Goodman GMH95, GCH95, GME95, GCH9 User Manual

GMH95/GCH95/GME95/GCH9

GAS-FIRED WARM AIR FURNACE

INSTALLATION INSTRUCTIONS

Installer: Affix all manuals adjacent to the unit.

(Type FSP CATEGORY IV Direct or Non Direct Vent Air Furnace)

These furnaces comply with requirements |

|

|

|

|

embodied in the American National Stan- |

|

® |

|

|

dard / National Standard of Canada ANSI |

|

|

|

|

Z21.47·CSA-2.3 Gas Fired Central Fur- |

C |

|

US |

|

naces. |

|

|

|

|

|

|

|

|

|

RECOGNIZE THIS SYMBOL AS A SAFETY PRECAUTION.

RECOGNIZE THIS SYMBOL AS A SAFETY PRECAUTION.

ATTENTION INSTALLING PERSONNEL

As a professional installer you have an obligation to know the product better than the customer. This includes all safety precautions and related items.

Prior to actual installation, thoroughly familiarize yourself with this Instruction Manual. Pay special attention to all safety warnings. Often during installation or repair it is possible to place yourself in a position which is more hazardous than when the unit is in operation.

Remember, it is your responsibility to install the product safely and to know it well enough to be able to instruct a customer in its safe use.

Safety is a matter of common sense...a matter of thinking before acting. Most dealers have a list of specific good safety practices...follow them.

The precautions listed in this Installation Manual are intended as supplemental to existing practices. However, if there is a direct conflict between existing practices and the content of this manual, the precautions listed here take precedence.

IO-299O 12/11

NOTE: Please contact your distributor or our website

for the applicable Specification Sheet referred to in this manual.

Goodman Manufacturing Company, L.P.

5151 San Felipe, Suite 500, Houston, TX 77056

www.goodmanmfg.com

© 2006-2011 Goodman Manufacturing Company, L.P.

Downloaded from www.Manualslib.com manuals search engine

Table of Contents

IMPORTANT NOTE TO THE OWNER REGARDING PRODUCT WARRANTY .................................................................................. |

4 |

I. Component Identification ..................................................................................................................................... |

5 |

II. Safety ....................................................................................................................................................................... |

6 |

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS .......................................................................................................... |

6 |

III. Product Application .............................................................................................................................................. |

6 |

IV. Location Requirements & Considerations .................................................................................................... |

7 |

GENERAL .................................................................................................................................................................. |

7 |

CLEARANCES AND ACCESSIBILITY ................................................................................................................................. |

8 |

FURNACE SUSPENSION ............................................................................................................................................... |

8 |

EXISTING FURNACE REMOVAL ...................................................................................................................................... |

8 |

THERMOSTAT LOCATION ............................................................................................................................................... |

9 |

V. Combustion & Ventilation Air Requirements .................................................................................................... |

9 |

VI. Installation Positions ......................................................................................................................................... |

11 |

VII. Horizontal Applications & Considerations .................................................................................................... |

11 |

GENERAL ................................................................................................................................................................ |

11 |

DRAIN TRAP AND LINES ............................................................................................................................................ |

11 |

LEVELING ............................................................................................................................................................... |

11 |

ALTERNATE VENT/FLUE AND COMBUSTION AIR CONNECTIONS ......................................................................................... |

11 |

ALTERNATE ELECTRICAL AND GAS LINE CONNECTIONS .................................................................................................. |

12 |

DRAIN PAN ............................................................................................................................................................. |

12 |

FREEZE PROTECTION ................................................................................................................................................ |

12 |

FURNACE SUSPENSION ............................................................................................................................................. |

12 |

VIII. Propane Gas /High Altitude Installations .................................................................................................... |

12 |

IX. Vent/Flue Pipe & Combustion Air Pipe ........................................................................................................... |

12 |

GENERAL ................................................................................................................................................................ |

12 |

DUAL CERTIFICATION: NON-DIRECT/DIRECT VENT ......................................................................................................... |

13 |

MATERIALS AND JOINING METHODS ............................................................................................................................ |

13 |

PROPER VENT/FLUE AND COMBUSTION AIR PIPING PRACTICES ...................................................................................... |

13 |

TERMINATION LOCATIONS ........................................................................................................................................... |

15 |

CANADIAN VENTING REQUIREMENTS ........................................................................................................................... |

15 |

STANDARD FURNACE CONNECTIONS ............................................................................................................................ |

15 |

ALTERNATE FURNACE CONNECTIONS ........................................................................................................................... |

16 |

NON-DIRECT VENT (SINGLE PIPE) PIPING ................................................................................................................... |

17 |

DIRECT VENT (DUAL PIPE) PIPING ............................................................................................................................. |

18 |

VENT/INTAKE TERMINATIONS FOR INSTALLATION OF MULTIPLE DIRECT VENT FURNACES ..................................................... |

19 |

CONCENTRIC VENT TERMINATION ................................................................................................................................ |

20 |

SIDE WALL VENT KIT ............................................................................................................................................... |

20 |

X. Condensate Drain Lines & Drain Trap ............................................................................................................. |

20 |

STANDARD RIGHT OR LEFT SIDE DRAIN HOSE CONNECTIONS ......................................................................................... |

21 |

UPRIGHT INSTALLATIONS-TRAP ON LEFT SIDE ............................................................................................................... |

23 |

HORIZONTAL INSTALLATIONS ....................................................................................................................................... |

24 |

XI. Electrical Connections ...................................................................................................................................... |

26 |

WIRING HARNESS .................................................................................................................................................... |

26 |

115 VOLT LINE CONNECTIONS ................................................................................................................................... |

26 |

JUNCTION BOX RELOCATION ...................................................................................................................................... |

26 |

24 VOLT THERMOSTAT WIRING ................................................................................................................................... |

27 |

GME95 FURNACE WITH 2-STAGE CONDENSER FIELD WIRING ...................................................................................... |

27 |

115 VOLT LINE CONNECTION OF ACCESSORIES (ELECTRONIC AIR CLEANER) .................................................................. |

27 |

24 VOLT HUMIDIFIER ................................................................................................................................................ |

28 |

XII. Gas Supply and Piping ..................................................................................................................................... |

28 |

GENERAL ................................................................................................................................................................ |

28 |

GAS PIPING CONNECTIONS ....................................................................................................................................... |

28 |

PROPANE GAS TANKS AND PIPING ............................................................................................................................. |

31 |

XIII. Circulating Air & Filters ................................................................................................................................... |

31 |

DUCTWORK - AIR FLOW ............................................................................................................................................ |

31 |

CHECKING DUCT STATIC ............................................................................................................................................ |

32 |

BOTTOM RETURN AIR OPENING [UPFLOW MODELS] ..................................................................................................... |

32 |

2 |

|

Downloaded from www.Manualslib.com manuals search engine

FILTERS - READ THIS SECTION BEFORE INSTALLING THE RETURN AIR DUCTWORK ............................................................ |

33 |

UPRIGHT INSTALLATIONS ............................................................................................................................................ |

33 |

HORIZONTAL INSTALLATIONS ....................................................................................................................................... |

33 |

XIV. Startup Procedure & Adjustment .................................................................................................................. |

33 |

HEAT ANTICIPATOR SETTING ........................................................................................................................................ |

33 |

DRAIN TRAP PRIMING ............................................................................................................................................... |

33 |

FURNACE OPERATION ................................................................................................................................................ |

33 |

GAS SUPPLY PRESSURE MEASUREMENT .................................................................................................................... |

34 |

GAS MANIFOLD PRESSURE MEASUREMENT AND ADJUSTMENT ....................................................................................... |

35 |

GAS INPUT RATE MEASUREMENT (NATURAL GAS ONLY) ............................................................................................... |

35 |

TEMPERATURE RISE ................................................................................................................................................. |

36 |

CIRCULATOR BLOWER SPEEDS .................................................................................................................................. |

36 |

CIRCULATOR BLOWER FAN TIMING ADJUSTMENT .......................................................................................................... |

36 |

SETTING FURNACE OPERATING MODE ......................................................................................................................... |

37 |

XV. Normal Sequence of Operation ...................................................................................................................... |

37 |

POWER UP ............................................................................................................................................................. |

37 |

HEATING MODE ....................................................................................................................................................... |

37 |

(MODE DIP SWITCH IS SET TO “1 STG” POSITION) ..................................................................................................... |

37 |

(MODE DIP SWITCH IS SET TO “2 STG” POSITION) ..................................................................................................... |

37 |

COOLING MODE ...................................................................................................................................................... |

