Honeywell S8910U3000 Installation Manual

S8910U3000

UNIVERSAL HOT SURFACE IGNITION MODULE

INSTALLATION INSTRUCTIONS

Installation of this product must be performed by a trained and qualified service technician.

APPLICATION

The S8910U Universal Hot Surface Ignition Module is designed to provide easy field replacement for a wide range of hot surface ignition modules manufactured by Honeywell, Robertshaw and White-Rodgers. The S8910U Module provides operating control of a direct ignition system using a 120 Vac hot surface igniter. The S8910U replaces existing flame rectification type hot surface ignition modules with the following characteristics:

•120 Vac (up to 5A) timed warmup hot surface ignition elements.

•Single rod (local sense) or dual rod (remote sense) hot surface ignition.

•One or three ignition trials per call for heat.

•Four-second or seven-second ignition trials.

•Prepurge of 32 seconds or less.

•Up to 96 seconds between trial purge times (three-trial mode only).

•Natural or LP gas.

The S8910U is not designed to replace:

•Intermittent pilot ignition controls.

•Direct spark ignition controls.

•Proven 120 Vac hot surface ignition controls.

•24 Vac element hot surface ignition controls.

•240 Vac input/120 Vac element hot surface ignition controls.

•120 Vac timed warmup hot surface ignition controls

—Ignition trial time shorter than four seconds.

—Ignition trial time longer than twelve seconds.

—Edge connectors rather than male quick-connects.

The S8910U package contains the S8910U control, and easy- to-use instructions, and the accessories required to adapt the existing hot surface ignition module. The accessory bag assembly includes the White-Rodgers adapter, Robertshaw ground lead, four 1/4 in. female .032 quick-connects, one 3/16 in. female .032 quick-connect, and nine wire labels. The wiring labels are included to assure proper marking of the wires attached to the existing module.

A complete list of the specific Honeywell and other modules that the S8910U is designed to replace is provided in Tables 1 through 3.

NOTE: The S8910U is intended to replace only defective ignition controls. The service technician should make sure that the other parts of the appliance and control system operate safely and reliably before replacing the ignition control.

WARNING

EXPLOSION HAZARD. CAN CAUSE INJURY OR EQUIPMENT DAMAGE.

The S8910U can only be used for direct replacement. Check Tables 1 through 3 before replacing an existing hot surface module with the S8910U. If the existing module is not listed, do not use the S8910U to replace it. Always refer to the cross-reference table for proper DIP switch settings.

Electrical Ratings:

Control Voltage: 24 V, 60 Hz. Maximum Valve Contact Rating: 2 A. Current Draw: 0.4 A plus valve load.

Hot Surface Igniter Voltage: 120 Vac, 60 Hz. Contact Rating at 120 Vac: 5 A.

IMPORTANT

The S8910U is designed for 60 Hz applications. Timings change by 20 percent in 50 Hz applications.

Hot Surface Igniter or Igniter-Sensor:

Norton Model 201 or 271 or equivalent.

NOTE: If an igniter other than a Norton Model 201 or 271 is used, the igniter must meet the following minimum specifications required over the life of the igniter:

•Igniter must reach 1832 °F (1000 °C) within the selected warm up time of 7, 17, 34 or 45 seconds with 102 Vac applied.

•Igniter must maintain at least 500M ohm insulation resistance between the igniter leadwires and the igniter mounting bracket.

•Igniter must not develop an insulating layer on its surface (over time) that would prevent flame sensing.

•Igniter surface area immersed in flame must not exceed one-fourth of the grounded area immersed in flame. This would prevent flame sensing.

34-00008EFS-01

S8910U3000

•Igniter current draw at 132 Vac must not exceed 5A.

Sensor:

Separate sensor required for remote sensing applications.

Wiring:

Use existing appliance wiring. If repair or replacement of leadwires is required, follow instructions on appliance label. Use included quick connect terminals and wiring adaptors according to instructions.

Prepurge:

32 seconds.

Igniter Warmup:

7 (12), 17 (27), 34 or 45 seconds. Numbers in parenthesis represent second and third trial for ignition timings.

Purge between Trials for Ignition:

96 seconds (32 second prepurge and 64 seconds interpurge).

Flame Failure Response Time:

1.5 seconds maximum.

Ignition Sequence:

The number of trials for ignition and trial time are determined by selectable DIP switches.

Ambient Operating Temperature:

-40 to +175 °F (-40 to +79 °C).

Accessory Kit (Included):

•White-Rodgers adapter.

•Robertshaw ground lead.

•Four 1/4 in. female .032 quick-connects.

•One 3/16 in. female .032 quick-connect.

•Nine wire labels.

Approvals:

IAS Design Certified: Certification Report No. C2027002.

IMPORTANT

The specifications given in this publication do not include normal manufacturing tolerances. Therefore, this unit may not exactly match the listed specifications. Also, this product is tested and calibrated under closely controlled conditions, and some minor differences in performance can be expected if those conditions are changed.

The S8910U package contains the S8910U control, and easy- to-use instructions, plus the accessories required to adapt the existing hot surface ignition module. The accessory bag assembly includes the White-Rodgers adapter, Robertshaw ground lead, four 1/4 in. female .032 quick-connects, one 3/16 in. female .032 quick-connects, and nine wiring labels. The wiring labels are included to assure proper marking of the wires attached to the existing module.

A complete listing of the specific Honeywell and other modules that the S8910U is designed to replace is provided in Tables 1 through 3.

NOTE: The S8910U is intended to replace only defective ignition controls. The service technician should make sure that the other parts of the appliance and control system operate safely and reliably before replacing the ignition control.

Model Available:

S8910U Universal Hot Surface Ignition Module.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the TRADELINE® Catalog or price sheets for complete ordering number. If you have additional questions, need further information, or would like to comment on our products or services, please write or phone:

1.Your local Honeywell Environmental and Combustion Controls Sales Office (check white pages of your phone directory).

2.Honeywell Customer Care 1985 Douglas Drive North

Minneapolis, Minnesota 55422-4386

3.http://customer.honeywell.com or http://customer.honeywell.ca

International Sales and Service Offices in all principal cities of the world. Manufacturing in Belgium, Canada, China, Czech Republic, Germany, Hungary, Italy, Mexico, Netherlands, United Kingdom, and United States.

