Honeywell L8124A, L8124C, L8124E, AQUASTAT L8124L, L8124M User Manual

L8124A,C,E,L and M

Aquastat® Relays

|

INSTALLATION INSTRUCTIONS |

APPLICATION |

SPECIFICATIONS |

These immersion type controllers are used with forced hydronic heating systems that include domestic hot water service. All models provide high limit, low limit and circulator control. Table 1 lists the various models and their applications.

These Aquastat® relays have a diaphragm powerhead and MicroSwitch™ assembly that respond to temperature changes in the boiler water. L8124 can provide multizone control by using a separate circulator and R845 Relay for each zone. L8124E and L have large transformers and extra terminals for supplying power to low voltage valves. L8124L includes a large transformer and extra terminals for low voltage zone valves. L8124M is for use in a wood-coal/gas-oil multifuel heating system. Circulator is independently controlled by the thermostat.

Do not use these Aquastat® Relays where the pressure can exceed 100 psi (690 kPa) on the bulb if inserted directly or 200 psi (1380 kPa) when using an immersion well, or where the ambient temperature can exceed 150°F (66°C) at the case or 265°F (129°C) at the sensing element.

Low Limit:

Setting: 110°F to 220°F (43°C to 104°C), adjustable. Differential: 10°F to 25°F (6°C to 14°C), adjustable.

High Limit:

Setting: 130°F to 240°F (54°C to 116°C), adjustable. Differential: 10°F (6°C), fixed.

WARNING

WARNING

Explosion Hazard.

Can cause serious injury, death or property damage.

Use this product only in systems with a pressure relief valve.

Table 1. Model Descriptions.

|

|

Can Be Used For |

No. of V8043 Zone |

Electrical Ratings |

|

|

Burner |

Valves Powered |

|

|

|

Model |

Control |

Multizone With |

Without Additional |

|

|

Number |

Circuit |

Circulatorsa |

Transformer |

Burner Circuit |

Circulator Circuit |

L8124A |

120V |

Yes |

— |

Same as L8124A,C,L |

120 Vac: 7.4A (full load), |

|

|

|

|

circulator rating. |

44.4A (locked rotor). |

L8124C |

|

|

|

||

|

|

|

|

240 Vac: 3.7A (full load), |

|

|

|

|

|

|

|

L8124L |

|

|

3 |

|

22.2A (locked rotor). |

L8124E |

24V |

|

2 |

1.25A at 24 Vac; 30 VA |

|

|

|

|

|

(total load) B1-B2, Tv-Z. |

|

L8124M |

120V |

|

— |

Same as L8124A. |

None. |

a Multizone control can be provided by using a separate circulator and R845 Relay for each zone.

® U.S. Registered Trademark |

|

Copyright © 2001 Honeywell • All Rights Reserved |

95-6571-11 |

|

L8124A,C,E,L AND M AQUASTAT® RELAYS

INSTALLATION

When Installing This Product…

1.Read these instructions carefully. Failure to follow them could damage the product or cause a hazardous condition.

2.Check the ratings given in the instructions and on the product to make sure the product is suitable for your application.

3.Installer must be a trained, experienced service technician.

4.After installation is complete, check out product operation as provided in these instructions.

WARNING

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or equipment damage.

Disconnect power supply before beginning installation to prevent electrical shock or equipment damage.

IMPORTANT

1.Terminals on these Aquastat Relays are approved for copper wire only.

2.Immersion well must fit sensing element and

bulb must rest against bottom of well.

Bend the tubing, if necessary, to hold the bulb against the bottom of the well. Do not make a sharp bend in the tubing. A sharp bend can produce a break in the tubing and cause loss of fill. This condition will cause the high and low limit controllers to be continuously made.

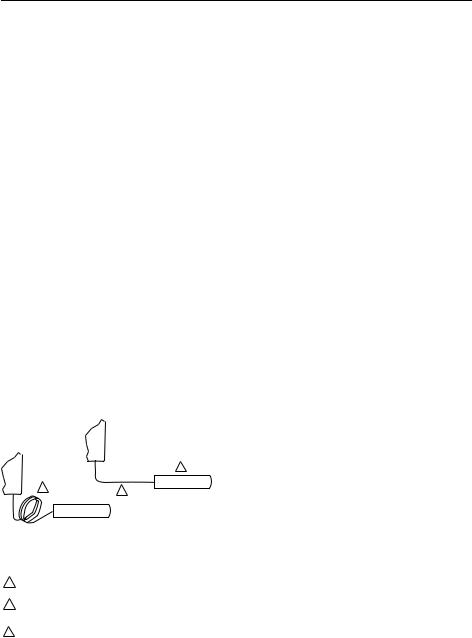

Select models have an adjustable capillary length. See Fig. 1.

