Genie Z-45 User Manual

Second Edition

Second Printing

Part No. 82600

Operator’s Manual

with Maintenance Information

Bi-Energy PowerIC Power

Genie Z-45/25 & Genie Z-45/25J Part No. 82600

Operator's Manual Second Edition · Second Printing

Copyright © 1998 by Genie Industries

First Edition: Seventh Printing, May 2002

Second Edition: Second Printing, August 2004

"Genie" and "Z" are registered trademarks of

Genie Industries in the U.S.A. and many other

countries.

These machines comply with

ANSI/SIA 92.5-1992.

Printed on recycled paper

Printed in U.S.A.

Important

Read, understand and obey these safety rules and

operating instructions before operating this machine.

Only trained and authorized personnel shall be

permitted to operate this machine. This manual should

be considered a permanent part of your machine and

should remain with the machine at all times. If you

have any questions, call Genie Industries.

Contents

Page

Safety ........................................................................ 1

Controls ..................................................................... 7

Pre-operation Inspection........................................... 10

Maintenance............................................................. 12

Function Tests.......................................................... 16

Workplace Inspection................................................ 23

Operating Instructions............................................... 24

Transport and Lifting Instructions .............................. 29

Decals ...................................................................... 32

Specifications ........................................................... 36

Contact us:

Internet: http://www.genielift.com

E-mail: techpub@genieind.com

Part No. 82600 Genie Z-45/25 & Genie Z-45/25J 1

Operator's ManualSecond Edition · Second Printing

Safety Rules

Danger

Failure to obey the instructions and

safety rules in this manual will result

in death or serious injury.

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator's

manual.

1 Avoid hazardous situations.

Know and understand the safety rules before

going on to the next section.

2 Always perform a pre-operation inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

You read, understand and obey the

manufacturer's instructions and safety rules—

safety and operator's manuals and machine

decals.

You read, understand and obey employer's

safety rules and worksite regulations.

You read, understand and obey all applicable

governmental regulations.

You are properly trained to safely operate the

machine.

2 Genie Z-45/25 & Genie Z-45/25J Part No. 82600

Operator's Manual Second Edition · Second Printing

SAFETY RULES

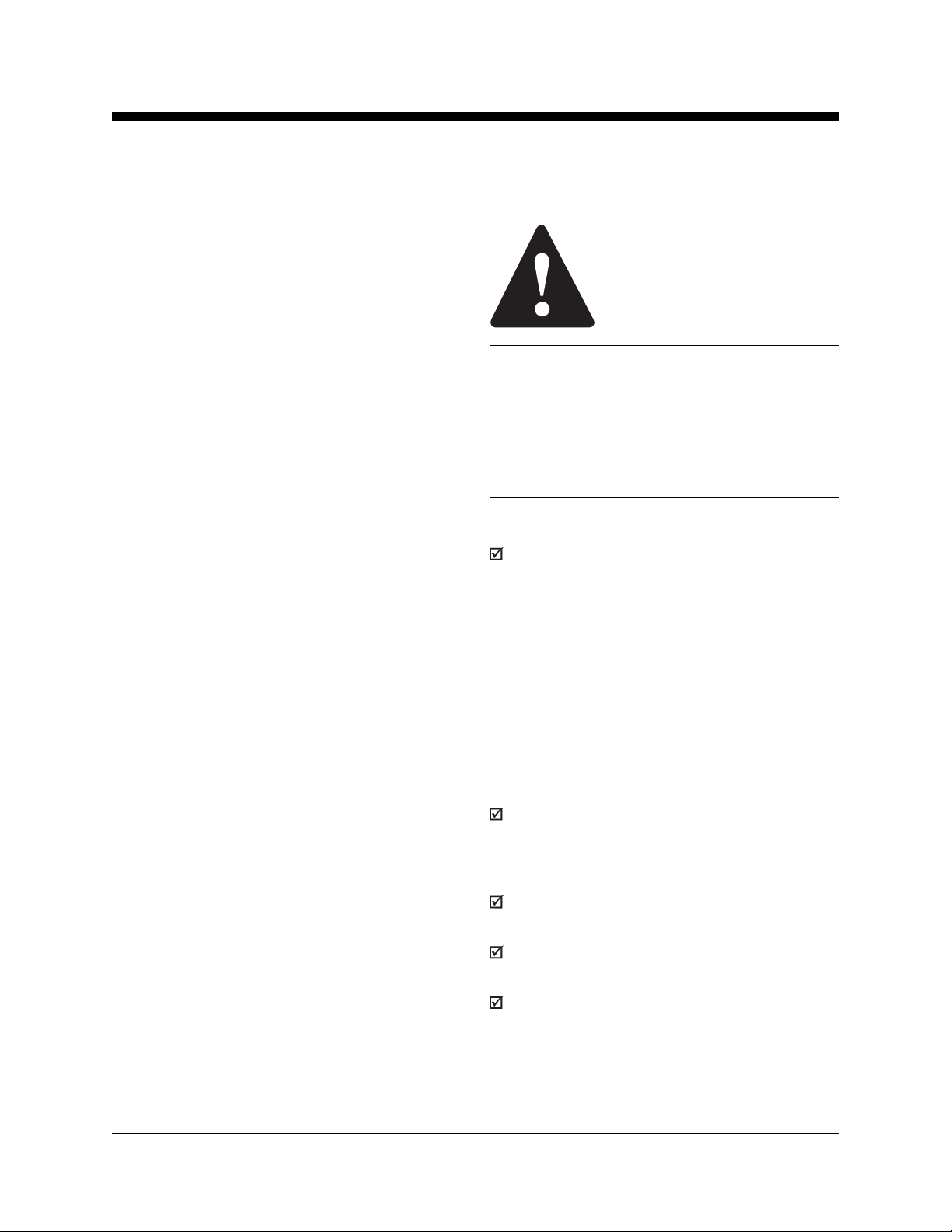

Electrocution Hazards

This machine is not electrically insulated and will

not provide protection from contact with or

proximity to electrical current.

Maintain safe distances from electrical power lines

and apparatus in accordance with applicable

governmental regulations and the following chart.

