Invacare Arrow RWD, Torque? SP RWD, Ranger X? RWD, 3G Storm Arrow RWD, 3G Storm Torque SP RWD Service Manual

...

Service Manual

3G Storm Series® Wheelchairs

Arrow® RWD

Torque SP RWD

Ranger X RWD

DEALER: KEEP THIS MANUAL. THE PROCEDURES

IN THIS MANUAL MUST BE PERFORMED BY AN

AUTHORIZED DEALER ONLY

W

A

R

N

I

N

G

WARNING

WARNING

THE PROCEDURES IN THIS MANUAL SHOULD ONLY BE PERFORMED BY

A QUALIFIED SERVICE TECHNICIAN.

DO NOT SERVICE OR OPERATE THIS EQUIPMENT WITHOUT FIRST

READING AND UNDERSTANDING THIS MANUAL AND THE OWNER’S

MANUAL SUPPLIED WITH THE WHEELCHAIR. IF YOU ARE UNABLE TO

UNDERSTAND THE WARNINGS, CAUTIONS, AND INSTRUCTIONS,

CONTACT INVACARE TECHNICAL SUPPORT BEFORE ATTEMPTING TO

SERVICE OR OPERATE THIS EQUIPMENT - OTHERWISE INJURY OR

DAMAGE MAY RESULT.

SPECIAL NOTES

S

P

E

C

A

L

N

O

T

E

S

WARNING/CAUTION notices as used in this manual apply to hazards or unsafe practices

which could result in personal injury or property damage.

NOTICE

I

THE INFORMATION CONTAINED IN THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT

NOTICE.

WHEELCHAIR USER

As a manufacturer of wheelchairs, Invacare endeavors to supply a wide variety of

wheelchairs to meet many needs of the end user. However, final selection of the type

of wheelchair to be used by an individual rests solely with the user and his/her healthcare

professional capable of making such a selection.

WHEELCHAIR TIE-DOWN RESTRAINTS AND SEAT POSITIONING STRAPS

Invacare recommends that wheelchair users NOT be transported in vehicles of any

kind while in wheelchairs. As of this date, the Department of Transportation has not

approved any tie-down systems for transportation of a user while in a wheelchair, in a

moving vehicle of any type.

It is Invacare’s position that users of wheelchairs should be transferred into appropriate seating in vehicles for transportation and use be made of the restraints made

available by the auto industry. Invacare cannot and does not recommend any wheelchair transportation systems.

AS REGARDS RESTRAINTS - SEAT POSITIONING STRAPS - IT IS THE OBLIGATION OF THE DME

DEALER, THERAPISTS AND OTHER HEALTHCARE PROFESSIONALS TO DETERMINE IF A SEATING

POSITIONING STRAP IS REQUIRED TO ENSURE THE SAFE OPERATION OF THIS EQUIPMENT BY

THE USER. SERIOUS INJURY CAN OCCUR IN THE EVENT OF A FALL FROM A WHEELCHAIR.

SAVE THESE INSTRUCTIONS

2

TABLE OF CONTENTS

TABLE OF CONTENTS

NOTE: The information in this owner's manual applies to the STORM ARROW , STORM TORQUE X, RANGER

X, and the RECLINER Wheelchairs except where specified.

SPECIAL NOTES ................................................................................................................................... 2

SPECIFICATIONS

FOR ARROW.................................................................................................................................... 5

FOR TORQUE SP ........................................................................................................................... 6

FOR RANGER X .............................................................................................................................. 7

PROCEDURE 1 - GENERAL GUIDELINES ...........................................................................................8

REP AIR OR SERVICE INFORMA TION ..............................................................................................8

OPERA TING INFORMATION .............................................................................................................8

WARNING/CAUTION LABEL LOCA TION....................................................................................... 10

PROCEDURE 2 - TROUBLESHOOTING ............................................................................................ 12

FIELD LOAD TEST .........................................................................................................................1 2

USING HYDROMETER TO CHECK BA TTER Y CELLS (LEAD ACID).............................................. 12

MOTOR TESTING........................................................................................................................... 13

MOTOR BRUSH INSPECTION ....................................................................................................... 14

ELECTRO-MECHANICAL P ARKING BRAKE TESTING................................................................... 14

PROCEDURE 3 - HARDWARE TORQUE SPECIFICATIONS .............................................................. 15

ST ANDARD SEAT FRAME.............................................................................................................. 15

CAPT AINS VAN SEA T...................................................................................................................... 16

ADJUST ABLE SEA T FRAME ...........................................................................................................16

BASE FRAME HARDWARE T ORQUE SPECIFICA TIONS .............................................................. 17

T

A

B

L

E

O

F

C

O

N

T

E

N

T

S

PROCEDURE 4 - ARMS ....................................................................................................................... 18

REPLACING ARMREST P ADS - CAPT AINS VAN SEA T .................................................................. 18

REPLACING CAPT AINS V AN SEAT ARMREST PLA TE ................................................................... 18

PROCEDURE 5 - UPHOLSTERY/POSITIONING STRAP .................................................................. 19

REPLACING SEA T POSITIONING STRAP - CAPT AINS VAN SEA TS............................................... 19

REPLACING BACK UPHOLSTERY ................................................................................................ 19

PROCEDURE 6 - SEAT FRAME........................................................................................................... 21

PREP ARATIONS FOR REMOVING/INST ALLING SEA T FRAME (ST ANDARD FRAME,

ADJUST ABLE FRAME AND CAPTAINS V AN SEA T.......................................................................... 21

REPLACING EXACT SAME SIZE ST ANDARD SEA T FRAME .......................................................... 2 2

REMOVING/INST ALLING STANDARD SEA T FRAME SUB-ASSEMBL Y ........................................... 22

CHANGING SEA T DEPTH ............................................................................................................... 23

CHANGING SEA T WIDTH (STANDARD AND ADJUST ABLE SEA T FRAME) ................................... 25

INST ALLING/REMOVING ADJUSTABLE SEA T FRAME SUBASSEMBL Y AND/OR

COMPONENT REPLACEMENT................................................................................................. 26

INST ALLING/REMOVING CAPT AINS VAN SEA T ASSEMBL Y........................................................ 28

REPLACING CAPT AINS V AN SEA T AND/OR CAPT AINS V AN SEA T FRAME .............................. 28

CONVERTING FROM ST ANDARD SEAT FRAME TO ADJUST ABLE SEA T FRAME

OR VICE VERSA....................................................................................................................... 29

CONVERTING FROM ADJUST ABLE SEA T FRAME TO CAPT AINS V AN SEA T

OR VICE VERSA....................................................................................................................... 29

CONVERTING FROM ST ANDARD SEA T FRAME TO CAPT AINS V AN SEA T

OR VICE VERSA....................................................................................................................... 30

REMOVING/INST ALLING SEA T P AN.............................................................................................. 30

MOUNTING PLA TE - SEA T ANGLE ADJUSTMENT AND INST ALLA TION ORIENTA TION ............ 31

PROCEDURE 7 - BASE FRAME .......................................................................................................... 32

REPLACING SEA T MOUNTING PLATES......................................................................................... 32

REPLACING SEA T SUPPOR T BRACKETS.................................................................................... 32

REPLACING SEA T SUPPOR T BRACKET T-NUTS ........................................................................33

REPLACING BA TTERY CHARGER BRACKET AND T-NUT............................................................ 34

REMOVING/INST ALLING SEAT STOP SCREWS............................................................................ 34

PROCEDURE 8 - BACK FRAME.......................................................................................................... 35

REPLACING CJ BACK BRACKETS................................................................................................ 35

CHANGING BACK HEIGHT ............................................................................................................. 36

BACK ANGLE ADJUSTMENT.......................................................................................................... 38

3

TABLE OF CONTENTS

TABLE OF CONTENTS (Continued)

PROCEDURE 9 - BATTERIES ............................................................................................................. 39

T

A

B

L

E

O

F

C

O

N

T

E

N

T

S

INST ALLING/REMOVING BATTERIES INT O/FROM BATTERY BOX(ES)......................................... 39

DISCONNECTING/CONNETING BA TTERY CABLES...................................................................... 40

WHEN TO CHARGE BATTERIES ................................................................................................... 44

CHARGING BA TTERIES ................................................................................................................. 44

REPLACING BA TTERIES................................................................................................................ 46

REMOVING/INST ALLING GROUP 24 BATTER Y BOXES FOR WHEELCHAIRS NOT

EQUIPPED WITH VENT TRA Y ..................................................................................................... 47

REMOVING/INST ALLING GROUP 24 BATTER Y BOXES FOR WHEELCHAIRS NOT

EQUIPPED WITH VENT TRA Y ..................................................................................................... 48

INST ALLING/REMOVING BATTER Y BOX - 22NF BATTER Y BASE FRAME ..................................... 49

PROCEDURE 10 - WIRING HARNESS .................................................................................................. 50

REMOVIN G/INSTALLING THE WIRING HARNESS............................................................................ 50

ADJUSTING LIMIT SWITCH............................................................................................................. 54

PROCEDURE 11 - RETENTION STRAP/RETAINER......................................................................... 55

REPLACING BA TTERY BOX RET AINER/RET AINER CLIP - GROUP 24 BA TTERY BASE FRAMES.. 55

PROCEDURE 12 - WHEELS/MOTORS ............................................................................................. 57

REPLACING PNEUMA TIC TIRES/TUBES - DRIVE WHEELS/CASTERS ........................................... 57

REMOVING/INST ALLING DRIVE WHEELS......................................................................................... 57

REMOVING/INST ALLING DRIVE WHEEL HUB ................................................................................... 58

INST ALLING WHEEL LOCK BRACKET ONTO WHEEL CHAIR ......................................................... 58

REMOVING/INST ALLING CASTERS .................................................................................................. 59

REPLACING FORKS ......................................................................................................................... 59

REMOVING/INST ALLING THE MOTOR (CONVENTIONAL MOTOR WITH GEARBOX) ...................... 60

REMOVING/INST ALLING THE MOTOR (GEARLESS BRUSHLESS MOTOR).................................... 61

PROCEDURE 13 - ELECTRONICS .................................................................................................... 66

REPOSITIONING MKIV JOYSTICK - V AN SEAT MODELS.................................................................. 63

REMOVING/INST ALLING MKIV CONTROLLER .................................................................................. 64

PROCEDURE 14 - RECLINER ........................................................................................................... 68

POSITIONING LIMIT SWITCH ............................................................................................................ 68

ADJUSTING LIMIT SWITCH................................................................................................................ 68

REPLACING RECLINER CABLE ASSEMBLIES ................................................................................. 69

REPLACING/ADJUSTING GAS CYLINDERS ...................................................................................... 70

CHANGING BACK HEIGHT ................................................................................................................ 71

CHANGING SEA T DEPTH .................................................................................................................. 72

CHANGING SEA T WIDTH .................................................................................................................. 72

EQUIPMENT OPTION INST ALLING/REPLACING ADJUSTABLE 16 TO 19-INCH DEEP

RECLINER SEA T FRAME ONT O ARROW OR X BASE FRAME.................................................... 73

PROCEDURE 16 - RWD WHEELCHAIRS ............................................................................................. 74

REMOVING/INST ALLING GROUP 24 BATTERY BOX SUB-FRAME........................................................ 7 4

REMOVING/INST ALLING 22NF BATTERY BOX TRA Y ............................................................................ 7 6

EQUIPMENT OPTION CONVERTING 22NF BATTERY BOX TRAY TO GROUP 24 BA TTERY

BOX SUB FRAME ......................................................................................................................... 76

SHOCK OR RUBBER ELEMENT REPLACEMENT FOR WHEELCHAIRS

EQUIPPED WITH GROUP 24 BA TTERIES....................................................................................... 79

SHOCK OR RUBBER ELEMENT REPLACEMENT FOR WHEELCHAIRS

EQUIPPED WITH 22NF BA TTERIES .............................................................................................. 81

SHOCK SPRING REPLACEMENT ....................................................................................................... 8 2

REMOVING/INSTALLING GEARBOX .................................................................................................... 83

ADJUSTING WEIGHT DISTRIBUTION .................................................................................................. 84

REPOSITIONING MOTOR/GEARBOX ................................................................................................. 8 5

REPOSITIONING THE GEARLESS/BRUSHLESS MOTOR ................................................................... 8 6

REPLACING SUSPENSION ARM FOR WHEELCHAIRS WITH MOTOR/GEARBOX ASSEMBL Y............. 87

REPLACING THE SUSPENSION ARM FOR WHEELCHAIRS WITH GEARLESS/BRUSHLESS MOTOR. 88

ANTI-TIPPER WHEEL REPLACEMENT ............................................................................................... 8 9

REMOVING INST ALLING THE ANTI-TIP ASSEMBLY .............................................................................. 89

LIMITED WARRANTY........................................................................................................................... 91

4

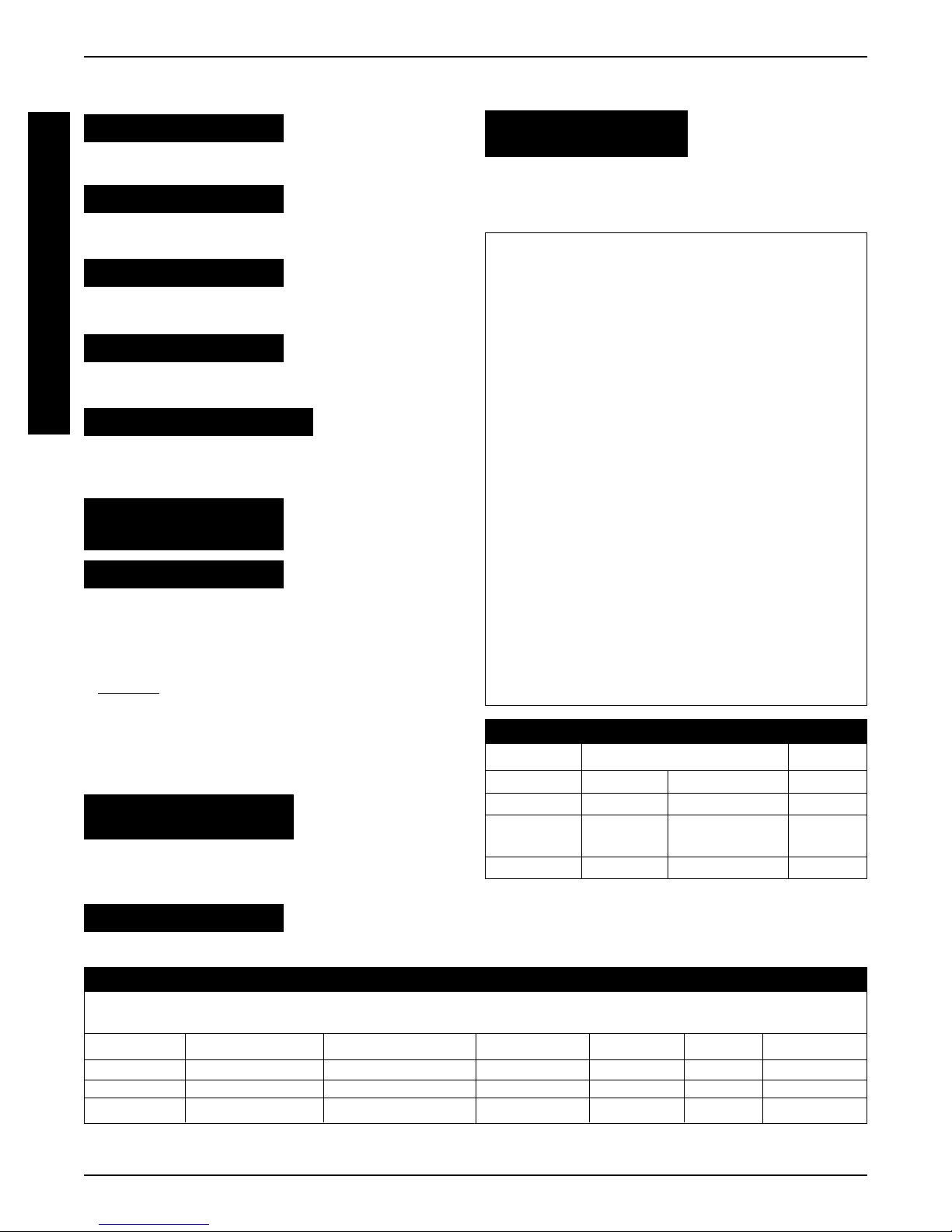

SPECIFICATIONS FOR ARROW

S

P

E

C

I

F

I

C

A

T

I

O

N

S

Seat Width Range:

Standard 12 to 24-inches

Recliner 14 to 24-inches

Seat Depth Range:

Standard 12 to 22-inches

Recliner 14 to 22-inches

Back Height Range:

Standard 12 to 24-inches

Recliner 18-1/2 to 26-inches

Back Angle Range:

Standard 80

Recliner 90o to 170

Seat-to-Floor (approximate)

Standard: 17-1/2 -inches

Optional: 19-3/4-inches

Overall Width of Base:

(w/o joystick) 25-inches

o

to 1 15

21-inches

SPECIFICATIONS

Drive Axle: ◆ Adjustable

u

Non-Recliners ONLY.

Drive Wheels/Tires:

(Foam Filled or Pneumatic)

Standard: 14 X 3-inches

Optional: 14 X 4-inches

S

P

E

C

I

F

I

C

PHYSICAL DIMENSIONS

Casters w/Precision

Sealed Bearings

o

o

Semi-Pneumatic

Standard: 8 X 2-1/4-inches

Option: 6 X 2-inches (w/ shock fork)

Pneumatic or Foam Filled

Standard: 8 X 2-inches

Option: 9 X 2-3/4-inches

Anti-Tippers (3-inch wheels): Standard

Caster Forks: Standard, Shock Fork (Optional)

A

T

I

O

N

S

Overall Height

Standard: 34-1/4-inches

Minimum: 34-1/4-inches

Maximum: 44-1/4-inches

Recliner

Low Seat Frame: 51-1/2-inches

Med. Seat Frame: 53-3/4-inches

High Seat Frame: 55-1/2 inches

Overall Length

(without front riggings)

Standard: 29-1/2-inches

Long Frame: 32-1/2-inches

Weight

Gearless/Brushless Motor

W/O GP24 Batteries: 174 lbs.

With GP24Batteries: 278 lbs.

Shipping (approx.): 214 lbs.