38 |

FAN ONLY MODE .................................................................................................................................................... |

38 |

XVI. Operational Checks ......................................................................................................................................... |

38 |

BURNER FLAME ....................................................................................................................................................... |

38 |

XVII. Safety Circuit Description ............................................................................................................................. |

38 |

GENERAL ................................................................................................................................................................ |

38 |

INTEGRATED CONTROL MODULE ................................................................................................................................. |

38 |

PRIMARY LIMIT ........................................................................................................................................................ |

38 |

AUXILIARY LIMIT ...................................................................................................................................................... |

38 |

ROLLOUT LIMIT ........................................................................................................................................................ |

38 |

PRESSURE SWITCHES ............................................................................................................................................... |

39 |

FLAME SENSOR ....................................................................................................................................................... |

39 |

XVIII. Troubleshooting............................................................................................................................................. |

39 |

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS ........................................................................................................ |

39 |

DIAGNOSTIC CHART .................................................................................................................................................. |

39 |

FAULT RECALL ........................................................................................................................................................ |

39 |

RESETTING FROM LOCKOUT ...................................................................................................................................... |

39 |

XIX. Maintenance ..................................................................................................................................................... |

39 |

ANNUAL INSPECTION ................................................................................................................................................. |

39 |

FILTERS .................................................................................................................................................................. |

40 |

BURNERS ................................................................................................................................................................ |

40 |

INDUCED DRAFT AND CIRCULATOR BLOWERS ................................................................................................................ |

40 |

CONDENSATE TRAP AND DRAIN SYSTEM (QUALIFIED SERVICER ONLY) ........................................................................... |

40 |

FLAME SENSOR (QUALIFIED SERVICER ONLY)............................................................................................................. |

40 |

IGNITER (QUALIFIED SERVICER ONLY) ........................................................................................................................ |

40 |

FLUE PASSAGES (QUALIFIED SERVICER ONLY) ........................................................................................................... |

40 |

XX. Before Leaving an Installation ....................................................................................................................... |

41 |

XXI. Repair & Replacement Parts .......................................................................................................................... |

41 |

WARNING

WARNING

GOODMAN WILL NOT BE RESPONSIBLE FOR ANY INJURY OR PROPERTY

DAMAGE ARISING FROM IMPROPER SERVICE OR SERVICE PROCEDURES.

IF YOU INSTALL OR PERFORM SERVICE ON THIS UNIT, YOU ASSUME

RESPONSIBILITY FOR ANY PERSONAL INJURY OR PROPERY DAMAGE WHICH

MAY RESULT. MANY JURISDICTIONS REQUIRE A LICENSE TO INSTALL OR

SERVICE HEATING AND AIR CONDITIONING EQUIPMENT.

3

Downloaded from www.Manualslib.com manuals search engine

WARNING

WARNING

IF THE INFORMATION IN THESE INSTRUCTIONS IS NOT FOLLOWED EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

- DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

-WHAT TO DO IF YOU SMELL GAS:

*DO NOT TRY TO LIGHT ANY APPLIANCE.

*DO NOT TOUCH ANY ELECTRICAL SWITCH; DO NOT USE

ANY PHONE IN YOUR BUILDING.

* IMMEDIATELY CALL YOUR GAS SUPPLIER FROM A NEIGHBORS PHONE. FOLLOW THE GAS SUPPLIERS INSTRUCTIONS.

* IF YOU CANNOT READCH YOUR GAS SUPPLIER, CALL THE FIRE DEPARTMENT.

- INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER, SERVICE AGENCY OR THE GAS SUPPLIER

WARNING

WARNING

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL TO SHUT OFF, TURN OFF THE MANUAL GAS SHUTOFF VALVE EXTERNAL TO THE FURNACE BEFORE TURNING OFF THE ELECTRICAL SUPPLY.

SHIPPING INSPECTION

All units are securely packed in shipping containers tested according to International Safe Transit Association specifications. The carton must be checked upon arrival for external damage. If damage is found, a request for inspection by carrier’s agent must be made in writing immediately.

The furnace must be carefully inspected on arrival for damage and bolts or screws which may have come loose in transit. In the event of damage the consignee should:

1.Make a notation on delivery receipt of any visible damage to shipment or container.

2.Notify carrier promptly and request an inspection.

3.With concealed damage, carrier must be notified as soon as possible - preferably within five days.

4.File the claim with the following support documents within a nine month statute of limitations.

•Original or certified copy of the Bill of Lading, or indemnity bond.

•Original paid freight bill or indemnity in lieu thereof.

•Original or certified copy of the invoice, showing trade and other discounts or reductions.

•Copy of the inspection report issued by carrier’s representative at the time damage is reported to carrier.

CARBON MONOXIDE POISONING HAZARD

Special Warning for Installation of Furnace or Air Handling Units in

Enclosed Areas such as Garages, Utility Rooms or Parking Areas

Carbon monoxide producing devices (such as an automobile, space heater, gas water heater, etc.) should not be operated in enclosed areas such as unventilated garages, utility rooms or parking areas because of the danger of carbon monoxide (CO) poisoning resulting from the exhaust emissions. If a furnace or air handler is installed in an enclosed area such

as a garage, utility room or parking area and a carbon monoxide producing device is operated therein, there must be adequate, direct outside ventilation.

This ventilation is necessary to avoid the danger of CO poisoning which

can occur if a carbon monoxide producing device continues to operate in the enclosed area. Carbon monoxide emissions can be (re)circulated throughout the structure if the furnace or air handler is operating in any mode.

CO can cause serious illness including permanent brain damage or death.

B10259--216

TO THE INSTALLER

Before installing this unit, please read this manual thoroughly to familiarize yourself with specific items which must be adhered to, including but not limited to: unit maximum external static pressure, gas pressures, BTU input rating, proper electrical connections, circulating air temperature rise, minimum or maximum CFM, and motor speed connections.

4

The carrier is responsible for making prompt inspection of damage and for a thorough investigation of each claim. The distributor or manufacturer will not accept claims from dealers for transportation damage.

Keep this literature in a safe place for future reference.

IMPORTANT NOTE TO THE OWNER REGARDING PRODUCT WAR-

RANTY

Your warranty certificate is supplied as a separate document with the unit installed by your contractor. Read the limited warranty certificate carefully to determine what is and is not covered and keep the warranty certificate in a safe place. If you are unable to locate the warranty certificate please contact your installing contractor or contact customer service (877-254-4729) to obtain a copy.

To receive the Lifetime Heat Exchanger Limited Warranty (good for as long as you own your home) and the 10-year Parts Limited Warranty, online registration must be completed within 60 days of installation. Online registration is not required in California or Quebec. Complete warranty details available from your local dealer or at www.goodmanmfg.com.

To register your Goodman® brand unit, go to www.goodmanmfg.com. and click “Warranty Registration”. Complete registration as prompted.

Product limited warranty certificates for models currently in production can be viewed at www.goodmanmfg.com. If your model is not currently in production or does not appear on the website, please contact your installing contractor or contact customer service (877- 254-4729) to obtain a copy of your warranty certificate.

Each product overview page contains a Product Warranty link; by clicking on it you will be able to view the limited warranty coverage for that specific product. To view warranty registration information, click on the Product Warranty text on the left navigation panel on the home page of each website. The Online Product Registration pages are located in this same section.

Downloaded from www.Manualslib.com manuals search engine

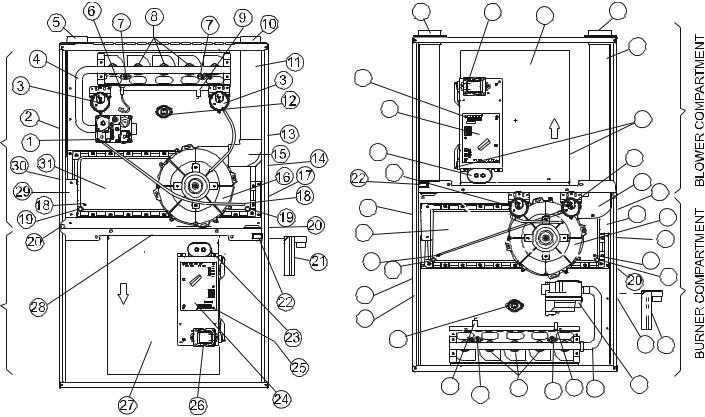

I. COMPONENT IDENTIFICATION

| <![if ! IE]> <![endif]>COMPARTMENTBURNER |

* |

* |

* |

|

* |

|

|

* |

* |

|

|

|

|

||

* |

* |

* |

|

|

|

|

|

| <![if ! IE]> <![endif]>BLOWER COMPARTMENT |

|

|

|

|

|

Upflow/Horizontal |

|

1Gas Valve

2Gas Line Entrance (Alternate)

