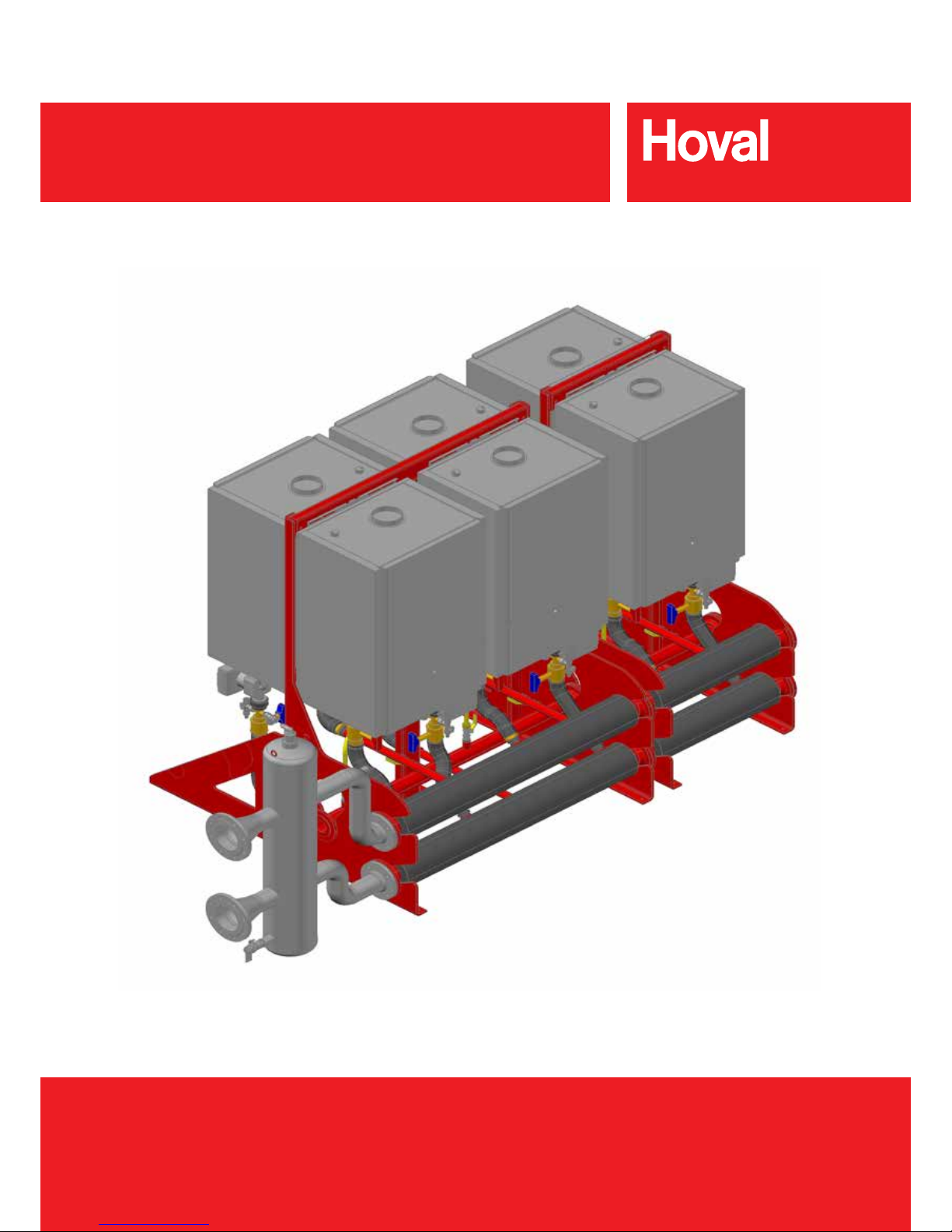

Hoval TopGas Cascade 60, TopGas Cascade 80, TopGas Cascade 100, TopGas Cascade 120 Technical Information And Assembly Instructions

Technical Information and Assembly Manual

Output range 60 to 720 kW

4215256-00 - 11/16 Subject to modification

TopGas Cascade

Condensing Gas Boilers

2

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

Contents

Page No.

1. Important Information 4

1.1. Documentation 4

1.2. Guarantee 4

1.3. Other instructions 4

1.4. Safety instructions 4

1.5. Related Installation Documents 5

1.6. Transport and Storage 5

1.7. Installation. Location requirements 5

2. Technical Description 6

2.1. Technical Description 6

2.2. Cascade Product Codes 6

3. Technical Data 7

3.1. Technical data, TopGas

®

Cascade 60 7

3.2. Technical data, TopGas

®

Cascade 80 8

3.3. Technical data, TopGas

®

Cascade 100 9

3.4 Technical data, TopGas

®

Cascade 120 10

3.5. Technical Drawings, cascade in-line frame mounted 11

3.6. Technical Drawings, cascade back to back frame mounted 17

3.7. Technical Drawings, optional single and two boiler low loss headers 22

3.8. Technical Drawings, optional cascade low loss headers 23

3.9. Technical Drawings, optional cascade air and dirt separators 24

4. Installation requirements 25

4.1. Hydraulic Installation 25

4.2. Recommendations 25

4.3. Water Quality 25

4.4. Gas Connection 25

4.5. Flue Gas Connection, Chimney 26

4.6. Electrical Connections 26

4.7. Ventilation 26

4.8. Automatic Air Vent 26

4.9. Condensate Drainage 26

5. TopGas Cascade Assembly 27

5.1. Step 1: Build the frame (2-4 boiler inline, 3-4 boiler back to back) 27

5.1.1. Step 1: Build the frame (1 boiler inline, 2 boiler back to back) 29

5.2. Step 2: Mount the boilers 31

5.3. Step 3: Pipe the gas from the header to the boilers 32

5.4 Step4:Connectthenipplestotheowandreturnheaders 34

5.5. Step5:Connecttheboilertotheowandreturnheader(TopGas60and80) 35

5.5.1 Step5:Connecttheboilertotheowandreturnheader(TopGas100and120) 36

5.6. Step6:Connecttheblankinganges 37

5.7. Step 7: Fit the pre-formed insulation wrap 38

5.8. Step 8: Fitting the back boiler connections 38

6. Accessories - Hydraulics and Gas 40

6.1. Low loss header 40

6.2. Air and dirt separator 41

3

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

6.3. TopGas 60 single boiler low loss header 41

6.4. TopGas 80 single or two boiler low loss header 41

6.5. TopGas 100,120 single boiler low loss header 41

6.6. Boiler circulating pump, TopGas (60,80) 41

6.7. Pump insulation cover, TopGas (60,80) 41

6.8 Boiler circulating pump, TopGas (100,120) 41

6.9. Boilerowandreturnconnectionvalveset,TopGas(60,80) 42

6.10 Boilerowandreturnconnectionvalveset,TopGas(100,120) 42

6.11 Gas Filter 42

6.12 Liquid gas conversion kit 42

7. Accessories Controls 43

8. Accessories - Flues (Individual - concentric) 46

8.1. Connection C100/150 to 2xE100PP 46

8.2. 1000mm extension (including support bracket) 46

8.3. 500mm extension (including support bracket) 46

8.4. Vertical terminal (black) with cap 46

8.5. Vertical adapter with 2 sample points 46

8.6. Vertical adapter with condensing drain connection, siphon kit & 2 sample points 46

8.7. 45° elbow 46

8.8. 90° elbow 46

8.9. Support bracket 46

8.10. Leadpitchedroofashing 46

8.11. Aluminiumatroofashing 47

8.12. Wall terminal kit (for horizontal discharge) 47

8.13. Air inlet non-return damper for TopGas (60-120) only 47

9. Accessories - Flues (Individual - Plume kit) 48

9.1. Plume management kit 48

9.2. Plume 90° elbow 48

9.3. Plume 45° elbow 48

9.4. Plume extension 48

9.5. Plume nose piece 48

10. Typical Hydraulic Schematic 49

Hoval Service and Spares Contact details 50

4

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

1. Important Information

1.1. Documentation

Hoval gas boilers are only to be installed and placed in operation

by suitably qualied technicians; these instructions are therefore

intended to give a brief description of the Hoval TopGas Cascade

for the specialist covering the installation, commissioning, and

subsequent maintenance of these units. Other documents apply

in addition to these instructions. We accept no liability for any

damage caused by failure to observe these instructions.

The installation of boilers and their ancillary equipment is

normally carried out by the Heating Engineer, and for the purpose

of this manual he / she is regarded as the installer, and, as such,

it is his / her responsibility to ensure that he / she has read and

understood the contents of this manual before installing the

boiler.

1.2. Guarantee

Important Note: Proper functionality is only guaranteed if the

installation and operating instructions are observed and the boiler

is regularly maintained. The installation should be in accordance

with current I.E.E. Regulations, relevant British & European

Standards and Codes of Practice, Building Regulations and Local

Authority Bylaws.

Troubleshooting and damage repair caused by contaminated

operating media (gas, water, combustion air), unsuitable

chemical additives to the heating water, incorrect handling, faulty

installation, inadmissible modications and damage due to the

exercising of force are not covered by our warranty; the same

applies to corrosion through halogen compounds, e.g. from spray

cans, paints, adhesives, solvents and cleaning agents. Hoval

gas boilers are only to be installed by competent and qualied

persons. No modications are to be made to the boilers.

1.3. Other instructions

Depending on the model, any further instructions are enclosed

with the individually packed components. For any adjustments

and additional accessories please refer to the relevant Technical

Information Installation Instructions for the individual Hoval

TopGas boilers and any relevant installation Standards and

Regulations.

1.4. Safety instructions

Installation and maintenance of the boiler must only be

performed by a competent person with valid accreditation from

the Health and Safety Executive in accordance with the “Gas

Safety (Installation and Use) Regulations 1998”. The existing

regulations, rules and guidelines must be observed when doing

so. The competent person is also responsible for inspection,

maintenance and repairs to the boiler, and alterations to the gas

volume setting.

There is a risk of injury or death to the user or others, or of

damage to the product and other property, in the event of

improper use or use for which it is not intended. The product is

intended as a heat generator for closed hot water/central heating

installations and for hot water generation.

The system may only be placed in operation when all relevant

standards and safety regulations have been complied with. The

following conditions must be satised:

• Safety valve installed (closed system)

• Power supplies connected and tested

• Controls system commissioned

• System lled with water and suitably treated

• Expansion vessel connected and charged

• Boilers connected to an appropriate ue or chimney

• Burner parameters are set correctly

When maintaining working on individual appliances or the

TopGas cascade assembly;

• Allow the gas boilers to cool

• Switch off the boilers and isolate from the electrical supply

• Shut off the gas isolating valve to either the individual

appliance or the cascade gas header

• Close the isolation valves of the appliance (heating ow and

return)

• Replace all removed covers and cladding on completion of

the repair / maintenance work

• Do not exceed the maximum operating pressure and

temperature of the gas boiler (see identication plate)

What to do in an emergency if you smell gas

Installation errors, damage, tampering, unauthorised installation

sites or similar can cause gas to escape and result in a risk of

poisoning and explosion. If there is a smell of gas in the building,

proceed as follows:

• Avoid rooms that smell of gas

• If possible, open doors and windows fully and ensure

adequate ventilation

• Do not use naked ames (e.g. lighters, matches)

• Do not smoke

• Do not use any electrical switches, mains plugs, doorbells,

telephones

• Close the gas meter isolator device or the main isolator

• If possible, close the gas isolator cock in the gas supply

• Leave the building

• If you can actually hear gas leaking, leave the building

immediately and ensure that others do not enter the building

• Alert the re brigade and police when you are outside the

building

• Notify the gas supply company or National Grid Transco

0800 111 999 by telephone from outside the building!