Footrests: T elescoping Front Rigging Supports, Swing-

Away (Std), Heavy Duty (Opt.), 2-in. and 4-in. longer Pivot

Slide Tube (Opt)

Armrests: Flip Back, Fixed or Adjustable Height (Desk

and Full Length)

Seat Angle Adjustment: Adjustable (0

Back Angle Adjustment: Adjustable (80

increments)

Seat Cushion: Cushion (Optional)

Chair Upholstery Options: Naugahyde and Nylon

Battery requirements: See chart on page 46

Weight Limitations: Arrow with gearless/brushless

motor - up to 300 lbs. Arrow with 4 pole motor - up to

400 lbs.

o

to 10o)

o

to 1 15o in 5

PERFORMANCE

RA TING SPEED RANGE

G/B motor 4 Pole Motor

300 lbs up to 8 mph N/A up to 29

o

4 Pole Motor

Without Batteries: 162 lbs.

With Batteries: 266 lbs.

Shipping (approx.): 202 lbs.

400 lbs N/A up to 4.5 mph up to 19

Range will vary with battery conditions, surface, terrain and operators weight.

5

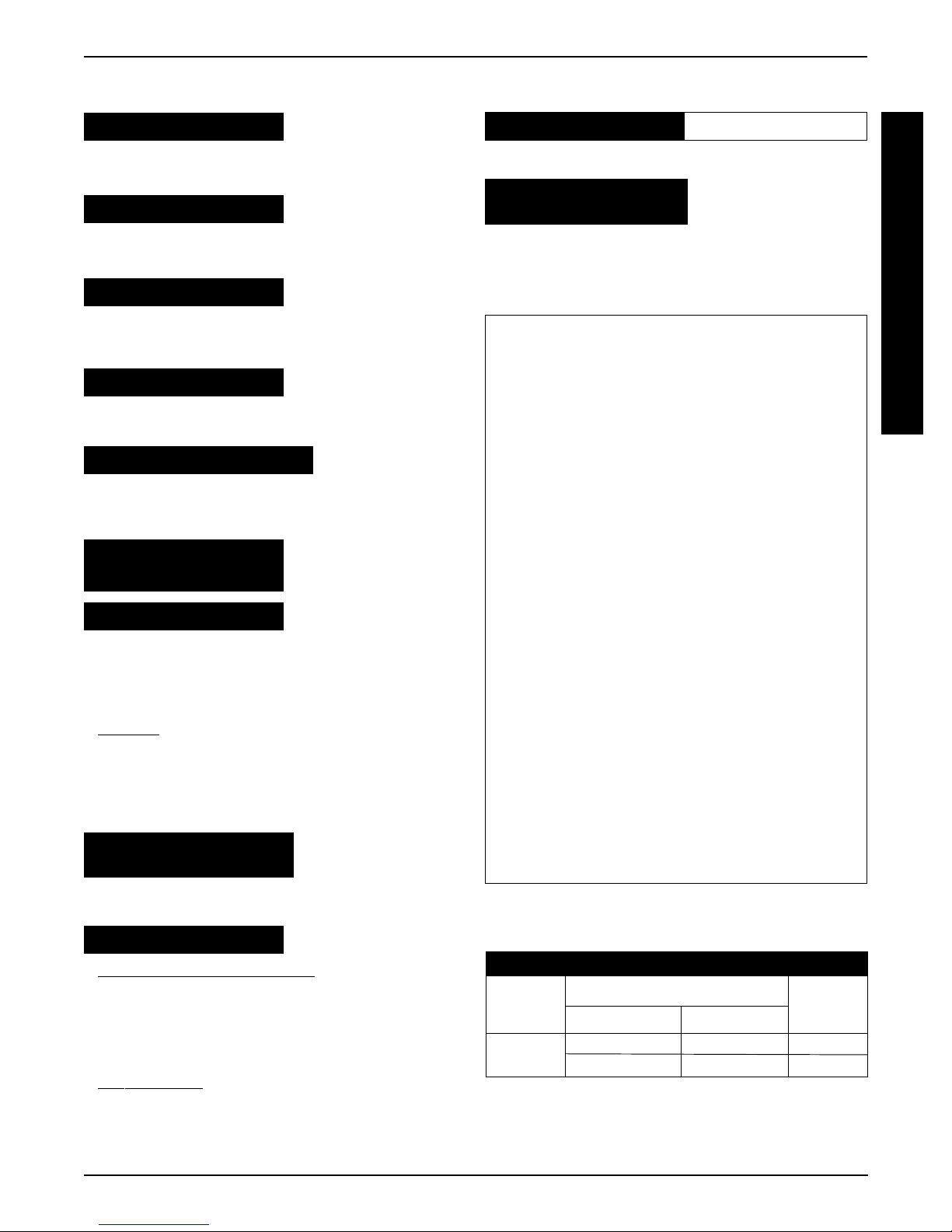

SPECIFICATIONS - TORQUE SP

SPECIFICATIONS - TORQUE SP

S

P

E

C

I

F

I

C

A

T

I

O

N

S

Seat Width Range:

Standard 12 to 22-inches

Recliner 14 to 22-inches

Seat Depth Range:

Standard 12 to 22-inches

Recliner 16 to 22-inches

Back Height Range:

Standard 12 to 24-inches

Recliner 18-1/2 to 26-inches

Back Angle Range:

Standard 80

Recliner 90o to 170

Seat-to-Floor (approximate)

Standard: 17-1/2-inches

Optional: 19-3/4-inches

Overall Width of Base:

(w/o joystick) 25-inches

Overall Height

Standard: 34-1/4-inches

Minimum: 34-1/4-inches

Maximum: 44-1/4-inches

Recliner

Low Seat Frame: 51-1/2-inches

Med. Seat Frame: 53-3/4-inches

High Seat Frame: 55-1/2 inches

Overall Length

(without front riggings)

Standard: 29-1/2-inches

Long Frame: 32-1/2-inches

Drive Axle: ◆ Adjustable

o

to 1 15

21-inches

Drive Wheels/Tires:

(Foam Filled or Pneumatic)

Standard: 14 X 3-inches

Optional: 14 X 4-inches

PHYSICAL DIMENSIONS

Casters w/Precision

Sealed Bearings

Semi-Pneumatic

Standard: 8 X 1-1/4-in

Option: 6 X 2-in.(w/ shock fork)

o

o

Pneumatic or Foam Filled

Standard: 8 X 2-inches

Option: 9 X 2-3/4-inches

Anti-Tippers (3-inch wheels): Standard

Caster Forks: Standard, Shock Fork (Optional)

Footrests: Telescoping Front Rigg Supports, Swing-

Away , Heavy Duty , 4-in. longer Pivot Slide Tube (Opt)

Armrests: Flip Back, Fixed or Adjustable Height (Desk

and Full Length)

Seat Angle Adjustment: Adjustable (0

Back Angle Adjustment: Adjustable (80

o

to 10o)

o

to 1 15o in 5

o

increments)

Seat Cushion: Cushion (Optional)

Chair Upholstery Options: Naugahyde and Nylon

PERFORMANCE

RA TING SPEED RANGE

G/B motor 4 Pole Motor

250 lbs N/A up to 4.5 mph up to 19

251-300 lbs up to 8 mph up to 29

up to 4.5 mph up to 19

301-350 lbs N/A up to 4.5 mph up to 19

Range will vary with battery conditions, surface, terrain and operators weight.

u

Non-Recliners ONLY.

BATTERY REQUIREMENTS , WEIGHT LIMITATIONS, CHAIR WEIGHT

MODEL MOTOR LIMITATION BATTERIES W/O BATT. W/ BATT. WEIGHT

U250TQ 4 Pole Motor Up to 250 lbs *22NF 154 228 194 lbs

251-300TQ 4 Pole Motor 251-300 lbs *22 NF 154 22 8 194 lbs

251-300TQ Gearless/Brushless 251-300 lbs Group 24 16 6 27 0 206 lbs

301-350TQ 4 Pole Motor 301-350 lbs Group 24 154 2 58 194 lbs

* Two batteries inside one battery box.

WEIGHT CHAIR WEIGHT SHIPPING

6

SPECIFICATIONS - TORQUE SP

SPECIFICATIONS - RANGER X

Seat Width Range:

Standard 12 to 22-inches

Recliner 14 to 22-inches

Seat Depth Range:

Standard 12 to 22-inches

Recliner 14 to 22-inches

Back Height Range:

Standard 12 to 24-inches

Recliner 18-1/2 to 26-inches

Back Angle Range:

Standard 80

Recliner 90o to 170

Seat-to-Floor (approximate)

Standard: 17-1/2-inches

Optional: 19-3/4-inches

Overall Width of Base:

(w/o joystick) 25-inches

Overall Height

o

to 1 15

21-inches

o

o

Drive Axle: ◆ Adjustable

u

Non-Recliners ONLY.

Drive Wheels/Tires:

(Foam Filled or Pneumatic)

Standard: 14 X 3-inches

Optional: 14 X 4-inches

PHYSICAL DIMENSIONS

Casters w/Precision

Sealed Bearings

Semi-Pneumatic

Standard: 8 X 2-1/4-in

Option: 6 X 2-in. (w/ shock fork)

Pneumatic or Foam Filled

Standard: 8 X 2-inches

Option: 9 X 2-3/4-inches

Anti-Tippers (3-inch wheels): Standard

Caster Forks: Standard, Shock Fork (Optional)

Footrests: T elescoping Front Rigging Supports, Swing-

Away (Std), Heavy Duty (Opt.), 4-in. longer Pivot Slide

Tube (Opt)

S

P

E

C

I

F

I

C

A

T

I

O

N

S

Standard: 34-1/4-inches

Minimum: 34-1/4-inches

Maximum: 44-1/4-inches

Recliner

Low Seat Frame: 51-1/2-inches

Med. Seat Frame: 53-3/4-inches

High Seat Frame: 55-1/2 inches

Overall Length

(without front riggings)

Standard: 29-1/2-inches

Long Frame: 32-1/2 -in ches

Weight

Gearless/Brushless Motor

Without GP 24 Batteries: 174 lbs.

With GP 24 Batteries: 278 lbs.

Shipping (approx.): 214 lbs.

4 Pole Motor

Without GP 24 Batteries: 162 lbs.

With GP 24 Batteries: 266 lbs.

Armrests: Flip Back, Fixed or Adjustable Height (Desk

and Full Length)

Seat Angle Adjustment: Adjustable (0

Back Angle Adjustment: Adjustable (80

o

to 10o)

o

to 100o in 5

o

increments)

Seat Cushion: Cushion (Optional)

Chair Upholstery Options: Naugahyde and Nylon

Battery requirements: Group 24

Weight Limitations: 300 lbs.

PERFORMANCE

RA TING SPEED RANGE

G/B motor 4 Pole Motor

300 lbs up to 6.5 mph up to 19

up to 8.0 mph up to 29

Range will vary with battery conditions, surface, terrain and operators weight.

Shipping (approx.): 202 lbs.

7

This Procedure Includes the Following:

Repair or Service Information

G

Operating Information

E

N

Safety/Handling of Wheelchairs

E

R

A

L

G

U

I

D

E

L

I

N

E

S

REPAIR OR SERVICE INFORMATION

Set-up of the Electronic Control Unit is to be performed ONLY by individuals certified by

Invacare. The final tuning adjustments of the controller may affect other activities of

the wheelchair. Damage to the equipment could occur under these circumstances. If

non-certified individuals perform any work on these units, the warranty is void.

OPERATING INFORMATION

Performance adjustments should only be made by professionals of the healthcare field

or persons fully conversant with this process and the driver's capabilities. Incorrect

settings could cause injury to the driver, bystanders, damage to the chair and to surrounding property.

After the wheelchair has been set-up, check to make sure that the wheelchair performs to the specifications entered during the set-up procedure. If the wheelchair

does NOT perform to specifications, turn the wheelchair OFF immediately and reenter

set-up specifications. Repeat this procedure until the wheelchair performs to specifications.

GENERAL GUIDELINESPROCEDURE 1

GENERAL WARNINGS

DO NOT operate on roads, streets or highways.

DO NOT climb, go up or down ramps or traverse slopes greater than 9

o

.

DO NOT attempt to move up or down an incline with a water, ice or oil film.

DO NOT attempt to drive over curbs or obstacles. Doing so may cause your wheelchair

to turn over and cause bodily harm or damage to the chair.

DO NOT use parts, accessories, or adapters other than those authorized by Invacare.

DO NOT leave the power button ON when entering or exiting your wheelchair.

DO NOT stand on the frame of the wheelchair.

DO NOT use the footplates as a platform. When getting in or out of the wheelchair,

make sure that the footplates are in the upward position or swing footrests towards the

outside of the chair.

ALWAYS wear your seat positioning strap.

TIRE PRESSURE

DO NOT use your wheelchair unless it has the proper tire pressure (P.S.I.). DO NOT

overinflate the tires. Failure to follow these suggestions may cause the tire to explode

and cause bodily harm. The recommended tire pressure is listed on the side wall of the

tire.

8

GENERAL GUIDELINES PROCEDURE 1

GENERAL WARNINGS (CONTINUED)

ELECTRICAL

Grounding Instructions:

DO NOT, under any circumstances, cut or remove the round grounding prong from any

plug used with or for Invacare products. Some devices are equipped with three-prong

(grounding) plugs for protection against possible shock hazards. Where a two-prong

wall receptacle is encountered, it is the personal responsibility and obligation of the

customer to contact a qualified electrician and have the two-prong receptacle replaced with a properly grounded three-prong wall receptacle in accordance with the

National Electrical Code. If you must use an extension cord, use ONLY a three-wire

extension cord having the same or higher electrical rating as the device being connected. In addition, Invacare has placed RED/ORANGE WARNING TAGS on some

equipment. DO NOT remove these tags.

BATTERIES

The warranty and performance specifications contained in this manual are based on

the use of deep cycle gel cell or sealed lead acid batteries. Invacare strongly

recommends their use as the power source for this unit.

G

E

N

E

R

A

L

G

U

I

D

E

L

I

N

E

S

Carefully read battery/battery charger information prior to installing, servicing or

operating your wheelchair.

RAIN TEST

INVACARE has tested it’s power wheelchairs in accordance with ISO 7176 Part 9

“Rain Test”. This provides the end user or his/her attendant sufficient time to remove

his/her power wheelchair from a rain storm and retain wheelchair operation.

DO NOT leave power wheelchair in a rain storm of any kind.

DO NOT use power wheelchair in a shower or leave it in a damp bathroom while

taking a shower.

DO NOT leave power wheelchair in a damp area for any length of time.

Direct exposure to rain or dampness will cause the chair to malfunction electrically

and mechanically; may cause the chair to prematurely rust.

Check to ensure that the battery covers are secured in place, joystick boot is NOT

torn or cracked where water can enter and that all electrical connections are

secure at all times.

DO NOT use the joystick if the boot is torn or cracked. If the joystick boot becomes

torn or cracked, replace IMMEDIATELY.

WEIGHT TRAINING

Invacare DOES NOT recommend the use of its wheelchairs as a weight training

apparatus. Invacare wheelchairs have NOT been designed or tested as a seat

for any kind of weight training. If occupant uses said wheelchair as a weight

training apparatus, INVACARE SHALL NOT BE LIABLE FOR BODILY INJURY AND THE

WARRANTY IS VOID.

