Greenheck IGX Installation Manual

Part #474681

Packaged DX Module

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage!

As used in Greenheck models

•DGX

•IGX

•MSX

Recognized Component

General Safety Information

Only qualified personnel should install and maintain this system. Personnel should have a clear understanding of these instructions and should be aware of general safety precautions. Improper installation can result in electric shock, possible injury due to coming in contact with moving parts, as well as other potential hazards. Other considerations may be required if high winds or seismic activity are present. If more information is needed, contact a licensed professional engineer before moving forward.

1.Follow all local electrical and safety codes, as well as the National Electrical Code (NEC), the National Fire Protection Agency (NFPA), where applicable.

Follow the Canadian Electric Code (CEC) in Canada.

2.Unit must be securely and adequately grounded.

3.Verify that the power source is compatible with the equipment.

4.Never open access doors to the unit while it is running.

DANGER

•Always disconnect power before working on or near this equipment. Lock and tag the disconnect switch or breaker to prevent accidental power up.

•If this unit is equipped with optional gas accessories, turn off gas supply whenever power is disconnected.

CAUTION

This unit is equipped with a compressed refrigerant system. If a leak in the system should occur, immediately evacuate and ventilate the area. An EPA Certified Technician must be engaged to make repairs or corrections. Refrigerant leaks may also cause bodily harm.

CAUTION

When servicing the unit, the internal components may be hot enough to cause pain or injury. Allow time for cooling before servicing.

Packaged DX Module for Make-Up Air 1

Receiving

This module is installed as a component of a makeup air unit and does not require any special handling. Refer to the Receiving portion of the unit Installation, Operation and Maintenance (IOM) Manual for complete instructions on receiving, unpacking and handling.

Unpacking

The unit is shipped as a complete installed unit. Protective coverings have been installed on the face of the condenser coil that should be left in place until installation of the unit is complete. The only item that was shipped loose with the unit is the P Trap kit. Verify that the P Trap kit has been received. Refer to Unpacking instructions in unit IOM.

Handling

Units are to be rigged and moved by the lifting brackets provided. Do not forklift. Refer to the Handling portion of the unit IOM for complete instructions on handling.

Storage

Units are protected against damage during shipment. If the unit cannot be installed and operated immediately, precautions need to be taken to prevent deterioration of the unit during storage. The user assumes responsibility of the unit and accessories during storage. The manufacturer will not be responsible for damage during storage. The following suggestions are provided solely as a convenience to the user.

Inspection and Maintenance During Storage

While in storage, inspect units once per month. Keep a record of inspection and maintenance performed. If moisture or dirt accumulations are found on the parts, the source should be located and eliminated. At each inspection, rotate all moving parts by hand ten to fifteen revolutions to distribute lubricant on motor and bearings. If paint deterioration begins, consideration should be given to touch-up or repainting. Units with special coatings may require special techniques for touch-up or repair.

Machined parts coated with rust preventative should be restored to good condition promptly if signs of rust occur. Immediately remove the original rust preventative coating with petroleum solvent and clean with lint-free cloths. Polish any remaining rust from the surface with crocus cloth or fine emery paper and oil. Do not destroy the continuity of the surfaces. Wipe clean thoroughly with Tectyl® 506 (Ashland, Inc.) or the equivalent. For hard to reach internal surfaces or for occasional use, consider using Tectyl® 511M Rust Preventative or WD 40® or the equivalent.

Table of Contents

General Safety Information. . . . . . . |

. |

. |

. |

1 |

Receiving, Handling, Storage . . . . . . |

. |

. |

. |

2 |

Product Overview . . . . . . . . . . . . . . 2 |

||||

Subassemblies. . . . . . . . . . . . . . . . 3 |

||||

Coils . . . . . . . . . . . . . . . . . . . 3 |

||||

Dampers. . . . . . . . . . . . . . . . . . 3 |

||||

DX System . . . . . . . . . . . . . . . . . 3 |

||||

Installation |

|

|

|

|

Service Clearances. . . . . . . . . . . . . |

|

|

|

4 |

Additional Clearances for Packaged DX Units.. . 4 Lifting . . . . . . . . . . . . . . . . . . . 4

