Invacare G40 Service Manual

SERVICE-MMANUAL

The manual contains:

Information on troubleshooting

Information on testing parts

Repair instructions

Edition: 12.2001

Invacare

®

G40 with ACS-System

General information

This service manual contains all information necessary for maintenance and servicing of the “G40” wheelchair.

• Maintenance and servicing work is to be carried out in accordance with this service manual.

• Comply with all safety instructions

• Information on operation, general maintenance and servicing can be found in the operating manual of “G40”.

• Refer to the replacement parts catalog for information on ordering replacement parts.

• Maintenance and repair work on the “G40” may onla be performed by qualified personnel.

-Maintenance technicians should at least be trained in a relevant field, e.g. as a two-wheeled vehicle or

orthopaedics technician, or have an equivalent amount of professional experience.

-Personnel should also be familiar with electrical measurement equipment (multimeters).

• Should you encounter difficulties or have any questions, please contact INVACARE-SERVICE:

Switchboard: Tel. +049 (0)5731-754-0

Fax. +049 (0)5731-754-111

Service: Tel. +049 (0)5731-7545-(70-80)

Fax. +049 (0)5731-7542-(08-16)

Adress: Invacare Deutschland GmbH

Dehmer Str. 66

D-32549 Bad Oeynhausen

PO Box: Invacare Deutschland GmbH

Postfach 60 01 06

D-32 527 Bad Oeynhausen

• INVACARE can not be held liable for changes to the “G40” resulting from maintenance and servicing work

carried out incorrectly or not according to the relevant instructions.

Information concerning transportation

• If the wheelchair has to be sent away to the manufacturer for more serious repairs, always use the original

packaging for transportation.

• Please include a detailed account of the fault.

• We reserve the right to make changes in the interests of technical progress.

2

NOTE:

This symbol indicates general information concerning special features and helpful advice for installation.

ACAUTION:

Please pay special attention to this symbol. It indicates

>Safety instructions<.

You will notice the following symbols in this repair manual:

3

Contents

1.0 Safety and installation instructions . . . . . .4

2.0 List of tools . . . . . . . . . . . . . . . . . . . . . . . .5

3.0 Inspection plan . . . . . . . . . . . . . . . . . . . . .6

4.0 Operation troubles . . . . . . . . . . . . . . . . . . .8

4.1 General instructions . . . . . . . . . . . . . . . . . .8

4.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . .8

5.0 Error messages at remote . . . . . . . . . . . . .10

5.1 Error codes of remote . . . . . . . . . . . . . . .10

6.0 Arrangement of assembly groups, components

and operation elements . . . . . . . . . . . . . .12

7.0 Checks and repair work at seatsystem

14

7.1 Armrests and sides . . . . . . . . . . . . . . . . .14

7.2 Legrests . . . . . . . . . . . . . . . . . . . . . . . . .15

7.3 Backrest with frame, upholstery and hand

grip . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

7.4 Backrest adjusting . . . . . . . . . . . . . . . . . .18

7.5 Seatframe, seat shell and padding . . . . .19

8.0 Checks and repair work at chassis . . . . . .20

8.1 Chassis covering, grips and cover coating20

8.2 Wheels and tyres . . . . . . . . . . . . . . . . . . .21

8.3 Back-wheel suspension . . . . . . . . . . . . . .22

8.4 Front.wheel suspension . . . . . . . . . . . . . .23

8.5 Handbrake . . . . . . . . . . . . . . . . . . . . . . . .24

9.0 Checks and repair work at motor, gears,

servo and steering . . . . . . . . . . . . . . . . . .26

9.1 Driving motor and gears . . . . . . . . . . . . .26

9.2 Power-assisted steering unit . . . . . . . . . .28

10.0 Checks and repair work at

power supply

10.1 Batteries, battery box and check of . . . . . .

battery voltage . . . . . . . . . . . . . . . . . . . . .29

10.2 Battery charging . . . . . . . . . . . . . . . . . . .30

10.3 Battery charger unit . . . . . . . . . . . . . . . . .31

11.0 Checks and repair work at

lighting system . . . . . . . . . . . . . . . . . . . . .32

11.1 Front lighting system . . . . . . . . . . . . . . .32

11.2 Back lighting system . . . . . . . . . . . . . . . .33

12.0 Checks and repair work at

electronics . . . . . . . . . . . . . . . . . . . . . . . .34

12.1 Main module . . . . . . . . . . . . . . . . . . . . . .34

12.2 Remote . . . . . . . . . . . . . . . . . . . . . . . . . .35

12.3 Light servo module . . . . . . . . . . . . . . . . .36

12.4 Speedometer . . . . . . . . . . . . . . . . . . . . .37

13.0 Continuity check of cables . . . . . . . . . . . .38

14.0 Programming of wheelchair . . . . . . . . . . .39

15.0 Storing of wheelchair . . . . . . . . . . . . . . . .39

4

1.0 Safety and installation instructions

The safety instructions are provided in the interests of working safety and must under all circumstances be

complied with.

