Gorenje Aerogor ECO COMPACT INVERTER 13A, Aerogor ECO COMPACT INVERTER 10A, Aerogor ECO Inverter 13 A, Aerogor ECO Inverter 10 A, Aerogor POWER EVI Inverter 18 A Installation Manual

...

www.gorenje.com

V 2.0

Aerogor ECO Inverter 10A/13A

Aerogor ECO COMPACT Inverter 10A/13A

Aerogor POWER EVI Inverter 15A/18A

INSTALLATION MANUAL

TABLE OF CONTENTS

1 BEFORE USE ................................................................................................................ 1

1.1 WARNINGS ............................................................................................................ 1

1.2 DISPOSAL .............................................................................................................. 3

1.3 HEATING SYSTEM REQUIREMENTS (MANDATORY) ......................................... 3

1.4 INCLUDED IN THE PACKAGE ............................................................................... 4

1.5 TECHNICAL TABLE ................................................................................................ 5

1.5.1 AEROGOR ECO COMPACT INVERTER 10A, 13A ......................................... 5

1.5.2 AEROGOR ECO INVERTER 10A, 13A ............................................................ 6

1.5.3 AEROGOR POWER EVI INVERTER 15A, 18A ............................................... 7

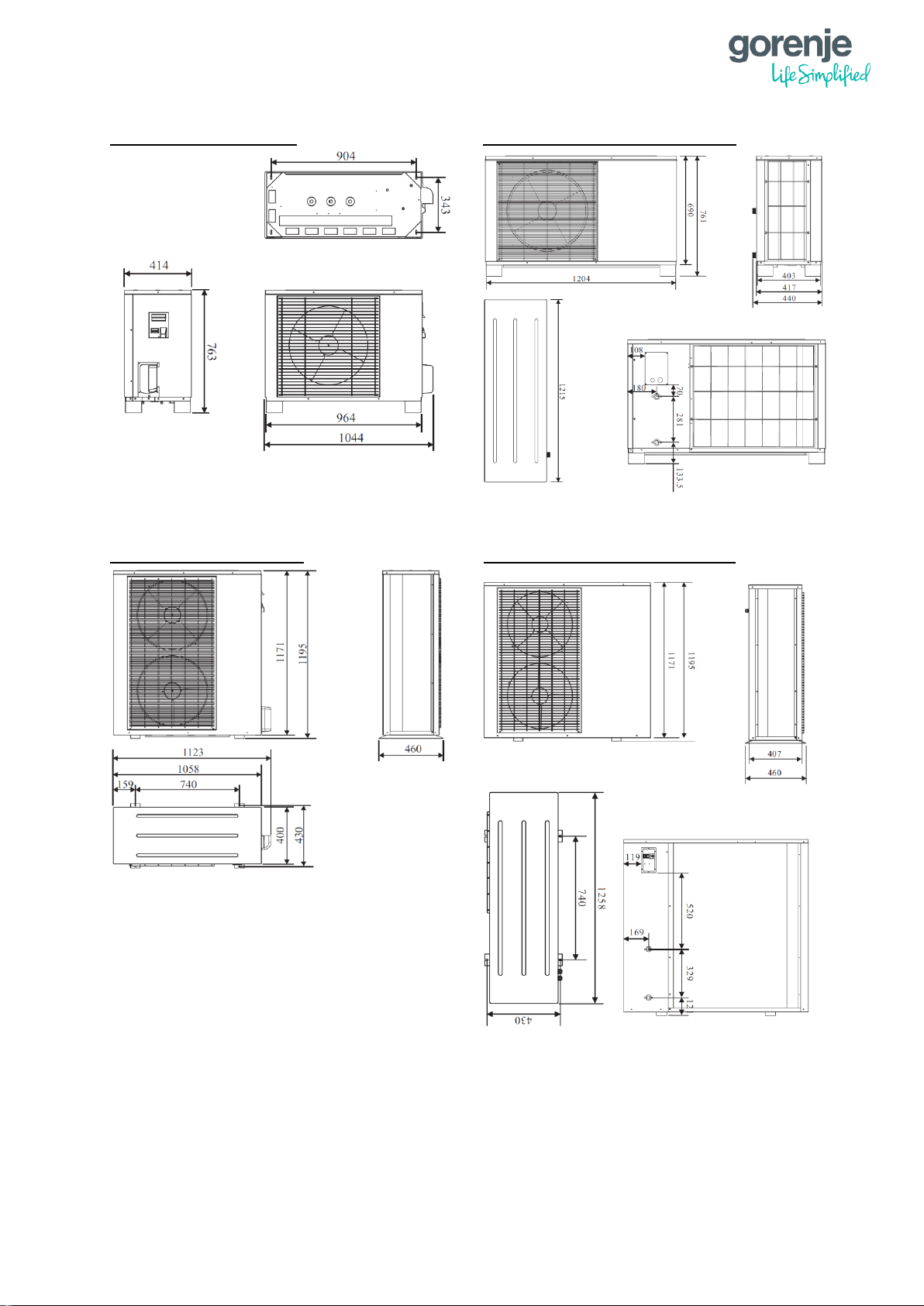

1.6 DIMENSIONS ......................................................................................................... 8

