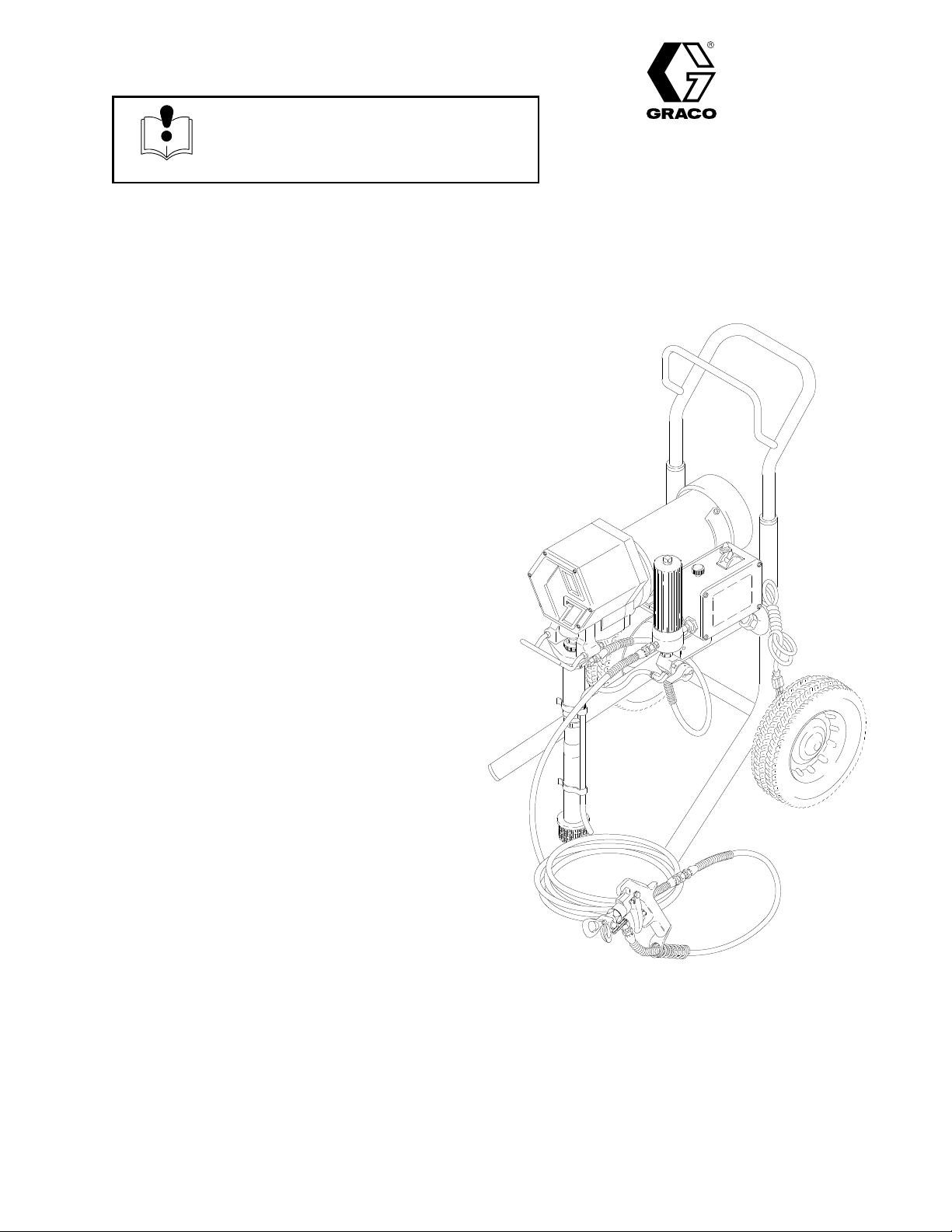

Hitachi SERIES D, 220-856 User Manual

INSTRUCTIONS-PARTS

LIST

307–830

This

manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

EM590

2750 psi (190 bar, 19 MPa) Maximum Working Pressure

Model

Basic

Model

Same

3 ft (0.9 m) whip hose and spray gun with RAC IV

DripLess T

220–856, Series D

sprayer on Upright cart without hose or gun

231–590, Series A

as 220–856 and includes 50 ft (15.1 m) hose,

ip Guard and 517 size SwitchT

Airless Paint Sprayer

ip

First

choice when

quality counts.

