Greenheck PVF, PVG User Manual

|

Document 474645 |

|

Model PVF and PVG |

® |

Indirect Gas-Fired Heat Modules |

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage!

Recognized Component

Model PVF

Model PVG

General Safety Information

These indirect gas-fired furnaces are commonly used in many different manufacturer’s ventilating products. For unit-specific information, refer to the Installation, Operation and Maintenance manual (IOM) for the unit in which this furnace is installed.

•Both the furnace units are listed for installation in the United States and in Canada.

•Installation of gas-fired duct furnaces must conform with local building codes. In the absence of local building codes, installation must conform to the National Fuel Gas code, ANSI Z223.1 or in Canada, CAN/CGA-B149 Installation codes.

•All electrical wiring must be in accordance with the regulations of the National Electric Code, ANSI/ NFPA-70.

•Unit is approved for installation downstream from refrigeration units. In these conditions, condensate could form in the duct furnace and provision must be made to dispose of the condensate.

FOR YOUR SAFETY

If you smell gas:

1.Open windows.

2.Do not touch electrical switches.

3.Extinguish any open flame.

4.Immediately call your gas supplier.

FOR YOUR SAFETY

The use and storage of gasoline or other flammable vapors and liquids in open containers in the vicinity of this appliance is hazardous.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause injury or death. Read the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment.

Indirect Gas-Fired Heat Modules |

1 |

®

NOTE

This unit is an indirect gas-fired heat module that will be referred to in this manual as a furnace.

Receiving

Since this furnace is already installed in a ventilation unit, follow the Receiving Instructions for the unit which are provided in the unit-specific Installation, Operating and Maintenance manual (IOM).

Unpacking

If unit is to be installed, tested and operated right away, locate and remove all packing materials from the furnace, including any protective coverings that may be on the combustion air intake and on the furnace exhaust. Follow Unpacking Instructions as found in the unit-specific IOM.

Storage

If unit must be stored after it is received, follow the unitspecific storage instructions found in the unit IOM. Also plug all piping.

Unit Identification

It is necessary to know the unit model number, the burner control turndown and the serial number. This information is needed when ordering replacement parts and is available on labels located on the unit.

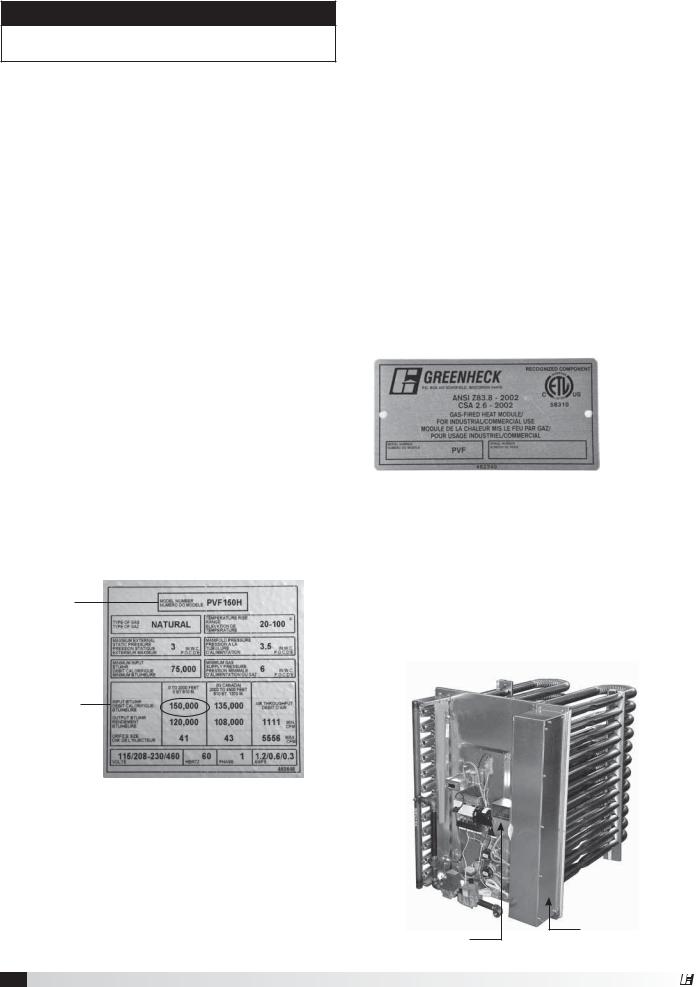

Furnace Model Number

On the furnace access door or immediately next to the door is a Mylar data label. See image below. Locate the furnace model number at the top of the label and record it here:

Furnace Model Number: _____________________

Model

Number

Minimum Input

BTU/HR

Input

BTU/HR

Typical Furnace Data Label

2Indirect Gas-Fired Heat Modules

Burner Control Turndown

Burner turndown ratio is used in many places and must be calculated. On the data label, locate the INPUT BTU/HR (the largest number on the label) and also

the MINIMUM INPUT BTU/HR. Calculate the burner turndown ratio and record it.

INPUT BTU/HR |

= |

Burner Control |

||

MINIMUM BTU/HR |

Turndown Ratio |

|||

Example: |

150,000 |

= |

2 |

|

75,000 |

||||

|

|

|

||

The turndown ratio is 2:1 in this example.

