Husqvarna FS 520, FS 524, FS 513 User Manual

Operator’s manual

Read these instructions carefully and make sure you understand them before using the machine.

Manual del operador

Lea cuidadosamente estas instrucciones y asegúrese de que las comprende bien antes de usar el FS 4800.

Manuel d’utilisation

Veuillez lire attentivement ces instructions et assurez-v ous de bien les comprendre avant d’utiliser la machine modèle FS 4800.

FS 513, FS 520, FS 524

CONTENTS and INTRODUCTION

Contents |

|

Section |

Page |

Contents & Introduction................................................ |

3 |

Symbols and Decals.................................................... |

4-8 |

Safety Instructions..................................................... |

9-12 |

Parts Identification (What Is What)......................... |

14-16 |

Assembly................................................................. |

17-21 |

Operation ................................................................ |

22-27 |

Maintenance & Lubrication ................................... |

28-32 |

Trouble Shooting Guide............................................... |

33 |

Wiring diagram........................................................ |

34-38 |

Technical Data......................................................... |

39-40 |

Accessories.................................................................. |

41 |

Conformity Certificates................................................. |

42 |

Contact Information....................................................... |

43 |

Introduction

Thank you for purchasing your new machine from Husqvarna Construction Products. We have provided important safety messages in this manual and on the machine. Please read these messages carefully. A safety message alerts you to potential hazards that could hurt you or others. Each safety message is preceded by a symbol or the safety alert symbol ( ) and one of two words, WARNING, or CAUTION.

) and one of two words, WARNING, or CAUTION.

These signal words mean:

WARNING: Indicates a hazardous situation which, if not avoided COULD result in death or serious injury.

WARNING: Indicates a hazardous situation which, if not avoided COULD result in death or serious injury.

CAUTION: Indicates a hazardous situation, which, if not avoided, COULD result in minor or moderate injury. It may also be used to alert against unsafe practices.

CAUTION: Indicates a hazardous situation, which, if not avoided, COULD result in minor or moderate injury. It may also be used to alert against unsafe practices.

Each message tells you what the hazard is, what can happen, and what you can do to avoid or reduce injury. Other important messages are preceded by the word NOTICE.

NOTICE means:

NOTICE: Indicates a hazardous situation which, if not avoided, could result in property damage. Your machine or other property can be damaged if you don’t follow this instruction.

The safety labels should be periodically inspected and cleaned by the user to maintain good legibility at a safe viewing distance. If the label is worn, damaged, or is illegible, it should be replaced.

WARNING!

WARNING!

Before operating machine, read and understand this entire operation manual & engine operation manual supplied with engine.

Be familiar with machine before operation!

Model Identification: Record machine serial number plate information below for future reference

A.Model:______________________________________

B.Machine Serial No:____________________________

C.Year of Manufacture ___________________________

D.Mass of Machine (kg) __________________________

E.Engine Power (KW) ___________________________

F.Blade Diameter (mm) __________________________

G.Blade Speed (Revolutions / Minute) _______________

H.Electric Motor Voltage (If Equipped) _______________

I.Electric Motor Phase (If Equipped) _________________

J.Electric Motor Amperage (if Equipped) _____________

Other information not shown on machine serial plate:

Engine Serial No: _______________________________

See Engine Operation Manual for location.

Purchase Date:_________________________________

SYMBOLS and DECALS

Please read the instructions for use prior to operating the machine for the first time.

This symbol indicates that the machine is in conformance with the applicable European directive.

Mandatory

Indication

Prohibition

Warning Triangle

Wear Eye Protection

Wear Breathing Protection

The use of hearing protection is mandatory

Wear Head Protection

Wear Safety Shoes

Wear Appropriate Clothing

Remove the blade prior to Hoisting, Loading, Unloading and Transporting the Machine.

Emergency Shutdown, Transmission Stop

Use In Well Ventilated Area

Do Not Use In Flammable Areas

Machinery Hazard, Keep hands and Feet Clear.