9

GENERAL GUIDELINESPROCEDURE 1

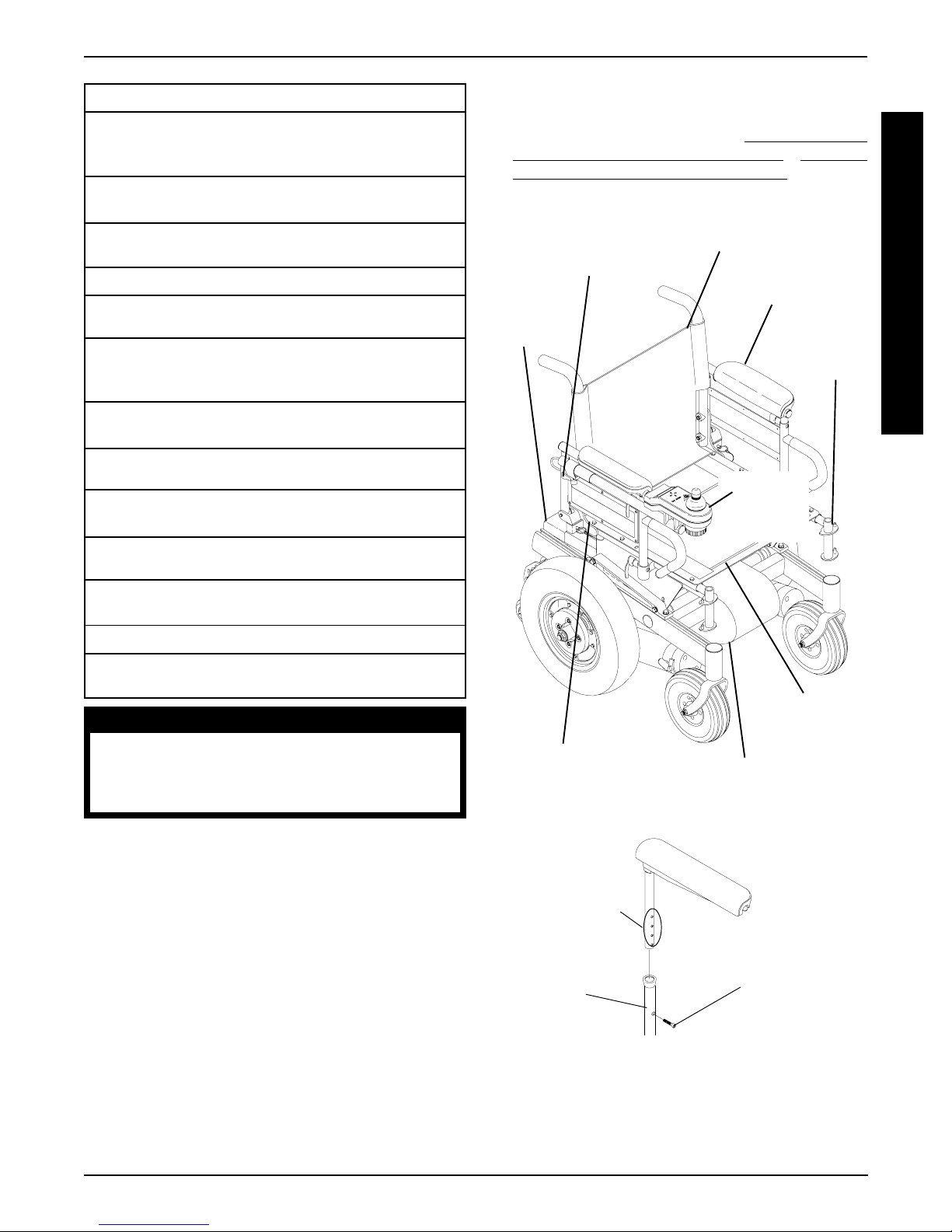

WARNING/CAUTION LABEL LOCATION

G

E

N

E

R

A

L

G

U

I

D

E

L

I

N

E

S

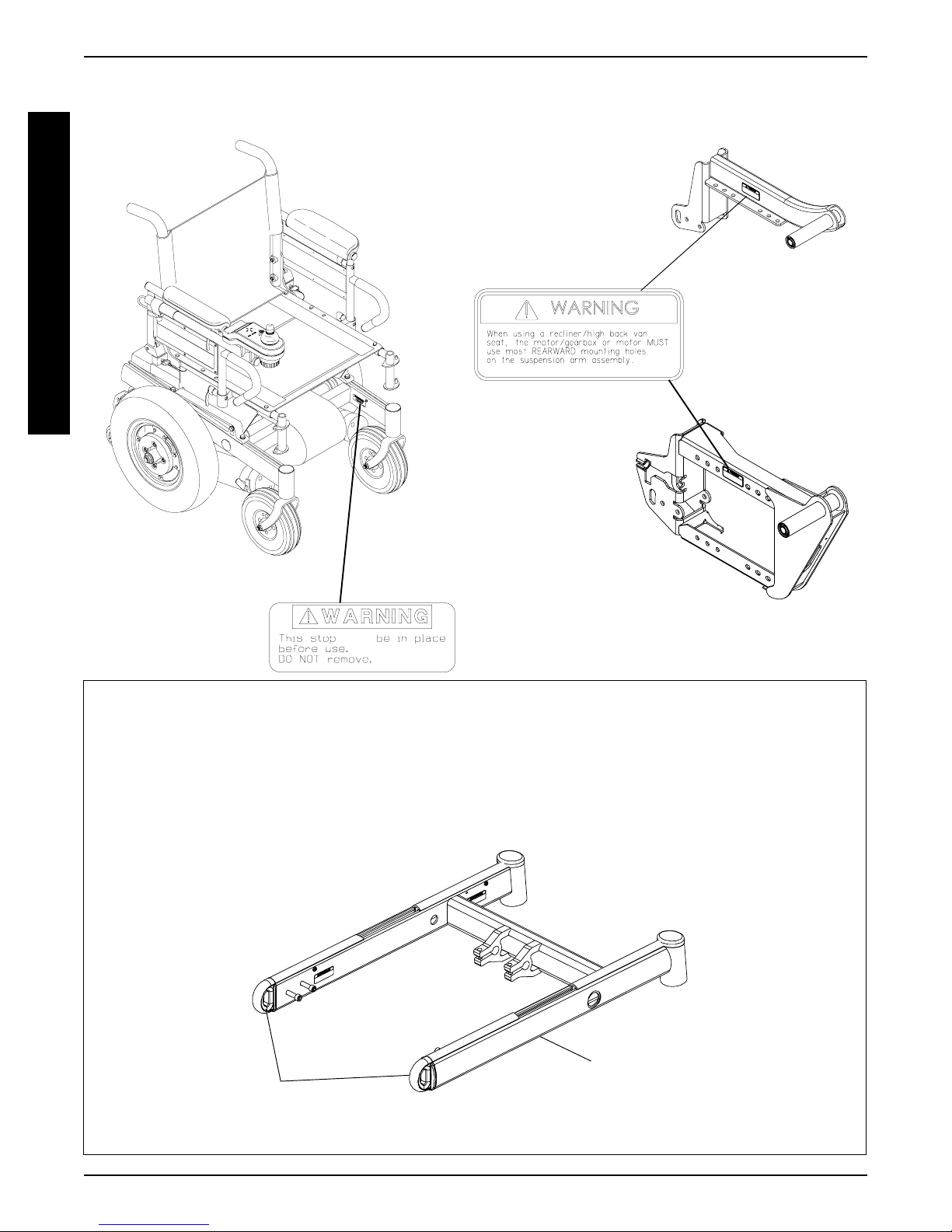

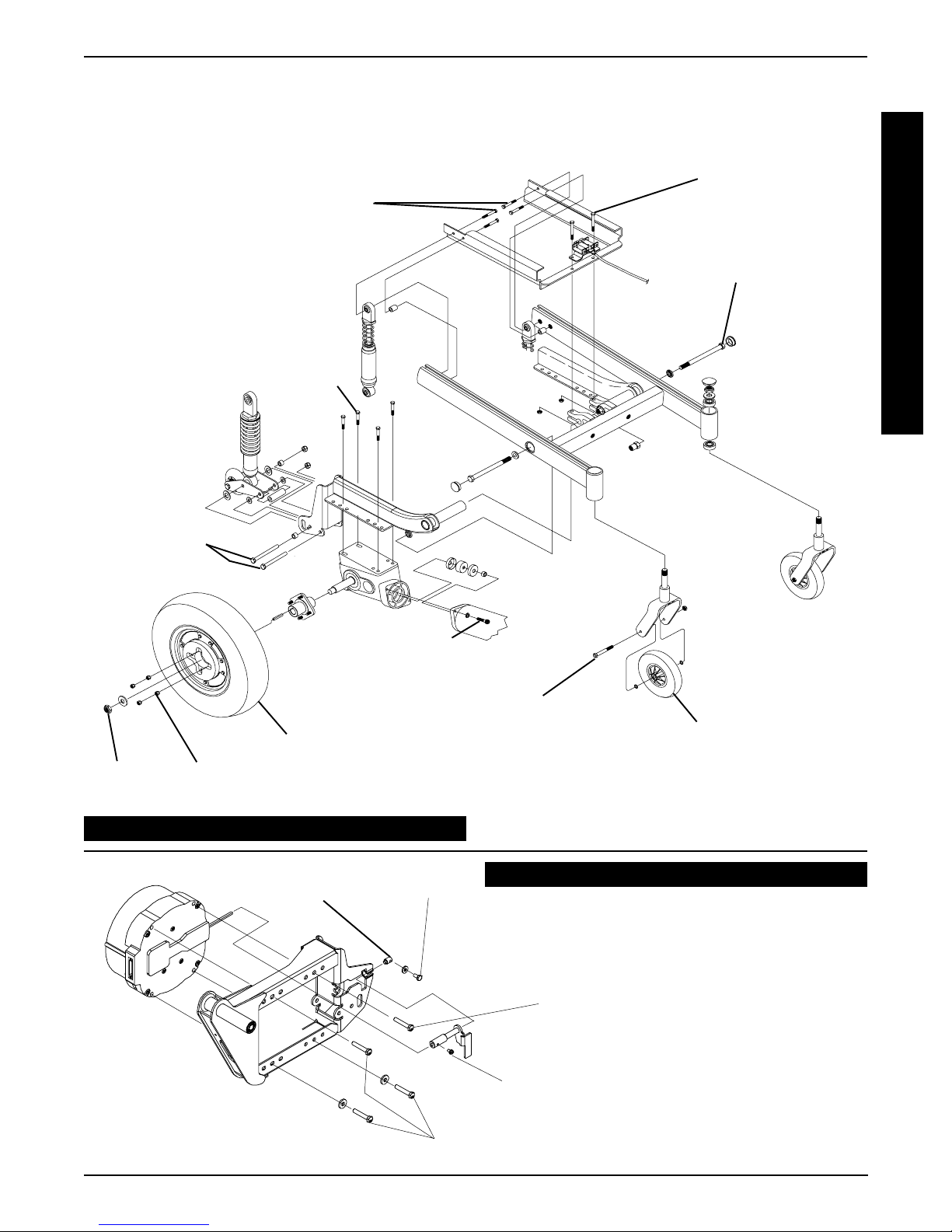

SUSPENSION ARM

USED

WITH CONVENTIONAL

MOTOR/GEARBOX

ASSEMBLY

SUSPENSION ARM USED

NOTE: WARNING LABEL also

found on side frame near the rear

of the chair.

MUST

1070497

WITH GEARLESS/

BRUSHLESS MOTOR

SHIPPING TIE DOWN RESTRAINTS

Invacare recommends that wheelchair users NOT be transported in vehicles of any

kind while in wheelchairs. As of this date, the Department of Transportation has not

approved any tie-down systems for transportation of a user while in a wheelchair,

in a moving vehicle of any type.

Frame end cap can only be used as a shipping tie-down point for an UNOCCUPIED

wheelchair.

FRONT OF

WHEELCHAIR

WHEELCHAIR

Frame End

Caps

REAR OF

Base Frame

10

GENERAL GUIDELINES PROCEDURE 1

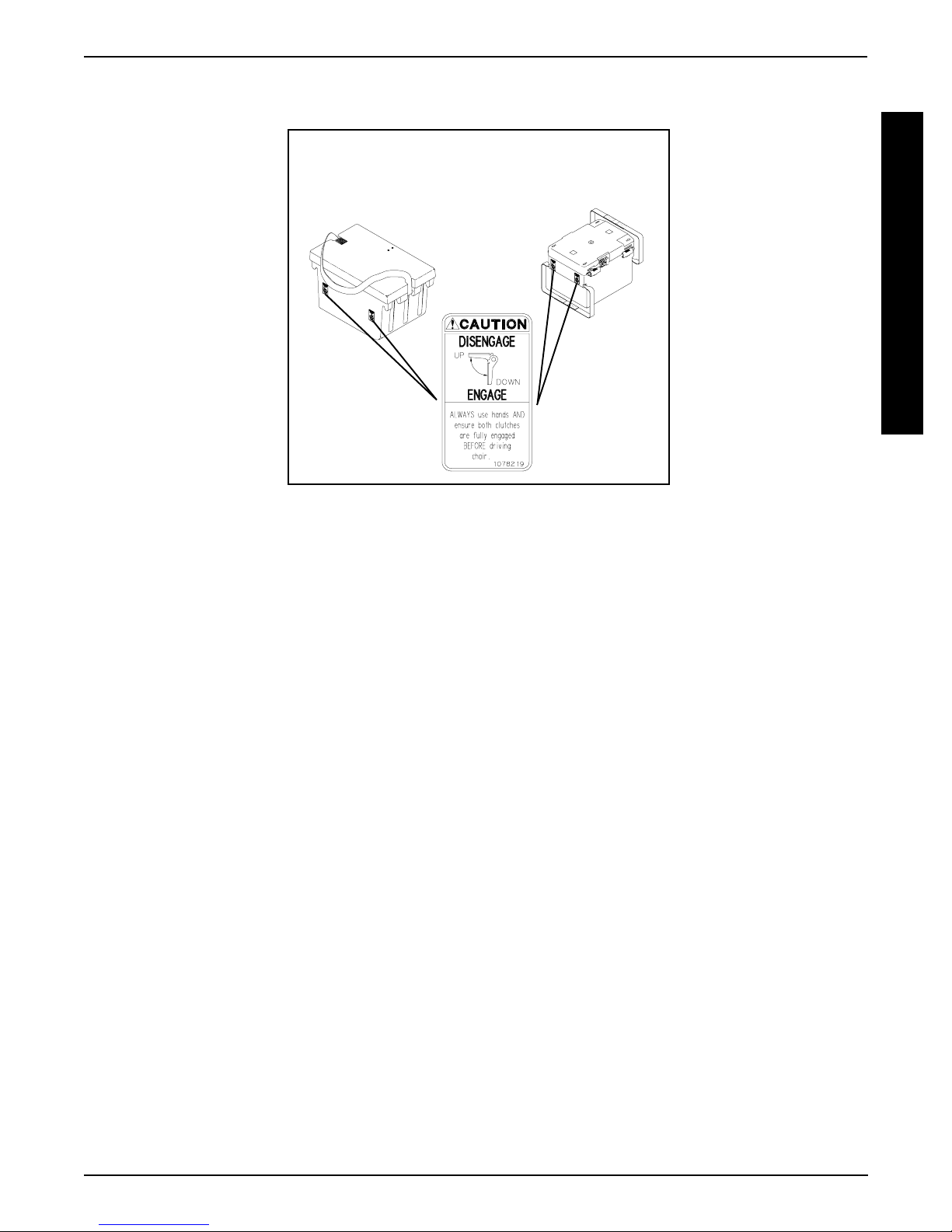

WARNING/CAUTION LABEL LOCATION

NOTE: These caution labels are only found on battery boxes used with the gearless/brushless motor

GROUP 24 BATTERIES

22NF BATTERIES

G

E

N

E

R

A

L

G

U

I

D

E

L

I

N

E

S

11

PROCEDURE 2

TROUBLESHOOTING

This Procedure Includes the Following:

Field Load Test

T

Using Hydrometer To Check Battery Cells (Lead

R

O

O

O

G

Acid)

U

Motor Testing

B

Motor Brush Inspection

L

E

Electro-Mechanical Parking Brake Testing

S

H

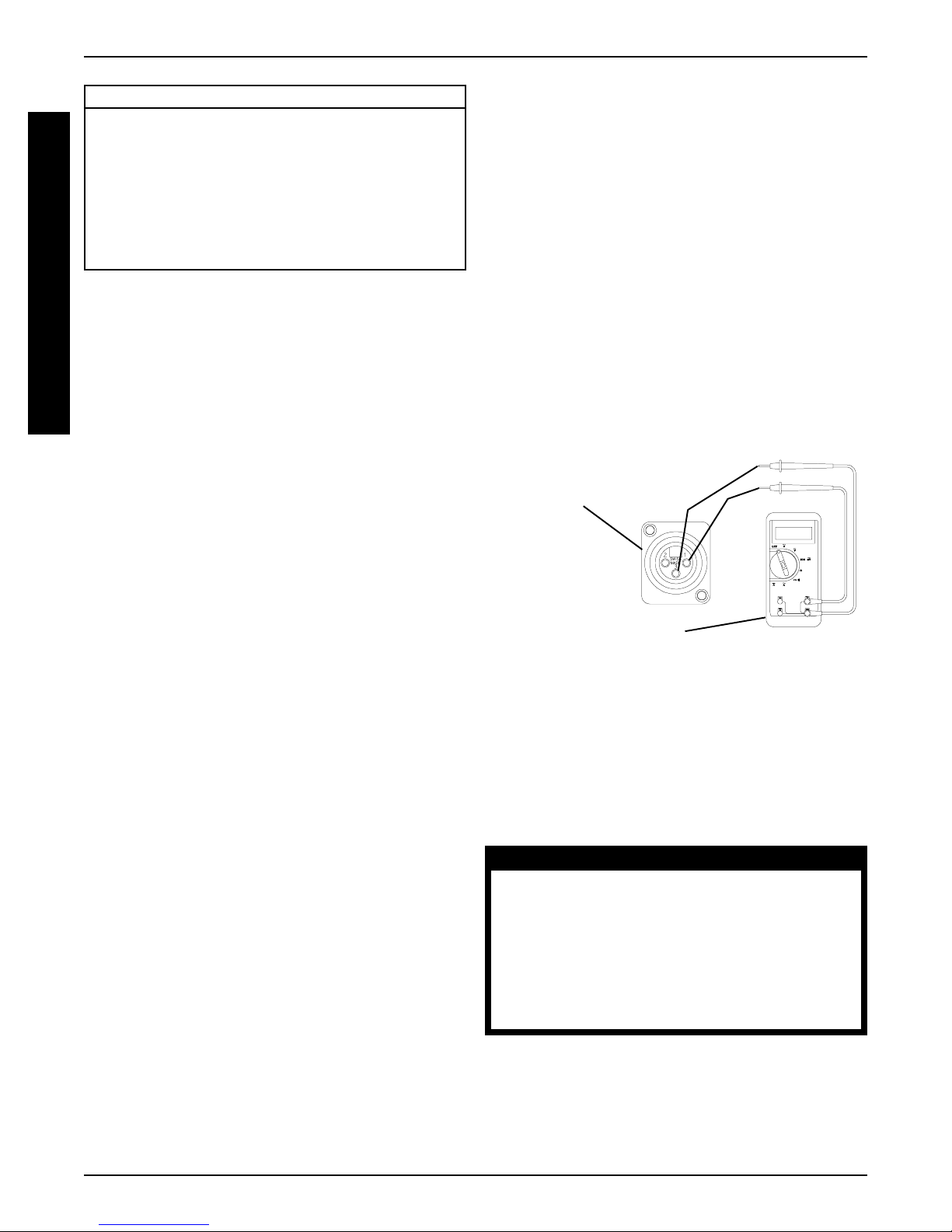

FIELD LOAD TEST (FIGURE 1)

NOTE: The following test can also be performed through

T

the controller of the wheelchair along with a remote pro-

I

grammer. Refer to the individual CONTROLLER

N

MANUAL supplied with each wheelchair.

Old batteries lose their ability to store and release power, due

to increased internal resistance. This means that as you try

to take power from the battery , some of that power is used up

in the process of passing through the battery , resulting in less

voltage at the posts. The more power drawn, the lower the

voltage available. When this lost voltage drops the output 1.0

volts under load (2.0 for a pair), replace the batteries.

