Page 1

Description for gantry axis

Position capture with motor encoder (indirect measurement)

In a gantry axis

Switch the main switch of the machine on.

Do not confirm the Power interrupted message

but immediately call the MP list.

Deactivate the position encoder for the axis concerned.

For this purpose enter the value 0 for this axis in MP 110.x.

As a precaution MP 860.x should have the value 0 for the gantry

slave axis (no compensating movement after ref erence run).

Deselect reference run for the gantry axes concerned by

entering the value 0 in MP 1340.x for each axis.

Set the limits of the traverse range for the gantry axis to

Enter the value from MP 1054.x (distance of one m otor revolution)

Enter the line count of the motor encoder of the gantry axis

concerned (visible e.g. in the diagnostics functions of iTNC 530

Increase the limits of the traverse range set by the operator to maximum

Record the currents (I noml) for the gantry axes in the integrated

oscilloscope. If the two current signals diverge distinctively, the

reason is most likely mechanical restraint of the gantry axes (non-

parallelism). In this event consult your machine tool builder, as to

whether you may move the gantry axes under this condition

(different current signals, non-parallelism of the gantry axes)!

maximum (MP 910.x to MP 922.x)

in MP 331.x of the axis concerned.

or in the motor table) in MP 332.x.

Exit the MP list and switch the machine on.

(MOD key -> TRAVERSE RANGE soft key)

Move the axis carefully!

Display of error messages

such as synchronism monitoring,

movement monitoring,

standstill monitoring?

No

Now you can traverse carefull with indirect measurement!

Yes

Press and hold

EMERGENCY

STOP and invert

MP 210.x for the

axis concerned.

17 – 300 HEIDENHAIN Service Manual iTNC 530

Page 2

18 Referencing

18.1 Definition

The position value (the coordinates) of an axis position is defined with respect to a freely

selectable datum. When the axes are moved, the ACTUAL position is calculated incrementally.

If there is an interruption in power, the reference between the axis position and the position

value is lost.

Reference marks HEIDENHAIN linear encoders are designed with one or more reference marks. The reference

marks identify an axis position at a known distance from the machine datum. The position of the

freely selectable datum is defined with respect to the machine datum.

The datum and the actual position can be reproduced as soon as the reference marks are

traversed.

+Z

Workpiece

datum

0

Machine table

Measuring system

REF Value

–44.985

10 20 30 40

Workpiece

REF Value

0

+X

Reference mark

Machine datum

Machine

datum

Distance between the scale reference point and the machine datum

Spindle preset A corresponding angle encoder or also the motor encoder in the spindle motor may be used for

The machine datum is determined by the machine manufacturer.

It is required for:

Defining the limits of traverse (software limit switches)

Moving to machine-referenced positions (such as tool change positions)

Setting the workpiece datum

For distance-coded reference marks, the machine datum is defined with respect to the scale

reference point, which is at the first reference mark after the beginning of the measuring length.

MP 960.x contains the distance between scale reference point and machine datum

.

Note

After removing and remounting a measuring system MP 960.x may have to be altered.

See “Re-Setting the Machine Datum” on page 17 – 284.

spindle orientation.

MP 3430.x contains the deviation of the reference mark from the desired position.

Note

After exchanging the angle encoder or the motor encoder in the spindle motor, it might be

necessary to set MP 3430 again.

See “Resetting the Spindle Orientation” on page 17 – 293.

May 2006 18 – 301

Page 3

18.2 Traversing the Reference Marks

The reference marks must be traversed after any interruption in power: This can be done in two

different ways:

Press the NC-START key. --> The reference marks are traversed automatically.

(the sequence of axes and how often the NC-START key must be pressed was determined by

the machine manufacturer).

or:

Press the machine axis-direction button. --> The user determines the sequence for the

referencing of the axes.

DANGER

When servicing, the machine may be in a position where the sequence for the automatic

referencing of axes could result in a collision and thus a damage or injury to the machine or

persons (e.g., error message with reboot).

Determine the sequence for the reference run yourself!

Please ensure that the last set Tilt working plane function active orinactive has been

called correctly.

Enter a low feed rate and press the corresponding axis direction keys in succession!

If necessary, ask the machine operator!

Soft key PASS OVER REFERENCE MARK

External reference pulse

If after power on of the machine no or not all reference marks were traversed (e.g., due to a

previous change to another operating mode) with PASS OVER REFERENCE MARK the

reference mark traverse must be activated. Select the manual operating mode and press the

soft key.

--> Traverse reference points appears on the screen.

After the reference marks have been traversed:

The software limit switches are activated.

The most recently saved datum and machine datum are reproduced.

PLC positioning and positioning with M91 and M92 become possible.

The counter is set to zero for axes in an open loop.

If the reference mark of the encoder cannot be used, e.g. owing to an unfavorable transmission

of motor and rotary axis, an external reference pulse may be evaluated.

In MP 4130.x a fast PLC input is defined for an external reference pulse.

In MP 1360.x the number of the fast PLC input is entered for the axis concerned.

MP 1350.x = 6 for the axis concerned.

18 – 302 HEIDENHAIN Service Manual iTNC 530

Page 4

Reference end position

To prevent the axes from violating their traverse limits when traversing the reference marks,

each axis requires a trip dog (at the reference end position). The trip dogs must be installed by

the machine tool builder at the ends of the traverse range. The switch signals from the trip dogs

are sent to free PLC inputs. The PLC program must gate these PLC inputs with W1054 for

“reference end position.”

The axis will automatically be positioned to the software limit switch if …

It is beyond the positive software limit switch and is moving in the positive direction to the

positive trip dog.

It is beyond the negative software limit switch and is moving in the negative direction to the

negative trip dog.

Encoders with EnDat interface

Double reference run

Encoders with EnDat interface can be connected to the position and speed inputs of the MC 422

(B) and CC 42x. With these encoders there is no need to traverse the reference marks. The

position value is only read when the control is switched on. It cannot be read again.

When connecting a position encoder with an EnDat interface:

MP1350.x = 5 for the axis concerned

When connecting a speed encoder with an EnDat interface:

The iTNC automatically attempts to communicate with the encoder.

When connecting a speed encoder with an EnDat interface as a position encoder:

MP1350.x = 5 for the axis concerned

MP110.x = 0 for the axis concerned

Note

If use of multiturn encoders with EnDat interfaces results in overruns, the corresponding

information is entered in the system file NCDATA.SYS. For a control exchange, this file must

be transferred or MP960.x must be readjusted (see “Exchange of HEIDENHAIN

Components” on page 26 – 411)!

During the double reference run, the absolute position is first output via the EnDat interface of

the speed encoder. If at a later time the reference mark of the position encoder is traversed, the

control continues to work with this reference.

Set the corresponding bits in MP1355 to 1 for the axes for which the double reference run is

to be used.

The distance between the speed encoder and the position encoder is entered in MP1356.x.

If the reference mark of the position encoder is first traversed, the message Set MP1356.<axis

number> to <value> appears.

Enter this value in MP1356.x.

Possible causes of error

The causes of error of encoders also apply here

--> see “Possible Causes of Error” on page 17 – 280 and

see “Possible Causes of Error” on page 17 – 287.

Especially for the referencing, the following causes of error are possible:

Defective trip dog (reference end position)

Shifted magnetic sheet (wrong or no reference mark is evaluated)

Trip dogs are too close to the reference mark signal (during reference run via the motor

encoder, a wrong reference position is evaluated)

May 2006 18 – 303

Page 5

Machine parameters

MP960.x Machine datum

Input: –1.79769313486E+308 to

+1.79769313486E+308 [mm] or [°]

Values with respect to the scale reference point

MP1320 Direction for traversing the reference marks

Format: %xxxxxxxxxxxxxx

Input: Bits 0 to 13 represent axes 1 to 14

0: Positive

1: Negative

MP1330.x Velocity for traversing the reference marks

Input: 80 to 300 000 [mm/min]

MP1331.x Velocity for leaving the reference mark end position for axes 1 to 9

(only for rotary encoders MP1350 = 2)

Input: 10 to 300 000 [mm/min]

MP1340.x Sequence for traversing the reference marks

Input: 0: No evaluation of reference marks

1 to 14: Axes 1 to 14

MP1350.x Sequence for finding the reference mark

Input: 0: Linear encoder with distance-coded reference marks (old routine)

1: Position encoder with one reference mark

2: Special type (length measurement with ROD)

3: Linear encoder with distance-coded reference marks (new routine)

4: Same as 3 except that two reference marks are evaluated

5: Encoder with EnDat interface

6: Reference pulse via fast PLC input

MP1355 Double reference run

Format: %xxxxxxxxxxxxxx

Input: Bits 0 to 13 represent axes 1 to 14

0: Reference run as defined in MP1350.x

1: Double reference run

MP1356.x Distance between speed and position encoder for double reference run

Input: –99 999.999 to +99 999.999 [mm] or [°]

MP1357.x W1032 for double reference run

Input: 0: Reset W1032 if the reference run has been over the EnDat interface of the

speed encoder

1: Reset W1032 if the reference mark was traversed with the position encoder

MP1360.x Fast PLC input for reference pulse

Input: 0: No fast PLC input for reference pulse

1 to 5: Fast PLC input for reference pulse (MP4130.x)

MP1360.x Fast PLC input for reference pulse

Input: 0: No fast PLC input for reference pulse

1 to 5: Fast PLC input for reference pulse (MP4130.x)

18 – 304 HEIDENHAIN Service Manual iTNC 530

Page 6

Position encoder

with distancecoded reference

marks

Function when MP1350.x = 3

Closed

Open

Traverse direction MP1320

Reference marks

Trip dog

"Reference end position"

May 2006 18 – 305

Page 7

Function when MP1350.x = 0. This setting is used only to ensure compatibility. Do not use for

new installations.

Reference marks

Trip dog

Closed

Open

Traverse direction MP1320

Press external START key

"Reference end position"

No Yes

Traverse direction from

MP 1320

Trip dog

"Reference end position"

closed?

Pass over two consecutive

reference marks

Is the machine

outside the software

limit switch range?

No

Invert traverse direction

from MP1320

Yes

Machine moves to

software limit switch range

Machine stops

If during automatic referencing the trip dog is not closed until it is in the reference end position

range, the contouring control will ignore this signal. It is therefore necessary that there are at

least two reference marks in the range of the reference end position.