Muffler Hot. May Cause Burns and / or

Ignition of Material. Avoid Contact.

Danger, Poison Exhaust Gas

No Non-working Personnel In Area

No Smoking

Do Not Operate Without Blade Guard in

Place

Always Keep All Guards In Place

Water Supply On

Water Supply Off

Water Supply

SYMBOLS and DECALS |

|

|

|

Blade Water Safety Switch |

Electrical Switch-Start |

Engine Coolant Temperature |

Repairs Are To Be Done By An Authorized |

|

Dealer Only |

Keep Work Area Clean/Well Lit, Remove All |

|

Safety Hazards |

Headlight |

Dangerously High Noise Level |

Diamond Blade |

Pay Extreme Attention to The Care And |

Blade Diameter |

Protection Of The Machine Before Starting Up |

|

Remove Tools From Area and Machine |

Blade Engagement |

|

|

Engine Oil Pressure |

Pulley diameter |

|

|

|

Number of Revolutions Per Minute, Rota- |

Oil Required |

tional Speed |

Dipstick, Maintain Proper Oil Level |

Blade Flange Diameter |

Lubrication Point |

Blade Depth Stop |

High Speed |

Cutting Depth Indicator – Depth of Cut |

Low Speed |

Parking Brake |

Electrical Switch-Off |

Parking Brake Applied |

Electrical Switch-On |

Parking Brake Released |

SYMBOLS and DECALS

Machine Mass (Kilograms)

Positive Battery Terminal

Blade Depth Indicator – Zero

Electric Motor

Engine

Engine Speed Revolutions/Minute

Engine Start

Unleaded Fuel Only

Engine Stop

Engine Start

Engine Run

Disengage to Start Engine (Neutral Start)