34-00008EFS—01 |

2 |

S8910U3000

Table 1. White-Rodgers Control to Honeywell S8910U Cross Reference.

NOTES: This list is for reference only. Honeywell reserves the right to add or delete models at any time, based on new or updated information.

|

S8910U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Remove |

|

|

|

|

|

|

|

Black |

Local (L) or |

Lockout |

|

|

Igniter |

Between |

|

Jumper |

Remote (R) |

Time |

Ignition |

PrePurge |

Warmup |

Trial Purge |

Model Numbers |

|

Sensing |

(sec) |

Trials |

(sec) |

(sec) |

(sec) |

|

|

|

|

|

|

|

|

S8910U |

— |

Local or |

4 |

1 |

32 |

34 |

NA |

Specifications |

|

Remote |

|

|

|

|

|

|

|

3 |

|

|

96 |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

7 |

1 |

|

|

NA |

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

96 |

|

|

|

|

|

|

|

|

50E47-1 thru 9 |

Yes |

R |

4 |

1 |

0 |

17 |

NA |

|

|

|

|

|

|

|

|

50E47-10 thru 19 |

Yes |

R |

4 |

1 |

0 |

45 |

NA |

|

|

|

|

|

|

|

|

50E47-20 thru 29 |

Yes |

R |

4 |

1 |

30 |

17 |

NA |

|

|

|

|

|

|

|

|

50E47-30 thru 39 |

Yes |

R |

4 |

1 |

30 |

45 |

NA |

|

|

|

|

|

|

|

|

50E47-40 thru 49 |

Yes |

R |

4 |

3 |

30 |

17 |

90 |

|

|

|

|

|

|

|

|

50E47-50 thru 59 |

Yes |

R |

4 |

3 |

30 |

45 |

90 |

|

|

|

|

|

|

|

|

50E47-60 thru 69 |

Yes |

R |

4 |

3 |

0 |

17 |

60 |

|

|

|

|

|

|

|

|

50E47-70 thru 79 |

Yes |

R |

4 |

3 |

0 |

45 |

60 |

|

|

|

|

|

|

|

|

50E47-101 thru 109 |

Yes |

R |

7 |

1 |

0 |

17 |

NA |

|

|

|

|

|

|

|

|

50E47-110 thru 119 |

Yes |

R |

7 |

1 |

0 |

45 |

NA |

|

|

|

|

|

|

|

|

50E47-120 thru 129 |

Yes |

R |

7 |

1 |

30 |

17 |

NA |

|

|

|

|

|

|

|

|

50E47-130 thru 139 |

Yes |

R |

7 |

1 |

30 |

45 |

NA |

|

|

|

|

|

|

|

|

50E47-140 thru 149 |

Yes |

R |

7 |

3 |

30 |

17 |

90 |

|

|

|

|

|

|

|

|

50E47-150 thru 159 |

Yes |

R |

7 |

3 |

30 |

45 |

90 |

|

|

|

|

|

|

|

|

50E47-160 thru 169 |

Yes |

R |

7 |

3 |

0 |

17 |

60 |

|

|

|

|

|

|

|

|

50E47-170 thru 179 |

Yes |

R |

7 |

3 |

0 |

45 |

60 |

|

|

|

|

|

|

|

|

50E47-201 thru 209 |

Yes |

R |

4 |

1 |

0 |

17 |

NA |

|

|

|

|

|

|

|

|

50E47-210 thru 219 |

Yes |

R |

4 |

1 |

0 |

45 |

NA |

|

|

|

|

|

|

|

|

50E47-220 thru 229 |

Yes |

R |

4 |

1 |

30 |

17 |

NA |

|

|

|

|

|

|

|

|

50E47-230 thru 239 |

Yes |

R |

4 |

1 |

30 |

45 |

NA |

|

|

|

|

|

|

|

|

50E47-240 thru 249 |

Yes |

R |

4 |

3 |

30 |

17 |

90 |

|

|

|

|

|

|

|

|

50E47-250 thru 259 |

Yes |

R |

4 |

3 |

30 |

45 |

90 |

|

|

|

|

|

|

|

|

50E47-260 thru 269 |

Yes |

R |

4 |

3 |

0 |

17 |

60 |

|

|

|

|

|

|

|

|

50E47-270 thru 279 |

Yes |

R |

4 |

3 |

0 |

45 |

60 |

|

|

|

|

|

|

|

|

50E47-301 thru 309 |

Yes |

R |

7 |

1 |

0 |

17 |

NA |

|

|

|

|

|

|

|

|

50E47-310 thru 319 |

Yes |

R |

7 |

1 |

0 |

45 |

NA |

|

|

|

|

|

|

|

|

50E47-320 thru 329 |

Yes |

R |

7 |

1 |

30 |

17 |

NA |

|

|

|

|

|

|

|

|

50E47-330 thru 339 |

Yes |

R |

7 |

1 |

30 |

45 |

NA |

|

|

|

|

|

|

|

|

50E47-340 thru 349 |

Yes |

R |

7 |

3 |

30 |

17 |

90 |

|

|

|

|

|

|

|

|

50E47-350 thru 359 |

Yes |

R |

7 |

3 |

30 |

45 |

90 |

|

|

|

|

|

|

|

|

50E47-360 thru 369 |

Yes |

R |

7 |

3 |

0 |

17 |

60 |

|

|

|

|

|

|

|

|

50E47-370 thru 379 |

Yes |

R |

7 |

3 |

0 |

45 |

60 |

|

|

|

|

|

|

|

|

50F47-1 thru 9 |

Yes |

R |

4 |

1 |

0 |

17 |

NA |

|

|

|

|

|

|

|

|

50F47-10 thru 19 |

Yes |

R |

4 |

1 |

0 |

45 |

NA |

|

|

|

|

|

|

|

|

50F47-20 thru 29 |

Yes |

R |

4 |

1 |

17 |

17 |

NA |

|

|

|

|

|

|

|

|

50F47-30 thru 39 |

Yes |

R |

4 |

1 |

17 |

45 |

NA |

|

|

|

|

|

|

|

|

50F47-40 thru 49 |

Yes |

R |

4 |

3 |

17 |

17 |

77 |

|

|

|

|

|

|

|

|

3 |

34-00008EFS—01 |

S8910U3000

Table 1. White-Rodgers Control to Honeywell S8910U Cross Reference. (Continued)

