General AUHA12LN, AUHA12LALN, AUHA14LN, AUHA14LALN Installation Manual

G

Cassette Type

3

2

1

3

2

1

SPLIT TYPE AIR CONDITIONER

INSTALLATION

INSTRUCTION SHEET

(PART NO. 9377778017-03)

For authorized service personnel only.

DANGER

WARNING

CAUTION

Never touch electrical components immediately after the power supply has been turned off. Electrical shock may occur. After

turning off the power, always wait 5 minutes or more before touching electrical components.

The basic installation work procedures are the same as conventional refrigerant models.

However, pay careful attention to the following points:

1 Since the working pressure is 1.6 times higher than that of conventional refrigerant models, some of the piping and

installation and service tools are special. (See the table below.)

Especially, when replacing a conventional refrigerant model with a new refrigerant R410A model, always replace the

conventional piping and flare nuts with the R410A piping and flare nuts.

2 Models that use refrigerant R410A have a different charging port thread diameter to prevent erroneous charging with

conventional refrigerant and for safety. Therefore, check beforehand. [The charging port thread diameter for R410A is

1/2 UNF 20 threads per inch.]

3 Be more careful that foreign matter (oil, water, etc.) does not enter the piping than with refrigerant models. Also, when

storing the piping, securely seal the openings by pinching, taping, etc.

4 When charging the refrigerant, take into account the slight change in the composition of the gas and liquid phases, and

always charge from the liquid phase side whose composition is stable.

Special tools for R410A

Tool name

Gauge manifold

Charge hose

Vacuum pump

Gas leakage detector

Copper pipes

It is necessary to use seamless copper pipes and it is desirable that the

amount of residual oil is less than 40 mg/10 m. Do not use copper pipes

having a collapsed, deformed or discolored portion (especially on the interior

surface). Otherwise, the expansion valve or capillary tube may become

blocked with contaminants.

As an air conditioner using R410A incurs pressure higher than when

using conventional refrigerant, it is necessary to choose adequate materials.

Thicknesses of copper pipes used with R410A are as shown in the table.

Never use copper pipes thinner than that in the table even when it is

available on the market.

This mark indicates procedures which, if improperly performed, are most likely to result in the death of or

serious injury to the user or service personnel.

This mark indicates procedures which, if improperly performed, might lead to the death or serious injury of

the user.

This mark indicates procedures which, if improperly performed, might possibly result in personal harm to

the user, or damage to property.

DANGER

This air conditioner uses new refrigerant HFC (R410A).

Pressure is high and cannot be measured with a conventional gauge. To prevent erroneous mixing of other

refrigerants, the diameter of each port has been changed.

It is recommended the gauge with seals –0.1 to 5.3 MPa (–76 cmHg to 53 kgf/cm

3.8 MPa (–76 cmHg to 38 kgf/cm

To increase pressure resistance, the hose material and base size were changed.

A conventional vacuum pump can be used by installing a vacuum pump adapter.

Special gas leakage detector for HFC refrigerant R410A.

2

) for low pressure.

Contents of change

2

) for high pressure. –0.1 to

Thicknesses of Annealed Copper Pipes (R410A)

Pipe outside diameter

6.35 mm (1/4 in.)

9.52 mm (3/8 in.)

12.70 mm (1/2 in.)

15.88 mm (5/8 in.)

19.05 mm (3/4 in.)

Thickness

0.80 mm

0.80 mm

0.80 mm

1.00 mm

1.20 mm

For authorized service personnel only.

WARNING

1 For the air conditioner to operate satisfactorily, install it as outlined in this installation instruction sheet.

2 Connect the indoor unit and outdoor unit with the air conditioner piping and cords available from our standards parts. This instal-

lation instruction sheet describes the correct connections using the installation set available from our standard parts.

3 Installation work must be performed in accordance with national wiring standards by authorized personnel only.

4 Do not turn on the power until all installation work is complete.

CAUTION

This installation instruction sheet describes how to the indoor unit only.

To install the outdoor unit, refer to the installation instruction sheet included with the outdoor unit.

To install the remote controller, refer to the installation instruction sheet included with the remote controller unit.

••

• Be careful not to scratch the air conditioner when handling it.

••

••

• After installation, explain correct operation to the customer, using the operating manual.

••

••

• Let the customer keep this installation instruction sheet because it is used when the air conditioner is serviced or moved.

••

CONNECTION PIPE REQUIREMENT

CAUTION

Refer to the installation instruction sheet of the outdoor unit for description of the length of connecting pipe or for difference of

its elevation.

MODEL

Diameter

••

• Use pipe with water-resistant heat insulation.

••

Small

Large

12,000 14,000/18,000 24,000

BTU/h model BTU/h model BTU/h model

6.35 mm (1/4 in.) 6.35 mm (1/4 in.) 6.35 mm (1/4 in.)

