Goodman Mfg GMV95, GCV9 User Manual

PRODUCT SPECIFICATIONS

Applies to 95% furnaces only.

GMV95: UP TO 95% AFUE GCV9: UP TO 93% AFUE

HEATING INPUT: 46,000–115,000 BTU/H

*To receive the Lifetime Heat Exchanger Limited Warranty, 10-Year Unit Replacement Limited Warranty and 10-Year Parts Limited Warranty, online registration must be completed within 60 days of installation. Online registration is not required in California or Québec. Full warranty details available at www.goodmanmfg.com.

GMV95/GCV9

MULTI-POSITION,

TWO-STAGE/VARIABLE-SPEED

GAS FURNACE

The Goodman® brand GMV95/ GCV9 Two-Stage, VariableSpeed Gas Furnaces feature a patented aluminized-steel tubular heat exchanger and durable Silicon Nitride Hot Surface Ignition system.

Standard Features

•Patented TuffTube™ dual-diameter tubular heat exchanger with Lifetime Limited Warranty* for as long as the original registered homeowner owns their home plus 10-Year Limited Unit Replacement Warranty*

•Two-stage gas valve operates with two-stage or singlestage thermostats

•Efficient and quiet variable-speed circulator motor gently ramps up or down according to heating or cooling demand

•110V Silicon Nitride igniter designed for long igniter life

•Furnace control board with self-diagnostics, color-coded lowvoltage terminals, and provisions for electronic air cleaner and 120-volt or 24-volt humidifiers

•Low constant fan allows homeowner to activate very low speed to efficiently circulate air throughout the home. This setting costs as little as a 100-watt light bulb to operate.

•Dual-certified for sealed combustion direct vent (2-pipe) or non-direct vent (1-pipe) applications

•Quiet two-speed induced draft blower

•All models comply with California NOx emissions standards

Cabinet Features

•Fully insulated, heavy-gauge steel cabinet with durable baked-enamel finish

•Foil-faced insulation lines the heat exchanger

•Easy-to-install top venting is standard; alternate flue/vent located on the right (GMV95)

•Designed for multi-position installation – GMV95: upflow, horizontal left or right; GCV9: downflow, horizontal left or right

•Airtight solid bottom for side return applications and easy-cut tabs for effortless removal in bottom air inlet applications

•Convenient left or right connection for gas and electric service

•Coil and furnace fit flush for most installations

Contents |

|

Nomenclature ................................................................................................ |

2 |

Product Specifications ................................................................................ |

3 |

Dimensions ..................................................................................................... |

4 |

Blower Performance Specifications........................................................ |

7 |

Wiring Diagrams......................................................................................... |

13 |

Accessories................................................................................................... |

15 |

SS-GMV95 |

www.goodmanmfg.com |

6/09 |

|

|

Supersedes 3/09 |

|

|

|

SPECIFICATIONS

NOMENCLATURE

|

G |

M |

V |

95 |

70 |

4 |

B |

X |

A |

|

|

1 |

2 |

3 |

4,5 |

6,7,8 |

9 |

10 |

11 |

12 |

|

Brand |

|

|

|

|

|

|

|

|

Revisions |

|

G |

Goodman® Brand |

|

|

|

|

|

|

|

A |

Initial Release |

|

or Distinctions™ |

|

|

|

|

|

|

|

B |

1st Revision |

|

|

|

|

|

|

|

|

|

C |

2nd Revision |

Airflow Direction |

|

|

|

|

|

|

|

|

|

|

C |

Downflow/Horizontal |

|

|

|

|

|

|

|

|

|

D |

Dedicated Downflow |

|

|

|

|

|

|

|

|

NOx |

H |

High Airflow |

|

|

|

|

|

|

|

N |

Natural Gas |

K |

Dedicated Upflow |

|

|

|

|

|

|

|

X |

Low NOx |

M |

Upflow/Horizontal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cabinet Width |