3Pressure Switch

4Gas Manifold

5Combustion Air Intake Connection / “Coupling”

6Hot Surface Igniter

7Rollout Limit

8Burners

9Flame Sensor

10Flue Pipe Connection / “Coupling”

11Flue Pipe (Internal)

12Primary Limit

13Gas Line Entrance

14Flue Pipe Connection (Alternate)

15Rubber Elbow

16Induced Draft Blower

17Electrical Connection Inlets (Alternate)

18Coil Front Cover Pressure Tap

19Coil Front Cover Drain Port

20Drain Line Penetrations

21Drain Trap

5 |

26 |

|

27 |

|

|

10 |

|

|

|

|

|

|

|

11 |

|

25 |

|

|

|

|

|

|

|

24 |

|

|

|

|

|

28 |

|

|

|

|

|

|

|

|

|

23 |

|

|

|

|

|

3 |

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

15 14 |

||

17 |

|

|

|

|

|

||

|

|

|

|

|

29 |

16 |

|

31 |

|

|

|

|

|

||

|

|

|

|

|

|

30 |

|

|

|

|

|

|

|

|

|

18 19 |

|

|

|

|

|

18 |

19 |

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

|

|

|

|

|

|

|

12 |

|

|

|

|

|

2 |

21 |

|

|

|

|

|

|

||

9 |

7 |

8 |

7 |

6 |

4 |

1 |

|

|

|

||||||

Counterflow/Horizontal |

|

|

|||||

22Blower Door Interlock Switch

23Capacitor

24Integrated Control Module (with fuse and diagnostic LED)

2524-Volt Thermostat Connections

26Transformer (40 VA)

27Circulator Blower

28Auxiliary Limit

29Junction Box

30Electrical Connection Inlets

31Coil Front Cover

5

Downloaded from www.Manualslib.com manuals search engine

II. SAFETY

Please adhere to the following warnings and cautions when installing, adjusting, altering, servicing, or operating the furnace.

WARNING

WARNING

TO PREVENT PERSONAL INJURY OR DEATH DUE TO IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE, REFER TO THIS MANUAL. FOR ADDITIONAL ASSISTANCE OR INFORMATION, CONSULT A QUALIFIED INSTALLER, SERVICE AGENCY OR THE GAS SUPPLIER.

WARNING

WARNING

THIS PRODUCT CONTAINS OR PRODUCES A CHEMICAL OR CHEMICALS WHICH MAY CAUSE SERIOUS ILLNESS OR DEATH AND WHICH ARE KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

WARNING

WARNING

HIGH VOLTAGE!

TO AVOID PROPERTY DAMAGE, PERSONAL INJURY OR DEATH DUE TO ELECTRICAL SHOCK, THE FURNACE MUST BE LOCATED TO PROTECT THE ELECTRICAL COMPONENTS FROM WATER.

WARNING

WARNING

DO NOT UTILIZE THE HEATING UNIT WITHOUT REASONABLE ROUTINE INSPECTION, MAINTENANCE AND SUPERVISION. IF THE UNIT IS IN A BUILDING THAT IS OR WILL BE VACANT, CARE SHOULD BE TAKEN TO ROUTINELY INSPECT, MAINTAIN AND MONITOR THE UNIT. IN THE EVENT THAT THE BUILDING MAY BE EXPOSED TO FREEZING TEMPERATURES AND WILL BE VACANT, DRAIN ALL WATER-BEARING PIPES, PROPERLY WINTERIZE THE BUILDING, AND TURN OFF ALL WATER SOURCES. IN THE EVENT THAT THE BUILDING IS EXPOSED TO FREEZING TEMPERATURES AND IS VACANT, ANY HYDRONIC COIL UNITS SHOULD ALSO BE DRAINED AND AN ALTERNATIVE HEAT SOURCES UTILIZED.

or shuffle your feet, do not touch ungrounded objects, etc.). If you come in contact with an ungrounded object, repeat step 2 before touching control or wires.

4.Discharge your body to ground before removing a new control from its container. Follow steps 1 through 3 if installing the control on a furnace. Return any old or new controls to their containers before touching any ungrounded object.

III.PRODUCTAPPLICATION

This furnace is primarily designed for residential home-heating applications. It is NOT designed or certified for use in mobile homes, trailers or recreational vehicles. This unit is NOT designed or certified for outdoor applications. The furnace must be installed indoors (i.e., attic space, crawl space, or garage area provided the garage area is enclosed with an operating door).

This furnace can be used in the following non-industrial commercial applications:

Schools, Office buildings, Churches, Retail stores Nursing homes, Hotels/motels, Common or office areas

In such applications , the furnace must be installed with the following stipulations:

•It must be installed per the installation instructions provided and per local and national codes.

•It must be installed indoors in a building constructed on site.

•It must be part of a ducted system and not used in a free air delivery application.

•It must not be used as a “make-up” air unit.

•It must be installed with two-pipe systems for combustion air, especially if VOC’s or other contaminants are present in the conditioned space.

•All other warranty exclusions and restrictions apply This furnace is an ETL dual-certified appliance and is appropriate for use with natural or propane gas (NOTE: If using propane, a propane conversion kit is required).

Dual certification means that the combustion air inlet pipe is optional and the furnace can be vented as a:

Non-direct vent (single pipe) central forced air furnace in which combustion air is taken from the installation area or from air ducted from the outside or,

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS

NOTE: Discharge static electricity accumulated in the body before touching the unit. An electrostatic discharge can adversely affect electrical components.

Use the following precautions during furnace installation and servicing to protect the integrated control module from damage. By putting the furnace, the control, and the person at the same electrostatic potential, these steps will help avoid exposing the integrated control module to electrostatic discharge. This procedure is applicable to both installed and non-installed (ungrounded) furnaces.

1.Disconnect all power to the furnace. Do not touch the integrated control module or any wire connected to the control prior to discharging your body’s electrostatic charge to ground.

2.Firmly touch a clean, unpainted, metal surface of the furnaces near the control. Any tools held in a person’s hand during grounding will be discharged.

3.Service integrated control module or connecting wiring following the discharge process in step 2. Use caution not to recharge your body with static electricity; (i.e., do not move

6

Direct vent (dual pipe) central forced air furnace in which all combustion air supplied directly to the furnace burners through a special air intake system outlined in these instructions.

This furnace may be used as a construction site heater ONLY if the following conditions are met:

•The vent system is permanently installed per these installation instructions.

•A room thermostat is used to control the furnace. Fixed jumpers that provide continuous heating CANNOT be used.

•Return air ducts are provided and sealed to the furnace.

•A return air temperature range between 60ºF (16ºC) and 80ºF (27ºC) is maintained.

•Air filters are installed in the system and maintained during construction, replaced as appropriate during construction, and upon completion of construction are replaced.

•The input rate and temperature rise are set per the furnace rating plate.

Downloaded from www.Manualslib.com manuals search engine

•100% outside air is provided for combustion air requirements during construction. Temporary ducting can be used.

NOTE: Do not connect the temporary duct directly to the furnace. The duct must be sized according to the instructions under Section V, Combustion and Ventilation Air Requirements, Section 5.3.3.

The rated heating capacity of the furnace should be greater than or equal to the total heat loss of the area to be heated. The total heat loss should be calculated by an approved method or in accordance with “ASHRAE Guide” or “Manual J-Load Calculations” published by the Air Conditioning Contractors of America.

IV. LOCATION REQUIREMENTS & CONSIDERATIONS

•The furnace heat exchanger, components, duct system, air filters and evaporator coils are thoroughly cleaned following final construction clean up.

•All furnace operating conditions (including ignition, input rate, temperature rise and venting) are verified according to these installation instructions.

NOTE: The Commonwealth of Massachusetts requires that the following additional requirements must also be met:

•Gas furnaces must be installed by a licensed plumber or gas fitter.

•A T-handle gas cock must be used.

•If the unit is to be installed in an attic, the passageway to and the service area around the unit must have flooring.

To ensure proper installation and operation, thoroughly read this manual for specifics pertaining to the installation and application of this product.

WARNING

WARNING

POSSIBLE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH DUE TO FIRE, EXPLOSION, SMOKE, SOOT, CONDENSATION, ELECTRICAL SHOCK OR CARBON MONOXIDE MAY RESULT FROM IMPROPER INSTALLATION, REPAIR, OPERATION, OR MAINTENANCE OF THIS PRODUCT.

