General ASHA18LE, ASHA18LEC, AOHR18LEC Installation Manual

SPLIT TYPE

ROOM AIR CONDITIONER

WALL MOUNTED

INVERTER

SERVICE

INSTRUCTION

Models Indoor unit Outdoor unit

AS*A18LEC

type

AO*R18LEC

R410A

1. SPECIFICATION

CONTENTS

AS*A18LEC.....................................................................................................................

2. DIMENSIONS

AS*A18LEC.....................................................................................................................

3. REFRIGERANT SYSTEM DIAGRAM

AS*A18LEC.....................................................................................................................

4. CIRCUIT DIAGRAM

AS*A18LEC.....................................................................................................................

5. DESCRIPTION OF EACH CONTROL OPERATION

1. COOLING OPERATION..............................................................................................

2. HEATING OPERATION..............................................................................................

01-01

02-01

03-01

04-01

05-01

05-02

3. DRY OPERATION......................................................................................................

4. AUTO CHANGEOVER OPERATION.........................................................................

5. INDOOR FAN CONTROL...........................................................................................

6. OUTDOOR FAN CONTROL.......................................................................................

7. LOUVER CONTROL...................................................................................................

8. COMPRESSOR CONTROL........................................................................................

9. TIMER OPERATION CONTROL................................................................................

10. ELECTRONIC EXPANSION VALVE CONTROL........................................................

11. TEST OPERATION CONTROL..................................................................................

12. PREVENT TO RESTART FOR 3 MINUTES ( 3 MINUTES ST )................................

13. FOUR-WAY VALVE EXTENSION SELECT...............................................................

14. AUTO RESTART........................................................................................................

15. MANUAL AUTO OPERATION ( Indoor unit body operation ).....................................

16. FORCED COOLING OPERATION............................................................................

17. COMPRESSOR PREHEATING..................................................................................

18. COIL DRY OPEARTION CONTROL..........................................................................

19. DEFROST OPERATION CONTROL..........................................................................

05-03

05-04

05-05

05-07

05-08

05-10

05-11

05-13

05-13

05-13

05-13

05-13

05-14

05-14

05-14

05-14

05-15

20. OFF DEFROST OPERATION CONTROL..................................................................

21. 10°C HEAT OPERATION...........................................................................................

22. VARIOUS PROTECTIONS......................................................................................... 05-18

05-17

05-17

6. REFRIGERANT CAUTION -R410A-

1. R410A TOOLS............................................................................................................

