Page 1

https://truckmanualshub.com/

EC Declaration of conformity - update 05/01/’10

1. We hereby declare that the following machine comply with the machine directive 2006/42/EC,

EMC-directive 2004/108/EC, Non-road mobile machinery emission directive 97/68/EC (amended by

2002/88/EC, 2004/26/EC, 2006/105/EC) and noise emission 2000/14/EC (amended by 2005/88/EC).

Forklifts Model :

Serial Nr. :

2. Manufacturer Hyundai Heavy Industries Co. Ltd.

1 Chonha-Dong, Dong-Ku

Ulsan

The republic of Korea

Authorized representative :

Owner of the technical fi le for

machine production.

(TCF : Technical Construction File)

3. Harmonized European directives : ISO3691-1.3, ISO 20898:2008, EN ISO 2867:2008

4. Noise level :

Certain n˚ :

Date :

Conformity assessment procedure :

Authorized entity :

Engine power :

Guaranteed sound power level :

Hyundai Heavy Industries Europe N.V.

Vossendal 11

2440 Geel

Belgium

e13*2000/14*2005/88*0059*08

2009-06-17

Attachment VIII following the periodical inspection on technical

extended with “Information on the scope of delivery” by TÜV

Rheinland.

Société Nationale de Certification et d’Homologation s.à r.l

CE0499 11, route de Luxembourg

5230 Sandweiler

Luxemburg

*** kW

*** dB (A)

*******

***

5. Remarks

*****

Managing Director

Geel, Belgium

**/**/****

Page 2

Lift trucks are specialized machines with unique operating characteristics, designed to perform a specific

job. Their function and operation is not like a car or ordinary truck. They require specific instructions

and rules for safe operation and maintenance.

Safe operation of lift trucks is of primary importance to HYUNDAI.

Our experience with lift truck accidents has shown that when accidents happen and people are killed or

injured, the causes are:

ÂÂ

Operator not properly trained

Â

Operator not experienced with lift truck operation

ÂÂ

Basic safety rules not followed

Â

Lift truck not maintained in safe operating condition

For these reasons, HYUNDAI wants you to know about the safe operation and correct maintenance of

your lift truck.

This manual is designed to help you operate your lift truck safely.

This manual shows and tells you about safety inspections and the important general safety rules and

hazards of lift truck operation. It describes the special components and features of the truck and

explains their function. The correct operating procedures are shown and explained. Illustrations and

important safety messages are included for clear understanding. A section on maintenance and

lubrication is included for the lift truck mechanic.

The operator's manual is not a training manual. It is a guide to help trained and authorized operators

safety operate their lift truck by emphasizing and illustrating the correct procedures. However, it cannot

cover every possible situation that may result in an accident. You must watch for hazards in your work

areas and avoid or correct them. It is important that you know and understand the information in this

manual and that you know and follow your company safety rules!

Be sure that your equipment is maintained in a safe condition. Do not operate a damaged or

malfunctioning truck. Practice safe operation every time you use your lift truck. Let's join together to set

high standards in safety.

Remember, before you start operating this lift truck, be sure you understand all driving procedures. It is

your responsibility, and it is important to you and your family, to operate your lift truck safely and

efficiently.

Be aware that the Federal Occupational S

afety and Health Act(OSHA) and state laws require

that operators be completely trained in the safe operation of lift trucks; It is also an (OSHA)

requirement that a machine inspection be performed before every shift. If you need training in

operating or inspecting your lift truck, ask your supervisor.

HYUNDAI lift trucks are built to take hard work, but not abuse. They are built to be dependable, but they

are only as safe and efficient as the operator and the persons responsible for maintaining them. Do not

make any repairs to this truck unless you have been trained in safe lift truck repair procedures and are

authorized by your employer.

This manual describes procedures for operation, handling, lubrication, maintenance, checking and

adjustment. It will help the operator realize peak performance through effective, economical and safe

machine operation.

A MESSAGE TO HYUNDAI LIFT TRUCK OPERATORS

0-1

https://truckmanualshub.com/

Page 3

HYUNDAI welcomes you to the growing group of professionals who own, operate and maintain

HYUNDAI lift trucks. We take pride in the long tradition of quality products and superior value the

HYUNDAI name represents. This manual familiarizes you with safety, operating, and maintenance

information about your new lift truck. It has been specially prepared to help you use and maintain your

HYUNDAI lift truck in a safe and correct manner.

Your HYUNDAI lift truck has been designed and built to be as safe and efficient as today's technology

can make it. As manufactured, for some models, it meets all the applicable mandatory requirements of

ANSI B56.1-1988 Safety Standard for Powered Industrial Trucks. Some trucks are also furnished with

equipment to help you operate safety; for example, load back rest, parking brake and horn are standard

equipment.

Safe, productive operation of a lift truck requires both skill and knowledge on the part of the operator.

The operator must know, understand, and practice the safety rules and safe driving and load handling

techniques described in this manual. To develop the skill required, the operator must become familiar

with the construction and features of the lift truck and how they function, the operator must understand

its capabilities and limitations, and see that it is kept in a safe condition.

Routine Servicing and Maintenance

Regular maintenance and care of your lift truck is not only important for economy and utilization

reasons; it is essential for your safety. A faulty lift truck is a potential source of danger to the operator,

and to other personnel working near it. As with all quality equipment, keep your lift truck in good

operating condition by following the recommended schedule of maintenance.

Operator Daily Inspection - Safety and Operating Checks

A lift truck should always be examined by the operator, before driving, to be sure it is safe to operate.

The importance of this procedure is emphasized in this manual with a brief illustrated review and later

with more detailed instructions. HYUNDAI dealers can supply copies of a helpful

Dri

vers Daily

Checklist.

It is an OSHA requirement.

Planned Maintenance

In addition to the daily operator inspection, HYUNDAI recommends that a planned maintenance and

safety inspection program(PM) be performed by a trained and authorized mechanic on a regular basis.

The PM will provide an opportunity to make a thorough inspection of the safety and operating condition

of your lift truck. Necessary adjustments and repairs can be done during the PM, which will increase the

life of components and reduce unscheduled downtime and increase safety. The PM can be scheduled

to meet your particular application and lift truck usage.

The procedures for a periodic planned maintenance program that covers inspections, operational

checks, cleaning, lubrication, and minor adjustments are outlined in this manual. Your HYUNDAI dealer

is prepared to help you with a Planned Maintenance Program by trained service personnel who know

your lift truck and can keep it operating safely and efficiently.

Service Manual

In-depth service information for trained service personnel is found in Service Manual.

INTRODUCTION

0-2

https://truckmanualshub.com/

Page 4

This manual is a digest of essential information about the safe operation, the features and functions and

explains how to maintain your lift truck. This manual is organized into nine major parts:

Section 1. Safety hints

, reviews and illustrates accepted practices for safe operation of a lift truck.

Section 2. Operating Hazards

, warns of conditions that could cause damage to the truck or injury to

the operator or other personnel.

Section 3. Know Your Truck

, describes the major operating components, systems, controls, and other

features of your truck and tells how they function.

Section 4. Operator Maintenance and Care

, presents details on how to perform the operator's daily

safety inspection and refuel the lift truck.

Section 5. Starting and Operating Procedures

, discusses specific instructions on the safe, efficient

operation of your lift truck.

Section 6. Emergency Starting and Towing

, gives instructions for towing your truck in an emergency

and for using battery jumper cables to start your truck in an emergency.

Section 7. Planned Maintenance and Lubrication

, describes the PM (Planed Maintenance) program.

Section 8. Specifications

, provides reference information and data on features, components, and

maintenance items.

Section 9. Troubleshooting

, provides trouble symptoms, causes and methods of remedy.

Section10. Testing and Adjusting

, gives instructions for testing and adjusting.

ö

TThe descriptions and specifications included in this manual were in effect at the time of printing.

HYUNDAI reserves the right to make improvements and changes in specifications or design, without

notice and without incurring obligation. Please check with your authorized HYUNDAI dealer for

information on possible updates or revisions.

The examples, illustrations, and explanations in this manual should help you improve your skill and

knowledge as a professional lift truck operator and take full advantage of the capabilities and safety

features of your new lift truck.

The first section of the manual is devoted to a review, with illustrations and brief messages, of general

safety rules and the major operating hazards you can encounter while operating a lift truck. Next, you

will find description's of the components of your specific lift truck model and how the instruments,

gauges, and controls operate. Then, you will find a discussion of safe and efficient operating

procedures, followed by instruction's on how to tow a disabled lift truck. The later sections of the manual

are devoted to maintenance and truck specifications.

Take time to carefully read the

Know Your Truck

section. By acquiring a good basic understanding of

your truck's features, and how they function, you are better prepared to operate it both efficiently and

safely.

In

Planned Maintenance

, you will find essential information for correct servicing and periodic

maintenance of your truck, including charts with recommended maintenance intervals and component

capacities. Carefully follow these instructions and procedures.

Each major section has its own table of contents, so that you can find the various topics more easily.

HOW TO USE THIS MANUAL

0-3

https://truckmanualshub.com/

Page 5

We urge you to first carefully read the manual from cover to cover. Take time to read and understand

the information on general safety rules and operating hazards. Acquaint yourself with the various

procedures in this manual. Understand how all gauges, indicator lights, and controls function. Please

contact your authorized HYUNDAI dealer for the answers to any questions you may have about your lift

truck's features, operation, or manuals.

Operate your lift truck safely; careful driving is your responsibility.

Drive defensively and think about the safety of people who are working nearby. Know your truck's

capabilities and limitations. Follow all instructions in this manual, including all symbols( ) and

messages to avoid damage to your lift truck or the possibility of any harm to yourself or others.

This manual is intended to be a permanently attached part of your lift truck. Keep it on the truck as a

ready reference for anyone who may drive or service it. If the truck you operate is not equipped with a

manual, ask your supervisor to obtain one and have it attached to the truck. And, remember, your

HYUNDAI dealer is pleased to answer any questions about the operation and maintenance of your lift

truck and will provide you with additional information should you require it.

ö

I

Illustrations may differ from your machine, but they are applicable to your machine.

ö

0-4

https://truckmanualshub.com/

Page 6

Â

Noise level (2000/14/EC and EN 12053) are as followings.

EC REGULATION APPROVED

Model

15D/18D/20DA-7E

20D/25D/30D/33D-7E

20DF/25DF/30DF/33DF-7, 35DF-7

35D/40D/45D-7E, 50D-7AE

35DS/40DS/45DS/50DA-7E

50D/60D/70D-7E, 80D-7E

50DF/60DF/70DF-7

50DS/60DS/70DS-7E

LPA

81

dB

80

dB

80

dB

82

dB

82

dB

82

dB

82

dB

82

dB

LWA(EU only)

101

dB

103

dB

103

dB

106

dB

106

dB

107

dB

107

dB

107

dB

Â

The value of vibrations transmitted by the operator's seat are lower than standard value of

(2002/44/EC)