Prior to all inspection and repair work:

• Read this service manual and the appertaining user manual.

• Ensure that minimum qualifications for performing relevant work are fulfilled (see chapter entitled “General

information”).

Caution:

• Note that some components are heavy. You should take this into account above all when removing

the batteries.

• The power supply for the wheelchair must be switched off before any conductive parts are removed.

Remove the batteries.

• When performing tests on conductive parts, ensure that the contacts are not short-circuited.

> Danger of fire and injury from burns <

• Only use tools which are in perfect working order and are not damaged.

During work and assembly:

• Mark the current settings of the wheelchair (seat, armrests, back etc.) and the combination of cable connections before carrying out disassembly work. This will make assembly an easier task afterwards.

ACHTUNG:

• Support the raised wheelchair with suitable supports before you begin assembly. Use the bottom tube

. frames of the chassis. Also see the illustration G40, bottom view, chapter 6.0.

• You should under no circumstances use “normal” nuts instead of self-locking nuts.

• Always use correctly-sized washers or separators.

Note:

• All plug connectors are fitted with mechanical clamps which prevent slipping when the wheelchair is in

operation.

• These clamps must be pressed in to release the connectors.

• When carrying out assembly work, ensure that the clamps are fitted properly.

• For checks and repair works you can fold up the seat system and arrest. This position is called

service position.

Prior to initial use / after repair work:

Caution:

• Check firm mounting of all fastening screws.

• Check that all parts are properly locked in place.

• Check regulation tyre pressure (2.5 bar) before starting the machine.

• Always perform a test-drive after repair work.

5

2.0 List of tools

A standard toolkit comprising the following minimum inventory is required:

Combination ring and open-end spanner SW 6, 7, 8, 10, 11, 12, 13, 17, 19

Allan key 2,5 mm, 3mm, 4mm, 5 mm, 6 mm, 8mm, 10mm

Torque wrench (commercially available)

Socket spanner set

Screwdrivers for slotted screws various

Crosstip screwdriver No.1, No.2

Side-cutting pliers

Flat pliers

Round pliers

Cable lug pliers

Wooden or plastic hammer

Tyre repair set (commercially available)

Air pressure gauge

Valve extraction tools

Special tool for removing wheel bearing

Multimeter with test points and various cable clips

Bridging cable

Soldering iron 30W

Assembly pliers for Starlock caps (commercially available)

Removing tools for font wheel hub (available by INVACARE-Service)

You will require the following for setting at the ACS control:

Programming unit Item no.

Software package, incl. interface cable and dongle Item no.

