Hayter Mowers LT324 User Manual

LT324

TRIPLE TURF MOWER

CODE 924C

OPERATOR'S MANUAL

THIS MANUAL SHOULD BE REGARDED AS PART OF THE MACHINE, AS IT GIVES ESSENTIAL INFORMATION REGARDING MACHINE SAFETY, OPERATION AND SPECIFICATIONS.

English Version

FROM SERIAL NO: 924C001001 MANUAL PART NO: 924916(REV.0.)

Issue: 01.10.04

ATTENTION

THIS SYMBOL MEANS

BE ALERT!

YOUR SAFETY IS INVOLVED

READ THIS MANUAL BEFORE USING THE LT324 MOWER.

IT IS ESSENTIAL THAT OPERATORS STUDY IT FOR THEIR OWN SAFETY.

ALL OPERATORS SHOULD SEEK AND OBTAIN PROFESSIONAL AND PRACTICAL INSTRUCTIONS ON THE SAFE USE OF THE MOWER. THESE SERVICES ARE AVAILABLE THROUGH HAYTER LIMITED OR HAYTER APPROVED COMMERCIAL DEALERS.

1.4 |

CONTENTS |

1.4 |

CONTENTS |

Page No. |

|

|

SAFETY PRECAUTIONS. |

1.6 - 1.14 |

Training. |

1.6 |

Preparation. |

1.6 - 1.7 |

Operation. |

1.7 - 1.9 |

Handling and storage of fluids. |

1.10 |

Maintenance and storage. |

1.11 |

Decals. |

1.12 - 1.14 |

EC CONFORMITY INFORMATION. |

1.15 - 1.16 |

Noise levels. |

1.15 |

EC Declaration of Conformity. |

1.16 |

INTRODUCTION. |

1.17 |

SPECIFICATIONS. |

1.18 - 1.24 |

Engine. |

1.18 |

Transmission system. |

1.19 |

Cutterhead drive system. |

1.19 |

Cutterhead lift system and steering. |

1.20 |

Hydraulic system. |

1.20 |

Vehicle specifications. |

1.21 |

Operator controls. |

1.22 |

Instrumentation. |

1.22 |

Weight and dimensions. |

1.23 |

Recommended lubricants and hydraulic fluids. |

1.23 |

Cutterheads. |

1.24 |

OPERATING THE MOWER. |

1.25 - 1.40 |

Safety Notice |

1.25 |

Operator presence controls. |

1.25 |

Identification of controls. |

1.26 |

Braking system. |

1.27 |

Throttle control. |

1.27 |

Travel. |

1.27 |

Transport latches. |

1.28 |

Differential lock. |

1.28 |

Speed Control Pedal. |

1.28 |

Operator platform latching mechanism. |

1.29 |

Adjustable Steering Column. |

1.30 |

Operator Seat. |

1.31 |

Warning systems. |

1.32 |

Audible warning horn. |

1.32 |

Ignition key. |

1.33 |

Engine pre-heat indicator light. |

1.33 |

Fuel level gauge. |

1.33 |

924916KG251004

1.5 |

CONTENTS |

1.5 |

CONTENTS |

Continued. |

Page No. |

Hourmeter. |

|

1.33 |

Transmission neutral indicator light. |

1.34 |

|

Cutterdeck drive switch indicator light. |

1.34 |

|

Parking brake indicator light. |

1.34 |

|

Hydraulic return filter indicator light. |

1.34 |

|

Hydraulic transmission filter indicator light. |

1.34 |

|

Cutterhead position control. |

1.35 |

|

Cutterhead drive engagement. |

1.35 |

|

Weight transfer/traction assistance. |

1.36 |

|

Starting the engine. |

|

1.36 - 1.37 |

Stopping the engine. |

|

1.37 |

General operating hints. |

1.38 |

|

Cutterhead general information. |

1.39 |

|

MK3 200mm Fixed Cutterhead. |

1.40 |

|

MK3 254mm Fixed Cutterhead. |

1.40 |

|

MK3 200mm Floating Cutterhead. |

1.41 |

|

Centre Cutterhead Height of Cut Correction Adjustment |

1.41 |

|

MAINTENANCE. |

|

1.42 - 1.60 |

Maintenance |

|

1.42 - 1.43 |

Engine. |

|

1.44 |

Running in period. |

|

1.44 |

Running in period - at first 50 hours. |

1.44 - 1.45 |

|

Daily and before use. |

|

1.46 - 1.49 |

Every 50 hours. |

|

1.50 - 1.51 |

Every 250 hours. |

|

1.52 |

Every 500 hours. |

|

1.53 - 1.55 |

Cutterhead cylinder to bottom blade adjustment. |

1.56 |

|

Cutterhead backlapping. |

1.57 |

|

Cutterhead grinding. |

|

1.58 |

Cutterhead bottom blade replacement. |

1.58 |

|

Raising the mower off the ground. |

1.59 |

|

Towing the mower. |

|

1.60 - 1.61 |

GRASS CUTTING FAULTS. |

1.62 - 1.64 |

|

TROUBLE SHOOTING. |

1.65 - 1.71 |

|

ELECTRICAL CIRCUIT DIAGRAM . |

1.72 - 1.73 |

|

HYDRAULIC CIRCUIT DIAGRAMS. |

1.74 - 1.76 |

|

WARRANTY. |

|

1.77 |

NOTES. |

|

1.78 |

CUSTOMER INFORMATION. |

1.79 |

|

|

|

|

924916KG251004

1.6 |

SAFETY PRECAUTIONS |

1.6 |

READ THIS MANUAL BEFORE USING THE LT324 MOWER, IT IS ESSENTIAL THAT OPERATORS STUDY IT FOR THEIR OWN SAFETY.

THE FOLLOWING PRECAUTIONS MUST BE TAKEN TO HELP PREVENT ACCIDENTS. A CAREFUL OPERATOR WHO USES COMMON SENSE IS THE SAFEST OPERATOR.

TRAINING

Read the instructions carefully. Be familiar with the controls and the proper use of the equipment. Learn how to stop the mower quickly in an emergency.

Never allow children or people unfamiliar with these instructions to use the mower. Local regulations may restrict the age of the operator.

Never mow while people, especially children, or pets are nearby.

Never mow while people, especially children, or pets are nearby.

Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people or their property.

Do not carry passengers.