WARNING

WARNING

TO PREVENT PERSONAL INJURY, PROPERTY DAMAGE OR DEATH DUE TO FIRE, DO NOT INSTALL THIS FURNACE IN A MOBILE HOME, TRAILER OR RECREATIONAL VEHICLE.

To ensure proper furnace operation, install, operate and maintain the furnace in accordance with these installation and operation instructions, all local building codes and ordinances. In their absence, follow the latest edition of the National Fuel Gas Code (NFPA 54/ANSI Z223.1), and/or CAN/CSA B149.1-05.1-05 Installation Codes, local plumbing or waste water codes, and other applicable codes.

A copy of the National Fuel Gas Code (NFPA 54/ANSI Z223.1) can be obtained from any of the following:

American National Standards Institute 1430 Broadway

New York, NY 10018

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Cleveland, OH 44131

A copy of the CAN/CSA B149.1-05.1-05 Installation Codes can also be obtained from:

CSA International

178 Rexdale Boulevard

Etobicoke, Ontario, Canada M9W 1R3

7

GENERAL

WARNING

WARNING

TO PREVENT POSSIBLE EQUIPMENT DAMAGE, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH, THE FOLLOWING BULLET POINTS MUST BE OBSERVED WHEN INSTALLING THE UNIT.

Follow the instructions listed below when selecting a furnace location. Refer also to the guidelines provided in Section V, Combustion and Ventilation Air Requirements.

•Centrally locate the furnace with respect to the proposed or existing air distribution system.

•Ensure the temperature of the return air entering the furnace is between 55°F and 100°F when the furnace is heating.

•Provide provisions for venting combustion products outdoors through a proper venting system. Special consideration should be given to vent/flue pipe routing and combustion air intake pipe when applicable. Refer to Section IX, Vent/Flue Pipe and Combustion Air Pipe - Termination Locations for appropriate termination locations and to determine if the piping system from furnace to termination can be accomplished within the guidelines given. NOTE: The length of flue and/or combustion air piping can be a limiting factor in the location of the furnace.

•Locate the furnace so condensate flows downwards to the drain. Do not locate the furnace or its condensate drainage system in any area subject to below freezing temperatures without proper freeze protection. Refer to

Section X, Condensate Drain Lines and Trap for further details.

•Ensure adequate combustion air is available for the furnace. Improper or insufficient combustion air can expose building occupants to gas combustion products that could include carbon monoxide. Refer to Section V, Combustion and Ventilation Air Requirements.

•Set the furnace on a level floor to enable proper condensate drainage. If the floor becomes wet or damp at times, place the furnace above the floor on a concrete base sized approximately 1-1/2" larger than the base of the furnace. Refer to the Section VII, Horizontal Applications and Considerations for leveling of horizontal furnaces.

•Ensure upflow or horizontal furnaces are not installed directly on carpeting, or any other combustible material. The only combustible material allowed is wood.

•A special accessory subbase must be used for upright counterflow unit installations over any combustible material (including wood). Refer to subbase instructions for installation details. (NOTE: A subbase will not be required if an air conditioning coil is located beneath the furnace between the supply air opening and the combustible floor.

Downloaded from www.Manualslib.com manuals search engine

•Exposure to contaminated combustion air will result in safety and performance-related problems. Do not install the furnace where the combustion air is exposed to the following substances:

chlorinated waxes or cleaners chlorine-based swimming pool chemicals water softening chemicals

deicing salts or chemicals carbon tetrachloride

A furnace installed in a confined space (i.e., a closet or utility room) must have two ventilation openings with a total minimum free area of 0.25 square inches per 1,000 BTU/hr of furnace input rating. Refer to the Specification Sheet applicable to your model for minimum clearances to combustible surfaces. One of the ventilation openings must be within 12 inches of the top; the other opening must be within 12 inches of the bottom of the confined space. In a typical construction, the clearance between the door and door frame is usually adequate to satisfy this ventilation requirement.

halogen type refrigerants

cleaning solutions (such as perchloroethylene) printing inks

paint removers varnishes hydrochloric acid cements and glues

antistatic fabric softeners for clothes dryers and masonry acid washing materials

•Seal off a non-direct vent furnace if it is installed near an area frequently contaminated by any of the above substances. This protects the non-direct vent furnace from airborne contaminants. To ensure that the enclosed non-direct vent furnace has an adequate supply of combustion air, vent from a nearby uncontaminated room or from outdoors. Refer to the Section V, Combustion and Ventilation Air Requirements for details.

•If the furnace is used in connection with a cooling unit, install the furnace upstream or in parallel with the cooling unit. Premature heat exchanger failure will result if the cooling unit is placed ahead of the furnace.

•If the furnace is installed in a residential garage, position the furnace so that the burners and ignition source are located not less than 18 inches (457 mm) above the floor. Protect the furnace from physical damage by vehicles.

•If the furnace is installed horizontally, the furnace access doors must be vertical so that the burners fire horizontally into the heat exchanger. Do not install the unit with the access doors on the “up/top” or “down/bottom” side of the furnace.

CLEARANCES AND ACCESSIBILITY

Installations must adhere to the clearances to combustible materials to which this furnace has been design certified. The minimum clearance information for this furnace is provided on the unit’s clearance label. These clearances must be permanently maintained. Clearances must also accommodate an installation’s gas, electrical, and drain trap and drain line connections. If the alternate vent/flue connection is used, additional clearance must be provided to accommodate these connections. Refer to Section IX, Vent Flue Pipe and Combustion Air Pipe for details. NOTE: In addition to the required clearances to combustible materials, a minimum of 24 inches service clearance must be available in front of the unit.

T O P

|

|

|

|

|

T O P |

|

S ID E |

S ID E |

|

S ID E |

|

|

|

|

|

|

||||

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

B O T TO M |

|

|

|

B O T TO M |

|

|

||

|

U pflow |

|

C ou nte rflo w |

H orizon tal |

||

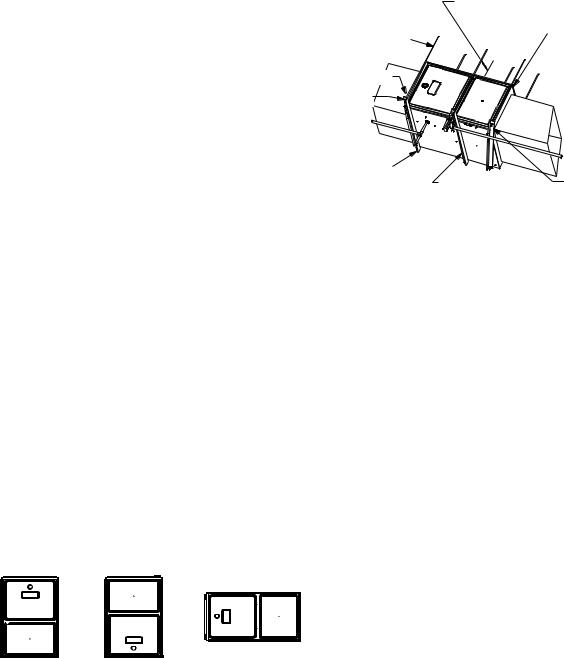

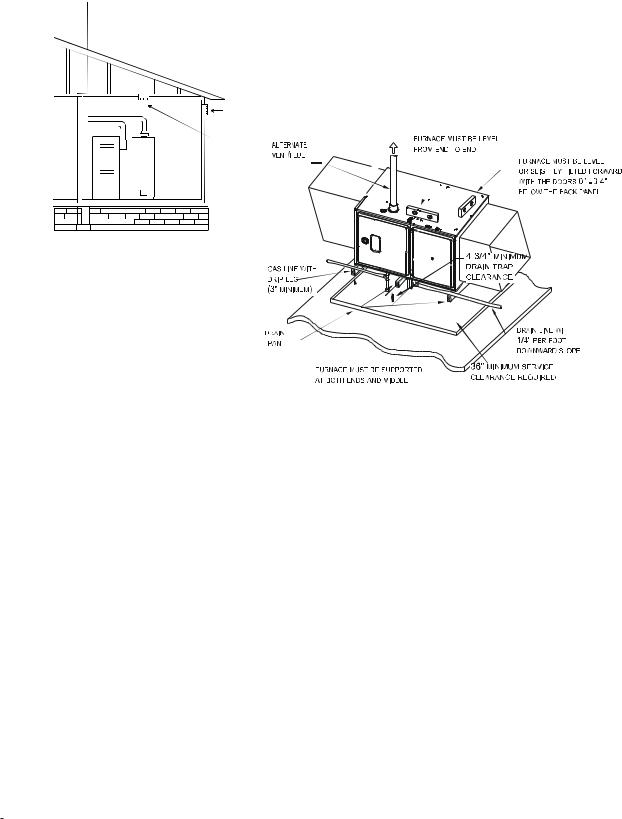

FURNACE SUSPENSION

If suspending the furnace from rafters or joists, use 3/8" threaded rod and 2”x2”x1/8” angle iron as shown below. The length of rod will depend on the application and the clearances necessary.