0-5

https://truckmanualshub.com/

Page 7

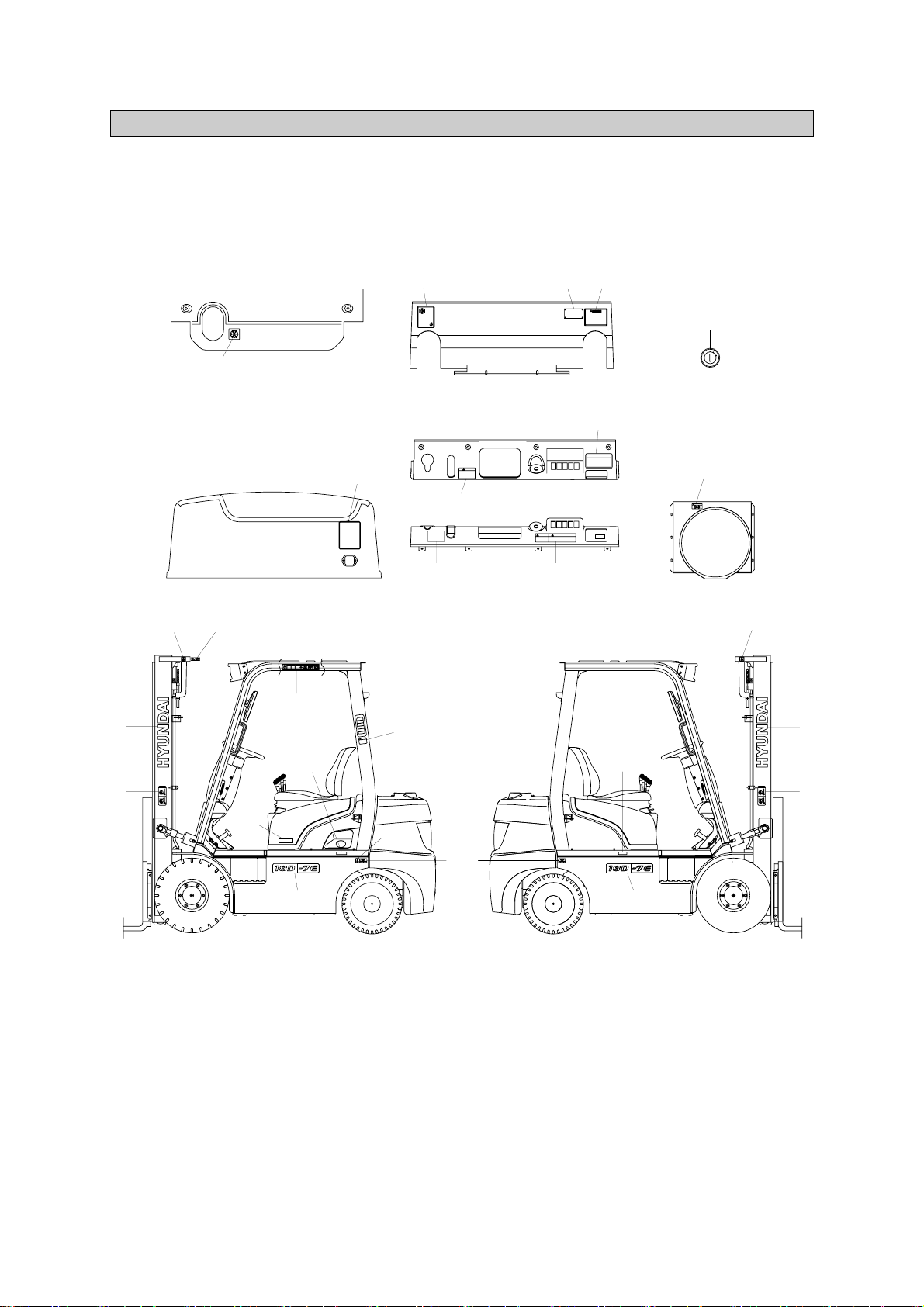

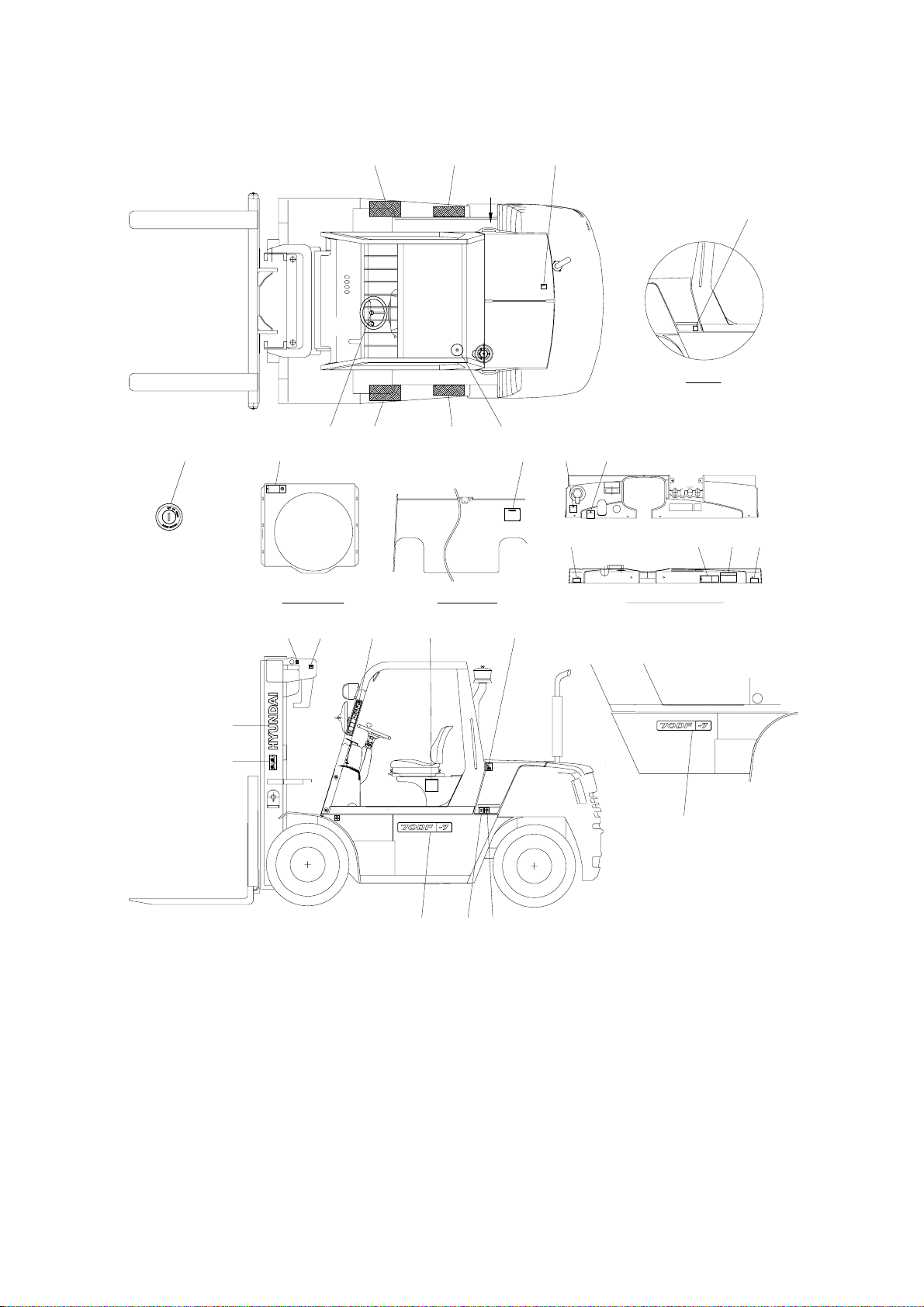

1. LOCATION

Always keep these labels clean. If they are lost or damaged, attach them again or replace them with

new labels.

15D/18D/20DA-7E

SAFETY LABELS

0-6

1 Logo

2 Warning plate

3 Tire caution

4 Air intake

5 Start key

6 Radiator & fan

8 Hydraulic oil

10 Start warning

11 Hand caution

12 Diesel fuel

13 Temperature

14 Parking brake

15 Warning safety

16 Hook

17 Safety instruction

18 Brake fluid

20 Model name

21 Noise

22 Load chart

23 Label(UL)

24 Name plate(CE)

25 Name plate(UL)

26 Fuse

27 Bonnet cover

START SWITCH

5

12

15

11

16

1

2

20

8

20

1

2

16

27

3

10

18

14

DASHBOARD COVER

DASHBOARD

SUB BONNET

BONNET

FAN SHROUD

17

6

24

,

25

13

22

21

16

4

23

26

15D7EOM101

1)

https://truckmanualshub.com/

Page 8

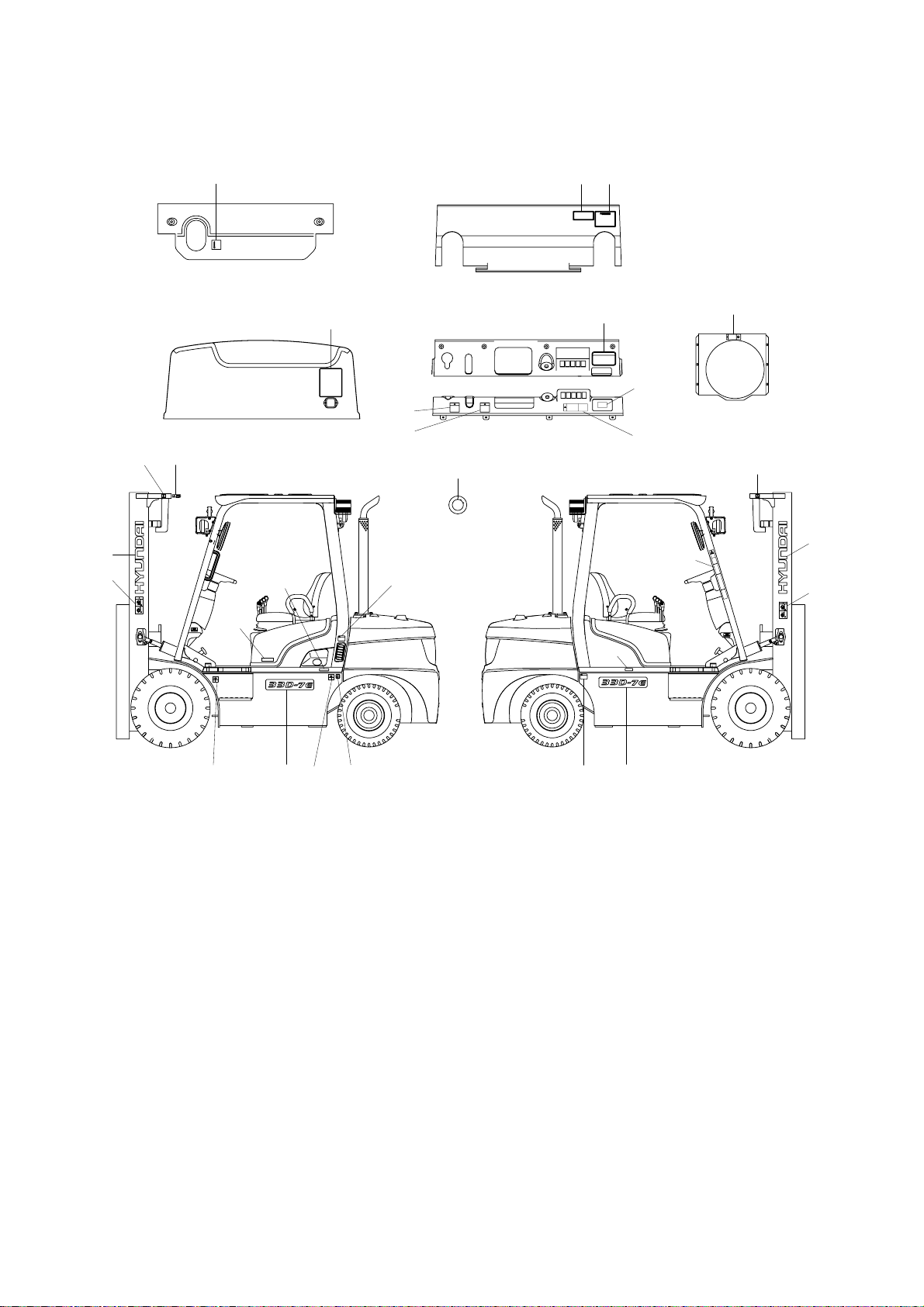

20D/25D/30D/33D-7E

TRAVEL power can be shutdown

When an operator leaves more than 3seconds

without parking and neutral position.

SAFETY INSTRUCTION

ENGINE AIR INTAKE

KEEP WATER AND OTHER

FOREIGN MATERIALS OUT.

A

B

C

D

91FJ-00180

91FP-00340

A

B

C

D

91FP-00340

SUB BONNET

13

BONNET

22

DASHBOARD

DASHBOARD COVER

FAN SHROUD

17

14

18

10

6

START SWITCH

5

16

11

1

2

15

12

20

24, 25

8

LOAD CAPACITY CHART

16

2

1

16

3

3

26

27

20

4

3

23

20D7EOM101

2)

0-7

1 Logo

2 Warning plate

3 Tire caution

4 Air intake

5 Start key

6 Radiator & fan

8 Hydraulic oil

10 Start warning

11 Hand caution

12 Diesel fuel

13 Temperature

14 Parking brake

15 Warning safety

16 Hook

17 Safety instruction

18 Brake fluid

20 Model name

21 Noise

22 Load chart

23 Label(UL)

24 Name plate(CE)

25 Name plate(UL)

26 Fuse

27 Bonnet cover

https://truckmanualshub.com/

Page 9

20DF/25DF/30DF/33DF-7, 35DF-7

91FP-00340

A

B

C

D

13

22

5

16

11

1

2

14

18

9

26

17

24, 25

6

FAN SHROUD

27

3 20 12 3 16

8

BONNET

DASH BOARDSUB BONNET

DASH BOARD COVER

START SWITCH

15

21

4

23

35DFOM101

3)

