Husqvarna 343FR, 343F, 345FXT, 345FX, 343R User Manual

...

Operator′s manual

343F 345FX 345FXT 343FR 343FRM 343R 345RX

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

English

KEY TO SYMBOLS

Symbols

WARNING! Clearing saws, brushcutters and trimmers can be dangerous! Careless or incorrect use can result in serious or fatal injury to the operator or others. It is extremely important that you read and understand the contents of the operator’s manual.

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

Always wear:

•A protective helmet where there is a risk of falling objects

•Approved hearing protection

•Approved eye protection

Max. speed of output shaft, rpm

This product is in accordance with applicable EC directives.

Watch out for thrown objects and ricochets.

The operator of the machine must |

|

|

|

ensure, while working, that no |

15 m |

15 m |

|

persons or animals come closer than |

|||

50FT |

50FT |

15 metres.

Machines fitted with saw blades or

grass blades can be thrown violently

to the side when the blade comes into contact with a fixed object.This is called blade thrust. The blade is capable of amputating an arm or leg.

Always keep people and animals at least 15 metres from the machine.

Always wear approved protective gloves.

Wear sturdy, non-slip boots.

Only use non-metallic, flexible cutting attachments, i.e. trimmer heads with trimmer cord.

Noise emission to the environment according to the European Community’s Directive. The machine’s emission is specified in chapter Technical data and on label.

Other symbols/decals on the machine refer to special certification requirements for certain markets.

Switch off the engine by moving the stop switch to the STOP position before carrying out any checks or maintenance.

Always wear approved protective gloves.

Regular cleaning is required.

Visual check.

Approved eye protection must always be used.

2 – English

CONTENTS

Contents |

|

KEY TO SYMBOLS |

|

Symbols ................................................................ |

2 |

CONTENTS |

|

Contents ............................................................... |

3 |

Note the following before starting: ........................ |

3 |

INTRODUCTION |

|

Dear Customer, .................................................... |

4 |

WHAT IS WHAT? |

|

What is what on the brush cutter? ........................ |

5 |

What is what on the brush cutter? ........................ |

6 |

What is what on the brush cutter? ........................ |

7 |

GENERAL SAFETY PRECAUTIONS |

|

Important .............................................................. |

8 |

Personal protective equipment ............................. |

8 |

Machine′s safety equipment ................................. |

9 |

Cutting equipment ................................................ |

12 |

ASSEMBLY |

|

Assembling the handlebar and throttle ................. |

15 |

Transport position, handlebar ............................... |

15 |

Assembling the cutting equipment ....................... |

16 |

Fitting the blade guard/combination guard, grass |

|

blade and ball-bearing-mounted support cup ....... |

16 |

Fitting the blade guard and saw blade .................. |

17 |

Fitting the trimmer guard and trimmer head Trimmy |

|

SII ......................................................................... |

18 |

Fitting the shredder blade and the shredder blade |

|

guard (343FRM) ................................................... |

18 |

Fitting other guards and cutting attachments ....... |

19 |

Adjusting the harness and brush cutter ................ |

20 |

Standard harness ................................................. |

20 |

Triobalance harness ............................................. |

20 |

FUEL HANDLING |

|

Fuel safety ............................................................ |

22 |

Fuel ...................................................................... |

22 |

Fuelling ................................................................. |

23 |

STARTING AND STOPPING |

|

Check before starting ........................................... |

24 |

Starting and stopping ........................................... |

24 |

WORKING TECHNIQUES |

|

General working instructions ................................ |

26 |

MAINTENANCE |

|

Carburettor ........................................................... |

31 |

Muffler .................................................................. |

32 |

Cooling system ..................................................... |

32 |

Air filter ................................................................. |

32 |

Bevel gear ............................................................ |

33 |

Drive shaft ............................................................ |

33 |

Spark plug ............................................................ |

33 |

Winter use ............................................................. |

34 |

Maintenance schedule .......................................... |

35 |

TECHNICAL DATA |

|

Technical data ....................................................... |

36 |

EC-declaration of conformity ................................ |

41 |

Note the following before starting:

Please read the operator’s manual carefully.

