Page 1

Industrial & Commercial Thermal

AGA

Burner control unit PFU 780

Technical Information · GB

6 Edition 02.12l

• For pilot and main burners of unlimited capacity in

thermoprocessing equipment pursuant to EN 7462

• Separate flame control for pilot burner and main burner by UV,

ionisation or a further option of using the furnace chamber

temperature

• Display of the program status, unit parameters and flame signal;

Manual mode for burner adjustment and for diagnostic purposes

Page 2

Table of contents

Burner control unit PFU 780.........................1

Table of contents ....................................2

1 Application ........................................4

1.1 Examples of application ...........................6

1.1.1 Stage-controlled main burner with alternating

pilot burner ..................................................6

1.1.2 Stage-controlled main burner with permanent

pilot burner ..................................................7

1.1.3 Modulating-controlled burner ........................8

1.1.4 PFU 780..D: High temperature equipment............9

2 Certification ..................................... 10

3 Function ..........................................11

3.1 Connection diagram ..............................11

3.1.1 PFU 780 ..............................................11

3.1.2 PFU 780..K2 .........................................12

3.2 PFU 780 program sequence......................13

3.3 Program status and fault messages..............16

4 Parameters .......................................18

4.1 Scanning the parameters .........................19

4.2 Flame control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.1 Flame signal, pilot burner ...........................20

4.2.2 Flame signal, main burner...........................20

4.2.3 Program status when the most recent fault

occurred . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.4 Switch-off threshold of the flame amplifier.........20