9.52 mm (3/8 in.) 12.70 mm (1/2 in.) 15.88 mm (5/8 in.)

CAUTION

Install heat insulation around both the gas and liquid pipes. Failure to do so may cause water leaks.

Use heat insulation with heat resistance above 120 °C. (Reverse cycle model only)

In addition, if the humidity level at the installation location of the refrigerant piping is expected to exceed 70%, install heat

insulation around the refrigerant piping. If the expected humidity level is 70-80%, use heat insulation that is 15 mm or thicker and

if the expected humidity exceeds 80%, use heat insulation that is 20 mm or thicker.

If heat insulation is used that is not as thick as specified, condensation may form on the surface of the insulation.

In addition, use heat insulation with heat conductivity of 0.045 W/(m·K) or less (at 20 °C).

ELECTRICAL REQUIREMENT

Connection cord (mm2)

MAX.

2.5

••

• Use conformed cord with Type 245 IEC57.

••

••

• Install all electrical works in accordance to the standard.

••

••

• Install the disconnect device with a contact gap of at least 3 mm in all poles nearby the units. (Both indoor unit and outdoor unit)

••

MIN.

1.5

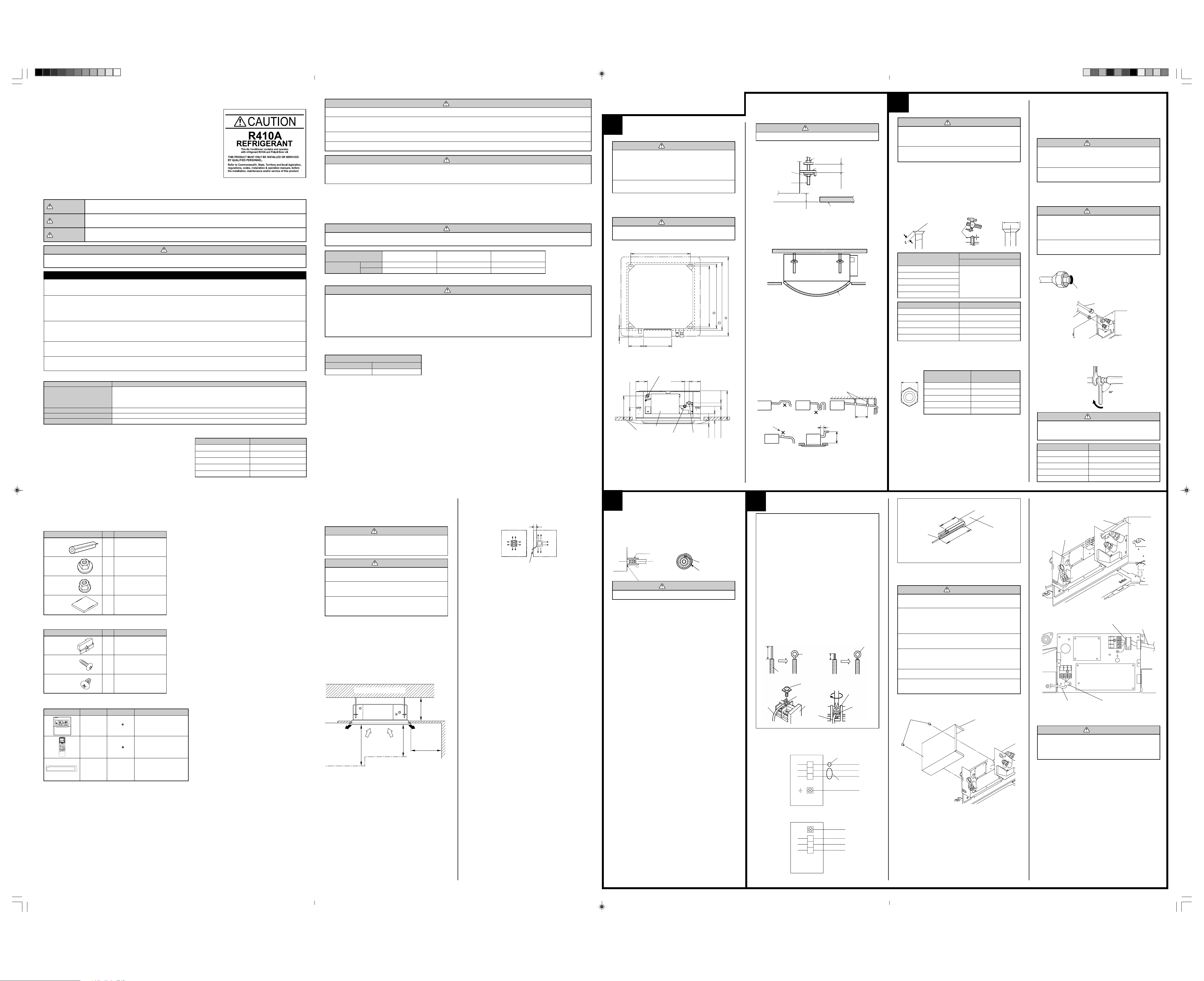

INSTALLATION PROCEDURE

Install the air conditioner as follows:

