Invacare EC-Track Installation & Technical Description

Invacare® EC-Track®

Installation & Technical Description,

Installation og teknisk beskrivelse,

Installation et description technique,

Montering og teknisk beskrivelse,

Montering och teknisk beskrivning

enRailsystemforceilinghoistRobin®/Robin

Mover®

ServiceManual................................3

daSkinnesystemtilRobin®/RobinMover®

løftemotor

Servicemanual.................................29

frSystèmederailspourlève-personnesurrail

Robin®/RobinMover®

Manueldemaintenance........................55

SkinnesystemfortakmontertRobin®-/Robin

no

Mover®-løfter

Servicehåndbok................................83

svSkensystemförtaklyftenRobin®/RobinMover®

Servicemanual.................................109

PROVIDER:Keepthismanual.

TheproceduresinthismanualMUSTbeperformedbyaqualied

technician.

©2019InvacareCorporation

Allrightsreserved.Republication,duplicationormodicationinwholeorinpartisprohibitedwithoutpriorwritten

permissionfromInvacare.Trademarksareidentiedby™and®.AlltrademarksareownedbyorlicensedtoInvacare

Corporationoritssubsidiariesunlessotherwisenoted.

Contents

1General.........................................4

1.1Aboutthismanual..............................4

1.2GeneralSafety.................................4

1.3WarrantyInformation...........................4

2Railsystem......................................5

2.1Singlerailsystem..............................5

2.2Traversesystem................................6

2.3RoomTransfer.................................7

2.4Rails,Brackets&Accessories......................8

3Installation.......................................14

3.1GeneralInstallationInstructions....................14

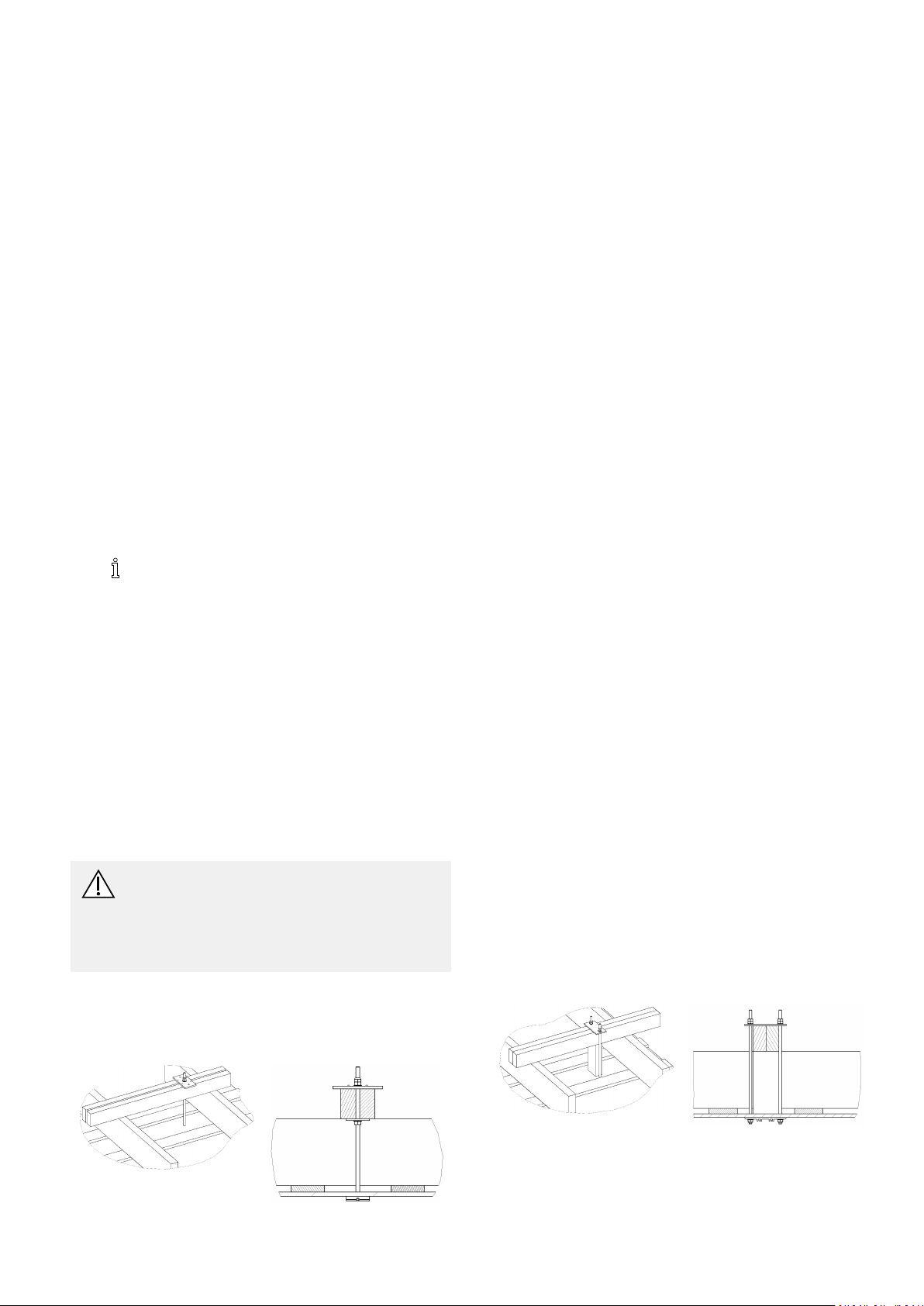

3.2CeilingMountingSystem.........................14

3.2.1ConcreteCeiling.............................14

3.2.2ConcreteCeilingwithSuspendedCeiling...........15

3.2.3WoodenCeiling.............................17

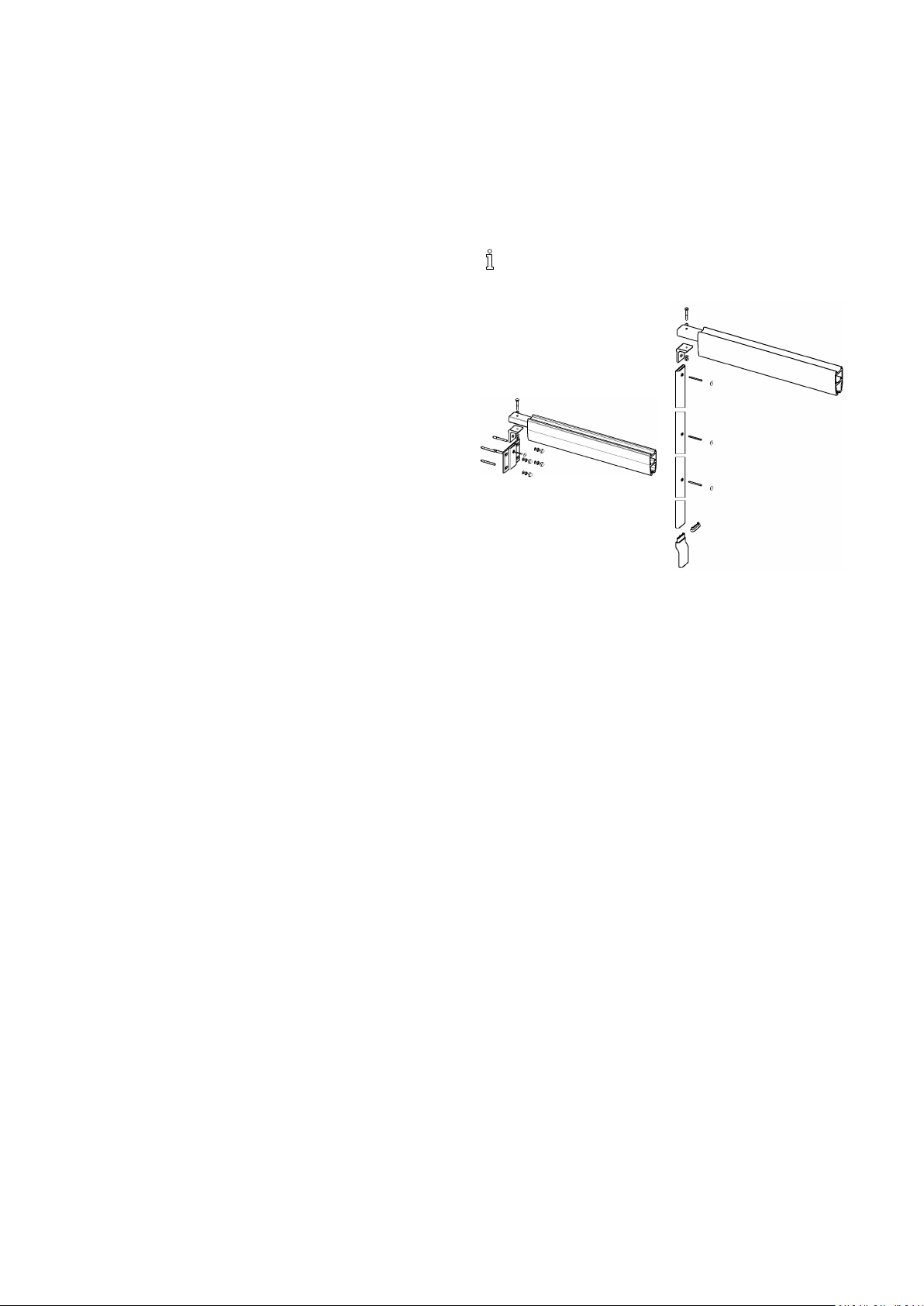

3.3Wallinstallation–endhungrail...................18

3.3.1RailproleMandL..........................18

3.4Wallinstallation–sidehungbracketorside/endhung

bracket.....................................19

3.5Curves......................................19

3.6Railcoupling..................................20

3.6.1RailcouplingforproleMandL................20

3.6.2RailcouplingforproleS......................20

3.7Wallsupportlegs..............................20

3.8Mountingtraversesystem........................21

3.9Installationoftrackswitches......................22

3.10Transitcoupling...............................22

3.10.1Adjustingtheholeinthewall/dooropening.......22

3.10.2Installingthetransitcoupling..................23

3.10.3Installingandconnectingcontrolbuttonand

3.10.4Installingatraversesystemwithlockxturefor

3.10.5Installationofasinglerailforacouplingsystem....24

3.10.6Mountingthepositioningxturesonparallelrail

3.11Installingtheceilinghoisttotherailsystem..........25

3.11.1InstallingRobin®............................25

3.11.2InstallingRobin®Mover......................26

3.12Inspection/checkoftherailsystem...............26

4T echnicalData....................................28

4.1Therailsystem................................28

4.2Dimensionsfordifferenttrackinstallations............28

powersupply..............................24

transitcoupling.............................24

S-proleandM/L-proles.....................24

Invacare®EC-Track®

1General

1.1Aboutthismanual

Thisinstallationmanualisintendedasaninstructionwhen

planningandcarryingouttheinstallation.Inorderto

ensuresafetywhenhandlingtheproduct,readthemanual

carefullyandfollowthesafetyinstructions.

Forpre-saleanduserinformation,pleaseseetheuser

manual.FindtheusermanualonInvacare’swebsiteor

contactyourInvacarerepresentative(seeaddressesatthe

endofthismanual).

Symbolsinthismanual

Inthismanual,hazardsareindicatedbysymbols.The

symbolsareaccompaniedbyasignalwordthatindicates

theseverityoftherisk.

WARNING

Indicatesahazardoussituationthatcould

resultinseriousinjuryordeathifitisnot

avoided.

CAUTION

Indicatesahazardoussituationthatcould

resultinminororslightinjuryifitisnot

avoided.

IMPORTANT

Indicatesahazardoussituationthatcould

resultindamagetopropertyifitisnot

avoided.

TipsandRecommendations

Givesusefultips,recommendationsand

informationforefcient,trouble-freeuse.

1.2GeneralSafety

WARNING!

Safetyrulesbeforeinstallation

–Allinstallationsmustcomplywiththenational

rulesandstandards.

–Useonlyapprovedinstallationcomponents.

–Ateverypointofsuspension,theroof/ceiling

structuremustbeabletowithstandastatic

loadofatleast300kg.

–Beforemountingarailsystem,theroof,

walls,andoormustbeexaminedcarefully.

Determinetheexactmaterialsinvolvedinthe

roofandwalls.Thisexaminationmustonly

becarriedoutbyasuitablyqualiedperson.

–Therailsystemmustbemountedonlyby

suitablyqualiedpersons.

StressT est

InaccordancewiththeEuropeanstandardEN10535,the

systemshallbestresstestedwith300kg.Thisshouldbe

doneateachxingpoint.Thistestistobecarriedout

asatestingofthesubstratum’sabilitytokeeptherail

systeminplace.Thistestshallbecarriedoutbyasuitably

qualiedperson.

1.3WarrantyInformation

Termsandconditionsofthewarrantyarepartofthe

generaltermsandconditionsparticulartotheindividual

countriesinwhichthisproductissold.

ContactinformationforyourlocalInvacareofceislocated

insidethebackcoverofthismanual.

Givesinformationabouttherequiredtools.

ThisproductfeaturestheCEmark,in

compliancewiththeMedicalDevice

Regulation2017/745Class1.Thelaunchdate

ofthisproductisstatedintheCEdeclaration

ofconformity.

4

1586749-C

Railsystem

2Railsystem

2.1Singlerailsystem

Asinglerailsystemissuitedinsituationswherethelifting

isdoneatspecicorlimitedplaces(e.g.underneaththe

track).

Asinglerailsystemconsistsofonestraightrail.Thisrail

maybemountedparalleltothewallsordiagonallyinthe

room.

Therailsystemcanbeoptionallyextendedwithcurves

withanglesof30°,45°,60°and90°.

Therailsystemcanbeinstalledonthewallortheceiling.

Withasinglerailsystemitispossibletohidethe

installationintheceilingsothatonlytheopeningofthe

railisvisible.

1586749-C5

Invacare®EC-Track®

2.2Traversesystem

Atraversesystemissuitedforcaseswhenanunlimitednumberofliftingplacesisrequiredintheroom.

Atraversesystemconsistsoftwoparallelrailsmountedontheceilingorthewall.Ineachparallelrail,atraversetrolleyis

insertedwitchcantravelthefulllengthoftheparallelrails,fromendstoptoendstop.

Acrosstheparallelrailsatraverserailismountedtothetwotraversetrolleys.Thisinstallationcanbecarriedoutin

differentways,asshownintheillustrationsbelow.Withahoisttrolleyinsertedinthetraverserail,thehoistcantravel

thefulllengthofthetraverserail.

Thesystempermitsanunlimitednumberofliftingplaces,sincethetraversesystemcoverstheentireroom.