NOTES: This list is for reference only. Honeywell reserves the right to add or delete models at any time, based on new or updated information.

|

S8910U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Remove |

|

|

|

|

|

|

|

Black |

Local (L) or |

Lockout |

|

|

Igniter |

Between |

|

Jumper |

Remote (R) |

Time |

Ignition |

PrePurge |

Warmup |

Trial Purge |

Model Numbers |

|

Sensing |

(sec) |

Trials |

(sec) |

(sec) |

(sec) |

|

|

|

|

|

|

|

|

S8910U |

— |

Local or |

4 |

1 |

32 |

34 |

NA |

Specifications |

|

Remote |

|

|

|

|

|

|

|

3 |

|

|

96 |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

7 |

1 |

|

|

NA |

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

96 |

|

|

|

|

|

|

|

|

50F47-50 thru 59 |

Yes |

R |

4 |

3 |

17 |

45 |

77 |

|

|

|

|

|

|

|

|

50F47-60 thru 69 |

Yes |

R |

4 |

3 |

0 |

17 |

60 |

|

|

|

|

|

|

|

|

50F47-70 thru 79 |

Yes |

R |

4 |

3 |

0 |

45 |

60 |

|

|

|

|

|

|

|

|

50F47-101 thru 109 |

Yes |

R |

7 |

1 |

0 |

17 |

NA |

|

|

|

|

|

|

|

|

50F47-110 thru 119 |

Yes |

R |

7 |

1 |

0 |

45 |

NA |

|

|

|

|

|

|

|

|

50F47-120 thru 129 |

Yes |

R |

7 |

1 |

17 |

17 |

NA |

|

|

|

|

|

|

|

|

50F47-130 thru 139 |

Yes |

R |

7 |

1 |

17 |

45 |

NA |

|

|

|

|

|

|

|

|

50F47-140 thru 149 |

Yes |

R |

7 |

3 |

17 |

17 |

77 |

|

|

|

|

|

|

|

|

50F47-150 thru 159 |

Yes |

R |

7 |

3 |

17 |

45 |

77 |

|

|

|

|

|

|

|

|

50F47-160 thru 169 |

Yes |

R |

7 |

3 |

0 |

17 |

60 |

|

|

|

|

|

|

|

|

50F47-170 thru 179 |

Yes |

R |

7 |

3 |

0 |

45 |

60 |

|

|

|

|

|

|

|

|

50F47-201 thru 209 |

Yes |

R |

4 |

1 |

0 |

17 |

NA |

|

|

|

|

|

|

|

|

50F47-210 thru 219 |

Yes |

R |

4 |

1 |

0 |

45 |

NA |

|

|

|

|

|

|

|

|

50F47-220 thru 229 |

Yes |

R |

4 |

1 |

17 |

17 |

NA |

|

|

|

|

|

|

|

|

50F47-230 thru 239 |

Yes |

R |

4 |

1 |

17 |

45 |

NA |

|

|

|

|

|

|

|

|

50F47-240 thru 249 |

Yes |

R |

4 |

3 |

17 |

17 |

77 |

|

|

|

|

|

|

|

|

50F47-250 thru 259 |

Yes |

R |

4 |

3 |

17 |

45 |

77 |

|

|

|

|

|

|

|

|

50F47-260 thru 269 |

Yes |

R |

4 |

3 |

0 |

17 |

60 |

|

|

|

|

|

|

|

|

50F47-270 thru 279 |

Yes |

R |

4 |

3 |

0 |

45 |

60 |

|

|

|

|

|

|

|

|

50F47-301 thru 309 |

Yes |

R |

7 |

1 |

0 |

17 |

NA |

|

|

|

|

|

|

|

|

50F47-310 thru 319 |

Yes |

R |

7 |

1 |

0 |

45 |

NA |

|

|

|

|

|

|

|

|

50F47-320 thru 329 |

Yes |

R |

7 |

1 |

17 |

17 |

NA |

|

|

|

|

|

|

|

|

50F47-330 thru 339 |

Yes |

R |

7 |

1 |

17 |

45 |

NA |

|

|

|

|

|

|

|

|

50F47-340 thru 349 |

Yes |

R |

7 |

3 |

17 |

17 |

77 |

|

|

|

|

|

|

|

|

50F47-350 thru 359 |

Yes |

R |

7 |

3 |

17 |

45 |

77 |

|

|

|

|

|

|

|

|

50F47-360 thru 369 |

Yes |

R |

7 |

3 |

0 |

17 |

60 |

|

|

|

|

|

|

|

|

50F47-370 thru 379 |

Yes |

R |

7 |

3 |

0 |

45 |

60 |

|

|

|

|

|

|

|

|

34-00008EFS—01 |

4 |

S8910U3000

Table 2. Robertshaw Control to Honeywell S8910U Cross Reference.