Burner Turndown: _______________

Furnace Serial Number

The furnaces are assigned the same serial number as the main ventilating unit. On the main unit control access door is a stamped metal plate identifying the unit serial number. Record that information here.

Furnace/Unit Serial Number: _____________________

Typical Unit ID Plate

ETL Listing

Model PVF and PVG furnaces have been ETL tested as gas-fired heat modules intended for installation as a component within heating equipment in duct or cabinet mounted applications. They are ETL Recognized Components.

Product Overview

Burner |

|

Heat |

||||||

Assembly |

Exchangers |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Collector

Combustion Box

Blower

®

Table of Contents

General Safety Information . . . . . . . . . . . . . . 1 Receiving, Unpacking, Storage . . . . . . . . . . . . 2

Unit Identification |

. . . |

. . . . . . . . . . . . . . . . 2 |

Furnace Model Number . . . . . . . . . . . . . . . . 2 |

||

Burner Control Turndown . . . . . . . . . . . . . . . 2 |

||

Furnace Serial Number |

. . . . . . . . . . . . . . . . 2 |

|

ETL Listing . . . . |

. . . . . . . . . . . . . . . . . . . 2 |

|

Product Overview |

. . . . . . . . . . . . . . . . . . . 2 |

|

Furnace Control Center

Furnace Control Center Components. . . . . . . . 4 Typical Furnace Control Logic. . . . . . . . . . . . 4

