HEIDENHAIN iTNC 530 User Manual

User’s Manual

HEIDENHAIN

Conversational

Programming

iTNC 530

NC Software

606 420-01

606 421-01

English (en)

6/2010

Controls of the TNC

1

50

0

50

100

F %

1

50

0

50

100

S %

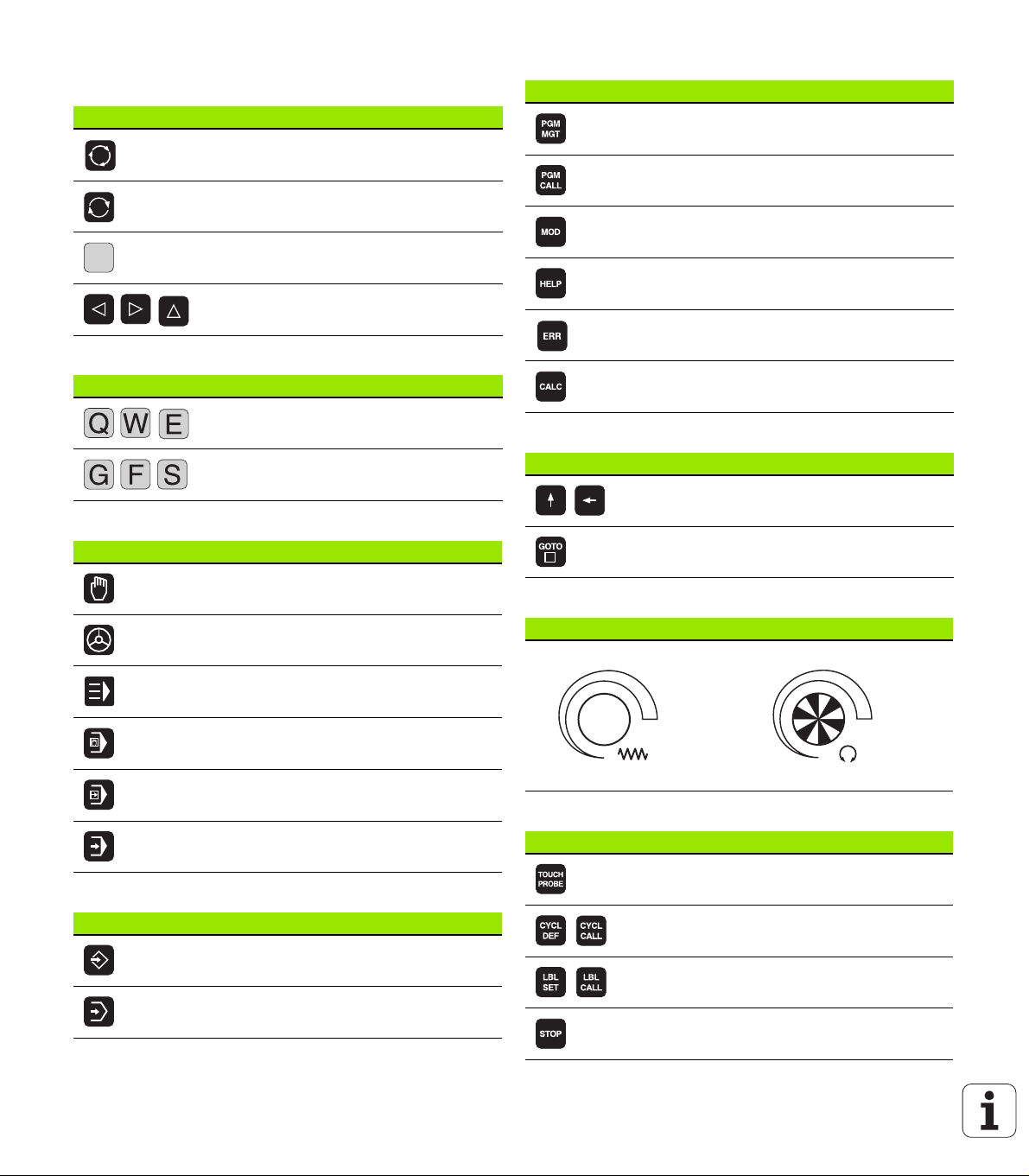

Keys on visual display unit

Key Function

Split screen layout

Toggle the display between machining

and programming modes

Soft keys for selecting functions on

screen

Shifts between soft-key rows

Alphanumeric keyboard

Key Function

File names, comments

DIN/ISO programming

Machine operating modes

Key Function

Manual Operation

Electronic Handwheel

Program/file management, TNC functions

Key Function

Select or delete programs and files,

external data transfer

Define program call, select datum and

point tables

Select MOD functions

Display help text for NC error messages,

call TNCguide

Display all current error messages

Show calculator

Navigation keys

Key Function

Move highlight

Go directly to blocks, cycles and

parameter functions

Potentiometer for feed rate and spindle speed

Feed rate Spindle speed

Programming modes

Key Function

smarT.NC

Positioning with Manual Data Input

Program Run, Single Block

Program Run, Full Sequence

Programming and Editing

Test Run

Cycles, subprograms and program section repeats