1.6.1 INDOOR UNITS ............................................................................................... 8

1.6.2 OUTDOOR UNITS ........................................................................................... 9

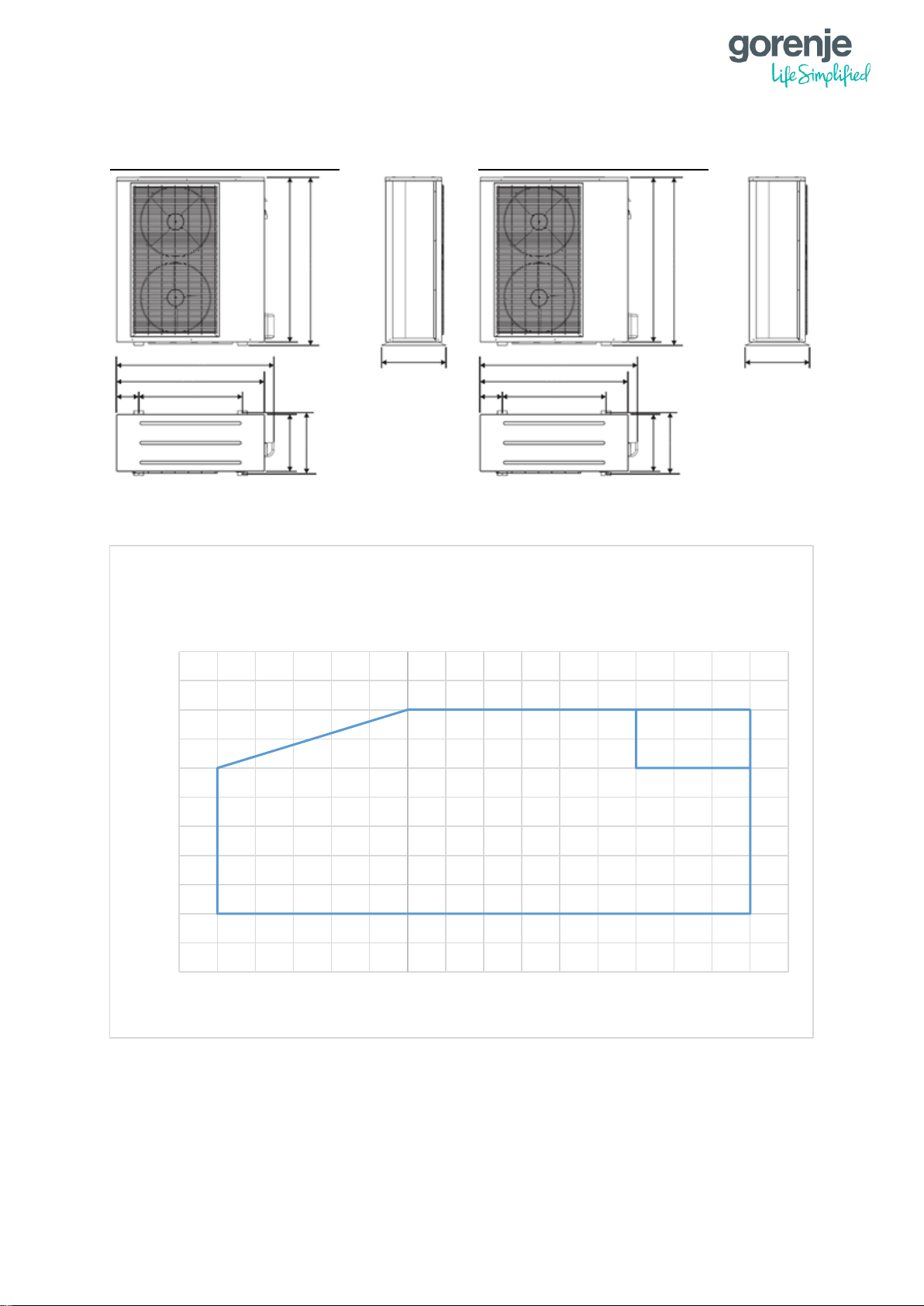

1.7 OPERATING RANGE ............................................................................................10

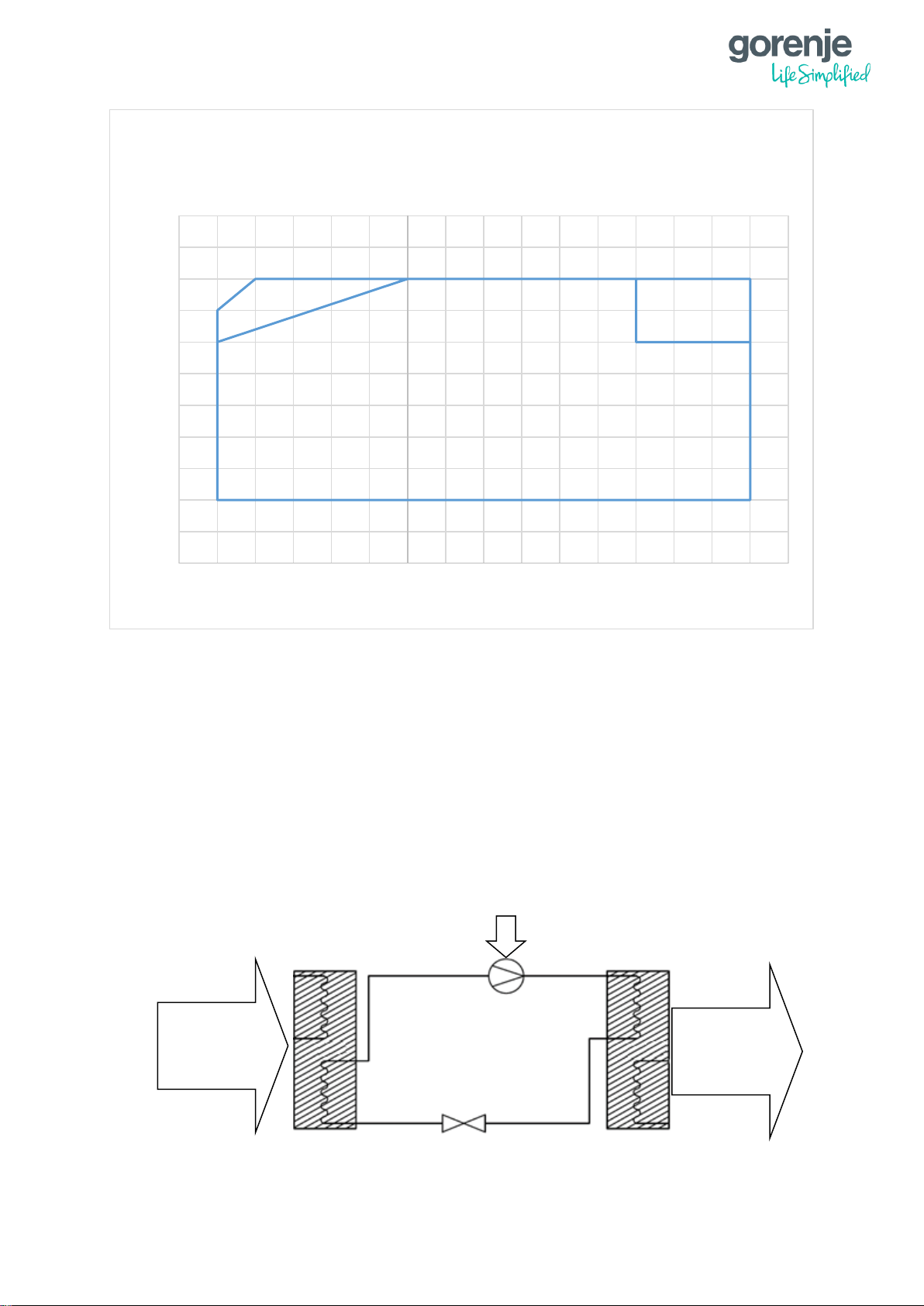

1.8 WORKING PRINCIPLE ..........................................................................................11

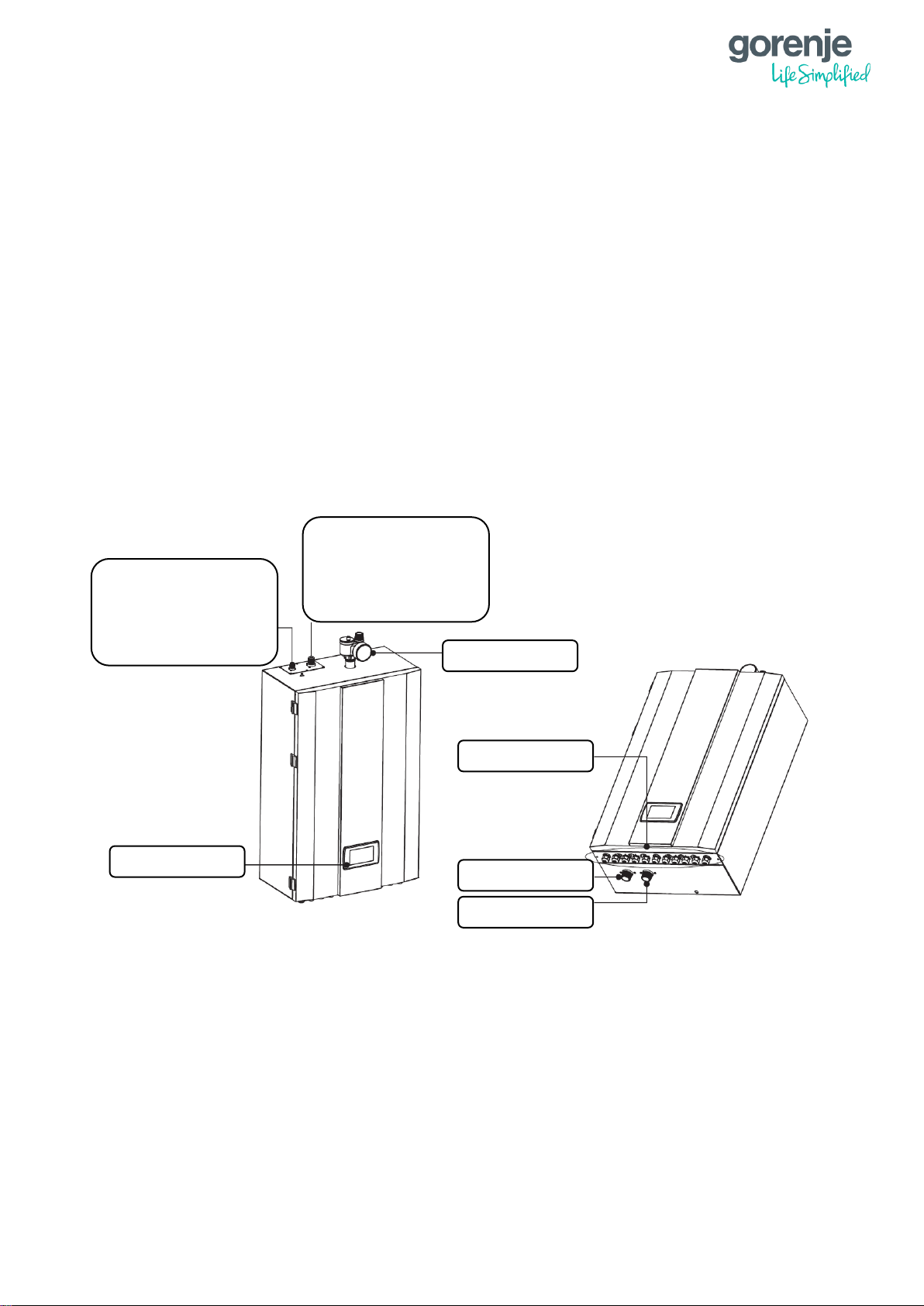

1.9 MAIN COMPONENTS ............................................................................................12

1.9.1 INDOOR UNITS ..............................................................................................12

1.9.2 OUTDOOR UNITS ..........................................................................................14

1.9.3 AEROGOR POWER EVI INVERTER 15A/ 18A ..............................................16

2 INSTALLATION .............................................................................................................17

2.1 INSTALLATION OF THE INDOOR UNIT ...............................................................17

2.2 INSTALLATION OF THE OUTDOOR UNIT............................................................18

2.3 FOUNDATION .......................................................................................................20

2.3.1 INSTALLATION OF C PROFILE AND LEGS ..................................................21

2.4 INSTALATION OF THE REFRIGERANT SYSTEM (SPLIT TYPE) .........................22

2.4.1 Height difference between indoor and outdoor unit .........................................24

2.5 INSTALATION OF HYDRAULIC CONNECTIONS (COMPACT TYPE) ..................26

3 ELECTRICAL WIRING ..................................................................................................27

3.1 AEROGOR ECO INVERTER 10A, 13A AND AEROGOR POWER EVI INVERTER

15A, 18A ...........................................................................................................................27

3.1.1 INDOOR UNIT ................................................................................................27

3.1.2 TEMPERATURE SENSORS ...........................................................................28

3.1.3 CONNECTION BETWEEN INDOOR AND OUTDOOR UNIT ..........................29

3.2 AEROGOR ECO COMPACT INVERTER 10A, 13A ...............................................30

3.2.1 INDOOR UNIT ................................................................................................30

3.2.2 TEMPERATURE SENSORS ...........................................................................31

3.2.3 CONNECTION BETWEEN INDOOR AND OUTDOOR UNIT ..........................32

4 CONTROL UNIT ...........................................................................................................33

4.1 DESCRIPTION OF SYMBOLS ON THE CONTROL UNIT .....................................33

4.2 DESCRIPTION OF THE TEMPERATURES ON THE CONTROL UNIT .................36

5 QUICK SETTINGS ........................................................................................................37

5.1 PARALLEL MOVE OF THE HEATING CURVE ......................................................37

5.1.1 SETTING THE PARALLEL MOVE OF THE HEATING CURVE – HEATING

CIRCUIT 1 .....................................................................................................................37

5.1.2 SETTING THE PARALLEL MOVE OF THE HEATING CURVE – HEATING

CURVE 2.......................................................................................................................38

5.1.3 SETTING THE DHW TEMPERATURE ...........................................................38

5.2 SETTING THE FIXED TEMPERATURE OF HEATING CIRCUIT ...........................39

5.2.1 SETTING THE FIXED TEMPERATURE FOR THE FIRST HEATING CIRCUIT

39

5.2.2 SETTING THE FIXED TEMPERATURE FOR THE SECOND HEATING

CIRCUIT .......................................................................................................................39

6 USER INTERFACE .......................................................................................................40

6.1 ARRANGMENT OF MENUS ..................................................................................40

6.2 MENU ACCESS .....................................................................................................40

6.3 SETTINGS .............................................................................................................41

6.3.1 Heating/Cooling Circuit 1 .................................................................................41

6.3.2 Heating/Cooling circuit 2 .................................................................................45

6.4 DHW SETTINGS ....................................................................................................47

6.5 DHW STORAGE ....................................................................................................49

6.5.1 Sanitary Hot Water Storage Function ..............................................................50

6.5.2 Sanitary Hot Water Storage Timer ...................................................................50

6.5.3 Reheating Function .........................................................................................50

6.5.4 Reheating Function Timer ...............................................................................50

6.5.5 Reheating Set Temp. ......................................................................................50

6.5.6 Reheating Restart ∆T Setting ..........................................................................51

6.6 REDUCED SETPOINT ...........................................................................................51

6.6.1 Reduced Setpoint ............................................................................................51

6.6.2 Temp. Drop/Rise .............................................................................................51

6.6.3 Timer for Reduced Setpoint Function ..............................................................51

6.6.4 Quiet Operation ...............................................................................................52

6.6.5 Allowable Temp. Drifting .................................................................................52

6.6.6 Timer for Quiet Operation ................................................................................52

6.7 ANTI – LEGIONELLA .............................................................................................52

6.7.1 Anti – Legionella Program ...............................................................................52

6.7.2 Day and Time ..................................................................................................53

6.7.3 Setpoint ...........................................................................................................53

6.7.4 Duration ..........................................................................................................53

6.7.5 Finish Time .....................................................................................................53

6.8 VACATION MODE .................................................................................................53

6.8.1 Vacation Mode ................................................................................................53

6.8.2 Sanitary Hot Water Temp. Drop during Vacation Mode ...................................54

6.8.3 Heating Water Temp. Drop during Vacation Mode ..........................................54

6.8.4 Vacation Start Date .........................................................................................54

6.8.5 Vacation Finish Date .......................................................................................54

6.9 USER MANAGEMENT ...........................................................................................54

6.9.1 Permission Level .............................................................................................54

6.9.2 Heating/Cooling ON/OFF timer .......................................................................54

6.9.3 Language ........................................................................................................55

6.9.4 Set Date and Time ................................................................ ..........................55

6.9.5 Distribution System Setting .............................................................................55

6.9.6 Save Current Settings .....................................................................................55

6.9.7 Load Saved Settings .......................................................................................55

6.9.8 Switch to Factory Settings ...............................................................................55

6.10 MODE SETTINGS..................................................................................................56

6.10.1 Sanitary Hot Water ..........................................................................................56

6.10.2 Heating............................................................................................................56

6.10.3 Cooling ................................................................ ............................................56

6.10.4 Basic Operation Modes ...................................................................................56

6.10.5 Cooling and Heating Switch ............................................................................57

6.10.6 Ambient Temp. To Start Heating .....................................................................57

6.10.7 Ambient Temp. To Start Cooling .....................................................................58

6.11 BACKUP HEATING ................................................................................................58

6.11.1 Backup Heating Sources for Heating ...............................................................59

6.11.2 Priority for Backup Heating Sources (HBH) .....................................................59

6.11.3 Backup Heating Source for Sanitary Hot Water ...............................................60

6.11.4 Priority for Backup Heating Sources (HWTBH) ................................................60

6.11.5 Heating Source Start Accumulating Value (HBH) ............................................60

6.11.6 Water Temperature Rise Reading Interval (hwtbh) ..........................................60

6.11.7 Emergency Operation .....................................................................................60

6.12 WATER PUMP SETTINGS ...................................................................................61

6.12.1 Circulation Pump P0 Type ...............................................................................61

6.12.2 Speed Setting of Circulation Pump P0 ............................................................62

6.12.3 Working Mode of Circulation Pump P0 ............................................................62

6.12.4 Pump Off Interval for P0 ..................................................................................62

6.12.5 Pump On Time for P0 ......................................................................................62

6.12.6 Buffer Tank .....................................................................................................62

6.12.7 P1 For Heating Operation ...............................................................................62

6.12.8 P1 For Cooling Operation ................................................................................62

6.12.9 P1 with High Temp. Demand ...........................................................................62

6.12.10 P2 for Heating Operation .............................................................................62

6.12.11 P2 for Cooling Operation .............................................................................63

6.12.12 P2 with High Temp. Demand .......................................................................63

6.13 FLOOR CURING ....................................................................................................63

6.13.1 Floor Curing ....................................................................................................64

6.13.2 Floor Curing Current Stage .............................................................................64

6.13.3 Floor Curing Current Stage Running Duration .................................................64

6.13.4 Floor Curing Current Stage Set Temperature ..................................................64

6.13.5 Floor Curing Current Stage Valid Running Duration ........................................64

6.13.6 Floor Current Total Running Duration ..............................................................64

6.13.7 Highest Water Temp. in Floor Curing Operation ..............................................64

6.14 ELECTRICAL UTILITY LOCK ................................................................................65

6.14.1 Electrical Utility Lock .......................................................................................65

6.14.2 Operation Signal for Electrical Utility Lock .......................................................66

6.14.3 HBH During Electrical Utility Lock....................................................................66

6.14.4 P0 during Electrical Utility Lock .......................................................................66

6.14.5 Heating Eco Operation ....................................................................................66

6.14.6 Ambient Temp. to Start Heating Eco Operation ...............................................66

6.15 OTHER OPTIONS..................................................................................................67

6.15.1 Motorized Diverting Valve switching time ........................................................67

6.15.2 Power on Time for Motorized Diverting Valve ..................................................67

6.15.3 Refrigerant Recycle Function ..........................................................................67

6.15.4 Control Panel Backlight Light ..........................................................................67

6.15.5 Exit System .....................................................................................................68

6.15.6 Anti-freezing protection ...................................................................................68

6.15.7 Mode Switch during Defrosting ........................................................................68

6.15.8 Mode Signal Output.........................................................................................68

6.15.9 Mode Signal type ............................................................................................68

6.15.10 Fan Speed Limit ..........................................................................................68

6.15.11 Defrosting Logic Selection ...........................................................................69

6.15.12 Activate Wi-Fi module or not? ......................................................................69

6.15.13 Accept setting from Wi-Fi module? ..............................................................69

6.15.14 Connection to the server ..............................................................................69

6.15.15 Connection to the router ..............................................................................69

6.15.16 MAC ............................................................................................................69

6.15.17 WI-FI module IP address .............................................................................69

6.15.18 SSID ............................................................................................................69

6.15.19 Password .....................................................................................................69

6.15.20 Server address ............................................................................................69

6.15.21 Service port .................................................................................................69

6.16 UNIT REAL-TIME DATA ................................ ........................................................70

7 ERROR CODES............................................................................................................70

7.1 ERROR CODES SHOWN ON THE DISPLAY ........................................................70

7.2 ERROR CODE MENU ...........................................................................................70

7.2.1 ACCESSING THE ERROR CODE MENU .......................................................70

7.2.2 INFORMATIONS IN THE ERROR CODE MENU ............................................71

7.2.3 INFO PAGE ....................................................................................................71

7.3 ERROR CODE LIST ..............................................................................................73

8 CLEANING THE MAGNETIC/DIRT FILTER CALEFFI ..................................................79

9 WATER PRESSURE IN THE SYSTEM .........................................................................80

10 WIRING .....................................................................................................................81

10.1 INDOOR UNIT - ALL INVERTERS .........................................................................81

10.2 INDOOR UNIT TERMINALS – ECO10A,13A, POWER EVI 15A, 18A ....................83

10.3 OUTDOOR PCB ECO INVERTER .........................................................................84

10.4 DRIVE FOR EEV ...................................................................................................86

10.5 OUTDOOR UNIT – POWER EVI INVERTER 15A, 18A .........................................87

10.6 OUTDOOR UNIT DRIVE – AEROGOR POWER EVI 15A, 18A .............................89

1

1 BEFORE USE

Thank you for purchasing our product. We ask that you carefully read the manual and to take

into account all of the instructions regarding device operation in order to prevent possible

damage to the device or personnel. Technical data can be changed without notice because

of product upgrades. Please look at the rating label on the device for latest technical

specifications.

1.1 WARNINGS

Warnings in this manual address most important topics for proper and safe operation of the

heat pump, for this reason follow them directly. For further questions contact your installer or

technical support from Gorenje d.d. Contact details are on the last page of this document.

Before first use, read this manual.

This unit can be used by children aged from 8 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge

if they have been given supervision or instruction concerning use of the unit in a safe

way and understand the hazards involved. Children should not play with the unit.

Cleaning and user maintenance shall not be made by children without supervision.

Installation, dismantlement and maintenance must be carried out by qualified

personnel. Any change to structure of the unit is prohibited since they can lead to

personal injury or damage to the unit.

Water or any other kind of fluid should not come in contact with the unit, it may cause

electric shock or destruction of the unit.

If the power cord gets loose or damaged, it must be repaired by qualified personnel.

2

To avoid electrical shock, make sure to disconnect the power supply 1 minute or more

before servicing the electrical parts. Even after 1 minute, measure the voltage at the

terminals of main circuit capacitors or electrical parts before touching. Make sure

those voltages are lower than the safe value.

Do not touch the grill of the ventilator while the device is operating.

Improper installation or attachment of equipment or accessories could result in

electric shock, short-circuit, leaks, fire or other damage to the equipment. Be sure

only to use accessories made by Gorenje which are specifically designed for use with

the equipment and have them installed by a professional.

Power supply to the device must be grounded.

For sanitary hot water, please always add a mixture valve before water tap and set it

to proper temperature.

Do not touch the fins of the coil with bare fingers, it might cause injury.

It is mandatory to use a suitable fuse for the heat pump and make sure the power

supply to the unit corresponds to the specifications. Otherwise the unit might be

damaged.