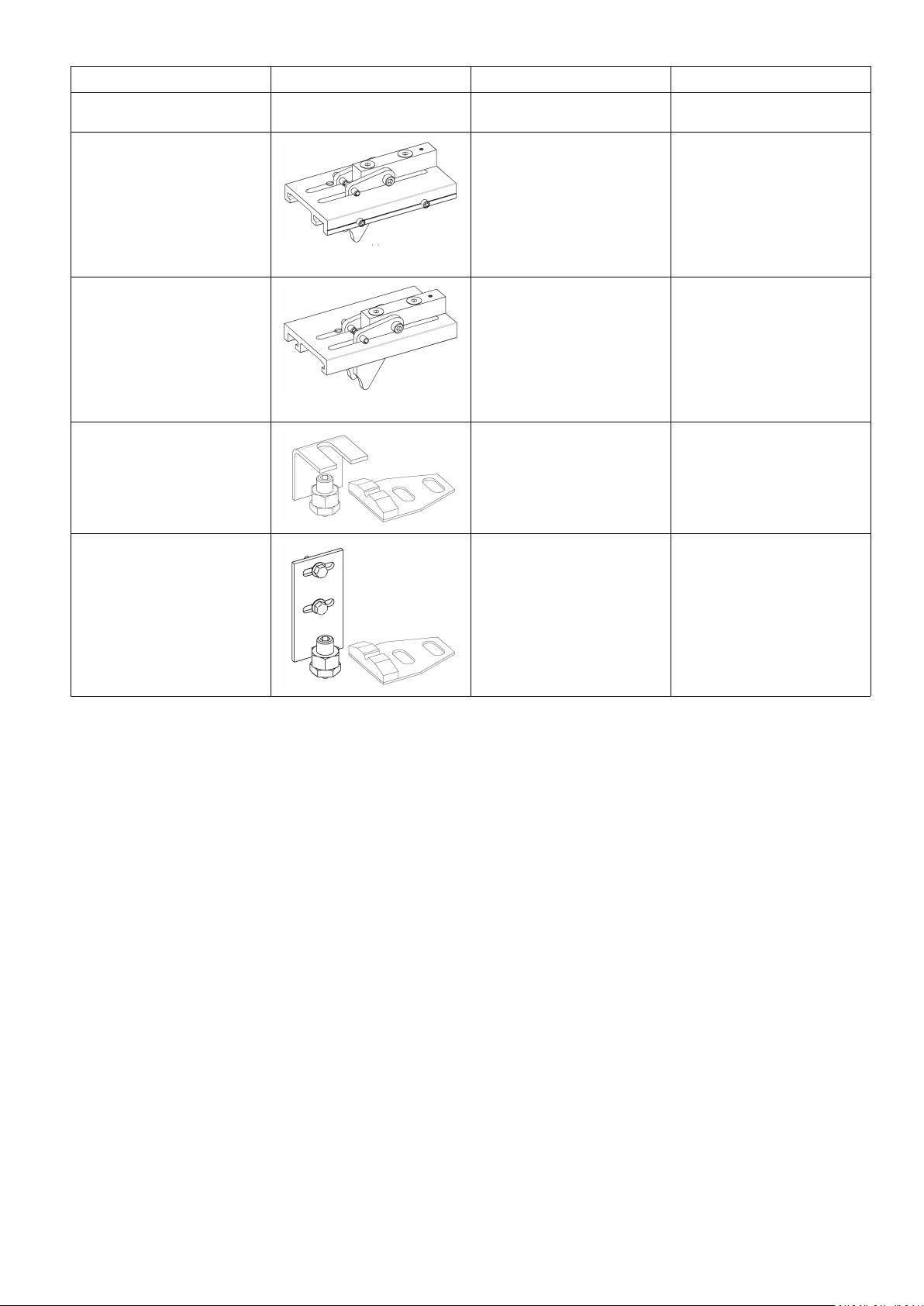

Combinationsoftraversesystems

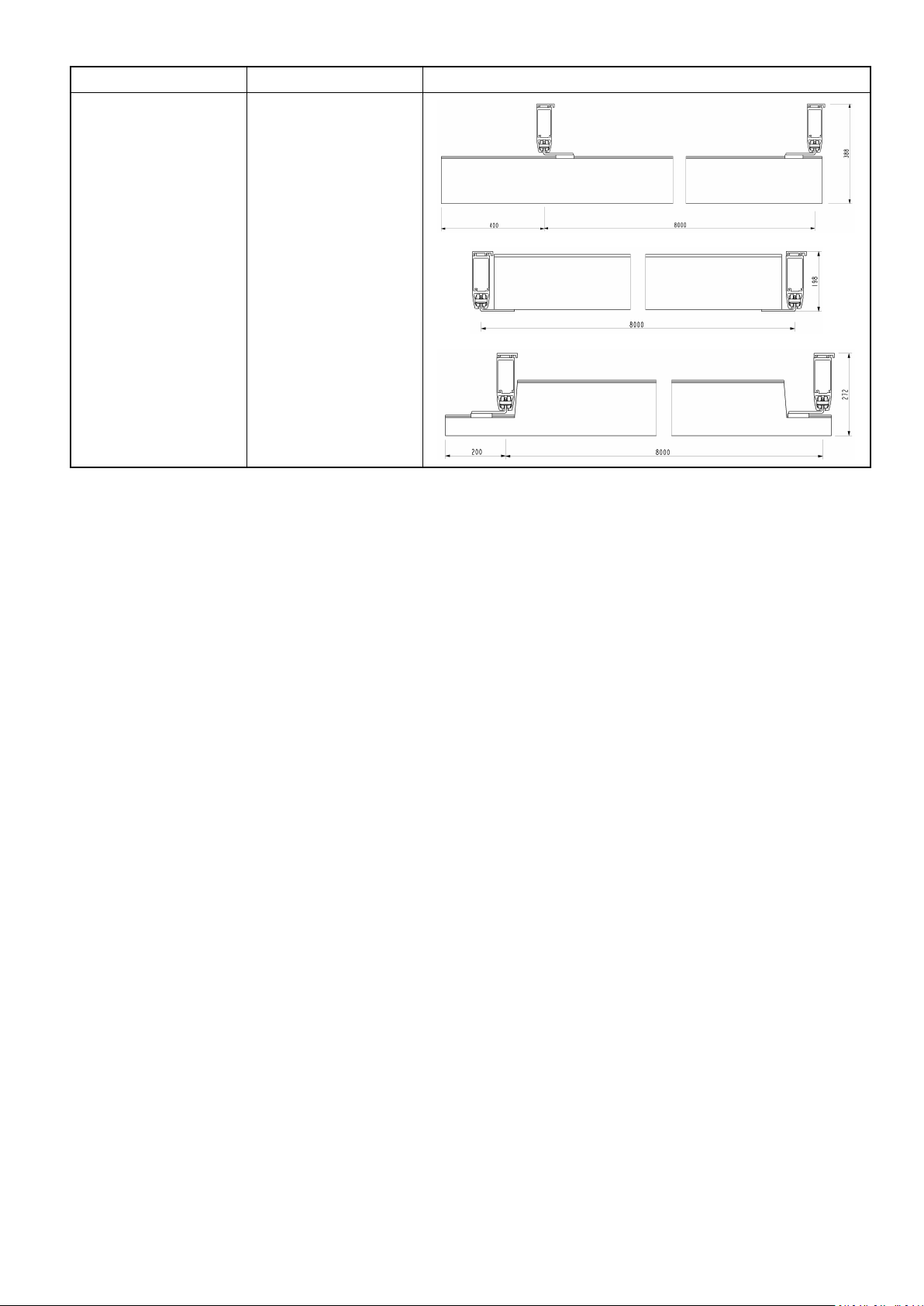

RailsCombinationPossiblecombinations

Parallel:S-Prole

Traverse:S-Prole

Under-hungtraverse:

Between-hungtraverse:

Parallel:S-Prole

Traverse:M-Prole

Parallel:S-Prole

Traverse:L-Prole

Parallel:M-Prole

Traverse:M-Prole

Under-hungtraverse:

Partlybetween-hung

traverse:

Under-hungtraverse:

Under-hungtraverse:

Between-hungtraverse:

Partlybetween-hung

traverse:

Parallel:M-Prole

Under-hungtraverse:

Traverse:L-Prole

61586749-C

RailsCombinationPossiblecombinations

Parallel:L-Prole

Under-hungtraverse:

Traverse:L-Prole

Between-hungtraverse:

Partlybetween-hung

traverse:

Railsystem

2.3RoomTransfer

Roomtransferwithtwohoists

RoomtransfercanbedonebyusingtwoRobinhoists;

oneineachroom.T oeasethisoperation,anInvacare

room-to-roomtrolleyisused.

Roomtransferispossibleinbothsingle-orroomcovering

installations.Itisimportantthattherailsarelocated

asclosetothedoorwayaspossible.Wheninstallinga

roomcoveringrailsystemintendedforroomtransfer,

thetraverserailmustbeinstalledperpendiculartothe

wallwiththedoorway.Thedistancebetweenthetwo

endstopbuffersmustnotexceed600mm.Toobtainthe

bestpossibleresultduringroomtransfer ,theremustbea

minimumdistanceof1.85mbetweentheoorandthe

undersideofthehoist.Thismustbekeptinmindduring

installationoftherailsystem.

Roomtransferwithtransit(transitcoupling)

Asanalternativetheroomtransfercanbeachievedby

aninstalledtransitcoupling.

Thecouplingcanbeusedtoconnecteithertwotraverse

systemsoronetraversesystemandonesinglerailsystem.

Thecouplingisoperatedelectricallybyacontrolbutton

mountedonthewall.Thecouplingisdeliveredwitha

standardlengthof800mm.

Forfurtherinformationseechapters2.4Rails,Brackets&

Accessories,page8and3.10Transitcoupling,page22.

1586749-C

7

Invacare®EC-Track®

2.4Rails,Brackets&Accessories

RailprolesS,M,L

Type

Description

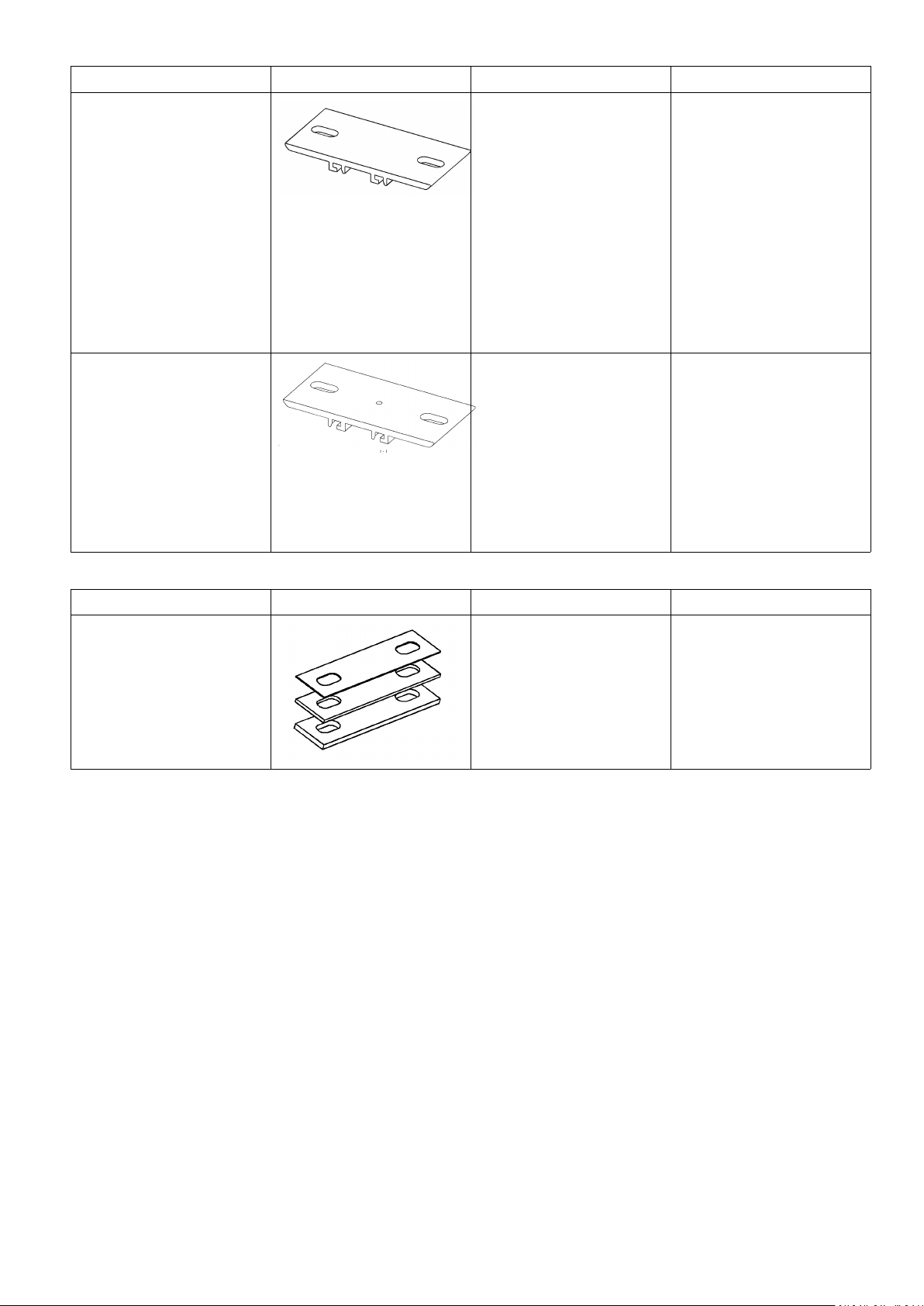

RailproleSMax.length=7.8m

Max.spanwithoutsupport:

2m

RailproleMMax.length=7.8m

Max.spanwithoutsupport:

4m

RailproleLMax.length=7.8m

Max.spanwithoutsupport:

8m

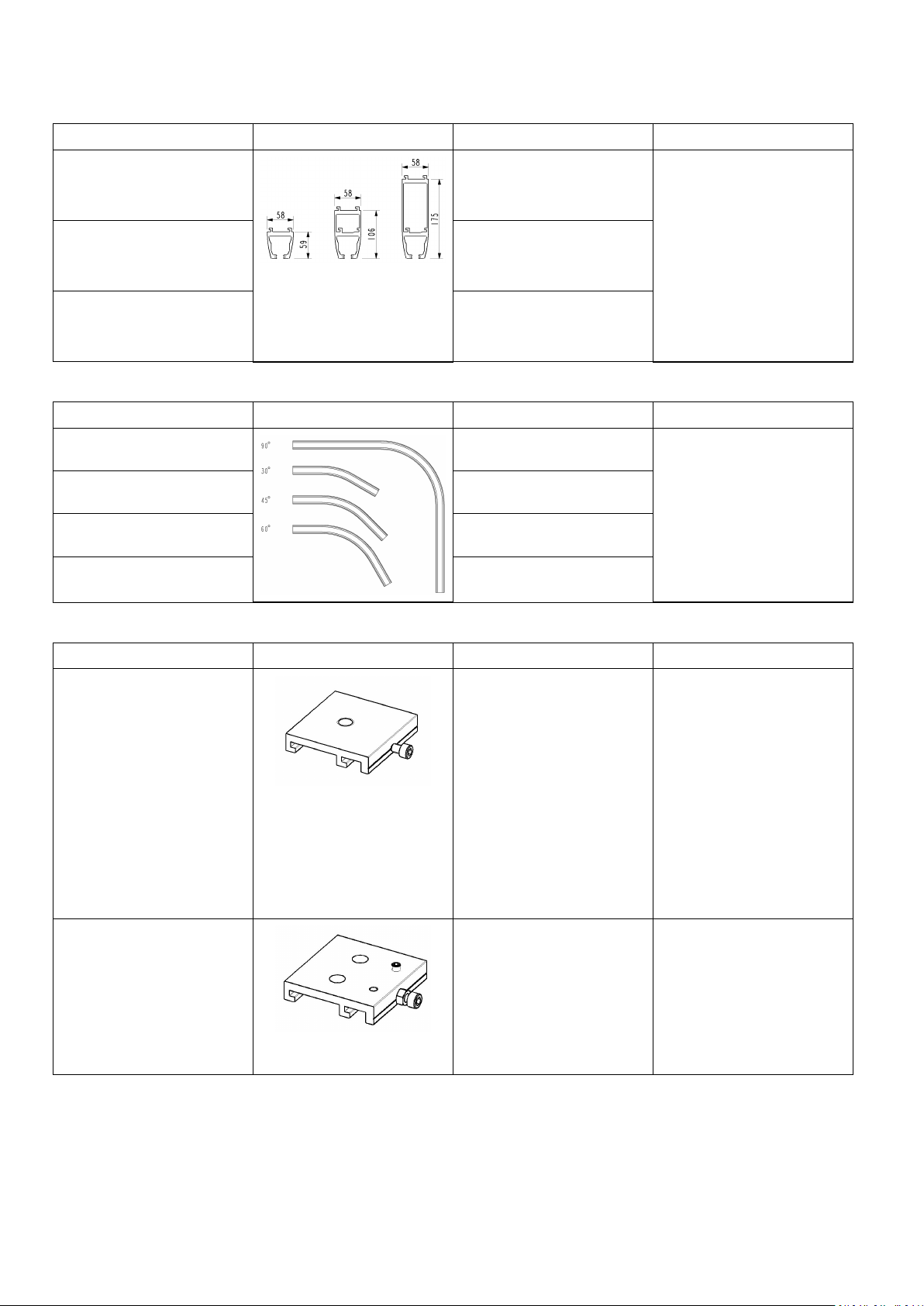

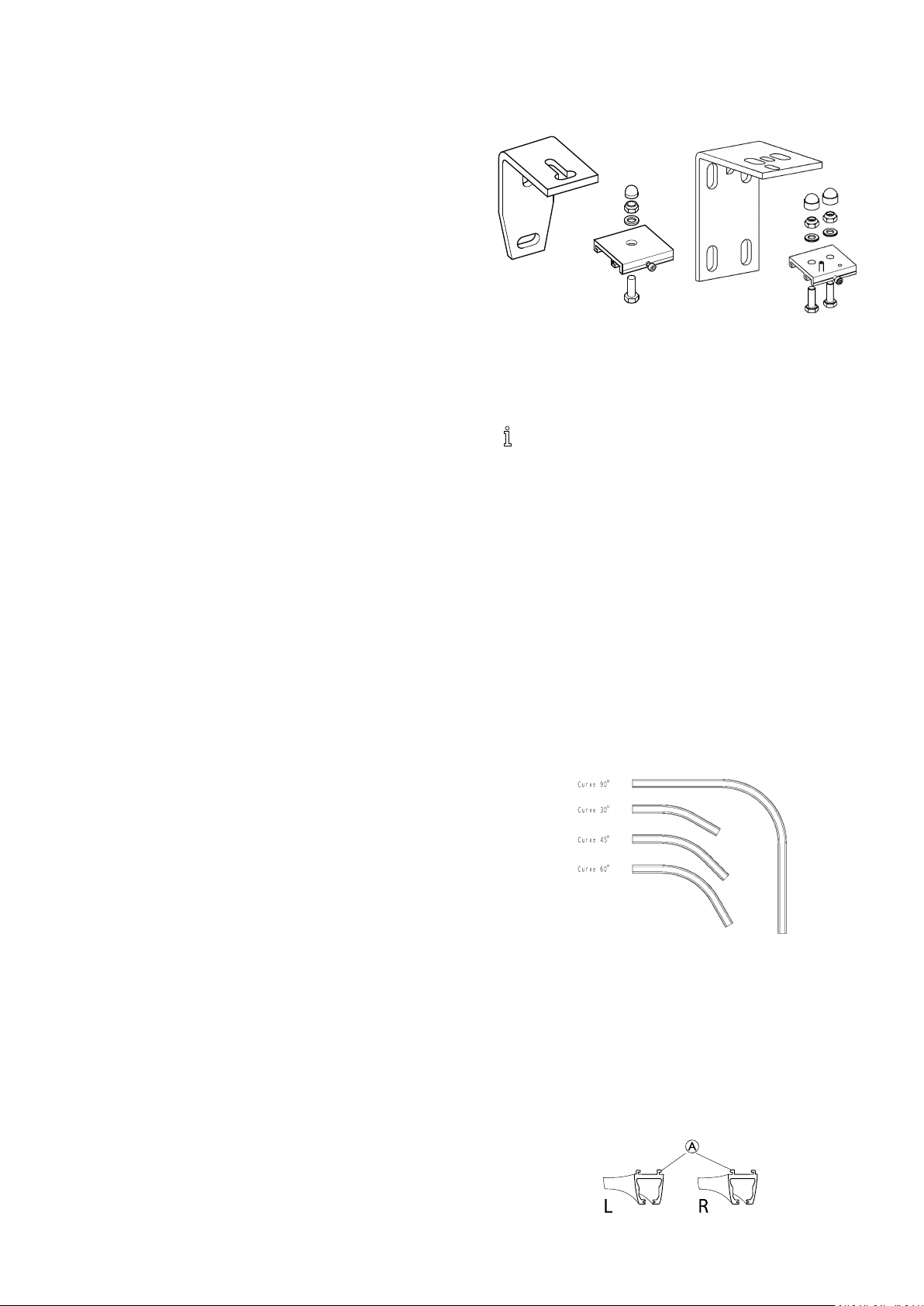

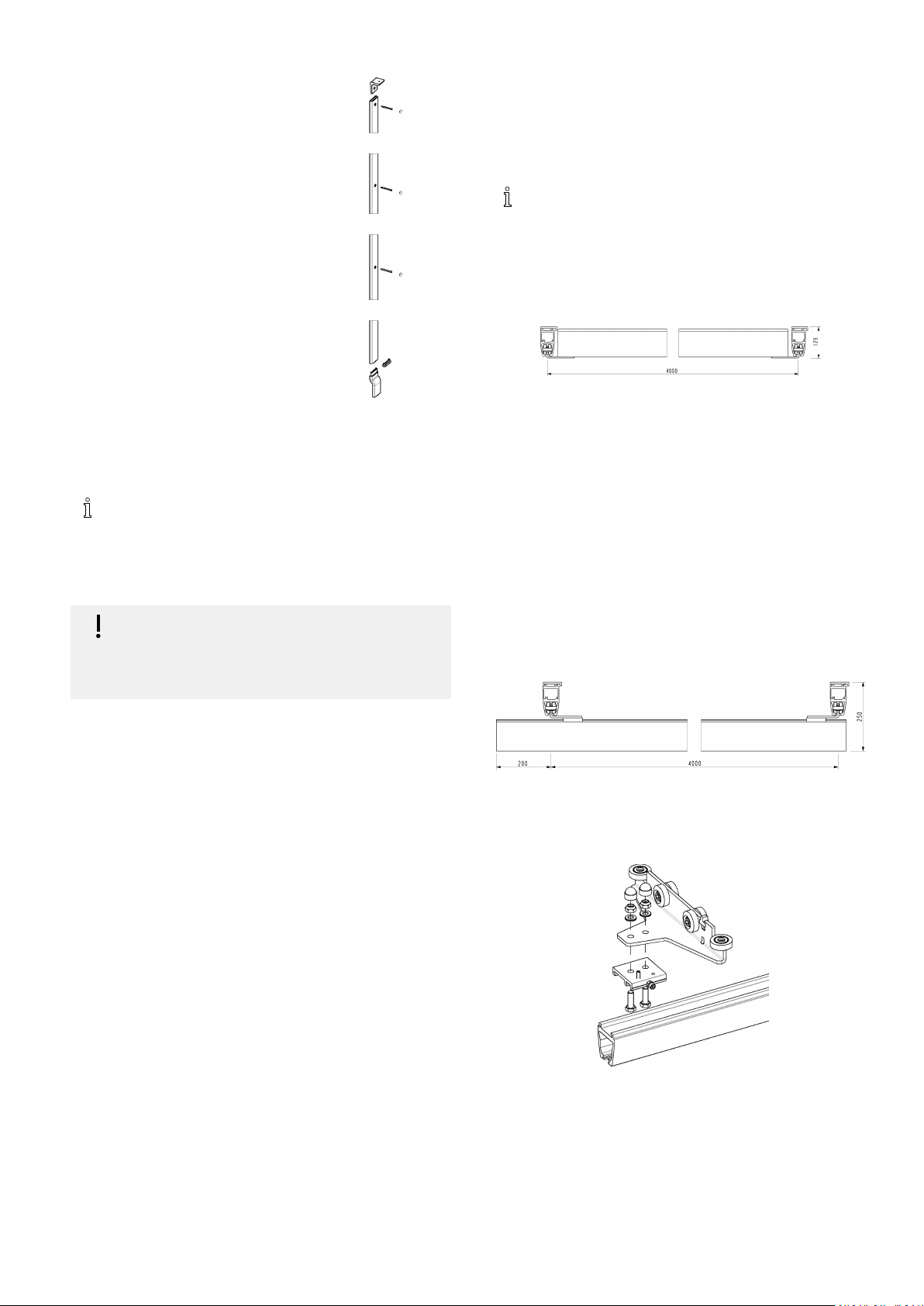

Curves30°,45°,60°,90°

Type

Curve30°

Description

RailproleSwithcurve30°

and2x200mmstraightrail

Curve45°

RailproleSwithcurve45°

and2x200mmstraightrail

Curve60°

RailproleSwithcurve60°

and2x200mmstraightrail

Curve90°

RailproleSwithcurve90°

and2x600mmstraightrail

Info

color:white

Info

Allcurveshavearadiusof

400mm.