Typical Furnace, Electrical and |

|

|

Control Components . . . . . . . . . . . . . |

. . |

. 5 |

Gas-Fired Burner Turndown . . . . . . . . . |

. . |

. 6 |

Electronic Modulation . . . . . . . . . . . . . |

. . |

. 6 |

Two Stage Valve . . . . . . . . . . . . . . . . |

. . |

. 6 |

Combinations . . . . . . . . . . . . . . . . . |

. . |

. 6 |

Available Turndown Control Options . . . . |

. . |

. 6 |

Installation of Venting for Outdoor Units . . |

. . |

. 7 |

Installation of Venting for Indoor Units . . . |

. . |

. 7 |

Venting Methods . . . . . . . . . . . . . . . . . . 8 |

||

Installation of Standard Indoor Venting |

|

|

Horizontal . . . . . . . . . . . . . . . . . . . |

. . |

. 8 |

Vertical. . . . . . . . . . . . . . . . . . . . . |

. . |

. 8 |

Installation of Concentric Venting |

|

|

Horizontal . . . . . . . . . . . . . . . . . . . |

. 9-10 |

|

Vertical. . . . . . . . . . . . . . . . . . . . . |

10-11 |

|

Two-Pipe Venting - Horizontal. . . . . . . . . |

11-12 |

|

Two-Pipe Venting - Vertical . . . . . . . . . . |

. . |

12 |

Installation of Control Wiring . . . . . . . . |

. . |

13 |

Installation of Discharge Air Sensor . . . . |

. . |

13 |

Installation of Gas Piping. . . . . . . . . . . |

13-14 |

|

Gas Supply Requirements . . . . . . . . . . |

. . |

14 |

Connect the Supply Gas Line . . . . . . . . . |

. . |

14 |

Installation Addition Regulator . . . . . . . . |

. . |

14 |

Testing the System for Leaks . . . . . . . . . |

. . |

14 |

Gas Pressure Test Ports. . . . . . . . . . . . |

. . |

14 |

Sequence of Operation . . . . . . . . . . . . |

. . |

15 |

Start-Up / Standby . . . . . . . . . . . . . . |

. . |

15 |

Heat Mode. . . . . . . . . . . . . . . . . . . |

. . |

15 |

Recovery from Lockout . . . . . . . . . . . . |

. . |

15 |

Performance Data . . . . . . . . . . . . . . |

. . . |

15 |

Gas Valves . . . . . . . . . . . . . . . . . . |

. . . |

16 |

Start-Up - Furnaces (all units) . . . . . . . |

. . . |

17 |

4:1 Turndown Electronic Modulation . . . . |

. . . |

18 |

Adjust High Fire and Low Fire Settings . . |

. . . |

18 |

Modulating Valve High Fire Setting . . . . |

. . . |

18 |

Modulating Valve Low Fire Setting . . . . |

. . . |

18 |

8 Stage Combustion . . . . . . . . . . . . |

. . . |

19 |

Single Stage . . . . . . . . . . . . . . . . . |

. . . |

19 |

2 Stage Combustion . . . . . . . . . . . . . . . |

20 |

|

Combination Turndown Configurations . . . . . . |

20 |

|

Troubleshooting |

|

|

Ignition Controller . . . . . . . . . . . . . . |

. . . |

21 |

4:1 Electronic Modulation . . . . . . . . . . |

. 22-23 |

|

2:1 Electronic Modulation . . . . . . . . . . |

. . . |

24 |

8 Stage . . . . . . . . . . . . . . . . . . . |

. 25-26 |

|

Single and Two Stage . . . . . . . . . . . . |

. . . |

27 |

Reference: FX Controller . . . . . . . . . . |

. . . |

28 |

Stand-Alone Furnace Control . . . . . . . . |

. . . |

28 |

Program Mode . . . . . . . . . . . . . . |

. . . |

28 |

Inlet Air Sensor (optional) . . . . . . . . . |

. . . |

28 |

Discharge Air Temperature . . . . . . . . |

. . . |

28 |

Outside Air Temperature . . . . . . . . . |

. . . |

29 |

Go to High Fire Mode . . . . . . . . . . . |

. . . |

29 |

Return to Normal Operation. . . . . . . . |

. . . |

29 |

Access to Set Points Menu . . . . . . . . |

. . . |

29 |

Access the Discharge Air Temperature . . |

. . . |

29 |

Access the Inlet Air Sensor (optional). . . |

. . . |

29 |

Access the Room Override Setting . . . . |

. . . |

29 |

Furnace Control with Microprocessor. . . . . 29-30

Maintenance |

|

|

Combustion Blower Motor |

. . . . . . . . . . . . |

30 |

Burners and Orifices . . . |

. . . . . . . . . . . . |

30 |

Heat Exchanger . . . . . . |

. . . . . . . . . . . . |

30 |

Flue Collector Box. . . . . |

. . . . . . . . . . . . |

30 |

Electrical Wiring . . . . . . |

. . . . . . . . . . . . |

30 |

Gas Train . . . . . . . . . |

. . . . . . . . . . . . |

30 |

Replacement Parts . . . . |

. . . . . . . . . . . . |

30 |

Maintenance Log . . . . . |

. . . . . . . . . . . . |

31 |

Our Commitment . . . . . |

. . . . . . . . Backcover |

|

Indirect Gas-Fired Heat Modules |

3 |

®

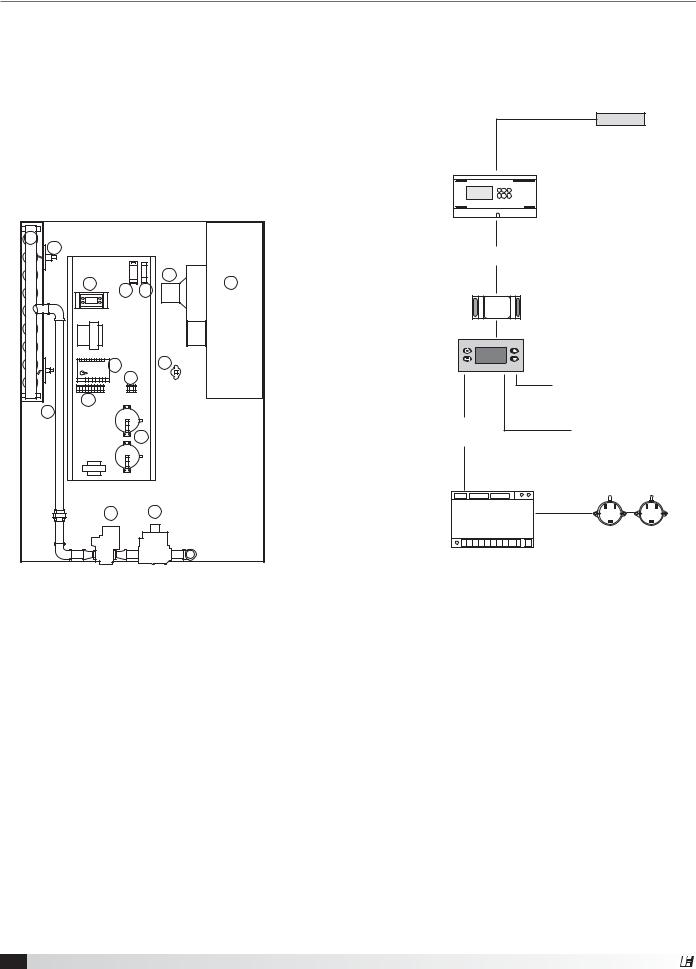

Furnace Control Center

Each ventilating unit containing a furnace or a pair of furnaces will have a furnace control center located on the furnace vest plate. The control center receives high voltage AC from the main unit control center and in most cases, also receives low voltage control signals (call for heat) from the main unit control center. In all cases, see the unit-specific wiring schematic located inside the main control center door.

Furnace Control Center Components

(Components and their locations will vary.)

Components shown are for a typical 4:1 turndown electronic modulation configuration.

13 |

|

|

|

|

10 |

|

|

|

|

5 |

|

|

3 |

14 |

4 |

2 |

|

||

|

|

|

||

|

6 |

|

8 |

|

|

|

1 |

|

|

7 |

|

|

|

|

6a |

|

|

|

|

|

|

9 |

|

|

|

12 |

|

11 |

|

High Voltage Side

1.Power Distribution Block

2.Inducer Relay (controls combustion fan)

3.Combustion Blower

Low Voltage Side

4.Input Converter

5.FX Controller (modulates heat and switches entire unit on/off

6.Spark Generator (also has high voltage present) 6a. Spark Igniter

7.24 volt Terminal Strip

Control Sensors

8.High Temperature Sensor (auto reset)

9.Airflow Switches

10.Flame Sensor

Gas Train

11.Combination Valve

12.Modulating Valve

13.Burner Manifold

14.Collector Box

Typical Furnace Control Logic

In all cases, refer to the unit-specific wiring diagram located on the unit control center door.

This illustration is only for a typical 4:1 turndown electronic modulation configuration

Temperature Sensor

If there is no DDC, the sensor is connected to the FX.