18 – 306 HEIDENHAIN Service Manual iTNC 530

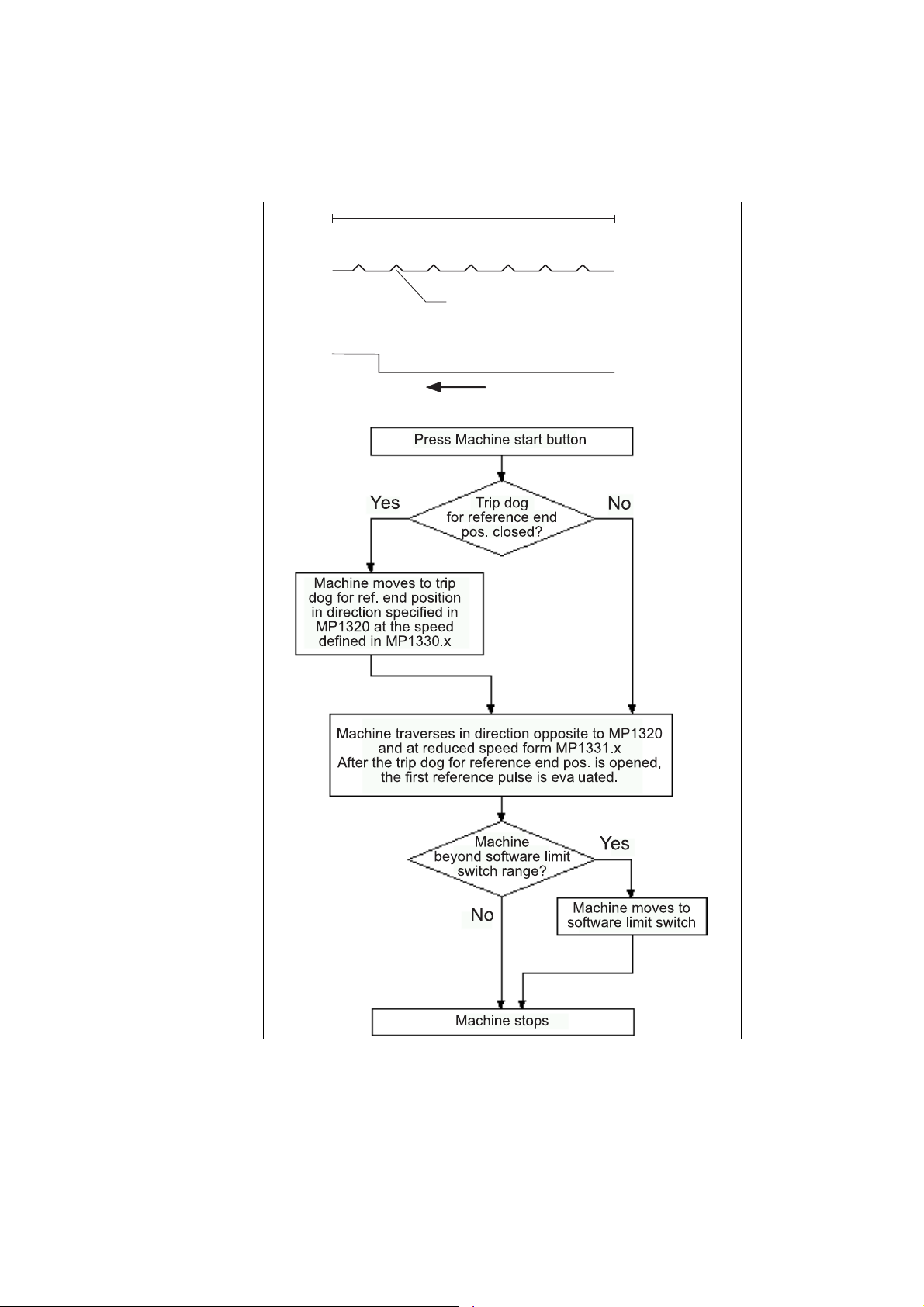

Page 8

Position encoder with one reference mark

Function when MP1350.x = 1

Reference marks

Closed

Open

Traverse direction MP1320

Press the external START key

No Yes

Trip dog

"Reference end position"

closed?

Machine traverse in direction from

MP1320 with velocity from

MP1330.x to the trip dog

"Reference end positon"

Machine traverse in inverted direction

from MP1320 and with reduced velocity from MP1331.x

The first reference pulse after opening of the trip dog

"Reference end position" is evaluated

Trip dog

"Reference end position"

Is the

machine outside

the software limit

switch range?

No

Machine stops

Ye s

Machine moves to

software limit switch

May 2006 18 – 307

Page 9

Linear measurement through rotary encoder

Function when MP1350.x = 2

For linear measurement using a rotary encoder, a reference pulse is produced at each revolution

of the encoder. Ensure that during referencing the same reference pulse is always evaluated.

This can be realized with the trip dog for reference end position.

Measuring length

Reference pulse

Desired reference pulse

Closed

Open

Traverse direction MP1320

Trip dog

"Reference end position"

18 – 308 HEIDENHAIN Service Manual iTNC 530

Page 10

18.3 Deselect Referencing for Axes

For axis examinations it is possible to deselect the referencing MP 1340.x.

Enter value 0 (= no evaluation of the reference mark) for the corresponding axis.

Note

In MP1340.x the sequence for the reference mark run is listed.

With following entries, i.e.:

MP1340.0 : 3

MP1340.1 : 2

MP1340.2 : 1

... first the 3rd axis is referenced (e.g., Z axis), then the 2nd axis (e.g., Y axis) and

subsequently the 1st axis (e.g., X axis).

If you now want to deselect the X axis, you must enter MP1340.2 = 0!

May 2006 18 – 309

Page 11

18 – 310 HEIDENHAIN Service Manual iTNC 530

Page 12

19 Checking the Enables on the iTNC

19.1 General

With an operating axis (axis in control) ...

No terminal symbol is shown

The "STIB" star (control in operation) is shown.

The feed rate enable must not be highlighted.

The position display changes in case of a movement.

READY

symbol

Clamping

symbol

Position display

Feed rate

display

To operate with axes or spindles the appropriate enables are required.

If one or several enables are missing, an error message is output or the axes and/or the spindles

cannot be operated.

The following conditions must be fulfilled to drive digital axes and spindles:

I3 set

(X42/4, Control-is-ready signal acknowledgement)

I32 set

(X42/33, global drive enabling; the functionality of the I 32 global drive enabling is defined in

MP 2050.

24V at X150 / 151 for the corresponding axis group is available.

(X150/151 are not wired on every machine,

but if they are, you can see in MP 2040, how the axis groups are assigned)

May 2006 19 – 311

Page 13

Drives ready for operation

(on the HEIDENHAIN inverter system the green LEDs READY at the drive modules UM xxx

or at the output stages of a compact inverter) must be lit.

Note

If a drive is taken in control, there must be a READY signal from the drive module after a

defined time. For this purpose the corresponding relays must trigger.

The iTNC monitors the time between power on of the control and the READY signal of the

drive modules via the PWM cables.

If the READY signal is missing after the waiting time has passed, the error message

8B40 No drive release <axis>appears.

E.g., a connection may be interrupted, or the relays trigger too slowly or the drive is

defective, etc.

The permissible waiting time is entered in MP2170.

It is possible that this error message is not generated as the PLC program does not hook up

the current and speed controllers as long as the ready signal of the drives is missing. -->

Observe the green READY-LEDs of the drives. --> See “Checking the Readiness of the

Inverter System” on page 19 – 322

PLC module 9161 called

(This module serves to activate the current and speed controllers individually for each axis.

If necessary ask the machine manufacturer, in which program part this module is called.)

Note

The word W1024 contains the axes enabled by the NC.

The word W1060 contains the axes for which the feed rate was individually enabled by

the PLC.

If the marker M4563 is set, the PLC enables the feed rate in all axes.

(Use either W1060 or M4563.)

The word W1040 contains the axes in which the control loop is opened by the PLC

(e.g., with. clamping axes).

The PLC module 9169 serves to call those axes for which I32 does not switch off the drives.

MP2040 Axis groups for drive enabling through X150 / X151

Format: %xxxxxxxxxxxxxx

Input: 0: Axis not assigned

1: Axis assigned

MP2040.0-5: Groups 1 to 6

MP2040.6-7: Reserved, enter %00000000000000

MP2050 Functionality of drive enabling I32 (X42/33)

Input: 0: Emergency stop for all axes, Module 9169 not effective

1: Emergency stop for all axes that are not excepted with Module 9169

2: I32 and Module 9169 are without functionality

MP2170 Waiting time between the switch-on of the drive and the drive’s standby

signal

Input: 0.001 to 4.999 [s]

0: 2 [s]

19 – 312 HEIDENHAIN Service Manual iTNC 530

Page 14

19.2 Examination

The iTNC 530 features comprehensive diagnosis possibilities.

--> See “Integrated Diagnosis Functions” on page 7 – 41.

These diagnosis functions can be used for the following examinations!

Selection of the supply device

Select the power supply unit used

(not all status information of non-HEIDENHAIN inverters can mostly be used):

May 2006 19 – 313

Page 15

19.2.1 Examination of the Output Control-is-ready (X41/pin34) and Input Control-is-ready signal acknowledgement I3 (X42/pin 4)

If the message Relay external DC voltage missing does not disappear after pressing the key

Control ON, carry out the folllowing fault diagnosis:

“Control is Ready“ check

Switch control on as far as possible.

Check status of the Acknowledgment: Control

is Ready (-NE1) indicator in the Drive

diagnosis window (or check in the

PLC TABLE, whether I3 is set.)

Acknowledgment present

(green indicator or

I3 = 1)?

No

+ 24 V present at input

Acknowledgment: Control is Ready

(X42/PIN4)?

No

EMERGENCY STOP chain

(EMERG. STOP button, axis limit

switches, etc.) interrupted?

No

+24 V present at output

Control is Ready

(X41/PIN34)?

Yes

Yes

Yes

Yes

The control records the

acknowledgment. The message

Relay external DC voltage missing

should disappear. If it does not,

please call HEIDENHAIN!

The PLC does not detect the

high level. Probably the input I3

on the MC is defective.

-> Replace the MC!

Remove the interruption.

There is still an interruption which

needs to be removed. (Use the circuit

diagram of the machine.)

No

Supply voltage present for

output Control is Ready (connector

X34/PIN1 = 24V, PIN2 = 0V)?

No

Find the reason and correct the error.

(Make use of the circuit di agram of the machine.)

Yes

The Control is Ready output of the

MC is probably defective.

-> Replace the MC!