Key Function

Define touch probe cycles

Define and call cycles

Enter and call labels for subprogramming

and program section repeats

Program stop in a program

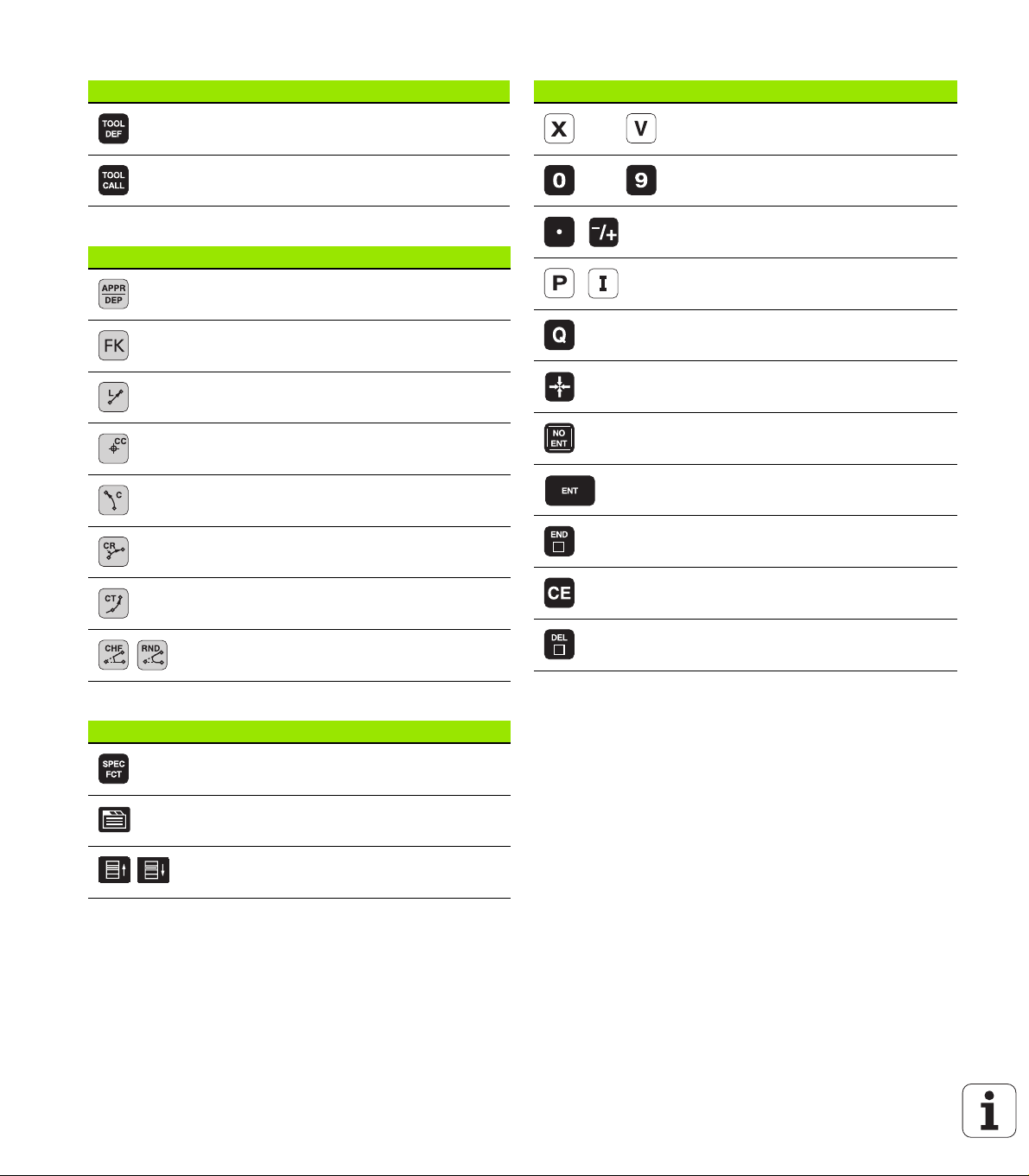

Tool functions

Key Function

Define tool data in the program

Coordinate axes and numbers: Entering and editing

Key Function

Select coordinate axes or

enter them into the program

Call tool data

Programming path movements

Key Function

Approach/depart contour

FK free contour programming

Straight line

Circle center/pole for polar coordinates

Circle with center

Circle with radius

Circular arc with tangential connection

Chamfering/corner rounding

Numbers

Decimal point / Reverse algebraic sign

Polar coordinate input / Incremental

values

Q parameter programming /

Q parameter status

Save actual position or values from

calculator

Skip dialog questions, delete words

Confirm entry and resume dialog

Conclude block and exit entry

Clear numerical entry or TNC error

message

Abort dialog, delete program section

Special functions / smarT.NC

Key Function

Show special functions

smarT.NC: Select next tab on form

smarT.NC: Select first input field in

previous/next frame

About this Manual

The symbols used in this manual are described below.