Supersedes Rev

Rev. F

. E

GRACO INC. P.O. BOX 1441

http://www.graco.com

COPYRIGHT

Graco

Inc. is registered to I.S. EN ISO 9001

MINNEAPOLIS, MN

1987, GRACO INC.

01744C

55440–1441

Table

of Contents

Warnings 2.

Setup 5

Startup

Maintenance

Flushing 9

Application

Troubleshooting 11

Motor

Displacement

Connecting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Methods

Brush Replacement

Pump

Rod and Bearing Housing

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

10.

13.

14.

15.

Symbols

Warning Symbol

WARNING

This

symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

Drive

Housing

Motor 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure

Pressure

Parts

Parts

Technical

Graco

Accessories 27

Graco Warranty 28.

Control

Control Adjustment

– Pressure Control

– Upright Sprayer

Data

Phone Number

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.

19.

21.

23.

25.

27.

27.

Caution Symbol

CAUTION

This

symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

FIRE AND EXPLOSION HAZARD

Improper

result in a fire or explosion and serious injury

grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

.

If there is any static sparking or you feel an electric shock while using this equipment,

ing immediately. Do not use the equipment until you identify and correct the problem.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being sprayed.

Keep the spray area free of debris, including solvent, rags, and gasoline.

Electrically disconnect all equipment in the spray area.

Extinguish all open flames or pilot lights in the spray area.

Do not smoke in the spray area.

Do not turn on or of

Do not operate a gasoline engine in the spray area.

Use only with a grounded outlet that matches the grounded plug of this equipment.

f any light switch in the spray area while operating or if fumes are present.

stop spray-

WARNING

INJECTION HAZARD

Spray

from the gun, leaks or ruptured components can inject fluid into your body and cause extremely

serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can also

cause serious injury

Fluid injected into the skin is a serious injury

injury

. Get immediate medical attention.

Do not point the gun at anyone or at any part of the body

Do not put your hand or fingers over the spray tip.

Do not stop or deflect leaks with your hand, body

Do not “blow back” fluid; this is not an air spray system.

Always have the tip guard and the trigger guard on the gun when spraying.

Check the gun dif

Be sure the gun trigger safety operates before spraying.

Lock the gun trigger safety when you stop spraying.

.

fuser operation weekly

. The injury may look like just a cut, but it is a serious

.

, glove or rag.

. Refer to the gun manual.

Follow the

checking or servicing the equipment.

T

ighten all fluid connections before operating the equipment.

Check the hoses, tubes, and couplings daily

repair high pressure couplings; you must replace the entire hose.

Fluid hoses must have spring guards on both ends, to help protect them from rupture caused by

kinks or bends near the couplings.

Pressure Relief Procedure

on page 1

1 if the spray tip clogs and before cleaning,

. Replace worn or damaged parts immediately

TOXIC FLUID HAZARD

Hazardous

inhaled, or swallowed.

Know the specific hazards of the fluid you are using.

Store hazardous fluid in an approved container

state and national guidelines.

Always wear protective eyewear

solvent manufacturer

fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

. Dispose of hazardous fluid according to all local,

, gloves, clothing and respirator as recommended by the fluid and

.

MOVING PARTS HAZARD

. Do not

Moving

parts can pinch or amputate your fingers.

Keep clear of all moving parts when starting or operating the pump.

Before servicing the equipment, follow the

equipment from starting unexpectedly

Pressure Relief Procedure

.

on page 1

1 to prevent the

WARNING

EQUIPMENT MISUSE HAZARD

INSTRUCTIONS

Equipment

This equipment is for professional use only

Read all instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are not sure, call your distributor

Do not alter or modify this equipment. Use only genuine Graco parts.

Check equipment daily

Do not exceed the maximum working pressure of the lowest rated system component. Refer to the

T

Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the

nical Data

Do not use 1,1,1–trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

misuse can cause the equipment to rupture or malfunction and result in serious injury

.

echnical Data

. Repair or replace worn or damaged parts immediately

on page 27 for the maximum working pressure of this equipment.

.

section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

.

fluids containing such solvents in pressurized aluminum equipment. Such use could result in a

chemical reaction, with the possibility of explosion.

Do not use hoses to pull equipment.

Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 82C (180F) or below –40C (–40

F).

.

Tech-

Do not lift pressurized equipment.

Comply with all applicable local, state, and national fire, electrical, and safety regulations.