1

INDOOR UNIT INSTALLATION

WARNING

1 Install the air conditioner in a location which can with-

stand a load do at least five times the weight of the

main unit and which will not amplify sound or vibration. If the installation location is not strong enough,

the indoor unit may fall and cause injuries.

2 If the job is done with the panel frame only, there is a

risk that the unit will come loose. Please take care.

1. INSTALLING BODY

Cealing openings and hanging bolt installation diagram

WARNING

When fastening the hangers, make the bolt positions uniform.

530 mm (Hanging bolt position)

570 mm (Indoor unit)

75 mm

135 mm 250 mm

114 mm

215 mm

Drain pipe (O.D. ø25.4)

Control box

Ceiling

40 mm 99 mm102 mm

Liquid pipe

Gas pipe

540 mm (Hanging bolt position)

30 mm

123 mm

58 mm

30 mm

(1) Install special nut A, then special nut B onto the hanging bolt.

(2) Raise the body and mount its hooks onto the hanging bolt between

the special nuts.

(3) Turn special nut B to adjust the height of the body.

Perform final tightening by tightening the double nut firmly.

2. LEVELING

Using a level, or vinyl hose filled with water, fine adjust so that the body is

level.

700 mm (Decoration Panel)

580 – 660 mm (Cealing openings)

262 mm

3. INSTALLING DRAIN PIPE

Note: Install the drain pipe.

••

• Install the drain pipe with downward gradient (1/50 to 1/100) and so

••

there are no rises or traps in the pipe.

••

• Use general hard polyvinyl chloride pipe (VP25) [outside diameter 32

••

mm (1-1/4”)] and connect it with adhesive (polyvinyl chloride) so that

there is no leakage.

••

• When the pipe is long, install supporters.

••

••

• Do not perform air bleeding.

••

••

• Always heat insulate the indoor side of the drain pipe.

••

••

• When desiring a high drain pipe height, raise it up to 700 mm or less

••

from the ceiling within a range of 150 mm from the body. A rise dimension over this range will cause leakage.

Air bleeding

Special nut B

Hanging bolt

Rise

19 mm

WARNING

Special nut A

Hook

Trap

150 mm or less

30 mm

or more

Ceiling

Supporter

After installing the

body, tighten the nuts.

Vinyl hose

1.5 to 2.0 m

Max. 700 mm

2

CONNECTING THE PIPE

CAUTION

1 Do not use mineral oil on flared part. Prevent mineral

oil from getting into the system as this would reduce

the lifetime of the units.

2 While welding the pipes, be sure to blow dry nitrogen

gas through them.

1. FLARING

(1) Cut the connection pipe to the necessary length with a pipe cutter.

(2) Hold the pipe downward so that cuttings will not enter the pipe and

remove the burrs.

(3) Insert the flare nut (always use the flare nut attached to the indoor

and outdoor units respectively) onto the pipe and perform the flare

processing with a flare tool.

Use the special R410A flare tool, or the conventional flare tool.

Check if [L] is flared uniformly

and is not cracked or scratched.

Die

A

Pipe

Pipe outside diameter

6.35 mm (1/4 in.)

9.52 mm (3/8 in.)

12.70 mm (1/2 in.)

15.88 mm (5/8 in.)

19.05 mm (3/4 in.)

Pipe outside diameter

6.35 mm (1/4 in.)

9.52 mm (3/8 in.)

12.70 mm (1/2 in.)

15.88 mm (5/8 in.)

19.05 mm (3/4 in.)

When using conventional flare tools to flare R410A pipes, the dimension

A should be approximately 0.5 mm more than indicated in the table (for

flaring with R410A flare tools) to achieve the specified flaring. Use a thickness gauge to measure the dimension A.

Width across

flats

Pipe outside

diameter

6.35 mm (1/4 in.)

9.52 mm (3/8 in.)

12.70 mm (1/2 in.)

15.88 mm (5/8 in.)

19.05 mm (3/4 in.)

Dimension A

Flare tool for R410A, clutch type

0 to 0.5

Dimension B

9.1

13.2

16.6

19.7

24.0

Width across flats

of Flare nut

17 mm

22 mm

26 mm

29 mm

36 mm

(mm)

0

(mm)

-0.4

B

2. BENDING PIPES

The pipes are shaped by your hands. Be careful not to collapse them.