DDC

Located in

unit main (optional) control center

Call for heat

JOHNSON

CONTROLS

Input Converter |

(optional) |

|

|

FX Controller |

|

|

Activates and modulates |

|

Modulating Valve |

Activates |

Controls Speed |

Ignition Controller |

of Combustion |

|

Blower |

Ignition

Controller

|

|

|

|

|

|

Activates |

|

|

|

|

|

|

|

|

|

|

|

|

|

Combustion Blower |

Activates |

|

|

|

|

Spark to Igniter |

|

|

|

|

|

|||

Combination Valve

1.Microprocessor (if present) senses low temperature on temperature sensor, sends 10 VDC signal to signal input converter.

2.Input converter changes analog signal to a form that can be read by the FX controller and sends the signal to the FX controller (call for heat).

3.FX controller receives call for heat, activates modulating valve and the ignition controller.

4.Ignition controller receives call for heat from FX controller, sends spark to igniter and activates the combination valve. It looks for verification that the combustion blower is running.

5.Flame sensor detects flame and ignition controller shuts off igniter.

4 Indirect Gas-Fired Heat Modules

®

Typical Furnace, Electrical and Control Components

Microprocessor

The microprocessor provides the call for heat to the ignition controller and also

monitors the discharge air temperature. It is found only in the unit main control center. On units with electronic modulation, it also determines the required burner firing rate.

Discharge Air Temp Sensor

This sensor is shipped with all units and must be field-installed in the discharge air duct. This may be located in the main unit control center or the furnace control center depending on the control type.

Input Converter

The input converter takes an analog signal from a microprocessor or a BMS

and converts it to a control signal that can be used by the FX programmable controller. It is found in the furnace control center.

FX Programmable Controller

Used on all 4:1 electronic modulating controls and 8:1 staged turndown.

The FX controller turns on and electronically modulates gas valves. It will also enable the

ignition module. The FX controller has a digital readout and four push buttons, one for Function, one for Enter and two for scrolling up or down. It is pre-programmed at the factory for each specific furnace configuration and it may be used to control two furnaces at the same time.

Ignition Controller

This controller is found only in the furnace control center. It has an LED indicator

light on the top right of the controller that will flash GREEN for normal operation or RED for an error. Some furnace configurations have two of these controllers.

Burner Manifold

Airflow Switch

Airflow switches are used on both furnaces and are found on the furnace vest plate. If the combustion blower is multi-speed, there will be two of them and each will switch in response to a different pressure. The switch is connected to the combustion blower

by means of a vacuum tube and is used to sense operation of the combustion blower. The internal switch is Normally Open (NO). If the blower fails to operate, the open circuit will cause the ignition controller to disable the furnace.

Flame Igniter

The igniter receives a high voltage input from the ignition controller to produce a spark between the two electrodes. It operates only during the ignition phase. On split burner manifolds, there will be two igniters.

Flame Sensor

The flame sensor is identical to the flame igniter. It is located on the opposite end of the burner manifold from the igniter.

Auto Reset High Temperature

Limit Switch

This limit switch is installed through the vest plate into the supply air plenum.

A350 and S350 Control System

Used on two stage and |

|

|

single stage controls. Used |

|

|

in conjunction with a field- |

|

|

installed remote temperature |

|

|

sensor. Has an LED indicator |

|

|

light to show when the |

|

|

output relay is energized. |

|

|

When used with multiple |

|

|

stages, the S350 controller is |

A350 |

S350 |

used for the extra stages. |

Controller |

Controller |

Single Section |

Split Burner |

Burner Manifold |

Manifold |

Indirect Gas-Fired Heat Modules |

5 |

®

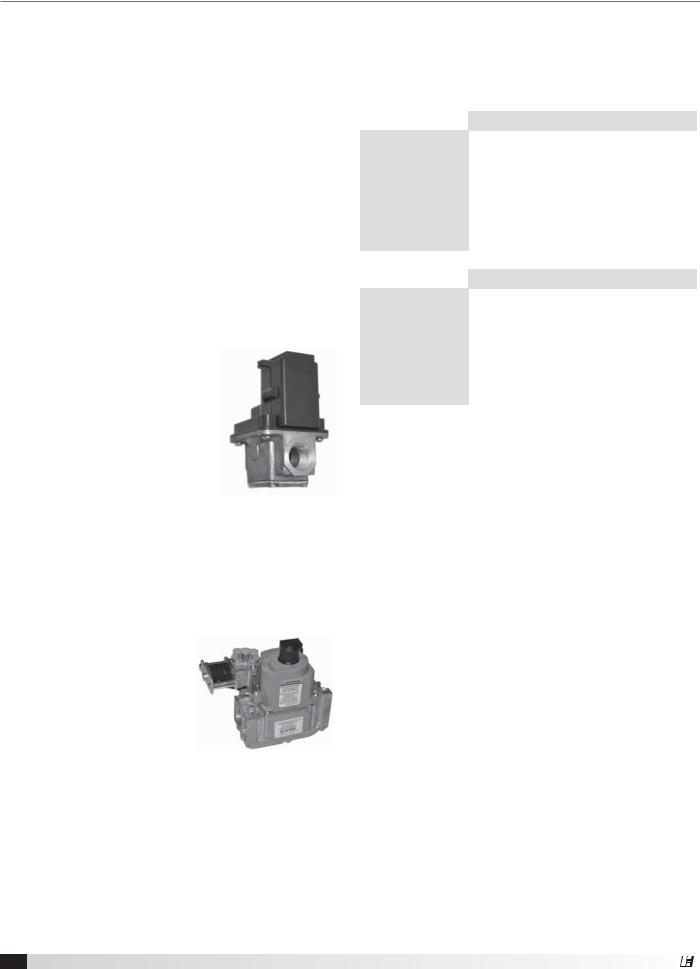

Gas-Fired Burner Turndown

Furnaces are available in single stage, multi-stage or electronically modulated configurations. In single stage, the entire furnace is either on or off. In multi-stage furnaces, combustion occurs in stages and is expressed as the number of different stages (example: 8 stage). Electronically modulated furnaces have continuously variable firing rates. In both staged and electronically modulated furnaces, the result is burner turndown. Turndown is the capability of the furnace to operate