NOTE: This

is an example of the DANGER label on

your sprayer

. This label is available in other

languages, free of charge. See page 27 to order

FIRE

AND

EXPLOSION HAZARD

Spray

painting, flushing or cleaning equipment with flammable liquids in

confined

Use outdoors or in extremely well ventilated areas. Ground equipment,

hoses,

A

cloths,

arcs

switches on and of

Failure to follow this warning can result in death or serious injury

areas can result in fire or explosion.

containers and objects being sprayed.

void all ignition sources such as static electricity from plastic drop

open flames

from connecting or disconnecting power cords or turning light

such as pilot lights, hot objects such as cigarettes,

f.

.

READ AND UNDERSTAND ALL LABELS AND INSTRUCTION MANUALS BEFORE USE

.

SKIN INJECTION

HAZARD

Liquids

can be injected into the body by high pressure airless spray or

leaks

– especially hose leaks.

Keep body clear of the nozzle. Never stop leaks with any part of the

body

. Drain all pressure before removing parts.A

ing of gun by always setting safety latch when not spraying.

Never spray without a tip guard.

In case of accidental skin injection, seek immediate

“Surgical T

Failure to follow this warning can result in amputation or serious injury

reatment”.

void accidental trigger

-

.

4 307-830

Setup

WARNING

T

o reduce the risk of serious bodily injury caused

by static sparking, fluid injection or over–pressuri

zation and rupture of the hose or gun, all hoses

must be electrically conductive, the gun must have

a tip guard, and each part must be rated for at least

2750 psi (190 bar

, 19 MPa)

Working Pressure.

CAUTION

T

o avoid damaging the pressure control, which may

result in poor equipment performance and compo

nent damage:

1.

Always use grounded, flexible spray hose (85) at

least 50 ft (15 m) long.

2.

Never use a wire braid hose as it is too rigid to

act as a pulsation dampener

3.

Never install any shutof

(15) and the main hose. See Fig. 1.

.

f device between the filter

WARNING

1. Connect the hoses and gun to the sprayer.

a 1/4 in. ID, 50 ft (15 m) long (minimum) main

hose (85). For more flexible gun movement, install

-

-

a 3/16 in. ID, 3 ft (0.9 m) hose (86) between the

main hose and the gun (87). Don’t use thread

sealant, and don’t install the spray tip yet!

2. Fill the packing nut/wet-cup (221)

Throat Seal Liquid (TSL), supplied.

3.

Check the electrical service.

a.

Electrical requirements: 120 V

15A (minimum).

b.

Use a grounded electrical outlet located at

least 20 ft (6 m) from the spray area.

c.

Do not remove the grounding prong of the

power supply cord, and do not use an

ungrounded adapter

d.

Extension cord specifications: 15A, 3 wires,

grounding type. Note that long lengths reduce

sprayer performance. A maximum extension

cord length of 200 ft (60 m) is recommended.

.

1/3 full with

AC, 60 Hz,

Use

FIRE AND EXPLOSION HAZARD

Proper electrical grounding is essential

to reduce the risk of fire or explosion

which can result in serious bodily injury

and property damage. See the warning

section

ARD

grounding instructions.

FIRE OR EXPLOSION HAZ

on page 2 for more detailed

-

4. Flush the pump

pump parts after factory testing. See

page 9.

5.

Prepare the paint.

the paint thoroughly

nylon mesh bag to remove particles that could clog

the filter

, if used, or the spray tip.