3/8" DIAMETER THREADED ROD

(6 PLACES)

HOLD DOWN

NUTS

SUPPORT

NUTS

PROVIDE 8" MINMUM CLEARANCE BETWEEN

CENTER ROD AND FURNACE CABINET

TO ALLOW FOR CIRCULATOR BLOWER REMOVAL

ASSURE FURNACE IS LEVEL FROM

END TO END AND HAS A SLIGHT

FORWARD TILT WITH THE FRONT

OF THE FURNACE 0"-3/4"

BELOW THE BACK OF THE FURNACE

2"X2"X1/8" ANGLE IRON |

|

|

(3 PLACES) |

POSITION AS CLOSE AS POSSIBLE |

TILT OUTWARD TO ALLOW FOR |

|

DOOR AND CIRCULATOR BLOWER |

|

|

TO BLOWER DECK TO ALLOW FOR |

|

|

REMOVAL |

|

|

CIRCULATOR BLOWER REMVOAL |

|

|

|

|

|

Suspended Furnace |

|

EXISTING FURNACE REMOVAL

NOTE: When an existing furnace is removed from a venting system serving other appliances, the venting system may be too large to properly vent the remaining attached appliances.

The following vent testing procedure is reproduced from the American

National Standard/National Standard of Canada for Gas-Fired Central Furnaces ANSI Z21.47-Latest Edition, CSA-2.3b--Latest Edition Section 1.23.1.

The following steps shall be followed with each appliance connected to the venting system placed in operation, while any other appliances connected to the venting system are not in operation:

a.Seal any unused openings in the venting system;

b.Inspect the venting system for proper size and horizontal pitch, as required by the National Fuel Gas Code, ANSI Z223.1 or the CSA B149.1-05.1-05 Installation Codes and these instructions. Determine that there is no blockage or restriction, leakage, corrosion and other deficiencies which could cause an unsafe condition;

c.In so far as practical, close all building doors and windows and all doors between the space in which the appliance(s) connected to the venting system are located and other spaces of the building. Turn on clothes dryers and any appliance not connected to the venting system. Turn on any exhaust fans, such as range hoods and bathroom exhausts, so they shall operate at maximum speed. Do not operate a summer exhaust fan. Close fireplace dampers;

d.Follow the lighting instructions. Place the appliance being inspected in operation. Adjust thermostat so appliance shall operate continuously;

*NOTE: Please contact your distributor or our website for the applicable Specification Sheet referred to in this manual. 8

Downloaded from www.Manualslib.com manuals search engine

e.Test for draft hood equipped spillage at the draft hood relief opening after 5 minutes of main burner operation. Use the flame of a match or candle;

f.After it has been determined that each appliance connected to the venting system properly vents when tested as outlined above, return doors, windows, exhaust fans, fireplace dampers and any other gas burning appliance to their previous conditions of use;

g.If improper venting is observed during any of the above tests, the common venting system must be corrected.

Corrections must be in accordance with the latest edition of the National Fuel Gas Code NFPA 54/ANSI Z223.1 and/or CSA B149.1- 05.1-05 Installation Codes.

If resizing is required on any portion of the venting system, use the appropriate table in Appendix G in the latest edition of the National Fuel Gas Code ANSI Z223.1 and/or CSA B149.1-05.1-05 Installation Codes.

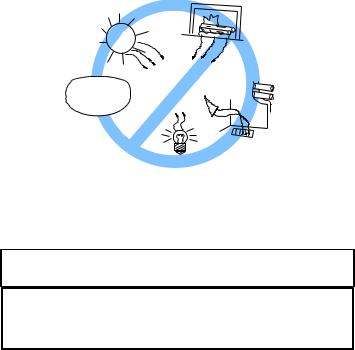

THERMOSTAT LOCATION

The thermostat should be placed approximately five feet from the floor on a vibration-free, inside wall in an area having good air circulation. Do not install the thermostat where it may be influenced by any of the following:

•Drafts, or dead spots behind doors, in corners, or under cabinets.

•Hot or cold air from registers.

•Radiant heat from the sun.

•Light fixtures or other appliances.

•Radiant heat from a fireplace.

•Concealed hot or cold water pipes, or chimneys.

•Unconditioned areas behind the thermostat, such as an outside wall.

DRAFTS OR DEAD SPOTS |

HOT |

-BEHIND DOORS |

COLD |

-IN CORNERS |

|

-UNDER CABINETS |

|

Thermostat Influences

Consult the instructions packaged with the thermostat for mounting instructions and further precautions.

V. COMBUSTION & VENTILATION AIR REQUIREMENTS

WARNING

WARNING

POSSIBLE PROPERTY DAMAGE PERSONAL INJURY OR DEATH MAY OCCUR IF THE FURNACE IS NOT PROVIDED WITH ENOUGH FRESH AIR FOR PROPER COMBUSTION AND VENTILATION OF FLUE GASES. MOST HOMES REQUIRE OUTSIDE AIR BE SUPPLIED TO THE FURNACE AREA.

Improved construction and additional insulation in buildings have reduced heat loss by reducing air infiltration and escape around doors and windows. These changes have helped in reducing heating/cooling costs but have created a problem supplying com-

bustion and ventilation air for gas fired and other fuel burning appliances. Appliances that pull air out of the house (clothes dryers, exhaust fans, fireplaces, etc.) increase the problem by starving appliances for air.

House depressurization can cause back drafting or improper combustion of gas-fired appliances, thereby exposing building occupants to gas combustion products that could include carbon monoxide.

If this furnace is to be installed in the same space with other gas appliances, such as a water heater, ensure there is an adequate supply of combustion and ventilation air for the other appliances. Refer to the latest edition of the National Fuel Gas Code NFPA 54/ ANSI Z223.1 (Section 5.3), or CSA B149.1-05 Installation Codes (Sections 7.2, 7.3, or 7.4), or applicable provisions of the local building codes for determining the combustion air requirements for the appliances.

Most homes will require outside air be supplied to the furnace area by means of ventilation grilles or ducts connecting directly to the outdoors or spaces open to the outdoors such as attics or crawl spaces.

The following information on air for combustion and ventilation is reproduced from the National Fuel Gas Code NFPA 54/ANSI Z223.1 Section

5.3.

5.3.1General:

(a)The provisions of 5.3 apply to gas utilization equipment installed in buildings and which require air for combustion, ventilation and dilution of flue gases from within the building. They do not apply to (1) direct vent equipment which is constructed and installed so that all air for combustion is obtained from the outside atmosphere and all flue gases are discharged to the outside atmosphere, or (2) enclosed furnaces which incorporate an integral total enclosure and use only outside air for combustion and dilution of flue gases.

(b)Equipment shall be installed in a location in which the facilities for ventilation permit satisfactory combustion of gas, proper venting and the maintenance of ambient temperature at safe limits under normal conditions of use. Equipment shall be located so as not to interfere with proper circulation of air. When normal infiltration does not provide the necessary air, outside air shall be introduced.

(c)In addition to air needed for combustion, process air shall be provided as required for: cooling of equipment or material, controlling dew point, heating, drying, oxidation or dilution, safety exhaust, odor control, and air for compressors.

(d)In addition to air needed for combustion, air shall be supplied for ventilation, including all air required for comfort and proper working conditions for personnel.

(e)While all forms of building construction cannot be covered in detail, air for combustion, ventilation and dilution of flue gases for gas utilization equipment vented by natural draft normally may be obtained by application of one of the methods covered in 5.3.3 and 5.3.4.

(f)Air requirements for the operation of exhaust fans, kitchen ventilation systems, clothes dryers, and fireplaces shall be considered in determining the adequacy of a space to provide combustion air requirements.

5.3.2Equipment Located in Unconfined Spaces:

In unconfined spaces (see definition below) in buildings, infiltration may be adequate to provide air for combustion ventilation and dilution of flue gases. However, in buildings of tight construction (for example, weather stripping, heavily insulated, caulked, vapor barrier, etc.), additional air may need to be provided using the methods described in 5.3.3- b or 5.3.4.