Do not bend the pipes in an angle more than 90

When pipes are repeatedly bend or stretched, the material will harden,

making it difficult to bend or stretch them any more. Do not bend or

stretch the pipes more than three times.

°.

CAUTION

1 To prevent breaking of the pipe, avoid sharp bends.

Bend the pipe with a radius of curvature of 150 mm or

over.

2 If the pipe is bent repeatedly at the same place, it will

break.

3. CONNECTION PIPES

Indoor unit

(1) Detach the caps and plugs from the pipes.

CAUTION

1 Be sure to apply the pipe against the port on the in-

door unit correctly. If the centering is improper, the flare

nut cannot be tightened smoothly. If the flare nut is

forced to turn, the threads will be damaged.

2

Do not remove the flare nut from the indoor unit pipe

until immediately before connecting the connection pipe.

(2) Centering the pipe against port on the indoor unit, turn the flare nut

with your hand.

To prevent gas leakage, coat the flare

surface with alkylbenzene oil (HAB).

Do not use mineral oil.

Connection pipe

(Gas)

Connection pipe

(Liquid)

Indoor unit

(3) When the flare nut is tightened properly by your hand, use a torque

wrench to finally tighten it.

Holding spanner

Body side

Torque wrench

CAUTION

Hold the torque wrench at its grip, keeping it in the right

angle with the pipe, in order to tighten the flare nut

correctly.

Flare nut Tightening torque

6.35 mm (1/4 in.) dia.

9.52 mm (3/8 in.) dia.

12.70 mm (1/2 in.) dia.

15.88 mm (5/8 in.) dia.

19.05 mm (3/4 in.) dia.

14 to 18 N·m (140 to 180 kgf·cm)

33 to 42 N·m (330 to 420 kgf·cm)

50 to 62 N·m (500 to 620 kgf·cm)

63 to 77 N·m (630 to 770 kgf·cm)

100 to 110 N·m (1,000 to 1,100 kgf·cm)

STANDARD PARTS

The following installation parts are furnished.

Use them as required.

INDOOR UNIT ACCESSORIES

Name and Shape

Coupler heat

insulation

Special nut A

(large flange)

Special nut B

(small flange)

Template

(Carton top)

DECORATION PANEL ACCESSORIES

Name and Shape

Connector cover

Screw

Screw

OPTIONAL PARTS

Exterior

Parts name

Wired remote

controller

Wireless

controller

Air outlet

shutter plate

remote

Q’ty

For indoor side pipe joint

2

For installing indoor unit

4

For installing indoor unit

4

For cealing openings

1

cutting

Also used as packing

Q’ty

For covering connector

4

For mounting decoration

4

panel

For mounting connector

1

cover

Model No.

UTB

-

UD

-

NA

UTB

-

YDZA

UTR

Application

Application

Summary

Unit control is performed by

wired remote controller

Unit control is performed by

wireless remote controller

Install the plate at outlet

when carrying out 3-way

direction operation.

SELECTING THE MOUNTING

POSITION

Decide the mounting position with the customer as follows:

WARNING

Select installation locations that can properly support the

weight of the indoor. Install the units securely so that they

do not topple or fall.

CAUTION

1 Do not install where there is the danger of combustible

gas leakage.

2 Do not install the unit near heat source of heat, steam,

or flammable gas.

3 If children under 10 years old may approach the unit,

take preventive measures so that they cannot reach

the unit.

(1) Install the indoor unit on a place having a sufficient strength so that it

withstands against the weight of the indoor unit.

(2) The inlet and outlet ports should not be obstructed; the air should be

able to blow all over the room.

(3) Leave the space required to service the air conditioner.

(4) The ceiling rear height as shown in the figure.

(5) A place from where the air can be distributed evenly throughout the

room by the unit.

(6) A place from where drainage can be extracted outdoors easily.

(7) Install the unit where noise and vibrations are not amplified.

Strong and durable ceiling

262 mm

or more

1,000 mm

1,000 mm

2,500 mm

Floor

This product can be installed at a height of up to 3.5 m. Perform the Function Setting on the remote control in accordance with the installed height.

Obstruction

or more

or more

or more

Discharge Direction Setting

• The discharge direction can be selected as shown below.

100 mm or more

(4 directions)

* For a 3-way outlet, make sure to perform the Function Setting on the

remote control. Also, make sure to use the optional shutter panel to

block the outlet.

* The ceiling height cannot be set in the 3-way outlet mode. Therefore,

do not change the setting in the “Setting the Ceiling Height” at 6 FUNCTION SETTING.

* When the outlet is shut, be sure to install the optional Air outlet

shutter plate kit.

For the details of installation, please refer to Installation Manual of kit.