Description |

|

|

|

|

|

|

|

A |

14” |

|

V |

Two-Stage/Variable-speed |

|

|

|

|

|

|

B |

17½” |

|

H |

Two-Stage/Multi-speed |

|

|

|

|

|

|

|

C |

21” |

S |

Single-Stage/Multi-speed |

|

|

|

|

|

|

D |

24½” |

|

E |

Two-Stage/X-13 Motor |

|

|

|

|

|

|

|

|

|

AFUE |

|

|

|

|

|

|

|

Maximum CFM @ 0.5” ESP |

||

95 |

95% |

|

|

|

|

|

|

|

3 |

1,200 |

9 |

90%+ |

|

|

|

|

|

|

|

4 |

1,600 |

8 |

80% |

|

|

|

|

|

|

|

5 |

2,000 |

|

|

|

|

|

MBTU/h |

|

|

|

|

|

|

|

|

045: 45,000 |

115: 115,000 |

|

|

|

|||

|

|

|

070: 70,000 |

140: 140,000 |

|

|

|

|||

|

|

|

090: 90,000 |

|

|

|

|

|

|

|

Important EnergyStar Notice: EnergyStar ratings are dependent upon conditions beyond equipment installation. Proper sizing and installation of equipment is critical to achieve optimal performance. Split system air conditioners and heat pumps must be matched with appropriate coil components to meet EnergyStar criteria. Ask your contractor for details or visit www.energystar.gov.

2 |

www.goodmanmfg.com |

SS-GMV95 |

|

|

|

PRODUCT S

SPECIFICATIONS

|

GMV95 |

GMV95 |

GMV95 |

GMV95- |

GCV9 |

GCV9 |

GCV9 |

|

0453BXB |

0704CXB |

0905DXB |

1155DXB |

0704CXB |

0905DXB |

1155DXA |

Heating Capacity |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

High Fire Input¹ |

46,000 |

69,000 |

92,000 |

115,000 |

69,000 |

92,000 |

115,000 |

|

|

|

|

|

|

|

|

High Fire Output¹ |

45,000 |

67,000 |

90,000 |

109,000 |

65,000 |

87,000 |

109,000 |

|

|

|

|

|

|

|

|

Low Fire Input¹ |

32,000 |

48,000 |

64,000 |

80,000 |

48,000 |

64,000 |

80,000 |

|

|

|

|

|

|

|

|

Low Fire Output¹ |

30,800 |

46,400 |

61,700 |

77,400 |

45,000 |

60,100 |

77,400 |

|

|

|

|

|

|

|

|

AFUE² |

95 |

95 |

95 |

95 |

93 |

93 |

93 |

|

|

|

|

|

|

|

|

Tons AC @ 0.5” ESP |

1.5 - 3.0 |

1.5 - 4.0 |

2.0 - 5.0 |

2.0 - 5.0 |

1.5 - 4.0 |

2.0 - 5.0 |

2.0 - 5.0 |

|

|

|

|

|

|

|

|

Temperature Rise Range (°F) |

30 - 60 |

30 - 60 |

30 - 60 |

30 - 60 |

30 - 60 |

30 - 60 |

40-70 |

|

|

|

|

|

|

|

|

Circulator Blower |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Size (D x W) |

10” X 7” |

10” X 10” |

11” X 10” |

11” X 10” |

10” x 10” |

11” X 10” |

11” X 10” |

|

|

|

|

|

|

|

|

Horespower @ 1750 RPM |

½ |

¾ |

1 |

1 |

¾ |

1 |

1 |

|

|

|

|

|

|

|

|

Speed |

|

Variable |

|

|

Variable |

|

|

|

|

|

|

|

|

|

|

Vent Diameter³ |

2” |

2” |

3” |

3” |

2” |

3” |

3” |

|

|

|

|

|

|

|

|

No. of Burners |

2 |

3 |

4 |

5 |

3 |

4 |

5 |

|

|

|

|

|

|

|

|

Filter Size (in²) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Disposable |

288 |

384 |

480 |

486 |

384 |

480 |

486 |

|

|

|

|

|

|

|

|

Permanent |

576 |

768 |

960 |

972 |

768 |

960 |

972 |

|

|

|

|

|

|

|

|

Electrical Data |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Min. Circuit Ampacity (amps)4 |