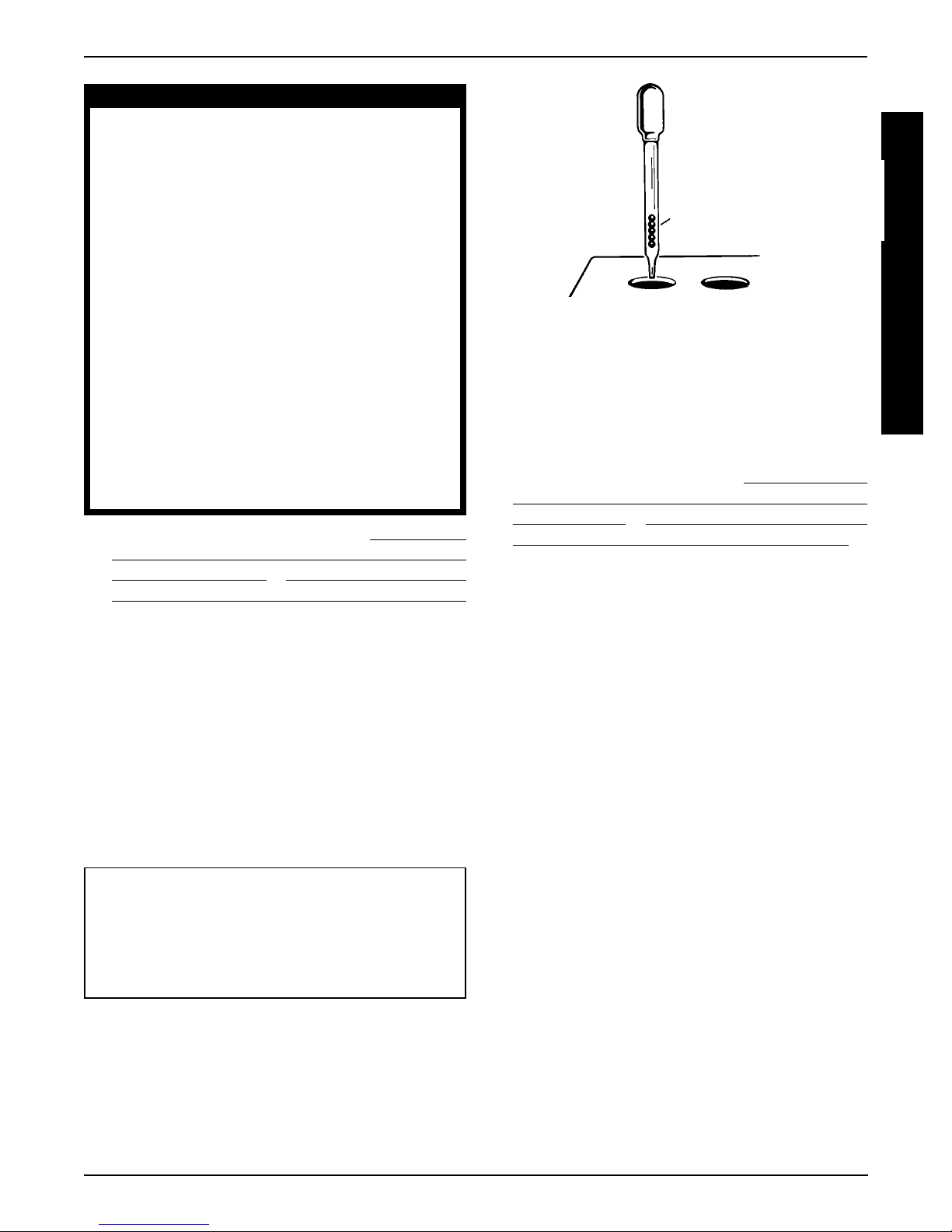

4. Place the voltmeter leads into the charger plug on the

wheelchair. Most digital voltmeters are not af fected by

polarity , however, analog meters (meters with swinging needles) can be and should be used carefully . A

good meter reading should be 25.5 to 26 VDC.

5. Have two (2) individuals (one [1] on each arm) apply

as much downward pressure as possible on the arms

of the wheelchair.

6. Turn the wheelchair ON and push the joystick forward, trying to drive the wheelchair through the stationary object. This puts a heavy load on the batteries

as they try to push through the stationary object. Read

the meter while the motors are straining to determine

the voltage under load.

NOTE: If the voltage drops to less than 23.5 volts from a

pair of fully charged batteries while under load, they should

be replaced regardless of the unloaded voltages.

Battery Charger

(-)

Connector

(+)

Testing under load is the only way to spot this problem.

While special battery load testing equipment is available,

it is costly and difficult to transport.

Use a digital voltmeter to check battery charge level at the charger

connector. It is located on the base of the wheelchair frame.

NOTE: READ the instructions CAREFULLY before using the digital voltmeter.

NOTE: Invacare recommends that ONLY qualified ser-

vice personnel perform this test.

1. Ensure that power is OFF.

2. Make sure battery is fully charged. An extremely discharged battery will exhibit the same symptoms as a

bad one.

3. Remove the footrests from the wheelchair and place

the CASTERS of the wheelchair against a wall,

workbench or other stationary object.

Digital Voltmeter

FIGURE 1 - FIELD LOAD TEST

USING HYDROMETER TO CHECK

BATTERY CELLS (LEAD ACID)

(FIGURE 2)

NOTE: Perform this procedure when a digital voltmeter is

not available.

WARNING

NEVER smoke or strike a match near the

batteries. If the caps of the battery cells

are removed, NEVER look directly into

them when charging the battery.

The use of rubber gloves and chemical

goggles or face shields is recommended

when working with batteries.

12

TROUBLESHOOTING

WARNING

PROCEDURE 2

When reading a hydrometer, DO NOT allow any liquid to come in contact with

your eyes or skin. It is a form of acid and

can cause serious burns, and in some

cases, blindness. If you do get battery acid

on you, flush the exposed areas with cool

water IMMEDIATELY. If the acid comes into

contact with eyes or causes serious burns,

get medical help IMMEDIATELY.

The battery acid can damage your wheelchair, clothing, and household items.

Therefore, take readings cautiously and

only in designated areas.

ONLY use distilled water when topping off

the battery cells.

Most batteries are not sold with instructions.

However, warnings are frequently noted

on the cell caps. Read them carefully.

1. Remove the battery box(es). Refer to

INST ALLING/

REMOVING BA TTERY BOXES - GROUP 24 BA TTERY BASE FRAMES or INST ALLING/REMOVING

BA TTERY BOX - 22NF BATTER Y BASE FRAMES

in PROCEDURE 9 of this manual.

2. Remove the battery caps from the battery .

3. Squeeze the air from the hydrometer.

4. Place the hydrometer into a battery cell.

Number of Floating

Balls Will Vary

TROUBLESHOOTING

According to Charge

FIGURE 2 - USING HYDROMETER TO CHECK

BATTERY CELLS (LEAD ACID)

9. Flush hydrometer in cold running water by allowing

the water to rise into hydrometer as far as possible.

Do this several times to guard against burn damage.

10. Replace the battery caps.

11. Reinstall battery boxes. Refer to

INSTALLING/REMOVING BA TTERY BOXES - GROUP 24 BATTERY

BASE FRAMES or INST ALLING/REMOVING BA TTERY BOX - 22NF BATTERY BASE FRAMES in

PROCEDURE 9 of this manual.

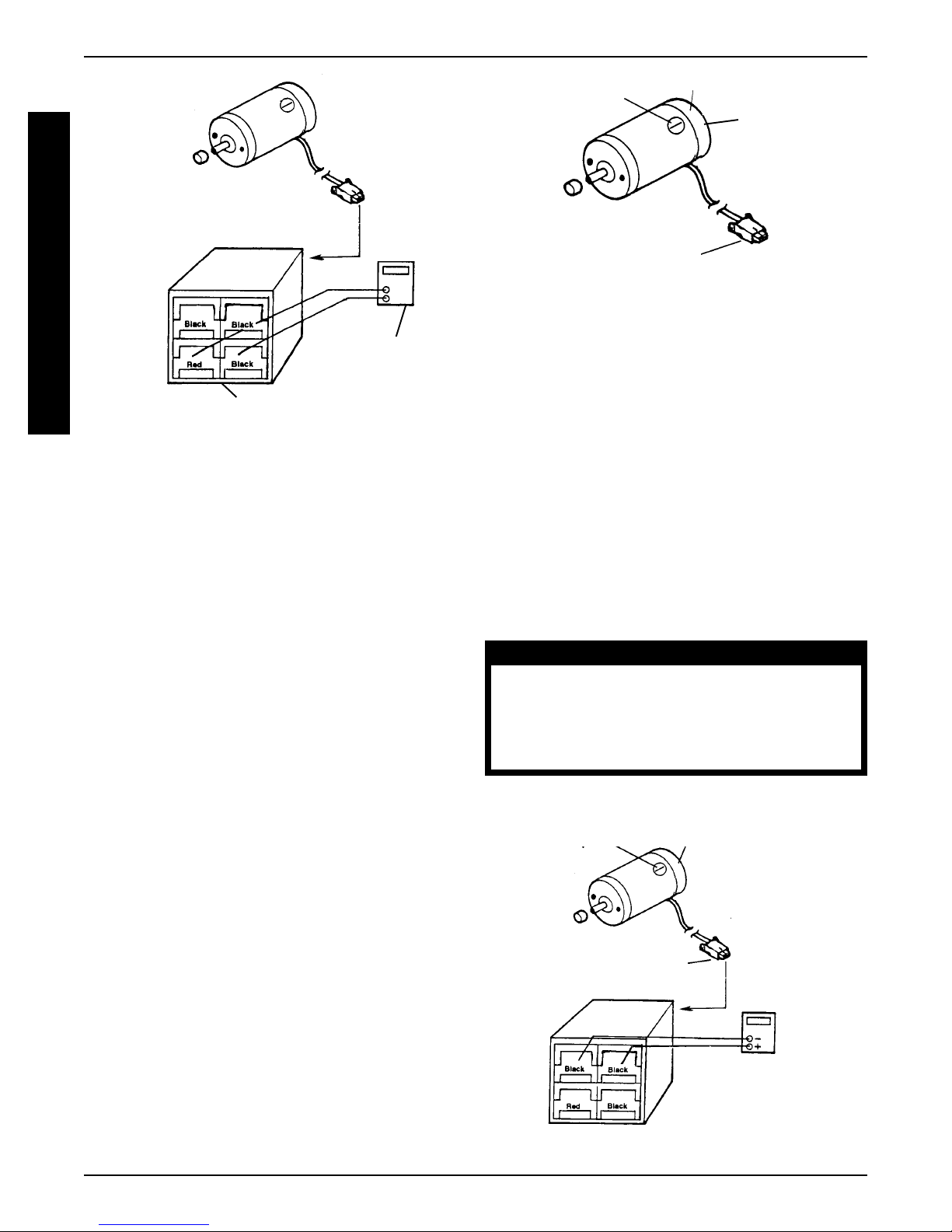

MOTOR TESTING (FIGURE 3)

NOTE: This procedure should only be performed on

wheelchairs with the conventional motor/gearbox assembly . For gearless/brushless motors, there are no serviceable parts. Return motor to manufacturer for testing.

T

R

O

U

B

L

E

S

H

O

O

T

I

N

G

NOTE: DO NOT fill hydrometer more than 3/4 full.

5. Draw up sufficient acid to cover float balls.

6. T ap lightly to remove air bubbles.

7. Number of floating balls indicates charge.

Number of Floating Balls

0 Discharged

1 25% Charged

2 50% Charged

3 75% Charged

4 100% Charged

* 5 Overcharged

* Check charging system.

8. Flush the liquid back into the same cell after reading

the float. Repeat this step until all cells have been properly read. A shorted or dead cell can be detected when

it is the only cell that does not charge.

1. On the 4-pin motor connector, locate the two (2) contacts in the red and black housings.

2. Set the digital multimeter to measure ohms (Ω).

3. Measure the resistance between the two (2) motor

contacts.

NOTE: A normal reading is between 1 and 5 ohms

(Ω). A reading of 0 ohms (Ω) or in excess of 15 ohms

(Ω) indicates a problem. High readings are generally

caused by bad connections and/or damaged brushes.

Contact authorized dealer or Invacare.

13

T

R

O

U

B

L

E

S

H

O

O

G

T

I

N

Motor Connector

Motor Connector

FIGURE 3 - MOTOR TESTING

Ohmmeter

Ohmmeter

MOTOR BRUSH INSPECTION

(FIGURE 4)

NOTE: This procedure should only be performed on wheelchairs with conventional motor/gearbox assembly .

There are two (2) contact brushes on STORM motors

located under the brush caps on the motor housing. If

these caps are hard to remove they are either overtightened or the motor has become very hot. Let motors cool. If caps still cannot be removed, it is recommended that the motor be sent to Invacare Technical

Services for inspection/repair.

NOTE: It is very important to note which way the brush

comes out of the motor. The brush MUST be placed into

the motor exactly the same way to ensure good contact

with the commutator.

1. Once the motor brush caps have been removed, pull

the brushes out of the motor. The end of the brushes

should be smooth and shiny and the spring should

not be damaged or discolored. If one or both of the

brushes are damaged, only the damaged or worn

brushes need be replaced. It is very important that

any time a brush is replaced, it must be “burned in”.

This is accomplished by running the motor for one

hour in each direction with a half hour break in-between. This should also be done with little or no load

on the motor, i.e., put the wheelchair up on blocks so

the drive (large) wheels do not contact the ground

and run the wheelchair. A motor with only one brush

replaced will only carry a small percentage of its rated

load capacity until the NEW brush is burned in.

TROUBLESHOOTINGPROCEDURE 2

Cap

Motor

4 Pin Motor Connector

FIGURE 4 - MOTOR BRUSH INSPECTION

ELECTRO-MECHANICAL PARKING

BRAKE TESTING (FIGURE 5)

NOTE: This procedure should only be performed on

wheelchairs with conventional motor/gearbox assembly .

1. On the four-pin motor connector, locate the side by

side connectors in the black housings.

2. Set the digital multimeter to read ohms (Ω).

3. Measure the resistance between the two (2) brake contacts. A normal reading is 100 ohms (Ω). A reading of 0

ohms (Ω) or a very high reading; i.e., MEG ohms or O.L.

(out of limit) indicates a shorted brake or an open connection respectively . If either condition exists, send the motor

to Invacare T echnical Service for inspection/repair.

CAUTION

A shorted electro-mechanical brake will

damage the brake output section in the controller. DO NOT connect a shorted electromechanical brake to a good controller module. A shorted brake MUST be replaced.

NOTE: A bad motor can damage the controller module

but a bad controller will NOT damage a motor.

