Hoshizaki KM-1301SAH-3, KM-1301SWH-3, KM-1301SRH-3 User Manual

Hoshizaki

“A Superior Degree

of Reliability”

www.hoshizaki.com

Models

KM-1301SAH/3

KM-1301SWH/3

KM-1301SRH/3

Stackable Crescent Cuber

Hoshizaki America, Inc.

SERVICE MANUAL

™

Number: 73169

Issued:1-21-2009

Revised: 8-6-2009

IMPORTANT

Only qualied service technicians should install, service, and maintain the

icemaker. No service or maintenance should be undertaken until the technician

has thoroughly read this Service Manual. Failure to service and maintain

the equipment in accordance with this manual may adversely affect safety,

performance, component life, and warranty coverage.

Hoshizaki provides this manual primarily to assist qualied service technicians in the

service and maintenance of the icemaker.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, write, or send an e-mail message to the Hoshizaki Technical

Support Department for assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 3069

Attn: Hoshizaki Technical Support Department

Phone: 1-800-33-1940 Technical Support

(770) 487-331

Fax: 1-800-843-1056

(770) 487-3360

E-mail: techsupport@hoshizaki.com

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem.

3

CONTENTS

Important Safety Information ................................................................................................. 6

I. Specications ..................................................................................................................... 7

A. Icemaker ....................................................................................................................... 7

1. KM-1301SAH (air-cooled) ....................................................................................... 7

. KM-1301SAH3 (air-cooled) ..................................................................................... 8

3. KM-1301SWH (water-cooled) ................................................................................ 9

4. KM-1301SWH3 (water-cooled) ............................................................................. 10

5. KM-1301SRH (remote air-cooled) ......................................................................... 11

6. KM-1301SRH3 (remote air-cooled) ....................................................................... 1

B. Condenser Unit ........................................................................................................... 13

1. URC-14F ............................................................................................................... 13

II. General Information ......................................................................................................... 15

A. Construction ................................................................................................................ 15

1. KM-1301SAH, KM-1301SAH3 (air-cooled) ........................................................... 15

. KM-1301SWH, KM-1301SWH3 (water-cooled) .................................................... 16

3. KM-1301SRH, KM-1301SRH3 (remote air-cooled) .............................................. 17

B. Sequence of Operation ............................................................................................... 18

1. Sequence Cycles and Shutdown .......................................................................... 18

a) 1-Minute Fill Cycle ........................................................................................... 18

b) Initial Harvest Cycle ........................................................................................ 18

c) Freeze Cycle ................................................................................................... 18

d) Pump-Out Cycle ............................................................................................. 19

e) Harvest Cycle ................................................................................................. 19

f) Shutdown .......................................................................................................... 19

. Sequence Flow Chart ............................................................................................ 0

C. Control Board ............................................................................................................. 1

1. Control Board Layout ............................................................................................

. Features ................................................................................................................ 3

a) Maximum Water Supply Period - 6 minutes .................................................... 3

b) Harvest Backup Timer and Freeze Timer ........................................................ 3

c) High Temperature Safety ................................................................................. 3

d) Low Water Safety ............................................................................................ 3

e) High Voltage and Low Voltage Cut-outs .......................................................... 3

f) LED Lights and Audible Alarm Safeties ............................................................ 4

3. Controls and Adjustments ..................................................................................... 5

a) Default Dip Switch Settings ............................................................................. 5

b) Harvest Timer (S4 dip switch 1 & ) ................................................................ 5

c) Pump-Out Timer (S4 dip switch 3 & 4) ............................................................ 6

d) Pump-Out Frequency Control (S4 dip switch 5 & 6) ........................................ 6

IMPORTANT

This manual should be read carefully before the icemaker is serviced or

maintenance operations are performed. Only qualied service technicians

should install, service, and maintain the icemaker. Read the warnings

contained in this booklet carefully as they give important information regarding

safety. Please retain this booklet for any further reference that may be

necessary.

4

e) Harvest Pump Timer (S4 dip switch 7) ............................................................ 7

f) Factory Use (S4 dip switch 8) ........................................................................... 7

g) Freeze Timer (S4 dip switch 9 & 10) ............................................................... 7

h) Float Switch Control (S5 dip switch 1) ............................................................ 8

i) Rell Counter (S5 dip switch through 5) ........................................................ 8

D. Bin Control .................................................................................................................. 9

E. Float Switch ................................................................................................................ 9

F. Thermistor ................................................................................................................... 9

G. Control Switch ............................................................................................................ 9

III. Technical Information ..................................................................................................... 30

A. Water Circuit and Refrigeration Circuit ....................................................................... 30

1. KM-1301SAH, KM-1301SAH3 (air-cooled) ........................................................... 30

. KM-1301SWH, KM-1301SWH3 (water-cooled) .................................................... 31

3. KM-1301SRH, KM-1301SRH3 (remote air-cooled) ............................................... 3

B. Wiring Diagrams ......................................................................................................... 33

1. Auxiliary Code T-0, U-0 ........................................................................................ 33

a) KM-1301SAH (air-cooled) ................................................................................ 33

b) KM-1301SWH (water-cooled) .......................................................................... 34

c) KM-1301SRH (remote air-cooled) ................................................................... 35

d) KM-1301SAH3 (air-cooled) and KM-1301SWH3 (water-cooled) ..................... 36

e) KM-1301SRH3 (remote air-cooled) ................................................................. 37

. Auxiliary Code U-1 and Later ............................................................................... 38

a) KM-1301SAH (air-cooled) ............................................................................... 38

b) KM-1301SWH (water-cooled) ......................................................................... 39

c) KM-1301SRH (remote air-cooled) ................................................................... 40

d) KM-1301SAH3 (air-cooled) and KM-1301SWH3 (water-cooled) ..................... 41

e) KM-1301SRH3 (remote air-cooled) ................................................................. 4

C. Performance Data ...................................................................................................... 43

1. KM-1301SAH (air-cooled) ..................................................................................... 43

. KM-1301SAH3 (air-cooled) ................................................................................... 44

3. KM-1301SWH (water-cooled) .............................................................................. 45

4. KM-1301SWH3 (water-cooled) ............................................................................ 46

5. KM-1301SRH (remote air-cooled) ........................................................................ 47

6. KM-1301SRH3 (remote air-cooled) ....................................................................... 48

IV. Service Diagnosis .......................................................................................................... 49

A. Diagnostic Procedure ................................................................................................ 49

B. Control Board Check .................................................................................................. 53

C. Bin Control Check ....................................................................................................... 54

D. Float Switch Check and Cleaning ............................................................................... 54

1. Float Switch Check ................................................................................................ 54

. Float Switch Cleaning ............................................................................................ 55

E. Thermistor Check ....................................................................................................... 56

F. Diagnostic Charts ........................................................................................................ 57

5

V. Removal and Replacement of Components ................................................................... 65

A. Service for Refrigerant Lines ...................................................................................... 65

1. Refrigerant Recovery ............................................................................................ 65

. Brazing .................................................................................................................. 66

3. Evacuation and Recharge (R-404A) ..................................................................... 66

B. Removal and Replacement of Compressor ................................................................ 67

C. Removal and Replacement of Expansion Valve......................................................... 68

D. Removal and Replacement of Hot Gas Valve or Liquid Line Valve............................ 69

E. Removal and Replacement of Evaporator .................................................................. 70

F. Removal and Replacement of Air-Cooled Condenser ................................................ 71

G. Removal and Replacement of Water-Cooled Condenser .......................................... 7

H. Removal and Replacement of Remote Air-Cooled Condenser .................................. 73

I. Removal and Replacement of Water Regulating Valve (water-cooled model) ............ 74

J. Adjustment of Water Regulating Valve (water-cooled model) .................................... 75

K. Removal and Replacement of Headmaster (Condensing Pressure Regulator - C.P.R.)

(remote air-cooled model) ......................................................................................... 75

L. Removal and Replacement of Thermistor ................................................................... 76

M. Removal and Replacement of Fan Motor (air-cooled and remote air-cooled models) 77

N. Removal and Replacement of Inlet Water Valve ........................................................ 77

O. Removal and Replacement of Pump Motor................................................................ 78

P. Removal and Replacement of Control Board ............................................................. 79

VI. Cleaning and Maintenance ............................................................................................ 80

A. Cleaning and Sanitizing Instructions ........................................................................... 80

1. Cleaning Procedure ............................................................................................... 81

. Sanitizing Procedure - Following Cleaning Procedure .......................................... 8

B. Maintenance Instructions ............................................................................................ 83

C. Preparing the Icemaker for Long Storage .................................................................. 83

6

Important Safety Information

Throughout this manual, notices appear to bring your attention to situations which could

result in death, serious injury, or damage to the unit.

WARNING Indicates a hazardous situation which could result in death or

serious injury.

CAUTION Indicates a situation which could result in damage to the unit.

IMPORTANT Indicates important information about the use and care of the

unit.

WARNING

This icemaker should be destined only to the use for which it has been

expressly conceived. Any other use should be considered improper and

therefore dangerous. The manufacturer cannot be held responsible for

eventual damage caused by improper, incorrect, and unreasonable use.

To reduce the risk of death, electric shock, serious injury, or re, follow

basic precautions including the following:

• Electrical connection must be hard-wired and must meet national, state, and

local electrical code requirements. Failure to meet these code requirements

could result in death, electric shock, serious injury, re, or severe damage to

equipment.

• This unit requires an independent power supply. See the nameplate for

proper voltage and breaker/fuse size. Failure to use a proper breaker or fuse

can result in a tripped breaker, blown fuse, or damage to existing wiring. This

could lead to heat generation or re.

• THIS UNIT MUST BE GROUNDED. Failure to properly ground this unit

could result in death or serious injury.

• This unit should be disassembled or repaired only by qualied service

personnel to reduce the risk of electric shock, injury, or re.

• Do not make any alterations to the unit. Alterations could result in electric

shock, injury, re, or damage to the unit.

7

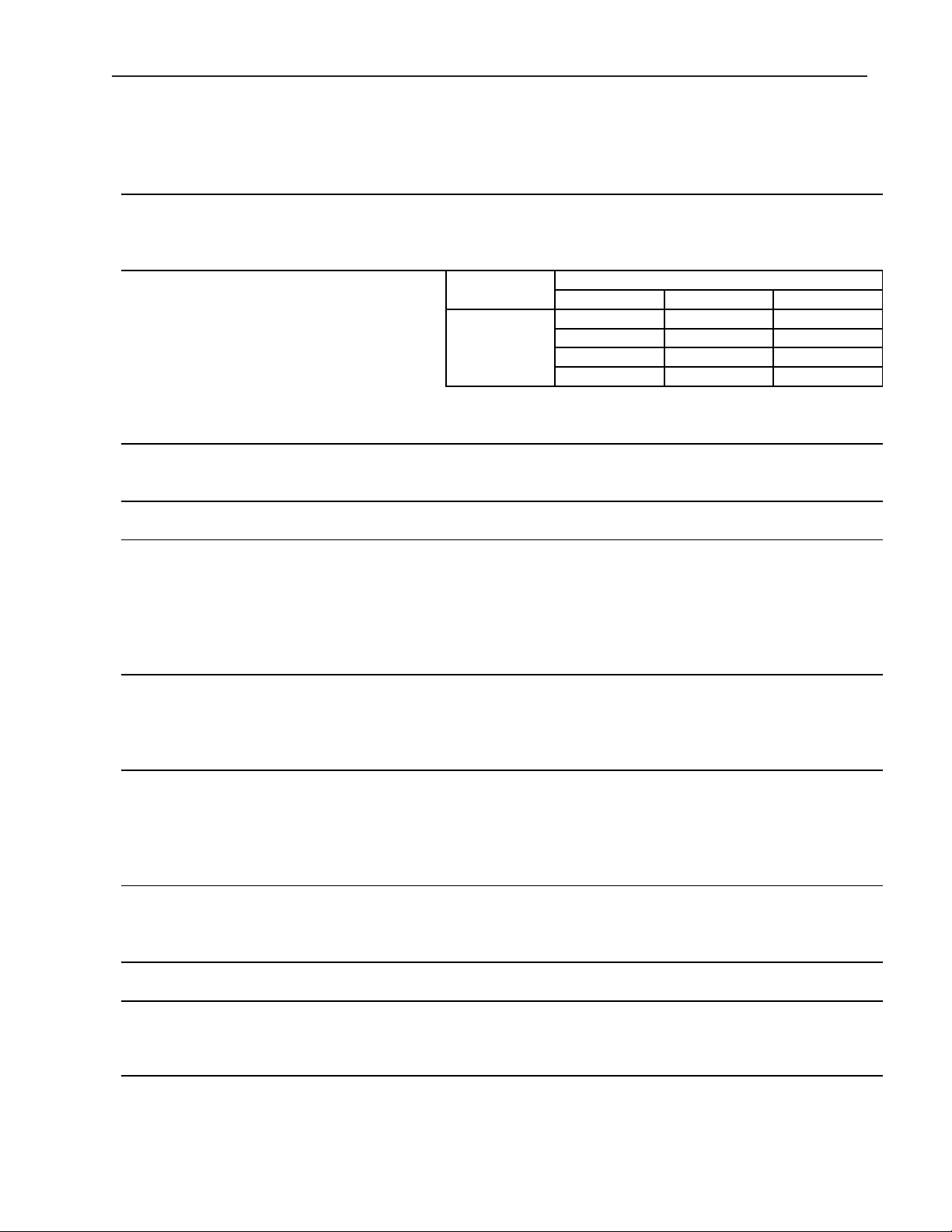

I. Specications

A. Icemaker

1. KM-1301SAH (air-cooled)

Note: We reserve the right to make changes in specications and design without prior

notice.