WARNING! Long-term exposure to noise ! can result in permanent hearing

impairment. So always use approved hearing protection.

WARNING! Under no circumstances may ! the design of the machine be modified

without the permission of the manufacturer. Always use genuine accessories. Non-authorized modifications and/or accessories can result in serious personal injury or the death of the operator or others.

WARNING! A clearing saw, brushcutter ! or trimmer can be dangerous if used

incorrectly or carelessly, and can cause serious or fatal injury to the operator or others. It is extremely important that you read and understand the contents of this operator’s manual.

English – 3

INTRODUCTION

Dear Customer,

Congratulations on your choice to buy a Husqvarna product! Husqvarna is based on a tradition that dates back to 1689, when the Swedish King Karl XI ordered the construction of a factory on the banks of the Husqvarna River, for production of muskets. The location was logical, since water power was harnessed from the Huskvarna River to create the waterpowered plant. During the more than 300 years of beeing, the Husqvarna factory has produced a lot of different products, from wood stoves to modern kitchen appliances, sewing machines, bicycles, motorcycles etc. In 1956, the first motor driven lawn mowers appeared, followed by chain saws in 1959, and it is within this area Husqvarna is working today.

Today Husqvarna is one of the leading manufacturers in the world of forest and garden products, with quality as our highest priority. The business concept is to develop, manufacture and market motor driven products for forestry and gardening as well as for building and construction industry. Husqvarna′s aim is also to be in the front edge according to ergonomics, usability, security and environmental protection. That is the reason why we have developed many different features to provide our products within these areas.

We are convinced that you will appreciate with great satisfaction the quality and performance of our product for a very long time to come. The purchase of one of our products gives you access to professional help with repairs and service whenever this may be necessary. If the retailer who sells your machine is not one of our authorised dealers, ask for the address of your nearest service workshop.

It is our wish that you will be satisfied with your product and that it will be your companion for a long time. Think of this operator′s manual as a valuable document. By following its′ content (using, service, maintenance etc) the life span and the second-hand value of the machine can be extended. If you will sell this machine, make sure that the buyer will get the operator′s manual.

Thank you for using a Husqvarna product.

Husqvarna AB has a policy of continuous product development and therefore reserves the right to modify the design and appearance of products without prior notice.

4 – English

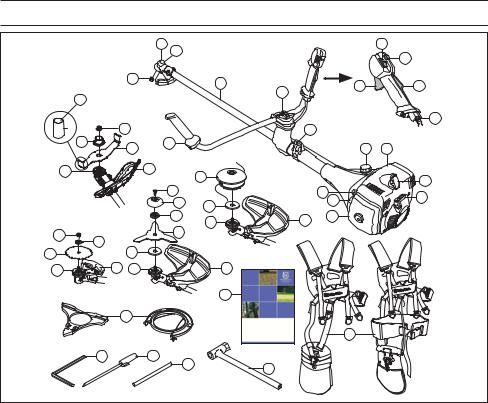

WHAT IS WHAT?

|

|

3 |

|

|

8 |

|

|

2 |

|

|

32 |

|

|

|

|

|

|

|

31 |

|

|

|

|

|

|

5 |

17 |

7 |

9 |

|

|

|

|

|

33 |

18 |

|

|

|

10 |

|

|

6 |

|

|

|

|

19 |

|

|

|

|

|

|

|

|

13 |

11 |

|

|

|

|

|

||

20 |

|

|

|

|

|

1 |

|

22 |

|

|

|

|

|

|

|

23 |

|

|

|

|

|

|

|

34 |

|

34 |

|

14 |

12 |

|

|

15 |

|||

|

|

|

|

|

|

21 |

4 |

21 |

4 |

16 |

|

|

|

|

|

|

|

|

|

|

25 |

|

|

|

|

26 |

|

|

|

|

|

|

|

30 |

|

27 |

|

28 |

|

|

|

|

|

29 |

24 |

|

|

|

|

|

|

|

What is what on the brush cutter? (343R, 345RX)

