INFICON UL1000 User Manual

Catalog-No.

from software version

TECHNICAL HANDBOOK

UL1000 Fab and

UL1000

Helium Leak Detector

UL 1000:

550 - 000A

550 - 001A

550 - 002A

UL 1000 Fab:

550 - 100A

550 - 101A

V5.14

iina70e1-m (1408) Translation of the original handbook

2

iina70e content.fm Technical Handbook(1408)

Table of Contents 3

iina70e content.fm Technical Handbook(1408)

Table of Contents

1 General Information 7

1.1 Notes on the Use of this Handbook 7

1.1.1 Safety Symbols 7

1.1.2 Indications 8

1.1.3 Symbols of Vacuum Technology 8

1.1.4 Definiton of Terms 8

1.2 Support from INFICON Service 10

1.2.1 Service Centers 11

1.3 Introduction 13

1.3.1 Purpose 13

1.3.2 Technical Data 15

1.3.2.1 Physical Data 15

1.3.2.2 Electrical Data 15

1.3.2.3 Other Data 16

1.3.2.4 Ambient Conditions 16

1.4 Unpacking 16

1.4.1 Supplied Equipment 17

1.4.2 Accessories and Options 18

1.4.2.1 Sniffer line SL200 18

1.4.2.2 Toolbox 18

1.4.2.3 Helium Bottle Holder 18

1.4.2.4 ESD Mat 18

1.4.2.5 RC1000 Remote control 19

1.4.2.6 Test chamber TC1000 20

2 Installation 21

2.1 Transportation 21

2.2 Working Location 23

2.3 Electrical Connections 25

2.3.1 Mains Power 25

2.3.2 Connections for the Data Acquisition Systems 27

2.3.2.1 Accessories 28

2.3.2.2 Digital Out 28

2.3.2.3 Digital In 29

2.3.2.4 Recorder 30

2.3.2.5 RS232 31

2.3.2.6 Remote Control 31

2.4 Vaccum Connections 32

2.4.1 Inlet Port 32

2.4.2 Exhaust 32

2.4.3 Vent 32

2.4.4 Purge-connection (UL1000 Fab) /

Gas ballast (UL1000) 32

2.5 Default parameters 33

4 Table of Contents

iina70e content.fm Technical Handbook(1408)

3 First Operation Check 34

3.1 Needed Equipment 34

3.2 Description of the Initial Operation 34

3.2.1 Start up and Measure 34

3.2.2 Internal Calibration 37

3.2.3 Verification 37

4 Description and Working Principle 38

4.1 Introduction 38

4.2 Components of the UL1000 and UL1000 Fab 38

4.2.1 Vacuum System 39

4.2.2 Control Panel 40

4.2.2.1 LC Display 41

4.2.2.2 START Button 41

4.2.2.3 STOP Button 41

4.2.2.4 ZERO Button 41

4.2.2.5 MENU Button 43

4.2.2.6 Soft Keys 43

4.2.2.7 Numerical Entries 43

4.3 Working Modes 45

4.3.1 Vacuum Mode 45

4.3.2 Sniffer Mode 47

4.3.3 Auto Leak Test Mode 47

5 Operation of the UL1000 and UL1000 Fab 48

5.1 Display 48

5.2 The Screen in Run-Up Mode 48

5.3 Display in stand-by mode 49

5.3.1 Purging 49

5.4 The Screen in Measurement Mode 49

5.4.1 Call for Calibration 49

5.4.2 Speaker Volume 50

5.4.3 Status Line in the Display 50

5.4.4 Numerical Display Mode 51

5.4.5 Trend Mode 51

6 Description of the Menu 52

6.1 Main Menu 52

6.2 View 54

6.2.1 Scale linear/logarithmic 55

6.2.2 Display-range auto/manual 55

6.2.3 Time axis 56

6.2.4 Contrast 56

6.2.5 Background in Stand-by 57

6.2.6 Decimal places 57

6.2.7 Lower display limit 58

6.3 Mode 58

6.3.1 Auto Leak Test 59

Table of Contents 5

iina70e content.fm Technical Handbook(1408)

6.4 Trigger & Alarms 61

6.4.1 Trigger Level 1 61

6.4.2 Trigger Level 2 62

6.4.3 Volume 62

6.4.4 Units 63

6.4.5 Alarm delay 63

6.4.6 Audio alarm type 64

6.4.6.1 Pinpoint 64

6.4.6.2 Leak rate prop. 64

6.4.6.3 Setpoint 65

6.4.6.4 Trigger alarm 65

6.5 Calibration 65

6.6 Settings 66

6.6.1 Vacuum settings 67

6.6.1.1 Automatic purge (UL1000 Fab only) 67

6.6.1.2 Vent delay 67

6.6.1.3 Vacuum ranges 68

6.6.1.4 Leak rate internal test leak 69

6.6.1.5 Machine factor 69

6.6.1.6 Auto Leak Test adjustments 69

6.6.2 Zero & Background 73

6.6.2.1 Background Suppression 73

6.6.2.2 Zero 73

6.6.3 Mass 74

6.6.4 Interfaces 75

6.6.4.1 Control Location 75

6.6.4.2 RS232 Protocol 76

6.6.4.3 Recorder output 77

6.6.4.4 Scaling Recorder Output 78

6.6.5 Miscellaneous 79

6.6.5.1 Time&Date 79

6.6.5.2 Language 79

6.6.5.3 Leak rate filter 80

6.6.5.4 Mains Frequency 80

6.6.5.5 Service interval exhaust filter 80

6.6.5.6 Service message exhaust filter 81

6.6.6 Parameter save / load 81

6.6.6.1 Load parameter set 81

6.6.6.2 Save parameter set 82

6.6.7 Monitoring functions 82

6.7 Information 85

6.7.1 Service 85

6.8 Access Control 86

6.8.1 Access to CAL function 86

6.8.2 Access to Trigger&Alarme menu 87

6.8.3 Change Device PIN 87

6.8.4 Change Menu-PIN 87

7 Calibration 88

7.1 Introduction 88

6 Table of Contents

iina70e content.fm Technical Handbook(1408)

7.2 The calibration routines 88

7.2.1 Internal Calibration 89

7.2.1.1 Automatic Internal Calibration 89

7.2.1.2 Manual Internal Calibration 89

7.2.2 External Calibration 89

7.3 Factor of Calibration - Range of Values 93

8 Error And Warning Messages 94

8.1 Hints 94

8.2 List of Errors & Warnings 95

9 Maintenance Work 99

9.1 General Information 99

9.2 Maintenance or Service at INFICON 100

9.3 Key to the Maintenance Plan 100

9.4 Maintenance Plan 101

9.5 Maintenance Groups 102

9.5.1 1500 Hours Maintenance 102

9.5.2 4000 Hours Maintenance 102

9.5.3 8000 Hours Maintenance 103

9.5.4 16000 Hours Maintenance 103

9.5.5 Notes refering the maintenance of the SplitFlow 80 104

9.6 Description of the Maintenance Work 104

9.6.1 Opening the Instrument for Maintenance Purposes 105

9.7 Checking and Replacing the Filter Insert 106

9.8 Replacing the Exhaust Silencer 108

9.9 Checking/Emptying the Exhaust Filter 109

9.9.1 Replacing the Filter Insert 109

9.10 Monitoring the Oil Level of the D16 B and Topping up the Oil 111

9.11 Oil Change for the D16B 112

9.12 Scroll Pumps (UL1000 and UL1000 Fab only) 114

Appendix 115

A Diagram 115

B Index 116

C Declaration of Conformity 118

General Information 7

iina70e 01.fm technical handbook(1408)

1 General Information

Notice: We recommend that you carefully read this technical handbook to ensure

optimum operating conditions right from the start.

This technical handbook contains important informations on the functions,

installation, start-up and operation of th e UL 10 00 and UL1 0 00 Fa b.

General

We reserve the right to modify the design and the specified data. The illustrations are

not binding.

1.1 Notes on the Use of this Handbook

1.1.1 Safety Symbols

Important remarks concerning operational safety and protection are emphasised as

follows:

Caution

Information on correct handling or use. Disregard can lead to malfunctions or minor

equipment damage.

Warning

Information on preventing extensive equipment and environmental damage.

STO P

Danger

Information on preventing any kind of physical injury.

Skilled personnel

Indicates procedures that must be performed by skilled personnel only.

8 General Information

iina70e 01.fm technical handbook(1408)

1.1.2 Indications

Tipp Information on helpful procedures.

Notice: Information on special technical requirements that the user must comply

with.

The references to diagrams consists of the chapter number, figure number and the

item number in this order. F or example : Fig. 2-4/ 7 refers to item 7 in t he figure 4 of

chapter 2.