to remove the oil left in to protect

Flushing

Remove any paint skin. Stir

. Strain the paint through a fine

on

307-830 5

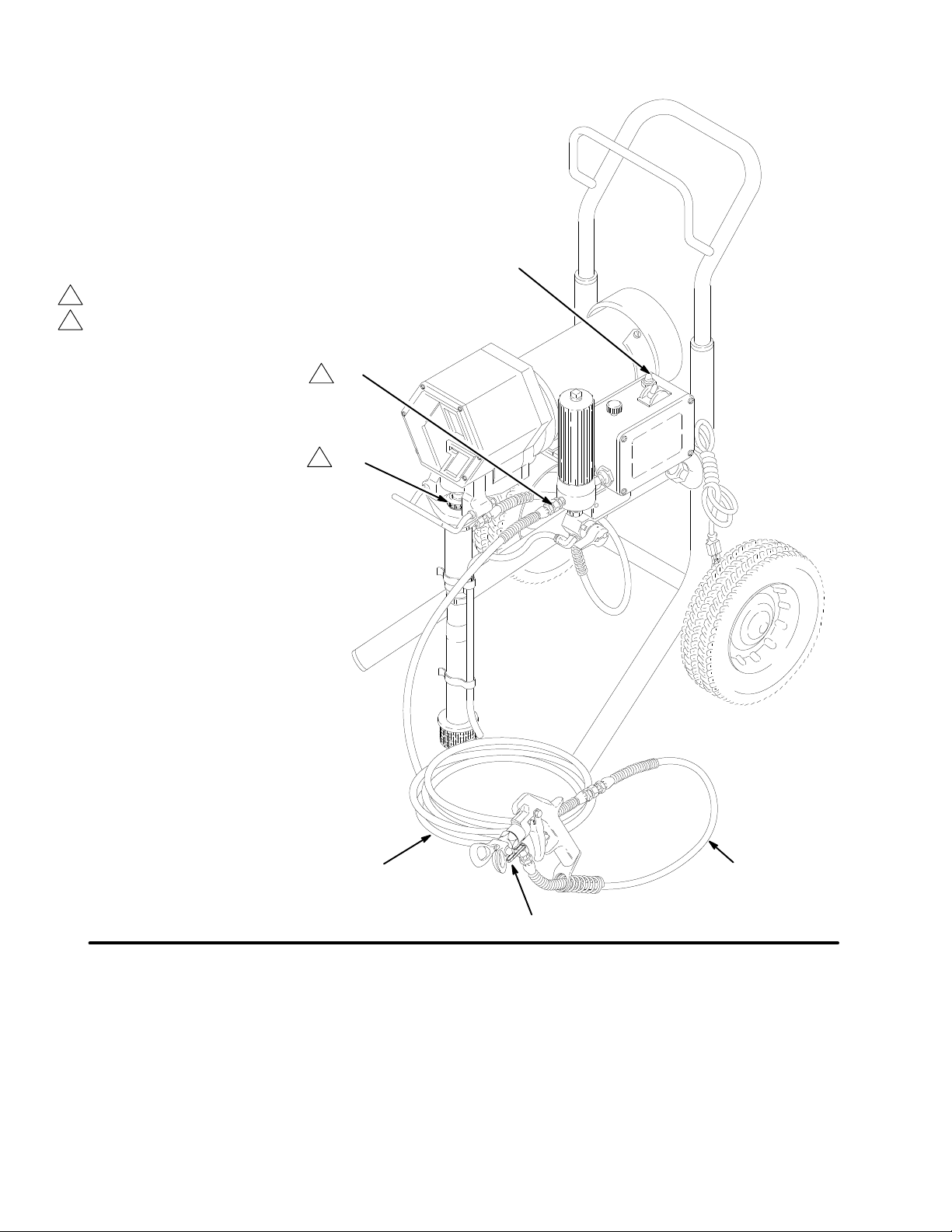

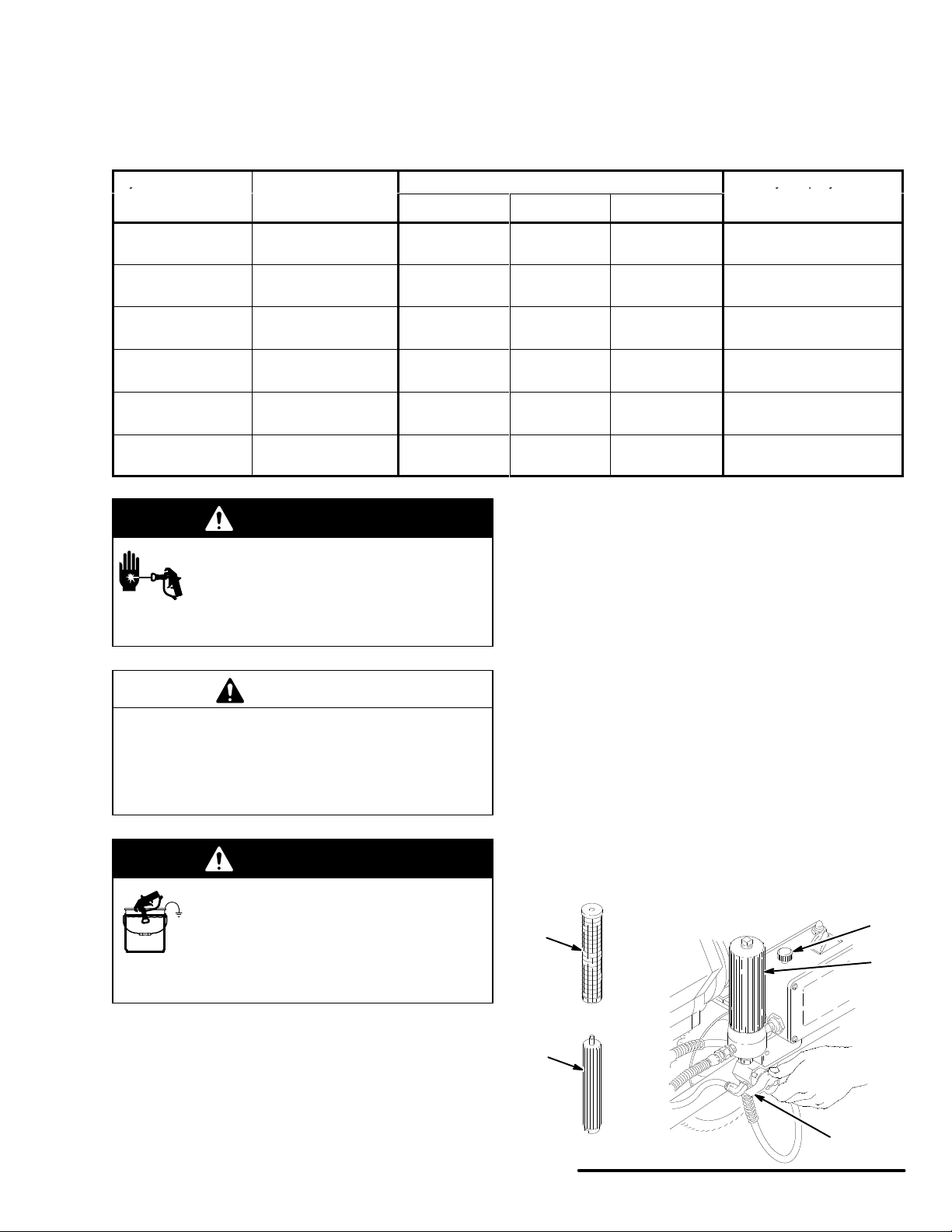

Keep

1/3 full with TSL at all times

Never install any shutof

f device here

Setup

114

15b

221

Fig.

1

6 307-830

85

87

86

01744C

Use

this procedure to help you start and operate the

sprayer properly and safely

.

Startup

5. Check all fluid connections for leaks

the

tightening connections.

Pressure Relief Procedure

. Follow

on page 1

1 before

WARNING

INJECTION HAZARD

T

o reduce the risk of serious bodily

injury

, follow the

dure W

ing or repairing any part of the spray system.

NOTE:

See page 9.

NOTE:

1. Turn the pressure adjusting knob (A) fully

2. Put the intake tube (3) in the fluid container.

3.

Flush the sprayer if this is a first-time startup.

See Fig. 3 except where noted.

counterclockwise to minimum pressure.

Plug in the sprayer

arning

Pressure Relief Proce

on page 1

.

1 before check

6. Install the spray tip and tip guard.

trigger safety latch. Install the spray tip according

to the instructions supplied with it.

-

-

7. Adjust the spray pattern.

Increase the pressure slowly just until spray

a.

from the gun is completely atomized. Use the

lowest pressure needed to get the desired

results. This reduces overspray and fogging,

decreases tip wear and extends sprayer life.

b.

If more coverage is needed, use a larger tip

rather than increasing the pressure.

c. T

est the spray pattern. Adjust the spray tip

pattern according to the instructions supplied

with the gun or tip.

