Greenheck EDD-601 Installation Manual

EDD-601

Stationary Louver

Dual Drainable Blade

Application and Design

EDD-601 is a weather louver designed to protect air intake and exhaust openings in building exterior walls. Design incorporates a drainable head member and stationary horizontal blades to

channel water to the jambs which guides the water through vertical downspouts for escape at the sill. The EDD-601 is an extremely efficient louver with AMCA LICENSED PERFORMANCE DATA enabling designers to select and apply with confidence.

Standard Construction

Frame . . . . . . . .Heavy gauge extruded 6063-T5 aluminum, 6 in. x 0.081 in. nominal wall thickness

Blades . . . . . . . .Dual drainable design, heavy gauge extruded 6063-T5 aluminum, 0.081 in. nominal wall thickness, positioned at 37º and 45º angles on approximately

6 in. centers

Construction . . Mechanically fastened

Birdscreen. . . . .3/4 in. x 0.051 in. fl attened expanded aluminum in removable frame, inside mount (rear)

Finish. . . . . . . . .Mill

Minimum Size . .12 in. W x 16 in. H

Maximum Single

Section Size . . .120 in. W or 120 in. H (limited to 70 ft. sq.)

Options (at additional cost)

• A variety of bird and insect screens

• Blank off panel

• Clip angles

• Extended sill

• Filter rack

• Flanged frame

• Glazing adaptor

•Hinged frame

•Security bars

• Welded construction

• 0.125 in. nominal wall thickness

• A variety of architectural finishes including: Clear anodize

Integral color anodize Baked enamel paint Kynar paint

*Width and height dimensions furnished approximately ¼ inch under size.

PERFORMANCE DATA |

EDD-601 |

Free Area Chart (Sq. ft.)

Stationary Louver Dual Drainable Blade

Extruded Aluminum

Louver |

|

|

|

|

|

|

|

|

Louver Width in Inches |

|

|

|

|

|

|

|

|

|

|

|

Greenheck |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Height |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fan |

|

in |

12 |

18 |

24 |

30 |

36 |

42 |

48 |

54 |

60 |

66 |

72 |

78 |

84 |

90 |

96 |

102 |

108 |

114 |

120 |

|

|

|

|

Inches |

|

|

|

Corporation |

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

16 |

0.44 |

0.72 |

1.01 |

1.29 |

1.57 |

1.86 |

2.14 |

2.35 |

2.64 |

2.92 |

3.21 |

3.49 |

3.77 |

4.06 |

4.34 |

4.55 |

4.84 |

5.12 |

5.41 |

|

|

|

certifies that |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the EDD- |

18 |

0.50 |

0.83 |

1.15 |

1.47 |

1.80 |

2.12 |

2.45 |

2.69 |

3.02 |

3.34 |

3.67 |

3.99 |

4.32 |

4.64 |

4.97 |

5.21 |

5.53 |

5.86 |

6.18 |

|

|

|

|

|

|

|

601 louvers |

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24 |

0.70 |

1.16 |

1.61 |

2.07 |

2.52 |

2.98 |

3.43 |

3.77 |

4.23 |

4.68 |

5.14 |

5.59 |

6.05 |

6.50 |

6.96 |

7.30 |

7.75 |

8.21 |

8.66 |

|

|

|

|

|

|

|

shown |

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

0.94 |

1.55 |

2.16 |

2.77 |

3.38 |

3.99 |

4.60 |

5.06 |

5.67 |

6.28 |

6.89 |

7.50 |

8.11 |

8.73 |

9.34 |

9.79 |

10.40 |

11.01 |

11.63 |

|

|

|

herein |

|

|

||||||||||||||||||||||

36 |

1.19 |

1.95 |

2.72 |

3.49 |

4.26 |

5.03 |

5.80 |

6.38 |

7.15 |

7.92 |

8.68 |

9.45 |

10.22 |

10.99 |

11.76 |

12.34 |

13.11 |

13.88 |

14.64 |

|

are licensed to bear the |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AMCA Seal. The ratings |