6

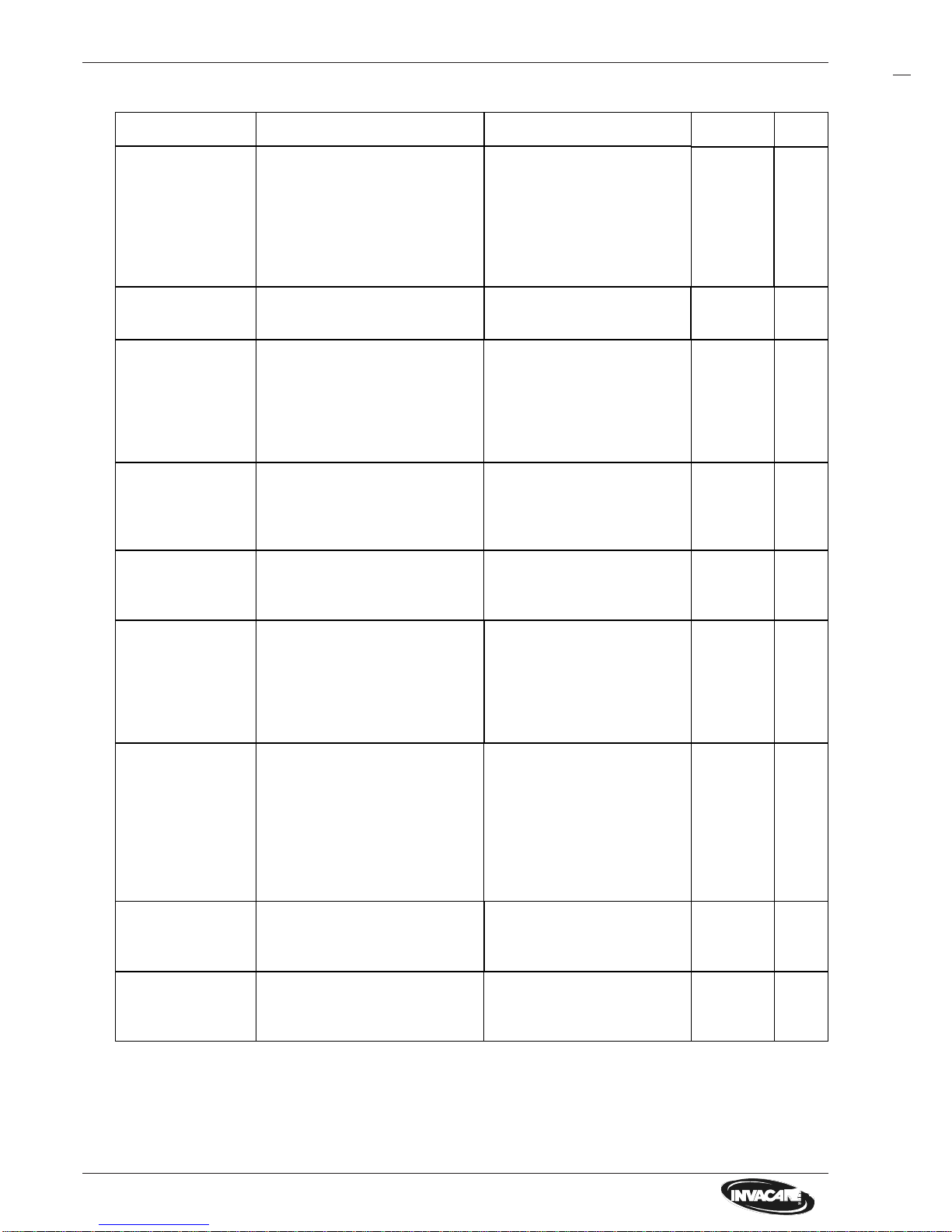

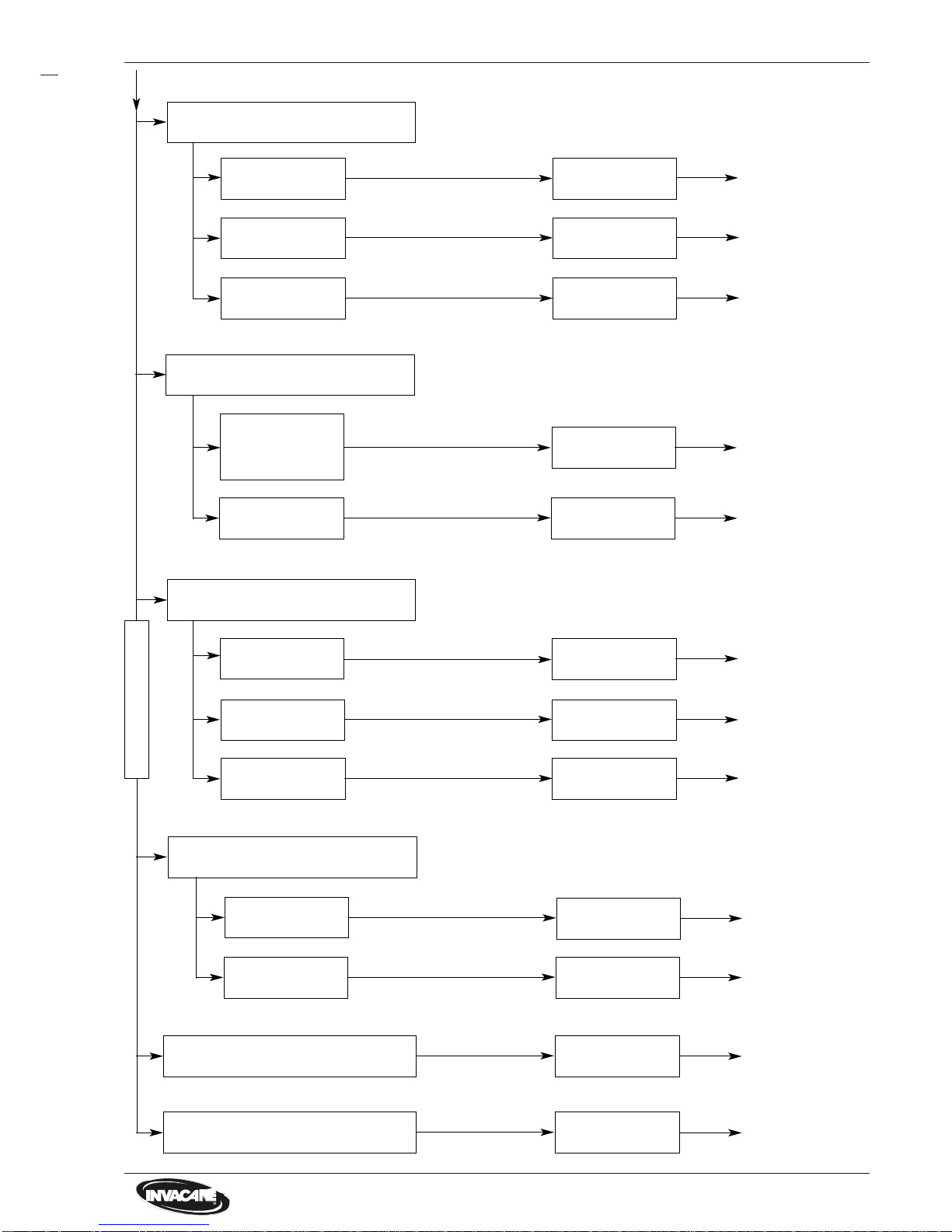

3.0 Inspecton plan

Component

Armrests and sides

Action

> Tighten screws. Repla-

ce overlay.

> Tighten screws. Repla-

ce sides.

> Replace.

Check

• Damage to and attachment

of armrests

• Damage to and attachment of side panels

• Mirrors

Seat > Tighten screws. Repla-

ce parts.

• Damage and screw

fastenings, stitching

Backrest with safety

belt

> Adjust or replacebow-

den wire, gas spring.

> Tighten screws. Repla-

ce parts.

> Replace.

• Adjustment function

• Damage and screw

fastenings, stitching

• Belt and belt buckle

Latching mechanism

of seat in service

position

> Make moving

> Tighten screws.

Replace parts.

• Damage and secure latching into place

Legrests > Tighten, replace.

> Tighten, replace.

• Welded joint, lock, screw

attachment

• Footboard

Chassis with frame,

side grips and cover-

ing

> Tighten, replace.• Screw attachments, wel-

ded joints, damages

!

Wheel suspension and

wheels

> Replace.

> Replace.

> Adjust, replace.

> Fit on new ones.

• Function and damage of

shock absorbers

• Wheel suspension

• Wheel bearing

• Tyre equipment

Hand brake > Adjust, replace.

> Tighten, adjust,

replace.

> Replace.

• Function

• Loose bowden wires, sleeves damaged

• Wear, damage of brake

discs and brake calipers

Drive and steering

asssembly

> Adjust, replace.

> Adjust, replace.