AC SUPPLY VOLTAGE 208-230/60/1 (3 wire with neutral for 115V)

AMPERAGE 12.4 A ( 5 Min. Freeze AT 104°F / WT 80°F)

MINIMUM CIRCUIT AMPACITY 20 A

MAXIMUM FUSE SIZE 20 A

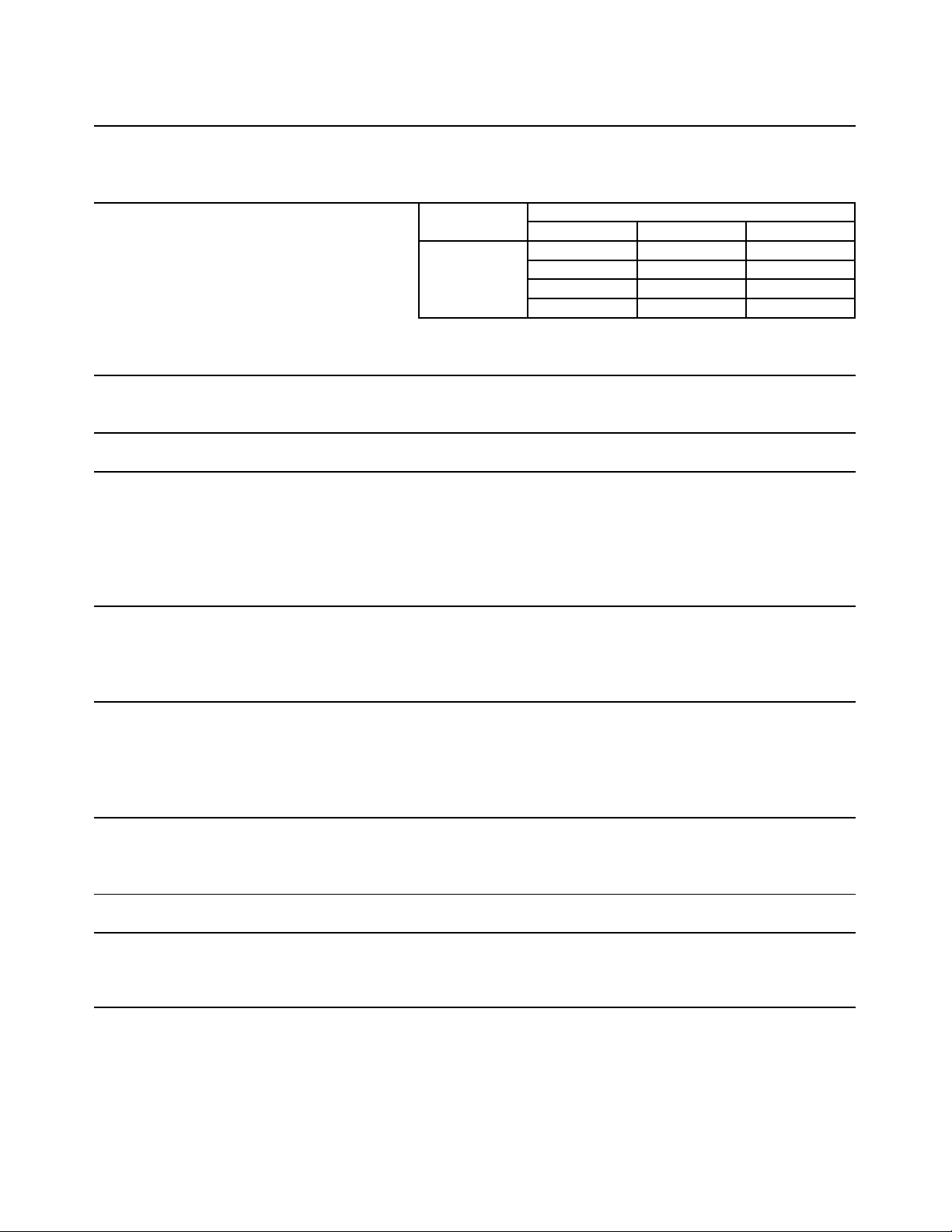

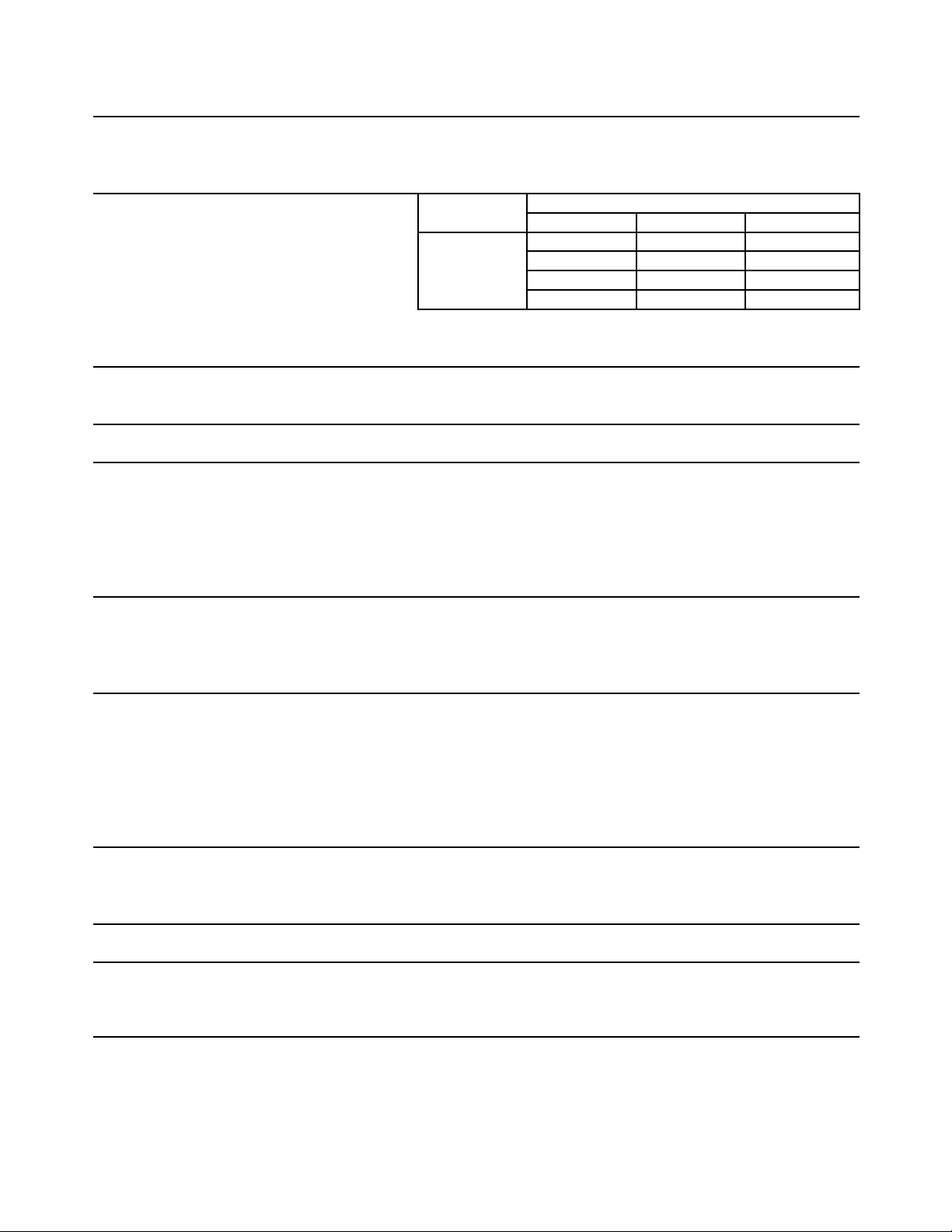

APPROXIMATE ICE PRODUCTION Ambient WATER TEMP. (°F)

PER 24 HR. Temp.(°F) 50 70 90

lbs./day ( kg/day ) 70 *1329 (603) 1281 (581) 1188 (539)

Reference without *marks 80 1292 (586) 1217 (552) 1109 (503)

90 1281 (581) *1164 (528) 1060 (481)

100 1253 (568) 1140 (517) 965 (438)

SHAPE OF ICE Crescent Cube

ICE PRODUCTION PER CYCLE 29.8 lbs. (13.5 kg) 1440pcs.

APPROXIMATE STORAGE CAPACITY N/A

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 2180(4.5) 2160(3.9)

WATER gal./24HR (gal./100 lbs.) 183(15.7) 605(45.5)

CEC/CEE TIER LEVEL 3

ENERGY STAR YES

EXTERIOR DIMENSIONS (WxDxH) 48" x 27-3/8" x 27-3/8" (1219 x 695 x 695 mm)

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 275 lbs. (125 kg), Shipping 315 lbs. (143 kg)

CONNECTIONS - ELECTRIC Permanent - Connection

- WATER SUPPLY Inlet 1/2" FPT

- DRAIN Outlet 3/4" FPT

- CONDENSATE DRAIN 3/8" OD Tube

CUBE CONTROL SYSTEM Float Switch

HARVESTING CONTROL SYSTEM Hot Gas and Water, Thermistor and Timer

ICE MAKING WATER CONTROL Timer Controlled. Overflow Pipe

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM Thermostat

COMPRESSOR Hermetic, Model CS14K6E-PFV-237

CONDENSER Air-Cooled , Fin and tube type

EVAPORATOR Vertical type, Stainless Steel and Copper

REFRIGERANT CONTROL Thermostatic Expansion Valve

REFRIGERANT CHARGE R404A, 3 lb. 15.5 oz. (1800g)

DESIGN PRESSURE High 467PSIG, Low 230PSIG

P.C. BOARD CIRCUIT PROTECTION High Voltage Cut-out ( Internal )

COMPRESSOR PROTECTION Auto-reset Overload Protector ( Internal )

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

LOW WATER PROTECTION Float Switch

ACCESSORIES -SUPPLIED N/A

-REQUIRED Ice Storage Bin

OPERATING CONDITIONS VOLTAGE RANGE 187 - 253 V

AMBIENT TEMP. 45 -100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

8

Note: We reserve the right to make changes in specications and design without prior

notice.

2. KM-1301SAH3 (air-cooled)

AC SUPPLY VOLTAGE 208-230/60/3

AMPERAGE 9.5 A ( 5 Min. Freeze AT 104°F / WT 80°F)

