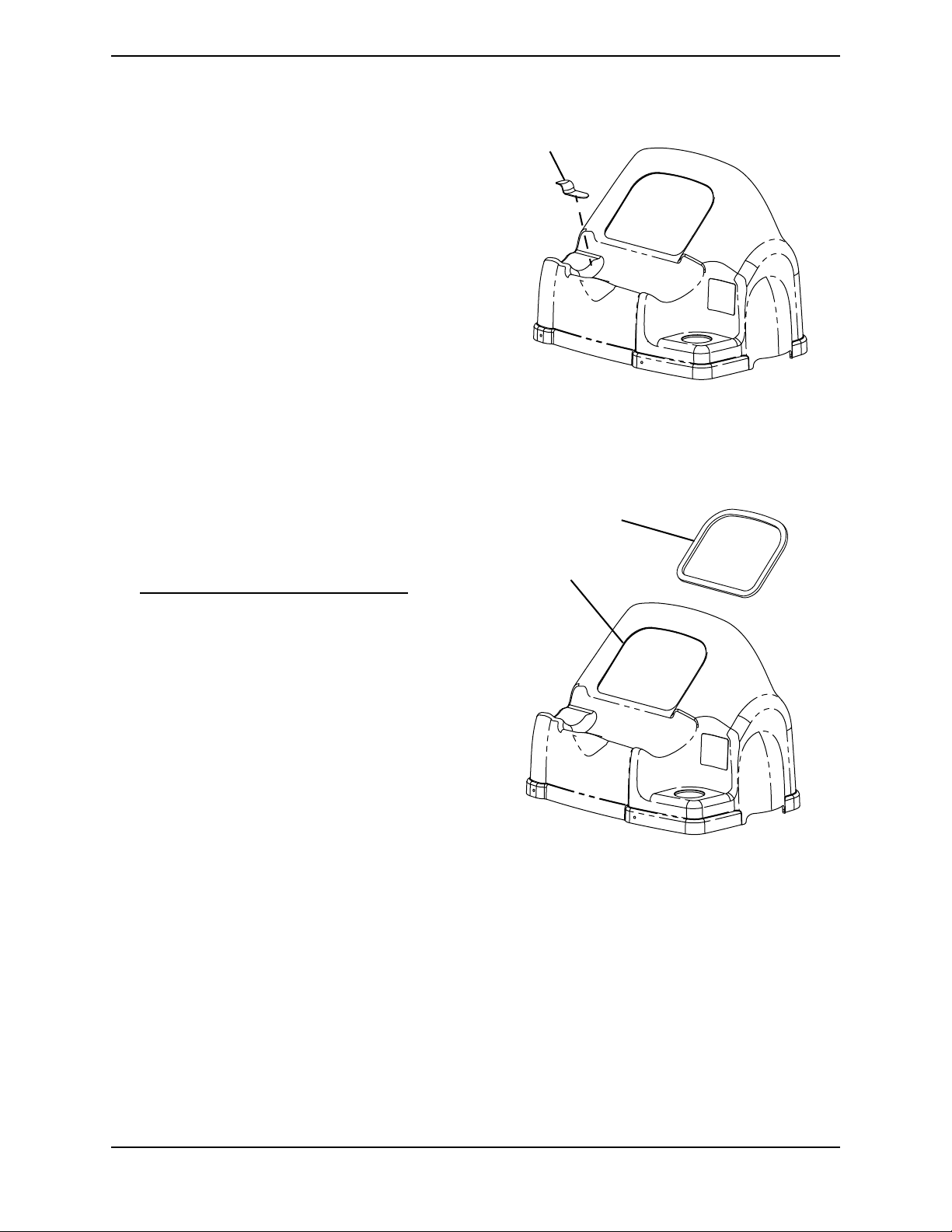

SECTION 5—CABINET ASSEMBLY

Mounting Screws

Cabinet

REAR VIEW

Mounting Screws

Base Assembly

Cabinet

SECTION 5—CABINET ASSEMBLY

Removing/Installing the Cabinet

DANGER

To prevent electrical shock, ALWAYS disconnect HomeFill from electrical outlet

before servicing.

NOTE: For this procedure, refer to FIGURE 5.1.

Tools required for this procedure are:

• Phillips screwdriver

Removing

1. Unplug the power cord from the electrical outlet.

2. Remove cylinder (if attached). Refer to Disconnecting Cylinder From Compressor on

page 22.

3. Remove the four mounting screws that secure the cabinet assembly to the base

assembly.