• Check function in driving

and freewheel operation

• Check toggle link

Chapter

7.1

7.5

7.3

7.5

8.1

8.2

bis

8.4

8.5

9.0

7.2

7

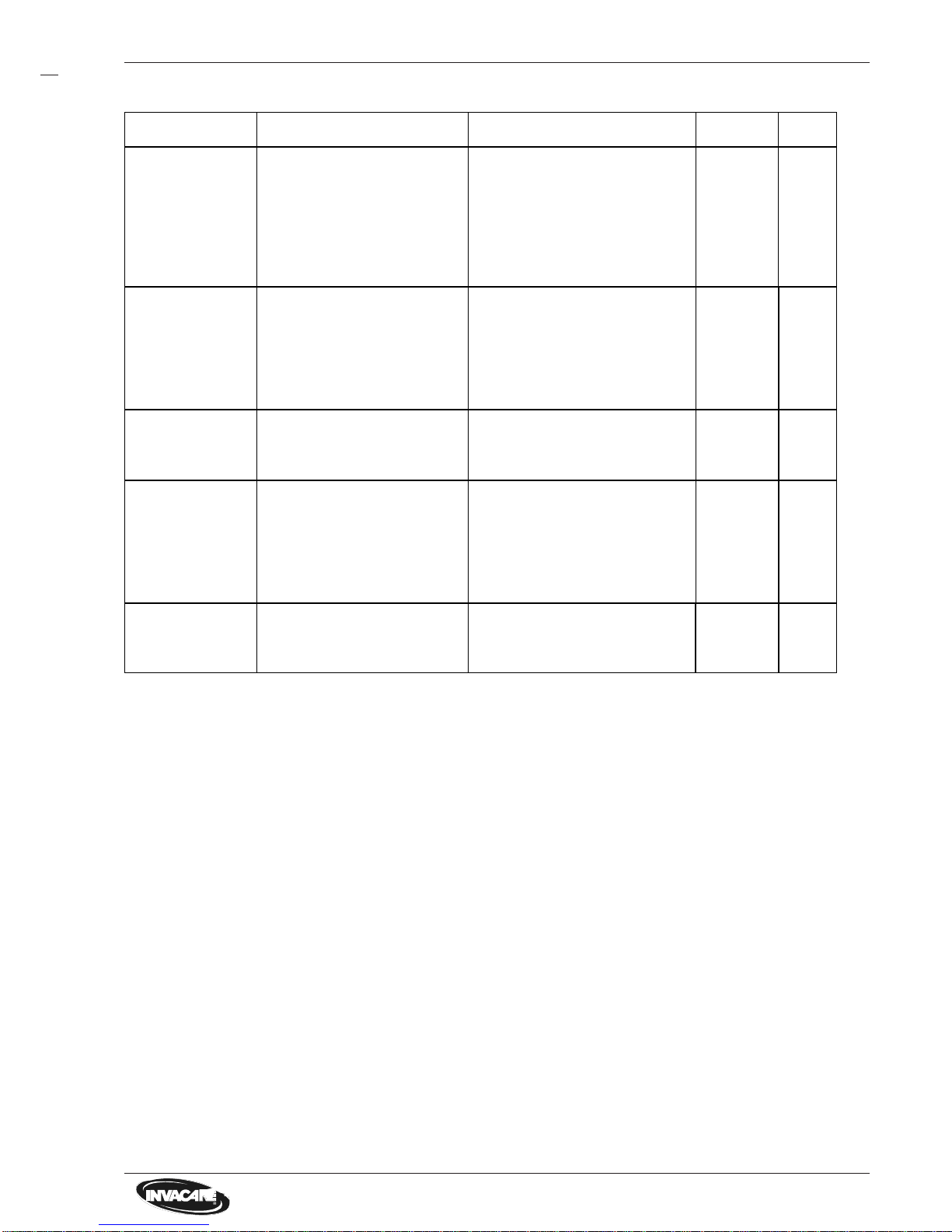

Component

Batteries

Action

> Clean contacts, replace

battery or box

> Tighten, replace.

> Charge battery, replace.

Check

• Damage of battery and

box, corrosion on

contacts

• Check of contacts and

pole clips

• Check battery voltage

!

Light-servo module

and lighting system

> Replace cable, connector

or module.

> Replace lights.

> Replace light bulbs.

• Function servo- and light

module

• Damage of lights

• Function of light bulbs

Speedometer > Replace batteries, cable,

connector, speedometer or

sensor.

• Check function

Drive electronic and

main module

> Replace module.

> Replace cable, connector

or module.

• Status display flashes

• Voltage supply

Drive electronic

Remote

> Tighten, replace.

> Replace.

> Replace remote.

> Replace cable, connector

or panel.