19 – 314 HEIDENHAIN Service Manual iTNC 530

Page 16

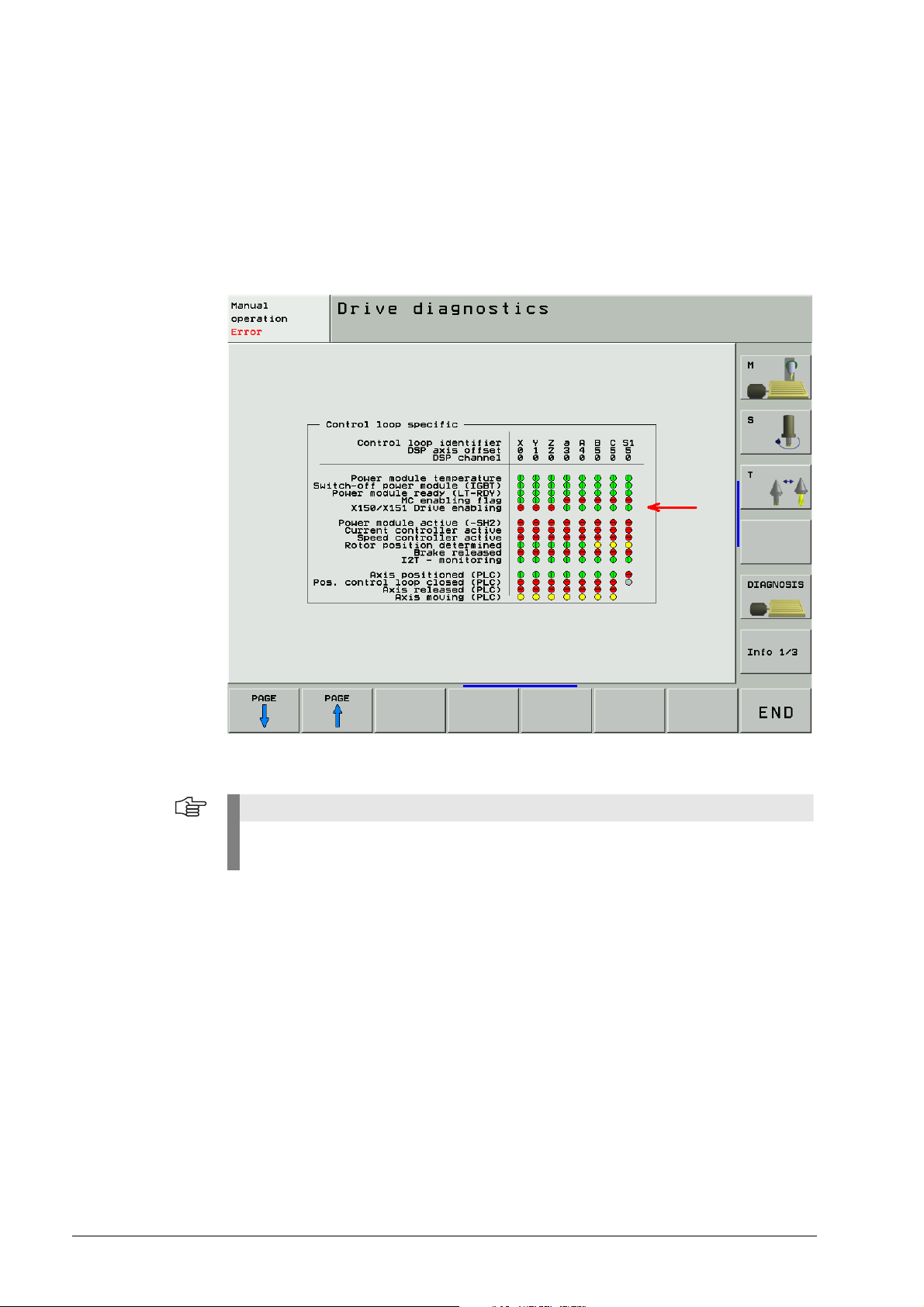

Page from the DSP diagnosis of drives

Call via the soft keys DIAGNOSIS --> DRIVE DIAGNOSIS --> DSP

See “Integrated Diagnosis Functions” on page 7 – 41.

Excerpt from the basic circuit diagram

Here you can see the terminals that can be measured

(the PLC inputs and outputs are mostly connected to a strip in the electrical cabinet).

May 2006 19 – 315

Page 17

Sliding switch on I/O module

Note

If the Control-is-ready output on the MC is defective, you can use the Control-is-ready

output of a PLC expansion board as makeshift:

PL 405 B or PL 410 B: X8 / pin16

PL 510, input/output module PLD 16-8: X6 / terminal 8

(The function of this terminal can be set with a sliding switch on the rear side of the

corresponding I/O modules, setting 1 = "Control is ready", See “X6: PLC outputs on the PL

510” on page 13 – 197)

19 – 316 HEIDENHAIN Service Manual iTNC 530

Page 18

Error message

EMERGENCY STOP

DEFECTIVE

If the error message "Emergency Stop Defective" appears when the machine is switched on,

carry out the error diagnosis as follows:

Error message EMERGENCY STOP Defective

The machine is switched on.

Is the input I3

(X42/PIN4) permanently

on high level?

No

Switch the main switch of the machine off.

Disconnect and secure the original wires.

Insert a bridge between X41/PIN34 and X42 /PIN4

(output and input of Control is Ready).

Observe that the potent ia l of the power supply is the

same -> See „“Caution“ box below this chart.

Switch the main switch of the machine on.

Does the error message

EMERGENCY STOP Defective

reappear?

Yes

Yes

Find the reason and correct

the error. (Make use of

the circuit diagram

of the machine.)

The MC is probably

defective.

-> Replace the MC.

No

The fall time of the relay triggered by the output X41/

PIN34 is probably too long.

-> Replace the relay.

Caution

If 24 V is supplied to the control-is-ready output from the HEIDENHAIN inverter system via

connector X34, potential differences between the 24 V machine voltage and the 24 V from

the inverter can result in compensating currents.

Therefore it is perferable to supply X34 with machine voltage before you insert a bridge

between the "Control-is-ready" input and output during the following investigation!

May 2006 19 – 317

Page 19

Bridge inserted

Acknowledgment:

Control is Ready

I3

Control is Ready

Note

The function of the Control-is-ready output of an I/O module PLD 16-8 can also be tested

with this method.

Note

Course of the emergeny stop (or booting) routine.

--> See “Monitoring Functions” on page 9 – 55!

19 – 318 HEIDENHAIN Service Manual iTNC 530

Page 20

19.2.2 Checking the Global Drive Enable I32, Connector X42 / pin 33

If you can switch on the machine but cannot move with a digital axis/spindle, check the

following:

Checking I32

Switch the control on as far as possible.

Check the status of the

Drive enabling (-NE2) in the

Drive diagnostics window

(or check in the PLC TABLE, whether

I32 is set).

Yes

Acknowledgment present

(green indicator or

I32 = 1) ?

No

Yes

The control records the

acknowledgment! If, however, you

still cannot operate the digital

axes/spindle, please call your

machine tool builder or HEIDENHAIN!

No

Is an

NC-STOP signal pending?

(marker 4560 = 0)?

Yes

Find the reason (e.g. break between

NC-STOP button an d control or

stuck NC-STOP button) and

correct the error.

+ 24 V available at X42/PIN33 ?

No

The conditions for drive enabling

are not fulfilled (door contacts,

permissive keys etc.)

Use the circuit diagram of the machine

to check the contacts, relays, wiring, etc.

The PLC does not detect the high

level. Probably the input I3 2 on the

MC is defective. -> Replace the MC!

May 2006 19 – 319

Page 21

Page from the DSP diagnosis of drives

Call via the soft keys DIAGNOSIS --> DRIVE DIAGNOSIS --> DSP

See “Integrated Diagnosis Functions” on page 7 – 41.

Excerpt from the basic circuit diagram

Here you can see the terminals that can be measured

(the PLC inputs and outputs are mostly connected to a strip in the electrical cabinet).

Drive enabling

for all axes

I32

Drive enabling

for axis groups

Do not connect,

If MP2040 = 0

19 – 320 HEIDENHAIN Service Manual iTNC 530

Page 22

19.2.3 Checking the Drive Enabling for the Axis Groups via Connector X150 and X151 (if Wired)

Check whether 24V are available for the axis group to be traversed.

The axis groups for the drive enabling via X150 (main DCB) and X151 (auxiliary DCB) are

defined in MP2040.

Check according to the integrated drive diagnosis whether the corresponding axis groups are

released:

Note

If no axis groups are defined in MP 2040, the default setting of the drive release is active

(via X150 / X151).

May 2006 19 – 321

Page 23

19.2.4 Checking the Readiness of the Inverter System

Selection of the power supply unit

Select the power supply unit used for the integral diagnosis functions

(mostly not all status information of non-HEIDENHAIN inverters can be used):

Green “READY” LED on

Check according to the integrated drive diagnosis whether the corresponding axis groups are

released:

19 – 322 HEIDENHAIN Service Manual iTNC 530

Page 24

Check according to the integrated drive diagnosis whether the power modules are ready:

Open the electrical cabinet and also check whether the green READY-LEDs on the compact

inverter or the power supply unit light up (a non-HEIDENHAIN inverter is probably also

equipped with a corresponding LED or display).

Inverters LED

UE 1xx, UE 2xx B compact inverter READY

UE 2xx compact inverter AXIS/SPINDLE READY

UR 2xx, UR 2xxD compact inverter READY UV

UV 120, UV 140, UV 150, UV 1xx D,

UVR 1xx,

READY UV and

POWER MODULE READY

UVR 1xx D power supply unit

UV 130D power supply unit READY

UV 130 D power supply unit READY UV

Check if the green READY-LED lights up on, e.g.

on the compact inverter

on the UM axis module

on the HEIDENHAIN interface board for the SIMODRIVE system

for the axis to be traversed.

(A non-HEIDENHAIN inverter is probably also equipped with a corresponding LED or display.)

May 2006 19 – 323

Page 25

If the READY LEDs are not lit, proceed as follows:

Check the supply of the inverter system.

Check the electrical cabinet (relays, wiring, etc.).

Check the ribbon cables and the plug-type connectors at the inverter system.

Note

Use the circuit diagram of the machine tool for this purpose.

Further inspection routines --> see service manual for Inverter Systems and Motors!

Red LED SH1 The SH1 signal (safe stop 1) indicated by a red LED at the inverter, is generated by the computer

of the iTNC. The signal is low-active, i.e. line-break proof.

If the computer is not ready for operation or if an error is pending, SH1 is output. The red SH1

LED and the green READY LED at the inverter can never be lit a the same time. They are

mutually locked.

Red LED SH2 The SH2 signal (safe stop 2) indicated by a red LED at the inverter, is generated by the controller

of the iTNC. The signal is low-active, i.e. line-break proof.

If an axis or spindle is not controlled, SH2 is pending and the red LED is on.

This is for example the case with clamped axes or if a spindle is not controlled.

SH2 and READY are on simultaneously.

Note

HEIDENHAIN interface cards for the SIMODRIVE system:

The cards for the plug-type connectors (ribbon cables) are equipped with the green READY

LED and the red LEDs SH1 and SH2.

The cards with D-Sub connectors are equipped with the green READY LED and the red

LEDs RESET X1 und RESET X2 for the respective axis.

RESET X1, RESET X2 correspond to the SH2 signal.

The first generation of the cards with D-Sub connectors feature a green IF LED and a red

NB LED.

IF stands for "pulse enable" (German: Impulsfreigabe) and means that the axis module is

ready.

NB means that the axis module is "not ready" (nicht bereit).

For further information on the drives please refer to the service manual "Inverter Systems

and Motors".

19 – 324 HEIDENHAIN Service Manual iTNC 530

Page 26

19.2.5 Checking PLC Modules, Markers and Words

For the following investigations, the PLC diagnosis functions are used.

--> See “PLC Diagnosis” on page 10 – 73.

For these PLC analyses it might be helpful or often even necessary to contact the machine

manufacturer for support.

Check whether the PLC module 9161 is called in the corresponding PLC program.

(ask the machine manufacturer in which program block this PLC module is called).

For this purpose enter the PLC TRACE mode.

This module serves to activate the current and speed controllers individually for each axis.

Check the value in the word W1024.

For this purpose enter the PLC TABLE.

The word W1024 contains the axes enabled by the NC.

Check the value in the word W1060 or whether the marker 4563 is set.

For this purpose enter the PLC TABLE.

The word W1060 contains the axes for which the feed rate was individually enabled

by the PLC.

If the marker M4563 is set, the PLC enables the feed rate in all axes.

(Either W1060 or M4563 is used.)

Check the value in the word W1040.

For this purpose enter the PLC TABLE.

The word W1040 contains the axes in which the control loop is opened by

the PLC (e.g., clamping axes).

May 2006 19 – 325

Page 27

Note

The value of the words is displayed in hexadecimal or decimal format.The hexadecimal

format is distinguished by a leading $. A hexadecimal digit comprises 4 bits. I.e. you can,

for example, calculate for which axes the feed rate is enabled.

Example: W1024 = $004F

The first HEX digit has the value F, that is the first 4 axes are enabled

0+21+22+23

(2

The second HEX digit has the value 4, i.e. the 7th axis is enabled (22 = 4).

In the binary format this is 0100 1111 and in the decimal format this is the value 79.

= 1+2+4+8 = F).

Value of

indivdual places

Place value

considered

$ 0 0 4 F

0 1 0 0 1 1 1 1

0

23 22 21 2

23 22 21 2

0+4+0+0 8+4+2+1

4

27 26 25 2

4

15

23 22 21 2

0+64+0+0 + 8+4+2+1

79

= HEX

= BIN

0

0

= DEC

19 – 326 HEIDENHAIN Service Manual iTNC 530

Page 28

20 Interface to the Drives

20.1 Digital Drives

20.1.1 Introduction

Digital drive systems are also referred to as inverter systems.