MINIMUM CIRCUIT AMPACITY 20 A

MAXIMUM FUSE SIZE 20 A

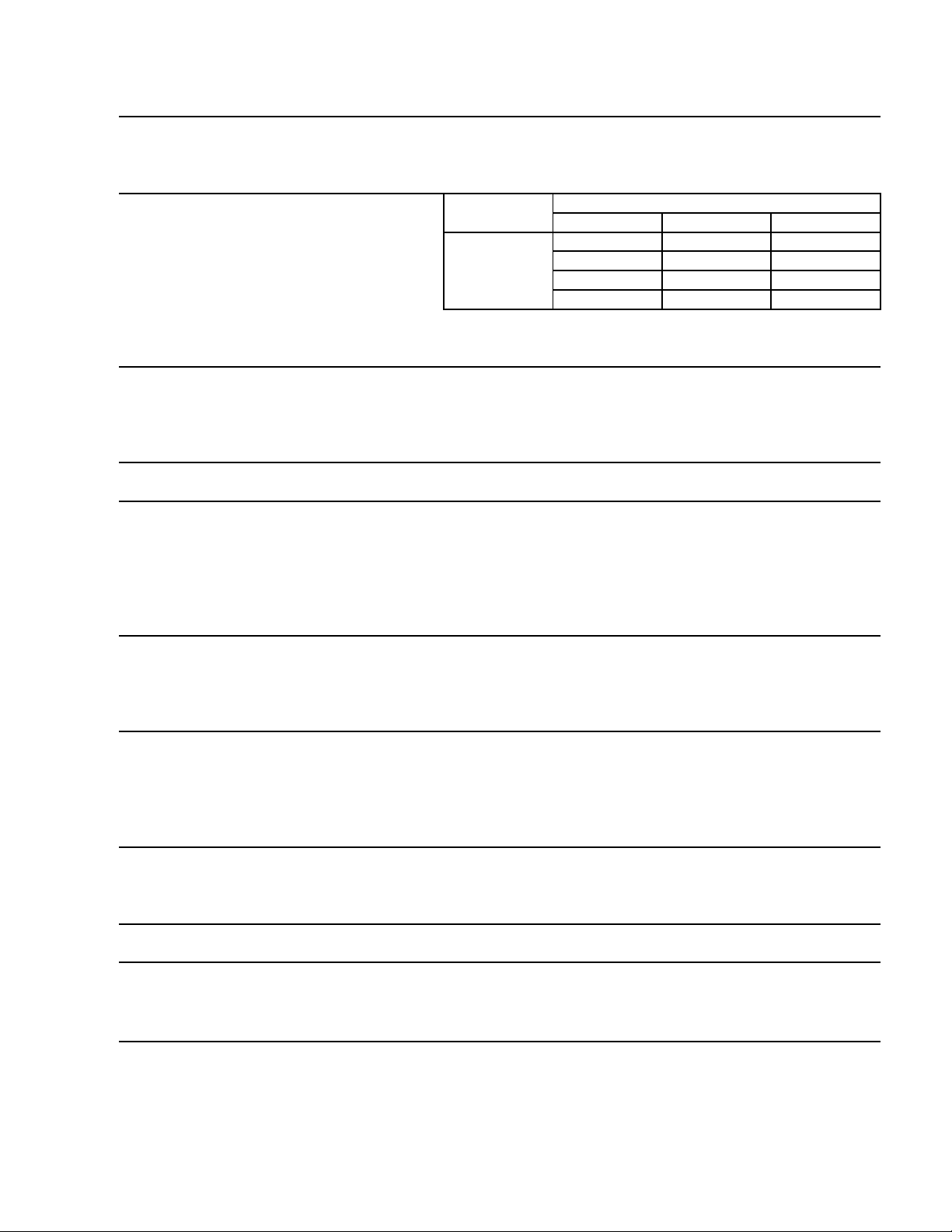

APPROXIMATE ICE PRODUCTION Ambient WATER TEMP. (°F)

PER 24 HR. Temp.(°F) 50 70 90

lbs./day ( kg/day ) 70 *1298 (589) 1257 (570) 1162 (527)

Reference without *marks 80 1267 (575) 1204 (546) 1086 (493)

90 1257 (570) *1159 (526) 1049 (476)

100 1225 (556) 1133 (514) 947 (430)

SHAPE OF ICE Crescent Cube

ICE PRODUCTION PER CYCLE 30.4 lbs. (13.8 kg) 1440pcs.

APPROXIMATE STORAGE CAPACITY N/A

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 2220(4.6) 2090(3.9)

WATER gal./24HR (gal./100 lbs.) 181(15.6) 511(39.4)

CEC/CEE TIER LEVEL 3

ENERGY STAR YES

EXTERIOR DIMENSIONS (WxDxH) 48" x 27-3/8" x 27-3/8" (1219 x 695 x 695 mm)

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 275 lbs. (125 kg), Shipping 315 lbs. (143 kg)

CONNECTIONS - ELECTRIC Permanent - Connection

- WATER SUPPLY Inlet 1/2" FPT

- DRAIN Outlet 3/4" FPT

- CONDENSATE DRAIN 3/8" OD Tube

CUBE CONTROL SYSTEM Float Switch

HARVESTING CONTROL SYSTEM Hot Gas and Water, Thermistor and Timer

ICE MAKING WATER CONTROL Timer Controlled. Overflow Pipe

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM Thermostat

COMPRESSOR Hermetic, Model CS14K6E-TF5-237

CONDENSER Air-Cooled, Fin and tube type

EVAPORATOR Vertical type, Stainless Steel and Copper

REFRIGERANT CONTROL Thermostatic Expansion Valve

REFRIGERANT CHARGE R404A, 3 lb. 15.5 oz. (1800g)

DESIGN PRESSURE High 467PSIG, Low 230PSIG

P.C. BOARD CIRCUIT PROTECTION High Voltage Cut-out ( Internal )

COMPRESSOR PROTECTION Auto-reset Overload Protector ( Internal )

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

LOW WATER PROTECTION Float Switch

ACCESSORIES -SUPPLIED N/A

-REQUIRED Ice Storage Bin

OPERATING CONDITIONS VOLTAGE RANGE 187 - 253 V

AMBIENT TEMP. 45 -100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

9

3. KM-1301SWH (water-cooled)

Note: We reserve the right to make changes in specications and design without prior

notice.

AC SUPPLY VOLTAGE 208-230/60/1 (3 wire with neutral for 115V)

AMPERAGE 8.2 A ( 5 Min. Freeze AT 104°F / WT 80°F)

MINIMUM CIRCUIT AMPACITY 20 A

MAXIMUM FUSE SIZE 20 A

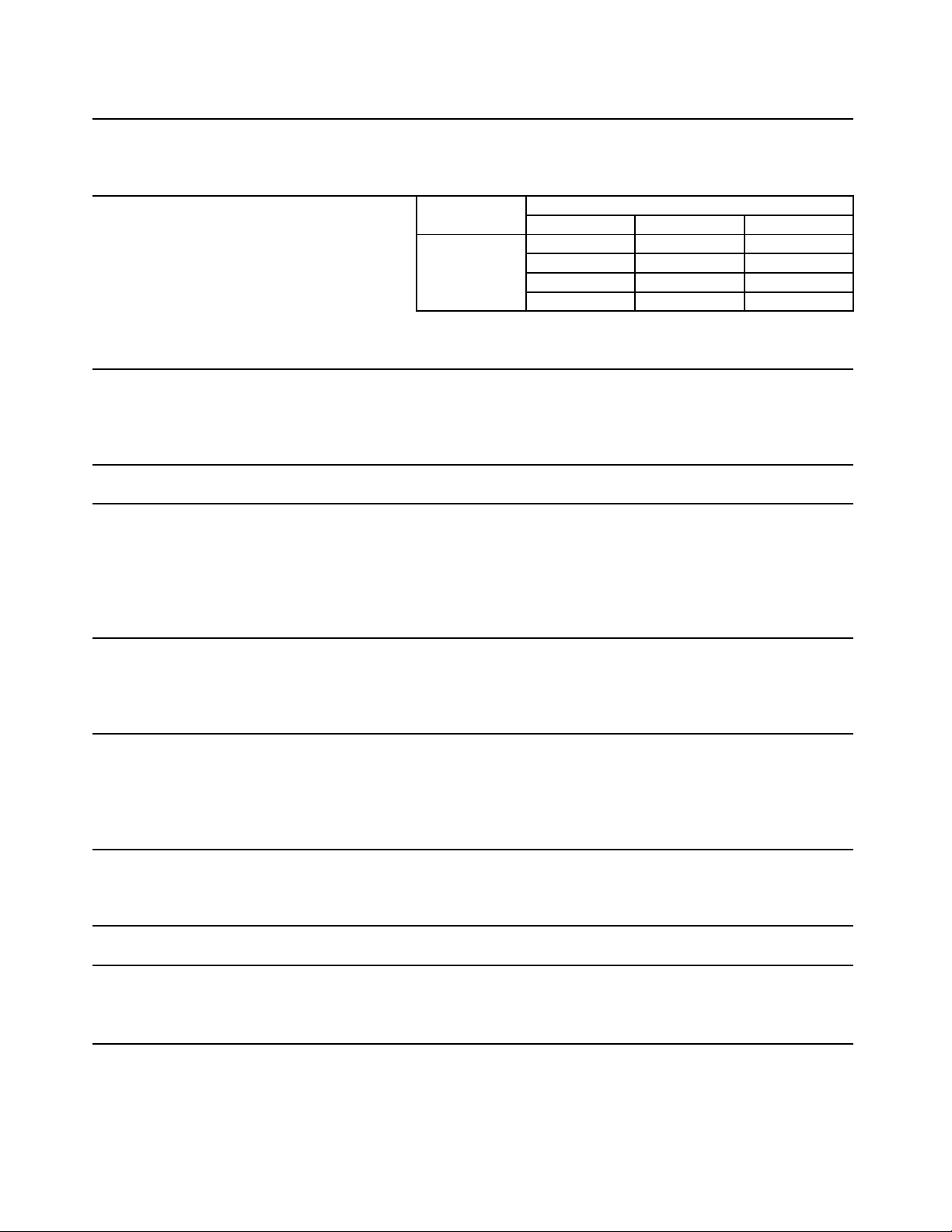

APPROXIMATE ICE PRODUCTION Ambient WATER TEMP. (°F)

PER 24 HR. Temp.(°F) 50 70 90

lbs./day ( kg/day ) 70 *1318 (598) 1319 (599) 1249 (567)

Reference without *marks 80 1319 (598) 1321 (599) 1211 (549)

90 1319 (599) *1323 (600) 1228 (557)

100 1281 (581) 1301 (590) 1141 (518)

SHAPE OF ICE Crescent Cube

ICE PRODUCTION PER CYCLE 31 lbs. (14.1 kg) 1440pcs.

APPROXIMATE STORAGE CAPACITY N/A

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 1760(3.2) 1740(3.2)

WATER gal./24HR (gal./100 lbs.) 257(19.4) 546(41.4)

WATER COOLED CONDENSER 1561(118) 861(65)

gal./24HR (gal./100 lbs.)

CEC/CEE TIER LEVEL 3

ENERGY STAR N/A

EXTERIOR DIMENSIONS (WxDxH) 48" x 27-3/8" x 27-3/8" (1219 x 695 x 695 mm)

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 265 lbs. (120 kg), Shipping 315 lbs. (143 kg)

CONNECTIONS - ELECTRIC Permanent - Connection

- WATER SUPPLY Inlet 1/2" FPT Cond. Inlet 1/2" FPT

- DRAIN Outlet 3/4" FPT Cond. Outlet 3/8" FPT

- CONDENSATE DRAIN 3/8" OD Tube

CUBE CONTROL SYSTEM Float Switch

HARVESTING CONTROL SYSTEM Hot Gas and Water, Thermistor and Timer

ICE MAKING WATER CONTROL Timer Controlled. Overflow Pipe

COOLING WATER CONTROL Water Regulator

BIN CONTROL SYSTEM Thermostat

COMPRESSOR Hermetic, Model CS12K6E-PFV-237

CONDENSER Water-cooled, Tube in tube type

EVAPORATOR Vertical type, Stainless Steel and Copper

REFRIGERANT CONTROL Thermostatic Expansion Valve

REFRIGERANT CHARGE R404A, 2 lb. 8.2 oz. (1140g)

DESIGN PRESSURE High 427PSIG, Low 230PSIG

P.C. BOARD CIRCUIT PROTECTION High Voltage Cut-out ( Internal )

COMPRESSOR PROTECTION Auto-reset Overload Protector ( Internal )

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

LOW WATER PROTECTION Float Switch

ACCESSORIES -SUPPLIED N/A

-REQUIRED Ice Storage Bin

OPERATING CONDITIONS VOLTAGE RANGE 187 - 253 V

AMBIENT TEMP. 45 -100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

10

4. KM-1301SWH3 (water-cooled)

Note: We reserve the right to make changes in specications and design without prior

notice.