3

1

2

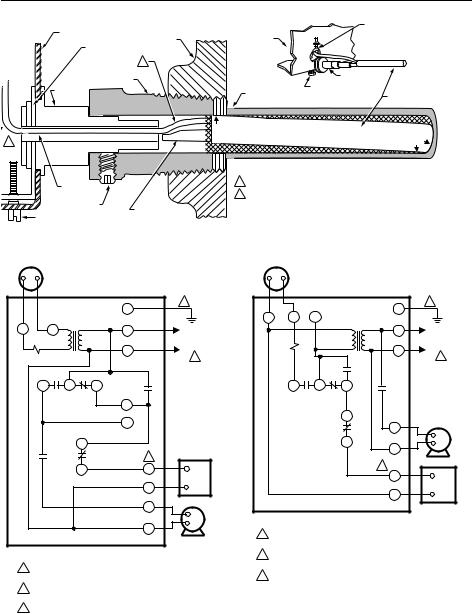

with the relay.) Refer to form 68-0040, Wells and Fittings for Temperature Controllers, to order well. A compression fitting is available for applications where direct immersion of the sensing bulb is desired. A 124904 Well Adapter (see Fig. 2) can be ordered separately to adapt some other wells to the mounting clamp. The boiler must be provided with a tapping that allows horizontal mounting of the well. It should be located where boiler water of average temperature can circulate around the well.

1.Turn off all power and drain the boiler.

2.If no tapping is provided, prepare one, properly sized and threaded, at the selected location.

3.Install the immersion well in the boiler tapping and tighten securely.

NOTE: Do not use the case as a handle to tighten.

4.Refill boiler and check for water leakage.

5.Loosen but do not remove the clamp screw on the bottom (L8124A,E) or on top (L8124C,L,M) of case.

6.Insert the element in the well until it bottoms. See Fig. 2.

7.Fit the case onto the well so that the clamp on the case slides over the flange on the well. Securely tighten clamp screw.

WIRING

WARNING

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or equipment damage.

Disconnect power before wiring to prevent electrical shock or equipment damage.

All wiring must comply with local electrical codes and ordinances. The limits given in the Specifications section must not be exceeded when applying this control. Terminals on these Aquastat Relays are approved for copper wire only.

Refer to the insert on the inside of the Aquastat Relay cover or to Table 1 for electrical ratings and maximum load information. Use manufacturer instructions when wiring controlled equipment or refer to typical hookups in Fig. 3 through 11.

CAUTION:

CAUTION:

EXCESSIVE HANDLING OR SHARP BENDS CAN DAMAGE THE CAPILLARY.

1SENSING ELEMENT IS FACTORY FORMED FOR 1.5 IN. INSULATION WELL ASSEMBLIES.

2FOR 3 IN. INSULATION WELL ASSEMBLIES, PULL OUT SUFFICIENT CAPILLARY TO ASSURE THAT THE CAPSULE BOTTOMS IN THE WELL.

3STRAIGHTEN CAPILLARY SUFFICIENTLY SO IT DOES NOT

INTERFERE WITH INSERTION OF THE CAPSULE INTO THE WELL. M8882

Fig. 1. Adjusting the capillary length.

Mounting

Each relay is suitable for use with an immersion well for insertion into the boiler. (Check individual OS number specifications to determine whether a well is supplied

WARNING

WARNING

Explosion Hazard.

Can cause severe injury, death or property damage.

Use this product only in systems with a pressure relief valve.

If the B1 terminal on the device being replaced is a 1/4 in. (6 mm) tab terminal, use the existing wiring harness terminals to install the replacement device. If the B1 terminal on the device being replaced is a screw terminal, insert the provided tab terminal to screw terminal adapter on the 1/4 in. (6 mm) tab terminal of the replacement device. After the adapter is installed, the existing wraparound wire end may be reused to make an electrical connection to the B1 terminal.