1 |

Grass blade |

18 |

Locking screw |

2 |

Grease filler cap, bevel gear |

19 |

Support cup |

3 |

Bevel gear |

20 |

Support flange |

4 |

Cutting attachment guard |

21 |

Drive disc |

5 |

Shaft |

22 |

Trimmer head |

6 |

Handlebar |

23 |

Spark plug cap and spark plug |

7 |

Throttle control |

24 |

Socket spanner |

8 |

Stop switch |

25 |

Operator′s manual |

9 |

Throttle lockout |

26 |

Transport guard |

10 |

Support eyes for harness |

27 |

Allen key |

11 |

Cylinder cover |

28 |

Carburettor screwdriver |

12 |

Starter handle |

29 |

Locking pin |

13 |

Fuel tank |

30 |

Harness |

14 |

Choke control |

31 |

Locking nut |

15 |

Air purge |

32 |

Start throttle button |

16 |

Air filter cover |

33 |

Adjusting the throttle wire |

17 |

Handle adjustment |

34 |

Metal cup |

English – 5

WHAT IS WHAT?

|

3 |

|

|

8 |

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

18 |

|

5 |

9 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

29 |

|

|

|

|

|

17 |

|

|

|

|

|

10 |

|

|

6 |

|

|

13 |

11 |

|

18 |

|

|

||

|

19 |

|

|

|

|

1 |

|

|

|

|

21 |

|

|

|

14 |

|

|

|

|

|

|

12 |

|

|

|

|

|

15 |

|

|

|

|

|

|

|

20 |

4 |

23 |

|

16 |

|

|

|

|

|

|

24

22

28

25 |

26 |

27 |

What is what on the brush cutter? (343F, 345FX, 345FXT)

1 |

Saw blade |

16 |

Air filter cover |

2 |

Grease filler cap, bevel gear |

17 |

Handle adjustment |

3 |

Bevel gear |

18 |

Locking nut |

4 |

Cutting attachment guard |

19 |

Support flange |

5 |

Shaft |

20 |

Drive disc |

6 |

Handlebar |

21 |

Spark plug |

7 |

Throttle control |

22 |

Socket spanner |

8 |

Stop switch |

23 |

Operator′s manual |

9 |

Throttle lockout |

24 |

Transport guard |

10 |

Support eyes for harness |

25 |

Allen key |

11 |

Cylinder cover |

26 |

Carburettor screwdriver |

12 |

Starter handle |

27 |

Locking pin |

13 |

Fuel tank |

28 |

Harness |

14 |

Choke control |

29 |

Switch for heated handle (345FXT) |

15 |

Air purge |

|

|

6 – English

WHAT IS WHAT?

|

|

3 |

|

|

|

|

|

8 |

|

|

2 |

|

|

|

|

|

33 |

|

|

|

|

|

|

|

|

|

|

|

19 |

|

|

5 |

|

7 |

9 |

|

|

|

|

|

|

|||

|

|

|

|

|

|

17 |

||

26 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

34 |

x 2 |

|

19 |

|

|

|

10 |

|

|

|

|

|

|

|

|

|

||

21 |

|

6 |

|

|

|

|

13 |

11 |

|

|

35 |

|

|

|

|

||

20 |

|

4 |

|

25 |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

18 |

|

|

|

|

|

|

|

|

|

|

|

|

24 |

|

|

|

|

14 |

12 |

|

|

23 |

|

|

|

|

15 |

|

|

|

|

22 |

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

21 |

|

20 |

|

4 |

16 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

19 |

|

1 |

|

|

|

|

|

|

21 |

|

|

|

|

|

|

|

|

1 |

|

22 |

|

|

|

|

|

|

20 |

4 |

20 |

|

|

4 |

|

|

|

|

|

|

|

|

32 |

|

|

|

|

|

26 |

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

|

27 |

|

28 |

29 |

|

|

|

|

|

|

|

|

|

|

31 |

|

|

|

|

|

|

|

|

|

|

|

What is what on the brush cutter? (343FR, 343FRM)