Please discard the batteries as sorted municipal waste at the accessible collection

point.

Instalation of a residual current device (RCD) having a rated residual operating

current of 300 mA.

3

1.2 DISPOSAL

This marking indicates that this product should not be disposed with

other household wastes throughout the EU. To prevent possible harm to

the environment or human health from uncontrolled waste disposal,

recycle it responsibly to promote sustainable reuse of material

resources. To return your used device, please use the return and

collection systems or contact the retailer where the product was

purchased. They can take this product for environmental safe recycling.

1.3 HEATING SYSTEM REQUIREMENTS (MANDATORY)

• Installed magnetic filter and dirt separator filter.

• If city water is used for filling of the heating system, the water quality must

comply with local regulations.

• Heating system pressure must be between 1 - 1.8 bar.

• Safety valve (3 bar) must be installed in the heating system.

• Expansion vessels must be installed according to heating system.

• Heat pump must be installed into closed loop heating system.

• Installation maintenance must be carried out by qualified personnel.

• If the heat pump is being installed into an existing hydraulic system, the

system must be cleaned according to standard procedures.

4

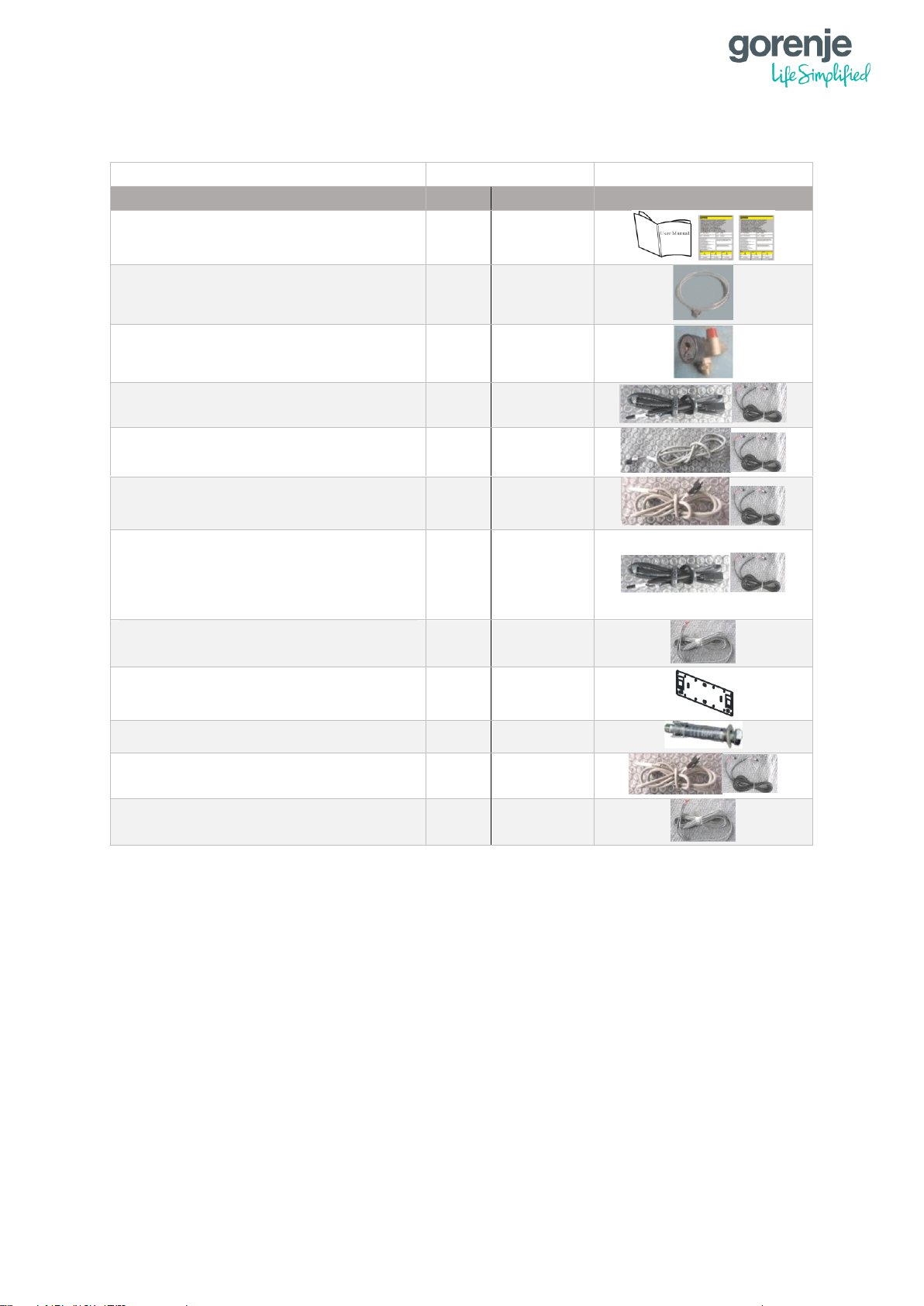

1.4 INCLUDED IN THE PACKAGE

NAME

QUANTITY

SYMBOLIC IMAGE

SPLIT

COMPACT

Installation Manual, Warranty cards

1

1

Drain pipe

1

1

Safety kit

1

1

TR – Room temp. sensor +

extension cable (10m)

1

1

TC – Heat/Cool temp. sensor +

extension cable (10m)

1

1

TW – DHW temp sensor + extension

cable (10m)

1

1

TV1 – mixing circuit 1 temp. sensor

+ extension cable (10m)

TV2 – mixing circuit 1 temp. sensor

+ extension cable (10m)

1

1

Communicaton cable

(20m)(shielded)

1

1

Bracket for indoor unit

1

1

Expansion bolts

2

1

Connection cable for Tui, Tuo, Tup

(20m)(shielded)

/

3 x 1

Connection cable for the Flow

Switch (20m) (shielded)

/

1

5

1.5 TECHNICAL TABLE

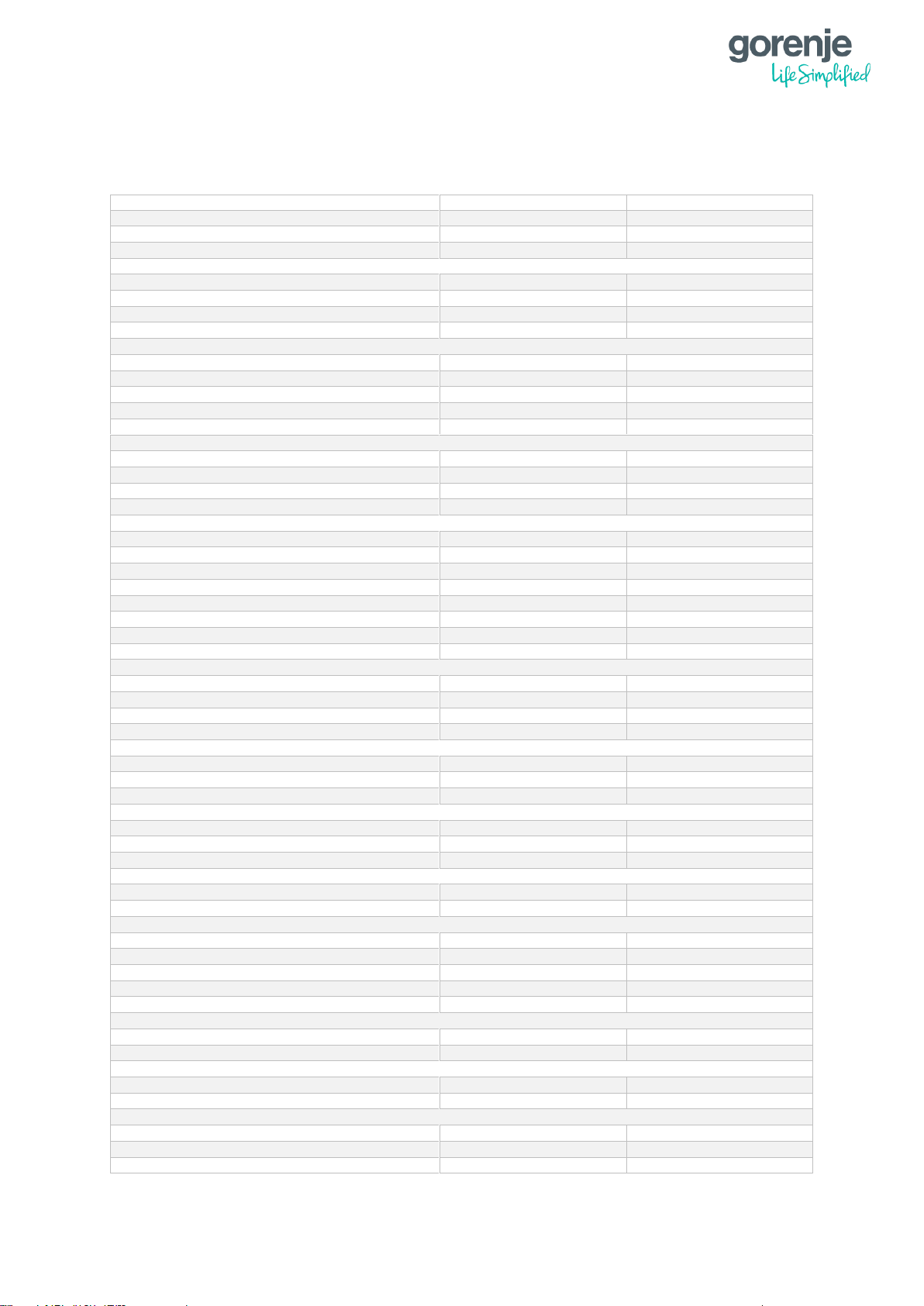

1.5.1 AEROGOR ECO COMPACT INVERTER 10A, 13A

MODEL

ECO COMPACT INVERTER 10A

ECO COMPACT INVERTER 13A

ErP Energy efficiency class

A++

A++

SCOP 35°C (floor heating) EN 14825

3,83

4,08

P

design

for SCOP EN 14825

6,3 kW

7,46 kW

HEATING MODE (A7/W35)

Heating capacity*

4,57 – 10,50 kW

4,1 -12,2 kW

COP - Coefficient of Performance*

3,80 – 4,71

4,0 - 4,57

Max. temperature of heating water

55 °C

55 °C

Operating range of heat pump - Heating (Ambient temp.)

-25 do +45 °C

-25 do +45 °C

COOLING MODE (A35/W7)

Cooling capacity**

2,60 – 8,00 kW

2,34 – 7,91 kW

Rated input power**

1,10 – 3,50

0,97 – 2,98 kW

EER - Energy Efficiency Ratio**

2,30 – 3,22 kW

2,40 – 3,03

Min. temperature of cooling water

7 °C

7 °C

Operating range of heat pump - Cooling (Ambient temp.)

0 to +65 °C

0 to +65 °C

POWER SUPPLY - SPECIFICATION

Voltage

220-240 V/50 Hz/1 Ph

220-240 V/50 Hz/1 Ph

Rated input power*

0,91 – 3,05 kW

0,96 - 3,02 kW

Fuse for heat pump

1 X 1p/20A/C

1 x 1p/20A/C

Fuse for electrical flow heater

3 X 1p/10A/C

3 x 1p/10A/C

REFRIGERANT SPECIFICATION

Type of refrigerant

R410A

R410A

Refrigerant - mass

1,9 kg

3 kg

GWP (global warming potential)

2088 GWP

2088 GWP

Quantity of hydrofluorocarbons in tonnes of CO2 equivalent

4,051 t CO2 Equiv.

6,264 t CO2 Equiv.

Type of compressor

DC inverter (twin rotary)

DC inverter (twin rotary)

Hermetically sealed equipment (indoor/outdoor unit)

Yes

Yes

Type fo connection between outdoor-indoor unit

Refrigerant connection

Water connection

Dimensions of refrigerant pipes connectors

3/8” - 1/2”

/

FAN

Fan type

1 x Axial

2 x Axial

Air flow

3100 m3/h

4100 m3/h

Rated power

60 W

2 x 60 W

„ESP“ – External Static Pressure of the Fan (data per piece)

45 W

50 W

WATER SIDE HEAT EXCHANGER

Type

Plate heat exchanger

Plate heat exchanger

Pressure drop

30 kPa

40 kPa

Dimensions of water piping connection

G1"

G1"

ALLOWABLE FLOW - SECONDARY (WATER) SIDE

Min. water flow

1,15 m3/h

1,32 m3/h

Nominal water flow

1,44 m3/h

2,2 m3/h

Max. water flow

2,16 m3/h

2,63 m3/h

SOUND POWER AND PRESSURE LEVEL

Sound power level LwA - Indoor unit

45 dB(A)

46 dB(A)

Sound power level LwA - Outdoor unit

58 dB(A)

59 dB(A)

SOUND PRESSURE LEVEL ON DISTANCE

Indoor unit - 1 m

37 dB(A)

38 dB(A)

Outdoor unit - 1 m

50 dB(A)

51 dB(A)

Outdoor unit - 5 m

36 dB(A)

37 dB(A)

Outdoor unit - 10 m

30 dB(A)

31 dB(A)

Outdoor unit - 15 m

26 dB(A)

27 dB(A)

NET DIMENSIONS

Indoor unit (WxHxD)

505 x 946 x 288 mm

562 x 686 x 260 mm

Outdoor unit (WxHxD)

1044 × 763 × 414 mm

1258 x 1195 x 407 mm

NET WEIGHT

Indoor unit

50 kg

25 kg

Oudoor unit

75 kg

140 kg

SERIAL INTEGRATED COMPONENTS

Electrical flow heater

6 kW (3ph / 2 stages)

6 kW (3ph / 2 stages)