For digital drives three-phase ac motors are used.

The most important motors are:

Synchronous motors (e.g., HEIDENHAIN axis motors)

Asynchronous motors (e.g., HEIDENHAIN spindle motors)

Linear motors

Torque motors

The digital servo amplifiers are controlled via so-called PWM interfaces (PWM = Pulse Width

Modulation).

The position, speed and current controllers are located in the HEIDENHAIN control.

Following PWM interfaces are located on the CC 422 / 424 controller unit

(every digital axis/spindle has its own PWM ribbon-cable connector):

X51 to X56

X57 to X64 (depending on the expansion stage)

Note

On the CC 424 (not CC 422), the speed encoder inputs are firmly assigned to the PWM

outputs. --> See following table!

MP 112.x for the variable assignment of the speed encoders is not available for the CC 424!

Drive control board

of CC 424

1X51X15

1X52X16

1X53X17

1X54X18

1X55X19

1X56X20

2X57X80

2X58X81

2X59X82

2X60X83

Caution

The service on the CC 424 and CC 422 is different.

Ensure to use the correct instructions!

PWM output

(MP120.x/MP121.x)

Speed encoder input

May 2006 20 – 327

Page 29

MP 100 contains the axis sequence (first, second, third axis etc.).

Caution

MP 100 must not be edited!

The allocation of PWM outputs to the axes can be found in the machine parameters

MP 120.x

Note

The connectors as of X57 can be assigned as of MP 120.6 (7th axis), but not those before!

The allocation of PWM outputs to the spindles can be found in the machine parameters

MP 121.x.

20.1.2 Possible Causes of Errors

Defective PWM interface or defective CC

Defective cable

Defective power module

Defective motor

Poor shielding and grounding

Mechanical defects

Error in the NC or PLC software

Wear and tear of mechanical parts

Deterioration of the machine

Defective HEIDENHAIN interface board for the SIMODRIVE 611 drive system

Wrong grounding in connection with the so-called HEIDENHAIN interface boards

There is wide variety of possible error causes.

Profound knowledge of the machine and the interaction of the components is very helpful for

this type of error.

If error messages are generated, press the HELP key. To obtain information on possible error

causes and tips for error elimination.

20 – 328 HEIDENHAIN Service Manual iTNC 530

Page 30

20.1.3 Trouble Shooting: Exchanging PWM Outputs on the CC 422

To find out whether the PWM interface on the control or the connected drive system is

defective, you can try another PWM interface on the control.

Use the interface of a funtioning axis!

Modular setup with CC 422

UV

UM

UM

UM

UP

UV 105

CC 422

MC 422

Example: Error in X-axis

Assumed machine parameters

PWM

PWM

For fault diagnosis, proceed as follows:

MP 100.x = - - - - -CZYX (X = 1st axis, Y = 2nd axis, Z = 3rd axis, C = 4th axis)

MP 2180.x = 0 (PWM frequency = 5 kHz for all axes)

MP 120.0 = 51 (X axis on PWM output X51)

MP 120.1 = 52 (Y axis on PWM output X52)

MP 120.2 = 53 (Z axis on PWM output X53)

MP 120.3 = 54 (C axis on PWM output X54)

MP 121.0 = 56 (1. Spindle on PWM output X56)

MP 121.1 = 0 (2. spindle not active)

Notes and preliminary actions

Exchange the PWM output a functioning axis

(depending on the configuration of the PWM frequencies, unassigned PWM outputs may not

be active)

Please observe that only within the groups X51 to X56 (main drive-control board)

and X57 to X64 (drive-control board) an exchange is possible!

The same PWM frequency should be set for axes to be exchanged!

If different PWM frequencies are entered in parameter group MP 2180.x, ask the machine

manufacturer or HEIDENHAIN for further service measures (the assignment of the machine

parameter blocks for the current or speed controller by means of MP 130.x must also be

regarded).

Before exchanging the speed encoder inputs, deactivate the evaluation of the electronic

ID labels in MP 7690!

Enter value 1 for each bit.

May 2006 20 – 329

Page 31

Block dDiagram

Note

Always exchange both, the cable and interface assignment by means of machine

parameters!

Note

It is not relevant for this test routine which drive modules are connected!

20 – 330 HEIDENHAIN Service Manual iTNC 530

Page 32

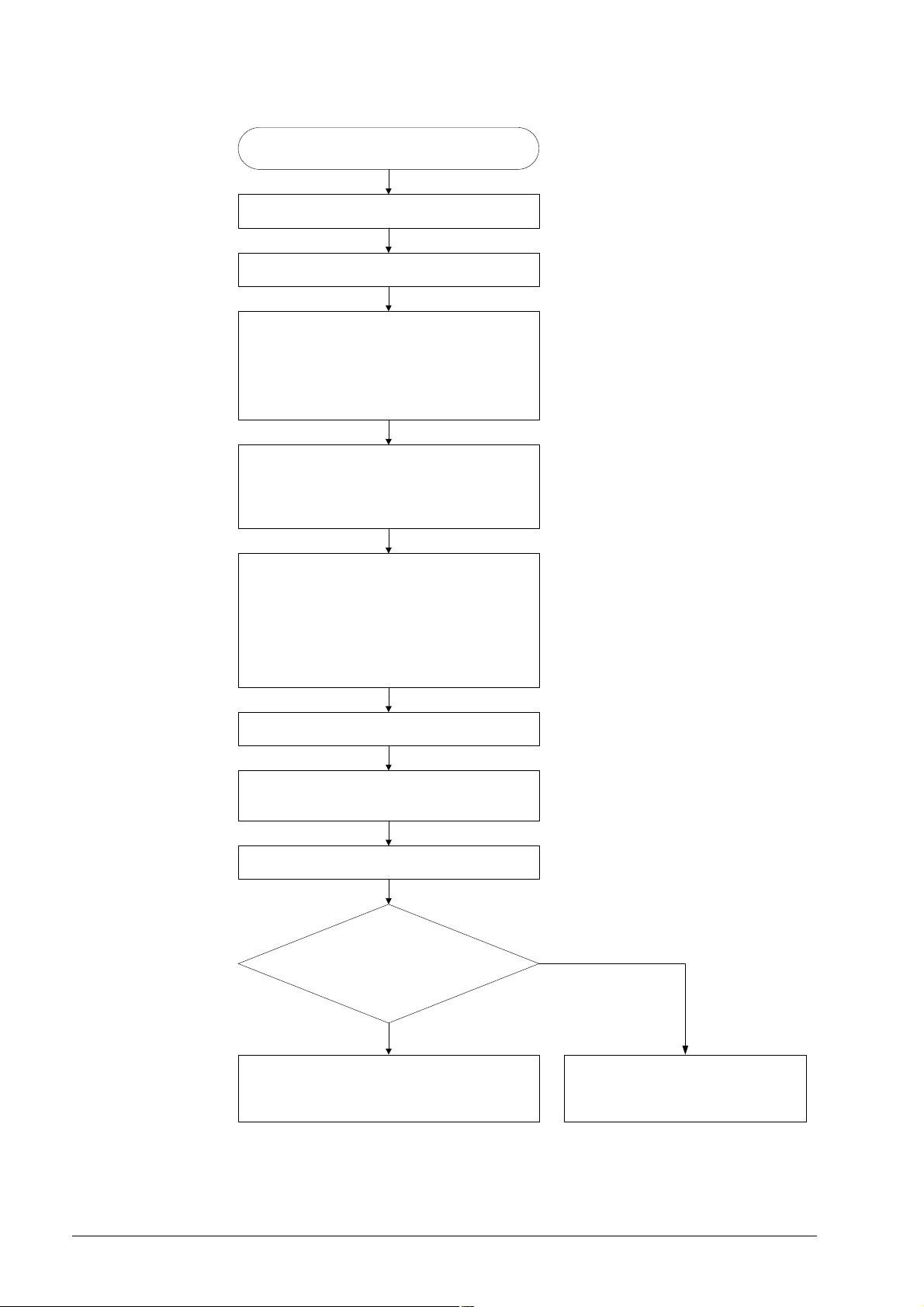

Flowchart CC 422

Interchanging the PWM outputs of CC 422

Switch off the main switch of the machine tool.

Unscrew the cover plate from the inverter system.

Interchange the PWM ribb on cables of the axes

concerned at CC 422 (in the example:

Connectors X51 and X52) .

CAUTION: Handle the ribbon cable connectors

with care! Do not bend the pins!

Screw the cover plate to the inverter system.

CAUTION: Do not damage the ribbon cable!

Switch the main switch of the mac hin e on.

Do not confirm the Power interrupted message

but immediately call the MP list and in

MP120.x interchange the entry values of

the axes concerned.

(In the example: MP 120 . 0 : 52 / MP 120.1: 51)

Confirm the Power interrupted message and

switch the control voltage on.

Traverse the axes.

Does the error pattern

move to the other axis?

(In the example from

X to Y)

Yes

The defect is probably located

in the PWM interface of CC 422.

No

The defect is probably locat ed

in the drive system (power module,

motor, cables, etc.)

Note

Set MP 7690 (evaluation of the electronic ID label) to its original state after the test!

May 2006 20 – 331

Page 33

Corrective action If you have found out that the interface on the CC 422 is defective …

Exchanging the CC. --> See “Exchange of HEIDENHAIN Components” on page 26 – 411.

If you have detected that the error is outside the control (servo amplifier, motor, cable, etc.):

Start the following routine. --> See “Trouble Shooting: Exchanging Power Modules or Output

Stages of the Same Type” on page 20 – 337

20 – 332 HEIDENHAIN Service Manual iTNC 530

Page 34

20.1.4 Trouble Shooting: Exchanging PWM Outputs on the CC 424

To find out whether the PWM interface on the control or the connected drive system is

defective, you can try another PWM interface on the control.

Use the interface of a funtioning axis!

Modular setup with CC 424

Example: Error in X-axis

Assumed machine parameters

Notes and preliminary actions

For fault diagnosis, proceed as follows:

MP 100.x = - - - - -CZYX (X = 1st axis, Y = 2nd axis, Z = 3rd axis, C = 4th axis)

MP 2180.x = 0 (PWM frequency = 5 kHz for all axes)

MP 120.0 = 51 (X-axis at motor power stage connection X51)

MP 120.1 = 52 (Y-axis at motor power stage connection X52)

MP 120.2 = 53 (Z-axis at motor power stage connection X53)

MP 120.3 = 54 (C-axis at motor power stage connection X54)

MP 121.0 = 56 (1. spindle at motor power stage connection X56)

MP 121.1 = 0 (2. spindle not active)

Exchange the PWM output a functioning axis

(depending on the configuration of so-called single-speed and double-speed outputs,

unassigned PWM outputs may not be active)

So-called single-speed and double-speed PWM outputs with equal PWM frequency can be

exchanged for test purposes.

Please observe that only within the groups X51 to X56 (main drive-control board)

and X57 to X64 (drive-control board) an exchange is possible!

The firmly assigned motor encoder output must also be exchanged!

The same PWM frequency should be set for axes to be exchanged!

If different PWM frequencies are entered in parameter group MP 2180.x, ask the machine

manufacturer or HEIDENHAIN for further service measures (the assignment of the machine

parameter blocks for the current or speed controller by means of MP 130.x must also be

regarded).

Master-slave axes function only on the outputs X51 to X53 and X52 to X54.

Before exchanging the speed encoder inputs, deactivate the evaluation of the electronic

ID labels im MP 7690!

Enter value 1 for each bit.