at less than full capacity, accomplished by reducing the amount of gas flow when the unit is operating. The advantage in being able to turn down firing rate is that when the demand for heat is low, the furnace will not cycle as often. Turndown is expressed as a ratio and is found by dividing the maximum BTU input by the minimum BTU input.

Electronic Modulation

Turndown is specified by the customer. Most common is the use of an electronically-controlled gas valve which provides a 4:1 turndown. The entire furnace is sized appropriately for the maximum heat

output ordered by the customer, but it can operate as low as 25% of its maximum capacity. The electronically-controlled gas valve will modulate the combustion rate continuously, dependent on the output from an FX controller. With this method, all the burners fire at the same time but at a varying

capacity. The Modulating Valve is used in conjunction with an FX electronic controller and a combination valve which provides an ON/OFF function.

Two Stage Valve

The two-stage valve is switched electrically from closed to full output to half output, producing a 2:1 turndown. In some cases, multiple furnaces may be used in a ventilating unit. When this is

done with two single-stage furnaces, it is possible to run just one furnace at a time, resulting in a 2:1 turndown. If each furnace is already

configured for a 2:1 turndown, the overall result can then be a 4:1 turndown.

Combinations

Various combinations of the methods outlined may be used to accomplish the turndown requested by the customer.

Available turndown control options include:

|

Electronic Modulation |

|

|

|

4:1 uses modulating valve and FX |

Single Furnace |

programmable controller |

Unit |

2:1 uses modulating valve and |

|

1092 control system |

|

|

|

8:1 uses one 4:1 modulating furnace with |

Two Furnace |

FX controller and one 2 stage furnace |

Unit |

4:1 uses two 4:1 modulating furnaces |

|

running in parallel |

|

|

|

Staged |

|

|

|

|

Single Furnace |

8 stage |

|

|

||

2 stage |

||

Unit |

||

|

||

1 stage |

||

|

||

|

|

|

|

16 stage uses one 8 stage furnace and |

|

Two Furnace |

one single-stage furnace |

|

Unit |

4 stage uses two 2 stage furnaces |

|

|

2 stage uses two single-stage furnaces |

|

|

|

6 Indirect Gas-Fired Heat Modules

®

Installation of Venting for

Outdoor Units

Follow Guidelines

All of the following guidelines must be followed when installing the unit.

WARNING

Do not install units in locations where flue products can be drawn into adjacent building openings such as windows, fresh air intakes, etc. Distance from vent terminal to adjacent public walkways, adjacent buildings, operable windows and building openings shall conform with the local codes. In the absence of local codes, installation shall conform with the

National Fuel Gas Code, ANSI Z223.1 or the Canadian CAN/CGA B-149 Installation Codes.

WARNING

The following guidelines must be followed for all outdoor units:

1.Building materials that will be affected by flue gases should be protected.

2.Maintain minimum horizontal clearance of 4 feet from electric meters, gas meters, regulators and relief equipment. In Canada, the minimum clearance is 6 feet.

3.The combustion blower discharge on outdoor units must be located a minimum of 42 inches from any combustible materials.

4.Do not modify or obstruct the combustion air inlet cover or the combustion blower weatherhood.

5.Do not add vents other than those supplied by the manufacturer.

6.During the winter, keep the unit clear of snow to prevent any blockage of the combustion venting.

Install Stack (optional)

Clearance may require an exhaust stack. Install an exhaust stack as needed to the exhaust connection on the unit. Install a vent terminator on the exhaust pipe.

Exhaust transition and vent termination must be purchased from the factory for proper operation. Exhaust pipe is by others.

Installation of Venting for

Indoor Units

WARNING

The following guidelines must be followed for all indoor units:

1.Installation of venting must conform with local building codes. In the absence of local codes, installation must conform with the National Fuel Gas Code, ANSI Z223.1 or in Canada, CAN/ CGA-B149 installations codes.

2.For the exhaust pipe, use pipe approved for a Category III appliance or single wall, 26 gauge or heavier galvanized vent pipe. The piping is required to be gas-tight by ANSI.

3.For the combustion air pipe on separated combustion units, sealed single-wall galvanized air pipe is recommended.

4.The joints must be sealed with a metallic tape or Silastic™ suitable for temperatures up to 350°F.

5.A minimum of 12 inches of straight vent pipe is recommended after the exhaust connection and before any elbows.

6.Vertical combustion air pipes should be fitted with a tee, drip leg and clean-out cap to prevent any moisture in the combustion air pipe from entering the unit.

7.To reduce condensation, insulate any vent runs greater than 5 feet.

