Honeywell MV876B1018 F76S User Manual

F76S Water Filters and

MV876B Automatic-Backwash Controls

PRODUCT DATA

MV876B1018 (Bayonet fitting for F76S)

MV876B1000

(for F76A,G)

F76S

FEATURES

F76

•Built-in backwash impeller provides efficient cleaning with supply pressures as low as 22 psi.

•Increased flow capacity on 1/2 in. to 1-1/4 in. models provides lower pressure drop.

•Robust backwash mechanism.

•No shut-off or disassembly is required for cleaning.

•During backwash, the F76S continues to supply filtered water without interruption through a secondary screen.

•Memory ring indicates when the next manual backwash is due.

MV876

•MV876B1018 bayonet fitting simplifies upgrade to automatic backwash.

•16 field-selectable backwash intervals (from every four minutes to once every three months) on the MV876B eliminate need for external timer.

•Connections for external control on the MV876B provide for use in automated systems and differential pressure control.

•MV876B can be turned manually to initiate backwash.

•Battery (AA) backup to insure completion of backwash cycle in spite of power loss.

APPLICATION

The F76S is a high flow capacity water filter used at point-of- entry (POE) to remove sediment and debris from residential or commercial water systems. Used as a prefilter, the F76S protects elements of the water system, including specialized treatment devices such as taste/odor or reverse osmosis (R/O) or other common fixtures and appliances. The flow, filtering capacity, and ease of cleaning make the F76S the ideal filter for the most demanding applications.

The MV876 Automatic-Backwash Control is available as an accessory. This control is fitted to the drain valve and is programmed by the user to automatically perform the backwash function according to the desired interval.

|

Contents |

Application ........................................................................ |

1 |

Features ........................................................................... |

1 |

Specifications ................................................................... |

2 |

Ordering Information ........................................................ |

2 |

Planning the Installation ................................................... |

4 |

Installation ........................................................................ |

5 |

Wiring ............................................................................... |

8 |

Operation .......................................................................... |

8 |

F76S Replacement Parts List ........................................... |

10 |

F76A,G Replacement Parts List ....................................... |

12 |

® U.S. Registered Trademark

Copyright © 1999 Honeywell Inc. • All Rights Reserved |

623015- 4 |

F76S WATER FILTERS AND MV876B AUTOMATIC-BACKWASH CONTROLS

SPECIFICATIONS

F76S:

Models:

Water filters with 100 micron screens and hose connections. F76S1007: 1/2 in. sweat and NPT threaded tailpieces. F76S1015: 3/4 in. sweat and NPT threaded tailpieces. F76S1023: 1 in. sweat and NPT threaded tailpieces. F76S1031: 1-1/4 in. sweat and NPT threaded tailpieces. F76S1049: 1-1/2 in. NPT threaded tailpieces. F76S1056: 2 in. NPT threaded tailpieces.

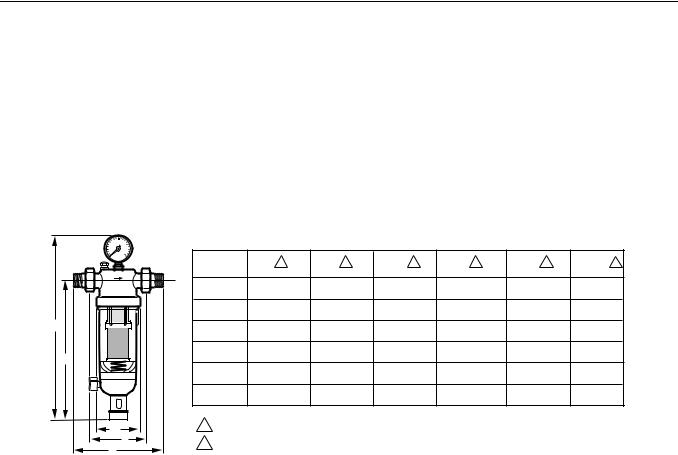

Dimensions: See Fig. 1.

Materials of Construction:

Body: Brass.

Screen: Stainless Steel.

Internal Construction: Acetal Copolymer.

Seals: NBR.

Ball Valve: Brass with PTFE Seals.

Sump: Engineered Plastic.

NOTE: Bronze sump available.

Inlet Pressure:

Minimum: 22 psi (with unrestricted backwash discharge). Maximum:

Plastic Sump: 232 psi. Bronze Sump: 400 psi.

NOTE: Pressures above 200 psi require an inlet pressure gauge with a range wider than the standard.