This symbol indicates that important notes about the

function described must be adhered to.

This symbol indicates that there is one or more of the

following risks when using the described function:

Danger to workpiece

Danger to fixtures

Danger to tool

Danger to machine

Danger to operator

This symbol indicates that the described function must be

adapted by the machine tool builder. The function

described may therefore vary depending on the machine.

This symbol indicates that you can find detailed

information about a function in another manual.

About this Manual

Would you like any changes, or have you found any errors?

We are continuously striving to improve documentation for you.

Please help us by sending your requests to the following e-mail

address: tnc-userdoc@heidenhain.de.

HEIDENHAIN iTNC 530 5

TNC Model, Software and Features

This manual describes functions and features provided by TNCs as of

the following NC software numbers.

TNC model NC software number

iTNC 530, HSCI and HeROS 5 606 420-01

iTNC 530, HSCI and HeROS 5 606 421-01

The suffix E indicates the export version of the TNC. The export

version of the TNC has the following limitations:

Simultaneous linear movement in up to 4 axes

HSCI (HEIDENHAIN Serial Controller Interface) identifies the new

hardware platform of the TNC controls.

HeROS 5 identifies the new operating system of HSCI-based TNC

controls.

The machine tool builder adapts the usable features of the TNC to his

machine by setting machine parameters. Some of the functions

described in this manual may therefore not be among the features

provided by the TNC on your machine tool.

TNC functions that may not be available on your machine include:

TNC Model, Software and Features

Tool measurement with the TT

Please contact your machine tool builder to become familiar with the

features of your machine.

6

Many machine manufacturers, as well as HEIDENHAIN, offer

programming courses for the TNCs. We recommend these courses as

an effective way of improving your programming skill and sharing

information and ideas with other TNC users.

User’s Manual for Cycle Programming:

All of the cycle functions (touch probe cycles and fixed

cycles) are described in a separate manual. Please contact

HEIDENHAIN if you require a copy of this User’s Manual.

ID: 670 388-xx

smarT.NC user documentation:

The smarT.NC operating mode is described in a separate

Pilot. Please contact HEIDENHAIN if you require a copy of

this Pilot. ID: 533 191-xx.

TNC Model, Software and Features

HEIDENHAIN iTNC 530 7

Software options

The iTNC 530 features various software options that can be enabled

by you or your machine tool builder. Each option is to be enabled

separately and contains the following respective functions:

Software option 1

Cylinder surface interpolation (Cycles 27, 28, 29 and 39)

Feed rate in mm/min for rotary axes: M116

Tilting the machining plane (Cycle 19, PLANE function and 3-D ROT

soft key in the Manual operating mode)

Circle in 3 axes with tilted working plane

Software option 2

Block processing time 0.5 ms instead of 3.6 ms

5-axis interpolation

Spline interpolation

3-D machining:

M114: Automatic compensation of machine geometry when

TNC Model, Software and Features

working with swivel axes

M128: Maintaining the position of the tool tip when positioning

with tilted axes (TCPM)

FUNCTION TCPM: Maintaining the position of the tool tip when

positioning with tilted axes (TCPM) in selectable modes

M144: Compensating the machine’s kinematic configuration for

ACTUAL/NOMINAL positions at end of block

Additional parameters for finishing/roughing and tolerance

for rotary axes in Cycle 32 (G62)

LN blocks (3-D compensation)

DCM Collision software option Description

Function that monitors areas defined by the

machine manufacturer to prevent collisions.

DXF Converter software option Description

Extract contours and machining positions

from DXF files (R12 format).

Additional dialog language software

option

Function for enabling the conversational

languages Slovenian, Slovak, Norwegian,

Latvian, Estonian, Korean, Turkish, Romanian,

Lithuanian.

8

Page 377

Page 252

Description

Page 654

Global Program Settings software option Description

Function for superimposing coordinate

transformations in the Program Run modes,

handwheel superimposed traverse in virtual

axis direction.

AFC software option Description

Function for adaptive feed-rate control for

optimizing the machining conditions during

series production.

KinematicsOpt software option Description

Touch-probe cycles for inspecting and

optimizing the machine accuracy.

3D-ToolComp software option Description

3-D radius compensation depending on the

tool’s contact angle for LN blocks.

Page 395

Page 406

User’s Manual for

Cycles

Page 406

TNC Model, Software and Features

HEIDENHAIN iTNC 530 9

Feature content level (upgrade functions)

Along with software options, significant further improvements of the

TNC software are managed via the Feature Content Level (FCL)

upgrade functions. Functions subject to the FCL are not available

simply by updating the software on your TNC.