All drivers should seek and obtain professional and practical instruction. Such instruction should emphasise:

-The need for care and concentration when working with this machine.

-The need to slow down when making tight turning manoeuvres. Failure to take adequate care can affect stability leading to loss of control of the machine particularly when operating in transport mode.

-Control of a ride-on-machine sliding on a slope will not be regained by application of the brake. The main reasons for loss of control are:

-Insufficient wheel grip.

-Being driven too fast.

-Inadequate braking.

-The type of machine is unsuitable for the task.

-Lack of awareness of the effect of ground conditions, especially slopes.

-Incorrect load distribution.

PREPARATION

Check that the machine complies with all applicable regulations, including those in force when used on the public highway.

While mowing, always wear substantial footwear and long trousers. Do not operate the equipment when barefoot or wearing open sandals. Eye protection should be worn.

Thoroughly inspect the area where the equipment is to be used and remove all objects which can be thrown by the machine.

Never operate the machine without first checking that the operator platform latching mechanism is fully engaged and in good working order, refer - ‘OPERATOR PLATFORM LATCHING MECHANISM’.

924916KG251004

1.7 |

SAFETY PRECAUTIONS |

1.7 |

|

|

|

PREPARATION Continued.

Ensure that the cutterheads are fully raised with the latches and safety locks engaged in position before transporting the mower.

Ensure that the cutterheads are fully raised with the latches and safety locks engaged in position before transporting the mower.

Replace faulty silencers. |

Check the condition of the tyres and ensure that they are inflated to the correct pressures, refer - SPECIFICATIONS.

Check the condition of the tyres and ensure that they are inflated to the correct pressures, refer - SPECIFICATIONS.

This is particularly important if the machine is to be taken on the public highway.

Check that the mower is in good working order, paying particular attention to the brakes and steering. Also ensure that the forward/reverse speed control pedals move freely to neutral when released.

Check that the mower is in good working order, paying particular attention to the brakes and steering. Also ensure that the forward/reverse speed control pedals move freely to neutral when released.

Before use, always visually inspect to see that the blades, blade bolts and cutting cylinders are not worn or damaged. Replace worn or damaged components.

Before use, always visually inspect to see that the blades, blade bolts and cutting cylinders are not worn or damaged. Replace worn or damaged components.

Check the mower hydraulic system, particularly the hydraulic hoses, fittings and hose supports. Worn, crushed or damaged hoses can burst, with risks to health and damage to the machine and surrounding turf areas.

Check the mower hydraulic system, particularly the hydraulic hoses, fittings and hose supports. Worn, crushed or damaged hoses can burst, with risks to health and damage to the machine and surrounding turf areas.

After refuelling and adding oil to the hydraulic oil tank ensure that the caps are replaced securely.

After refuelling and adding oil to the hydraulic oil tank ensure that the caps are replaced securely.

Check that all linkages, connections and pivot nuts are secure and that wheel nuts are torqued correctly, refer - SPECIFICATIONS.

Check that all linkages, connections and pivot nuts are secure and that wheel nuts are torqued correctly, refer - SPECIFICATIONS.

Before operating the machine ensure that there are no foreign objects or liquids on the platform or pedals - ALWAYS KEEP THE OPERATOR PLATFORM CLEAN/CLEAR.

Before operating the machine ensure that there are no foreign objects or liquids on the platform or pedals - ALWAYS KEEP THE OPERATOR PLATFORM CLEAN/CLEAR.

OPERATION

Do not operate the engine in a confined space where dangerous carbon monoxide fumes can collect. |

Mow only in daylight or in good artificial light. |

Before attempting to start the engine, engage the parking brake, disengage the cutterhead drive system and ensure that the forward/reverse speed controls are in the neutral position.

Before attempting to start the engine, engage the parking brake, disengage the cutterhead drive system and ensure that the forward/reverse speed controls are in the neutral position.

Never operate the machine without first checking that the operator platform latching mechanism is fully engaged and in good working order, refer - OPERATOR PLATFORM LATCHING MECHANISM.

Never operate the machine without first checking that the operator platform latching mechanism is fully engaged and in good working order, refer - OPERATOR PLATFORM LATCHING MECHANISM.

Stored energy devices are charged when the outer wing units are in transport position. Always operate the relevant lift controls to provide hydraulic support for the wing units suspensions before attempting to release the transport latches.

Stored energy devices are charged when the outer wing units are in transport position. Always operate the relevant lift controls to provide hydraulic support for the wing units suspensions before attempting to release the transport latches.

924916KG251004

1.8 |

SAFETY PRECAUTIONS |

1.8 |

|

|

|

OPERATION

Continued.

Continued.

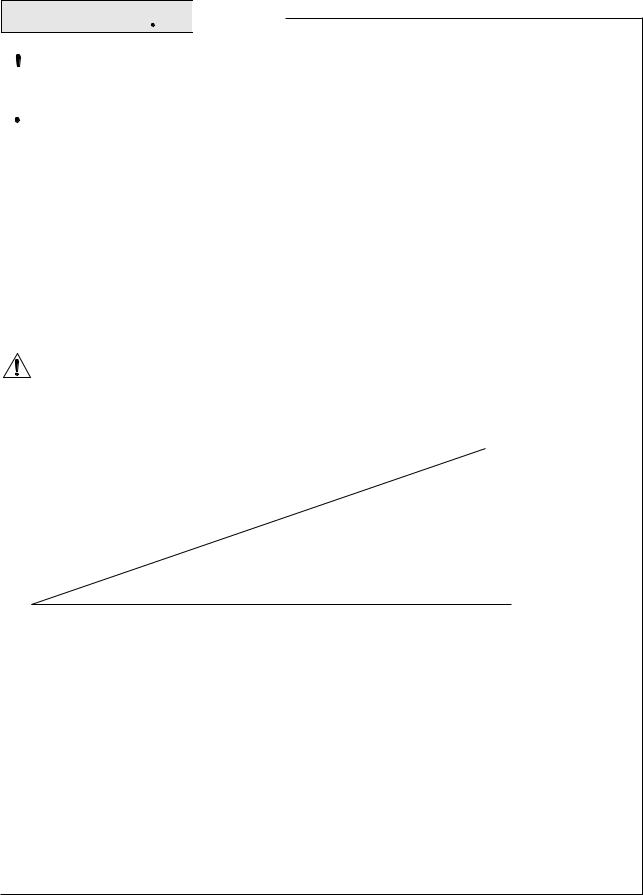

Do not use on a slope of more than 19 degrees. Where ground conditions are such that there may be a risk of the mower rolling over, the requirements of SI 1998 No 2306 "Provision and Use of Work Equipment Regulations" should be considered, refer - INTRODUCTION - Optional Extras.