Voltage Minimum Safe

Phase to Phase Approach Distance

Feet Meters

0 to 300V Avoid Contact

300V to 50KV 10 3.1

50KV to 200KV 15 4.6

200KV to 350KV 20 6.1

350KV to 500KV 25 7.6

500KV to 750KV 35 10.7

750KV to 1000KV 45 13.7

Allow for platform movement, electrical line sway or

sag and beware of strong or gusty winds.

Keep away from the machine if it contacts

energized power lines. Personnel on the ground or

in the platform must not touch or operate the

machine until energized power lines are shut off.

Do not use the machine as a ground for welding.

Do not operate the machine during lightning or

storms.

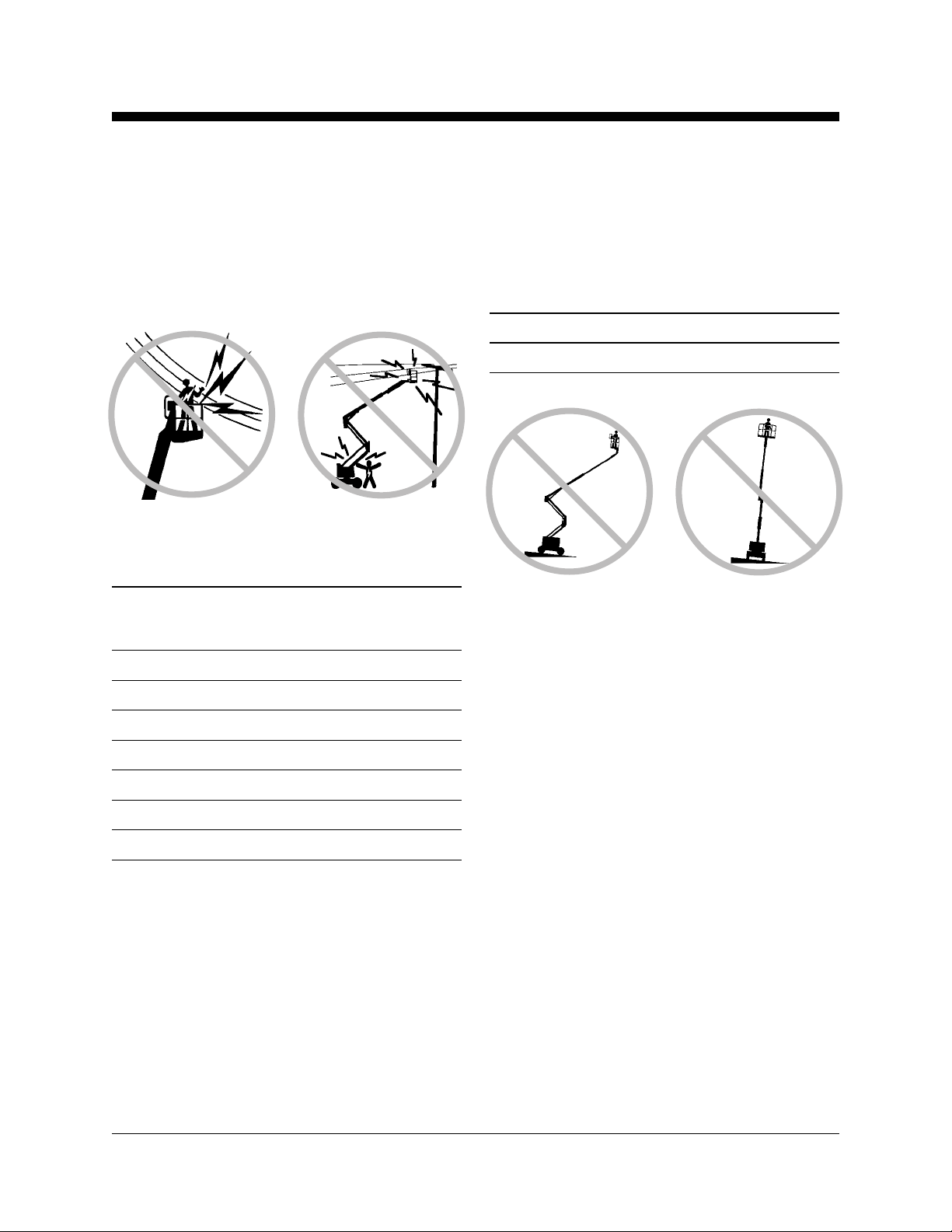

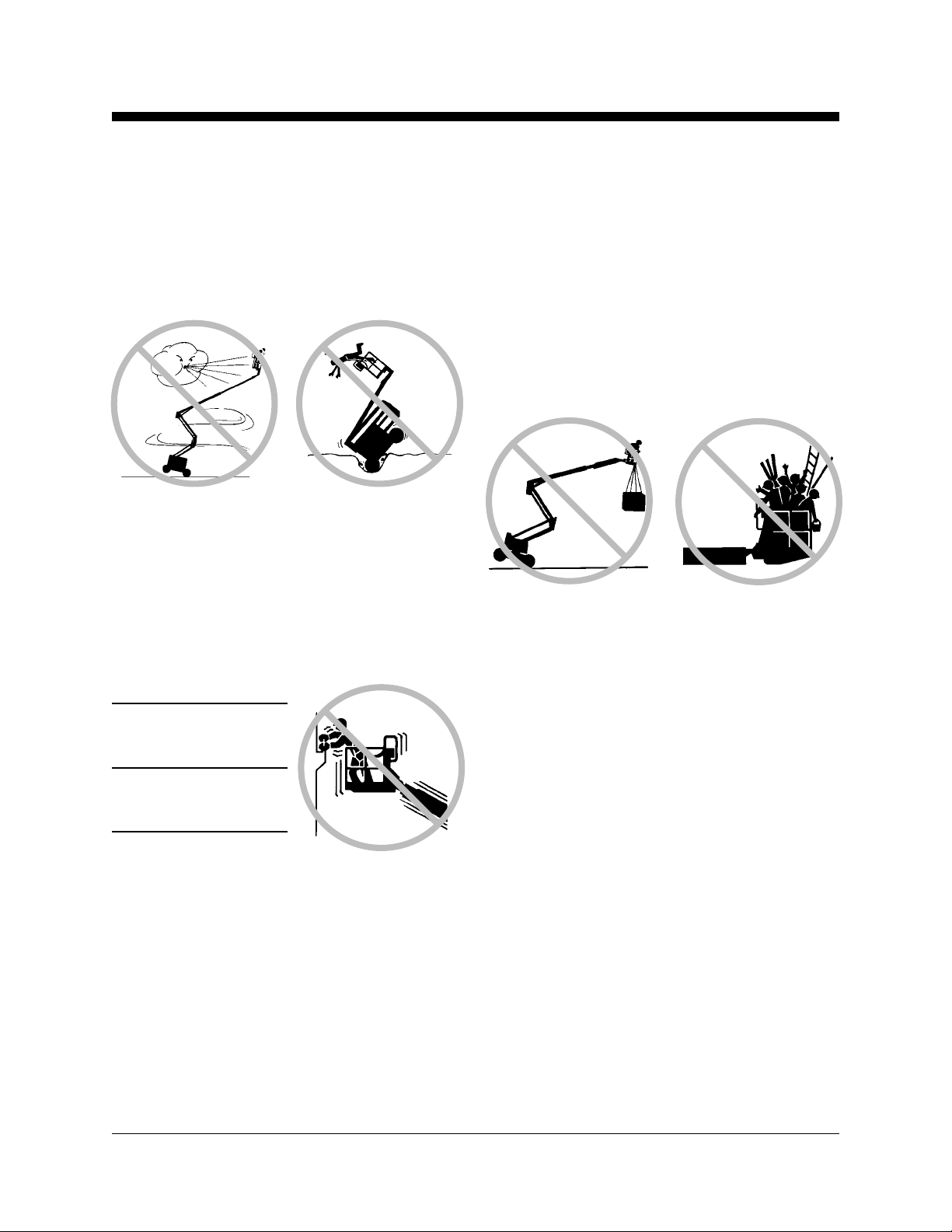

Tip-over Hazards

Occupants, equipment and materials shall not

exceed the maximum platform capacity.

Maximum platform capacity 500 lbs 227 kg

Maximum occupants 2

Do not raise or extend the boom unless the

machine is on a firm, level surface.

Do not depend on the tilt alarm as a level indicator.

The tilt alarm sounds in the platform only when the

machine is on a severe slope.

If the tilt alarm sounds:

Do not extend, rotate or raise the boom above

horizontal. Move the machine to a firm, level

surface before raising the platform. If the tilt alarm

sounds when the platform is raised, use extreme

caution to retract the boom and lower the platform.

Do not rotate the boom while lowering. Move the

machine to a firm, level surface before raising the

platform.

Do not use the platform controls to free a platform

that is caught, snagged or otherwise prevented

from normal motion by an adjacent structure. All

personnel must be removed from the platform

before attempting to free the platform using the

ground controls.

Do not alter or disable the limit switches.

Part No. 82600 Genie Z-45/25 & Genie Z-45/25J 3

Operator's ManualSecond Edition · Second Printing

SAFETY RULES

Do not operate the machine in strong or gusty

winds. Do not increase the surface area of the

platform or the load. Increasing the area exposed to

the wind will decrease machine stability.