• Attachment

• Cables, plug connections

• Function joystick

• Voltage supply

Chapter

10.1

bis

10.2

12.3

und

11.0

12.1

12.2

12.4

8

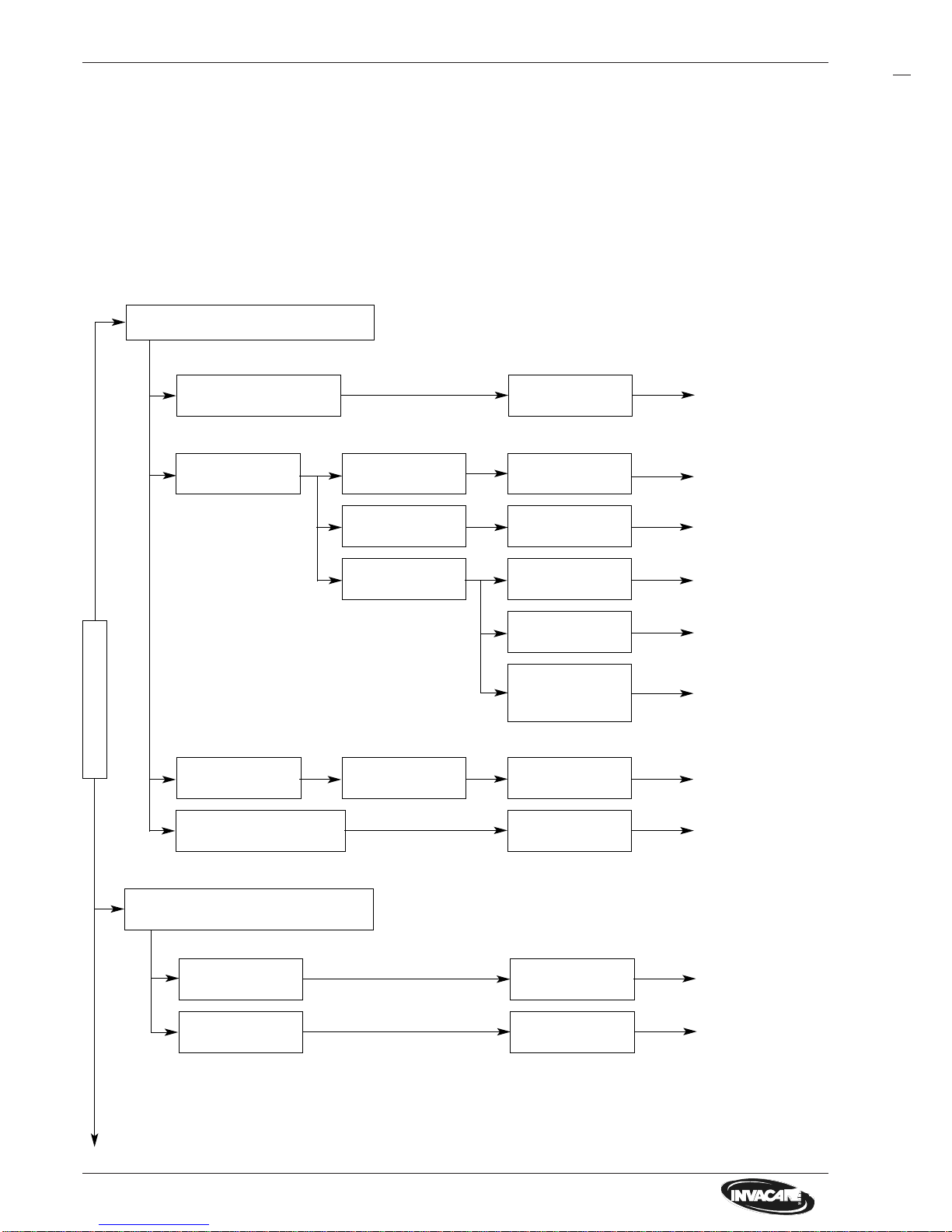

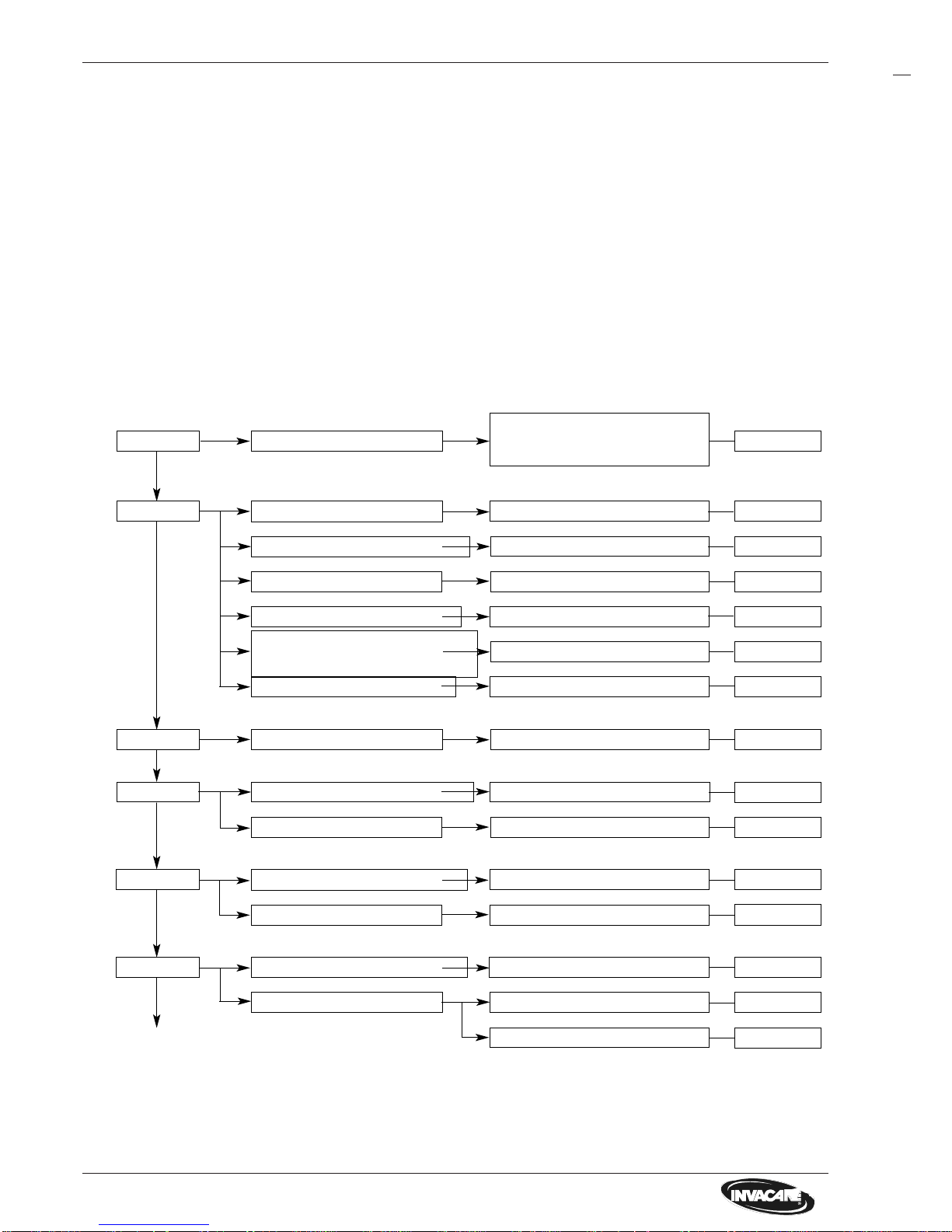

4.0 Operation troubles

4.1 General instructions

Do the following if there are any troubles in driving mode, at lighting system or power supply:

• Analyze the in 4.2 described troubleshooting.