Do not use on a slope of more than 19 degrees. Where ground conditions are such that there may be a risk of the mower rolling over, the requirements of SI 1998 No 2306 "Provision and Use of Work Equipment Regulations" should be considered, refer - INTRODUCTION - Optional Extras.

Ground conditions affect traction. Particular conditions may not permit safe operation on the slope limits stated.

Ground conditions affect traction. Particular conditions may not permit safe operation on the slope limits stated.

Remember there is no such thing as a "safe" slope. Travel on grass slopes requires particular care. To guard against overturning or loss of traction when travelling or mowing on a slope:

-

-

-

-

-

-

-

-

Never park on a slope. |

Exercise extreme care when changing direction on a slope. Do not stop or start suddenly.

Engage drive slowly. Keep machine speed low. Avoid tight turns.

Stay alert for humps, hollows and other hidden hazards. Keep away from sharp inclines and steep drops.

A thorough risk assessment should be carried out by a competent person before travelling or mowing on a slope.

|

slope |

19 |

Degree |

|

Ground level

3DA176

924916KG251004

1.9 |

SAFETY PRECAUTIONS |

1.9 |

OPERATION |

Continued. |

|

Watch out for traffic when crossing or near roadways.

Watch out for traffic when crossing or near roadways.

Use extreme caution when reversing.

Use extreme caution when reversing.

Disengage the cutterhead drive system before crossing surfaces other than grass.

Disengage the cutterhead drive system before crossing surfaces other than grass.

When using the machine, never direct discharge of material towards bystanders or allow anyone near the machine while in operation.

When using the machine, never direct discharge of material towards bystanders or allow anyone near the machine while in operation.

Never operate the mower with defective guards, shields or without safety protective devices in place and in good working order.

Never operate the mower with defective guards, shields or without safety protective devices in place and in good working order.

Do not change the engine governor settings or overspeed the engine. Operating an engine at excessive speed may increase the risk of personal injury.

Do not change the engine governor settings or overspeed the engine. Operating an engine at excessive speed may increase the risk of personal injury.

Before leaving the operator's position:

Before leaving the operator's position:

-Disengage the drive to the cutterheads.

-Lift cutterheads to the transport position and securely lock the safety latches or alternatively lower cutterheads to the ground.

-Change into neutral and set the parking brake.

-Stop the engine and remove the ignition key.

Engage the parking brake, disengage the drive to the cutterheads, stop the engine and remove ignition key :

Engage the parking brake, disengage the drive to the cutterheads, stop the engine and remove ignition key :

-Before releasing blockages.

-Before checking, cleaning or working on the mower.

-After striking a foreign object. Inspect the mower for damage and make repairs before restarting and operating the equipment.

-If the machine starts to vibrate abnormally ( check immediately ).

-Before refuelling.

-Before making cutterhead adjustments.

Disengage the drive to the cutterheads when transporting or not in use.

Disengage the drive to the cutterheads when transporting or not in use.

Reduce the throttle setting during engine run - out.

Reduce the throttle setting during engine run - out.

Never work on the mower when the engine is running.

Never work on the mower when the engine is running.

Always keep feet and hands well away from the cutting cylinders when making adjustments.

Always keep feet and hands well away from the cutting cylinders when making adjustments.

Never operate the mower without first checking that the operator platform is securely latched.

Never operate the mower without first checking that the operator platform is securely latched.

924916KG251004

1.10 |

SAFETY PRECAUTIONS |

1.10 |

|

|

|

HANDLING AND STORAGE OF FLUIDS

Hydraulic Oil

Hydraulic Oil

-Avoid contact with eyes and prolonged contact with skin.

-Protective goggles should be worn when pouring.

-Use of gloves or barrier cream is recommended.

-Wash hands thoroughly after contact.

-Store under cover, away from heat and sources of ignition.

Diesel Oil

-Avoid skin and eye contact.

-Wear impervious gloves when regular contact is likely and goggles when there is risk of splashing.

-Wash hands thoroughly after contact.

-Store in a cool dry well ventilated place away from heat and sources of ignition, in vessels specifically designed for storing fuel oils.

Lubricating Oil

-Avoid skin and eye contact.

-Wear impervious gloves when regular contact is likely and goggles when there is risk of splashing.

-Wash hands thoroughly after contact.

-Store in a cool dry well ventilated place away from heat and sources of ignition.

AntiFreeze

-Keep away from heat, sparks, and flames.

-Avoid skin and eye contact and breathing vapours.

-Store in a closed container in a cool dry well ventilated area.

924916KG251004

1.11 |

SAFETY PRECAUTIONS |

1.11 |

|

|

|

MAINTENANCE AND STORAGE

Take care when rotating a cutting cylinder as this can cause other cylinders to rotate. |

When the machine is to be parked, stored or left unattended, lift the cutterheads to the transport position and engage the safety locks or lower the cutterheads to the ground.

When the machine is to be parked, stored or left unattended, lift the cutterheads to the transport position and engage the safety locks or lower the cutterheads to the ground.

Keep all nuts, bolts, and screws tight to be sure the equipment is in safe working condition. |

Allow the engine to cool before storing in any enclosure. |

To reduce the risk of fire, keep the engine, silencer, fuel tank and battery compartment free of grass, leaves or excessive grease.

To reduce the risk of fire, keep the engine, silencer, fuel tank and battery compartment free of grass, leaves or excessive grease.

Frequently check fuel lines and fittings for cracks or leaks and replace if necessary. |

Replace worn or damaged parts for safety. |

Ensure that all safety decals are properly secured and in good condition. |

If the fuel tank has to be drained, this should be done outdoors. |

Be careful during adjustment of the machine to prevent entrapment of the fingers between moving blades and fixed parts of the machine.

Be careful during adjustment of the machine to prevent entrapment of the fingers between moving blades and fixed parts of the machine.

Never attempt to disconnect any part of the hydraulic system before de-pressurisation. This may be achieved by lowering all cutterheads to the ground, stopping the engine and removing the ignition key.