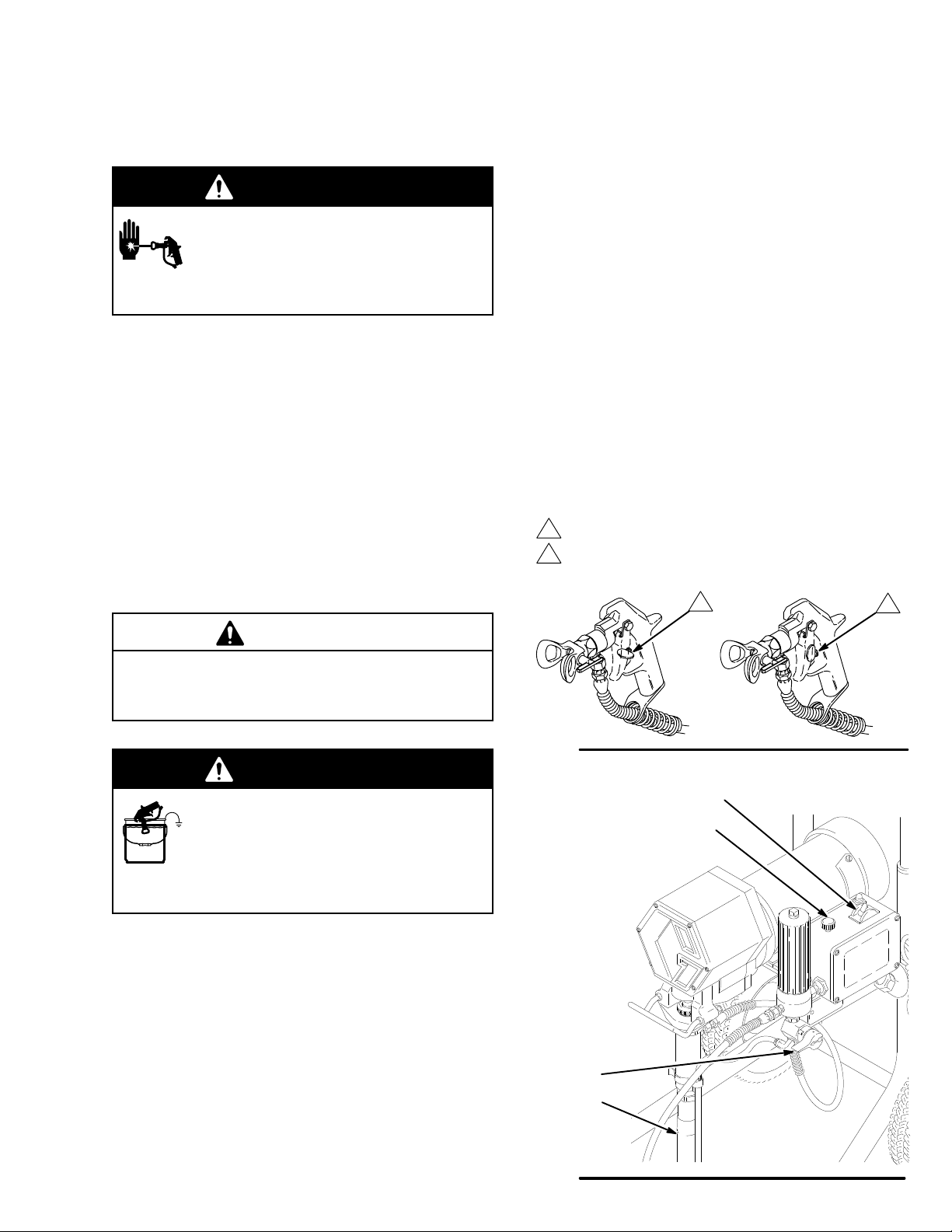

Trigger

safety latch shown engaged (SAFE)

T

rigger safety latch shown disengaged (OFF SAFE)

Engage the

CAUTION

Do not run the pump without fluid in it for more than

30 seconds to avoid damage to the displacement

pump packings.

WARNING

FIRE AND EXPLOSION HAZARD

T

o reduce the risk of static sparking and

splashing when flushing, always remove

the spray tip from the gun and hold a

metal part of the gun firmly to the side of grounded

metal pail.

4.

Prime the pump.

a. Open

b. Disengage

the

pressure drain valve (44). T

sprayer switch (105a). Slowly turn the pressure

adjusting knob (A) clockwise until the sprayer

starts.

When fluid comes from the

the trigger safety latch. See Fig. 2.

Holding a metal part of the gun firmly against a

grounded metal pail, trigger the gun until all air

is forced out of the system and the paint flows

freely from the gun.

urn on the

valve close it.

Fig. 2

105a

A

44

3

c.

Release the trigger and engage the trigger

safety latch.

Fig.

3

01745C

Maintenance

WARNING

INJECTION HAZARD

T

o reduce the risk of serious bodily

injury

, follow the

dure W

ing or repairing any part of the spray system.

arning

Pressure Relief Proce

on page 1

1 before check

Cleaning a Clogged Tip

WARNING

To

reduce the risk of serious bodily injury from from

fluid injection:

NEVER operate the spray gun with the tip guard

removed.