All upgrade functions are available to you without surcharge

when you receive a new machine.

Upgrade functions are identified in the manual with FCL n, where n

indicates the sequential number of the feature content level.

You can purchase a code number in order to permanently enable the

FCL functions. For more information, contact your machine tool

builder or HEIDENHAIN.

FCL 4 functions Description

Graphical depiction of the protected

space when DCM collision monitoring is

active

Page 381

Handwheel superimposition in stopped

condition when DCM collision

monitoring is active

TNC Model, Software and Features

3-D basic rotation (set-up

compensation)

FCL 3 functions Description

Touch probe cycle for 3-D probing User’s Manual for

Touch probe cycles for automatic datum

setting using the center of a slot/ridge

Feed-rate reduction for the machining of

contour pockets with the tool being in

full contact with the workpiece

PLANE function: Entry of axis angle Page 458

User documentation as a

context-sensitive help system

smarT.NC: Programming of smarT.NC

and machining can be carried out

simultaneously

smarT.NC: Contour pocket on point

pattern

Page 380

Machine Manual

Cycles

User’s Manual for

Cycles

User’s Manual for

Cycles

Page 154

Page 115

smarT.NC Pilot

10

FCL 3 functions Description

smarT.NC: Preview of contour

programs in the file manager

smarT.NC Pilot

smarT.NC: Positioning strategy for

machining point patterns

FCL 2 functions Description

3-D line graphics Page 146

Virtual tool axis Page 576

USB support of block devices (memory

sticks, hard disks, CD-ROM drives)

Filtering of externally created contours Page 420

Possibility of assigning different depths

to each subcontour in the contour

formula

DHCP dynamic IP-address

management

Touch-probe cycle for global setting of

touch-probe parameters

smarT.NC: Graphic support of block

scan

smarT.NC: Coordinate transformation smarT.NC Pilot

smarT.NC: PLANE function smarT.NC Pilot

smarT.NC Pilot

Page 125

User’s Manual for

Cycles

Page HIDDEN

User’s Manual for

Touch Probe Cycles

smarT.NC Pilot

TNC Model, Software and Features

Intended place of operation

The TNC complies with the limits for a Class A device in accordance

with the specifications in EN 55022, and is intended for use primarily

in industrially-zoned areas.

Legal information

This product uses open source software. Further information is

available on the control under

U Programming and Editing operating mode

U MOD function

U LEGAL INFORMATION soft key

HEIDENHAIN iTNC 530 11

New functions 606 42x-01 since the predecessor versions 340 49x-05

Opening and Editing of externally created files is new (see

“Additional tools for management of external file types” on page

128)

New functions in the task bar added (see “Soft-key row” on page

86)

Enhanced functions for configuration of the Ethernet interface (see

“Configuring the TNC” on page 625)

Improvements regarding Functional Safety FS (option):

General information on Functional Safety FS (see “General

Information” on page 534)

Explanation of terms (see “Explanation of terms” on page 535)

Checking the axis positions (see “Check axis positions” on page

536)

Activating feed-rate limitation (see “Activating feed-rate

limitation” on page 538)

Improvements regarding the general status views of a TNC with

functional safety (see “Additional Status displays” on page 538)

The new HR 510, HR 520 and HR 550 FS handwheels are supported

(see “Traversing with electronic handwheels” on page 522)

New software option 3-D ToolComp: 3-D tool radius compensation

depending on the tool’s contact angle on blocks with surface normal

vectors (LN blocks, see "3-D tool radius compensation depending on

the tool’s contact angle (3D-ToolComp software option)", page 489)

3-D line graphics is now also possible in full-screen mode (see “3-D

Line Graphics (FCL2 Function)” on page 146)

A file selection dialog for selecting files in different NC functions and

in the table view of the pallet table is available now (see “Calling any

program as a subprogram” on page 274)

DCM: Saving and restoring of fixture situations

DCM: The form for test program generation now also contains icons

and tooltips (see “Check the position of the measured fixture” on

page 388)

DCM, FixtureWizard: Touch points and probing sequence are shown

more clearly now

DCM, FixtureWizard: Designations, touch points and measuring

points can be shown or hidden as desired.(see “Operating

FixtureWizard” on page 385)

DCM, FixtureWizard: Chucking equipment and insertion points can

now also be selected by mouse click

DCM: A library with standard chucking equipment is available now

(see “Fixture templates” on page 384)

New functions 606 42x-01 since the predecessor versions 340 49x-05

DCM: Tool carrier management (see “Tool Holder Management

(DCM Software Option)” on page 392)

12

In the Test Run mode, the working plane can now by defined

manually (see “Setting a tilted working plane for the test run” on

page 600)