May 2006 20 – 333

Page 35

Block Diagram

Note

Always exchange both, the cable and interface assignment by means of machine

parameters!

Note

It is not relevant for this test routine which drive modules are connected!

20 – 334 HEIDENHAIN Service Manual iTNC 530

Page 36

Flowchart CC 424

Interchanging the PWM outputs of CC 424

Switch off the main switch of the machine tool.

Unscrew the cover plate from the inverter system.

Interchange the PWM ribbon cables of the axes

concerned at CC 424

(in the example: Connectors X51 and X52).

CAUTION: Handle the ribbon cable connectors

with care! Do not bend the pins!

Connect the motor encoder cables to the correct

PWM outputs of the CC 424

(in the example: Connectors X15 and X16).

See assignment in the introduction to this chapter.

Screw the cover plate to the inverter system.

CAUTION: Do not damage the ribbon cable!

Switch the main switch of the machine on.

Do not confirm the Power interrupted message but

immediately call the MP list and in MP 120.x

interchange the entry values of the axes concerned.

(In the example: MP 120.0: 52 and MP 120.1: 51)

Confirm the Power interrupted message and switch

the control voltage on.

Traverse the axes.

Does the error pattern

move to the other axis?

(In the example from

X to Y)

Yes

No

The defect is probably located in

the drive system (power module,

motor, cables, etc.)

The defect is probably loca ted

in the PWM interface of CC 424.

Note

Set MP 7690 (evaluation of the electronic ID label) to its original state after the test!

May 2006 20 – 335

Page 37

Corrective action If you have found out that the interface on the CC 424 is defective …

Exchanging the CC --> See “Exchange of HEIDENHAIN Components” on page 26 – 411.

If you have detected that the error is outside the control (servo amplifier, motor, cable, etc.):

Start the following routine. --> See “Trouble Shooting: Exchanging Power Modules or Output

Stages of the Same Type” on page 20 – 337

20 – 336 HEIDENHAIN Service Manual iTNC 530

Page 38

20.1.5 Trouble Shooting: Exchanging Power Modules or Output Stages of the Same Type

General If you have found out that the PWM interface on the CC is in order, you can test if a traverse of

the faulty axis with …

a dimensionally identical power module (modular inverter system) or

an output stage with equal power (2-axis-module, compact inverter)

is possible.

DANGER

If you want to use other types of power stages or output stages, we strongly recommend

contacting your machine manufacturer or HEIDENHAIN. Otherwise you could cause

damage or injury to machine or persons!

Use one of the following units:

Either a replacement unit

Or a power stage or output stage already located in the electrical cabinet but is not used (with

compact inverters, e.g., a output stage with equal power could be available)

Or the power stage or output stage of a functioning axis

Note

It is not necessary to exchange a machine parameter for this test routine!

It does not matter whether the power stages are from HEIDENHAIN or other

manufacturers.

Caution

If you strongly suspect that the motor of the axis to be examined causes a short circuit

(penetration of humidity, etc.), you must not connect it to another power stage as it could

be destroyed!

DANGER

Always secure vertical axes from falling down before you perform this test!

DANGER

Danger of electrical shock!

Make sure that the main switch of the machine is switched off and that any connectors and

terminals are free of potential before you engage or disengage them.

May 2006 20 – 337

Page 39

Assumed configuration for two 1-axis modules

UM 12x: X111 (PWM connection of channel 1) connected with X51 (iTNC, X axis)

X81 (motor connection of channeel 1) connected with motor X axis

UM 11x: X111 (PWM connection of channel 1) connected with X52 (iTNC, Y axis)

X81 (motor connection of channel 1) connected with motor Y axis

Assumed configuration for one 2-axis module

Example: Error in X axis

Block diagram for two 1-axis modules

UM 12x: X111 (PWM connection of channel 1) connected with X51 (iTNC, X axis)

X112 (PWM connection of channel 1) connected with X52 (iTNC, Y axis)

X81 (motor connection of channel 1) connected with motor X axis

X82 (motor connection of channel 2) connected with Y-axis

For fault diagnosis, proceed as follows:

Caution

If motor brakes are connected to the power stages, they have also to be exchanged (X344,

X392, X393, X394, depending on the model. --> see Service Manual for Inverter Systems

and Motors)!

Motor brakes can be connected to current HEIDENHAIN inverter modules and compact

inverters. The motor brake is also powered via a connector on the inverter. The trigger

signals for the motor brakes are transmitted via the PWM bus.

20 – 338 HEIDENHAIN Service Manual iTNC 530

Page 40

Flowchart for two 1-axis modules

Interchanging power modules of the same type

Switch off the main switch of the machine tool.

Unscrew the cover plate from the inverter system.

Interchange the PWM ribb on cables of the axes

concerned at the power modu les or output

stages (in the example: connectors X111).

CAUTION: Handle the ribbon cable connectors

with care! Do not bend the pins!

Screw the cover plate to the inverter system.

CAUTION: Do not damage the ribbon cable!

Connect the motor connec tors to the

power module or to the compact inverter

in accordance with the PWM inputs

(in the example: connectors X81).

CAUTION: If motor brakes are to be controlled

by the power module, their connections has

to be altered as well!

Switch the main switch of the mac hin e on.

Confirm the Power interrupted message and

switch the control voltage on.

Traverse the axes.

Does the error pattern

move to the other axis

(in the example from

X to Y)?

No

Yes

The defect is probably located

in the power module / output stage.

The defect is probably due to the

motor, the motor cable, the PWM

ribbon cable or the mechanics.

May 2006 20 – 339

Page 41

20.1.6 Trouble Shooting: Exchanging the HEIDENHAIN Interface Boards for the SIMODRIVE 611 System

If a SIMODRIVE 611 system is used in connection with the HEIDENHAIN control, there are

HEIDENHAIN interface boards in the Siemens drive modules to adapt the PWM signals.

Boards of the same type

Boards of different types

Before using other drive modules for examination of faulty axes, you may exchange

dimensionally identical expansion boards.

Observe the following:

The machine is not under power when you exchange the boards

Boards of the same type are exchanged (1-axis module or 2-axis module, metallically isolated

or not metallically isolated --> See “Important Notes on the Use of HEIDENHAIN Interface

Boards in SIMODRIVE System” on page 5 – 29)

The grounding is correct --> See “Important Notes on the Use of HEIDENHAIN Interface

Boards in SIMODRIVE System” on page 5 – 29

If you do not have boards of the same type, under certain circumstances you may exchange

boards for 1-axis modules for boards for 2-axis modules and vice versa.

Difficulties can be:

Some 2-axis module boards (ID number smaller than 359002-xx) require the corresponding

enabling signals of the control on every PWM interface. If such a board is inserted in a 1-axis

module and one PWM interface is not assigned, the complete board is not released.

If a 1-axis module board is inserted in a 2-axis module for test purposed, the corresponding

axis can be inspected (if the other axis is to be inspected, to motor output on the power stage

must be reconnected).

For these tests it might be necessary to deselect axes that cannot be contolled by MP 10.

With some machines this might be difficult.

--> If necessary, ask the HEIDENHAIN service agency!

Caution

Boards with metallic isolation of HEIDENHAIN PWM signals to the Siemens interface must

not be replaced by boards without metallic isolation and vice versa!

--> See “Important Notes on the Use of HEIDENHAIN Interface Boards in SIMODRIVE

System” on page 5 – 29

20 – 340 HEIDENHAIN Service Manual iTNC 530

Page 42

20.2 Analog Drives

20.2.1 Introduction

Analog servo amplifiers ars also referred to as analog servos.

For analog drives often DC motors are used.

The analog servo amplifiers are controlled via ±10V interfaces.

The position controller is located in the MC, speed and current controller in the servo amplifier.

The HEIDENHAIN control also supplies the nominal speed value. This is why the ± 10V interface

is also designated as nominal speed value interface.

On the MC 42x (B) there are the following analog nominal speed value outputs:

X8 and X9

On each of these D-Sub connectors there are several analog channels.

MP 100 contains the axis sequence (first, second, third axis etc.).

Caution

MP 100 must not be edited!

The allocation of nominal speed value outputs to the axes can be found in the machine

parameters.

MP 120.x

The allocation of nominal speed value outputs to the spindles can be found in the machine

parameters.

MP 121.x

20.2.2 Possible Causes of Errors

Defective nominal speed value interface of the MC (X8, X9)

Defective cable

Defective servo amplifier

Defective motor (carbon brushes, tachometer brushes, winding, etc.)

Poor shielding and grounding

Mechanical defects

Errors in the NC or PLC software

Wear and tear of mechanical parts

Deterioration of the machine

There is wide variety of possible error causes.

Profound knowledge of the machine and the interaction of the components is very helpful for

this type of error.

If error messages are generated, press the HELP key. To obtain information on possible error

causes and tips for error elimination.

20.2.3 Testing the Analog Nominal Speed Value Interface

The control outputs an analog voltage of 0 V to maximum ± 10 V (the analog voltage is entered

in MP 1050.x).

This voltage can be measured at the connecting terminals of the servo amplifier or directly at the

MC with the HEIDENHAIN test adapter.

May 2006 20 – 341

Page 43

Investigation with the integrated oscilloscope

With the integrated oscilloscope the Volt. analog voltage can observed:

Error: No axis traverse!

See “Integrated Oscilloscope” on page 8 – 49.

It is a prerequisite that the release conditions (e.g., door contacts, permissive buttons, etc.)

for the axis movements are given.

For the axes to be traversed ...

No terminal symbol before the axis concerned must be shown.

The feed rate display (F …) must not be highlighted.

The "STIB" star (control in operation) must be shown.

If necessary, ask the machine operator!

20 – 342 HEIDENHAIN Service Manual iTNC 530

Page 44

Flowchart If nevertheless one or several analog axes do not function, you may investigate the following:

Analog axis does not move

Switch the machine off and connect a multimeter

to the terminal strip of the servo amplifier of the

(Use the circuit diagram of the machine.)

Switch off the main switch of the machine.

Do not confirm the Power interrupted message but

immediately call the MP list and increase the tolerances

for movement and following-err or monitoring in the axis

to be checked:

(Note down the original values and restore them later.)

axis to be checked.

MP 1140.x : 9.99 [V]

MP 1410.x : 30 [mm]

MP 1420.x : 30 [mm]

MP 1710.x : 300 [mm]

MP 1720.x : 300 [mm]

Switch the machine on and

set the position display to LAG.

Turn the feed-rate potentiometer to zero

and start reference run for the defective axis

(e.g. with axis direction button).

Slowly turn up the feed-rate potentiometer

and observe the display of the multimeter.

Yes

Does the mulitmeter read a

voltage in the range of +/- 10 V?

No

Switch the machine off and disconnect the analog

servo amplifier from the speed command cable.

Repeat the above procedure with the servo a mplifier

disconnected.

Yes

Does the mulitmeter read a

voltage in the range of +/- 10 V?

The MC operates correctly;

the defect is probably due to the

analog servo amplifier and its

cables, to the motor etc.

No

MC or speed command cable defective.

May 2006 20 – 343

Page 45

Note

If the control functions properly, a nominal speed value interface can be read in the above

routine until the monitoring value (movement, servo lag, etc.) is reached. The nominal speed

value voltage 0 V is output together with the corresponding error messages.

Battery box If available, you can investigate whether the analog servo amplifier can be operated with a

"Battery box" (not a HEIDENHAIN unit).

This battery box replaces the control and provides the analog servo amplifier with a nominal

speed value of ± 10 V.

(The servo amplifier must be released. --> If necessary, ask the machine manufacturer!)