Circulation water pump - A energy class

Grundfos UPM GEO 25-85 180

Grundfos UPM GEO 25-85 180

3-way diverting valve for DHW tank

Optional external

Optional external

6

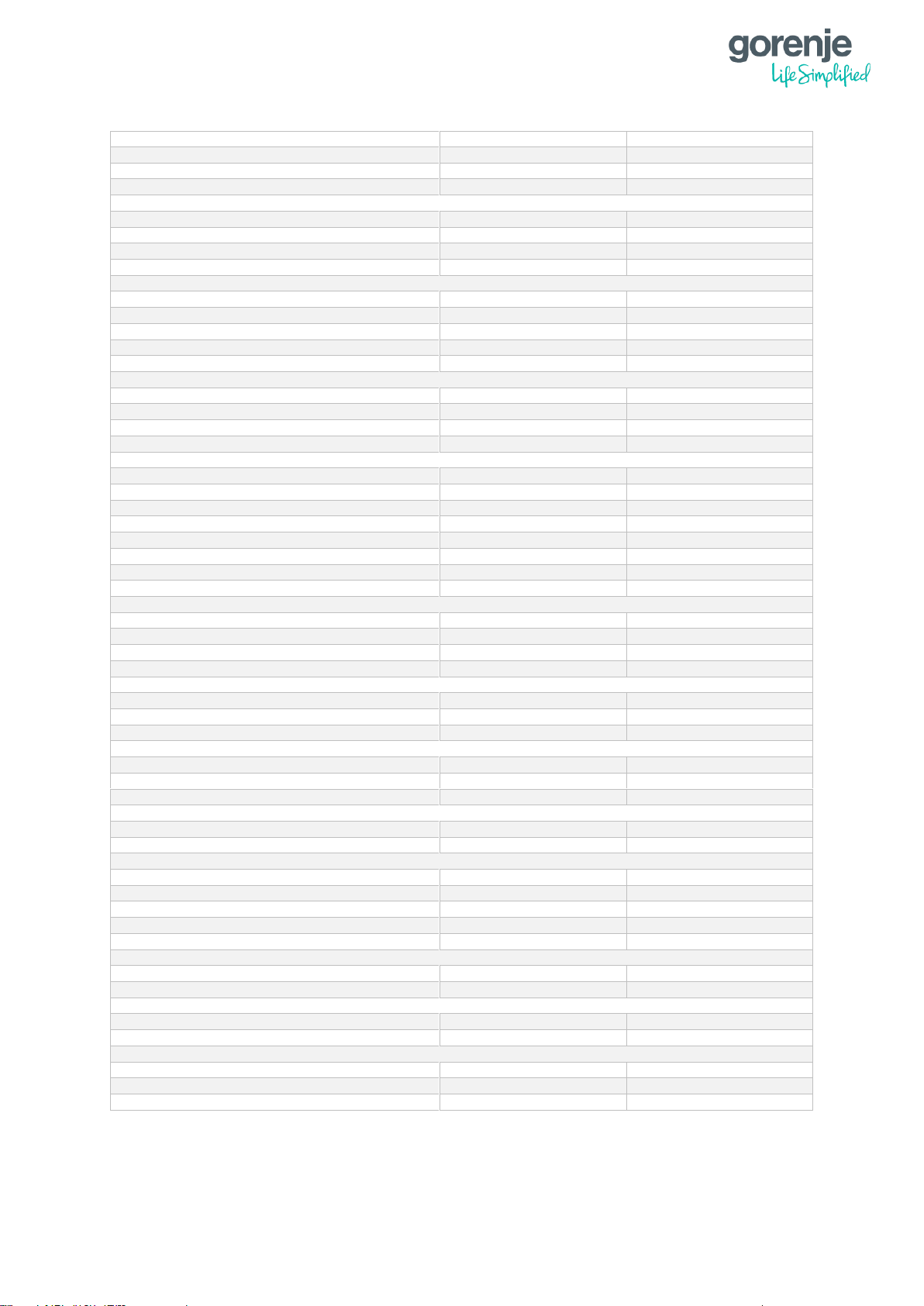

1.5.2 AEROGOR ECO INVERTER 10A, 13A

MODEL

ECO INVERTER 10A

ECO INVERTER 13A

ErP Energy efficiency class

A++

A++

SCOP 35°C (floor heating) EN 14825

3,83

4,08

P

design

for SCOP EN 14825

6,3 kW

7,46 kW

HEATING MODE (A7/W35)

Heating capacity*

4,57 – 10,50 kW

4,1 -12,2 kW

COP - Coefficient of Performance*

3,80 – 4,71

4,0 - 4,57

Max. temperature of heating water

55 °C

55 °C

Operating range of heat pump - Heating (Ambient temp.)

-25 do +45 °C

-25 do +45 °C

COOLING MODE (A35/W7)

Cooling capacity**

2,60 – 8,00 kW

2,34 – 7,91 kW

Rated input power**

1,10 – 3,50 kW

0,97 – 2,98 kW

EER - Energy Efficiency Ratio**

2,30 – 3,22

2,40 – 3,03

Min. temperature of cooling water

7 °C

7 °C

Operating range of heat pump - Cooling (Ambient temp.)

0 to +65 °C

0 to +65 °C

POWER SUPPLY - SPECIFICATION

Voltage

220-240 V/50 Hz/1 Ph

220-240 V/50 Hz/1 Ph

Rated input power*

0,91 – 3,05 kW

0,96 - 3,02 kW

Fuse for heat pump

1 X 1p/20A/C

1 X 1p/20A/C

Fuse for electrical flow heater

3 X 1p/10A/C

3 X 1p/10A/C

REFRIGERANT SPECIFICATION

Type of refrigerant

R410A

R410A

Refrigerant - mass

1,9 kg

3 kg

GWP (global warming potential)

2088 GWP

2088 GWP

Quantity of hydrofluorocarbons in tonnes of CO2 equivalent

4,051 t CO2 Equiv.

6,264 t CO2 Equiv.

Type of compressor

DC inverter (twin rotary)

DC inverter (twin rotary)

Hermetically sealed equipment (indoor/outdoor unit)

Yes

Yes

Type fo connection between outdoor-indoor unit

Refrigerant connection

Refrigerant connection

Dimensions of refrigerant pipes connectors

3/8” - 1/2”

3/8” - 5/8”

FAN

Fan type

1 x Axial

2 x Axial

Air flow

3100 m3/h

4100 m3/h

Rated power

60 W

2 x 60 W

„ESP“ – External Static Pressure of the Fan (data per piece)

45 W

50 W

WATER SIDE HEAT EXCHANGER

Type

Plate heat exchanger

Plate heat exchanger

Pressure drop

30 kPa

40 kPa

Dimensions of water piping connection

G1"

G1"

ALLOWABLE FLOW - SECONDARY (WATER) SIDE

Min. water flow

1,15 m3/h

1,32 m3/h

Nominal water flow

1,44 m3/h

2,2 m3/h

Max. water flow

2,16 m3/h

2,63 m3/h

SOUND POWER AND PRESSURE LEVEL

Sound power level LwA - Indoor unit

45 dB(A)

46 dB(A)

Sound power level LwA - Outdoor unit

58 dB(A)

59 dB(A)

SOUND PRESSURE LEVEL ON DISTANCE

Indoor unit - 1 m

37 dB(A)

38 dB(A)

Outdoor unit - 1 m

50 dB(A)

51 dB(A)

Outdoor unit - 5 m

36 dB(A)

37 dB(A)

Outdoor unit - 10 m

30 dB(A)

31 dB(A)

Outdoor unit - 15 m

26 dB(A)

27 dB(A)

NET DIMENSIONS

Indoor unit (WxHxD)

505 x 946 x 288 mm

505 x 946 x 288 mm

Outdoor unit (WxHxD)

1044 × 763 × 414 mm

1123 x 1195 x 400 mm

NET WEIGHT

Indoor unit

50 kg

58 kg

Oudoor unit

75 kg

113 kg

SERIAL INTEGRATED COMPONENTS

Electrical flow heater

6 kW (3ph / 2 stages)

6 kW (3ph / 2 stages)

Circulation water pump - A energy class

Grundfos UPM GEO 25-85 180

Grundfos UPM GEO 25-85 180

3-way diverting valve for DHW tank

Optional external

Optional external

7

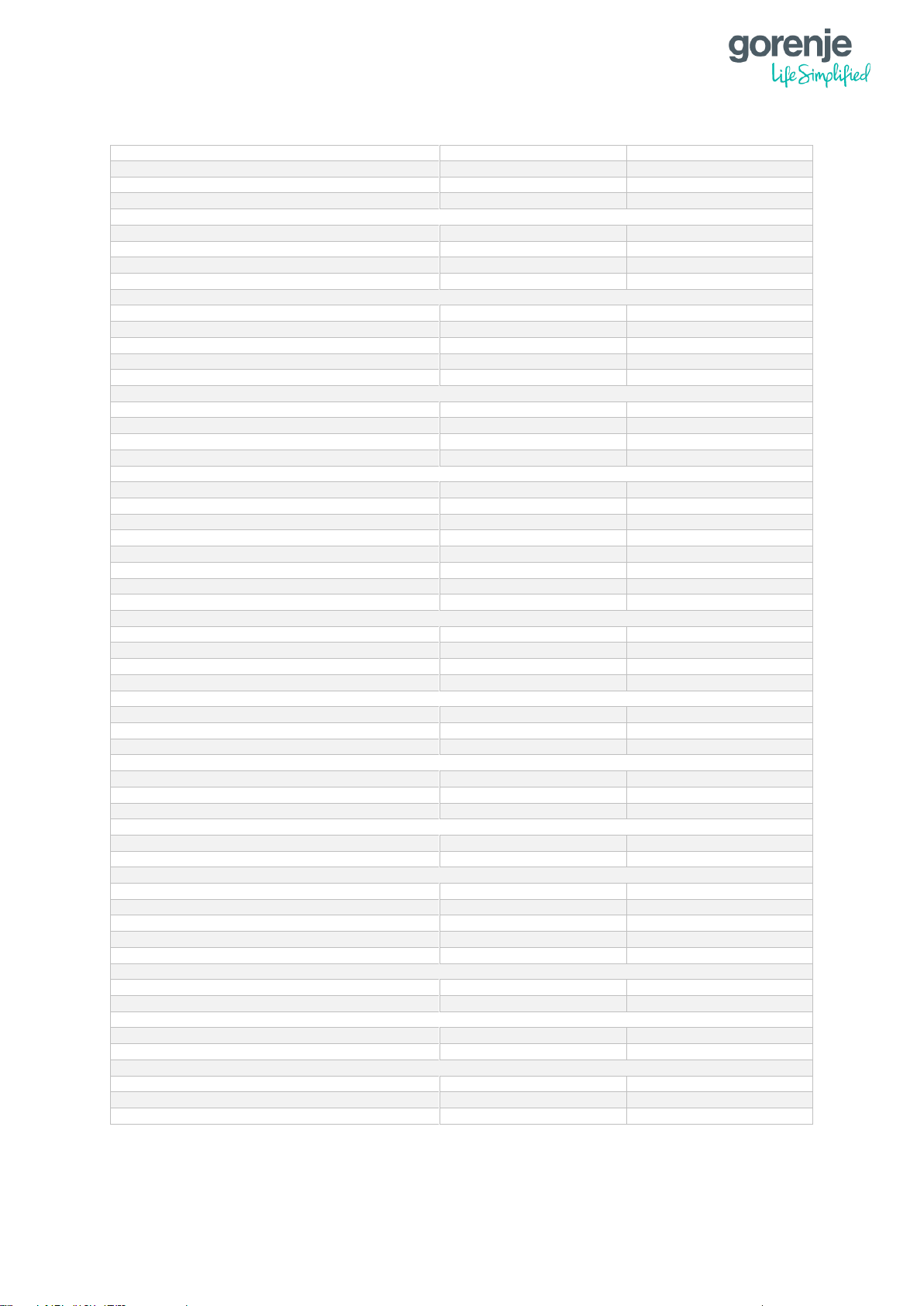

1.5.3 AEROGOR POWER EVI INVERTER 15A, 18A

MODEL

POWER EVI INVERTER 15A

POWER EVI INVERTER 18A

ErP Energy efficiency class

A+

A+

SCOP 35°C (floor heating) EN 14825

3,46

3,42

P

design

for SCOP EN 14825

10,97 kW

13,48 kW

HEATING MODE (A7/W35)

Heating capacity*

6,60 - 14,60 kW

8,2 - 18,0 kW

COP - Coefficient of Performance*

3,80 - 4,46

3,91 - 4,43

Max. temperature of heating water

55 °C

55 °C

Operating range of heat pump - Heating (Ambient temp.)

-25 do +45 °C

-25 do +45 °C

COOLING MODE (A35/W7)

Cooling capacity**

5,56 - 10,00 kW

6,4 - 15,1 kW

Rated input power**

1,57 - 3,82 kW

2,19 – 6,42 kW

EER - Energy Efficiency Ratio**

1,85 - 3,52

2,35 - 2,92

Min. temperature of cooling water

7 °C

7 °C

Operating range of heat pump - Cooling (Ambient temp.)

0 to +65 °C

0 to +65 °C

POWER SUPPLY - SPECIFICATION

Voltage

380-415 V/50 Hz/3 Ph

380-415 V/50 Hz/3 Ph

Rated input power*

1,53 - 4,92 kW

1,53 - 4,92 kW

Fuse for heat pump

1 x 3p/16A/C

1 x 3p/16A/C

Fuse for electrical flow heater

3 x 1p/10A/C

3 x 1p/10A/C

REFRIGERANT SPECIFICATION

Type of refrigerant

R410A

R410A

Refrigerant - mass

6,2 kg

6,6 kg

GWP (global warming potential)

2088 GWP

2088 GWP

Quantity of hydrofluorocarbons in tones of CO2 equivalent

12,946 t CO2 Equiv.

13,780 t CO2 Equiv.

Type of compressor

Scroll EVI DC Inverter

Scroll EVI DC Inverter

Hermetically sealed equipment (indoor/outdoor unit)

Yes

Yes

Type fo connection between outdoor-indoor unit

Refrigerant connection

Refrigerant connection

Dimensions of refrigerant pipes connectors

3/8" - 3/4"

3/8" - 3/4"

FAN

Fan type

2 x Axial

2 x Axial

Air flow

4200 m3/h

4500 m3/h

Rated power

2 x 80

2 x 80

„ESP“ – External Static Pressure of the Fan (data per piece)

50

50

WATER SIDE HEAT EXCHANGER

Type

Plate heat exchanger

Plate heat exchanger

Pressure drop

35

35

Dimensions of water piping connection

G1"

G1"

ALLOWABLE FLOW - SECONDARY (WATER) SIDE

Min. water flow

1,4 m3/h

1,86 m3/h

Nominal water flow

2,56 m3/h

3,09 m3/h

Max. water flow

2,7 m3/h

3,7 m3/h

SOUND POWER AND PRESSURE LEVEL

Sound power level LwA - Indoor unit

47 dB(A)

52 dB(A)

Sound power level LwA - Outdoor unit

68 dB(A)

72 dB(A)

SOUND PRESSURE LEVEL ON DISTANCE

Indoor unit - 1 m

39 dB(A)

44 dB(A)

Outdoor unit - 1 m

60 dB(A)

65 dB(A)

Outdoor unit - 5 m

46 dB(A)

51 dB(A)

Outdoor unit - 10 m

40 dB(A)

45 dB(A)

Outdoor unit - 15 m

36 dB(A)

41 dB(A)

NET DIMENSIONS

Indoor unit (WxHxD)

505 x 946 x 303 mm

505 x 946 x 288 mm

Outdoor unit (WxHxD)

1172 x 1194 x 410 mm

1440 x 1271 x 460 mm

NET WEIGHT

Indoor unit

32 kg

55 kg

Oudoor unit

151 kg

180 kg

SERIAL INTEGRATED COMPONENTS

Electrical flow heater

6 kW (3ph / 2 stages)

6 kW (3ph / 2 stages)

Circulation water pump - A energy class

Grundfos UPM GEO 25-85 180

Grundfos UPMXL GEO25-125 130

3-way diverting valve for DHW tank

Optional external

Optional external

(*) Measured according to standard EN 14511. Heating condition: water inlet/outlet temperature 30°C/35°C, ambient

temperature DB/WB 7°C/6°C.