Allcurvesaresupplied

asrightorleftcurves.

Characteristicsforrightand

left,seechapter3.5Curves,

page19

Ceilingbrackets

Type

Description

Ceilingbracket,QuickCeilingbracketswithhidden

xingparts.T obeused

forceilinginstallationof

single-railandtraverse

systems.

Sizes(WxDxH):

•30x68x14mm

(forcurves)

•70x68x14mm

(forordinaryceiling

supension)

•120x68x14mm

(forrailcoupling)

Ceilingbracket,Quick,

Traverse

Bracketsfortraverse

systemandsidehung

wallinstallation

Thebracketismounted

beneaththetraversetrolley ,

attheunderhungandpartly

between-hungtraverse

assembly.

Info

Installation:Seechapter3.2

CeilingMountingSystem,

page14.

81586749-C

Railsystem

Type

Description

Ceilingbracket,StandardCeilingbracketswithvisible

xingparts

Tobeusedforceiling

installationofsingle-railand

traversesystems.

Sizes(WxDxH):

•30x146x14mm(for

curves)

•70x146x14mm(for

ordinaryceiling

supension)

•120x146x14mm(for

railcoupling)

Standardceilingbracketwith

lock

Ceilingbracketwithlock

screwmeasuring(70x146).

Usedforceilinginstallation,

withmin.1perstraight

rail.Thisensuresthatthe

railisnotdisplacedafter

installation.

Sizes(WxDxH):

•70x146x14mm

Info

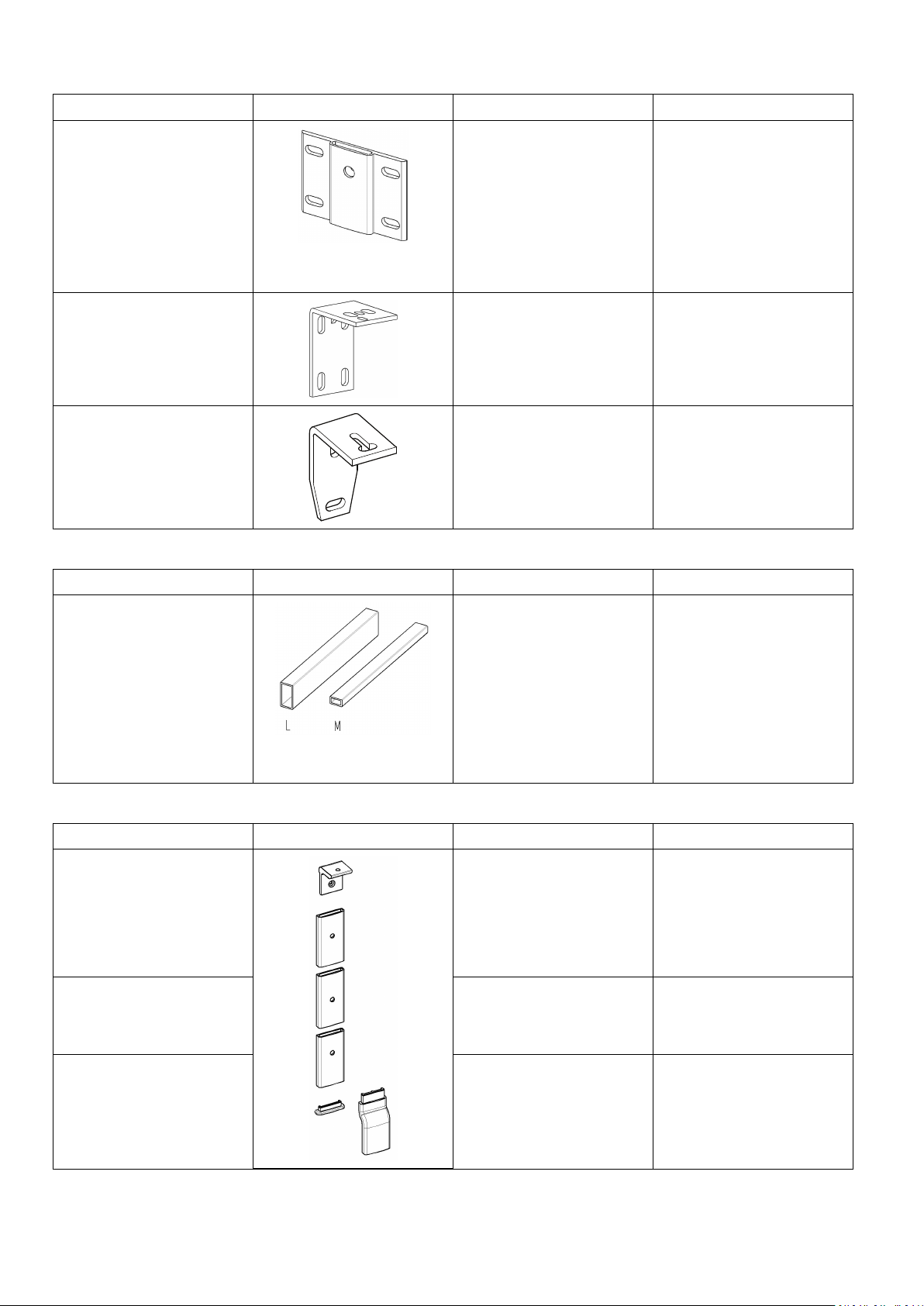

Shims

Type

Shimforstandardceiling

bracket

Description

Availableforceilingbrackets

in30,70,120mmwidth.

Height:

•1mm

•3mm

•5mm

Info

Shimsaretobeusedin

installationstocompensate

possibledifferencesofthe

heightintheroof/ceiling

structure.

1586749-C9

Invacare®EC-Track®

Wallbrackets

Type

Description

Wallbracket,endhungTobeusedwheninstalling

trackstoawall.Theycanbe

usedwhenthewallshave

sufcientlyhighcarrying

capacitywhenmounting

straightanddiagonallytoa

wall.

Tobeusedwithinserttubes

andconsole.

Wallbrackets,sidehungTobeusedwheninstalling

trackssidehung.Canbe

appliedifthewallhas

sufcientstrength.

Wallbracket,sideandend

hung

Tobeusedwheninstalling

trackseithersideorend

hung.Canbeappliedifthe

wallhassufcientstrength.

Inserttubes

Info

Installation:Seechapter3.3

Wallinstallation–endhung

rail,page18.

Installation:Seechapter3.4

Wallinstallation–sidehung

bracketorside/endhung

bracket,page19

Installation:Seechapter3.4

Wallinstallation–sidehung

bracketorside/endhung

bracket,page19

Type

InserttubeforrailproleM

orL

Description

Tobeusedwhenmounting

railendhungtowall,when

couplingtworails,orwhen

mountingrailsdiagonallyin

aroom.

•Inserttubeforrail

proleM:Length800

mm.

•Inserttubeforrail

proleL:Length1m.

Wallsupportleg,consoleandwallsupportfoot

Type

Description

WallsupportlegTobeusedifthewalldoes

nothavesufcientcarrying

capacitywhenmountingthe

railtothewall.Maybeused

forthemonorailsystemsas

wellasthetraversesystems.

Leglength:2.6m/3m

WallsupportconsoleTheconsoleisalsoused

togetherwiththeendhung

wallbracketwhenmounting

straightordiagonal.

WallsupportfootLowfootforroomswithout

skirtingboard

Info

Inserttubeissupplied

dependingontheparticular

mountingsituation.

Info

Installation:Seechapter3.7

Wallsupportlegs,page20

Highfootforroomswith

skirtingboardpanalongthe

oor

101586749-C

EndStop

Railsystem

Type

Description

Info

Endstop Theendstopismounted

atallrailoutlets,which

ensuresthatthetrolleysdo

notleavetherailsystem.

Whentheendstopis

mounted,therubberplugis

tofacetowardsthetrolley.

endstopfortraverserail Whenthetraversesystemis

between-hung,thetraverse

railsendstopistobe

mountedinthetraverse

trolley.

Whentherailsaremounted

toawall,theendstopisto

beplacedsofarintotherail

thatthehoistdoesnothit

thewall

Insomecountries/localareasthereisademandfordoublesecuringoftheendstops.Suchextrasecuringcanbe

achievedbyinstallingoneofthefollowing:

•M5x16mmthreadformingscrew(e.g.Bufab/SweboltMRXorequal),10mmfromeachendoftherail,25mm

fromtherailunderside(thescrewcanbeinstalledinapre-drilledholeØ4,3mm).

•Ø6,3x22mmthreadformingscrew(e.g.Bufab/SweboltR6Borequal),10mmfromeachendoftherail,18

mmfromtherailunderside.

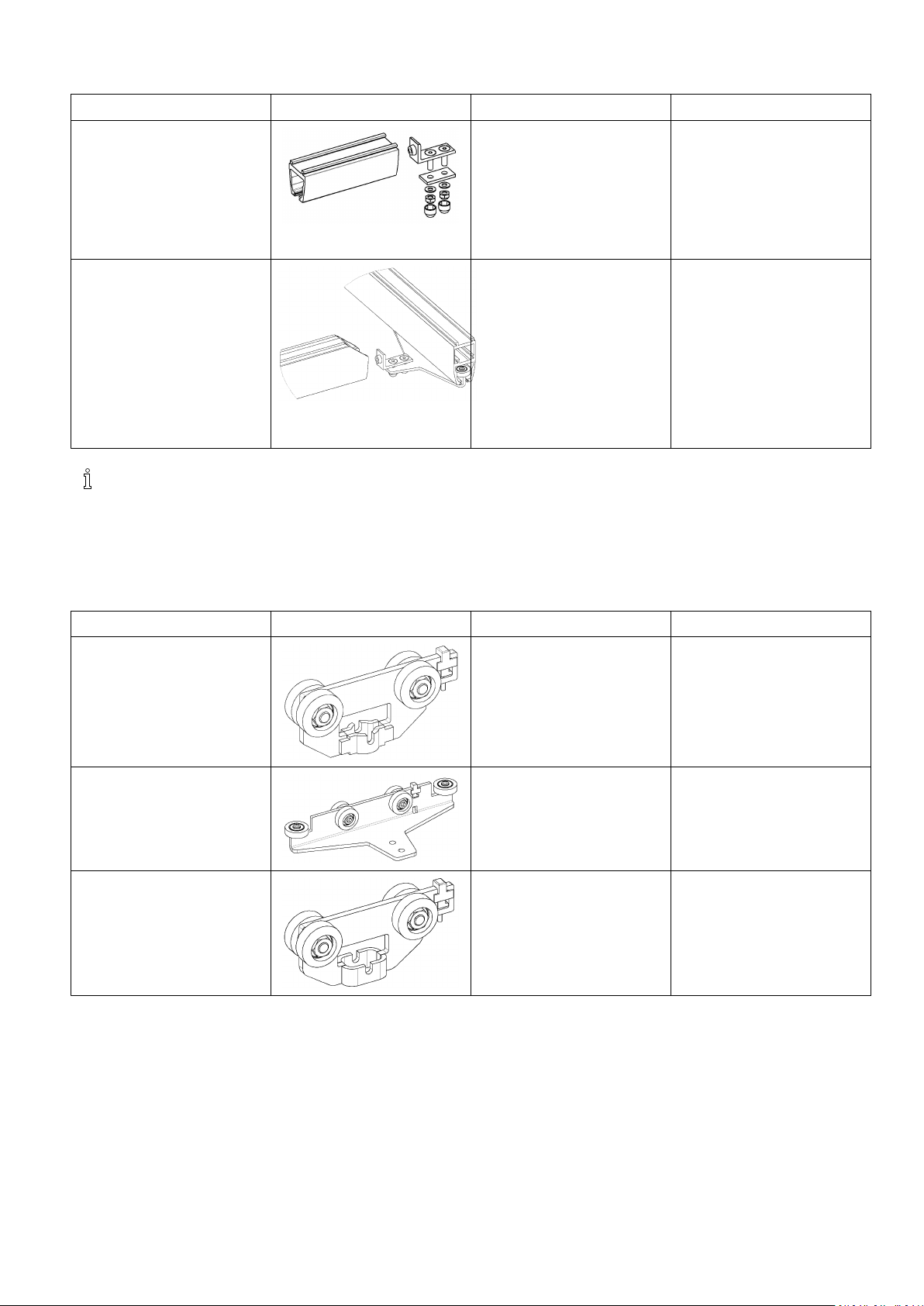

Trolleys

Type

HoistTrolley

Description

The hoist trolley is used for

individual mono rail systems

as well as traverse systems.

The hoist trolley is used

when a Robin ceiling hoist is

to be mounted in the track

system.

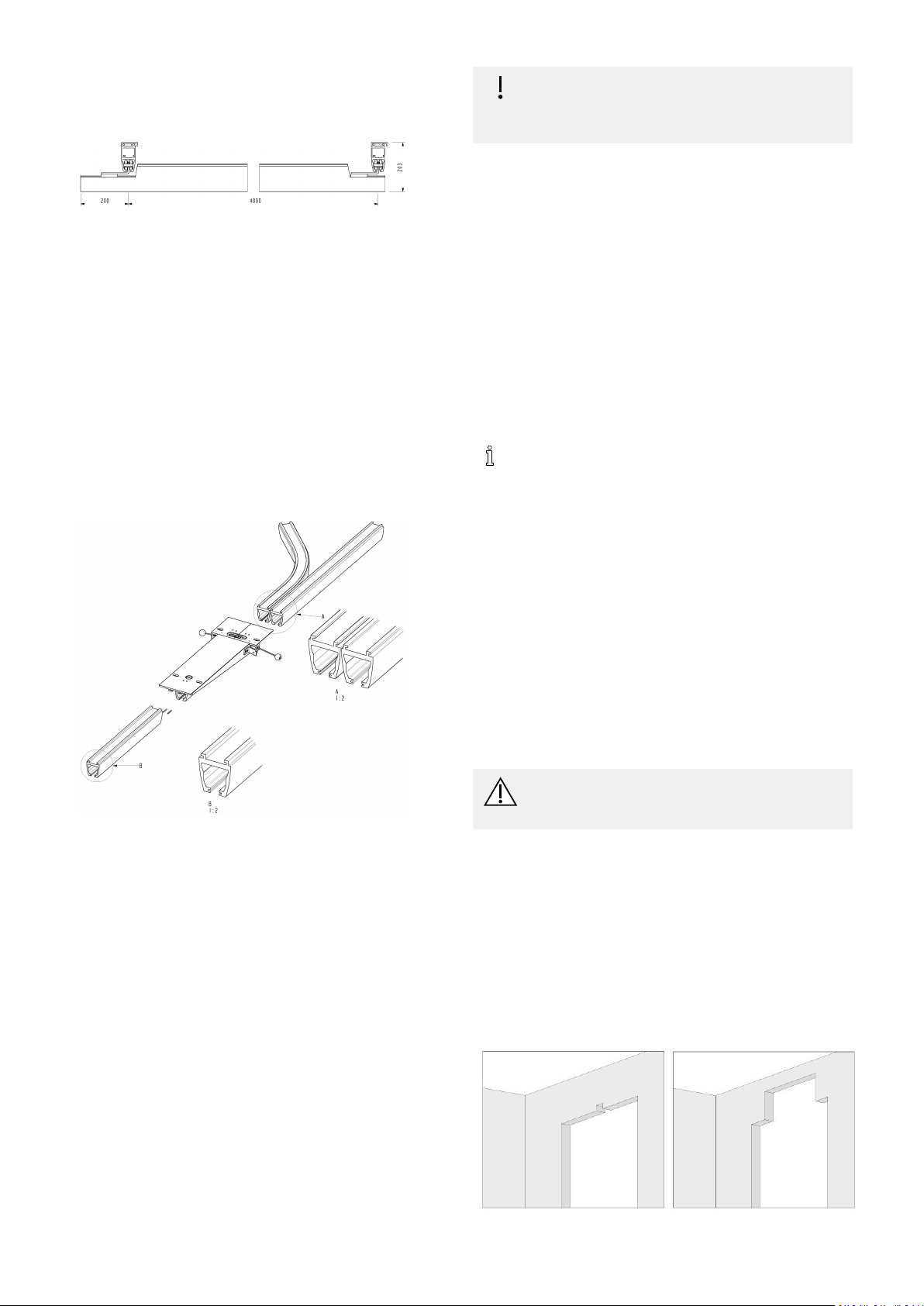

TraverseTrolley Thetraversetrolleyisused

whenmountingatraverse

system.Foratraverse

system,2traversetrolleys

arealwaysused.

Room-To-RoomTrolley Theroom-to-roomtrolleyis

usedwhenatransferfrom

oneroomtoanotheris

required,typicallythrougha

doorway.

Info

1586749-C

11

Invacare®EC-Track®

RailEndPlugs

Type

Description

RailendplugS,M,LRailendplugsaresupplied

forrailprolesof3sizes.