Stop Engine and Engage Transmission to Engage Parking Brake

SYMBOLS and DECALS

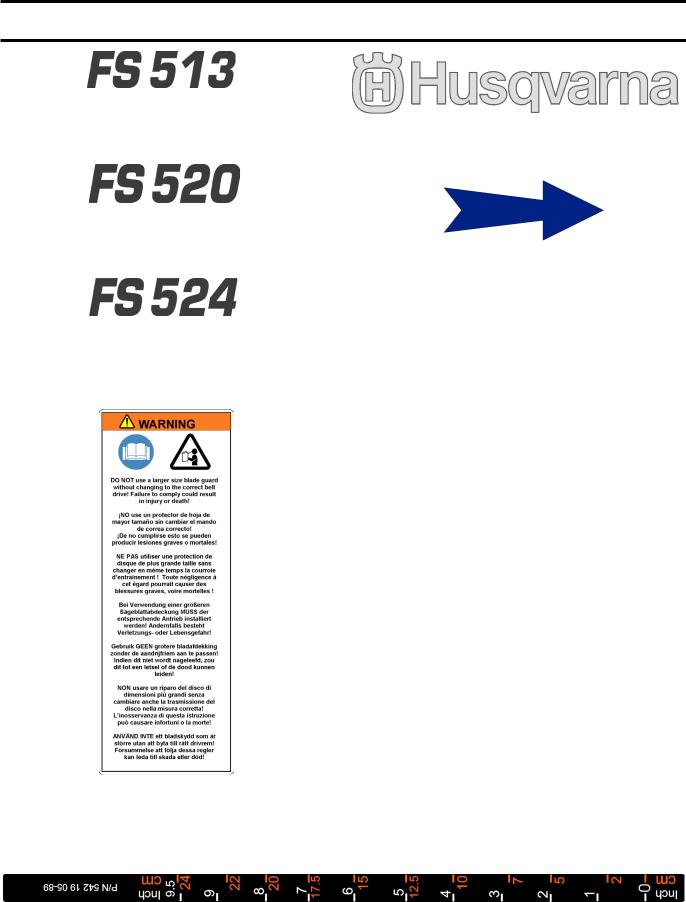

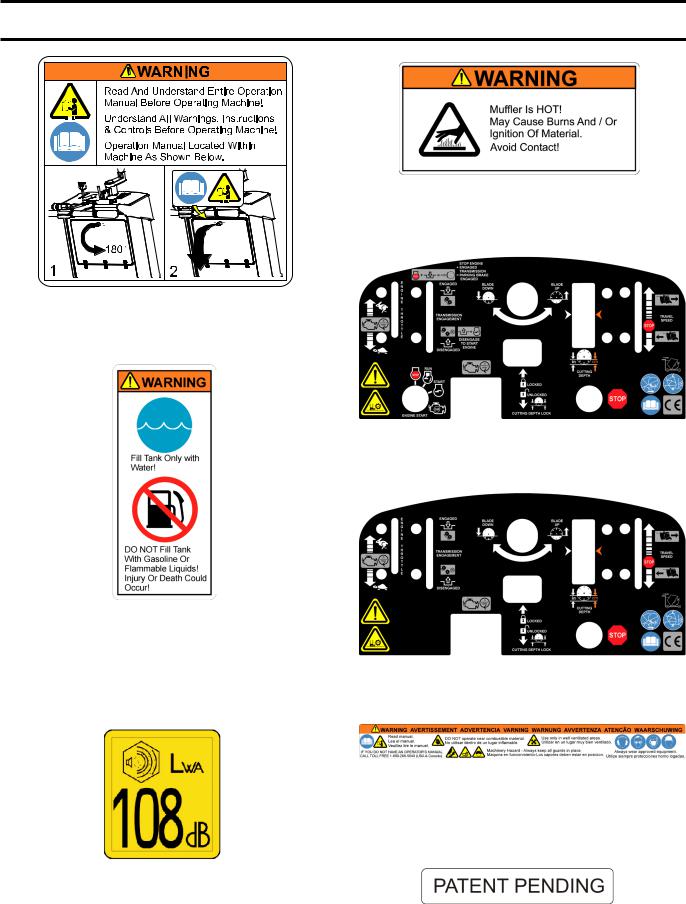

P/N 542 19 07-08 (2)

Location: Left and Right Side of Cowl

(FS 513 Only)

P/N 542 19 07-09 (2)

Location: Left and Right Side of Cowl

(FS 520 Only)

P/N 542 19 07-10 (2)

Location: Left and Right Side of Cowl

(FS 524 Only)

P/N 542 19 07-33

Location: Front of Cowl

P/N 543 85 00-37

“Blade Guard Arrow (FS 524 - 600mm Only)

Top of Rear Blade Guard (600 mm FS 520-FS 524 Only)

P/N 542 16 72-98 (2x)

Location: Left and Right Side of Blade Guard

(FS 513, 520 Only) P/N 542 19 06-46 Local Service Location: Side of Frame

P/N 542 19 05-89

Location: Depth Gauge

SYMBOLS and DECALS

P/N 542 16 90-65

Location: Top of Belt Guard

P/N 542 19 05-93

Location: Rear of Cowl

P/N 542 19 06-36

Location: Top of Cowl, FS 520, FS 524

P/N 542 19 06-17

Location: Water Tank (If Equipped)

P/N 502 24 01-01

Location: Top of Cowl, FS 513

P/N 542 19 06-38

Location: Rear of Cowl

P/N 543 04 57-88 SOUND LEVEL - 108dBA

Location: Upper RH Frame

P/N 542 16 12-35 PATENT PENDING

Location: Upper RH Frame

SAFETY INSTRUCTIONS

General use

WARNING!

WARNING!

Before operating machine, read and understand this entire operation manual & engine operation manual supplied with engine.

Be familiar with machine before operation!

Operator must wear personal protective equipment & clothing appropriate to the work he is doing.