(**) Measured according to standard EN 14511. Cooling condition: water inlet/outlet temperature 12°C/7°C and ambient

temperature 35°C.

8

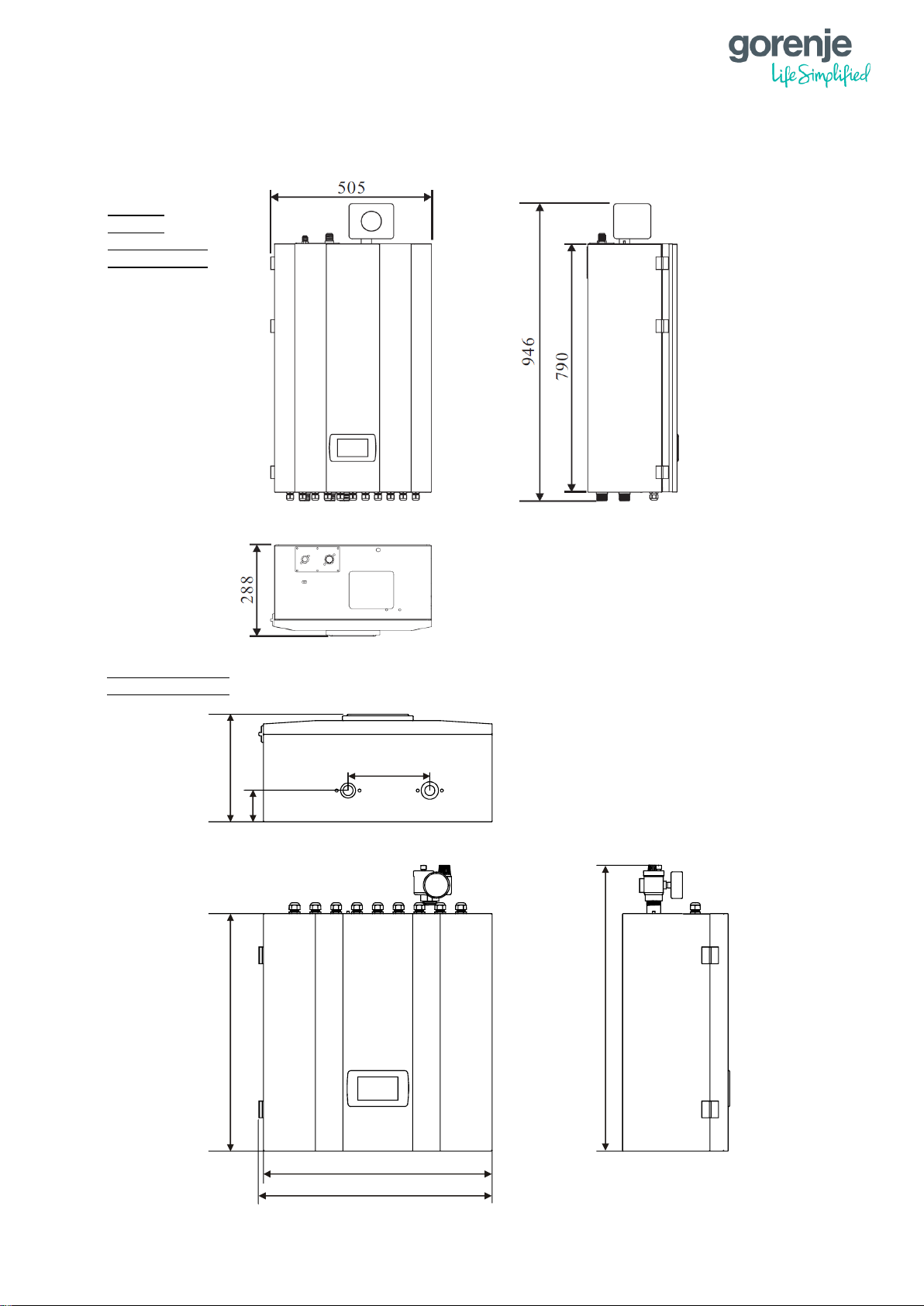

1.6 DIMENSIONS

1.6.1 INDOOR UNITS

ECO 10 A

ECO 13 A

POWER EVI 15 A

POWER EVI 18 A

ECO COMPACT 10 A

ECO COMPACT 13 A

Unit:mm

260

196.5

570

550

686

561.5

75

9

1.6.2 OUTDOOR UNITS

AEROGOR ECO INVERTER 10A AEROGOR ECO COMPACT INVERTER 10A

AEROGOR ECO INVERTER 13A, AEROGOR ECO COMPACT INVERTER 13A

10

AEROGOR POWER EVI INVERTER 15A AEROGOR POWER EVI INVERTER 18A

1.7 OPERATING RANGE

10

15

20

25

30

35

40

45

50

55

60

65

-30 -25 -20 -15 -10 -5 0 5 10 15 20 25 30 35 40 45 50

Outlet water temperature [

°C]

Outside Ambient temperature [°C]

Operating range - heating mode:

Aerogor ECO Inverter 10-13 A

Aerogor COMPACT ECO Inverter 10-13 A

ECO

1443

1373

860

222

460

402

460

1272

1294

460

1241

1171

715

182

1171

1193

402

460

11

1.8 WORKING PRINCIPLE

A heat pump operates similarly as a refrigerator. In a refrigerator, liquids evaporate due to

received thermal energy from the surrounding air and this energy is emitted at a desired spot

during condensation (Carnot’s cycle). A heat pump works in the opposite direction: it accepts

thermal energy from the surrounding air and emits it in heated premises, using the natural

heat collector of the environment. Ground and surface water, earth’s warmth, solar energy

and ambient air can be used as energy sources. The system is composed of four units:

evaporator, compressor, condenser and damper. Heat energy is transferred via the coolant.

In the evaporator, the coolant receives heat energy and evaporates. In the compressor, the

vapour is compressed, which makes it heat up intensively. This hot vapour transmits thermal

energy from the condenser to the heating water and liquefies. In the damper, the coolant

expands (pressure reduces to the starting pressure, from there it proceeds to the evaporator

and the cycle repeats).

10

15

20

25

30

35

40

45

50

55

60

65

-30 -25 -20 -15 -10 -5 0 5 10 15 20 25 30 35 40 45 50

Maximum outlet water temperture [

°C]

Outside ambient temperature [°C]

Operating range - heating mode:

Aerogor POWER EVI Inverter 15 A

Aerogor POWER EVI Inverter 18 A

Heat from

ambient

Produced

heat for

heating

Electric

energy

ECO

EVI

Compressor

Expansion

valve

Evaporator

Evaporator

Condenser

Condenser

12

Inverter heat pumps use variable-speed compressors. Traditional heat pumps use fixed

power/rotation speed compressors. In inverter compressors, the compressor speed

constantly adapts to the heat losses of the room and the energy value of the source (air,

brine or water, depending on the system). In traditional heat pumps, the power of the

compressor is always the same. Compressor starts with full power and when it achieves the

desired values/temperatures, it shuts off and waits until it restarts. Inverter heat pumps work

for a longer period, but with lower power (adjusting to the premises), which means lower

consumption of electric energy.

1.9 MAIN COMPONENTS

1.9.1 INDOOR UNITS

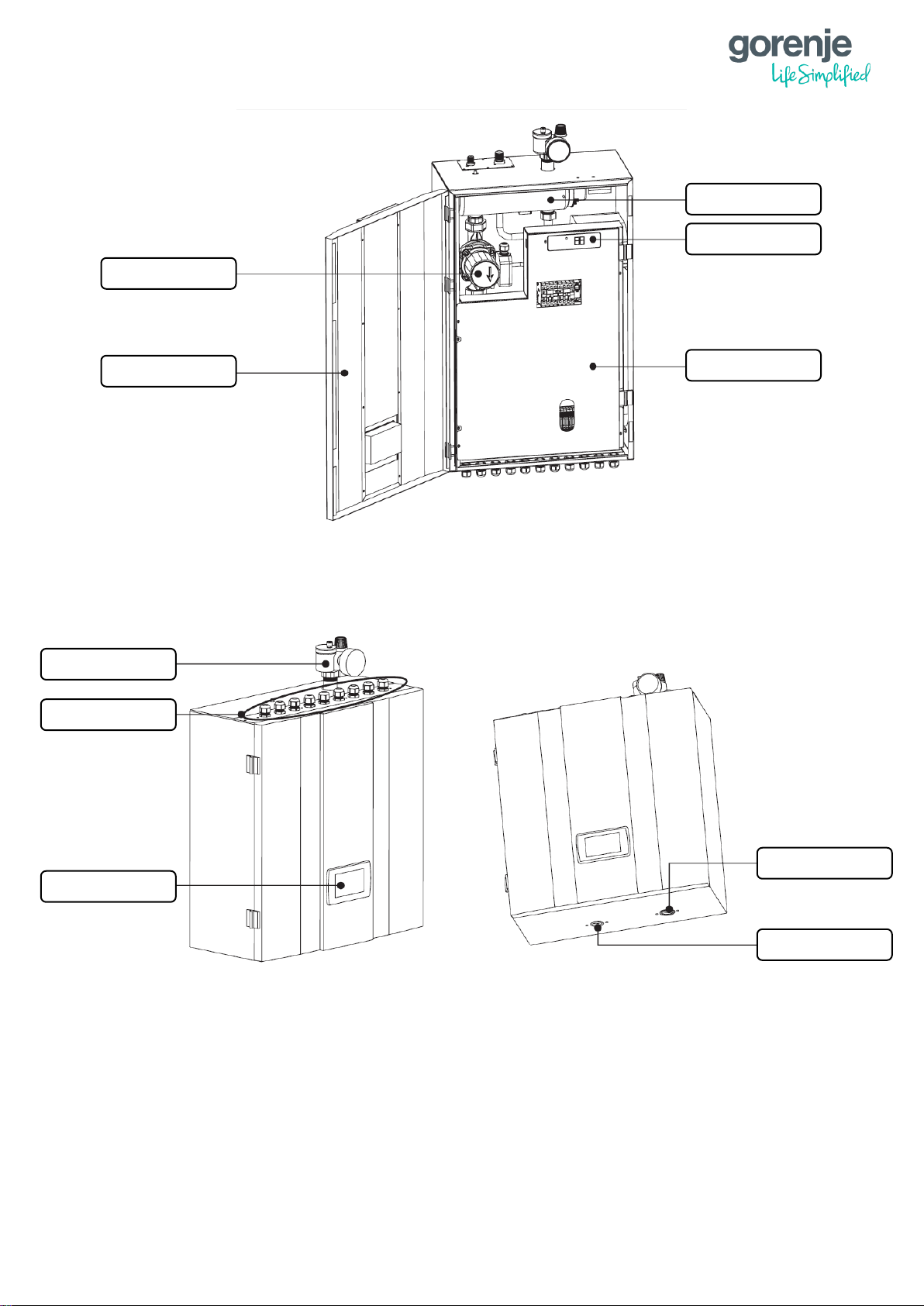

1.9.1.1 AEROGOR ECO INVERTER 10A/13A AND AEROGOR POWER EVI INVERTER

15A/18A

Refrigerant Connector

ECO 10A: 3/8"

ECO 13A: 3/8"

POWER EVI 15A: 3/8"

POWER EVI 18A: 3/8"

Refrigerant Connector

ECO 10A: 1/2"

ECO 13A: 5/8"

POWER EVI 15A: 3/4"

POWER EVI 18A: 3/4"

Operation panel

Cable gland

Water outlet G1"

Water inlet G1"

Safety valve kit

13

1.9.1.2 AEROGOR ECO COMPACT INVERTER 10A/13A

Operation panel

Cable gland

Safety valve kit

Water inlet G1"

Water outlet G1"

Water pump

Door

Electric heater

Digital thermostat

Electric box cover

14

1.9.2 OUTDOOR UNITS

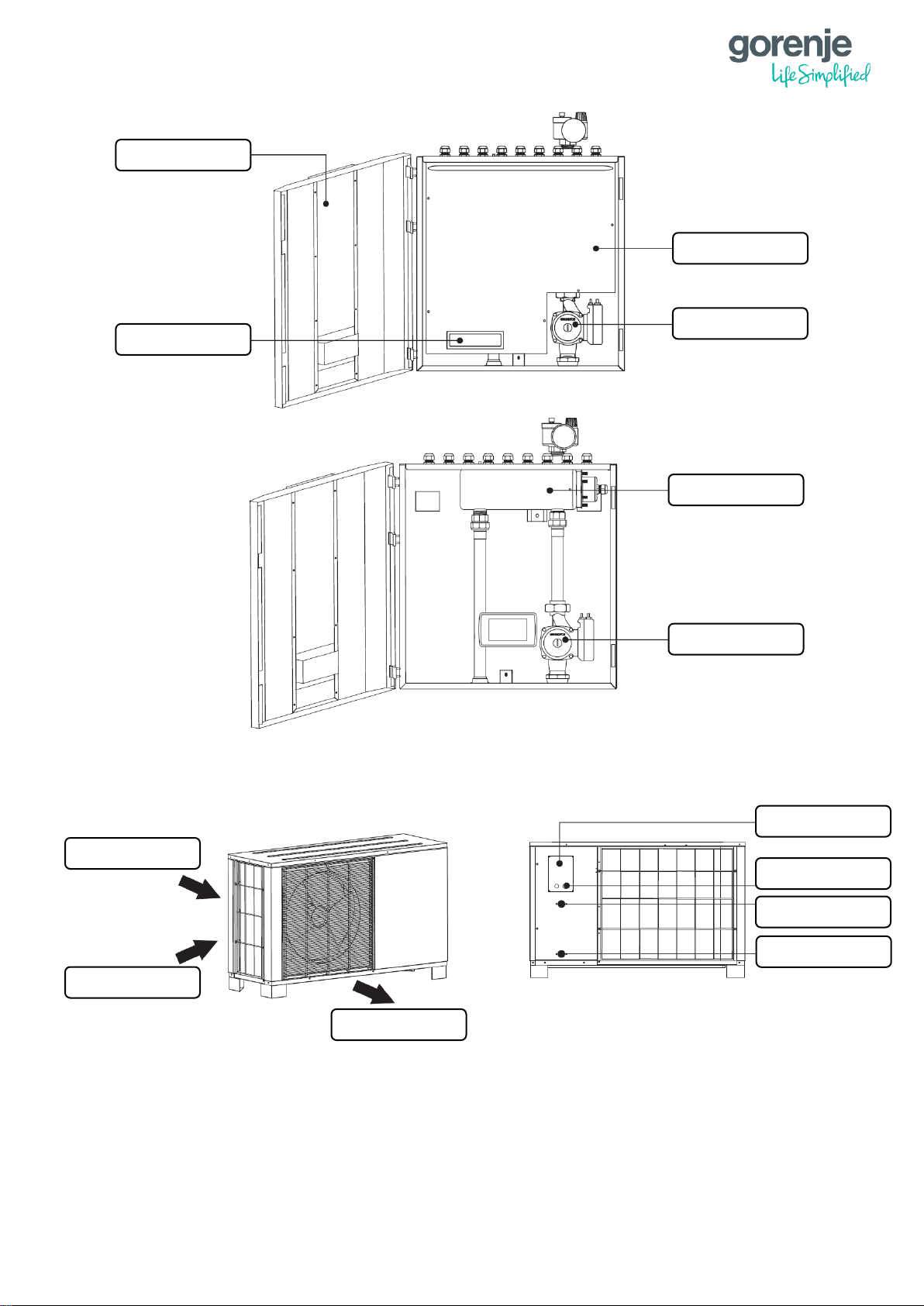

1.9.2.1 AEROGOR ECO COMPACT INVERTER 10A

Electric heater

Water pump

Water pump

Electric box cover

Digital thermostat

Door

Cover

Cable fixture

Air inlet

Air inlet

Air outlet

Water outlet G1"