8.All vent pipe connections should be made with at least three corrosion-resistant sheet metal screws.

9.Refer to the National Fuel Gas Code for additional piping guidelines.

NOTE

Vent piping is supplied by others and not supplied by manufacturer.

NOTE

The drip leg should be cleaned out periodically during the heating season.

NOTE

Clearances from combustible material for indoor units are determined by the National Fuel Gas Code and/or other local codes.

Indirect Gas-Fired Heat Modules |

7 |

®

Venting Methods

There are three venting methods for indoor mounted units. For each method, the units can be vented horizontally through an exterior wall or vertically through the roof. Specific venting instructions are provided for each method and shown in the following pages. Construct the vent system as shown in these instructions. Refer to your unit specific submittal to determine the applicable venting option.

The venting method options are:

Standard Indoor Venting

•uses building air for combustion

•vents exhaust to outdoors

•one exterior roof or wall penetration

Separated Combustion Concentric Venting

•uses outside air for combustion

•vents exhaust to outdoors

•one exterior roof or wall penetration

Separated Combustion 2-Pipe Venting

•uses outside air for combustion

•vents exhaust to outdoors

•two exterior roof or wall penetrations

NOTE

For each method, the units can be vented horizontally through an exterior wall or vertically through the roof. Refer to the specific venting instructions for your unit. Construct the vent system as shown in these instructions.

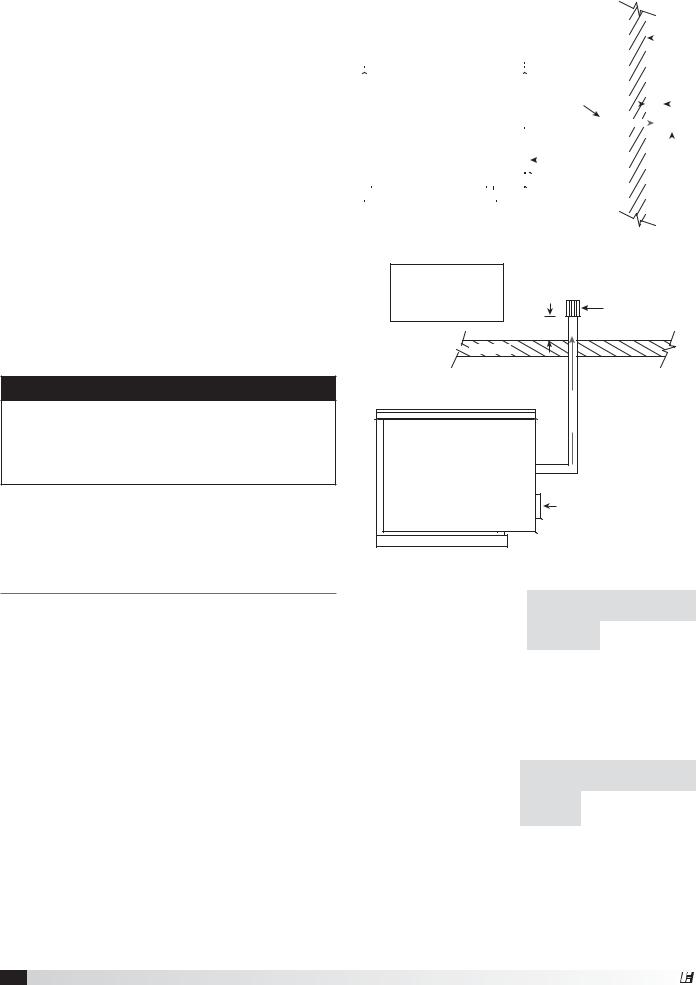

Installation of Standard Indoor

Venting

Standard indoor venting uses one penetration through an exterior wall or roof for venting the flue exhaust. The combustion air is supplied from the air inside the building. Units must not be installed in a potentially explosive, flammable, or corrosive atmosphere. To prevent premature heat exchanger failure, do not locate unit where chlorinated, halogenated or acid vapors are present.

When units are installed in tightly sealed buildings, provisions should be made to supply an adequate amount of infiltration air from the outside. The rule of thumb is that an opening of one square inch should be provided for every 1000 BTUs per hour of input rating.

Vent terminals must be used. Construct the vent system as shown in the drawings. Reference the Vent Pipe Diameter table and Exhaust Vent Pipe table for additional details.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Exterior |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

A = 12 inch minimum |

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wall |

||||

|

|

|

|

|

Pitch vent pipe |

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

downward |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

from furnace |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

¼ inch per foot |

|

|

|

|

A |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EXHAUST |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

Air Inlet |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Exhaust |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vent |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Terminal |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Standard Indoor Venting - Horizontal

A = 12 inch minimum

B = 12 inch minimum, but should size

according to expected snow depth

B

Roof Line

Roof Line

EXHAUST

A

A

Exhaust Vent

Terminal

Air Inlet

Standard Indoor Venting - Vertical

Vent Pipe Diameter |

|

|

|

Furnace Size |

Exhaust Pipe |

||

|

|||

Select the vent pipe |

(MBH) |

Diameter (inches) |

|

diameter. Use only the |

75-175 |

4 |

|

specified pipe diameter. |

200-400 |

6 |

|

|

|

Installing Exhaust Vent Pipe

Install the vent pipe with a minimum downward slope (from the unit) of 1/4-inch per foot (horizontal venting only). Securely suspend the pipe from overhead structures at points no greater than 3 feet apart.