1 |

Blade |

19 |

Locking nut |

2 |

Grease filler cap, bevel gear |

20 |

Drive disc |

3 |

Bevel gear |

21 |

Support flange |

4 |

Cutting attachment guard |

22 |

Metal cup |

5 |

Shaft |

23 |

Support cup |

6 |

Handlebar |

24 |

Locking screw |

7 |

Throttle control |

25 |

Trimmer head |

8 |

Stop switch |

26 |

Transport guard |

9 |

Throttle lockout |

27 |

Allen key |

10 |

Support eyes for harness |

28 |

Carburettor screwdriver |

11 |

Cylinder cover |

29 |

Locking pin |

12 |

Starter handle |

30 |

Harness |

13 |

Fuel tank |

31 |

Socket spanner |

14 |

Choke control |

32 |

Operator′s manual |

15 |

Air purge |

33 |

Start throttle button |

16 |

Air filter cover |

34 |

Adjusting the throttle wire |

17 |

Handle adjustment |

35 |

Shredder blade (343FRM) |

18 |

Spark plug cap and spark plug |

|

|

English – 7

GENERAL SAFETY PRECAUTIONS

Important

IMPORTANT!

The machine is only designed for trimming grass, grass clearing and/or forestry clearing.

The only accessories you can operate with this engine unit are the cutting attachments we recommend in the chapter on Technical data.

Never use the machine if you are tired, if you have drunk alcohol, or if you are taking medication that could affect your vision, your judgement or your co-ordination.

Wear personal protective equipment. See instructions under the heading ”Personal protective equipment”.

Never use a machine that has been modified in any way from its original specification.

Never use a machine that is faulty. Carry out the checks, maintenance and service instructions described in this manual. Some maintenance and service measures must be carried out by trained and qualified specialists. See instructions under the heading Maintenance.

All covers, guards and handles must be fitted before starting. Ensure that the spark plug cap and ignition lead are undamaged to avoid the risk of electric shock.

The machine operator must ensure that no people or animals come closer than 15 metres while working. When several operators are working in the same area the safety distance should be at least twice the tree height and no less than 15 metres.

WARNING! This machine produces an ! electromagnetic field during operation.

This field may under some circumstances interfere with active or passive medical implants. To reduce the risk of serious or fatal injury, we recommend persons with medical implants to consult their physician and the medical implant manufacturer before operating this machine.

WARNING! Running an engine in a ! confined or badly ventilated area can

result in death due to asphyxiation or carbon monoxide poisoning.

Personal protective equipment

IMPORTANT!

A clearing saw, brushcutter or trimmer can be dangerous if used incorrectly or carelessly, and can cause serious or fatal injury to the operator or others. It is extremely important that you read and understand the contents of this operator’s manual.

You must use approved personal protective equipment whenever you use the machine. Personal protective equipment cannot eliminate the risk of injury but it will reduce the degree of injury if an accident does happen. Ask your dealer for help in choosing the right equipment.

WARNING! Listen out for warning signals ! or shouts when you are wearing hearing protection. Always remove your hearing protection as soon as the engine stops.

HELMET

A helmet should be worn if the trees being cleared are taller than 2 m.

HEARING PROTECTION

Wear hearing protection that provides adequate noise reduction.

EYE PROTECTION

Always wear approved eye protection. If you use a visor then you must also wear approved protective goggles. Approved protective goggles must comply with standard ANSI Z87.1 in the USA or EN 166 in EU countries.

GLOVES

Gloves should be worn when necessary, e.g., when fitting cutting attachments.

8 – English

GENERAL SAFETY PRECAUTIONS

BOOTS

Wear boots with steel toe-caps and non-slip sole.

CLOTHING

Wear clothes made of a strong fabric and avoid loose clothing that can catch on twigs and branches. Always wear heavy, long pants. Do not wear jewellery, shorts sandals or go barefoot. Secure hair so it is above shoulder level.

FIRST AID KIT

Always have a first aid kit nearby.

Machine′s safety equipment

This section describes the machine′s safety equipment, its purpose, and how checks and maintenance should be carried out to ensure that it operates correctly. See the ”What is what?” section to locate where this equipment is positioned on your machine.

The life span of the machine can be reduced and the risk of accidents can increase if machine maintenance is not carried out correctly and if service and/or repairs are not carried out professionally. If you need further information please contact your nearest service workshop.

IMPORTANT!

All servicing and repair work on the machine requires special training. This is especially true of the machine′s safety equipment. If your machine fails any of the checks described below you must contact your service agent. When you buy any of our products we guarantee the availability of professional repairs and service. If the retailer who sells your machine is not a servicing dealer, ask him for the address of your nearest service agent.