Water inlet G1"

15

1.9.2.2 AEROGOR ECO COMPACT INVERTER 13A

1.9.2.3 AEROGOR ECO INVERTER 10A

Air inlet

Air outlet

Cover

Cable fixture

Water outlet G1"

Water inlet G1"

Air inlet

Air outlet

Handle

Refrigerant connector

3/8" and 1/2"

Valve cover

16

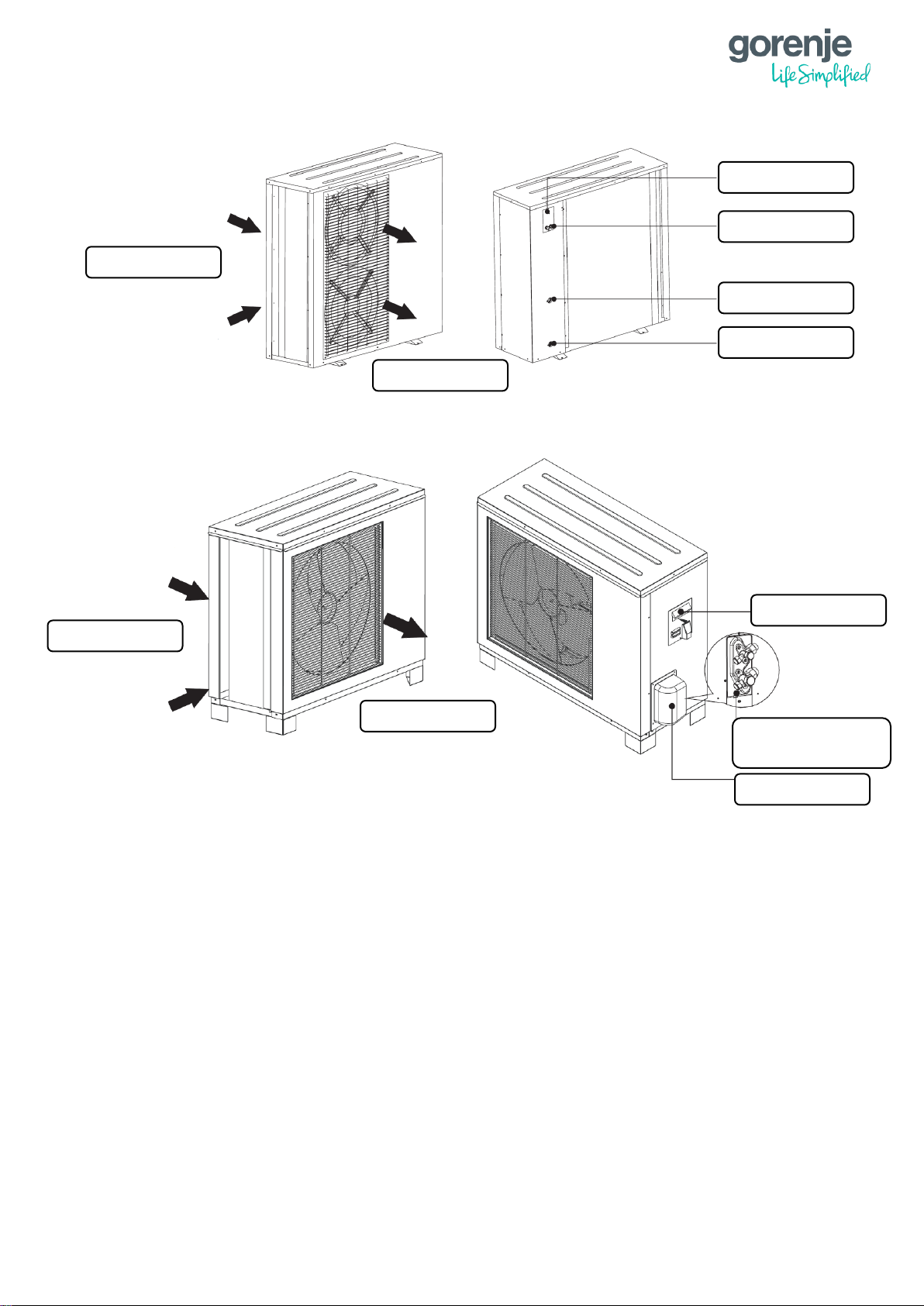

1.9.2.4 AEROGOR ECO INVERTER 13A

1.9.3 AEROGOR POWER EVI INVERTER 15A/ 18A

Handle

Refrigerant connector

3/8" and 5/8"

Valve cover

Air inlet

Air outlet

Refrigerant connector

3/4"

3/8"

Cable gland

Air outlet grill

17

2 INSTALLATION

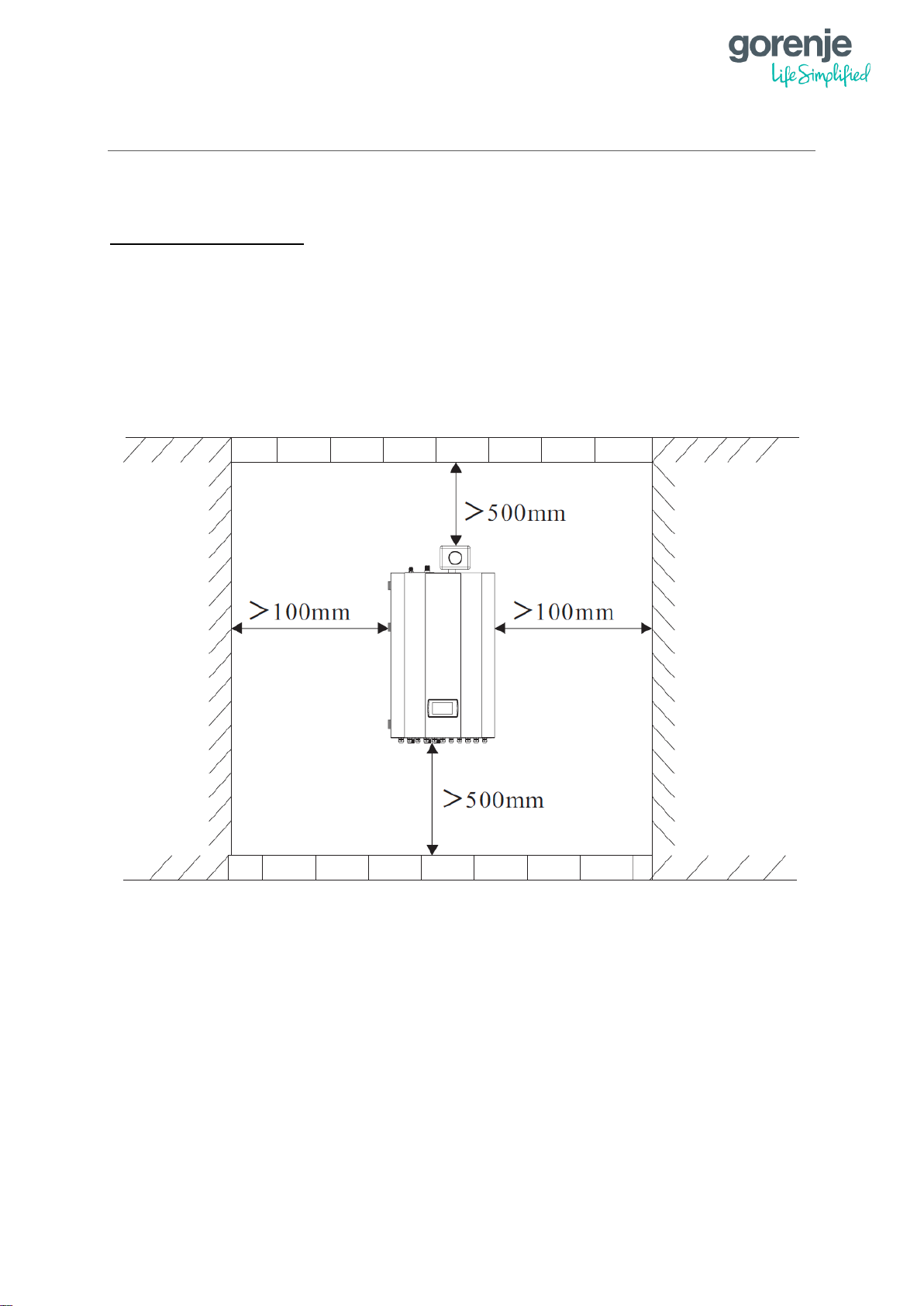

2.1 INSTALLATION OF THE INDOOR UNIT

INSTALLATION NOTES:

1. The indoor unit should be installed indoors and mounted on the wall with water

connections facing downwards.

2. The indoor unit shall be placed in a dry and well-ventilated environment.

3. It is forbidden to install the indoor unit in an environment where there exist volatile,

corrosive or flammable liquids or gases.

4. There should be enough space left around the indoor unit for further maintenance.

Please choose a suitable position to install the indoor unit as follows:

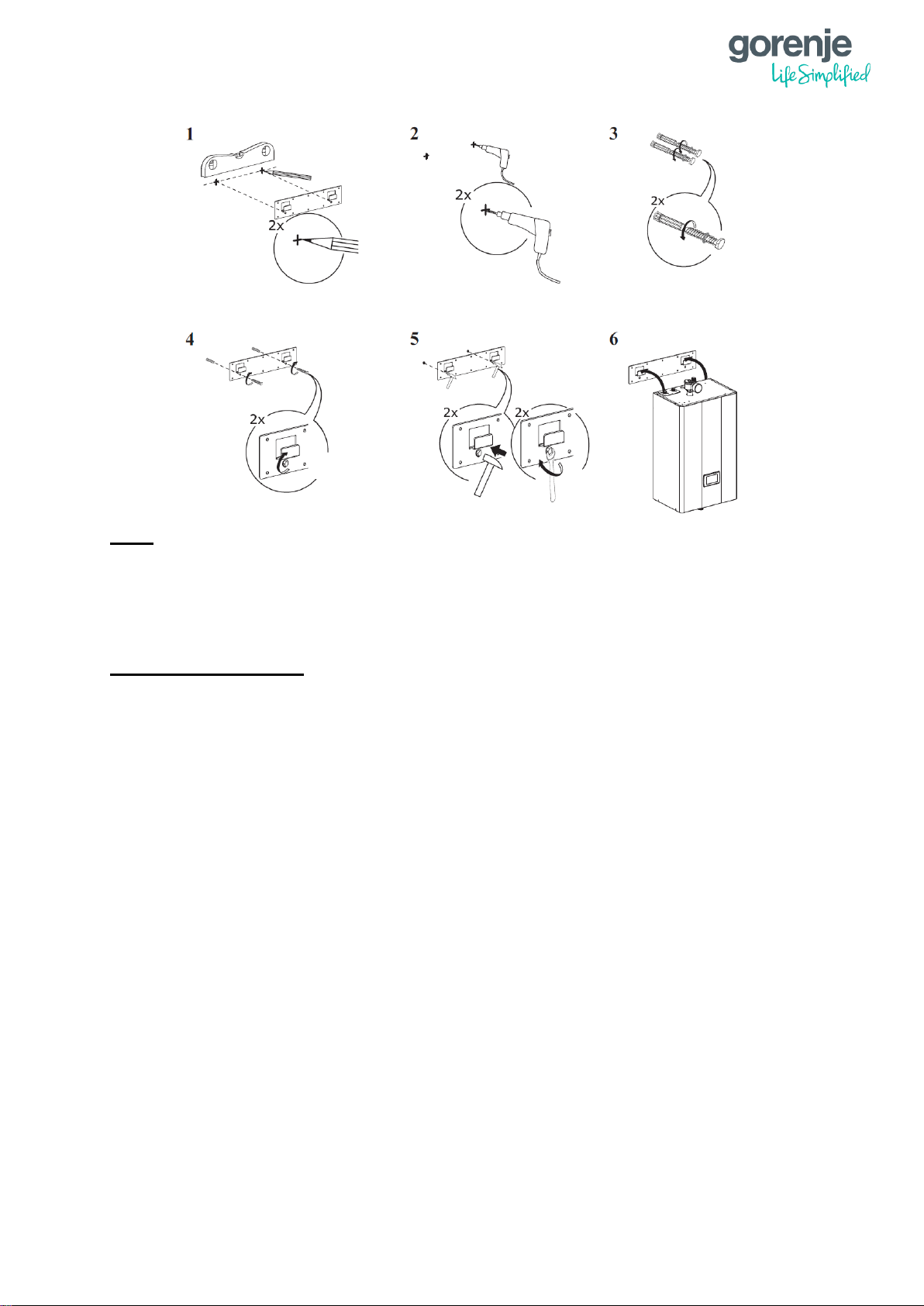

Indoor unit should be mounted on the wall as followed:

1. Take out the expansion bolts and mounting board from the box and put the mounting

board on the wall horizontally.