||

42 |

1.43 |

2.36 |

3.29 |

4.22 |

5.15 |

6.07 |

7.00 |

7.70 |

8.63 |

9.56 |

10.49 |

11.41 |

12.34 |

13.27 |

14.20 |

14.90 |

15.83 |

16.75 |

17.68 |

|

|||

|

shown are based on |

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

48 |

1.68 |

2.77 |

3.86 |

4.94 |

6.03 |

7.12 |

8.21 |

9.03 |

10.12 |

11.20 |

12.29 |

13.38 |

14.47 |

15.56 |

16.65 |

17.46 |

18.55 |

19.64 |

20.73 |

|

tests and procedures |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

54 |

1.93 |

3.17 |

4.42 |

5.67 |

6.92 |

8.17 |

9.42 |

10.36 |

11.60 |

12.85 |

14.10 |

15.35 |

16.60 |

17.85 |

19.10 |

20.03 |

21.28 |

22.53 |

23.78 |

|

performed in accordance |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

with AMCA Publication |

||

60 |

2.17 |

3.58 |

4.99 |

6.40 |

7.81 |

9.22 |

10.62 |

11.68 |

13.09 |

14.50 |

15.91 |

17.32 |

18.73 |

20.13 |

21.54 |

22.60 |

24.01 |

25.42 |

26.83 |

|

|||

|

511 and comply with |

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

66 |

2.42 |

3.98 |

5.55 |

7.12 |

8.68 |

10.25 |

11.82 |

12.99 |

14.56 |

16.13 |

17.70 |

19.26 |

20.83 |

22.40 |

23.97 |

25.14 |

26.71 |

28.27 |

29.84 |

|

|||

|

the requirements of the |

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

72 |

2.66 |

4.39 |

6.11 |

7.84 |

9.57 |

11.29 |

13.02 |

14.31 |

16.04 |

17.77 |

19.49 |

21.22 |

22.94 |

24.67 |

26.40 |

27.69 |

29.42 |

31.14 |

32.87 |

|

AMCA Certified Ratings |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Program. The AMCA |

||

78 |

2.91 |

4.79 |

6.68 |

8.56 |

10.45 |

12.33 |

14.22 |

15.63 |

17.52 |

19.40 |

21.29 |

23.18 |

25.06 |

26.95 |

28.83 |

30.25 |

32.13 |

34.02 |

35.90 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Certified Ratings Seal |