Personal protective equipment, such as hearing & eye protection, is mandatory.

The working area must be completely clear, well lit and all safety hazards removed.

Any persons not involved in the work, should leave the area.

WARNING! Do not contact the tool when machine is in operation.

Fuel Safety:

WARNING! Take care when handling fuel. Bear in mind the risk of fire, explosion and inhaling fumes.

•Only store fuel in containers approved for the purpose.

•Only refuel machine with engine OFF. Never remove fuel cap and fill the fuel tank while the engine is running.

•Always refuel in a well ventilated area.

•Never fill a fuel tank indoors.

•Allow engine to cool before refueling.

Never fuel machine in vicinity of sparks or flames. Do not use machine in flammable area.

Do not smoke while fueling or using the machine.

•Move machine 10 feet (3 meters) from refueling point before starting engine.

•Never start the machine:

1)If fuel has been spilled on the machine. Wipe off spillage and allow remaining fuel to evaporate.

2)If you have spilled fuel on yourself or your clothes. Use soap and water to wash any part of your body that has come in contact with fuel.

3)If the machine is leaking fuel. Check regularly for leaks from the fuel cap and fuel lines.

•Store and transport machine and fuel so that there is

no risk of any leakage or fumes coming into contact with sparks or flames, for example, electrical machinery or electric motors, electrical relays / switches, or boilers.

DUST WARNING

DUST WARNING

Cutting, especially when DRY cutting, generates dust that comes from the material being cut, which frequently contains silica. Silica is a basic component of sand, quartz, brick clay, granite and numerous other minerals and rocks. Exposure to excessive amount of such dust can cause:

•Respiratory diseases (affecting your ability to breath), including chronic bronchitis, silicosis and pulmonary fibrosis from exposure to silica. These diseases may be fatal;

•Skin irritation and rash; and

•Cancer according to NTP* and IARC*

*National Toxicology Program, International Agency for Research on Cancer

Take precautionary steps

•Avoid inhalation of and skin contact with dust, mist and fumes;

•Wet cut when feasible, to minimize dust;

•Wear and ensure that all bystanders wear appropriate respiratory protection such as dust masks designed to filter out microscopic particles. (See OSHA 29 CFR Part 1910.1200)

California Prop 65 Warning:

Use of this product can cause exposure to materials known to the State of California to cause cancer and/or birth defects or other reproductive harm.

SAFETY INSTRUCTIONS

WARNING

POISON EXHAUST GAS

THIS SAW IS SHIPPED FROM THE FACTORY WITHOUT A CATALYTIC CONVERTER.

THE ENGINE PRODUCES CARBON MONOXIDE EXHAUST EMISSIONS AND IS NOT SAFE FOR USE IN ENCLOSED AREAS. USE OF A CATALYTIC CONVERTER REDUCES THE CARBON MONOXIDE EXHAUST EMISSIONS, BUT STILL IS NOT SAFE FOR USE IN ENCLOSED AREAS.

USE ONLY IN WELL-VENTILATED AREAS. WORK SITE AIR QUALITY MUST COMPLY WITH OSHA 29 CFR 1910.1000 PER TABLE Z-1, LIMITS FOR AIR CONTAMINANTS.

MONITOR WORKSPACE AIR QUALITY TO INSURE COMPLIANCE. FAILURE TO COMPLY WILL RESULT IN

DANGER TO LIFE AND CAUSE PERMANENT INJURY OR DEATH.