Color:white.

Tobeusedattheclosureof

bothendsofallrails.

Mounting:Pressintotherail

proleaftertherailsystem

ismounted.

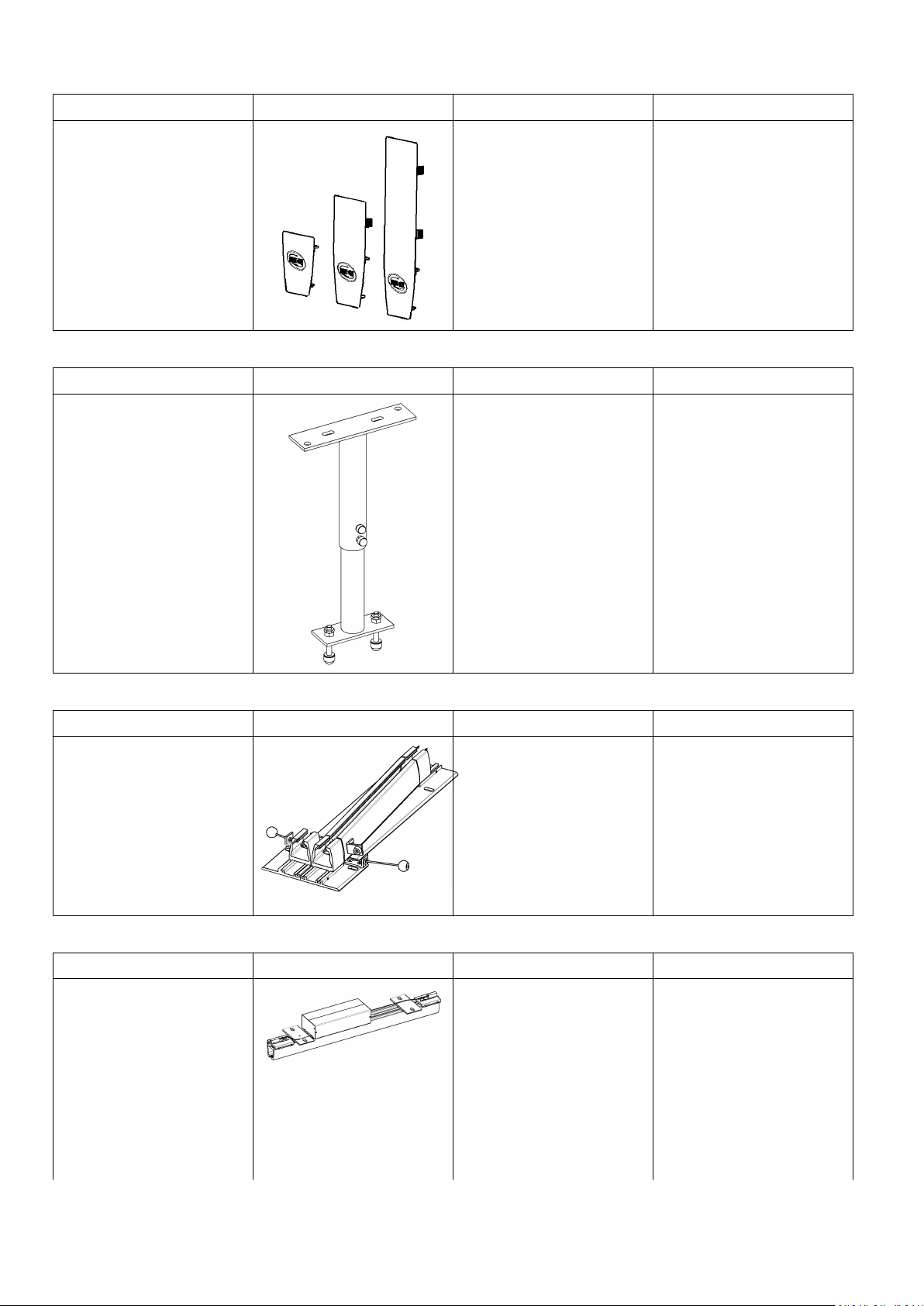

Pendles

Type

Description

Pendles,adjustablePendlesareappliedifthere

isaneedforinstallinga

lowerrailsystemthanthe

originalceilinglevel.Canbe

usedinhiddeninstallationas

wellasvisibleinstallations.

Sizes(adjustablelength):

•200–300mm

•280–460mm

•440–740mm

Info

Info

Installation:See3.2.2

ConcreteCeilingwith

SuspendedCeiling,page15.

TrackSwitch

Type

Description

Trackswitch,manualThetrackswitchismanually

operatedandisinstalled

withastandardceiling

bracket.Thetrackswitchis

usedincombinationwitha

ceilinginstalledsinglerail

systemwithS-prole,where

achangeindirectionis

requiredduringmovement

ofthepatient.

TransitCoupling

Type

Description

TransitcouplingThetransitcouplingis

operatedelectricallyand

mountedwithpendlesin

theceilingonbothsidesof

thewall.Length:800mm.

Thecouplingisusedfor

movementofapatientfrom

oneroomtoanother .

•intraversesystemswith

S-,M,-andL-rails.

Info

Installation:Seechapter3.9

Installationoftrackswitches,

page22

Info

Controlbutton(forthe

wall),andatransformerare

enclosedwhendelivered.

Installation:Seechapter3.6

Railcoupling,page20

12

1586749-C

Railsystem

Type

Lockxturefortraverse

proleS

Lockxturefortraverse

proleM/L

Positioningxturesfor

parallelrailS-prole

Description

•inasinglerailsystem

withonlyS-prolerails.

Tobemountedonthe

traverseproleinthe

endthatiscoupled.Itis

mountedtoensurethatthe

traverserailandcoupling

arelockedandconnected

correctlybeforeroom

transfercanbedone.

Tobemountedonthe

traverseproleinthe

endthatiscoupled.Itis

mountedtoensurethatthe

traverserailandcoupling

arelockedandconnected

correctlybeforeroom

transfercanbecarriedout.

Tobemountedonthe

parallelrail,closetothe

coupling,topositionthe

traverserailcorrectlyin

proportiontothecoupling.

Info

Positioningxturesfor

parallelrailM/L-prole

Tobemountedonthe

parallelrail,closetothe

coupling,topositionthe

traverserailcorrectlyin

proportiontothecoupling.

1586749-C13

Invacare®EC-Track®

3Installation

3.1GeneralInstallationInstructions

Beforeinstallingarailsystem,acarefulandaccurate

measuringoftheroomisessential.Itisequallyimportant

todeterminetheconditionoftheceiling,thewallsand

theoorinordertodecidewhethertomounttherailson

theceilingoronthewalls.Next,youneedtodecidehow

manyliftingplacesareneededintheroom.

Whendeningtheliftingplaces,anindividualassessment

isrequired,whichtakesintoconsiderationthebuildofthe

individualuserandnumberofnurses.

Thefollowingplacementoftypicalliftingplacesmaybe

usedasarecommendedguideline:

Bed1mfrominsideofthebed

headend

Toilet150mmfromthefront

edge

Bathtub

Changingtable1mfromtheheadendof

1/3wayup(sitting

position),½wayup

(recliningposition)

thetable

Wheninstallingrailswithbracketsdirectlyontheceiling,

makesurethattheceilingisevenandhorizontal.(Shims

ofrespectively1mm,3mmand5mmthickness,maybe

usedtoleveloutanyunevenness.)

Keyholefortheinstallationpoint

AnyEC-Tracksystemmustbepreparedwithaninstallation

pointforthehoist.

Thisinstallationpointappearsasa32mmroundmilled

grooveonthebottomoftherailinwhichthehoististo

beinstalled.Thismilledgrooveiscalledkeyhole.

Wheninstallingtherailsystem,itiscrucialthatthis

installationpointisplacedaccordingtotheinstructions

below.

1.Generally,thekeyholemustalwaysbeplacedasclose

aspossibletotheendofarail.However,itmustbe

atleast250mmawayfromtherailend.

2.Iftherailgoesfromwalltowall,itshouldbeplaced

min.400mmfromtherailproleend.

3.Ifatraversesystemismounted,thekeyholeshould

beplacedascloseaspossibleacrosstheendofthe

rail.However,itmustbeatleast250mmawayfrom

therailend.

Ifthetraverserailcontinuesallthewayouttothe

walls,itshouldbeplacedmin.400mmfromtheend

oftherail.

Whenmeasuringfortheselectedrailsystem,takeinto

considerationasuitableparkingplaceforthehoistwhenit

isnotinuse.Asuitablespotcouldbenearawall,where

thehoistchargerismountedonthewall.

Checkthecustomizedrailaswellasthebracketsandother

accessoriesagainstthedrawing.

Checkthatanyburrsandmetalshavingshavebeen

removedfromtherailstopreventthisdebrisfromgetting

stuckinthetrolleywheelsproducingnoiseanderratic

operation.

Incaseofsinglerailsandcurvedrailsneedingcoupling,

usetheenclosedpipepins.

1.Pushthepipepinshalfwayintotheonerail.Holes

aredrilledtoØ3.2mmintherailthattheprevious

mentionedrailistobeconnectedto.Thenthenext

railisinsertedoverthepipepins.

2.Pushthenextrailintotheprotrudingpins.Donot

drillfurtherholesintherstrail.

3.Mountthebracketforrailcoupling.

When installing a traverse system where the parallel rails

are running from wall to wall, the minimum distance from

rail to wall must be 60 mm, insert the traverse trolley and

the rail end stop into the parallel rails before installation.

If not, the parallel rails must end min. 350 mm from the

wall to permit subsequently installation of the trolley.

3.2CeilingMountingSystem

3.2.1ConcreteCeiling

Whenreferringtomountinginconcreteceilings,we

differentiatebetweenmassiveconcrete(factorymoulded

concreteelements,prestressedconcretesurfaces,armored

concrete)andhollowsurfaces.

MountingwithQuickCeilingBracket

Whenusingquickceilingttings,allceilingttingsareto

bemountedintheceiling.Thentherailmaybemounted

inthese.Atleast3ceilingttingsshallbeusedperrail.

Theremustsubsequentlybemax.700mmbetweeneach

tting.Theremustbemax.200mmfromtheendofthe

railtothersttting.

When installing a mono rail system or a traverse rail in a

traverse system, it is important that the rail at one end

stops min. 160 mm from the wall to permit subsequently

installation of the hoist trolley.

At secondary installation of Robin Mover the distance

must be minimum 300 mm.

14

Measureuptoallttingsatthesametime.Itisimportant

thatthedrilledholesareonastraightline.Theprecise

markingfortheholesistobecarriedoutusinglaser

technique,chalkline,etc.

Mountinginmassiveconcreteandhollowsurfaces:

1586749-C

Installation

1.Drillholeswitha15mmhammerdrilltoadepthof

54mm.Blowholesclean.

2.InsertM12strokeanchorsintothehole(e.g.Hilti

HKD-SM12orequal).

Whenusingasettingtool(e.g.HiltiHSD-GM12x50

orequal),theanchorwillbecorrectlyfastenedinthe

concrete.

3.Mountthequickttingbyscrewingthepre-mounted

threadedrodinthestrokeanchor .

Itisimportantthatanadhesiveisusedonatting

andnutwhenthethreadedrodismountedtotting.

Inordertoensuretheachievementofmax.

strength,thethreadedrodshouldbescrewedmin.

14mmintotheanchor.

Whenusingastrokeanchorincombination

withthequickbracket,optimumaccuracyisa

requirement.Asanalternative,twocomponent

adhesivemortarforconcretecanberecommended.

Whenallttingsaremounted,pushthehoisttrolley

intotherail.Thehoisttrolleymayfacebothways.If

thetraversetrolleyistobemountedintotherail,itis

importantthatthisfacescorrectlyinconnectiontothe

followingmountingofthetraverserail.

Theendstopismountedinbothendsoftherail.Theend

stopispushedintotherailwiththerubberplugrst,and

fastenedinitiallylooselywithyourngers.

Liftuptherail,adjustthelengthofitandfastenitinto

allceilingttings.

Placetheadjustableendstopscorrectlyandtighten

appropriately.Itisimportantthattheendstopisplaced

sothatthehoistdoesnothitthewall.

Forparallelrailsinatraversesystem,itisimportantthat

theendstopisplacedsothatthetraversetrolleyshitthe

endstopatthesametime.

MountingwithStandardCeilingBracket

Theceilingbracketsarepushedontotherailand

distributedwithmax.2mbetweeneachbracketand200

mmfromthelastbracketattheendoftherail.Useat

leastthreebracketsperrail.Itisrecommendedtousean

unevennumberofbrackets,ifonlyonepersonisinstalling

therail.Thus,onebracketisplacedonthecentercreating

balancewhentherailishungintherstbolt.

Inatleastoneendoftherail,useabracketwith

lockingscrewtobesecuredtotherail.

1.Measurefortheholefortheoneexpansionboltof

thecenterbracket.

Drilltheholetoadepthofapprox.80mmwithan

8mm.impactdrillbit.Theholeisdeeperthanthe

expansionboltlengthtofacilitatedismountinglater

on.Fordismounting,youcanthendrivetheboltfully

ininsteadofpullingitout.

2.DriveanexpansionboltM8x75(e.g.HiltiHSAor

equal)in,leavingsufcientroomforthebracket

thickness(6mm),thelockingwasher(2mm)andthe

nut(7mm)plusalittleallowance.Whenyouhave

driveninthebolt,removethenutandthewasher.

3.Insertthehoisttrolleyintherail.Thetrolleycanbe

orientedinbothdirections.

4.Ifyouareinstallingthetraversetrolley,makesurethat

itiscorrectlyorientedforthesubsequentinstallation

ofthetraverserail.

5.Installendstopsatbothendsoftherail.Insertthe

adjustableendstopsintherailwiththerubberplug

siderstandthesteelplatetowardstothebottomof

therail.Fingertightenthescrews.

6.Lifttherailinplace,mountthewashersandnutsand

tightenthemlightly.Adjusttheraillengthwiseand

anglewise,andtightenthenut.

7.Drilltheholeforthebracketintheoneendofthe

railbutontheoppositesideoftherail.Drivein

theexpansionbolt,makethenaladjustmentsand

tighten.

Next,drilltheremainingholesatoneendofthe

bracketslot.Ifthedrillbithitsareinforcementbar

beforetheholeis(50mm)deep,simplydrillatthe

otherendoftheslot.Ifthedrillhitsthereinforcement

barsagain,movethebracketapprox.20-25mmalong

therail.Thebracketwillthencoverthefailedholes.

Iftheholedepthisbetween50-70mm,use

anextensionboltM8x57.

8.Driveintheremainingexpansionbolts,placethe

washersandnutsandtighten.

9.Positiontheadjustablerailstopscorrectlyandtighten.

Makesuretopositiontheendstopssothatthehoist

doesnothitthewall.

Wheninstallingparallelrailinatraversesystem,be

suretopositiontheendstopsattheexactsame

pointstoensurethatthetraversetrolleyhittheend

stopssimultaneously.

3.2.2ConcreteCeilingwithSuspendedCeiling

Forroomswithsuspendedceilingswhicharedifcultto

dismount,itisrecommendedtochooseasolutionwith

wall-mountedorwallsupportmountedrails.

Ifthefalseceilingcanbeeasilyremovedorincaseofa

newmountingofaxedsuspendedceiling,werecommend

aninstallationwithloweringbracketsforaestheticreasons.

Forthissolution,usethelowestrailproleS.

MountingwithPendlingBrackets

Inthecaseofceilingmounting,itmayoftenbenecessary

topendletheraildownward.Thisneedmayariseinthe

evenofmountinginaroomwithasuspendedceiling,

whereyouhavetopendlebetweentheoriginalceilingand

thesuspendedceiling,oriftheceilingissohighthatyou

havetopendletheraildowninordertoensurethatthe

hoist’sliftingintervalsareusedaswellaspossible.

Therearemorepossibilitieswhencarryingoutamounting

withpendles:

1586749-C15

Invacare®EC-Track®

A–Pendlingusingthreadedrodsandroundspacerpipes,

cuton-siteattheinstallationplace.Mountingbyusingthis

methodisdescribedindetailinthissection.

B–Mountingusingadjustablependles.Thispendle

consistsofanupperandlowerpart.Bypushingtheupper

partontotheoutsideofthelowerpart,theadjustable

pendlemaycoveragiveninterval.Asstandard,apendle

canbesuppliedwiththefollowingintervals:

•200–300mm

•280–460mm

•440–740mm

Whenthecorrectpendlespacinghasbeendeterminedin

connectionwiththeassembly,thependleispulledout

tothislength,andfastenedwithascrew.Thenaholeis

drilledallthewaythroughtoanM8x65bolttolockthe

pendleinthedesiredlength.

Theupperpartofthependleshouldbemountedinthe

ceilingasdescribedinchapters3.2.1ConcreteCeiling,

page14

and3.2.3WoodenCeiling,page17aswhen

mountingwithstandardbracket.

Thelowerpartofthependleshouldbeattachedtothe

nalstandardceilingtting,asshowninthesketchbelow:

•1.Pendle,upperpart

•2.Pendleunderpart

•3.Spacerpipethroughloweredceiling,Ø15

•4.Standardceilingbracket

•5.Throughlockingbolt,M8x65

Thependlemayalsobesuppliedwithpredetermined

dimensions,avoidingadjustmenton-site.

Rememberalsotoorderceilingbracketswhen

orderingpendle.

•M8lockednuts,2pcs.

•AluminiumpipesØ40,2pcs.

•Ceilingbracket(standard),1pcs.

•Removablesuspendedceiling.

•M8threadedrods,2pcs.

•Lockingwashers,2pcs.11x35x2.

(AnHKDanchorcanbeusedasanalternative,whichthe

rodsarexeddirectlyinto).

1.Togettherightlengthofthependlingbrackets,use

thedistancebetweentheconcreteceilingandthe

lowerfaceofthesuspendedceilingasyourstarting

point.

Thisdistanceisusedtodeterminethelengthofthe

pendlebracketpipeandthethreadedrod.Their

lengthmustequalthepreviouslymeasureddistance

describedabove.

2.Wheninstalling,rstinstalltheyokeforthecenter

ceilingbracket.Todothis,followtheinstructions

fortheinstallationdirectlyinaconcreteceiling.In

thiscase,however,theholesaredrilledforboth

expansionsboltsatthesametime.

3.Whendrivingintheexpansionbolts,leaveapprox.

15mmprotrudingbelowthenut,sothatyoucan

screwthecouplingnutontoittohalfitslength.

Counter-tightenthecouplingnutagainsttheexpansion

boltnut.Measurefortheholeinasuspendedceiling

anddrill/cutthisholetoØ40mm.

4.AttachanM8nutontothethreadedrod(approx.20

mmontotherod)andscrewtherodintothecoupling

nutuntilithitstheexpansionboltandcounter-tighten

thenut.

5.Aftercompletion,pushthetwoaluminiumpipesinto

theholesandfastentherailasdescribedintheusual

instructioninstructions.