AC SUPPLY VOLTAGE 208-230/60/3

AMPERAGE 6.1 A ( 5 Min. Freeze AT 104°F / WT 80°F)

MINIMUM CIRCUIT AMPACITY 20 A

MAXIMUM FUSE SIZE 20 A

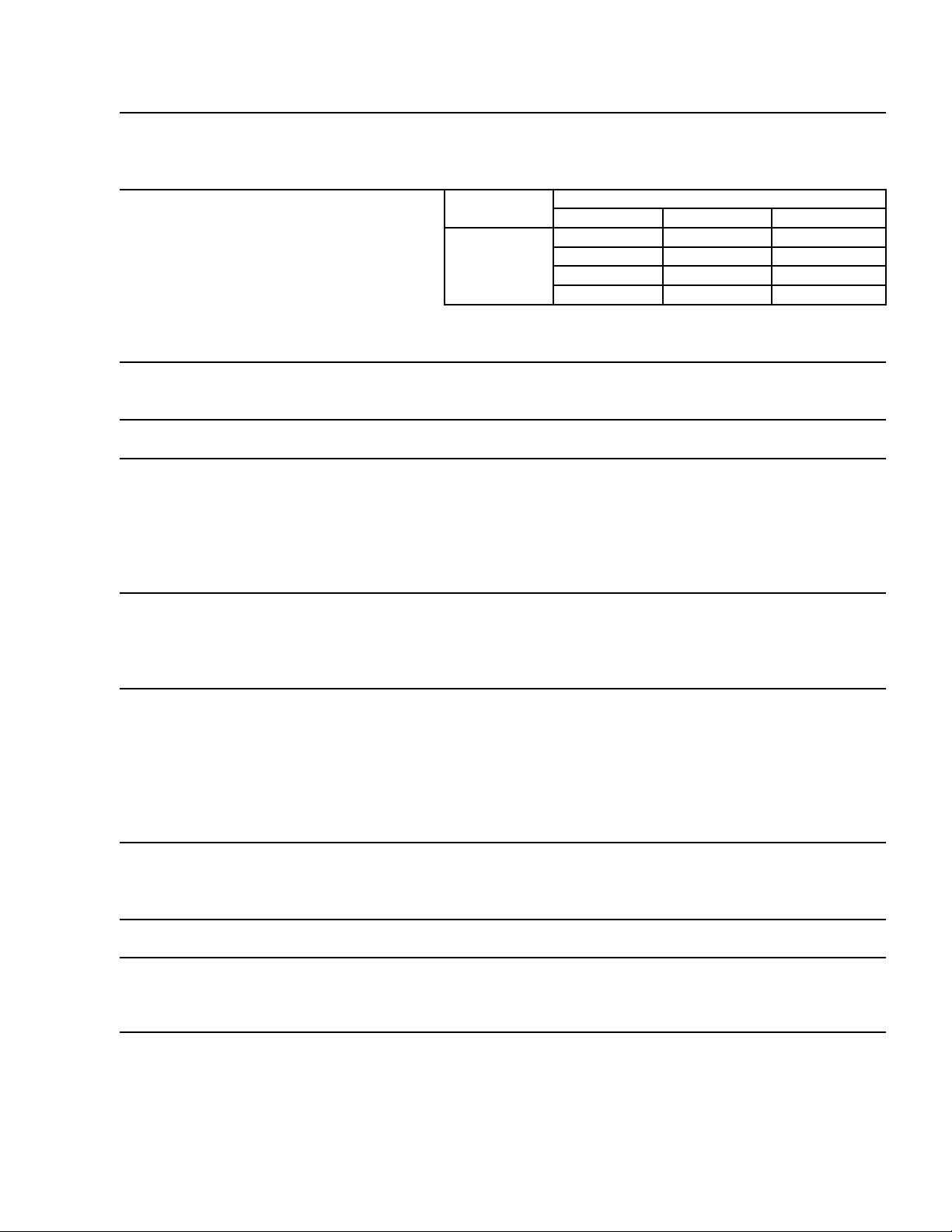

APPROXIMATE ICE PRODUCTION Ambient WATER TEMP. (°F)

PER 24 HR. Temp.(°F) 50 70 90

lbs./day ( kg/day ) 70 *1333 (605) 1323 (600) 1246 (565)

Reference without *marks 80 1326 (601) 1311 (594) 1198 (544)

90 1323 (600) *1300 (590) 1201 (545)

100 1286 (584) 1277 (579) 1110 (503)

SHAPE OF ICE Crescent Cube

ICE PRODUCTION PER CYCLE 32.2 lbs. (14.6 kg) 1440pcs.

APPROXIMATE STORAGE CAPACITY N/A

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 1840(3.4) 1770(3.2)

WATER gal./24HR (gal./100 lbs.) 248(19.1) 557(41.8)

WATER COOLED CONDENSER 1547(119) 857(64)

gal./24HR (gal./100 lbs.)

CEC/CEE TIER LEVEL 3

ENERGY STAR N/A

EXTERIOR DIMENSIONS (WxDxH) 48" x 27-3/8" x 27-3/8" (1219 x 695 x 695 mm)

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 265 lbs. (120 kg), Shipping 315 lbs. (143 kg)

CONNECTIONS - ELECTRIC Permanent - Connection

- WATER SUPPLY Inlet 1/2" FPT Cond. Inlet 1/2" FPT

- DRAIN Outlet 3/4" FPT Cond. Outlet 3/8" FPT

- CONDENSATE DRAIN 3/8" OD Tube

CUBE CONTROL SYSTEM Float Switch

HARVESTING CONTROL SYSTEM Hot Gas and Water, Thermistor and Timer

ICE MAKING WATER CONTROL Timer Controlled. Overflow Pipe

COOLING WATER CONTROL Water Regulator

BIN CONTROL SYSTEM Thermostat

COMPRESSOR Hermetic, Model CS12K6E-TF5-237

CONDENSER Water-cooled, Tube in tube type

EVAPORATOR Vertical type, Stainless Steel and Copper

REFRIGERANT CONTROL Thermostatic Expansion Valve

REFRIGERANT CHARGE R404A, 2 lb. 8.2 oz. (1140g)

DESIGN PRESSURE High 427PSIG, Low 230PSIG

P.C. BOARD CIRCUIT PROTECTION High Voltage Cut-out ( Internal )

COMPRESSOR PROTECTION Auto-reset Overload Protector ( Internal )

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

LOW WATER PROTECTION Float Switch

ACCESSORIES -SUPPLIED N/A

-REQUIRED Ice Storage Bin

OPERATING CONDITIONS VOLTAGE RANGE 187 - 253 V

AMBIENT TEMP. 45 -100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

11

5. KM-1301SRH (remote air-cooled)

Note: We reserve the right to make changes in specications and design without prior

notice.

AC SUPPLY VOLTAGE 208-230/60/1 (3 wire with neutral for 115V)

AMPERAGE 13.5A ( 5 Min. Freeze AT 104°F / WT 80°F)

MINIMUM CIRCUIT AMPACITY 20 A

MAXIMUM FUSE SIZE 20 A

APPROXIMATE ICE PRODUCTION Ambient WATER TEMP. (°F)

PER 24 HR. Temp.(°F) 50 70 90

lbs./day ( kg/day ) 70 *1353 (614) 1315 (596) 1219 (553)

Reference without *marks 80 1324 (600) 1264 (573) 1144 (519)

90 1315 (596) *1222 (554) 1110 (504)

100 1281 (581) 1196 (542) 1008 (457)

SHAPE OF ICE Crescent Cube

ICE PRODUCTION PER CYCLE 31.1 lbs. (14.1 kg) 1440pcs.

APPROXIMATE STORAGE CAPACITY N/A

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 2090(4.1) 2010(3.6)

WATER gal./24HR (gal./100 lbs.) 203(16.6) 479(35.4)

CEC/CEE TIER LEVEL 3

ENERGY STAR YES

EXTERIOR DIMENSIONS (WxDxH) 48" x 27-3/8" x 27-3/8" (1219 x 695 x 695 mm)

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 255 lbs. (116 kg), Shipping 315 lbs. (143 kg)

CONNECTIONS - ELECTRIC Permanent - Connection

- WATER SUPPLY Inlet 1/2" FPT

- DRAIN Outlet 3/4" FPT

- CONDENSATE DRAIN 3/8" OD Tube

CUBE CONTROL SYSTEM Float Switch

HARVESTING CONTROL SYSTEM Hot Gas and Water, Thermistor and Timer

ICE MAKING WATER CONTROL Timer Controlled. Overflow Pipe

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM Thermostat

COMPRESSOR Hermetic, Model CS12K6E-PFV-279

CONDENSER Air-Cooled Remote, Condenser Unit URC-14F

EVAPORATOR Vertical type, Stainless Steel and Copper

REFRIGERANT CONTROL Thermostatic Expansion Valve

Condensing Pressure Regulator on URC-14F

REFRIGERANT CHARGE R404A, 10 lbs. 5.8 oz. (4700g)

(Icemaker 5 lbs. 15.2 oz. Cond. Unit 4 lbs. 6.5 oz.)

DESIGN PRESSURE High 467PSIG, Low 230PSIG

P.C. BOARD CIRCUIT PROTECTION High Voltage Cut-out ( Internal )

COMPRESSOR PROTECTION Auto-reset Overload Protector ( Internal )

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

LOW WATER PROTECTION Float Switch

ACCESSORIES -SUPPLIED N/A

-REQUIRED Ice Storage Bin, Remote Condenser Unit

OPERATING CONDITIONS VOLTAGE RANGE 187 - 253 V

AMBIENT TEMP. 45 -100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

1

6. KM-1301SRH3 (remote air-cooled)

Note: We reserve the right to make changes in specications and design without prior

notice.

AC SUPPLY VOLTAGE 208-230/60/3

AMPERAGE 10.7A ( 5 Min. Freeze AT 104°F / WT 80°F)

MINIMUM CIRCUIT AMPACITY 20 A

MAXIMUM FUSE SIZE 20 A

APPROXIMATE ICE PRODUCTION Ambient WATER TEMP. (°F)

PER 24 HR. Temp.(°F) 50 70 90

lbs./day ( kg/day ) 70 *1339 (607) 1297 (589) 1203 (546)

Reference without *marks 80 1307 (593) 1243 (564) 1127 (511)

90 1297 (589) *1197 (543) 1088 (494)

100 1266 (574) 1171 (531) 988 (448)

SHAPE OF ICE Crescent Cube

ICE PRODUCTION PER CYCLE 30.7 lbs. (13.9 kg) 1440pcs.

APPROXIMATE STORAGE CAPACITY N/A

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 2140(4.3) 2090(3.8)

WATER gal./24HR (gal./100 lbs.) 192(16.0) 463(34.6)

CEC/CEE TIER LEVEL 3

ENERGY STAR YES

EXTERIOR DIMENSIONS (WxDxH) 48" x 27-3/8" x 27-3/8" (1219 x 695 x 695 mm)

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 255 lbs. (116 kg), Shipping 315 lbs. (143 kg)

CONNECTIONS - ELECTRIC Permanent - Connection

- WATER SUPPLY Inlet 1/2" FPT

- DRAIN Outlet 3/4" FPT

- CONDENSATE DRAIN 3/8" OD Tube

CUBE CONTROL SYSTEM Float Switch

HARVESTING CONTROL SYSTEM Hot Gas and Water, Thermistor and Timer

ICE MAKING WATER CONTROL Timer Controlled. Overflow Pipe

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM Thermostat

COMPRESSOR Hermetic, Model CS12K6E-TF5-279

CONDENSER Air-Cooled Remote, Condenser Unit URC-14F

EVAPORATOR Vertical type, Stainless Steel and Copper

REFRIGERANT CONTROL Thermostatic Expansion Valve

Condensing Pressure Regulator on URC-14F

REFRIGERANT CHARGE R404A, 10 lbs. 5.8 oz. (4700g)

(Icemaker 5 lbs. 15.2 oz. Cond. Unit 4 lbs. 6.5 oz.)

DESIGN PRESSURE High 467PSIG, Low 230PSIG

P.C. BOARD CIRCUIT PROTECTION High Voltage Cut-out ( Internal )

COMPRESSOR PROTECTION Auto-reset Overload Protector ( Internal )

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

LOW WATER PROTECTION Float Switch

ACCESSORIES -SUPPLIED N/A

-REQUIRED Ice Storage Bin, Remote Condenser Unit

OPERATING CONDITIONS VOLTAGE RANGE 187 - 253 V

AMBIENT TEMP. 45 -100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

13

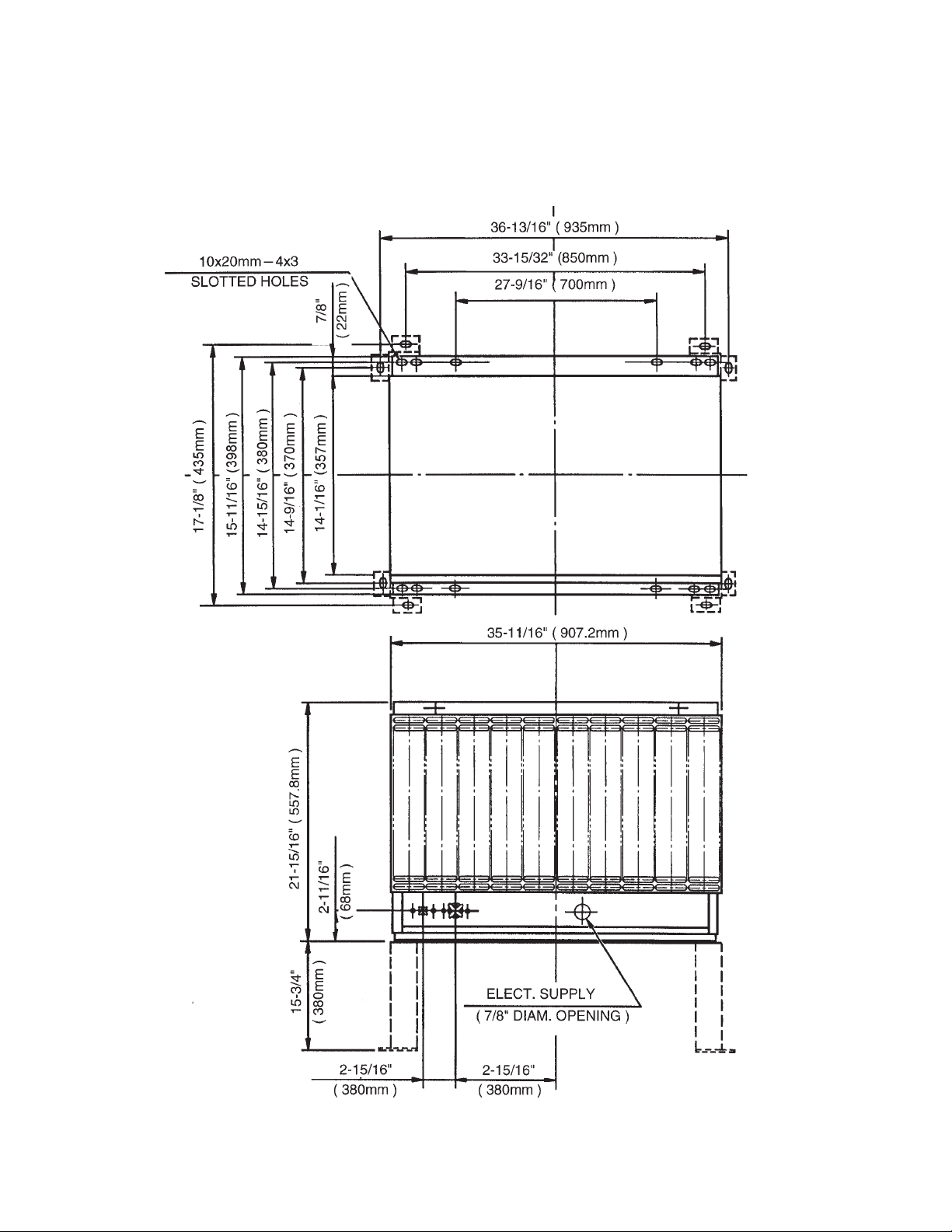

B. Condenser Unit

1. URC-14F

Unit: inches (mm)