10.4 |

12.8 |

14.6 |

14.6 |

12.8 |

14.6 |

14.6 |

Max. Overcurrent Protection5 |

15 amps |

15 amps |

15 amps |

15 amps |

15 amps |

15 amps |

15 amps |

Ship Weight (lbs) |

133 |

135 |

172 |

175 |

135 |

172 |

175 |

|

|

|

|

|

|

|

|

1– Natural Gas BTU/h

2– DOE AFUE based upon Isolated Combustion System (ICS)

3– Installer must supply one or two PVC pipes: one for combustion air (optional) and one for the flue outlet (required). Vent pipe must be either 2” or 3” in diameter, depending upon furnace input, number of elbows, length of run and installation (1 or 2 pipes). The optional Combustion Air Pipe is dependent on installation/code requirements and must be 2” or 3” diameter PVC.

4– Minimum Circuit Ampacity = (1.25 x Circulator Blower Amps) + ID Blower amps. Wire size should be determined in accordance with National Electrical Codes. Extensive wire runs will require larger wire sizes.

5– Maximum Overcurrent Protection Device refers to maximum recommended fuse or circuit breaker size. May use fuses or HACR-type circuit breakers of the same size as noted.

Notes:

•All furnaces are manufactured for use on 115 VAC, 60 Hz, single-phase electrical supply.

•Gas Service Connection ½” FPT

•Important: Size fuses and wires properly and make electrical connections in accordance with the National Electrical Code and/or all existing local codes.

SS-GMV95 |

www.goodmanmfg.com |

3 |

|

|

|

SPECIFICATIONS

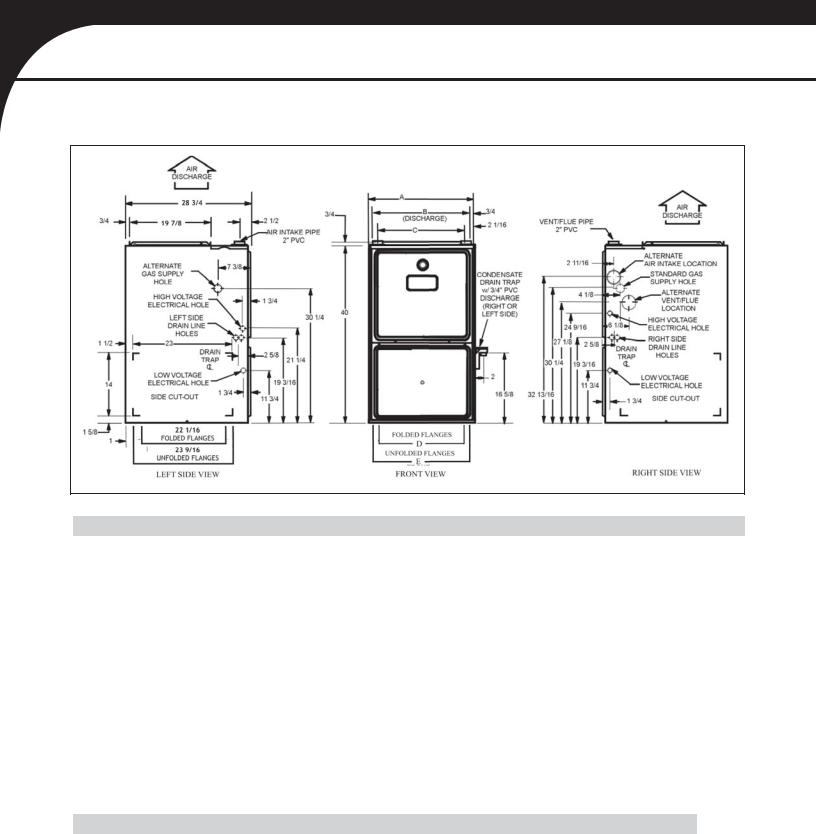

GMV95 DIMENSIONS

Model |

A |

B |

C |

D |

E |

GMV950453BXB |

17½” |

16” |

13⅛” |

12⅛” |

13⅝” |

GMV950704CXB |

21” |

19½” |

16⅛” |

16 |

17½” |

GMV950905DXB |

24½” |

23” |

20⅝” |

19⅜” |

20⅞” |

GMV951155DXB |

24½” |

23” |

20⅝” |

19⅜” |

20⅞” |

Notes:

•Installer must supply one or two PVC pipes: one for combustion air (optional) and one for the flue outlet (required). Vent pipe must be either 2” or 3” in diameter, depending upon furnace input, number of elbows, length of run and installation

(1 or 2 pipes). The optional Combustion Air Pipe is dependent on installation/code requirements and must be 2” or 3” diameter PVC.

•Line voltage wiring can enter through the right or left side of the furnace. Low-voltage wiring can enter through the right or left side of furnace.

•Conversion kits for high-altitude natural gas operation are available. Contact your Goodman distributor or dealer for details.

•Installer must supply following gas line fittings, according to which entrance is used:

Left—Two 90º elbows, one close nipple, straight pipe

Right—Straight pipe to reach gas valve

•For bottom return: Failure to unfold flanges may reduce airflow by up to 18%. This could result in performance and noise issues.

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS

Position |

Sides |

Rear |

Front |

Bottom |

Flue |

Top |

Upflow |

0” |

0” |

3” |

C |

0” |

1” |

Horizontal |

6” |

0” |

3” |

C |

0” |

6” |

C = If placed on combustible floor, the floor MUST be wood ONLY.

Notes:

•For servicing or cleaning, a 24” front clearance is required.

•Unit connections (electrical, flue and drain) may necessitate greater clearances than the minimum clearances listed above.

•In all cases, accessibility clearance must take precedence over clearances from the enclosure where accessibility clearances are greater.

4 |

www.goodmanmfg.com |

SS-GMV95 |

|

|

|

PRODUCT S

GCV9 DIMENSIONS

FOLDED FLANGES

FOLDED FLANGES

UNFOLDED FLANGES

UNFOLDED FLANGES

Model |

A |

B |

C |

D |

E |

|

|

|

|

|

|

GCV90704CXB |

21” |

19½” |

16⅛” |

18” |

19½” |

|

|

|

|

|

|

GCV90905DXB |

24½” |

23” |

20⅝” |

21½” |

23” |

|

|

|

|

|

|

GCV91155DXB |

24½” |

23” |

20⅝” |

21½” |

23” |

|

|

|

|

|

|

Notes:

•Installer must supply one or two PVC pipes: one for combustion air (optional) and one for the flue outlet (required). Vent pipe must be either 2” or 3” in diameter, depending upon furnace input, number of elbows, length of run, and installation (1 or 2 pipes). The optional Combustion Air Pipe is dependent on installation/code requirements and must be 2” or 3” diameter PVC.

•Line voltage wiring can enter through the right or left side of the furnace. Low-voltage wiring can enter through the right or left side of furnace.

•Conversion kits for high-altitude natural gas operation are available. Contact your Goodman distributor or dealer for details.

•Installer must supply following gas line fittings, according to which entrance is used: Left—Two 90º Elbows, one close nipple, straight pipe

Right—Straight pipe to reach gas valve

•For bottom return: Failure to unfold flanges may reduce airflow by up to 18%. This could result in performance and noise issues.

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS

Position |

Sides |

Rear |

Front |

Bottom |

Flue |

Top |

Downflow |

0” |

0” |

3” |

NC |

0” |

1” |

Horizontal |

6” |

0” |

3” |

C |

0” |

6” |

C = If placed on combustible floor, the floor MUST be wood ONLY.

NC = For installation on non-combustible floors only. A combustible floor sub-base must be used for installations on combustible flooring.

Notes:

•For servicing or cleaning, a 24” front clearance is required.

•Unit connections (electrical, flue and drain) may necessitate greater clearances than the minimum clearances listed above.

•In all cases, accessibility clearance must take precedence over clearances from the enclosure where accessibility clearances are greater.

SS-GMV95 |

www.goodmanmfg.com |

5 |

|

|

|

Loading...

Loading...