5

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

1.5. Related Installation Documents

To ensure the safe installation and continued satisfactory

operation of your appliance, all works shall be carried out by a

competent installer fully conversant with the required current and

up to date, acts, standards, laws and regulations relevant for this

range of equipment at the time of installation. Installers shall carry

out a full site risk assessment and put into place all necessary

steps and procedures to comply with the Health and Safety at

Work Act and ensure safety of themselves and others with regard

to manual handling and working at height requirements.

Attention shall be paid to (but not restricted to) the following:

• Gas Safety (Installation and Use) regulations

• Non Domestic Heating, Cooling and Ventilation Compliance

Guide

• All current Building Regulations for England and Wales

(Includes Approved Codes of Practice and Approved

Documents for building regulations e.g. L1, L2A, L2B, L8)

• The Building Standards, Scotland, and any requirements

determined by the local authorities within

• BS 7671 Requirements for electrical installations. IEE Wiring

Regulations

• The Electricity at Work Regulations

• The Clean Air Act 1993, 1968 1993 and the 3rd Edition

of the Chimney Height memorandum 1981. (installations

exceeding 150 kW)

• The Water supply (water ttings) regulations 1999

• BS 5440-1 Flueing and ventilation for gas appliances

• BS 5854 Code of practice for ues and ue structures in

buildings

• BS EN 12828 Design of water-based heating systems

• BS 6644 Specication for the installation of gas red hot

water boilers with rated inputs between 70 kW (net) and

1.8 MW (net) (2nd and 3rd family gases)

• BS 6700 Specication for the design, installation, testing

and maintenance of services supplying water for domestic

use within buildings and their curtilages

• BS 6880 Code of practice for low temperature heating

systems with outputs greater than 45 kW:

Part 1 Fundamental and design considerations

Part 2 Selection of equipment

Part 3 Installation, commissioning and maintenance

• BS 6981 Installation of low pressure gas pipework of up to

35mm in domestic premises

• BS 4814 Specication for: Expansion vessels using an

internal diaphragm, for sealed hot water and heating

systems

• BS 7074 Application, selection and installation of expansion

vessels and ancillary equipment for sealed water systems

Part 1 Code of practice for domestic heating and hot

water

Part 2 Code of practice for low and medium

temperature hot water systems

• BS 7593 Code of practice for treatment of water in domestic

hot water central heating systems

• BS EN 13831 Closed expansion vessels with built in

diaphragm

• BS EN 14336 Heating systems in buildings. Installation and

commissioning of water based heating systems

• Directive VDI 2035 Prevention of damage in water heating

systems due to scale formation

• Institute of Gas Engineers Publications:

IGE/UP/1 (Edition 2) Strength testing, tightness testing

and direct purging of industrial and commercial gas

installations

IGE/UP/1A (Edition 2) Strength testing, tightness

testing and direct purging of small, low pressure

industrial and commercial natural gas installations

IGE/UP/1B (Edition 2) Tightness testing and direct

purging of small natural gas installations

IGE/UP/2 (Edition 2) Installation pipework on industrial

and commercial premises

IGE/UP/7 (Edition 2) Gas in timber and light steel

framed buildings

IGE/UP/10 Installation of gas appliances in industrial

and commercial premises. Part 1 Flued appliances

1.6. Transport and Storage

Please remove the packing materials and examine the

consignment for correctness, completeness and possible

transport damage. The equipment is to be transported and stored

only in its original packing. Interim storage of Hoval gas boilers

should only to take place in weather protected rooms and only in

the original packing. The ambient conditions for storage must be

within the following limits:

• Air temperature: -10°C - 50°C

• Air humidity: 50 - 85% relative humidity

• No condensation

1.7. Installation. Location requirements

The installation site of the boiler cascade should allow proper

connection of the ue duct work to all the boilers in the cascade.

In addition, there should be adequate room for maintenance and

air circulation around the cascade of boilers.

The boiler cascade must be set up in a separate installation

room.

A oor standing boiler cascade must be installed on a at, or level

re proof oor.

All boilers must have a minimum clearance of 500mm at the front

for preventative maintenance and commissioning work to be

carried out.

6

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

2. Technical Description

2.2. Cascade Product Codes

In-line frame mounted (not including optional low loss header or air/dirt separator)

Back to back frame mounted (not including low loss header or air/dirt separator)

Boiler Model No of boilers: One Two Three Four Five Six

TopGas 60 - 7015844 7015845 7015846 7015847 7015848

TopGas 80 - 7015824 7015823 7015822 7015821 7015820

TopGas 100 - 7015801 7015800 7015802 7015816 7015817

TopGas 120 - 7015859 7015828 7015827 7015826 7015825

2.1. Technical Description

The Hoval TopGas Cascade allows a number of individual Hoval

TopGas boilers to be mounted into a common arrangement.

A cascade of one to six TopGas (60), (80), (100) or (120) boilers

can be arranged in-line on a free standing frame. As an alternative

a cascade of two to six boilers can be arranged back to back on a

free standing frame.

Each individual Hoval TopGas boiler is a gas red appliance

suitable and approved as a heat producer for hot water heating

systems with a maximum ow temperature of 85°C and a

maximum operating pressure of 2.5 bar.

TopGas boilers are suitable for operation with either Natural Gas

or LPG.

Each boiler has an Aluminium Alloy integrated heat exchanger

complete with integral down ring pre-mix burner and is capable

of full condensing operation. The combustion air is drawn into the

boiler via the burner fan through openings in the top casing of each

boiler. This is directly from the plant room or via an air/ue gas con-

centric chimney arrangement allowing the boiler to be operated in

a room sealed (or room air independent) manner. The combustion

air is mixed with an incoming gas supply to match the individual

boiler output and combustion is completed across a high tempera-

ture stainless steel mesh adjacent to the heat exchanger. The hot

gases are forced through the heat exchanger to cool and deliver

their energy to the heating system and then discharged via the

ue. If the gases are cooled below their dew point condensation

will occur on the boiler surfaces.

Each TopGas boiler within the cascade is supplied with exible

ow and return hydraulic connections including ttings; a valve set

incorporating isolation valves, safety valve, non return valve, and

a drain valve; an A-rated circulating pump; and a gas connection

kit including an isolation valve, 28mm TracPipe and necessary t-

tings. A condensate trap is supplied with each boiler to be tted

and piped to drain by the installer.

A pipework header set is supplied with each cascade to allow all

the individual TopGas boilers to be connected together to create

the cascade. The LTHW and gas header size will vary depend-

ing on the cascade type. An insulation wrap is tted to the LTHW

header pipework.

When assembled the TopGas cascade boilers can be individually

controlled via an external building management system or can be

sequenced by the optional heating controller set TopTronic

®

E ZE1

into the master boiler with an additional TopTronic®E ZE3

module tted into all the other boilers in the cascade. A wired con-

nection must be tted between each boiler and a common ow

sensor tted into the pipework to allow control via the boiler(s).

The cascade of boilers are connected to LTHW and gas headers

forming a primary circuit via an optional low loss header or air/dirt

separator.

Each cascade is designed to operate with a ∆T of 20°C on the

primary circuit. When the optional low loss header or air/dirt sepa-

rator the secondary sized can operate with either an 11 or 20°C ∆T.

Each boiler in the cascade requires a suitable ue connection to

discharge products of combustion.

Note that the boilers require a minimum working pressure of 1 bar

and therefore the system pressure must be in line with this and

must encompass the required volume of expansion.

Each cascade is made up of individual boilers each of the same

size. It is NOT possible to arrange a cascade with different size

TopGas boilers. Please see the cascade options listed below.

For further information on the TopGas boiler please refer to the

Technical Information and Installation Instructions, document No.

4214783.

Boiler Model No of boilers: One Two Three Four Five Six

TopGas 60 7015818 7015839 7015840 7015841 7015842 7015843

TopGas 80 7015865 7015864 7015863 7015862 7015861 7015860

TopGas 100 7015799 7015773 7015812 7015813 7015814 7015815

TopGas 120 7015871 7015870 7015869 7015868 7015867 7015866

7

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

3.1. Technical data, TopGas® Cascade 60

Number of TopGas Boilers in Cascade Two Three Four Five Six

Nominal output at 80/60°C with Natural Gas kW 113.2 169.8 226.4 283.0 339.6

Nominal output at 40/30°C with Natural Gas kW 124.0 186.0 248.0 310.0 372.0

Nominal output at 80/60°C with LPG kW 113.2 169.8 226.4 283.0 339.6

Nominal output at 40/30°C with LPG kW 122.2 183.3 244.4 305.5 366.6

Nominal load with Natural Gas kW 115.4 173.1 230.8 288.5 346.2

Nominal load with Propane kW 115.4 173.1 230.8 288.5 346.2

Operating pressure, minimum/maximum bar 4 / 1 4 / 1 4 / 1 4 / 1 4 / 1

Operating temperature, maximum °C 85 85 85 85 85

Boiler water content litres 10.8 16.2 21.6 27.0 32.4

Boiler weight (dry, excluding frame and headers) kg 198 297 396 495 594

Frame, header and xings weight (inline) kg 259 459 518 718 777

Frame, header and xings weight (back to back) kg 248 301 317 517 565

Boiler full load efciency @ 80/60°C (nCV basis/ gCV basis) % 99.4/89.6 99.4/89.6 99.4/89.6 99.4/89.6 99.4/89.6

Boiler part load efciency @ 40/30°C (nCV basis/ gCV basis) % 110.4/99.5 110.4/99.5 110.4/99.5 110.4/99.5 110.4/99.5

UK Part L Seasonal efciency % 97.6 97.6 97.6 97.6 97.6

Standing losses at 70°C W 210 315 420 525 630

NO

X

emissions (dry and stoichoimetric) mg/kWh 27 27 27 27 27

Natural Gas pressure, minimum/maximum mbar 17.4 - 50 17.4 - 50 17.4 - 50 17.4 - 50 17.4 - 50

LPG pressure, minimum/maximum mbar 37 - 50 37 - 50 37 - 50 37 - 50 37 - 50

Gas consumption (corrected 0°C, 1013mbar)