Cap

4 Pin Motor Connector

FIGURE 5 - ELECTRO-MECHANICAL

PARKING BRAKE TESTING

Motor

Ohmmeter

14

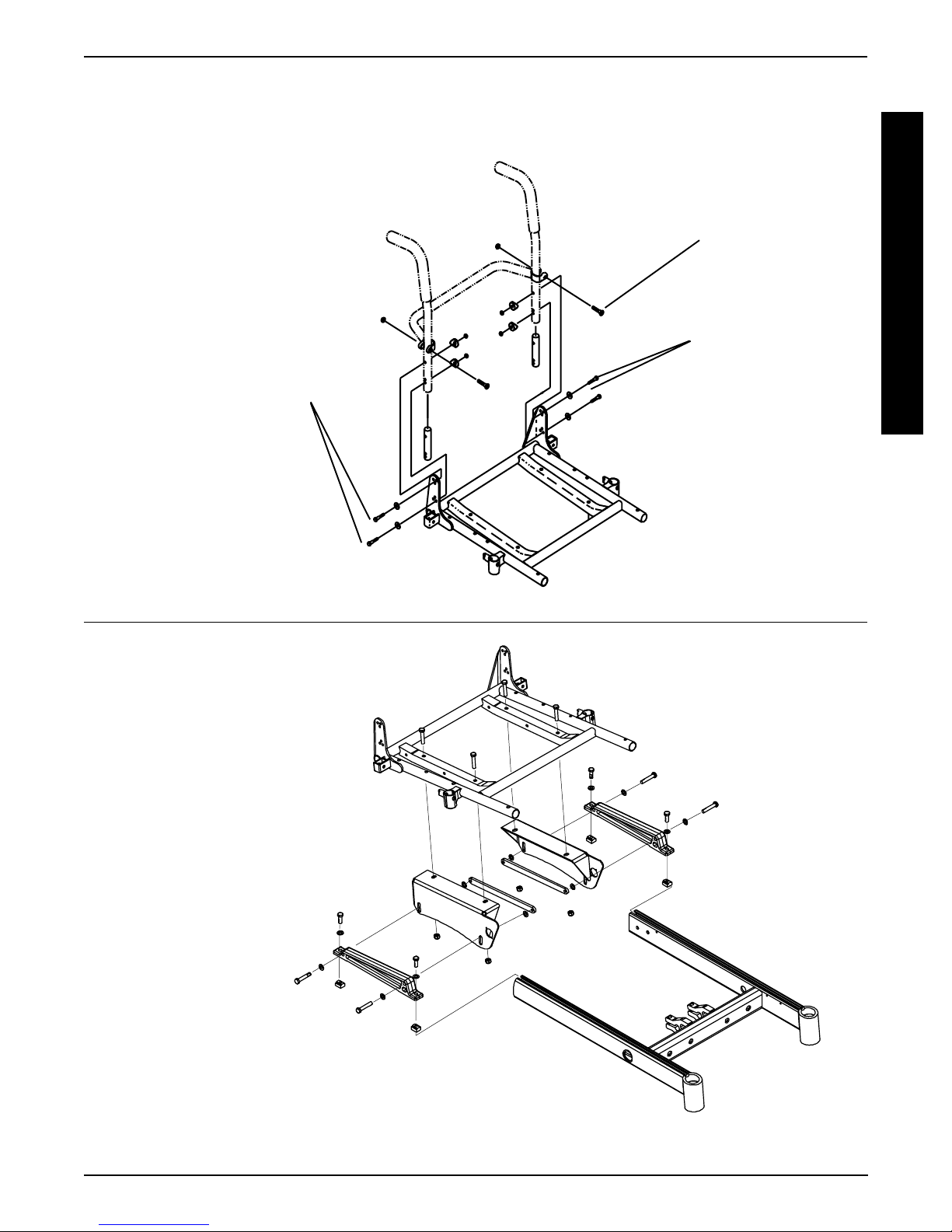

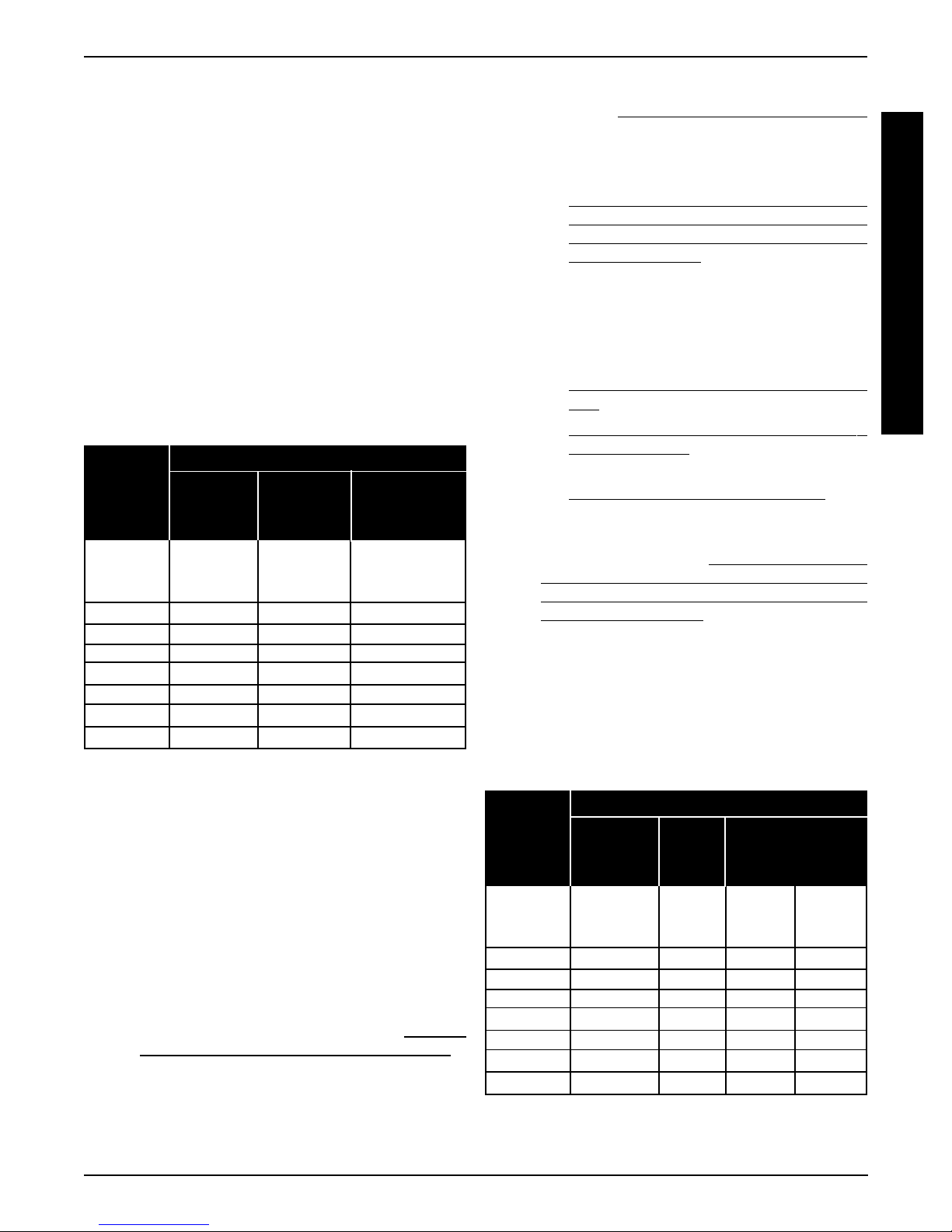

PROCEDURE 3HARDWARE TORQUE SPECIFICATIONS

HARDWARE TORQUE SPECIFICATIONS

STANDARD SEAT FRAME

*Torque to

60 in-lbs

*Loctite and

*Loctite® and

T orque to

75 in-lbs

T orque to

75 in-lbs

T

O

R

Q

U

E

S

P

E

C

I

F

I

C

A

T

I

O

N

S

T orque to

156 in-lbs

**Torque to

156 in-lbs

**Torque to

156 in-lbs

NOTE:

* These torque specifications also apply to the adjustable seat frame assembly.

** These torque specifications also apply to the captains van seat and adjustable seat frame assemblies.

15

PROCEDURE 3 HARDWARE TORQUE SPECIFICATIONS

HARDWARE TORQUE SPECIFICATIONS

T

O

R

Q

U

E

*CAPTAINS VAN SEAT

*ADJUSTABLE SEAT FRAME

S

P

E

C

I

F

I

C

A

T

I

O

N

S

Torque to

156-in-lbs

Torque to

75-in-lbs

Torque to

156-in-lbs

Loctite and Torque to

75 in-lbs

Torque to

156-in-lbs

T orque to

156 in-lbs

Torque to

156-in-lbs

T orque to

156 in-lbs

* NOTE: For additional torque specifications, refer to the torque specifications drawing for the standard

seat frame assembly.

16

REAR OF

WHEELCHAIR

T orque to

156 in/lbs

(Torque to 156

in-lbs and back

off 1/4 turn)

BASE FRAME HARDWARE

TORQUE SPECIFICATIONS

Loctite and torque to

156 in/lbs

Loctite and

T orque to

156 in-lbs

PROCEDURE 3HARDWARE TORQUE SPECIFICATIONS

T orque to

156 in/lbs

T orque to

85 ft-lbs

T

O

R

Q

U

E

S

P

E

C

I

F

I

C

A

T

I

O

N

S

Loctite and

torque to

75 in/lbs

Wheel Halves -

T orque to

540 in-lbs

T orque to

156 in/lbs

Torque to 156 in/lbs

CONVENTIONAL MOTOR/GEARBOX

Adjustment

Screw

Torque

to 75 in-lbs.

FRONT OF

WHEELCHAIR

8 - inch Wheels -

Torque to 120 in-lbs

9 - inch Wheels -

Torque to 156 in-lbs

8 - inch - Torque to 18 in-lbs

9 - inch - Torque to 156 in-lbs

Wheel Halves

GEARLESS/BRUSHLESS MOTOR

NOTE: All torque specifications called out for the conventional motor/gearbox assembly are applicable to

the gearless/brushless motor except for the following:

Torque to 13 ft-lbs.

Torque to 25 in-lbs.

Torque to 13 ft-lbs.

17

ARMSPROCEDURE 4

This Procedure Includes the Following:

Replacing Armrest Pads - Captains Van Seats

Replacing Captains Van Seat Armrest Plate

WARNING

A

R

M

S

After ANY adjustments, repair or service

and BEFORE use, make sure that all attaching hardware is tightened securely - otherwise injury or damage may result.

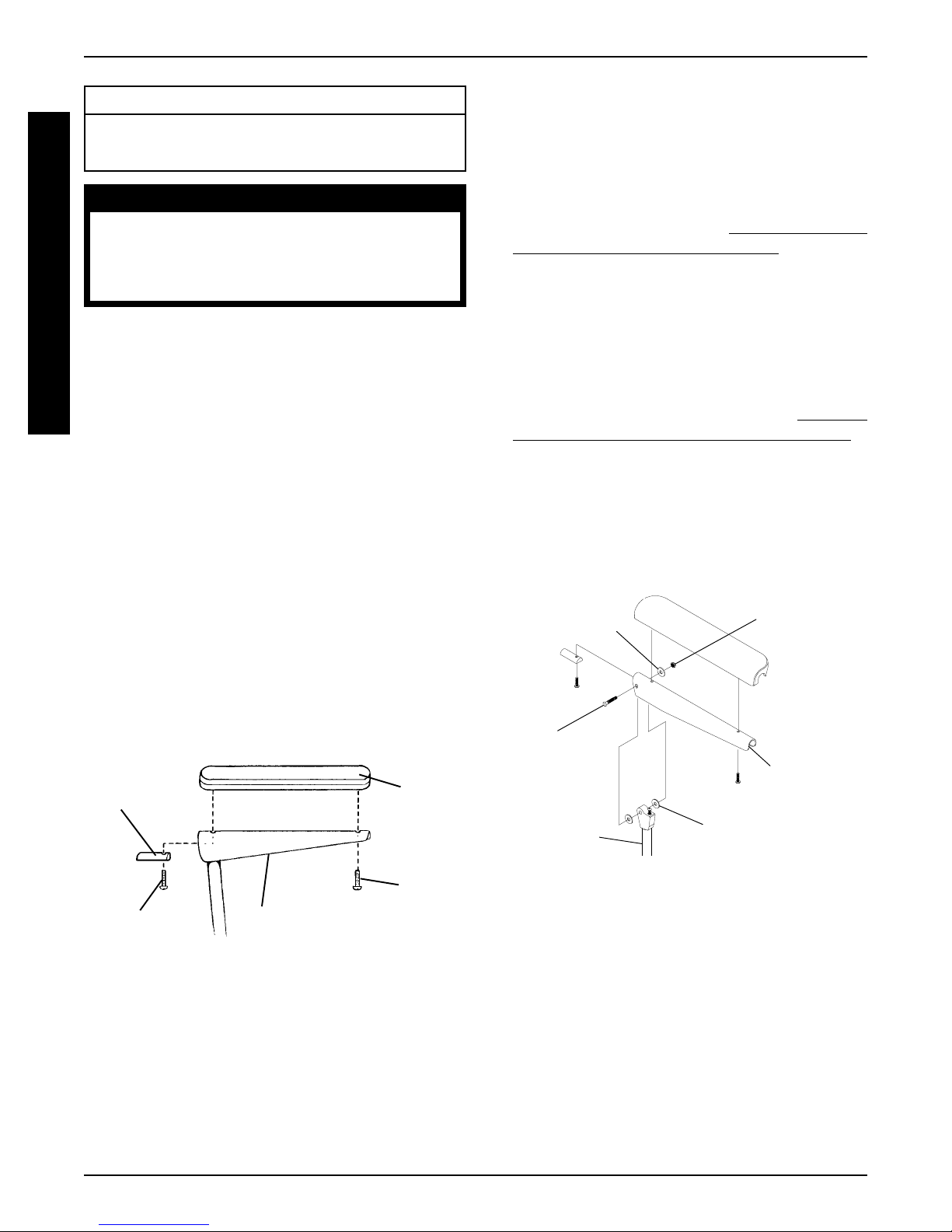

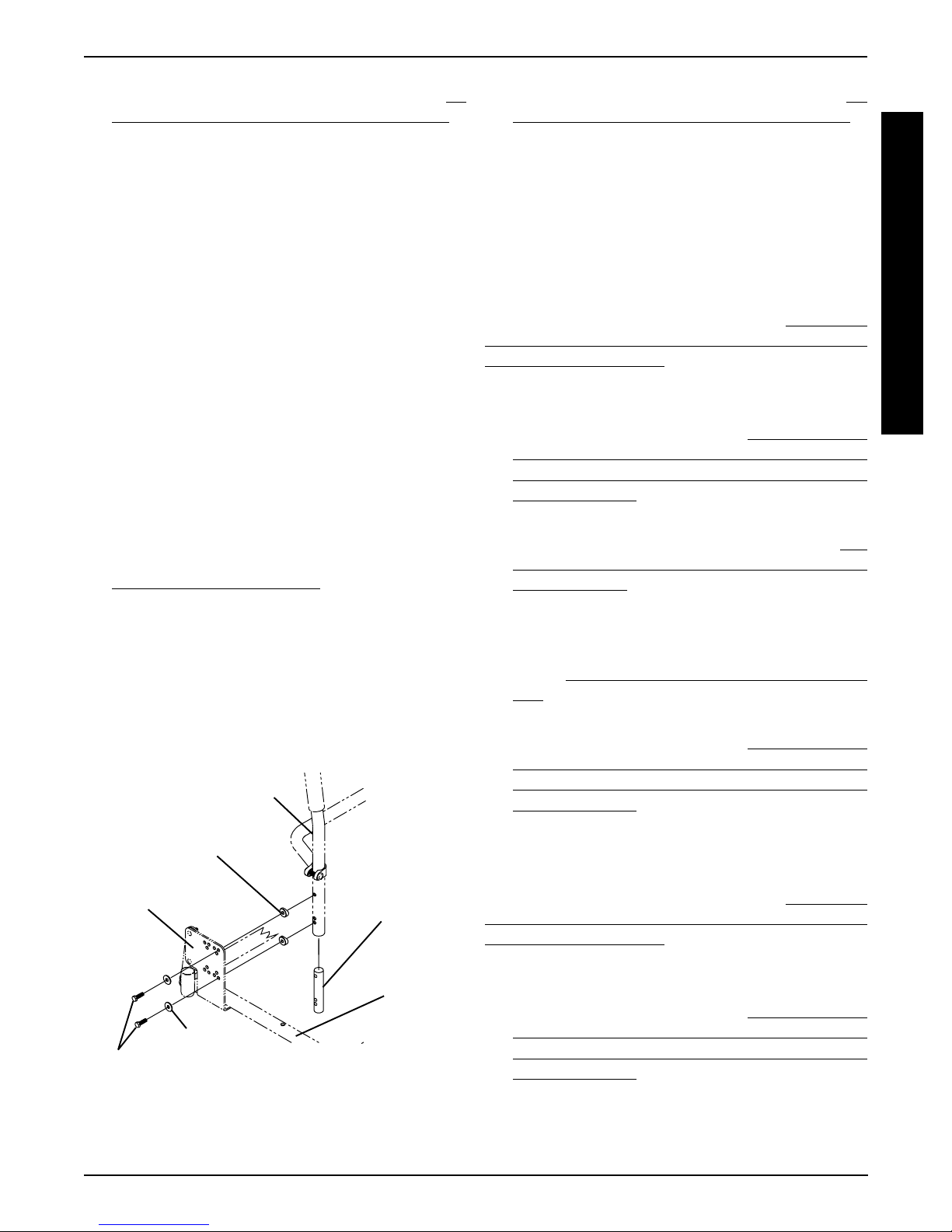

REPLACING ARMREST PADS CAPTAINS VAN SEATS (FIGURE 1)

1. Remove the mounting screws that secures the front

of the armrest pad to the armrest plate.

2. Remove the mounting screw that secures the rear of

the armrest pad and armrest insert to the armrest

plate.

3. Remove the existing armrest pad and position the

NEW armrest pad on the armrest plate.

4. Line up the mounting holes in the armrest insert, armrest plate and NEW armrest pad.

REPLACING CAPTAINS VAN SEAT

ARMREST PLATE (FIGURE 2)

1. If necessary , remove the three (3) mounting screws,

spacers and locknuts that secure the joystick mounting bracket to the armrest plate.

2. Remove armrest pad. Refer to

REST P ADS - CAPTAINS V AN SEATS in this procedure of the manual.

3. Remove the mounting screw, washers and locknut that

secure the existing armrest plate to the arm weldment.

4. Position the NEW armrest plate on the armrest weldment

and secure with the mounting screw, washers, and locknut. Refer to FIGURE 2 for correct hardware orientation.

5. Reinstall van style armrest pad. Refer to

ING ARMREST P ADS - CAPT AINS VAN SEA TS in

this procedure of the manual.

6. If necessary , reinstall the three (3) mounting screws,

spacers and locknuts that secure the joystick mounting bracket to the armrest plate.

7. Repeat STEPS 1-6 for the opposite armrest plate, if

necessary .

REPLACING ARM-

REPLAC-

5. Reinstall the rear mounting screw through the armrest insert, armrest plate and armrest pad and tighten

securely .

6. Reinstall the front mounting screw into the armrest

plate and NEW armrest pad and tighten securely.

FRONTREAR

Armrest

Insert

Mounting

Screw

FIGURE 1 - REPLACING ARMREST PADS -

CAPTAINS VAN SEATS

Armrest Plate

Armrest

Pad

Mount-

ing

Screw

Washer

Mounting

Screw

Arm

Weldment

FIGURE 2 - REPLACING CAPTAINS VAN SEAT

ARMREST PLATE

Washer

Locknut

Armrest

Plate

18

UPHOLSTERY/POSITIONING STRAP PROCEDURE 5

This Procedure Includes the Following:

Replacing Seat Positioning Strap - Captains Van

Seats

Replacing Back Upholstery

WARNING

After ANY adjustments, repair or service

and BEFORE use, make sure that all attaching hardware is tightened securely - otherwise injury or damage may result.

REPLACING SEAT POSITIONING

STRAP - CAPTAINS VAN SEATS

(FIGURE 1)

1. Remove the van style seat from the van seat frame.

Refer to INST ALLING/REMOVING CAPTAINS V AN

SEA T ASSEMBLY in PROCEDURE 6 of this manual.

2. Remove the two (2) rear mounting screws, washers,

and locknuts that secure the seat positioning straps

to the van seat frame.

NOTE: The washer is positioned between the seat positioning strap and the mounting screw.

3. Secure the NEW seat positioning strap halves with

the mounting screws, washers and locknuts to the

van seat frame and torque to 75-inch pounds.

4. Reinstall the van style seat to the van seat frame.

Refer to

SEA T ASSEMBLY in PROCEDURE 6 of this manual.

Seat Positioning

INST ALLING/REMOVING CAPTAINS V AN

Van Seat Frame

Strap

REAR OF SEAT

FRAME

Mounting

Screw

REPLACING BACK UPHOLSTERY

(FIGURE 2)

1. Remove one (1) armrest from the wheelchair. Refer to

INST ALLING/REMOVING FLIP BACK ARMRESTS in

PROCEDURE 4 of the owner’s manual, 1081227.

2. If applicable, remove the two (2) mounting screws

and locknuts that secure the spreader bar to the back

canes.

3. Remove the two (2) mounting screws and washers

that secure the existing back upholstery to the back

canes.

4. Cut the tie-wraps that secure the bottom of the existing back upholstery to the back canes.

NOTE: Note the back angle before disassembly for proper

reinstallation.

5. On the side of the wheelchair that the armrest was

removed, remove one (1) of the mounting screws,

washer, spacer, and locknut that secures the back

cane to the seat frame.

NOTE: T o avoid losing the insert in each back cane, thread

the mounting screw just removed through the cane from

the inside of the wheelchair to hold the insert in place.

6. Remove the other mounting screw , washer , spacer,

and locknut that secures the back cane to the seat

frame.

7. Slide the back cane out of the spreader bar (If applicable) and the existing back upholstery .

8. Remove other armrest from the chair. Refer to

STALLING/REMOVING FLIP BACK ARMRESTS in

PROCEDURE 4 of the owner’s manual, 1081227.

9. Repeat STEPS 5-7 for the opposite side of the wheelchair.

10. Slide the other back cane out of the spreader bar (if

applicable) and the existing back upholstery .

IN-

U

P

H

O

L

S

T

E

R

Y

P

O

S

I

T

I

O

N

I

N

G

S

T

R

A

P

Locknuts

Washer

FIGURE 1 - REPLACING SEAT POSITIONING

STRAP - CAPTAINS VAN SEATS

FRONT OF SEAT

FRAME

11. Slide one(1) back cane into NEW back upholstery

and through spreader bar (if applicable).

12. Secure back cane to the seat frame from the outside

of the wheelchair with the existing two (2) mounting

screws, washers, spacers, and locknuts. Use Loctite

242 and torque to 75-in/lbs.

13. Repeat STEPS 11-12 for opposite back cane.

14. Secure the top of the NEW back upholstery to the

back canes with the two (2) existing mounting screws.