|

S8910U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Remove |

|

|

|

|

|

|

|

Black |

Local (L) or |

Lockout |

|

|

Igniter |

Between |

|

Jumper |

Remote (R) |

Time |

Ignition |

PrePurge |

Warmup |

Trial Purge |

Model Numbers |

|

Sensing |

(sec) |

Trials |

(sec) |

(sec) |

(sec) |

|

|

|

|

|

|

|

|

S8910U |

— |

Local or |

4 |

1 |

32 |

34 |

NA |

Specifications |

|

Remote |

|

|

|

|

|

|

|

3 |

|

|

96 |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

7 |

1 |

|

|

NA |

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

96 |

|

|

|

|

|

|

|

|

HS780-17NL-104A |

No |

L |

4 |

1 |

0 |

17 |

NA |

|

|

|

|

|

|

|

|

HS780-17NL-108A |

No |

L |

8a |

1 |

0 |

17 |

NA |

HS780-17NL-304A |

No |

L |

4 |

3 |

0 |

17 |

17 |

|

|

|

|

|

|

|

|

HS780-17NL-308A |

No |

L |

8a |

3 |

0 |

17 |

17 |

HS780-17NR-104A |

Yes |

R |

4 |

1 |

0 |

17 |

NA |

|

|

|

|

|

|

|

|

HS780-17NR-306A |

Yes |

R |

6a |

3 |

0 |

17 |

17 |

HS780-17NR-308A |

Yes |

R |

8a |

3 |

0 |

17 |

17 |

HS780-34NL-108A |

No |

L |

8a |

1 |

0 |

34 |

NA |

HS780-34NL-304A |

No |

L |

4 |

3 |

0 |

34 |

34 |

|

|

|

|

|

|

|

|

HS780-34NL-306A |

No |

L |

6a |

3 |

0 |

34 |

34 |

HS780-34NL-308A |

No |

L |

8a |

3 |

0 |

34 |

34 |

HS780-34NL-312A |

No |

L |

12b |

3 |

0 |

34 |

34 |

HS780-34NR-104A |

Yes |

R |

4 |

1 |

0 |

34 |

NA |

|

|

|

|

|

|

|

|

HS780-34NR-306A |

Yes |

R |

6a |

3 |

0 |

34 |

34 |

HS780-34NR-308A |

Yes |

R |

8a |

3 |

0 |

34 |

34 |

HS780-34NR-312A |

Yes |

R |

12b |

3 |

0 |

34 |

34 |

HS780-34PL-308A |

No |

L |

8a |

3 |

34 |

34 |

34 |

aThe S8910U and the original control lockout times are different. The S8910U lockout time is within the design tolerance lockout time of the original control.

bThe lockout time of the S8910U is shorter than the original control. Be sure to observe the appliance operation under a variety of input conditions to assure reliable operation.

5 |

34-00008EFS—01 |

S8910U3000

Table 3. Honeywell Control to Honeywell S8910U Cross Reference.

|

S8910U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Remove |

|

|

|

|

|

|

|

Black |

Local (L) or |

Lockout |

|

|

Igniter |

Between |

|

Jumper |

Remote (R) |

Time |

Ignition |

PrePurge |

Warmup |

Trial Purge |

Model Numbers |

|

Sensing |

(sec) |

Trials |

(sec) |

(sec) |

(sec) |

|

|

|

|

|

|

|

|

S8910U |

— |

Local or |

4 |

1 |

32 |

34 |

NA |

Specifications |

|

Remote |

|

|

|

|

|

|

|

3 |

|

|

96 |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

7 |

1 |

|

|

NA |

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

96 |

|

|

|

|

|

|

|

|

S89C1004 |

No |

L |

6a |

1 |

0 |

34 |

NA |

S89C1012 |

No |

L |

6a |

1 |

0 |

34 |

NA |

S89C1046 |

No |

L |

4 |

1 |

0 |

34 |

NA |

|

|

|

|

|

|

|

|

S89C1087 |

No |

L |

6a |

1 |

0 |

34 |

NA |

S89C1103 |

No |

L |

4 |

1 |

0 |

34 |

NA |

|

|

|

|

|

|

|

|

S89D1002 |

Yes |

R |

6a |

1 |

0 |

34 |

NA |

S89G1005 |

No |

L |

4 |

3 |

0 |

34 |

30 |

|

|

|

|

|

|

|

|

S89G1013 |

No |

L |

6a |

3 |

0 |

34 |

30 |

S89G1021 |

No |

L |

11b |

3 |

0 |

34 |

30 |

S89G1047 |

No |

L |

6a |

3 |

0 |

34 |

30 |

S89H1003 |

Yes |

R |

4 |

3 |

0 |

34 |

30 |

|

|

|

|

|

|

|

|

S89H1011 |

Yes |

R |

6a |

3 |

0 |

34 |

30 |

S89H1029 |

Yes |

R |

11b |

3 |

0 |

34 |

30 |

S89J1008 |

No |

L |

6a |

1 |

0 |

34 |

NA |

S890C1007 |

No |

L |

6a |

1 |

30 |

34 |

NA |

S890D1006 |

Yes |

R |

6a |

1 |

30 |

34 |

NA |

S890G1003 |

No |

L |

4 |

3 |

30 |

34 |

30 |

|

|

|

|

|

|

|

|

S890G1011 |

No |

L |

6a |

3 |

30 |

34 |

30 |

S890G1029 |

No |

L |

11b |

3 |

30 |

34 |

30 |

S890G1037 |

No |

L |

6a |

3 |

30 |

34 |

30 |

S890H1002 |

Yes |

R |

4 |

3 |

30 |

34 |

30 |

|

|

|

|

|

|

|

|

S890H1010 |

Yes |

R |

6a |

3 |

30 |

34 |

30 |

S890H1028 |

Yes |

R |

11b |

3 |

30 |

34 |

30 |

aThe S8910U and the original control lockout times are different. The S8910U lockout time is within the design tolerance lockout time of the original control.

bThe lockout time of the S8910U is shorter than the original control. Be sure to observe the appliance operation under a variety of input conditions to assure reliable operation.

34-00008EFS—01 |

6 |

S8910U3000

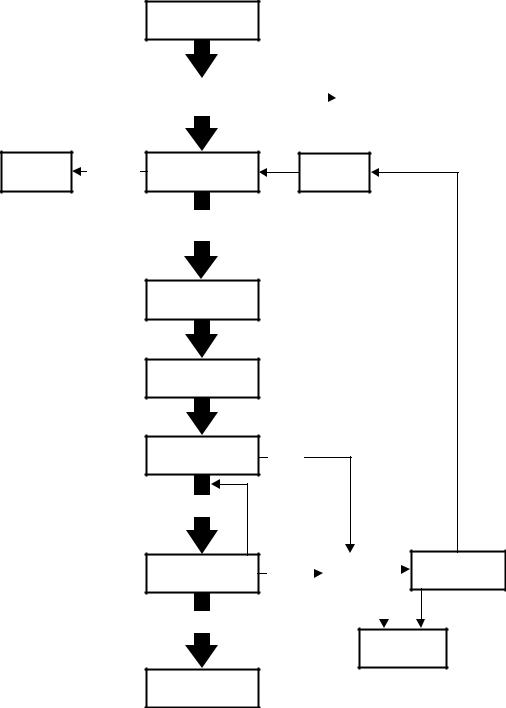

Table 4. DIP switch configuration.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Trial count = 1 try |