Never attempt to disconnect any part of the hydraulic system before de-pressurisation. This may be achieved by lowering all cutterheads to the ground, stopping the engine and removing the ignition key.

Avoid skin or eye contact with hydraulic or diesel fluids. Wear protective clothing.

Avoid skin or eye contact with hydraulic or diesel fluids. Wear protective clothing.

Leaking fluids under pressure can penetrate the skin or eyes, causing serious injury.

Leaking fluids under pressure can penetrate the skin or eyes, causing serious injury.

Always use a piece of cardboard or paper when searching for leaks.

Health and Safety at Work Act:

In accordance with section 6 of the Health and Safety at Work Act 1974, the LT324 Mower has been designed and constructed so that, in so far as is reasonably practical, it will not endanger the safety and health of those working with it. This is, however, subject to the machine being properly used and maintained according to the conditions stated in this manual and elsewhere, which have been found necessary as a result of the research and testing of Hayter Limited.

924916KG251004

1.12 |

SAFETY PRECAUTIONS |

1.12 |

|

|

|

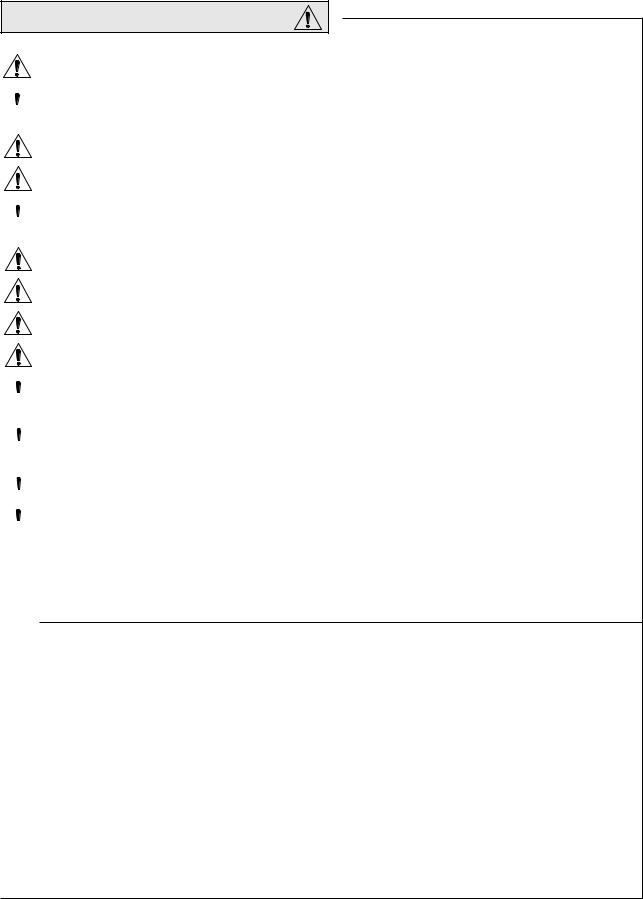

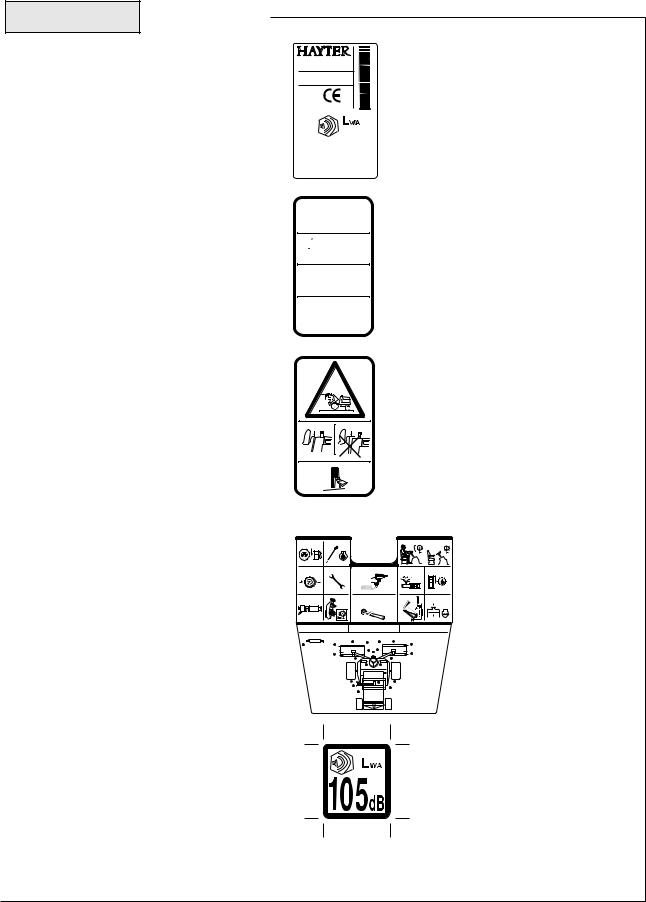

DECALS

Decal - Control Panel Part No: 924898

Location: Control Panel. |

|

|

a) Ignition Switch |

h) Cutters - Off |

|

b) Engine Speed - Slow |

i) |

Cutters - Forward |

c) Engine Speed - Fast |

j) |

Horn |

d) Parking Brake - Engage |

k) Cutters - Lift |

|

e) Parking Brake - Disengage |

l) |

Cutters - Hold |

f) Weight Transfer - Control |

m)Cutters - Drop/Float |

|

g) Cutters - Reverse |

n) Hour Meter |

|

g

h

a |

|

b |

c |

d |

e |

|

|

|

|

||

) 0 .924898(REV |

|

O |

|

P |

P |

III |

II |

I |

|

|

|

|

|

|

|

|

f |

|

|

|

|

|

kg |

i |

|

|

|

|

|

|

|

j |

k l |

m |

n |

a |

|

|

b |

|

c |

Decal - Inclines Part No: 924857 (1)

Location: Centre Platform.

a) Warning - Travel slowly when turning and on slopes

b)Warning - Maximum Slope without ROPS

c)Warning - Seat belt must be worn with a ROPS fitted.