4.2.5 High temperature operation with PFU..D . . . . . . . . . . . .21

4.2.6 UVS check ........................................... 24

4.3 Pilot and main burner monitoring ................25

4.3.1 Permanent pilot burner...............................27

4.3.2 Interrupted pilot burner .............................28

4.4 Behaviour in start-up position/standby ..........29

4.4.1 Flame simulation check in start-up position/

standby ....................................................29

4.4.2 Minimum burner pause time t

4.5 Behaviour during start-up ........................31

....................30

BP

4.5.1 Safety time on start-up tSA ..........................31

4.5.2 Flame proving period t

4.5.3 Minimum combustion time t

4.5.4 Burner start-up at tempts ...........................33

...........................32

FS

......................32

B

4.6 Behaviour during operation.......................35

4.6.1 Safety time during operation tSB for pilot and main

burners ....................................................35

4.6.2 Fault lock-out or restart , pilot burner ...............35

4.6.3 Fault lock-out or restart, main burner ................37

4.7 Air valve control PFU..L ...........................39

4.7.1 Purge.................................................39

4.7.2 Cooling in start-up position/standby ...............39

4.7.3 Burner start ..........................................39

4.7.4 Air valve opens in the case of external activation

(not during start-up).......................................40

4.7.5 Air valve opens in the case of external activation

(even during start-up) ......................................41

4.7.6 Air valve opens with valve V2 ........................ 42

4.7.7 Air valve opens with operating signal ................43

4.7.8 Low fire over run time t

4.7.9 Behaviour of the air valve in the event of a fault

lock-out.................................................... 45

after a normal shut-down 44

KN

4.8 Manual operation ................................ 46

4.8.1 Manual mode limited to 5 minutes..................46

4.9 Password .........................................47

5 Selection ........................................ 48

5.1 Calculating the safety time t

.................. 48

SA

5.2 Selection table ....................................49

5.2.1 Type code............................................49

6 Project planning information .................... 50

6.1 Cable selection .................................. 50

6.1.1 Ignition cable........................................50

6.1.2 Ionisation cable .....................................50

6.1.3 UVLeitung ..........................................50

6.2 Ignition electrode ................................ 50

6.2.1 Electrode gap .......................................50

PFU 780 · Edition 02.12l 2

= To be continued

▼

Page 3

6.2.2 Star electrodes ......................................50

6.3 Minimum combustion time.......................51

6.4 Safety interlocks (Limits) .........................51

6.5 Emergency stop ..................................52

6.5.1 In the event of fire or electric shock . . . . . . . . . . . . . . . . . 52

6.5.2 Via the safety interlocks (limits)..................... 52

6.6 Reset ..............................................52

6.6.1 Parallel reset......................................... 52

6.6.2 Permanent remote reset ............................ 52

6.6.3 Automatic remote reset (PLC) ...................... 52

6.6.4 Burner start ......................................... 52

6.6.5 Restart and start-up attempts ......................52

6.7 Fault message ....................................53

6.8 Protecting the pilot burner from overload ........53

6.9 Installation........................................53

6.10 Wiring............................................53

6.10.1 UVS sensor wiring..................................53

6.11 PFU switched off ................................53

6.12 Furnace control .................................54

6.13 Note on EC type-examination...................54

6.14 Mains switch ....................................54

6.15 Changing parameters ...........................54

7 Flame control .....................................55

7.1 With ionisation sensor ............................55

7.2 With UV sensor ....................................55

7.3 Via the temperature in high temperature

equipment ............................................55

8 Accessories...................................... 56

8.1 High-voltage cable ...............................56

8.2 BCSoft ............................................56

8.3 Stickers for labelling ..............................56

8.4 “Changed parameters” stickers ..................56

8.5 Radio interference suppressed electrode

adapters ..............................................57

8.6 Socket connectors ................................57

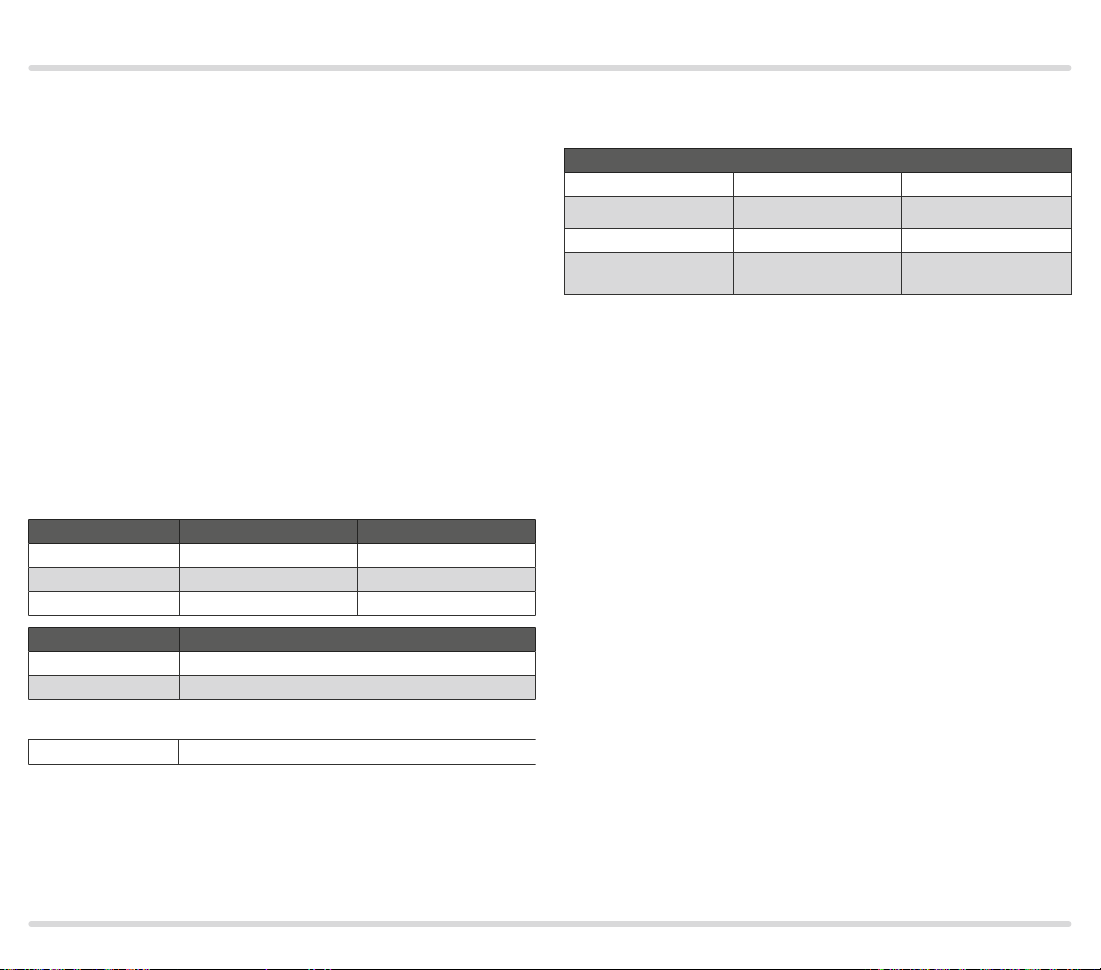

8.7 Module subrack ...................................57

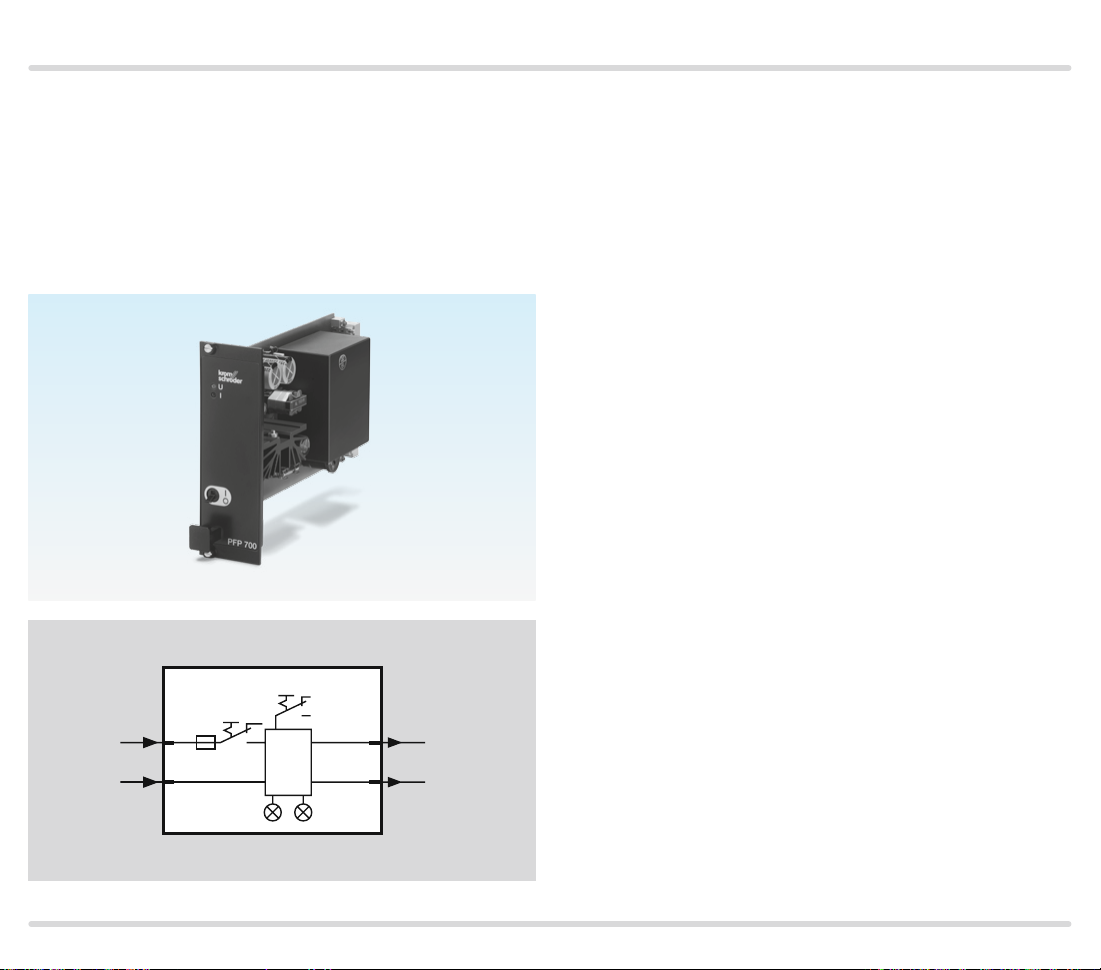

8.8 Power supply PFP 700............................58

8.9 Relay module PFR 704 ...........................59

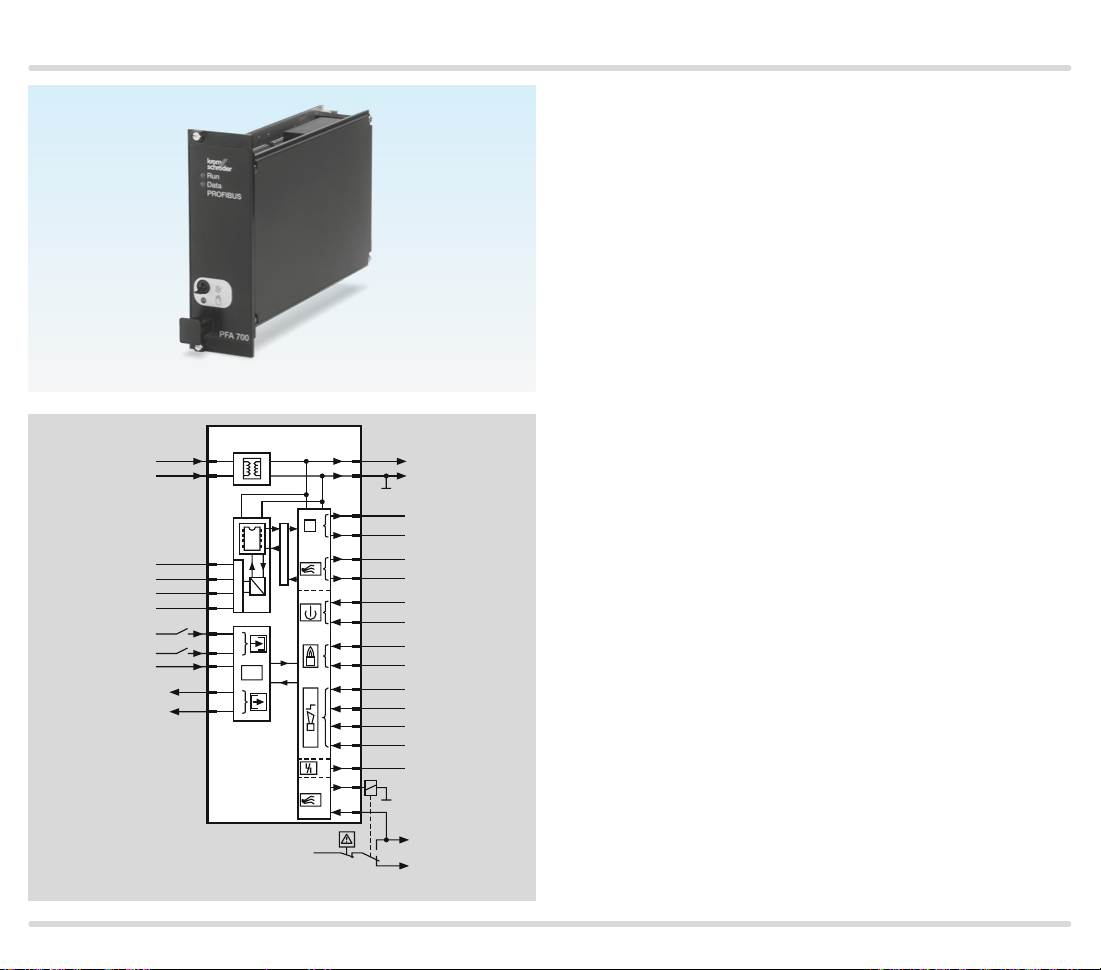

8.10 Field bus interface PFA 700.................... 60

8.11 Impulse system MPT 700 .......................61

9 Technical data ....................................62

9.1 Safety-specific characteristic values .............64

9.2 Operating controls................................65

10 Maintenance cycles ............................ 66

11 Legend ..........................................67

12 Glossary........................................ 68

12.1 Waiting time

tW ..............................68

12.2 Safety time on start-up tSA ..................... 68

12.3 Ignition time t

................................. 68

Z

12.4 Flame simulation/Flame simulation delay

time t

12.5 Safety time during operation t

..........................................68

LV

.............69

SB

12.6 Flame signal .....................................69

12.7 Fault lock-out ....................................69

12.8 Safety interlocks (Limits) ........................69

12.9 Pilot gas valve V1 ................................69

12.10 Main gas valve V2 ..............................69

12.11 Continuous operation..........................70

12.12 Air valve.........................................70

12.13 Diagnostic coverage DC .......................70

12.14 Mode of operation..............................70

12.15 Safe failure fraction SFF .......................70

12.16 Probability of dangerous failure PFH

12.17 Mean time to dangerous failure MT TF

........70

D

.......70

d

Feedback ...........................................71

Contact.............................................71

PFU 780 · Edition 02.12l 3

= To be continued

▼

Page 4

Application

Module subrack

BGT for instance

serves to accommodate several

function units. It

is provided with

a backplane with

screw terminals

for simple, reliable

wiring.

1 Application

The burner control units PFU 780 control, ignite and

monitor gas burners for intermittent or continuous operation. As a result of their fully electronic design they

react quickly to various process requirements and are

therefore also suitable for frequent cycling operation.

The PFU 780 can be used for industrial burners of un-

limited capacity which are ignited by pilot burners. Pilot

and main burners are controlled and monitored independently. This reduces the main burner start-up time.

The pilot burner can burn permanently or be switched

off. The main burners may be modulating or stagecontrolled.

the burner always ignites in a safe condition after it has

been restarted.

The burner control unit is used for burners with me-

chanical combustion air supply where the fan is controlled by a separate logic and for atmospheric burners.

The air valve control on the PFU 780L assists the fur-

nace control for cooling, purging and capacity control

tasks.

The program status, the unit parameters and the level

of the flame signal can be read directly from the unit.

Pilot and main burners can be controlled manually for

commissioning and diagnostic purposes.

▼

On industrial furnaces, the PFU 780 reduces the load

on the central furnace control by taking over tasks that

only relate to the burner, for example it ensures that

PFU 780 · Edition 02.12l 4

Page 5

Application

If the local requirements on the burner control units

change, the PC software BCSoft can be adjusted to the

unit parameters of the application by using the optical

interface.

To support service personnel, BCSoft offers a conveni-

ent visualisation system of the input and output signals

and the error history.

Intermittent shuttle kiln in the ceramics industry

Bogie hearth forging furnace in the metallurgical industry

Walking beam furnace with overhead firing

PFU 780 · Edition 02.12l 5

Page 6

Application

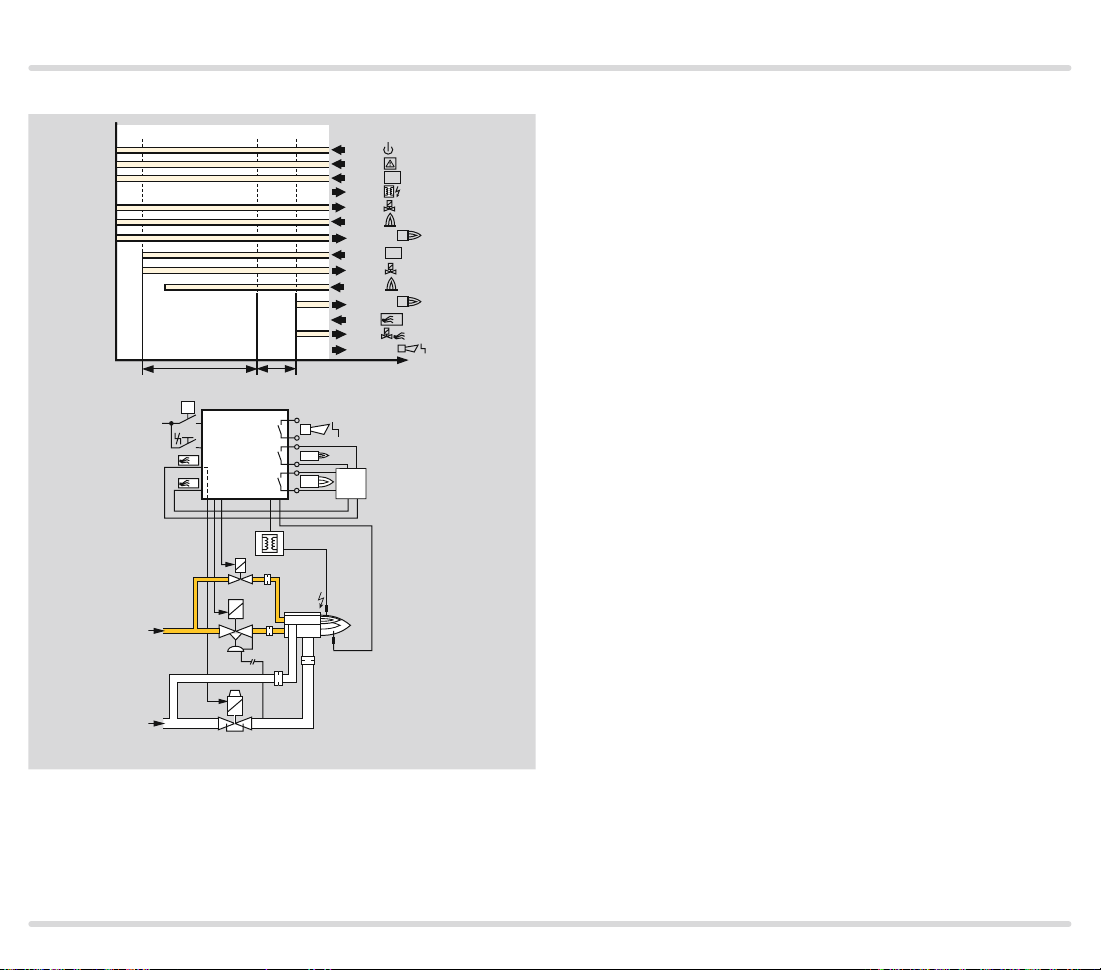

PFU 780

22e

1.1 Examples of application

1.1.1

Stage-controlled main burner

with alternating pilot burner

L1, N, PE

DI

P

SPS

PLC

CPE

DI

26e 10c

22a

A

P

ϑ1

ϑ2

14a 30e 10a

10e

µC

28c 16c 18e

18a

2e

4e

2c

4c

6a

6e

1

2

TZI

VBY

1

2

UV

VAG

Control: Main burner ON/OFF.