WARNING! Never use a machine with ! faulty safety equipment. The machine’s

safety equipment must be checked and maintained as described in this section. If your machine fails any of these checks contact your service agent to get it repaired.

Throttle lockout

The throttle lockout is designed to prevent accidental operation of the throttle control. When you press the lock

(A) (i.e. when you grasp the handle) it releases the throttle control (B). When you release the handle the throttle control and the throttle lockout both move back to their original positions. This movement is controlled by two independent return springs.This arrangement means that the throttle control is automatically locked at the idle setting.

Make sure the throttle control is locked at the idle setting when the throttle lockout is released.

Press the throttle lockout and make sure it returns to its original position when you release it.

Check that the throttle control and throttle lockout move freely and that the return springs work properly.

See instructions under the heading Start. Start the machine and apply full throttle. Release the throttle and check that the cutting attachment stops and remains at a standstill. If the cutting attachment rotates with the throttle in the idle position then the carburettor idle setting must

English – 9

GENERAL SAFETY PRECAUTIONS

be checked. See instructions under the heading Maintenance.

Stop switch

Use the stop switch to switch off the engine.

Start the engine and make sure the engine stops when you move the stop switch to the stop setting.

Cutting attachment guard

This guard is intended to prevent loose objects from being thrown towards the operator. The guard also protects the operator from accidental contact with the cutting attachment.

Check that the guard is undamaged and not cracked. Replace the guard if it has been exposed to impact or is cracked.

Always use the recommended guard for the cutting attachment you are using. See chapter on Technical data.

WARNING! Never use a cutting

! attachment without an approved guard. See the chapter on Technical data. If an incorrect or faulty guard is fitted this can cause serious personal injury.

Vibration damping system

Your machine is equipped with a vibration damping system that is designed to minimize vibration and make operation easier.

Use of incorrectly wound cord or an incorrect cutting attachment increases the level of vibration. See instructions under the heading Cutting equipment.

The machine′s vibration damping system reduces the transfer of vibration between the engine unit/cutting equipment and the machine′s handle unit.

Regularly check the vibration damping units for cracks or deformation. Check that the vibration damping element is undamaged and securely attached.

WARNING! Overexposure to vibration ! can lead to circulatory damage or nerve

damage in people who have impaired circulation. Contact your doctor if you experience symptoms of overexposure to vibration. Such symptoms include numbness, loss of feeling, tingling, pricking, pain, loss of strength, changes in skin colour or condition. These symptoms normally appear in the fingers, hands or wrists. The risk increases at low temperatures.

Quick release

There is an easily accessible, quick release fitted at the front as a safety precaution in case the engine catches fire, or in any other situation that requires you to free yourself from the machine and harness. See instructions under the heading Adjusting the harness and brush

10 – English

GENERAL SAFETY PRECAUTIONS

cutter. Certain harnesses also have a quick release fitted to the support hook.

Check that the harness straps are correctly positioned. Once the harness and machine have been adjusted, check that the harness quick release works correctly.

Muffler

The muffler is designed to keep noise levels to a minimum and to direct exhaust fumes away from the user. A muffler fitted with a catalytic converter is also designed to reduce harmful exhaust gases.

In countries that have a warm and dry climate there is a significant risk of fire. We therefore fit certain mufflers with a spark arrestor mesh. Check whether the muffler on your machine is fitted with this kind of mesh.

For mufflers it is very important that you follow the instructions on checking, maintaining and servicing your machine. See instructions under the heading Checking, maintaining and servicing the machine’s safety equipment.

Never use a machine that has a faulty muffler.

Regularly check that the muffler is securely attached to the machine.

If the muffler on your machine is fitted with a spark arrestor mesh this must be cleaned regularly. A blocked mesh will cause the engine to overheat and may lead to serious damage.

WARNING! Mufflers fitted with catalytic ! converters get very hot during use and remain so for some time after stopping.

This also applies at idle speed. Contact can result in burns to the skin. Remember the risk of fire!