Natural Gas E (HU 9.97kWh/m3) m3/h 13.6 20.19 26.92 33.65 40.38

Propane (HU 25.9 kWh/m3) m3/h 4.4 6.6 8.8 11 13.2

Operating voltage

(1)

V/Hz 230/50 230/50 230/50 230/50 230/50

Control voltage V/Hz 24/50 24/50 24/50 24/50 24/50

Type of protection IP 20 20 20 20 20

Condensate quantity (40/30°C Natural Gas) l/h 10.8 16.2 21.6 27.0 32.4

Condensate pH value 4-6 4-6 4-6 4-6 4-6

Flue gas mass ow kg/h 190.2 285.3 380.4 475.5 570.6

Flue gas temperature 80/60°C °C 65.6 65.6 65.6 65.6 65.6

Flue gas temperature 50/30°C °C 44.8 44.8 44.8 44.8 44.8

(1) Each boiler in the cascade requires a 230Vac, 10amp power supply

3. Technical data

8

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

3.2. Technical data, TopGas® Cascade 80

Number of TopGas Boilers in Cascade Two Three Four Five Six

Nominal output at 80/60°C with Natural Gas kW 147.4 221.1 294.8 368.5 442.2

Nominal output at 40/30°C with Natural Gas kW 162.0 243.0 324.0 405.0 486.0

Nominal output at 80/60°C with LPG kW 147.4 221.1 294.8 368.5 442.2

Nominal output at 40/30°C with LPG kW 159.8 239.7 319.6 399.5 479.4

Nominal load with Natural Gas kW 150.8 226.2 301.6 377.0 452.4

Nominal load with Propane kW 148.8 223.2 297.6 372.0 446.4

Operating pressure, minimum/maximum bar 4 / 1 4 / 1 4 / 1 4 / 1 4 / 1

Operating temperature, maximum °C 85 85 85 85 85

Boiler water content litres 10.8 16.2 21.6 27.0 32.4

Boiler weight (dry, excluding frame and headers) kg 198 297 396 495 594

Frame, header and xings weight (inline) kg 259 459 518 718 777

Frame, header and xings weight (back to back) kg 248 301 317 517 565

Boiler full load efciency @ 80/60°C (nCV basis/ gCV basis) % 98.8/89.0 98.8/89.0 98.8/89.0 98.8/89.0 98.8/89.0

Boiler part load efciency @ 40/30°C (nCV basis/ gCV basis) % 110.8/99.9 110.8/99.9 110.8/99.9 110.8/99.9 110.8/99.9

UK Part L Seasonal efciency % 97.8 97.8 97.8 97.8 97.8

Standing losses at 70°C W 210 315 420 525 630

NOX emissions (dry and stoichoimetric) mg/kWh 28 28 28 28 28

Natural Gas pressure, minimum/maximum mbar 17.4 - 50 17.4 - 50 17.4 - 50 17.4 - 50 17.4 - 50

LPG pressure, minimum/maximum mbar 37 - 50 37 - 50 37 - 50 37 - 50 37 - 50

Gas consumption (corrected 0°C, 1013mbar)

Natural Gas E (HU 9.97kWh/m3) m3/h 15 22.5 30 37.5 45

Propane (HU 25.9 kWh/m3) m3/h 5.76 8.64 11.52 14.4 17.28

Operating voltage

(1)

V/Hz 230/50 230/50 230/50 230/50 230/50

Control voltage V/Hz 24/50 24/50 24/50 24/50 24/50

Type of protection IP 20 20 20 20 20

Condensate quantity (40/30°C Natural Gas) l/h 14.2 21.3 28.4 35.5 42.6

Condensate pH value 4-6 4-6 4-6 4-6 4-6

Flue gas mass ow kg/h 249 373.3 498 622.5 747

Flue gas temperature 80/60°C °C 74.4 74.4 74.4 74.4 74.4

Flue gas temperature 40/30°C °C 52 52 52 52 52

(1) Each boiler in the cascade requires a 230Vac, 10amp power supply

9

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

3.3. Technical data, TopGas® Cascade 100

Number of TopGas Boilers in Cascade Two Three Four Five Six

Nominal output at 80/60°C with Natural Gas kW 180.8 271.2 361.6 452 542.4

Nominal output at 40/30°C with Natural Gas kW 200 300 400 500 600

Nominal output at 80/60°C with LPG kW 180.8 271.2 361.6 452 542.4

Nominal output at 40/30°C with LPG kW 200 300 400 500 600

Nominal load with Natural Gas kW 186 279 372 465 558

Nominal load with Propane kW 186 279 372 465 558

Operating pressure, minimum/maximum bar 4 / 1 4 / 1 4 / 1 4 / 1 4 / 1

Operating temperature, maximum °C 85 85 85 85 85

Boiler water content litres 14 21 28 35 42

Boiler weight (dry, excluding frame and headers) kg 232 348 464 580 696

Frame, header and xings weight (inline) kg 293 505 586 798 879

Frame, header and xings weight (back to back) kg 272 347 367 579 639

Boiler full load efciency @ 80/60°C (nCV basis/ gCV basis) % 98.3/88.6 98.3/88.6 98.3/88.6 98.3/88.6 98.3/88.6

Boiler part load efciency @ 40/30°C (nCV basis/ gCV basis) % 110.9/99.9 110.9/99.9 110.9/99.9 110.9/99.9 110.9/99.9

UK Part L Seasonal efciency % 97.8 97.8 97.8 97.8 97.8

Standing losses at 70°C W 230 345 460 575 690

NOX emissions (dry and stoichoimetric) mg/kWh 26 26 26 26 26

Natural Gas pressure, minimum/maximum mbar 17.4 - 50 17.4 - 50 17.4 - 50 17.4 - 50 17.4 - 50

LPG pressure, minimum/maximum mbar 37 - 50 37 - 50 37 - 50 37 - 50 37 - 50

Gas consumption (corrected 0°C, 1013mbar)

Natural Gas E (HU 9.97kWh/m3) m3/h 18.64 27.96 37.28 46.6 55.92

Propane (HU 25.9 kWh/m3) m3/h 7.18 10.77 14.36 17.95 21.54

Operating voltage

(1)

V/Hz 230/50 230/50 230/50 230/50 230/50

Control voltage V/Hz 24/50 24/50 24/50 24/50 24/50

Type of protection IP 20 20 20 20 20

Condensate quantity (40/30°C Natural Gas) l/h 17.8 26.7 35.6 44.5 53.4

Condensate pH value 4-6 4-6 4-6 4-6 4-6

Flue gas mass ow kg/h 310 465 620 775 930

Flue gas temperature 80/60°C °C 69 69 69 69 69

Flue gas temperature 40/30°C °C 48 48 48 48 48

(1) Each boiler in the cascade requires a 230Vac, 10amp power supply

10

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

3.4. Technical data, TopGas® Cascade 120

Number of TopGas Boilers in Cascade Two Three Four Five Six

Nominal output at 80/60°C with Natural Gas kW 215.2 322.8 430.4 538 645.6

Nominal output at 40/30°C with Natural Gas kW 240 360 480 600 720

Nominal output at 80/60°C with LPG kW 215.2 322.8 430.4 538 645.6

Nominal output at 40/30°C with LPG kW 240 360 480 600 720

Nominal load with Natural Gas kW 223 334.5 446 557.5 669

Nominal load with Propane kW 223 334.5 446 557.5 669

Operating pressure, minimum/maximum bar 4 / 1 4 / 1 4 / 1 4 / 1 4 / 1

Operating temperature, maximum °C 85 85 85 85 85

Boiler water content litres 14 21 28 35 42

Boiler weight (dry, excluding frame and headers) kg 232 348 464 580 696

Frame, header and xings weight (inline) kg 293 505 586 798 879

Frame, header and xings weight (back to back) kg 272 347 367 579 639

Boiler full load efciency @ 80/60°C (nCV basis/ gCV basis) % 97.7/88.0 97.7/88.0 97.7/88.0 97.7/88.0 97.7/88.0

Boiler part load efciency @ 40/30°C (nCV basis/ gCV basis) % 109.0/98.2 109.0/98.2 109.0/98.2 109.0/98.2 109.0/98.2

UK Part L Seasonal efciency % 96.3 96.3 96.3 96.3 96.3

Standing losses at 70°C W 230 345 460 575 690

NO

X

emissions (dry and stoichoimetric) mg/kWh 27 27 27 27 27

Natural Gas pressure, minimum/maximum mbar 17.4 - 50 17.4 - 50 17.4 - 50 17.4 - 50 17.4 - 50

LPG pressure, minimum/maximum mbar 37 - 50 37 - 50 37 - 50 37 - 50 37 - 50

Gas consumption (corrected 0°C, 1013mbar)

Natural Gas E (H

U

9.97kWh/m3) m3/h 21.4 32.1 42.8 53.5 64.2

Propane (HU 25.9 kWh/m3) m3/h 8.34 12.51 16.68 20.85 25.02

Operating voltage

(1)