d) |

Caution |

|

|

|

|

e) |

Read Operators Manual |

|

|

|

|

f) |

Stop engine/Remove ignition key before servicing or |

|

0 - 19° |

19°+ |

|

|

|

|

|

||

|

maintenance |

|

|

|

(1) |

g) |

Beware of flying objects |

|

|

|

924857 |

|

|

|

|

||

h) |

Keep Bystanders Clear |

|

|

|

h |

|

d |

e |

f |

g |

Decal - Danger Latch Part No: 70-13-077 |

|

Location: LH / RH / Centre Arms |

|

a) Caution |

|

b) Stop engine/Remove ignition key before releasing or |

|

operating safety latches. |

|

a |

b |

|

Decal - Diesel Part No: 70-13-07

Location: Fuel Tank a a) Diesel fuel only

Decal - Transmission Oil Part No: 70-13-071 Location: Oil Filler Bracket Mounted Behind Fuel tank.

a)Transmission Oil

b)Read and understand the Operators Manual.

a |

b |

|

|

|

IMPORTANT /WICHTIG /BELANGRIJK |

|

BEFORE USE :FILL MA |

|

MENDEDOILTOCORRECTAILUR |

|

DOSOWILLCAUSESERIOAND |

|

VALIDATEWARRANTY. |

|

AVANTL'UTILISATION : EST |

|

REMPLIR LATONDEUSEVEC UNE |

|

SPECIFIEE AUNIVEAU |

|

L'ENDOMMAGERSERIEUSEMENT |

|

LAGARANTIE. |

|

VOR DEM GEBRAUCH:LLENFS |

|

MASCHINEMITEMPFOHLBI |

|

AUF DEN RICHTIGENAND. |

|

NICHTBEACHTUNGDIES |

|

KANNZU ERNSTHAFTENHRE |

|

UNDDABEIWIRDDIEGARTIG |

|

VOOR GEBRUIK: VUL M |

|

VORRGESCHREVEN OLIE |

|

NIVEAU. HET NIETDEZV |

|

INSTRUKTIE LEIDT TO |

|

VERVANDEGARANTIELV. |

1.13 |

SAFETY PRECAUTIONS |

1.13 |

DECALS Continued.

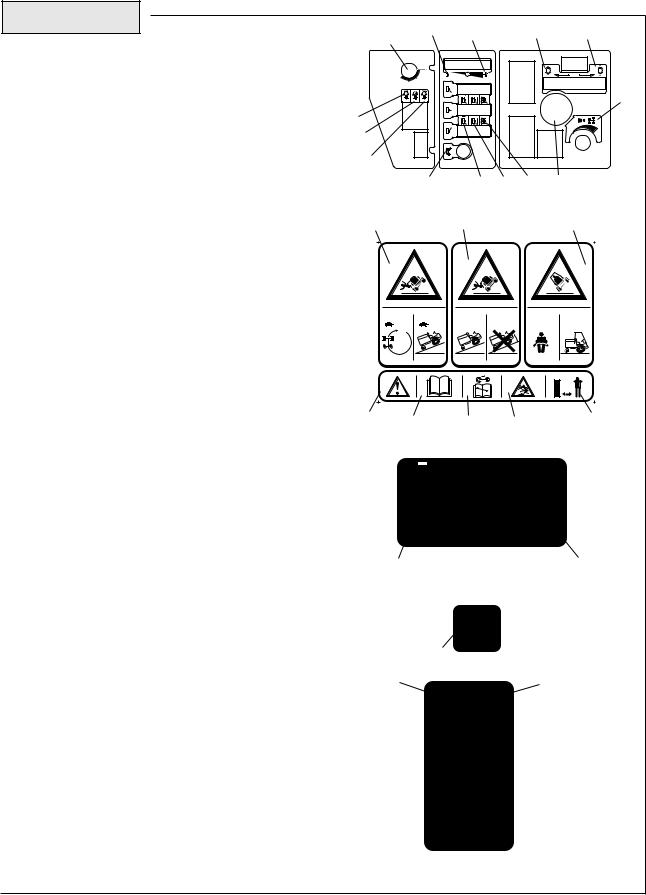

Decal - Jacking / Support Point Part No: 70-13-072 |

|

|

Location: Front Axle - 2 Points |

|

|

Rear Towing Eye |

a |

|

a) Jacking and Support Point |

||

|

Decal - Engine Fan / Radiator Part No: 70-13-073 Location: Engine Fan Cowl

a)Danger of Severing Fingers

b)Caution

c)Warning - Hot Surfaces

Decal - Tyre Pressure Part No. 950832

Location: LH/RH Chassis - 4 Places

a)Mowing

b)Road Travel

70-13-073 REV (.0.)

a b c

a

b

ONLYREMOVETORCAPWHENENGINEISCADIA

ILFAUTTOUJOURSATTENDRELEREF AVANTDERETIRERLETEBOUCHONDURA.

VERWIJDERDERADIATORDOPPTDEMOTORISAFSNADA

HEIZKORPERDECKELENTFERNENER.