9

Downloaded from www.Manualslib.com manuals search engine

Space, Unconfined.

For purposes of this Code, a space whose volume is not less than 50 cubic feet per 1,000 BTU per hour of the aggregate input rating of all appliances installed in that space. Rooms communicating directly with the space in which the appliances are installed through openings not furnished with doors, are considered a part of the unconfined space.

5.3.3Equipment Located in Confined Spaces:

(a)All Air from Inside the Building: The confined space shall be provided with two permanent openings communicating directly with an additional room(s) of sufficient volume so that the combined volume of all spaces meets the criteria for an unconfined space. The total input of all gas utilization equipment installed in the combined space shall be considered in making this determination. Each opening shall have a minimum free area of 1 square inch per 1,000 BTU per hour of the total input rating of all gas utilization equipment in the confined space, but not less than 100 square inches. One opening shall be within 12 inches of the top and one within 12 inches of the bottom of the enclosure.

Chimney or Gas Vent

Chimney or Gas Vent

NOTE: Each opening must have a free area of not less than one square inch per 1000 BTU of

the total input rating of all equipment in the enclosure, but not less than 100 square inches.

Opening

Opening

Water

Furnace Heater

Opening

Opening

Equipment Located in Confined Spaces; All Air from Inside Building. See 5.3.3-a.

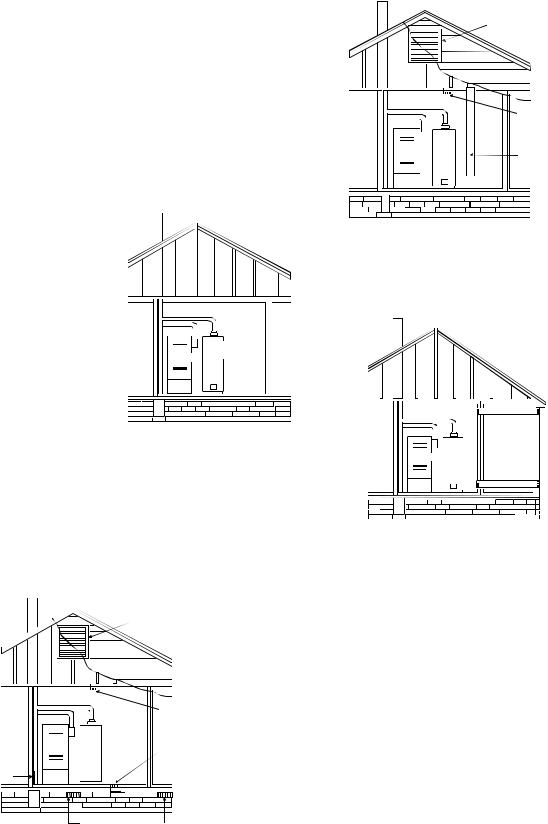

(b)All Air from Outdoors: The confined space shall be provided with two permanent openings, one commencing within 12 inches of the top and one commencing within 12 inches of the bottom of the enclosure. The openings shall communicate directly, or by ducts, with the outdoors or spaces (crawl or attic) that freely communicate with the outdoors.

1.When directly communicating with the outdoors, each opening shall have a minimum free area of 1 square inch per 4,000 BTU per hour of total input rating of all equipment in the enclosure.

Chimney or Gas Vent

Chimney or Gas Vent

Ventilation louvers (each end of attic)

NOTE: The inlet and outlet air openings must each have a free area of not less than one square inch per 4000 BTU of the

total input rating of all equipment in the enclosure.

|

|

|

|

|

Outlet Air |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Water |

|||

|

|

|

Heater |

|

|

|

Furnace |

Inlet Air |

|||||

|

|

|

||||

|

|

|

|

|

||

Alternate air inlet

Ventilation louvers for unheated crawl space

Equipment Located in Confined Spaces; All Air from Outdoors— Inlet Air from Ventilated Crawl Space and Outlet Air to Ventilated Attic. See 5.3.3-b

2.When communicating with the outdoors through vertical ducts, each opening shall have a minimum free area of 1 square inch per 4,000 BTU per hour of total input rating of all equipment in the enclosure.

Chimney or Gas Vent

Chimney or Gas Vent

Ventilation louvers (each end of attic)

NOTE: The inlet and outlet air openings must each have a free area of not less than one square inch per 4000 BTU of the

total input rating of all equipment in the enclosure.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Outlet Air |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Water |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Heater |

|

|

|

|

|

|

|

|

|

|

|

Furnace |

Inlet air duct |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[ends 1 ft (300 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

above floor] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Equipment Located in Confined Spaces; All Air from Outdoors Through Ventilated Attic. See 5.3.3-b.

3.When communicating with the outdoors through horizontal ducts, each opening shall have a minimum free area of 1 square inch per 2,000 BTU per hour of total input rating of all equipment in the enclosure.

Chimney or Gas Vent

Chimney or Gas Vent

|

NOTE: The air duct openings |

|

must have a free area of not |

|

less than one square inch per |

|

2000 BTU of the total input |

|

rating of all equipment in the |

Outlet air duct |

enclosure*. |

|

Water

Furnace Heater

Inlet air duct

*If the appliance room is located against an outside wall and the air openings communicate directly with the outdoors, each opening shall have a free area of not less than one square inch per 4,000 BTU per hour of the total input rating of all appliances in the enclosure.

Equipment Located in Confined Spaces; All Air from Outdoors. See 5.3.3-b.

4.When ducts are used, they shall be of the same cross-sectional area as the free area of the openings to which they connect. The minimum dimension of rectangular air ducts shall not be less than 3 inches.

10

Downloaded from www.Manualslib.com manuals search engine

NOTE: The single opening must have

a free area of not less than one  Chimney or Gas Vent square inch per 3000 BTU of

Chimney or Gas Vent square inch per 3000 BTU of

the total input rating of all equip-

ment in the enclosure, but not less than the sum of the areas of all vent connectors in the confined space.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Opening |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alternate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Water |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Opening |

|

|

|

|

|

|

|

|

|

|

|

|

Heater |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Location |

||

|

|

|

|

|

|

Furnace |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VII. HORIZONTALAPPLICATIONS & CONSIDERATIONS

GENERAL

Horizontal applications, in particular, may dictate many of the installation’s specifics such as airflow direction, ductwork connections, flue and combustion air pipe connections, etc. The basic application of this furnace as a horizontal furnace differs only slightly from an upright installation. When installing a furnace horizontally, additional consideration must be given to the following:

LOCATION

Equipment Located in Confined Spaces; All Air from Outdoors - Single Air Opening. See 5.3.3-b.

5.When directly communicating with the outdoors, the single opening shall have a minimum free area of 1 square inch per 3,000 BTU per hour of total input rating of all equipment in the enclosure.

5.3.4Specially Engineered Installations:

The requirements of 5.3.3 shall not necessarily govern when special engineering, approved by the authority having jurisdiction, provides an adequate supply of air for combustion, ventilation, and dilution of flue gases.

5.3.5 Louvers and Grilles:

In calculating free area in 5.3.3, consideration shall be given to the blocking effect of louvers, grilles or screens protecting openings. Screens used shall not be smaller than 1/4 inch mesh. If the area through a design of louver or grille is known, it should be used in calculating the size of opening required to provide the free area specified. If the design and free area is not known, it may be assumed that wood louvers will have 20-25 percent free area and metal louvers and grilles will have 60-75 percent free area. Louvers and grilles shall be fixed in the open position or interlocked with the equipment so that they are opened automatically during equipment operation.

5.3.6 Special Conditions Created by Mechanical Exhausting or Fireplaces:

Operation of exhaust fans, ventilation systems, clothes dryers, or fireplaces may create conditions requiring special attention to avoid unsatisfactory operation of installed gas utilization equipment. Air from Inside Building. See 5.3.3-a.

VI. INSTALLATION POSITIONS

This furnace may be installed in an upright position or horizontal on either the left or right side panel. Do not install this furnace on its back. For upright upflow furnaces, return air ductwork may be attached to the side panel(s) and/or basepan. For horizontal upflow furnaces, return air ductwork must be attached to the basepan. For both upright or horizontal counterflow furnaces, return ductwork must be attached to the basepan (top end of the blower compartment). NOTE: Ductwork must never be attached to the back of the furnace. For upflow installations requiring 1,800 CFM or more, use either two side returns or a bottom return or a combination of side and bottom. Contact your distributor for proper airflow requirements and number of required ductwork connections. Refer to “Recommended Installation Positions” figure for appropriate installation positions, ductwork connections, and resulting airflow arrangements.