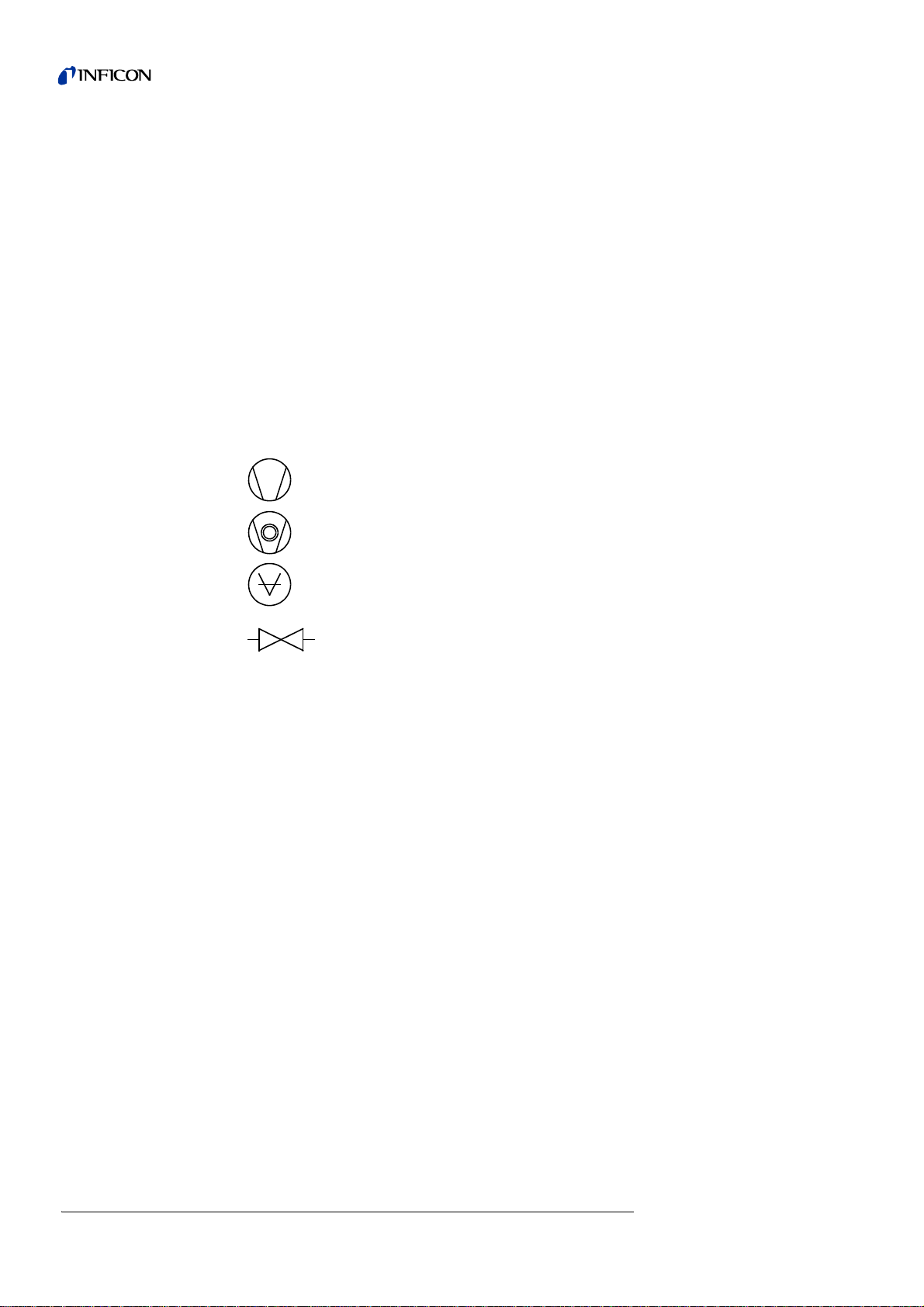

1.1.3 Symbols of Vacuum Technology

Given in the following are some important vacuum symbols which are used in this

manual.

Vacuum pump in general

Turbomolecular pump

Measuring instrument

Valve

1.1.4 Definiton of Terms

Autoranging

The range of the preamplifier and the vacuum ranges are selected automatically.

The autoranging feature of the UL1000 Fab covers the entire range or leak rates

depending on the selected operating mode. Not only the leak rate signal, but also the

pressure in the test sample (inlet pressure P1) and the forevacuum pressure (P2) are

used for control purposes. Range switching between the main ranges is performed

via valves. Fine range switching within the m ain ranges is implemen ted by switching

over the gain factor of the preamplifier.

Autotune

Mass alignment

This function automatically aligns the mass spectrometer so that a maximum leak

rate is displayed. The control processor changes the voltage which erates the ions

in the selected mass range until a maximum ion current is detected by the ion

detector. During each calibration the mass alignment is run automatically.

General Information 9

iina70e 01.fm technical handbook(1408)

Auto zero

Measurement and automatic adaptation to the helium background.

This function determines the internal ZERO level of the unit which is then deducted

from the currently measured leak rate signal. This function is enabled by pressing

the Start key provided the UL1000 or UL1000 Fab have ru n at least 20 s in "Standby"

mode or in "Ventilation" mode.

If the before suppressed helium background further decreases and only the display

limit appears, the ZERO-level will be adjusted automatically

Menu

The menu allows the user to program the UL10 00 and UL 100 0 Fab accordin g to his

requirements. The menu has a tree architecture.

Default

Status of the UL1000 and UL1000 Fab when supplie d by the fa cto ry .

GROSS

GROSS is a measurement mode which allows high inlet pressure (1 to 15 mbar).

The smallest detectable leak rate is 1x10

-6

mbar l/s.

FINE

FINE is the medium measurement mode with inlet pressure between 2 and 0,4mbar.

Detection limit is 1x10

-10

mbar l/s.

ULTRA

ULTRA is the most sensitive measuring range with inlet pressures below 0,4 mbar.

The minimum detectable leak rate is 5x10

-12

mbar l/s.

Foreline pressure

Pressure in the foreline between Turbo pump and scroll pump.

Minimum detectable leak rate

The smallest leak rate the UL1000 and UL1000 Fab is able to detect

( 5x10

-12

mbar l/s).

Internal helium background

The existing helium partial pressure in the measurement system. The level of the

internal helium background is measured in the Stand-by mode and subtracted from

the measured signal.

Measure Measurement mode

The UL1000 and UL1000 Fab measures the leak rate of the test sample.

10 General Information

iina70e 01.fm technical handbook(1408)