(3 directions)

Piping position

3

INSTALLING THE COUPLER

HEAT INSULATION

After checking for gas leaks, insulate by wrapping insulation around the

two parts (gas and liquid) of the indoor unit coupling, using the coupler

heat insulation.

After installing the coupler heat insulation, wrap both ends with vinyl tape

so that there is no gap.

Coupler heat insulation

Body

Be sure to overlap the

insulation

CAUTION

Must fit tightly against body without any gap.

No gap

Coupler heat insulation

4

ELECTRICAL WIRING

HOW TO CONNECT WIRING TO THE

TERMINALS

A. For solid core wiring

(1) Cut the wire end with a wire cutter or wire-cutting pliers, then strip

the insulation to about 25 mm of expose the solid wire.

(2) Using a screwdriver, remove the terminal screw(s) on the terminal

board.

(3) Using pliers, bend the solid wire to form a loop suitable for the

terminal screw.

(4) Shape the loop wire properly, place it on the terminal board and

tighten securely with the terminal screw using a screwdriver.

B. For strand wiring

(1) Cut the wire end with a wire cutter or wire-cutting pliers, then strip

the insulation to about 10 mm of expose the strand wiring.

(2) Using a screwdriver, remove the terminal screw(s) on the terminal

board.

(3) Using a round terminal fastener or pliers, securely clamp a round

terminal to each stripped wire end.

(4) Position the round terminal wire, and replace and tighten the

terminal screw using a screwdriver.

Strip 25 mm

Wire

A. Solid wire

Insulation

Loop

Screw with

special washer

Round terminal

Terminal

board

Wire

B. Strand wire

Strip 10 mm

Screw with

special washer

Round

terminal

1. CONNECTION DIAGRAMS

Connection cord (to outdoor unit)

Control line

Power line

Round

terminal

Keep the earth wire longer than the other wires.

20 mm

Earth wire

30 mm or more

• Use a 4-core wire cord.

Power supply cord

or connection cord

2. CONNECTION OF WIRING

WARNING

1 Before starting work, check that power is not being

supplied to the indoor unit and outdoor unit.

2 Match the terminal board numbers and connection

cord colors with those of the outdoor unit.

Erroneous wiring may cause burning of the electric

parts.

3 Connect the connection cords firmly to the terminal

board. Imperfect installation may cause a fire.

4 Always fasten the outside covering of the connection

cord with the cord clamp. (If the insulator is chafed,

electric leakage may occur.)

5 Always connect the ground wire.

6 Install the remote controller wires so as not to be di-

rect touched with your hand.

(1) Remove the control box cover and install each connection wire

Screw

Control box cover

(2) After wiring is complete, secure the remote controller cord, connec-

tion cord, and power cord with the cord clamps.

Connection cord

(to outdoor unit)

Wired remote controller

cord (option)

Wired remote controller cord

(option)

(3) Install control box cover.

Cord clamp

Cord clamp

Connection cord

(to outdoor unit)

CAUTION

Do not bundle the remote controller cord, or wire the remote controller cord in parallel, with the indoor unit connection wire (to the outdoor unit) and the power supply

cord. It may cause erroneous operation.

07B047_9377778017-03_f.p65 2007.2.26, 10:16 AM1

Indoor unit

side

Wired remote controller cord (option)

*

Red

White

Black

Indoor unit

side

Ground the remote controller ip it has a ground wire

*

(Continued to the next page)