Measuring setup with test adapter

If available, you can connect the test adapter between connection X8 or X9 of the MC and the

nominal speed value cable. Connect a multimeter to the corresponding pin sockets of the test

adapter.

Assignment for the analog channels. --> See “X8: Analog output 1 to 6” on page 13 – 144; See

“X9: Analog output 7 to 13” on page 13 – 144

20 – 344 HEIDENHAIN Service Manual iTNC 530

Page 46

Specifications of the analog outputs

Load capacity: RL Š 5 kW, I £2 mA

CL £ 2 nF

Short-circuit stability: one output short-circuit proof at a time

Voltage range: Uamax = +10 V ± 100 mV

Uamin = -10 V ± 100 mV

Resolution: 14 bit = 16 384 steps

Smallest step:

10V

-------------- - 0.610 mV=

16384

May 2006 20 – 345

Page 47

20.2.4 Adjusting the Electrical Offset (Drift Adjustment)

General An offset adjustment is required or recommendable, in case of the following:

The axis drifts.

Servo lag of the axis at standstill is impermissibly high.

You have exchanged the MC.

You have exchanged the servo amplifier.

You have exchanged the motor.

You have replaced the motor brushes.

You have replaced cables or electrical lines at the machine.

If you receive the error message EXCESSIVE OFFSET <AXIS>.

Note

The drift adjustment only needs to be carried out with analog axes.

Offset Adjustment at servo amplifier

Analog servo amplifiers are no HEIDENHAIN products.

Follow the instructions of the servo manufacturer (operating instructions, etc.)!

Here are two proposals.

Proposal 1:

Check or set following machine parameters (if you change the machine parameter, please

take a note of the original values).

MP 1080.x (integral factor for offset) : 0 (switched off)

MP 1391.x, 1392.x (velocity feedforward control) : 1 (switched on)

MP 7290.x (display step) : 6 (0.1 µm)

Switch on the machine completely.

Select the Manual operating mode

Select the Programming and Editing operating mode

Call window for code number

Enter the code number

Confirm

End compensation

20 – 346 HEIDENHAIN Service Manual iTNC 530

Page 48

Axes to be adjusted must be in control (if necessary, ask the machine manufacturer).

Switch position display to LAG.

Adjust the offset at the servo amplifier until the individual axes either display the value 0 or

oscillate around 0 (approximate value ± 3-5 µm).

Note

Use also the integrated oscilloscope with the settings s actual, s nominal, s diff.

--> See “Integrated Oscilloscope” on page 8 – 49.

Reset the machine parameters and the position display to the original values.

Carry out offset fine adjustment with the code number 75368.

-->See “Offset fine adjustment by code number” on page 20 – 348

Proposal 2:

Switch off main switch of machine.

Disconnect the nominal speed value cable from the control.

Bring the nominal value of the axis to be adjusted to zero potential (short-circuit the ± 10 V

line with 0 V line of the corresponding axis).

Note

You can also produce a D-Sub connector for every analog nominal value interface X8 and X9.

There is a bridge between ± 10 V and 0 V (See “X8: Analog output 1 to 6” on page 13 – 144;

See “X9: Analog output 7 to 13” on page 13 – 144) for every channel in these connectors.

Connect the corresponding connector to the nominal speed value cable that you have

disconnected from the control (X8, X9).

Advantage of this method: The nominal value cable is included in the offset adjustment of

the servo amplifier.

Switch on main switch of machine.

Do not acknowledge the Power interrupt message. Call machine parameter list.

Set parameter 120.x to zero. --> No nominal value output, only display of axes.

(If necessary, deselect the reference point traverse in MP 1340.x).

Switch on the machine completely.

Establish the controller enabling on the servo amplifier or check whether it is on.

(if necessary, ask the machine manufacturer)!

Select Manual operation, set the display to the actual value and set the axis to zero.

Adjust the servo amplifier ideally to standstill. The axis movement can be seen on the actual

value display and possibly on a pulley.

Restore original condition (cabeling, parameters).

Carry out offset fine adjustment with the code number 75368. -->See “Offset fine adjustment

by code number” on page 20 – 348

May 2006 20 – 347

Page 49

Offset fine adjustment by code number

Note

Before you carry out an offset fine adjustment via code number, you must first adjust the

offset at the servo amplifier!

The control can compensate only ± 100 mV with the offset fine adjustment by code

number!

This corresponds to 1 % of the ± 10 V interface!!

An insufficient offset adjustment on the servo amplifier can thus not be compensated any

more with the code number adjustment.

The axes to be compensated must be in the position control loop. --> If necessary, ask the

machine manufacturer!

Select the Programming and Editing operating mode

Call window for code number

Enter the code number

Confirm

The iTNC displays the offset values of the analog axes in the dialog line.

The values show the setting of the voltage in 0.15-mV steps.

Display value 10 means: 10 · 0.15 mV = 1.5 mV. The displayed offset value consists of the offset

values that are generated in the motor controller and in the control.

Press the corresponding soft key in order to …

Carry out an offset compensation. Offset adjusting via code number

compensates the current offset values. By the offset adjustment with the code

number, the current offset of the entire control loop is compensated. Later

changes in offset are not compensated.

Do not carry out an offset compensation, or end a previous compensation.

Exit the menu without making any changes.

20 – 348 HEIDENHAIN Service Manual iTNC 530

Page 50

20.2.5 Speed Adjustment at Servo Amplifier (Tachometer Adjustment)

General Speed adjustment at servo amplifier needs to be carried out in case of the following:

You have updated the mechanical design of the axis

(e.g., guideway, bearing, belt, coupling, ball screw, etc.)

You have exchanged the servo amplifier or the motor

You have replaced the motor brushes.

Servo lag at constant traverse is impermissibly high

The aim of speed adjustment is to achieve that the output nominal speed value is equal to the

really measured actual speed value (Vnom = Vact).

Note

Adjusting only needs to be carried out with analog axes.

Execution Analog servo amplifiers are no HEIDENHAIN products.

Follow the instructions of the servo manufacturer (operating instructions, etc.)!

Here is a proposal:

Check or set the following machine parameter (if you change the machine parameter, please

take note of the original input values).

MP 7290.x (display step) : 6 (0.1 µm)

Switch position display to LAG.

Enter the following test program (e.g. for X axis,select a larger traverse range than indicated

in example X + 100)

DANGER

Enter this test program with the machine operator. Please be careful to prevent a collision

(retract Z axis first, etc.)!

0 BEGIN PGM tacho_adjustment X MM

1LBL 1

2 L X+ 0 F MAX

3 L X + 100 F MAX

4 CALL LBL 1 REP 100

5 END PGM tacho_adjustment X MM

Set the feed rate potentiometer to zero.

Run the program in the Program Run, Full Sequence operating mode and turn the feed rate

potentiometer slowly to 100 %.

Adjust tachometer generator at the servo amplifier using the servo lag display as follows:

For operation with velocity feedforward control, adjust the servo lag display

to 0 (ideally).

For operation with servo lag, adjust the servo lag display as follows:

m

-------- min

LAG [mm] =

Traversing speed

--------------------------------------------------------- kv-Faktor

May 2006 20 – 349

Page 51

Comparison of noml. and actl. speed in the integrated oscilloscope

Note

Read the traverse speed from the display:

The kv factor for the lag mode is defined in MP 1810.x.

It is possible that a multiplication factor for the kv factor is active for the displayed traverse

speed (MP 1820.x). A characteristic curve kink point must be entered in MP 1830.x. Contact

the machine manufacturer!

Repeat the adjustment procedure for all axes.

Reset the original values in machine parameter MP 7290.x.

Note

It might be helpful to use the integrated oscilloscope. The signals Vnoml and Vactl can be

recorded and compared. The quality of the speed adjustment can thus be controlled and

improved, if required.

20 – 350 HEIDENHAIN Service Manual iTNC 530

Page 52

20.3 Switching the Position Display for Service Purposes

Call Press the following key combination to switch the position display:

Select a machine operating mode (manual, Program Run, Full Sequence, etc.).

Activate MOD function.

Description of settings

Press GOTO to open a list box.

Possible position displays:

ACTL. Actual position

REF Distance to machine datum

LAG Current following error

NOML Nominal position

DIST. Distance to go

Using the arrow keys, select the desired position display.

Press ENT to activate the position display.

Exit subordinate mode.

May 2006 20 – 351

Page 53

20 – 352 HEIDENHAIN Service Manual iTNC 530

Page 54

21 Visual Display Unit

21.1 General

One of the two flat-panel displays are connected to the iTNC 530:

BF 150 with horizontal and vertical soft keys

BF 120 with horizontal soft keys

The BF is …

supplied with 24 V dc voltage from the electrical cabinet power supply unit.

is driven with display signals from the control.

The screen interface ...

connector X49 on the MC for the BF 120

connector X149 on the MC for the BF 150

... is HEIDENHAIN-specific. A conventional flat-panel screen cannot be connected.

21.2 Possible Causes of Errors

Defective screen

Erroneous power supply 24 V-

Defective monitor cable

No display signals from the control

Defective unit that is connected to the control and impairs it strongly

Defective screen soft keys

May 2006 21 – 353

Page 55

21.3 Fault Diagnosis

Visual display unit soft keys

The soft keys of the BF screens are connected by flat cable with the keypad board of the TE.

Service diagnosis --> see “Checking the Keys” on page 22 – 360.

Monitor If the screen remains black, check …

if the fan is running.

if the 24 V supply on the 2-pin connection of the visual display unit.

if the screen cable is in good order.

If this is not the reason you can test whether the screen information can be read out, e.g., with

the HEIDENHAIN PC software TNCremoNT.

Connect the control to the laptop/PC.

--> see “Connection Setup” on page 16 – 247.

Click on one of the "camera" symbols.

If the display information is now available on the laptop/PC, the graphics board of the control is

probably in order.

If this does not function, probably the MC (graphics board, etc.) is defective!?

Note

If you can see the display information with TNCremoNT, it is not completely sure that all

areas of the graphics board are in good order!

You can also perform the following test:

Switch off the machine.

Make sure that all connectors and cables are labeled.

Disconnect all connectors (exept the screen connector, the supply connector X69 and the 5 V

supply terminal) from the MC and the CC.

Press EMERGENCY STOP.

Switch on the machine.

If the screen is now functioning, the control is impaired by a defective unit such that the

screen cannot be operated properly.

Note

Now you can connect all connectors to the MC and CC one after the other (the machine must

always be switched off) and observe when the error occurs again (in this case the black

screen). Subsequently, search the error of the connected unit including cable.

Note

If you have found out that the screen itself is defective, then a further inspection of the flatpanel display is not possible without special test equipment.