On machines without encoders in the rotary axes, the rotary axis

coordinates to define the virtual axis direction VT can now be

specified via M114 (see “Virtual axis VT” on page 405)

In Manual mode the RW-3D mode for position display is now also

available (see “Position Display Types” on page 636)

Entries in the tool table TOOL.T (see “Tool table: Standard tool data”

on page 166)

New DR2TABLE column for definition of a compensation table for

tool radius compensation depending on the tool’s contact angle

New LAST_USE column, into which the TNC enters the date and

time of the last tool call

Q parameter programming: QS string parameters can now also be

used for jump addresses of conditional jumps, subprograms or

program section repeats (see "Calling a subprogram", page 272, see

"Calling a program section repeat", page 273 and see "Programming

If-Then decisions", page 299)

The generation of tool usage lists in the Program Run modes can be

configured in a form (see “Settings for the tool usage test” on page

184)

The behavior during deletion of tools from the tool table can now be

influenced via machine parameter 7263

(see “Editing tool

tables” on page 172)

In the positioning mode TURN of the PLANE function you can now

define a clearance height to which the tool is to be retracted before

tilting to tool axis direction (see “Automatic positioning:

MOVE/TURN/STAY (entry is mandatory)” on page 460)

The following additional functions are now available in the expanded

tool management (see “Tool management (software option)” on

page 187):

Columns with special functions are also editable now

The form view of the tool data can now be exited with or without

saving changed values

The table view now offers a search function

Indexed tools are now shown correctly in the form view

The tool sequence list includes more detailed information now

The loading and unloading list of the tool magazine can now be

loaded and unloaded by drag and drop

Columns in the table view can be moved simply by drag and drop

Several special functions (SPEC FCT) are now available in the MDI

operating mode (see “Programming and Executing Simple

Machining Operations” on page 578)

There is a new manual probing cycle that can be used to

compensate workpiece misalignments by rotating the rotary table

(see “Workpiece alignment using 2 points” on page 561)

New functions 606 42x-01 since the predecessor versions 340 49x-05

HEIDENHAIN iTNC 530 13

New touch probe cycle for calibrating a touch probe by means of a

calibration sphere (see User's Manual for Cycle Programming)

KinematicsOpt: Better support for positioning of Hirth-coupled axes

(see User's Manual for Cycle Programming)

KinematicsOpt: An additional parameter for determination of the

backlash in a rotary axis was introduced (see User's Manual for

Cycle Programming)

New Cycle 275 for Trochoidal Slot Milling (see User’s Manual for

Cycle Programming)

In Cycle 241 "Single-Fluted Deep-Hole Drilling" it is now possible to

define a dwell depth (see User's Manual for Cycle Programming)

The approach and departure behavior of Cycle 39 "Cylinder Surface

Contour" can now be adjusted (see User's Manual for Cycle

Programming)

New functions 606 42x-01 since the predecessor versions 340 49x-05

14

Changed functions 606 42x-01 since the predecessor versions 340 49x-06

Q parameter programming: In the FN20 function WAIT FOR you can

now enter 128 characters (see “FN 20: WAIT FOR: NC and PLC

synchronization” on page 318).

In the calibration menus for touch probe length and radius, the

number and name of the active tool are also displayed now (if the

calibration data from the tool table are to be used, MP7411 = 1, see

"Managing more than one block of calibrating data", page 555).

During tilting in the Distance-To-Go mode, the PLANE function now

shows the angle actually left to be traversed until the target position

(see “Position display” on page 445).

The approach behavior during side finishing with Cycle 24 (DIN/ISO:

G124) was changed (see User's Manual for Cycle Programming).