|

|

1 |

|

2 |

|

|

3 |

|

|

4 |

|

|

|

|

||||||

|

ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ON |

|

|

|

2 |

|

|

3 |

|

|

4 |

|

|

|

Trial count = 3 tries |

|

|||

|

1 |

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ON |

|

|

|

2 |

|

|

3 |

|

|

4 |

|

|

|

Trial for ignition period = 4 seconds |

||||

|

1 |

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

3 |

|

|

4 |

|

|

|

Trial for ignition period = 7 seconds |

|||

|

1 |

|

|

2 |

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ON |

|

|

|

2 |

|

|

3 |

|

|

4 |

|

|

|

Igniter warm-up time = |

34 seconds |

|||

|

1 |

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Igniter warm-up time = |

45 seconds |

|

1 |

|

|

2 |

|

|

3 |

|

|

4 |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Igniter warm-up time = |

17 seconds |

|

|

ON |

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|||

|

|

1 |

|

|

2 |

|

|

3 |

|

|

|

|

|

(27 seconds 2nd and 3rd trial) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Igniter warm-up time = |

7 seconds |

|

|

ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

1 |

|

|

2 |

|

|

3 |

|

|

4 |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

(12 seconds 2nd and 3rd trial) |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M35557 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

REVIEW THE INSTALLATION

WARNING

FIRE OR EXPLOSION HAZARD.

CAN CAUSE PROPERTY DAMAGE, SEVERE INJURY, OR DEATH.

Follow these warnings exactly:

1.Review the installation as outlined in this section.

2.Plan for frequent maintenance as described in the Maintenance section.

When hot surface ignition systems are used on central heating equipment in barns, greenhouses, and commercial properties and on heating appliances such as commercial cookers, agricultural equipment, industrial heating equipment and pool heaters, heavy demands are made on the controls. Special steps may be required to prevent nuisance shut-downs and control failure due to frequent cycling, and severe environmental conditions related to moisture, corrosive chemicals, dust or excessive heat. These applications require Honeywell Home and Building Control Engineering review; contact your Honeywell Sales Representative for assistance.

Review the following conditions that can apply to your specific installation and take the precautionary steps suggested.

Frequent Cycling

These controls are designed for use on appliances that typically cycle only three to four times an hour during the heating season. In year-around applications with greater cycling rates, the control can wear out more quickly. Perform a monthly checkout.

Water or Steam Cleaning

If a module or gas control gets wet, replace it. If the appliance is likely to be cleaned with water or steam, cover the controls and wiring to protect from water or steam flow. Mount the controls high enough above the bottom of the cabinet to avoid getting wet during normal cleaning procedures. A NEMA 4 enclosure is recommended for the ignition module.

High Humidity or Dripping Water

Dripping water can cause the module to fail. Never install an appliance where water can drip on the controls.

In addition, high ambient humidity can cause the gas control to corrode and fail.

If the appliance is in a humid atmosphere, make sure air circulation around the controls is adequate to prevent condensation. Also, regularly check out the system. A NEMA 4 enclosure is recommended for the ignition module.

Corrosive Chemicals

Corrosive chemicals can attack the module and gas control, eventually causing a failure. If chemicals are used for routine cleaning, avoid contact with the controls. Where chemicals are suspended in air, as in some industrial or agricultural applications, A NEMA 4 enclosure is recommended for the ignition module.

Dust or Grease Accumulation

Heavy accumulations of dust or grease can cause controls to malfunction. Where dust or grease can be a problem, provide covers for the module and the gas control to limit contamination. A NEMA 4 enclosure is recommended for the ignition module.

7 |

34-00008EFS—01 |

S8910U3000

Heat

Excessively high temperatures can damage controls. Make sure the maximum ambient temperature at the control does not exceed the rating of the control. If the appliance operates at very high temperatures, use insulation, shielding, and air circulation, as necessary, to protect the controls. Proper insulation or shielding should be provided by the appliance manufacturer; verify proper air circulation is maintained when the appliance is installed.

INSTALLATION

When Installing this Ignition System...

1.Read these instructions carefully. Failure to follow them could damage the components or cause a hazardous condition.

2.Check Tables 1, 2, and 3 to confirm that the S8910U is a direct replacement for the existing module.

3.Installer must be a trained, experienced service technician.

4.After installation is complete, check out component and appliance operation as provided in these instructions.

WARNING

FIRE OR EXPLOSION HAZARD.

CAN CAUSE PROPERTY DAMAGE, SEVERE INJURY, OR DEATH.

1.If the ignition module gets wet, it can malfunction, leading to accumulation of explosive gas.

—Never install where water can flood, drip or condense on the module.

—Never use a module that has been wet. Replace it.

2.Liquefied petroleum (LP) gas is heavier than air and can not vent upward naturally.

—Do not light pilot or operate electric switches, lights or appliances until you are sure the appliance area is free of gas.

3.Do not attempt to disassemble or clean the module. Improper reassembly and cleaning can cause unreliable operation.

CAUTION

CAUTION

1.Disconnect the power supply before beginning wiring to prevent electrical shock or equipment damage.

2.If a new gas control is to be installed, turn off the gas supply before starting the installation. Conduct a Gas Leak Test according to the gas control manufacturer instructions after the gas control is installed.

3.If a module must be mounted where it can be exposed to moisture or water, provide a suitable waterproof enclosure.

4.Using the wire labels provided, label all wires before disconnecting. Wiring errors can cause improper appliance operation and create dangerous conditions such as bypassing safety features.

Perform Preinstallation Safety Inspection

A preinstallation safety check of the appliance and venting system must be done before the replacement module is installed. If a condition is detected that could result in unsafe operation, shut off the appliance and advise the owner of the unsafe condition. Correct any potentially unsafe condition before proceeding with the installation.

Remove Old Module

Disconnect power supply before doing any work on the unit. Disconnect and tag the wires from the old module using the wire labels provided. Remove the old module from its mounting location.

Mount New Ignition Module

Mount the S8910U Module in the same location as the old module. Protect the module from exposure to water, moisture, corrosive chemicals and excessive dust and grease. Assure that ambient temperature at the module is within the range listed in the Application section.