4. Lift the cabinet straight up off of the base assembly.

Installing

1. Position the cabinet on the base assembly as shown.

2. Secure the cabinet to the base assembly with four mounting screws. Securely tighten.

3. Reattach cylinder. Refer to Connecting the Cylinder to the Compressor on page 20.

4. Plug power cord into electrical outlet.

FIGURE 5.1 Removing/Installing the Cabinet

Part No 1154316 25 HomeFill® II AW Compressor

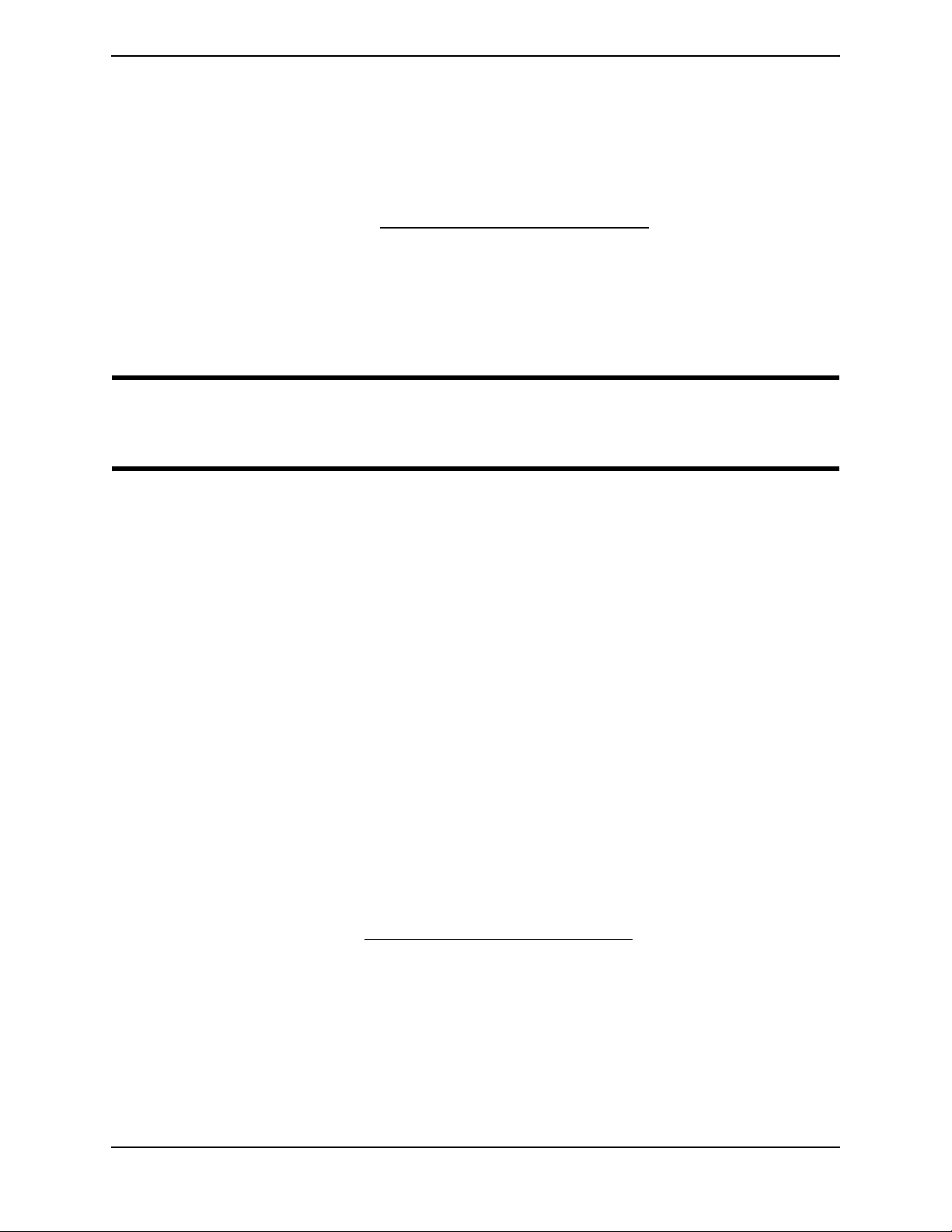

SECTION 5—CABINET ASSEMBLY

DETAIL “A”

DETAIL “B”

Cabinet Filter

Grid

DETAIL “C”

NOTE: Lip of the filter grid MUST

be on the outside of the cabinet to

secure the filter grid in place.

Lip

Lip

Plastic Rivets

Filter Grid

Removing/Installing the Cabinet Filter Grid

NOTE: For this procedure, refer to FIGURE 5.2.

Tools required: Flat head screwdriver and .09 mm drill bit

Removing

1. Remove the cabinet. Refer to Removing/Installing the Cabinet on page 25.

2. Perform one of the following:

• For units that have plastic rivets, remove the plastic rivets by pushing the rivets

from the inside out with a .09 mm drill bit, proceed to STEP 3.

• For units without plastic rivets, proceed to STEP 3.

3. Using the flat head screwdriver, pry the lip of the cabinet filter grid out of the cabinet

(Detail “C”).

Installing

NOTE: For units that have plastic rivets, the cabinet MUST be replaced to use the new filter grid.

1. Install the cabinet filter grid (Detail “B”) to the inside of the cabinet. Ensure that the

lip of the cabinet filter grid is on the outside of the cabinet.

2. Install the cabinet. Refer to Removing/Installing the Cabinet on page 25.

FIGURE 5.2 Removing/Installing the Cabinet Filter Grid

HomeFill® II AW Compressor 26 Part No 1154316

SECTION 5—CABINET ASSEMBLY

Pad

Control Panel

Opening

Foam Gasket

Replacing Non-Skid Adhesive Back Pad

NOTE: For this procedure, refer to

FIGURE 5.3.