1 Logo

2 Warning plate

3 Tire caution

4 Air intake

5 Start key

6 Radiator & fan

8 Hydraulic oil

10 Start warning

11 Hand caution

12 Diesel fuel

13 Temperature

14 Parking brake

15 Warning safety

16 Hook

17 Safety instruction

18 Brake fluid

20 Model name

21 Noise

22 Load chart

23 Label(UL)

24 Name plate(CE)

25 Name plate(UL)

26 Fuse box

27 Bonnet cover

0-8

https://truckmanualshub.com/

Page 10

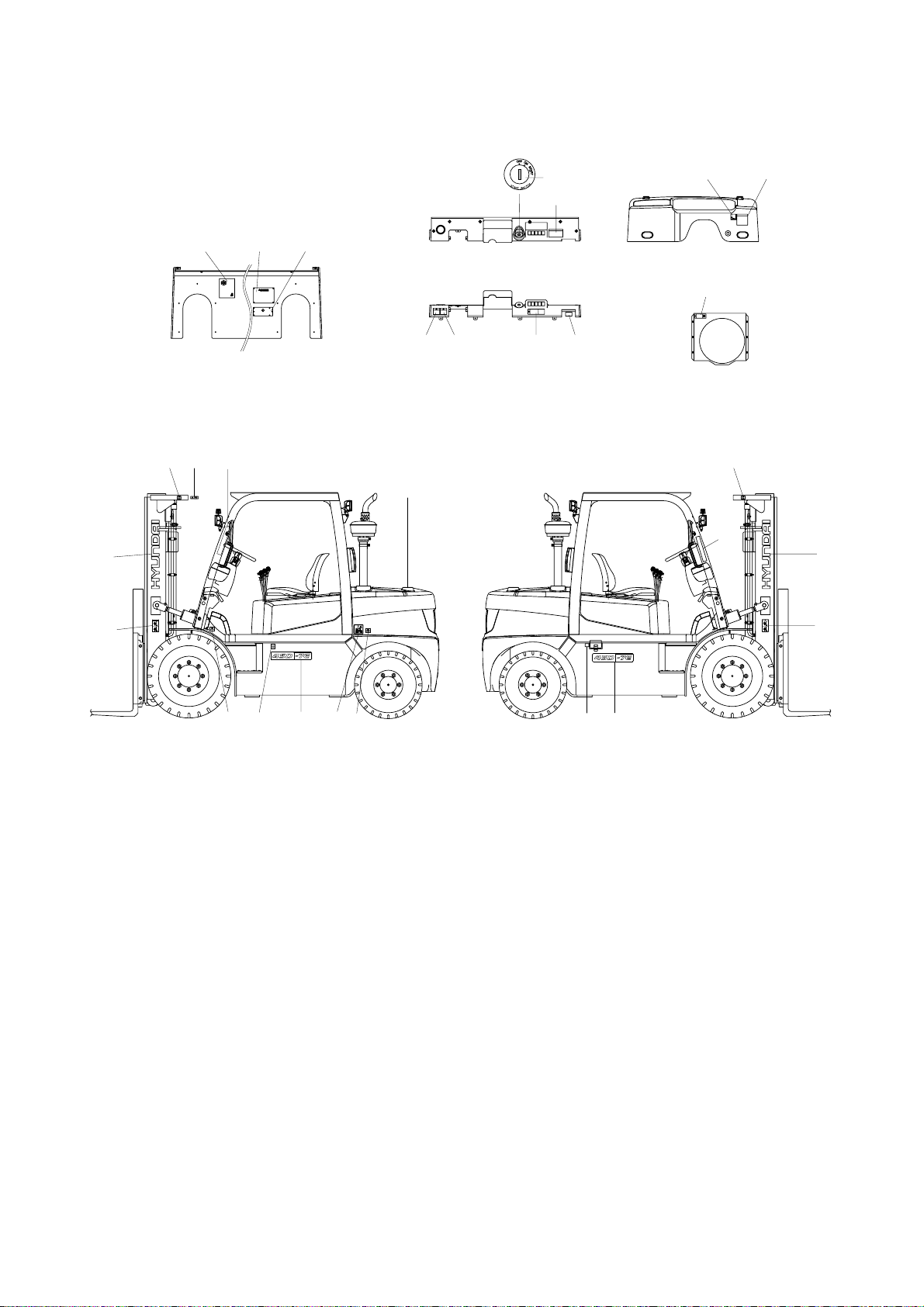

35D/40D/45D-7E, 50D-7AE, 35DS/40DS/45DS/50DA-7E

5

16

11

1

2

15

29

8

25

18

28

6

22

10

14

12

20

20

1

2

16

13

91FP-00340

91FP-00340

15

BONNET

FAN SHROUD

DASH BOARD

DASH BOARD COVER

26

21

24

23,

17

3

3

35D7EOM101

4)

0-9

1 Logo

2 Warning plate

3 Tire caution

5 Start key

6 Radiator & fan

8 Hydraulic oil

10 Start warning

11 Hand caution

12 Diesel fuel

13 Temperature

14 Parking brake

15 Warning safety

16 Hook

17 Safety instruction

18 Brake fluid

20 Model name

21 Noise

22 Load chart

23 Label(UL)

24 Name plate(CE)

25 Name plate(UL)

26 Fuse

28 Engine room

29 Hanger

https://truckmanualshub.com/

Page 11

50D/60D/70D-7E, 80D-7E

5

10

6

14

FAN SHROUD

PARKING BRAKE

DASH BOARD COVER

32 12 19

13

32 1931

HEAD GUARD

22

21

23

25

15 16

1

2

26

28

16

20

28

17

2083

16

3

1

2

16 11

30

28

24

80D7EOM101

5)

0-10

1 Logo

2 Warning plate

3 Tire caution

5 Start key

6 Radiator cap & fan

8 Hydraulic oil

10 Start warning

11 Hand caution

12 Fuel

13 Temperature

14 Parking brake

15 Warning safety

16 Hook

17 Safety instruction

19 No step

20 Model name

21 Noise

22 Load chart

23 Label-UL

24 Name plate (CE)

25 Name plate (UL)

26 Fuse

28 Engine room

30 Cab tilting warning

31 Accumulator

32 Safety work

https://truckmanualshub.com/

Page 12

50DS/60DS/70DS-7E

25

10

14

24

,

26

23

21

17

18

START SWITCH

5

DASHBOARD COVER

DASHBOARD

FAN SHROUD

6

13

3

22

8

11

20

1

2

29

16

15

2

11

16

1

20

3

12

31

50DS7EOM101

6)

1 Logo

2 Warning plate

3 Tire caution

5 Start key

6 Radiator & fan

8 Hydraulic oil

10 Start warning

11 Hand caution

12 Diesel

13 Temperature

14 Parking brake

15 Warning safety

16 Hook

17 Safety instruction

18 Brake fluid

20 Model name

21 Noise

22 Load chart

23 Label(UL)

24 Name plate(CE)

25 Name plate(UL)

26 Fuse

29 Hanger

31 Accumulator

0-11

https://truckmanualshub.com/

Page 13

50DF/60DF/70DF-7

DASH BOARDFAN SHROUD DASH BOARD COVER

VIEW A

32 32 13

12

A

26 32 32 31

5 6 24 18 14

10 17 2121

16 11

1

2

15 22

20

20

19

83

50DF7OM101

7)

1 Logo

2 Warning plate

3 Tire caution

5 Start key

6 Radiator cap & fan

8 Hydraulic oil

10 Start warning

11 Hand caution

12 Fuel

13 Temperature

14 Parking brake

15 Warning safety

16 Hook

17 Safety instruction

18 Brake fluid wet

19 Hanger

20 Model name

21 Grease

22 Load capacity

24 Name plate (CE)

26 Sound

31 Accumulator

32 Safety work

0-12

https://truckmanualshub.com/

Page 14

2. DESCRIPTION

There are several specific warning labels on this machine please become familiarized with all warning

labels. Item numbers are based on the 15D/18D/20DA-7E

Replace any safety label that is damaged, or missing.

WARNING PLATE

(item 2)

This warning label is positioned on the both

side of the mast.

Never stand or work under the raised

forks even if the hydraulic safety lock

lever is

applied.

In case of working under the forks, it is

essential to support the carriage with

blocks.

1)

TEMPERATURE

(item 13)

This warning label is positioned on the left

of top side of sub bonnet.

Coolant must be checked as specified in

the maintenance chart.

2)

0-13

053

+07

20DE0FW06

25L7A0OM06

https://truckmanualshub.com/

053

+07

㷔,

92SB-00250

㶊

Page 15

RADIATOR CAP & FAN

(item 6)

This warning label is positioned on the

cooling fan shroud of the radiator to warn of

the danger or injury from spinning fan

blades and forbid to open the filler cap of

the radiator because operator might get

scalded due to spouting of hot water. When

the engine is running. Be sure that you keep

your hands, fingers, arms, and clothing

away from a spinning fan. Don't stand in line

with a spinning fan. Fan blades can break at

excessively high RPM and be thrown out of

the engine compartment.

Never open the filler cap while engine

running or at high coolant temperature.

3)

25L7A0OM07

HAND CAUTION

(item 11)

This label is positioned on respectively near

the front fender and the rear fender of the

left side of the main frame.

It warns of the danger of injury from

move m ent betw e en rails , c hains,

sheaves, fork carr

iage, and other parts of

the mast assembly. Do not climb on or

reach into the mast. Personal injury wil

l

result if any part of your body is put

between moving parts of the mast.

4)

TIRE CAUTION

(item 3)

This label is positioned on both side of main

frame.

Tire p ressure m ust be chec k ed in

accordance with the maintenance chart.

Refer to page 5-3

for the regulated tire

air pressure(A and B).

5)

35DEOM103

20DEOM104

0-14

https://truckmanualshub.com/

Page 16

0-15

50D7EFW04

CABIN TILTING WARNING

(item 30)

This warning label is positioned on the left

top side of the frame.

Refe r to p age 7- 28 fo r safe tilt i ng

procedures.

7)

HOOK (

item 16)

This warning label is positioned respectively

on the both top side of mast and near rear

tire of the both side of the main frame.

Ref er to page 7-5 9 f or safe loading

procedures.

6)

92FT-40640

50DEOM35

SAFETY INSTRUCTION

(item 17)

This warning label is positioned on the

dashboard cover if the truck is for USA or

equipped with *

OPSS

.

This forklift is equipped with an operator

exis t ence sensing syst e m pe r

ANSI/

ASME B56.1-7.21.10 / 7.21.11 and

ASME ISO 3691.

Powered travel movement of the truck shall

be possible only if the operator is in the

normal operating position. Transmission will

automatically shift to neutral upon the exiting

of the operator.

The forward/reverse lever must be cycled

through neutral with the operator in the

normal operating position to regain powered

direction control.

8)

1.

2.

25L7A0OM02

OPSS : Operator Presence Sensing System

https://truckmanualshub.com/

Page 17

PARKING BRAKE

(item 14)

This warning plate is located on the right

side of the parking brake lever.

Pull by sufficient tension for constant

parking ability.

11)

ö

SSTART WARNING

(item 10)

This warning and caution plate are located

on the right side of the dashboard cover.

Start key switch after 5~6 seconds from

ON posi t ion. I t n eeds appr o x 5 ~6

seconds to se

t correct position of throttle.

Warnings before leaving the operator seat.

Be sure to lower the attachment to the

ground.

Apply the parking brake.

Cautions before starting or operating the

truck.

Put the gear shift lever in the neutral.

Apply the brake.

Read this operator's manual carefully.

10)

ö

1.

2.

0-16

92AD-00920

P

5 6'

~

I

50DEFW55

25L7A0OM04

-

-

-

-

-

BRAKE FLUID

(item 18)

This warning label is located on the left side

of dashboard cover.

9)

25L7A0OM03

https://truckmanualshub.com/

Page 18

0-17

25L7AOM09-1

WARNING SAFETY

(item 15)

This warning label is positioned on the front

outside of overhead guard stay-LH.

Refer to operator's manual in detail.

Always buckle up the seat belt for safety

operation.

When the operator get off the machine,

always pull the parking brake lever so that

the machine can keep with stopping

condition.

The people should not pass through

under forks and other attachments which

are lifted or being lifted.

Do not jump down from the machine. It

can be caused that the operator have

severe injury or death in the event of a tip

over.

Outstretch the legs as widely as possible

and grasp firmly the steering handle.

Learn the body to the opposite direction

in order to avoid severe injury or death

when the machine is tipped over.

Refer to page 3-8 for details.

12)

Η

Θ

Ι

Κ

Λ

Μ

Ν

ö

NNOISE

(item 21)

This warning plate is located on the front

side of dashboard.

13)

35L7FW09

BONNET COVER

(item 27)

This decal is located on the left bottom side

of the bonnet cover.

Before open the bonnet cover, be sure to

open the cain rear doors.

14)

https://truckmanualshub.com/

1

2

3

4

5

6

7

Page 19

1. DIRECTION

GUIDE

The directions of this machine indicate forward,

backward, right and left when machine is in the

travelling direction.

Left

Right

Front

Rear

D255SM01

2. SERIAL NUMBER

Inform following when you order parts or the machine is out of order.

MACHINE SERIAL NUMBER

It's shown on front of the right side frame.

1)

D255SM02

Important safety hint

It indicates matters which can cause the great loss on the machine or the surroundings.