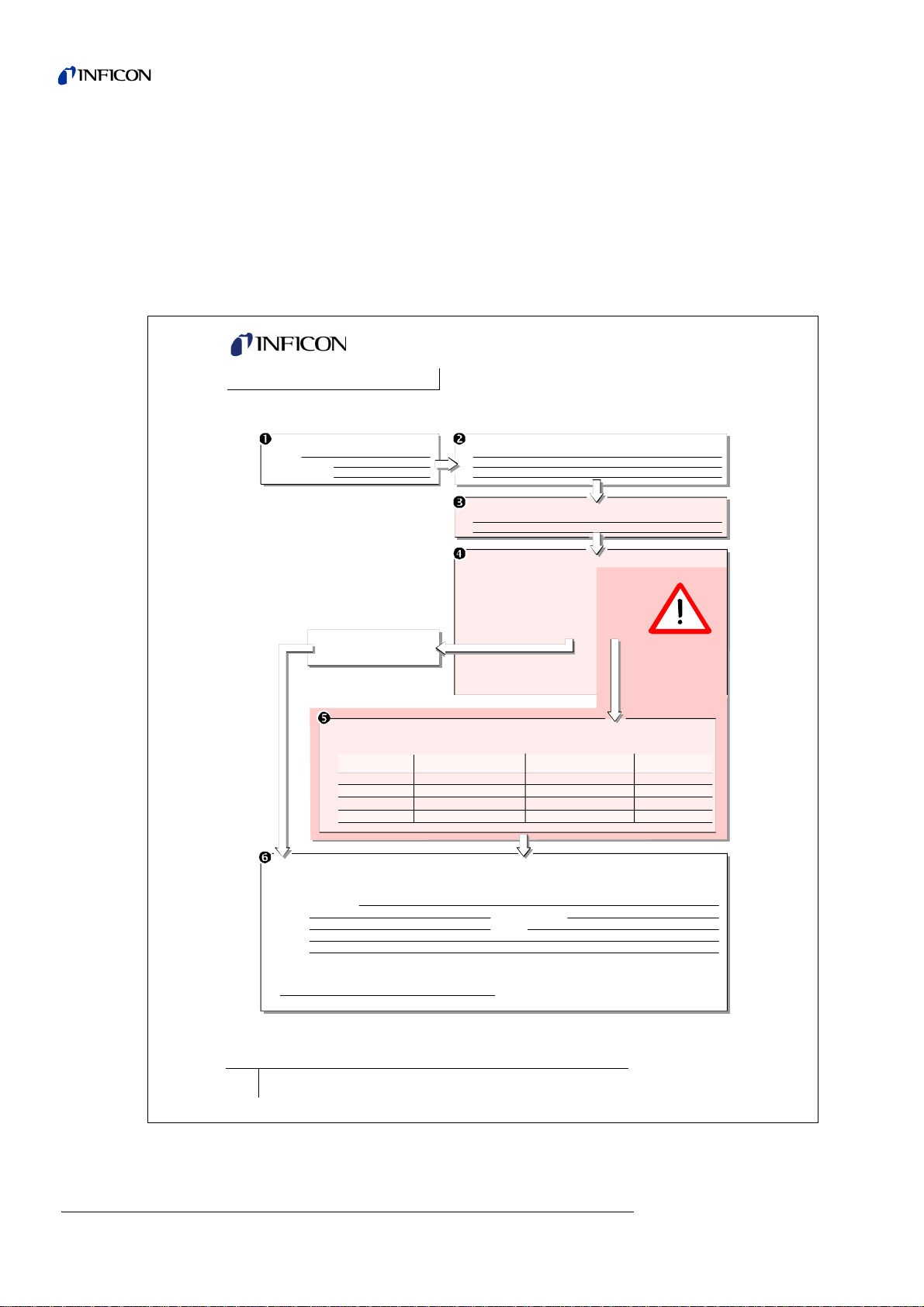

1.2 Support from INFICON Service

If an instrument is returned to INFICON or an authorised representative of INFICON,

please indicate wether the instrument is free of substances damaging to healths or

wether it is contaminated. If it is contaminated also indicate the nature of the hazard.

INFICON must return any appliances without a Declaration of Contamination to the

sender’s address. A form for stating details as to the type of contamination is

reproduced in Fig. 1-1.

A maintenance and service contract is recommended.

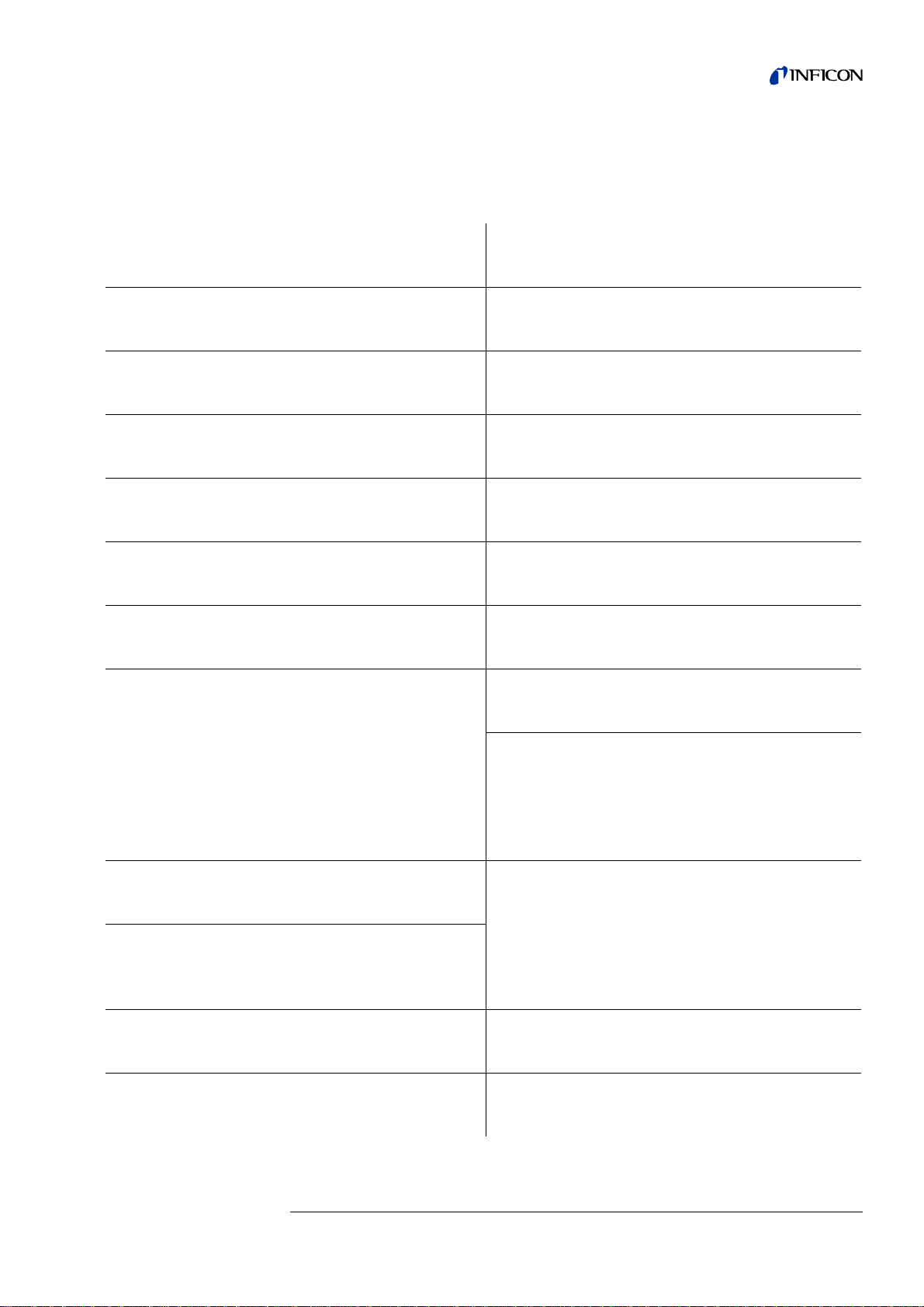

Fig. 1-1: Declaration of Contamination form

INFICON GmbH

Bonner Str. 498,50968 Cologne, Germany

Tel: +49 221 3474 2222 Fax: +49 221 3474 2221

www.inficon.com leakdetection.service

@

inficon.co

m

zisa01e1-a

Declaration of Contamination

Legally binding declaration:

I/we hereby declare that the information on this form is complete and accurate and that I/we will assume any further costs that may

arise. The contaminated product will be dispatched in accordance with the applicable regulations.

Organization/company

Address Post code, place

Phone Fax

Email

Name

Date and legally binding signature Company stamp

1) or not containing any amount

of hazardous residues that

exceed the permissible ex-

posure limits

Process related contamination of product:

toxic no

1) yes

caustic n o

1) yes

biological hazard no

yes

2)

explosive no

yes

2)

radioactive no

yes

2)

other harmful substances no

1) yes

The service, repair, and/or disposal of vacuum equipment and components will only be carried out if a correctly completed declaration has

been submitted. Non-completion will result in delay.

This declaration may only be completed (in block letters) and signed by authorized and qualified staff.

Copies:

Original for addressee - 1 copy for accompanying documents - 1 copy for file of sender

Harmful substances, gases and/or by-products

Please list all substances, gases, and by-products which the product may have come into contact with:

Trade/product name

Chemical name

(or symbol)

Precautions associated

with substance

Action if human contact

Description of product

Type

Article Number

Serial Number

Reason for return

Operating fluid(s) used (Must be drained before shipping.)

The product is free of any sub-

stances which are damaging to

health yes

This form can be downloaded

from our website.

2) Products thus contam i-

nated will not be ac-

cepted without written

evidence of deconta mi-

nation!

General Information 11

iina70e 01.fm technical handbook(1408)