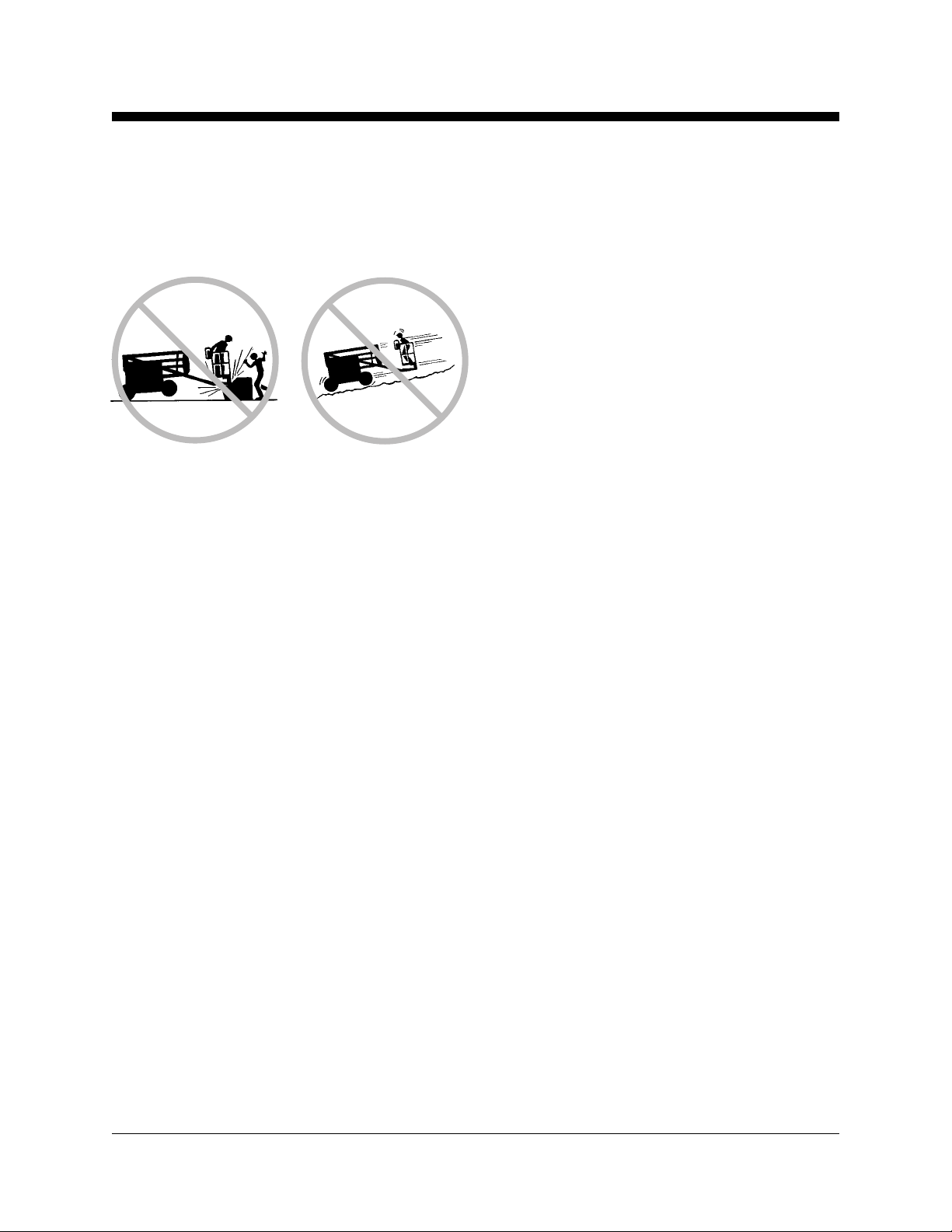

Use extreme care and slow speeds while driving

the machine in stowed position across uneven

terrain, debris, unstable or slippery surfaces and

near holes and drop-offs.

Do not drive the machine on or near uneven terrain,

unstable surfaces or other hazardous conditions

with the boom raised or extended.

Do not push off or pull toward any object outside

of the platform.

Maximum allowable

side force - ANSI & CSA

150 lbs / 667 N

Maximum allowable

side force - CE

90 lbs / 400 N

Do not alter or disable machine components that in

any way affect safety and stability.

Do not replace items critical to machine stability

with items of different weight or specification.

Do not modify or alter an aerial work platform

without prior written permission from the

manufacturer. Mounting attachments for holding

tools or other materials onto the platform, toeboards

or guard rail system can increase the weight in the

platform and the surface area of the platform or the

load.

Do not place or attach overhanging loads to any

part of this machine.

Do not transport tools and materials unless they are