1. Peel the existing pad from the cabinet

and discard.

2. Peel the backing from the new pad.

3. Attach the new pad to the cabinet.

FIGURE 5.3 Replacing Non-Skid Adhesive

Replacing Foam Gasket

Back Pad

NOTE: For this procedure, refer to

FIGURE 5.4.

1. Remove the cabinet. Refer to

Removing/Installing the Cabinet on

page 25.

2. Peel the existing foam gasket from the

inside of the control panel opening and

discard.

3. Peel the backing from the new foam

gasket.

4. Attach the new foam gasket to the

inside of control panel opening.

FIGURE 5.4 Replacing Foam Gasket

Part No 1154316 27 HomeFill® II AW Compressor

SECTION 6—PANEL ASSEMBLY

Mounting Screw

Fan Inlet Seal

DETAIL “A”

DETAIL “B”

Mounting

Screws

Isolator Plate

Fan Mounting

Bracket

Mounting

Screws

Isolator Plate

Wire

Connectors

(Not shown)

Exhaust Fan

Airflow

Arrow points

to back of

unit

SECTION 6—PANEL ASSEMBLY

Replacing Exhaust Fan

NOTE: For this procedure, refer to FIGURE 6.1.

Tools required for this procedure are:

• Phillips screwdriver

• Torque Wrench

1. Remove the cabinet. Refer to Removing/Installing the Cabinet on page 25.

2. Note the wire orientation of the two wires located on the exhaust fan.

3. Disconnect the two wires from exhaust fan wire connectors.

4. Remove the four mounting screws securing the fan inlet seal to the exhaust fan (Detail

“B”).

5. Set the fan inlet seal aside for re-use.

6. Remove the four mounting screws securing the exhaust fan to the isolator plate.

NOTE: Before securing exhaust fan in place, ensure airflow arrow (molded into the side of the fan)

points toward the back and out of the unit.

7. Secure the exhaust fan to the isolator plate with four mounting screws. The mounting

screws MUST be torqued to 20–30 in-lbs (2.26-3.39 Nm).

8. Secure the fan inlet seal to the exhaust fan with four mounting screws. The mounting

screws MUST be torqued to 20–30 in-lbs (2.26-3.39 Nm).

9. Connect the two wires to the exhaust fan in the orientation previously noted.

10. Install cabinet. Refer to Removing/Installing the Cabinet

on page 25.

FIGURE 6.1 Replacing Exhaust Fan

HomeFill® II AW Compressor 28 Part No 1154316

Removing/Installing Control Panel

NOTE: For this procedure, refer to FIGURE 6.2.

Tools required for this procedure are:

• Phillips screwdriver

SECTION 6—PANEL ASSEMBLY

1. Remove the cabinet. Refer to Removing/Installing the Cabinet

2. Remove the two mounting screws securing the top of the control panel (Detail “A”).

3. Loosen the two mounting screws securing the bottom of the control panel (Detail “A”).

4. Slowly pull the control panel back to expose the circuit board and its connections.

5. Disconnect the three wiring harnesses from the three connectors on the circuit board

(Detail “B”).

on page 25.

CAUTION

DO NOT disconnect the opaque oxygen sensor tube from the sensor as this may

damage the circuit board.

6. Disconnect the opaque oxygen sensor tube from the barbed fitting opposite the sensor

(Detail “B”).

7. Note the location of the two wire connectors of the power switch for later replacement.

8. Disconnect the two wire connectors from the power switch (Detail “B”).

9. Disconnect bleed resistor from the control panel (Detail “C”).

10. Remove the control panel.

Installing

1. Connect bleed resistor to the control panel (Detail “C”).

2. Connect the two wire connectors to the power switch (Detail “B”) in the orientation

noted previously.

3. Connect the opaque oxygen sensor tube to the barbed fitting on the opposite end of

the sensor (Detail “B”).

4. Connect the three wiring harnesses to the three connectors on the circuit board (Detail

“B”).

5. Secure the bottom of the control panel with two mounting screws. Securely tighten.

6. Secure the top of the control panel with two mounting screws. Securely tighten.

7. Install the cabinet. Refer to Removing/Installing the Cabinet on page 25.

Part No 1154316 29 HomeFill® II AW Compressor

Mounting

Screws

Mounting

Screws

Control Panel

Base Assembly

Opaque Oxygen

Sensor Tube

Sensor

Wiring Harness

Connection

Wiring Harness

Connection

Wiring Harness

Connection

Circuit

Board

Wire Connectors

Power Switch

Bleed Resistor

Assembly 2

Control Panel

DETAIL “A”

CAUTION

DO NOT disconnect

the opaque oxygen

sensor tube from the

sensor.

Partial View of

Circuit Board

SECTION 6—PANEL ASSEMBLY

FIGURE 6.2 Removing/Installing Control Panel

HomeFill® II AW Compressor 30 Part No 1154316

Loading...

Loading...