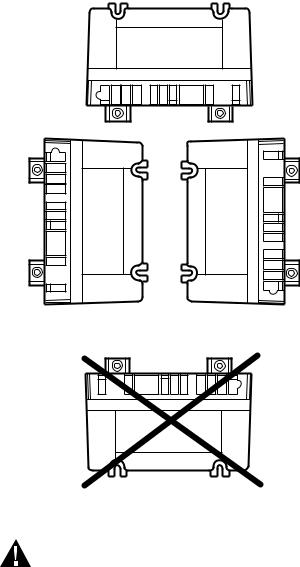

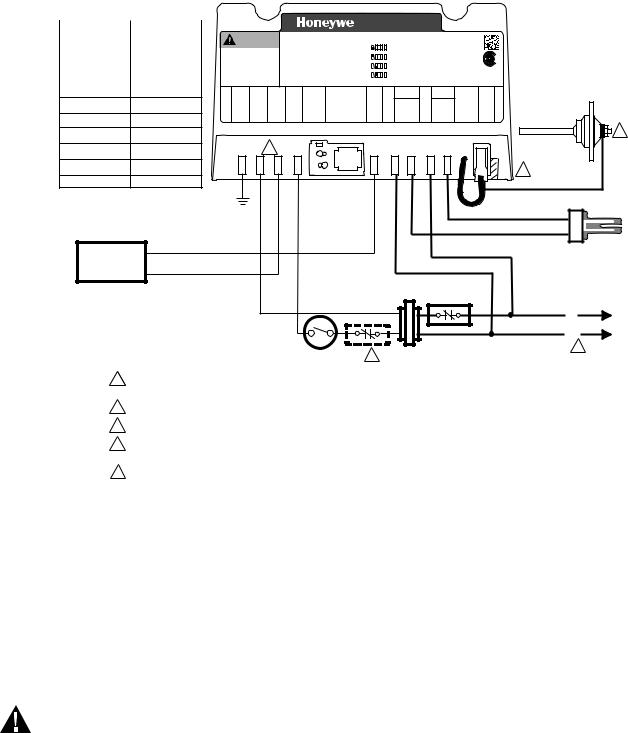

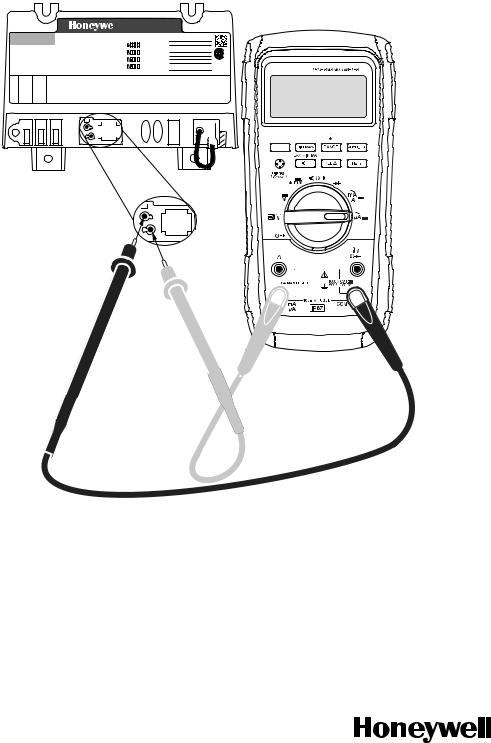

Mount the module with the terminals down to protect from dripping water and dust. The module can also be mounted with terminals on either side. Do not mount with the terminals pointing up. Refer to Fig. 1 for mounting recommendations. When it is necessary to drill new mounting holes, use the S8910U as a template to mark the mounting hole pattern. Drill new holes as required. Fasten securely with four No. 6-32 machine or No. 8 sheet metal screws.

34-00008EFS—01 |

8 |

MOUNT IN ONE OF THESE POSITIONS

TERMINALS FACING DOWN

TERMINALS FACING LEFT |

TERMINALS FACING RIGHT |

|

|

DO NOT MOUNT

WITH TERMINALS FACING UP

M2647A

Fig. 1. Module mounting recommendations.

WARNING

EXPLOSION HAZARD. CAN CAUSE

INJURY OR EQUIPMENT DAMAGE.

Only trained professional gas appliance service technicians should install and check out the S8910U.

Selectable DIP switches allow the ignition module to be customized for the appropriate trial count, trial for ignition period, and igniter warm-up time. Use only the appropriate DIP switch configuration as given in Table 4 on page 7. Refer to Tables 1, 2, and 3 for appropriate number of ignition trials, warm-up, prepurge and between trial prepurge timings.

Improper DIP switch configuration can result in appliance malfunction.

S8910U3000

Wire the Module

CAUTION

CAUTION

1.Check the wiring diagram furnished by the appliance manufacturer, if available, and compare with Table 5. Carefully follow any special instructions affecting the general procedures outlined in this section.

2.Disconnect the power supply before making wiring connections to prevent electrical shock or equipment damage.

IMPORTANT

1.Be sure all wiring complies with applicable electrical codes and ordinances.

2.Hot surface igniter leadwires should not be allowed to rest against grounded metal surfaces.

3.A common ground is required for the S8910U and the main burner. The 24V (GND) terminal internally grounds one side of the transformer. Any auxiliary controls or limits must not be in the grounded leg. In addition, the appliance should be earth-grounded.

4.Make sure the transformer has adequate VA. The ignition module requires 0.4A at 24 Vac. Add the current draws of all other devices in the control circuit, including the pilot and main valves in the gas control, and multiply by 24 to determine the total VA requirement of these components. Add this total to 9.6 VA (for the ignition module). The result is the minimum transformer VA rating. Use a Class II transformer when replacement is required.

5.Check that L1 (hot) and L2 (neutral) are wired to the proper terminals.

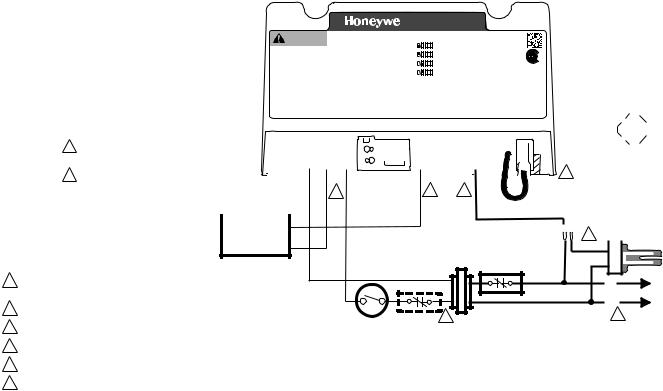

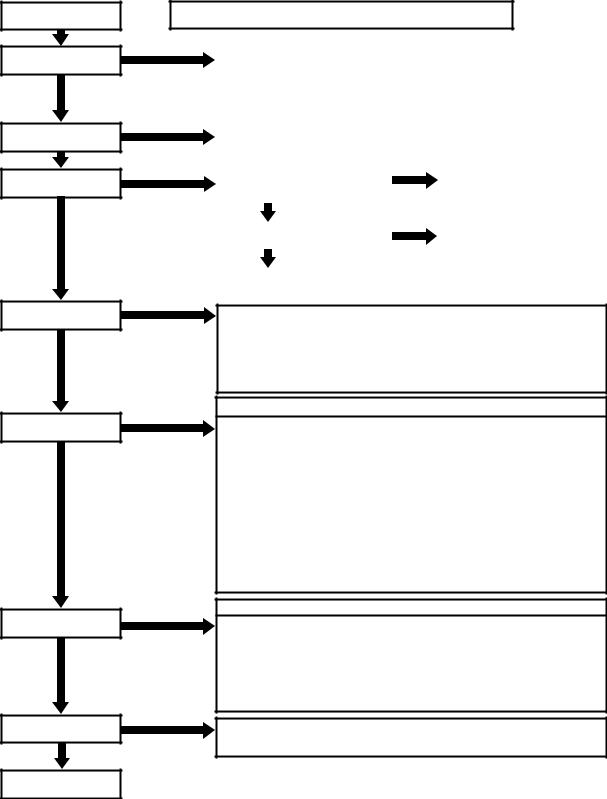

1.Connect the wires to the S8910U Ignition Module as shown in Table 5. Make sure that adequate system ground is provided as indicated in the wiring table. See Fig. 2 through 4. Where a change in quick-connect is required, cut off the original quick-connect, strip the leadwire and firmly crimp in place the proper quick-connect supplied.

2.Verify the thermostat anticipator setting as explained in the preceding IMPORTANT, item 4.

9 |

34-00008EFS—01 |

S8910U3000

Table 5. Replacement Wiring Terminals.

|

|

|

|

|

|

Replacement Control |

|

Original Control |

|

|

|

|

|

|

|

S8910U |

Honeywell |

White Rodgers |

Robertshaw |

Terminal Function |

Terminal |

S89/S890 Terminal |

50E/F47 Terminal |

HS780 Terminal |

|

|

|

|

|

|

|

|

|

|

Burner Ground Connection |

GND (BURNER) |

GND (BURNER)a |

GND |

TR (GND CLIP)b |

Tranformer Secondary |

24V (GND) |

24V (GND)a |

TR |

GND |

(unswitched leg) |

|

|

|

|

|

|

|

|

|

Main Valve Common |

VALVE (GND) |

VALVE (GND)a |

MVa (next to TR |

—c |

|

|

|

terminal) |

|

|

|

|

|

|

Transformer Secondary |

24V |

24Va |

TH |

TH |

(switched leg) |

|

|

|

|

|

|

|

|

|

Main Valve Operator |

VALVE |

VALVE |

MVd |

VALVEd |

120 Vac Neutral Leg Power Supply |

L2 120V NEUTRALe |

L2 120V NEUTRAL |

— |

L2 |

120 Vac Hot Leg Power Supply |

L1 120V HOT |

L1 120V HOT |

Lf |

L1 |

Hot Surface Igniter Element |

HSI 120V NEUTRALe |

HSI 120V |

— |

IGN |

Hot Surface Igniter Element |

HSI 120V HOT |

HSI 120V |

IGNg |

IGN |

Flame Sensor |

SENSEh |

SENh |

FP i |

RSh |

aRemove quick-connect and replace with the included 1/4 in. quick-connect.

bUse green adapter cable (provided) to connect S8910U GND (BURNER) terminal to chassis ground.

cDo not use the S8910U VALVE (GND) terminal. VALVE (GND) and 24V (GND) are interconnected in the appliance wiring.

dRemove quick-connect and replace with the included 3/16 in. quick-connect.

eDo not use this terminal if model being replaced does not have 120V neutral power supply connection.

fUse the black wire on the included adapter cable.

gUse the orange wire on the included adapter cable.

hOn remote sense models, remove jumper quick-connect from S8910U sense terminal, cut jumper wire at circuit board and discard. On local sense models, leave black jumper connected.

iRemove jumper from S8910U sense terminal, cut jumper wire at circuit board and discard.

34-00008EFS—01 |

10 |

S8910U3000

S8910U HOT SURFACE IGNITER CONTROL

|

TERMINAL CROSS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Golden Valley, MN 55422 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Assembled in Mexico |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

REFERENCE |

|

|

|

|

|

WARNING |

|

S8910U Hot Surface Ignition |

|

Selection Tab |

|

|

|

|

|

LED States |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

Input Voltages = 120 & 24 VAC, 60 Hz |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