evenly distributed and can be safely handled by

person(s) in the platform.

Do not place ladders or scaffolds in the platform or

against any part of this machine.

Do not use the machine on a moving or mobile

surface or vehicle.

Be sure all tires are in good condition, air-filled tires

are properly inflated and lug nuts are properly

tightened.

Do not replace factory-installed tires with tires of

different specification or ply rating.

Z-45/25 and Z-45/25J Narrow Base Models: Do

not use air-filled tires. These machines are

equipped with foam-filled tires. Wheel weight and

proper counterweight configuration are critical to

stability.

4 Genie Z-45/25 & Genie Z-45/25J Part No. 82600

Operator's Manual Second Edition · Second Printing

SAFETY RULES

Do not use the machine as a crane.

Do not push the machine or other objects with the

boom.

Do not contact adjacent structures with the boom.

Do not tie the boom or platform to adjacent

structures.

Do not place loads outside the platform perimeter.

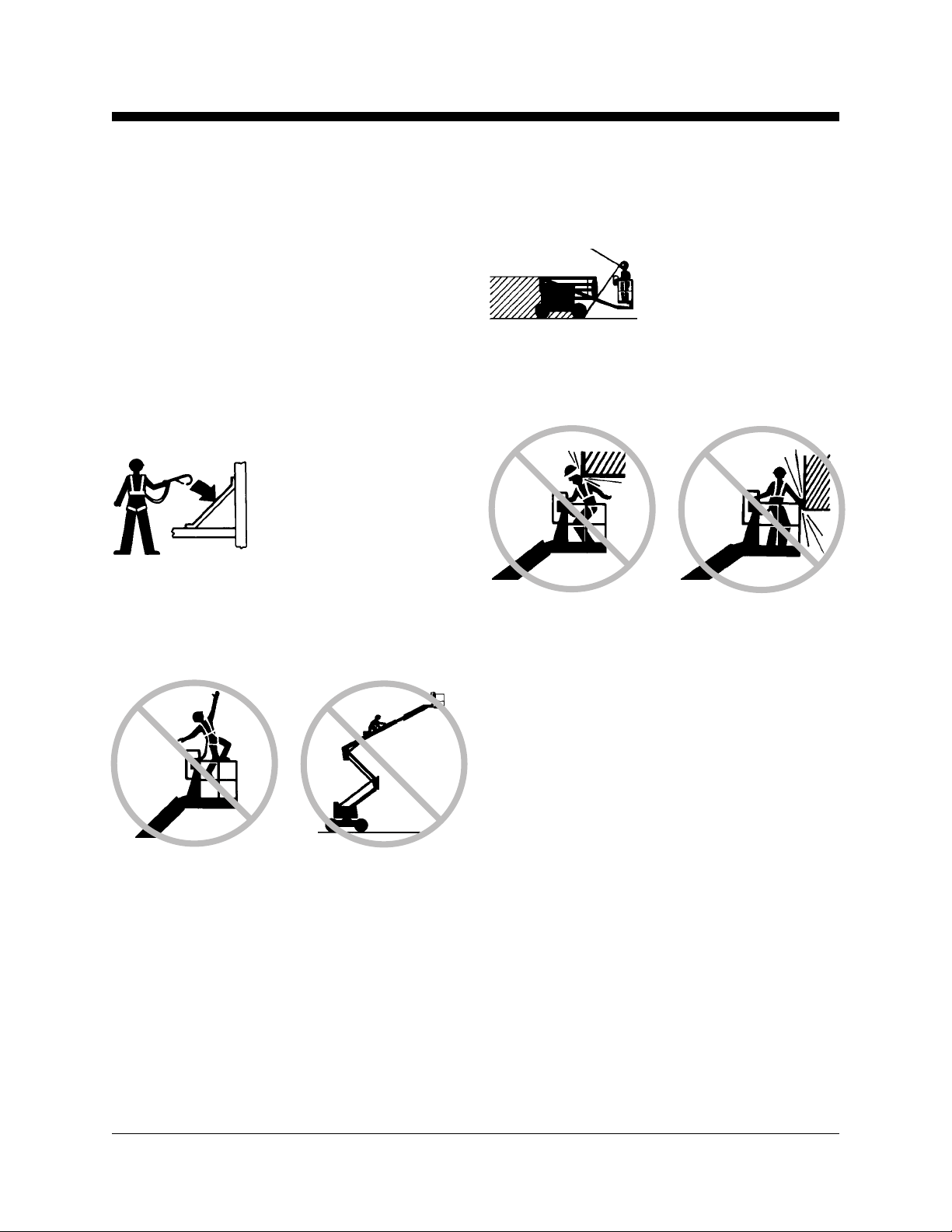

Fall Hazards

Occupants must wear a

safety belt or harness in

accordance with

governmental regulations.