HEIDENHAIN iTNC 530 15

Changed functions 606 42x-01 since the predecessor versions 340 49x-06

Changed functions 606 42x-01 since the predecessor versions 340 49x-06

16

Table of Contents

First Steps with the iTNC 530

1

Introduction

2

Programming: Fundamentals, File

Management

3

Programming: Programming Aids

4

Programming: Tools

5

Programming: Programming Contours

6

Programming: Miscellaneous Functions

7

Programming: Data Transfer from DXF

Files

8

Programming: Subprograms and Program

Section Repeats

9

Programming: Q Parameters

10

Programming: Miscellaneous Functions

11

Programming: Special Functions

12

Programming: Multiple Axis Machining

13

Programming: Pallet Editor

14

Positioning with Manual Data Input

15

Test Run and Program Run

16

MOD Functions

17

Tables and Overviews

18

HEIDENHAIN iTNC 530 17

1 First Steps with the iTNC 530 ..... 45

1.1 Overview ..... 46

1.2 Machine Switch-On ..... 47

Acknowledge the power interruption and move to the reference points ..... 47

1.3 Programming the First Part ..... 48

Select the correct operating mode ..... 48

The most important TNC keys ..... 48

Create a new program/file management ..... 49

Define a workpiece blank ..... 50

Program layout ..... 51

Program a simple contour ..... 52

Create a cycle program ..... 55

1.4 Graphically Testing the Program ..... 58

Select the correct operating mode ..... 58

Select the tool table for the test run ..... 58

Choose the program you want to test ..... 59

Select the screen layout and the view ..... 59

Start the program test ..... 60

1.5 Tool Setup ..... 61

Select the correct operating mode ..... 61

Prepare and measure tools ..... 61

The tool table TOOL.T ..... 61

The pocket table TOOL_P.TCH ..... 62

1.6 Workpiece Setup ..... 63

Select the correct operating mode ..... 63

Clamp the workpiece ..... 63

Align the workpiece with a 3-D touch probe system ..... 64

Set the datum with a 3-D touch probe ..... 65

1.7 Running the First Program ..... 66

Select the correct operating mode ..... 66

Choose the program you want to run ..... 66

Start the program ..... 66

HEIDENHAIN iTNC 530 19

2 Introduction ..... 67

2.1 The iTNC 530 ..... 68

Programming: HEIDENHAIN conversational, smarT.NC and ISO formats ..... 68

Compatibility ..... 68

2.2 Visual Display Unit and Keyboard ..... 69

Visual display unit ..... 69

Sets the screen layout ..... 70

Operating panel ..... 71

2.3 Operating Modes ..... 72

Manual Operation and Electronic Handwheel ..... 72

Positioning with Manual Data Input ..... 72

Programming and Editing ..... 73

Test Run ..... 73

Program Run, Full Sequence and Program Run, Single Block ..... 74

2.4 Status Displays ..... 75

“General” status display ..... 75

Additional status displays ..... 77

2.5 Window Manager ..... 85

Soft-key row ..... 86

2.6 Accessories: HEIDENHAIN 3-D Touch Probes and Electronic Handwheels ..... 87

3-D touch probes ..... 87

HR electronic handwheels ..... 88

20

3 Programming: Fundamentals, File Management ..... 89

3.1 Fundamentals ..... 90

Position encoders and reference marks ..... 90

Reference system ..... 90

Reference system on milling machines ..... 91

Polar coordinates ..... 92

Absolute and incremental workpiece positions ..... 93

Setting the datum ..... 94

3.2 Creating and Writing Programs ..... 95

Organization of an NC program in HEIDENHAIN Conversational ..... 95

Define the blank: BLK FORM ..... 95

Creating a new part program ..... 96

Programming tool movements in conversational format ..... 98

Actual position capture ..... 100

Editing a program ..... 101

The TNC search function ..... 105

3.3 File Management: Fundamentals ..... 107

Files ..... 107

Show externally created files on the TNC ..... 109

Data backup ..... 109

3.4 Working with the File Manager ..... 110

Directories ..... 110

Paths ..... 110

Overview: Functions of the file manager ..... 111

Calling the file manager ..... 112

Selecting drives, directories and files ..... 113

Creating a new directory (only possible on the drive TNC:\) ..... 116

Creating a new file (only possible on the drive TNC:\) ..... 116

Copying a single file ..... 117

Copying files into another directory ..... 118