Thedistancebetweenthesuspendedceilingand

theceilingbracketmustbemin.1-5mmto

preventdamagestothefalseceiling.

FixedSuspendedCeiling

Incaseofaxedsuspendedceiling,therailinstallationis

carriedoutintwosteps.Theloweringbrackettherefore

needstobesecuredwithoutthesupportfromtheceiling

bracket.

RemovableSuspendedCeiling

Incaseofaremovablesuspendedceiling,thespaceabove

thesuspendedceilingisaccessibleandpendlebrackets

andrailcanbeinstalledatthesametime.

•Concreteceiling.

•ExpansionboltsM8x75,2pcs.

•Yokes,(Steelplateforeveninstallationsurface),2

pcs.3mm.

•M8nuts,6pcs.

•Concreteceiling.

•ExpansionboltsM8x75,2pcs.

•Yoke(Steelplateforeveninstallationsurface),1pcs.

3mm.

•M8nuts,4pcs.

•M8couplingnuts,2pcs.(Collectingsleeve).

161586749-C

•M8couplingnuts,2pcs.

•M8lockingnuts,2pcs.

•AluminiumpipesØ40,2pcs.

•DistancepipesØ20(ornutsandwashers),2pcs.

•Ceilingbracket(standard),1pcs.

•Suspendedceiling.

Installation

•M8threadedrods,2pcs.

•Lockingwashers,2pcs.

(AHKDanchorcanbeusedasanalternative,whichthe

rodsarexeddirectlyinto).

1.Cutthependlebracketpipetoalengthequallingthe

distancemeasuredbetweentheconcreteceilingand

thelowerfaceofthesuspendedceilingminus50mm.

Thislengthisappropriateforadoublegypsumlayerin

theceilingandanextraallowanceof12mm.

2.Cutthethreadedrodtoalengthequallingthedistance

betweentheconcreteceilingandthelowerfaceof

thesuspendedceilingminus10mm.

3.Wheninstalling,rstinstallthetopyokeforthecenter

bracketoftherailInstalltheyokeasdescribedin

theinstallationinstructionsfordirectinstallationina

concreteceiling.Inthiscase,however,drillbothholes

fortheexpansionboltsatthesametime.

4.Whendrivingintheexpansionbolts,leaveapprox.

15mmtoprotrudingbelowthenut,sothatyou

canscrewthecouplingnutontoittoitshalflength.

Counter-tightenthecouplingnutagainsttheexpansion

boltnut.

5.Attachanutapprox.20mmontothethreadedrod

andscrewthethreadedrodintothecouplingnut,until

ittouchestheexpansionbolt,andcounter-tighten

thenut.

6.Attachthebottomyokeandsecureitwithnuts.

Avoidpaintonthebottomsectionofthe

threadedrodsuntiltheinstallationiscomplete.

7.Preparetherestoftheinstallationpointsaftera

carefulandaccuratemeasuring.

Firststepoftheinstallationisnowcompleteand

theconstructionofthesuspendedceilingcanbe

completed.

Inthenalinstallation,positionthedistancepipeinthe

suspendedceiling.Thispipewillprotectthesuspended

ceiling.Cutthedistancepipetoalengthcreatinga

distanceof1-5mmbetweenthelowerfaceofthe

suspendedceilingandtheupperfaceoftheinstallation

bracket;insteadofpipes,nutsandwasherscanbeused

toensuretherecommendeddistance.

3.2.3WoodenCeiling

CAUTION!

–Donotinstallrailstoawoodenceilingwith

tensionscrews,suchascoachscrews.

–Donotinstallrailstoawoodenceilingwith

plainwoodscrews,withouthavingperformed

ariskassessment.

QuickBracket

Itisprovidedthattheceilingtimberworkisaccessible

fromabove.Whenbeingmountedintheceilingtimber

work,exchangeshouldbeplacedasreinforcement.When

reinforcing,itisimportanttoselectexchangewoodthat

isdimensionedtotoleratethedistancebetweentwo

ceilingbeams,sosufcientcarryingcapacityisachieved.

Whenhavingmarkeduptoallceilingbracketsinthe

ceiling,youshouldexaminewhetherthereisfreespace

abovetheceilingmaterial.Whenthisisdone,holeswith

adiameterofØ12.5mmaredrilledthroughtheceiling

material.Theholesmaynowbelocalizedfromabove,

theycanbepreparedfortheexchanges,andyoumay

measurehowlongthethreadedrodsshouldbe.The

exchangeshouldcoveratleasttwoceilingbeamsoneach

sideofthesuspensionpoint.Whenusingexchanges,

two45x95mmexchangesshouldbeplacedparallelto

eachother,atadistanceof14mm,providingapassage

foranM12threadedrod.Fordeterminingthelengthof

thethreadedrod,determinetheceilingbeam’sheight+

lengthofexchangewood+ceilingmaterial+60mmfor

washerandnuts.

Placetheadaptedthreadedrodbetweentheexchange

woodandputinawasherandnutbeforethethreaded

rodisguidedfurtherdownthroughtheceilingandposition

itwithanaluminiumplate,atighteningwasherandnut

overtheexchangewood.Thealuminiumplateisscrewed

intotheexchangewoodfromthetop.Letapproximately

25mmthreadedrodprotrudedownundertheceiling

material.Aquickceilingbracketmaynowbescrewedonto

thethreadedrodbeneaththeceilingmaterial.Theceiling

bracketisfastenedwithanM12lownut.Thethreaded

rodistobescrewedentirelythroughthenut,butmust

protrudefurtherdownthatbelowthetting.

Whenmountingthebracketandnut,itisimportantto

useadhesiveonbracketaswellasnut.Whenallbrackets

aremounted,liftuptherail,adjustthelengthandsecure

it.Beforetherailisfasteneduptotheceiling,whichis

donefromabovetheceiling,itshouldbecheckedthatthe

exchangewoodisrestingonbothceilingbeams.Ifnot,

somethingshouldbeplacedbetween.

Thenutovertheexchangewoodisnowsecuredcarefully

untilthebracketliesevenlywiththeceilingmaterial.Itis

importantnottotightensomuchthattheceilingmaterial

ispulledupbetweentheceilingbeams.Whenthisis

done,asteelplateisplacedinaroundthethreadedrod

belowtheexchangewood,andthenutissecuredupinto

thesteelplate,thuslockingtheposition.

Finally,alocknutissecuredagainstthenutontheupside

oftheexchangewood.Trolleys,endstopandrailend

plugsaremountedasdescribedinsection5.2.1.

StandardBracket

Insomecases,mountingtoaceilingtimberworkmaybe

analternativetomountingtowallorwallsupport.

1586749-C

•ThreadedrodsM10,2pcs.

•M10nuts4pcs.

•Yoke1pcs.

•Braces45x90x1500mm,2pcs.

17

Invacare®EC-Track®

•Beamlayer.

•Underroof/ceiling.

•Ceilingbracket,1pcs.

•LockingnutsM10,2pcs.

•Washer,2pcs.11x35x2.

In some cases, installation with passing screws may be an

alternative to wall or wall support installation.

This requires that the roof beam layer can be accessed

from above. This is often the case in one-storied houses.

To reinforce the roof beam layer, exchanges of 45x95 mm

are placed edgeways.

Instead of the expansion bolts, a M10 threaded rod of

appropriate length is used. An installation plate (yoke

rests on top of the braces.

The exchange must rest on the roof beams on both sides

of the suspension. If this is not possible, the exchange

must be secured to prevent them from tilting when loaded.

The minimum number of three mounting points per rail

for concrete ceiling does not apply to wooden ceilings.

Here, the max. free span determines the number of

mounting points.

The rest of the installation process is similar to the process

for concrete ceilings. It is, however, necessary to drill

both holes for the center bracket (the standard bracket at

the same time.

Cut the threaded rods to appropriate length and attach

the washers and M10 nuts locking nuts.

The threaded rods are to be screwed from below and up

through the yoke. The yoke is fastened from above to the

exchanges with nails and screws.

Before the rail is fastened to the ceiling, which is done

from above, you should double-check that the exchange

wood is resting on two ceiling beams. If not, something

should be placed between.

Be careful when tightening the nuts to prevent damage to

the suspended ceiling.

3.3 Wall installation – end hung rail

The following are recommendations only. Alternatively,

expansion bolts with the similar thickness and quality can

be applied. Always follow the recommendations from

your supplier.

For freely suspended installation, the end of the rails

may be attached to the wall with wall brackets or wall

support. Choose wall support, if you are in doubt of

the load bearing capacity of the wall material. When

installing freely suspended rails, the max. rail length must

be observed, depending on the selected rail prole. The

distance between the walls must be max. 2 m for rail

prole S , 4 m for rail p role M an d 8 m for ra il prole L.

If you need to mount or dismount a hoist trolley after

installation, the distance from one wall to the rail must

be at least 160 mm. At secondary installation of Robin

Mover, the distance must be minimum 300 mm. If you

need to mount or dismount the traverse trolley after

installation, the distance between the one wall and the rail

must be at least 350 mm. (Minimum distance from rail to

wall must always be 60 mm. If you have a wall-mounted

rail prole S , y ou c annot m ount o r d ismount t he trolley

after installation.

3.3.1RailproleMandL

Wheninstallingwallbracketsorwallsupportlegs,leavea

gapfromtheceilingtotheupperedgeofthewallbracket

oroorsupport.Thegapshouldbeatleast:

•80mmforrailproleM

•150mmforrailproleL

Whenusingwallsupportlegs,cutthesupportlegprole

toanappropriatelengthattheoorend.

Remembertomakeallowancefortheoorsupport

foot.

Incaseofskirtingboards,eitherusethehighwallsupport

foot,orcutawaytheskirtingboard.

Alwaysinstallwallsupportlegsrightatthewallintheir

fulllength.

Markforholesusingalevel,anddrilltheholes.

Concretewall

Whenmountingafreelyhangingrailintoaconcretewall,

awallbracketshouldbeusedformounting.

Formounting,werecommendusingeitherexpansionbolts

M10x68(e.g.HiltiHSAorequal),drillingdepthmin.60

mm,Ø10,oradhesivemortar(e.g.HiltiHIT-HY150and

HASM10orequal),drillingdepthmin.95mm,Ø12(when

mountedinwetrooms,usestainlesssteelHASquality

A4-70).

Brickwall

Whenmountingintobricks,ordinarywallbracketsshould

beused.However,werecommendusingoorsupportsif

thebrickwallisveryporous.

Formountingintomassivebricks,werecommendusing

adhesivemortar(e.g.HiltiHIT-HY50andHASM10or

equal),drillingdepthmin.90mmin½brickand170mm

in1/1brick,Ø12.,(whenmountedinwetrooms,use

stainlesssteelHASqualityA4-70).

Formountinginhollowbricks,werecommendusingeither

aframesheerconnector(e.g.HiltiHRDUGTorequal),

drillingdepthmin.80mm,Ø10,oradhesivemortar(e.g.

HiltiHIT-HY20,andHASM10orequal),drillingdepthmin.

95mm,Ø16.

Formountingintoporousbrickwork,werecommendusing

adhesivemortar(e.g.HiltiHIT-HY50andHASM10or

equal),drillingdepthmin.90mmin½brickand170

181586749-C

Installation

RL

mmin1/1brick,Ø12.Ifwallsupportsareusedwhen

mounting,useHASM8,drillingdepthmin.80mm,Ø10.

Lightweightconcrete

Whenmountinginlightconcrete,youmayeitherusewall

bracketsorwallsupports,dependingontheconditionof

thewall.Formounting,werecommendusingadhesive

mortar(e.g.HiltiHIT-HY50andHASM10orequal),

drillingdepthmin.90mm,Ø12(M8formountingofwall

supports).

Youmayalsousealightconcretesheerconnector(e.g.

HiltiHGN,HUD-110Lorequal),drillingdepthmin.90

mm,Ø10/HUD-18L,drillingdepthmin.80mm,Ø8.

Gypsumwall

Referalsotochapter3.7Wallsupportlegs,page20.

1.Completetheinstallationofthewallbracketorthe

wallsupportlegwithconsole,wallsupportfootand

plugsforcoveringthescrewholes.

2.Insertthehoisttrolleyorthetraversetrolleyintherail.

Thehoisttrolleycanbeorientedinbothdirections,

whereastheorientationofthetraversetrolleymust

correspondtothelayoutofthetraversesystem.

3.Insertendstopsatbothendsoftherailand

nger-tightenthematrst.

4.Inserttheinsertiontubeintherail.Theholeinthe

tubemustfaceoutwards.

5.Lifttherailwhileholdingontotheinsertiontubeto

preventitfromslidingintotherail.

6.Mounttheinsertiontubeontheconsoleatthewall

bracketorthewallsupportleg.

7.Adjusttheraillengthwisetoachievethecorrect

distancebetweenthewallandtherail.

8.Theremustbeanoverlapofatleast300mmbetween

therailandtheinsertiontube.Checktoverifyby

lookingthroughtheinspectionholeonthesideofthe

rail.Theinspectionholeislocatedexactly300mm

fromtheendoftherail

9.Whentherailisproperlypositioned,drillaØ7mm

holethroughtherailandtheinsertiontube,approx.

100mmfromtheendoftherail.Securetherailin

positionwithpassingboltsM6withlockingnuts.

10.Afterpositioningtherail,adjusttheendstoptoits

properposition.Whenpositioningtheendstop,

makesurethatthehoistwillnothitthewall.Witha

traversesystem,ensurethatthetwotraversetrolleys

hittheendstopsimultaneously.

Angular,wall-mounted

Therailcanbemounteddiagonallyintheroom.Therail

mustbeangledmax.45°.

Themountingiscarriedoutasdescribedforordinarywall

mountingwithorwithoutwallsupports.However ,the

tubeisdeliveredpreparedforangledmounting.

3.4Wallinstallation–sidehungbracket

orside/endhungbracket

Wheninstallingarailsystemsidehung,theparallelrails

canbeinstalledclosetothewall.

Wheninstallingarailsystemsidehung,thewallmusthave

suchstrength,thatwallsupportlegsareunnecessary.

WheninstallingSprole,2000mmisthemaximum

distancebetweeneachxationpoint,butatleast3points

arenecessary.

WheninstallingMprole,4000mmisthemaximum

distancebetweeneachxationpoint,butatleast3points

arenecessary.

Alwaysmeasurethedistancebetweenbothwalls

accurately,inthecorrectheightandlocationofthesystem.

Thewallbracketcanbeadjusted+/-6mm.Ifmoreis

required,useaplateof6mmbetweenbracketandwall.

Finalappearanceisinuencedbytheparallelism

betweenwallandrail.Beaccurate.

Thetraversesystemmeasurementshere,istheroomsize

measured,deducted206mm(ifbetween-hunginstalled),

and62mm(ifunder-hunginstalled).

Again,thisrequiresanaccuratemeasurementaswell

assomeconsideringoftheadjustabilityduetowall

unevenness.

Wallinstallationdependsonthestructureofthewall.

Alwaysfollowrecommendationsinchapter3.3.1Rail

proleMandL,page18.Afterinstallingthewallbrackets

andthetwoparallelrails,followinstructionsinsection3.8

Mountingtraversesystem,page21

.

3.5Curves

Followingcurvesareavailable:

•Angle30°0.2+0.2mstraightends

•Angle45°0.2+0.2mstraightends

•Angle60°0.2+0.2mstraightends

•Angle90°0.6+0.6mstraightends

Allcurveshavearadiusof400mm.

Thecurvesareavailablewithright-handbendsand

left-handbends.Itisespeciallyimportanttodistinguish

betweenrightandleftcurves,whenseveralcurvesare

includedinthesamerailsystem.

1586749-C19

Invacare®EC-Track®

•Leftcurves(L):MountingchannelsAfacingoutfrom

thecurve.

•Rightcurves(R):MountingchannelsAfacinginward

intothecurve.

Pipepinsandcouplingbracketswithlockscrewsareused

tocouplecurveswithstraightrails.

Bracketpositionsonthecurves

Angle30°0.2+0.2mstraightends:Acouplingbracketat

bothends,ifthecurveisconnectedtostraightrails.

Angle45°0.2+0.2mstraightends:Acouplingbracketat

bothends,ifthecurveisconnectedtostraightrailsanda

narrowbracketatthemiddleofthecurve.

Angle60°0.2+0.2mstraightends:Onecouplingbracket,

atbothendsifthecurveisconnectedtostraightrailsand

anarrowbracketatthemiddleofthecurve.

Angle90°0.6+0.6mstraightends:Onecouplingbracket,

ifthecurveisconnectedtostraightrailsandanarrow

bracketatthemiddleofthecurve.

Forinstallationinstructionsforcurves,seesection:5.2.1.1,

section5.2.1.2.

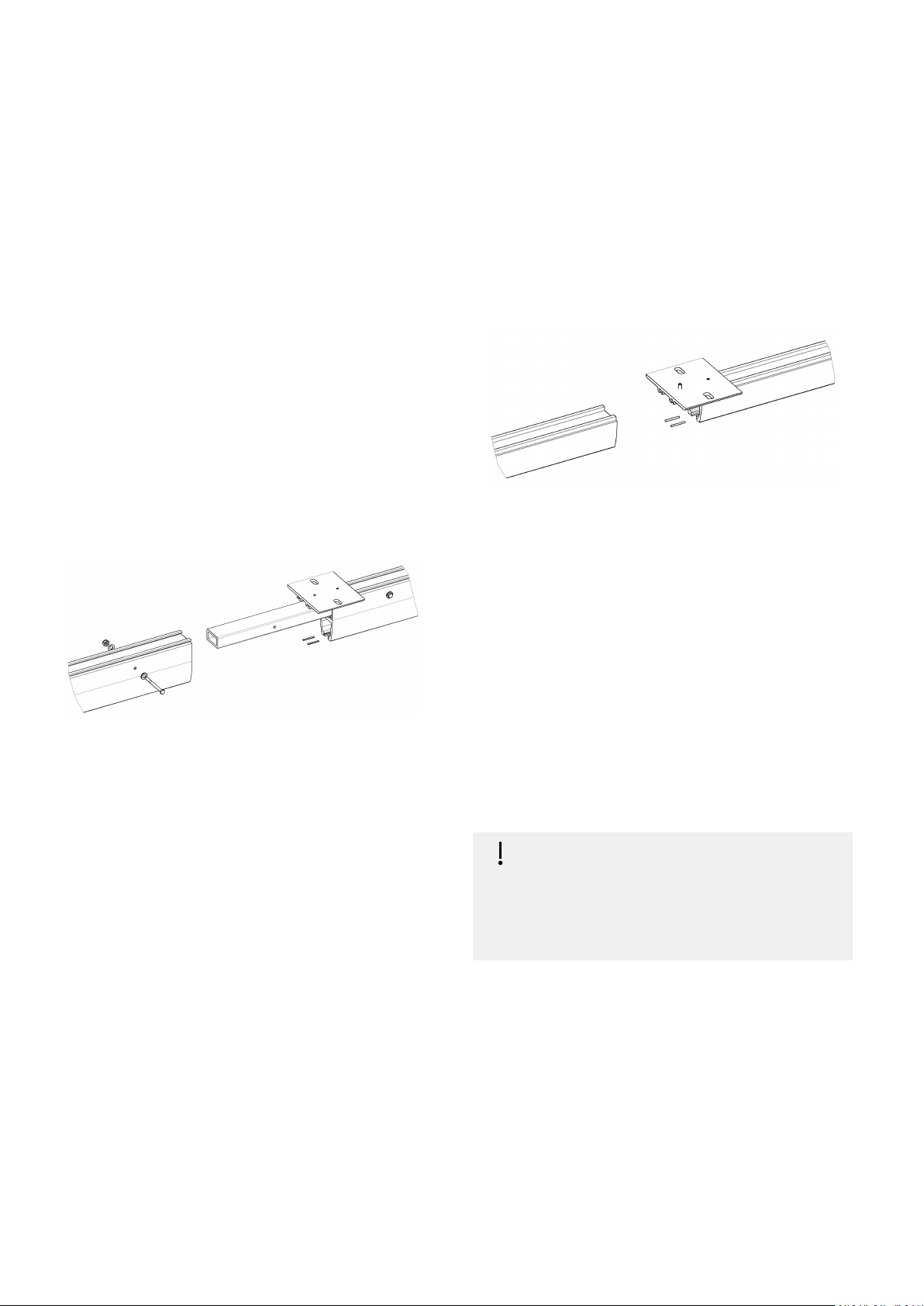

3.6Railcoupling

3.6.1RailcouplingforproleMandL

Thefollowingitemsareusedforrailcoupling:

•RailproleMno.1.