V/Hz 230/50 230/50 230/50 230/50 230/50

Control voltage V/Hz 24/50 24/50 24/50 24/50 24/50

Type of protection IP 20 20 20 20 20

Condensate quantity (40/30°C Natural Gas) l/h 20.6 30.9 41.2 51.5 61.8

Condensate pH value 4-6 4-6 4-6 4-6 4-6

Flue gas mass ow kg/h 372 558 744 930 1116

Flue gas temperature 80/60°C °C 74.9 74.9 74.9 74.9 74.9

Flue gas temperature 40/30°C °C 52.7 52.7 52.7 52.7 52.7

(1) Each boiler in the cascade requires a 230Vac, 10amp power supply

11

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

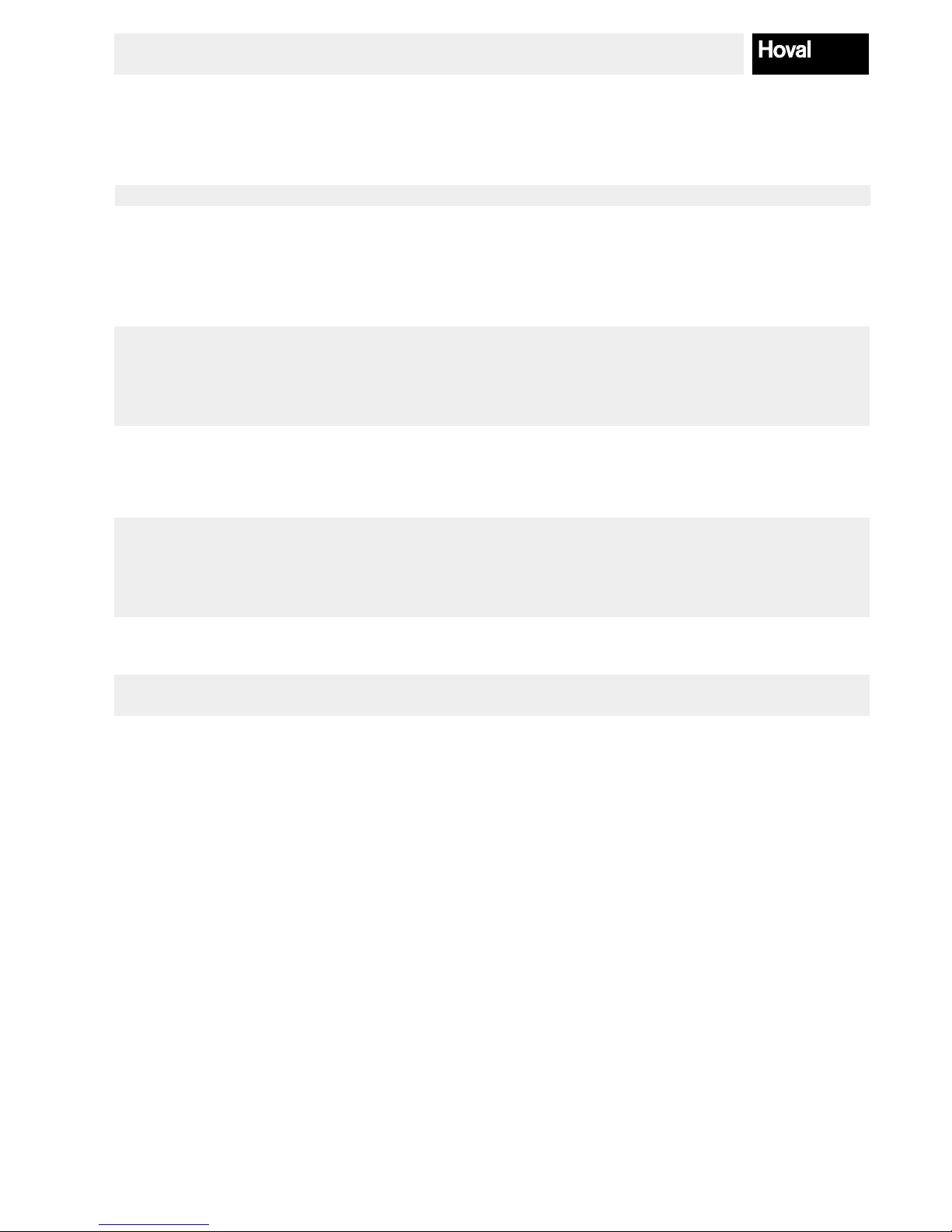

3.5. Technical Drawings, cascade in-line frame mounted

Connections

1. Gas DN65 PN6

2. Heating Flow DN80 PN6

3. Heating Return DN80 PN6

4. Condensate Drain trap DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G1”

Connections

1. Gas DN65 PN6

2. Heating Flow DN100 PN6

3. Heating Return DN100 PN6

4. Condensate Drain DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G¾”

Note: Condensate drainage, uing, safety valve discharge and boiler drain pipework to be supplied and tted by the installer (not by Hoval)

Blanking anges can be tted either side of the header assembly to suit site requirements

Optional low loss header or air/dirt seperator not shown

One boiler, in-line frame mounted - 1 x TopGas 60 (7015818), 1 x TopGas 80 (7015865)

One boilers, in-line frame mounted - 1 x TopGas 100 (7015799) , 1 x TopGas 120 (7015871)

12

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

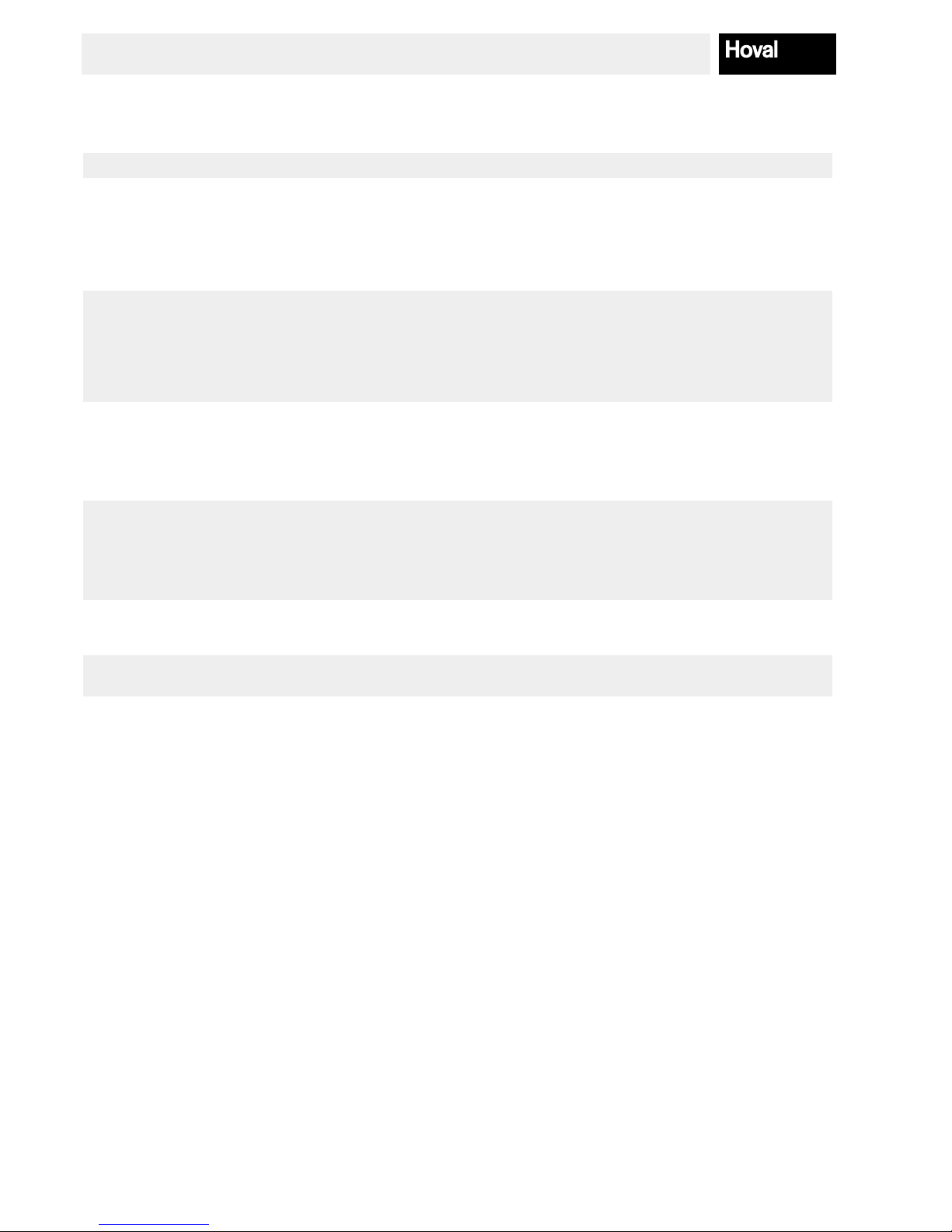

3.5. Technical Drawings, cascade in-line frame mounted

Connections

1. Gas DN65 PN6

2. Heating Flow DN100 PN6

3. Heating Return DN100 PN6

4. Condensate Drain DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G¾”

Note: Condensate drainage, uing, safety valve discharge and boiler drain pipework to be supplied and tted by the installer (not by Hoval)

Blanking anges can be tted either side of the header assembly to suit site requirements

Optional low loss header or air/dirt seperator not shown

Two boilers, in-line frame mounted - 2 x TopGas 60 (7015839) , 2 x TopGas 80 (7015864)

Two boilers, in-line frame mounted - 2 x TopGas 100 (7015773), 2 x TopGas 120 (7015870)

Connections

1. Gas DN65 PN6

2. Heating Flow DN80 PN6

3. Heating Return DN80 PN6

4. Condensate Drain trap DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G1”

13

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

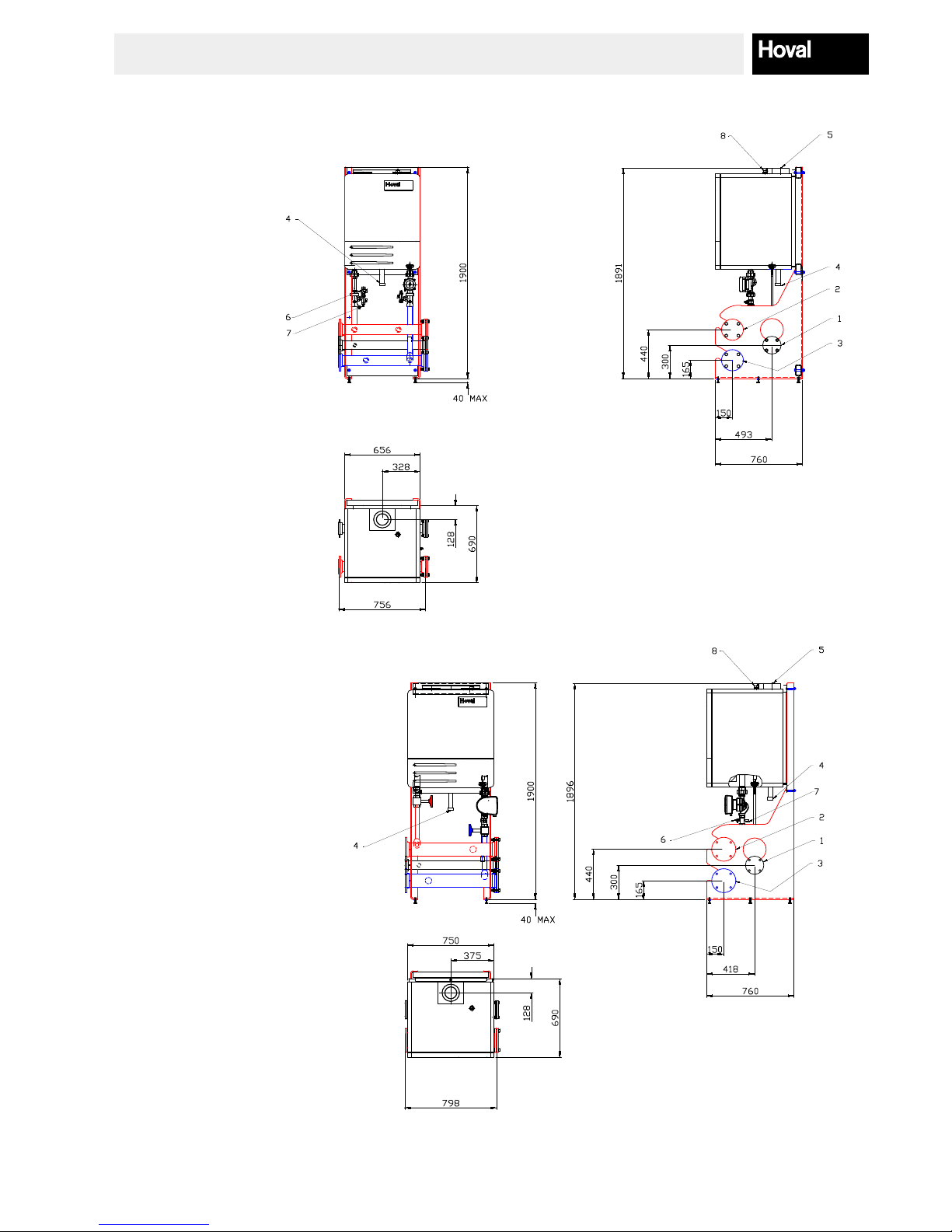

Connections

1. Gas DN65 PN6

2. Heating Flow DN100 PN6

3. Heating Return DN100 PN6

4. Condensate Drain DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G¾”

Note: Condensate drainage, uing, safety valve discharge and boiler drain pipework to be supplied and tted by the installer (not by Hoval)