Differential: Maximum Recommended: 42 psi.

Operating Pressure Drop: Maximum Recommended: 3 psi (with clean screen).

Temperature (maximum):

Plastic Sump: 104°F (40°C).

Bronze Sump: 158°F (70°C).

Pipe Sizes (in in.): 1/2, 3/4, 1, 1-1/4, 1-1/2, and 2.

Connections: Union on inlet and outlet: External NPT threaded or sweat.

Capacity: See Table 1.

Screen Sizes:

Shipped with Device: 100 microns.

Available Kits: 20, 50, and 200 microns.

NOTE: 20 microns = 900 mesh (approximate). 50 microns = 350 mesh (approximate). 100 microns = 175 mesh (approximate). 200 microns = 70 mesh (approximate).

MV876 Automatic-Backwash Controls:

Models:

MV876B1000: Valve with 24 Vac motor and timer replaces ball valve drain port for automatic backwash at preprogrammed intervals. 24V transformer not included. For use with F76A,G Filters only.

MV876B1018: Bayonet mounted shaft of 24 Vac motor and timer replaces ball valve manual control for automatic backwash at preprogrammed intervals. 24V transformer not included. For use with F76S Filters only.

Specifications:

Power: 4 VA.

Current: 170 mA.

Voltage: 24 Vac.

Cycle time: 20 seconds (approximate).

Timer: Variable. See Table 2.

Accessories (for F76S only except where noted):

0900747 Sump O Ring Kit (10 O rings) for 1/2 to 1-1/4 in. F76S. 0900748 Sump O Ring Kit (10 O rings) for 1-1/2 to 2 in. F76S. 0901444 Gasket Package (10 gaskets) for any 1/2 in. and

3/4 in. F76.

0901445 Gasket Package (10 gaskets) for any 1 in. F76. 0901446 Gasket Package (10 gaskets) for any 1-1/4 in. F76. 0901447 Gasket Package (10 gaskets) for any 1-1/2 in. F76. 0901448 Gasket Package (10 gaskets) for any 2 in. F76. AF11S-1A Screen insert (100 microns) for 1/2 to 1-1/4 in. F76S. AF11S-112A Screen insert (100 microns) for 1-1/2 to 2 in. F76S. AF11S-1B Screen insert (20 microns) for 1/2 to 1-1/4 in. F76S. AF11S-112B Screen insert (20 microns) for 1-1/2 to 2 in. F76S. AF11S-1C Screen insert (50 microns) for 1/2 to 1-1/4 in. F76S.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or phone:

1.Your local Home and Building Control Sales Office (check white pages of your phone directory).

2.Home and Building Control Customer Logistics

Honeywell Inc., 1885 Douglas Drive North Minneapolis, Minnesota 55422-4386 (612) 951-1000

In Canada—Honeywell Limited/Honeywell Limitée, 155 Gordon Baker Road, North York, Ontario M2H 3N7.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

62-3015—4 |

2 |

F76S WATER FILTERS AND MV876B AUTOMATIC-BACKWASH CONTROLS

Accessories (continued):

AF11S-112C Screen insert (50 microns) for 1-1/2 to 2 in. F76S. AF11S-1D Screen insert (200 microns) for 1/2 to 1-1/4 in. F76S. AF11S-112D Screen insert (200 microns) for 1-1/2 to 2 in. F76S. KF11S-1A Clear Plastic Filter Sump Kit for 1/2 to 1-1/4 in. F76S. KF11S-112A Clear Plastic Filter Sump Kit for 1-1/2 to 2 in. F76S. FT09RS-1A Bronze Filter Sump Kit for 1/2 to 1-1/4 in. F76S.

FT09RS-112A Bronze Filter Sump Kit for 1-1/2 to 2 in. F76S. KH11S-1A Ball Valve Assembly for 1/2 to 2 in. F76S. M76K-200 Pressure Gauge, 200 psi maximum.

M76K-400 Pressure Gauge, 400 psi maximum. U76S5007 Sweat Tailpiece for any 1/2 in. F76. U76S5015 Sweat Tailpiece for any 3/4 in. F76. U76S5023 Sweat Tailpiece for any 1 in. F76.

U76S5031 Sweat Tailpiece for any 1-1/4 in. F76. U76S5039 Sweat Tailpiece for any 1-1/2 in. F76. U76S5047 Sweat Tailpiece for any 2 in. F76.

U76T1004 Threaded Tailpiece for any 1/2 in. F76. U76T1014 Threaded Tailpiece for any 3/4 in. F76. U76T1022 Threaded Tailpiece for any 1 in. F76.