The main burner can be started with

reduced capacity after the operating signal from the pilot burner has

been detected. The pilot burner is

switched off automatically after the

main burner has started up. When

the main burner is switched off, the

pilot burner automatically switches

on again.

A UV sensor monitors the flame signal from pilot and main burners. UV

sensor UVD 1 is used for continuous operation, UV sensor UVS for

intermittent operation.

02–04 02–04 06–08 06–08

VR..L

ϑ1

1

ϑ2

2

t

PFU 780 · Edition 02.12l 6

Page 7

Application

PFU 780

22e

1.1.2 Stage-controlled main burner with permanent pilot burner

Control: Main burner ON/OFF.

L1, N, PE

DI

P

SPS

PLC

CPE

DI

26e 10c

22a

A

P

VBY

ϑ1

ϑ2

14a 30e 10a

10e

µC

26a

28c 16c 18e

18a

TZI

1

2

2e

4e

2c

4c

6a

6e

1

2

VAG

The main burner can be started with

reduced capacity after the operating signal from the pilot burner has

been detected. Pilot and main burners can be operated simultaneously.

Both are ionisation-controlled independently.

04 02–04 06–08 06–08

VR..R

04

ϑ1

1

ϑ2

2

t

PFU 780 · Edition 02.12l 7

Page 8

Application

PFU 780

1.1.3

Modulating-c ontrolled burner

Control: Main burner continuous

The butterfly valve for air BV is

moved to ignition position in order

L1, N, PE

DI

P

SPS

PLC

mA

CPE

DI

26e 10c

22a

16c 18e

VBY

28c

TZI

1

26a

ϑ1

µC

2

10e

18a

ϑ2

14a

2e

4e

2c

4c

6a

6e

1

2

VAG

to start the main burner. The main

burner can be started at low-fire

rate after the operating signal from

the pilot burner has been detected.

The control system controls the

burner capacity via the butterfly

valve for air BV after the operating

state has been signalled. Pilot and

main burners can be operated simultaneously.

M

BV+IC

PFU 780 · Edition 02.12l 8

Page 9

Application

PFU 780..D

STWL1>750 °C

PFU 780..D

1.1.4 PFU 780..D: High temperature equipment

The flame is controlled indirectly on

the basis of the temperature. During

the start-up process, as long as the

wall temperature is below auto ignition temperature the flame must be

controlled by conventional methods. When the working temperature

has exceeded 750°C, the safety

temperature monitor (STW) takes

over the indirect flame control.

µC

26a

18a

22a

DI

PFU 780 · Edition 02.12l 9

µC

26a

18a

22a

DI

Page 10

Certification

2 Certification

Certified pursuant to SIL

For systems up to SIL 3 pursuant to EN 61508

Pursuant to EN ISO 138491:2006, Table 4, the PFU

can be used up to PL e.

EC type-tested and certified

pursuant to

– Gas Appliances Directive (2009/142/EC) in conjunc-

tion with EN 298:200401,

Meets the requirements of the

– Low Voltage Directive (2006/95/EC),

– EMC Directive (2004/108/EC).

AGA approved

AGA

Australian Gas Association, Approval No.: 5597

www.aga.asn.au/product _directory

PFU..T is FM approved

Factory Mutual Research Class: 1997.

Suitable for applications pursuant to NFPA 86.

www.approvalguide.com

PFU 780 · Edition 02.12l 10

Page 11

Function

L1 (L1)

N (L2)

24 V

0 V

P

30e

26e

DI

22a

30a

20c

230 V

28c

N

26a

18a

ϑ1

10e

12e

ϑ2

14a

14e

A

10a

12a

10c

12c

32c

24c

c2

c1

PFU 780

F1

1

2

µC

sk1

l

22e

v1

16c

v2

18e

N

3.1 Connection diagram

V1

V2

For cable selection and wiring, see page 50 (Project

planning information).

3.1.1 PFU 780

For the explanation of symbols, see page 67 (Legend).

2a

a

4a

2e

s

4e

2c

m

n

A

S

SK

M

N

L

V2

V1

C

1

4c

6a

6e

max. 1 A, 24 V

2

3 Function

Z

I

26a

28c

N

18a

26a

28c

N

UVS

18a

1

2

20c

3

24c

PFU 780 · Edition 02.12l 11

Page 12

Function

L1 (L1)

3.1.2 PFU 780..K2

P

30e

26e

DI

22a

PFU 780..K2

F1

sk1

l

v1

v2

22e

16c

18e

N

V1

V2

As a replacement unit for burner control unit PFU 798.

For the explanation of symbols, see page 67 (Legend).

N (L2)

24 V

0 V

Z

I

26a

ϑ2

30a

32c

24c

20c

230 V

c2

28c

N

c1

26a

18a

ϑ1

10e

12e

14a

14e

A

10a

12a

10c

12c

28c

N

1

2

µC

28c

N

26a

18a

UVS

2a

a

4a

2e

s

4e

2c

m

n

A

S

SK

M

N

L

V2

V1

C

1

4c

6a

6e

18a

1

2

20c

3

24c

max. 1 A, 24 V

2

PFU 780 · Edition 02.12l 12

Page 13

Function

A

00

01

02

Switch on PFU 780

In the event of fault signal:

Safety interlocks (Limits)

Start-up position/standby

flame simulation check

Flame simulation check

next start-up attempt (P10)

Reset

If parameter P15 = 1:

Pilot burner start-up

with ϑ1 signal

Wait until

waiting time t

has elapsed

If parameter P15 = 0:

Safety time t

running (P22),

ignition in process,

V1 opens and min.

combustion time tB

starts to elapse (P20)

If no flame detected:

or fault lock-out

W

SA1

PFU 780

If the air valve control is used,

the unit offers the following

additional functions:

In start-up position, the air

valve can be opened for cool-

(display A0).

ing

Using parameter 31, it can be

determined whether the air

valve can be activated externally during start-up (display

A1).

The air valve can be set to open

together with V1 (display

via parameter 30.

A2

)

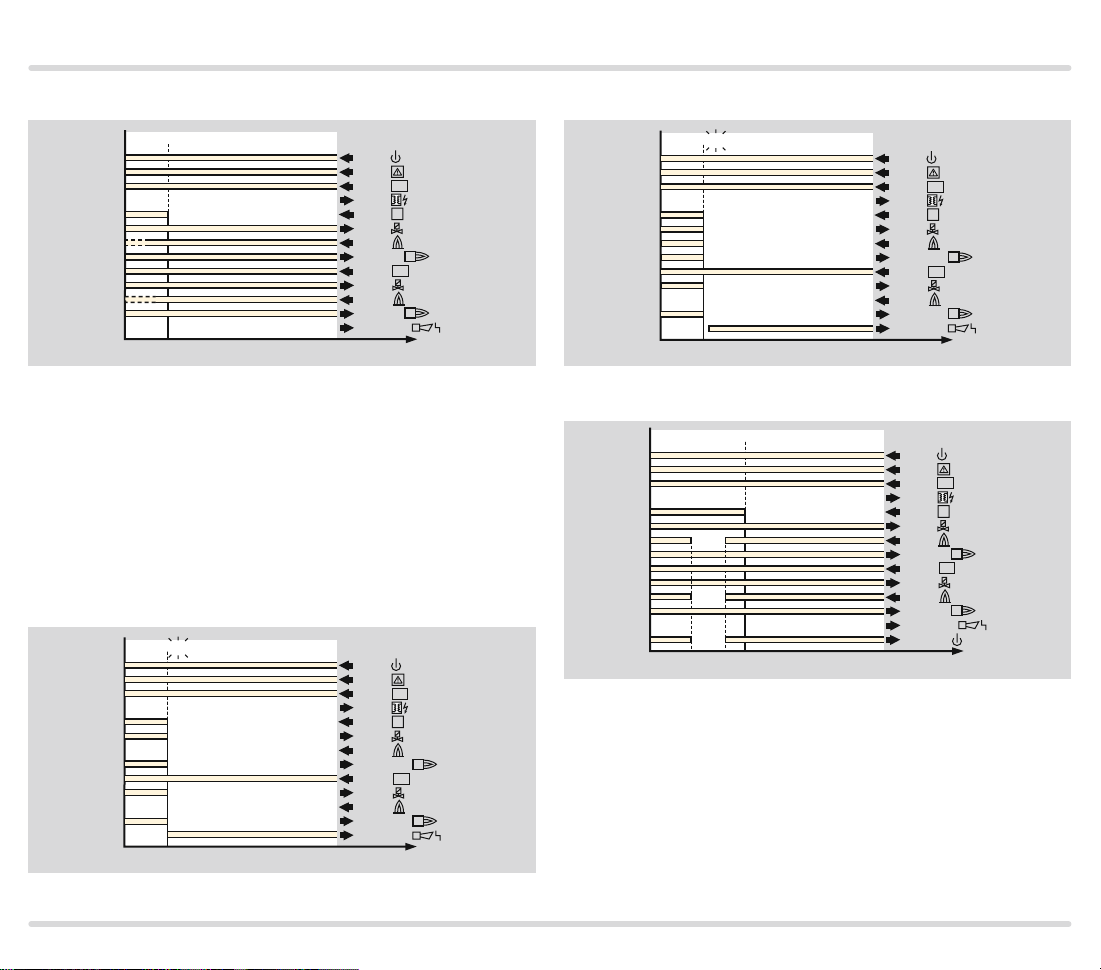

3.2

PFU 780 program sequence

Normal start-up

If an “old” fault is still being signalled after switching on, it will be

necessary to reset this first.