Blanking anges can be tted either side of the header assembly to suit site requirements

Optional low loss header or air/dirt seperator not shown

Three boilers, in-line frame mounted - 3 x TopGas 60 (7015840), 3 x TopGas 80 (7015863)

Three boilers, in-line frame mounted - 3 x TopGas 100 (7015812), 3 x TopGas 120 (7015869)

3.5. Technical Drawings, cascade in-line frame mounted

Connections

1. Gas DN65 PN6

2. Heating Flow DN80 PN6

3. Heating Return DN80 PN6

4. Condensate Drain trap DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G1”

14

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

Connections

1. Gas DN65 PN6

2. Heating Flow DN100 PN6

3. Heating Return DN100 PN6

4. Condensate Drain DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G¾”

Note: Condensate drainage, uing, safety valve discharge and boiler drain pipework to be supplied and tted by the installer (not by Hoval)

Blanking anges can be tted either side of the header assembly to suit site requirements

Optional low loss header or air/dirt seperator not shown

Four boilers, in-line frame mounted - 4 x TopGas 60 (7015841), 4 x TopGas 80 (7015862)

Four boilers, in-line frame mounted - 4 x TopGas 100 (7015813), 4 x TopGas 120 (7015868)

3.5. Technical Drawings, cascade in-line frame mounted

Connections

1. Gas DN65 PN6

2. Heating Flow DN80 PN6

3. Heating Return DN80 PN6

4. Condensate Drain trap DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G1”

15

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

Connections

1. Gas DN65 PN6

2. Heating Flow DN100 PN6

3. Heating Return DN100 PN6

4. Condensate Drain DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G¾”

Note: Condensate drainage, uing, safety valve discharge and boiler drain pipework to be supplied and tted by the installer (not by Hoval)

Blanking anges can be tted either side of the header assembly to suit site requirements

Optional low loss header or air/dirt seperator not shown

Five boilers, in-line frame mounted - 5 x TopGas 60 (7015842), 5 x TopGas80 (7015861)

Five boilers, in-line frame mounted - 5 x TopGas 100 (7015814), 5 x TopGas 120 (7015867)

3.5. Technical Drawings, cascade in-line frame mounted

Connections

1. Gas DN65 PN6

2. Heating Flow DN80 PN6

3. Heating Return DN80 PN6

4. Condensate Drain trap DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G1”

16

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

Connections

1. Gas DN65 PN6

2. Heating Flow DN100 PN6

3. Heating Return DN100 PN6

4. Condensate Drain DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G¾”

Note: Condensate drainage, uing, safety valve discharge and boiler drain pipework to be supplied and tted by the installer (not by Hoval)

Blanking anges can be tted either side of the header assembly to suit site requirements

Optional low loss header or air/dirt seperator not shown

Six boilers, in-line frame mounted - 6 x TopGas 60 (7015843), 6 x TopGas 80 (7015860)

Six boilers, in-line frame mounted - 6 x TopGas 100 (7015815), 6 x TopGas 120 (7015866)

3.5. Technical Drawings, cascade in-line frame mounted

Connections

1. Gas DN65 PN6

2. Heating Flow DN80 PN6

3. Heating Return DN80 PN6

4. Condensate Drain trap DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G1”

17

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

Connections

1. Gas DN65 PN6

2. Heating Flow DN100 PN6

3. Heating Return DN100 PN6

4. Condensate Drain DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G¾”

Note: Condensate drainage, uing, safety valve discharge and boiler drain pipework to be supplied and tted by the installer (not by Hoval)

Blanking anges can be tted either side of the header assembly to suit site requirements

Optional low loss header or air/dirt seperator not shown

Two boilers, back to back frame mounted - 2 x TopGas 60 (7015844), 2 x TopGas 80 (7015824)

Two boilers, back to back frame mounted - 2 x TopGas 100 (7015801), 2 x TopGas 120 (7015859)

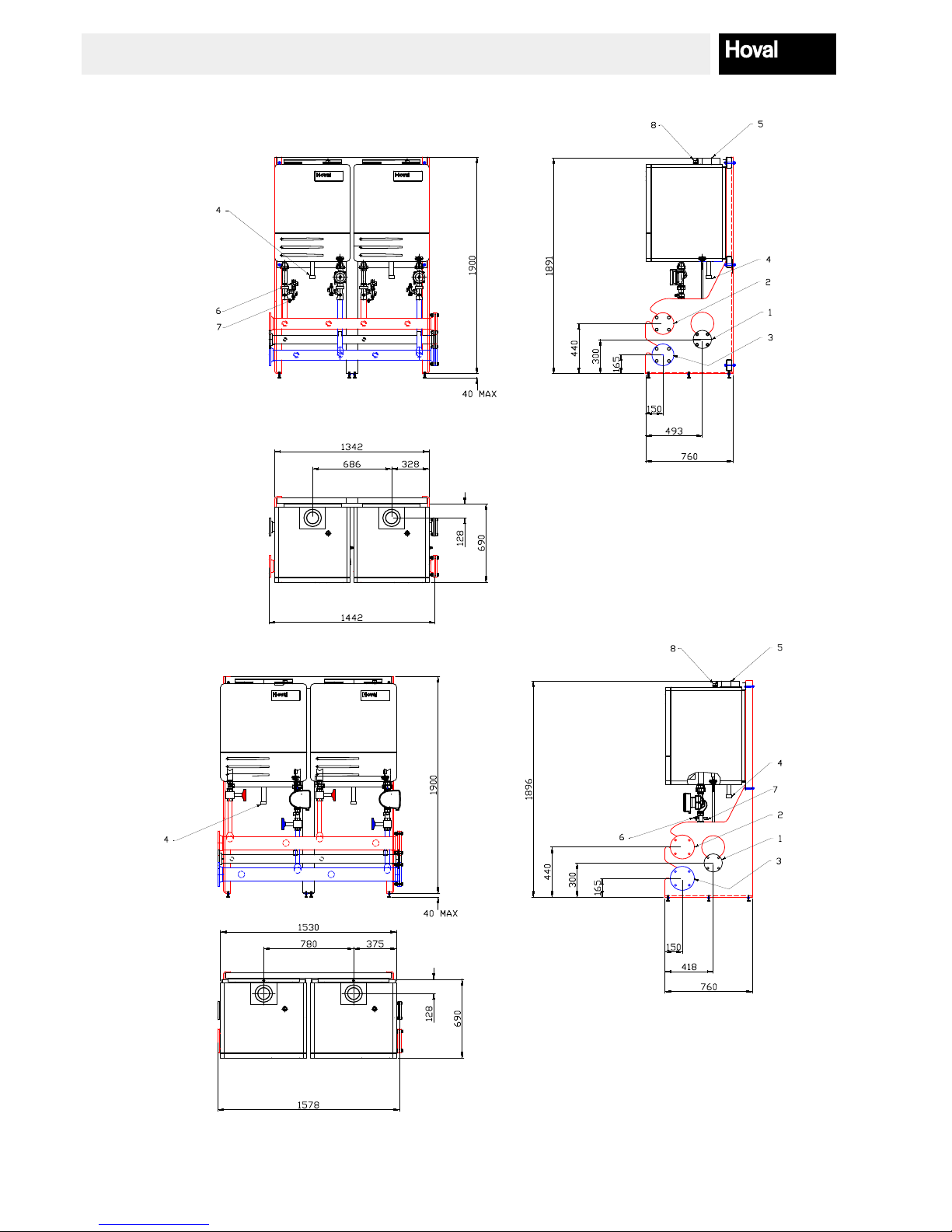

3.6. Technical Drawings, cascade back to back frame mounted

Connections

1. Gas DN65 PN6

2. Heating Flow DN80 PN6

3. Heating Return DN80 PN6

4. Condensate Drain trap DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G1”

18

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

Connections

1. Gas DN65 PN6

2. Heating Flow DN100 PN6

3. Heating Return DN100 PN6

4. Condensate Drain DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G¾”

Note: Condensate drainage, uing, safety valve discharge and boiler drain pipework to be supplied and tted by the installer (not by Hoval)

Blanking anges can be tted either side of the header assembly to suit site requirements

Optional low loss header or air/dirt seperator not shown

Three boilers, back to back frame mounted - 3 x TopGas 60 (7015845), 3 x TopGas 80 (7015823)

Three boilers, back to back frame mounted - 3 x TopGas 100 (7015800), 3 x TopGas 120 (7015828)

3.6. Technical Drawings, cascade back to back frame mounted

Connections

1. Gas DN65 PN6

2. Heating Flow DN80 PN6

3. Heating Return DN80 PN6

4. Condensate Drain trap DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G1”

19

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

Connections

1. Gas DN65 PN6

2. Heating Flow DN100 PN6

3. Heating Return DN100 PN6

4. Condensate Drain DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G¾”

Note: Condensate drainage, uing, safety valve discharge and boiler drain pipework to be supplied and tted by the installer (not by Hoval)

Blanking anges can be tted either side of the header assembly to suit site requirements

Optional low loss header or air/dirt seperator not shown

Four boilers, back to back frame mounted - 4 x TopGas 60 (7015846), 4 x TopGas 80 (7015822)

Four boilers, back to back frame mounted - 4 x TopGas 100 (7015802), 4 x TopGas 120 (7015827)

3.6. Technical Drawings, cascade back to back frame mounted

Connections

1. Gas DN65 PN6

2. Heating Flow DN80 PN6

3. Heating Return DN80 PN6

4. Condensate Drain trap DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G1”

20

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

Connections

1. Gas DN65 PN6

2. Heating Flow DN100 PN6

3. Heating Return DN100 PN6

4. Condensate Drain DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G¾”

Note: Condensate drainage, uing, safety valve discharge and boiler drain pipework to be supplied and tted by the installer (not by Hoval)

Blanking anges can be tted either side of the header assembly to suit site requirements

Optional low loss header or air/dirt seperator not shown

Five boilers, back to back frame mounted - 5 x TopGas 60 (7015847), 5 x TopGas 80 (7015821)

Five boilers, back to back frame mounted - 5 x TopGas 100 (7015816), 5 x TopGas 120 (7015826)