Condensate Drain (P Trap). . . . . . . . . . |

|

4 |

Switch S4. . . . . . . . . . . . . . . . . 4 |

||

Component Operation |

|

|

Compressor Components. . . . . . . . . . . 5 |

||

Electrical Components. . . . . . . . . . . |

|

5 |

Refrigerant Components. . . . . . . . . . . 5 |

||

Additional Control Components. . . . . . |

. . |

5 |

Factory Installed Refrigeration System |

|

|

Components. . . . . . . . . . . . . . . . 6 |

||

Sequence of Operation |

|

|

Control Sequence. . . . . . . . . . . . . |

|

7 |

Optional Variable Air Volume. . . . . . . |

. . |

. 7 |

Start-Up Unit |

|

|

Model and Serial Number . . . . . . . . |

. . |

. 8 |

Pre-Start-Up Checklist.. . . . . . . . . |

. . |

9 |

Special Tools Required . . . . . . . . . |

. . |

. 9 |

Voltage Imbalance. . . . . . . . . . . . . . 9 |

||

Start-Up Checklist. . . . . . . . . . . . . 10 |

||

Troubleshooting |

|

|

Refrigeration Circuit. . . . . . . . . . . |

11-14 |

|

Routine Maintenance |

|

|

Monthly. . . . . . . . . . . . . . . . . . 15 Annually . . . . . . . . . . . . . . . . . 15 Maintenance Procedures. . . . . . . . . . . 15

Reference

Component Location. . . . . . . . . . . . 15

Maintenance Log. . . . . . . . . . . Backcover

Warranty . . . . . . . . . . . . . . Backcover

2 Packaged DX Module for Make-Up Air Unit

®

Product Overview

The Packaged DX Module for make-up air is a horizontally configured unit that is installed as a package in make-up air units and is designed for outdoor installations. The Packaged DX Module is used to temper the air that is supplied to the building. The make-up air unit is designed to provide sufficient air to replace air that is exhausted from the building and this module is designed to provide necessary cooling.

The DX system comes fully charged with R-410A refrigerant from the factory and is ready for operation upon arrival.

Units may be supplied with one or two compressors based on required cooling capacity. All units with multiple compressors allow for staging of compressors to meet a wider range of outdoor air loads while reducing the number of cycles per compressor.

Compressed Refrigerant

All packaged DX modules are charged with environmentally friendly R-410A compressed refrigerant. Do not use tools or parts designed for other refrigerants on this unit.

Safety Listing

Make-up air units are listed per ANSI/UL 1995, Heating and Cooling Equipment and are ETL Certified.

Supplemental Installation, Operation and Maintenance Manuals

Refer to the Installation, Operation and Maintenance manual for the Make-Up Air unit for additional information.

Models and Capacities

The Packaged DX Module for Make-Up Air Units is manufactured in three different platform sizes, each

of which has several |

|

|

|

different output tonnage |

Platform |

Tonnage |

|

options. Examine |

H12 |

3, 5, 6, 8 |

|

shipping documents to |

|

|

|

H22 |

7, 9, 10 |

||

verify correct model of |

|||

|

|

||

H32 |

10, 12, 16 |

||

the module as received. |

|||

|

|

||

|

|

Model Number

A metal plate is located on the fixed panel access to the control center. The plate is marked with the Platform Type and Tonnage (for example, H12-6). Record the model number here:

Subassemblies:

Coils

Every module is supplied with a single DX evaporator coil. If there is only one cooling circuit, then the DX coil is not divided. If two cooling circuits are specified, then the DX coil will be a split-face. A single condenser coil is attached to the exterior of the module. If more than one cooling circuit is present, that condenser coil will be of split-face configuration.

Dampers

Only an inlet damper may be installed in a PDX module and it will only be found when the module is installed in either model IGX or MSX that was not ordered with an inlet damper module.

DX System

The DX system in the module is a complete, sealed unit with compressed R-410A refrigerant. It consists of one or two compressors, evaporator and condenser coils and the following integral components:

•expansion valves

•liquid line filter-drier

•service / charging valves

•moisture indicating sight glass

•crankcase heater on each compressor

Each DX system incorporates the following:

•high pressure manual reset cutout

•low pressure auto-reset cutout

Packaged DX Module for Make-Up Air Unit 3

Installation

Service Clearances

All make-up air units require minimum clearances on all sides for routine maintenance. Filter replacement, drain pan inspection and cleaning, fan bearing lubrication and belt adjustment are all examples of routine maintenance that must be performed. Blower and motor assemblies and coil and filter sections are always provided with a service door or panel for proper component access. Clearances for component removal may be greater than the service clearances. Refer to submittal drawings for these clearance dimensions. See also Page 4 of this manual.