924812 REV.(0)

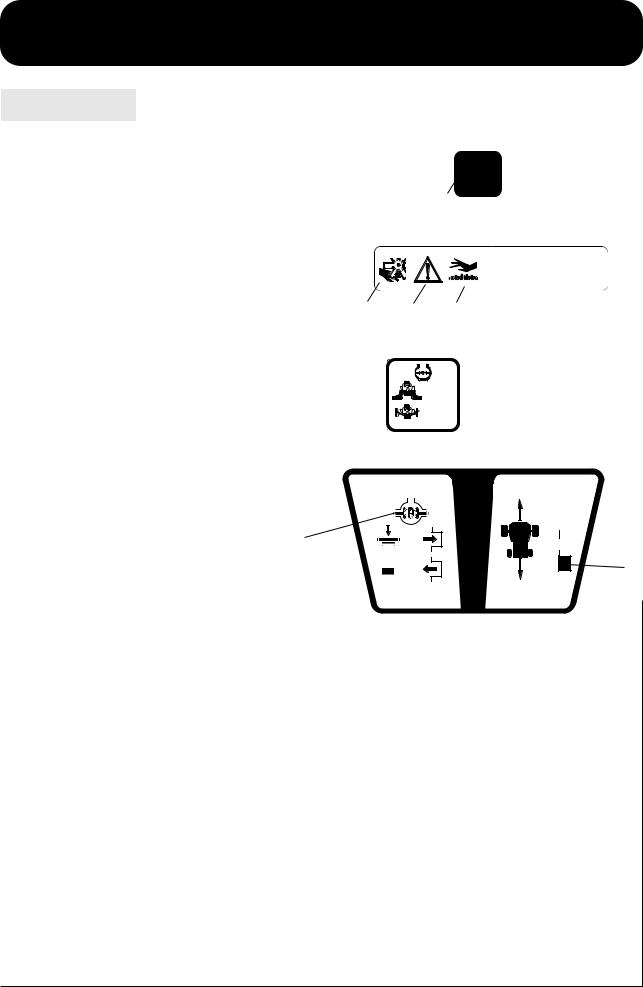

Decal - Diff Lock / Control Pedal Part No: 924812

Location: Centre Platform. |

|

|

a) Differential Lock |

a |

|

b) Depress to engage Diff-lock |

||

|

c)Release to Dis-engage Diff-lock

d)Forward Speed & Directional Control

e)Reverse Speed & Directional Control

b

c

c

d

d

e

924916KG251004

1.14 |

SAFETY PRECAUTIONS |

1.14 |

|

|

|

DECALS Continued.

Decal - Serial Number

Location: Rear Bulkhead

Decal - Prevent Platform

Damage

Part No. 924828

Location : Platform, Seatwell.

SPELLBROOK, BISHOP’S STORTFORD,

HERTS. CM23 4BU. ENGLAND.

CODE 924C LT324

- TRIPLE TURF MOWER

Kg |

1025 |

2004 |

RPM 2800 |

||

kW |

26.1 |

|

Serial No: 924C001001

105dB

PREVENT PLATFORM DAMAGE !

ENGAGE PARKING BRAKE AND DROP CUTTERHEADS BEFORE RAISING/LOWERING PLATFORM.

POUR EVITER DES DOMMAGES, METTRE LE FREIN DE PARKING ET POSER LES TETES DE COUPES AVANT DE BOUGER LA PLATE-FORME.

..

SCHADEN VERMEIDEN - PARKBREMSE FESTSETZEN UND DIE SCHNEIDEINHEITEN HERUNTERLASSEN BEVOR DIE SITZPLATTFORM GEKIPPT WIRD.

VOORKOM BESCHADIGING! ZET MACHINE OP HANDREM EN LAAT DE KOOIEN ZAKKEN, VOORDAT HET BEDIENINGS PLATFORM NAAR VOREN GEKANTELD OF TERUG GEPLAATST WORDT.

924828 REV.0.

Decal - Warning Platform Latch

Part No. 924868

Location: Next to Platform Latch Warning - Prevent Accidents: Ensure platform is correctly seated and the latch is fully locked before operating the machine.

924868 REV .0

Decal - Maintenance

Part No. 924882

Location: Underside of Engine Cover next to Latch.

DAILY MAINTENANCE

FUEL LEVEL |

ENGINE OIL |

|

FUEL |

|

|

E |

F |

D |

TYRES |

FASTENERS |

|

AIR CLEANER |

CUTTERHEADS |

|

|

DAILY |

|

50 HOURS MAINTENANCE

CLEAN AND INSPECT THE MACHINE.

WHEEL NUT TORQUE

FRONT: 200Nm

REAR: 54Nm

GREASE POINTS

DAILY (IF FITTED)

DAILY MAINTENANCE

SEAT SWITCH

HOSE LINES |

HYDRAULIC OIL |

RADIATOR/ |

COOLANT LEVEL |

SCREENS |

30 - 40mm |

50 HOURS (WEEKLY)

50 HOURS (WEEKLY)

924882(Rev 1)

Decal - Noise

Part No. 922854

Location: Base of Seat on GRP

924916KG251004

1.15 |

EC CONFORMITY INFORMATION |

1.15 |

|

|

|

NOISE LEVELS

Operators Daily Personal Noise Exposure: HAYTER LIMITED have no control over site conditions, duration of use, state of maintenance or adjustment of the mower. All of these factors will affect the operator's daily personal noise exposure level - LEP,d

Under typical working conditions operators could be exposed to a daily personal noise exposure level in excess of 85 dB (A) LEP,d

Sound pressure level:

The maximum sound pressure level at the operator's position is 84 dB (A) measured in accordance with European Standard EN836.

Sound power level:

The maximum sound power level is 105 dB(A) measured in accordance with EC Directive 2000/14/EC.

If ear protection is required, ear protectors with good attenuation in the 63 - 8000 Hz frequency range should be used.

Employers of personnel using this machine are advised to read the 'Noise at Work Regulations' as the operator's daily personal exposure level could be above the 'First Action Level'.

SPELLBROOK, BISHOP’S STORTFORD,

HERTS. CM23 4BU. ENGLAND.

CODE 924C LT324

- TRIPLE TURF MOWER

Kg |

1025 |

2004 |

RPM 2800 |

||

kW |

26.1 |

|

Serial No: 924C001001

105dB

Wear Hearing

Protection

924916KG251004

1.16 |

EC CONFORMITY INFORMATION |

1.16 |

EC DECLARATION OF CONFORMITY

EC DECLARATION OF CONFORMITY

HAYTER LIMITED,

Spellbrook, Bishop’s Stortford, Herts CM23 4BU ENGLAND

declare that the lawnmower: |

|

|

|

|

|

Type: |

Ride-On Cylinder Lawnmower |

|

Model Name. |

LT324 Triple Turf Mower |

|

Model No.: |

CODE 924C |

|

Cutting Width: |

2120 mm |

|

Speed of rotation of cutting device: |

1050 rpm |

|

Engine Manufacturer: |

Kubota |

|

Speed of rotation of engine: |

2850 rpm |

|

Complies with the provisions of Directive: 98/37/EC Essential Health & Safety Requirements Relating to the Design & Construction of Machinery and Safety Components, as amended and the regulations transposed into national law.

Also Directive 89/336/EEC Electromagnetic Compatibility, as amended and the regulations transposed into national law.

Also Directive 2000/14/EC Noise emission in the environment by equipment for use outdoors and the regulations transposed into national law.

Procedure applied for the conformity assessment: ANNEX VI, procedure 1.

Notified Body: Sound Research Laboratories Ltd. Holbrook House, Little Waldingfield,

Sudbury, Suffolk, COL0 OTH, ENGLAND

Notified body identification No: 1088

Measured sound power level: |

101 dB(A) |

Guaranteed sound power level: |

105 dB(A) |

Complies with harmonised standards: EN 292, EN 836 and EN ISO 14982.