It indicates the useful information for operator

3. SYMBOLS

ö

0-18

https://truckmanualshub.com/

Page 20

CONTENTS

FOREWORD

A message to hyundai lift truck operators

------------------------------------------------------------

0-1

Introduction

-----------------------------------------------------------------------------------------------------------------

0-2

How to use this manual

--------------------------------------------------------------------------------------------

0-3

EC regulation approved

-------------------------------------------------------------------------------------------

0-5

Safety labels

---------------------------------------------------------------------------------------------------------------

0-6

Guide(Direction, Serial number, Symbols)

-----------------------------------------------------------

0-18

1. SAFETY HINTS

1. Daily inspection

-----------------------------------------------------------------------------------------------------

1-1

2. Do's and don'ts

------------------------------------------------------------------------------------------------------

1-2

3. Seat belts

---------------------------------------------------------------------------------------------------------------

1-4

4. No riders

-----------------------------------------------------------------------------------------------------------------

1-5

5. Pedestrians

------------------------------------------------------------------------------------------------------------

1-6

6. Operator protection

----------------------------------------------------------------------------------------------

1-7

7. Fork safety

-------------------------------------------------------------------------------------------------------------

1-8

8. Pinch points

-----------------------------------------------------------------------------------------------------------

1-9

9. Travel

-----------------------------------------------------------------------------------------------------------------------

1-10

10. Grades, ramps, slopes and inclines

------------------------------------------------------------------

1-11

11. Tip over

-------------------------------------------------------------------------------------------------------------------

1-12

12. Surface and capacity

-------------------------------------------------------------------------------------------

1-14

13. Parking

--------------------------------------------------------------------------------------------------------------------

1-15

14. Refueling

----------------------------------------------------------------------------------------------------------------

1-16

15. Step

-------------------------------------------------------------------------------------------------------------------------

1-17

16. Operator's safety rules

----------------------------------------------------------------------------------------

1-18

2. OPERATING HAZARDS

1. Loose loads

-----------------------------------------------------------------------------------------------------------

2-1

2. Long and wide loads

--------------------------------------------------------------------------------------------

2-2

3. Rear swing

-------------------------------------------------------------------------------------------------------------

2-2

4. Low overhead clearance

-------------------------------------------------------------------------------------

2-3

5. Fast turns and high loads

-----------------------------------------------------------------------------------

2-3

6. Drop-offs

----------------------------------------------------------------------------------------------------------------

2-4

7. Right angle stacking

---------------------------------------------------------------------------------------------

2-4

8. Chain slack

------------------------------------------------------------------------------------------------------------

2-5

9. Pallets and skids

---------------------------------------------------------------------------------------------------

2-5

10. Caution for electrical lines

----------------------------------------------------------------------------------

2-6

11. Lifting loads

------------------------------------------------------------------------------------------------------------

2-7

https://truckmanualshub.com/

Page 21

3. KNOW YOUR TRUCK

1. General locations

--------------------------------------------------------------------------------------------------

3-1

2. Data/safety plates and decals

----------------------------------------------------------------------------

3-7

3. Instruments and controls

------------------------------------------------------------------------------------

3-9

4. Indicator symbols

-------------------------------------------------------------------------------------------------

3-15

5. Operating lever and switch

---------------------------------------------------------------------------------

3-28

6. Others

---------------------------------------------------------------------------------------------------------------------

3-34

4. OPERATOR MAINTENANCE AND CARE

1. Daily safety inspection

-----------------------------------------------------------------------------------------

4-1

2. Fuel safety practices

--------------------------------------------------------------------------------------------

4-3

5. STARTING AND OPERATING PROCEDURES

1. Before operating the truck

----------------------------------------------------------------------------------

5-1

2. Check before starting

------------------------------------------------------------------------------------------

5-2

3. Check before starting engine

-----------------------------------------------------------------------------

5-3

4. Seat adjustment

----------------------------------------------------------------------------------------------------

5-8

5. Starting from a safe condition

----------------------------------------------------------------------------

5-9

6. General starting and operating tips

------------------------------------------------------------------

5-10

7. Starting the engine

-----------------------------------------------------------------------------------------------

5-11

8. Check after starting engine

--------------------------------------------------------------------------------

5-12

9. Levers and pedals

------------------------------------------------------------------------------------------------

5-14

10. Operating safely

----------------------------------------------------------------------------------------------------

5-16

11. Load handling

--------------------------------------------------------------------------------------------------------

5-18

12. Shut down procedure

-------------------------------------------------------------------------------------------

5-24

6. EMERGENCY STARTING AND TOWING

1. How to tow a disabled truck

----------------------------------------------------------------------------------

6-1

2. How to use battery jumper cables

-----------------------------------------------------------------------

6-3

7. PLANNED MAINTENANCE AND LUBRICATION

1. Introduction

------------------------------------------------------------------------------------------------------------

7-1

2. Safe maintenance practices

-------------------------------------------------------------------------------

7-2

3. Instructions before maintenance

-----------------------------------------------------------------------

7-5

4. Planned maintenance intervals

-------------------------------------------------------------------------

7-8

5. Maintenance chart

-----------------------------------------------------------------------------------------------

7-18

6. How to perform planned maintenance

-------------------------------------------------------------

7-25

7. Replacement and check

-------------------------------------------------------------------------------------

7-30

8. Lubrication chart

---------------------------------------------------------------------------------------------------

7-49

9. Greasing point

-------------------------------------------------------------------------------------------------------

7-52

https://truckmanualshub.com/

Page 22

10. Handling machine in extremely hot places

------------------------------------------------------

7-55

11. Cold weather operation

---------------------------------------------------------------------------------------

7-56

12. Storage

-------------------------------------------------------------------------------------------------------------------

7-57

13. Transport

----------------------------------------------------------------------------------------------------------------

7-58

14. Loading and unloading by crane

-----------------------------------------------------------------------

7-59

15. Recommendation table for lubricants

---------------------------------------------------------------

7-60

16. Fuel and lubricants

-----------------------------------------------------------------------------------------------

7-61

8. SPECIFICATIONS

1. Specification table

--------------------------------------------------------------------------------------------------

8-1

2. Specification for major components

-------------------------------------------------------------------

8-9

3. Tightening torque

---------------------------------------------------------------------------------------------------

8-29

9. TROUBLESHOOTING

1. Engine system

--------------------------------------------------------------------------------------------------------

9-1

2. Electrical system

----------------------------------------------------------------------------------------------------

9-2

3. Torque flow system

------------------------------------------------------------------------------------------------

9-3

4. Steering system

-----------------------------------------------------------------------------------------------------

9-7

5. Brake system

----------------------------------------------------------------------------------------------------------

9-8

6. Hydraulic system

----------------------------------------------------------------------------------------------------

9-10

10. TESTING AND ADJUSTING

1. Engine system

--------------------------------------------------------------------------------------------------------

10-1

2. Drive system

-----------------------------------------------------------------------------------------------------------

10-5

3. Travel system

----------------------------------------------------------------------------------------------------------

10-9

4. Steering system

-----------------------------------------------------------------------------------------------------

10-10

5. Adjustment of parking brake lever

----------------------------------------------------------------------

10-11

https://truckmanualshub.com/

Page 23

1-1

At the beginning of each shift, inspect your truck

and fill out a check, maintenance and lubrication

table.

Check for damage and maintenance problems.

Have repairs made before you operate the truck.

Do not make repairs yourself. Lift truck

mechanics are trained professionals. They know

how to make repairs safely.

1. SAFETY HINTS

1. DAILY INSPECTION

D35AOM01

https://truckmanualshub.com/

Page 24

1-2

Do watch for pedestrians.

2. DO'S AND DON'TS

D35AOM03

Do wear safety equipment when required.

D35AOM05

Don't mix drugs or alcohol with your job.

Don't block safety or emergency equipment.

D35AOM04

D35AOM02

Don't smoke in NO SMOKING areas or when refueling.

D35AOM06

https://truckmanualshub.com/

Page 25

1-3

Don't operate the truck outdoors in rainy day.

ö

EExclude the truck equipped cabin.

D35AOM07

Exhaust gas is dangerous.

Do not operate the truck at the inhouse, if possible.

Provide adequate ventilation when working in a closed space.

D35AOM08

https://truckmanualshub.com/

Page 26

1-4

3. SEAT BELTS

Seat belts can reduce injuries.

B207OM10

Alwa y s bu c kle u p for the machin e

equipped with safety belt.

D507OM09

https://truckmanualshub.com/

Page 27

1-5

D255OM11A

D255OM12A

4. NO RIDERS

The operator is the only one who should be

on a truck.

Never transport personnel on the forks of a

lift truck.

1)

2)

https://truckmanualshub.com/

Page 28

1-6

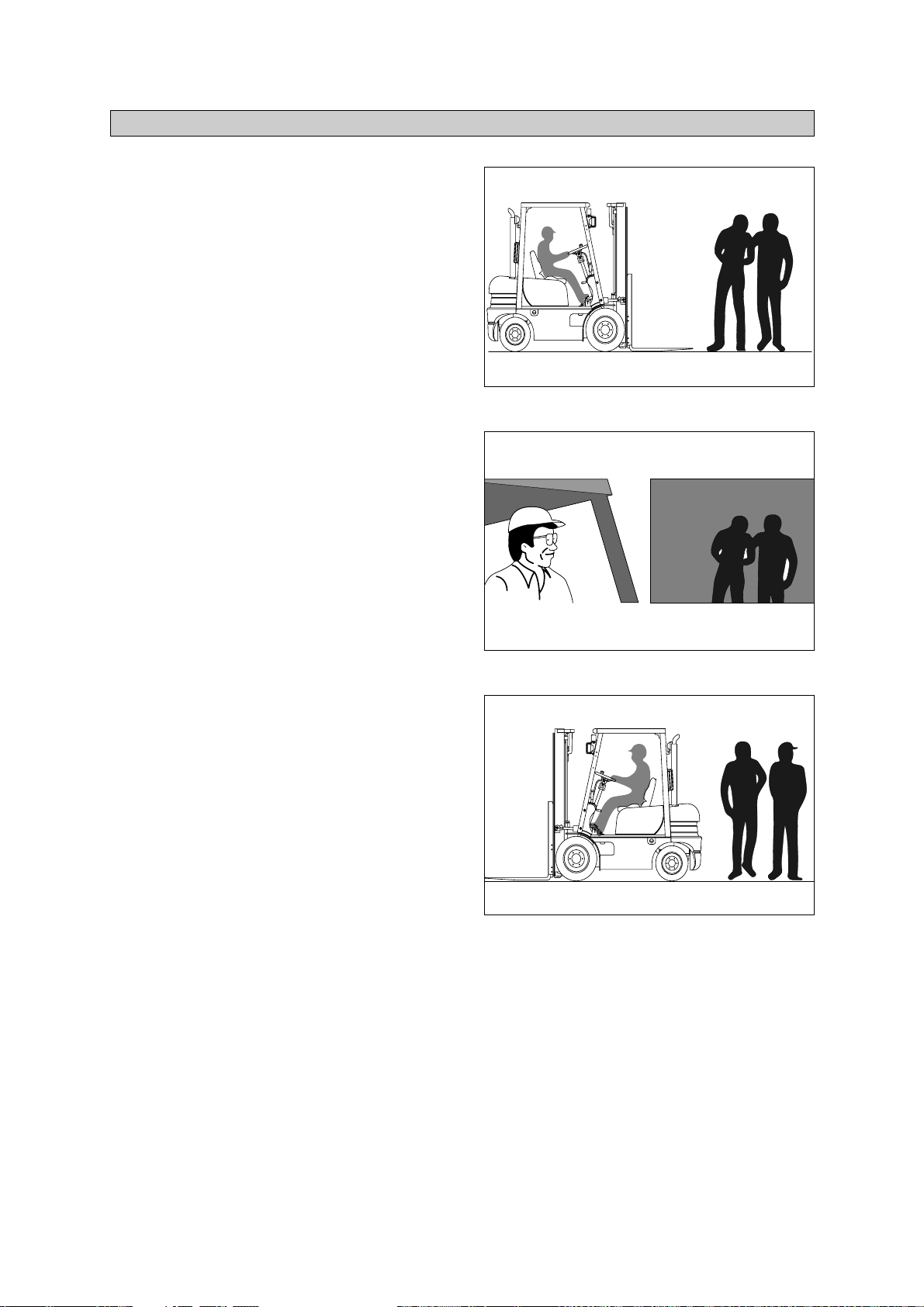

Watch where you are going. Look in the

direction of travel. Pedestrians may use the

same roadway you do. Sound your horn at

all intersections or blind spots.

D35AOM13

Watch for people in your work area even if

your truck has warning lights or alarms.

People may not watch for you.

D35AOM14

Watch for people standing back, even when

you are parked.

D35AOM15

5. PEDESTRIANS

1)

2)

3)

https://truckmanualshub.com/

Page 29

1-7

6. OPERATOR PROTECTION

D35AOM16

Keep under the overhead guard.

Always keep your body within the confines of

the truck.

Do not operate truck without overhead

guard, unless condition prevent use of a

guard.

1)

2)

https://truckmanualshub.com/

Page 30

1-8

Never allow anyone to walk under raised forks.

D255OM17A

There is special equipment to raise people for

overhead work.

DO NOT USE LIFT TRUCKS.

D255OM12A

Always lower the load slowly.

Raise and lower with mast vertical or tilted

slightly back(Never forward).