Attach the lanyard to the

anchor provided in the

platform.

Do not sit, stand or climb on the platform guard

rails. Maintain a firm footing on the platform floor at

all times.

Do not climb down from the platform when raised.

Keep the platform floor clear of debris.

Lower the platform entry mid-rail or close the entry

gate before operating.

Collision Hazards

Be aware of limited sight

distance and blind spots

when driving or operating.

Be aware of the boom position when rotating the

turntable.

Check the work area for overhead obstructions or

other possible hazards.

Be aware of crushing hazards when grasping the

platform guard rail.

Operators must comply with employer, job site and

governmental rules regarding the use of personal

protective equipment.

Observe and use the color-coded direction arrows

on the platform controls and drive chassis for drive

and steer functions.

Part No. 82600 Genie Z-45/25 & Genie Z-45/25J 5

Operator's ManualSecond Edition · Second Printing

Do not lower the boom unless the area below is

clear of personnel and obstructions.

Limit travel speed according to the condition of the

ground surface, congestion, slope, location of

personnel, and any other factors which may cause

collision.

Do not operate a boom in the path of any crane

unless the controls of the crane have been locked

out and/or precautions have been taken to prevent

any potential collision.

No stunt driving or horseplay while operating a

machine.

Explosion and Fire Hazards

Do not start the engine if you smell or detect liquid

petroleum gas (LPG), gasoline, diesel fuel or other

explosive substances.

Do not refuel the machine with the engine running.

Refuel the machine and charge the battery only in

an open, well-ventilated area away from sparks,

flames and lighted tobacco.

Do not operate the machine in hazardous locations

or locations where potentially flammable or

explosive gases or particles may be present.

Do not spray ether into engines equipped with glow

plugs.

Damaged Machine Hazards

Do not use a damaged or malfunctioning machine.

Conduct a thorough pre-operation inspection of the

machine and test all functions before each work

shift. Immediately tag and remove from service a

damaged or malfunctioning machine.

Be sure all maintenance has been performed as

specified in this manual and the

Genie Z-45/25 &

Genie Z-45/25J Service Manual.

Be sure all decals are in place and legible.

Be sure the operator’s, safety and responsibilities

manuals are complete, legible and in the storage

container located on the platform.

Bodily Injury Hazard

Do not operate the machine with a hydraulic oil or

air leak. An air leak or hydraulic leak can penetrate

and/or burn skin.

Always operate the machine in a well-ventilated

area to avoid carbon monoxide poisoning.

Improper contact with components under any cover

will cause serious injury. Only trained maintenance

personnel should access compartments. Access

by the operator is only advised when performing a

pre-operation inspection. All compartments must

remain closed and secured during operation.

SAFETY RULES

6 Genie Z-45/25 & Genie Z-45/25J Part No. 82600

Operator's Manual Second Edition · Second Printing

SAFETY RULES

Battery Safety

Burn Hazards

Batteries contain acid. Always wear protective

clothing and eyewear when working with batteries.

Avoid spilling or contacting battery acid. Neutralize

battery acid spills with baking soda and water.

Explosion Hazard

Keep sparks, flames and lighted tobacco away

from batteries. Batteries emit explosive gas.

Electrocution Hazard

Avoid contact with electrical terminals.

Component Damage Hazards

Do not use any battery or charger greater than 12V

to jump-start the engine.

Do not use the machine as a ground for welding.