The safety interlocks (terminal 26e)

must be closed and the burner control unit must be switched on.

The PFU 780 conducts a self-test

when in the start-up position (the

burner is switched off). If it does

not determine a malfunction of the

internal electronic circuitry or of the

flame sensors, the burner can be

started. The pilot burner start-up is

activated via the signal input “Startup signal ϑ1” (terminal 10e). Once

the start-up signal ϑ1 has been

applied, the PFU 780 opens valve

V1 and ignites the burner. The ignition time t

is constant. If a flame

Z

is detected during the safety time

t

, the flame proving period t

SA1

starts after the safety time t

SA1

FS1

has

elapsed.

If the pilot burner has been started

successfully and its flame has

stabilised, the burner control unit

issues the Enable signal for main

burner operation. The operation signalling contact for the pilot burner

(terminals 2c/4c) closes.

▼

PFU 780 · Edition 02.12l 13

Page 14

If no flame detected:

next start-up attempt (P10)

or fault lock-out

Function

03

04

05

Flame proving period t

running (P23)

In the event of flame failure:

restart or fault lock-out

Operating signal

Pilot burner closes

In the event of flame failure:

restart or fault lock-out

Main burner start-up

with ϑ2 signal

Wait until

min. burner pause time t

has elapsed (P21)

FS1

BP

The PFU coordinates the correct

The air valve can be set to open

together with V1 (display

via parameter 30.

A3

)

program run for the pilot and main

burners. The main burner can be

started via the signal input “Startup signal ϑ2” (terminals 14a/14c) if

required.

Once the start-up signal ϑ2 has

been applied (terminals 14a and

The air valve can be set to open

together with V1 (display A4)

via parameter 30.

14e), the PFU 780 opens valve V2.

The main burner is ignited by the

pilot burner.

If a flame is detected during the

safety time t

The air valve can be set to open

A5

together with V1 (display

via parameter 30.

)

time t

burner has been started successfully and its flame has stabilised,

the operation signalling contact

period t

FS2

has elapsed. If the main

SA2

, the flame proving

SA2

starts after the safety

(terminals 6a/6e) closes.

If parameter P15 = 0:

Flame simulation check

Start-up of the pilot burner

without flame signal

If no flame is detected during the

06

Safety time t

min. combustion time tB

starts to elapse (P20)

running (P24),

SA2

V2 opens and

The air valve can be set to open

with V2 or to be activated externally (display

eter 30.

A6

) via param-

safety time t

out occurs or up to three further

start-up attempts occur. (Parameter 10, “Pilot burner start-up at-

, either a fault lock-

SA1

tempts”).

If no flame detected:

next start-up attempt (P11)

or fault lock-out

▼

PFU 780 · Edition 02.12l 14

Page 15

If no flame detected:

next start-up attempt (P11)

or fault lock-out

Function

07

08

08

00

Flame proving period

t

running (P25)

FS2

In the event of flame failure:

restart or fault lock-out

Operating signal

Main burner closes

In the event of flame failure:

restart or fault lock-out

Normal shut-down

via ϑ signal for

pilot and main burners

If min. combustion time t

has elapsed:

Operation signalling contact

V1 and V2 close,

min. burner pause time tBP

starts to elapse (P21)

opens,

Behaviour of the pilot burner in

the event of flame failure during

The air valve can be set to open

with V2 or to be activated externally (display A7) via parameter 30.

operation

If the flame fails during operation,

either an immediate fault lock-out

occurs or a restart occurs. This procedure can be set via the optical in-

The air valve can be set to open

with the operating signal or to

be activated externally (display

A8

) via parameter 30.

terface (parameter 12, “Pilot burner

restart”).

Behaviour of the main burner in

the event of flame failure during

start-up

If no flame is detected during the

safety time t

, either a fault lock-

SA2

out occurs or up to three further

start-up attempts occur. (Parameter 11, “Main burner start-up attempts”).

B

Behaviour of the main burner in

the event of flame failure during

operation

If the flame fails during operation,

either an immediate fault lock-out

occurs or a restart occurs. This procedure can be set via the optical interface (parameter 13, “Main burner

restart”).

PFU 780 · Edition 02.12l 15

Page 16

Function

3.3 Program status and fault messages

During operation, the 7-segment display shows the program status. In the event of a fault, the PFU halts the

program run, the display blinks and it then displays the

cause of the fault.

Program status

Start-up position/standby

Cooling

Waiting time/Pause time

Safety time on star t-up, pilot burner

Flame proving period, pilot burner

Operation, pilot burner

Waiting time, main burner

Safety time on star t-up, main burner

Flame proving period, main burner

Operation, main burner

Purge

Air valve

High temperature operation**

DISPLAY

The burner control unit can be reset using the Reset

button or the remote reset.

Fault message (blinking*)

00

A0

1

2

3

4

5

6

7

8

P0

Flame failure during flame proving period, pilot burner

Flame failure during flame proving period, main burner

Flame simulation, pilot burner

Start-up without fl ame signal, pilot burner

Flame failure during operation, pilot burner

Flame simulation, main burner

Start-up without fl ame signal, main burner

Flame failure during operation, main burner

A

. .

10

32

33

35

36

51

Short-circuit on ignition or valve output

Faulty remote reset

Supply voltage too low

Faulty parameterisation

Short-circuit on a valve output

Safety interlock failure

▼

PFU 780 · Edition 02.12l 16

Page 17

Function

Program status

DISPLAY

52

53

In Manual mode, two dots will blink on the display in program status 01–08.

** Optionally available.

Fault message (blinking*)

Permanent reset

Time bet ween two start-ups is too short

PFU 780 · Edition 02.12l 17

Page 18

Parameters

4 Parameters

Description Parameter Value range

Flame signal, pilot burner 01

Flame signal, main burner 02

0–30 µA

0–30 µA

Factory default

setting

Program status when the most recent fault occurred 03 x0–x8

Switch-off threshold, pilot burner 04

Switch-off threshold, main burner 05

1–20 µA 1 µA

1–20 µA 1 µA

Start-up attempts, pilot burner 10 1–4 1

Start-up attempts, main burner 11 1–4 1

Restart, pilot burner 12 0; 1 0

Restart, main burner 13 0; 1 0

Safety time during operation for V1 and V2 t

SB

14 1; 2 s 1 s

Flame simulation check in start-up position/standby 15 0; 1 1

Permanent pilot burner 16 0; 1 1

Minimum combustion time t

Minimum burner pause time t

B

BP

Pilot burner safety time on start-up t

Pilot burner flame proving period t

FS1

Main burner safety time on start-up t

Main burner flame proving period t

SA1

24 3; 5 s

SA2

FS2

20 25 s t

21 0–250 s 0 s

22 3; 5; 10 s

23 0–25 s 0 s

25 0–25 s 0 s

Air valve control 30 0; 2; 3 0

Air valve c an be activated ex ternally on star t-up 31 0; 1 0

Air valve closed/can be activated in the event of malfunction 32 0; 1 1

High temperature operation** 33 2; 3

Adjustable*

SA

▼

PFU 780 · Edition 02.12l 18

Page 19

Parameters

Description Parameter Value range

Manual mode limited to 5 minutes 34 0; 1 1

UVS check (1 x in 24 hours) 35 0; 1 0

Low fire over run time 36 0; 5; 15; 25 s 0 s

Purge 42 0; 1 1

Multi-flame control 45 0; 1 0

Password 50 0000–9999 1234

* Adjustable using BCSoft sof tware and a PC opto-adapter

** Please quote in your order.

0 = Function inactive

1 = Function active

Factory default

setting

On parameterisation, ensure that the program sequence started matches the application. Select the

parameters so that the burner can restart as intended

in all operating phases.

4.1 Scanning the parameters

During operation, the 7-segment display shows the program status.

The flame signal and all following parameters of the

PFU can be scanned one after the other by repeatedly

pressing the Reset/Information button (for 2 s).

In the event of a fault, the PFU halts the program run,

the display blinks and it then displays the cause of the

fault in coded form.

Adjustable*

PFU 780 · Edition 02.12l 19

Page 20

Parameters

4.2 Flame control

4.2.1 Flame signal, pilot burner

Parameter 01

Flame signal of the pilot burner, display in μA, measuring range: 0–30 μ A.

4.2.2 Flame signal, main burner

Parameter 02

Flame signal of the main burner, display in

ing range: 0–30 μ A.

Program st atus when the m ost rece nt fault occurr ed

4.2.3

Parameter 03

Program status when the most recent fault occurred

This indicates the program status in which the last

burner fault occurred (e.g. the unit indicates that a

flame simulation has been detected with a blinking

01

).

In parameter 03, it is now shown which program position the unit was in when the fault was detected (waiting time

01

or standby

00

).

Result: A flame simulation was detected during the

waiting time or standby.

μA, measur-

4.2.4 Switch-off threshold of the flame amplifier

Parameter 04, pilot burner switch-off threshold

Parameter 05, main burner switch-off threshold

The sensitivity at which the burner control unit still de-

tects a flame can be set between 1 and 20

μA.

Example: In the case of UV control with the UV sensor

UVS, the signal of the burner to be monitored is influenced by other burners.

The set value can be incremented in parameter 04 so

that only the flame of the system’s “own” burner is detected.

The measured flame signal of the system’s “own” burner

should be at least 3

μA (empirical value) higher than the

set switch-off threshold.