D255OM01

7. FORK SAFETY

https://truckmanualshub.com/

Page 31

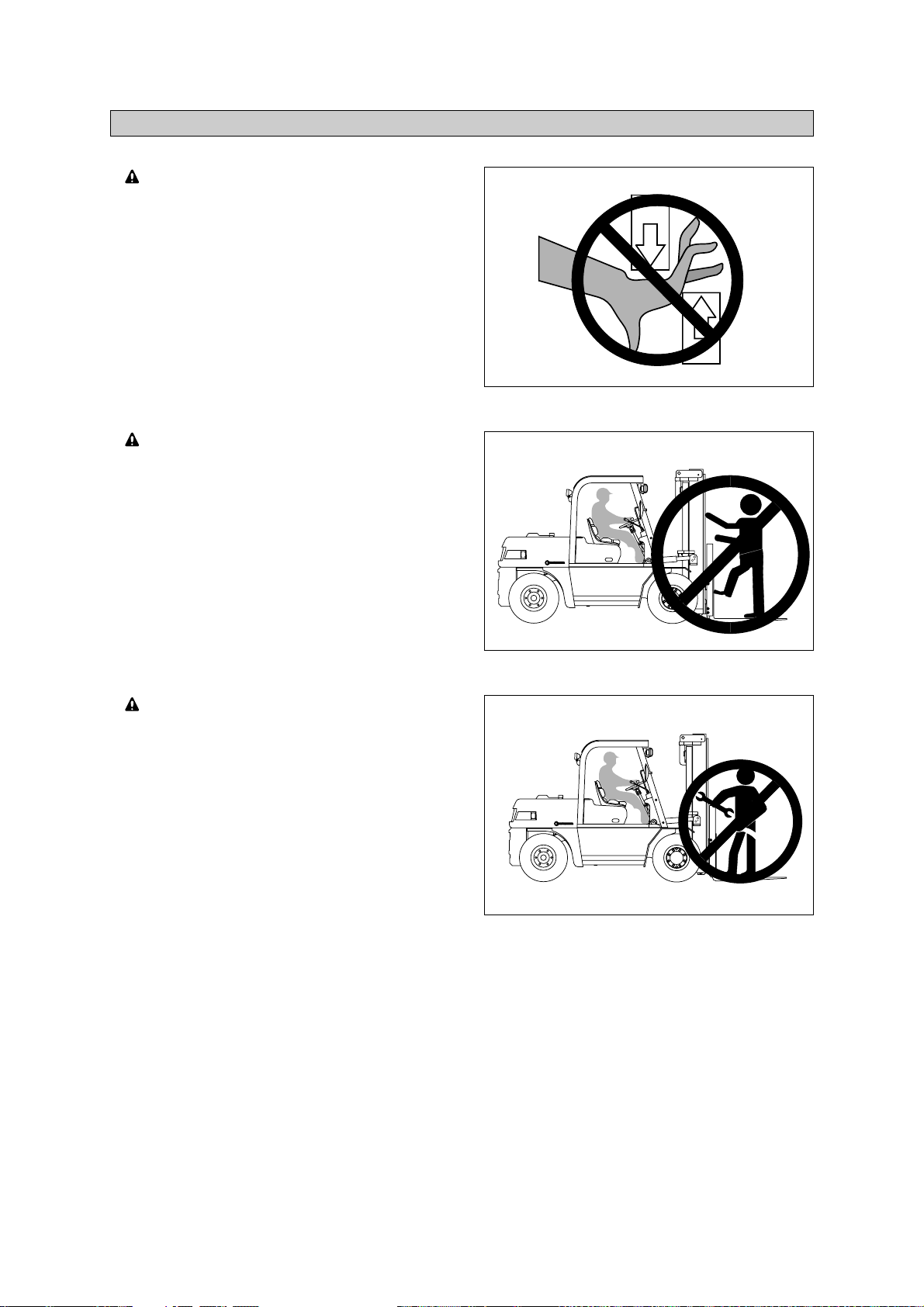

1-9

Keep hands, feet and legs out of the

mast.

D255OM61

Don't use the mast as a ladder.

D255OM62

Never try to repair the mast, carriage,

chain, or attachment by yourself. Always

get a trained mechani

c.

D255OM63

8. PINCH POINTS

https://truckmanualshub.com/

Page 32

1-10

Travel with the load near the floor/ground,

with mast tilted back to cradle the load

whenever possible.

Never lift or lower the load when the

truck is in motion.

D35AOM23

When handling bulky loads that restrict your

vision operate your truck in reverse to

improve visibility. Be sure to pivot in the

seat to give maximum visibility.

D255OM24A

Unstable loads are a hazard to you and to

your fellow workers. Always make certain

that the load is well stacked and evenly

positioned across both forks. Never

attempt to lift a load with only one fork.

Wrong

D255OM25A

9. TRAVEL

1)

2)

3)

https://truckmanualshub.com/

Page 33

1-11

10. GRADES, RAMPS, SLOPES AND INCLINES

D255OM26A

D255OM27A

Unloaded-Forks downgrade

Loaded - Forks upgrade

1)

2)

Never turn on a grade, either loaded or unloaded.

https://truckmanualshub.com/

Page 34

1-12

LATERAL TIP OVER

Lateral tip over can occur with a combination

of speed and sharpness of turn. This

combination will exceed the stability of the

truck. This condition is even more likely with

an unloaded truck.

With the load or mast raised, lateral tip over

can occur while turning and/or braking when

traveling in reverse or accelerating and

turning while traveling forward.

Lateral tip over can occur loaded or

unloaded by turning on an incline or ramp.

D35AOM28

LONGITUDINAL TIP OVER

Longitudinal tip over can occur with

combination of overloading and load

elevated also with capacity load and

elevated. This combination will exceed the

stability of the truck. This condition is even

more likely with excessive forward tilt,

braking in forward travel or accelerating

rearward.

Longitudinal tip over can occur by driving

with the load down slope on a steep grade.

Lateral and longitudinal tip over can occur if

the truck is driven over objects on the floor or

ground, off the edge of improved surfaces, or

into potholes in the road surface, or by running

into overhead objects or collisions.

An off dock type of tip over can occur if the

truck is steered too close to the dock edge,

driven off the edge of the dock or ramp, or if

the highway truck or trailer rolls away from the

dock or is driven away during loading.

The conditions listed above can be further

aggravated by overloading, exc

essive tilt,

or off center loads.

Lift truck tip over can cause serious injury

or death if the operator is trapped between

the truck and the ground.

D35AOM29

11. TIP OVER

1)

2)

(1)

(2)

(3)

(1)

(2)

https://truckmanualshub.com/

Page 35

1-13

WHAT TO DO IN CASE OF A TIP OVER

D35AOM30

3)

If your truck starts to tip over, do not

jump.

Brace yourself as illustrated right.

1. Make sure your seat belt is fastened

securely, if the truck is equipped with

seat belt.

2. Stay in your seat.

3. Grip the wheel.

4. Brace your feet.

Your chances for

survival in a tip-over

are better if you stay with the truck, in

your seat.

3

1

2

4

https://truckmanualshub.com/

Page 36

1-14

12. SURFACE AND CAPACITY

TIPOVER

Seat belts can reduce injuries.

ALWAYS BUCKLE UP.

D35AOM31

B207OM10

Avoid these conditions. They can cause a

truck to tip over or lose traction for braking or

driving.

Know the weight of your truck and load.

Especially when using elevators, know

the capacity of the ele

vator you intend to

use. Do not overload.

https://truckmanualshub.com/

Page 37

1-15

Never park on a grade.

D35AOM33

Always come to a complete stop before

leaving truck. Be sure travel control is in

NEUTRAL.

D35AOM34

Lower forks fully to floor and tilt forward.

OFF

ON

START

2

1

D255OM35A

Set parking brake.

Position 1 : Lock

Position 2 : Release

Turn key to OFF position.

13. PARKING

1)

2)

3)

4)

5)

20D7OM24

https://truckmanualshub.com/

Page 38

1-16

Before adding oil, check around machine

for oil leakage.

D255OM02

Keep away from fire when adding oil or

during operation.

DIESEL

D255OM03

After adding oil, wipe off any oil spilled on

machine.

D255OM04

14. REFUELING

1)

2)

3)

https://truckmanualshub.com/

Page 39

1-17

When getting on or off the machine, use the

step provided.

D255OM05

Do not jump up or down from the machine.

D255OM06

15. STEP

1)

2)

https://truckmanualshub.com/

Page 40

Traction safety warning

This function works when the key switch is ON or START position.

The transmission shifts automatically to neutral in 2 seconds from the driver's off the seat.

At the same time, the alarm will sound intermittently.

To release the function, the forward-reverse lever must be cycled through neutral with the

operator in the normal operating position to regain powered directional control.

1-18

All operational functions require that the

operator be seated in the operator's seat.

Alwa y s buc k le up if a seat belt is

provided.

D35AOM23

Parking brake must be locked in the PARK

POSITION before exiting from the vehicle.

Parking brake must remain locked in the

park position(2) except when an operator

is in the normal ope

rating position.

2. Lock(Park)

1. Release(Drive)

D507OM24

16. OPERATOR'S SAFETY RULES

1)

2)

ANSI/ASME REGULATIONS (

USA ONLY

)

This forklift truck is equipped with an Operator Existence Sensing System per ANSI/ASME

B56.1 ~ 7.21.10 and 7.21.11.

3)

(1)

Η

Θ

Ι

Κ

https://truckmanualshub.com/

HYUNDAI

Page 41

2-1

Loose or unbalanced loads are dangerous.

Observe these precautions.

Never carry loose or uneven material.

2. OPERATING HAZARDS

1. LOOSE LOADS

D255OM39

Center wide loads.

D35AOM40

Stack and band loose material.

D35AOM41

Avoid sudden braking or starting

When the machine is loaded, do not

drive at maximum speed.

D255OM07

https://truckmanualshub.com/

Page 42

2-2

With long or wide loads, you need more

room. So slow down and watch your

clearance.

When extra-long material makes it

necessary to travel with the load elevated,

do so with extreme care and be alert to

load end-swing when turning.

A long load redu

ces the capacity of the

truck. Know and understand your truck

load rating.

2. LONG AND WIDE LOADS

D35AOM42

When turning, be sure the rear end of

the truck doe s not swing into racks,

posts, etc. Watch for pedes

trians beside

the truck.

3. REAR SWING

D255OM43

https://truckmanualshub.com/

Page 43

2-3

Know the height of your truck, with and

without a load. Check your clearances.

Keep the load low and

tilted back.

4. LOW OVERHEAD CLEARANCE

B207OM44

Watch overhead clearance:

Moving into overhead structures can tip

a truck over, or spill a load.

B207OM45

Slow down before turning.

The truck can tip over.

D255OM46

Turn too sharp with a raised load and

your truck can tip even at slow speeds.

Travel with a load raised

only when

removing or depositing a load.

D255OM07

5. FAST TURNS AND HIGH LOADS

https://truckmanualshub.com/

Page 44

2-4

To avoid these hazards, you must:

Talk to the truck driver yourself: make sure

the driver does not move the trailer until you

are done.

Apply trailer brakes.

Use wheel chocks.

Use trailer-to-dock locking system if

available.

The impact of moving in and out of a

trailer may cause the trail

er to creep or

move.

D35AOM48

D35AOM49

6. DROP-OFFS

When right angle stacking or moving with

a raised load to clear low objects, avoid

sharp turns and move

slowly.

7. RIGHT ANGLE STACKING

D35AOM50

1)

2)

3)

4)

https://truckmanualshub.com/

Page 45

2-5

Slack chains mean rail or carriage hangup.

Raise the forks before you move, or

broken chains can resu

lt.

In case forks with loads are stuck while

lowering the mast, lift the mast again and

prevent chains f

rom being slack.

8. CHAIN SLACK

D35AOM51

D35AOM52

Do n o t move o r store material s on

damaged pallets or skids. Items can fall

through them causing severe

injury or

death.

Be sure the pallet or skid you are using

is in good condition and does not have

defecti

ve or missing components and

fasteners.

9. PALLETS AND SKIDS

D35AOM53

https://truckmanualshub.com/

Page 46

2-6

When moving the machine with the mast

raised, watch out electrical lines over the

machine.

The operatin

g near the electrical lines is

very dangerous.

Operate within safe working permitted as

below.

10. CAUTION FOR ELECTRICAL LINES

D255SF01

D255SF02

If the machine touches the electric power

lines, keep sitting on the operator’s seat

and make sure the

pers o nnel on the

ground not to touch the machine until

turning off the electric current.

Jump off the ma

chine without contacting

the machine when you need to get off.

Supply voltage

6.6 kV

33.0 kV

66.0 kV

154.0 kV

275.0 kV

Min safe separation

3m(10 ft)

4m(13 ft)

5m(16 ft)

8m(26 ft)

10m(33 ft)

https://truckmanualshub.com/

Page 47

2-7

Never permit any persons to stand or

pass under lifted load.

11. LIFTING LOADS

D255OM08

D255OM09

Never use wire rope to lift a load.

Never operate the side shift while the forks

are not equipped with supports such as a

load table for the load.

Never travel the fork lift while the side

shift is moved with load.

In case of moving the side shift with load,

it can be caused load dropping or

overturning of the fork lift due to

unbalanced weight.