5

SUMOTUWETH FR

SA

3 4

ON

1 2

1 2 3 1 2 3 1 2 3

1 2 3

1 2 3

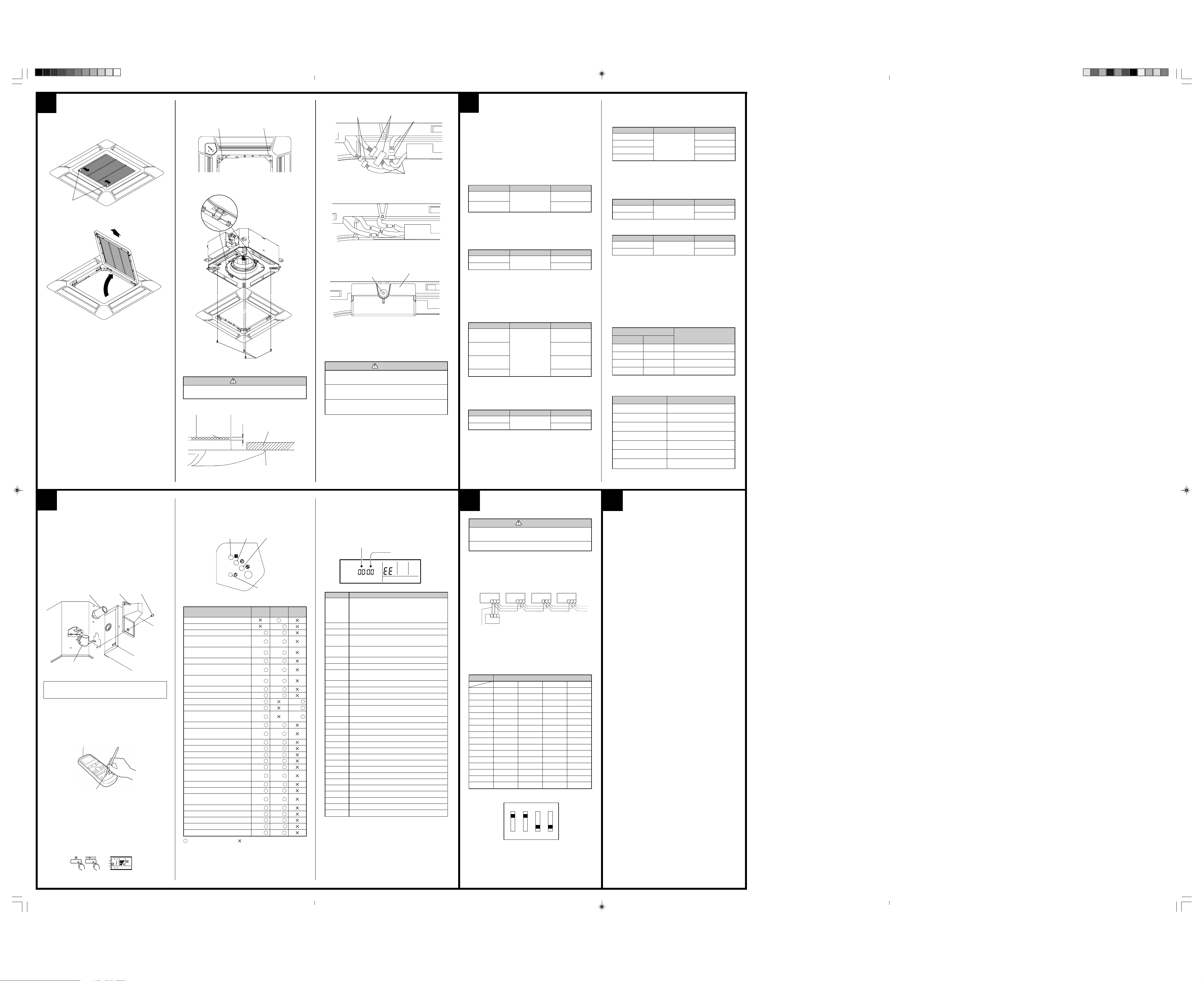

DECORATION PANEL

INSTALLATION

1. REMOVE THE INTAKE GRILLE

(1) Slide the 2 grille hook

Grille hook

(2) Open the intake grille and remove.

2. INSTALL PANEL TO INDOOR UNIT

(1) Install the decoration panel on the indoor unit.

“DRAIN” mark

* Align the stamped marks on the decoration panel against the pipe and the drain

of the indoor unit.

Use only the supplied screws to install the decoration

panel.

Indoor unit

Sealant

Decoration panel

“PIPE” mark

CAUTION

5 ~ 7

Screw

Cealing

No gap between cealing and

decoration panel around entire

periphery

(2) Connect the connector.

Wire (louver): WHITE

• Arrange the wires as illustrated below.

(3) Attach the connector cover.

Wire (display): WHITE

Screw

Wire (louver): RED

Indoor unit side

Connector cover

3. ATTACH THE INTAKE GRILLE

The installation is the reverse of “REMOVING THE INTAKE GRILLE”.

The intake grille can be rotated and installed 4 ways to suit the user’s

preference.

CAUTION

1 The louver angle cannot be changed if the power is not

on, (If moved by hand, it may be damaged.)

2 The grille assembly is directional relative to the air con-

ditioner body.

3 Install so that there is no gap between the grille as-

sembly and the air conditioner body.

6

• Follow the instructions in the Local Setup Procedure, which is supplied

with the remote control, in accordance with the installed condition. After

the power is turned on, perform the Function Setting on the remote

control.

• The settings may be selected between the following two: Function

Number or Setting Value.

• Settings will not be changed if invalid numbers or setting values are

selected.

FUNCTION SETTING

Setting the Ceiling Height

• Select the setting values in the table below according to the height of

the ceiling. (The unit is factory-set to “00”.)

Setting Description

Standard

(2.5 m to 3.0 m)

High ceiling

(3.0 m to 3.5 m)

The ceiling height values are for the 4-way outlet.

Do not change this setting in the 3-way outlet mode.