General Information

Carbon monoxide (CO) has the distinction of being one of the few commonly encountered industrial gasses that is both highly toxic (poison) and odorless. When inhaled, CO acts as a chemical asphyxiant by preferentially combining with hemoglobin in the blood stream. As a result, the hemoglobin is not able to transport its normal amount of oxygen, which results in under-oxygenation of tissues. Symptoms of low-level CO exposure include headaches, dizziness, confusion, and nausea. However, loss of consciousness, permanent injury and death may result from continued or more intense exposure. Because of the health hazards associated with CO inhalation, the Occupational Safety and Health Administration (OSHA) have imposed personal exposure limits. The OSHA exposure limits, which are specified in the 29 CFR 1910.1000 (1998 Revision), allow for a 200 PPM Ceiling Limit and a TWA of 35 PPM per 8-hour shift/40-hr workweek. It is strongly recommended that the OSHA 29 CFR 1910.1000 (Code of Federal Regulations) be consulted for more information on exposure limits for various hazardous materials. If CO Poisoning is suspected immediately remove the victim to fresh air and obtain emergency medical attention.

Proper Ventilation:

THIS SAW IS SHIPPED FROM THE FACTORY WITHOUT A CATALYTIC CONVERTER. It is important to be aware that saws with catalytic converters reduce CO and hydrocarbon (HC) emissions. The exhaust still contains CO. If the workspace is too confined or under-ventilated, CO may accumulate until it eventually exceeds OSHA limits. When this happens, action must be taken to remove workers from areas of high concentration. Operators and work area supervisors should take precautions to insure adequate ventilation of the workspace at all times. Carbon monoxide detection monitors should be used to determine that adequate ventilation exists.

WARNING

HEARING HAZARD

DURING NORMAL USE OF THIS MACHINE, OPERATOR MAY BE EXPOSED TO A NOISE

LEVEL EQUAL TO 85 dB (A) OR GREATER. TEMPORARY AND/OR PERMANENT DAMAGE TO HEARING MAY RESULT. HEARING PROTECTION REQUIRED.

10

SAFETY INSTRUCTIONS

SAFETY FIRST!

WARNINGS

WARNINGS

DO’s AND DO NOT’s

WARNING: FAILURE TO COMPLY WITH THESE WARNINGS AND OPERATING

INSTRUCTIONS COULD RESULT IN DEATH OR SERIOUS BODILY INJURY.

DO

DO Read this entire operator’s manual before operating this machine. Read and understand all warnings, instructions, controls, and symbol definitions contained in this manual, and on the machine.

DO always give a copy of this manual to the equipment user. If you need extra copies, call TOLL FREE 1 800 288-5040 in USA, or +1-913-928-1300 for International, or see “contact information” section of this manual.

DO keep all guards in place and in good condition.

DO wear safety approved hearing, eye, head and respiratory protection. DO read and understand all warnings and instructions on the machine.

DO keep all parts of your body away from the blade and all other moving parts. DO know how to stop the machine quickly in case of emergency.

DO shut off the engine and allow it to cool before refueling or doing maintenance.

DO inspect the blade, flanges and shafts for damage before installing the blade. DO use the blade flange size shown for each blade size.

DO use only steel center diamond blades manufactured for use on concrete saws.

DO use only the blade flanges supplied with the saw. Never use damaged or worn blade flanges.

DO use only blades marked with a maximum operating speed greater than the blade shaft speed. Verify speed by checking blade shaft rpm and pulley diameters and blade flange diameters.

DO verify saw drive configuration by checking blade shaft RPM, pulley diameters, and blade flange diameter.

DO read all safety materials and instructions that accompany any blade used with this machine.

DO inspect each blade carefully before using it. If there are any signs of damage or unusual wear, DO NOT USE

THE BLADE.

DO mount the blade solidly and firmly, Wrench tighten the arbor nut.

DO make sure the blade and flanges are clean and free of dirt and debris before mounting the blade on the saw.

DO use the correct blade for the type of work being done. Check with blade manufacturer if you do not know if blade is correct.

DO use caution and follow the instructions when loading and unloading the machine.

DO operate this machine only in well ventilated areas. Breathing Poison Exhaust Gas could result in death. DO instruct bystanders on where to stand while the machine is in operation.

DO establish a training program for all operators of this machine.