3.6. Technical Drawings, cascade back to back frame mounted

Connections

1. Gas DN65 PN6

2. Heating Flow DN80 PN6

3. Heating Return DN80 PN6

4. Condensate Drain trap DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G1”

21

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

Connections

1. Gas DN65 PN6

2. Heating Flow DN100 PN6

3. Heating Return DN100 PN6

4. Condensate Drain DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G¾”

Note: Condensate drainage, uing, safety valve discharge and boiler drain pipework to be supplied and tted by the installer (not by Hoval)

Blanking anges can be tted either side of the header assembly to suit site requirements

Optional low loss header or air/dirt seperator not shown

Six boilers, back to back frame mounted - 6 x TopGas 60 (7015848), 6 x TopGas 80 (7015820)

Six boilers, back to back frame mounted - 6 x TopGas 100 (7015817), 6 x TopGas 120 (7015825)

3.6. Technical Drawings, cascade back to back frame mounted

Connections

1. Gas DN65 PN6

2. Heating Flow DN80 PN6

3. Heating Return DN80 PN6

4. Condensate Drain trap DN40

5. Flue Concentric 100/150mm

6. Safety Valve R1”

7. Boiler Drain G1”

22

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

3.7. Technical Drawings, optional single and two boiler low loss headers

Single or two TopGas 80 boiler low loss header (2057322)

Please see Accessories section for further information

Single TopGas 100,120 boiler low loss header (6043445)

Connections

1. Primary Flow DN100 PN6

2. Primary Return DN100 PN6

3. Secondary Flow DN100 PN6

4. Secondary Return DN100 PN6

150

650

270

450

75

80

500

2 1/2" BSP

Boiler Return

2 1/2" BSP

System Return

2 1/2"

Boiler Flow

2 1/2"

System Flow

150

Single TopGas 60 boiler low loss header (2057320)

83

234

35

330

90

400

171

1" BSP

Boiler Return

1 1/2" BSP

System Return

1" BSP

Boiler Flow

1 1/2" BSP

System Flow

90

Please see Accessories section for further information

Please see Accessories section for further information

23

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

3.8. Technical Drawings, optional cascade low loss headers

Low loss header for all TopGas 100,120 cascades (6042824)

Connections

1. Primary Flow DN80 PN6

2. Primary Return DN80 PN6

3. Secondary Flow DN125 PN6

4. Secondary Return DN125 PN6

5. Automatic Air Vent Connection 1/2” BSP

6. Pocket Connection 1/2” BSP (plugged)

7. Drain Point 1/2” BSP (plugged)

Connections

1. Primary Flow DN100 PN6

2. Primary Return DN100 PN6

3. Secondary Flow DN150 PN6

4. Secondary Return DN150 PN6

5. Automatic Air Vent Connection 1/2” BSP

6. Pocket Connection 1/2” BSP (plugged)

7. Drain Point 1/2” BSP (plugged)

Low Loss Herader for TopGas 100/120 cascades (6042824)

Please see Accessories section for further information

Please see Accessories section for further information

Low Loss Herader for TopGas 45,60 & 80 cascades (6042897)

Low loss header for all TopGas 60,80 cascades (6034283)

24

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

3.9. Technical Drawings, optional cascade air and dirt separators

Air and dirt separator for all TopGas 60 and TopGas 80 cascades (2067549)

Air and dirt separator for all TopGas 100 and TopGas 120 cascades (2066122)

Connections

1. Primary Flow DN80 PN6

2. Primary Return DN80 PN6

3. Secondary Flow DN125 PN6

4. Secondary Return DN125 PN16

5. Automatic Air Vent

6. Pocket Connection 1/2” BSP (plugged)

7. Drain Valve 1/2” BSP (plugged)

Connections

1. Primary Flow DN100 PN6

2. Primary Return DN100 PN6

3. Secondary Flow DN150 PN6

4. Secondary Return DN150 PN6

5. Automatic Air Vent

6. Pocket Connection 1/2” BSP (plugged)

7. Drain Valve 1/2” BSP (plugged)

Air Dirt Seperator for TopGas 100 & 120 Cascades

Please see Accessories section for further information

Please see Accessories section for further information

25

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

4. Installation Requirements

4.3. Water Quality

The heating water must be treated in the TopGas Cascade to the

correct standard. Specic information can be found in the TopGas

Technical information Installation instructions document:

TopGas 35-120, document: 4214 783

The system heating water must be tested anually as a minimum

but Hoval recommend this to be done twice a year or after

every drain down and re-ll. If the water treatment specialist

recommends that this needs to be done more frequently please

follow their advice.

On account of the danger of spot corrosion the chloride, nitrate

and sulphate contents of the heating water must not exceed

200mg/l in total.

The pH value of the heating water should lie between 8,0 and 8,5

after 6 - 12 weeks of heating operation.

The boilers have aluminium heat exchangers which are in contact

with the heating water: Any inhibitors used must take account

of this and specialist advice should be sought prior to lling the

system based on local water quality conditions.

4.4. Gas Connection

The gas installation must fully conform with IGE/UP/2 and all re-

lated regulations.

The incoming natural gas supply to the TopGas Cascade must be

between 18-50 mbar with all connected appliances at full output.

For LPG this must be between 37-50 mbar.

All gas pipework must be tested and purged in accordance with

IGE/UP/1 or IGE/UP/1A.

Any gas work performed must be done by competent persons

holding a valid qualication.

4.1. Hydraulic Installation

Water from each safety valve discharge can cause severe burns.

Install the safety valve to ensure that there is no danger to other

persons. Route the safety valve discharge pipe to a tundish and

pipe to drain (not supplied by Hoval).

Flush the heating installation thoroughly prior to installation as

any foregin bodies or contaminants in the pipework may damage

the boiler.

If oxygen ingress is possible ensure that de-aeration equipment

is installed. If the plant is topped up with raw water ensure the

overall water quality still meets the required specication. The

totalamountofllingandreplacementheatingsystemwater

which is used throughout the total service life of the boiler

must not exceed three times the service capacity of the

plant.

4.2. Recommendations

It is recommended that each system should be lled and relled

with treated water and specialist companies will be able to advise

in this respect. Before lling check the following:

• All connections are made and tightened

• Sensor and instrument pockets are tted and water tight

• Spare sockets are tted with plugs and are water tight

• All valves in the heating circuit are open

• The installation is completely vented

• if a pressurisation unit is installed reference should be made

to the manufacturers lling instructions and applied

• The installation is fully ushed

• A suitable strainer and air/dirt separator are tted to protect

the equipment supplied.

For connection to the system a hydraulic header has to be used.

Hoval offer an optional low loss header kit or an air and dirt

separator that can act as a hydraulic header between the boiler

cascade and the heating system. These options should be

installed adjacent to the boiler cascade and advice should be

sought from Hoval technical if an alternative method is to be

adopted.

The pump set supplied with each boiler in the cascade is sized

to provide a ΔT of 20 K across each boiler ow and return. An

electrical ying lead is provided for the installer to connect each

pump to it’s respective TopGas boiler. A minimum ow must be

maintained through a boiler that is ring or being called to re. As

standard the TopGas boilers have a pump over-run feature that

maintains water ow through the boilers for ve minutes after it

has completed its ring sequence.

To allow the boiler to operate correctly it must have a minimum

water pressure of 1 bar. If this is not present an error code P27

will be displayed on each individual boiler control panel and the

boiler will not operate.

IMPORTANT NOTE:

Following assembly of the TopGas

Cascade arrangement it is the installer’s

responsibility to carry out suitable

water-side and gas-side pressure tests

and a ue system tightness test. These

tests are to be carried out by suitably

qualiedpersonnel.

26

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

4.5. Flue Gas Connection, Chimney

Each boiler in the TopGas cascade must be tted with a ue to

safely exhaust the products of combustion from the plant room.

Each boiler can be congured such that it takes it air directly from

the boiler plant room (room air dependent) or via closed concentric

ue/air supply system (room sealed or room air independent).

In the case of room sealed operation each of the boilers within

the cascade must be tted with individual concentric (100/150mm)

ue.

The maximum length of the concentric ue allowable will depend

on the TopGas model and the proposed layout or route of the ue.

Where the boiler cascade takes its air supply directly from the

plant room, It is possible to combine one or more TopGas boilers

into a common ue duct, where each boiler within the cascade is

connected to a common duct or ducts via an individual ue con-

nection piece. In this case all boilers in the cascade should be

provided with the optional air inlet non-return ap (available as an

accessory for the TopGas 60-120) boilers or with an external non-

return ap (not Hoval supply).

In all cases the ue terminal positions should comply with the re-

quirements of BS 5440-1 in the case of cascades with a total heat

input <70 kW net CV basis, or the requirements of BS 6644 when

the aggregate heat input of the cascade >135 kW on a net CV ba-

sis (note that this may limit the number of low level horizontal ue

discharge options available).

Owing to the water vapour content and the relatively low tempera-

ture of the ue gases then further condensation can be expected

within the ue system and therefore provision must be made to

remove this from the ue with appropriate trapped drains. There

must be a fall on horizontal sections of the ue to prevent stand-

ing condensate, and the ue must be able to withstand the mildly

acidic nature of the condensate. The ue system must be pressure

tight and able to operate under a positive pressure without prod-

ucts of combustion escaping into the plant room or other parts of

the building that the ue passes through.

Where appliance is to be room sealed (LAS) then a Hoval ue

adaptor piece with sample points (part no. 2042406) must be tted

on the boiler to allow the boilers to be commissioned and serviced.

Only ue gas systems or components tested and approved should

be connected to the Hoval TopGas boiler or the Hoval TopGas

boiler cascade.

It is important that a ue sample point is tted on both sides of the

concentric ue system or on the ue side of a conventional ue.

4.6. Electrical Connections

The electrical installation must fully conform with BS7671 and all

other regulations.

Each boiler requires its own 230Vac, 10A power supply with an

isolator mounted locally to the boiler (not by Hoval).

When a TopGas Cascade is purchased with the TopTronic E cas-

cade control system each boiler will need to be connected together

with a three core communications cable (not by Hoval). Please

refer to the electrical wiring diagram supplied with the cascade

package. This will detail other optional electrical items that have

been purchased. See the Accessories section in this document

for futher details.

4.7. Ventilation

Sufcient air must be supplied to each boiler to ensure that the

requirements of combustion and cooling are met and to afford a

general level of ventilation in the plant room.

In ALL cases the necessary ventilation to the Hoval TopGas

cascade must be in line with the requirements set out in BS 6644,

IGE/UP/10 and any local requirements.

Cooling air around the boilers must be sufcient such that the

temperatures in the installation location do not exceed those listed

in BS 6644.

4.8. Automatic Air Vent

All TopGas boilers are tted with automatic air vents. These must

be left open and operative at ALL times! If the cap is closed then

damage will occur to the boilers.

4.9. Condensate Drainage

Each TopGas boiler is supplied with a condensate trap which must

be tted. This must then be piped to the drain but with a suitable

air gap between the discharge point and the drain or galley so this

pipe cannot pressurise (not by Hoval).