19

UPHOLSTERY/POSITIONING STRAPPROCEDURE 5

NOTE: When replacing the back upholstery, back assembly or changing back height, follow these guidelines

for spreader bar height:

STANDARD MODELS

U

P

H

O

L

S

T

E

R

Y

P

O

S

I

T

I

O

N

I

N

G

S

T

R

A

P

BACK HEIGHT u SPREADER BAR

HEIGHT

16-inches* 5-inches

17-inches* 5-inches

18-19-inches* 7-inches

20-24-inches 7-inches

NOTE: Spreader Bar required on ALL back heights between 20-24-inches. *Spreader bar required on back

heights 16,17,18, or 19 ONL Y if the width or depth of the

chair exceeds 19-inches.

uHeight of Spreader Bar from Bottom of Back

Canes to Top of Spreader Bar Clamp.

Back Cane

(STEPS 3, 12)

Mounting

Screw

(STEPS 3, 14)

Washer

(STEPS 3, 14)

Back

Upholstery

(STEPS 3, 7)

Locknut

(STEP 2)

HEAVY DUTY MODELS

NOTE: Spreader bar required on all back heights.

BACK HEIGHT u SPREADER BAR

HEIGHT

16-17-inches 5-inches

18-24-inches 7-inches

uHeight of Spreader Bar from Bottom of Back

Canes to Top of Spreader Bar Clamp.

15. If applicable, reposition the spreader bar at the correct

height for the corresponding back height and torque

the mounting hardware to 60-in/lbs.

16. Reinstall the armrest onto the wheelchair. Refer to INST ALLING/REMOVING FLIP BACK ARMRESTS in

PROCEDURE 4 of the owner’s manual, 1081227.

Locknuts

(STEPS 5, 6)

Spacers

(STEPS 5, 6)

Locknut

(STEP 2)

Spreader Bar

(STEPS 2, 7, 16)

Mounting

Screw

(STEP 2)

Insert

Washers

(STEPS 5, 6)

Mounting Screws

Torque to 75 in/lbs

(STEPS 5, 6)

FIGURE 2 - REPLACING BACK UPHOLSTERY

Mounting Screw

Torque to 60 in/lbs

(STEP 2)

Mounting

Screws

(STEPS 5, 6)

Washers

(STEPS 5, 6)

Seat Frame

20

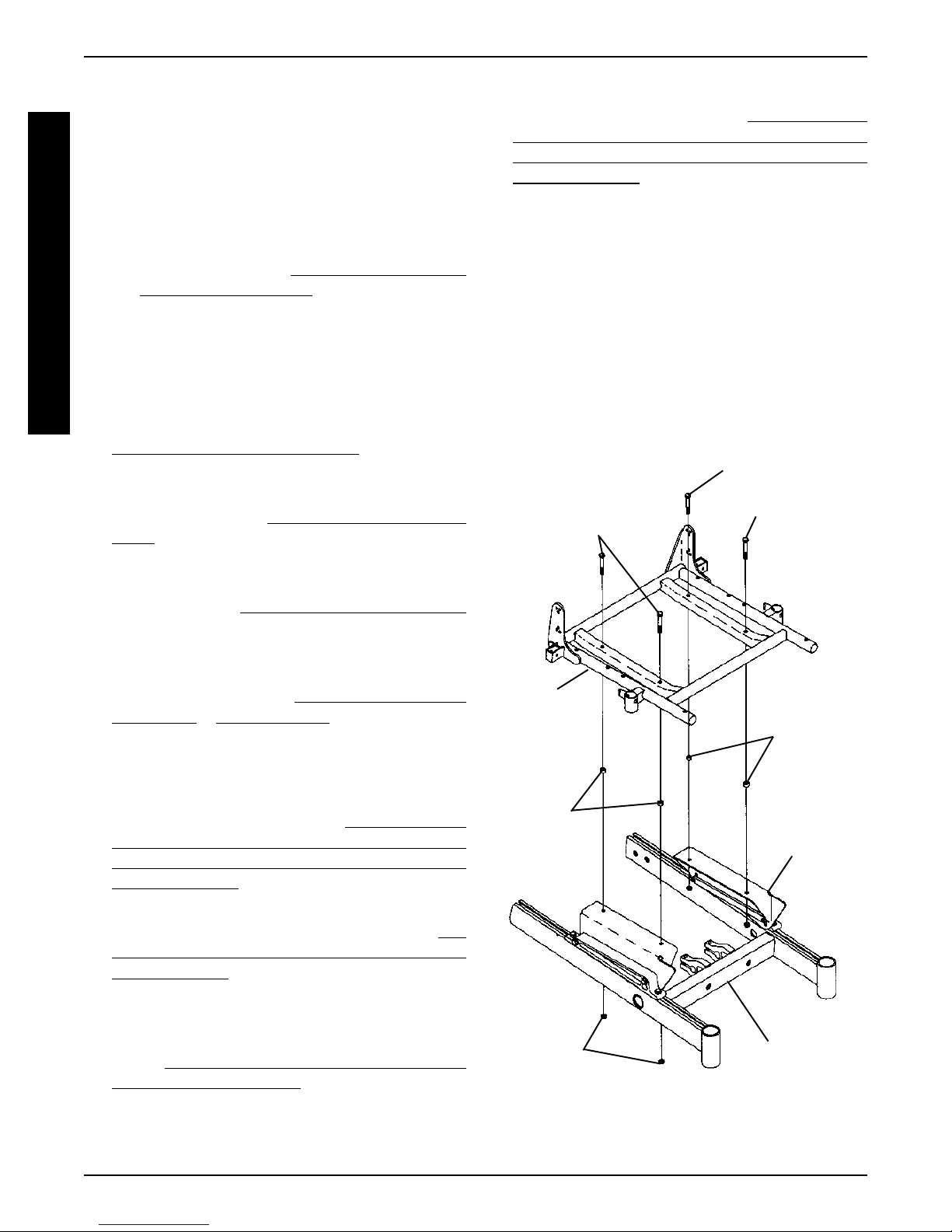

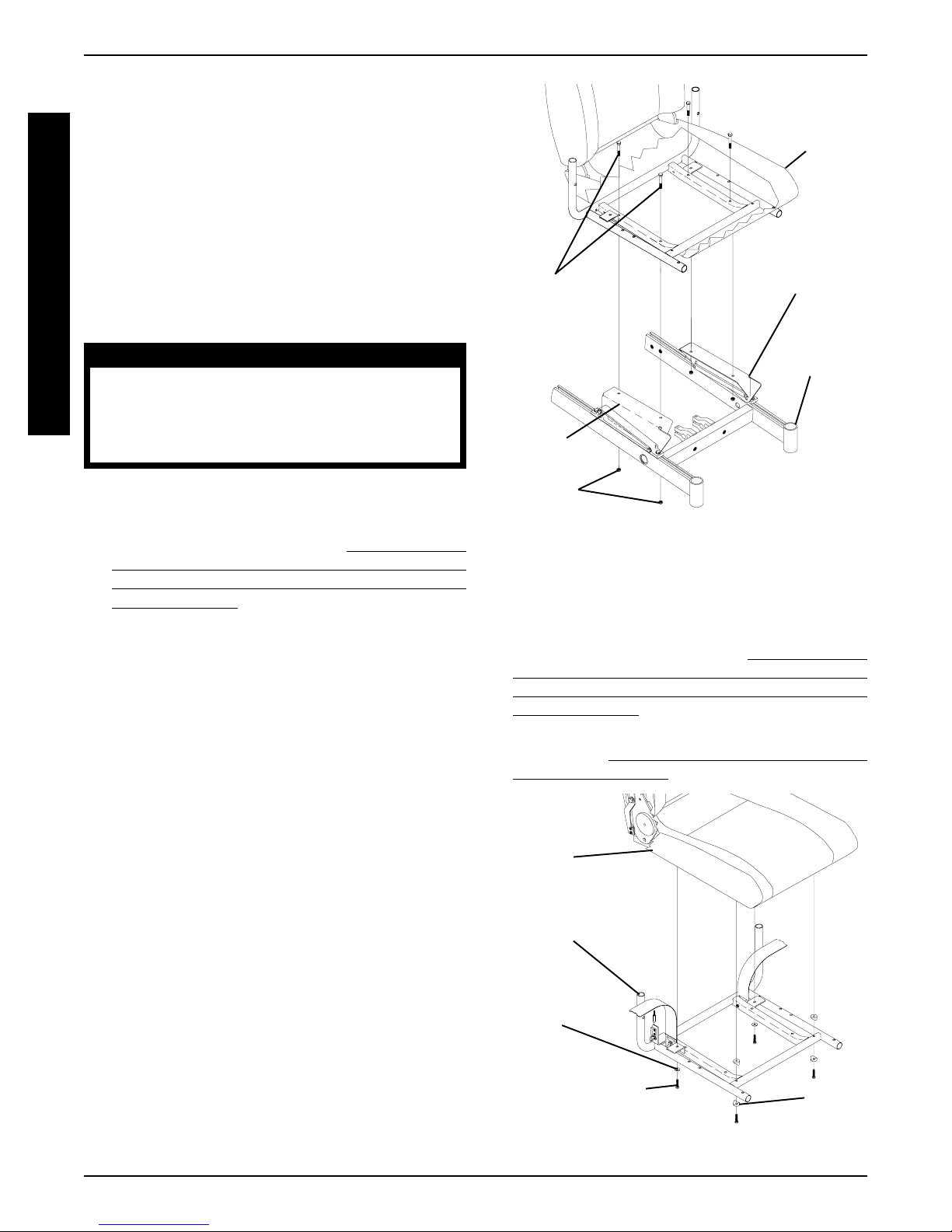

PROCEDURE 6SEAT FRAME

This Procedure includes the following:

Preparation for Removing/Installing Seat Frame

(Standard Frame, Adjustable Frame,

and Captains Van Seat) ............................Page 21

Replacing Exact Same Size Standard

Seat Frame ..............................................Page 22

Removing/Installing Standard Seat Frame

Sub-Assembly .........................................Page 22

Changing Seat Depth ...............................Page 23

Changing Seat Width (Standard and Adjustable

Seat Frame) ............................................. Page 25

Installing/Removing Adjustable Seat Frame

Sub-Assembly and/or Component

Replacement ........................................... Page 26

Installing/Removing Captains Van Seat

Assembly ................................................Page 28

Replacing Captains Van Seat and/or Captains

Van Seat Frame .......................................Page 28

Converting From Standard Seat Frame to Adjust-

able Seat Frame or Vice V ersa..................Page 29

Converting From Adjustable Seat Frame to

Captains Van Seat or V ice Versa...............Page 29

Converting From Standard Seat Frame to Cap-

tains Van Seat or V ice Versa.....................Page 30

Removing/Installing Seat Pan ..................Page 30

Mounting Plate - Seat Angle Adjustment and

Installation Orientation .............................Page 31

WARNING

After ANY adjustments, repair or service and

BEFORE use, make sure that all attaching

hardware is tightened securely - otherwise

injury or damage may result.

1. Remove footrest assemblies. Refer to PROCEDURE

4 in of the owner’s manual, 1081227.

2. Remove battery box(es). Refer to

MOVING GROUP 24 BATTERY BOXES or INSTALLING/REMOVING 22NF BATTERY BOX in PROCEDURE 9 of this manual.

Adjustment Lock

Lever for Joystick

(STEP 4)

Battery

Box(es)

(STEP 2)

Seat Positioning

Strap (STEP 7)

Back Upholstery

(STEP 10)

Controller, Left/Right Motor

Connectors (STEPS 8,9)

INSTALLING/RE-

Flip Back

Armrests

(STEP 6A)

Footrest

Location

(STEP 1)

Joystick

(STEPS

3,5)

Seat Pan

(STEP 7)

S

E

A

T

F

R

A

M

E

NOTE: The procedures in this section of the manual refer to NON-RECLINER seat frames only , EXCEPT Seat

Angle Adjustment. For recliner seat frames, refer to PROCEDURE 14 of this manual.

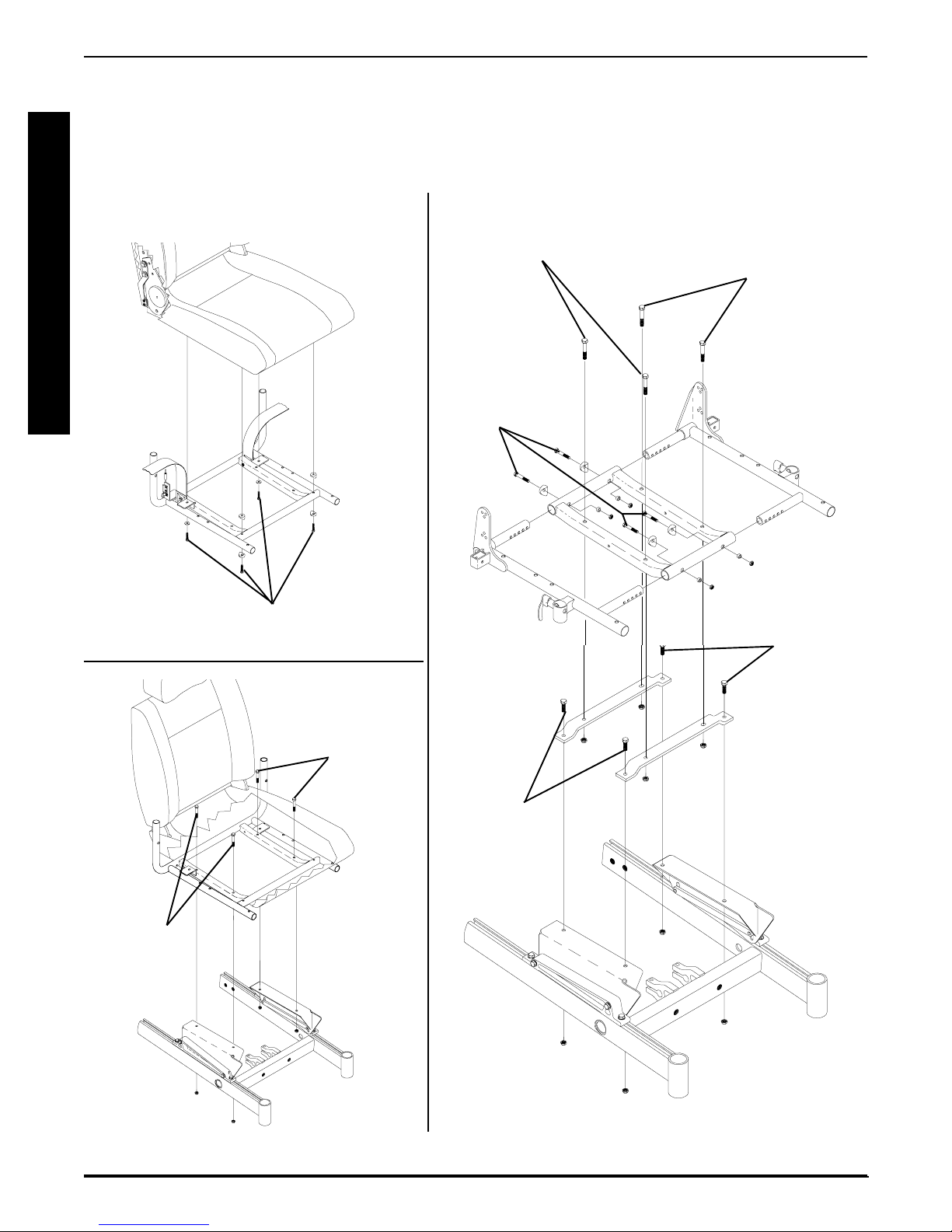

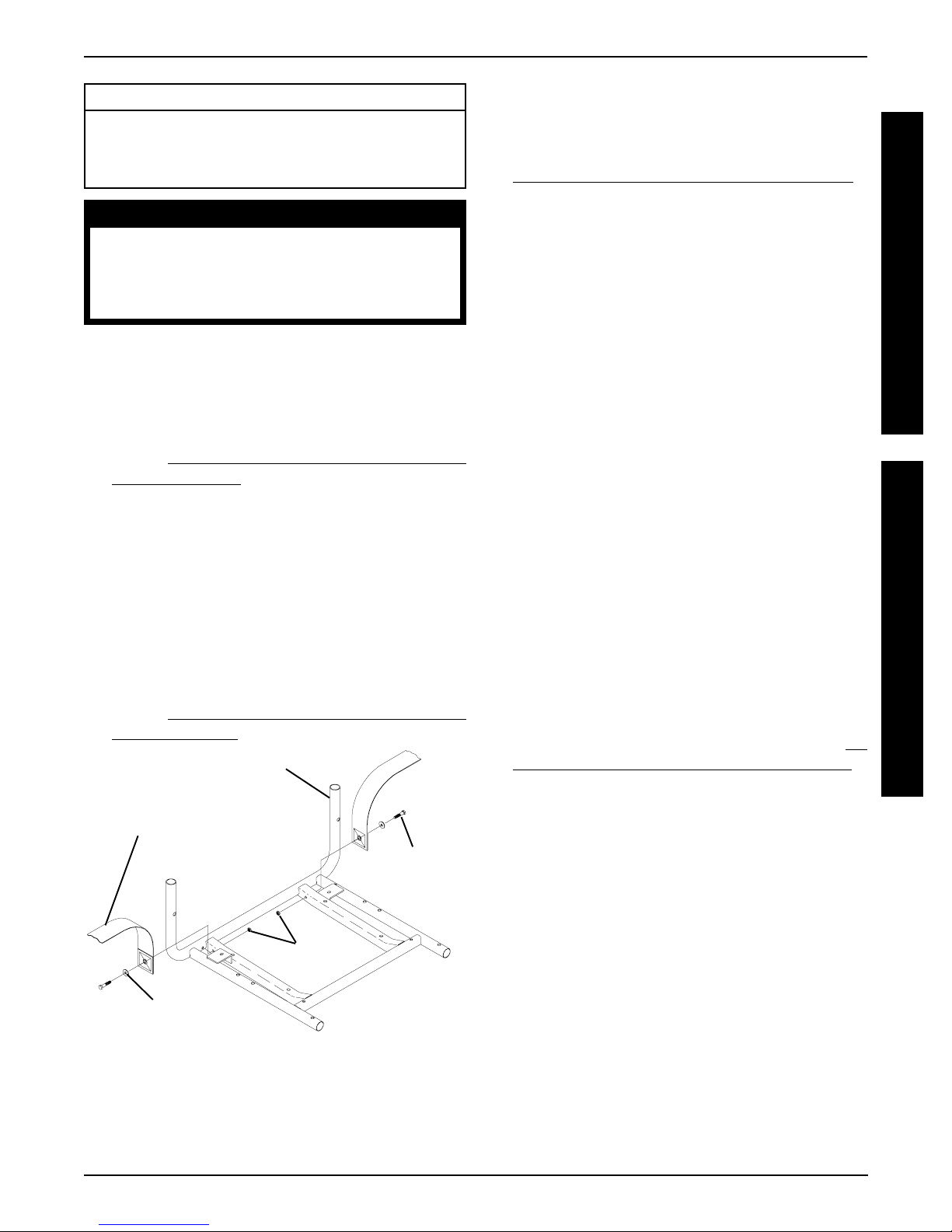

PREPARATIONS FOR REMOVING/

INSTALLING SEAT FRAME

(STANDARD FRAME, ADJUSTABLE

FRAME, AND CAPTAINS VAN SEAT)

(FIGURE 1)

NOTE: When installing/replacing components of the wheelchair, refer to the individual procedure for correct use of

LOCTITE 242 and torque specifications or PROCEDURE

3 of this manual.