The fork lift can be overturned due to the

unbalanced load.

35D7EOM61

12. SIDE SHIFT

https://truckmanualshub.com/

Page 48

2-8

It should be observed that the side shift

with load is operated in netural position

before traveling.

When operating side shift with load,

operate slowly so that it can not avoid

from dropping of the load or overturning

of the fork lift.

35D7EOM63

Never move the load to push or pull of it by

the side shift.

It can be caused damaging of the loads or

injuring of the people.

35D7EOM62

While traveling the fork lift with the load on

the side shift, if the operator lift or lower the

load without shifting it in the netural position,

it can be overturned the fork lift due to

unstabled load.

When lifting or lowering the side shift with

load, it should be observed that the load is

moved into the netural position.

35D7EOM64

https://truckmanualshub.com/

Page 49

2-9

Do not operate the fork positioner with a

load, or with the fork arm on the ground.

Never move the levers to operate the

pork positioner suddenly and quickly.

It can be caused to drop

the load.

35D7EOM65

13. FORK POSITIONER

https://truckmanualshub.com/

Page 50

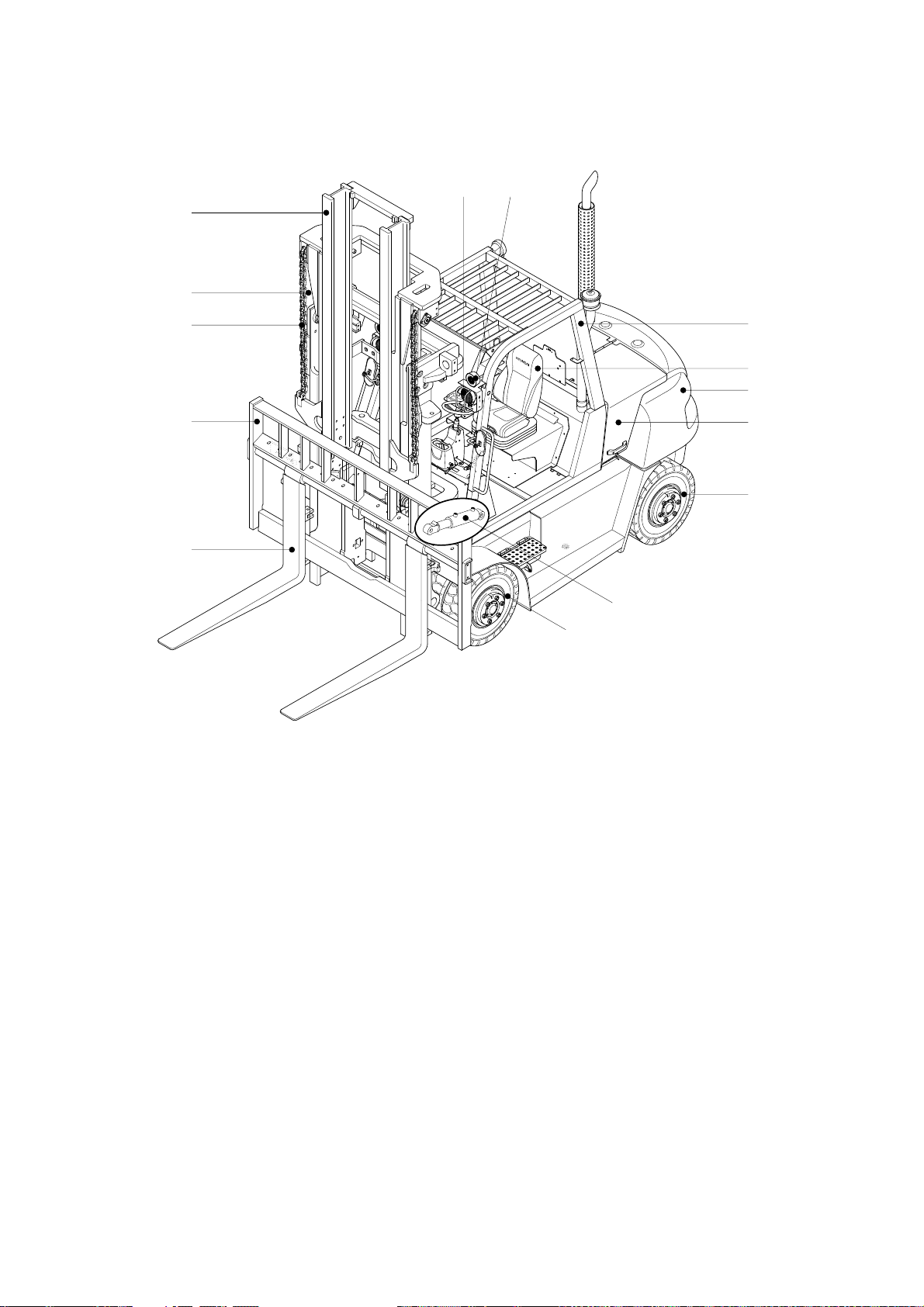

3-1

3. KNOW YOUR TRUCK

1. GENERAL LOCATIONS

1 Mast

2 Lift chain

3 Lift cylinder

4 Backrest

5 Tilt cylinder

6 Lift bracket

7Forks

8 Overhead guard

9 Turn signal lamp

10 Head lamp

11 Operator's seat

12 Bonnet

13 Counterweight

14 Rear wheel

15 Front wheel

16 Rear combination lamp

9

10

1

2

4

6

7

15

5

14

12

13

16

11

8

3

15D7EOM54

15D/18D/20DA-7E

1)

https://truckmanualshub.com/

Page 51

3-2

1 Mast

2 Lift chain

3 Lift cylinder

4 Backrest

5 Tilt cylinder

6 Lift bracket

7Forks

8 Overhead guard

9 Turn signal lamp

10 Head lamp

11 Operator's seat

12 Bonnet

13 Counterweight

14 Rear wheel

15 Front wheel

16 Rear combination lamp

1

2

3

4

5

6

7

15

9

16

8

11

10

13

12

14

20D7OM01

20D/25D/30D/33D-7E, 20DF/25DF/30DF/33DF-7, 35DF-7

2)

https://truckmanualshub.com/

Page 52

3-3

1 Mast

2 Lift chain

3 Lift cylinder

4 Backrest

5 Tilt cylinder

6 Lift bracket

7Forks

8 Overhead guard

9 Turn signal lamp

10 Head lamp

11 Operator's seat

12 Bonnet

13 Counterweight

14 Rear wheel

15 Front wheel

16 Rear combination lamp

4

6

7

1

2

3

15

5

14

12

13

16

11

8

10

9

35DS7EOM54

35D/40D/45D-7E, 50D-7AE, 35DS/40DS/45DS/50DA-7E

3)

https://truckmanualshub.com/

Page 53

3-4

1 Mast

2 Lift chain

3 Lift cylinder

4 Backrest

5 Tilt cylinder

6Forks

7 Overhead guard

8 Turn signal lamp

9 Head lamp

10 Operator's seat

11 Bonnet

12 Counterweight

13 Rear wheel

14 Front wheel

15 Rear combination lamp

4

6

1

2

3

14

5

9

13

11

12

7

10

8

15

50DEOM54

50D/60D/70D-7E, 80D-7E

4)

https://truckmanualshub.com/

Page 54

3-5

1 Mast

2 Lift chain

3 Lift cylinder

4 Backrest

5 Tilt cylinder

6 Lift bracket

7Forks

8 Overhead guard

9 Turn signal lamp

10 Head lamp

11 Operator's seat

12 Bonnet

13 Counterweight

14 Rear wheel

15 Front wheel

16 Rear combination lamp

4

6

7

1

2

3

15

5

14

12

13

16

11

8

10

9

50DS7EOM54

50DS/60DS/70DS-7E

5)

https://truckmanualshub.com/

Page 55

3-6

1 Mast

2 Lift chain

3 Lift cylinder

4 Backrest

5 Tilt cylinder

6Forks

7 Overhead guard

8 Turn signal lamp

9 Head lamp

10 Operator's seat

11 Bonnet

12 Counterweight

13 Rear wheel

14 Front wheel

15 Rear combination lamp

6

4

2

3

98

7

10

12

11

13

5

14

1

60DF7CM54

50DF/60DF/70DF-7

6)

https://truckmanualshub.com/

Page 56

3-7

1

2

3

5

4

TRUCK DATA AND CAPACITY PLATE

Truck model number or registered name

Truck serial number

An identification number assigned to this particular truck and should be used when requesting

information or ordering service parts for this truck from your authorized HYUNDAI dealer. The

serial number is also stamped on the frame.

Attachment des

cription(If any installed)

The user must see that the truck is marked to identify the attachment(s), including the weight of

the truck/attachment combination and truck capacity with the attachment.

Capacity rating, load center, and lifting height data

Shows the maximum load capacity of this truck with relation to load centers and fork heights(See

diagram on plate). Personal injury and damage to the truck can occur if these capacities are

exceeded.

Do not exceed the

maximum capacity specified.

Truck weight

The approximate weight of the truck without a load on the forks. This weight plus the weight of the

load must be considered when operating on elevators, elevated floors, etc. to be sure they are

safe.

Before modifications that affect the stability of safety sy

stems are made written approval

from HYUNDAI. This is an OSHA requirement. Contact your authorized HYUNDAI dealer

for a new nameplate showing the revised capacity.

1)

(1)

(2)

(3)

(4)

(5)

D255OM56

2. DATA/SAFETY PLATES AND DECALS

https://truckmanualshub.com/

Page 57

3-8

Safety and warning decals are placed in conspicuous locations on the

truck to remind you of essential procedures or to prevent you from

making an error that could damage the truck or possibly cause personal

injury. You should know, understand, and follow these instructions.

Safety and warning decals. Should be replaced immediately if missing

or defaced(Damaged or illegible). Refer to your Service manual for the

location of all decals.

Operator/Tip-over warning decal

This decal is located on the front right hand leg of the drivers overhead. Its

purpose is to remind the operator that staying in the seat provides the best

chance of avoiding injury in the event of a truck-tipping or driving off a dock

mishap.

Lift trucks can be tipped over if operated improperly. Experience with lift truck

accidents has shown that the driver cannot react quickly enough to jump

clear of the truck and overhead guard as the truck tips. To protect operators

from severe injury or death in the event of a tip over, it is best to be held

securely in the seat. So, please, always buckle up when driving your lift

truck.

15D/18D/20DA, 20D/25D/30D/33D ONLY

15DEOM59K

25L7AOM09

%%%"&%%%%&0/-:

OPERATOR SAFETY WARNING DECAL

2)