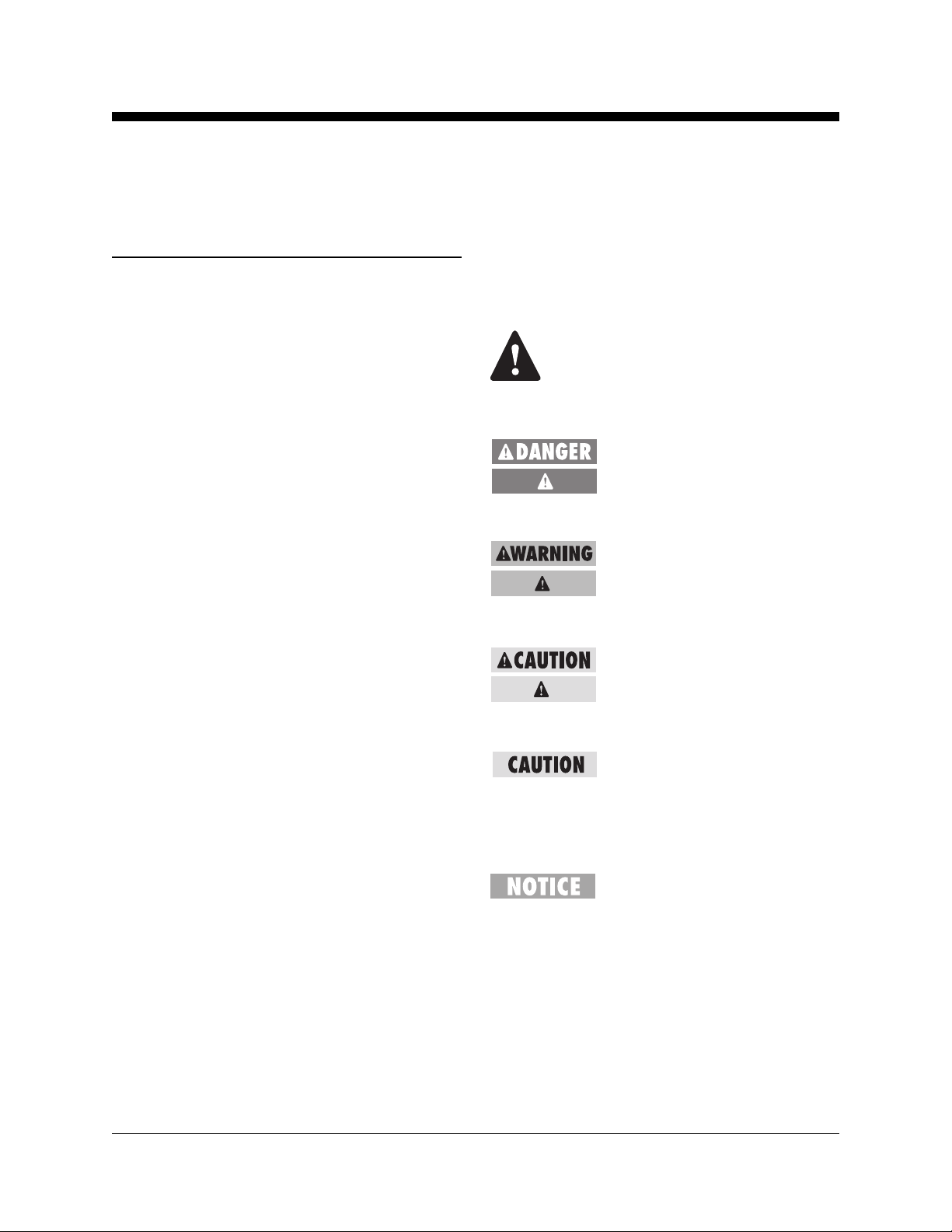

Decal Legend

Genie product decals use symbols, color coding

and signal words to identify the following:

Safety alert symbol—used to alert

personnel to potential personal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Red—used to indicate the

presence of an imminently

hazardous situation which, if not

avoided, will result in death or

serious injury.

Orange—used to indicate the

presence of a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

Yellow with safety alert symbol—

used to indicate the presence of a

potentially hazardous situation

which, if not avoided, may cause

minor or moderate injury.

Yellow without safety alert

symbol—used to indicate the

presence of a potentially

hazardous situation which, if not

avoided, may result in property

damage.

Green—used to indicate operation

or maintenance information.

Part No. 82600 Genie Z-45/25 & Genie Z-45/25J 7

Operator's ManualSecond Edition · Second Printing

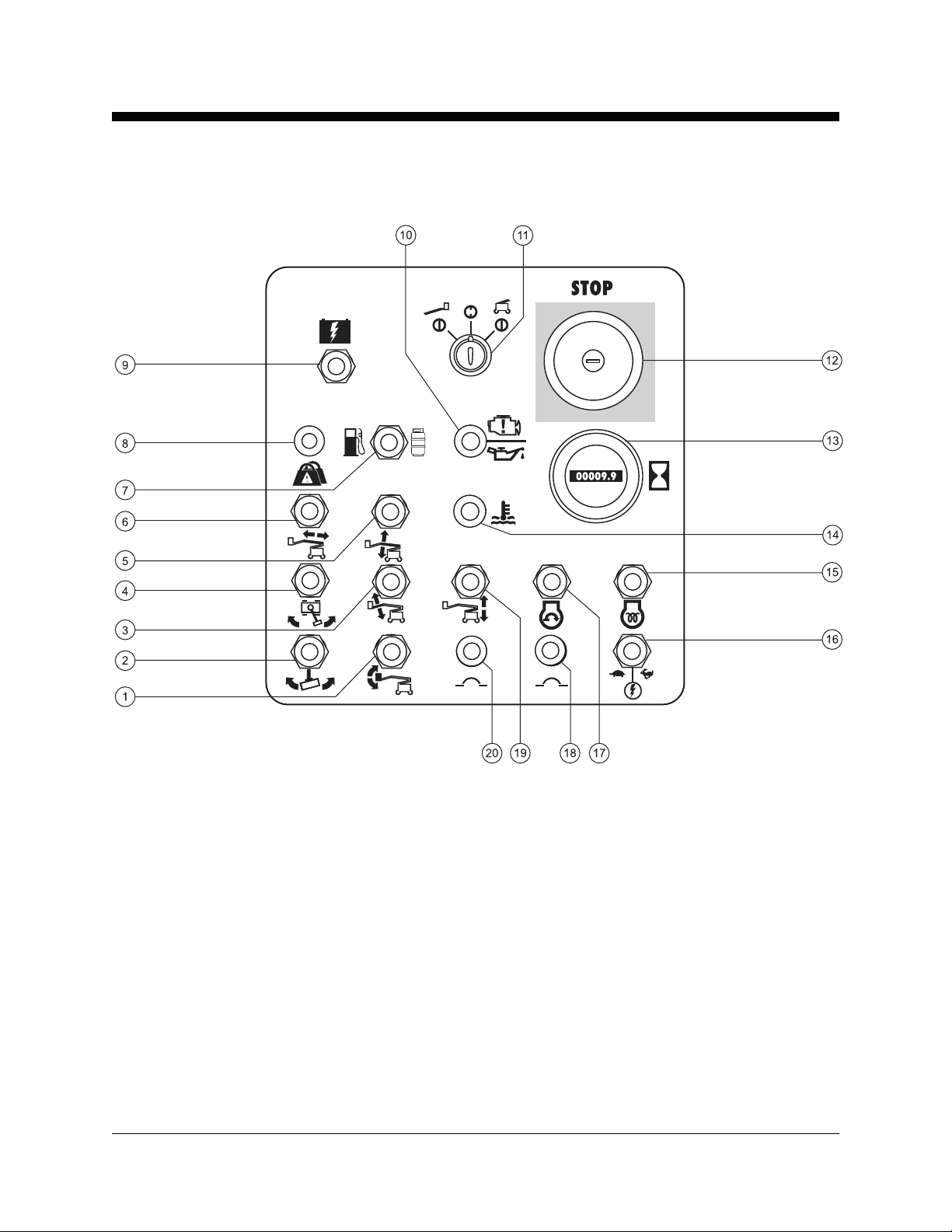

Controls

Ground Control Panel

1 Platform level switch

2 Platform rotate switch

3 Z-45/25J models only: Jib boom up/down switch

4 Turntable rotate switch

5 Primary boom up/down switch

6 Primary boom extend/retract switch

7 Gasoline/LPG models: Fuel select switch

8 Platform overload indicator light (if equipped)

9 Auxiliary power switch

1 0 Gasoline/LPG models: Check engine light

Diesel models: Oil pressure light

1 1 Key switch for platform/off/ground selection

1 2 Red Emergency Stop button

13 Hour meter

1 4 Diesel models: Water temperature light

1 5 Diesel models: Glow plug switch (if equipped)