Horizontal Furnace

DRAIN TRAP AND LINES

In horizontal applications the condensate drain trap is secured to the furnace side panel, suspending it below the furnace. A minimum clearance of 4 3/4 inches below the furnace must be provided for the drain trap. Additionally, the appropriate downward piping slope must be maintained from the drain trap to the drain location. Refer to Section X, Condensate Drain Trap and Lines for further details. If the drain trap and drain line will be exposed to temperatures near or below freezing, adequate measures must be taken to prevent condensate from freezing.

LEVELING

Leveling ensures proper condensate drainage from the heat exchanger and induced draft blower. For proper flue pipe drainage, the furnace must be level lengthwise from end to end. The furnace should also be level from back to front or have a slight tilt with the access doors downhill (approximately 3/4 inches) from the back panel. The slight tilt allows the heat exchanger condensate, generated in the recuperator coil, to flow forward to the recuperator coil front cover.

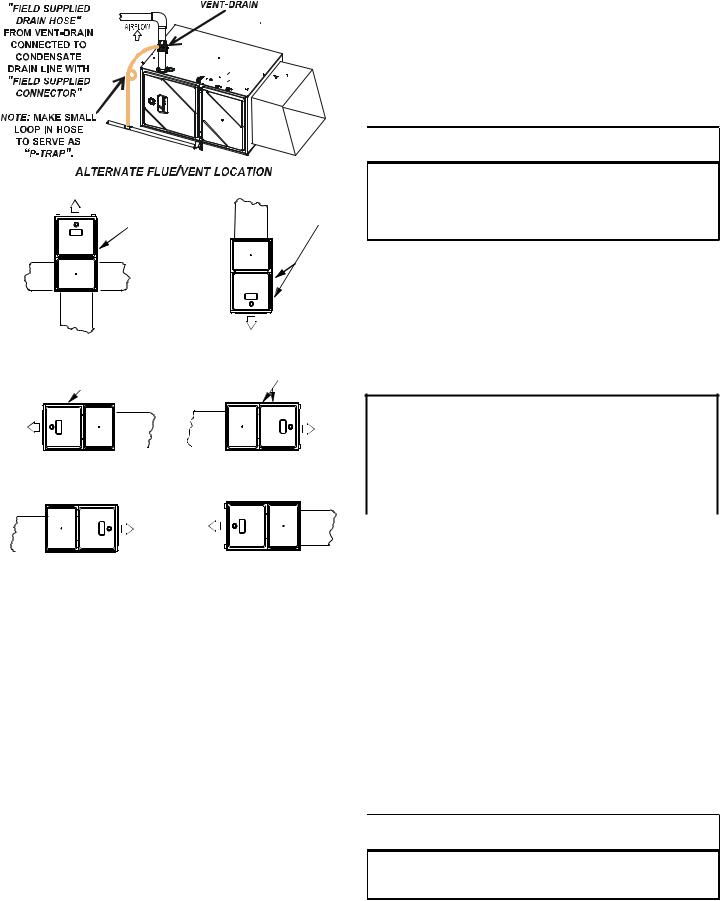

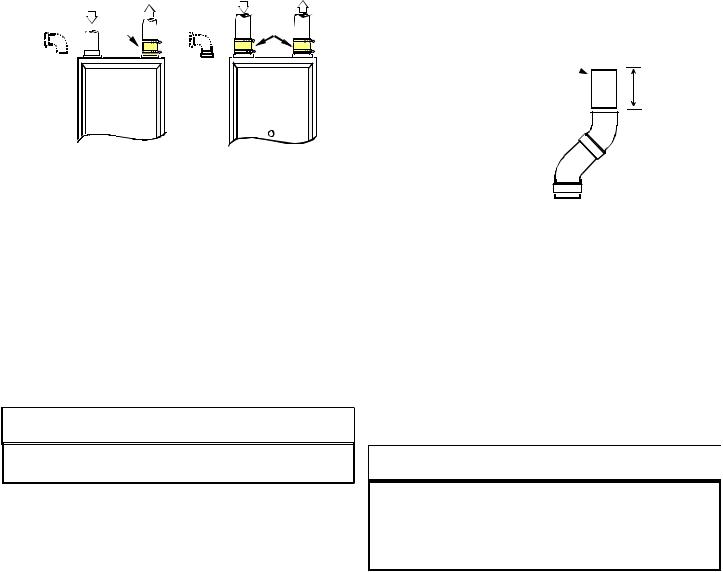

ALTERNATE VENT/FLUE AND COMBUSTION AIR CONNECTIONS

In horizontal installations, provisions for alternate vent/flue piping is available for upflow furnaces with left air discharge. Counterflow furnaces include provisions for both alternate vent/flue and combustion air piping with right air discharge. These configurations allow the flue and combustion air piping to be run vertically through the furnace. Refer to the “Recommended Installation Positions” figure for further detail. The standard piping connections may also be used in these positions. Refer to Section IX, Vent/Flue Pipe and Combustion Air Pipe for details concerning the conversion to the alternate vent/flue air connections.

When using the horizontal alternate vent configuration, you must use the RF000142 vent drain kit. See following illustration.

11

Downloaded from www.Manualslib.com manuals search engine

AIR |

|

|

Bottom |

ALTERNATE FLUE AND |

DISCHARGE |

|

|||

|

COMBUSTION AIR PIPE |

|||

|

ALTERNATE FLUE PIPE |

|

Return |

|

|

|

LOCATIONS |

||

|

LOCATION |

|

Duct |

|

|

|

|

||

|

|

|

Connection |

|

Side |

Side |

|

|

|

Return |

Return |

|

|

|

Duct |

Duct |

|

|

|

Connection |

Connection |

|

|

|

|

Bottom |

|

|

|

|

Return |

|

|

|

|

Duct |

|

|

AIR |

|

Connection |

|

|

|

|

|

DISCHARGE |

||

|

|

|

||

|

UPFLOW |

COUNTERFLOW |

||

|

UPRIGHT |

|

UPRIGHT |

|

|

|

|

|

ALTERNATE FLUE AND |

|

ALTERNATE FLUE |

|

|

COMBUSTION AIR PIPE |

|

|

|

LOCATIONS |

|

|

PIPE LOCATION |

|

|

|

|

Bottom |

Bottom |

|

|

|

Return |

Return |

|

AIR |

AIR |

Duct |

Duct |

|

|

|

DISCHARGE |

|||

DISCHARGE |

Connection |

Connection |

|

|

|

|

|||

UPFLOW HORIZONTAL |

COUNTERFLOW HORIZONTAL |

|||

LEFT AIR DISCHARGE |

RIGHT AIR DISCHARGE |

|||

|

|

|

|

Bottom |

Bottom |

|

|

|

Return |

Return |

AIR |

AIR |

|

Duct |

Duct |

|

Connection |

||

Connection |

DISCHARGE |

DISCHARGE |

|

|

UPFLOW HORIZONTAL |

COUNTERFLOW HORIZONTAL |

|

LEFT AIR DISCHARGE |

||

RIGHT AIR DISCHARGE |

||

|

Recommended Installation Positions

NOTE: Alternate “vertical” piping connections can not be used when an upflow furnace is installed with supply air discharging to the right, or when a counterflow furnace is installed with supply air discharging to the left. In either case, use the standard flue and combustion air piping connections.

ALTERNATE ELECTRICAL AND GAS LINE CONNECTIONS

This furnace has provisions allowing for electrical and gas line connections through either side panel. In horizontal applications the connections can be made either through the “top” or “bottom” of the furnace.

DRAIN PAN

A drain pan must be provided if the furnace is installed above a conditioned area. The drain pan must cover the entire area under the furnace (and air conditioning coil if applicable).

FREEZE PROTECTION

Refer to Section VII, Horizontal Applications and Conditions - Drain Trap and Lines.

FURNACE SUSPENSION

If the furnace is installed in a crawl space it must be suspended from the floor joist or supported by a concrete pad. Never install the furnace on the ground or allow it to be exposed to water. Refer to

Section IV, Location Requirements and Considerations - Furnace Suspension for further details.

VIII. PROPANE GAS /HIGH ALTITUDE INSTALLATIONS

WARNING

WARNING

POSSIBLE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH MAY OCCUR IF THE CORRECT CONVERSION KITS ARE NOT INSTALLED. THE APPROPRIATE KITS MUST BE APPLIED TO ENSURE SAFE AND PROPER FURNACE OPERATION. ALL CONVERSIONS MUST BE PERFORMED BY A QUALIFIED INSTALLER OR SERVICE AGENCY.