2. Mark the location of the holes for the bolts on the wall.

3. Drill the holes with proper diameter for the expansion bolts.

4. Unscrew the nuts from the expansion bolts.

5. Fix the mounting board on the expansion bolts a little bit, but don’t be too tight.

6. Use a hammer to pound the expansion bolts into the drilled holes.

7. Fasten the nuts by turning the wrench to fix the mounting board on the wall.

8. Hang the indoor unit onto the mounting board and make sure it’s placed well before

you let go your hands.

9. At this point, the installation is finished.

18

Note:

You must choose very firm wall for installation, otherwise the bolts may get loose and

therefore damaging the unit.

2.2 INSTALLATION OF THE OUTDOOR UNIT

INSTALLATION NOTES:

1. The outdoor unit can be located in an open space, corridor, balcony, roof or hanged

on the wall.

2. The outdoor unit shall be placed in dry and well-ventilated environment; If the outdoor

unit is installed in a humid environment, electronic components may get corroded or

short circuited.

3. Outdoor unit mustn’t be installed in an environment where there exist volatile,

corrosive or flammable liquids or gasses.

4. Please don’t install outdoor unit close to bedroom or living room because it produces

some noise when it’s operating.

5. It is recommended to install an awning above the outdoor unit, to protect the snow

from clogging in the air inlet and outlet to ensure normal operation.

6. Please ensure there is drainage system around the location to drain the condensate

water under defrost mode.

7. When installing the unit, tilt it by 1 cm/m to enable rain water drainage.

8. Install outdoor unit far away from the exhaust port of the kitchen to avoid oil smoke

entering into outdoor unit heat exchanger.

9. Please don’t install the indoor and outdoor unit in damp locations. The units should be

free from corrosive and moisture surrounding otherwise the lifetime of the unit might

be shortened.

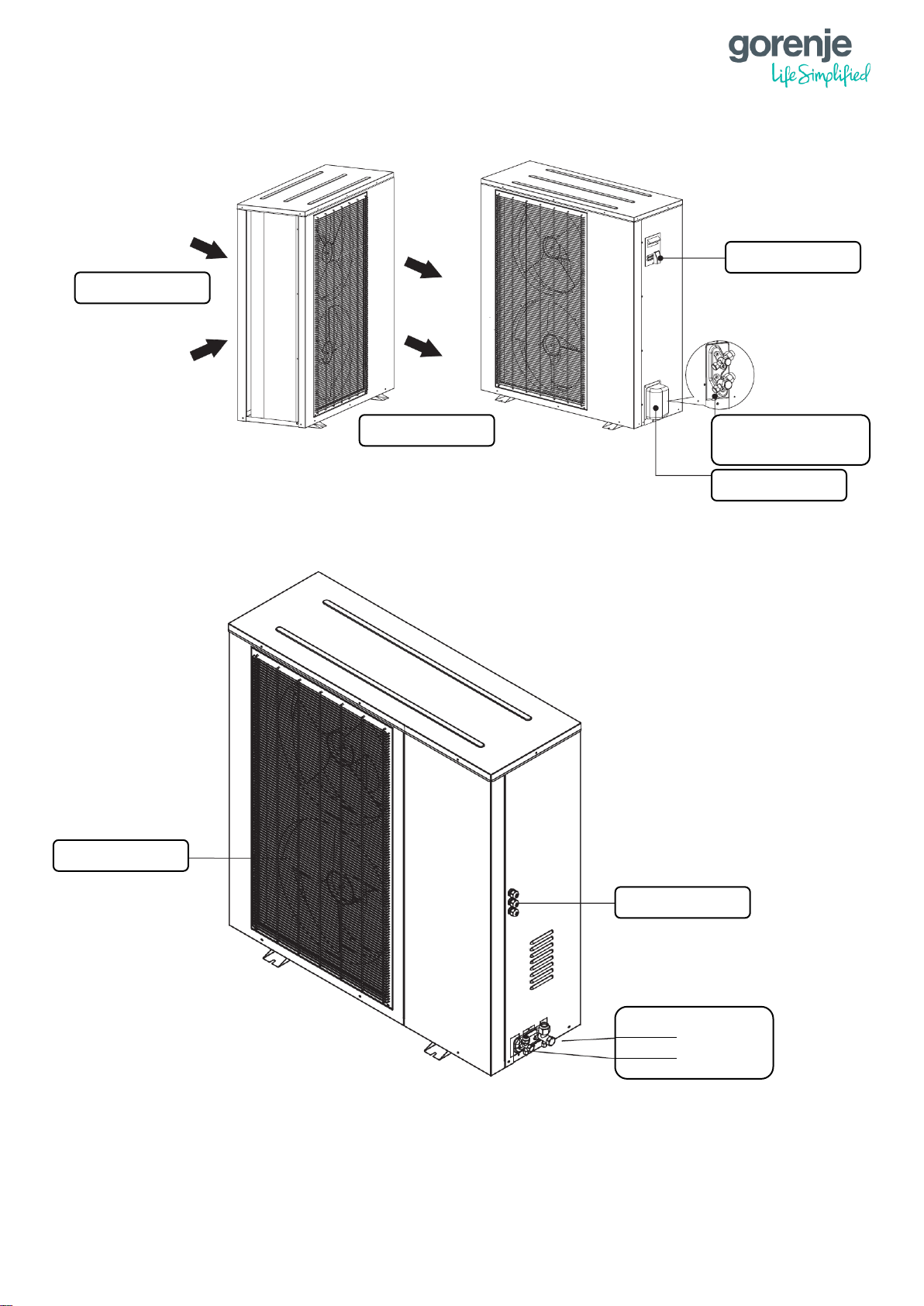

10. Please ensure enough space around the outdoor unit for better ventilation and

maintenance.

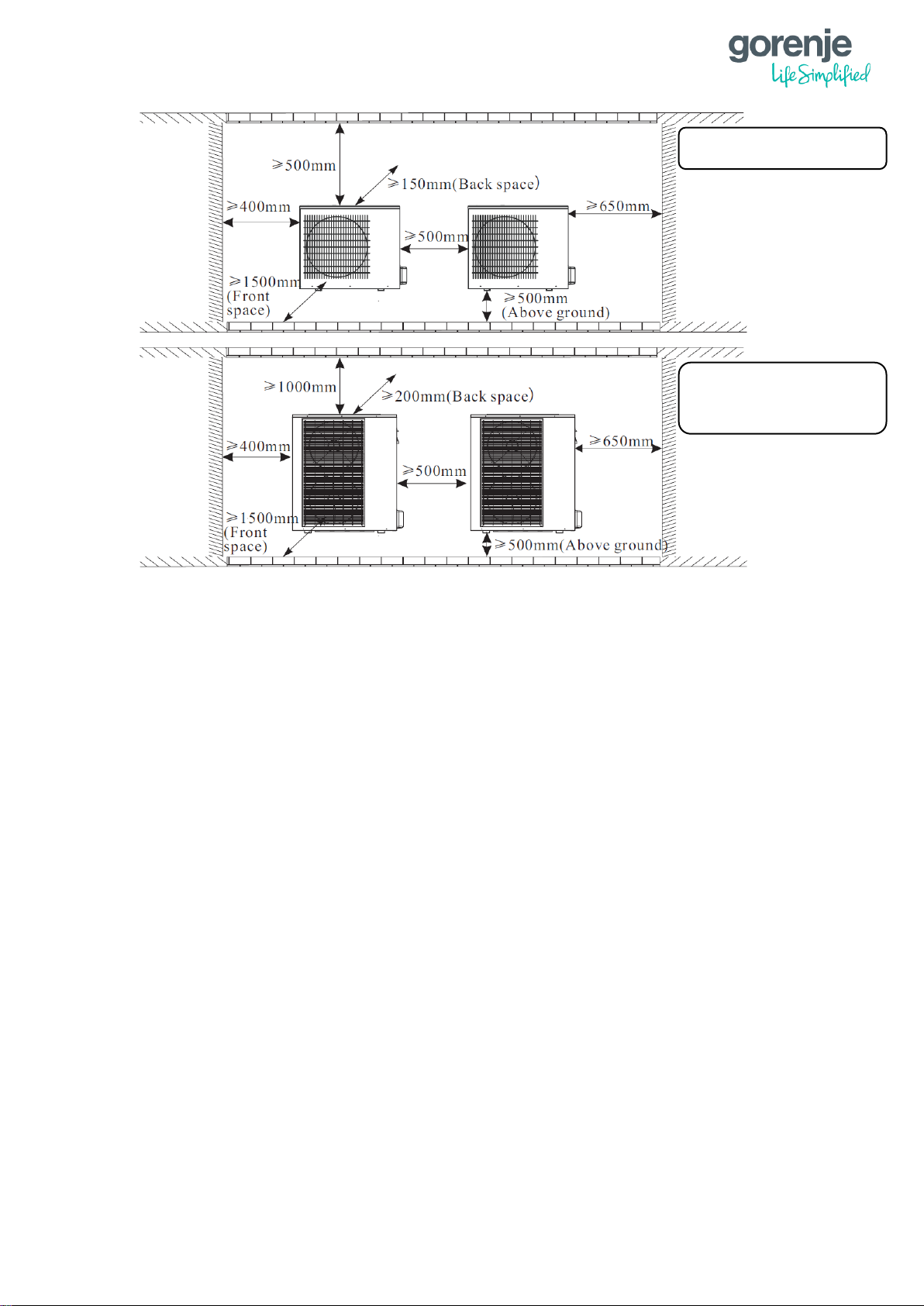

Please refer to the illustration below.

19

User can either use the dedicated mounting bracket from the supplier or prepare a suitable

bracket for the unit installation. Make sure the installation meets the following requirements:

1. The unit must be installed on flat concrete blocks or a dedicated mounting bracket.

The bracket should be able to support at least 5 times of the unit weight.

2. All nuts must be tightened after the bracket is fixed otherwise it may cause damage to

the equipment.

3. Double check and make sure the installation of the unit is firm enough.

4. The bracket can be made from stainless steel, galvanized steel, aluminium and other

materials as required by the user.

5. Besides the mounting bracket, the user can also install the outdoor unit on two

concrete blocks or a raised concrete platform. Please make sure that the unit is

securely fastened after installation.

6. Please see the dimensions of outdoor unit when choosing a suitable wall bracket.

Hole for piping should lean a little bit to outside (≥ 8 degrees) to keep the rain or condensate

water from flowing back indoors.

AEROGOR ECO INVERTER 10A

AEROGOR COMPACT INVERTER 10A

AEROGOR ECO INVERTER 13A

AEROGOR COMPACT INVERTER 13A

AEROGOR POWER EVI INVERTER 15A

AEROGOR POWER EVI INVERTER 18A

20

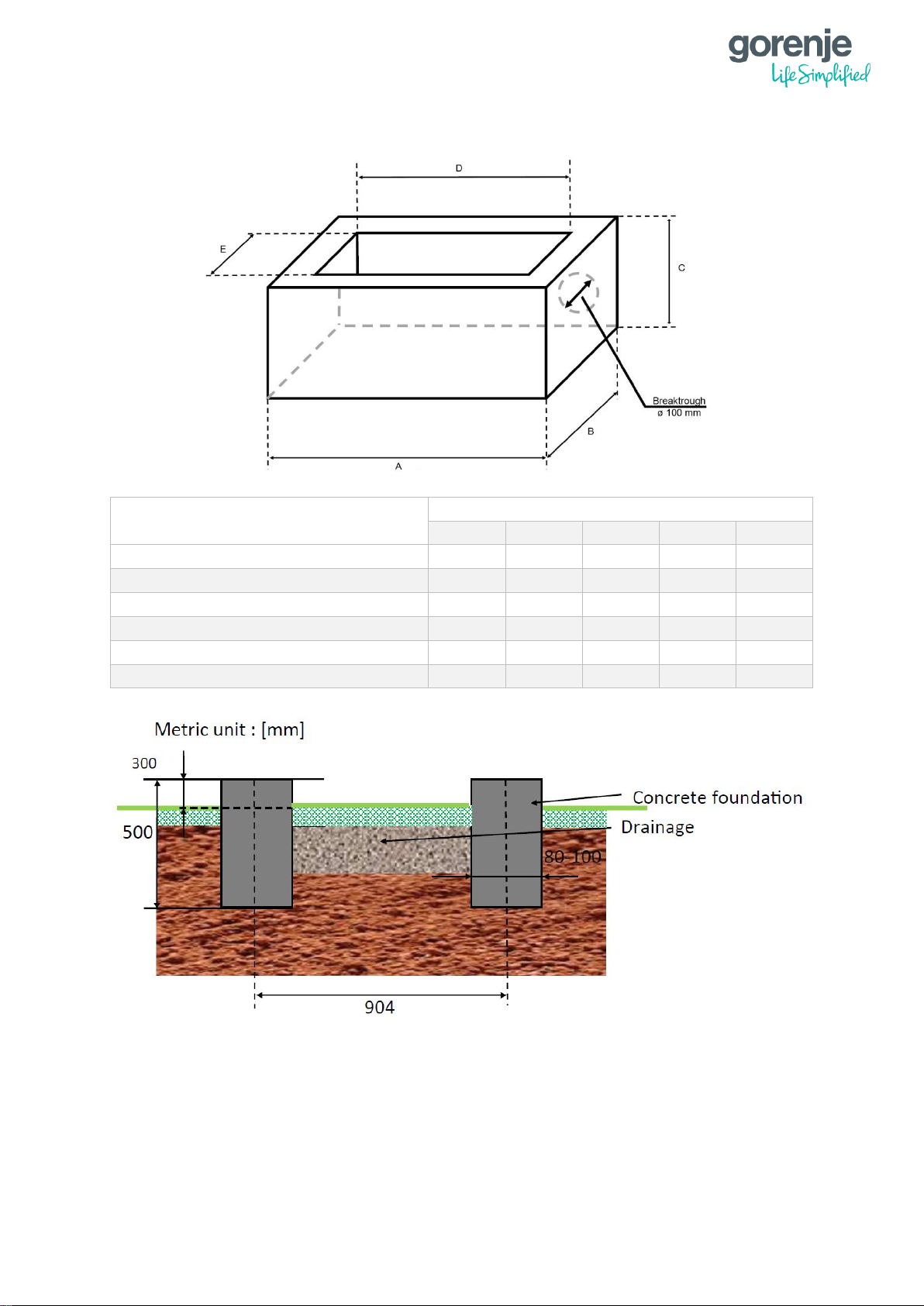

2.3 FOUNDATION

MODEL

SIZE (mm)