No isolating or non-return valves should be tted in the

condensate discharge pipework and the pipework material should

be suitable for use with condensate.

27

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

Find a suitable space and prepare the frame for assembly. Each frame will come with:

4 x 75mm M10 bolts (2056546) 2 x side plates

4 x M10 nuts (2042599) 1 x vertical centre support

8 x M10 washers (2042608) 2 x horizontal support arms

1 x 1/8” Gas test nipple (2056819)

1 x 1/4” to 1/8” reducing bush (2068414) 1 x horizontal cross bar

12 x 50mm M16 bolts (2053287)

12 x M16 nuts (2044783)

24 x M16 washers (2042610)

Flow, return and gas connection gaskets

8 x M10 adjustable feet (2067454)

2 x DN80 Unions (TG60, 80) 2067951

2 x DN100 Unions (TG100,120) 2043066

Insulation wrap on LTHW pipework (not shown)

Fit the adjustable feet to both the center support and both side

plates. Set to the correct length and tighten using a 22mm spanner.

5.TopGas Cascade Assembly, 2 boilers in-line and 3 or 4 boilers back to back

Lay out the frame work on the oor and ensure you have all correct

components. You will see M10 holes to the outside ends on both

support arms. Ensure these are at the bottom so they line up with

the side plates.

Support arms will have:

2 x 180mm M10 bolts (2056533)

2 x M10 nuts (2042599)

4 x M10 washers (2042608)

Screw the M10 bolts (2056533) through both support arms and

centre support with a washer (2042608) either side and tighten to

45Nm and stand the frame up.

28

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

Hold up the center piece and support arms and align with the side

piece. Place the M10 bolt (2056546) through the support arm and

through the side piece with a washer either side (if holes do not

align then adjust the feet as appropriate) and add the M10 nut

(2042599). Repeat this process for the other side and tighten bolts

to 45Nm.

The cross bar has an alignment hole in the middle of the underside

as shown in the picture to the right. This slots onto the top of the

centre support so that the holes at either end align with the holes

on the side pieces. Thread both the M10 bolt (2056546) through the

crossbar and side pieces with a washer either side, add the M10

nut, then tighten both to 45Nm.

Once you have bolted the center piece and side pieces together

you should have the stand as shown to the right. To ensure that the

frame is stable check with a spirit level.

The frame should now look like the image to the right. Please ensure

that all of the bolts have washers either side of the frame work and

are all tightened to 45Nm.

29

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

If the cascade arrangment purchased is a three or four boiler back

to back model, you will receive rear support legs as shown opposite.

These are to be tted onto the rear of the side plates as shown. You

will also recieve extension pipes that will connect the ex connections to the header. Each rear support will come with the xings:

2 x 75mm M10 bolts (2056546)

2 x M10 nuts (2042599)

4 x M10 washers (2042608)

3 x M8 adjustable feet (2067454)

Build as shown and tighten to 45Nm.

Fit the adjustable feet to both of the side plates. Set to the correct

length and tighten using a 22mm spanner.

5.1.1 Step 1: Build the frame (1 boiler inline 2 boiler back to back)

6 x 75mm M10 bolts (2056546) 2 x side plates

6 x M10 nuts (2042599) 2 x horizontal support beam

12 x M10 washers (2042608) 1 x horizontal cross bar

1 x 1/8” Gas test nipple (2056819)

1 x 1/4” to 1/8” reducing bush (2068414)

12 x 50mm M16 bolts (2053287)

12 x M16 nuts (2044783)

24 x M16 washers (2042610)

Flow, return and gas connection gaskets

6 x M10 adjustable feet (2067454)

2 x DN80 Unions (TG60, 80) (2067951)

2 x DN100 Unions (TG100,120) (2043066)

30

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

Hold the crossbar in place and thread the M10 bolts (2056546)

through the crossbar and the aligned hole in the framework. Tighten

the nuts after both bolts are through the holes to make the align-

ment easier.

Once you have bolted the crossbar piece to the frame then screw in

the engineering studs by hand into the installed inserts.

Hold the middle support beam in place and thread the M10 bolts

(2056546) through the beam and the aligned hole in the framework. Ensure that the holes are to the bottom of the beam for boiler

alignment. Tighten the nuts after both bolts are through the holes to

make the alignment easier.

Place the gas pipe into the respective hole and the ow pipe (top

slot) and the return pipe (bottom slot) and ensure they are securely

in place with the alignment slots, this will ensure that the connec-

tions are correctly aligned.

Hold the two side pieces in line and align the holes at the bottom with

the holes in the bottom support beam using the M10 bolts (2056546).

Tighten the nuts after both bolts are through the holes to make the

alignment easier.

Build as shown and tighten to 45Nm.

Build as shown and tighten to 45Nm.

Build as shown and tighten to 45Nm.

31

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

If there are multiple sets of headers in your installation please

connect them and tighten to 180Nm ensuring they have the correct

gaskets between them:

65mm NB - 110mm OD, 78mm ID (2056845)

80mm NB - 132mm OD, 90mm ID (2043206)

100mm NB - 165mm OD, 115mm ID (2043208)

Connect each TopGas boiler to the frame using:

2 x M10 engineering studs (2067745)

2 x M10 nuts (2042608)

Tighten to a maximum of 60Nm.

Ensure that the boiler is safely lifted into position using

appropriate lifting equipment.

5.2. Step 2: Mount the boilers

If the cascade arrangment purchased is a two boiler back to back

model, you will receive rear support legs as shown opposite. These

are to be tted onto the rear of the side plates as shown. You will

also receive extension pipes that will connect the ex connections to

the header. Each rear support will come with the xings:

1 x 75mm M10 bolts (2056546)

1x 35mm M10 bolts (2042537)

2 x M10 nuts (2042599)

4 x M10 washers (2042608)

2 x M8 adjustable feet (2067454)

32

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

Using PTFE tape (or other suitable thread sealing media), wrap both

sides of the 1” nipple (2043076) before screwing into the header.

Ensure sealing media used is suitable for natural gas.

Fit the nipple into the header and tighten ensuring a good seal is

made.

Fit the 1” gas isolation valve (2067892) to the nipple. On the outlet

of the gas isolation valve, t the TracPipe connector (2067994). Before tting apply PTFE tape (or other suitable thread sealing media).

Ensure sealing media used is suitable for natural gas. Screw into

the top of the valve and tighten ensuring a good seal is made. Note,

ensure that the valve is in the correct orientation, when the valve is

open the handle must point upwards.

Attach the 3/4” to 1” concentric reducer (2042714) to the gas con-

nection on the boiler and then t the TracPipe connector (2067994).

Before tting apply PTFE tape (or other suitable thread sealing me-

dia). Ensure sealing media used is suitable for natural gas. Screw

into both sides of the boss and tighten ensuring a good seal is made.

TopGas Cascade Assembly

5.3. Step 3: Pipe the gas from the header to the boilers

33

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

TopGas Cascade Assembly

Measure the gap between the two TracPipe connectors and cut the

28mm TracPipe to length using a rotary tube cutter. Cut between

corrugations. Take care not to tighten the pipe cutter too tightly as

it may cause deformations. You will have been supplied a 500mm

length of TracPipe per boiler TopGas 60,80,100,120 (2067839).

Measure carefully - do not cut this too short. Ensure the cut has a

good smooth edge.

Using a knife, cut back the insulation on the TracPipe approximately 25mm to allow the tting to slide onto the pipe.

Slide on the brass union and t the sealing washer to the next available full corrugation. Pull the brass union back over the sealing

washer once complete. Do this to both ends of the pipe.

Once the pipe is complete, t it to both connector ends to the ttings

now attached to the boiler and the header. Tighten these to a value

of 61Nm. Once complete apply tape to the exposed stainless steel

pipework as this will reduce the risk of any external damage.

Fit the loose 1/4” to 1/8” reducing bush into the 1/4” socket tted on

top of the horizontal gas header, then t

the 1/8” gas nipple into the bush using

suitable sealing media.

34

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

TopGas Cascade Assembly

Prepare all exible pipework nipples as below using PTFE tape (or

other suitable thread sealing media). There will be 4 off per boiler.

Please be aware that you do not apply PTFE tape to the side with

the at face suitable for a gasket.

Screw these nipples into the headers and also into the valve sets.

Tighten to ensure a good seal is made.

When installing a back to back arrangement you will be supplied

extention pieces for the ow, return and gas pipe that screw into the

connection on the header.

TopGas 100,120 Flow and Return Extension pipe (5041198)

TopGas 60,80 Flow and Return Extension pipe (5041200)

TopGas 60-120 Gas Extension pipe (5041199)

5.4.Step4:Connectthenipplestotheowandreturnheaders

35

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

TopGas Cascade Assembly

Fit the ow pipe valve set to the boiler complete with supplied gasket and union (2067951) and tighten. Ensure all valves are correctly

aligned as per the picture.

5.5.Step5:Connecttheboilertotheowandreturnheaders(TopGas60and80)

Fit the supplied circulation pump to the return connection of the

boiler with a gasket joint. Be aware of the ow direction, this should

be pointing up towards the boiler. When satised that all is correct

tighten the union (2067951).

Fit the remaining return pipe valve set to the underside of the pump

using the supplied gasket and tighten. Ensure all valves are correctly aligned as per the picture below. When complete t the two

piece pump insulation housing (2056817).

The pump will be supplied with a 2m long MOLEX connector lead

(2056730) that wires into terminals 25, N, E.

Arrange the pump (2056729) and valve set (6012948) ready to be

connected to the boiler. Please be aware that all of the gaskets

must be tted in the correct positions as shown in the picture on

the right.

Note: the pump may be different to the one shown in the

photograph.

36

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

5.5.1.Step5:Connecttheboilertotheowandreturnheaders(TopGas100and120)

Fit the ow pipe valve set to the boiler complete with supplied gasket and union (2043066) and tighten. Ensure all valves are correctly

aligned as per the picture.

Fit the supplied circulation pump (2064823) to the return connection

of the boiler with a gasket joint. Be aware of the ow direction, this

should be pointing up towards the boiler. When satised that all is

correct tighten the union (2043066).

Fit the remaining return pipe valve set to the underside of the pump

using the supplied gasket and tighten. Ensure all valves are correctly aligned as per the picture to the right. When complete t the

two piece pump insulation housing supplied with the pump.

The pump will be supplied with a 2m long MOLEX connector lead

(2068178) that wires into terminals 25, N, E.

Arrange the pump (2064823) and valve set (6042514) ready to be

connected to the boiler. Please be aware that all of the gaskets

must be tted in the correct positions as shown in the picture on

the right.

Note: the pump may be different to the one shown in the

photograph.

37

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

Fit one side of the exible pipe to the nipple on the header and the

other side to the respective valve. A gasket must be used at either

end to ensure a water tight seal. Tighten accordingly.

TopGas Cascade Assembly

Tighten the M16 nuts and bolts to 180Nm.

When assembled decide which end of the headers you would like to

connect the system pipework to. At the opposing end you need to t

blanking anges with their associated gaskets.