WARNING! The inside of the muffler ! contain chemicals that may be

carcinogenic. Avoid contact with these elements in the event of a damaged muffler.

WARNING! Bear in mind that:

! The exhaust fumes from the engine are hot and may contain sparks which can start a fire. Never start the machine indoors or near combustible material!

Locking nut

A locking nut is used to secure some types of cutting attachment.

When fitting, tighten the nut in the opposite direction to the direction of rotation of the cutting attachment. To remove it, undo the nut in the same direction as the cutting attachment rotates. (CAUTION! The nut has a left-hand thread.) When loosening and tightening the saw blade nut, there is a risk of injury from the teeth of the saw blade. You should therefore always ensure that your hand is shielded by the blade guard when doing this. Always use a socket spanner with a shaft that is long enough to allow this. The arrow in the diagram shows the area where you

English – 11

GENERAL SAFETY PRECAUTIONS

should operate the socket spanner when loosening or tightening the nut.

The nylon lining inside the locking nut must not be so worn that you can turn it by hand. The lining should offer a resistance of at least 1.5 Nm. The nut should be replaced after it has been put on approx. 10 times.

Locking screw

The lock screw must be tightened securely for ball- bearing-mounted support cups.

Cutting equipment

This section describes how to choose and maintain your cutting equipment in order to:

•Reduce the risk of blade thrust.

•Obtain maximum cutting performance.

•Extend the life of cutting equipment.

IMPORTANT!

Only use cutting attachments with the guards we recommend! See the chapter on Technical data.

Refer to the instructions for the cutting attachment to check the correct way to load the cord and the correct cord diameter.

Keep the teeth of the blade correctly sharpened! Follow our recommendations. Also refer to the instructions on the blade packaging.

Maintain the correct blade setting! Follow our instructions and use the recommended file gauge.

WARNING! Always stop the engine ! before doing any work on the cutting

attachment.This continues to rotate even after the throttle has been released. Ensure that the cutting attachment has stopped completely and disconnect the HT lead from the spark plug before you start to work on it.

WARNING! Using an incorrect cutting ! attachment or an incorrectly sharpened

blade increases the risk of blade thrust.

Cutting equipment

Saw blades are intended for cutting fibrous types of wood.

Grass blades and grass cutters are intended for cutting coarse grass.

Shredder blades are intended for cutting coarse grass and bushes.

A trimmer head is intended for trimming grass.

General rules

Only use cutting attachments with the guards we recommend! See the chapter on Technical data.

Keep the teeth of the blade correctly sharpened! Follow our instructions and use the recommended file gauge. An

12 – English

GENERAL SAFETY PRECAUTIONS

incorrectly sharpened or damaged blade increases the risk of accidents.

Keep the correct setting on the saw blade! Follow our instructions and use the recommended setting tool. An incorrectly set saw blade increases the risk of jamming and blade thrust, and damage to the saw blade.

Check the cutting attachment for damage or cracks. A damaged cutting attachment should always be replaced.

Sharpening grass cutters and grass blades

•See the cutting attachment packaging for correct sharpening instructions. Sharpen blades and cutters using a single-cut flat file.

•Sharpen all edges equally to maintain the balance of the blade.

WARNING! Always discard a blade that is ! bent, twisted, cracked, broken or

damaged in any other way. Never attempt to straighten a twisted blade so that it can be reused. Only use original blades of the specified type.

Sharpening the saw blade

•See the cutting attachment packaging for correct sharpening instructions.

A correctly sharpened blade is essential for working efficiently and to avoid unnecessary wear to the blade and brush cutter.

•Make sure that the blade is well supported when you file it. Use a 5.5 mm round file with a file holder.

•The filing angle is 15°. File alternate teeth to the right and those in between to the left. If the blade has been heavily pitted by stones it may be necessary to dress the top edges of the teeth with a flat file, in exceptional cases. If so, this should be done before filing with a round file. The top edges must be filed down by the same amount for all the teeth.

Adjust the blade setting. This should be 1 mm.

English – 13

GENERAL SAFETY PRECAUTIONS

Trimmer head

IMPORTANT!

Always ensure the trimmer cord is wound tightly and evenly around the drum, otherwise the machine will generate harmful vibration.