Standards Used: EN292, EN836 and ENISO14982

Signed |

Date: 01.10.04 |

|

Technical Documentation Kept at: |

|

HAYTER LIMITED, |

S.A. |

Spellbrook, Bishop’s Stortford, |

(Technical Director) |

Herts CM23 4BU ENGLAND |

VIBRATION INFORMATION

Lawnmower vibration information. Vibration at the operators contact position measured in accordance with European Standards EN 836.

-steering wheel does not exceed 2.5ms-2

-at seat does not exceed 0.5ms-2

924916KG251004

1.17 |

INTRODUCTION |

1.17 |

|

|

|

INTRODUCTION

The Hayter LT324 Triple Turf Mower is a diesel engine powered self propelled machine with hydraulic systems for ground drive, cutterhead drives and steering. The machine operates in two wheel drive with automatic four wheel drive on demand. A differential lock function may be selected. The transmission system is converted automatically to engage drive to all 4 wheels when the machine speed decreases as a result of front wheel traction slip. 2WD is automatically re-engaged when traction slip is reduced.

The Hayter LT324 Triple Turf Mower is a precision built machine designed solely for cutting grass and similar low lying ground vegetation within the limitations stated in this manual. Use in any other way is considered as contrary to the intended use. Compliance with and strict adherence to the conditions of operation, service and repair as specified in this Operators Manual also constitute essential elements of the intended use. The way in which this machine is operated and maintained will have a profound effect on its performance and reliability.

This manual contains advice on the Hayter LT324 Triple Turf Mower which should be operated, serviced and repaired only by persons who are familiar with its particular characteristics and who are acquainted with the relevant safety procedures.

The safety precautions listed herein and all other generally recognised regulations on safety and all road traffic regulations must be observed at all times.

Any arbitrary modifications carried out to this machine may relieve Hayter Limited of liability for any resulting damage or injury.

In the pursuit of continuous product development Hayter Limited reserve the right to alter specifications without notice.

Cutterhead Variants: The Hayter LT324 can be fitted with a range of cutterhead configurations and optional extras:

Cutterhead |

Cylinder diameter |

Number of blades |

|

Fixed |

|

|

Floating Heads with smooth |

||||||||

|

Heads |

|

|

or grooved front rollers |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MK3 Cutterhead |

200mm |

4, 6, 8, 10. |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4, 6 |

|

|

|

|

|

|

|

|||||||

|

|

254mm |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Optional Extras:

Beacon Kit - Amber flashing warning light.

Lighting Kit - Complies with EC traffic regulations.

R.O.P.S ( Roll Over Protective Structure ) 2 post design.

Cab R.O.P.S. - Full weather protection and roll - over protection.

A R.O.P.S. must be fitted to ensure operator safety when working on slopes in excess of 19 degrees, refer - SAFETY PRECAUTIONS.

A R.O.P.S. must be fitted to ensure operator safety when working on slopes in excess of 19 degrees, refer - SAFETY PRECAUTIONS.

When fitting optional extra kits to the mower be sure to fix the serial number decal supplied with the kit to the rear bulkhead underneath the engine cover. This will help the Hayter spare parts department to supply the correct spare parts throughout the service life of the mower.

Left and Right: Throughout this manual the terms 'Left' and 'Right' refer to the machine when looking

in the direction of forward travel.

924916KG251004

1.18 |

SPECIFICATIONS |

1.18 |

SPECIFICATIONS

ALL FIGURES ARE NOMINALLY QUOTED AT THE RATED ENGINE SPEED OF 2800 RPM UNLESS OTHERWISE STATED.

ENGINE

Type: |

Kubota V1505 -BB. |

|

4 Cylinders in line. |

Power Rating: |

35hp (26.1 kw) @ 2800 RPM. |

|

DIN 70020. |

Capacity: |

1498 cc. |

Air Cleaner: |

Clean air drawn through screened air intake in-front of |

|

radiator via a cyclonic air cleaner with built in pre-cleaner. |

Cooling System: |

Water-Cooled. |

Battery: |

12V. 480 Amps S.A.E. |

Alternator: |

40 Amps. |

Starter: |

1.2 KW Electric. |

Cold Starting: |

Glow Plug. |

Idle Speed: |

1250(+50) R.P.M. |

Fuel Type: |

Diesel. |

IMPORTANT: PREVENT DAMAGE - for further information regarding the engine, refer to - ENGINE MANUAL .

924916KG251004

1.19 |

SPECIFICATIONS |

1.19 |

TRANSMISSION SYSTEM

Drive Type:

Pump:

Wheel Motors:

Differential Lock:

Drive:

Relief Valve Setting:

Hydraulic.

Variable displacement hydraulic piston pump with integral charge pump and pedal control.

Front Axle - Radial piston, fixed displacement, with integral disc brake (pressure released).

Rear Axle - Gear motor, fixed displacement.

Electro - hydraulic control valve with pedal control.

2WD (front axle) with differential lock (selectable) and automatic 4WD on demand (forward & reverse).

Main service relief 300 bar (4350 psi) differential. Charge pressure relief 18.5 bar (268 psi) differential.

CUTTERHEAD DRIVE SYSTEM

Drive Type:

Pump:

Delivery Rate:

Cutterhead Motors:

Control:

Relief Valve Setting:

Hydraulic.

Hydraulic gear type.

31 Litres per minute.

Hydraulic gear type, reversible, pressure balanced with integral differential pressure sensing relief check valve. Direct drive.

Electro-hydraulic.

Automatic diverter valve safety cut-off.

250 bar (3625 psi) differential.