21 – 354 HEIDENHAIN Service Manual iTNC 530

Page 56

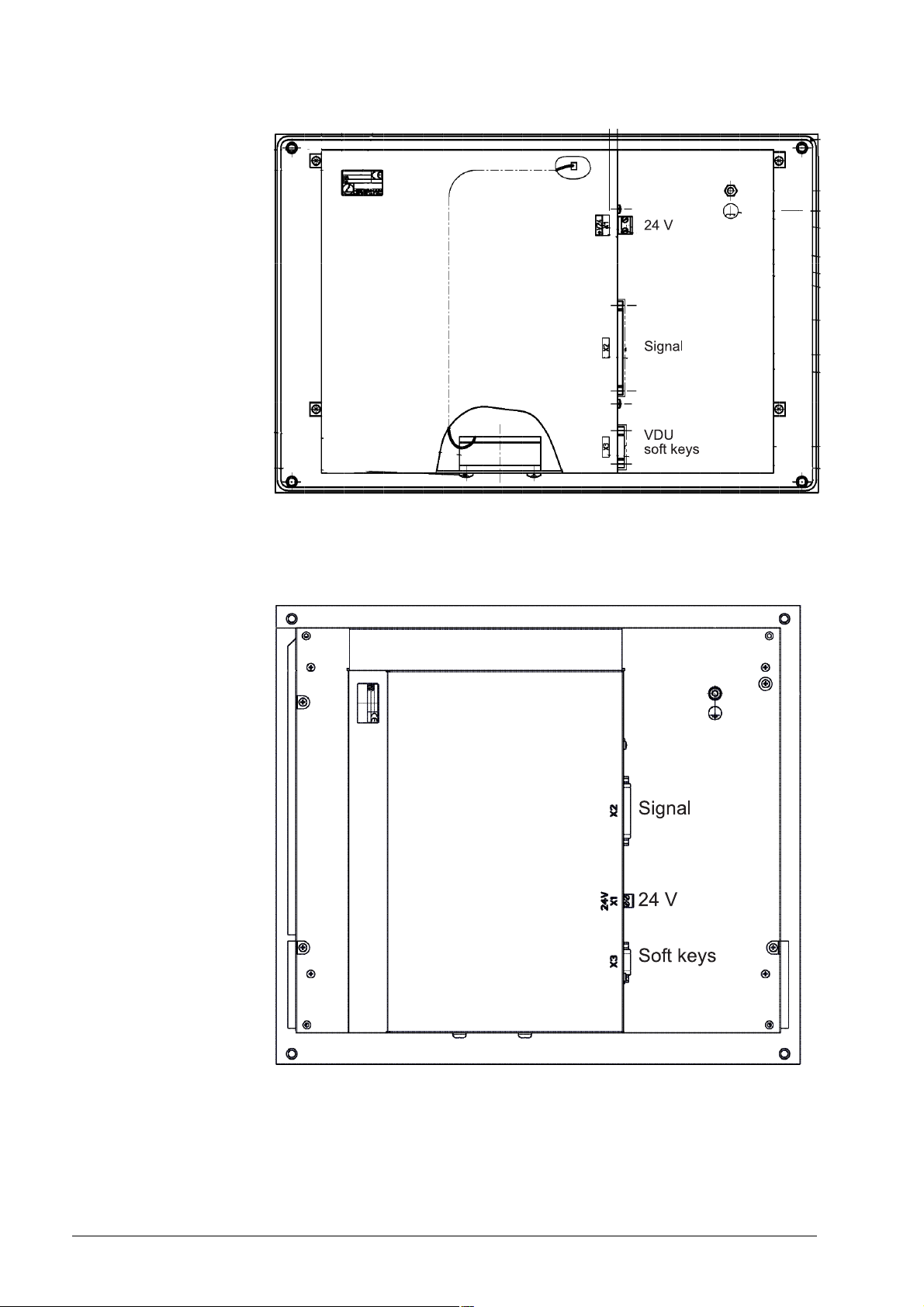

Rear view BF 120

Rear view BF 150

May 2006 21 – 355

Page 57

21 – 356 HEIDENHAIN Service Manual iTNC 530

Page 58

22 Keyboard Unit

22.1 General

The keyboard units are available with individual keys and as membrane keyboard.

The screen soft keys are connected to the keypad board.

The key signals on the control are transferred by a matrix. Every crosspoint of a SL (ScanLine)

with a RL (ReturnLine) is assigned to a certain key.

If HR 420 electronic handwheel is active, the operation of the machine via keypad is locked.

For iTNC 530 single-processor controls a TE 420 can be used; for dual-processor controls,

however, a mouse pad and additional Windows keys are required (Te 530, 530 B).

For the HEIDENHAIN programming surface smarT.NC additional keys are necessary.

(TE 530 B, TE 520 B).

22.2 Front View of the Keyboard Units

TE 420

May 2006 22 – 357

Page 59

TE 530 (with mouse pad and additonal Windows keys)

TE 530 B (with additonal smarT.NC keys)

22 – 358 HEIDENHAIN Service Manual iTNC 530

Page 60

TE 520 B (with additional smarT.NC keys, without mouse pad)

22.3 Possible Causes of Error

Note

Defective keys cannot contact any more or are in continuous contact.

Strong contramination --> Key gets caught

Jammed chips --> Key gets caught

Defective contact --> Key does not report to the control any more

Penetrated liquid

Defective keypad board

Defective cable between screen and keypad (screen softkeys)

Defective cable between keypad and control

Defective interface on the control

Worn potentiometer wiper

Defective mouse pad

May 2006 22 – 359

Page 61

22.4 Checking the Keys

This includes the keys on the TE keypad unit and the keys (soft keys) on the BF flat-panel

display. The soft keys of the screen are connected by ribbon cable with the keypad board.

Correct operation?

Make sure that the key in the selected operating mode really functions.

--> Ask the machine operator or look it up in the User's Manual!

Visual inspection First check the keypad visually!

Is the key strongly contaminated (grease, dust, oil, etc.)?

Are there jammed chips?

The key may thus get caught.

In such a case, the keypad must be cleaned carefully.

DANGER

When liquid cleaning agents have be used, the electrical units must dry completely before

they are operated again.

Does the control receive the key signal?

To be sure you can observe the key code in PLC word W274 when

the keys are pressed:

Press EMERGENCY STOP.

Reboot the control.

Do not acknowledge the "Power interrupted" message.

Call the PLC table for the words (see “The TABLE Function” on page 10 – 76).

Press the key to be examined and check if the display changes to the valid key code and/or

the key reacts correspondingly. --> See note.

Text file KEYTEST.A

Note

When examining these keys, please check if the following reactions are generated:

END --> To leave the PLC table.

PG UP --> The cursor jumps one page up.

PG DN --> The cursor jumps one page down.

GOTO --> A target must be entered at the top of the screen

(press NO ENT to exit!).

END BLOCK --> To leave the PLC table.

MACHINE OPERATING MODES --> The corresponding machine operating mode is called.

As an alternative to test whether the control receives the key signals, you can create a text file,

e.g. KEYTEST.A.

The keys pressed on the ASCII field (blue keys) are displayed directly. Other keys mostly

generate the message "Key non-functional" or a corresponding reaction, e.g., change to a

machine operating mode.

22 – 360 HEIDENHAIN Service Manual iTNC 530

Page 62

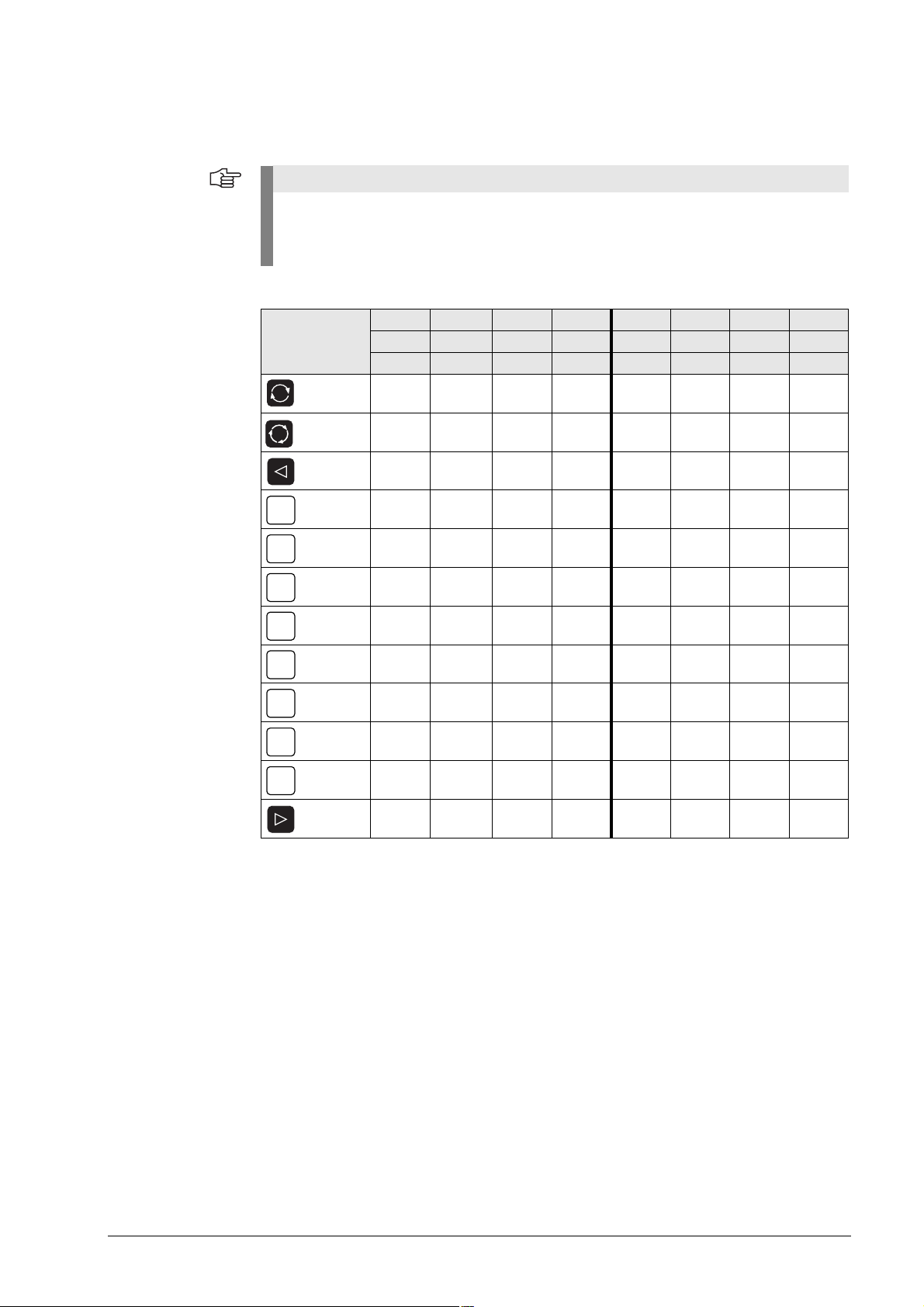

Principle of the key matrix

Is a line (cable, board) or the key defectibe?

The keys are evaluated via a matrix. Every key is located above a crosspoint of SL (= scan line)

and RL (= return line). --> see “Key Matrix of the Keyboard Units” on page 22 – 367 or see “Key

Matrix of the Keyboard Units” on page 22 – 382.

Inspection of the keyboard

Use the key matrix to find a key that is

selected by the same RL line as the

defective key (and which functions in

the selected operating mode).

Press this key.

No

Any reaction?

Yes

Use the key matrix to find a key that is

selected by the same SL line as the

defective key (and which functions in

the selected operating mode).

Press this key.

No

Any reaction?

The line to the matrix is interrupted.

Check the keyboard cable (measure

the cable, try replacement, etc.)

and the connectors.

Is the keyboard PCB defective?

Yes

The matrix lines (keyboard cable,

keyboard PCB) are in order.

The contact of the key is

probably defective.

May 2006 22 – 361

Page 63

Measuring setup with test adapter

The functioning of the keypad connected is tested with the following setup.

The following special appliance is required.

--> see “Test Adapter, ID 375830-01” on page 29 – 456:

Switch off the machine.

Disconnect the keypad cable on connector X45 of the MC.

Connect the keypad cable to the test adapter.

Connect the measuring lines of a multimeter to the pin sockets of the test adapter.

Use the correspondig key matrix with the pin layout. --> see “Key Matrix of the Keyboard

Units” on page 22 – 367.

Set the multimeter to ohm measurement or continuity test.