•Only use the recommended trimmer heads and trimmer cords. These have been tested by the manufacturer to suit a particular engine size. This is especially important when a fully automatic trimmer head is used. Only use the recommended cutting attachment. See the chapter on Technical data.

•Smaller machines generally require small trimmer heads and vice versa. This is because when clearing using a cord the engine must throw out the cord radially from the trimmer head and overcome the resistance of the grass being cleared.

•The length of the cord is also important. A longer cord requires greater engine power than a shorter cord of the same diameter.

•Make sure that the cutter on the trimmer guard is intact.This is used to cut the cord to the correct length.

•To increase the life of the cord it can be soaked in water for a couple of days. This will make the line tougher so that it lasts longer.

14 – English

ASSEMBLY

Assembling the handlebar and throttle

CAUTION! Some models have the throttle handle fitted at the factory.

•Remove the screw at the rear of the throttle handle.

•Slide the throttle handle onto the right side of the handlebar, (see diagram).

•Align the screw hole in the throttle handle with the hole in the handlebar.

•Refit the screw in the hole in the rear of the throttle handle.

•Screw the screw through the handle and handlebar. Tighten it.

•Unscrew the knob from the handlebar mounting.

•Position the handlebar as shown. Fit the mounting components and tighten the knob lightly.

343R, 345RX |

343F, 345FX, 345FXT |

343FR, 343FRM |

•Put on the harness and hang the machine from the support hook. Now make a final adjustment so that

the machine is in a comfortable working position when it hangs from the harness.

•Tighten the knob.

Transport position, handlebar

•The handlebar can easily be turned to fit along the shaft for easier transportation and storage.

•Loosen the knob.Turn the handlebar clockwise so that the throttle handle rests against the engine.

•Now twist the handlebar around the shaft. Tighten the knob.

•Fit the transport guard to the cutting attachment.

English – 15

ASSEMBLY

Assembling the cutting equipment

WARNING!

! When fitting the cutting attachment it is extremely important that the raised section on the drive disc/support flange engages correctly in the centre hole of the cutting attachment. If the cutting attachment is fitted incorrectly it can result in serious and/or fatal personal injury.

WARNING! Never use a cutting

! attachment without an approved guard. See the chapter on Technical data. If an incorrect or faulty guard is fitted this can cause serious personal injury.

IMPORTANT! If a saw blade or grass blade are to be used the machine must be equipped with the correct handlebar, blade guard and harness.

Fitting the blade guard/ combination guard, grass blade and ball-bearing-mounted support cup

•Hang the trimmer guard/combination guard (A) on the two hooks on the plate holder (M). Bend the guard around the shaft and tighten it with the bolt (L) on the opposite side of the shaft. Use the locking pin (C). Place the locking pin in the groove on the screw head and tighten. See diagram.

L

M

M

C

A

CAUTION! Always use the recommended guard for the cutting attachment you are using. See chapter on Technical data.

•Fit the drive disc (B) on the angle gear’s output shaft.

•Centre the metal cup (P) on the drive disc’s blade guide.

•Turn the output shaft until one of the holes in the drive disk aligns with the corresponding hole in the gear housing.

•Insert the locking pin (C) in the hole to lock the shaft.

•Position the blade (D) with the drive disk (B). Make sure that the blade is centered by fitting it to the guide on the drive disk.

•Fit the support flange (F) on the output shaft so that it rests against the blade.

N

E

E

F

D

P

B

A

A

C

ML

•Screw the support cup (E) onto the output shaft threads (CAUTION! Left-hand thread). Tighten to a torque of 35-50 Nm (3.5-5.0 kpm). Use the socket spanner in the tool kit. Note that the locking pin (C) must remain inside the gear housing to lock the drive disk. Hold the shaft of the socket spanner as close to the blade guard/combination guard as possible.

WARNING! Tighten the lock screw (N) in ! the center hole of the support cup.

Tighten to a torque of 35-50 Nm (3.5-5.0 kpm), CAUTION! Left-hand thread. If the lock screw is not fitted in the support cup, there is a risk that the support cup will come unscrewed. This means that the blade will also come loose, which could result in serious or fatal injury to the operator or others.

16 – English

Loading...

Loading...