DO clear the work area of unnecessary people. Never allow anyone to stand in front of or behind the blade while the engine is running.

DO make sure the blade is not contacting anything before starting the engine. DO use caution when lifting and transporting this machine.

DO always tie down the machine when transporting.

DO use caution and follow instructions when setting up or transporting the machine. DO have all service performed by competent service personnel

DO verify the blade arbor hole matches the machine spindle before mounting the blade.

DO always check for buried hazards, such as electrical or gas lines before sawing. Always contact local utilities before operation in unknown areas.

DO move the machine at least 10 feet (3 meters) from the fueling point before starting the engine and make sure the fuel cap is on the machine and properly tightened.

DO lift machine only from specified lifting point.

DO clean the machine after each day’s use.

DO use the proper blade flange size for each blade size. Never use damaged or worn blade flanges.

DO use caution when handling fuel.

DO only cut in a straight line, and only saw as deep as the job specifications require.

11

SAFETY INSTRUCTIONS

SAFETY FIRST!

WARNINGS

DO’s AND DO NOT’s

WARNING: FAILURE TO COMPLY WITH THESE WARNINGS AND OPERATING

WARNING: FAILURE TO COMPLY WITH THESE WARNINGS AND OPERATING

INSTRUCTIONS COULD RESULT IN DEATH OR SERIOUS BODILY INJURY.

DO NOT

DO NOT operate this machine unless you have read and understood this operator’s manual. DO NOT operate this machine without the blade guard, or other protective guards in place. DO NOT stand behind or in front of the blade path while the engine is running.

DO NOT leave this machine unattended while the engine is running. DO NOT work on this machine while the engine is running.

DO NOT operate this machine when you are tired, fatigued or under the influence of drugs or alcohol.

DO NOT use a wet blade without adequate water supply to the blade.

DO NOT exceed maximum blade speed shown for each blade size. Excessive speed could result in blade breakage.

DO NOT operate the machine if you are uncertain of how to run the machine. DO NOT use damaged equipment or blades.

DO NOT touch or try to stop a moving blade with your hand. DO NOT cock, jam, wedge or twist the blade in a cut.

DO NOT transport a cutting machine with the blade mounted on the machine. DO NOT use a blade that has been dropped or damaged.

DO NOT use carbide tipped blades.

DO NOT touch a dry cutting diamond blade immediately after use. These blades require several minutes to cool after each cut.

DO NOT use damaged or worn blade flanges.

DO NOT allow other persons to be near the machine when starting, refueling, or when the machine is in operation.

DO NOT operate this machine in an enclosed area. Breathing Poison Exhaust Gas could result in death.

DO NOT operate this machine in the vicinity of anything that is flammable. Sparks could cause a fire or an explosion.

DO NOT allow blade exposure from the guard to be more than 180 degrees. DO NOT operate this machine with the belt guards or blade guard removed.

DO NOT operate this machine unless you are specifically trained for its operation.

DO NOT use a blade that has been over heated (Core has a bluish color). DO NOT jam material into the blade.

DO NOT grind on the side of the blade.

DO NOT tow this machine behind a vehicle.

DO NOT operate this machine with the any guards or shields removed.

DO NOT cut deeper than 1” per pass with a dry blade. Step cut to achieve deeper cuts.

DO NOT operate this machine while under the influence of drugs or alcohol.

*****************

This saw was designed for certain applications only. DO NOT modify this saw or use for any application other than for which it was designed. If you have any questions relative to its application, DO NOT use the saw until you have written Husqvarna Construction Products and we have advised you.