https://truckmanualshub.com/

Page 58

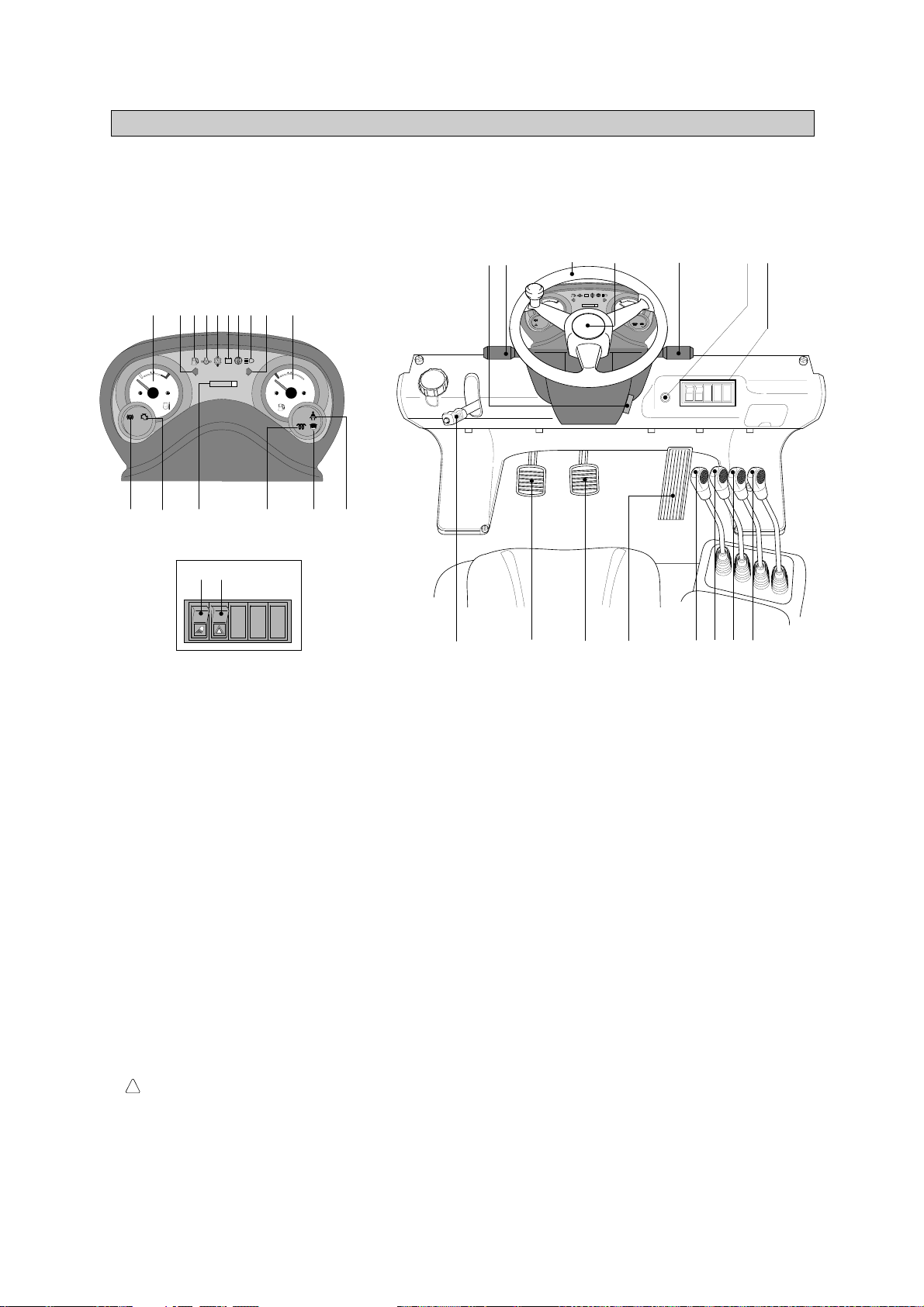

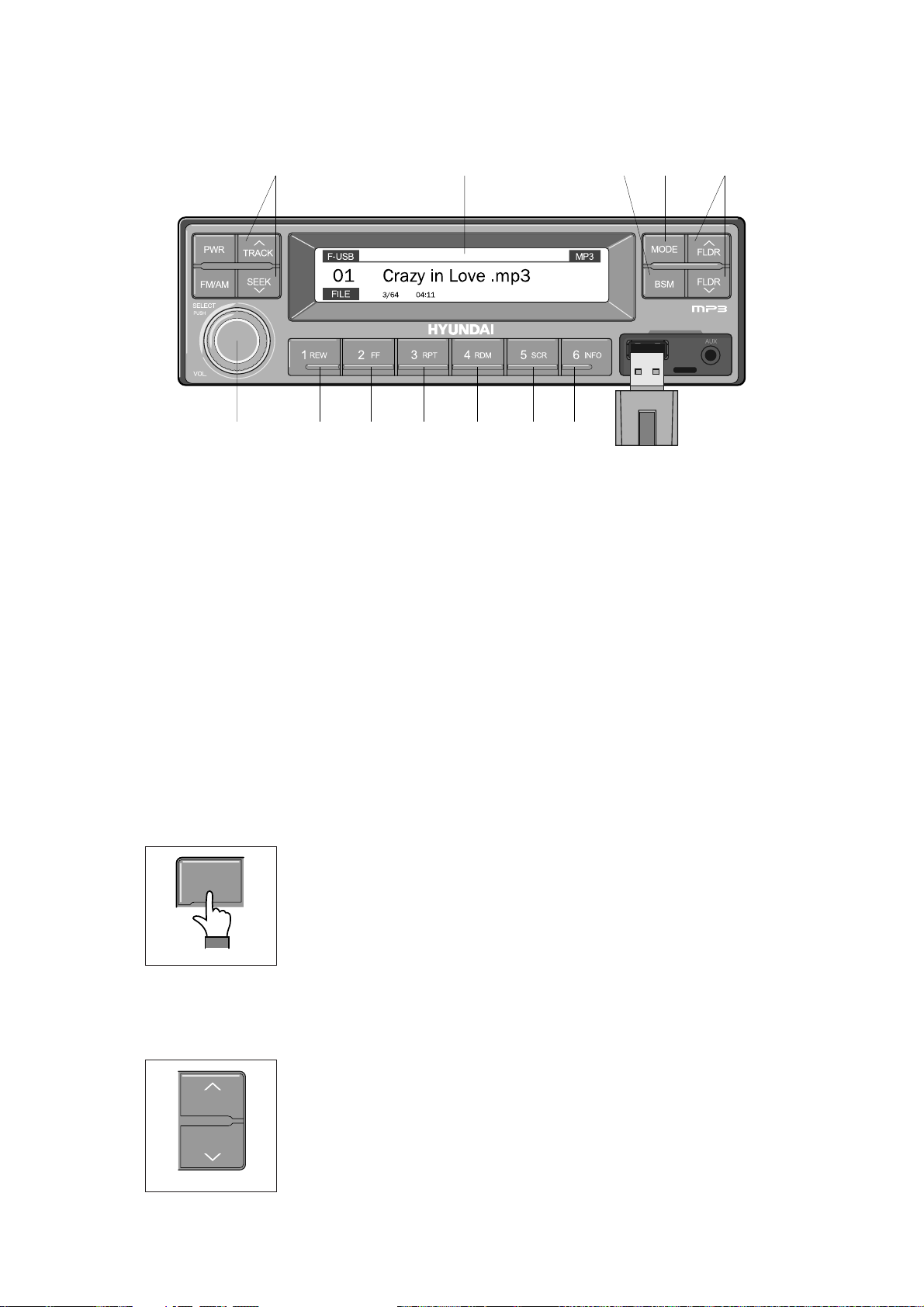

3-9

3. INSTRUMENTS AND CONTROLS

DETAIL A

HYUNDAI

H

E

F

000000

C

LPG

+

-

17

18

19

1

234578910

11

1213

14 15 16

A

20 21 22 24 25 26 27

32

28

3334

23

6

HYUNDAI

H

E

F

000000

C

+

-

29,30,31

15D7EOM641

Familiarize yourself with the controls and follow safe operating procedures.

15D/18D/20DA-7E

1)

1 Start switch

2 Water temperature gauge

3 Left turn signal lamp

4 Fuel level warning lamp

5 Engine oil pressure warning lamp

6 Battery charge warning lamp

7 T/M oil temp warning lamp

8 Air cleaner element warning lamp

9 Head lamp signal lamp

10 Right turn signal lamp

11 Fuel gauge

12 Engine check lamp

13 Parking brake signal lamp

14 Hour meter

15 Preheater signal lamp

16 Water separator lamp

17 Work lamp switch(opt)

18 Hazard lamp switch(opt)

19 Seat belt warning lamp

20 Parking brake lever

21 Inching pedal

22 Brake pedal

23 Accelerator pedal

24 Lift lever

25 Tilt lever

26 Attach lever 1(opt)

27 Attach lever 2(opt)

28 Horn button

29 Head lamp switch

30 Illumination lamp

31 Turn signal switch

32 Steering wheel

33 Forward-reverse lever

34 Steering column adjust

lever

https://truckmanualshub.com/

Page 59

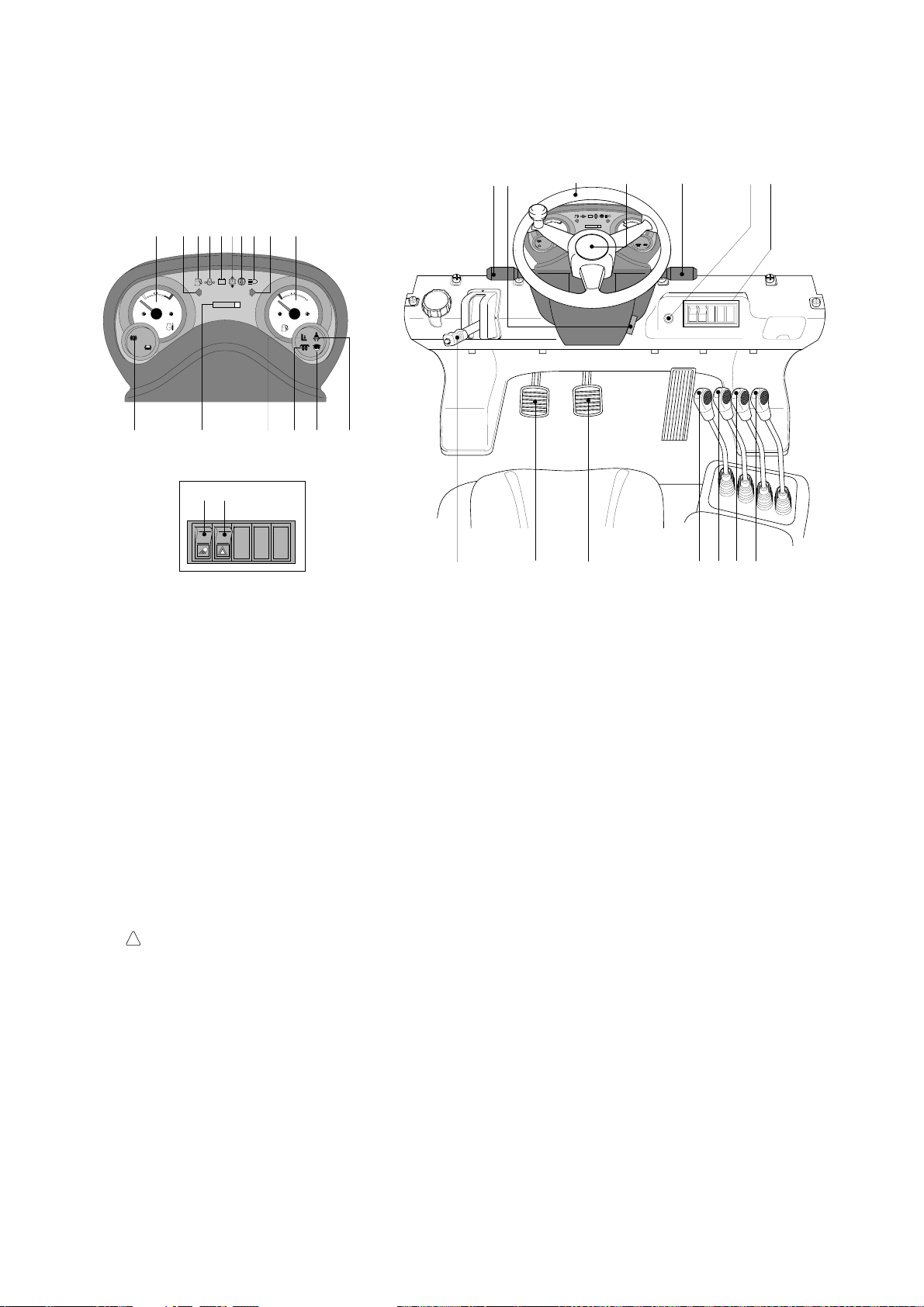

3-10

DETAIL A

HYUNDAI

H

E

F

000000

C

LPG

+

-

17

18

19

1

234578910

11

1213

14 15 16

A

20 21 22 24 25 26 27

32

28

3334

23

6

HYUNDAI

H

E

F

000000

C

+

-

29,30,31

15D7EOM641

Familiarize yourself with the controls and follow safe operating procedures.

20D/25D/30D/33D-7E, 20DF/25DF/30DF/33DF-7, 35DF-7

2)