The minimum vent length |

|

|

|

|

Vent |

Minimum |

Maximum |

||

is 5 feet for horizontal |

||||

Length |

(feet) |

(feet) |

||

and 10 feet for vertical. |

||||

|

|

|

||

Horizontal |

5 |

70 |

||

The maximum vent |

||||

|

|

|

||

Vertical |

10 |

70 |

||

length is 70 feet. The |

||||

|

|

|

||

|

|

|

total equivalent vent length must include elbows. The equivalent length of a 4 inch elbow is 6 feet and the equivalent length of a 6 inch elbow is 10 feet.

Attach the vent terminal to the end of the exhaust pipe.

8Indirect Gas-Fired Heat Modules

®

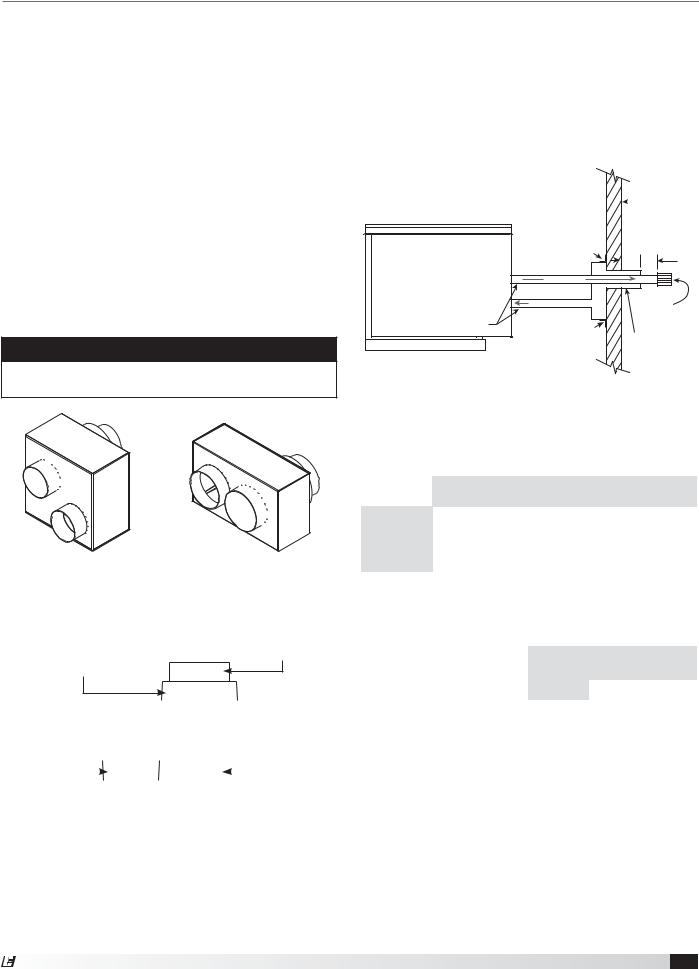

Installation of Concentric Venting

Concentric venting allows the exhaust pipe and combustion air pipe to pass through a single hole in the roof or wall of the building. A concentric venting adapter (CVA) is required for concentric venting.

The concentric venting adapter is designed for indoor installations and should never be installed on the exterior of the building.

The exhaust pipe must terminate with the vent terminal. For horizontal venting, the combustion air pipe must terminate with the combustion air guard. For vertical venting, the combustion air pipe must terminate with the inlet terminal. Depending on what was ordered, one of these vent terminals will be provided in the optional venting kit along with the concentric venting adapter (CVA).

If venting vertically through the roof, refer to the vertical concentric venting instructions. If venting horizontally through the wall, refer to the horizontal concentric venting instructions.

NOTE

Vent piping is supplied by others and not supplied by manufacturer.

CVA-4 |

CVA-6 |

4-inch Concentric |

6-inch Concentric |

Venting Adapter |

Venting Adapter |

Exhaust Connection

Combustion Air Connection Concentric Side

Concentric Side

|

|

|

|

|

CVA |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Combustion Air Connection |

|

|

Exhaust Connection |

|||||||

Non-Concentric Side |

|

|

Non-Concentric Side |

|||||||

Top View

Concentric Venting – Horizontal

Refer to the diagram below for venting on horizontal concentric systems. Maintain at least 12 inches from the combustion air inlet guard to the exhaust vent terminal (Dim. B). To prevent water from running into the combustion air pipe and to allow for easy installation

of the combustion air inlet guard, the combustion air pipe must terminate at least 2 inches from the exterior surface of the outside wall (Dim. A).

A = 2 inch minimum |

|

Exterior |

|

B = 12 inch minimum |

|

||

|

|

Wall |

|

|

|

|

|

|

Mounting |

|

|

|

Bracket |

|

|

|

A |

B |

|

|

EXHAUST |

|

|

Pitch vent pipe |

COMBUSTION AIR |

Exhaust |

|

Vent |

|||

downward |

|||

|

Terminal |

||

from furnace |

|

||

1/4 inch per foot |

Mounting |

|

|

|

Bracket |

|

|

|

Combustion |

||

|

Air Inlet Guard |

||

Vent Connection Diameter

Vent terminals must be used (one vent terminal included with each furnace). Construct the vent system as shown in the drawings and refer to the table for the correct vent connection diameters.

|

Non-Concentric Vent |

Concentric Vent |

||

|

Connection Diameter |

Connection Diameter |

||

|

|

|

|

|

Furnace Size |

Exhaust |

Combustion Air |

Exhaust |

Combustion Air |

(MBH) |

(inches) |

(inches) |

(inches) |

(inches) |

|

|

|

|

|

75-175 |

4 |

4 |

4 |

6 |

|

|

|

|

|

200-400 |

6 |

6 |

6 |

8 |

|

|

|

|

|

Vent Length

Refer to table for minimum and maximum vent lengths. The total equivalent vent length must include elbows.