Function Number

20

Setting Value

00

01

Setting the Outlet Directions

• Select the setting values in the table below for using a 3-way outlet.

(The unit is factory-set to “00”.)

Setting Description

4-way

3-way

Function Number

22

Setting Value

00

01

Setting the Filter Sign

• The indoor unit has a sign to inform the user that it is time to clean the

filter.

• Select the time setting for the filter sign display interval in the table

below according to the amount of dust or debris in the room. (The unit

is factory-set to “00”)

• If you do not wish the filter sign to be displayed, select the setting value

for “No indication”.

Setting Description

Standard

(2,500 hours)

Long interval

(4,400 hours)

Short interval

(1,250 hours)

No indication

Function Number

11

Setting Value

00

01

02

03

Setting the Cooler Room Temperature Correction

• Depending on the installed environment, the room temperature sensor

may require a correction. The settings may be selected as shown in the

table below. (The unit is factory-set to “00”.)

Setting Description

Standard

Lower control

Function Number

30

Setting Value

00

01

Setting the Heater Room Temperature Correction

• Depending on the installed environment, the room temperature sensor

may require a correction. The settings may be changed as shown in the

table below. (The unit is factory-set to “00”.)

Setting Description

Standard

Lower control

Slightly warmer control

Warmer control

Function Number

31

Setting Value

00

01

02

03

Setting Other Functions

• The following settings are also possible, depending on the operating

conditions. (The unit is factory-set to “00”.)

Auto Restart

Setting Description

Yes

No

Indoor Room Temperature Sensor Switching Function (Wired remote controller only)

Setting Description

No

Yes

• If setting value is “00”, room temperature is controlled by the indoor unit

temperature sensor.

• If setting value is “01”, room temperature is controlled by either indoor

unit temperature sensor or remote control unit sensor.

Function Number

40

Function Number

42

Setting Value

00

01

Setting Value

00

01

[When using the wireless remote controller]

SWITCHING REMOTE CONTROL UNIT SIGNAL

CODES

• Confirm the setting of the remote control unit signal code and the printed

circuit board setting.

If these are not confirmed, the remote control unit cannot be used to

operate for the air conditioner.

Jumper wire

JM1

Connect

Disconnect

Connect

Disconnect

JM2

Connect

Connect

Disconnect

Disconnect

Remote control unit

signal code

A (Primary setting)

b

c

d

Setting record

• Record any changes to the settings in the following table.

Setting

Ceiling height

Outlet direction

Filter sign

Cooler room temperature

correction

Heater room temperature

correction

Auto restart

Indoor room temperature

sensor switching function

After completing the FUNCTION SETTING, be sure to turn off the power

and turn it on again.

Setting Value

7

TEST RUN

CHECK ITEMS

(1) Is operation of each button on the remote control unit normal?

(2) Does each lamp light normally?

(3) Do not air flow direction louvers operate normally?

(4) Is the drain normal?

(5) Is there any abnormal noise and vibration during operation?

• Do not operate the air conditioner in the running state for a long time.

CHECKING DRAINAGE

To check the drain, remove the water cover and fill with 1rof water as

shown in the figure.

The drain pump operates when operating in the cooling mode.

Drain pipe

Watering pot

• Test running

When the air conditioner is run by pressing the remote control unit test

run button, the OPERATION and TIMER lamps flash slowly at the same

time.

Wire cover

Screw

[Using the wireless remote control]

• For the operation method, refer to the operating manual.

• The outdoor unit may not operate depending on the room temperature.

In this case, press the test run button on the remote control unit while

the air conditioner is running. (Point the transmitter section of the remote control unit toward the air conditioner and press the test run button with the tip of a ball-point pen, etc.)

Transmitter section

Test run button

•

To end test operation, press the remote control unit START/STOP button.

(When the air conditioner is run by pressing the test run button, the

OPERATION indicator lamp and TIMER indicator lamp and TIMER indicator lamp will simultaneously flash slowly.)

[Using the wired remote control]

• For the operation method, refer to the operating manual.

(1) Stop the air conditioner operation.

(2) Press the master control button and the fan control button simultane-

ously for 2 seconds or more to start the test run.

TROUBLESHOOTING

[Troubleshooting with the indoor display]

Troubleshooting at the display is possible either on the wired or wireless

remote control.

FILTER LAMP

(ORANGE)

The OPERATION, TIMER and FILTER lamp operate as follows table according to the error contents.