PFU 780 · Edition 02.12l 20

Page 21

Parameters

▼

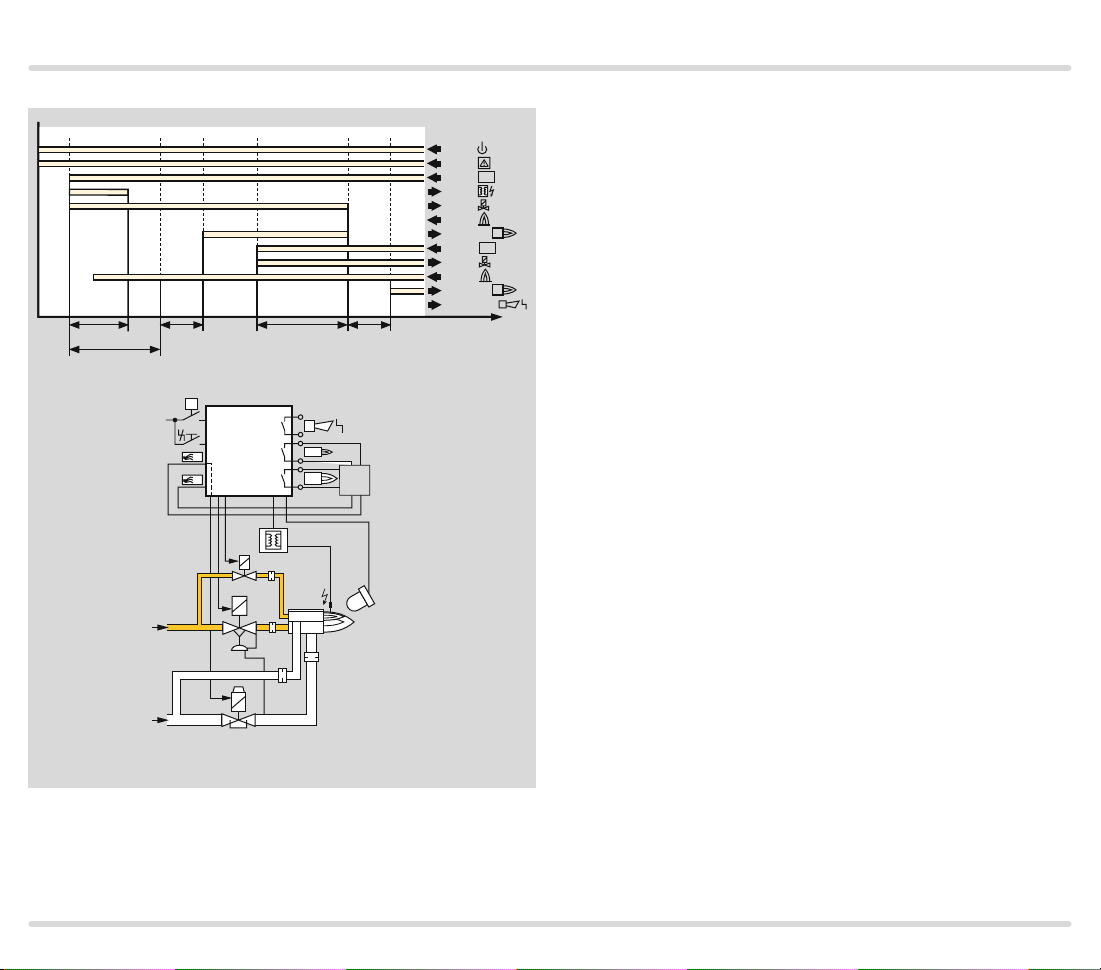

4.2.5 High temperature operation with PFU..D

Parameter 33

Operation of firing systems at temperatures above

750°C. The PFU features a safety-relevant DI input

(Digital Input). This input supports the “High temperature operation” function. If firing systems are operated

above 750°C, the system is considered to be a high

temperature equipment (see EN 7462). Flame control

must be in operation until the furnace wall temperature

has exceeded 750°C. Note the requirements of the

Standards!

Flame control can be dispensed with during high temperature operation to improve the system availability.

This means that no incorrect flame signals, e.g. signals

from a UV sensor which are interpreted as extraneous

signals due to reflection of UV radiation, may lead to

faults.

When the DI input is activated, the burner control unit

reverts to High temperature mode. This means: the PFU

operates without evaluation of the flame signal. The

safety function of the device-internal flame control system is placed out of operation.

In High temperature mode, the gas valves are opened

without flame control.

The precondition for high temperature operation is that

an external flame safeguard ensures the presence of

the flame in fail-safe manner indirectly via the temperature. For this purpose, we recommend a safety tem-

perature monitor with twin thermocouple (DIN 3440).

Sensor discontinuity, sensor short-circuit, failure of a

component or mains failure must set the installation to

a safe state.

The voltage may be applied to the DI input (terminal

22a) so as to activate High temperature mode only

when the temperature at the furnace wall has exceeded

750°C. The PFU starts the burner as usual, without

monitoring the presence of the flame.

0402 03

06 07 0800

t

t

Z

t

SA1

FS1

t

SA2tFS2

88

30a

26e

10e

28c

22a

16c

26a

2c–4c

14a

18e

18a

6a–6e

2e–4e

ϑ1

DI

V1

1

1

ϑ2

V2

2

2

t

If the temperature in the furnace chamber drops below

750°C, the DI input must be disconnected from the

electrical power supply and the furnace must be operated with the internal flame control system.

PFU 780 · Edition 02.12l 21

Page 22

Parameters

▼

The PFU then responds, depending on setting:

Parameter 33 = 1

0402 0301

06 07 0808

FA

t

W

t

t

t

SA1

FS1

Z

t

SA2tFS2

88

30a

26e

10e

28c

22a

16c

26a

2c–4c

14a

18e

18a

6a–6e

2e–4e

2a–4a

ϑ1

DI

V1

1

1

ϑ2

V2

2

2

t

If the flame fails during high temperature operation, the

ready contact opens for the duration of the flame failure (FA).

When High temperature mode is ended, the PFU

switches off the burner and restarts with flame simulation check (recommended in the case of UV control

with UVS).

Parameter 33 = 2

0402 0301

06 07 0808

t

t

t

t

W

Z

SA1

FS1

t

SA2tFS2

88

30a

26e

10e

28c

22a

16c

26a

2c–4c

14a

18e

18a

6a–6e

2e–4e

2a–4a

ϑ1

DI

V1

1

1

ϑ2

V2

2

2

t

When High temperature mode is ended, the PFU

switches off the burner and restarts with flame simulation check (recommended in the case of UV control

with UVS).

PFU 780 · Edition 02.12l 22

Page 23

Parameters

Parameter 33 = 3

08

08

88

30a

26e

10e

28c

22a

16c

26a

2c–4c

14a

18e

18a

6a–6e

2e–4e

ϑ1

DI

V1

1

1

ϑ2

V2

2

2

t

When High temperature mode is ended, the burner remains in operation and the PFU performs flame control

again (recommended in the case of ionisation control or

UV control with UVD).

If no flame signal is present when High temperature

mode is ended, the burner control unit performs a fault

lock-out, regardless of parameter 33.

Fault, pilot burner

04 04

88

30a

26e

10e

28c

22a

16c

26a

2c–4c

14a

18e

18a

6a–6e

2e–4e

ϑ1

DI

V1

1

1

ϑ2

V2

2

2

t

Fault, main burner

08

08

88

30a

26e

10e

28c

22a

16c

26a

2c–4c

14a

18e

18a

6a–6e

2e–4e

ϑ1

DI

V1

1

1

ϑ2

V2

2

2

t

Parameter 33 = 4

08

08

88

30a

26e

10e

28c

22a

16c

26a

2c–4c

14a

18e

18a

6a–6e

2e–4e

2a–4a

ϑ1

DI

V1

1

1

ϑ2

V2

2

2

t

If the flame fails during high temperature operation, the

ready contact is opened for the duration of the flame

failure.

When High temperature mode is ended, the burner remains in operation and the PFU performs flame control

again (recommended in the case of ionisation control or

UV control with UVD).

PFU 780 · Edition 02.12l 23

Page 24

Parameters

4.2.6 UVS check

Parameter 35

An automatic restart of the burner control unit can be

activated every 24 hours via this parameter. The time

starts each time the start-up signal (ϑ) is applied.

Parameter 35 = 0: Unlimited burner operation.

Parameter 35 = 1: An automatic restart is activated

once every 24 hours.

It must be ensured in this case that the program sequence started matches the application. This parameter may be set in this way only if the burner can restart

as intended in all operating phases.

PFU 780 · Edition 02.12l 24

Page 25

Parameters

t

4.3 Pilot and main burner monitoring

Burner control unit PFU 780 for pilot and main burner

combination of unlimited capacity.

Pilot burner: single-stage-controlled.

Main burner: modulating or stage-controlled.

The burner control unit PFU 780 has separate start-up

signal inputs for the pilot burner (terminal 10e) and the

main burner (terminal 14a). The burner control unit coordinates the program run (the interplay) of both burners. If required, the main burner can be started once the

pilot burner has reached its operating position. Benefit:

The time for starting up the main burner can be reduced

as low as its safety time. By using two flame amplifiers,

the pilot and main burners can be monitored separately.

The PFU 780 can also be used on indirectly ignited sur-

face burners with end point monitoring.

Three different operating modes are possible:

Permanent pilot burner

88 02–04 06–08 04 06–08 04

ϑ1

1

ϑ2

2

For applications which require a high system availabil-

ity or where a continuously burning flame is necessary.

The pilot burner is ignited once and remains constantly

in operation. The main burner is controlled separately.

Intermittent pilot burner

88 02–04 06–08 00 02–04 06–08 00

ϑ

1

2

t

Pilot and main burners are controlled with one start-

up signal (terminals 10e and 14a in parallel). The main

burner starts automatically after the operating signal

from the pilot burner has been detected. Operation is

terminated simultaneously for both burners.

PFU 780 · Edition 02.12l 25

Page 26

Parameters

Interrupted pilot burner

88 02–04 06–08 02–04 06–08

ϑ1

1

ϑ2

2

t

The pilot burner is switched off during the main burner

safety time t

no distinction can be made between the flame signals

of the pilot and main burners (e.g. if both burners can

be monitored with a single UV sensor). If the start-up

signal for the pilot burner is applied continually, the

pilot burner restarts immediately after the main burner

has been switched off.

. This type of flame control is required if

SA2

PFU 780 · Edition 02.12l 26

Page 27

Parameters

4.3.1 Permanent pilot burner Parameter 16 = 1

04 06 07 08 02 03 00

t

Z

t

SA1

t

FS1

ϑ

L1

PFU 780

A

P

t

SA2

TZI

VBY

VAG

1

t

1

SPS

2

PLC

CPE

2

FS2

88

30a

26e

10e

28c

16c

26a

2c–4c

14a

18e

18a

6a–6e

2e–4e

ϑ1

V1

1

1

ϑ2

V2

2

2

t

Operating mode: Permanent pilot burner

In the “Permanent pilot burner” operating mode, the pilot burner remains in operation until its start-up signal

drops.

If this parameter is activated (P16 = 1), both flames are

controlled independently in the case of pilot and main

burner monitoring.

Operating mode: Intermittent pilot burner

Start-up as in the illustration “Permanent pilot burner”

with the difference being that the start-up signal for pilot and main burners is applied synchronously and that

immediately after the flame proving period t

main burner is started.

FS1

, the

VR..R

PFU 780 · Edition 02.12l 27

Page 28

Parameters

4.3.2 Interrupted pilot burner Parameter 16 = 0

04 06 07 08 02 03 00

t

Z

t

SA1

t

FS1

ϑ

L1

PFU 780

A

P

VAS

t

TZI

SA2

t

FS2

1

SPS

2

PLC

CPE

88

30a

26e

10e

28c

16c

26a

2c–4c

14a

18e

18a

6a–6e

2e–4e

ϑ1

V1

1

1

ϑ2

V2

2

2

t

Operating mode: Interrupted pilot burner

If parameter 16 = 0, the pilot burner is switched off once

the safety time t

flame signal can be connected to terminals 18a or 26a.