NOTE: T o reinstall these components, reverse the following steps.

STEP 6B

Height

Adjustment

Holes

Captains

Van Seat

Base

FIGURE 1 - PREPARATIONS FOR REMOVING/

INSTALLING SEAT FRAME (STANDARD FRAME,

ADJUSTABLE FRAME, AND CAPTAINS VAN SEAT)

21

Socket

Screw

PROCEDURE 6 SEAT FRAME

3. Cut tie wraps and disconnect joystick from controller.

4. Turn the lever on the adjustment lock to release the

adjustment lock from the joystick mounting tube.

5. Remove the joystick from the wheelchair.

S

E

6. Perform one (1) of the following:

A

T

F

R

A

M

E

A. STANDARD OR ADJUSTABLE SEAT

FRAMES - Remove the flip-back armrests from

the wheelchair. Refer to

FLIP BACK ARMRESTS in PROCEDURE 4 of

the owner’s manual, 1081227.

B. CAPT AINS VAN SEAT - Remove the mounting

screw that secures the armrest to the van seat

frame. Repeat for opposite side.

7. For standard and adjustable seat frames, remove the

seat pan (including seat positioning straps). Refer to

REMOVING/INSTALLING SEAT P AN in this procedure

of the manual.

8. Disconnect battery and left/right motor connectors from

the controller. Refer to

NESS in PROCEDURE 10 of this manual.

INSTALLING/REMOVING

REPLACING WIRING HAR-

4. Reinstall the components previously removed in STEP

1. Perform the instructions outlined in

FOR REMOVING/INSTALLING SEAT FRAME (ST ANDARD FRAME, ADJUST ABLE FRAME, AND CAPT AINS V AN SEAT) in this procedure of the manual.

PREPARATIONS

REMOVING/INSTALLING

STANDARD SEAT FRAME

SUBASSEMBLY (FIGURE 2)

Removing

1. Remove the four (4) mounting screws, locknuts and

spacers, if applicable, that secure the standard seat

frame subassembly to the seat mounting plates.

2. Remove the existing standard seat frame.

Mounting Screws

Mounting Screws

(Torque to 156-

inch pounds)

(Torque to 156-

inch pounds)

9. Remove tie-wraps that secures the wiring harness to

the seat frame and the charger cable from its mounting bracket. Refer to

in PROCEDURE 10 of this manual.

10. For standard and adjustable seat frames, remove the

back upholstery (including back canes and spreader

bar, if applicable). Refer to

HOLSTERY in PROCEDURE 5 of the manual.

REPLACING WIRING HARNESS

REPLACING BACK UP-

REPLACING EXACT SAME SIZE

STANDARD SEAT FRAME

1. Perform the instructions outlined in PREPARA TIONS

FOR REMOVING/INSTALLING SEAT FRAME (ST ANDARD FRAME, ADJUST ABLE FRAME, AND CAPT AINS V AN SEA T) in this procedure of the manual.

2. Remove the existing standard seat frame subassembly and install the NEW standard frame. Refer to

MOVING/INST ALLING STANDARD SEAT FRAME

SUBASSEMBLY in this procedure of the manual.

3. FOR 12-15-INCH SEAT DEPTHS ONLY: Remove

the CJ back brackets from the existing standard seat

frame and install onto the NEW standard seat frame.

Refer to

ETS FROM SEAT FRAME in this procedure of the

manual.

REMOVING/INSTALLING CJ BACK BRACK-

RE-

Standard

Seat

Assembly

Spacer

(16-inch Wide

Only)

Locknuts

FIGURE 2 - REMOVING/INSTALLING

STANDARD SEAT FRAME SUB-ASSEMBLY

Base Frame

Spacer

(16-inch

Wide Only)

Seat

Mounting

Plate

22

PROCEDURE 6SEAT FRAME

Installing

1. Position NEW standard seat frame subassembly on

seat mount plates.

2. Secure NEW standard seat frame subassembly onto

seat mounting plates with the existing four (4) mounting screws, locknuts and spacers, if applicable. T orque

to 156-inch pounds.

CHANGING SEAT DEPTH

Standard Seat Frame

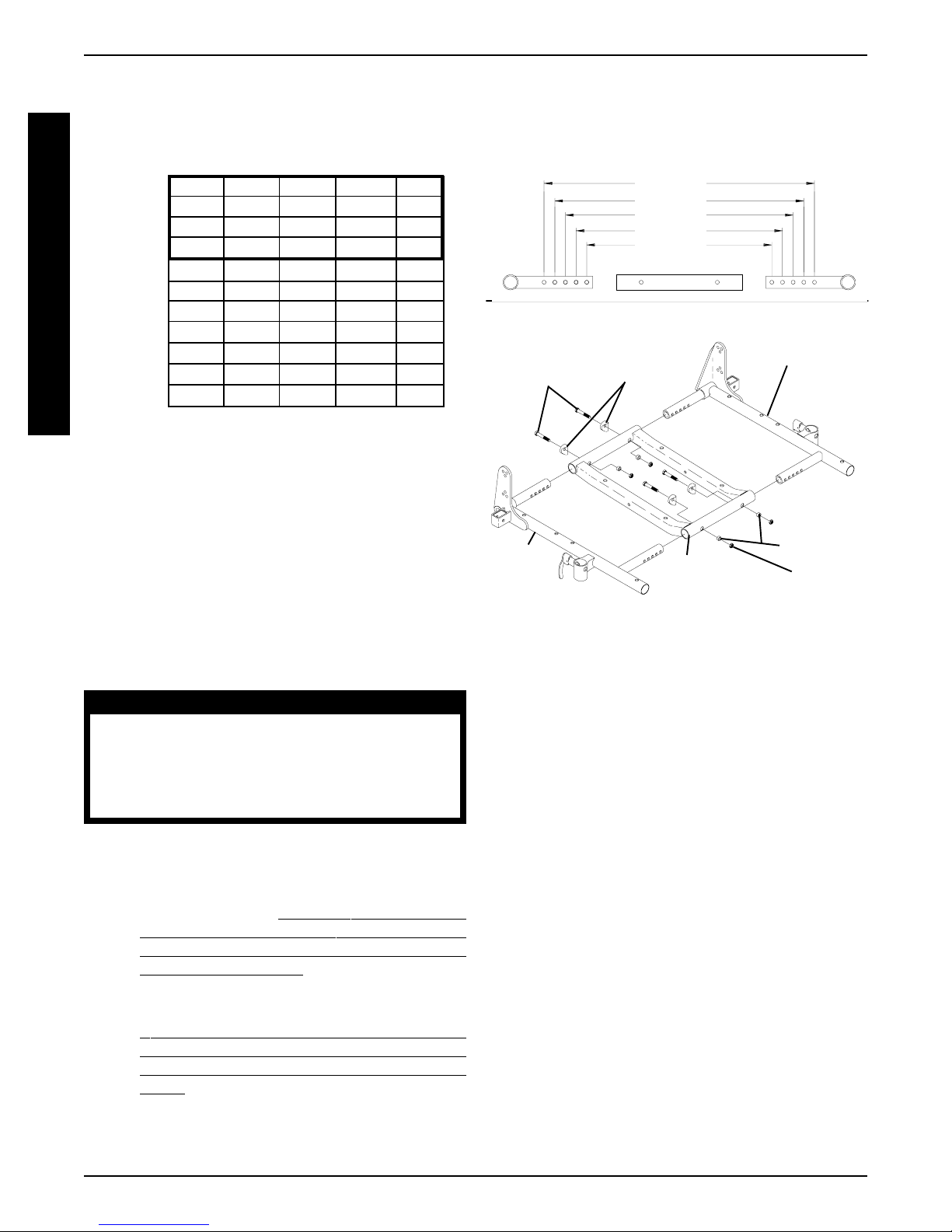

NOTE: Review the chart below. This will determine the components needed to obtain the desired seat depth.

COMPONENT IDENTIFICATION TABLE

FOR STANDARD SEAT FRAME

SEAT FRAME COMPONENTS

CJ BACK SEA T

SEA T BRACKETS SEAT FRAME

DEPTH REQUIRED P AN DEPTH

12-inches

to YES 17-inch 16-inch deep

15-inches

16-inches NO 16-inch 16-inch deep

17-inches NO 17-inch 16-inch deep

18-inches NO 18-inch 18-inch deep

19-inches NO 19-inch 18-inch deep

20-inches NO 20-inch 20-inch deep

21-inches NO 21-inch 20-inch deep

22-inches NO 22-inch 22-inch deep

1. Find current seat depth in left hand column in the chart.

2. Follow that row to right under seat frame components.

3. Verify and note the components of the current seat depth.

4. Repeat STEPS 1-3 for your desired seat depth.

B. If the desired change only requires a NEW seat

pan, refer to

in this procedure of the manual.

C. For all other seat depth changes, perform the fol-

lowing:

l

PREPARATIONS FOR REMOVING/INSTALLING SEAT FRAME (STANDARD

FRAME, ADJUST ABLE FRAME, AND CAPT AINS VAN SEAT) in this procedure of the

manual.

Perform one (1), two (2), or all three (3) of the procedures listed below depending on the components required for the desired seat depth determined from STEPS 1-5:

REMOVING/INST ALLING CJ BACK BRACK-

l

ETS in this procedure of the manual.

l

REMOVING/INST ALLING STANDARD SEAT

SUBASSEMBL Y in this procedure of the

manual.

l

REMOVING/INSTALLING SEAT P AN in this

procedure of the manual.

After completing the procedure(s) listed above, perform the steps outlined in

REMOVING/INST ALLING SEAT FRAME (ST ANDARD FRAME, ADJUSTABLE FRAME, AND

CAPTAINS VAN SEAT) to complete the desired

seat depth change.

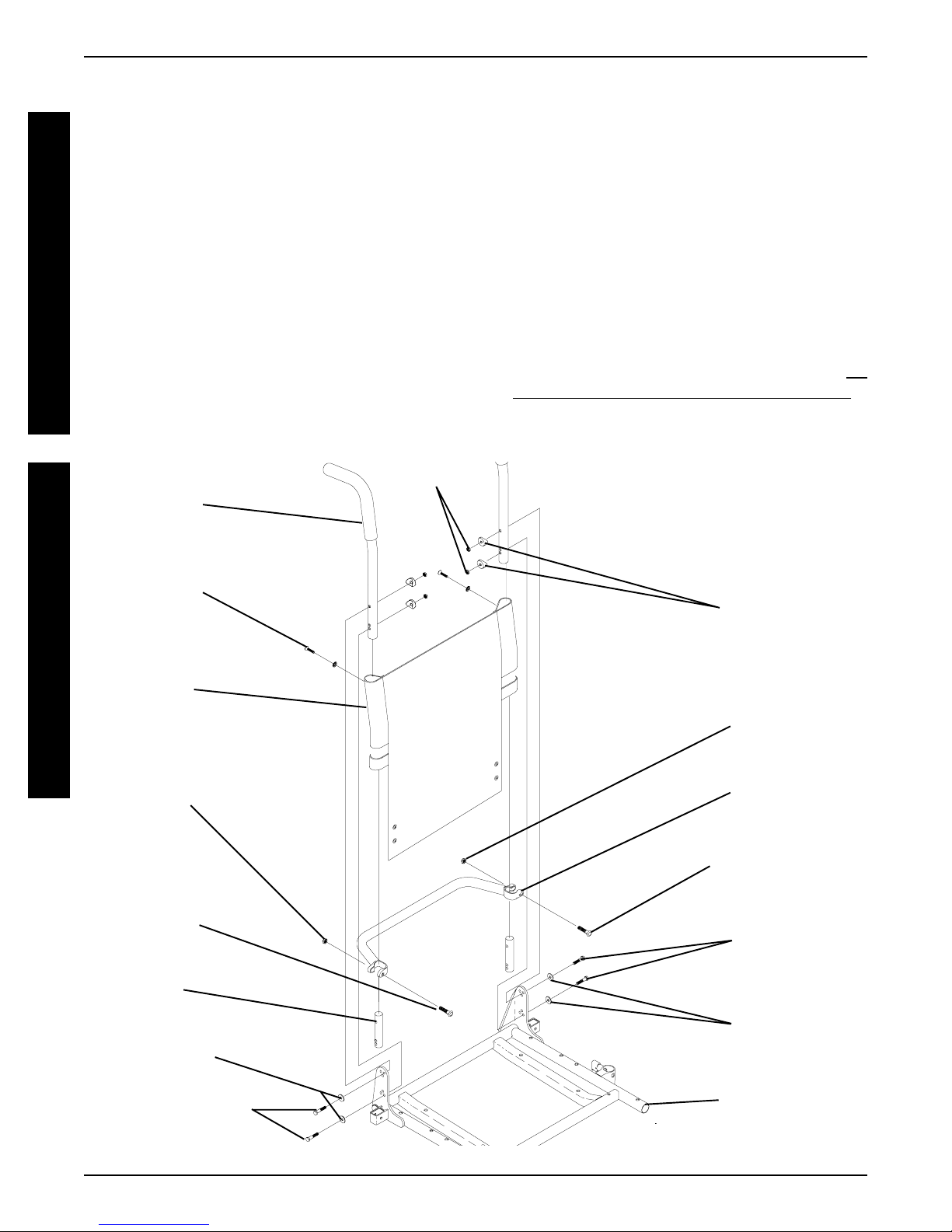

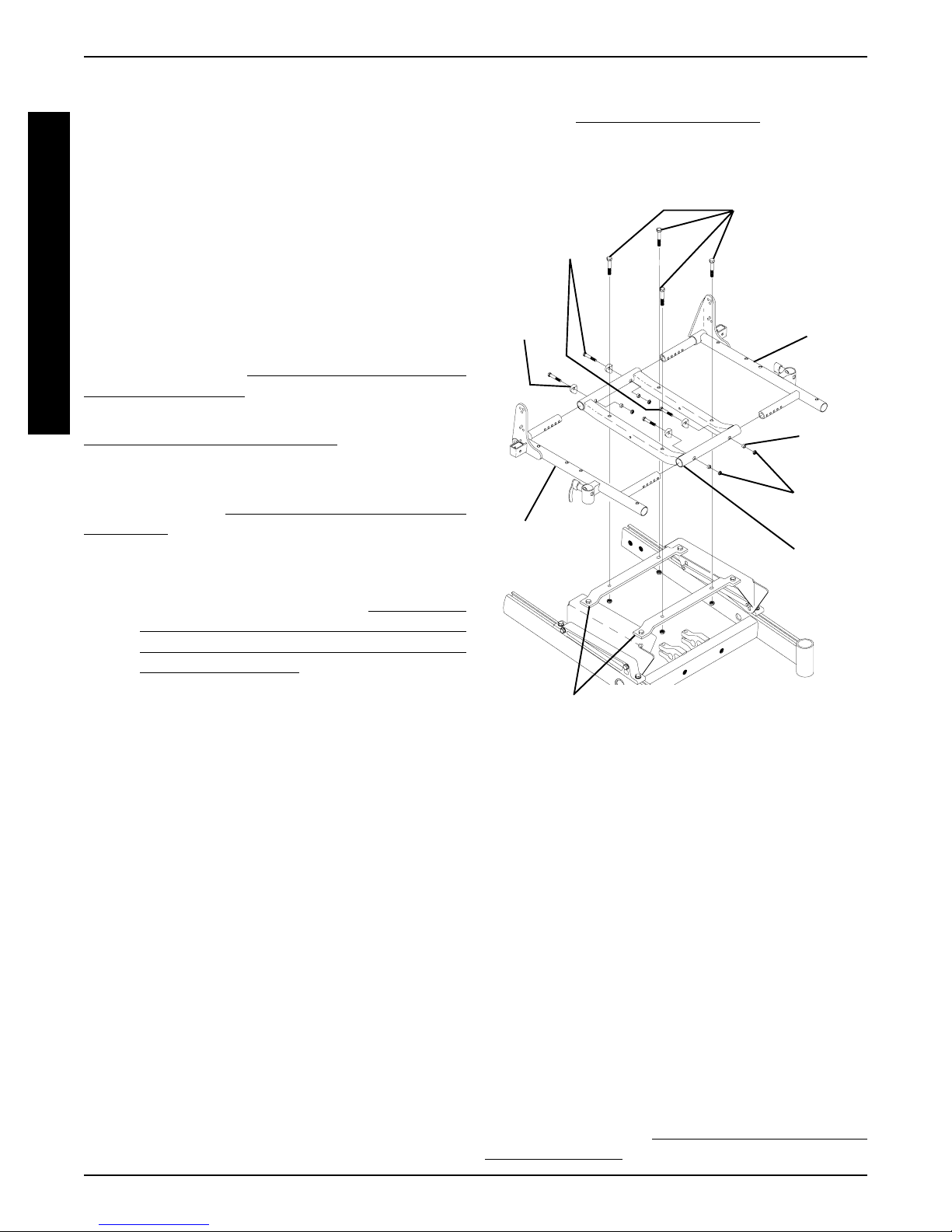

Adjustable Seat Frame (FIGURE 3)

REMOVING/INSTALLING SEA T PAN

PREP ARA TIONS FOR

NOTE: Review the chart below. This will determine the components needed to obtain your desired seat depth.

COMPONENT IDENTIFICATION TABLE

FOR STANDARD SEAT FRAME

SEAT FRAME COMPONENTS

CJ BACK

SEA T BRACKETS SEAT SIDE CENTER

DEPTH REQUIRED P A N FRAME FRAME

S

E

A

T

F

R

A

M

E

5. Compare existing components of the current seat depth

and the required components for the desired seat depth.