Additional Clearances for Packaged DX Units

Packaged DX units require additional service clearance because they must have unrestricted air movement around the condenser coil and condenser fans. Hot air is being discharged from the condenser fans during operation and the more clearance available, the better the chance of avoiding recirculation or coil starvation. This unit should never be placed under an overhang or inside a building. A minimum of 48 inches above the condenser fans is recommended.

Minimum 48 inches clearance

Condenser Fans

Minimum 42 inches clearance

Condenser Coil

End view of make-up air unit with Packaged DX

Lifting

All units equipped with this module are provided with either four or six lifting lugs. When the unit is being hoisted, all of the provided lugs must be used for support. Four lifting lugs are on the four corners of the unit, located at the base. In addition, there may be two more lifting lugs located at the top of the unit. The locations of those two top lugs varies somewhat from unit to unit.

Use spreader bars as shown to prevent damage to the cabinet. If top-mounted lifting lugs are present, they must be used in conjunction with the bottom-mounted lifting lugs when hoisting the unit.

Use lifting lugs on all four corners.

Lifting Details

Install Condensate Drain (P Trap)

The only installation step that is specific to the DX module is installation and priming of the engineered P trap. Locate the P trap kit that was shipped with the unit and install the kit in accordance with the enclosed instructions.

|

Condenser Fans |

42 inches clearance |

|

|

|

and |

|

|

|

|

Condenser Coil |

|

|

|

inches clearance |

|

Indirect Gas-Fired |

inches clearance |

|

|

Furnace |

|||

|

|

|||

48 |

Outdoor |

Unit Control Center |

36 |

|

Air Intake |

||||

|

|

|

||

|

|

42 inches clearance |

|

Provide and Install Switch S4

Each Packaged DX unit requires an On/Off switch to enable the unit to run. This is a user-supplied switch that may be a toggle switch mounted in a 2 x 4 inch electric box (mounted in a position chosen by the user), or it may be a simple jumper or even a control switch installed in a remote control panel supplied by the factory. See also “Additional Control Components” on page 5 of this manual.

4 Packaged DX Module for Make-Up Air Unit

Component Operation

Compressor Components

Each Packaged DX module has a complete set of compressor contactors, condenser fan contactors, relays and certain integral safety controls located in the module.

Additional Control Components

In addition to the control components located in the PDX module, various highand low-voltage circuits are found in the Make-Up Air Unit control center. See the unit-specific wiring diagram (found in the unit control center) for complete information.

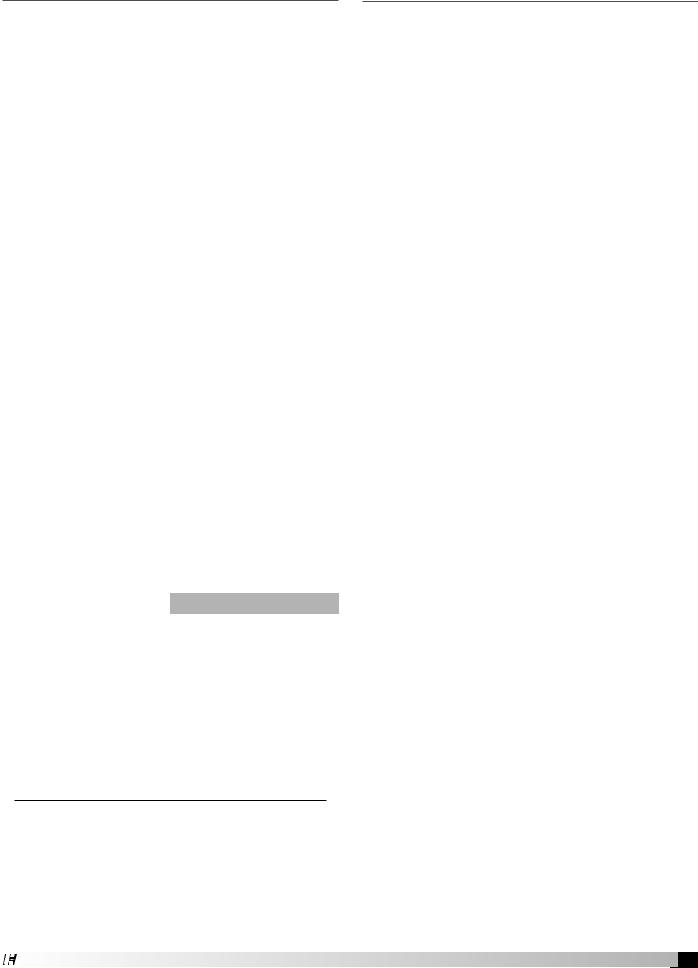

Typical Packaged DX Compressor Compartment

Electrical Components

1.High Voltage Terminal Strip

2.Compressor Relays

3.Condenser Fan Contactor

4A. Compressor Contactor (Circuit A)