1 6 Function enable switch

1 7 Engine start switch

1 8 15A breaker for engine electrical circuits

1 9 Secondary boom up/down switch

2 0 15A breaker for control electrical circuits

8 Genie Z-45/25 & Genie Z-45/25J Part No. 82600

Operator's Manual Second Edition · Second Printing

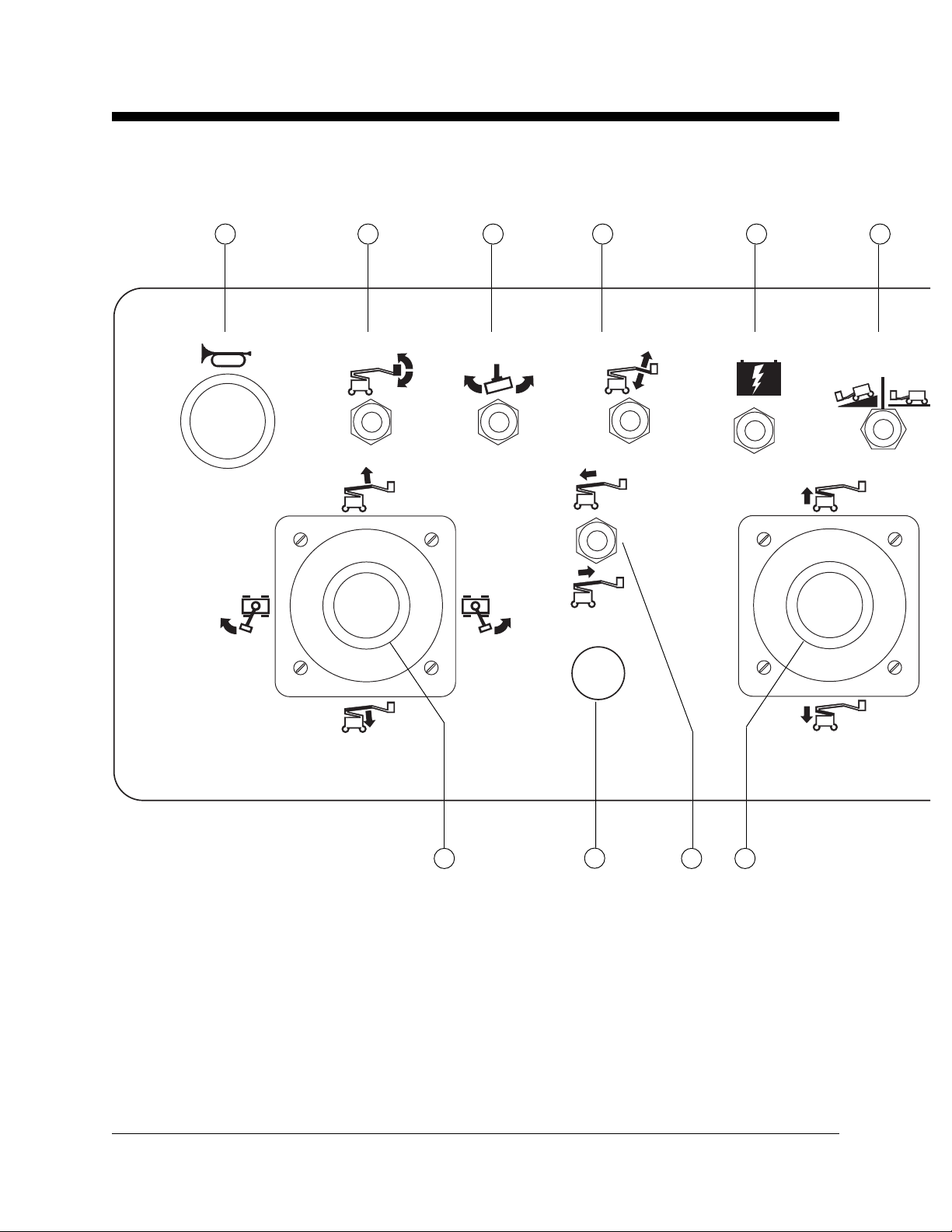

1 3

6 Drive speed select switch

7 Diesel models: Glow plug switch (if equipped)

8 Engine start switch

9 Engine idle (rpm) select switch

10 Gasoline/LPG models: Gasoline/LPG

select switch

Platform Control Panel

1 Horn button

2 Platform level switch

3 Platform rotate switch

4 Z-45/25J models only: Jib boom up/down switch

5 Auxiliary power switch

2

CONTROLS

4 5 6

171820

19

Part No. 82600 Genie Z-45/25 & Genie Z-45/25J 9

Operator's ManualSecond Edition · Second Printing

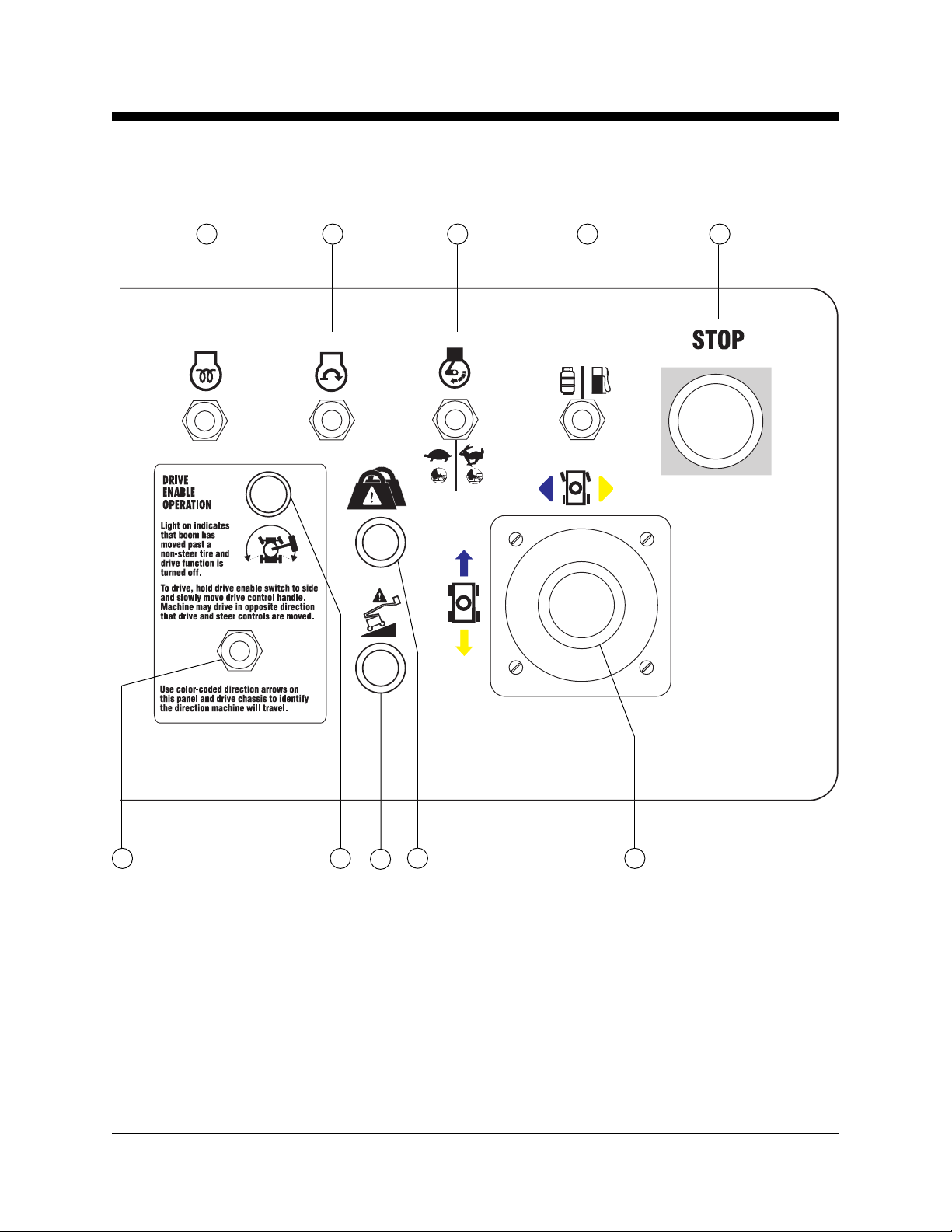

CONTROLS

1 1 Red Emergency Stop button

1 2 Dual axis proportional control handle for drive

and steer functions

OR Proportional control handle for drive function

and thumb rocker for steer function

1 3 Platform overload indicator light (if equipped)

1 4 Machine not level indicator light (if equipped)

1 5 Drive enable indicator light

117 8 9 10

1216 15

1 6 Drive enable switch

1 7 Proportional control handle for secondary boom

up/down function

1 8 Primary boom extend/retract switch

1 9 used for optional equipment

2 0 Dual axis proportional control handle for primary

boom up/down and turntable rotate

left/right functions

13

14

10 Genie Z-45/25 & Genie Z-45/25J Part No. 82600

Operator's Manual Second Edition · Second Printing

Pre-operation Inspection

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator's

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation

inspection.

Know and understand the pre-operation

inspection before going on to the next

section.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

Fundamentals

It is the responsibility of the operator to perform a

pre-operation inspection and routine maintenance.

The pre-operation inspection is a visual inspection

performed by the operator prior to each work shift.

The inspection is designed to discover if anything

is apparently wrong with a machine before the

operator performs the function tests.

The pre-operation inspection also serves to

determine if routine maintenance procedures are

required. Only routine maintenance items specified

in this manual may be performed by the operator.