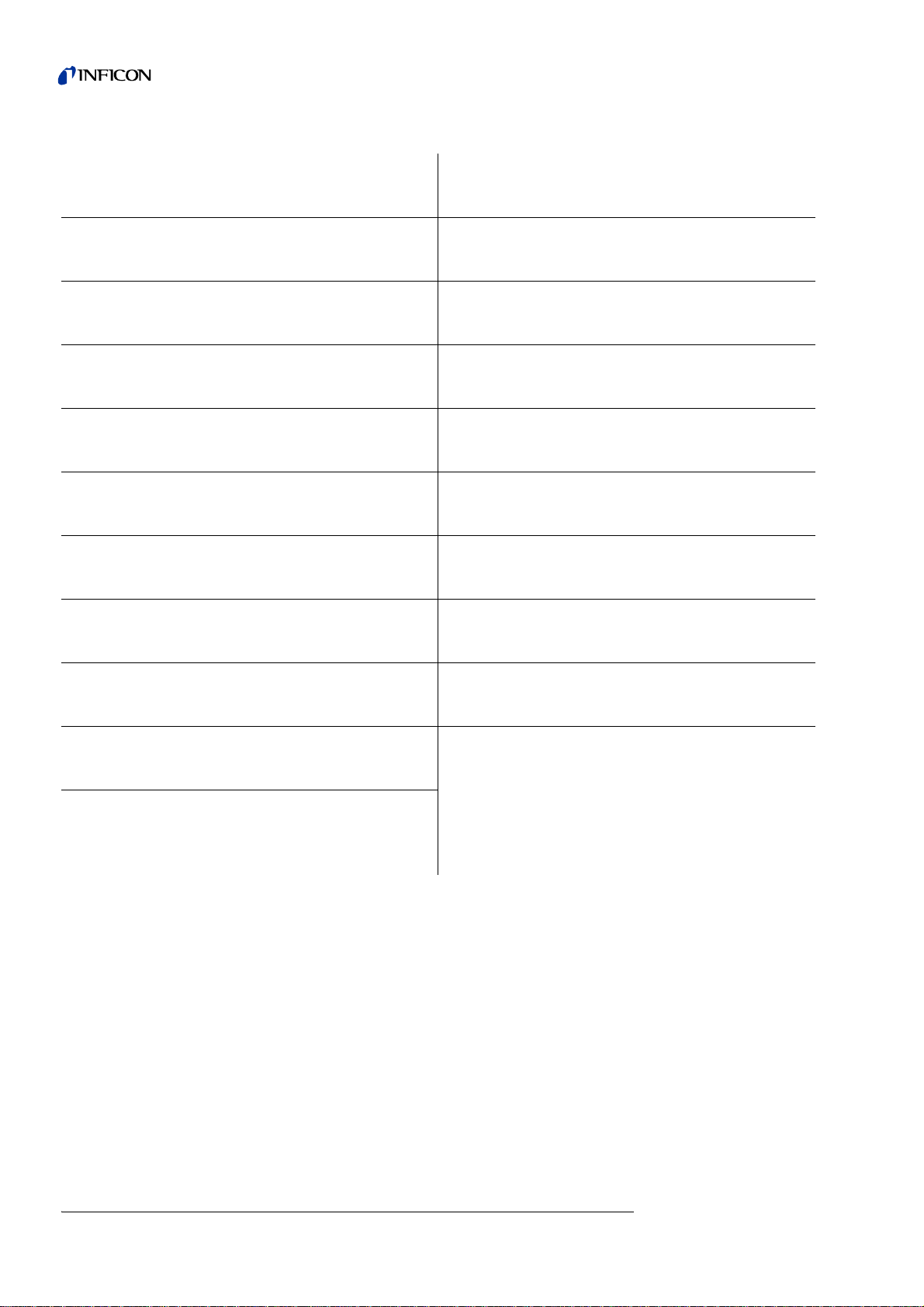

1.2.1 Service Centers

In case you urgently need assistance please get in touch with the local INFICON

Service in your country or the service hotline in Cologne, Ge rm a ny:

Algeria jhj@agramkow.dk Finland jhj@agramkow.dk

Agramkow

Sonderborg

Phone: +45 741 236 36

Fax: +45 744 336 46

Agramkow

Sonderborg

Phone: +45 741 236 36

Fax: +45 744 336 46

Belarus leakdetection.service@inficon.com France Christophe.Zaffanella@oerlikon.com

INFICON GmbH

Cologne

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

OLV France

Orsay

Phone: +33 476 351 584

Fax: +33 476 351 584

Belgium leakdetection.service@inficon.com Germany leakdetection.service@inficon.com

INFICON GmbH

Cologne

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

INFICON GmbH

Cologne

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Brazil fernandoz@prestvacuo.com.br Hungary adam.lovics@kon-trade.hu

PV Pest Vácuo Ltda.

Santa de Parnaíba

Phone: +55 114 154 4888

Fax: +55 114 154 4888

Kontrade

Budaörs

Phone: +36 23 50 38 80

Fax: +36 23 50 38 96

Bulgaria leakdetection.service@inficon.com India asdash@hotmail.com

INFICON GmbH

Cologne

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Dashpute

400 064

Phone: +91 22 888 0324

Fax: +91 22 888 0324

Canada reachus@vpcinc.ca Ireland reach.unitedkingdom@inficon.com

Vacuum Products Canada Ltd.

Ontario

Phone: +905.672.7704

Fax: +905.672.2249

INFICON

Blackburn

Phone: +44 1254 678 250

Fax: +44 1254 698 577

Central America infoqro@meisa.com Italy davide.giovanetti@inficon.com

MEISA S.a. de C.V.

Querètaro

Phone: +52 44 22 25 42 80

Fax: +52 44 22 25 41 57

INFICON GmbH

Castelnuovo

Phone: +39 045 6 40 25 56

Fax: +39 045 6 40 24 21

China reach.china@inficon.com Israel urimark@mark-tec.co.il

INFICON LTD

Hong Kong

Phone: +852.2862.8863

Fax: +852.2865.6883

Mark Technologies Ltd.

Kiriat Ono

Phone: +972 35 34 68 22

Fax: +972 35 34 25 89

INFICON LTD

Beijing

Phone: +86.10.6590.0164

Fax: +86.10.6590.0521

Japan reach.japan@inficon.com

INFICON LTD

Guangzhou

Phone: +86.20.8723.6889

Fax: +86.20.8723.6003

INFICON Co. Ltd.

Yokohama

Phone: +81.45.471.3396

Fax: +81.45.471.3387

INFICON LTD

Shanghai

Phone: +86.21.6209.3094

Fax: +86.21.6295.2852

Czech Republic filip.lisec@inficon.com Korea reach.korea@inficon.com

INFICON GmbH

Pilsen

Phone +420 734 331 758

Fax: +420 604 203 037

INFICON Ltd.

Sungnam city

Phone: +82 312 062 890

Fax: +82 312 063 058

Denmark jhj@agramkow.dk INFICON Ltd.

Suwon City

Phone: +82 312 062 890

Fax: +82 312 063 058

Agramkow

Sonderborg

Phone: +45 744 336 36

Fax: +45 744 336 46

INFICON Ltd.

Cheonan City

Phone: +82 312 062 890

Fax: +82 312 063 058

Egypt jhj@agramkow.dk Latvia leakdetection.service@inficon.com

Agramkow

Sonderborg

Phone: +45 741 236 36

Fax: +45 744 336 46

INFICON GmbH

Cologne

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Estonia leakdetection.service@inficon.com Lithuania leakdetection.service@inficon.com

INFICON GmbH

Cologne

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

INFICON GmbH

Cologne

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

12 General Information

iina70e 01.fm technical handbook(1408)

Mexico infoqro@meisa.com Spain richard.cunill@leyboldoptics.com

MEISA S.a. de C.V.

Querètaro

Phone: +52 442 225 42 80

Fax: +52 442 225 41 57

Leybold Optics Ibérica

Barcelona

Phone: +34 93 66 60 778

Fax: +34 93 66 64 612

Netherlands leakdetection.service@inficon.com Sweden jhj@agramkow.dk

INFICON GmbH

Cologne

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Agramkow

Sonderborg

Phone: +45 741 236 36

Fax: +45 744 336 46

Norway jhj@agramkow.dk Syria leakdetection.service@inficon.com

Agramkow

Sonderborg

Phone: +45 741 236 36

Fax: +45 744 336 46

INFICON GmbH

Cologne

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Poland kamola@vakpol.com Taiwan Susan.Chang@inficon.com

VAK-POL & GAZ Sp. zo.o

Pulawy

Phone: +48 60 23 15 212

Fax: +48 60 23 15 212

INFICON Company Limited

Chupei City, HsinChu Hsien

Phone: +886.3.5525.828

Fax: +886.3.5525.829

Portugal leakdetection.service@inficon.com Tunisia leakdetection.service@inficon.com

INFICON GmbH

Cologne

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

INFICON GmbH

Cologne

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Republic of South Africa vacuquip@hotmail.com Turkey jhj@agramkow.dk

Vacuquip

Randburg

Phone: +27 73 15 78 355 Agramkow

Sonderborg

Phone: +45 741 236 36

Fax: +45 744 336 46

Russia leakdetection.service@inficon.com Ukraine leakdetection.service@inficon.com

INFICON GmbH

Cologne

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

INFICON GmbH

Cologne

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Singapore reach.singapore@inficon.com United Kingdom reach.unitedkingdom@inficon.com

INFICON PTE LTD.

Singapur

Phone: +65.890.6250

Fax: +65.890.6266

INFICON

Blackburn

Phone: +44 1254 678 250

Fax: +44 1254 698 577

Slovakia filip.lisec@inficon.com United Arab Emirates leakdetection.service@inficon.com

INFICON GmbH

Pilsen

Phone +420 734 331 758

Fax: +420 604 203 037

INFICON GmbH

Cologne

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Slovenia medivak@siol.net USA service.usa@inficon.com

Medivac

Ljubljani

Phone: +386 15 63 91 50

Fax: +386 17 22 04 51

Inficon Inc.

East Syracuse, NY

Phone: +1.315.434.1167

Fax: +1.315.434.2551

South America except Brazil infoqro@meisa.com Inficon Inc.

San Jose, CA

Phone: +1.408.361.1200

Fax: +1.408.362.1556

MEISA S.a. de C.V.

Querètaro

Phone: +52 44 22 12 36 15

Fax: +52 44 22 12 19 40

Inficon Inc.