Theheatingsystemowandreturnpipeworkshouldbothconnect to the same end of the headers.

5.6.Step6:Connecttheblankinganges

38

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

5.7. Step 7: Fit the pre-formed insulation wrap

Fit the supplied pre-formed insulation wrap to the ow and return

headers, align the pre cut holes with the connections on the headers and push the insulation wrap together ensuring the the teeth on

the insulation wrap interlock.

Important Note:

Ifyouhaveabacktobackversionyouwillneedtotthepre-

formed insulation wrap before connecting the rear extension

pipes and connection sets.

5.8. Step 8: Fitting the back boiler connections

Fit the 1” gas isolation valve (2067892) to the extension pipe. On

the outlet of the gas isolation valve, t the TracPipe connector

(2067994). Before tting apply PTFE tape (or other suitable thread

sealing media). Ensure sealing media used is suitable for natural

gas.

.

Connect the ¾” connection to the 1” concentric reducer (see page

32) then follow all steps on page 33. Finally connect the 1” union on

the gas TracPipe onto the 1” nipple.

39

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

For the ow and return connections t the 1¼” union (TopGas

60,80) or 1½” union (TopGas 100,120) on the exible pipe to

the extension pipe. Before tting apply PTFE tape (or other

suitable thread sealing media). Tighten to ensure a good seal

is made.

See page 35 for the TopGas 60,80 or page 36 for TopGas

100,120 for pump and valve set connection instructions. Fit

the remaining side of the exible pipe to the respective valve.

A gasket must be used at either end to ensure a water tight

seal. Tighten accordingly.

40

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

6. Accessories - Hydraulics and Gas

6.1. Low loss header

Used to allow secondary system ow exibility.

Designed for a primary ∆T of 20°C.

Allows for the secondary side to work with a ∆T as low as 11°C.

Supplied with a 1/2” automatic air vent, plugged 1/2” drain

points and a plugged 1/2” BSP socket to accept an optional

cascade control ow temperature sensor (with pocket) where

required. Flanged on the primary side to connect directly to the

TopGas Cascade LTHW headers.

Two models avaiable:

DN80 PN6 inlet, DN125 PN6 outlet

For 2-6 x TopGas 60 and 2-6 x TopGas 80

DN100 PN6 inlet, DN150 PN6 outlet

For 2-6 x TopGas 100 and 2-6 x TopGas 120

6.2. Air and dirt separator

Effectively removes any dirt from the system whilst dispersing

any air present.

Used to allow secondary system ow exibility.

Designed for a primary ∆T of 20°C.

Allows for the secondary side to work with a ∆T as low as 11°C.

Supplied with a 1/2” automatic air vent, an 1/2” drain valve

and a plugged 1/2” BSP socket to accept an optional cascade

control ow temperature sensor (with pocket) where required.

Flanged on the primary side to connect directly to the TopGas

Cascade LTHW headers.

Two models avaiable:

DN80 PN6 inlet, DN125 PN6 outlet

For 1-6 x TopGas 60 and 1-6 x TopGas 80

DN100 PN6 inlet, DN150 PN6 outlet

For 1-6 x TopGas 100 and 1-6 x TopGas 120

ABOVE A STATIC HEAD OF 15 METRES A VACUUM

DEGASSER SHOULD BE FITTED AS WELL AS THE AIR

AND DIRT SEPARATOR. PLEASE CONSULT HOVAL

TECHNICAL FOR FURTHER INFORMATION (the static

height is taken from the installed location of the air and

dirt separator to the highest point in the system).

6034283

6042824

2067549

2066122

41

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

83

234

35

330

90

400

171

1" BSP

Boiler Flow

1 1/2" BSP

System Flow

Northgate

Newark

Nottinghamshire

NG24 1JN

THIS DRAWING IS COPYRIGHT OF HOVAL

AND SHALL NOT BE REPRODUCED WITHOUT PRIOR WRITTEN PERMISSION

TEL: 44(0 )1636 672711

FAX: 44(0 )1636 673532

www.hoval.co.uk

Drawing Status

Project Name

WorkInProgress

Northgate

Newark

Nottinghamshire

TEL: 44( 0 ) 1636 672711

FAX: 44( 0 ) 1636 673532

www.hoval.co.uk

6.3. TopGas 60 single boiler low loss header

Single TopGas 60 boiler low loss header

Complete with 1”BSP connections on the inlet and 1½” BSP on

the outlet.

2057320

6.4. TopGas 80 single or two boiler low loss header

Single or two TopGas 80 boiler low loss header

Complete with 2½” BSP connections on both the inlet and the

outlet.

2057322

6.6. Boiler Circulating pump, TopGas (60,80)

Seperate individual boiler A-rated circulating pump for TopGas

60,80.

Grundfos UPML 32-95 180 AUTO single phase pump with G2”

connections.

A 2m long electrical lead (with Molex connector) is available to

connect the pump to the boiler.

UPML 32-95 180 AUTO pump

Electrical connection lead

2056729

2056730

6.7. Pump insulation cover, TopGas (60,80)

Two piece insulation cover for Grundfos UPML 32-95 180

AUTO pump

2056817

6.5. TopGas 100,120 single boiler low loss header

Single TopGas 100 or TopGas120 boiler low loss header

Complete with DN100 PN6 anged connections on both the

inlet and the outlet.

6043445

83

234

35

330

90

400

171

1" BSP

Boiler Flow

1 1/2" BSP

System Flow

6.8. Boiler circulating pump, TopGas (100,120)

Seperate individual boiler A-rated circulating pump for TopGas

100,120.

Grundfos MAGNA 1 25-80 180 AUTO single phase pump with

G1½” connections.

A 2m long electrical lead is available to connect the pump to

the boiler.

Includes a two piece insulation cover

MAGNA 1 25-80 180 AUTO pump

Electrical connection lead

2064823

2068178

1

2

3

4

42

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

6.9.Boilerowandreturnconnectionvalveset,TopGas(60,80)

Connection set for TopGas (60,80)

For use with circulation pump mounted on the return connection.

consisting of:

Return:

Isolating valve R 1 ¼” with gland nut 2”. Side outlet branch with drain

cock and G ¾” connection for expansion vessel.

(Allows above Grundfos pump to be connected directly)

Flow:

Extension G 2” x L=180mm with integrated non-return valve. Isolating

valve R 1 ¼” with gland nut 2”. Side outlet branch with safety valve (3

bar) and drain cock.

6012948

6.12 Liquid gas conversion kit 619 568

6.11Gaslter

with measurement nozzle before and behind the lter inset (diameter: 9

mm)

Pore width of the lter inset < 50 µm

Max. pressure difference 10 mbar

Max. inlet pressure 100 mbar

Type Connection

Rp ¾″

Rp 1″

70612/6B 2007 995

70602/6B 2007 996

1

2

3

1

2

3

6.10.Boilerowandreturnconnectionvalveset,TopGas

(100,120)

Connection set for TopGas® (100,120)

For circulation pump mounted on the return connection

consisting of:

Return:

1½” x 1½” DN40 combined isolating ball valve, non-return valve,

safety valve (3bar) and drain cock.

Flow:

1½” x 1½” isolating ball valve.

Includes a pair of 1½” Female unions.

6042514

43

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

Accessories - Controls

Flow temperature guard

for underoor heating (per heating circuit 1

guard) 15-95 °C, differential gap 6 K, capillary

tube max. 700 mm, setting (visible from the outside) inside the housing cover

Clamp-on thermostat

RAK-TW1000.S

Thermostat with strap, without cable and plug

242 902

Cascade controls with

heating controller set TopTronic® E ZE1

When assembled the TopGas cascade

boilers can be individually controlled

via an external building management

system or can be sequenced by the

optional heating controller set

TopTronic®E ZE1 into the master boiler

with an additional TopTronic®E ZE3

modulettedintoalltheotherboilers

in the cascade. A wired connection must

bettedbetweeneachboileranda

commonowsensorttedintothe

pipework to allow control via the boiler(s).

Heating controller set TopTronic® E ZE1

(Can be built in) as supplement for basic boiler

control panel G04.

- Installation of the TopTronic

®

E basic module

heat generator in the controller

Notice

No additional module expansions or controller modules can be installed in the boiler

control panel! This means an additional mixer

circuit must be implemented using the TopTronic® E heating circuit/hot water module in

an external wall casing.

- Can be optionally networked with a total

of up to 16 controller modules (incl. solar

module)

Consisting of:

- TopTronic

®

E control module

- TopTronic® E basic module heat generator

- Rast-5 basic plug set

- tting accessories

- 1 pce. outdoor sensor AF/2P/K

- 1 pce. immersion sensor TF/2P/5/6T/S1,

L = 5.0 m with plug

- 1 pce. contact sensor ALF/2P/4/T/S1,

L = 4.0 m with plug

- cable set ZE1

Heating controller set TopTronic® E ZE3

Heating controller set TopTronic® E ZE3 is tted in

optional boilers 2-6. One TopTronic®E ZE3 module

should be ordered for each boiler.

For example:

4 x TopGas boilers part number includes:

1 x TopTronic® E touchscreen display

1 x TopTronic® E control module

4 x TopTronic® E ZE1 control

4 x TopTronic® E ZE3 module

Number of boilers Package part number

2 Boiler cascade

6043 453

3 Boiler cascade 6043 454

4 Boiler cascade 6043 455

5 Boiler cascade 6043 456

6 Boiler cascade 6043 457

44

TopGas Cascade 60 - 720 kW

4215256-00 - 11/16

6034 576

6037 062

6038 526

6038 507

6038 508

6038 509

6038 510

6034 575

TopTronic® E module expansions

for TopTronic® E basic module heat generator

Note

The supplementary plug set may have to be

ordered to implement functions differing from

the standard! Consult Hoval Technical for site

specic requirements.

+

Note

The ow rate sensor set must be ordered as

well.

TopTronic® E module expansion Universal

TTE-FE UNI

Expansion to the inputs and outputs of a controller module (basic module heat generator, heating circuit/domestic hot water module, solar

module, buffer module) for implementing vari-

ous functions

incl. tting accessories

Can be installed in:

Wall housing, control panel

TopTronic® E module expansion

heat accounting TTE-FE WMZ/EBZ

Expansion to the inputs and outputs for

the basic module heat generator for

implementing the following functions:

- Calculating total energy consumption

- Calculating the heat generator energy for

heating

- Calculating the heat generator energy for

hot water

incl. tting accessories

3x contact sensor ALF/2P/4/T L = 4.0 m

Can be installed in:

Wall housing

TopTronic® E module expansion heating

circuit TTE-FE HK

Expansion to the inputs and outputs of the basic

module heat generator or the heating circuit/domestic hot water module for implementing the

following functions:

- 1 heating circuit without mixer or

- 1 heating circuit with mixer

incl. tting accessories

1x contact sensor ALF/2P/4/T L = 4.0 m

Can be installed in:

Wall housing

Flow rate sensor sets

Size Connection Flow rate