6. Perform one (1) of the following:

A . If the current seat depth and the desired seat depth

is within the 12-15-inch seat depth range, this change

can be accomplished by repositioning the back

canes on the CJ back brackets. Refer to

ING SEA T DEPTH BETWEEN 12-15-INCHES in

this procedure of the manual.

CHANG-

12-inches

to YES 17-inch Short Short

15-inches

16-inches NO 16-inch Short Short

17-inches NO 17-inch Short Short

18-inches NO 18-inch Medium Short

19-inches NO 19-inch Medium Short

20-inches NO 20-inch Long Long

21-inches NO 21-inch Long Long

22-inches NO 22-inch X-Long Long

NOTE: Note the four (4) different lengths of side frames

short, medium, long, and X-long, as well as the two different

center frames, short and long. These components are interchanged to obtain the various different seat depths.

23

PROCEDURE 6 SEAT FRAME

1. Find current seat depth in left hand column in the chart.

2. Follow that row to right under seat frame components.

3. Verify and note the components of the current seat depth.

S

4. Repeat STEPS 1-3 for the desired seat depth.

E

5. Compare existing components of the current seat depth

A

and the required components for the desired seat depth.

T

T o adjust the depth of the seat on the wheelchair, use

F

the following guidelines:

R

If the current seat depth is and the desired seat depth are

A

within the 12-15-inch seat depth range, this change can be

M

accomplished by repositioning the back canes on the CJ

E

back brackets. Refer to

TWEEN 12-15-INCHES in this procedure of the manual.

If the desired change only requires a NEW seat pan, refer to

REMOVING/INST ALLING SEAT P AN in this procedure of

the manual.

If the desired change requires the removal/installation of CJ

back brackets, refer to

BRACKETS in PROCEDURE 8 of this manual.

If the desired change requires a new side frame, and/or new

center frame, perform the following steps:

CHANGING SEAT DEPTH BE-

REMOVING/INST ALLING CJ BACK

NOTE: If seat width adjustment is also desired, refer to CHANGING SEA T WIDTH in this procedure

of the manual for mounting hole locations and allowable seat width/seat depth combinations.

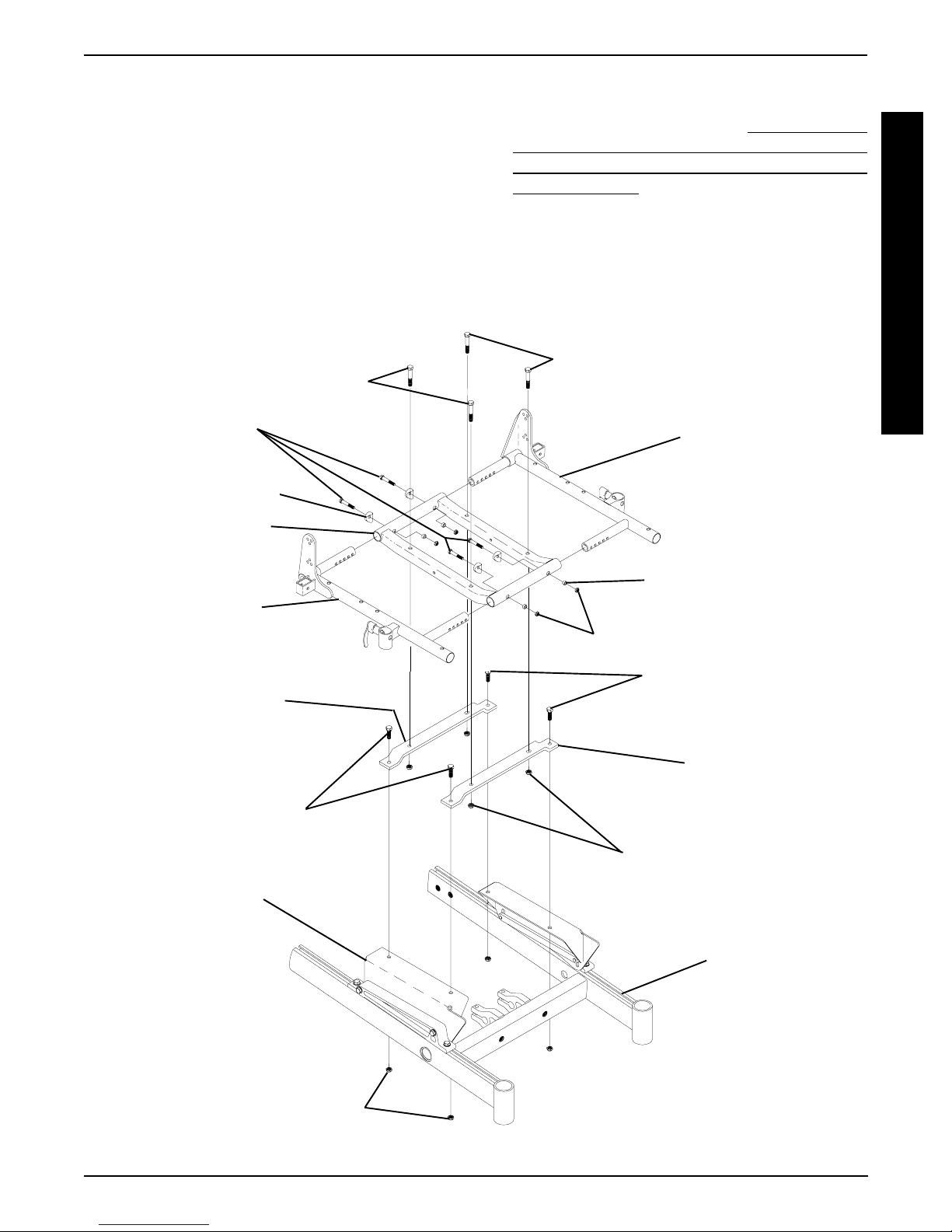

Mounting

Screws

(Torque to 75-

inch pounds)

Coved

Washers

Side Frame

Mounting Screws

(Torque to 156-

inch pounds)

Side

Frame

Spacers

Locknuts

Center

Frame

A . Perform the instructions outlined in

REMOVING/INST ALLING PREPARATIONS FOR

STANDARD FRAME, ADJUSTABLE FRAME, AND

CAPT AINS VAN SEAT in this procedure of the

manual.

SEA T FRAME

NOTE: Note the mounting hole position of the side

frame for proper installation of the NEW side frame.

B. Remove the two (2) mounting screws, coved wash-

ers, spacers, and locknuts that secure the side frame

to the center frame.

C. Remove the side frame from the center frame.

D. Repeat STEPS A and B for opposite side frame.

If the desired seat depth requires a new center

frame, determined in STEPS 1-5 perform STEPS

E - G, otherwise proceed to STEP H.

E. Remove the four (4) mounting screws that secure

the EXISTING center frame to support brackets.

F. Remove existing center frame from seat mount

plates.

G. Secure NEW center frame to support brackets with

the existing four (4) mounting screws and locknuts.

T orque to 156-inch pounds.

H. Secure NEW side frame to the center frame at the

position noted previously. Torque to 75-inch pounds.

Support Brackets

FIGURE 3- CHANGING SEAT DEPTH -

ADJUSTABLE SEAT FRAME

Changing Seat Depth Between 12 and 15Inches (FIGURE 4)

NOTE: There are two (2) sizes of CJ back brackets. Refer

to the following chart to determine if the seat depth required

is obtainable by repositioning the back canes only , or if the

CJ back brackets must be replaced.

CJ BACK BRACKET (SEAT DEPTH) RANGES

12 and 13-inches OR 14 and 15-inches

If seat depth required is within seat depth range of

the original CJ back brackets, only the back canes

need to be repositioned. Refer to the following procedure.

If the seat depth required is NOT within the seat depth

range of the original CJ back brackets, the CJ back

brackets must be replaced before repositioning the

back canes. Refer to

BACK BRACKETS in PROCEDURE 8 of this manual.

REMOVING/INSTALLING CJ

24

PROCEDURE 6SEAT FRAME

1. Remove the armrests from the wheelchair. Refer to INST ALLING/REMOVING FLIP BACK ARMRESTS in

PROCEDURE 4 of the owner’s manual, 1081227.

2. Cut the tie wraps that secure the back upholstery to the

CJ back brackets.

3. Pull the bottom of the back upholstery away from the

rear of the seat pan.

4. Remove mounting screw, washer and coved washer

from the top mounting hole of the CJ back bracket and

back cane.

NOTE: Before removing the back canes from the CJ back

brackets, note the BACK ANGLE for reinstallation.

NOTE: T o avoid losing the insert in each back cane, line up

the holes in the insert with the holes in the back cane and

start one of the screws through the cane from the inside of

the wheelchair to hold the insert in place.

5. Remove the mounting screw, washer and coved

washer from the bottom mounting hole of the CJ back

bracket and the back cane.

6. Reposition the back cane to the desired seat depth

and angle. If changing the back angle as well, refer to

BACK ANGLE ADJUSTMENT in PROCEDURE 8 of

this manual.

7. Secure bottom of the back upholstery to the seat pan.

8. Secure the bottom of the back upholstery to the CJ

back brackets with new tie wraps.

9. Use Loctite 242 and torque the mounting screws to

75-inch pounds.

10. Repeat the STEPS 1-9 for the opposite back cane.

Back Cane

Coved

Washers

1 1. Reinstall the armrests onto the wheelchair . Refer to

ST ALLING/REMOVING FLIP BACK ARMRESTS in

PROCEDURE 4 of the owner’s manual, 1081227.

IN-

CHANGING SEAT WIDTH

(STANDARD AND ADJUSTABLE

SEAT FRAME)

Standard Seat Frame

NOTE: If changing seat width below 16-inches wide, you must

convert to an adjustable seat frame. Refer to CONVERTING FROM STANDARD TO ADJUSTABLE SEAT

FRAME OR VICE VERSA in this procedure of the manual.

For all changes above 16-inches wide, perform the outlined

steps.

1. Perform the instructions outlined in PREPARATIONS

FOR REMOVING/INSTALLING SEAT FRAME (ST ANDARD FRAME, ADJUSTABLE FRAME, AND CAPTAINS VAN SEA T) in this procedure of the manual.

2. Remove the existing standard seat frame subassembly and install the NEW standard frame. Refer to

MOVING/INST ALLING STANDARD SEAT FRAME

SUBASSEMBLY in this procedure of the manual.

3. FOR 12-15-INCH SEAT DEPTHS ONLY: Remove

the CJ back brackets from the existing standard seat

frame and install onto the NEW standard seat frame.

Refer to

ETS in PROCEDURE 8 of t his manual.

4. Reinstall the components previously removed in STEP

1. Perform the instructions outlined in

FOR REMOVING/INSTALLING SEAT FRAME (ST ANDARD FRAME, ADJUST ABLE FRAME, AND CAPT AINS V AN SEA T) in this procedure of the manual.

Adjustable Seat Frame (FIGURE 5)

REMOVING/INSTALLING CJ BACK BRACK-

PREP ARATIONS

RE-

S

E

A

T

F

R

A

M

E

CJ Back

Bracket

Washers

Mounting Screws

FIGURE 4 - ADJUSTING SEAT DEPTH -

CHANGING SEAT DEPTH BETWEEN 12 AND

15-INCHES

Threaded

Insert

Seat

Frame

NOTE: If changing seat width above 16-inches wide, you

must convert to a standard seat frame. Refer to CONVERTING FROM STANDARD TO ADJUSTABLE SEAT

FRAME OR VICE VERSA in this procedure of the manual.

For all changes below 16-inches wide, perform the outlined

steps.

1. Perform the instructions outlined in PREPARATIONS

FOR REMOVING/INSTALLING SEAT FRAME (ST ANDARD FRAME, ADJUSTABLE FRAME, AND CAPTAINS VAN SEA T) in this procedure of the manual.

2. Review the following chart for the allowable seat width

and seat depth combinations for the adjustable seat

frame.

25

PROCEDURE 6 SEAT FRAME

ALLOW ABLE SEAT WIDTH AND DEPTH COMBINA TIONS

FOR ADJUST ABLE SEA T FRAME

SEAT WIDTH

S

E

A

T

F

R

A

M

E

12 ✓✓✓✓✓

S

13 ✓✓✓✓✓

E

14 ✓✓✓✓✓

A

15 ✓✓✓✓✓

T

16 ✓✓✓✓✓

17 N/A N/A ✓✓✓

D

18 N/A N/A ✓✓✓

E

19 N/A N/A ✓✓✓

P

20 N/A N/A ✓✓✓

21 N/A N/A ✓✓✓

T

22 N/A N/A ✓✓✓

H

NOTE: The seat widths and seat depths enclosed in the

outlined box will require the use of CJ back brackets and a

17-inch deep seat pan.

3. Remove the two (2) mounting screws, coved washers,

spacers, and locknuts that secure the side frame to the

center frame.

4. Adjust side frame to desired width determined from

STEP 2. See DETAIL “A” for proper mounting hole

position.

5. Secure side frame to center frame with existing mounting screws, coved washers, spacers, and locknuts.

Torque mounting screws to 75-inch pounds.

12 13 14 15 16

WARNING

Both side frames MUST be adjusted to the same

mounting hole position to maintain proper weight

balance of user and seat frame. If weight is not

balanced, injury to the assistant and/or user and

damage to the wheelchair may result.

6. Repeat STEPS 3-5 for opposite side frame.

7. Perform one (1) of the following:

A. For adjusting the seat width only, perform the in-

structions outlined in

MOVING/INST ALLING SEAT FRAME (STANDARD FRAME, ADJUSTABLE FRAME, AND

CAPTAINS VAN SEAT) in this procedure of the

manual.

NOTE: When performing the steps outlined in

PREPARATIONS FOR REMOVING/INSTALLING SEAT FRAME (STANDARD FRAME, ADJUSTABLE FRAME, AND CAPTAINS VAN

SEAT) the seat pan, seat cushion, back upholstery and spreader bar (if applicable), will need to

be replaced. Spreader bars are only required on

seat depths greater than 19-inches.

PREP ARA TIONS FOR RE-

B. For all other changes regarding seat frame changes,

refer back to the starting procedure to complete the

desired change.

DETDET

AIL AIL

““

AIL

“

AIL AIL

““

Center

Frame

A”A”

A”

A”A”

Side Frame

Spacers

Locknut

DET

DETDET

12-inches

13-inches

14-inches

15-inches

16-inches

STEPS 3-6STEPS 3-6

STEPS 3-6

STEPS 3-6STEPS 3-6

Mounting

Screws

Side

Frame

FIGURE 5 -CHANGING SEA T WIDTH - ADJUSTABLE

Coved

Washers

SEA T FRAME

INSTALLING/REMOVING

ADJUSTABLE SEAT FRAME

SUBASSEMBLY AND/OR

COMPONENT REPLACEMENT

(FIGURE 6)

Converting from Adjustable Seat Frame to

Standard Seat Frame or Captains Van Seat

NOTE: This section must be performed in conjunction with

a starting procedure.

1. Remove the four (4) mounting screws that secure the

two (2) support brackets of the adjustable seat frame

subassembly to the seat mounting plates.

2. T o complete conversion, refer back to the starting procedure to complete the desired change.

Converting from Standard Seat Frame or

Captains Van Seat To Adjustable Seat Frame

NOTE: This section must be performed in conjunction with

a starting procedure.

NOTE: When converting the seat frame, you will need a

seat pan, seat cushion, back upholstery and spreader bar (if

applicable). Spreader bars are only required on seat depths

of greater than 19-inches.

S

E

A

T

F

R

A

M

E

26

PROCEDURE 6SEA T FRAME

1. Secure both support brackets to the seat mounting plates

with four (4) mounting screws and locknuts. Torque

mounting screws to 156-inch pounds.

2. Secure the center frame to the support brackets with

four (4) mounting screws, locknuts, and spacers. T orque

to 156-inch pounds.

3. Insert the side frame into the center frame and secure

with mounting screw, coved spacer, spacer, and locknut. T orque to 75-inch pounds. Repeat for opposite side

frame.

Mounting Screws

(Torque to 156-inch pounds)

Mounting Screws

(Torque to 75-inch

pounds)

Coved Washer

Center Frame

Component Replacement

1. Perform the instructions outlined in

FOR REMOVING/INSTALLING SEAT FRAME (ST ANDARD FRAME, ADJUSTABLE FRAME, AND CAPT AINS V AN SEAT) in this procedure of the manual.

PREPARATIONS

NOTE: Note the mounting hole position of the current side

frame(s) for proper installation of the NEW side frame(s).

2. Remove the two (2) mounting screws, coved spacers,

spacers, and locknuts that secure the side frame to the

center frame.

Mounting Screws

(Torque to 156-inch pounds)

Side Frame

S

E

A

T

F

R

A

M

E

Side Frame

Support

Bracket

Mounting Screws

(Torque to 156-inch

pounds)

Mounting

Plate

Spacer

Locknuts

Mounting Screws

(Torque to 156-inch

pounds)

Support

Bracket

Locknuts

Base

Frame

Locknuts

FIGURE 6 - INST ALLING/REMOVING ADJUSTABLE SEA T FRAME SUBASSEMBLY AND/OR COMPONENT

REPLACEMENT

27

PROCEDURE 6 SEAT FRAME

3. Perform one (1) of the following:

A. If center frame needs replaced, repeat STEP 2 for

opposite side frame and proceed to STEP 4.

S

E

A

T

B. If opposite side frame needs replaced, repeat STEP

2, then proceed to STEP 6. Otherwise proceed to

STEP 6.

4. Remove the four (4) mounting screws and locknuts that

secure the center frame to the support brackets.

F

5. Secure NEW center frame to support brackets with ex-

R

A

M

E

isting four (4) mounting screws and locknuts. T orque to

156-inch pounds.

WARNING

Both side frames MUST be adjusted to the same

mounting hole position to maintain proper weight

balance of user and seat frame. If weight is not

balanced, injury to the assistant and/or user and

damage to the wheelchair may result.

6. Install new/existing side frame(s) into new/existing center frame at the mounting position previously noted.

Torque to 75-inch pounds.

7. Perform the instructions outlined in

FOR REMOVING/INSTALLING SEAT FRAME (ST ANDARD FRAME, ADJUST ABLE FRAME, AND CAPT AINS V AN SEAT) in this procedure of the manual.

PREPARATIONS

INSTALLING/REMOVING CAPTAINS

VAN SEAT ASSEMBLY (FIGURE 7)

Installing Captains Van Seat

1. Position the captains van seat on the seat mounting

plates at the position shown in FIGURE 7.

2. Line up mounting holes in the captains van seat frame

and the mounting holes in the seat mounting plates.