2. PRECAUTION FOR INSTALLATION.........................................................................

3. PRECAUTION FOR SERVICING...............................................................................

4. NEW REFRIGERANT R410A.....................................................................................

5. DEFFERENCE FROM CONVENTIONAL MODEL(R22) AND PRECAUTIONS........

7. TROUBLE SHOOTING

1. WHEN THE UNIT DOES NOT OPERATE AT ALL....................................................

2. SELF DIAGNOSIS FUNCTION..................................................................................

3. TROUBLE SHOOTING METHOD

4. SELF-DIAGNOSIS FUNCTION AND CHECKING POINTS.......................................

5. SERIAL SIGNAL DIAGNOSIS....................................................................................

6. IPM PROTECTION.....................................................................................................

7. TROUBLE SHOOTING OF REFRIGERANT CYCLE.................................................

8. APPENDING DATA

06-01

06-02

06-04

06-05

06-08

07-01

07-02

07-03

07-07

07-08

07-09

1. Jumper & Function setting..........................................................................................

2. Thermistor Resistance Values....................................................................................

9. REPLACEMENT PARTS

10. INSTALLATION MANUAL

08-01

08-02

WALL MOUNTED type

R410A

INVERTER

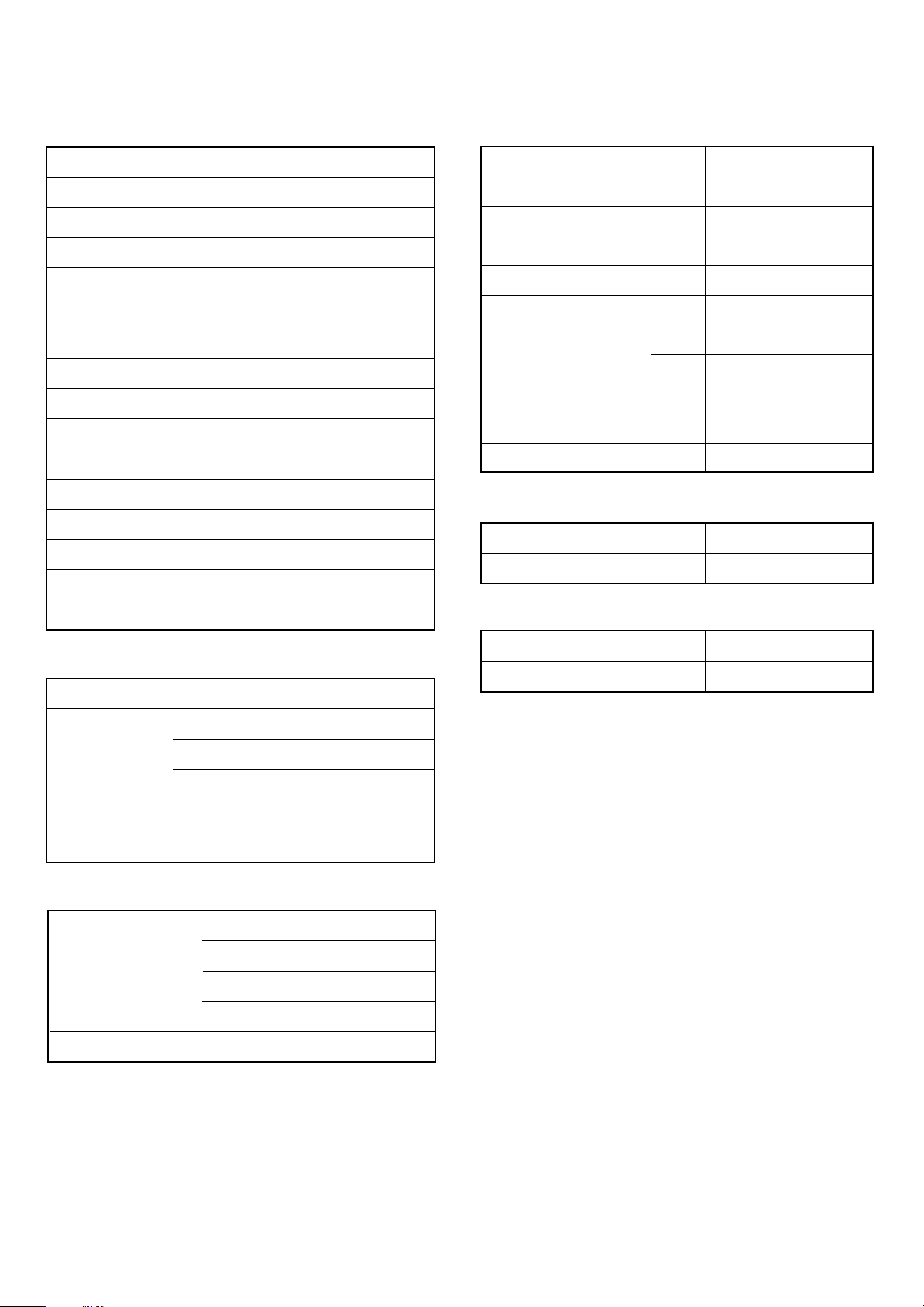

1 . SPECIFICATIONS

SPECIFICATIONS

ELECTRICAL DATA

INDOOR UNIT

OUTDOOR UNIT

POWER SOURCE

FREQUENCY

COOLING CAPACITY

HEATING CAPACITY 6.30 kW

RUNNING CURRENT (Cool)

RUNNING CURRENT (Heat)

INPUT WATTS (Cooling)

INPUT WATTS (Heating)

E.E.R. (Cooling)

C.O.P. (Heating)

MAXIMUM CURRENT (Cool)

MAXIMUM CURRENT (Heat)

MOISTURE REMOVAL

AS*A18LEC

AO*R18LEC

230 V

50 Hz

5.20 kW

6.8 A

7.6 A

1.52 kW

1.71 kW

3.42 kW/kW

3.68 kW/kW

9.0 A

12.5 A

2.8 L/hr

COMPRESSOR AND REFRIGERANT

Hermetic type,

TYPE

DISCRIMINATION

WEIGHT (with oil)

REFRIGERANT TYPE

PRECHARGED REFRIGERANT

Pipe Length

FULL CHARGE

ADDITIONAL CHARGE

MAX HEIGHT

15 m

20 m

25 m

4 pole, Rotary,

DC inverter motor

808 903 80

9.0 kg

R410A

1,200 g

1,200 g

1,300 g

1,400 g

20 g/m

20 m

DIMENSIONS

INDOOR UNIT

OUTDOOR UNIT

H x W x D

H x W x D

320 x 998 x 228 mm

620 x 790 x 298 mm

AIR CIRCULATION HIGH

FAN MOTOR

POWER SOURCE

High speed

INDOOR UNIT

OUTDOOR UNIT

Middle

Low

Quiet

NOISE LEVEL

High

INDOOR UNIT

(Cooling / Heating)

OUTDOOR UNIT (Cool / Heat)

Middle

Low

Quiet

900 m3/hr

230 V

1,220 r.p.m.