•RailproleMno.2.

•Insertiontube(forproleM).

•Couplingbracket(quickorstandard).

•Pipepins.

•Stopscrews.

•BoltM6.

•Washer.

•M6locknuts.

Pushtheinsertiontubehalfwayintorailproleno.1and

secureitwithapassingbolt.Furthermore,drilltheholes

forthepipepinsinrailproleno.2upto3.2mmina

depthcorrespondingtohalfthelengthofthepipepins.

Guidethepipepinshalfwayintorailproleno.1and

squeezethemtogetherintheend.

Pushthecouplingbrackethalfwayontorailproleno.1

andsecureitwiththestopscrew.

Thecouplingbracketisonlyrequiredwhenmountingthe

railontheceiling.Ifyouarecouplingatraverserail,the

couplingbracketisnotrequired.Pushtogetherrailprole

no.2andno.1andsecurethemwiththelockingscrew

inthecouplingbracketandthepassingbolt.

Installthecoupledrailusingtheinstructionsforinstallation

ofstraightrailproles,seesection5.2.

Whencouplinglongrails,itcanbedifculttoliftthe

coupledrailinonepiece.Inthiscase,rstinstalltherst

railontheceiling.Thenliftupthenextrailwhichhas

beenpreparedforcouplingandpushtherailstogether .

3.6.2RailcouplingforproleS

Thefollowingitemsareusedforrailcoupling:

•Railproleno.1

•Railproleno.2

•Couplingbracket(quickorstandard)

•Pipepins

•Stopscrews

1.Drilltheholesforthepipepinsinrailproleno.2up

to3.2mminadepthcorrespondingtohalfthelength

ofthepipepins.

2.Drivethepipepinshalfwayintorailproleno.1and

squeezethemtogetherintheend.

3.Pushthecouplingbrackethalfwayontorailproleno.

1andsecureitwiththestopscrew.

4.Insertrailproleno.2intothecouplingbracketand

drivethetworailstogether.

5.Tightenthestopscrewonrailproleno.2.

6.Installthecoupledrailsusingtheinstructionsfor

installationofstraightrailproles.

IMPORTANT!

Whencouplinglongrails,itcanbedifcultto

liftupthecoupledrailinonepiece.

–Inthiscase,rstinstalltherstrailonthe

ceiling.Thenliftthenextrailwhichhasbeen

preparedforcouplingandpushtherails

together.

3.7Wallsupportlegs

Wallsupportlegsareusedforinstallationongypsumwalls

andwallsofotherlightweightplatematerial.

201586749-C

Installation

•Wallsupportlegprole(adjust

length).

•Supportconsole.

•Wallsupportfoot.

•Plasticcoverplugs.

•ScrewsM6.

Thewallsupportlegiscutinthe

rightlength,intheendfacing

againsttheoor.

Whenmeasuringtheprolelength,

includeaminimumdistance

betweenthetopofthebracketand

theceiling.Minimumdistanceto

beobserved:

•M-prole:min.80mm

•L-prole:min.150mm

Mountthewallsupportlegonthewallwiththreescrews.

UseØ6mmscrews.Thewallmaterialdeterminesthe

choiceofscrews.

Formountingintogypsum,werecommendusing

(e.g.HiltiHGAorequal)sheerconnectorfor

cavities(e.g.HiltiHGAorequal).

Incaseofskirtingboards,eitherusethehighwall

supportfootorcuttheskirtingboards.

IMPORTANT!

–Remembertomakeallowanceforthewall

supportfoot.

–Alwaysinstallwallsupportlegdirectlyonthe

wallintheirfulllength.

•RailproleS:max.freespan2m,max.protrusion

200mm

•RailproleM:max.freespan4m,max.protrusion

200mm

•RailproleL:max.freespan8m,max.protrusion

400mm

Whenarailismountedaspartiallybetween-hung,

itisalwaysthemax.protrusionfortheS-prole

thatisapplicable.

Whenmountingthetraverserail,therearethreepossible

methods:

Thetraverserailisbetween-hung

Themeasurementforthetraverserailisalwaysthe

distancebetweenthetwoparallelrailsminus86mm.

Whenthetraverserailismountedbetween-hung,the

hoisttrolleyisinsertedinthetraverserailandtheend

stopsareplacedlooselyatbothendsofthetraverserail.

Rememberthattherubberplugontheendstopalways

shouldfaceinwardtowardthehoisttrolley.Lifttherailon

topofthetraversetrolley,sothattheendstop’s2bolts

alignwiththetwoholesinthetraversetrolley,thensecure

itwithwashersandlocknuts.Beforetherailissecurely

fastened,itisimportantthatthedistancebetweenthe

traverserailandeachoftheparallelrailsisequalinboth

ends.Whentherailissecured,installthecoverplugson

locknutsandintherails.

Thetraverserailisunder-hung

3.8Mountingtraversesystem

Theparallelrailsaremountedinceilingorwallas

describedintheprevioussectiononthecurrentmounting

conditions.

Eitherifthetwoparallelrailsaremountedusingquick

orstandardttings,itisimportantthatanydeviationof

parallelismofthetworailsdoesnotexceed+/-2mm.

Whenmountingparallelrails,itisimportanttotakeinto

accountwhetheritmustbepossibletoinsertatraverse

trolleylateronornot.Ifnot,therailsmayrunallthe

wayouttothewall(minimumdistancefromrailtowall

mustalwaysbe60mm).Inthiscaseitisimportantthat

thetraversetrolleyandendstoparepushedintothe

railbeforetherailismounted.However,ifitshouldbe

possibletoinsertthetrolleylateron,itisimportantthat

thereisaminimumdistancebetweentheoneendofthe

railandthewallof350mm.

Rememberthattheendstopintheparallelrailsistobe

placedsothatthetwotraversetrolleyshittheendstops

simultaneously.

Thedistancebetweentwoparallelrailsisalwaysmeasured

fromcentertocenterofthetworails.

Generally,thefollowingappliestothetraverserailwith

referencetothefreespanbetweentheparallelrailsas

wellasthemax.protrusionarailcanhandle.

Whentheparallelrailsaremountedandthetraverse

trolleysandendstopsarepositionedandsecured,install

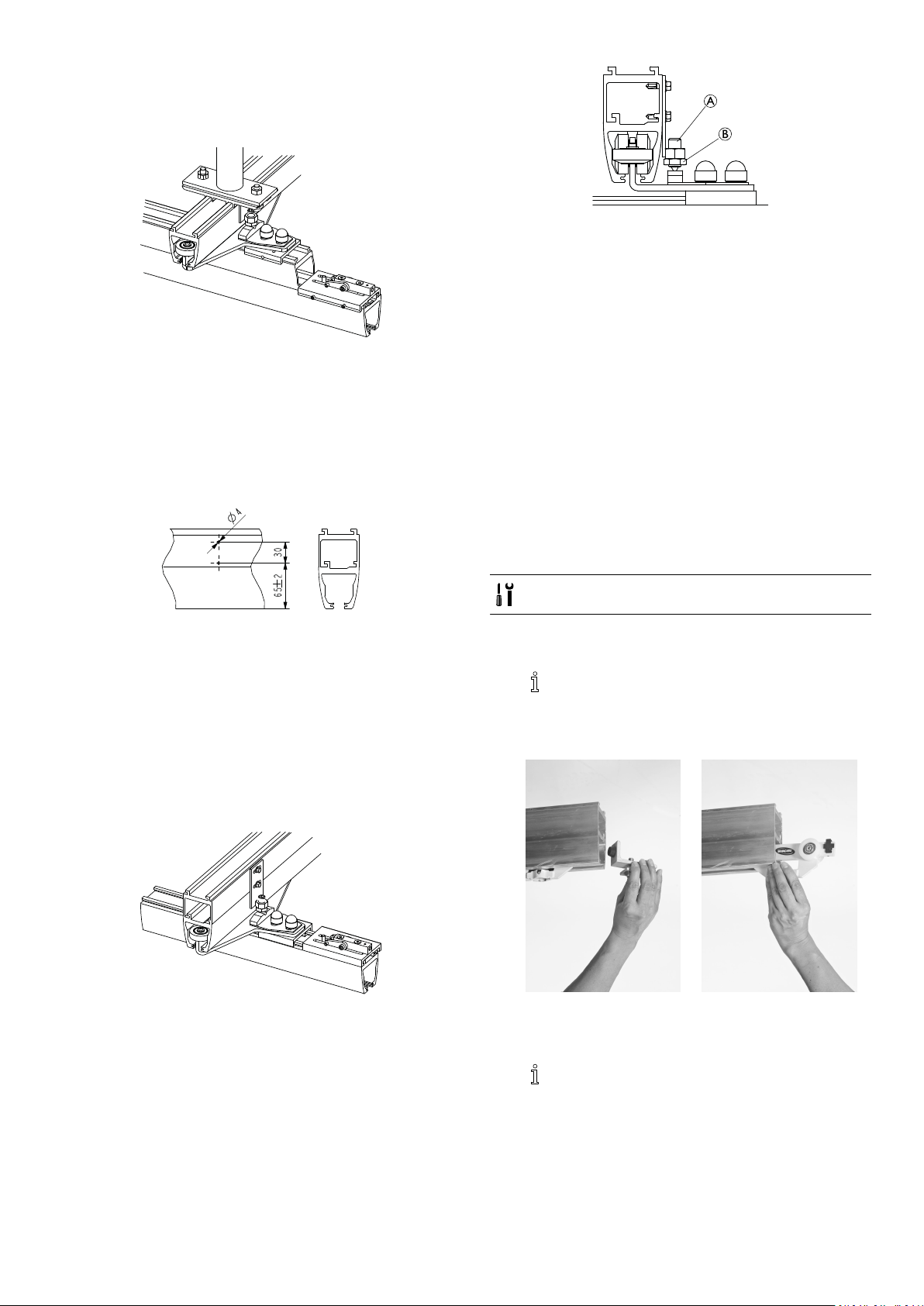

quicktraversebracketsunderneaththetraversetrolley,

asshownonthedrawing.

Regardlesswhetherthetwotraversetrolleysarefacing

oppositeeachotherorthesameway,itisimportantthat

thetwoquicktraversebracketsfacethesameway,orelse

therewillbeproblemswhenmountingtherail.

Whenthetraverserailiscorrectlyplacedlengthwiseand

securedinthequicktraversebracketwiththeAllenscrew,

therailislockedusingalathecenterscrew,whichis

1586749-C

21

Invacare®EC-Track®

screwedintothequicktraversebracketfromaboveuntilit

hasbeenscrewedallthewaydown.

Thetraverserailispartlybetween-hung

Whenthetraverserailispartlybetween-hung,thesame

mountingprincipleisusedaswithunder-hungtraverse

rail.Here,therailwillbecutupondelivery,sothatthe

quicktraversebracketmaybemountedtotherail’smiddle

suspensionpoint.

Rememberbeforemountingthetraverserailtodetermine

whetheritshouldbepossibletomountthehoisttrolley

laterornot.

3.9Installationoftrackswitches

Thetrackswitchisusedwhereachangeindirectionis

requiredduringmovementofthepatient.Thetrackswitch

ismanuallyoperated.Bycouplingofthetrackswitch

withbothstraightrailsaswellascurvedrails,different

combinationscanbeobtained.

IMPORTANT!

–Afterinstallation,thefunctionsofthetrack

switchandthefasteningoftheendstops

mustbeinspected.

3.10Transitcoupling

Thetransitcouplingisusedinsituationswhere

transportationfromoneroomtoanotherisrequired,using

onlyoneRobinmotor.Thecouplingisoperatedelectrically .

Thetransitcouplingcanbeinstalledindifferentrailsystem

combinations.Thecouplingcanbeusedtoconnecteither

twotraversesystemsoronetraversesystemandone

singlerailsystem.

Thecouplingisdeliveredwithastandardlengthof800

mm,andcanbeusedwherethewallis,upto170mm

thick.Thecouplingisdeliveredwithonecontrolbutton,

onepowersupplywith2metersofwire(whichmustbe

adjustedduringinstallation),andausermanual.

Ifatransitcouplingisneededinsituationswhere

thewallisthickerthan170mm,contactInvacare®.

Whenorderingthetransitcoupling,itisimportantto

orderlockxturesfortherailsinbothroom1and2.

Whencouplingtoasinglerailsystem,pleaseseesection

5.5aboutRailcoupling.Pendlesfortheinstallationarenot

deliveredwiththecoupling.Orderpendlesseparatelyin

requiredlengthforthecoupling.

Thetrackswitchcanonlybeusedincombinationwith

ceilinginstallationandS-prolerails.Thetrackswitchis

designedforstandardceilingbracket.

Duringorderingorinstallationofthestraightorcurved

singlerailsystem,itisimportanttobareinmindinwhich

directionthemountingdowelsofthetrackswitchare

facing.Onlyonestandardtrackswitchisavailable-refer

totheillustration.

Byinstallationinconcreteceiling,refertochapter3.2.1

ConcreteCeiling,page14

3.6.2RailcouplingforproleS,page20.

Are-boreintherailsisperformedwhencouplingtherails.

Thisre-boreisdoneinthetrackswitchatdelivery,and

thenecessarytubepinsaresupplied.Wheninstallingthe

railstotheswitch,remembertotightenthepre-installed

lockingscrewsonthetrackswitch-refertotheillustration.

Inconnectionwithinstallationofatrackswitchonto

differentceilingtypesorincombinationswithpendles,

contactInvacare®forfurtherinformation.

(standardbrackets),andchapter

Recommendedinstallation:

1.Transitcoupling

2.Traversesystem/singlerailsystem

3.Positioningxtures

4.Endtest–Functionandloadtest

3.10.1Adjustingtheholeinthewall/door opening

CAUTION!

–Beforemakingholeinwall,ensurewallisnot

loadbearing.

Theholemustalwaysbeplacedexactlyinthecenterof

thedooropening:

Ifitisrequiredthatonly

therailmustpassthrough

thewall,theholeneeds

tobeminimum73mm

highandminimum65mm

wide.

Ifincreasedliftingheight

isrequired,theholemust

bebigger .

Foraholeheightofmore

than80mm,thewidthhas

tobeatleast600mmfor

theceilinghoisttopass

through.

22

1586749-C

Installation

Thebestresultisobtained,ifthetransitcoupling

hasbeentakenintoconsiderationinthevery

beginningofthehouseconstruction.Thisway

thedooropeningcanbeconstructedwiththe

optimumliftingheight.