14

SPECIFICATIONS

MODEL: URC-14F

AC SUPPLY VOLTAGE 115/60/1 (Connection to Icemaker)

FAN MOTOR 115 V Total 2.6FLA 130W

EXTERIOR DIMENSIONS (WxDxH) 35-11/16" x 15-11/16" x 21-15/16" (907.2 x 398 x 557.8 mm)

DIMENSIONS INCLUDING LEGS (WxDxH) 37-13/16" x 18-1/8" x 36-15/16" (960 x 460 x 937.8 mm)

EXTERIOR FINISH Galvanized Steel

WEIGHT Net 80 lbs. ( 36 kg ) Shipping 87 lbs. ( 39 kg )

CONNECTIONS - ELECTRIC Permanent - Connection

- REFRIGERANT Discharge Line 1-1/16"-12 UNF Fitting (#10 AEROQUIP)

Liquid Line 5/8"-18 UNF Fitting (#6 AEROQUIP)

CONDENSER Air-cooled, Fin and tube type

FAN MOTOR PROTECTION Thermal Protection

REFRIGERANT CONTROL Condensing Pressure Regulator

REFRIGERANT CHARGE R-404A 4 lb. 7 oz. (2000g)

DESIGN PRESSURE High 467 PSIG

OPERATING CONDITIONS VOLTAGE RANGE 104 ~ 127 V

AMBIENT TEMP. -20 ~ 122 °F

ACCESSORIES -SUPPLIED Leg 2 pcs

Hex. Head Bolt w/Washer 8 x 16 8 pcs

Hex. Nut 8 8 pcs

15

II. General Information

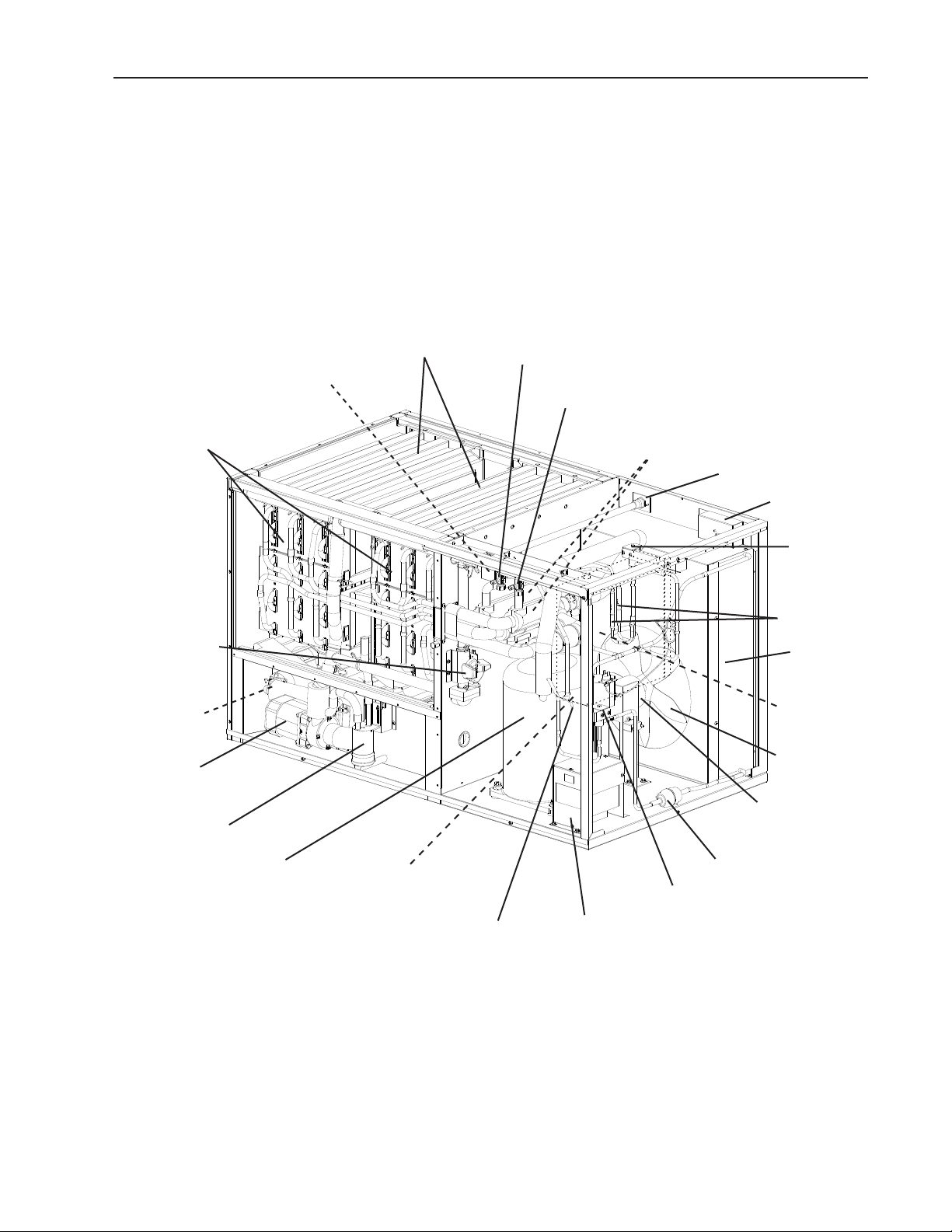

A. Construction

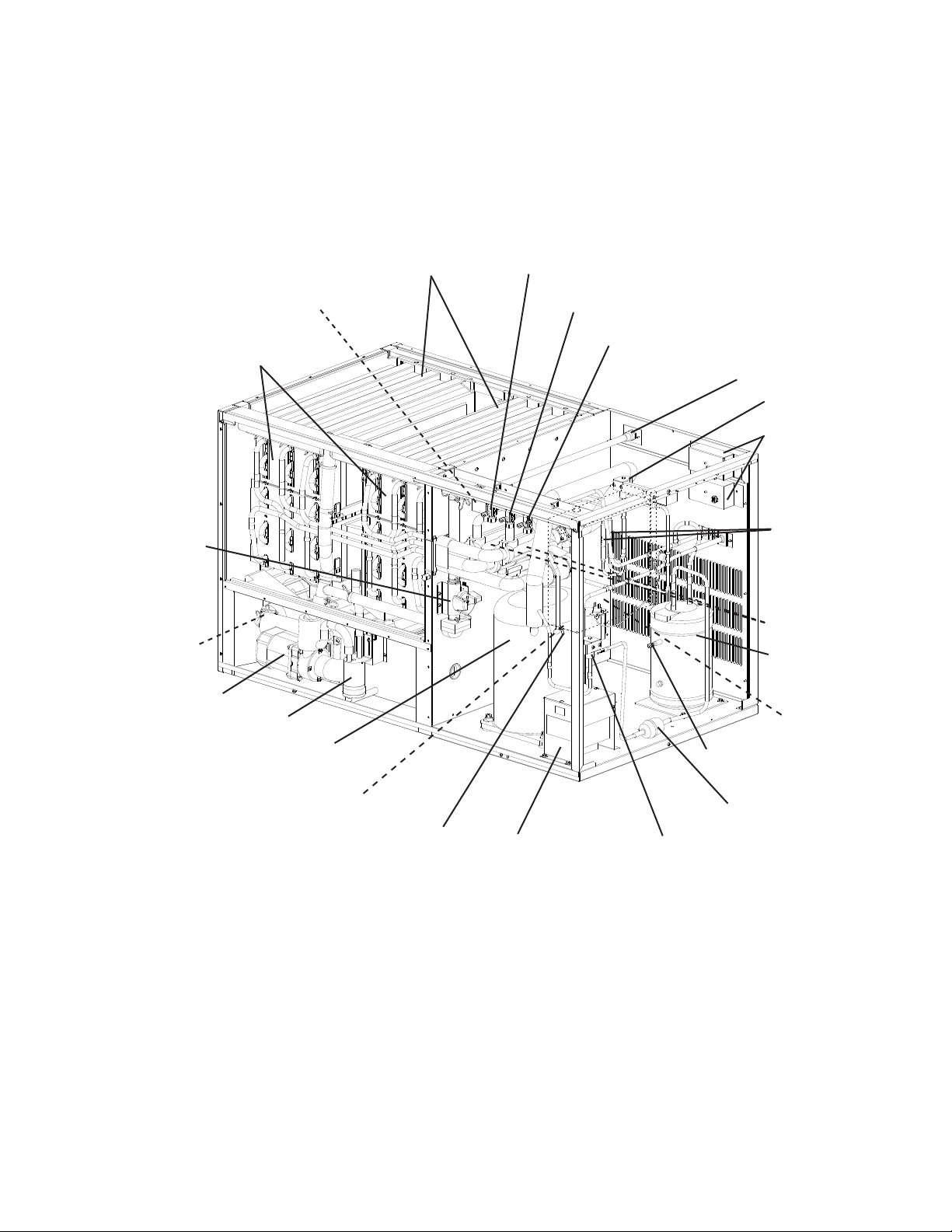

1. KM-1301SAH, KM-1301SAH3 (air-cooled)

Evaporator Assembly

Spray Tubes

Inlet Water Valve

Water Supply Inlet

Hot Gas Valve

Junction Box

Air-Cooled

Condenser

Check Valves

Control Box

Drier

Transformer Box

(KM-1301SAH3)

Control Switch

Bin Control Thermostat

Compressor

Cleaning Valve

Float Switch

Water Pump

Check Valve

(water)

Expansion Valves

Liquid Line Valve

Fan Motor

Fan Blade

Low-Side Service Valve

High-Side Service Valve

16

2. KM-1301SWH, KM-1301SWH3 (water-cooled)

Evaporator Assembly

Spray Tubes

Inlet Water Valve

Water Supply Inlet

Hot Gas Valve

Junction Box

Water Regulating

Valve

Check Valves

Control Box

Liquid Line Valve

Drier

Transformer Box

(KM-1301SWH3)

Control Switch

Bin Control Thermostat

Compressor

Cleaning Valve

Float Switch

Water Pump

Check Valve

(water)

Expansion Valves

Water-Cooled

Condenser

Low-Side Service Valve

High-Side Service Valve

17

3. KM-1301SRH, KM-1301SRH3 (remote air-cooled)

Evaporator Assembly

Spray Tubes

Inlet Water Valve

Water Supply Inlet

Hot Gas Valve

Junction Boxes

Receiver Tank

Check Valves

Control Box

Liquid Line Valve

Drier

Transformer Box

(KM-1301SRH3)

Control Switch

Bin Control Thermostat

Compressor

Cleaning Valve

Float Switch

Water Pump

Check Valve

(water)

Expansion Valves

Low-Side Service Valve

High-Side Service Valve

High-Side Liquid Service Valve

Access Valve

18

B. Sequence of Operation

IMPORTANT

This unit utilizes a thermostatic bin control. For operation, the K4 jumper

(4A4883G01) must be in place on the control board RED K4 connector.