Austin, TX

Phone: +1.512.448.0488

Fax: +1.512.448.0398

General Information 13

iina70e 01.fm technical handbook(1408)

1.3 Introduction

1.3.1 Purpose

The UL1000 and UL1000 Fab are helium leak detectors. These instruments may be

used to detect the location and the size of leaks on objects under test in two different

ways:

• when the test sample has been evacuated first and is sprayed with helium on the

outside. It is required that a vacuum connection is provided between the UL1000

and UL1000 Fab and the test sample (vacuum mode).

or

• when a helium overpressure is provided in the test sample and the test sample is

searched from the outside with a sniffer probe which is attached to the inlet port

(sniffer mode).

For UL1000 use only:

Notice: Pumping condensable gases and steams: When pumping test sample

water vapour that is inside can attain to the fore pump. With the water vapor

that is in the air - especially in humid areas or wh en using humid or wet test

samples - the acceptable compatibility of water vapor or capacity of water

vapor respectively can be exceeded.

The steam in the oil of the pump condenses when the water vapor rises over the

acceptable value. So the attribute of the oil ch anges and danger of corrosion occures

for the pump.

While using the leak detector with condensable gases and steams the oil of the fore

pump has to be controlled regularly. So you can recognize a condensation of water

vapor in the pump. Usually the oil is light and lucent. When water vapor is inside it

gets blear and milky at operating state temperature.

When turning the pump off water vapor condensates and rases the part of water in

the oil.

STO P

Danger

Caution: Danger of explosion

Hydrogen forms a highly explosive gas mixture with air.

Great caution is necessary when using hydrogen! No smoking, no naked flames,

avoid sparks.

Caution

The UL1000/UL1000 Fab is only allowed to be used as a leak detector. It ma y not

be used as a pump system (especially not for pumping off aggressive or humid

gasses)

14 General Information

iina70e 01.fm technical handbook(1408)

For UL1000 Fab use only:

If you plan to detect noxious matters please contact the manufacturer. Rules for

decontamination will be developed then. If the leak detector alreay has been in

contact with dangerous gases please fill the declaration of contamination, too, and

send it to INFICON before you send the parts.

Warning

The leak detector must not directly be switched off after the process, in which

condensable gases or steams are pumped, is finished. It must be ru nning (at least

20 minutes) with opend gas ballast valve (see Chapte r 5.3.1) until the oil of the

pump is free from detachted steams.

When not taking care of this instruction there can be a corrosion within the pump.

So damages will occure.

The height of the oil of the pump has to be controlled regularly.

The normal intervalls of changing the oil from the producer have to be taken care

of. See instructions of the rotary vane pump.

Caution

Gases that contain halogen melecules (i.e. fluorine, chlorine), i.e. refrigerants and

SF6, should not be pumped by the leak detector in higher contact rations an d over

a longer time period.

The coating layer of the cathodes (at the ion source) can be affected. This could

cause a burn out of the cathodes.

Caution

Condensable gases and steams can attain the inside of the leak detector and

destruct the fore pump.

With the water vapor that is in the air - especially in humid areas or when using

humid or wet test samples - the acceptable compatibility of water vapor or capacity

of water vapor respectively can be exceeded.

STO P

Danger

Dangerous gases pollute the machine.

So you must not use the machine for detecting toxical, acidity, microbiological,

explosive, radioactive or other noxious matters.

General Information 15

iina70e 01.fm technical handbook(1408)

1.3.2 Technical Data

1.3.2.1 Physical Data

Hinweis To get down to the minimum detected leak rate range some conditions

must be fulfilled:

• UL1000 and UL1000 Fab has fully warmed up

• Ambient conditions must be stable (temperature, no vibration/accelerations.)

• The part under test has been evacuated long enough (background is no longer

decreasing)

• ZERO must be active

1.3.2.2 Electrical Data

Max. inlet pressure 15 mbar

Minimum detectable Helium leak rates

• in vacuum mode (ULTRA) <5×10

-12

mbar l/s

limit of detection in sniffer mode <5×10

-8

mbar l/s

Maximum displayable helium leak rate in ULTRA 0.1 mbar l/s

Measurement range 12 decades

Time constant of the leak rate signal (blanked off,

63% of the final value)

<1 s

Pumping speed (Helium) at the inlet

Max. roughing capability 25 m

3

/h (50 Hz)

17.6 cfm (50 Hz)

30 m

3

/h (60 Hz)

21.1 cfm (60 Hz)

• in vacuum mode

– GROSS mode 8 l/s

– FINE mode 7 l/s

– ULTRA mode 2.5 l/s

Detectable masses 2, 3 and 4

Mass spectrometer 180° magnetic sector field

Ion source 2 filaments;

Iridium/Yttria-oxide

Inlet port DN 25 KF

Run-up time (after starting) 3 min

Part no. 550 - 000A, 550 - 100A 230 V 50 Hz

Part no. 550 - 001A, 550 - 101A 115 V 60 Hz

Part no. 550 - 00 2A 100 V 50/60 Hz

Power consumption 1100 VA

Type of protection IP20

Power cords (EU, USA, UK) 3 m

16 General Information

iina70e 01.fm technical handbook(1408)

1.3.2.3 Other Data

1.3.2.4 Ambient Conditions

1.4 Unpacking

Unpack the UL1000 and UL1000 Fab immediately after delivery, even if it will be

installed later on.

Examine the shipping container for any external damage. Completely remove the

packaging materials.

Check if the UL1000 and UL1000 Fab is complete (See Chapter 1.4.1) and carefu lly

examine the leak detector visually.

If any damage is discovered, report it immediately to the forwarding agent and

insurer. If the damaged part has to be replaced, please contact the orders

department.

Notice: Before starting up make sure that the transportation fixing is loosened.

(Please refer to chapter 2.1)

Tipp Retain the packaging materials in the event of complaints about damage.

Tipp For unpacking please use the wedge which is part of the packaging.

Valves solenoid

Dimensions (L × W × H) incl. handle in mm 1068 × 525 × 850

Dimensions (L × W × H) incl. handle in inches 42 × 21 × 33

Weight in kg 110

Weight in lbs 242

Noise level dB (A) < 70

Noise level dB (A) 0.5m distance < 56

Audio alarm dB (A) 90

Contamination level (to IEC 60664-1) 2

Overvoltage category (to IEC 60664-1) II

For use within buildings

Permissible ambient temperatur e (d ur in g op er at ion) +10 °C … +40 °C

Permissible storage temperature 0 °C … +60 °C

Max. rel. humidity 80% non condensing

Max. permissible height above sea level (during operation) 2000 m

General Information 17

iina70e 01.fm technical handbook(1408)