Copying a table ..... 119

Copying a directory ..... 120

Choosing one of the last files selected ..... 120

Deleting a file ..... 121

Deleting a directory ..... 121

Marking files ..... 122

Renaming a file ..... 124

Additional functions ..... 125

Working with shortcuts ..... 127

Additional tools for management of external file types ..... 128

Data transfer to or from an external data medium ..... 133

The TNC in a network ..... 135

USB devices on the TNC (FCL 2 function) ..... 136

HEIDENHAIN iTNC 530 21

4 Programming: Programming Aids ..... 139

4.1 Adding Comments ..... 140

Function ..... 140

Entering comments during programming ..... 140

Inserting comments after program entry ..... 140

Entering a comment in a separate block ..... 140

Functions for editing of the comment ..... 141

4.2 Structuring Programs ..... 142

Definition and applications ..... 142

Displaying the program structure window / Changing the active window ..... 142

Inserting a structuring block in the (left) program window. ..... 142

Selecting blocks in the program structure window ..... 142

4.3 Integrated Pocket Calculator ..... 143

Operation ..... 143

4.4 Programming Graphics ..... 144

Generating / not generating graphics during programming ..... 144

Generating a graphic for an existing program. ..... 144

Block number display ON/OFF ..... 145

Erasing the graphic ..... 145

Magnifying or reducing a detail ..... 145

4.5 3-D Line Graphics (FCL2 Function) ..... 146

Function ..... 146

Functions of the 3-D line graphics ..... 146

Highlighting NC blocks in the graphics ..... 148

Block number display ON/OFF ..... 148

Erasing the graphic ..... 148

4.6 Immediate Help for NC Error Messages ..... 149

Displaying error messages ..... 149

Display HELP ..... 149

4.7 List of All Current Error Messages ..... 150

Function ..... 150

Show error list ..... 150

Window contents ..... 151

Calling the TNCguide help system ..... 152

Generating service files ..... 153

4.8 The Context-Sensitive Help System TNCguide (FCL3 Function) ..... 154

Function ..... 154

Working with the TNCguide ..... 155

Downloading current help files ..... 159

22

5 Programming: Tools ..... 161

5.1 Entering Tool-Related Data ..... 162

Feed rate F ..... 162

Spindle speed S ..... 163

5.2 Tool Data ..... 164

Requirements for tool compensation ..... 164

Tool numbers and tool names ..... 164

Tool length L ..... 164

Tool radius R ..... 164

Delta values for lengths and radii ..... 165

Entering tool data into the program ..... 165

Entering tool data in the table ..... 166

Tool-carrier kinematics ..... 174

Using an external PC to overwrite individual tool data ..... 175

Pocket table for tool changer ..... 176

Calling tool data ..... 179

Tool change ..... 181

Tool usage test ..... 184

Tool management (software option) ..... 187

5.3 Tool Compensation ..... 192

Introduction ..... 192

Tool length compensation ..... 192

Tool radius compensation ..... 193

HEIDENHAIN iTNC 530 23

6 Programming: Programming Contours ..... 197

6.1 Tool Movements ..... 198

Path functions ..... 198

FK free contour programming ..... 198

Miscellaneous functions M ..... 198

Subprograms and program section repeats ..... 198

Programming with Q parameters ..... 199

6.2 Fundamentals of Path Functions ..... 200

Programming tool movements for workpiece machining ..... 200

6.3 Contour Approach and Departure ..... 204

Overview: Types of paths for contour approach and departure ..... 204

Important positions for approach and departure ..... 205

Approaching on a straight line with tangential connection: APPR LT ..... 207

Approaching on a straight line perpendicular to the first contour point: APPR LN ..... 207

Approaching on a circular path with tangential connection: APPR CT ..... 208

Approaching on a circular arc with tangential connection from a straight line to the contour: APPR LCT ..... 209

Departing on a straight line with tangential connection: DEP LT ..... 210

Departing on a straight line perpendicular to the last contour point: DEP LN ..... 210

Departure on a circular path with tangential connection: DEP CT. ..... 211

Departing on a circular arc tangentially connecting the contour and a straight line: DEP LCT ..... 211