1. Sequence Cycles and Shutdown

The steps in the sequence are as outlined below. When power is supplied, CB red

"POWER OK" LED and green "BC CLOSED" LED come on. The green "BC CLOSED"

LED is on continuously when the K4 jumper is in place. If CB yellow "BC OPEN" LED is

on, check that CB has the K4 jumper in place on CB RED K4 connector. This unit will not

operate unless the K4 jumper is in place. There is a 5-second delay before startup. Note

that the order of the component LEDs from the outer edge of CB is 1, 4, 3, .

a) 1-Minute Fill Cycle

LED 4 is on. WV and X relay (auxiliary code T-0 and U-0), X11 relay (auxiliary code

U-1 and later) energize and the 1-minute ll cycle begins. After 1 minute, CB checks for

a closed F/S. If F/S is closed, the harvest cycle begins. If not, WV remains energized

through additional 1-minute ll cycles until water lls the tank and closes F/S. This

serves as a low water safety to protect PM.

b) Initial Harvest Cycle

LEDs 1, 4, and are on. WV and X relay (auxiliary code T-0, U-0), X11 relay (auxiliary

code U-1 and later) remain energized, HGV, X1 relay (auxiliary code T-0, U-0),

X10 relay (auxiliary code U-1 and later), Comp, and FMR energize. CB monitors the

warming of the evaporator via the thermistor located on the suction line. When the

thermistor reaches 48°F (9°C), CB reads a 3.9 kΩ signal from the thermistor and turns

harvest termination over to the harvest timer (S4 dip switch 1 & ). The harvest timer

has settings of 60, 90, 10, and 180 seconds. For details, see "II.C.3.b) Harvest Timer

(S4 dip switch 1 & )." WV is energized during harvest for a maximum of 6 minutes or

the length of harvest minus 0 or 50 seconds (harvest pump timer (S4 dip switch 7)),

whichever is shorter. CAUTION! Do not adjust S4 dip switch 7 out of the factory

default position on this model. Adjustment outside of the factory default position

may result in damage to the icemaker. For details, see "II.C.3.e) Harvest Pump Timer

(S4 dip switch 7)." LED 4 goes off when WV and X relay (auxiliary code T-0, U-0),

X11 relay (auxiliary code U-1 and later) de-energize. LED 3 comes on and PM energizes

and runs for the last 0 or 50 seconds of harvest depending on S4 dip switch 7 setting.

This circulates water over the evaporator for the last 0 or 50 seconds of harvest. PM

is energized through the #5 pin (DBu wire) on the CB K1 ten-pin connector and the

X1 relay (auxiliary code T-0, U-0), X10 relay (auxiliary code U-1 and later). When the

harvest timer expires, the harvest cycle is complete. CB checks the position of F/S and

proceeds to the freeze cycle if it is closed or calls for a 1-minute ll cycle if it is open. The

minimum total time allowed by CB for a complete harvest cycle is minutes.

c) Freeze Cycle

LED 1 is on. Comp and FMR remain energized, PM energizes or remains energized

depending on harvest pump timer (S4 dip switch 7) setting. FM and LLV energize.

HGV and X1 relay (auxiliary code T-0, U-0), X10 relay (auxiliary code U-1 and later)

19

de-energize. For the rst 5 minutes, CB will not accept a signal from F/S. This minimum

5-minute freeze time is short cycle protection for Comp. At the end of 5 minutes, F/S

assumes control. As ice builds on the evaporator, the water level in the tank lowers. The

freeze cycle continues until F/S opens and terminates the cycle. There is a 15 second

delay before CB acknowledges an open F/S.

d) Pump-Out Cycle

LEDs 1, 3, and are on. LED 4 is on when S4 dip switch 3 & 4 are set to 3 off and 4 on.

CAUTION! Do not adjust S4 dip switch 3 & 4 to 3 off and 4 on. Adjustment to this

position on this model prevents the unit from operating correctly and may cause

damage. For details, see "II.C.3.c) Pump-Out Timer (S4 dip switch 3 & 4)." Comp and

FMR remain energized, HGV energizes, WV energizes if S4 dip switch 3 off and 4 on.

LLV and FM de-energize. PM stops for seconds then reverses, taking water from the

bottom of the tank and forcing pressure against the check valve seat allowing water to

go through the check valve and down the drain. At the same time, water ows through

the small tube to power ush F/S. When the pump-out timer expires, the pump-out is

complete.

The rst pump-out occurs after the 11th freeze cycle, then every 10th cycle thereafter.

The pump-out frequency control is factory set, and generally no adjustment is required.

However, where water quality is bad and the icemaker needs a pump-out more often, the

pump-out frequency can be adjusted. The pump-out frequency control (S4 dip switch 5 &

6) can be set to have a pump-out occur every cycle, or every , 5, or 10 cycles. Timing of

the rst pump-out is dependent on S4 dip switch 5 & 6 settings. See the table below. For

details, see "II.C.3.d) Pump-Out Frequency Control (S4 dip switch 5 & 6)."

S4 Dip Switch Setting

Pump-Out

Frequency

1st Pump-Out

No. 5 No. 6

OFF OFF Every cycle After nd freeze cycle

ON OFF Every cycles After 3rd freeze cycle

OFF ON Every 5 cycles After 6th freeze cycle

ON ON Every 10 cycles After 11th freeze cycle

e) Harvest Cycle

Same as the initial harvest cycle. See "II.B.1.b) Initial Harvest Cycle."

Note: Unit continues to cycle until BC is satised or power is turned off. The unit always

restarts at the 1-minute ll cycle.

f) Shutdown

When ice contacts the thermostatic bulb (BC switch open), BC shuts down the unit within

10 seconds. The bin control is factory set, and generally no adjustment is required.

However, adjustment may be needed in some conditions, particularly at higher altitude

locations.

Legend: BC–bin control; CB–control board; Comp–compressor; FMR–fan motor-remote;

FM–fan motor; F/S–oat switch; HGV–hot gas valve; LLV–liquid line valve;

PM–pump motor; WV–inlet water valve

0

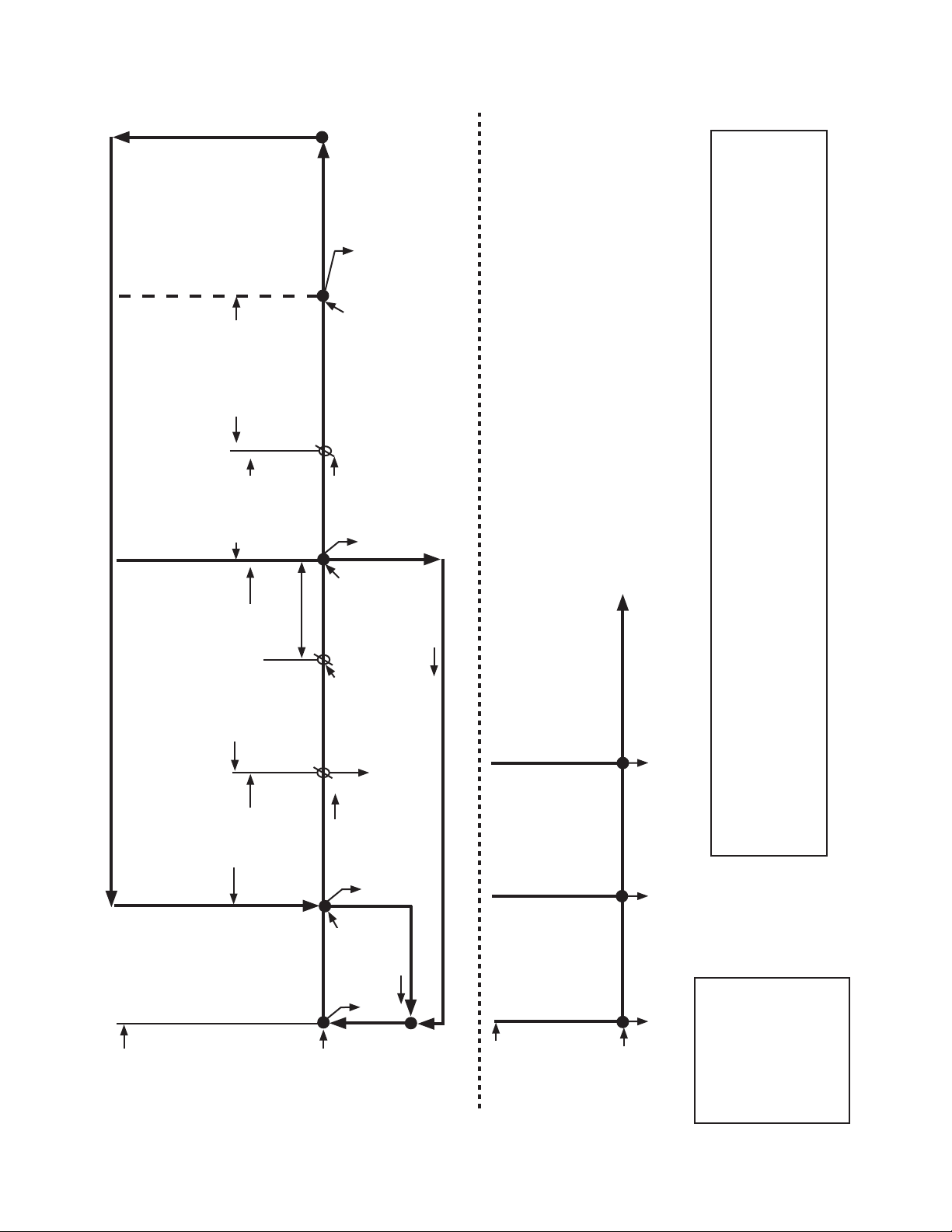

2. Sequence Flow Chart

• WV time: 6 min. or the length of harvest minus 0 or

50 sec. (S4 dip switch 7), whichever is shorter. DO

NOT ADJUST S4 dip switch 7 on this model.

• Maximum harvest time: 0 min.

F/S check

1 to 3-min. timer in control

(S4 dip switch 1 & )

Legend:

BC–bin control

Comp–compressor

FM–fan motor

FMR–fan motor-remote

F/S–oat switch

HGV–hot gas valve

LLV–liquid line valve

PM–pump motor

WV–inlet water valve

Components Energized when the Control Switch is in the "WASH" Position

The "WASH" position on the control switch is used when cleaning and sanitizing the unit. When in the "WASH" position, power is

supplied to the pump motor. With the cleaning valve closed, the cleaner and sanitizer ow over the outside of the evaporator plate

assembly. With the cleaning valve open, the cleaner and sanitizer ow over both the outside and the inside of the evaporator plate

assembly.

Note: Close the cleaning valve after cleaning and sanitizing are complete, otherwise the unit will not restart when the control

switch is placed in the "ICE" position.

"G" Control Board Sequence Flow Chart

1. 1-Minute

Fill Cycle

Cycle Steps

2. Harvest Cycle

Thermistor

in control

3. Freeze Cycle

• Minimum freeze time: 5 min.

• Maximum freeze time: freeze timer setting

(S4 dip switch 9 & 10)

F/S in control

4. Pump-Out Cycle

• Factory set for every

10th cycle (S4 dip

switch 5 & 6)

• Pump motor stops

for sec., then

reverses for 10/0

sec. (S4 dip switch

3 & 4)

WV energized

F/S open

WV continues

Comp energized

FMR energized

HGV energized

Thermistor temperature

reaches 48°F (9°C)

(3.9 kΩ or less).

Harvest timer starts.

F/S open

Comp continues

FMR continues

PM continues

FMS energized

LLV energized

HGV de-energized

F/S closed

Comp continues

FMR continues

HGV energized

PM de-energizes for sec.,

then reverses for 10/0 sec.

FM de-energized

LLV de-energized

F/S check

Initial startup

begins here

after 5-sec.

delay

If F/S is open, compressor stops and cycle returns to 1-Minute Fill Cycle

5-min. timer in

control

F/S closed

F/S open or freeze

timer expires

NOTE: Green "BC CLOSED" LED on continuously

when the K4 jumper is in place.

0 or 50 sec.

PM energized

WV de-energized

Harvest Pump

Timer

1. Bin Full

Within 10 sec.

after ice contacts

thermostatic bulb,

unit shuts down.

Shutdown

and Restart

BC Operation

Ice contacts

thermostatic bulb

2. Icemaker Off

All components

de-energized.

3. Ice Level Lowered

No ice touching

thermostatic bulb.

Icemaker starts at

"1. 1-Minute Fill Cycle."

BC closed

BC-open

All components

de-energized

To 1 above

KM-1301SAH/3, KM-1301SWH/3, and KM-1301SRH/3

1

C. Control Board

• A Hoshizaki exclusive solid-state control board is employed in KM-1301SAH/3,

KM-1301SWH/3, and KM-1301SRH/3, Stackable Crescent Cubers.

• All models are pretested and factory set.

CAUTION

1. The control board is fragile; handle very carefully.

. The control board contains integrated circuits, which are susceptible to

failure due to static discharge. It is especially important to touch the metal

part of the unit before handling or replacing the control board.

3. Do not touch the electronic devices on the control board or the back of the

control board.

4. Do not change wiring and connections. Do not misconnect K3, K4, and K5,

because the same connector is used for the thermistor, K4 jumper, and oat

switch. The control board RED K4 connector must have the K4 jumper in

place for proper operation.