• Check the status display at remote and analyze the error codes like in chapter 5.1.

• Do the required checks / repair work. Note the cross references in the appertaining chapters in the manual or

in the appertaining documentation.

Drive motor / steering

servo motor disengaged

Battery defective

Battery deep

discharged

Power supply

interrupted

Engage motors

Replace battery

Pre-charge battery

check overload

protector

check voltage at

remote

check voltage at

main module

Status display at

remote off

Status display at

remote flashes

Microswitch defective

(nur TÜV-Version 10 km/h)

Motor defective

Incorrect program-

ming

Check program-

ming

Replace motor

Check microswitch

Error code 1 - 12 Check error code

Wheelchair doesn´t drive

Störungen

Drive motor runs in a jerky manner

Chapter 6.0

Chapter 10.1

Chapter 10.2

not correct

Chapter 12.2

Chapter 12.1

Chapter 5

not correct

Chapter 9.1

Manual for pro-

gramming unit or

PCD-software

4.2 Troubleshooting

9

Remote defective Replace remote

Switch remote off

and on

Joystick not in

neutral position

when switch on

Status display flashes, after 4 sec. the

driving mode display also flashes

Chapter 12.2

Chapter 12.2

Motor defective

Incorrect program-

ming

Check program-

ming

Replace motor

Steering servo motor reacts slowly /

irregularly

Chapter 9.1

Manual for programming unit or

PCD-software

Light-/servo modu-

le defective

Replace light-

/servo module

Chapter 12.3

Cable / connector

defective

Check / replace

cable / connector

Replace light bulb

Light bulb defec-

tive

Lighting system defective

Chapterl 11.1/11.2

Chapter 11.1/11.2

Light-/servo modu-

le defective

Replace light-

/servo module

Chapter 12.3

Störungen

Charging unit

defective

Replace charging

unit

Replace battery

Battery defective

Charging batteries impossible

chapter 10.1

Chapter 10.3

Signal horn defective Replace remote

Chapter 12.2

Speedometer defective

Replace speedo-

meter

Chapter 12.4

10

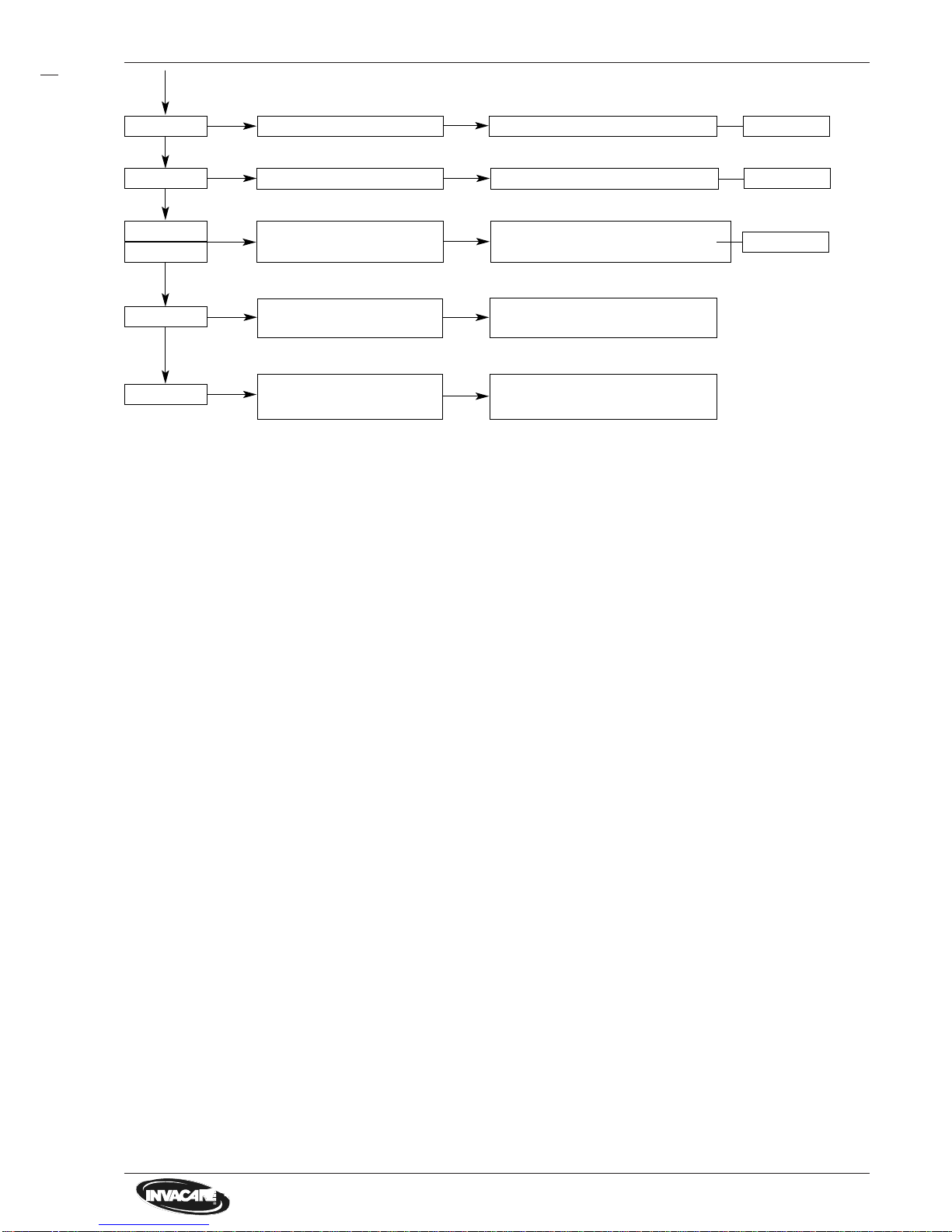

5.0 Error messages at remote

5.1 Error codes of remote

The following error codes refer to the G40 standard model with remote, main module and servo-/light module.

Do the follwing check before analyzing the error codes:

• Switch on and off the remote several times.

Wait five sec. before switching on again.

This check determines whether the error can automatically be corrected by the electronic system in which case

the flashing of status display is automatically deactivated.

If this is not the case, localize the error with the flash code.

2 x flashes

Flash codes on remote status display:

1 x flash Elektronic module defective

Steering servo disengaged