Error contents

Indoor signal error

Wired remote controller abnormal

Indoor room temperature sensor error

Indoor heat exchanger temperature

sensor (middle) error

Indoor heat exchanger temperature

sensor (inlet) error

Float switch operated

Outdoor discharge pipe temperature

sensor error

Outdoor heat exchanger temperature

sensor (outlet) error

Outdoor temperature sensor error

Compressor temperature sensor error

2-way valve temperature sensor error

3-way valve temperature sensor error

Outdoor heat exchanger temperature

sensor (middle) error

Indoor manual auto switch abnormal

Power supply frequency detection error

IPM protection

CT error

Compressor location error

Outdoor fan error

Connected indoor unit abnormal

Outdoor unit computer communication

error

Indoor fan abnormal

Discharge temperature error

Exessive high pressure protection on

cooling

4-way valve abnormal

Pressure switch abnormal

Compressor temperature error

Active filter abnormal

PFC circuit error

: 0.5s ON/0.5s OFF (Flash) : OFF

TIMER LAMP

(GREEN)

MANUAL AUTO

OPERATION

lamp (RED)

(2 times)

(2 times)

(2 times)

(2 times)

(3 times)

(3 times)

(3 times)

(3 times)

(3 times)

(3 times)

(3 times)

(4 times)

(4 times)

(5 times)

(5 times)

(5 times)

(5 times)

(5 times)

(5 times)

(6 times)

(7 times)

(7 times)

(7 times)

(7 times)

(7 times)

(8 times)

(8 times)

OPERATION LAMP

(RED)

TIMER lamp

(8 times)

(2 times)

(3 times)

(4 times)

(6 times)

(2 times)

(3 times)

(4 times)

(8 times)

(2 times)

(4 times)

(2 times)

(3 times)

(5 times)

(6 times)

(7 times)

(8 times)

(2 or 3 times)

(2 times)

(3 times)

(4 times)

(5 times)

(6 times)

(2 or 3 times)

(4 times)

(GREEN)

FILTER lamp

(ORANGE)

(2 times)

(3 times)

(4 times)

[Troubleshooting at the remote control LCD]

This is possible only on the wired remote control.

[SELF-DIAGNOSIS]

If an error occurs, the following display will be shown.

(“EE” will appear in the set room temperature display.)

Unit number

Error code

Ex. Self-diagnosis

Error code Error contents

01

13

26

27

00

02

04

28

09

0C

06

0A

15

1d

1E

29

20

2A

17

18

1A

1b

1F

1c

12

0F

24

2c

16

2b

19

25

If “CO” appears in the unit number display, there is a remote controller

error. Refer to the installation instruction sheet included with the remote

controller.

Indoor signal error

Wired remote controller abnormal

Indoor room temperature sensor error

Indoor heat exchanger temperature sensor (middle)

error

Indoor heat exchanger temperature sensor (inlet)

error

Float switch operated

Outdoor discharge pipe temperature sensor error

Outdoor heat exchanger temperature sensor (outlet)

error

Outdoor temperature sensor error

Compressor temperature sensor error

2-way valve temperature sensor error

3-way valve temperature sensor error

Outdoor heat exchanger temperature sensor (middle)

error

Indoor manual auto switch abnormal

Power supply frequency detection error

IPM protection

CT error

Compressor location error

Outdoor fan error

Connected indoor unit abnormal

Outdoor unit computer communication error

Indoor fan abnormal

Discharge temperature error

Exessive high pressure protection on cooling

4-way valve abnormal

Pressure switch abnormal

Compressor temperature error

Active filter abnormal

PFC circuit error

8

SPECIAL INSTALLATION

METHODS

CAUTION

1 When setting DIP switches, do not touch any other parts

on the circuit board directly with your bare hands.

2 Be sure to turn off the main power.

1. GROUP CONTROL SYSTEM

A number of indoor units can be operated at the same time using a

single remote controller.

(1) Wiring method (indoor unit to remote controller)

Indoor unit

No. 0

Remote controller wire

(2) DIP switch setting (indoor unit)

Set the unit number of each indoor unit using DIP switch on the indoor

unit circuit board. (see following table and figure.)

DIP switch is normally set to make unit number No. 0.

Indoor unit

Unit number DIP SWITCH No.

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Example : No. 3

Indoor unit

Remote

controller

1

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

No. 1

2

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

Indoor unit

No. 2

3

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

Indoor unit

No. 3

4

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

9

Explain the following to the customer in accordance with the operating

manual:

(1) Starting and stopping method, operation switching, temperature ad-

justment, timer, air flow switching, and other remote control unit op-

erations.

(2) Air filter removal and cleaning, and how to use the air louvers.

(3) Give the operating and installation manuals to the customer.

(4) If the signal code is changed, explain to the customer how it changed

(the system returns to signal code A when the batteries in the remote

control unit are replaced).

*(4) is applicable to using wireless remote control.

CUSTOMER GUIDANCE

(3) Press the start/stop button to stop the test run.

Test run display

PART NO. 9377778017-03

Loading...

Loading...