5. Always replace the whole control board assembly if it goes bad.

6. Do not short out power supply to test for voltage.

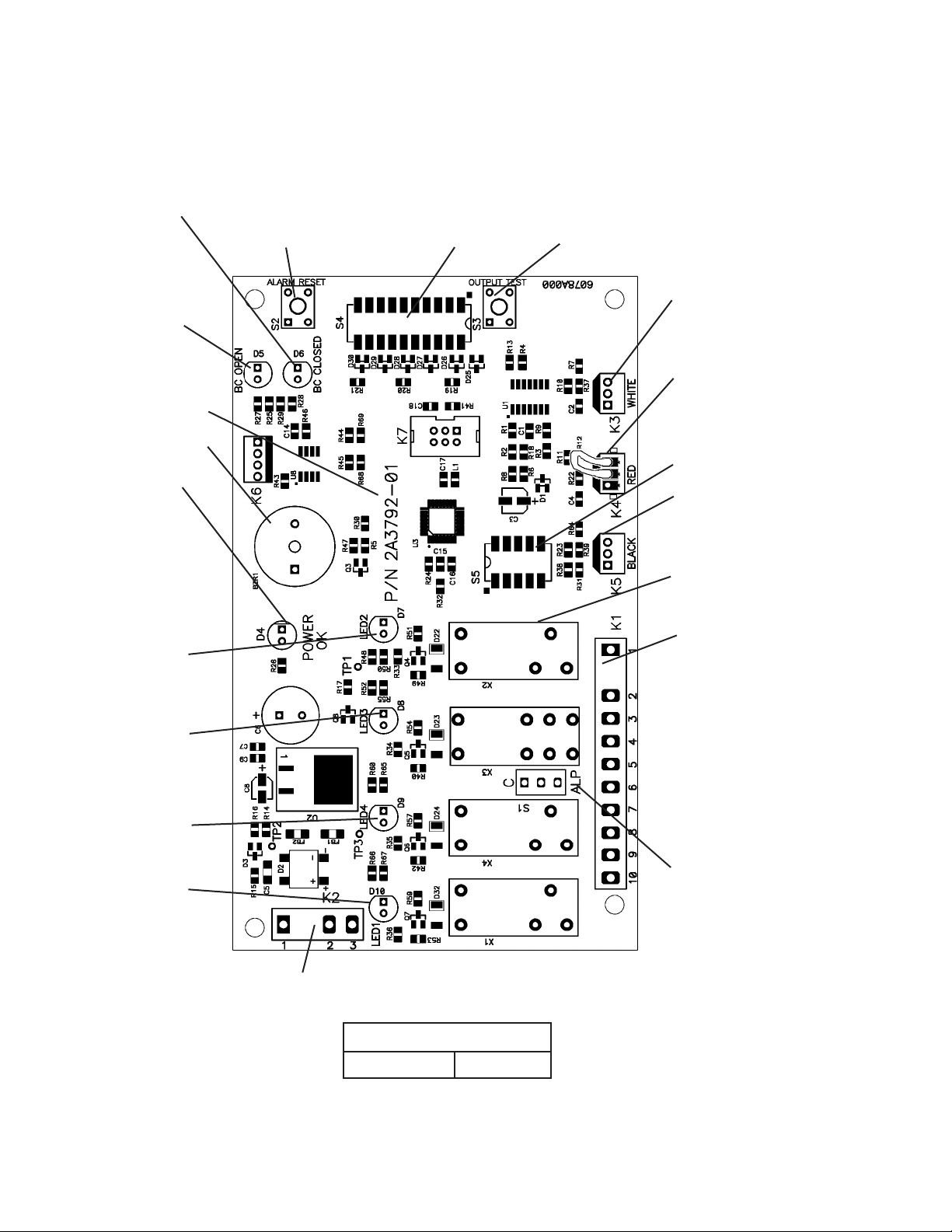

1. Control Board Layout

Control Board

Part Number A379-01

"G" Control Board

"ALARM RESET" Button

"OUTPUT TEST" Button

(used to test relays on control board)

WHITE K3 Connector

Harvest Control

(thermistor)

RED K4 Connector

K4 Jumper (4A4883G01

thermostatic bin control

application) or Mechanical

Bin Control

Label

(control board revision

level indicated on label

on side of relay)

BLACK K5 Connector

Float Switch

Part Number

K1 Ten-Pin Connector

Pins #1 through #10

#1, 9 Magnetic Contactor

# Hot Gas Valve (HGV)

#3 Liquid Line Valve (LLV),

Fan Motor (FM)

#4 Pump Motor (icemaking)

#5 Pump Motor (pump-out,

harvest (if applicable))

#6 Inlet Water Valve (WV)

#7, 10 Component Power

Supply

#8 Open

Switch for "C" control board

and "ALPINE" control board

(service control board only)

Bin Control Switch

Open LED (yellow)

(mechanical bin control

application only)

S4 Dip

Switch

Bin Control Switch

Closed LED (green)

(on continuously

in thermostatic bin

control application)

Alarm Buzzer

Power LED (red)

(lights when

power is supplied to

the control board)

LED (X Relay)

Hot Gas Valve (HGV)

Fan Motor (FM)

(FM off when LED on)

LED 3 (X3 Relay)

Pump Motor (PM)

(on at pump-out,

harvest (if applicable))

LED 4 (X4 Relay)

Inlet Water Valve (WV)

LED 1 (X1 Relay)

Compressor (Comp),

Fan Motor-Remote

(FMR)

K Connector

Transformer

S5 Dip Switch

Relay LEDs (4)

(indicate which

relays are energized

as listed below)

3

2. Features

a) Maximum Water Supply Period - 6 minutes

The inlet water valve will be open during harvest for 6 minutes or the length of harvest

minus 0 or 50 seconds (harvest pump timer (S4 dip switch 7)), whichever is shorter. For

details, see "II.C.3.e) Harvest Pump Timer (S4 dip switch 7)."

b) Harvest Backup Timer and Freeze Timer

The harvest backup timer shuts down the icemaker if, for two cycles in a row, the harvest

cycle takes more than 0 minutes to complete. The control board will signal this problem

using beeps every 3 seconds.

The freeze timer shuts down the icemaker if, for two cycles in a row, the freeze cycle

takes longer than the time specied to complete. The control board will signal this

problem using 3 beeps every 3 seconds. The freeze timer is factory set using S4 dip

switch 9 & 10. For details, see "II.C.3.g) Freeze Timer (S4 dip switch 9 & 10).

The "ALARM RESET" button on the control board must be pressed with power on to

reset either of these safeties.

c) High Temperature Safety

The temperature of the suction line in the refrigeration circuit is limited by the high

temperature safety. This protects the unit from excessively high temperatures. If the

evaporator temperature reaches 17°F±7°F (53°C±4°C), the control board reads a .8 kΩ

signal from the thermistor and shuts down the icemaker.

The control board will signal this problem using 1 beep every 3 seconds. The "ALARM

RESET" button on the control board must be pressed with power on to reset the safety.

d) Low Water Safety

The control board checks the position of the oat switch at the end of the initial 1-minute

ll cycle and at the end of each harvest cycle. If the oat switch is in the up position

(electrical circuit closed), the control board changes to the next cycle. If the oat switch

is in the down position (electrical circuit open), the control board changes to additional

1-minute ll cycles until water enters the tank and closes the oat switch. When the oat

switch closes, the control board changes to the next cycle. The unit will not start without

adequate water in the tank. This serves as a low water safety to protect the water pump.

For water-cooled model, if the condenser water supply is shut off, the unit is protected by

the high-pressure switch.

e) High Voltage and Low Voltage Cut-outs

The maximum and minimum allowable supply voltages of this icemaker are limited by

the high voltage and low voltage cut-outs. If miswiring (especially on single phase 3 wire

models) causes excessive voltage (147Vac±5% or more), the high voltage cut-out shuts

down the circuit in 3 seconds and the icemaker automatically stops. The control board

will signal this problem using 7 beeps every 3 seconds.

The icemaker also automatically stops in cases of insufcient voltage (9Vac±5% or

less). The control board will signal this problem using 6 beeps every 3 seconds.

When the proper supply voltage is resumed, the icemaker automatically starts running

again.

4

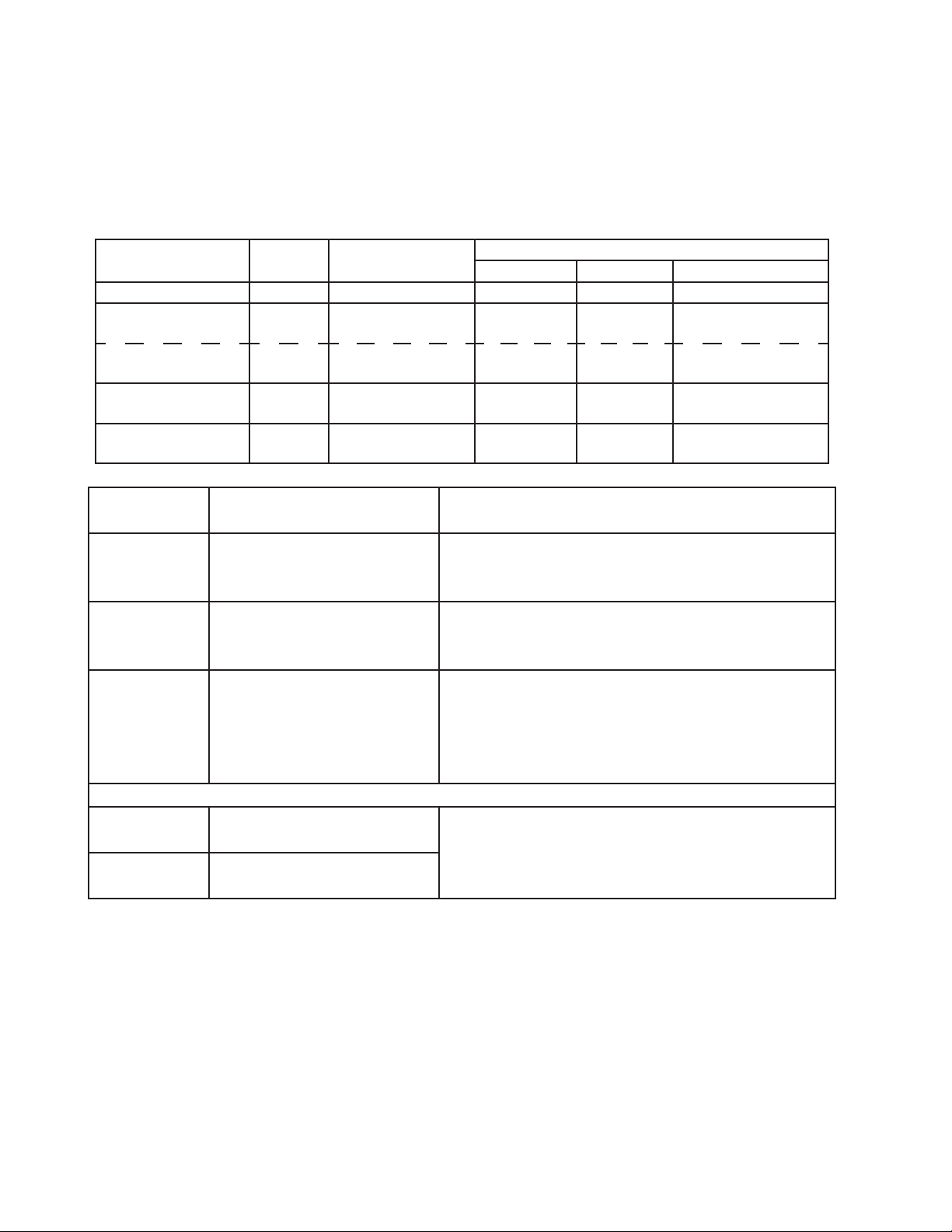

f) LED Lights and Audible Alarm Safeties

At startup, a 5-second delay occurs while the control board conducts an internal timer

check. A beep occurs when the control switch is moved to the "ICE" position.

The red LED indicates proper control voltage and will remain on unless a control voltage

problem occurs. The green LEDs 1 through 4 energize and sequence from initial startup

as listed in the table below. Note that the order of the LEDs from the outer edge of the

control board is 1, 4, 3, . For details, see "II.B. Sequence of Operation."

Sequence Step LED

Energized

Components

Time LEDs are On

Min. Max. Avg.

1-Minute Fill Cycle 4 WV 1 minute

Harvest Cycle 1, 4, Comp, FMR, WV,

HGV

minutes 0 minutes 3 to 5 minutes

Harvest Pump Timer 1, 3, Comp, FMR, PM,

HGV

0 seconds 50 seconds harvest pump timer

setting

Freeze Cycle 1 Comp, FM/FMR,

PM, LLV

5 minutes freeze timer

setting

30 to 35 minutes

Pump-Out Cycle 1, 4*, 3, Comp, FMR, WV*,

PM, HGV

10 seconds 0 seconds *pump-out timer

setting

The built-in safeties shut down the unit and have alarms as listed below.