924916KG251004

1.20 |

SPECIFICATIONS |

1.20 |

CUTTERHEAD LIFT SYSTEM AND STEERING |

|

|

Drive Type: |

Hydraulic. |

|

Pump: |

Hydraulic gear pump with integral relief valve. |

|

Delivery Rate: |

11 Litres per minute. |

|

Steering: |

Power beyond hydrostatic steering valve with priority flow to |

|

|

steering and auxiliary flow to cutterhead lift system. Manual |

|

|

emergency steering. |

|

Cutterhead Lift Control: |

Mechanical-hydraulic. |

|

Relief Valve: |

105 bar (1522 psi). |

|

Weight Transfer: |

Variable hydraulic applied weight transfer acting on all |

|

|

cutterheads. |

|

HYDRAULIC SYSTEM |

|

|

Hydraulic Oil Type: |

Refer - RECOMMENDED LUBRICANTS |

|

|

AND HYDRAULIC FLUIDS. |

|

Capacity: |

40 Litres. |

|

Cooling: |

Forced air finned tube oil cooler. |

|

Suction Line Filtration: |

125 micron no bypass mesh filter. |

|

Return line Filtration: |

10 micron with 2 bar (29 psi) bypass check valve. |

|

Transmission Filtration: |

10 micron no bypass pressure filter. |

|

Cleanliness Level: |

ISO Code 18/13 or better (ISO 4406) |

|

|

1300 - 2500 Particles/ml<15μ |

|

|

40 - 80 Particles/ml>15μ |

|

Maximum Oil Temperature: |

950C |

|

924916KG251004

1.21 |

SPECIFICATIONS |

1.21 |

VEHICLE SPECIFICATIONS

Travel Speed: |

0-22 km/hr |

(0-14 mph) |

forward. |

|

|

|||

|

|

0-11 km/hr |

(0-7 mph) |

reverse. |

|

|

||

Tyres |

Tyre Type |

|

|

Recommended Tyre Pressures |

|

|||

|

|

|

|

|

Turf Conditions |

Road Conditions |

Max Pressure |

|

Front axle |

26 x 12 - 12 |

4 ply |

0.7 bar |

1.4 bar |

1.7 bar |

|||

|

|

Trelleborg turf pattern. |

(10 psi ) |

(20 psi) |

(25 psi) |

|||

Rear axle |

18 x 9.5 - 8 |

6 ply |

0.7 bar |

1.4 bar |

1.7 bar |

|||

|

|

Dico turf pattern. |

|

(10 psi). |

(20 psi) |

(25 psi) |

||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Wheel Nut Torque Setting: Front axle |

|

200Nm |

|

|

||||

|

|

|

Rear axle |

|

54Nm |

|

|

|

Service Brakes: Closed loop hydrostatic service braking operating on drive wheels only.

Parking Brake: Lever operated oil immersed disc brakes on front wheels only. Pressurised hydraulic oil release with mechanical override for emergency towing purposes.

Ground Clearance: 180mm at 13mm cut height and with cutterheads raised.

Steering: Hydrostatic rear wheel steering, emergency manual steering.

Features: Tilting operator platform. Lockable engine cover.

Adjustable suspension seat with folding arms. Adjustable steering column.

Cutterhead parking latches with safety locks. Backlapping facility.

Differential lock ( selectable ).

Engine coolant and hydraulic oil overheat audible warning (horn). Variable cutterhead weight transfer/traction assistance.

2WD with 4WD on demand (forward & reverse). Hydraulic oil filter blocked telltales on control panel.

Safety Features: Neutral start interlock on transmission pump, parking brake and cutterhead drive switch.

Operator presence control (seat switch).

924916KG251004

1.22 |

SPECIFICATIONS |

1.22 |

|

|

|

|

|

OPERATOR CONTROLS |

|

|

|

|

|

|

|

Steering: |

|

Automotive padded steering wheel. |

|

Cylinder Drive: |

|

Electrical switch (forward - off - reverse). |

|

Engine Speed: |

|

Hand operated lever. |

|

Parking Brake: |

|

Hand operated lever. |

|

Forward and Reverse: |

|

Forward and reverse foot pedal. |

|

Ignition: |

|

Key start, shut - off and engine preheat. |

|

Differential Lock: |

|

Foot pedal. |

|

Cutterhead Position: |

|

Hand operated lever. |

|

Horn: |

|

Button switch. |

|

Weight Transfer: |

|

Hand wheel. |

|

INSTRUMENTATION

Warning Lights:

Gauges:

Indicator Lights:

Engine oil pressure. Battery charge.

Engine coolant temperature.

Hydraulic transmission oil temperature.

Digital hour meter. Fuel level.

Hydraulic oil level sight glass.

Engine pre-heat.

Hydraulic return filter blocked. Hydraulic transmission filter blocked. Cutterhead drive switch off.

Parking brake engaged. Transmission neutral.

924916KG251004

1.23 |

SPECIFICATIONS |

1.23 |

WEIGHT AND DIMENSIONS

Wheel Base: |

1440 mm. |

Working Width: |

2300 mm. |

Cutting Width: |

2120 mm. |

Transport Width: |

1575 mm at 13mm height of cut. |

Overall Length: |

2690 mm. |

Overall Height: |

1520 mm. |

Approx. Working Weight: |

1250 kg less operator, no options fitted. |

|

(The exact weight depends on the cutterhead configuration). |

RECOMMENDED LUBRICANTS AND HYDRAULIC FLUIDS

Grease Points: A good quality medium grease.

Engine: Refer - ENGINE OPERATORS MANUAL.

Hydraulic System:

|

Ambient Temperature Range |

|

|

||

|

0 - 30OC (32 - 86OF) |

|

|

15 - 40 OC (59 - 104OF) |

|

|

|

|

|||

|

|

|

|

|

|

|

I S O viscosity grade |

|

|

I S O viscosity grade |

|

|

46 hydraulic oil. |

|

|

68 hydraulic oil. |

|

|

|

|

|

|

|

Should you be in any doubt please contact your Hayter dealer. Using incorrect grades will cause premature wear of hydraulic components and invalidate warranty.

924916KG251004

1.24 |

SPECIFICATIONS |

1.24 |

CUTTERHEADS

|

MK3 200mm Cutterhead |

MK3 254mm Cutterhead |

Cutting Width: |

762 mm. |

762 mm. |

Cylinder Diameter: |

200 mm. |

254 mm. |

Cylinder Speed: |

1050 rpm approx. |

1050 rpm approx. |

Height of Cut: |

12 - 80 mm. |

12 - 80 mm. |

Number of Blades: |

4, 6, 8, 10 |

4, 6 |

Smooth Rear Roller: |

Standard. |

Standard. |

Smooth Front Roller: |

Optional. |

- |

Grooved Front Roller: |

Optional. |

- |

Configuration: |

Fixed / Floating. |

Fixed |

924916KG251004

Loading...

Loading...