95-6571—11 |

2 |

|

|

L8124A,C,E,L AND M AQUASTAT® RELAYS |

||

|

|

BACK OF |

|

IMMERSION |

CONTROLLER |

|

CONTROLLER |

|

WELL CLAMP |

CASE |

BOILER |

CASE |

|

|

|

|

|

||

IMMERSION |

|

|

|

|

WELL CLAMP |

|

|

|

|

|

1 |

|

|

|

IMMERSION |

|

|

ADAPTER |

|

WELL SPUD |

|

|

||

|

|

|

|

|

ADAPTER |

|

|

IMMERSION |

|

|

OLD IMMERSION |

WELL CLAMP |

SENSING |

|

|

|

|||

|

|

WELL ASSEMBLY |

SCREW |

BULB |

(A)

)

2

CAPILLARY

TUBE

SETSCREW

|

SHORT TUBE |

IMMERSION |

FITS IN CENTRAL |

WELL CLAMP SCREW |

RECESS OF ADAPTER |

(D)

(B)

HEAT-CONDUCTIVE COMPOUND

HEAT-CONDUCTIVE COMPOUND

1 BEND THE CAPILLARY TUBE TO HOLD THE SENSING BULB IN GOOD THERMAL CONTACT WITH THE IMMERSION WELL AT POINTS (A) AND (B).

2

ASSURE THAT CAPILLARY TUBE FITS FREELY IN THE ADAPTER SO THE TENSION OF THE CAPILLARY TUBE AT POINT (C) HOLDS THE SENSING BULB IN GOOD THERMAL CONTACT WITH THE IMMERSION WELL AT POINT (

M88

Fig. 2. Position of bulb in immersion well and use of well adapter when required.

|

LOW VOLTAGE |

|

|

|

|

|

THERMOSTAT |

|

|

|

|

|

|

L8124A,C |

|

|

|

|

|

|

|

|

2 |

|

|

|

G |

|

|

T |

T |

|

1 |

|

L1 |

|

|

|

|

|

(HOT) |

|

|

|

2 |

|

L2 |

1K |

|

|

|

|

1 |

W |

R |

B |

|

1K1 |

|

|

|

|

|

|

|

|

LOW LIMIT/ |

|

|

|

|

|

CIRCULATOR |

ZR |

|

|

|

|

|

|

|

|

|

|

|

|

ZC |

|

|

|

|

|

|

|

LINE VOLTAGE |

|

B |

|

|

|

OIL BURNER |

|

|

HIGH |

|

|

RELAY OR |

|

1K2 |

|

3 |

GAS VALVE |

|

|

LIMIT |

|

|||

|

|

|

|

|

|

|

R |

|

|

B1 |

|

|

|

|

|

B2 |

|

|

|

|

|

C1 |

|

|

|

|

|

C2 |

|

|

|

|

|

|

LINE VOLTAGE |

|

|

|

|

|

CIRCULATOR |

1POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2CONTROL CASE MUST BE CONNECTED TO EARTH GROUND. USE GROUNDING SCREW PROVIDED.

3 |

B1 IS 1/4 IN. TAB TERMINAL. |

M8802 |

Fig. 3. L8124A,C single zone connections and internal schematic.

|

LOW VOLTAGE |

|

|

|

|

|

THERMOSTAT |

|

|

|

|

|

|

|

L8124E |

|

|

|

|

|

|

|

2 |

|

|

|

|

G |

|

TV |

T |

Z |

|

|

|

|

|

|

|

1 |

L1 |

|

|

|

|

|

(HOT) |

|

1K |

|

|

2 |

L2 |

|

|

|

|

||

|

|

|

|

|

1 |

|

|

|

1K2 |

|

|

|

W |

R |

B |

1K1 |

|

|

|

|

|

|

|

|

|

LOW LIMIT/ |

|

|

|

|

|

CIRCULATOR |

|

|

|

|

|

|

R |

|

LINE VOLTAGE |

|

|

|

|

CIRCULATOR |

|

|

|

HIGH |

|

|

|

|

|

|

C1 |

|

|

|

|

LIMIT |

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

C2 |

|

|

|

|

|

3 |

|

|

|

|

|

B1 |

TR |

|

|

|

|

B2 |

TH |

|

|

|

|

|

LOW VOLTAGE |

|

|

|

|

|

GAS VALVE |

|

|

|

|

|

(eg, VR8300) |

1POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2CONTROL CASE MUST BE CONNECTED TO EARTH GROUND. USE GROUNDING SCREW PROVIDED.

M8803

3 B1 IS 1/4 IN. TAB TERMINAL.

Fig. 4. L8124E single zone connections and internal schematic.

3 |

95-6571—11 |

Loading...

Loading...