The equivalent length of a |

|

|

|

|

Vent |

Minimum |

Maximum |

||

4 inch elbow is 6 feet and |

||||

Length |

(feet) |

(feet) |

||

the equivalent length of a |

||||

|

|

|

||

Horizontal |

5 |

70 |

||

6 inch elbow is 10 feet. |

||||

|

|

|

||

|

|

|

Determine Venting Location

Determine the location of the concentric venting adapter (CVA) based on any clearances that must be maintained (follow all codes applicable).

Attach Mounting Brackets

Attach field-supplied, corrosion-resistant, mounting brackets to the CVA using corrosion-resistant sheet metal screws.

Indirect Gas-Fired Heat Modules |

9 |

®

Install Exhaust Pipe

Slide the exhaust pipe through the CVA. Provide enough exhaust piping to pass through the wall (or floor) and provide the minimum clearance of 12 inches between the exhaust pipe termination and the combustion air intake. With all required clearances satisfied, attach the exhaust pipe to the CVA.

Install Combustion Air Pipe

Attach a field-supplied combustion air pipe to the concentric side of the CVA.

Be sure to provide enough combustion air piping to pass through the wall and provide the minimum

clearance of 2 inches between the combustion air intake and the exterior surface of the outside wall.

Be sure to maintain the minimum clearance of

12 inches between the exhaust pipe termination and the combustion air intake.

Install CVA Assembly

Place the CVA assembly through the wall and verify that all minimum clearance requirements as specified in these instructions are met. Secure the CVA assembly to the wall with corrosion-resistant sheet metal screws through the mounting brackets.

Attach CVA Assembly to Unit

Attach the exhaust pipe to the unit’s combustion exhaust. Using an additional combustion air pipe, connect the unit’s combustion air supply intake to the combustion air connection on the CVA.

Install Combustion Air Inlet Guard and

Exhaust Vent Terminal

Slide the combustion air inlet guard over the exhaust pipe and fasten it to the combustion air pipe. Attach the exhaust vent terminal to the discharge end of the exhaust piping on the outside of the building.

Seal Opening

Seal the opening between the wall and the air intake pipe using an appropriate method.

10 Indirect Gas-Fired Heat Modules

Concentric Venting – Vertical

Refer to the diagram below for venting on vertical concentric systems. Maintain at least 12 inches between the top of the combustion air inlet terminals and the bottom of the exhaust terminal. (Dim. B).

The bottom of the combustion air intake pipe must terminate above the snow line or at least 12 inches above the roof, whichever is greater.

A tee with clean-out must be provided on the combustion air and exhaust pipe to prevent debris from entering the heat exchanger.

A = 12 inch minimum, but should size according to expected snow depth

B = 12 inch minimum |

|

|

|

|

|

|

|

|

|

|

|||||||||||

C = 12 inch minimum |

|

|

|

|

|

B |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

Roof Line |

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mounting |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

Bracket |

|

|

|

|

EXHAUST |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Exhaust Vent

Terminal

Combustion Air

Combustion Air

Inlet Terminal

|

|

|

|

|

Mounting |

|

|

|

|

|

|

||

|

COMBUSTION AIR |

|

|

Bracket |

||

|

|

|

|

|

||

|

|

|

|

|

|

Tee with |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

drip leg and |

|

|

|

|

|

|

clean-out cap |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Vent Connection Diameter

Vent terminals must be used. Construct the vent system as shown in the drawings and refer to the table for the correct vent connection diameters.

|

Non-Concentric Vent |

Concentric Vent |

||

|

Connection Diameter |

Connection Diameter |

||

|

|

|

|

|

Furnace Size |

Exhaust |

Combustion Air |

Exhaust |

Combustion Air |

(MBH) |

(inches) |

(inches) |

(inches) |

(inches) |

|

|

|

|

|

75-175 |

4 |

4 |

4 |

6 |

|

|

|

|

|

200-400 |

6 |

6 |

6 |

8 |

|

|

|

|

|

Vent Length

Refer to table. The total equivalent vent length must

include elbows. The |

|

|

|

|

Vent |

Minimum |

Maximum |

||

equivalent length of a |

||||

4 inch elbow is 6 feet and |

Length |

(feet) |

(feet) |

|

Vertical |

10 |

70 |

||

the equivalent length of a |

||||

6 inch elbow is 10 feet. |

|

|

|

Determine Venting Location

Determine the location of the concentric venting adapter (CVA) based on any clearances that must be maintained (follow all codes referenced in these instructions).

Attach Mounting Brackets

Attach field-supplied corrosion-resistant mounting brackets to the CVA using corrosion resistant sheet metal screws.

®

Loading...

Loading...