S8910U |

50E/F47 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HSI = 120V, 5A max. |

|

|

|

|

|

|

|

ON |

|

|

|

Trial count |

Control Status |

Color |

Pattern |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

Explosion Hazard. Can cause |

|

Valve = 24V, 2A max. |

|

|

|

|

|

|

OFF |

|

|

|

= 1 try (default) |

Device damaged- |

Red |

|

Steady |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

Total 24V Load = 0.4 + valve load |

|

ON |

|

|

|

Trial count |

replace control |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||

GND(BURNER) |

GND |

|

|

|

serious injury or death. |

|

U.S. Patent 8,085,521 |

|

|

|

|

|

|

OFF |

|

|

|

= 3 tries |

Ignition lockout |

Red |

|

Blink |

|

|

® |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

|

|

Disconnect power before ser- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ON |

|

|

|

Trial for ign. period |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

Prepurge Time = 32 Sec. |

|

|

|

|

|

|

|

|

|

|

Normal operation |

Green |

Steady |

C |

US |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

vicing. This device can mal- |

|

Igniter Warm Up Time = See Inst. Sh. 34-00008 |

OFF |

|

|

|

= 4 seconds (default) |

Weak flame signal |

Green |

Blink |

AUTO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

function if it gets wet. Never |

|

|

ON |

|

|

|

Trial for ign. period |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

Ignition Trial Time - See Selection Tab |

|

|

|

|

See Instruction Sheet 34- |

00008 |

SYSTEMS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||

24V (GND) |

TR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IGNITION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

try to use a device that has |

|

Number of Trials - See Selection Tab |

OFF |

|

|

|

= 7 seconds |

for additional states |

|

|

|

ANSI Z21.20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||

|

|

|

|

1 2 3 4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

been wet -- replace it. |

|

Between Trial Time - 96 Sec. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

32304204-001 Rev. A |

|

|

|

FLAME |

|||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

BURNER (GND) |

24V (GND) |

VALVE |

(GND) |

|

|

W-TH |

|

LED |

SYSTEM SETUP |

|

VALVE |

|

|

L2 HSI |

|

|

L1 HSI |

|

|

|

|

SENSE |

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||

VALVE (GND) |

MV (NEXT TO TR) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

See |

NOTE: ALWAYS apply |

|

|

|

|

|

|

|

120 VAC |

|

|

120 VAC |

|

See |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LED |

this control as instructed |

|

|

|

|

|

NEUTRAL |

|

|

HOT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

States |

in Instruction Sheet |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Instructions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

24V |

|

TH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

34-00008 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

for |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Single/Dual |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rod |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

VALVE |

|

MV |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Applications |

|

|

|

|

|

|

|

|

SENSOR |

|

|

|

|

|

|

|

|||||

L2 |

|

— |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L1 |

4 |

L |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

HSI |

|

— |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

HSI |

4 |

IGN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

SENSE |

FP |

|

BURNER |

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

GROUND |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ORANGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

MV |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BLACK |

|

|

|

|

|

|

HOT SURFACE |

|||||||||||||||||||

|

|

|

|

COMBINATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ADAPTER |

|

|

|

4 IGNITER |

|||||||||||||||||||||||||

|

|

|

|

GAS CONTROL MV |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

THERMOSTAT OR |

LIMIT |

|

|

CONTROLLER |

||

|

CONTROLLER |

||

1 |

L1 |

||

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD |

|||

|

PROTECTION AS REQUIRED. MAKE SURE L1 AND L2 ARE NOT REVERSED. |

(HOT) |

|

2 |

ALTERNATE LIMIT CONTROLLER LOCATION. |

L2 |

|

1 |

|||

|

2 |

3REMOVE JUMPER QUICK-CONNECT FROM S8910U. CUT WIRE AT CIRCUIT BOARD AND DISCARD.

4USE ADAPTER PLUG WITH BLACK AND ORANGE WIRES (SUPPLIED).

5CUT 3/16 IN. QUICK-CONNECT OFF WIRE AND REPLACE WITH 1/4 IN. QUICK-CONNECT (SUPPLIED).

6 CUT 3/16 IN. QUICK-CONNECT OFF WIRE AND REPLACE WITH 3/16 IN. QUICK-CONNECT (SUPPLIED). |

M8528E |

Fig. 2. Typical hookup when S8910U replaces White-Rodgers 50E/F47.

11 |

34-00008EFS—01 |

S8910U3000

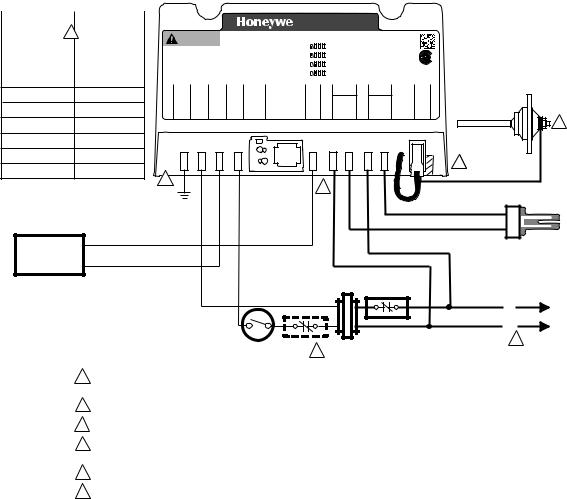

TERMINAL CROSS |

|

S8910U HOT SURFACE IGNITER CONTROL |

|

|

|||||||||||

REFERENCE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S8910U |

HS780 |

|

|

|

|

|

|

|

Golden Valley, MN 55422 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

Assembled in Mexico |

|

|

|

|

|

GND(BURNER) 6 |

TR (GND CLIP) |

WARNING |

|

S8910U Hot Surface Ignition |

Selection Tab |

|

LED States |

|

|

||||||

|

|

|

|

||||||||||||

|

|

|

|

|

Input Voltages = 120 & 24 VAC, 60 Hz |

|

|

|

|||||||

24V (GND) |

GND |

|

|

|

|

HSI = 120V, 5A max. |

ON |

|

Trial count |

Control Status |

Color |

Pattern |

|

||

Explosion Hazard. Can cause |

|

|

Valve = 24V, 2A max. |

OFF |

|

= 1 try (default) |

Device damaged- |

Red |

Steady |

|

|||||

|

|

|

|

||||||||||||

|

|

Total 24V Load = 0.4 + valve load |

ON |

|

Trial count |

replace control |

|

|

|

||||||

|

|

|

serious injury or death. |

|

|

U.S. Patent 8,085,521 |

|

OFF |

|

= 3 tries |

Ignition lockout |

Red |

Blink |

® |

|

|

|

|

Disconnect power before ser- |

|

|

|

|||||||||

VALVE (GND) |

— |

|

Prepurge Time = 32 Sec. |

ON |

|

Trial for ign. period |

Normal operation |

Green |

Steady |

C US |

|||||

vicing. This device can mal- |

|

Igniter Warm Up Time = See Inst. Sh. 34-00008 |

OFF |

|

= 4 seconds (default) |