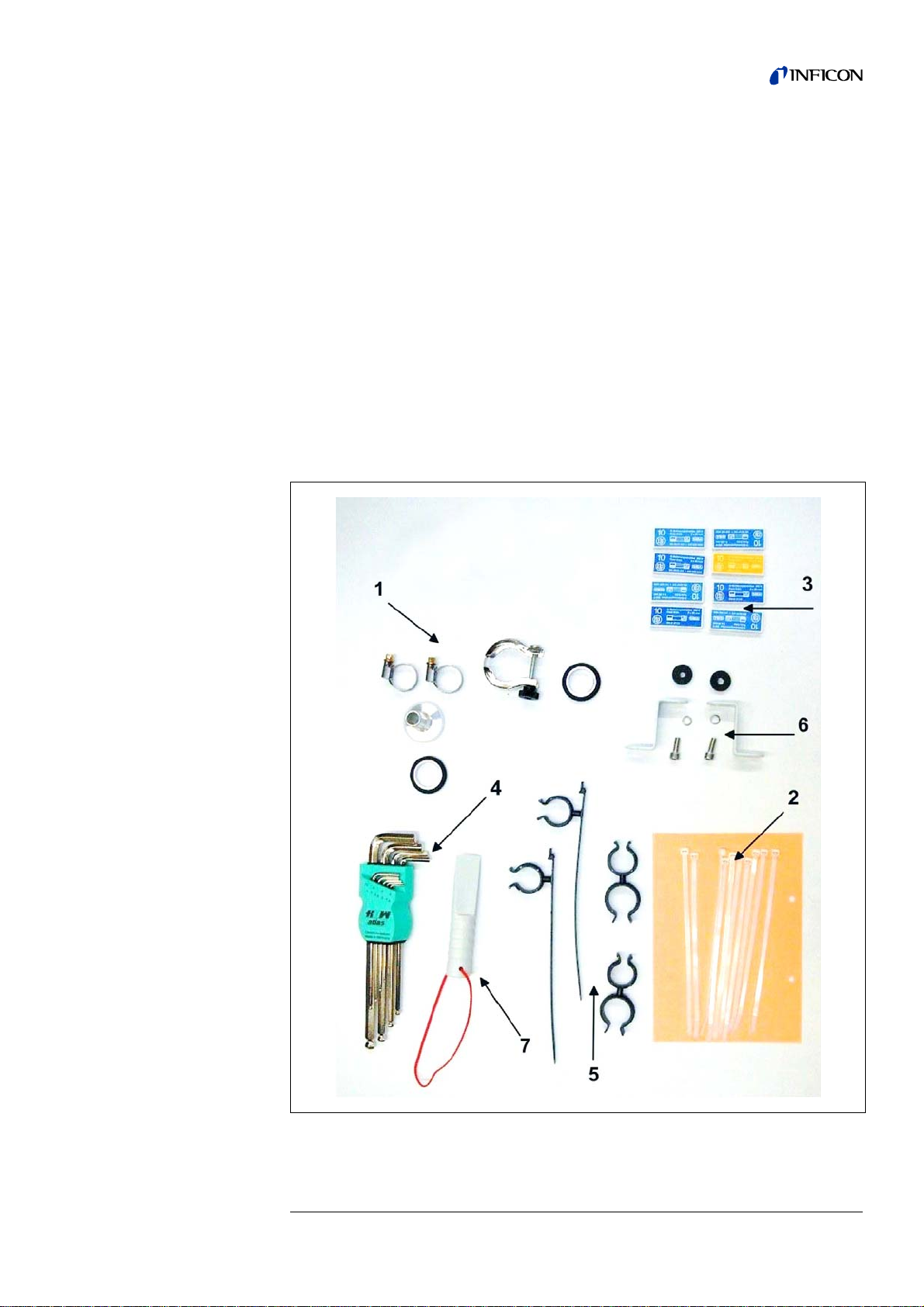

1.4.1 Supplied Equipment

• Helium Leak Detector UL1000 or UL1000 Fab

• Exhaust hose adapter with clamps (see arrow 1)

• power cord fixture

• Set of fuses (see arrow 2)

• Set of tools (see arrow 7)

• Bellow Clips (2 + 2) (see arrow 5)

• Folder with documents

– Technical Handbook UL1000 and UL1000 Fab

– Spare Parts List UL1000 and UL1000 Fab

• hooks to wrap power cord (with screws) (see arrow 6)

• Tool to open the UL1000 and UL1000 Fab (see arrow 7)

• O-Ring with filter (for use at applications with particles)

Fig. 1-2

18 General Information

iina70e 01.fm technical handbook(1408)

1.4.2 Accessories and Options

The following parts can be ordered additionally:

1.4.2.1 Sniffer line SL200

By use of the sniffer line the UL1000 and UL1000 Fab can easily be converted to a

sniffer leak detector. The length of the sniffer line is 4m (i.e. 12 feet).

1.4.2.2 Toolbox

The toolbox is a detachable compartment with a lockable lid. Fittings and small

fixtures can be stored plus the hand set (Please refer to Chapter 1.4.2.5). The

storage volume is approximately 5 l.

The toolbox is placed on the working surface and jammed by the handle.

1.4.2.3 Helium Bottle Holder

The helium bottle holder allows you to carry a helium reservoir a nd a spray g un with

the UL1000 and UL1000 Fab. Only small and midsize bottles (max 10 l, 200 bar) will

fit without influencing the stability of the UL1000 and UL1000 Fab.

1.4.2.4 ESD Mat

This mat is put on the working surface of the UL1000 and UL1000 Fab and is

clamped and grounded by the inlet port ring. It avoids electrical disch arge s between

the working surface and sensitive test parts.

• Sniffer Line SL200 14005

• Leak Ware 14090

• Helium Sniffer QUICK-TEST QT100 15594

• Tool Box (detachable) 551-000

• Helium Bottle Holder 551-001

• ESD Mat 551-002

• RC1000 Remote control

– RC1000WL wireless version

– RC1000C cable version

– Extension Cable, 8 m

551-015

551-010

14022

• Test chamber TC1000 551-005

• spray gun with hose 16555

• set of plugs 20099024

• LeakWare (software package) 14090

General Information 19

iina70e 01.fm technical handbook(1408)

1.4.2.5 RC1000 Remote control

The RC1000 is a wireless remote control that allows to operate the UL1000 and

UL1000 Fab from distance up to 100 m. It provides the functions START, STOP/

VENT, ZERO and speaker volume, and displays leak rate in bargaraph or in chart

mode. (see also Technical Handbook RC1000.)

Measured values can be stored in an internal memory for up to 24 hours of recording

time. The data can easily be downloaded to a USB stick to save it.

An internal trigger can be set to provide a warning if the limit leak rates are exceeded.

An optical warning is shown on the display and an acoustic warning signal is

sounded on the integrated loudspeaker or the connected headphones.

The RC1000 remote control is housed in a robust housing to enable ergonomic

working. Magnets on the underside of the unit enable it to be attached to horizontal

or vertical metal surfaces.

The RC1000 also enables remote operation of the leak test device in question using

a connection cable of up to 28 metres in length.

Fig. 1-3 RC1000 wireless remote control

20 General Information

iina70e 01.fm technical handbook(1408)

1.4.2.6 Test chamber TC1000

This test chamber turns the UL1000 / UL1000 Fab into a workstation to test

hermetically sealed components.

Testing according to MIL-STD 883 can be done easily, fast and accurate. The test

starts automatically when the chamber lid is closed, test parameters like cycle time

and rejectant level can be setted in the menu Auto Leak Test (see 6.6.1.6). The test

cycle runs automatically, the test result is also displayed by red / green LEDs directly

at the chamber.

Fig. 1-4 Test chamber TC1000

Installation 21

iina70e 02.fm technical handbook(1408)

2 Installation

2.1 Transportation

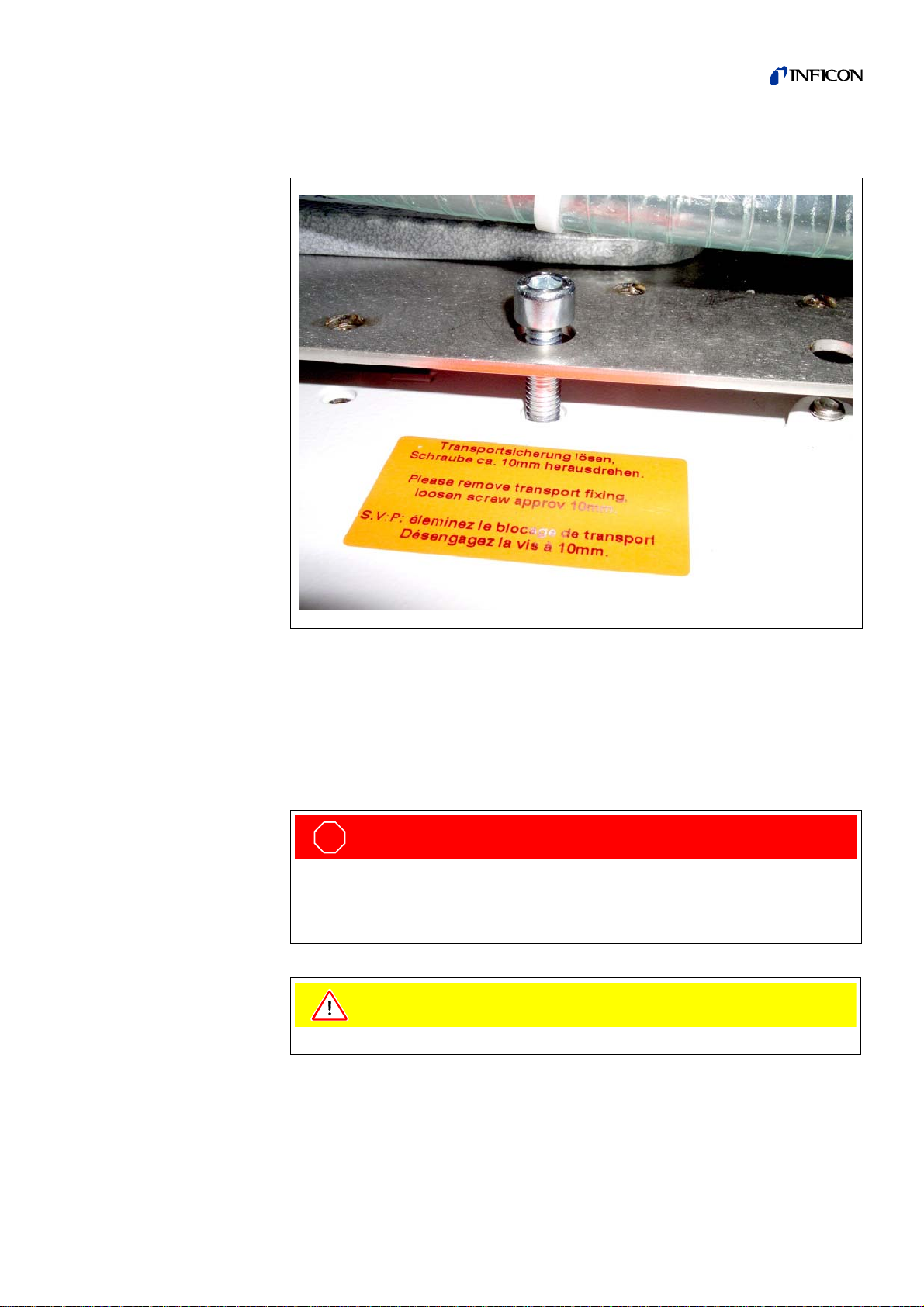

UL1000 Fab with Triscroll TS 620

For transportation the chassis plate where the pump is mounted on has to be

secured by a transportation fixing.