U76T1030 Threaded Tailpiece for any 1-1/4 in. F76. U76T1038 Threaded Tailpiece for any 1-1/2 in. F76. U76T1046 Threaded Tailpiece for any 2 in. F76.

ZR10K-1 Sump Wrench for any 1 in. or 1-1/4 in. F76. ZR10K-112 Sump Wrench for any 1-1/2 in. or 2 in. F76. ZR10K-12 Sump Wrench for 1/2 in. and 3/4 in. F76A,G. ZR10K-34 Sump Wrench for 1/2 in. and 3/4 in. F76S.

|

100 |

|

|

|

|

|

|

|

50 |

150 |

|

|

|

|

|

|

|

0 |

200 |

|

|

|

|

|

|

|

|

Honeywell |

|

|

|

|

|

|

|

|

Braukmann |

|

L 1 |

l 1 |

D 1 |

H 1 |

h 1 |

|

|

|

SIZE |

WEIGHT 2 |

|||||

|

|

1/2 INCH |

6-11/16 (170) |

4-5/16 (110) |

3-13/16 (97) |

17-11/16 (449) |

13-13/16 (350) |

6.4 (2.9) |

|

|

3/4 INCH |

7 (178) |

4-5/16 (110) |

3-13/16 (97) |

17-11/16 (449) |

13-13/16 (350) |

6.4 (2.9) |

H |

|

1 INCH |

8-1/4 (209) |

5-1/8 (130) |

3-13/16 (97) |

17-7/8 (453) |

13-13/16 (350) |

6.8 (3.1) |

|

|

|||||||

h |

|

1-1/4 INCH |

8-3/4 (222) |

5-1/8 (130) |

3-13/16 (97) |

17-7/8 (453) |

13-13/16 (350) |

7.3 (3.3) |

|

|

|

|

|

|

|

|

|

|

|

1-1/2 INCH |

9-11/16 (246) |

5-15/16 (150) |

4-3/4 (119) |

20-15/16 (532) |

16-7/16 (417) |

8.8 (4.0) |

|

|

2 IINCH |

10-1/2 (267) |

5-15/16 (150) |

4-3/4 (119) |

20-15/16 (532) |

16-7/16 (417) |

10.6 (4.8) |

D |

1 DIMENSIONS IN INCHES AND (MILLIMETERS). |

|

|

|

||||

|

|

|

|

|

|

|

||

|

l |

2 WEIGHT IN POUNDS AND (KILOGRAMS). |

|

|

|

M18084 |

||

L |

|

|

|

|||||

|

|

|

|

|

|

|

||

Fig. 1. F76S Dimensions.

Table 1. Capacity in Gallons Per Minute (gpm).

|

|

|

|

|

|

|

Pressure Drop |

|

|

Pipe Size (in.) |

|

||

|

|

|

|

|

|

|

(psi) Across Filter |

1/2 |

3/4 |

1 |

1-1/4 |

1-1/2 |

2 |

|

|

|

|

|

|

|

1 |

8 |

11 |

18 |

20 |

26 |

30 |

|

|

|

|

|

|

|

2 |

12 |

16 |

25 |

28 |

36 |

42 |

|

|

|

|

|

|

|

3 |

14 |

19 |

31 |

35 |

44 |

51 |

|

|

|

|

|

|

|

4 |

16 |

22 |

36 |

40 |

51 |

59 |

|

|

|

|

|

|

|

5 |

18 |

25 |

40 |

45 |

57 |

66 |

|

|

|

|

|

|

|

15 |

32 |

43 |

70 |

78 |

99 |

114 |

|

|

|

|

|

|

|

Flow Volume for 15 sec backwash at 60 psi inlet |

|

|||||

|

|

|

|

|

|

|

— |

3.2 |

3.2 |

4.0 |

4.0 |

4.7 |

4.7 |

|

|

|

|

|

|

|

NOTE: Cv is equal to capacity at 1 psi pressure drop.

Table 2. MV876B Timer Selections.

|

|

Program Value |

Backwash Interval |

1 |

4 minutes |

|

|

2 |

8 minutes |

|

|

3 |

16 minutes |

|

|

4 |

32 minutes |

|

|

5 |

1 hour |

|

|

6 |

2 hours |

|

|

7 |

4 hours |

|

|

8 |

8 hours |

|

|

9 |

17 hours |

|

|

10 |

34 hours |

|

|

11 |

3 days |

|

|

12 |

6 days |

|

|

13 |

11 days |

|

|

14 |

23 days |

|

|

15 |

45 days |

|

|

16 |

3 months |

|

|

3 |

62-3015—4 |

F76S WATER FILTERS AND MV876B AUTOMATIC-BACKWASH CONTROLS

PLANNING THE INSTALLATION

The F76S should be sized based on the required flow rate and the resulting pressure drop across the filter. As a guideline for most applications, the F76S should be sized to avoid pressure drops exceeding 3 psi.