This furnace is shipped from the factory configured for natural gas at standard altitude. Propane gas installations require an orifice change to compensate for the energy content difference between natural and propane gas.

High altitude installations may require both a pressure switch and an orifice change. These changes are necessary to compensate for the natural reduction in the density of both the gas fuel and the combustion air at higher altitude.

For installations above 7000 feet, please refer to your distributor for required kit(s).

GMH95, GCH95, GCH9 GAS ORIFICE CHART

Altitude |

|

Gas |

|

|

Kit |

|

Orifice |

Manifold |

Pressure |

|

|

|

|

Pressure |

Switch |

||||

|

|

|

|

|

|

|

|

||

|

|

Natural |

|

|

None |

#43 |

3.5" w.c. |

|

|

0-7000 |

|

|

|

|

|

|

|

|

None |

|

Propane |

|

|

LPM-05*1 |

#55 |

10.0" w.c. |

|||

|

|

|

|

|

|||||

|

|

|

|

LPM-06*2 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

GME95 GAS ORIFICE CHART |

|

|||||

Altitude |

|

Gas |

|

|

Kit |

|

Orifice |

Manifold |

Pressure |

|

|

|

|

Pressure |

Switch |

||||

|

|

|

|

|

|

|

|

||

|

|

Natural |

|

|

None |

|

#45 |

3.5" w.c. |

|

0-7000 |

|

|

|

|

|

|

|

|

None |

|

Propane |

|

|

LPM-06*2 |

|

#55 |

10.0" w.c. |

||

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

1LPM-05* supports White-Rodgers 2-stage valve only

2LPM-06* supports both Honeywell and White-Rodgers 2-stage valves NOTE: In Canada, gas furnaces are certified to 4500 feet.

Contact the distributor for a tabular listing of appropriate manufacturer’s kits for propane gas and/or high altitude installations. The indicated kits must be used to insure safe and proper furnace operation. All conversions must be performed by a qualified installer, or service agency.

IX. VENT/FLUE PIPE & COMBUSTION AIR PIPE

GENERAL

WARNING

WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN BODILY INJURY OR DEATH. CAREFULLY READ AND FOLLOW ALL INSTRUCTIONS GIVEN IN THIS SECTION.

12

Downloaded from www.Manualslib.com manuals search engine

WARNING

WARNING

UPON COMPLETION OF THE FURNACE INSTALLATION, CAREFULLY INSPECT THE ENTIRE FLUE SYSTEM BOTH INSIDE AND OUTSIDE OF THE FURNACE TO ASSURE IT IS PROPERLY SEALED. LEAKS IN THE FLUE SYSTEM CAN RESULT IN SERIOUS PERSONAL INJURY OR DEATH DUE TO EXPOSURE TO FLUE PRODUCTS, INCLUDING CARBON MONOXIDE.

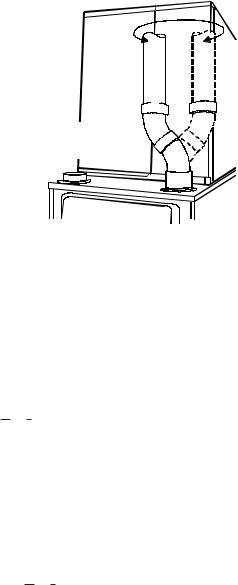

A condensing gas furnace achieves its high level of efficiency by extracting almost all of the heat from the products of combustion and cooling them to the point where condensation takes place. Because of the relatively low flue gas temperature and water condensation requirements, PVC pipe is used as venting material.

This furnace must not be connected to Type B, BW, or L vent or vent connector, and must not be vented into any portion of a factory built or masonry chimney except when used as a pathway for PVC as described later in this section. Never common vent this appliance with another appliance or use a vent which is used by a solid fuel appliance. Do not use commercially available “no hub connectors” other than those shipped with this product.

It is the responsibility of the installer to follow the manufacturers’ recommendations and to verify that all vent/flue piping and connectors are compatible with furnace flue products. Additionally, it is the responsibility of the installer to ensure that all piping and connections possess adequate structural integrity and support to prevent flue pipe separation, shifting, or sagging during furnace operation.

DUAL CERTIFICATION:NON-DIRECT/DIRECT VENT

This furnace is dual certified and may be installed as a non-direct vent (single pipe) or direct vent (dual pipe) appliance. A non-direct vent installation requires only a vent/flue pipe, while a direct vent installation requires both a vent/flue pipe and a combustion air intake pipe. Refer to the appropriate section for details concerning piping size, length, number of elbows, furnace connections, and terminations.

MATERIALS AND JOINING METHODS

WARNING

WARNING

TO AVOID BODILY INJURY, FIRE OR EXPLOSION, SOLVENT CEMENTS MUST BE KEPT AWAY FROM ALL IGNITION SOURCES (I.E., SPARKS, OPEN FLAMES, AND EXCESSIVE HEAT) AS THEY ARE COMBUSTIBLE LIQUIDS. AVOID BREATHING CEMENT VAPORS OR CONTACT WITH SKIN AND/OR EYES.

As an alternative to PVC pipe, primer, solvent cement, and fittings, ABS materials which are in compliance with the following specifications may be used. Two-or-three-inch ABS Schedule 40 pipe must meet ASTM D1527 and, if used in Canada, must be CSA listed. Solvent cement for ABS to ABS joints must meet ASTM D2235 and, if used in Canada, must be CSA listed. The solvent cement for the PVC to ABS transition joint must meet ASTM D3138. Fittings must be DWV type fittings meeting ASTM D2661 and ASTM D3311 and, if used in Canada, must be CSA listed. Carefully follow the pipe manufacturers’ instructions for cutting, cleaning, and solvent cementing PVC and/or ABS.

All 90° elbows must be medium radius (1/4 bend DWV) or long radius (Long sweep 1/4 bend DWV) types conforming to ASTM D3311. A medium radius (1/4 bend DWV) elbow measures 3 1/ 16” minimum from the plane of one opening to the centerline of the other opening for 2” diameter pipe, and 4 9/16” minimum for 3” pipe.

PROPER VENT/FLUE AND COMBUSTION AIR PIPING PRACTICES

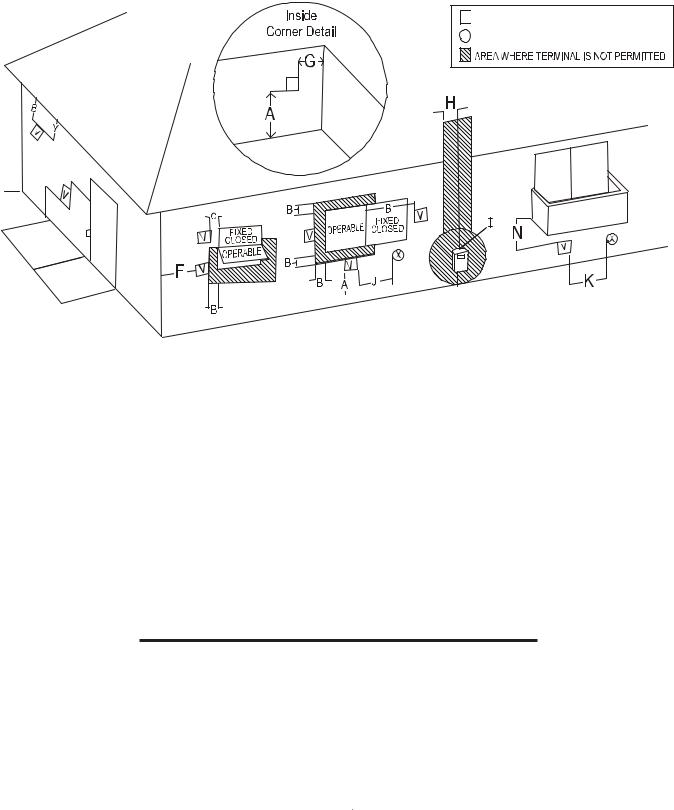

Adhere to these instructions to ensure safe and proper furnace performance. The length, diameter, and number of elbows of the vent/flue pipe and combustion air pipe (when applicable) affects the performance of the furnace and must be carefully sized. All piping must be installed in accordance with local codes and these instructions.

Piping must be adequately secured and supported to prohibit sagging, joint separation, and/or detachment from the furnace. Horizontal runs of vent/flue piping must be supported every three to five feet and must maintain a 1/4 inch per foot downward slope, back towards the furnace, to properly return condensate to the furnace’s drain system. Allowances should be made for minor expansion and contraction due to temperature variations. For this reason, particular care must be taken to secure piping when a long run is followed by a short offset of less than 40 inches.