Refer to the list on the next page and check each

of the items.

If damage or any unauthorized variation from

factory delivered condition is discovered, the

machine must be tagged and removed from

service.

Repairs to the machine may only be made by a

qualified service technician, according to the

manufacturer's specifications. After repairs are

completed, the operator must perform a

pre-operation inspection again before going on to

the function tests.

Scheduled maintenance inspections shall be

performed by qualified service technicians,

according to the manufacturer's specifications and

the requirements listed in the responsibilities

manual.

Part No. 82600 Genie Z-45/25 & Genie Z-45/25J 11

Operator's ManualSecond Edition · Second Printing

PRE-OPERATION INSPECTION

Pre-operation Inspection

o

Be sure that the operator’s, safety and

responsibilities manuals are complete, legible

and in the storage container located in the

platform.

o

Be sure that all decals are legible and in place.

See Decals section.

o

Check for engine oil leaks and proper oil level.

Add oil if needed. See Maintenance section.

o

Check for hydraulic oil leaks and proper oil level.

Add oil if needed. See Maintenance section.

o

Check for engine coolant leaks and proper level

of coolant. Add coolant if needed. See

Maintenance section.

o

Check for battery fluid leaks and proper fluid

level. Add distilled water if needed. See

Maintenance section.

o

Z-45/25 RT and Z-45/25J RT models: Check for

proper tire pressure. Add air if needed. See

Maintenance section.

Check the following components or areas for

damage, improperly installed or missing parts and

unauthorized modifications:

o

Electrical components, wiring and

electrical cables

o

Hydraulic hoses, fittings, cylinders and

manifolds

o

Fuel and hydraulic tanks

o

Drive and turntable motors and drive hubs

o

Boom wear pads

o

Tires and wheels

o

Engine and related components

o

Limit switches and horn

o

Alarms and beacons (if equipped)

o

Nuts, bolts and other fasteners

o

Platform entry mid-rail or gate

Check entire machine for:

o

Cracks in welds or structural components

o

Dents or damage to machine

o

Be sure that all structural and other critical

components are present and all associated

fasteners and pins are in place and properly

tightened.

o

After you complete your inspection, be sure that

all compartment covers are in place and

latched.

Loading...

Loading...