A B C D E

ECO COMPACT INVERTER 10A

1390

740

500

1230

580

ECO COMPACT INVERTER 13A

1460

720

500

1300

560

ECO INVERTER 10A

1230

600

500

1070

440

ECO INVERTER 13A

1320

600

500

1160

440

POWER EVI INVERTER 15A

1430

600

500

1270

440

POWER EVI INVERTER 18A

1700

600

500

1540

440

21

MODEL

SIZE (mm)

X

Y

ECO COMPACT INVERTER 10A

1140

340

ECO COMPACT INVERTER 13A

740

430

ECO INVERTER 10A

904

343

ECO INVERTER 13A

740

430

POWER EVI INVERTER 15A

720

430

POWER EVI INVERTER 18A

720

430

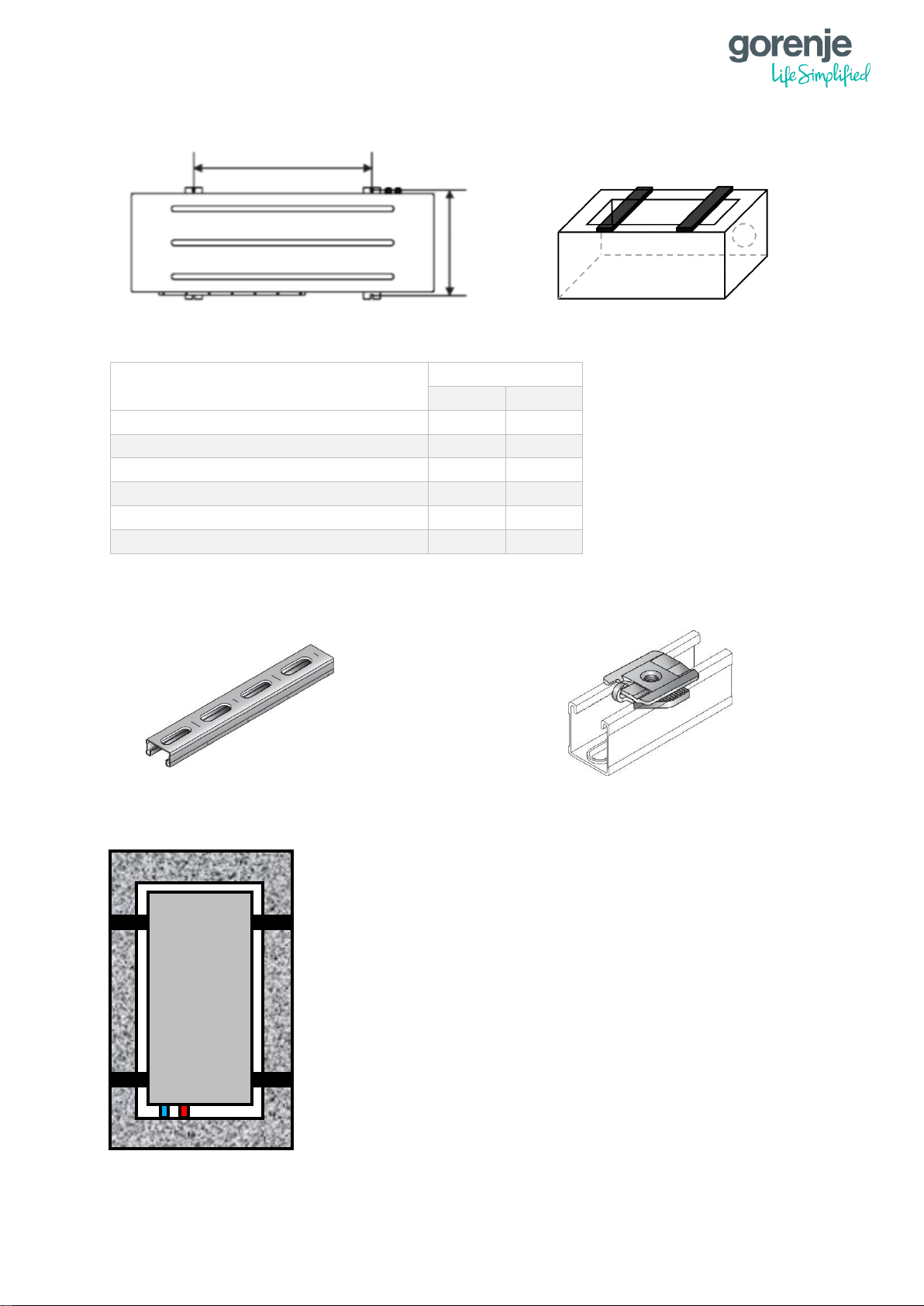

2.3.1 INSTALLATION OF C PROFILE AND LEGS

X

MM-C-16 Double installation profile

MM-S Connector for hose clamp

Y

H

Plan view of the heat pump

fixed on the foundation

22

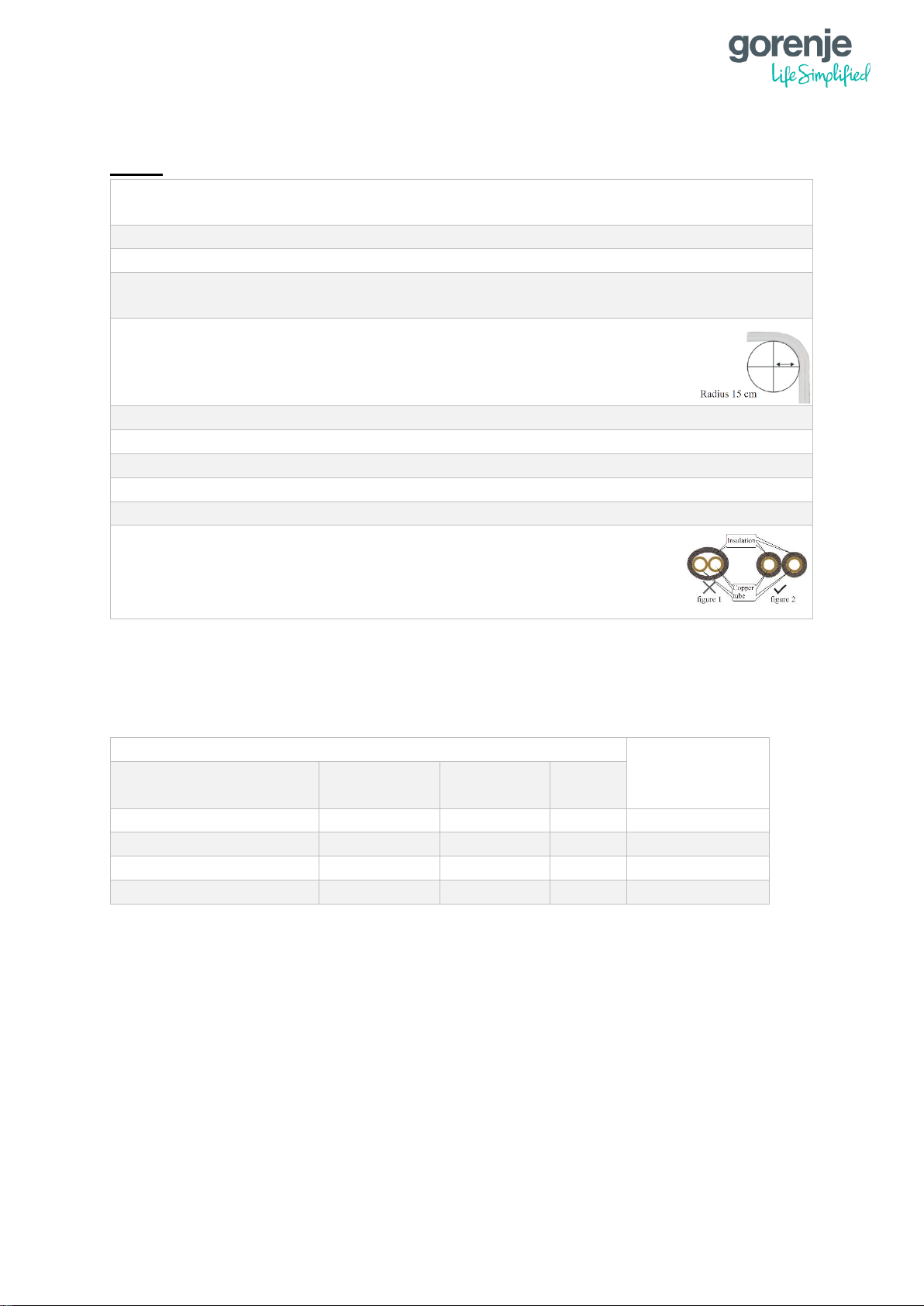

2.4 INSTALATION OF THE REFRIGERANT SYSTEM (SPLIT TYPE)

NOTE:

Only certified personnel are allowed to connect and operate with the refrigerant

system.

It is forbidden to start the unit without Evacuating the refrigerant system.

Pipes used for installation must comply with the specifications of the heat pump

Before starting the unit, always check if the refrigerant connections are sealed and

there is no leakage in the system.

The radius at pipe bends must not be less than 15 cm and the pipes

have to be without flaws.

Do not let any dirt in the refrigerant system

Always use tools without flaws.

Always Evacuate the refrigerant to 500 microns or below.

Evacuating the refrigerant system at sub-zero temperatures is forbidden.

Evacuating the refrigerant system at sub-zero temperatures is forbidden.

When insulating refrigerant pipes, insulate each pipe separately.

The split type heat pumps are factory loaded for a specific length. If the length is longer

than factory load, please check that it does not exceed the maximum length shown in the

table below:

For each meter that is longer than the factory load, you must add 40 g of refrigerant.

REFRIGIRANT PIPING LENGTH

CONNECTIONS

HEAT

PUMP

FACTORY

LOAD

MAXIMUM

LENGTH

ADD

ECO Inverter 10A

5 meters

12 meters

40 g/m

1/4" and 1/2"

ECO Inverter 13A

10 meters

15 meters

40 g/m

3/8" and 1/2"

Power EVI Inverter 15A

15 meters

18 meters

40 g/m

3/8" and 5/8"

Power EVI Inverter 18A

15 meters

18 meters

40 g/m

3/8" and 3/4"

23

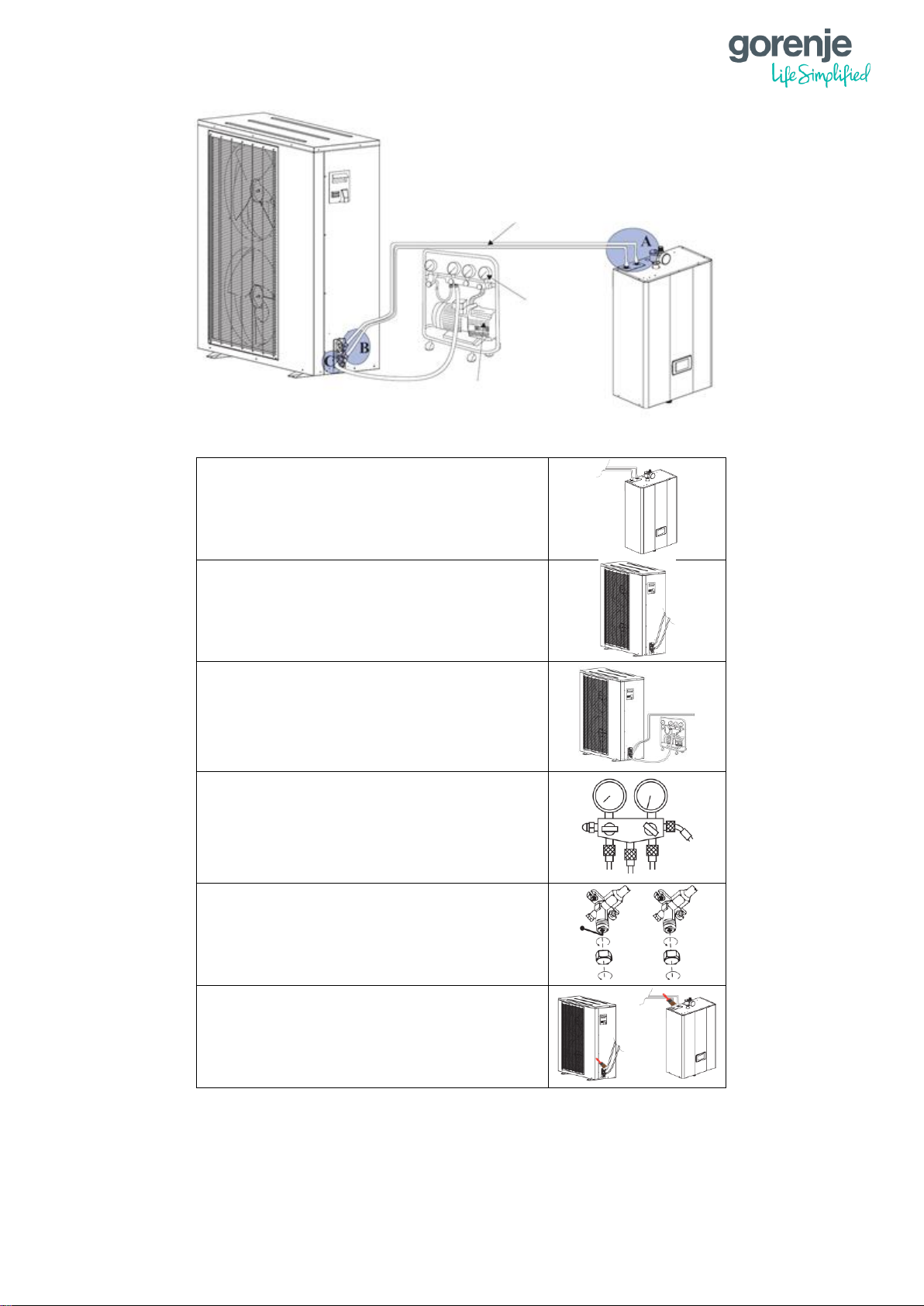

A – Connect the refrigerant piping to the

indoor unit.

B - Connect the other end of the refrigerant

pipes to the outdoor unit.

C – Prepare a vacuum pump and a

pressure gauge. Connect one tube of the

pressure gauge to the vacuum pump and

the other one to the high-pressure

refrigerant connector on the outdoor unit.

Open the pressure gauge and start the

vacuum pump to vacuum the unit to 500

microns or below. After that close, the

pressure gauge and stop vacuuming.

Take off the copper nuts off the connectors

and open the valves with hexagon spanner

as much as possible.

Check if there is any leakage with leakage

detector or soap water. If not, remove the

tubes of the gauges and put back the

copper nuts into the valves.

Vacuum pump

Pressure

gauge

Refrigerant pipe

connection

Loading...

Loading...