5 x flashes

Motor connection loose/defective

Drive motor defective Check/replace motor

Check/replace cable/connector

6 x flashes

Brake error at motor Check motor brake

Motor connection loose/defective Check/replace cable/connector

4 x flashes

Motor connection loose/defective Check/replace cable/connector

Drive motor defective Check/replace motor

3 x flashes

Drive motor disengaged*

Engage motor (Driving mode)

* Flash code can only be activated when you move the joystick in freewheel operation.

Check / replace status display of

modules

Cable/connector loose, defective

Servo-/light module defective

Back turn signal bulb defective **

Short circuit in Lighting system

Engage servo (Driving mode)

Check/replace connector/cable

Replace servo-/light module

Replace turn signal bulb

Check lighting system

Steering servo motor defective Check/replace servo motor

Check/replace motor

Chapter 12.0

Chapter 9.2

Chapter 13.0

Chapter 12.3

Chapter 9.2

Chapter 11.2

Chapter 11.0

Chapter 9.1

Chapter 19.0

Chapter 9.1

Chapter 13.0

Chapter 9.1

Chapter 9.1

Chapter 9.1

Chapter 9.1

** Flash code can only be activated when the turn signal is also switched on.

The flash codes can be generally deactivated by switching off and on at remote.

11

7 x flashes Battery deep discharged

9 x flashes

Incorrect data transfer bet-

ween the modules

10 x flashes

11 x flashes

Power-assisted steering- or

drive motor overloaded

Switch off and on the remote

12 x flashes

Compatibilityproblems bet-

ween the modules

8 x flashes Battery voltage too high

Chapter 10.2

Charge batteries

Chapter 10.3

Check charging unit

Check modules and Programming,

inform INVACARE-service

Chapter 14.0

Repair by INVACARE-service

necessary

12

6.0 Arrangement of assemblies, components and features

G40, front view

G40, side view

1 Leg rests complete, appertaining to seat

system

2 Chassiscovering

3 Seat shell, appertaining to seat system

4 Seat padding, appertaining to seat system

5 Back padding, appertaining to seat system

6 Mirror

7 Front lighting system, integrated in

seat shell

8 Front wheels, powered

9 Back wheel, steerable

10 Frame with back shell 11 and grip

grip 12

13 Sides complete with arm rests

14 Side grip

15 Covering

16 Remote with speedometer

17 Hand brake complete with brake

disc 18

19 Back rest adjusting, complete

20 Walking stick holder

21 Walking stick loop

The following illustrations show the arrangement of the main assemblies, components and features for righthanded people. The terms are the same as the component terms in the replacement parts catalog.

3

4

5

6

1

1

7

7

2

8

8

9

2

8

9

11

13

14

15

16

17

18

19

20

12

10

21

Loading...

Loading...