Husqvarna Construction Products North America

17400 West 119th Street, Olathe, Kansas 66061 USA

12

NOTES

13

PARTS IDENTIFICATION (WHAT IS WHAT)

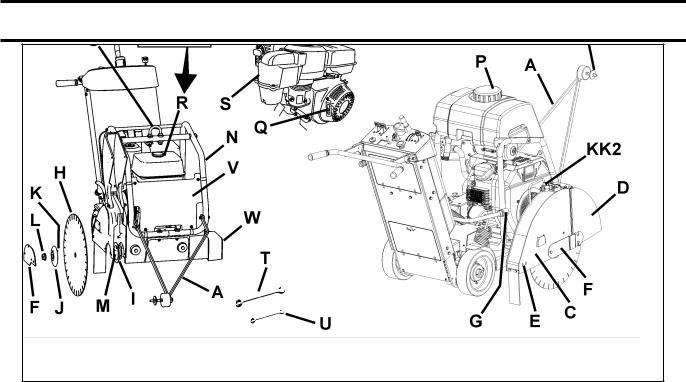

A.Front Pointer: Use to Guide machine in a straight line.

B.Guide Wheel: On Front Pointer (A). Align to cutting line and Blade (H) to produce straight cuts.

C.Blade Guard: Covers Blade (H). Must always be in place when operating machine! Note tool direction as marked on guard with an arrow.

D.Blade Guard Front: Part of Blade Guard. Can be raised to install Blade (H).

E.Blade Guard Rear Bolt: Holds Blade Guard (C) in position. Must be removed and relocated if Blade Guard

(C) is moved.

F.Blade Guard Latch Plate: Covers Outer Flange (J).

G.Water Hose Disconnect (G): Connects Blade Guard

(C) to Water Control Valve (KK1, KK2) or Water Tank (P). Can be used when Blade Guard (C) is mounted to left or right side of machine

H.Blade: Tool that cuts asphalt or concrete material – not included with machine.

I.Inner Flange: Arbor on which the Blade (H) is mounted. Replace if Damaged or worn.

J.Outer Flange: Used to hold Blade (H) in position. Contains Locking Pin (K) that must go through Blade (H). Replace if damaged or worn.

K.Locking Pin: Holds Blade (H) in position. Replace if Damaged or worn.

L.Blade Shaft Nut (L1 / L2): Holds Outer Flange (J) to machine. Nut (L1) on right side of machine has Left Hand threads. Nut (L2)(not shown) on left side of machine has Right Hand threads.

M.Blade Arbor: Blade (H) mounts on this surface.

N.Water Tank / Lifting Point Support: Holds Water Tank

(P). Supports Lifting Point (O).

14

O.Lifting Point: Lift machine only from this point!

P.Water Tank (If Equipped): 25 Liter (6.6 U.S. Gallon) water capacity. Fill only with water! Do not fill with gasoline or other flammable substances! Use only for dust suppression when cutting dry. Use only with laser welded (dry) Diamond Blades (H).

Q.Engine Starting Rope (FS 513 Only): Use to start engine. See engine operation manual.

R.Fuel Tank: Fuel fill point.

FS 520 / FS 524: Located at rear of machine. Fuel fill is located on Left hand side of fuel tank.

FS 513: Located on engine - See engine operation manual.

S.Engine Air Cleaner (FS 513 Shown): Check daily. Clean every four (4) hours if cutting in dusty conditions. See engine operation manual and maintenance section of this document.

T.Blade Shaft Wrench (27mm): Use for installing and removing Blade (H). Store in Tool Compartment (BB).

U.Wrench (13mm): Use for many maintenance items on machine. Store in Tool Compartment (BB).

V.Front Cover: Clips to Water Tank Support (N). Open to turn Engine Start Switch (DD) ON (1) or OFF (0) [FS 513 Only].

W.Shaft Guard: Protects Inner Flange (I). Always installed on opposite side of frame to Blade Guard (C).

X.Depth Control Grease Fitting: Not Shown. See Maintenance section of this document.

Y.Blade Guard Mounting Spade: Holds Blade Guard

(C) in position.

Z.Engine Oil Dipstick: Use to check engine oil level (Not Shown – See Operation Section of this document).

Loading...

Loading...