This transportation fixing consists of 2 screws at chassis of the UL1000 Fab (one on

each side).

To get access to these screws remove the side covers of the UL1000 Fab.

There are orange labels on the bottom part pointing to the screws:

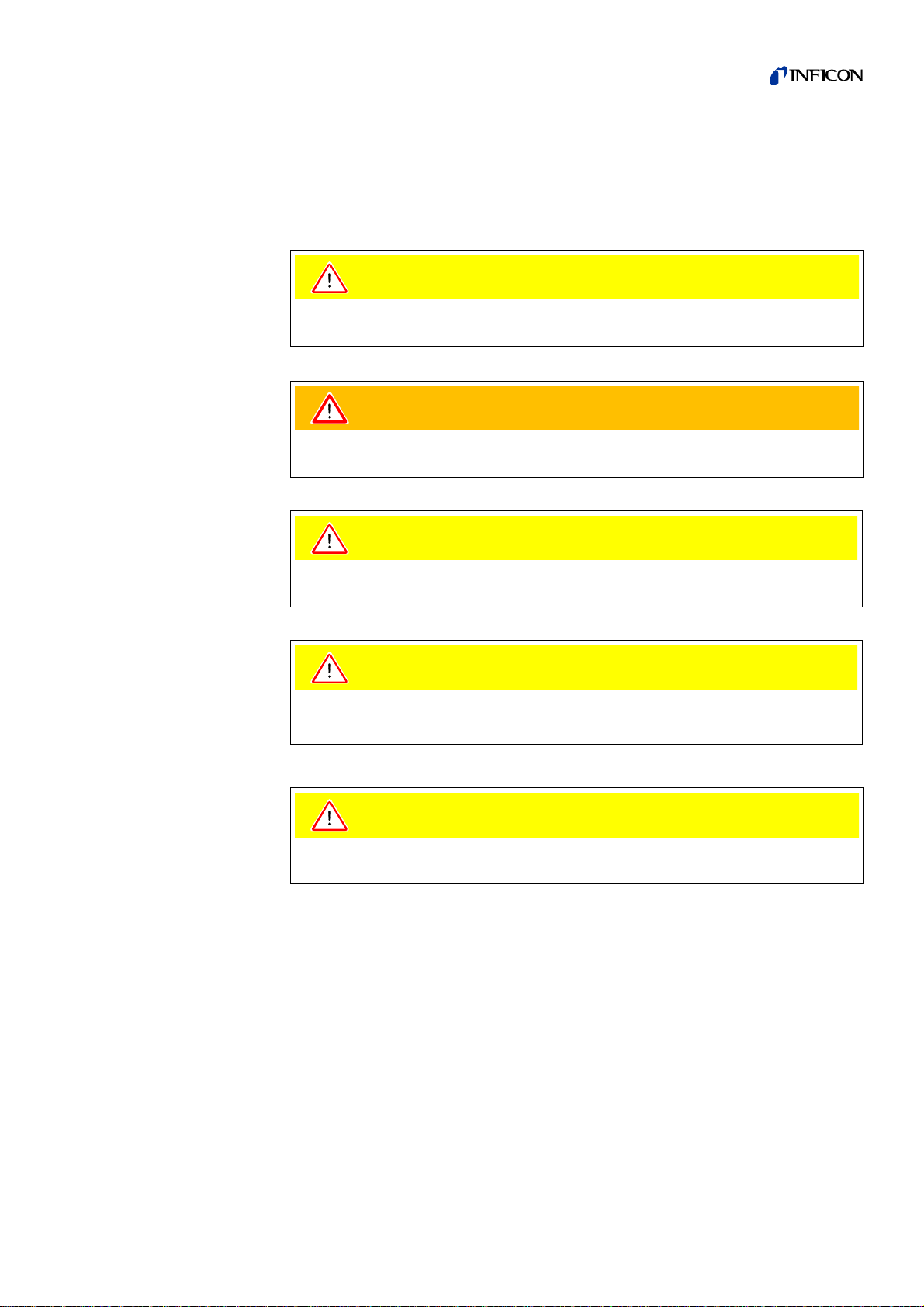

Caution

The UL1000 and UL1000 Fab is not equipped with any crane eyes and must

therefore not be transported using lifting equipment.

Warning

The UL1000 and UL1000 Fab must only be pushed or pulled along using the handle

provided for this purpose. Don’t use the handle to lift.

Caution

Your feet can be pinched.

Keep your feet away from the rollers. .

Caution

Your feet can be run over.

Do not pull the unit, push it

Caution

When transporting over longer distances the original pa ckaging must be used . The

castors must not be fixed when the UL1000 and UL1000 Fab is sh ipped in a crate.

22 Installation

iina70e 02.fm technical handbook(1408)

For transportation fixing the screws are tightened to the chassis plate. For oper ation

of the UL1000 Fab the screws should be loosened.

To loosen the screws first loosen the counter nut that is accessible from und erneath:

Fig. 2-1

Fig. 2-2

Installation 23

iina70e 02.fm technical handbook(1408)

Loosen the screws approximately 10 mm above the chassis plate and tighten then

the counter nuts again:

For transportation tighten the screws again and fix them by the counter nuts.

2.2 Working Location

Move the UL1000 and UL1000 Fab to the desired position and arrest the castors.

Fig. 2-3

STO P

Danger

Caution: Exhaust gases and fumes:

Exhaust gases and fumes from oil-sealed pumps may be harmful to health.

For operation in poorly ventilated rooms, an exhaust pipe should be connected to

exhaust connection 5 depending on the application and gases used.

Caution

Make sure that you can always reach the mains plug.

24 Installation

iina70e 02.fm technical handbook(1408)

It is recommended that you check all major helium sources in the vicinity of the

UL1000 and UL1000 Fab within a radius of about 10 m for the presence of any big

leaks. You may use the sniffer probe for this.

Warning

The UL1000 and UL1000 Fab must not be operated while standing in water or

when exposed to drip water. The same applies to all other kinds of liquids.

Warning

Avoid contact with bases, acids or solvents as well as exposure to extreme climatic

conditions.

Warning

The UL1000 and UL1000 Fab is designed for indoor use only.

Caution

Ensure a sufficient air cooling. The air inlet as well the air discharg e openings must

never be obstructed.

Caution

The UL1000 and UL1000 Fab can be locked by arresting the castors of the front

wheels to avoid movements on skewness.

Installation 25

iina70e 02.fm technical handbook(1408)

2.3 Electrical Connections

2.3.1 Mains Power

Notice: Generally the local regulations for electrical connections m ust be observed.

The mains voltage rating for the UL1000 and UL1000 Fab can be read off from the

name plate beneath the mains socket Fig. 2-6/7 at the back side. This vo ltage is fixed

and can not be changed.

A separate fuse for each of the mains conductors has been integ rated into the mains

switch.

The mains voltage is applied to the instrument via the detachable mains ca ble which

is supplied with the instrument. A mains socket Fig. 2-6/7 is available for this purpose

at the back side of the instrument.

Notice: The cable can be secured like shown in the following Figure.

Warning

Before connecting the UL1000 and UL1000 Fab to the mains you mu st make sure

that the mains voltage rating of the UL1000 and UL1000 Fab coincides with the

locally available mains voltage. The instrument must exclusively be connected to a

single phase supply with fuses for installation (Circuit breaker 16A max. according

to IEC/EN 60898 with tripping characteristic B).

STO P

Danger

Caution: mains voltage:

Improperly grounded or fused products can lead to fatal injuries.

Only 3-core mains cables having a protection ground conductor must be used.

Operation of the UL1000 and UL1000 Fab where the ground conductor has been

left unconnected is not permissible.

26 Installation

iina70e 02.fm technical handbook(1408)

Notice: If the machine is not operating the cable can be stored at the cable holders.

Fig. 2-4 secure fixture power cord

Fig. 2-5 storing power cord

Installation 27

iina70e 02.fm technical handbook(1408)

2.3.2 Connections for the Data Acquisition Systems

Tipp The sockets: Accessories, Digital Out, Digital In and Recorder have pin 1

on top. The pin numbers are counted downwards. The socket 2 and 3 are

coded mechanically to avoid a confusion with the counter plug. For the

connection with the counter plug (set of plugs 20099024) remove the

plastic pins at the plug, accordingly the plug fits the socket.