DO NOT hold your hand, body

the spray tip when cleaning or checking for a clog.

Always point the gun toward the ground or into a

pail.

, or a rag in front of

5. For very short shutoff periods,

tube in the paint, relieve pressure, and clean the

spray tip.

-

-

6. Flush the sprayer at the end of each work day

and fill it with mineral spirits to help prevent pump

corrosion and freezing. See page 9.

leave the suction

CAUTION

T

o prevent pump corrosion, and to reduce the

chance of fluid freezing in the pump or pressure

control in cold weather

type of paint in the sprayer when it is not in use.

Freezing can seriously damage the sprayer or result

in a loss of pressure or stalling.

7. Coil the hose and hang it on the hose rack

when storing it, even for overnight, to help protect

the hose from kinking, abrasion, coupling damage,

etc.

, never leave water or any

DO NOT try to “blow back” paint; this is NOT an air

spray sprayer

1.

Clean the front of the tip frequently

Pressure Relief Procedure

2.

Follow the cleaning instructions given in your

separate gun or spray tip instruction manual.

.

. Follow the

, page 1

1, first.

Shutdown and Care

1. Keep the packing nut/wet-cup (221) 1/3 full of

TSL

(Throat Seal Liquid, supplied) at all times to

help prevent fluid buildup on the piston rod and

premature wear of packings. Follow the

Relief Procedure

2. Keep the packing nut/wet-cup just tight

enough to stop leakage.

ing causes binding and excessive packing wear

Follow the

Then use a round punch or brass rod and light

hammer to adjust the nut.

Pressure Relief Procedure

, page 1

1, before adding TSL.

See Fig. 5. Overtighten

Pressure

, page 1

1.