4B. Compressor Contactor (Circuit B)

5.Low Voltage Terminal Strip

6.High Limit Safety Control – Direct Gas-Fired units only

Refrigeration Components

7A. Compressor (Circuit A)

7B. Compressor (Circuit B)

8A. High Pressure Sensor (Circuit A, Manual Reset)

8B. High Pressure Sensor (Circuit B, Manual Reset)

9A. Thermostatic Expansion Valve (TXV) (Circuit A)

9B. Thermostatic Expansion Valve (TXV) (Circuit B)

10A. Refrigerant Distributor (Circuit A)

10B. Refrigerant Distributor (Circuit B)

11. Condensate Drain (P trap here)

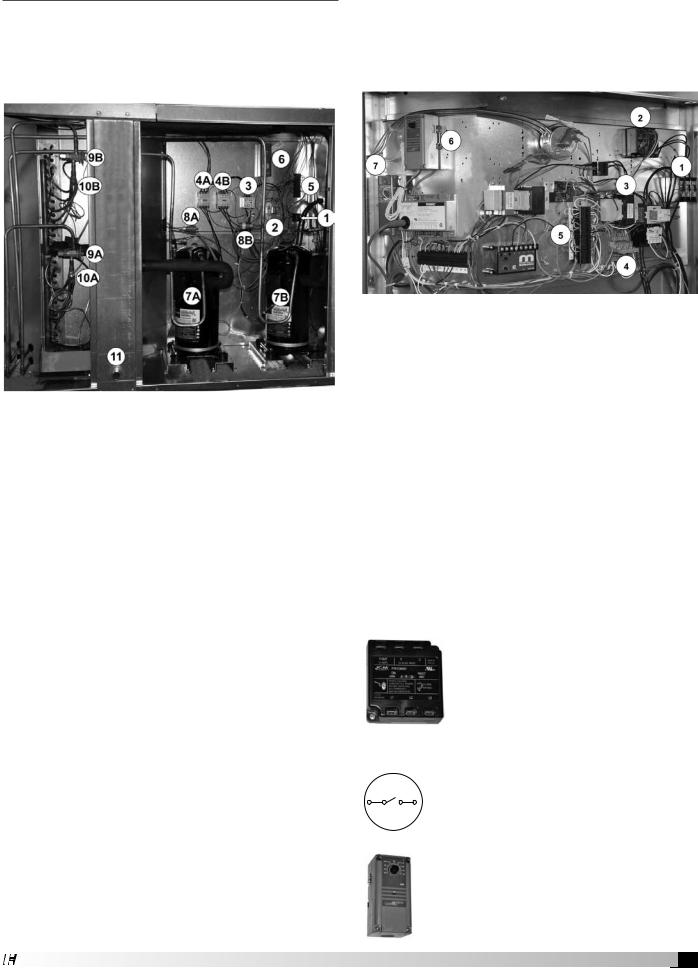

Typical Unit Control Center

1.Power Distribution Block - field-supplied power from main disconnect switch is terminated here.

2.Phase Monitor has jumpers going to power distribution block)

3.Transformer provides 24 VAC to various low voltage devices including the Phase Monitor and to Low Voltage Terminal Strip in compressor compartment.

4.Relays RC1 and RC2 are wired to the control center in the compressor compartment.

5.Low Voltage Terminal Strip - Switch S4 terminates here.

6.Thermostat TS5 monitors outdoor air temperature and turns the DX unit on or off.

7.Inlet Air Sensor monitors the incoming air temperature and will disable the DX unit if ambient temperatures are too low.

Phase Monitor constantly checks for loss of a phase, phase unbalance or phase reversal. It requires 24 VAC to operate. When a fault is detected, it cuts off the power supply to the low voltage terminal strip, disabling all motors. It has two LED indicator lights, showing “on” and “fault”.

Switch S4 (not shown) is terminated on Low Voltage Terminal Strip 5 above. S4 is field-supplied and field-installed unless ordered from the factory. See the unit specific wiring diagram.

Thermostat TS5 monitors outdoor air temperature. It is field-adjustable. If

there is more than one cooling circuit, an additional controller for the second stage will be provided.

Packaged DX Module for Make-Up Air Unit 5

Loading...

Loading...