||

84 |

3.15 |

5.20 |

7.24 |

9.29 |

11.33 |

13.38 |

15.42 |

16.96 |

19.00 |

21.05 |

23.09 |

25.14 |

27.18 |

29.23 |

31.27 |

32.81 |

34.85 |

36.90 |

38.94 |

|

|||

|

applies to air performance |

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

90 |

3.40 |

5.60 |

7.81 |

10.01 |

12.22 |

14.42 |

16.63 |

18.28 |

20.49 |

22.69 |

24.90 |

27.10 |

29.31 |

31.51 |

33.72 |

35.37 |

37.57 |

39.78 |

41.98 |

|

and water penetration |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

96 |

3.65 |

6.01 |

8.38 |

10.74 |

13.10 |

15.47 |

17.83 |

19.61 |

21.97 |

24.34 |

26.70 |

29.07 |

31.43 |

33.80 |

36.16 |

37.94 |

40.30 |

42.66 |

45.03 |

|

ratings. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

102 |

3.89 |

6.42 |

8.94 |

11.47 |

13.99 |

16.52 |

19.04 |

20.93 |

23.46 |

25.98 |

28.51 |

31.03 |

33.56 |

36.08 |

38.61 |

40.50 |

43.03 |

45.55 |

48.08 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

108 |

4.14 |

6.82 |

9.51 |

12.19 |

14.88 |

17.56 |

20.25 |

22.26 |

24.95 |

27.63 |

30.32 |

33.00 |

35.69 |

38.37 |

41.06 |

43.07 |

45.76 |

48.44 |

51.13 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

114 |

4.39 |

7.23 |

10.08 |

12.92 |

15.77 |

18.61 |

21.46 |

23.59 |

26.44 |

29.28 |

32.13 |

34.97 |

37.82 |

40.66 |

43.51 |

45.64 |

48.49 |

51.33 |

54.18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 |

4.63 |

7.64 |

10.64 |

13.65 |

16.65 |

19.66 |

22.67 |

24.92 |

27.92 |

30.93 |

33.94 |

36.94 |

39.95 |

42.95 |

45.96 |

48.21 |

51.22 |

54.22 |

57.23 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

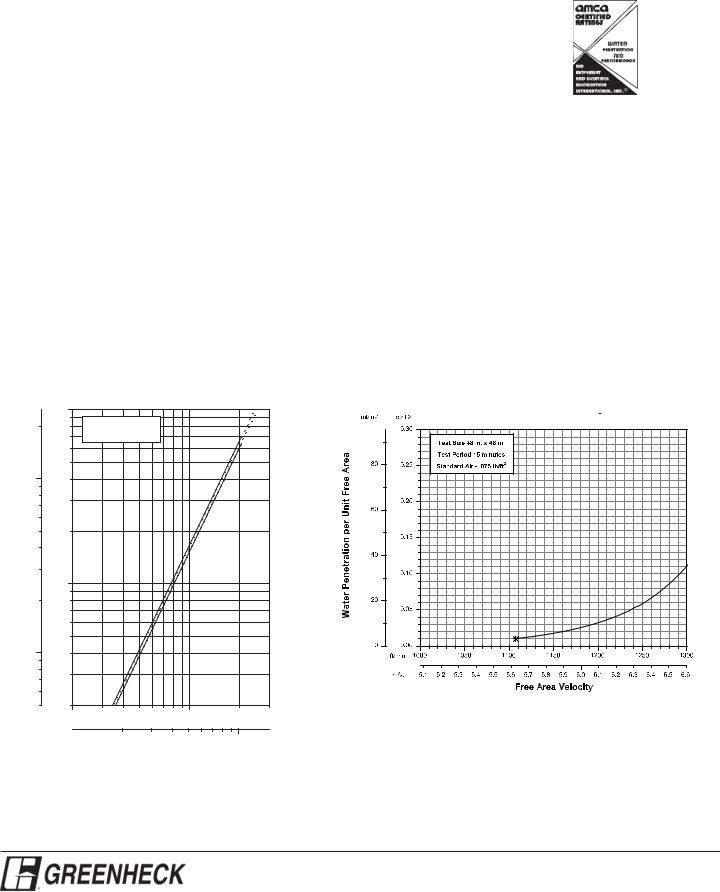

Airflow Resistance (Standard Air - .075 lb/ft3) |

||||||||||||||||

|

Pa |

in. wg |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

200 |

0.8 |

|

Test Size 48 in. x 48 in. |

|

|

|

|

|

|

|

|

|

|

||

|

|

0.7 |

|

Standard Air - .075 lb/ft3 |

|

|

|

|

|

|

|

|

|

|

||

|

|

0.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

100 |

0.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

90 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

80 |

0.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

70 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Drop |

50 |

0.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pressure |

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Intake |

|

|

|

|

|

|

|

|

|

Static |

|

0.1 |

|

|

|

|

|

Exhaust |

|

|

|

|

|

|

|

|

|

0.09 |

|

|

|

|

|

|

|

|

|

|

|

|

|||

20 |

0.08 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

0.07 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.06 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.05 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

0.04 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

0.03 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

0.02 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ft/min |

200 |

300 |

400 |

500 |

600 700 8009001000 |

|

|

|

|

2000 |

3000 |

|||

|

|

m/s |

|

|

2 |

|

3 |

|

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

Free Air Velocity

Model EDD-601 resistance to airflow (pressure drop) varies depending on louver application (air intake or air exhaust). Free area velocities (shown) are higher than average velocity through the overall louver size. See louver selection information.

Water Penetration (Standard Air - .075 lb/ft3)

Test size 48 in. x 48 in. Test duration of 15 min.

The AMCA Water Penetration Test provides a method for comparing various louver models and designs as to their efficiency in resisting the penetration of rainfall under specific laboratory test conditions. The

beginning point of water penetration is defined as that velocity where the water penetration curve projects through .01 oz. of water (penetration) per sq. ft. of louver free area. *The beginning point of water penetration for Model EDD-601 is 1107 fpm free area velocity.

These performance ratings do not guarantee a louver to be weatherproof or stormproof and should be used in combination with other factors including good engineering judgement in selecting louvers.

Loading...

Loading...