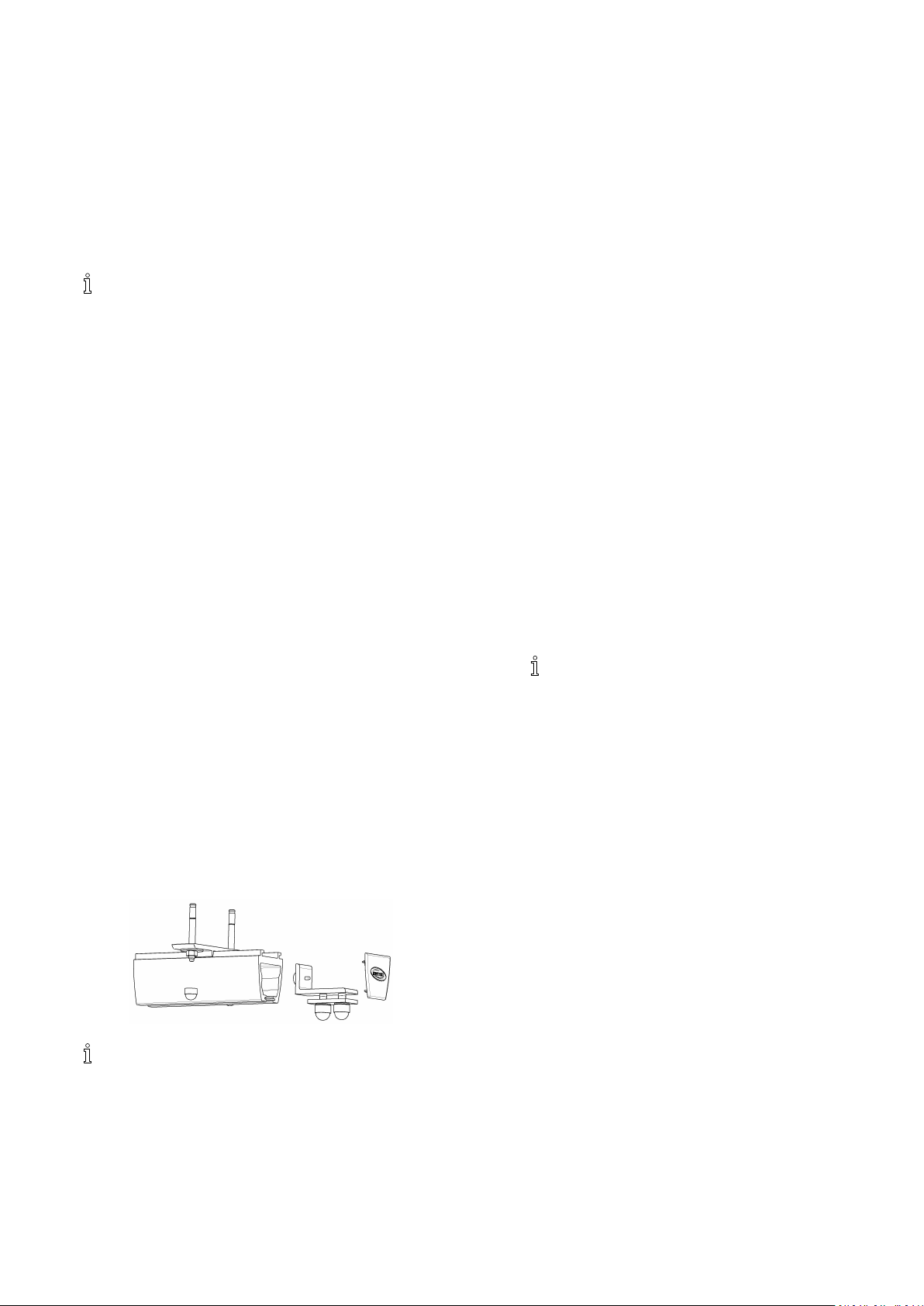

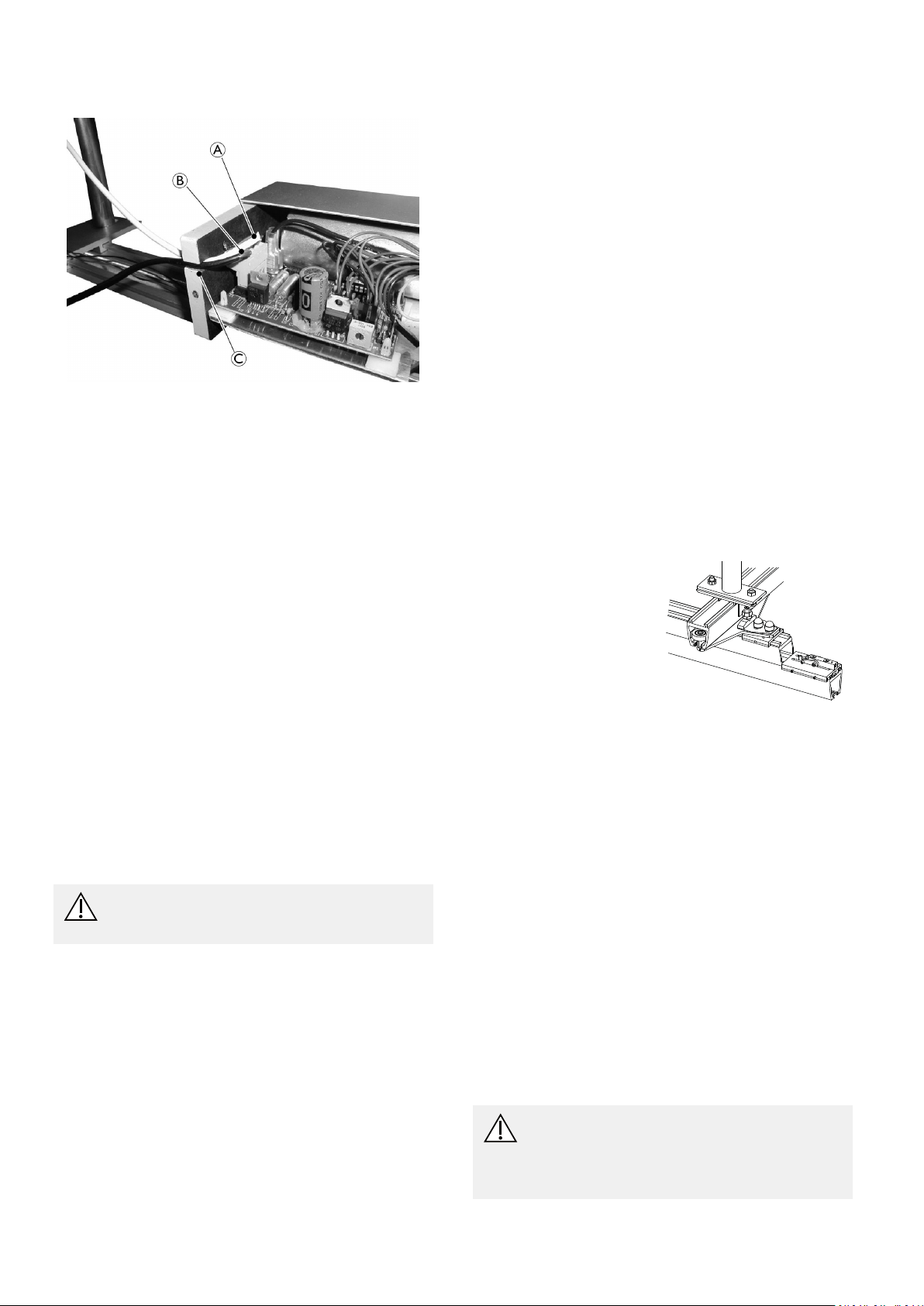

3.10.2Installingthetransitcoupling

Thecouplingisdeliveredassembledwithmotorbox,

xturesforpendlesandlockxtures.Thedeliveredtransit

couplingispreparedsothatthewholemotorboxisplaced

inoneofthetworoomsafterinstallation.

Themotorboxandlockxtures,havetobeplacedas

thetransitisdelivered,toensurefunctionalityandsafety.

Fixturesforpendlescanbeplacedfreelyaslongasit

complieswiththeconstructionofthesystem.Seemeasure

sketchbelow.

Itisveryimportantthatthethicknessofthewall

iscontrolledinadvance.

Wheninstallingthetransitcouplingitisveryimportant

thatthemotorboxisplacedintheroomwhereitwas

intendedwhenitwasordered,becausetheentiresystem

isconstructedunderconsiderationofwherethemotor

boxisplaced.

Installationwithpendlesisdescribedinchapter3.2.2

ConcreteCeilingwithSuspendedCeiling,page15.

Seethemeasuresketchbelowforfurtherinformation.

Installationofthetransitcouplingisonlypossibleusing

pendles.Thecouplingcanthereforeonlybeinstalled

whereceilingmountingispossible.

Thebestresultisobtainedinaconcreteceiling.

Wheninstallinginwoodenceilings,itisveryimportant

thatthetraversesystemandcouplingareinstalledinaway

thattheybenddownequallyandwithminimumbending.

Ifitisnecessarytostrengthentheceilinginawooden

ceilingconstruction,makesuretostrengthenwitha

connectedconstructionbetweenrailsystemandtransit

coupling.

Donotinstallthependlesindifferentraftersbecausethis

waythecouplingandtraversesystemwillnotbenddown

equallyandthecouplingwillnotworkcorrectly.

Measuresketchfortransitcoupling

1586749-C23

Invacare®EC-Track®

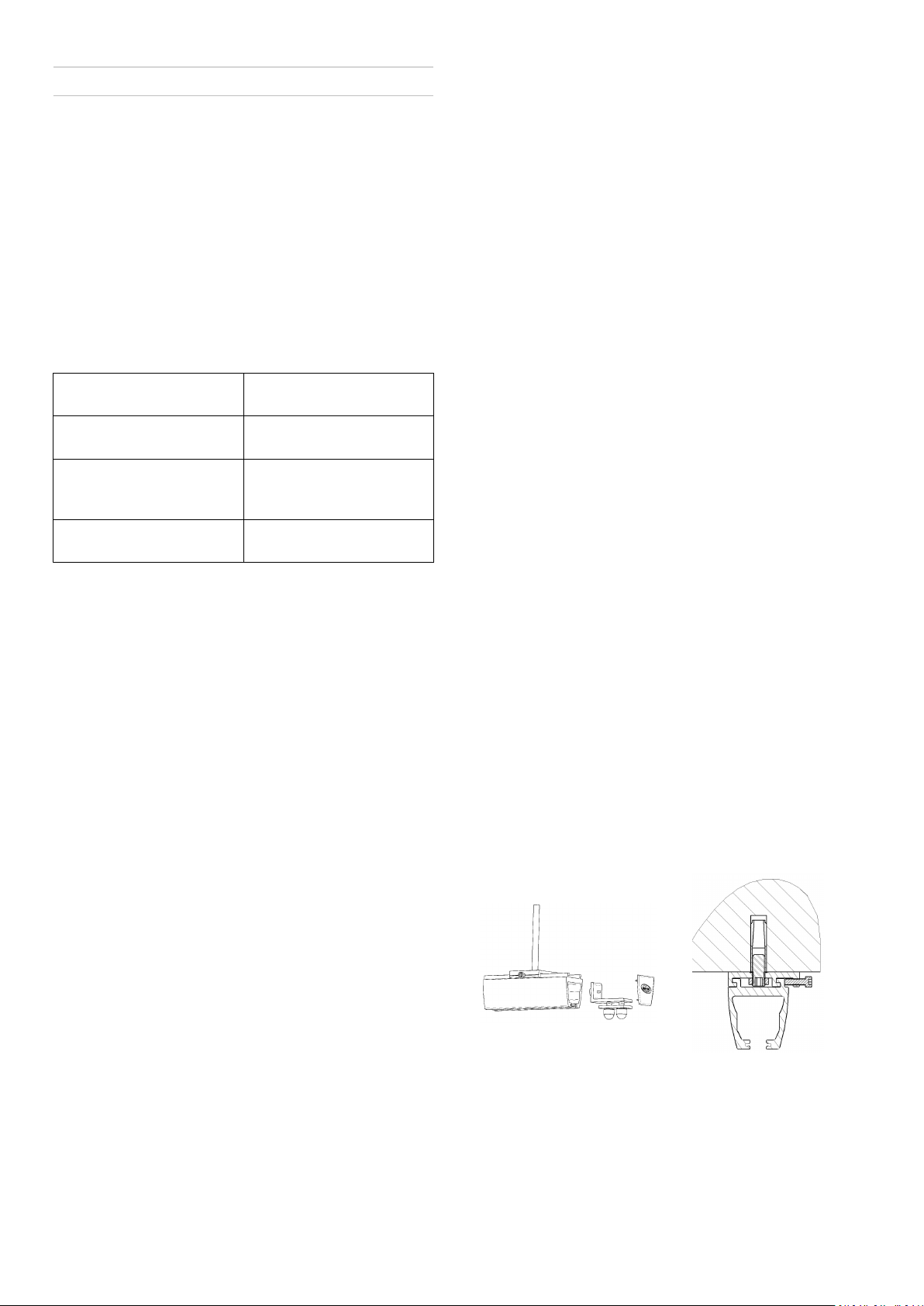

3.10.3Installingandconnectingcontrolbutton andpowersupply

Beforeconnectionofthecontrolbuttonandpowersupply ,

itisnecessarytodismountthecoversonthemotorbox.

Thecoversaredismountedbylooseningthetwoscrews,

whichholdseachcoverandpullingthecovershorizontally

totheside.

Thecontrolswitchismountedintheroomandatthe

height,theuserprefers.Thecontrolswitchisopenedwith

tools,andthebacksideismountedonthewallusingtwo

screwsØ3.5x30mm.

Thewireisshortenedtoasuitablelengthandconnected

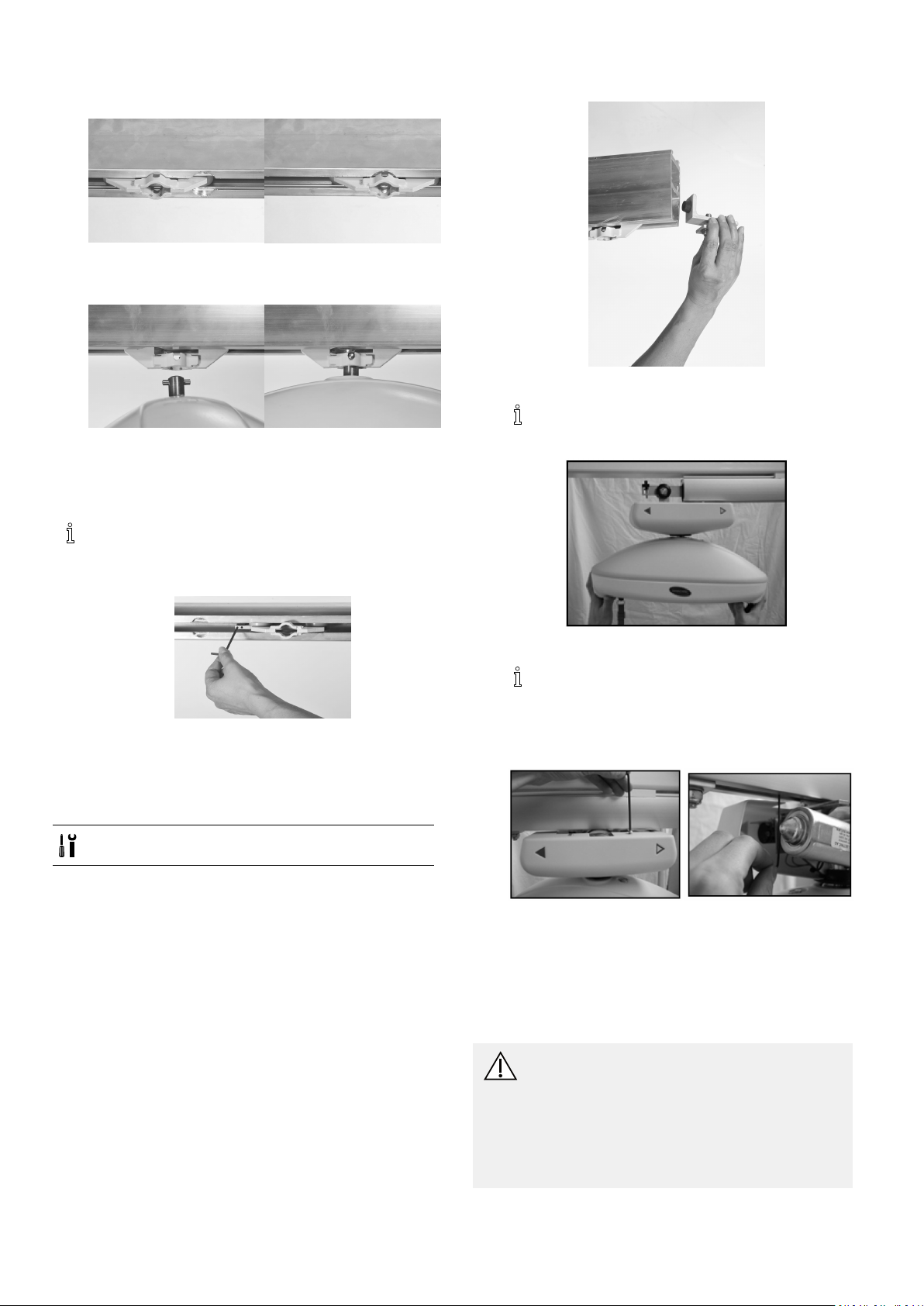

tothemotorbox.Seedrawingpos.A.

Thepowersupplyismountedonthewall,visibleor

hidden,dependingonwhatismostsuitable.Thepower

supplyismountedonaØ3.5x30mmscrewonthewall,

usingthe“key”holeonthebacksideofthepowersupply.

Atthebottomofthepowersupplythereisholefora

Ø3.5x30mmscrewwhichmakesitpossibletolockthe

powersupplyonthewall.Thewireisshortenedtoa

suitablelengthandconnectedtothemotorbox.See

drawingpos.B.

Thecoverisre-attached,whenthewiresareconnected

correctlyandthecontrolswitchistested.Rememberto

mountthewiresintheend-plate,inordertoavoidthat

thewireconictswiththecoverwhenitisre-attached.

Seedrawingpos.C.

CAUTION!

Itisveryimportantthattherearenoloose

wireshangingfromthecoupling.

Whentheparallelrailismounted,itisimportanttoensure

acorrectdistancetothecoupling.Seeimageinchapter

Measuresketchfortransitcoupling,page23.

Thetraverserailisadjustedtothespecicorderwhen

itisdelivered.Ifhoweveritisnecessarytoshortenthe

railfurther,itmustbeshortenedintheendoppositeto

wherethecouplingissituated.

Itispossibletousethefollowingtraverserailstogether

withatransitcouplingsystem:

•S,MandL-proles,under-hung

•MandL-prolespartlybetween-hung

Itisveryimportanttoensurethecorrectfreeoverhang

forthetraverserailspacingbetweenthependlesandfree

spanfromtherailstoensurethattherailscancouple

correctly.Seedrawingabove.

Whenthetraversesystemandthecouplingareinstalled

itisveryimportanttocontroltheheightbetweenthese

andadjustifnecessary.

Theloweredgeofthetraverserailmustnotdiffermore

than0.5mmfromthecouplingrail.Ifthereisadifference

inheight,thecouplingtrackmustbethelowest.

Itmaybenecessarytoadjusttheheightdifferently

accordingtotheuserweightortheconditionofthe

ceiling,tooptimizethefunctionofthecoupling.

Whenthelockxturesare

installed,itisveryimportant

thattheyareinlinewith

theendofthetraverserail

andthattheyareturned

correctlycomparedtothe

xtureonthecoupling,

beforetheyarelocked.See

drawing.

LockxturesforM-andL-prolesaredeliveredwitha

littleplate,whichisimportanttoinstall.

3.10.5Installationofasinglerailforacoupling system

Whenthecouplingisinstalledwithasinglerailinoneof

therooms,itispreparedforthis,withoutthelockxture,

whendelivered.

WhenthecouplingisinstalledwithanS-prolerail,the

railiscoupledasshowninchapter3.6.2Railcouplingfor

proleS,page20.

3.10.4Installingatraversesystemwithlock

xturefortransitcoupling

Ingeneralatraversesystemisinstalledasshownin

chapter3.8Mountingtraversesystem,page21.We

recommendthattheparallelrailofthetraversesystemis

mountedintheceilinginordertomakethefunctionof

thetransitcouplingasstableaspossible.

Wheninstallingtheparallelrail,rememberalwaystoplace

aceilingbracket/pendleinfrontofthetransitcoupling,

especiallyontherailclosesttothetransitcoupling.See

chapter3.10.6Mountingthepositioningxturesonparallel

railS-proleandM/L-proles,page24

24

.

Thependleismountedinthecouplingxture.

Therestofthesinglerailsystemisinstalledasshownin

chapters3.2CeilingMountingSystem,page14

Railcoupling,page20.

and3.6

3.10.6Mountingthepositioningxtureson

parallelrailS-proleandM/L-proles

CAUTION!

Itisveryimportantthateverythingisadjusted

correctlyandcarefullyfastenedduetosafety

andfunctionality.

–T estthesystemthoroughlyafterinstallation.

1586749-C

Thepositioningxtureismountedtoeasilypositionthe

A

B

traverserailinproportiontothecoupling.Thextureis

mountedontherailclosesttothecouplingandisturned

towardsthecoupling.Seedrawing.

ThepositioningxturefortheS-prolerailsispartly

mountedinthestandardxture.Itisthereforeimportant

toplaceastandardxturerightinfrontofthecouplingrail.

Installation

Adjustment of positioning xtures

The parallel rail part of the positioning xture c an be

adjusted further by loosening the screws and moving the

xture h orizontally u ntil t he r ail i s r ight i n f ront o f the

coupling.

After adjustment the xture c an b e fastened.

Note that there is some play, which must be divided

between both sides of the rail.