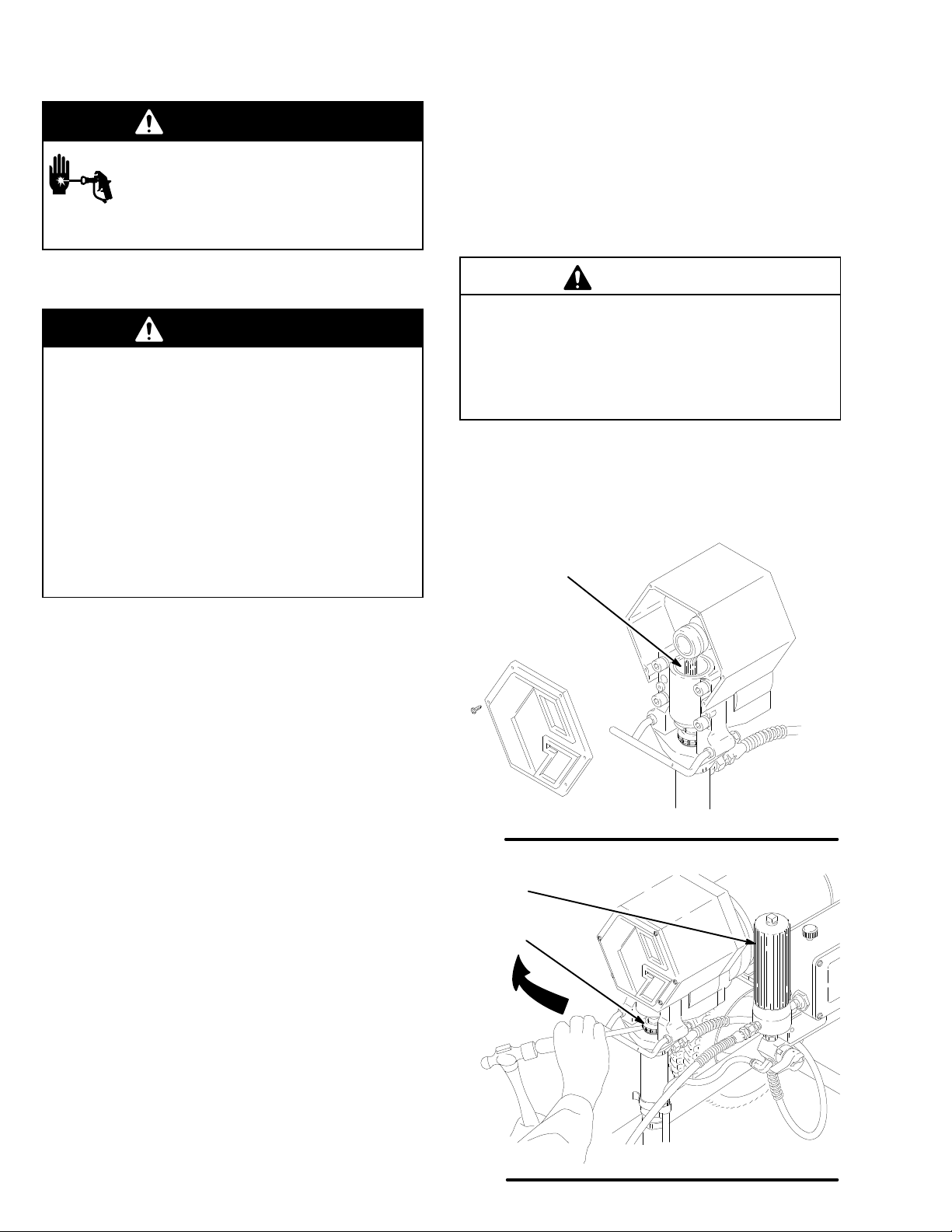

A

Fig. 4

15

-

.

221

7460A

3. Clean the fluid filter (15) often

the sprayer is stored. Follow the

Procedure

4. Lubricate the bearing housing (A)

100 hours of operation

Relief Procedure

cover

non-detergent oil. See Fig. 4.

, page 1

. Fill the bearing housing cavity with SAE 10

1, before cleaning the filter

. Follow the

, page 11. Remove the front

, and whenever

Pressure Relief

after every

Pressure

.

Fig. 5

01748C

Flushing

y

ypy

NOTE:

Several flushes may be required to clean the system and prepare it for the next fluid or storage. Use this

chart to determine the required flushes and use the procedure below for flushing.

*Use this category for flushing a brand new sprayer and flushing after storage.

System

fluid in it:

*Oil-based solvent

or paint

Oil-based solvent or

paint

Oil-based solvent or

paint

W

based paint

W

based paint

W

based paint

has this

ater or water-

ater or water-

ater or water-

Next fluid to be

sprayed:

Oil-based paint –

new color

W

ater-based paint

Prepare for storage

W

ater–based

paint – new color

Oil-based paint

Prepare for storage

Flushing order

Flush 1 Flush 2 Flush 3

Mineral spirits

Mineral spirits

Mineral spirits

W

arm soapy

water

W

arm soapy

water

W

arm soapy

water

none none

W

arm soapy

water

none none

Clean water

Clean water

Clean water

4.

Remove the spray tip from the gun.

Clean water

none

Mineral spirits

Mineral spirits

WARNING

5.

INJECTION

T

o reduce the risk of serious bodily

injury

, follow the

dure W

HAZARD

arning

Pressure Relief Proce

on page 1

1 before check

ing or repairing any part of the spray system.

CAUTION

-

-

Put the suction tube into a grounded metal pail

with 1/2 gallon of compatible solvent.

6.

Start the sprayer

the sprayer as you start to flush, trigger the gun

into another container until the next fluid appears,

then trigger the gun back into the fluid you are

pumping. Circulate the flushing fluid a couple of

minutes to thoroughly clean the system.

Before you spray or store

sprayer:

Prime with oil

Prime with water

Relieve pressure

Leave drain valve open

Prime with water

Prime with oil

Relieve pressure

Leave drain valve open

. See page 7. T

o save the fluid in

NEVER allow water or water–base material to freeze

in the pressure control. Doing so prevents the

sprayer from being started and causes serious

damage to the pressure control. Pump the water out

with mineral spirits.

WARNING

FIRE AND EXPLOSION HAZARD

T

o reduce the risk of static sparking and

splashing when flushing, always remove

the spray tip from the gun and hold a

metal part of the gun firmly to the side of grounded

metal pail.

1.

Relieve pressure. Engage the trigger safety latch.

2.

Remove the filter bowl (B) and screen (C). Rein

stall the bowl and support (D) only

screen separately

urn the pressure adjusting knob (A) fully counter

3. T

.

clockwise to the minimum pressure.

. Clean the

7.

Raise the suction tube and trigger the gun to force

solvent from the hose. Do not run the pump dry for

more than 30 seconds to avoid damaging the

pump packings! Relieve pressure.

8.

Remove the suction tube and clean separately

9.

Install the filter screen. Hand tighten the bowl.

.

A

C

B

D

-

-

Fig. 6

44

01749A

307-830 9

Loading...

Loading...