The pilot burner is switched off after the main burner

safety time t

SA2

has elapsed. In this setting, the

SA2

has elapsed.

VAG

VR..R

UV

1

2

PFU 780 · Edition 02.12l 28

Page 29

Parameters

4.4 Behaviour in start-up position/standby

4.4.1 Flame simulation check in start-up position/ standby

Parameter 15

This defines the instant for the flame simulation check.

88

00

t

LV

If the PFU notices an extraneous signal during the

flame simulation check, it starts the flame simulation

delay time tLV (25 s). If the extraneous signal is discontinued during this period, the burner can start up. Otherwise, a fault lock-out occurs. 1 blinks on the display

if an extraneous signal is detected by the pilot burner

and 5 blinks if an extraneous signal is detected by the

main burner.

Parameter 15 = 0: The flame simulation check is conducted after applying the start-up signal (ϑ) during the

waiting time t

.

W

Parameter 15 = 1: The flame simulation check is conducted provided no start-up signal (ϑ) is applied (during

the so-called start-up position/standby). This allows fast

start-up of the burner since there is no waiting time t

01

30a

26e

10e

28c

26a

16c

18e

2c–4c

2e–4e

ϑ1

V1

V2

1

t

.

W

The burner must have been switched off for at least 4 s

before start-up in order for the flame simulation check

to be conducted correctly.

Flame simulation check depending on parameter 16

(Pilot burner operating mode):

Parameter 15 = 1, Parameter 16 = 1

88 00 02 06

ϑ1

V1

ϑ2

V2

t

Parameter 15 = 0, Parameter 16 = 1

02

t

W1

06

t

W2

88 00 01 05

ϑ1

ϑ2

V1

V2

t

Parameter 15 = 1, Parameter 16 = 0

88 00 02 06

ϑ1

V1

ϑ2

V2

t

Parameter 15 = 0, Parameter 16 = 0

02

t

W1

06

t

W2

88 00 01 05

ϑ1

ϑ2

V1

V2

t

PFU 780 · Edition 02.12l 29

Page 30

Parameters

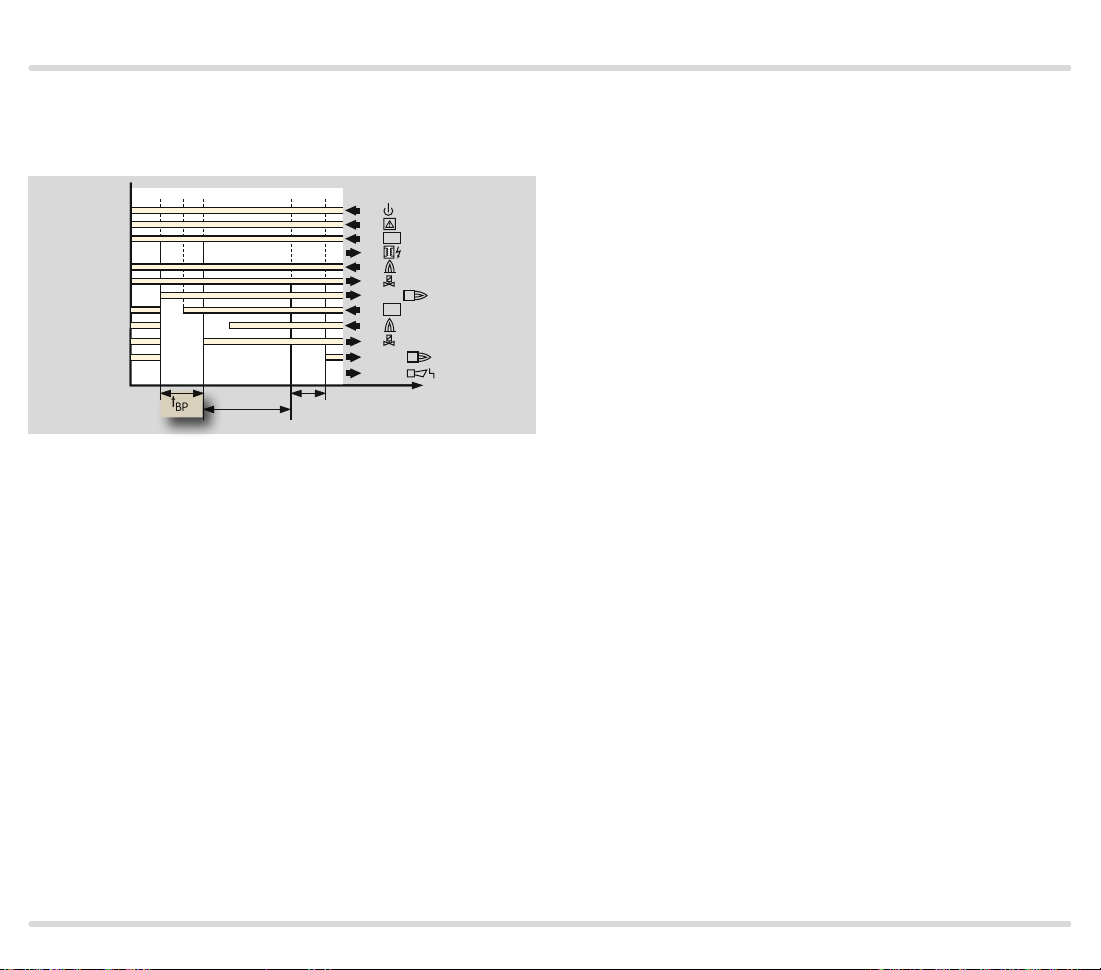

4.4.2 Minimum burner pause time tBP

Parameter 21

Programmable time between 0 and 250 s.

05 04

t

BP

t

SA2

t

FS2

88 08 06 07 08

1

5

ϑ

1

4

7

1

9

V1

12

16-17

ϑ

2

21

2

9

14 V2

28-29

18-19

1

2

t

An immediate restart of the main burner after a normal shut-down, a start-up attempt, restart, cooling

or purging is prevented by the pause time. The pause

time starts when the air valve is switched off. If a startup signal (ϑ2) is applied before expiry of this time, the

start-up is delayed until the end of the pause time.

After the pause time, the burner is started if the startup signal (ϑ) is applied.

The minimum burner pause time t

serves to adapt the

BP

program sequence to the requirements of the application.

The time should be set such that the system can be

moved to ignition position, i.e. butterfly valves can be

closed and, possibly, gas can be flared off, before a restart occurs.

See examples of application Stage-controlled main

burner with alternating pilot burner and Stage-controlled main burner with permanent pilot burner.

The pause time has an effect on the behaviour of the

main burner only. Background: The pilot burner is only

used in single-stage operation.

PFU 780 · Edition 02.12l 30

Page 31

Parameters

4.5 Behaviour during start-up

4.5.1 Safety time on start-up tSA

Pilot burner

Parameter 22

04 02 03 00

t

Z

t

SA1

Safety time on start-up t

t

FS

for the pilot burner.

SA1

88

30a

26e

10e

28c

26a

16c

18e

2c–4c

2e–4e

Main burner

Parameter 24

04 06 07 08 02 03 00

ϑ1

1

V1

V2

1

t

Safety time on start-up t

t

Z

t

SA1

t

FS1

t

SA2

for the main burner.

SA2

t

FS2

88

30a

26e

10e

28c

16c

26a

2c–4c

14a

18e

18a

6a–6e

2e–4e

ϑ1

V1

1

1

ϑ2

V2

2

2

t

PFU 780 · Edition 02.12l 31

Page 32

Parameters

4.5.2 Flame proving period tFS

Pilot burner

Parameter 23

t

Z

t

SA1

t

FS

Main burner

Parameter 25

04 06 07 08 02 03 00

t

Z

t

SA1

t

FS1

t

SA2

4.5.3 Minimum combustion time t

B

Parameter 20

04 06 07

88

04 02 03 00

30a

26e

ϑ1

10e

28c

1

26a

16c

V1

18e

V2

1

2c–4c

2e–4e

t

t

B

88

30a

26e

10e

16c

26a

2c–4c

14a

18e

18a

6a–6e

2e–4e

ϑ1

V1

1

1

ϑ2

V2

2

2

t

Programmable time to maximum 25 s during which the

main burner remains in operation. In the case of brief

activation of the start-up signal input (ϑ2) (e.g. with a

pulse), the combustion time tB is started, and the main

t

FS2

88

30a

26e

10e

28c

16c

26a

2c–4c

14a

18e

18a

6a–6e

2e–4e

ϑ1

V1

1

ϑ2

V2

2

t

burner remains in operation for at least this period.

1

2

Programmable time between 0 and 25 s.

This time elapses before the PFU starts the next pro-

gram step so as to give the flame time to stabilise.

PFU 780 · Edition 02.12l 32

Page 33

Parameters

4.5.4 Burner start-up attempts

Pilot burner

Parameter 10

This indicates the number of possible start-up attempts

of the burner.

In accordance with EN 7462, three start-ups are permitted in specific cases in the event of flame failure

during start-up, if the safety of the installation is not

impaired. Note the requirements of the Standards!

If no flame is detected during start-up, either a fault

lock-out is performed or further start-up attempts in

accordance with EN 7462 occur.

Pursuant to NFPA 86, only one start-up attempt is permitted in the event of flame failure during start-up. For

units approved by FM Approval (see type label), it is

only possible to select one start-up attempt.

1 start-up attempt

Parameter 10 = 1

02 00

t

Z

02

t

SA

88

30a

26e

10e

28c

26a

16c

18e

2c–4c

2e–4e

ϑ1

V1

V2

t

If no flame forms during start-up, a fault lock-out is

performed after expiry of time tSA. The display blinks

and shows the cause of the fault.

2 or 3 start-up attempts

Parameter 10 = 2, 3

02 00

t

Z

t

SA1

t

Z

88

30a

26e

ϑ1

10e

28c

26a

V1

16c

V2

18e

1

2c–4c

2e–4e

t

t

SA1

If several start-up attempts are set and if the PFU detects a flame failure during start-up, it closes valve V1

after the safety time t

has expired and attempts to

SA1

start up again. After the last programmed start-up attempt has been completed, the burner control unit conducts a fault lock-out. The display blinks and shows the

cause of the fault.

PFU 780 · Edition 02.12l 33

Page 34

Parameters

Main burner

Parameter 11

This indicates the number of possible start-up attempts

of the main burner.

In accordance with EN 7462, three start-ups are permitted in specific cases in the event of flame failure

during start-up, if the safety of the installation is not

impaired. Note the requirements of the Standards! If no

flame is detected during start-up, either a fault lock-out

is performed or further start-up attempts in accordance with EN 7462 occur.

Pursuant to NFPA 86, only one start-up attempt is permitted in the event of flame failure during start-up. For

units approved by FM Approval (see type label), it is

only possible to select one start-up attempt.

1 start-up attempt

Parameter 11 = 1

04 06 02 03 00

t

Z

t

SA1

t

FS1

t

SA2

06

88

30a

26e

10e

28c

16c

26a

2c–4c

14a

18e

18a

6a–6e

2e–4e

ϑ1

V1

1

1

ϑ2

V2

2

2

t

If no flame forms during the start-up of the main burner,

a fault lock-out is performed after expiry of time t

SA2

.

The display blinks and shows the cause of the fault.

2 or 3 start-up attempts

Parameter 11 = 2, 3

04 06 02 03 00

t

Z

t

SA1

t

FS1

t

SA2

05

t

06

t

W

SA2

05

t

06

06

t

W

SA2

88

30a

26e

10e

28c

16c

26a

2c–4c

14a

18e

18a

6a–6e

2e–4e

ϑ1

V1

1

1

ϑ2

V2

2

2

t

If several start-up attempts are set and if the PFU does

not detect a flame signal during start-up, it closes valve

V2 after the safety time t

has expired and attempts

SA2

to start up again. After the last programmed start-up

attempt has been completed, the burner control unit

conducts a fault lock-out. The display blinks and shows

the cause of the fault.

PFU 780 · Edition 02.12l 34

Page 35

Parameters

▼

4.6 Behaviour during operation

4.6.1

Safety time during operation tSB for pilot and main

burners

Parameter 14

This indicates the safety time during operation tSB

for valves V1 and V2. The default in accordance with

EN 298 is 1 s. The PFU has also the available option of

a safety time during operation tSB of 2 s. Prolonging the

time increases the installation availability in the case

of brief-duration signal fades (e.g. fades of the flame

signal). In accordance with EN 7462, the safety time

of the installation during operation (including closing

time of the valves) may not exceed 3 seconds (note the

requirements of the Standards).

4.6.2 Fault lock-out or restart, pilot burner

Parameter 12

This parameter determines whether the PFU starts a

one-off restart or performs an immediate fault lock-out

for the burner after an installation fault such as a flame

failure or failure of air flow (see also Project planning

information).

Immediate fault lock-out following flame failure

Parameter 12 = 0:

Pilot burner fault lock-out.

04

04

t

SB

88

30a

26e

10e

28c

26a

16c

18e

2c–4c

2e–4e

ϑ1

1

V1

V2

1

t

After a fault lock-out, the burner control unit can be

reset, either with the button on the front panel or using

an external button. Several burner control units can be

reset in parallel using the external button.

The PFU cannot be reset by mains failure. The fault

signalling contact does, however, open as soon as the

mains voltage fails.

See also parameter 32, Behaviour of the air valve in the

event of a fault lock-out.

PFU 780 · Edition 02.12l 35

Page 36

Parameters

Restart following flame failure

Parameter 12 = 1:

Restart following flame failure.

1x

88

04 04 03 01

30a

26e

ϑ1

10e

28c

1

26a

16c

>2 s

t

t

SB

t

Z

t

t

W

SA1

FS1

If the PFU detects a flame failure after a minimum operating time of 2 s, the valves are closed and the operation signalling contact is opened within time tSB.

The burner control unit now attempts to restart the

burner once. If the burner does not function, a fault

lock-out occurs. The display blinks and shows the

cause of the fault.

In accordance with EN 7462, a restart may be conducted only if the safety of the installation is not impaired. Restart is recommended for burners which occasionally display unstable behaviour during operation.

The precondition for a restart is that activation of the

restart allows the burner to restart as intended (in all

operating phases). In this case, it must be ensured that

the program sequence started by the PFU matches the

application.

2c–4c

2e–4e

V1

1

t

PFU 780 · Edition 02.12l 36

Page 37

Parameters

S

▼

4.6.3 Fault lock-out or restart, main burner

This parameter determines whether the PFU starts a

one-off restart or performs an immediate fault lock-out

for the main burner after a flame failure (see also Project planning information).

Immediate fault lock-out following flame failure

Parameter 13 = 0:

Main burner fault lock-out

08

08

t

B

88

30a

26e

10e

28c

16c

26a

2c–4c

14a

18e

18a

6a–6e

2e–4e

ϑ1

V1

1

1

ϑ2

V2

2

2

t

After a flame failure, the burner control unit performs

a fault lock-out within the safety time during operation

tSB. This involves disconnecting the power from the gas

valves and the ignition transformer. The fault signalling

contact closes, the display blinks and shows the current

program status (see table “Program status and fault

messages”).

After a fault lock-out, the burner control unit can be

reset, either with the button on the front panel or using

an external button. Several burner control units can be

reset in parallel using the external button.

The PFU cannot be reset by mains failure. The fault

signalling contact does, however, open as soon as the

mains voltage fails.

See also “Behaviour of the air valve in the event of a

fault lock-out”.

PFU 780 · Edition 02.12l 37

Page 38

Parameters

Restart following flame failure

Parameter 13 = 1:

Restart following flame failure.

1x

08

>2 s

06

05

t

SB

t

t

W2

SA2

07

08

t

FS2

88

30a

26e

10e

28c

16c

26a

2c–4c

14a

18e

18a

6a–6e

2e–4e

ϑ1

V1

1

1

ϑ2

V2

2

2

t

If the PFU detects a flame failure after a minimum operating time of 2 s, valve V2 is closed and the operation

signalling contact is opened within time tSB.

The burner control unit now attempts to restart the

main burner once. If the burner does not function, a

fault lock-out occurs. The display blinks and shows the

cause of the fault.

In accordance with EN 7462, a restart may be conducted only if the safety of the installation is not impaired. Restart is recommended for burners which occasionally display unstable behaviour during operation.

The precondition for a restart is that activation of the

restart allows the burner to restart as intended (in all

operating phases). In this case, it must be ensured that

the program sequence started by the PFU matches the

application.

PFU 780 · Edition 02.12l 38

Page 39

Parameters

4.7 Air valve control PFU..L

Parameter 30, Behaviour of the air valve during operation

Parameter 31, Behaviour of the air valve during start-up

Parameter 32, Behaviour of the air valve in the event of

a fault lock-out

The PFU..L features an adjustable air valve control. The

display shows that purging is currently being carried

out with

tivated for cooling or heating.

The PFU..L supports the following functions:

– Purge

– Cooling in start-up position/standby

– Switching of the burner between low and high burner

output during operation via the air valve

– To start up the burner as intended, external activation

of the air valve can be blocked during start-up (prevents synchronisation problems between the PFU

and the central control system)

– Controlling the air valve so that it

– opens with valve V2,

– opens once the main burner has reached its operat-

ing position

– Low fire over run time t

P 0

. A indicates that the air valve is being ac-

after a normal shut-down

KN

4.7. 1 Purge

Parameter 42 = 0: The air valve is closed when voltage is

applied to terminal 30e.

Parameter 42 = 1: The air valve is opened when voltage

is applied to terminal 30e.

In the case of multiple burner applications, burners with

mechanical combustion air supply are used. The air for

combustion and pre-purge is supplied by a central fan

controlled by a separate logic. This logic determines the

purging time.

The PFU..L supports centrally-controlled pre-purge or

post-purge. The PFU..L is informed that purging is currently being performed by input 30e. It then opens the

air valve, regardless of the status of the other inputs

(purging has priority). The display indicates

PFU 780..K2: For purging, the safety interlock (limits)

must activate input 26e and input 30e of the PFU.

4.7. 2 Cooling in start-up position/standby

The air valve can be activated externally via input 10a

for cooling in the start-up position. During activation of

the air valve the display shows

ing is currently being carried out.

4.7.3 Burner start

Parameters 30 and 31 determine the behaviour of the

air valve during burner start.

A 0

, indicating that cool-

P 0

.

PFU 780 · Edition 02.12l 39

Page 40

Parameters

PFU 780

A

P

L1

1

2

SPS

PLC

CPE

ϑ

VR..R

VAG

TZI

2

1

UV

VAS

4.7. 4

Air valve opens in the c ase of exter nal activation ( not

during start-up)

00 A0 00

A0

03

02

t

t

Z

t

SA1

06

04

t

t

FS1

SA2

FS2

88

A807

30a

26e

10e

28c

16c

26a

2c–4c

14a

18e

18a

6a–6e

10a

22e

2e–4e

Parameter 30 = 0:

The air valve opens if it is activated externally by input 30e.

Parameter 31 = 0:

The air valve remains closed during start-up

ϑ1

V1

1

1

ϑ2

V2

2

2

A

t

even if it is activated externally.

These settings are required on burners on which the

gas/air ratio is controlled via a pneumatic link and

which also need to be started at low fire, e.g. on twostage-controlled burners. In this case, activation of the

air valve during burner start via input 10a must be prevented.

External control allows switchover between low fire and

high fire during operation.

The air valve can be activated externally via input 10a

for cooling the burner in the start-up position/standby.

PFU 780 · Edition 02.12l 40

Page 41

Parameters

SA1

4.7. 5 Air valve opens in the case of external activation (even during start-up)

00 A0 00

A0

A2

L1

A4

FS1

PFU 780..L

VAS 1

VAG

A6

t

SA2

TZI

t

FS2

1

2

1

2

A3

t

t

Z

t

ϑ

A

P

88

A8 A7

30a

26e

ϑ1

10e

28c

V1

16c

1

26a

1

2c–4c

ϑ2

14a

V2

18e

2

18a

2

6a–6e

A

10a

22e

2e–4e

t

UV

Parameter 30 = 0:

The air valve opens if it is activated externally via input 10a.

Parameter 31 = 1:

The air valve can be activated even during start-up.

These settings may be selected only if the burner can

start with full air capacity.

The air valve can be activated externally via input 10a

for cooling the burner in the start-up position/standby.

VAS

PFU 780 · Edition 02.12l 41

Page 42

Parameters

SA1

4.7. 6 Air valve opens with valve V2

00 A0

00

02

L1

03

t

t

Z

t

ϑ

A

P

A6

04

t

FS1

PFU 780..L

SA2

TZI

VBY

VAG

1

t

FS2

1

2

2

SPS

PLC

CPE

Parameter 30 = 2:

88

A8 A7

30a

26e

ϑ1

10e

28c

V1

16c

1

26a

1

2c–4c

ϑ2

14a

V2

18e

2

18a

2

6a–6e

A

10a

22e

2e–4e

t

The air valve opens simultaneously with valve V2.

Application:

Single-stage-controlled main burner is switched ON/

OFF via the ϑ input.

The air valve can be activated externally via input 10a

for cooling the burner in the start-up position/standby.

VR..R

PFU 780 · Edition 02.12l 42

Page 43

Parameters

4.7.7 Air valve opens with operating signal

04

06

t

SA

ϑ

L1

A

P

t

FS

PFU 780..L

TZI

VBY

VAG

1

88

A8 07

30a

26e

ϑ1

10e

28c

V1

16c

1

26a

1

2c–4c

ϑ2

14a

V2

18e

2

18a

2

6a–6e

A

10a

22e

2e–4e

t

1

SPS

2

PLC

CPE

2

Parameter 30 = 3:

The air valve opens simultaneously with the operating

signal.

Application:

Two-stage-controlled main burner is switched ON/OFF

via the ϑ input.

The air valve can be activated externally via input 10a

for cooling the burner in the start-up position/standby.

VR..R

PFU 780 · Edition 02.12l 43

Page 44

Parameters

KN

PFU 780..L

A

L1

1

SPS

ϑ

4.7. 8

Low fire over run time tKN after a nor mal shut-down

A8

t

P

VG..N

VAS 1

GIK..B

VR..R

88

00

30a

26e

ϑ1

10e

28c

16c

26a

2c–4c

ϑ2

14a

18e

18a

6a–6e

22e

2e–4e

2

PLC

CPE

TZI

1

2

Parameter 36

Settings: 0; 3; 5; 10; 15; 25 or 60 (low fire over run time

in seconds)

This parameter is applicable to systems with a pneu-

V1

1

1

V2

2

2

matic link between gas and air and On/Off control.

Parameter 36 = 0 (low fire over run time t

KN

= 0 s):

Without low fire over run, the gas side is closed immediately owing to the quick-closing gas valve in the case

of On/Off control. The air side closes more slowly. The

t

air flowing in during the closing time increases the O2

content in the combustion chamber.

Parameter 36 = 3; 5; 10; 15; 25 or 60 (low fire over run

time t

= 3, 5, 10, 15, 25 or 60 s):

KN

The air valve closes slowly after the activation signal

has been switched off. The gas valve remains open for

tKN. This means that the burner, after deactivation of

the main burner start-up signal (ϑ2), is initially adjusted

down to low fire and then switched off completely.

Using the low fire over run function reduces the O

con-

2

tent in the furnace atmosphere.

Flame control is still operational. Can be used only in

the case of pneumatic link and On/Off control. It must

be ensured that no excess gas occurs.

The low fire over run time has an effect on the behaviour

of the main burner only.

Background: The pilot burner is only used in single-

stage operation.

PFU 780 · Edition 02.12l 44

Page 45

Parameters

4.7. 9

Behaviour of the air valve in the event of a fault lock-

out

Parameter 32:

This determines whether the air valve can be activated

in the case of a fault lock-out.

Parameter 32 = 0:

The air valve is closed in the event of a fault. It cannot be

activated externally via terminal 10a.

Parameter 32 = 1:

The air valve can be activated externally via input 10a

even during a fault, e.g. for cooling.

PFU 780 · Edition 02.12l 45

Page 46

Parameters

4.8 Manual operation

For convenient setting of the burner or analysing faults.

The parameter display is not available in Manual mode.

Manual mode can be accessed only if the unit was not

in Fault state before switching off. The following times/

functions are not active in Manual mode: start-up attempts, restart, minimum combustion time and cycle

lock.

If the Reset /Information button is pressed for 2 s during switch-on, the PFU reverts to Manual mode. Two

dots blink on the display.

In this operating mode, the burner control unit operates

independently of the status of the inputs (apart from

the pre-purge input and the safety interlocks. These are

of higher priority and will be processed first).

Each time after the button is pressed again, the PFU

moves to the next section of the program sequence

and stops there. After approx. 3 s, the flame signal will

be displayed instead of the program parameter. Briefly

pressing the Reset/Information button (< 1 s) displays

the relevant Manual mode step. If there is flame simulation during the start-up, the flame signal is displayed

immediately.

On units with air valve control, the air valve can be

opened and closed repeatedly by pressing the button

during operation.

Manual mode can be terminated by switching off the

PFU (On/Off button).

4.8.1 Manual mode limited to 5 minutes

Parameter 34:

Parameter 34 determines when Manual mode is termi-

nated.

Parameter 34 = 0:

Manual mode is not limited in time. If this function has

been selected, operation of the furnace may be continued manually in the event of failure of the central control system.

Parameter 34 = 1:

Manual mode ends automatically five minutes after the

last time the button was pressed. The PFU then moves

abruptly back to start-up position/standby.

PFU 780 · Edition 02.12l 46

Page 47

Parameters

4.9 Password

Parameter 50:

(Four-digit) password saved to protect parameter

settings. To prevent unauthorised changes to parameter settings, a password is stored in parameter 50.

Changes to parameter settings can only be made once

this number has been entered. The password can be

changed using BCSoft.

Note the effect of parameter settings on the safe functioning of your system.

The password set at the factory can be found in the de-

livery note supplied.

PFU 780 · Edition 02.12l 47

Page 48

Selection

5 Selection

5.1 Calculating the safety time tSA

PFU 780 · Edition 02.12l 48

Page 49

Selection

PF U 780LT

5.2 Selection table

Type L T N D* U* K2*

PF U 780

* If “none”, this specifi cation is omitted.

= standard, = available

Order example

5.2.1 Type code

Code Description

L Air valve control

T

N

D* Digital input to interrupt fl ame control

U* Preparation for UV sensor for continuous operation UVD 1

K2* Compatible with PFU 798

* If “none”, this specifi cation is omitted.

220–240 V~, 15/+10 %, 50/60 Hz

110–120 V~, 15/+10 %, 50/60 Hz

Mains voltage

PFU 780 · Edition 02.12l 49

Page 50

Project planning information

6 Project planning information

6.1 Cable selection

Use mains cable suitable for the type of operation and

complying with local regulations. Do not route PFU

cables in the same cable duct as frequency converter

cables or cables emitting strong fields.

6.1.1 Ignition cable

Use unscreened high-voltage cable, see page 56

(Accessories). Cable length: max. 5 m, recommended

< 1 m. Screw the ignition cable securely into the ignition

transformer and run to the burner by the shortest possible route.

The longer the ignition cable, the lower the ignition

capacity. Only use radio interference suppressed electrode adapters (with 1 kΩ resistor) for ignition electrodes, see see page 56 (Accessories) . Do not lay

UV/ionisation cable and ignition cables together and

lay them as far apart as possible.

6.1.2 Ionisation cable

Use unscreened high-voltage cable, see page 56

(Accessories) . Cable length: max. 100 m. Avoid external electrical interference. Install as far as possible

from mains and ignition cables and interference from

electro-magnetic sources. If possible, do not lay in a

metal conduit. Several ionisation cables can be routed

together.

6.1.3 UVLeitung

Cable length: max. 100 m. Avoid external electrical

interference. Install as far as possible from mains and

ignition cables and interference from electro-magnetic

sources. If possible, do not lay in a metal conduit. Several UV cables can be routed together.

6.2 Ignition electrode

6.2.1 Electrode gap

Gap between electrode and burner earth:

2 mm ± 0.5 mm.

6.2.2 Star electrodes

We recommend using 7.5 kV ignition transformers on

burners with star electrodes.

PFU 780 · Edition 02.12l 50

Page 51

Project planning information

6.3 Minimum combustion time

Even if the start-up signal (ϑ) is applied only briefly, the

time set under parameter 20 elapses before the burner

control unit shuts down the burner or signals a fault. To

stabilise the burner operation, a minimum combustion

time can be set independently of the central control

system. If the start-up signal (ϑ) drops once the sec-

ond safety time t

remains in operation for at least time tB. The minimum

combustion time tB starts to elapse following controller

enable. If the start-up signal drops before the second

safety time t

SA2

reverts directly to standby and the burner is not ignited.

The signal inputs for the pilot /main burner start-up sig-

nal cannot be used for a safety shut-down because the

unit controls the valves until the minimum combustion

time has elapsed.

04 06 07

has started to elapse, the burner

SA2

, e.g. during pre-purge, the control unit

88

30a

26e

ϑ1

10e

V1

16c

1

26a

1

2c–4c

ϑ2

14a

18e

V2

2

18a

2

6a–6e

2e–4e

t

B

t

haviour of the main burner. The minimum combustion

time for the pilot burner is limited to the safety time on

star t-up (t

SA1

).

Background: The pilot burner is only used in single-

stage operation.

6.4 Safety interlocks (Limits)

The limiters in the safety interlock (linking of all the rel-

evant safety control and switching equipment for the

use of the application, e.g. safety temperature limiter,

minimum and maximum gas pressure, tightness control) must isolate terminal 26e from the voltage supply.

If the safety interlock is interrupted, this is indicated by

a blinking

If the safety interlocks fail, an immediate program abort

with switch-off of all outputs occurs (even during the

safety time). If the safety interlocks are operational

again or the unit is switched back on, the program run is

restarted in standby.

51

on the display.

In the case of pilot/main burner monitoring, the minimum combustion time only has an effect on the be-

PFU 780 · Edition 02.12l 51

Page 52

Project planning information

6.5 Emergency stop

6.5.1 In the event of fire or electric shock

If there is a risk of fire, electric shock or similar, inputs

L1, N and 26e (safety interlocks) of the PFU should be

disconnected from the electrical power supply–this

should be reflected in the wiring on site.

6.5.2 Via the safety interlocks (limits)

The safety interlock turns off the power to input 26e,

such as in the event of air deficiency or similar.

6.6 Reset

6.6.1 Parallel reset

Several burner control units can be reset in parallel using the external button. The PFU cannot be reset by

mains failure.

6.6.2 Permanent remote reset

Permanent remote reset gives rise to a malfunction. If a

remote reset signal is permanently applied to terminals

52

10c/12c,

Reset with a pulse < 1 s.

6.6.3 Automatic remote reset (PLC)

In the case of automatic remote reset (PLC), the reset

pulse duration should not exceed 1 second. Check

compliance with standards.

If a fault is acknowledged by remote reset too often, er-

10

ror

flashes on the display to indicate a fault.

(Too many remote resets) is displayed. The error

can only be acknowledged with the Reset /Information

button on the unit.

The burner malfunction must be remedied. The malfunction can not be remedied by changing the method

of activation.

6.6.4 Burner start

A furnace start may only be initiated, if it has been en-

sured using an appropriate procedure that there is no

combustible mixture in the combustion/processing

chamber, in the connected areas or in the exhaust gas

system (heat exchanger, dust collector). This can be

achieved by pre-purge, which occurs immediately be-

fore ignition or within the period specified in the operat-

ing instructions.