Theonepartofthepositioningxtureismountedinthe

M10boltatthestandardceilingbracketinthesame

directionasthequickxtureonthetraversetrolley .The

traversepartofthepositioningxtureismountedonthe

Quickxtureofthetraversetrolley.Seedrawing.

ThepositioningxtureforM-/L-prolerailsismountedon

respectivelytheparallelandthetraverserail.Thetraverse

partofthepositioningxtureismountedonthequick

xtureofthetraversetrolley.

Thetraverserailandtransitcouplingmustbecoupled

whenmountingtheparallelrailpartofthepositioning

xture.Thiswayitispossibletotickupforcorrect

positionofthexturesbeforetheyaremounted.After

therightpositionistickedup,therailsareseparatedagain

beforetheØ4mmholesforthescrewsaredrilled.See

drawingbelow.

3.11 Installing the ceiling hoist to the rail system

Robin requires a trolley, guiding the ceiling hoist in the rail

system. Robin Mover has the trolley built-in and can be

installed directly to the rail system.

3.11.1 Installing Robin®

Tools:4mmAllenkey;17mmsocketwrench

1.Toinstallthetrolley ,removetheendstopthatis

attachedtotherailsystem.

Insomecountries/localareas,thereisa

demandfordoublesecuringoftheendstops.

Ifanextrasecuringscrewisinstalled,remove

thisscrewbefore.

Adjustmentofhardness

Thepositioningxturesmustbeadjustedtoahardness

thatmakesiteasyforthecouplingtocatchthetraverse

rail,butatthesametime,makesitpossiblefortherailto

passthecouplingwithoutgettingcaughtbythecoupling.

1.Ifthepositioningxtureisadjustedtoohard,loosen

theresilientblackscrewA.

2.Ifthepositioningxtureistoosoft,tightenscrewA.

3.TightenlocknutB(M12)afteranyadjustment.

2.Insertthetrolleyintotherail(nomatterwhichway,

asthetrolleyissymmetric).

3.Re-inserttheendstop.

Insomecountries/localareas,thereisa

demandfordoublesecuringoftheendstops.

Ifanextrasecuringscrewisrequired,install

thisscrew.SeealsoEndStop,page11.

1586749-C25

Invacare®EC-Track®

4.LocatethehoisttrolleyattheØ32mmroundrecess

intherail.

5.Liftthehoistandpushthesuspensionpinthrough

thetrolleyopening.

6.Turnthehoistby90degreestoxitinthetrolley.

7.Connectthehandcontrol.

8.Adjustthelengthoftheemergencystop/loweringcord

towithintheuser’sreach.

1.Removetheendstop.

2.Insertthewheelsofthehoistintotherail.

Thedirectionthehoistfacesdoesnotmatter

duringinstallation.

Ifthereisexcessiveresistance,orifthetrolley

unintentionallyrollsbyitselfduetoimbalancein

therailsuspensions,adjustthefrictionbrakeusing

a4mmAllenkey.

3.11.2InstallingRobin®Mover

Thetrolleyisbuilt-inonthehoist,andcanthereforenot

bepreinstalledintherail.

Tools:4mmAllenkey;17mmsocketwrench

3.Installtheendstop.

Tightentheboltto30Nm.

4.Iftoomuchresistanceisexperiencedwhenthe

hoistispulled,orthehoistmovestoofreelyand

unintentionally,adjustthefrictionbrake.

5.Connectthehandcontrol.

6.Adjustthelengthoftheemergencystop/loweringcord

towithintheuser’sreach.

3.12Inspection/checkoftherail

system

CAUTION!

Aftertheinstallationofarailsystem,theentire

systemmustbeinspected.

–Theinspectionofarailsystemmustonlybe

carriedoutbyasuitablyqualiedperson.

–TheinspectionmustfollowtheSafety

inspectionchecklist/Railsysteminthe

Invacare®Robin®ServiceManual.

261586749-C

Installation

InaccordancewiththeEuropeanstandardEN10535,the

systemshallbestresstestedwith300kg.Thisshouldbe

doneateachxingpoint.Thistestiscarriedoutasa

re-testingofthesystemstructuresabilitytosecurethe

railsysteminplace.

1586749-C

27

Invacare®EC-Track®

4TechnicalData

4.1 The rail system

All rail proles a re m anufactured in extruded aluminium.

The rails are available with white powder coating.

The rails are available in three different heights; S= 68

mm, M=114 mm and L=183 mm, providing a fee span of 2

m, 4 m and 8 m, respectively.

The prole width of all three p roles is 58 mm . Th e top of

the proles a re shaped to p ermit the coupling of the rails

to the installation brackets.

On delivery, the rail for the hoist will feature a milled

groove on its bottom. This groove is used for hoist

installation and is called keyhole.

Possible installations

Single rail can be installed on the ceiling or onto the wall

and oor. T he r ail p osition i n t he r oom c an b e either

parallel to a wall or angular in relation to a wall.

The traverse system can be installed on the ceiling or onto

the wall and oor. T he free s pan between t he two parallel

rails can be up to 8000 mm.

K

Measuredfrom

beneaththe

railtothesling

hook

H

Ceiling

mounted

RailproleS

Wall/oor

mounted

RailproleM

Wall/oor

mounted

RailproleL

Traverserailsystemheight

Robin Robin Mover

336mm396mm

410mm470mm

450mm510mm

519mm579mm

Curves are available in the S-prole a nd c an b e installed

on the ceiling. They are available in angles of 30°, 45°,

60° and 90°.

Special solutions

Installation with pendling brackets is used in the following

cases: When the height of the ceiling varies in the

lengthwise direction of the rail, or when the rail is to be

countersunk.

Angular installation is used when the rail has to be

installed in other angles than 90°.

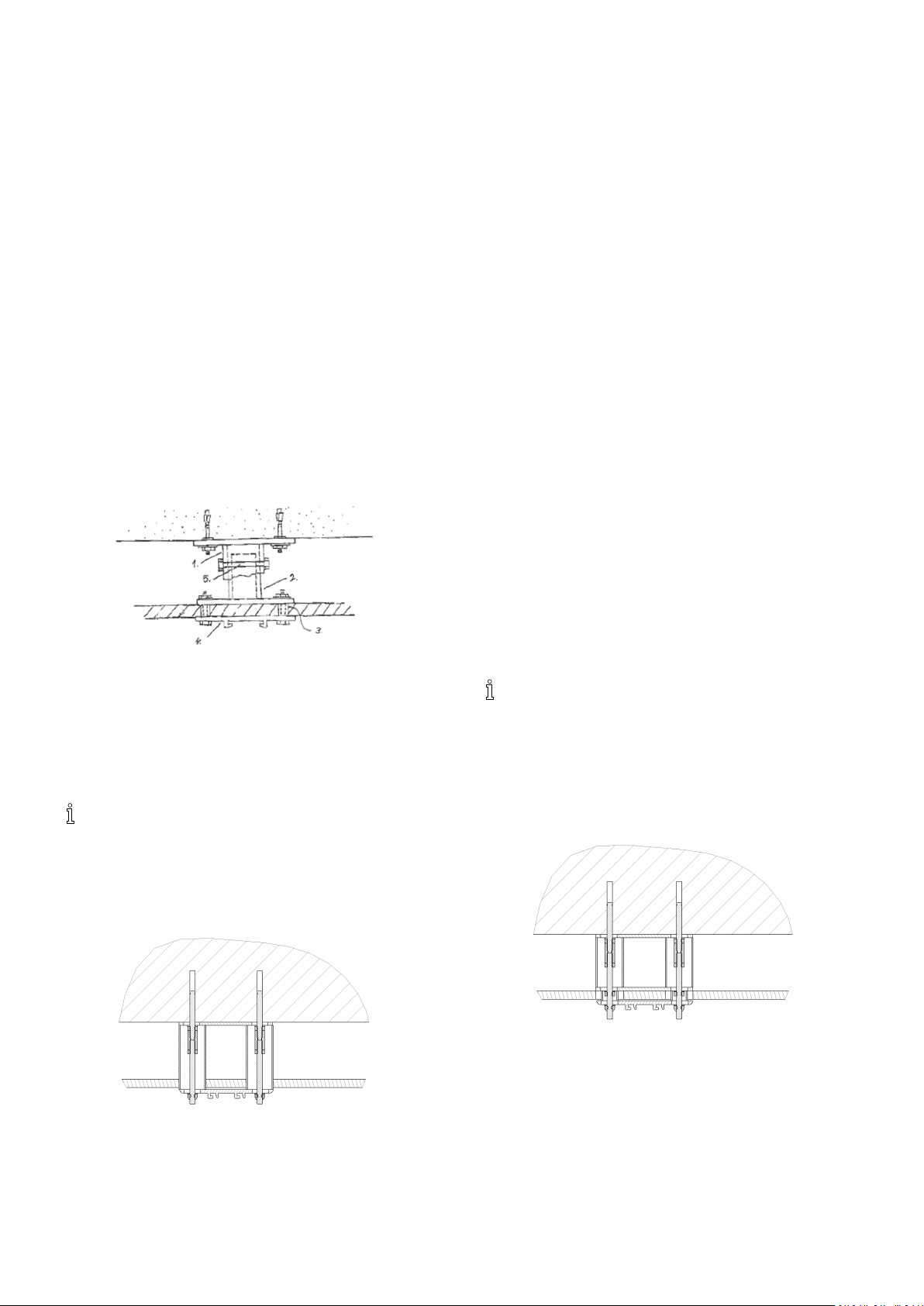

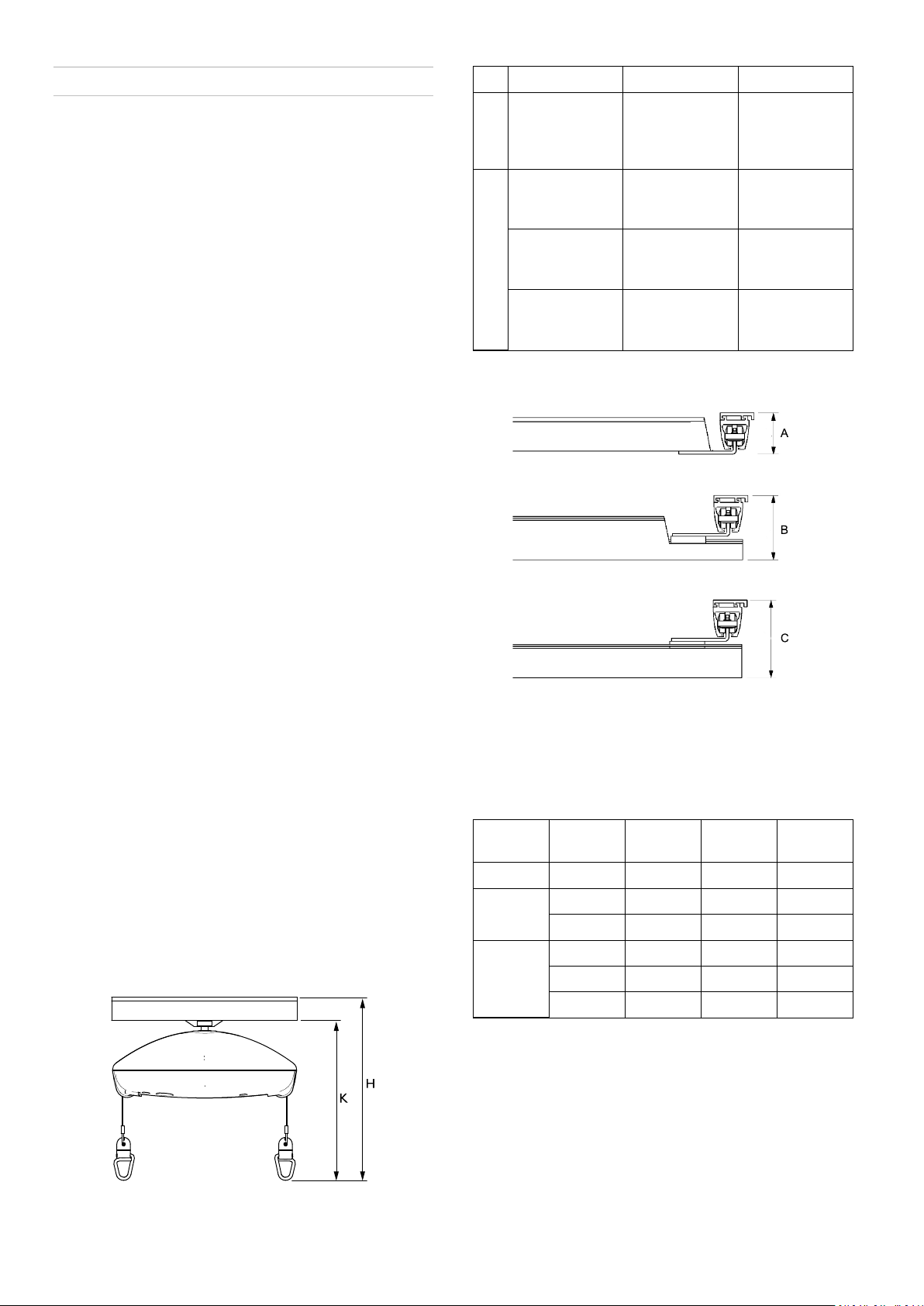

4.2 Dimensions for different track installations

The building dimensions of an installation is dened as

the distance between the ceiling underside and the hooks

of the hoist.

Single rail height

For the EC-Track system and Robin ceiling hoist, the

dimensions for being built-in, measured from the ceiling

with the rail mounted as close as possible to the ceiling,

are:

A=Between-hungtraverse

B=Partlybetween-hungtraverse

C=Under-hungtraverse

Possiblecombinations

Traverse

rail

S-proleS-prole

M-prole

L-prole

Parallel

rail

83mm

S-prole

M-prole

S-prole

M-prole

L-prole

129mm203mm250mm

198mm272mm388mm

A

—

——

——

B

—

156mm203mm

C

156mm

272mm

319mm

281586749-C

Indholdsfortegnelse

FORHANDLER:Opbevardennemanual.Procedurerneidenne

manualSKALudføresafenuddannettekniker.

1Generelt........................................30

1.1Omdennemanual.............................30

1.2Generelsikkerhed..............................30

1.3Garantioplysninger.............................30

2Skinnesystem.....................................31

2.1Enkeltskinnesystem.............................31

2.2Køresystem...................................32

2.3Forytningtilellerfralokale......................33

2.4Skinner,beslagogtilbehør........................34

3Installation.......................................39

3.1Generellemonteringsanvisninger...................39

3.2Loftsmonteringssystem..........................39

3.2.1Betonloft..................................39

3.2.2Betonloftmedophængtloft....................40

3.2.3Træloft...................................42

3.3Vægmontering–endeophængtskinne...............43

3.3.1SkinneprolMogL..........................43

3.4Vægmontering–sideophængtellerside-/endeophængt

beslag......................................44

3.5Kurver.......................................44

3.6Skinnetilkobling................................45

3.6.1SkinnetilkoblingtilprolMogL.................45

3.6.2SkinnetilkoblingforprolS.....................45

3.7Vægstøtteben.................................46

3.8Monteringafkøresystem.........................46

3.9Installationafskinneskift.........................47

3.10Transitkobling................................47

3.10.1Justeringafhulletivæggen/døråbningen.........47

3.10.2Monteringaftransitkoblingen..................48

3.10.3Monteringogtilslutningafbetjeningsknapog

3.10.4Monteringafetkøresystemmedlåseanordningtil

3.10.5Installationafenenkeltskinnetilet

3.10.6MonteringafplaceringsholdernepåS-prolenog

3.11Monteringafløftemotorenpåskinnesystemet........50

3.11.1MonteringafRobin®........................50

3.11.2MonteringafRobin®Mover...................51

3.12Eftersyn/kontrolafskinnesystemet.................51

4T ekniskeData.....................................53

4.1Skinnesystemet................................53

4.2Måltilforskelligeskinneinstallationer................53

strømforsyning.............................49

transitkobling..............................49

koblingssystem.............................49

M/L-prolenforparallelskinne.................49

Invacare®EC-Track®

1Generelt

1.1Omdennemanual

Denneinstallationsmanualerberegnetsomenvejledning

tilatplanlæggeogudføreinstallationen.Foratvikan

garanteresikkerhedenvedhåndteringafproduktet,skal

manualenlæsesomhyggeligt,ogsikkerhedsanvisningerne

skalfølges.

Seoplysningeromforsalgogbrugeroplysningeri

brugsanvisningen.Dukanndebrugsanvisningen

påInvacareshjemmesideellervedatkontaktedin

Invacare-forhandler(seadressersidstidennemanual).

Symboleridennemanual

Idennemanualvisesfaresituationermedsymboler.

Symbolerneledsagesafetsignalord,derangiver ,hvor

alvorligrisikoener.

ADVARSEL

Angiverenpotentieltfarligsituation,somkan

resultereialvorligkvæstelseellerdødsfald,

hvisdenikkeundgås.

FORSIGTIG

Angiverenpotentieltfarligsituation,somkan

resultereienmindreellerlillekvæstelse,hvis

denikkeundgås.

VIGTIGT

Angiverenpotentieltfarligsituation,somkan

resultereibeskadigelseafejendom,hvisden

ikkeundgås.

Tipsoganbefalinger

Givernyttigetips,anbefalingerogoplysninger,

dersikrereneffektiv,problemfrianvendelse.

Indeholderoplysningeromdetnødvendige

værktøj.

DetteprodukterCE-mærketi

overensstemmelsemedforordningen

2017/745ommedicinskudstyriklasse1.

Lanceringsdatoenfordetteproduktfremgår

afCE-overensstemmelseserklæringen.

1.2Generelsikkerhed

ADVARSEL!

Sikkerhedsreglerførmontering

–Alleinstallationerskaloverholdedenationale

reglerogstandarder.

–Brugkungodkendteinstallationskomponenter.

–Påhvertenkeltophængspunktskal

tag-/loftsstrukturenkunnebæreenstatisk

vægtpåmindst300kg.

–Førmonteringafetkøresystemskaltag,

væggeoggulvundersøgesgrundigt.Udfør

enpræcisvurderingaf,hvilkematerialer

derndesitagetogvæggene.Denne

undersøgelsemåkunforetagesafen

kompetentperson.

–Skinnesystemetmåkunmonteresaf

kompetentepersoner .

Stresstest

IhenholdtildeneuropæiskestandardEN10535skal

systemetstresstestesmed300kg.Detteskalgørespå

hvertenestefastgørelsespunkt.Dennetestskaludføres

somentestafsubstratetsevnetilatholdeskinnesystemet

påplads.Dennetestskalforetagesafenkompetent

person.

1.3Garantioplysninger

Garantivilkårog-betingelserindgårivoresgenerellevilkår

ogbetingelser ,dergælderspeciktforderespektivelande,

hvorproduktetsælges.

KontaktoplysningernetildinlokaleInvacare-forhandler

ndesindvendigtpåbagsidenafdennebrugsanvisning.

301586749-C

Loading...

Loading...