1 Start switch

2 Water temperature gauge

3 Left turn signal lamp

4 Fuel level warning lamp

5 Engine oil pressure warning lamp

6 Battery charge warning lamp

7 T/M oil temp warning lamp

8 Air cleaner element warning lamp

9 Head lamp signal lamp

10 Right turn signal lamp

11 Fuel gauge

12 Engine check lamp

13 Parking brake signal lamp

14 Hour meter

15 Preheater signal lamp

16 Water separator lamp

17 Work lamp switch(opt)

18 Hazard lamp switch(opt)

19 Seat belt warning lamp

20 Parking brake lever

21 Inching pedal

22 Brake pedal

23 Accelerator pedal

24 Lift lever

25 Tilt lever

26 Attach lever 1(opt)

27 Attach lever 2(opt)

28 Horn button

29 Head lamp switch

30 Illumination lamp

31 Turn signal switch

32 Steering wheel

33 Forward-reverse lever

34 Steering column adjust

lever

https://truckmanualshub.com/

Page 60

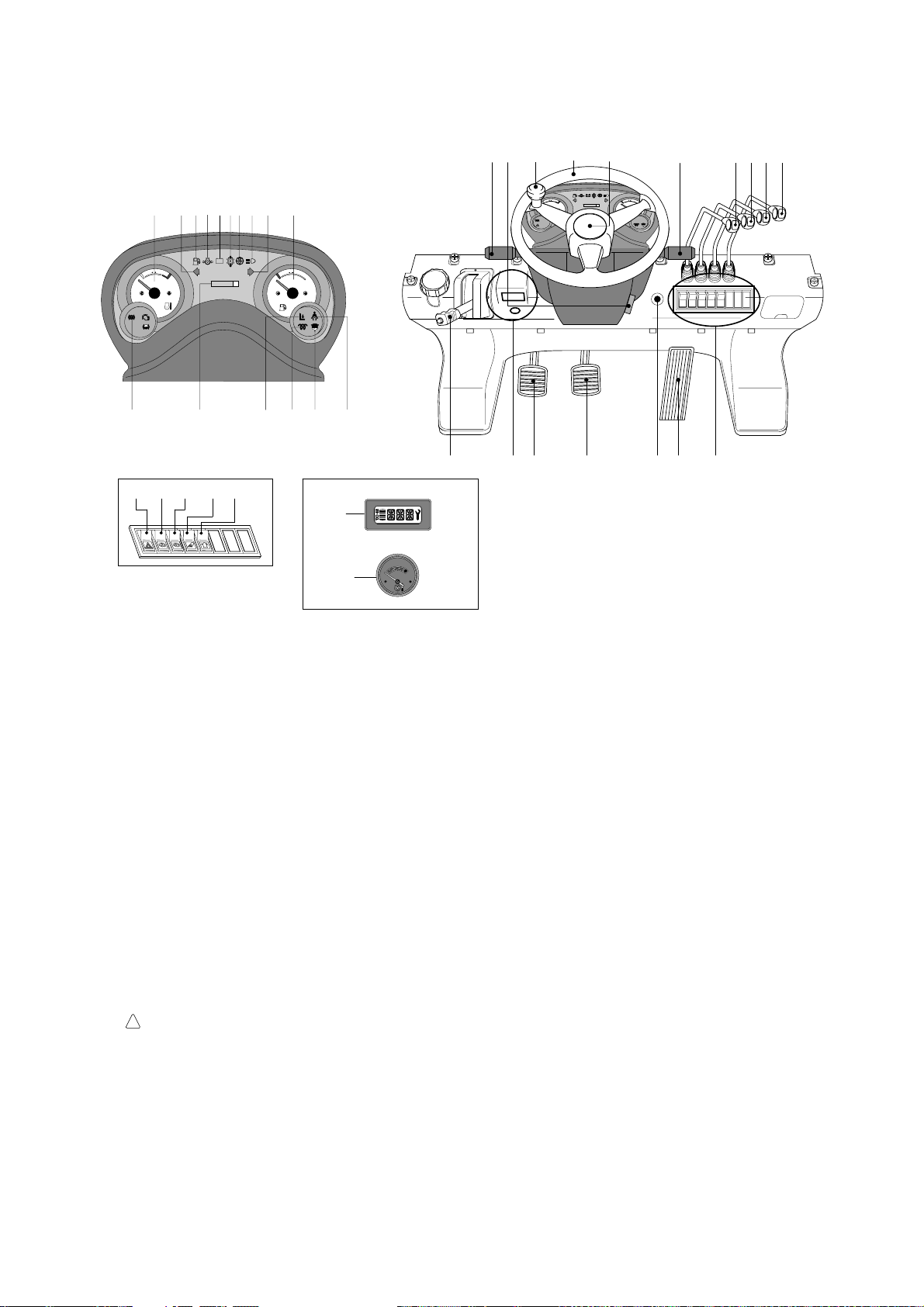

3-11

1 Start switch

2 Water temperature gauge

3 Left turn signal lamp

4 Fuel level warning lamp

5 Engine oil pressure warning lamp

6 Battery charge warning lamp

7 T/M oil temp warning lamp

8 Air cleaner element warning lamp

9 Head lamp signal lamp

10 Right turn signal lamp

11 Fuel gauge

13 Parking brake signal lamp

14 Hour meter

15 Preheater signal lamp

16 Water separator lamp

17 Work lamp switch(opt)

18 Hazard lamp switch(opt)

19 Seat belt warning lamp

20 Parking brake lever

21 Inching pedal

22 Brake pedal

23 Lift lever

24 Tilt lever

25 Attach 1 lever(opt)

26 Attach 2 lever(opt)

27 Horn button

28 Head lamp switch

29 Illumination lamp

30 Turn signal switch

31 Steering wheel

32 Forward-reverse lever

33 Steering column adjust lever

34 Operator safety lamp(OPSS)

DETAIL A

HYUNDAI

H

E

F

000000

C

LPG

+

-

17

18

19

1

2345 8910

11

13

14 15 16

A

20 21 22 23 24 25 26

31

27

32 33

HYUNDAI

H

E

F

000000

C

28,29,30

76

+

-

34

35DS7EOM64T

Familiarize yourself with the controls and follow safe operating procedures.

35D/40D/45D-7E, 50D-7AE, 35DS/40DS/45DS/50DA-7E

3)

https://truckmanualshub.com/

Page 61

3-12

1 Start switch

2 Water temperature gauge

3 Left turn signal lamp

4 LCD

5 Right turn signal lamp

6 Fuel gauge

7 Parking brake signal lamp

8 Fuel level warning lamp

9 Engine oil pressure warning lamp

10 T/M oil temp warning lamp

11 Battery charge warning lamp

12 Air cleaner element warning lamp

13 Head lamp signal lamp

14 Work lamp signal lamp

15 Preheater signal lamp

16 T/M display

17 T/M temperature gauge

18 Parking brake lever

19 Forward-reverse lever

20 Head lamp switch

21 Clearance lamp switch

22 Multi function switch

23 Washer switch

24 Lift lever

25 Tilt lever

26 Attach 1 lever(opt)

27 Attach 2 lever(opt)

28 Attach 3 lever(opt)

29 Full automatic switch

30 Clutch cutoff switch

31 Work lamp switch

32 Beacon lamp switch(opt)

33 Inching pedal

34 Brake pedal

35 Accelerator pedal

36 Steering wheel

37 Steering wheel

knob

38 Engine check lamp

39 Brake fail warning lamp

40 T/M error warning lamp

41 Water separator lamp

42

Engine coolant

temperature warning lamp

43 Seat belt warning lamp

44 OPSS lamp

45 Inching pilot lamp

46 Speed meter

47 Hazard lamp switch

48 Wiper switch

49 Buzzer stop button

50 Cabin tilt switch

51 Air conditioner controller

26 27 282524

A

47

30

29

31

32

48

23

19

33

35

34

20,21,2236

1

15 38 46 4 49 17 8 6 2

14

74210513339

40

9

41

43

44

11

45

12

16

18

37

CABIN TILT SWITCH

51

50

50DEOM64

50D/60D/70D-7E, 80D-7E

4)

Familiarize yourself with the controls and follow safe operating procedures.

https://truckmanualshub.com/

Page 62

3-13

1 Start switch

2 Water temperature gauge

3 Left turn signal lamp

4 Fuel level warning lamp

5 Engine oil pressure warning lamp

6 Battery charge warning lamp

7 T/M oil temp warning lamp

8 Air cleaner element warning lamp

9 Head lamp signal lamp

10 Right turn signal lamp

11 Fuel gauge

13 Parking brake signal lamp

14 Hour meter

15 Preheater signal lamp

16 Water separator lamp

17 T/M display

18 T/M temperature gauge

19 Seat belt warning lamp

20 Parking brake lever

21 Forward-reverse lever

22 Head lamp switch

23 Clearance lamp switch

24 Turn signal switch

25 Horn button

26 Lift lever

27 Tilt lever

28 Attach 1 lever(opt)

29 Attach 2 lever(opt)

30 Hazard lamp switch

31 Full automatic switch

32 Inching switch

33 Work lamp switch

34 Beacon lamp switch(opt)

35 Inching pedal

36 Brake pedal

37 Accelerator pedal

38 Steering wheel

39 Steering wheel

knob

40 Steering column adjust lever

41 OPSS lamp

HYUNDAI

H

E

F

000000

C

LPG

+

-

HYUNDAI

H

E

F

000000

C

+

-

30

31

32 33

DETAIL A

34

DETAIL B

OIL TEMP

17

18

A

B

37

20

2140 38 25 26272829

35 36

22,23,24

19

2345 8910

11

13

14 15 16

76

41

39

1

50DS7EOM64

50DS/60DS/70DS-7E

5)

Familiarize yourself with the controls and follow safe operating procedures.

https://truckmanualshub.com/

Page 63

3-14

1 Start switch

2 Water temperature gauge

3 Left turn signal lamp

4 Fuel level warning lamp

5 Engine oil pressure warning lamp

6 Battery charge warning lamp

7 T/M oil temp warning lamp

8 Air cleaner element warning lamp

9 Head lamp signal lamp

10 Right turn signal lamp

11 Fuel gauge

13 Parking brake signal lamp

14 Hour meter

15 Preheater signal lamp

16 Water separator check lamp

17 Work lamp switch(opt)

18 Hazard lamp switch(opt)

19 Beacon switch

20 Parking brake lever

21 Inching pedal

22 Brake pedal

23 Lift lever

24 Tilt lever

25 Attach 1 lever(opt)

26 Attach 2 lever(opt)

27 Horn button

28 Head lamp switch

29 Illumination lamp

30 Turn signal switch

31 Steering wheel

32 Forward-reverse lever

33 Steering column adjust lever

35 Engine check lamp (STD)

36 Operator safety lamp (OPT)

P

13 4 5 7 6 8

31421011

20

28

32

A

16

36

18

17

DETAIL A

91715

23

24 25 26

1

21 22

31

19

,29,30

33

27

35

60DF7EOM64T

Familiarize yourself with the controls and follow safe operating procedures.

50DF/60DF/70DF-7

6)

https://truckmanualshub.com/

Page 64

3-15

E

: Empty

F

: Full

Fill fuel tank regularly.

Never allow machine to run out fuel.

Do not overfill the fuel tank.

Always check the fuel level on level ground.

FUEL GAUGE

1)

This indicates the time of total machine operation.

All service intervals for periodic maintenance are based on

service meter readings.

The last digit advances by 1/10 hours.

50D/60D/70D-7E, 80D-7E : Refer to page 3-19.

HOUR METER

2)

4. INDICATOR SYMBOLS

(1)

(2)

(3)

ö

(1)

ö

(2)

ö

00000

0

15D7EOM02K

60DFOM10K

15D7EOM10K

E

F

1/2

160D7ECD04

%%%&%&

60DFOM02K

%'%'%'

%'%'%'

F

E

https://truckmanualshub.com/

Page 65

3-16

The indicator shows the engine cooling water temperature.

White range : Normal

Red range : Danger of overheating.

Action to take if indicator enters red range.

Stop operations immediately and move the truck to a safe

place.

Open the engine hood to improve the ventilation and run the

engine at low idling until the temperature drops to the white

range.

For details, see HANDLING MACHINE IN EXTREMELY

HOT PLACES, page 7-55.

WATER TEMPERATURE GAUGE

3)

C

H

Red

160D7ECD10

%%%&%&

H

C

15D7EOM03K

(1)

Η

Θ

Η

Θ

(2)

ö

60DFOM03K

This range indicates the temperature of transmission oil.

Â

White range : 40-107ÁC

(104-225ÁF

)

Â

Red range : 107ÁC

(225ÁF

) above

The white range indicates when operating.

Keep idling engine at low speed until the white range

indicates, before operation of machine.

If the indicator is in the red range, it means the transmission

is overheated. Be careful that the indicator does not move

into the red range.

TTRANSMISSION OIL TEMPERATURE GAUGE

(1)

(2)

4)

C

H

Red

160D7ECD11

%4%4%4&

%%%&%&

Η

Θ

This lamp informs the operator that transmission oil is above

the specified temperature.

Transmission oil temperature warning lamp ON : Abnormal

Transmission oil temperature warning lamp OFF : Normal

W

When this lamp lights up during operation, stop the engine

and check the machine.

TRANSMISSION OIL TEMP

ERATURE WARNING LAMP (1.5~4.5 ton, 50~70DF-7)

5)

D35AOM79

(1)

Η

Θ

ö

%'%'%'

https://truckmanualshub.com/

Page 66

This lamp informs the operator that fuel in the tank is below the

specified level. And this lamp prevents the engine from

stopping suddenly. This lamp is installed separate from the fuel

gauge.

If this lamp lights up, stop the engine and refill the fuel

immediately.

FUEL LEVEL WARNING LAMP

(1)

ö

99)

D35AOM83

This lamp lights up when the replacement time of element is

late and the element is dirty, so air influx is not smooth.

If this lamp lights up, clear the element or replace it.

AIR CLEANER ELEMENT WARNING LAMP

(1)

ö

D35AOM84

10)

This lamp shows that the alternator is not generating electricity.

When the starting switch is turned ON, the lamp will lights

up, but it should go out after the engine starts.

If the lamp lights up during operation, stop the engine and

check the fan belt tension and the electrical system.

BATTERY CHARGE WARNING LAMP

(1)

ö

ö

8

8)

3-17

This lamp lights up when key is turned to ON position. After a

while the heater signal lamp goes out, then turn the key to

START position.

PRE HEATER SIGNAL LAMP

(1)

6)

D35AOM80

This lamp informs the operator that the engine oil pressure is

below the specified level.

This lamp lights when starting switch is turned ON and goes

out when oil pressure becomes normal.

Immediately stop operation if this lamp lights up during

operation. Stop the engine and check the

machine if

necessary.

ENGINE OIL PRESSURE WARNING LAMP

(1)

(2)

ö

77)

D35AOM81

15D7EOM82K

+

-

https://truckmanualshub.com/

Page 67

3-18

This lamp shows that the head lamp lights up or not.