6.4 Path Contours—Cartesian Coordinates ..... 212

Overview of path functions ..... 212

Straight line L ..... 213

Inserting a chamfer between two straight lines ..... 214

Corner rounding RND ..... 215

Circle center CCI ..... 216

Circular path C around circle center CC ..... 217

Circular path CR with defined radius ..... 218

Circular path CT with tangential connection ..... 220

6.5 Path Contours—Polar Coordinates ..... 225

Overview ..... 225

Zero point for polar coordinates: pole CC ..... 226

Straight line LP ..... 226

Circular path CP around pole CC ..... 227

Circular path CTP with tangential connection ..... 228

Helical interpolation ..... 229

24

6.6 Path Contours—FK Free Contour Programming ..... 233

Fundamentals ..... 233

Graphics during FK programming ..... 235

Converting FK programs into HEIDENHAIN conversational format ..... 236

Initiating the FK dialog ..... 237

Pole for FK programming ..... 238

Free programming of straight lines ..... 238

Free programming of circular arcs ..... 239

Input possibilities ..... 239

Auxiliary points ..... 243

Relative data ..... 244

HEIDENHAIN iTNC 530 25

7 Programming: Data Transfer from DXF Files ..... 251

7.1 Processing DXF Files (Software Option) ..... 252

Function ..... 252

Opening a DXF file ..... 253

Basic settings ..... 254

Layer settings ..... 256

Specifying the reference point ..... 257

Selecting and saving a contour ..... 259

Selecting and storing machining positions ..... 262

Zoom function ..... 268

26

8 Programming: Subprograms and Program Section Repeats ..... 269

8.1 Labeling Subprograms and Program Section Repeats ..... 270

Labels ..... 270

8.2 Subprograms ..... 271

Operating sequence ..... 271

Programming notes ..... 271

Programming a subprogram ..... 271

Calling a subprogram ..... 272

8.3 Program Section Repeats ..... 273

Label LBL ..... 273

Operating sequence ..... 273

Programming notes ..... 273

Programming a program section repeat ..... 273

Calling a program section repeat ..... 273

8.4 Separate Program as Subprogram ..... 274

Operating sequence ..... 274

Programming notes ..... 274

Calling any program as a subprogram ..... 274

8.5 Nesting ..... 276

Types of nesting ..... 276

Nesting depth ..... 276

Subprogram within a subprogram ..... 277

Repeating program section repeats ..... 278

Repeating a subprogram ..... 279

8.6 Programming Examples ..... 280

HEIDENHAIN iTNC 530 27

9 Programming: Q Parameters ..... 287

9.1 Principle and Overview ..... 288

Programming notes ..... 290

Calling Q-parameter functions ..... 291

9.2 Part Families—Q Parameters in Place of Numerical Values ..... 292

Function ..... 292

9.3 Describing Contours through Mathematical Operations ..... 293

Function ..... 293

Overview ..... 293

Programming fundamental operations ..... 294

9.4 Trigonometric Functions ..... 295

Definitions ..... 295

Programming trigonometric functions ..... 296

9.5 Circle Calculations ..... 297

Function ..... 297

9.6 If-Then Decisions with Q Parameters ..... 298

Function ..... 298

Unconditional jumps ..... 298

Programming If-Then decisions ..... 299

Abbreviations used: ..... 299

9.7 Checking and Changing Q Parameters ..... 300

Procedure ..... 300

9.8 Additional Functions ..... 301

Overview ..... 301

FN 14: ERROR: Displaying error messages ..... 302

FN 15: PRINT: Output of texts or Q parameter values ..... 306

FN 16: F-PRINT: Formatted output of text and Q-parameter values ..... 307

FN 18: SYS-DATUM READ: Read system data ..... 311

FN 19: PLC: Transfer values to the PLC ..... 317

FN 20: WAIT FOR: NC and PLC synchronization ..... 318

FN 25: PRESET: Setting a new datum ..... 320

9.9 Entering Formulas Directly ..... 321

Entering formulas ..... 321

Rules for formulas ..... 323

Programming example ..... 324

28

9.10 String Parameters ..... 325

String processing functions ..... 325

Assigning string parameters ..... 326

Chain-linking string parameters ..... 327

Converting a numerical value to a string parameter ..... 328

Copying a substring from a string parameter ..... 329

Copying system data to a string parameter ..... 330

Converting a string parameter to a numerical value ..... 332

Checking a string parameter ..... 333

Finding the length of a string parameter ..... 334

Comparing alphabetic priority ..... 335

9.11 Preassigned Q Parameters ..... 336

Values from the PLC: Q100 to Q107 ..... 336

WMAT block: QS100 ..... 336

Active tool radius: Q108 ..... 336

Tool axis: Q109 ..... 337

Spindle status: Q110 ..... 337

Coolant on/off: Q111 ..... 337

Overlap factor: Q112 ..... 337

Unit of measurement for dimensions in the program: Q113 ..... 338

Tool length: Q114 ..... 338

Coordinates after probing during program run ..... 338

Deviation between actual value and nominal value during automatic tool measurement with the TT 130 ..... 339

Tilting the working plane with mathematical angles: rotary axis coordinates calculated by the TNC ..... 339

Measurement results from touch probe cycles (see also User’s Manual for Touch Probe Cycles) ..... 340

9.12 Programming Examples ..... 342

HEIDENHAIN iTNC 530 29

10 Programming: Miscellaneous Functions ..... 349

10.1 Entering Miscellaneous Functions M and STOP ..... 350

Fundamentals ..... 350

10.2 Miscellaneous Functions for Program Run Control, Spindle and Coolant ..... 351

Overview ..... 351

10.3 Miscellaneous Functions for Coordinate Data ..... 352

Programming machine-referenced coordinates: M91/M92 ..... 352

Activating the most recently entered datum: M104 ..... 354

Moving to positions in a non-tilted coordinate system with a tilted working plane: M130 ..... 354

10.4 Miscellaneous Functions for Contouring Behavior ..... 355

Smoothing corners: M90 ..... 355

Insert rounding arc between straight lines: M112 ..... 355

Do not include points when executing non-compensated line blocks: M124 ..... 356

Machining small contour steps: M97 ..... 357

Machining open contours corners: M98 ..... 359

Feed rate factor for plunging movements: M103 ..... 360

Feed rate in millimeters per spindle revolution: M136 ..... 361

Feed rate for circular arcs: M109/M110/M111 ..... 362

Calculating the radius-compensated path in advance (LOOK AHEAD): M120 ..... 363

Superimposing handwheel positioning during program run: M118 ..... 365

Retraction from the contour in the tool-axis direction: M140 ..... 366

Suppressing touch probe monitoring: M141 ..... 367

Delete modal program information: M142 ..... 368

Delete basic rotation: M143 ..... 368

Automatically retract tool from the contour at an NC stop: M148 ..... 369

Suppress limit switch message: M150 ..... 370

10.5 Miscellaneous Functions for Laser Cutting Machines ..... 371

Principle ..... 371

Output the programmed voltage directly: M200 ..... 371

Output voltage as a function of distance: M201 ..... 371

Output voltage as a function of speed: M202 ..... 372

Output voltage as a function of time (time-dependent ramp): M203 ..... 372

Output voltage as a function of time (time-dependent pulse): M204 ..... 372

30

Loading...

Loading...