EXAMPLE:What size F76S is required to provide a flow rate of 30 gpm? Reading across Table 1 at

3 psi pressure drop, a 1 in. filter can provide 31 gpm without exceeding 3 psi pressure drop.

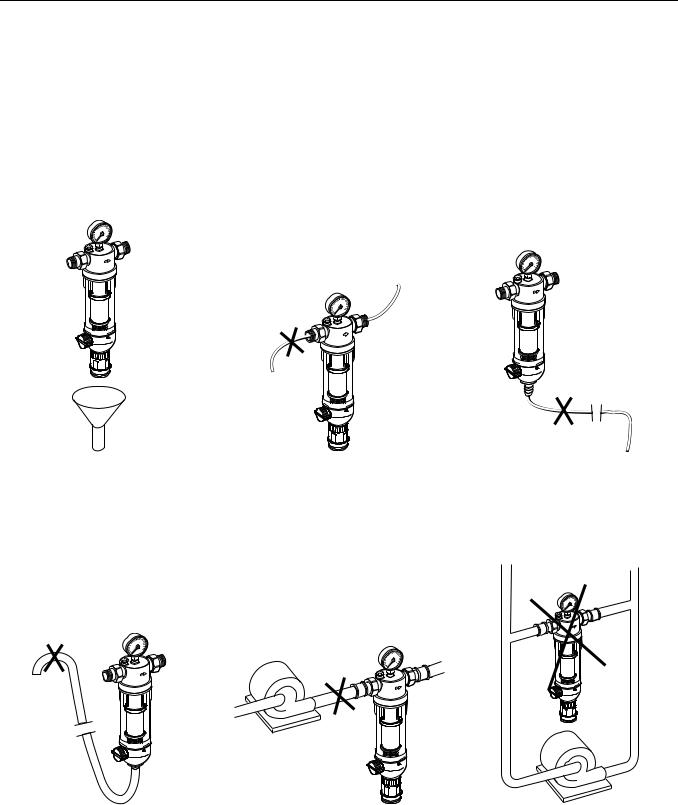

An increased pressure drop across the filter results when higher velocities are maintained to increase the capacity through any given size filter. Severe pressure drops will be encountered as capacity approaches that of the pipe size. To ensure the backwash cycle operates properly and cleaning action is not reduced, follow all recommendations in Fig. 2. Refer to Fig. 2a for an ideal installation.

NOTE: All filter installations are different. The size, type, and amount of dirt and debris and the flow rate must always be considered when choosing a screen and deciding to install multiple F76 Water Filters in parallel.

100 150

50

200 0

100  150

150

50

50

200  0

0

100  150

150

50

50

200  0

0

M16488 |

M16489 |

M16490 |

|

||

Fig. 2a. Ideal F76S installation. A funnel |

Fig. 2b. Ensure the inlet pipe is not |

Fig. 2c. Ensure the backwash outlet |

mounted directly under the backwash |

downsized. Do not use 1/4 or 3/8 inch |

pipe is not downsized, long, or |

port is the best installation layout. |

tubing on 1/2 or 3/4 inch models. |

crimped. Instead, install a short |

|

|

oversized pipe on the backwash outlet. |

|

|

Do not use a low capacity solenoid |

|

|

valve to automate the backwash cycle. |

100  150

150

50

50

200  0

0

100 150

50

200 0

100 150

50

200 0

M16491 |

M16492 |

M16478 |

|

||

Fig. 2d. Ensure the backwash outlet is |

Fig. 2e. Ensure the F76S is not used |

Fig. 2f. Ensure the F76S is not |

not raised above the F76S. If the |

with an undersized pump. An |

installed in a bypass across a pump. |

backwash outlet must be raised above |

undersized pump may not provide |

|

the F76S, increase inlet pressure 5 psi |

proper pressure or flow. |

|

for every 10 feet that it is raised. |

|

|

|

Fig. 2. Installation recommendations. |

|

62-3015—4 |

4 |

F76S WATER FILTERS AND MV876B AUTOMATIC-BACKWASH CONTROLS

Commercial and Industrial Installations (1-1/2 and 2 in. models)