No. of Beeps

(every 3 sec.)

Type of Alarm Notes

1 High Evaporator Temp.

(temperature > 17°F)

(53°C)

Check for harvest problem (stuck HGV or relay), hot

water entering unit, stuck HM, or shorted thermistor.

Harvest Backup Timer

(harvest > 0 min. for two cycles

in a row)

Check for open thermistor, HGV not opening, TXV or

LLV leaking by, low charge, or inefcient Comp.

3 Freeze Timer

(freeze > specied setting for

two cycles in a row)

Timer is factory set using S4 dip

switch 9 & 10

Check for F/S stuck closed (up), WV leaking by, HGV

leaking by, PM not pumping, TXV not feeding properly,

LLV not opening, low charge, HM not bypassing, or

inefcient Comp.

To reset the above safeties, press the "ALARM RESET" button with the power supply on.

6 Low Voltage

(9Vac±5% or less)

Red LED will turn off if voltage protection operates.

The control voltage safeties automatically reset when

voltage is corrected.

7 High Voltage

(147Vac±5% or more)

Legend: Comp–compressor; FM–fan motor; FMR–fan motor-remote; F/S–oat switch;

HGV–hot gas valve; HM–headmaster (C.P.R.); LLV–liquid line valve; PM–pump

motor; TXV–thermostatic expansion valve; WV–inlet water valve

5

3. Controls and Adjustments

CAUTION

Dip switches are factory set. Failure to maintain factory settings may adversely

affect performance and warranty coverage. For more information, contact

Hoshizaki Technical Support at 1-800-33-1940.

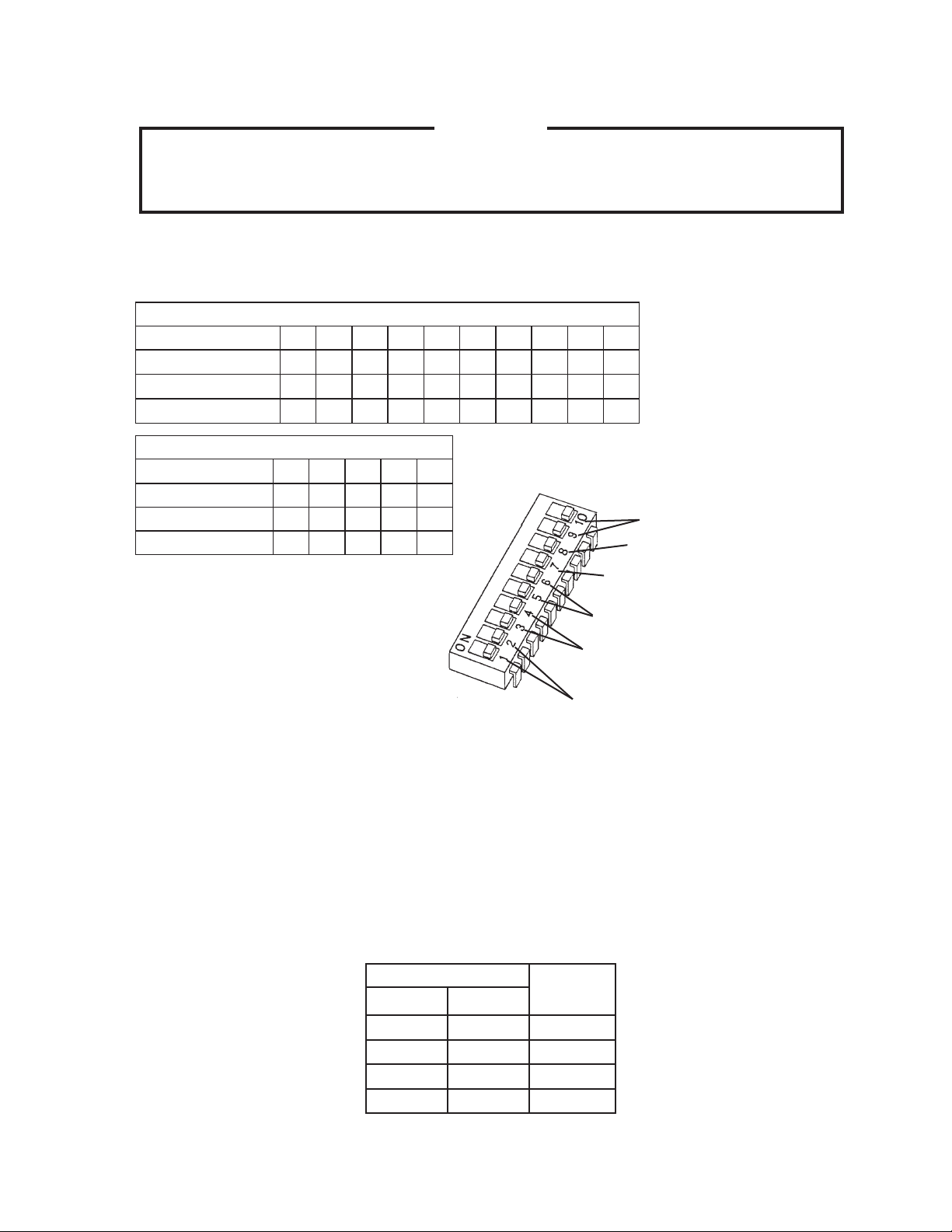

a) Default Dip Switch Settings

The dip switches are factory set to the following positions:

S4 Dip Switch

S4 Dip Switch No. 1 2 3 4 5 6 7 8 9 10

KM-1301SAH/3

OFF OFF ON ON ON ON ON OFF OFF OFF

KM-1301SWH/3

OFF OFF ON ON ON ON ON OFF OFF OFF

KM-1301SRH/3

OFF OFF ON ON ON ON ON OFF ON OFF

S5 Dip Switch (Do Not Adjust)

S5 Dip Switch No.

1 2 3 4 5

KM-1301SAH/3 OFF OFF OFF OFF OFF

KM-1301SWH/3 OFF OFF OFF OFF OFF

KM-1301SRH/3 OFF OFF OFF OFF OFF

Freeze Timer (9 & 10)

Pump-Out Frequency Control (5 & 6)

Pump-Out Timer (3 & 4)

(Do not adjust to 3 off and 4 on)

Harvest Timer (1 & )

Harvest Pump Timer (7)

(Do not adjust)

Factory Use (8)

b) Harvest Timer (S4 dip switch 1 & 2)

The harvest timer starts when the thermistor reads 48°F (9°C) at the evaporator outlet

and the control board reads the thermistor's 3.9 KΩ signal. The harvest timer is factory

set, and generally no adjustment is required. However, a setting longer than the factory

setting may be advised in cases where the ush provided at harvest needs to be

prolonged for extra cleaning. Before changing this setting, contact Hoshizaki Technical

Support at 1-800-33-1940 for recommendations. Keep in mind that setting the harvest

timer to a longer setting decreases 4-hour production.

S4 Dip Switch Setting Time

(seconds)

No. 1 No. 2

OFF OFF 60

ON OFF 90

OFF ON 10

ON ON 180

6

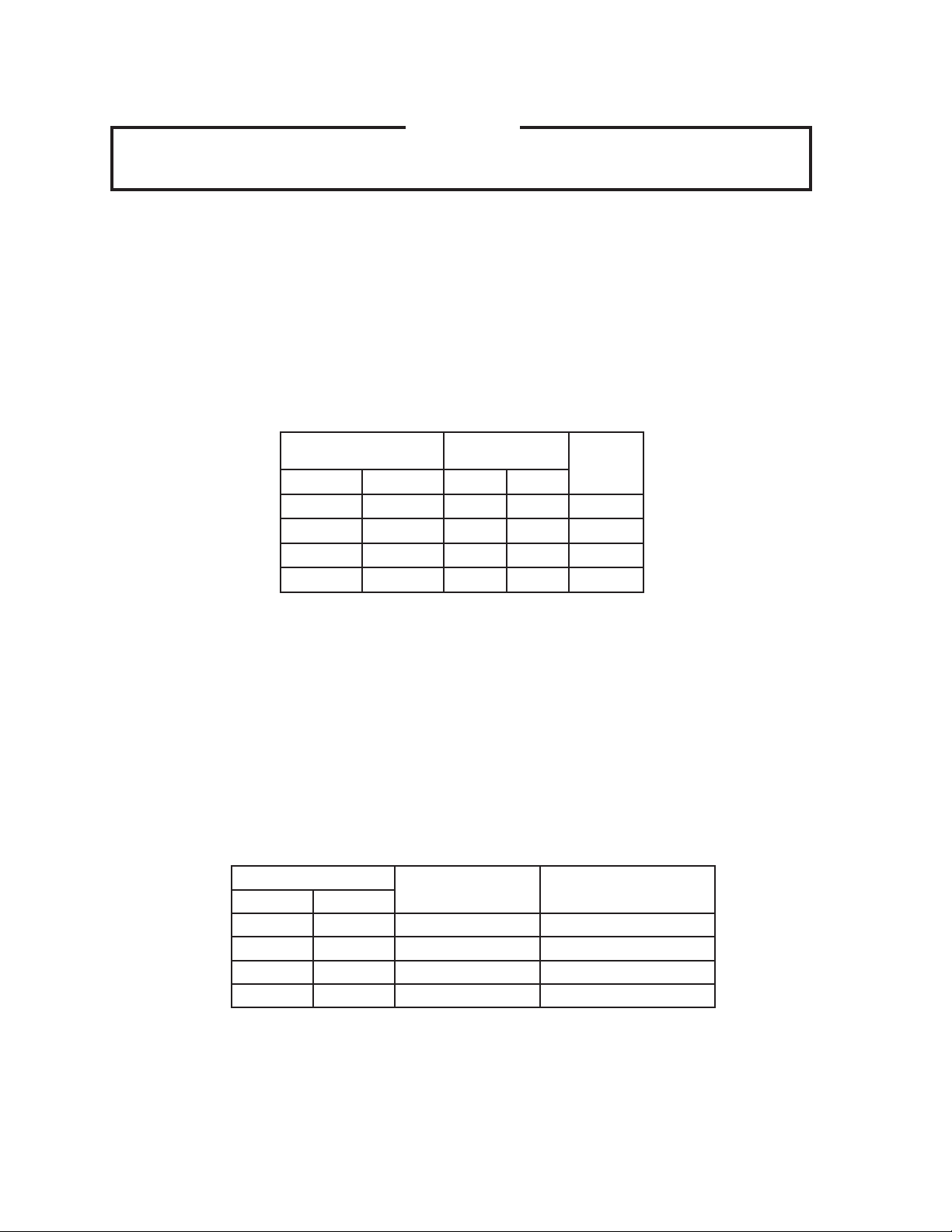

c) Pump-Out Timer (S4 dip switch 3 & 4)

CAUTION

Do not adjust S4 dip switch 3 off and S4 dip switch 4 on for this model.

Otherwise, pump motor does not rotate in the pump-out direction.

When a pump-out is called for, the pump motor stops after the preceding freeze cycle.

The pump motor restarts seconds later in the reverse direction, taking water from the

bottom of the tank and forcing pressure against the check valve seat allowing water to

go through the check valve and down the drain. At the same time, water ows through

the small tube to power ush the oat switch. The pump motor drains the water tank

for the time determined by the pump-out timer. The pump-out timer also acts in place

of the harvest timer during cycles with a pump-out. The pump-out timer is factory set,

and generally no adjustment is required. However, where water quality is bad and the

icemaker needs a longer pump-out time, the pump-out timer can be adjusted. The

pump-out timer control can be set to pump-out for 10 or 0 seconds.

S4 Dip Switch Setting Time (seconds)

Inlet

Water

Valve

No. 3 No. 4

T1

T2

OFF OFF 10 150 closed

ON OFF 10 180 closed

OFF ON 10 10 open

ON ON 0 180 closed

T1: Time to drain the water tank

T: Harvest timer at pump-out

d) Pump-Out Frequency Control (S4 dip switch 5 & 6)

The pump-out frequency control is factory set to drain the water tank every 10 cycles,

and generally no adjustment is required. However, where water quality is bad and the

icemaker needs a pump-out more often, the pump-out frequency can be adjusted. The

pump-out frequency control can be set to have a pump-out occur every cycle, or every

, 5, or 10 cycles.

Timing of the rst pump-out is dependent on S4 dip switch 5 & 6 settings. The rst

pump-out is factory set to occur after the 11th freeze cycle. See the table below.

S4 Dip Switch Setting

Pump-Out

Frequency

1st Pump-Out

No. 5 No. 6

OFF OFF Every cycle After nd freeze cycle

ON OFF Every cycles After 3rd freeze cycle

OFF ON Every 5 cycles After 6th freeze cycle

ON ON Every 10 cycles After 11th freeze cycle

Loading...

Loading...