Press the key to be examined. If it functions, the resistance value from SL to RL approaches

zero (regard the resistance of the measuring lines).

Note

Limitations for keypads as of TE 5xx:

A continuity test of the cross points of scan lines (SL) and the return line 0 (RL 0) is not

possible. There are logical gates between RL 0 and the corresponding keys. These gates

serve as keypad identifier as of TE 5 xx.

A direct ohmic measuring is thus not possible.

22 – 362 HEIDENHAIN Service Manual iTNC 530

Page 64

The functioning of the keypad interface on the MC can also be tested with the test adapter:

Disconnect the keypad from the MC.

Connect the test adapter instead to connector X45 of the MC.

You can now simulate the pressing of keys by bridging the corresponding pin sockets on the

test adapter.

(Please refer again to the key matrix which sockets must be connected.)

Caution

Do not generate a short circuit of the potentiometer voltage (PIN 36 and 37)!

Note

As the keypad interface X45 on the MC is designed as female, you can also connect the pins

with a wire bridge and thus conduct a simulation by pressing the keys.

May 2006 22 – 363

Page 65

22.5 Checking the Potentiometers

Potentiometer values in the PLC-TABLE

Potentiometer values in the oscilloscope

You can use the PLC table to determine whether the control receives the potentiometer signal.

The potentiometer setting is shown in the following PLC words:

W492 (=S override)

W494 (= F override)

Proceed as follows:

Press EMERGENCY STOP.

Call the PLC table for the words (see “The TABLE Function” on page 10 – 76).

Place the cursor at W492 or W494.

Select the decimal display.

Turn the potentiometer to be examined.

Check if the display can be changed from 0 to 15000 (with nonlinear characteristic curve)

or 0 to 150 (with linear characteristic curve).

The characteristic curve is defined in MP 7620 bit 3.

With the integrated oscilloscope you can also record the condition of PLC words.

-> see “Integrated Oscilloscope” on page 8 – 49.

The advantage of this method is that possible wiper interruptions of the potentiometers can be

recognized better than in the PLC TABLE.

For this investigation the machine must be switched on completely!

22 – 364 HEIDENHAIN Service Manual iTNC 530

Page 66

Measuring setup with test adapter

Procedure:

Switch off the machine.

Insert the measuring adapter at the MC connector X45 between MC and TE cable.

Switch the machine on again.

Using a multimeter, check the wiper voltages of the potentiometers.

Potentiometers PIN Voltage range

Feed rate override F% 37 = 0V / 35 = Wiper pot 0 ... approx. + 5 V

Spindle override S% 37 = 0V / 34 = Wiper pot 0 ... approx. + 5 V

May 2006 22 – 365

Page 67

22.6 Checking the Touch Pad

The touch pad on the TE 530 and 530B keypads functions also for the single-processor control

in connection with the Windows operating system of a dual-processor control and as of software

version smarT.NC!

This touch pad is not connected to the MC via keypad connector X45 but with a USB cable to

MC connector X141.

If the touch pad does not function, carry out the following test to find out if the touch pad itself

or the interface on the control is defective:

Try the second USB connector X142 on the control.

Note

If a new mouse or touch pad is connected, it functions only after the control has been

switched off and on again.

Try a commercially available mouse on the USB connectors of the control (the mouse should

function on a Windows 2000 PC).

If necessary, you can also extend the USB cable of the touch pad, connect it to a laptop and

test the functioning (the laptop must be equipped with a Windows operating system with the

corresponding mouse driver).

Note

As the touch pad is managed by Windows, there are also the corresponding Windows

settings. --> "My computer/Control Panel/Mouse…"

22 – 366 HEIDENHAIN Service Manual iTNC 530

Page 68

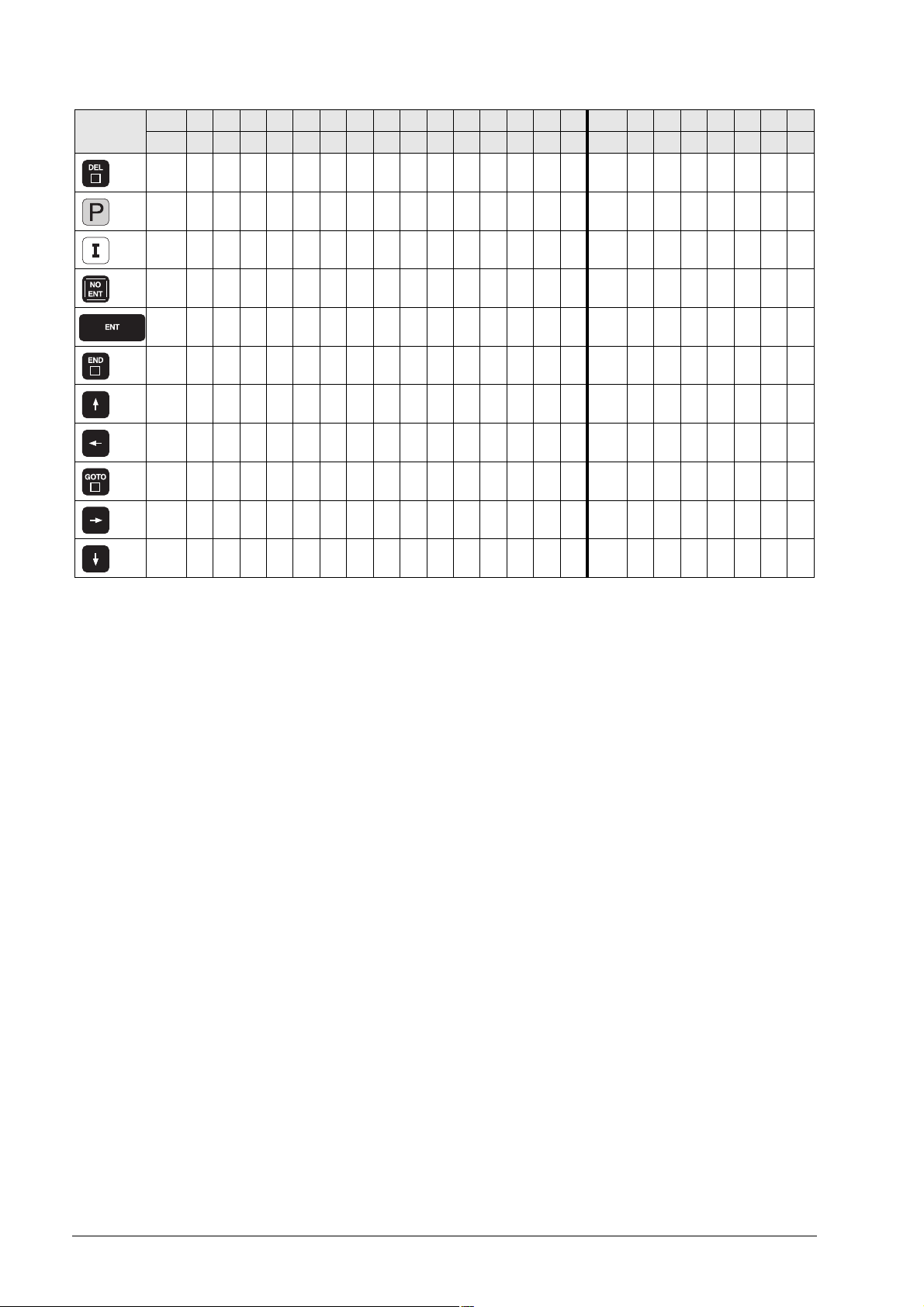

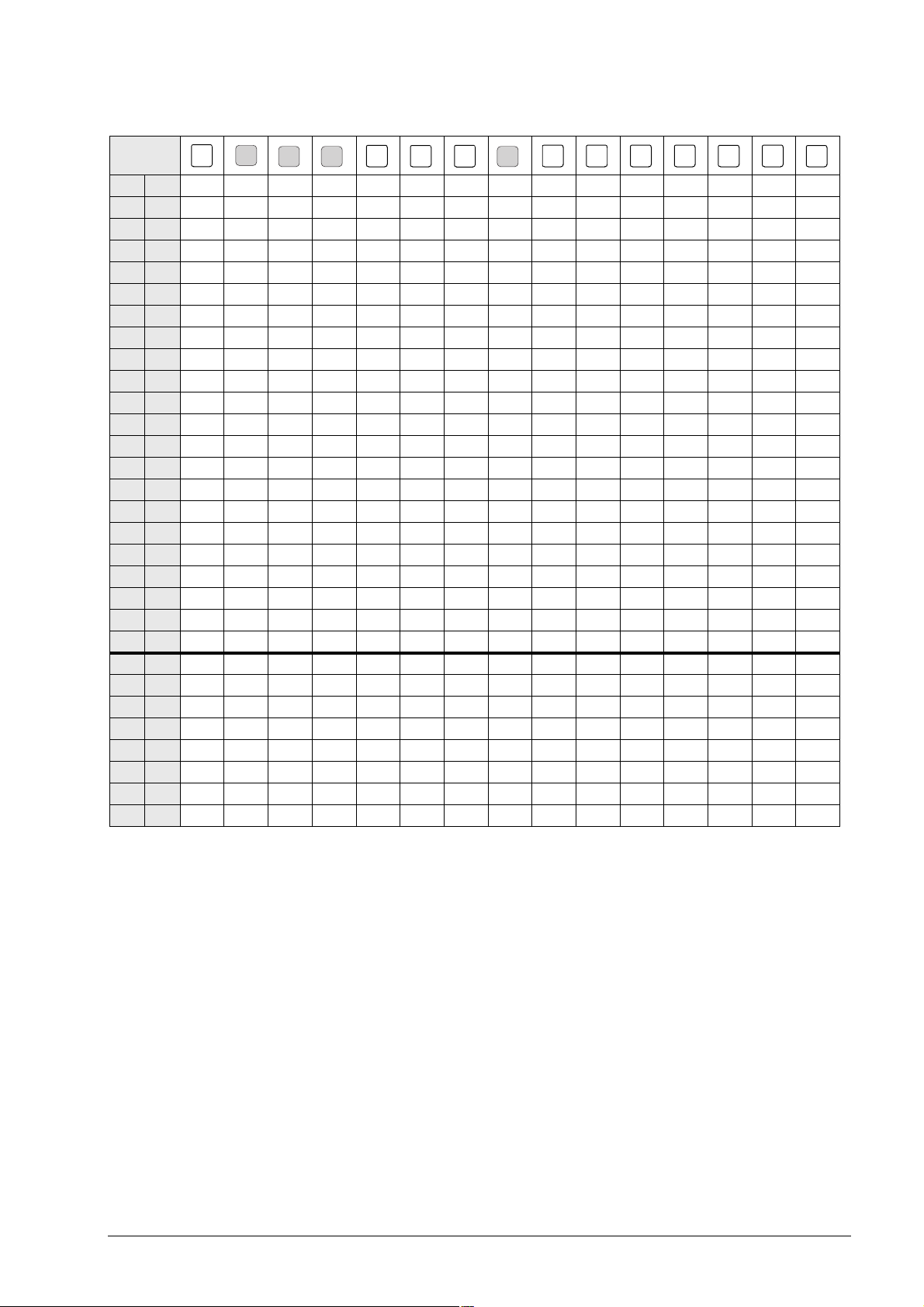

22.7 Key Matrix of the Keyboard Units

TE 420

X2 pin key 1 2 3 4 5 6 7 8 9 17 18 19 28 29 31 32 20 21 22 23 24 25 26 27

RL0 1 2 3 4 5 6 7 8 16 17 18 19 20 21 22 SL0 1 2 3 4 5 6 7

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX