Page 1

EDITION: DECEMBER 1999

REVISION: DECEMBER 2000

PUBLICATION NO. SM0E-1C33U6

QUICK REFERENCE INDEX

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any form, or

by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan Motor

Company Ltd., Tokyo, Japan.

Page 2

FOREWORD

This manual contains maintenance and repair procedures for the

2000 INFINITI I30.

In order to assure your safety and the efficient functioning of the

vehicle, this manual should be read thoroughly. It is especially

important that the PRECAUTIONS in the GI section be completely

understood before starting any repair task.

All information in this manual is based on the latest product information at the time of publication. The right is reserved to make

changes in specifications and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of

the technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a

manner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician

and the tools and parts available. Accordingly, anyone using service

procedures, tools or parts which are not specifically recommended

by INFINITI must first be completely satisfied that neither personal

safety nor the vehicle’s safety will be jeopardized by the service

method selected.

Page 3

PLEASE HELP MAKE THIS SERVICE MANUAL BETTER!

Your comments are important to INFINITI and will help us to improve our Service Manuals.

Use this form to report any issues or comments you may have regarding our Service Manuals.

Please print this form and type or write your comments below. Mail or fax to:

Nissan North America, Inc.

Technical Service Information

39001 Sunrise Drive, P.O. Box 9200

Farmington Hills, MI USA 48331

FAX: (248) 488-3910

SERVICE MANUAL: Model: Year:

PUBLICATION NO. (Please photocopy back cover):

VEHICLE INFORMATION VIN: Production Date:

Please describe any issues or problems in detail:

Page number(s)

Note: Please include a copy of each page, marked with your comments.

Are the trouble diagnosis procedures logical and easy to use? (circle your answer) YES NO

If no, what page number(s)?

Please describe the issue or problem in detail:

Is the organization of the manual clear and easy to follow? (circle your answer) YES NO

Please comment:

What information should be included in INFINITI Service Manuals to better support you in servicing or

repairing customer vehicles?

Note: Please include a copy of each page, marked with your comments.

DATE: YOUR NAME: POSITION:

DEALER: DEALER NO.: ADDRESS:

CITY: STATE/PROV./COUNTRY: ZIP/POSTAL CODE:

Page 4

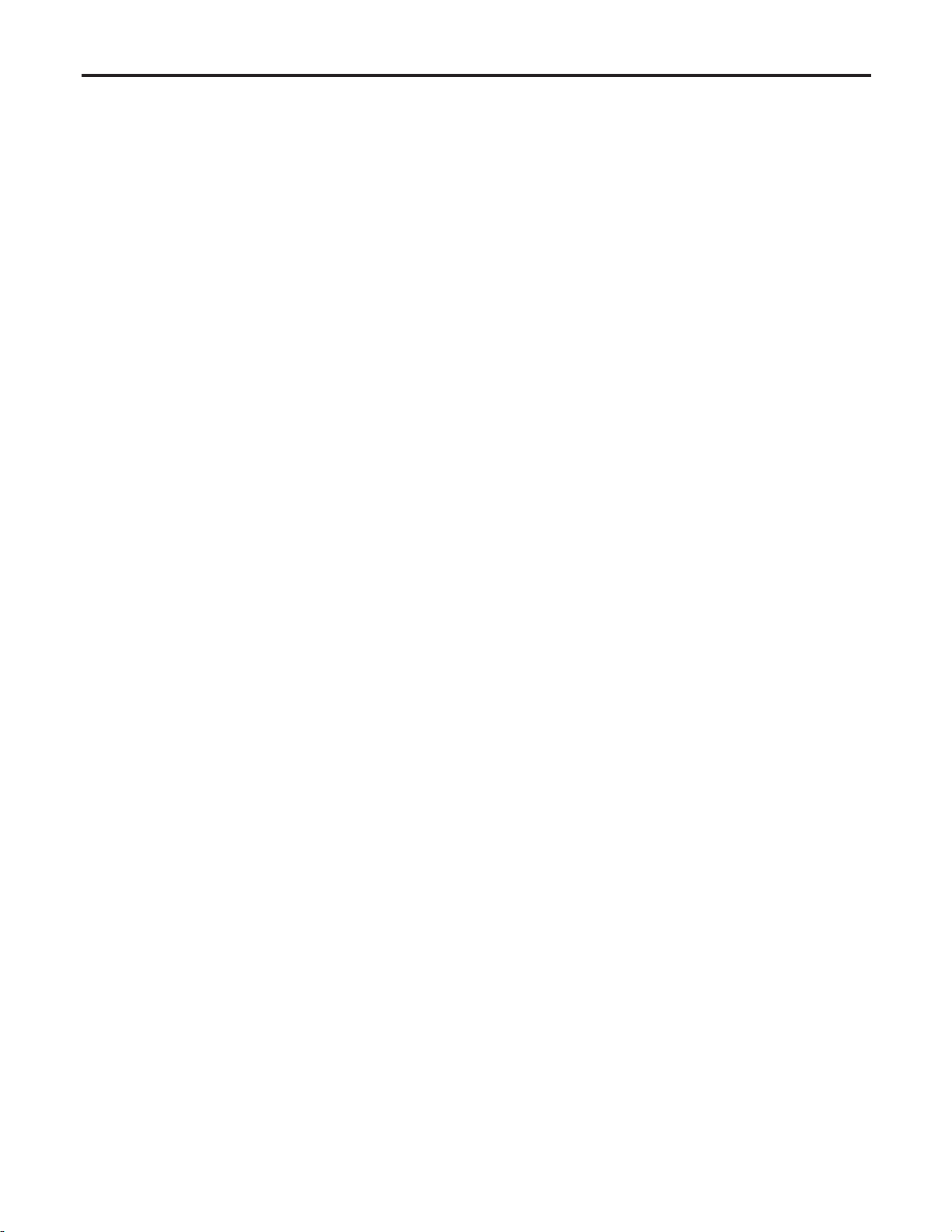

INCH TO METRIC CONVERSION TABLE

(Rounded-off for automotive use)

inches mm inches mm

.100 2.54 .610 15.49

.110 2.79 .620 15.75

.120 3.05 .630 16.00

.130 3.30 .640 16.26

.140 3.56 .650 16.51

.150 3.81 .660 16.76

.160 4.06 .670 17.02

.170 4.32 .680 17.27

.180 4.57 .690 17.53

.190 4.83 .700 17.78

.200 5.08 .710 18.03

.210 5.33 .720 18.29

.220 5.59 .730 18.54

.230 5.84 .740 18.80

.240 6.10 .750 19.05

.250 6.35 .760 19.30

.260 6.60 .770 19.56

.270 6.86 .780 19.81

.280 7.11 .790 20.07

.290 7.37 .800 20.32

.300 7.62 .810 20.57

.310 7.87 .820 20.83

.320 8.13 .830 21.08

.330 8.38 .840 21.34

.340 8.64 .850 21.59

.350 8.89 .860 21.84

.360 9.14 .870 22.10

.370 9.40 .880 22.35

.380 9.65 .890 22.61

.390 9.91 .900 22.86

.400 10.16 .910 23.11

.410 10.41 .920 23.37

.420 10.67 .930 23.62

.430 10.92 .940 23.88

.440 11.18 .950 24.13

.450 11.43 .960 24.38

.460 11.68 .970 24.64

.470 11.94 .980 24.89

.480 12.19 .990 25.15

.490 12.45 1.000 25.40

.500 12.70 2.000 50.80

.510 12.95 3.000 76.20

.520 13.21 4.000 101.60

.530 13.46 5.000 127.00

.540 13.72 6.000 152.40

.550 13.97 7.000 177.80

.560 14.22 8.000 203.20

.570 14.48 9.000 228.60

.580 14.73 10.000 254.00

.590 14.99 20.000 508.00

.600 15.24

METRIC TO INCH CONVERSION TABLE

(Rounded-off for automotive use)

mm inches mm inches

1 .0394 51 2.008

2 .079 52 2.047

3 .118 53 2.087

4 .157 54 2.126

5 .197 55 2.165

6 .236 56 2.205

7 .276 57 2.244

8 .315 58 2.283

9 .354 59 2.323

10 .394 60 2.362

11 .433 61 2.402

12 .472 62 2.441

13 .512 63 2.480

14 .551 64 2.520

15 .591 65 2.559

16 .630 66 2.598

17 .669 67 2.638

18 .709 68 2.677

19 .748 69 2.717

20 .787 70 2.756

21 .827 71 2.795

22 .866 72 2.835

23 .906 73 2.874

24 .945 74 2.913

25 .984 75 2.953

26 1.024 76 2.992

27 1.063 77 3.031

28 1.102 78 3.071

29 1.142 79 3.110

30 1.181 80 3.150

31 1.220 81 3.189

32 1.260 82 3.228

33 1.299 83 3.268

34 1.339 84 3.307

35 1.378 85 3.346

36 1.417 86 3.386

37 1.457 87 3.425

38 1.496 88 3.465

39 1.535 89 3.504

40 1.575 90 3.543

41 1.614 91 3.583

42 1.654 92 3.622

43 1.693 93 3.661

44 1.732 94 3.701

45 1.772 95 3.740

46 1.811 96 3.780

47 1.850 97 3.819

48 1.890 98 3.858

49 1.929 99 3.898

50 1.969 100 3.937

Page 5

TEST VALUE AND TEST LIMIT (GST ONLY — NOT APPLICABLE TO CONSULT-II)

The following is the information specified in Mode 6 of SAE J1979.

The test value is a parameter used to determine whether a system/circuit diagnostic test is “OK” or “NG” while

being monitored by the ECM during self-diagnosis. The test limit is a reference value which is specified as the

maximum or minimum value and is compared with the test value being monitored.

Items for which these data (test value and test limit) are displayed are the same as SRT code items.

These data (test value and test limit) are specified by Test ID (TID) and Component ID (CID) and can be dis-

played on the GST screen.

Self-diagnostic test item DTC

Three way catalyst function (Bank 1)

CATALYST

Three way catalyst function (Bank 2)

EVAP SYSTEM

HO2S

HO2S HTR

EGR SYSTEM EGR function

EVAP control system (Small leak)

EVAP control system purge flow monitoring P1447 06H 83H Min. 20mV

Heated oxygen sensor 1 (Bank 1)

Heated oxygen sensor 1 (Bank 2)

Heated oxygen sensor 2 (Bank 1)

Heated oxygen sensor 2 (Bank 2)

Heated oxygen sensor 1 heater (Bank 1)

Heated oxygen sensor 1 heater (Bank 2)

Heated oxygen sensor 2 heater (Bank 1)

Heated oxygen sensor 2 heater (Bank 2)

Attachment No.11

Test value

(GST display)

Test limitSRT item

Conversion

TID CID

P0420 01H 01H Max. 1/128

P0420 02H 81H Min. 1

P0430 03H 02H Max. 1/128

P0430 04H 82H Min. 1

P0440 05H 03H Max.

P1440 05H 03H Max.

P0133 09H 04H Max. 10ms

P0131 0AH 84H Min. 10mV

P0130 0BH 04H Max. 10mV

P0132 0CH 04H Max. 10mV

P0134 0DH 04H Max. 1s

P0153 11H 05H Max. 10ms

P0151 12H 85H Min. 10mV

P0150 13H 05H Max. 10mV

P0152 14H 05H Max. 10mV

P0154 15H 05H Max. 1s

P0139 19H 86H Min. 10mV/500ms

P0137 1AH 86H Min. 10mV

P0140 1BH 06H Max. 10mV

P0138 1CH 06H Max. 10mV

P0159 21H 87H Min. 10mV/500ms

P0157 22H 87H Min. 10mV

P0160 23H 07H Max. 10mV

P0158 24H 07H Max. 10mV

P0135 29H 08H Max. 20mV

P0135 2AH 88H Min. 20mV

P0155 2BH 09H Max. 20mV

P0155 2CH 89H Min. 20mV

P0141 2DH 0AH Max. 20mV

P0141 2EH 8AH Min. 20mV

P0161 2FH 0BH Max. 20mV

P0161 30H 8BH Min. 20mV

P0400 31H 8CH Min. 1

P0400 32H 8CH Min. 1

P0400 33H 8CH Min. 1

P0400 34H 8CH Min. 1

P1402 35H 0CH Max. 1

1/128mm

1/128mm

2

2

Page 6

FRONT & REAR SUSPENSION

GI

MA

CONTENTS

FRONT SUSPENSION ....................................................2

Precautions ..................................................................2

PRECAUTIONS

Preparation ..................................................................2

SPECIAL SERVICE TOOLS

COMMERCIAL SERVICE TOOLS

Noise, Vibration and Harshness (NVH)

Troubleshooting ...........................................................4

NVH TROUBLESHOOTING CHART

Components.................................................................5

On-vehicle Service.......................................................6

FRONT SUSPENSION PARTS

FRONT WHEEL ALIGNMENT

Coil Spring and Shock Absorber ...............................10

COMPONENTS

REMOVAL AND INSTALLATION

DISASSEMBLY

INSPECTION

ASSEMBLY

Stabilizer Bar .............................................................12

REMOVAL AND INSTALLATION

Transverse Link and Lower Ball Joint .......................13

REMOVAL AND INSTALLATION

INSPECTION

Service Data and Specifications (SDS).....................15

GENERAL SPECIFICATIONS (FRONT)

FRONT WHEEL ALIGNMENT (UNLADEN*1)

LOWER BALL JOINT

.........................................................2

........................................2

................................2

............................4

...................................6

.....................................6

.......................................................10

...............................11

........................................................11

...........................................................11

.............................................................12

...............................12

...............................13

...........................................................14

.....................15

.............16

...............................................16

SECTION

WHEELARCH HEIGHT (UNLADEN*)

WHEEL RUNOUT

REAR SUSPENSION.....................................................18

Precautions ................................................................18

PRECAUTIONS

Preparation ................................................................18

COMMERCIAL SERVICE TOOLS

Noise, Vibration and Harshness (NVH)

Troubleshooting .........................................................18

Components...............................................................19

On-vehicle Service.....................................................20

REAR SUSPENSION PARTS

REAR WHEEL ALIGNMENT

Removal and Installation ...........................................23

REMOVAL

INSTALLATION

Coil Spring and Shock Absorber ...............................25

REMOVAL AND INSTALLATION

DISASSEMBLY

INSPECTION

ASSEMBLY

Torsion Beam, Lateral Link and Control Rod ............26

DISASSEMBLY

INSPECTION

ASSEMBLY

Service Data and Specifications (SDS).....................28

GENERAL SPECIFICATIONS (REAR)

REAR WHEEL ALIGNMENT (UNLADEN*)

....................................................17

.......................................................18

...............................................................24

........................................................24

........................................................25

...........................................................25

.............................................................26

........................................................26

...........................................................26

.............................................................27

SU

.........................17

..............................18

...................................20

.....................................20

...............................25

.......................28

.................28

EM

LC

EC

FE

AT

AX

BR

ST

RS

BT

HA

SC

EL

IDX

Page 7

Precautions

SBR686C

FRONT SUSPENSION

Precautions

PRECAUTIONS

! When installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

Oil will shorten the life of rubber bushes. Be sure to wipe

off any spilled oil.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

! After installing removed suspension parts, check wheel

alignment and adjust if necessary.

! Use flare nut wrench when removing or installing brake

tubes.

! Always torque brake lines when installing.

! Lock nuts are unreusable parts; always use new ones.

When replacing, do not wipe the oil off the new lock nut

before tightening.

NHSU0001

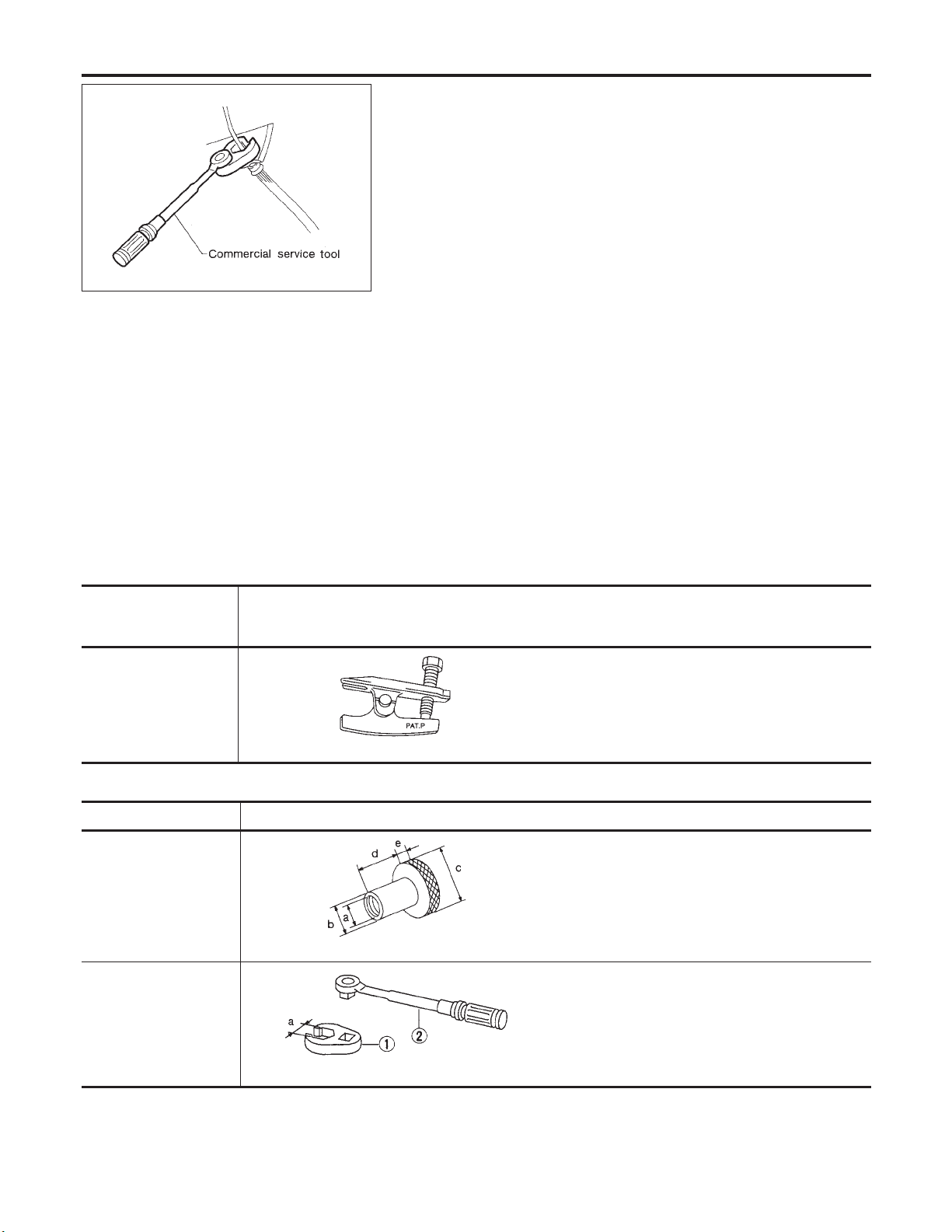

Preparation

SPECIAL SERVICE TOOLS

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

HT72520000

(J25730-A)

Ball joint remover

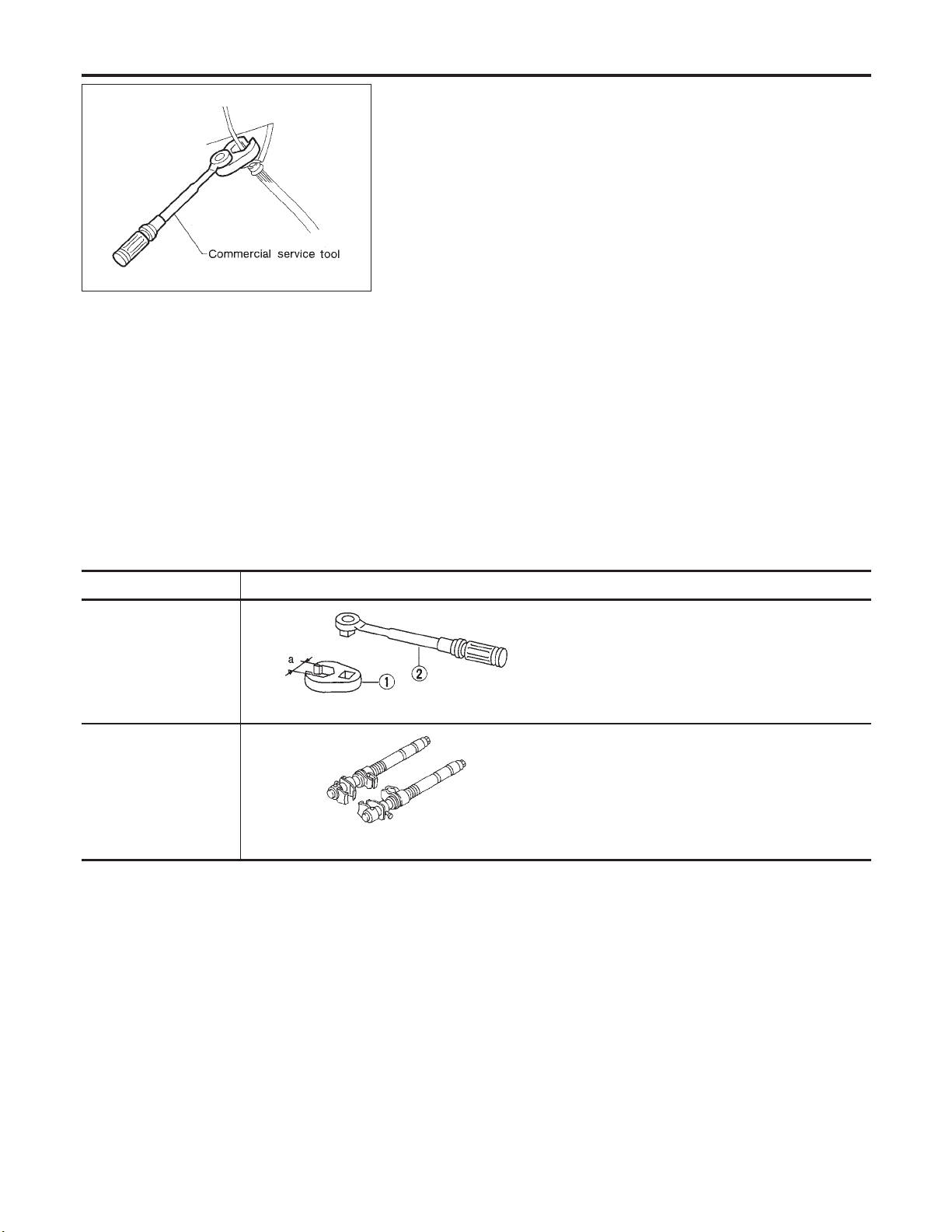

COMMERCIAL SERVICE TOOLS

Tool name Description

Attachment Wheel alignment

1 Flare nut crowfoot

2 Torque wrench

Description

Removing tie-rod outer end and lower ball joint

NT146

Measure wheel alignment

a: Screw M24 x 1.5 pitch

b: 35 mm (1.38 in) dia.

c: 65 mm (2.56 in) dia.

d: 56 mm (2.20 in)

e: 12 mm (0.47 in)

NT148

Removing and installing each brake piping

a: 10 mm (0.39 in)

NHSU0002

NHSU0003

NT360

SU-2

Page 8

Tool name Description

FRONT SUSPENSION

Preparation (Cont’d)

Spring compressor

Removing and installing coil spring

GI

MA

NT717

EM

LC

EC

FE

AT

AX

BR

ST

RS

BT

HA

SC

EL

IDX

SU-3

Page 9

FRONT SUSPENSION

Noise, Vibration and Harshness (NVH) Troubleshooting

Noise, Vibration and Harshness (NVH)

Troubleshooting

NVH TROUBLESHOOTING CHART

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

=NHSU0004

NHSU0004S01

Reference page

SU-5, 19

Possible Cause and

SUSPECTED

PARTS

Improper installation, looseness

Noise ЧЧЧЧЧЧ ×× ××××

Shake ×××× × ×× ××××

Vibration ЧЧЧЧЧ ×× × ×

Shimmy ×××× × × ××××

Judder ××× × ××××

SUSPENSION

Poor quality

ride or handling

ЧЧЧЧЧ ×× × ××

—

SU-11, 25

Shock absorber deformation,

damage or deflection

Bushing or mounting deterioration

—

—

Parts interference

Spring fatigue

SU-6

SU-10, 23

Suspension looseness

Incorrect wheel alignment

SU-6

SU-12

Stabilizer bar fatigue

Out-of-round

—

—

Imbalance

Incorrect air pressure

—

Uneven tire wear

—

—

Deformation or damage

Non-uniformity

—

Incorrect tire size

AX-3

AX-3

DRIVE SHAFT

AXLE

—

—

SUSPENSION

TIRES

—

BR-7

ROAD WHEEL

BRAKES

ST-5

STEERING

Noise ×××××××××××××

Shake ×××××××××××××

Vibration ××××××

Shimmy ×××××××××××××

Symptom

TIRES

Judder ××××××××××××

Poor quality

ride or handling

Noise ××××××××××

Shake ××××××××××

Shimmy,

Judder

Poor quality

ROAD WHEEL

ride or handling

×: Applicable

××××××××××

×××××××××

×××××××

SU-4

Page 10

FRONT SUSPENSION

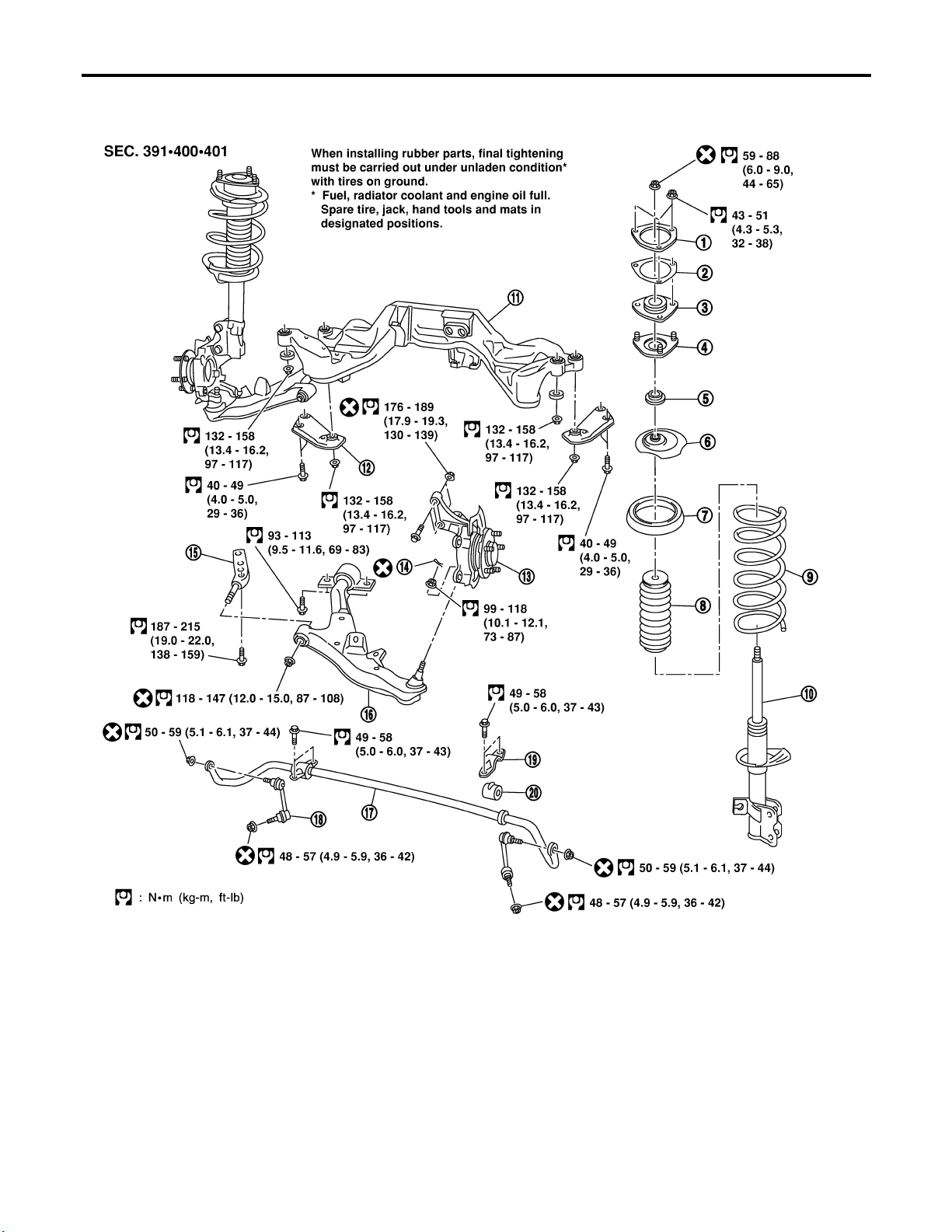

Components

Components

NHSU0005

GI

MA

EM

LC

EC

FE

AT

AX

1. Front suspension member

2. Stabilizer bar

3. Transverse link

4. Rebound stopper

5. Knuckle

6. Strut assembly

7. Coil spring

8. Strut mount plate

BR

ST

RS

BT

HA

SC

SSU009

EL

IDX

SU-5

Page 11

On-vehicle Service

SMA525A

FRONT SUSPENSION

On-vehicle Service

FRONT SUSPENSION PARTS

Check front axle and front suspension parts for excessive play,

cracks, wear or other damage.

! Shake each front wheel to check for excessive play.

! Make sure that cotter pin is inserted.

! Retighten all axle and suspension nuts and bolts to the speci-

fied torque.

Tightening torque:

Refer to “FRONT SUSPENSION”, SU-5.

! Check strut (shock absorber) for oil leakage or other damage.

! Check suspension ball joint for grease leakage and ball joint

dust cover for cracks or other damage.

If ball joint dust cover is cracked or damaged, replace transverse link.

NHSU0006

SFA392B

SFA818AA

SSU010

! Check spring height from top of wheelarch to the ground.

a) Vehicle must be unladen*, parked on a level surface, and tires

checked for proper inflation and wear (tread wear indicator

must not be showing).

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

b) Bounce vehicle up and down several times before measuring.

Standard height: Refer to SDS (SU-17).

c) Spring height is not adjustable. If out of specification, check for

worn springs or suspension parts.

! Check suspension ball joint end play.

a) Jack up front of vehicle and set the stands.

b) Clamp dial indicator onto transverse link and place indicator tip

on lower edge of brake caliper.

c) Make sure front wheels are straight and brake pedal is

depressed.

d) Place a pry bar between transverse link and inner rim of road

wheel.

e) While raising and releasing pry bar, observe maximum dial

indicator value.

Vertical end play: 0 mm (0 in)

f) If ball joint movement is beyond specifications, remove and

replace it.

FRONT WHEEL ALIGNMENT

NHSU0007

Before checking front wheel alignment, be sure to make a preliminary inspection (Unladen*).

*: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand

tools and mats in designated positions.

SU-6

Page 12

FRONT SUSPENSION

On-vehicle Service (Cont’d)

SFA975B

SFA981B

Preliminary Inspection

Aluminum wheel

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage.

If deformed, remove wheel and check wheel runout.

a. Remove tire from aluminum wheel and mount on a tire balance

machine.

b. Set dial indicator as shown in the illustration.

Wheel runout (Dial indicator value):

Refer to SDS, SU-17.

3. Check front wheel bearings for looseness.

4. Check front suspension for looseness.

5. Check steering linkage for looseness.

6. Check that front shock absorbers work properly.

7. Check vehicle posture (Unladen).

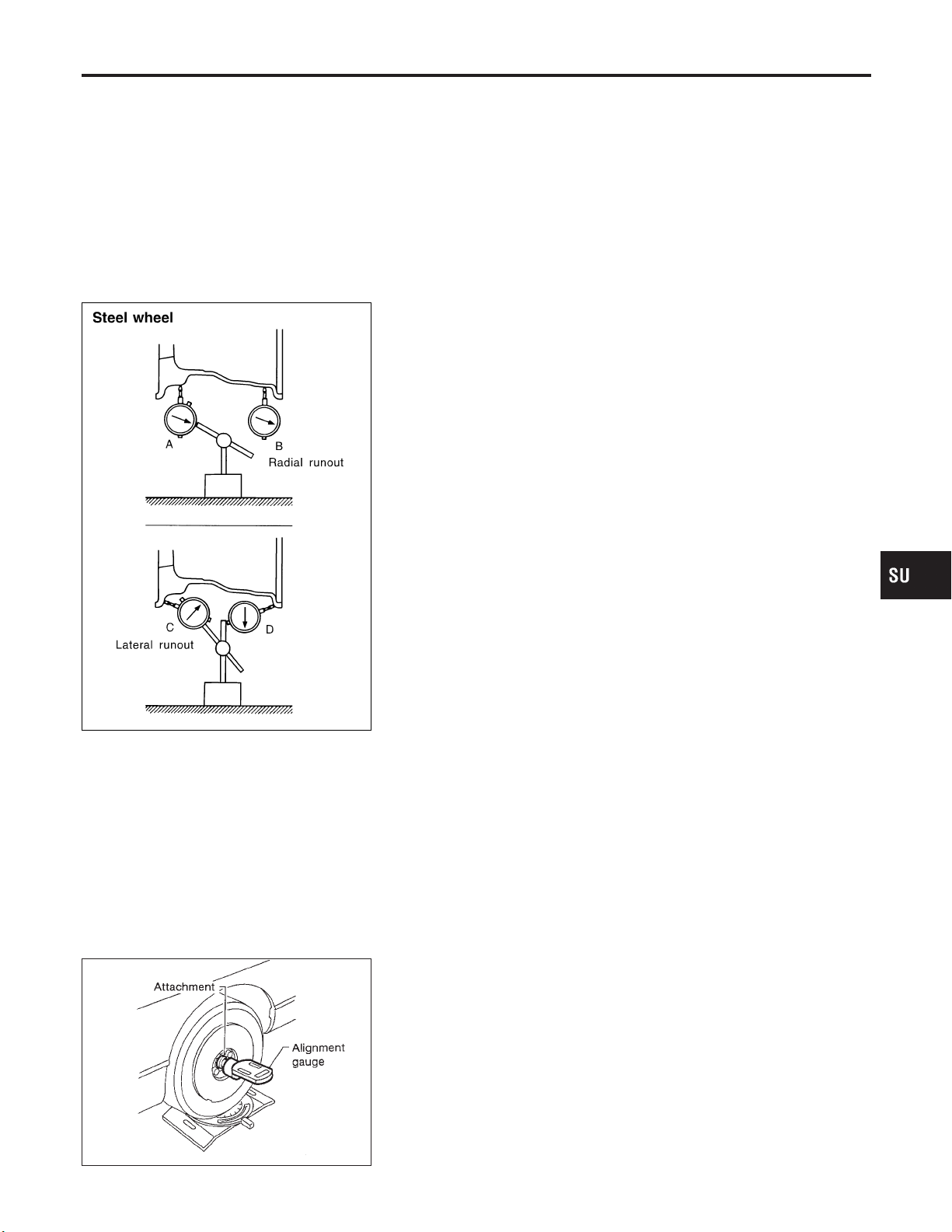

Steel wheel

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage.

If deformed, remove wheel and check wheel runout.

a. Remove tire from steel wheel and mount wheel on a tire bal-

ance machine.

b. Set two dial indicators as shown in the illustration.

c. Set each dial indicator to 0.

d. Rotate wheel and check dial indicators at several points

around the circumference of the wheel.

e. Calculate runout at each point as shown below.

Radial runout = (A + B)/2

Lateral runout = (C + D)/2

f. Select maximum positive runout value and the maximum

negative value.

Add the two values to determine total runout.

In case a positive or negative value is not available, use the

maximum value (negative or positive) for total runout.

If the total runout value exceeds the limit, replace steel wheel.

Wheel runout:

Refer to SDS, SU-17.

3. Check front wheel bearings for looseness.

4. Check front suspension for looseness.

5. Check steering linkage for looseness.

6. Check that front shock absorbers work properly.

7. Check vehicle posture (Unladen).

NHSU0007S01

NHSU0007S0103

NHSU0007S0104

GI

MA

EM

LC

EC

FE

AT

AX

BR

ST

RS

BT

HA

SC

EL

IDX

SU-7

Page 13

On-vehicle Service (Cont’d)

FRONT SUSPENSION

SRA096A

AFA050

Camber, Caster and Kingpin Inclination

NHSU0007S02

Camber, caster and kingpin inclination are preset at factory

and cannot be adjusted.

1. Measure camber, caster and kingpin inclination of both right

and left wheels with a suitable alignment gauge.

Camber, caster and kingpin inclination:

Refer to SDS, SU-16.

2. If camber, caster or kingpin inclination is not within

specification, inspect front suspension parts. Replace damaged or worn out parts.

Toe-in

NHSU0007S03

Measure toe-in using the following procedure.

WARNING:

! Always perform the following procedure on a flat surface.

! Make sure that no person is in front of the vehicle before

pushing it.

1. Bounce front of vehicle up and down to stabilize the posture.

2. Push the vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of tread (rear side) of both tires at the

same height as hub center. These are measuring points.

4. Measure distance “A” (rear side).

5. Push the vehicle slowly ahead to rotate the wheels 180

degrees (1/2 turn).

If the wheels have rotated more than 180 degrees (1/2 turn), try

the above procedure again from the beginning. Never push

vehicle backward.

6. Measure distance “B” (front side).

Total toe-in:

Refer to SDS, SU-16.

SFA234AC

SFA486A

SFA439BA

7. Adjust toe-in by varying the length of steering tie-rods.

a. Loosen lock nuts.

b. Adjust toe-in by screwing tie-rods in and out.

Standard length “L”:

Refer to ST-30, “SDS”.

c. Tighten lock nuts to specified torque.

Lock nut tightening torque:

Refer to ST-15, “POWER STEERING GEAR AND LINKAGE”.

Front Wheel Turning Angle

NHSU0007S04

1. Set wheels in straight-ahead position. Then move vehicle forward until front wheels rest on turning radius gauge properly.

2. Rotate steering wheel all the way right and left; measure turning angle.

Do not hold the steering wheel on full lock for more than

15 seconds.

Wheel turning angle (Full turn):

Refer to SDS, SU-16.

SU-8

Page 14

FRONT SUSPENSION

3. Check stopper bolt head to see whether it contacts stopper

bracket at specified outside wheel angle. If not, adjust stopper

bolt to contact stopper bracket at the correct angle.

Adjust protrusion of stopper bolt before placing stopper bolt

cap.

Apply grease to face of stopper bracket that bolt touches.

Tighten stopper bolt lock nut.

: 54 - 72 N·m (5.5 - 7.3 kg-m, 40 - 53 ft-lb)

SSU023

On-vehicle Service (Cont’d)

GI

MA

EM

LC

EC

FE

AT

AX

BR

ST

RS

BT

HA

SC

EL

SU-9

IDX

Page 15

Coil Spring and Shock Absorber

FRONT SUSPENSION

Coil Spring and Shock Absorber

COMPONENTS

=NHSU0008

1. Strut mount upper plate

2. Strut spacer

3. Strut mount insulator

4. Strut mount bracket

5. Strut mount bearing

6. Spring upper seat

7. Spring rubber seat

8. Bound bumper rubber

9. Coil spring

10. Shock absorber

11. Suspension member

12. Rebound stopper

13. Wheel hub and steering knuckle

14. Cotter pin

SU-10

SSU011-A

15. Bush link pin

16. Transverse link

17. Stabilizer

18. Connecting rod

19. Stabilizer clamp

20. Bushing

Page 16

FRONT SUSPENSION

Coil Spring and Shock Absorber (Cont’d)

SFA956A

SSU002

REMOVAL AND INSTALLATION

! Remove shock absorber fixing bolt and nut (to hoodledge).

! Do not remove piston rod lock nut on vehicle.

DISASSEMBLY

1. Set shock absorber on vise, then loosen piston rod lock nut.

! Do not remove piston rod lock nut at this time.

2. Compress spring with Tool so that shock absorber mounting

insulator can be turned by hand.

WARNING:

Make sure that the pawls of the two spring compressors are

firmly hooked on the spring. The spring compressors must be

tightened alternately so as not to tilt the spring.

3. Remove piston rod lock nut.

=NHSU0009

NHSU0010

GI

MA

EM

LC

EC

FE

AT

AX

SSU003

INSPECTION

Shock Absorber Assembly

! Check for smooth operation through a full stroke, both com-

pression and extension.

! Check for oil leakage on welded or gland packing portions.

! Check piston rod for cracks, deformation or other damage.

Replace if necessary.

Mounting Insulator and Rubber Parts

! Check cemented rubber-to-metal portion for separation or

cracks. Check rubber parts for deterioration.

Replace if necessary.

Thrust Bearing

! Check thrust bearing parts for abnormal noise or excessive

rattle in axial direction.

! Replace if necessary.

Coil Spring

! Check for cracks, deformation or other damage. Replace if

necessary.

NHSU0011

NHSU0011S01

NHSU0011S02

NHSU0011S06

NHSU0011S03

BR

ST

RS

BT

HA

SC

EL

IDX

SU-11

Page 17

Coil Spring and Shock Absorber (Cont’d)

FRONT SUSPENSION

SFA508A

SFA664A

ASSEMBLY

NHSU0012

! When installing coil spring on strut, it must be positioned as

shown in the figure at left.

! Install upper spring seat with its cutout facing the outer side of

vehicle.

Stabilizer Bar

REMOVAL AND INSTALLATION

! Remove stabilizer bar.

NHSU0017

SSU027

SSU026

SFA604B

! When installing stabilizer, make sure that band and clamp face

in their correct directions.

! Make sure that slit in bushing is in the position shown in the

figure.

SU-12

Page 18

FRONT SUSPENSION

! When removing and installing stabilizer bar.

SSU027

! Install stabilizer bar with ball joint socket properly placed.

Stabilizer Bar (Cont’d)

GI

MA

EM

LC

EC

FE

AT

SFA449BB

ARA027

SFA651A

! Check stabilizer for deformation or cracks. Replace if neces-

sary.

! Check rubber bushings for deterioration or cracks. Replace if

necessary.

! Check ball joint can rotate in all directions. If movement is not

smooth and free, replace stabilizer bar connecting rod.

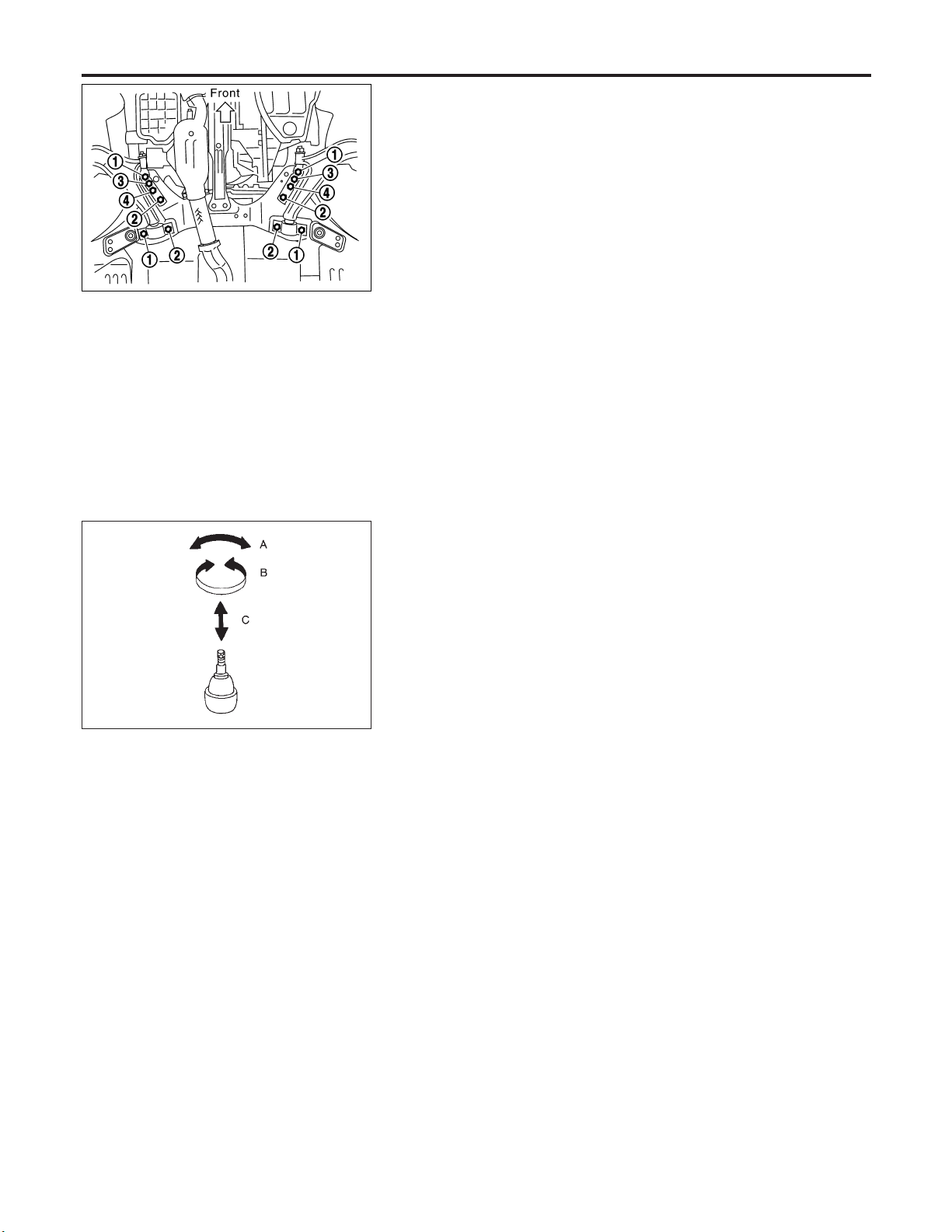

Transverse Link and Lower Ball Joint

REMOVAL AND INSTALLATION

1. Remove wheel bearing lock nut.

2. Remove tie-rod ball joint.

3. Remove strut lower bracket fixing bolts and nuts.

4. Separate drive shaft from knuckle by slightly tapping drive

shaft end.

Cover boots with shop towel so as not to damage them when

removing drive shaft.

5. Separate lower ball joint stud from knuckle with suitable tool.

Refer to AX-5, “FRONT AXLE — Wheel Hub and Knuckle”.

NHSU0018

AX

BR

ST

RS

BT

HA

SC

EL

IDX

SFA113A

SU-13

Page 19

Transverse Link and Lower Ball Joint (Cont’d)

SSU012

FRONT SUSPENSION

6. Remove fixing bolts.

7. Remove transverse link and lower ball joint.

8. Install fixing bolts in order of number.

Tightening torque:

Refer to “FRONT SUSPENSION”, SU-6.

9. During installation, final tightening must be carried out at curb

weight with tires on the ground.

10. After installation, check wheel alignment. Refer to “ON-VEHICLE SERVICE — Front Wheel Alignment”, SU-6.

INSPECTION

Transverse Link

! Check transverse link for damage, cracks or deformation.

Replace it if necessary.

! Check rubber bushing for damage, cracks and deformation.

Replace transverse link if necessary.

NHSU0019

NHSU0019S01

SFA858A

Lower Ball Joint

NHSU0019S02

! Check ball joint for play. Replace transverse link assembly if

any of the following cases occur. Ball stud is worn, play in axial

direction is excessive or joint is hard to swing.

Before checking, turn ball joint at least 10 revolutions so that

ball joint is properly broken in.

Swinging force “A”:

(measuring point: cotter pin hole of ball stud):

7.8 - 77.5 N (0.8 - 7.9 kg, 1.8 - 17.4 lb)

Turning torque “B”:

0.50 - 4.90 N·m (5.1 - 50 kg-cm, 4.4 - 43.4 in-lb)

Vertical end play “C”:

0 mm (0 in)

! Check dust cover for damage. Replace it and cover clamp if

necessary.

SU-14

Page 20

FRONT SUSPENSION

Service Data and Specifications (SDS)

GENERAL SPECIFICATIONS (FRONT)

Suspension type Independent MacPherson strut

Shock absorber type Double-acting hydraulic

Stabilizer bar Standard equipment

Service Data and Specifications (SDS)

=NHSU0020

GI

MA

EM

LC

EC

FE

AT

AX

BR

ST

RS

BT

HA

SC

EL

SU-15

IDX

Page 21

Service Data and Specifications (SDS) (Cont’d)

FRONT SUSPENSION

FRONT WHEEL ALIGNMENT (UNLADEN*1)

Tire size 225/50R17 215/55R16

Camber

Degree minute (Decimal degree)

Caster

Degree minute (Decimal degree)

Kingpin inclination

Degree minute (Decimal degree)

Total toe-in

Distance (A − B)

mm (in)

Angle (left plus right)

Degree minute (Decimal degree)

Wheel turning angle

Full turn*2

Inside

Degree minute (Decimal degree)

Outside

Degree minute (Decimal degree)

Minimum −1°00′ (−1.00°)

Nominal −0°15′ (−0.25°)

Maximum 0°30′ (0.50°)

Left and right difference 45′ (0.75°) or less

Minimum 2°00′ (2.00°)

Nominal 2°45′ (2.75°)

Maximum 3°30′ (3.50°)

Left and right difference 45′ (0.75°) or less

Minimum 13°30′ (13.50°)

Nominal 14°15′ (14.25°)

Maximum 15°00′ (15.00°)

Minimum 0 (0)

Nominal 1 (0.04)

Maximum 2 (0.08)

Minimum 0′ (0.00°)

Nominal 6′ (0.10°)

Maximum 12′ (0.20°)

Minimum 29°30′ (29.50°) 36°00′ (36.0°)

Nominal 33°00′ (33.0°) 39°30′ (39.50°)

Maximum 34°00′ (34.0°) 40°30′ (40.50°)

Nominal 28°30′ (28.50°) 32°00′ (32.00°)

=NHSU0021

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: On power steering models, wheel turning force (at circumference of steering wheel) of 98 to 147 N (10 to 15 kg, 22 to 33 lb) with

engine idle.

LOWER BALL JOINT

Swinging force “A”

(Measuring point: cotter pin hole of ball stud) N (kg, lb)

Turning torque “B” N·m (kg-cm, in-lb) 0.50 - 4.90 (5.1 - 50.0, 4.4 - 43.4)

Vertical end play “C” mm (in) 0 (0)

7.8 - 77.5 (0.8 - 7.9, 1.8 - 17.4)

NHSU0022

SU-16

Page 22

FRONT SUSPENSION

Service Data and Specifications (SDS) (Cont’d)

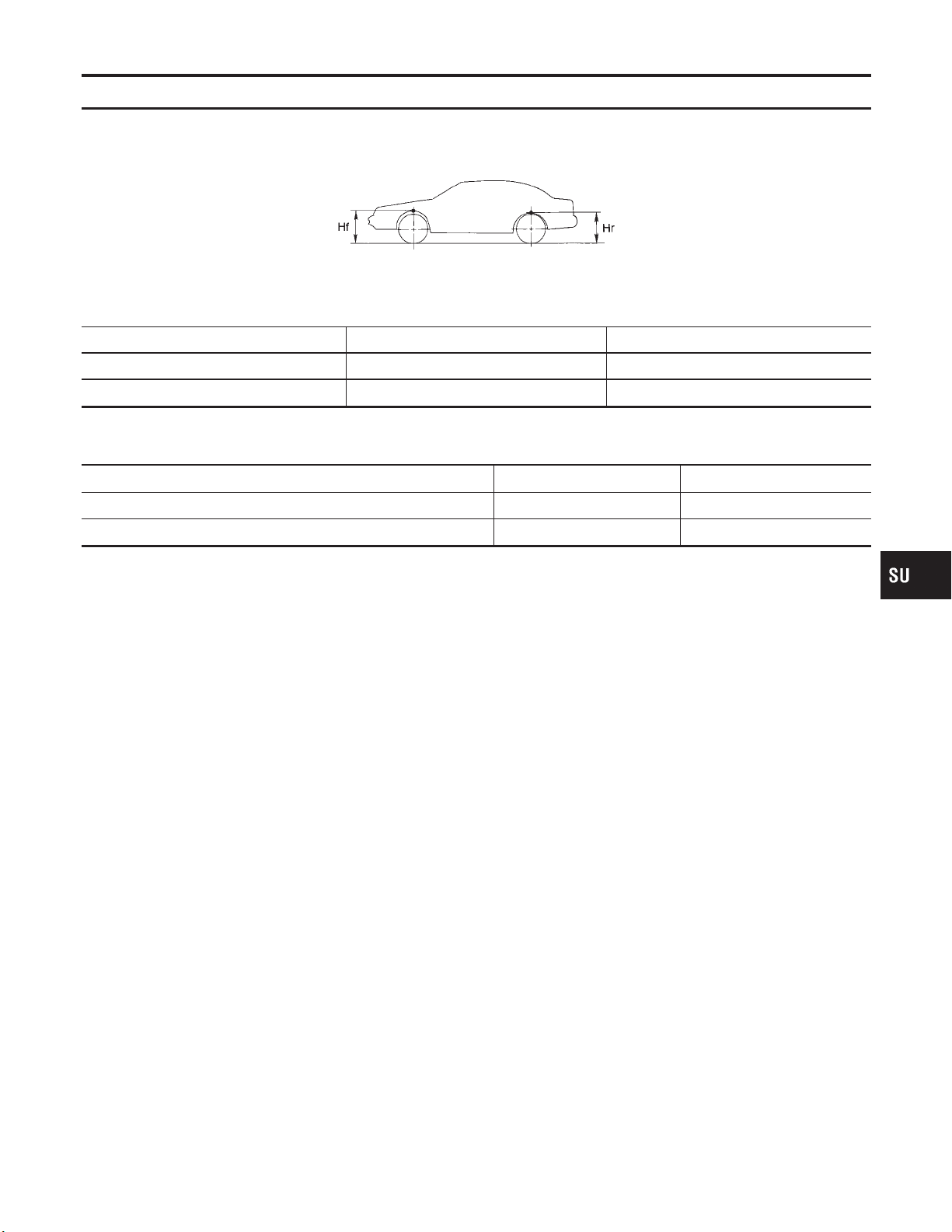

WHEELARCH HEIGHT (UNLADEN*)

Applied model Models with 225/50R17 tire Models with 215/55R16 tire

Front (Hf) mm (in) 706 (27.80) 698 (27.48)

Rear (Hr) mm (in) 694 (27.32) 683 (26.89)

*: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

WHEEL RUNOUT

Wheel type Aluminum Steel wheel

Radial runout limit mm (in) 0.3 (0.012) 0.5 (0.020)

Lateral runout limit mm (in) 0.3 (0.012) 0.8 (0.031)

=NHSU0041

SFA818A

NHSU0023

GI

MA

EM

LC

EC

FE

AT

AX

BR

ST

RS

BT

HA

SC

EL

IDX

SU-17

Page 23

Precautions

SBR686C

REAR SUSPENSION

Precautions

PRECAUTIONS

! When installing each rubber part, final tightening must be

carried out under unladen condition* with tires on ground.

Oil will shorten the life of rubber bushes. Be sure to wipe

off any spilled oil.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

! Use flare nut wrench when removing or installing brake

tubes.

! After installing removed suspension parts, check wheel

alignment.

! Do not jack up at the trailing arm and lateral link.

! Always torque brake lines when installing.

! Lock nuts are unreusable parts; always use new ones.

When replacing, do not wipe the oil off of the new lock nut

before tightening.

NHSU0024

COMMERCIAL SERVICE TOOLS

Tool name Description

Equivalent to

GG94310000

1 Flare nut crowfoot

2 Torque wrench

NT360

Spring compressor

NT717

Preparation

NHSU0026

Removing and installing brake piping

a: 10 mm (0.39 in)

Removing and installing coil spring

Noise, Vibration and Harshness (NVH)

Troubleshooting

Refer to “Noise, Vibration and Harshness (NVH) Troubleshooting”,

“FRONT SUSPENSION”, SU-4.

NHSU0027

SU-18

Page 24

REAR SUSPENSION

Components

Components

NHSU0028

GI

MA

EM

LC

EC

FE

AT

AX

1. Shock absorber mounting seal

2. Coil spring

3. Shock absorber

4. Suspension member

5. Control rod

6. Lateral link

7. Torsion beam

BR

ST

RS

BT

HA

SC

SSU013

EL

IDX

SU-19

Page 25

On-vehicle Service

SMA525A

REAR SUSPENSION

On-vehicle Service

REAR SUSPENSION PARTS

Check axle and suspension parts for excessive play, wear or damage.

! Shake each rear wheel to check for excessive play.

! Retighten all nuts and bolts to the specified torque.

Tightening torque:

Refer to “REAR SUSPENSION”, SU-19.

NHSU0029

SSU014

SMA113

! Check shock absorber for oil leakage or other damage.

! Check wheelarch height. Refer to “On-vehicle Service”,

“FRONT SUSPENSION PARTS”, SU-6.

REAR WHEEL ALIGNMENT

NHSU0030

Before checking rear wheel alignment, be sure to make a preliminary inspection (Unladen*).

*: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand

tools and mats in designated positions.

SFA975B

Preliminary Inspection

Aluminum wheel

NHSU0030S01

NHSU0030S0101

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If

deformed, remove wheel and check wheel runout.

a. Remove tire from aluminum wheel and mount on a tire balance

machine.

b. Set dial indicator as shown in the illustration.

Wheel runout (Dial indicator value):

Refer to SDS, SU-17.

SU-20

Page 26

REAR SUSPENSION

On-vehicle Service (Cont’d)

3. Check front wheel bearings for looseness.

4. Check front suspension for looseness.

5. Check steering linkage for looseness.

6. Check that front shock absorbers work properly.

7. Check vehicle posture (Unladen).

GI

MA

EM

SFA981B

Steel wheel

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage.

If deformed, remove wheel and check wheel runout.

a. Remove tire from steel wheel and mount wheel on a tire bal-

ance machine.

b. Set two dial indicators as shown in the illustration.

c. Set each dial indicator to 0.

d. Rotate wheel and check dial indicators at several points

around the circumference of the wheel.

e. Calculate runout at each point as shown below.

Radial runout = (A + B)/2

Lateral runout = (C + D)/2

f. Select maximum positive runout value and the maximum

negative value.

Add the two values to determine total runout.

In case a positive or negative value is not available, use the

maximum value (negative or positive) for total runout.

If the total runout value exceeds the limit, replace steel wheel.

Wheel runout:

Refer to SDS, SU-17.

3. Check front wheel bearings for looseness.

4. Check front suspension for looseness.

5. Check steering linkage for looseness.

6. Check that front shock absorbers work properly.

7. Check vehicle posture (Unladen).

NHSU0030S0102

LC

EC

FE

AT

AX

BR

ST

RS

BT

SFA948A

Camber

Camber is preset at factory and cannot be adjusted.

Camber:

Refer to SDS, SU-28.

! If the camber is not within specification, inspect and replace

any damaged or worn rear suspension parts.

NHSU0030S02

SU-21

HA

SC

EL

IDX

Page 27

On-vehicle Service (Cont’d)

REAR SUSPENSION

SFA614B

SFA234AC

Toe-in

NHSU0030S03

Toe-in is preset at factory and cannot be adjusted.

Measure toe-in using following procedure. If out of

specification, inspect and replace any damaged or worn rear

suspension parts.

WARNING:

! Perform following procedure always on a flat surface.

! Make sure that no person is in front of the vehicle before

pushing it.

1. Bounce rear of vehicle up and down to stabilize the posture.

2. Push the vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of the tread (rear side) of both tires at

the same height of hub center. This mark is a measuring point.

4. Measure distance “A” (rear side).

5. Push the vehicle slowly ahead to rotate the wheels 180

degrees (1/2 turn).

If the wheels have rotated more than 180 degrees (1/2 turn), try

the above procedure again from the beginning. Never push

vehicle backward.

6. Measure distance “B” (front side).

Total toe-in: A − B

Refer to SDS, SU-28.

SU-22

Page 28

REAR SUSPENSION

Removal and Installation

Removal and Installation

NHSU0031

GI

MA

EM

LC

EC

FE

AT

AX

1. Washer

2. Bushing

3. Shock absorber mounting seal

4. Shock absorber mounting bracket

5. Distance tube

6. Bushing

7. Bound bumper cover

8. Bound bumper

9. Coil spring

10. Shock absorber

11. Torsion beam

12. Control rod

13. Lateral link

14. ABS sensor

15. Suspension member

BR

ST

RS

BT

HA

SC

SSU015

EL

IDX

SU-23

Page 29

Removal and Installation (Cont’d)

REAR SUSPENSION

SSU016

SSU017

REMOVAL

NHSU0031S01

CAUTION:

! Before removing the rear suspension assembly, discon-

nect the ABS wheel sensor from the assembly. Failure to

do so may result in damage to the sensor wires and the

sensor becoming inoperative.

! Remove suspension assembly.

1. Remove tires, then remove brake hose lock plate.

2. Disconnect parking brake cable from caliper and remove brake

caliper and rotor.

Suspend caliper assembly with wire so as not to stretch brake

hose.

Be careful not to depress brake pedal, or piston will pop out.

Make sure brake hose is not twisted.

3. Using a transmission jack, raise torsion beam a little, and

remove nuts and bolts from the trailing arm, shock absorber

assembly (lower side) and lateral link.

4. Lower transmission jack, and remove suspension.

5. Remove trunk room trim. Refer to BT-39, “Trunk Room Trim”.

6. Remove strut securing nuts (upper side). Then pull out strut

assembly.

INSTALLATION

NHSU0031S02

! Install suspension assembly.

CAUTION:

Refill with new brake fluid “DOT 3”.

Never reuse drained brake fluid.

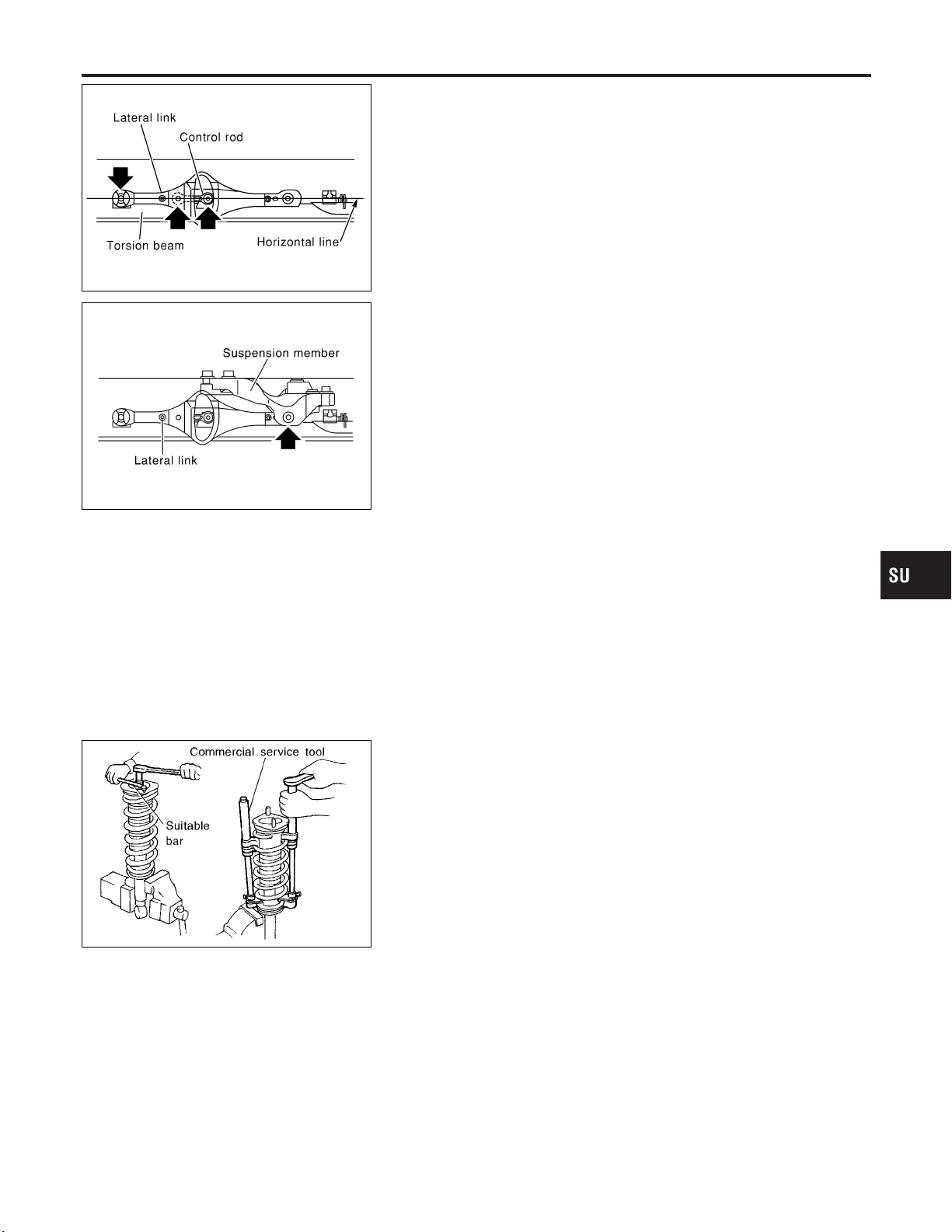

1. Install suspension member.

a. Temporarily tighten bolt 5.

b. Tighten all bolts in numerical order shown in the figure.

Tightening torque:

Refer to SU-23.

SSU020

SSU018

2. Attach control rod to lateral link. Do not tighten bolts at this

time.

3. Attach lateral link, control rod and torsion beam to vehicle. Do

not tighten bolts at this time.

SU-24

Page 30

REAR SUSPENSION

4. Using a transmission jack to lift the torsion beam, place lateral

link and control rod horizontally against torsion beam. Tighten

bolts and nuts to specified torque.

SSU019

5. Tighten lateral link at suspension member.

6. Attach shock absorber assembly to vehicle. Then tighten the

upper side of shock absorber assembly.

7. Remove transmission jack and lower torsion beam so that the

shock absorber assembly reaches full extension. Tighten torsion beam and lower side of shock absorber assembly to

specified torque.

Removal and Installation (Cont’d)

GI

MA

EM

LC

EC

FE

AT

SSU021

SRA806A

Coil Spring and Shock Absorber

REMOVAL AND INSTALLATION

Remove shock absorber upper and lower fixing nuts.

Do not remove piston rod lock nut on vehicle.

DISASSEMBLY

1. Set shock absorber in vise, then loosen piston rod lock nut.

Do not remove piston rod lock nut at this time.

2. Compress spring with Tool so that the shock absorber upper

spring seat can be turned by hand.

WARNING:

Make sure that the pawls of the two spring compressors are

firmly hooked on the spring. The spring compressors must be

tightened alternately so as not to tilt the spring.

3. Remove piston rod lock nut.

INSPECTION

Shock Absorber Assembly

! Check for smooth operation through a full stroke, both com-

pression and extension.

! Check for oil leakage on welded or gland packing portions.

! Check piston rod for cracks, deformation or other damage.

Replace if necessary.

NHSU0032

NHSU0033

NHSU0034

NHSU0034S01

AX

BR

ST

RS

BT

HA

SC

EL

IDX

Upper Rubber Seat and Bushing

Check rubber parts for deterioration or cracks.

Replace if necessary.

SU-25

NHSU0034S02

Page 31

Coil Spring and Shock Absorber (Cont’d)

REAR SUSPENSION

SRA699A

Coil Spring

NHSU0034S03

Check for cracks, deformation or other damage. Replace if

necessary.

ASSEMBLY

NHSU0035

! Locate upper spring seat as shown.

! When installing coil spring, be careful not to reverse top and

bottom direction. (Top end is flat.)

! When installing coil spring on shock absorber, it must be posi-

tioned as shown in figure at left.

CAUTION:

Do not reuse piston rod lock nut.

SFA436B

SSU025

Torsion Beam, Lateral Link and Control Rod

DISASSEMBLY

! Remove torsion beam assembly. Refer to “Removal and

Installation”, “REAR SUSPENSION”, SU-24.

! Remove lateral link and control rod from torsion beam.

INSPECTION

! Check for cracks, distortion or other damage. Replace if nec-

essary.

Standard length:

A 206.5 - 208.5 mm (8.13 - 8.21 in)

B 393.5 - 395.5 mm (15.49 - 15.57 in)

C 600 - 604 mm (23.62 - 23.78 in)

D 106 - 108 mm (4.17 - 4.25 in)

! Check all rubber parts for wear, cracks or deformation.

Replace if necessary.

NHSU0036

NHSU0037

SU-26

Page 32

REAR SUSPENSION

Torsion Beam, Lateral Link and Control Rod (Cont’d)

SRA793A

ASSEMBLY

1. Temporarily assemble lateral link and control rod.

! When installing the control rod, connect the bush with the

smaller inner diameter to the lateral link.

2. Temporarily install lateral link and control rod on torsion beam.

! When installing, place lateral link with the arrow topside.

NHSU0038

GI

MA

EM

LC

EC

FE

AT

AX

SSU022

SSU024

3. Place lateral link and control rod horizontally against torsion

beam, and tighten to the specified torque.

4. Install torsion beam assembly. Refer to “Removal and

Installation”, “REAR SUSPENSION”, SU-24.

BR

ST

RS

BT

HA

SC

EL

IDX

SU-27

Page 33

REAR SUSPENSION

Service Data and Specifications (SDS)

Service Data and Specifications (SDS)

GENERAL SPECIFICATIONS (REAR)

Suspension type Multi-link beam suspension

Shock absorber type Double-acting hydraulic

=NHSU0039

REAR WHEEL ALIGNMENT (UNLADEN*)

Camber

Degree minute (Decimal degree)

Total toe-in Distance (A − B)

mm (in)

Angle (left plus right)

Degree minute (Decimal degree)

*: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Minimum −1°45′ (−1.75°)

Nominal −1°00′ (−1.00°)

Maximum −0°15′ (−0.25°)

Minimum −3 (−0.12)

Nominal 1 (0.04)

Maximum 5 (0.20)

Minimum −16′ (−0.27°)

Nominal 5′30′′ (0.09°)

Maximum 26′ (0.43°)

NHSU0040

SU-28

Page 34

STEERING SYSTEM

GI

MA

CONTENTS

PRECAUTIONS ...............................................................2

Supplemental Restraint System (SRS) ″AIR

BAG″ and ″SEAT BELT PRE-TENSIONER″...............2

Precautions for Steering System.................................2

PREPARATION ...............................................................3

Special Service Tools ..................................................3

Commercial Service Tool .............................................4

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................5

NVH Troubleshooting Chart.........................................5

ON-VEHICLE SERVICE ..................................................6

Checking Steering Wheel Play....................................6

Checking Neutral Position on Steering Wheel ............6

PRE-CHECKING

CHECKING

Front Wheel Turning Angle..........................................6

Checking Gear Housing Movement ............................6

Checking and Adjusting Drive Belts ............................7

Checking Fluid Level ...................................................7

Checking Fluid Leakage ..............................................7

Bleeding Hydraulic System..........................................7

Checking Steering Wheel Turning Force ....................8

Checking Hydraulic System.........................................9

STEERING WHEEL AND STEERING COLUMN .........10

Components...............................................................10

Removal and Installation ...........................................10

STEERING WHEEL

STEERING COLUMN

........................................................6

...............................................................6

.................................................10

...............................................11

SECTION

Disassembly and Assembly.......................................13

Inspection...................................................................14

TILT MECHANISM

POWER STEERING GEAR AND LINKAGE ................15

Components...............................................................15

Removal and Installation ...........................................16

Disassembly...............................................................18

Inspection...................................................................19

.....................................................................19

BOOT

.....................................................................19

RACK

GEAR SUB-ASSEMBLY

GEAR HOUSING CYLINDER

TIE-ROD OUTER AND INNER SOCKETS

Assembly ...................................................................20

Adjustment .................................................................23

POWER STEERING OIL PUMP....................................25

Components...............................................................25

Pre-disassembly Inspection.......................................25

Disassembly...............................................................26

Inspection...................................................................27

Assembly ...................................................................27

SERVICE DATA AND SPECIFICATIONS (SDS) .........29

General Specifications...............................................29

Steering Wheel ..........................................................29

Steering Column ........................................................29

Steering Gear and Linkage .......................................30

Power Steering ..........................................................31

...................................................14

ST

...........................................19

....................................19

..................19

EM

LC

EC

FE

AT

AX

SU

BR

RS

BT

HA

SC

EL

IDX

Page 35

PRECAUTIONS

Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

Supplemental Restraint System (SRS) “AIR

BAG” and “SEAT BELT PRE-TENSIONER”

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER” used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to INFINITI I30 is as follows:

! For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steering wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

! For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring

harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in the RS section of this Service Manual.

WARNING:

! To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be performed by an authorized INFINITI dealer.

! Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by intentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the RS section.

! Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

NHST0001

Precautions for Steering System

! Before disassembly, thoroughly clean the outside of the unit.

! Disassembly should be done in a clean work area. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

! Place disassembled parts in order, on a parts rack, for easier and proper assembly.

! Use nylon cloths or paper towels to clean the parts; common shop rags can leave lint that might

interfere with their operation.

! Before inspection or reassembly, carefully clean all parts with a general purpose, non-flammable

solvent.

! Before assembly, apply a coat of recommended power steering fluid* to hydraulic parts. Vaseline

may be applied to O-rings and seals. Do not use any grease.

! Replace all gaskets, seals and O-rings. Avoid damaging O-rings, seals and gaskets during instal-

lation. Perform functional tests whenever designated.

*: Genuine Nissan PSF II or equivalent. Refer to MA-11, “Fluids and Lubricants”.

NHST0003

ST-2

Page 36

PREPARATION

Special Service Tools

Special Service Tools

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

KV48100700

(J26364)

Torque adapter

KV48102500

(J33914)

Pressure gauge adapter

ST27180001

(J25726-A)

Steering wheel puller

Description

Measuring pinion rotating torque

NT169

Measuring oil pressure

NT542

Removing steering wheel

NHST0004

GI

MA

EM

LC

EC

FE

AT

AX

HT72520000

(J25730-B)

Ball joint remover

KV48103500

(J26357 and J26357-

10)

Pressure gauge

KV48104400

(—)

Rack seal ring reformer

NT544

NT546

NT547

NT550

Removing ball joint

a: 33 mm (1.30 in)

b: 50 mm (1.97 in)

r: R11.5 mm (0.453 in)

Measuring oil pressure

Reforming teflon ring

a: 50 mm (1.97 in) dia.

b: 36 mm (1.42 in) dia.

c: 100 mm (3.94 in)

SU

BR

RS

BT

HA

SC

EL

IDX

ST-3

Page 37

Special Service Tools (Cont’d)

Tool number

(Kent-Moore No.)

Tool name

Description

PREPARATION

ST3127S000

1 GG91030000

(See J25765-A)

Torque wrench

2 HT62940000

(—)

Socket adapter

3 HT62900000

(—)

Socket adapter

Tool number Description

Oil pump attachment

NT541

NT774

Measuring turning torque

Commercial Service Tool

Disassembling and assembling oil pump

Unit: mm (in)

NHST0005

ST-4

Page 38

×: Applicable

Judder ×××××××

Symptom STEERING

Noise ЧЧЧЧЧЧЧЧЧ ЧЧЧЧЧЧ

Shake ××× ЧЧЧЧЧЧ

Vibration ЧЧЧЧЧ ××××

Shimmy ××× × ЧЧЧЧЧ

SUSPECTED PARTS

Possible cause and

Reference page

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

ST-5

Fluid level

Air in hydraulic system

Tie-rod ball joint swinging force

Tie-rod ball joint rotating torque

Tie-rod ball joint end play

Steering gear fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness or tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

ST-7

ST-7

ST-19

ST-19

ST-19

ST-7

ST-6

ST-8

MA-13

—

ST-10

ST-6

ST-14

ST-13

ST-15

AX-3

AX-3

SU-4

SU-4

SU-4

BR-7

NVH Troubleshooting Chart

NVH Troubleshooting Chart

NHST0006S01

NHST0006

IDX

EL

SC

HA

BT

RS

BR

SU

AX

AT

FE

EC

LC

EM

MA

GI

Page 39

Checking Steering Wheel Play

ON-VEHICLE SERVICE

SST489B

SST490BA

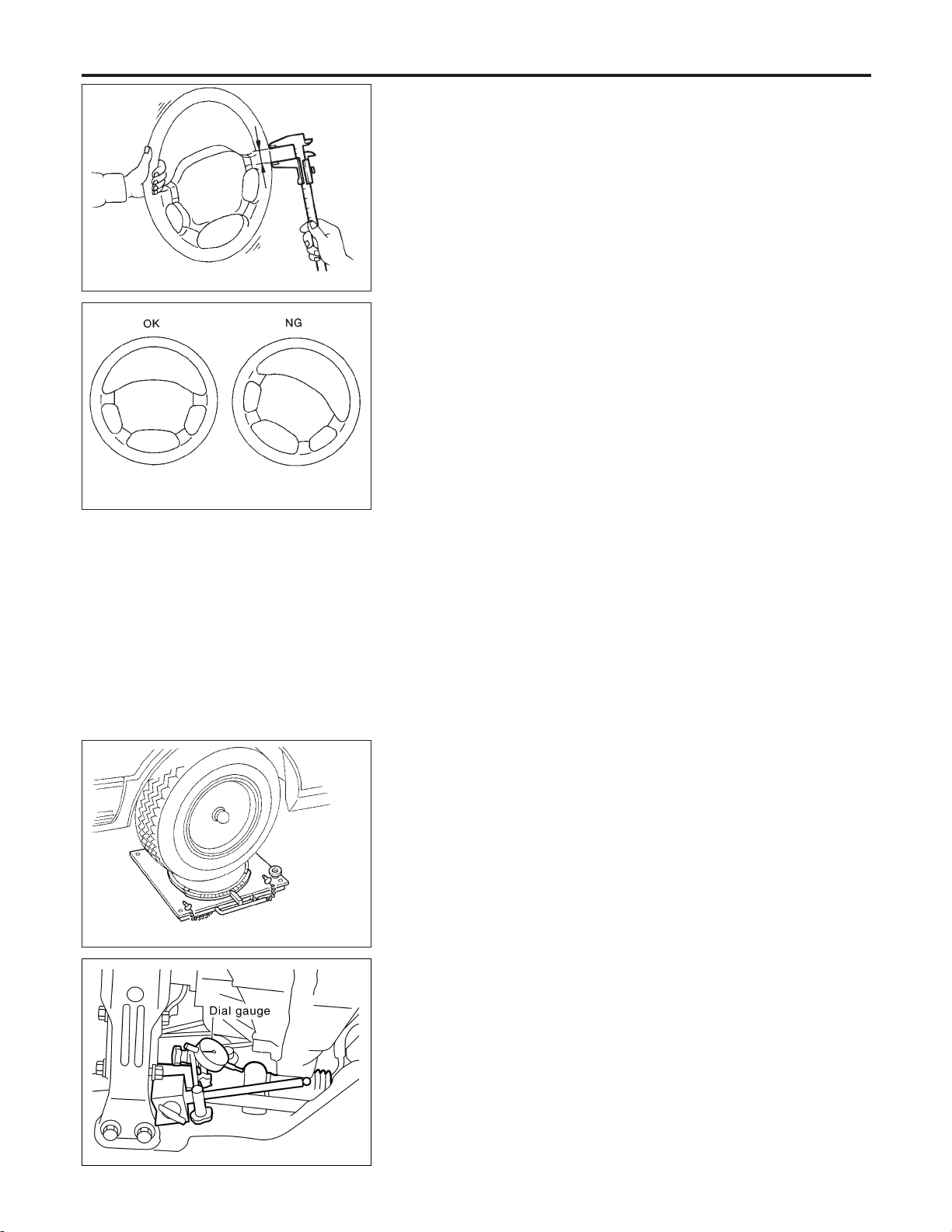

Checking Steering Wheel Play

NHST0007

! With wheels in a straight-ahead position, check steering wheel

play.

Steering wheel play:

35 mm (1.38 in) or less

! If it is not within specification, check the following for loose or

worn components.

Steering gear assembly

Steering column

Front suspension and axle

Checking Neutral Position on Steering Wheel

PRE-CHECKING

NHST0008

NHST0008S01

! Make sure that wheel alignment is correct.

Wheel alignment:

Refer to SU-16, SDS.

! Verify that the steering gear is centered before removing the

steering wheel.

CHECKING

NHST0008S02

1. Check that the steering wheel is in the neutral position when

driving straight ahead.

2. If it is not in the neutral position, remove the steering wheel and

reinstall it correctly.

3. If the neutral position is between two teeth, loosen tie-rod lock

nuts. Turn the tie-rods by the same amount in opposite directions on both left and right sides.

SMA127

SST849C

Front Wheel Turning Angle

NHST0009

1. Rotate steering wheel all the way right and left; measure turning angle.

Turning angle of full turns:

Refer to SU-16, SDS.

2. If it is not within specification, check rack stroke.

Rack stroke “S”:

Refer to SDS, ST-30.

Checking Gear Housing Movement

NHST0010

1. Check the movement of steering gear housing during stationary steering on a dry paved surface.

! Apply a force of 49 N (5 kg, 11 lb) to steering wheel to check

the gear housing movement.

Turn off ignition key while checking.

Movement of gear housing:

±2 mm (±0.08 in) or less

2. If movement exceeds the limit, replace mount insulator after

confirming proper installation of gear housing clamps.

ST-6

Page 40

ON-VEHICLE SERVICE

Checking and Adjusting Drive Belts

SST850C

SST851C

Checking and Adjusting Drive Belts

Refer to MA-13, “Checking Drive Belts”.

Checking Fluid Level

Check fluid level, referring to the scale on reservoir tank.

Use “HOT” range for fluid temperatures of 50 to 80°C (122 to

176°F).

Use “COLD” range for fluid temperatures of 0 to 30°C (32 to 86°F).

CAUTION:

! Do not overfill.

! Recommended fluid is Genuine Nissan PSF II or equiva-

lent. Refer to MA-11, “Fluids and Lubricants”.

Checking Fluid Leakage

Check the lines for improper attachment and for leaks, cracks,

damage, loose connections, chafing and deterioration.

1. Run engine between idle speed and 1,000 rpm.

Make sure temperature of fluid in oil tank rises to 60 to 80°C

(140 to 176°F).

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each “lock” position for five seconds

and carefully check for fluid leakage.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

4. If fluid leakage at connectors is noticed, loosen flare nut and

then retighten.

Do not overtighten connector as this can damage O-ring,

washer and connector.

5. If fluid leakage from power steering pump is noticed, check

power steering pump. Refer to ST-25.

6. Check rack boots for accumulation of power steering fluid.

NHST0011

NHST0012

NHST0013

GI

MA

EM

LC

EC

FE

AT

AX

SU

BR

RS

BT

HA

SC

Bleeding Hydraulic System

1. Raise front end of vehicle until wheels are clear of the ground.

2. Add fluid into oil tank to specified level. Then quickly turn steering wheel fully to right and left and lightly touch steering stoppers.

Repeat steering wheel operation until fluid level no longer

decreases.

3. Start engine.

Repeat step 2. above.

! Incomplete air bleeding will cause the following to occur. When

this happens, bleed air again.

NHST0014

ST-7

EL

IDX

Page 41

Bleeding Hydraulic System (Cont’d)

ON-VEHICLE SERVICE

a) Air bubbles in reservoir tank

b) Clicking noise in oil pump

c) Excessive buzzing in oil pump

Fluid noise may occur in the valve or oil pump. This is common

when the vehicle is stationary or while turning the steering wheel

slowly. This does not affect the performance or durability of the

system.

SST491B

SST090B

Checking Steering Wheel Turning Force

NHST0015

1. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating temperature. [Make sure temperature of fluid is approximately 60 to

80°C (140 to 176°F).]

Tires need to be inflated to normal pressure.

4. Check steering wheel turning force when steering wheel has

been turned 360° from the neutral position.

Steering wheel turning force:

39 N (4 kg, 9 lb) or less

5. If steering wheel turning force is out of specification, check

rack sliding force.

a. Disconnect steering column lower joint and knuckle arms from

the gear.

b. Start and run engine at idle to make sure steering fluid has

reached normal operating temperature.

c. Pull tie-rod slowly to move it from neutral position to ±11.5 mm

(±0.453 in) at speed of 3.5 mm (0.138 in)/s. Check that rack

sliding force is within specification.

Average rack sliding force:

216 - 284 N (22 - 29 kg, 49 - 64 lb)

Maximum force deviation:

98 N (10 kg, 22 lb)

d. Check sliding force outside the above range at rack speed of

40 mm (1.75 in)/s.

Rack sliding force:

Not more than 294 N (30 kg, 66 lb)

Maximum force deviation:

147 N (15 kg, 33 lb)

6. If rack sliding force is not within specification, overhaul steering gear assembly.

7. If rack sliding force is OK, inspect steering column. Refer to

ST-13.

ST-8

Page 42

ON-VEHICLE SERVICE

Checking Hydraulic System

SST834-F

Checking Hydraulic System

Before starting, check belt tension, driving pulley and tire pressure.

1. Set Tool. Open shut-off valve. Then bleed air. Refer to “Bleeding Hydraulic System”, ST-7.

2. Run engine at idle speed or 1,000 rpm.

Make sure temperature of fluid in tank rises to 60 to 80°C (140

to 176°F).

WARNING:

Warm up engine with shut-off valve fully opened. If engine is

started with shut-off valve closed, fluid pressure in oil pump

increases to maximum. This will raise oil temperature abnormally.

3. Check pressure with steering wheel fully turned to left and right

positions with engine idling at 1,000 rpm.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

Oil pump maximum standard pressure:

8,140 - 8,728 kPa (83 - 89 kg/cm

! If pressure reaches maximum operating pressure, system is

OK.

! If pressure increases above maximum operating pressure,

check power steering pump flow control valve. Refer to ST-25.

4. If power steering pressure is below the maximum operating

pressure, slowly close shut-off valve and check pressure

again.

CAUTION:

Do not close shut-off valve for more than 15 seconds.

! If pressure increases to maximum operating pressure, gear is

damaged. Refer to “Removal and Installation”, ST-16.

! If pressure remains below maximum operating pressure, pump

is damaged. Refer to “Disassembly”, ST-26.

5. After checking hydraulic system, remove Tool and add fluid as

necessary. Then completely bleed air out of system. Refer to

ST-7.

2

, 1,180 - 1,266 psi)

NHST0016

GI

MA

EM

LC

EC

FE

AT

AX

SU

BR

RS

ST-9

BT

HA

SC

EL

IDX

Page 43

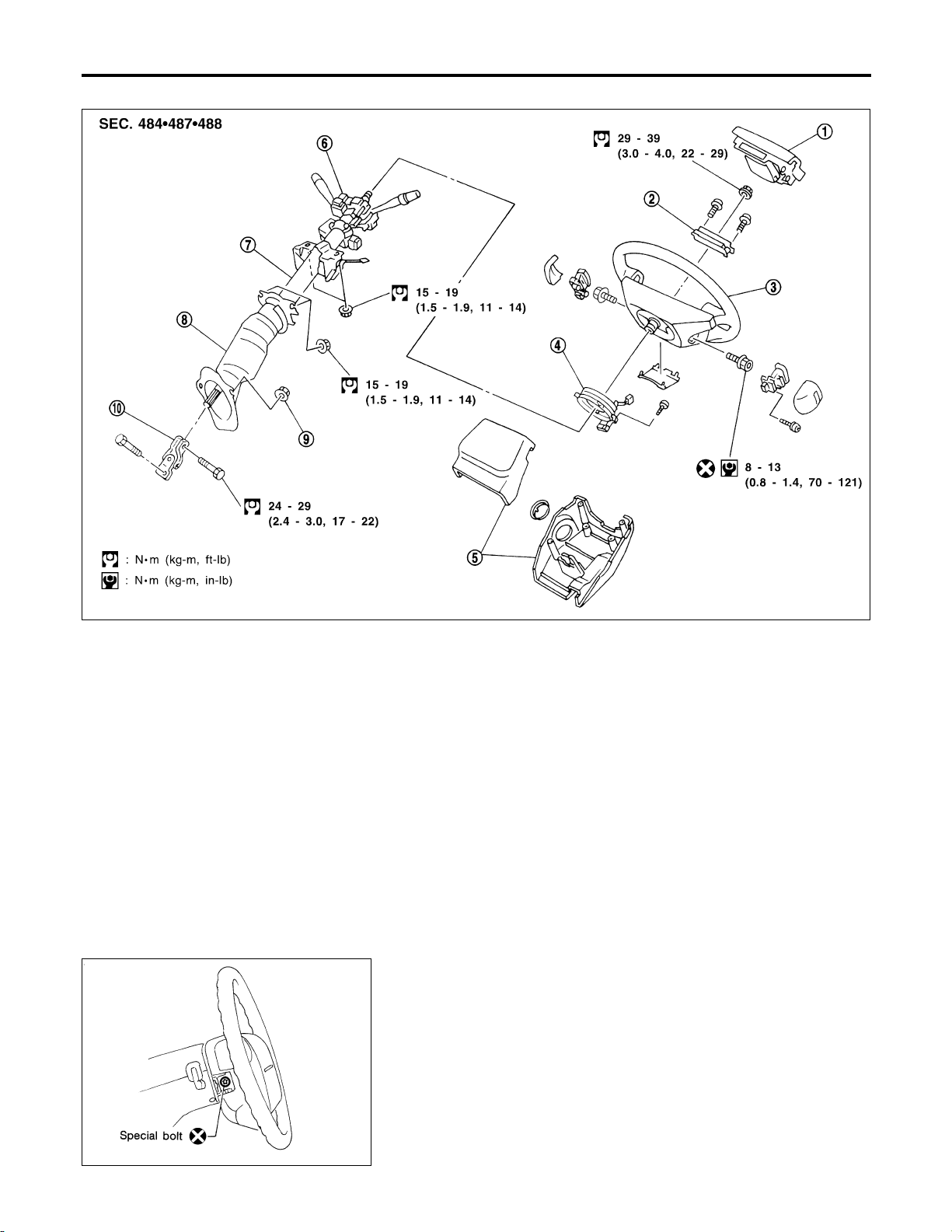

Components

STEERING WHEEL AND STEERING COLUMN

Components

NHST0017

1. Air bag module

2. Damper

3. Steering wheel

4. Spiral cable

5. Column cover

6. Combination switch

7. Steering column assembly

8. Boot

9. Clip

10. Lower joint

CAUTION:

! The rotation of the spiral cable (SRS “Air bag” component

part) is limited. If the steering gear must be removed, set

the front wheels in the straight-ahead direction. Do not

rotate the steering column while the steering gear is

removed.

! Remove the steering wheel before removing the steering

lower joint to avoid damaging the SRS spiral cable.

Removal and Installation

STEERING WHEEL

! Remove air bag module and spiral cable.

Refer to RS-20, “Removal — Air Bag Module and Spiral Cable”.

SST852C

NHST0018

NHST0018S01

SBF812E

ST-10

Page 44

STEERING WHEEL AND STEERING COLUMN

Removal and Installation (Cont’d)

! Align spiral cable correctly when installing steering wheel.

a) Set the front wheels in the straight-ahead position.

b) Make sure that the spiral cable is in the neutral position.

The neutral position is detected by turning left 2.5 revolutions

from the right end position. Align the two marks (

CAUTION:

The spiral cable may snap due to steering operation if the

cable is installed in an improper position.

Also, with the steering linkage disconnected, the cable may

snap by turning the steering wheel beyond the limited number

of turns. (The spiral cable can be turned up to 2.5 turns from

the neutral position to both the right and left.)

).

GI

MA

EM

LC

EC

FE

AT

SRS266

SST853C

SST329C

! Remove damper for steering wheel.

! Remove steering wheel with Tool.

STEERING COLUMN

! Remove key interlock cable.

! When installing steering column, fingertighten all lower bracket

and clamp retaining bolts; then tighten them securely. Do not

apply undue stress to steering column.

! When attaching coupling joint, be sure tightening bolt faces

cutout portion.

NHST0018S02

AX

SU

BR

RS

BT

HA

SC

EL

IDX

SST800A

ST-11

Page 45

STEERING WHEEL AND STEERING COLUMN

Removal and Installation (Cont’d)

! Align slit of lower joint with projection on dust cover. Insert joint

until surface A contacts surface B.

CAUTION:

After installation, turn steering wheel to make sure it moves

smoothly. Ensure the number of turns are the same from the

straight forward position to left and right locks. Be sure that

the steering wheel is in a neutral position when driving

straight ahead.

SST491C

ST-12

Page 46

STEERING WHEEL AND STEERING COLUMN

Disassembly and Assembly

Disassembly and Assembly

=NHST0019

GI

MA

EM

LC

EC

FE

AT

AX

1. Combination switch

2. Lock nut

3. Jacket tube assembly

4. Tilt lever

5. Tilt lever stopper

6. Steering column mounting bracket

7. Spring

8. Adjust bolt

9. Adjust bolt stopper

! When disassembling and assembling, unlock steering lock

with key.

! Remove combination switch.

! Install lock nut on steering column shaft and tighten the nut.

10. Nut

11. Column shaft assembly

12. Steering column lower cover

13. Lower joint

SU

SST854CA

BR

RS

BT

HA

SC

EL

IDX

SST490C

ST-13

Page 47

STEERING WHEEL AND STEERING COLUMN

Disassembly and Assembly (Cont’d)

! Steering lock

a) Break self-shear type screws with a drill or other appropriate

tool.

SST741A

b) Install new self-shear type screws and then cut off self-shear

type screw heads.

SST742A

SST855C

Inspection

NHST0020

! When steering wheel does not turn smoothly, check the steer-

ing column as follows and replace damaged parts.

a) Check column bearings for damage or unevenness. Lubricate

with recommended multi-purpose grease or replace steering

column as an assembly, if necessary.

b) Check jacket tube for deformation or breakage. Replace if

necessary.

! When the vehicle comes into a light collision, check length “L”.

Steering column length “L”:

542 - 544 mm (21.34 - 21.42 in)

If out of the specifications, replace steering column as an assembly.

SST582B

TILT MECHANISM

NHST0020S01

! After installing steering column, check tilt mechanism opera-

tion.

ST-14

Page 48

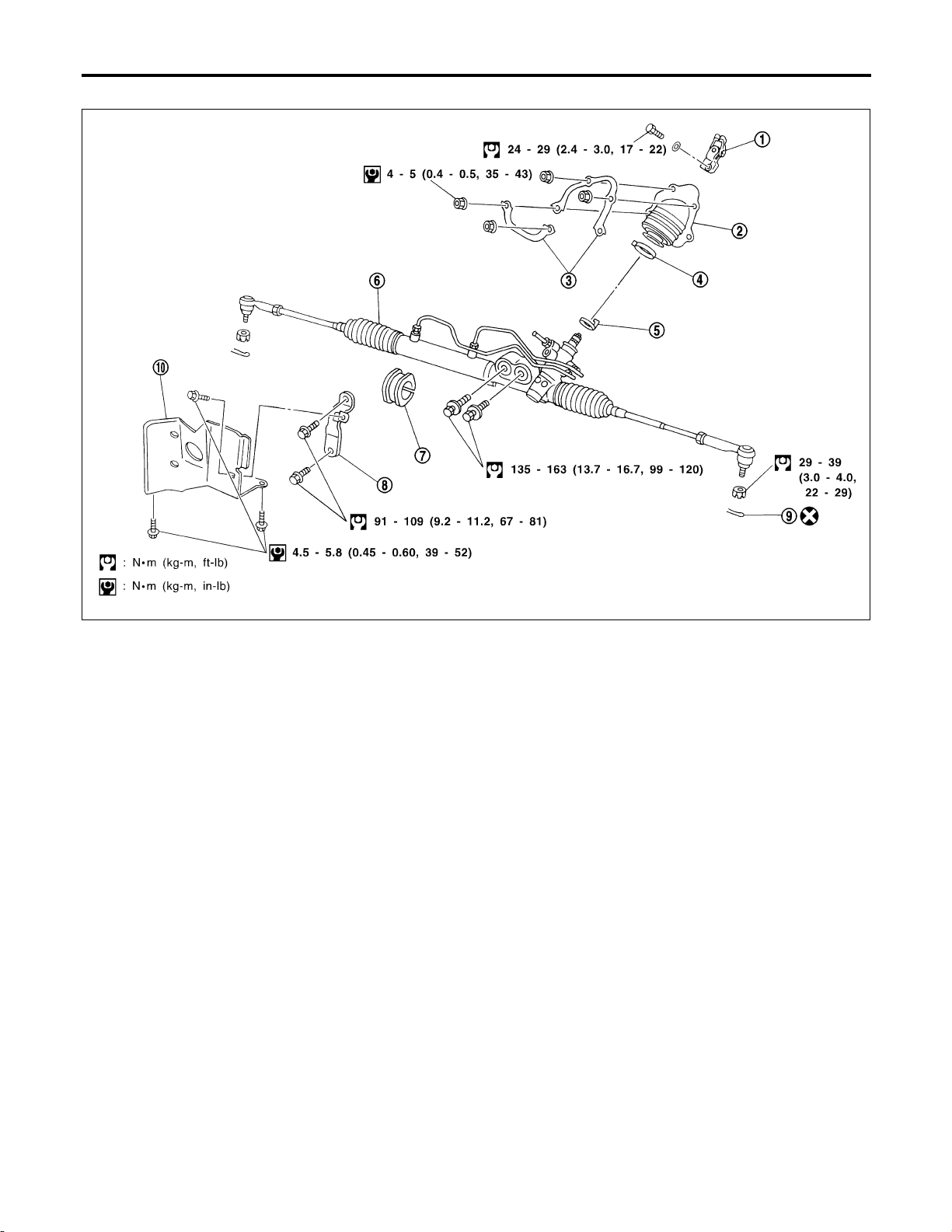

POWER STEERING GEAR AND LINKAGE

Components

Components

NHST0021

GI

MA

EM

LC

EC

FE

AT

AX

1. Rear cover cap

2. Gear sub-assembly

3. O-ring

4. Shim

5. Lock nut

6. Adjusting screw

7. Spring

8. Diaphragm spring

9. Washer

10. Spring seat

11. Retainer

12. Gear housing

13. Center bushing

14. Rack oil seal

15. Rack assembly

16. Rack seal ring

17. O-ring

18. Rack oil seal

19. End cover assembly

20. Boot band

21. Dust boot

22. Boot band

23. Spacer ring

24. Lock plate

25. Tie-rod inner socket

26. Tie-rod outer socket

27. Cotter pin

28. Gear housing tube

SU

BR

RS

BT

HA

SC

SST856C

EL

IDX

ST-15

Page 49

Removal and Installation

POWER STEERING GEAR AND LINKAGE

Removal and Installation

NHST0022

1. Lower joint

2. Hole cover

3. Insulator bracket

4. Clamp

5. Rear cover cap

6. Gear and linkage assembly

7. Rack mounting insulator

SST857C

8. Gear housing mounting bracket

9. Cotter pin

10. Heat insulator

ST-16

Page 50

POWER STEERING GEAR AND LINKAGE

Removal and Installation (Cont’d)

CAUTION:

! The rotation of the spiral cable (SRS “Air bag” component

part) is limited. If the steering gear must be removed, set

the front wheels in the straight-ahead direction. Do not

rotate the steering column while the steering gear is

removed.

! Remove the steering wheel before removing the steering

lower joint to avoid damaging the SRS spiral cable.

! Detach tie-rod outer sockets from knuckle arms with Tool.

1. Remove front exhaust tube. Refer to FE-11, “Removal and

SFA455BC

Installation”.

2. Set a suitable transmission jack under transaxle.

3. Remove center member and rear engine mounting. Refer to

EM-57, “Removal”.

4. Remove front stabilizer bar. Refer to SU-12, “Removal and

Installation”.

5. Remove steering gear assembly.

GI

MA

EM

LC

EC

FE

AT

SST858C

SST859C

! Install pipe connector.

! Observe specified tightening torque when tightening high-pres-

sure and low-pressure pipe connectors. Excessive tightening

will damage threads of connector or O-ring.

Connector tightening torque:

1 Low-pressure side

27 - 39 N·m (2.8 - 4.0 kg-m, 20 - 29 ft-lb)

2 High-pressure side

15 - 25 N·m (1.5 - 2.5 kg-m, 11 - 18 ft-lb)

! The O-ring in low-pressure pipe connector is larger than that

in high-pressure connector. Take care to install the proper

O-ring.

! Initially, tighten nut on tie-rod outer socket and knuckle arm to

29 to 39 N·m (3 to 4 kg-m, 22 to 29 ft-lb). Then tighten further

to align nut groove with first pin hole so that cotter pin can be

installed.

CAUTION:

Tightening torque must not exceed 49 N·m (5 kg-m, 36 ft-lb).

AX

SU

BR

RS

BT

HA

SC

EL

IDX

SST824A

ST-17

Page 51

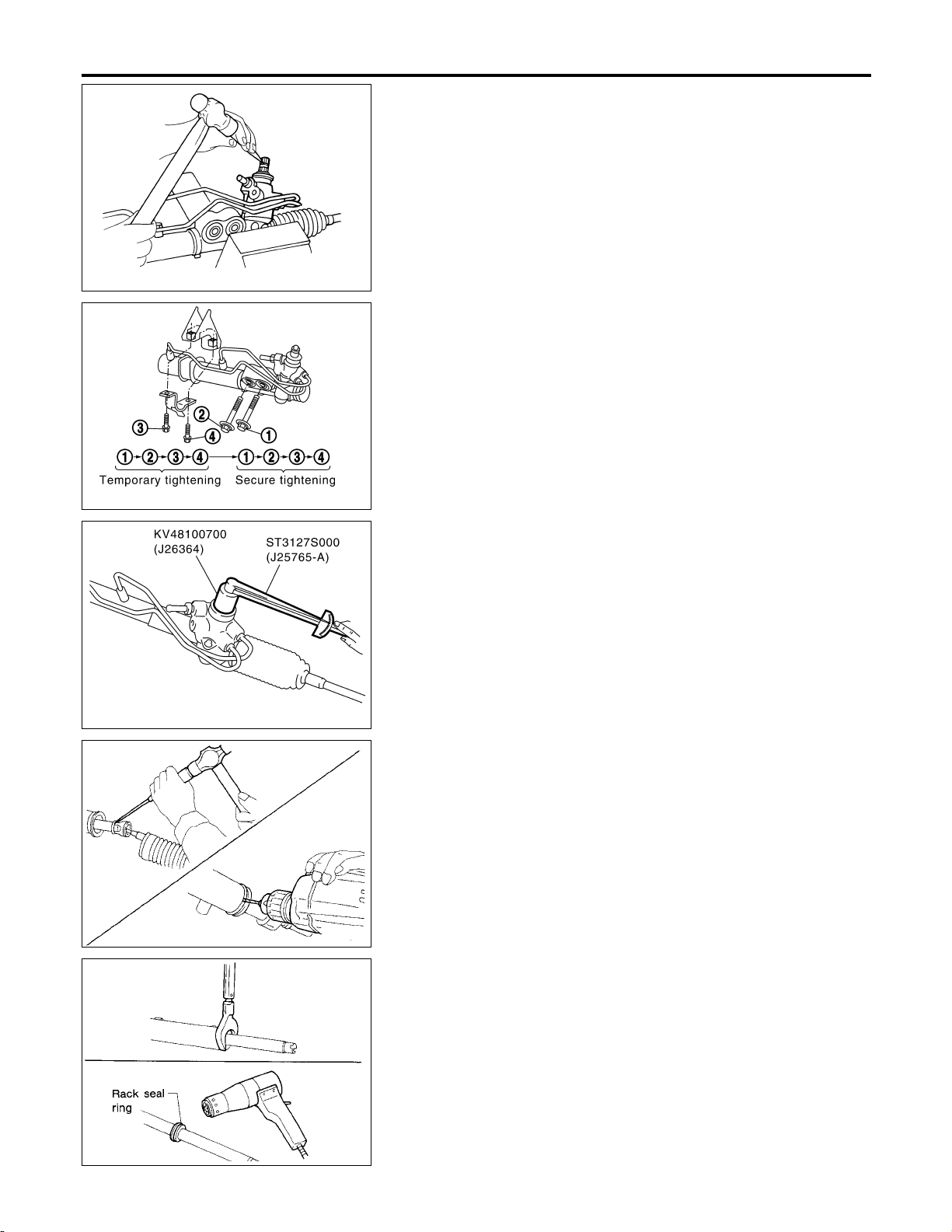

POWER STEERING GEAR AND LINKAGE

Removal and Installation (Cont’d)

! Before removing lower joint from gear, set gear in neutral

(wheels in straight-ahead position). After removing lower joint,

put matching mark on pinion shaft and pinion housing to record

neutral position.

! To install, set left and right dust boots to equal deflection.

Attach lower joint by aligning matching marks of pinion shaft

and pinion housing.

SST860C

! Tighten gear housing mounting bracket bolts in the order

shown.

SST861C

SST862C

SST051C

Disassembly

NHST0023

1. Prior to disassembling, measure pinion rotating torque. Record

the pinion rotating torque as a reference.

! Before measuring, disconnect gear housing tube and

drain fluid.

! Use soft jaws when holding steering gear housing. Handle

gear housing carefully, as it is made of aluminum. Do not

grip cylinder in a vise.

2. Remove gear sub-assembly, O-ring and shim.

Gear sub-assembly cannot be disassembled. If it is faulty,

replace with a new one.

3. Remove tie-rod outer sockets and boots.

4. Loosen tie-rod inner socket by prying up staked portion, and

remove socket and spacer.

5. Remove retainer.

6. Use a 2 to 2.5 mm (0.079 to 0.098 in) diameter drill to completely remove staked portion of gear housing end.

7. Remove end cover assembly with a suitable tool.

8. Draw out rack assembly.

9. Remove rack seal ring.

! Using a heat gun, heat rack seal to approximately 40°C

(104°F).

! Remove rack seal ring.

Be careful not to damage rack.

SST052C

ST-18

Page 52

POWER STEERING GEAR AND LINKAGE

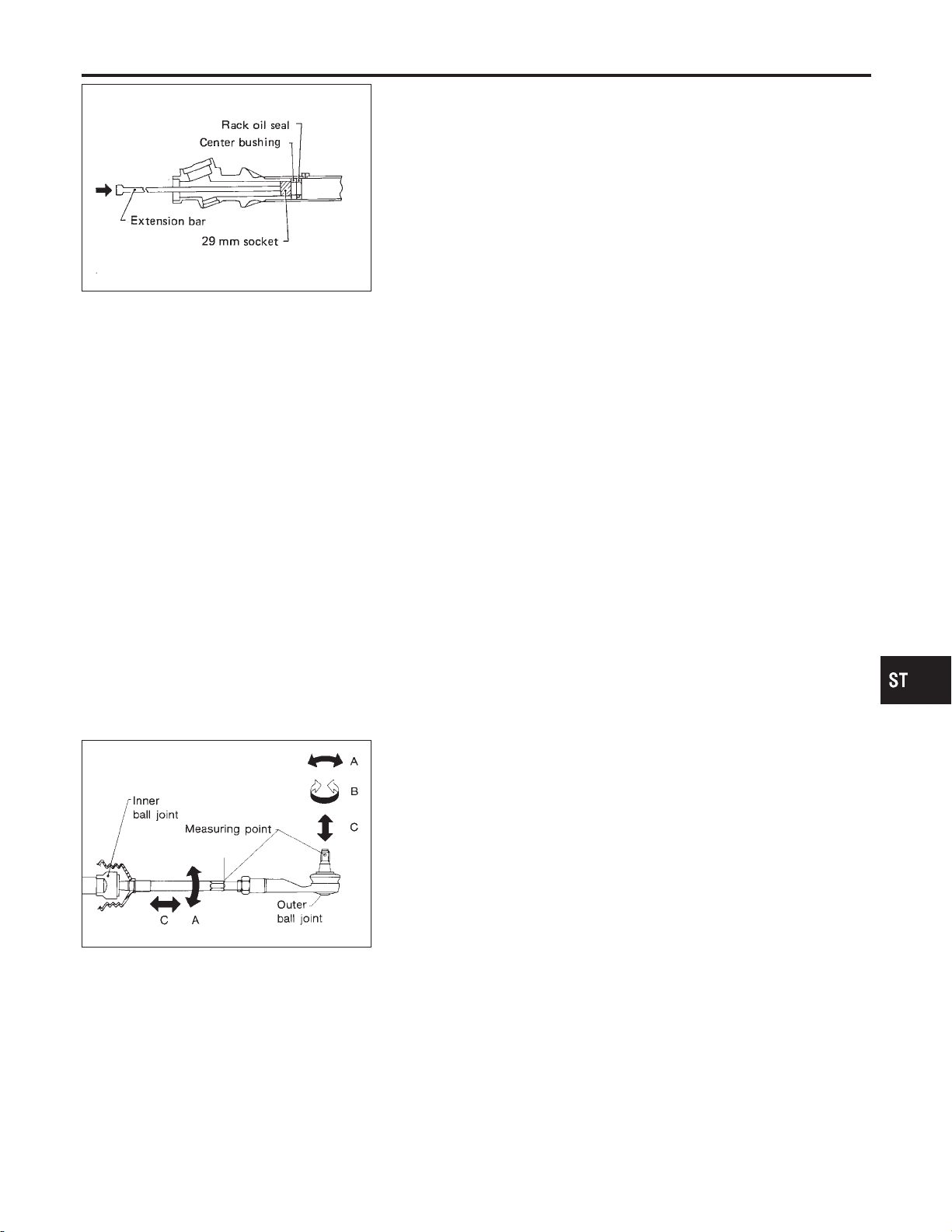

10. Remove center bushing and rack oil seal using tape wrapped

socket and extension bar.

Do not scratch inner surfaces of pinion housing.

SST472A

Disassembly (Cont’d)

GI

MA

EM

SST468C

Inspection

Thoroughly clean all parts in cleaning solvent or Genuine NISSAN

PSF II or equivalent. Blow dry with compressed air, if available.

BOOT

! Check condition of boot. If cracked excessively, replace it.

! Check boots for accumulation of power steering fluid.

RACK

Thoroughly examine rack gear. If damaged, cracked or worn,

replace it.

GEAR SUB-ASSEMBLY

! Check pinion gear. If it is worn or damaged, replace as a gear

sub-assembly.

! Manually spin bearing. If torque variations or free play are

noted, replace as a gear sub-assembly.

GEAR HOUSING CYLINDER

Check gear housing cylinder bore for scratches or other damage.

Replace if necessary.

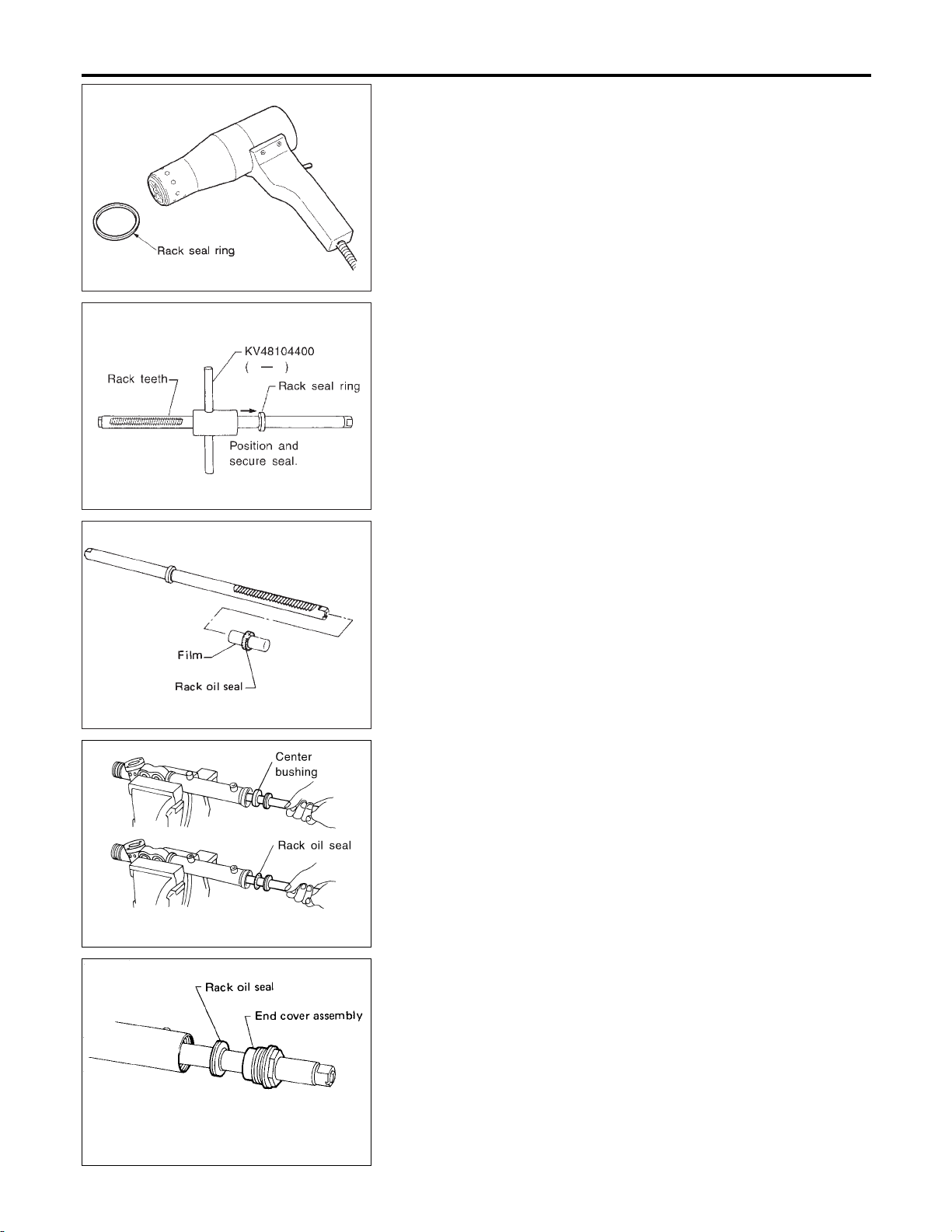

TIE-ROD OUTER AND INNER SOCKETS

! Check ball joints for swinging force.

Tie-rod outer and inner ball joints swinging force “A”:

Refer to SDS, ST-30.

! Check ball joint for rotating torque.

Tie-rod outer ball joint rotating torque “B”:

Refer to SDS, ST-30.

! Check ball joints for axial end play.

Tie-rod outer and inner ball joints axial end play “C”:

Refer to SDS, ST-30.

! Check condition of dust cover. If cracked excessively, replace

outer tie-rod.

NHST0024

NHST0024S01

NHST0024S02

NHST0024S03

NHST0024S04

NHST0024S05

LC

EC

FE

AT

AX

SU

BR

RS

BT

HA

SC

EL

IDX