Tipp The connections for external devices are safely seperated from the mains

and safe low voltage.

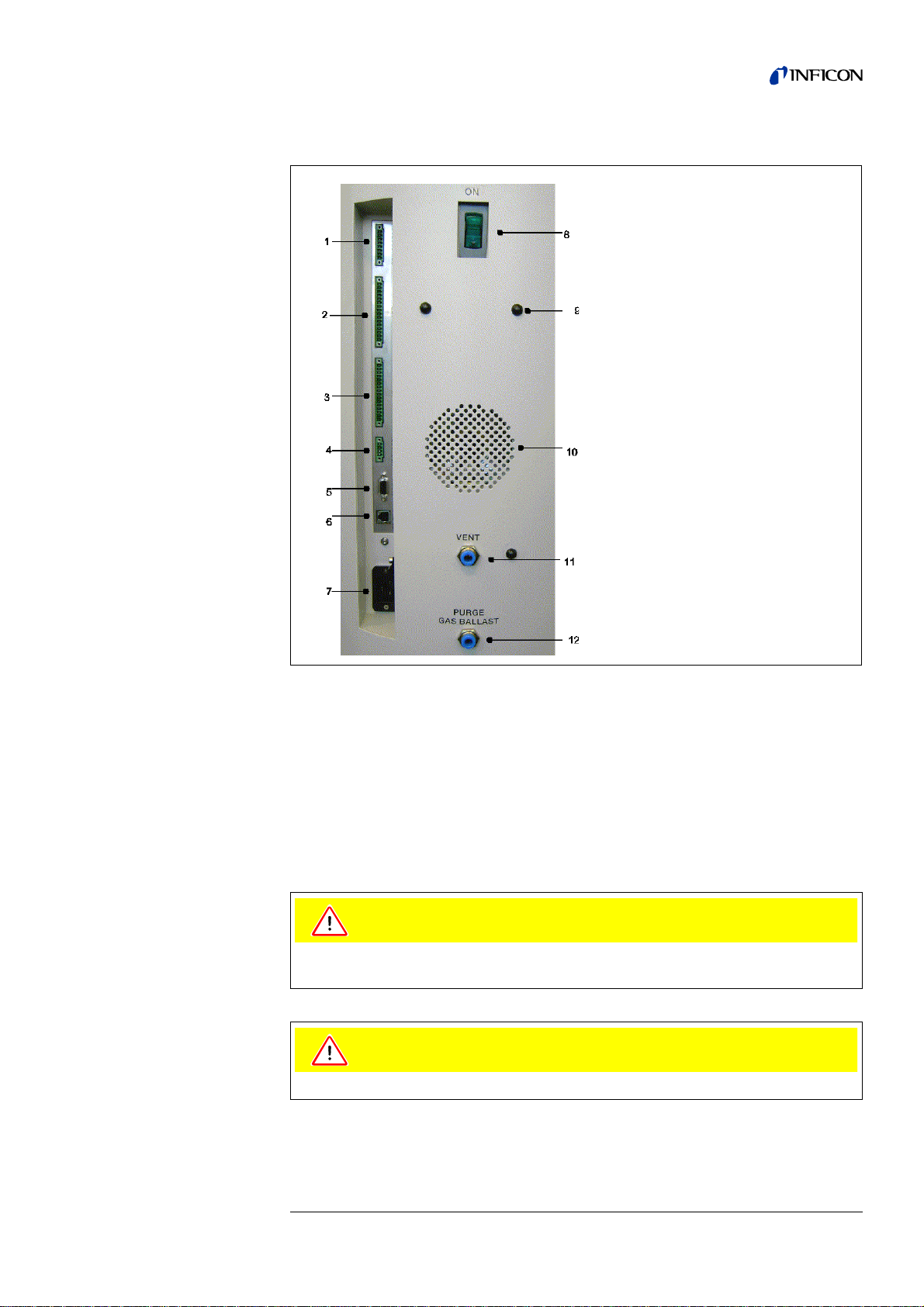

1. Accessories

2. Digital Out

3. Digital In

4. Recorder

5. RS232

6. Remote Control /

Wireless transmitter

7. Mains Socket

8. Mains Switch

9. Hole to mount cable hooks.

10. Speaker

11. Vent

12. Purge (UL1000 Fab) /

Gas ballast (UL1000)

Fig. 2-6

Caution

The electronic of the device can be destroyed. So just connect de vices to the le ak

detector that are seperated from the mains.

Caution

Just connect devices that don’t excess 25V AC/Amp.

28 Installation

iina70e 02.fm technical handbook(1408)

2.3.2.1 Accessories

The following accessories may be connected to the sniffer line SL200 (P lease refe r

to Chapter Fig. 2-6/1) or the test chamber TC1000:

Contact pins 1 and 3 are fused with a 0.8 A slow-blow fuse. The amount of power

which can be drawn is limited to 10 W. The contacts are numbered from top to

bottom.

2.3.2.2 Digital Out

The following relay outputs are available for further signal processing. The maximum

rating for the relay contacts is 60V AC/1A.

Description of the operation mode of the Digital Out.

Trigger 1:

Is open in case Trigger Level 1 is exceeded or the machine is not in condition of

measuring.

Trigger 2:

Is open in case Trigger Level 2 is exceeded or the machine is not in condition of

measuring.

Zero active:

Is closed in case Zero function is running.

Ready:

Is closed in case machine is ready for measurement (Emission on, no error).

CAL active

Closed when machine is in calibrating routine.

Pin Assignment

1 +24 V, constantly applied, power supply for the sniffer line SL200.

2 GND24

3, 6 Input

4, 5, 7, 8 Output

Pin Assignment

1 +24V, bridged with pin 1 of socket „Digital In“

2 GND_24V

3 Trigger 1

4 Trigger 2

5Free

6 Zero active

7 Ready

8 CAL active

9 Cal request

10 Error

11 Warning

12 Purge

13 Measure

14 Recorder Strobe

15 Common dig. out

16 Free

Installation 29

iina70e 02.fm technical handbook(1408)

CAL Request

Is opend in case of calibration request. During external calibration a open output

indicates that the external calibrated leak has to be clos ed .

Error

Open when an error is shown.

Warning

Open when a warning is shown.

Purge

Closed when purge is active.

Measure

Closed in case a machine is in measure mode.

Recorder Strobe

Closed in case recorder output is invalid. Only used when record output is set on

„leak rate“.

2.3.2.3 Digital In

These inputs can be used to control the UL1000 and UL1000 Fab with a

programmable logic control (PLC).

Description of operation mode of the Digital In.

Zero:

Change from low to high: activate zero

Change from high to low: deactivate zero

Start:

Change from low to high: activate START

Stop:

Change from low to high: activate STOP

When this inlet is longer high than anounced in chapter 6.6.1.2 then ventilate it

additionaly.

Pin Assignment

1 +24V, bridged with pin 1 of socket „Digital Out“

2 GND_24V

3Start

4Stop

5Zero

6CAL

7 Clear

8 Purge

9Free

10 Free

11 Common dig

12 Free

13 Free

14 Free

15 Free

16 Free

30 Installation

iina70e 02.fm technical handbook(1408)

Purge:

Change from low to high: activate purge

Change from high to low: deactivate purge

Clear:

Change from low to high: confirm error message

CAL:

Change from low to high:

When machine is in stand-by mode: start internal calibration. In case machine is

measurement mode: start external calibration. (Premise: external calibration test

leak has to be open and leak rate signal is stable)

Change from high to low:

External calibration: approve that external test leak is closed and leak rate signal is

stable.

High means: U > 13 V(approximately 7mA)

Low means: U < 7 V

The level of the logic signals must not exceed 35V.

Notice: Signals at these inputs are only accepted if the location of control is set to

„PLC“ or „Local and PLC“. Refer to Chapter 6.6.4.1

2.3.2.4 Recorder

The recorder output see Fig. 2-6/4 may be used to log th e leak rate, the inlet pressure

and the forevacuum pressure.

The measured values are provided by way of an analogu e signal in the ran ge of 0 V

… 10 V. The resolution is limited to 10 mV. The instrument which is connected to the

recorder output (e. g. X(t) chart recorder) should have an input resistance of no less

than 2.5 k. The measured values are available through pins 1 and 4. The reference

potential (GND) is available at pins 2 and 3. The contacts are numbered from top to

bottom.

Tipp A diagramm showing pressures and leakrate versus voltage is attach ed in

the appendix.

Notice: The chart recorder outputs are electrically isolated from other plugs. If, in

spite of this, hum interference is apparent it is recommended to operate the

UL1000 and UL1000 Fab and the chart recorder from the same mains

phase. If this is not possible, you must make sure that the frame ground of

both instruments is kept at the same potential.

Pin Assignment

1 Analog 1

2GND

3GND

4 Analog 2

Loading...

Loading...