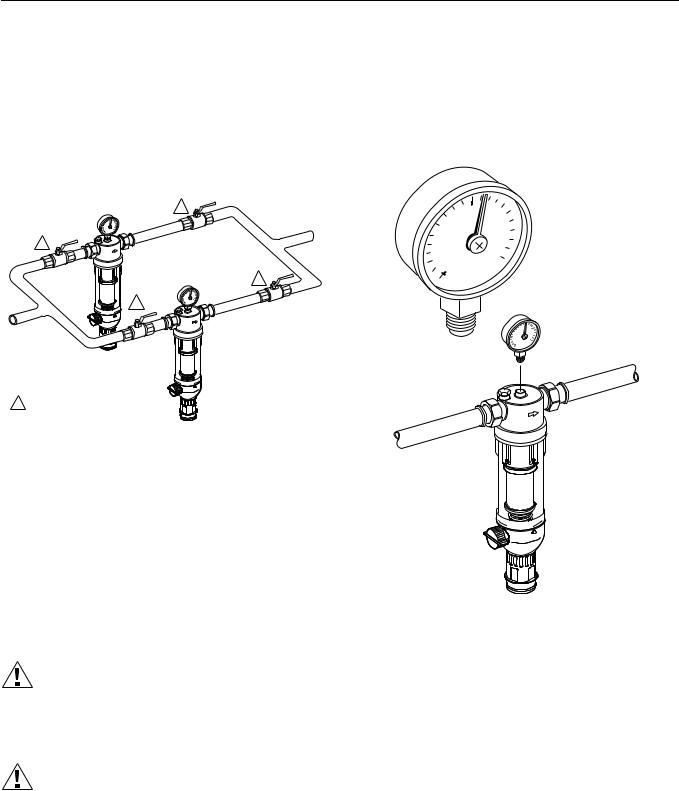

Commercial and industrial installations have high flow requirements. For proper operation, limit flow across the F76S screen. For example, a two-inch pipe may have a 120 gpm flow at 12 fps linear velocity across a clean screen. High linear velocity impacts dirt deeply into the screen, making it difficult to backwash and causing the screen to plug up quickly. In these situations, install multiple F76 filters in parallel. See Fig. 3.

1

100 150

50

200 0

1

1

100 150

50 200

1 |

0 |

INLET

PIPE

1 ISOLATION VALVE. |

M17360 |

Fig. 3. Parallel installation of three F76S Water Filters.

Advantages of parallel installation:

•Increased cleaning capacity. Backwash interval is reduced.

•Elimination of system downtime. Can backwash one F76S while the others maintain required flow.

Another consideration in commercial and industrial installations is the backwash interval. Because of the high flow requirements, screens need cleaning on a regular basis. An MV876 Automatic-Backwash Control can be installed to backwash the F76S automatically.

INSTALLATION

CAUTION

Equipment Damage Hazard.

Excessive pressure or temperature can damage the device.

Ensure water temperature and pressure are below maximum ratings specified.

CAUTION

Equipment Damage Hazard.

Excessive heating can damage internal parts.

Before sweating, separate the tailpieces and nuts from the filter body.

F76S

When installing an F76S, use the following procedure:

1.Shut off water supply by closing the water supply valve.

2.Install the F76S in the water line with the arrow pointing

in the direction of water flow.

3.Install pressure gauge in the F76S center port (see Fig. 4).

IMPORTANT

When using an MV876, stop here and install the MV876.

4.Ensure the F76S air vent is open.

5.Slowly open the water supply valve.

6.Once the F76S sump fills with water, close the air vent and fully open the water supply valve.

100  150

150

50

50

200 0

0

Honeywell

Braukmann

100 150

50

200

0 Honeywell Braukmann

M16480

Fig. 4. Installing the F76S.

MV876

When adding an MV876 to an existing F76, the procedure can vary depending on the F76 model.

Installation on an F76S

1.Open the backwash outlet ball valve.

2.Remove the backwash outlet handle.

3.Install the MV876. See Fig. 5 and 6.

NOTE: When you rotate the MV876, it closes the backwash outlet ball valve.

4.Ensure the F76S air vent is open.

5.Slowly open the water supply valve.

6.Once the F76S sump fills with water, close the air vent and fully open the water supply valve.

7.Program the desired backwash interval by pushing the program button until the desired interval number

appears in the display.

5 |

62-3015—4 |

Loading...

Loading...