1,020 r.p.m.

900 r.p.m.

710 r.p.m.

1,050 r.p.m.

43 dB / 42 dB

37 dB / 37 dB

33 dB / 33 dB

26 dB / 25 dB

50 dB / 52 dB

WEIGHT

INDOOR UNIT

OUTDOOR UNIT

Gross / Net

Gross / Net

18 kg / 14 kg

45 kg / 40 kg

01-01

WALL MOUNTED type

R410A

INVERTER

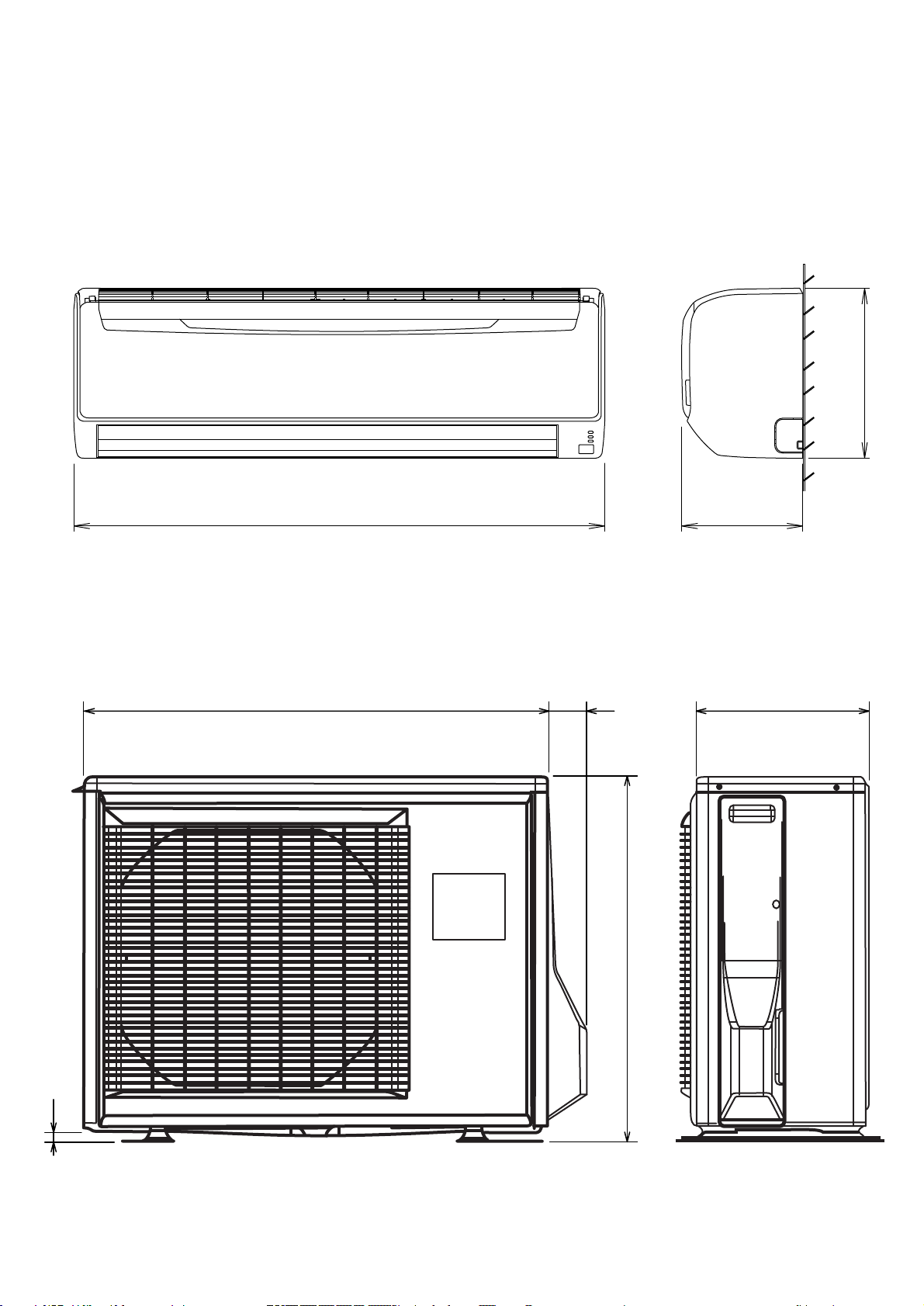

2 . DIMENSIONS

INDOOR UNIT

DIMENSIONS

(unit : mm)

320

OUTDOOR UNIT

998

228

29867790

620

20

02-01

WALL MOUNTED type

R410A

INVERTER

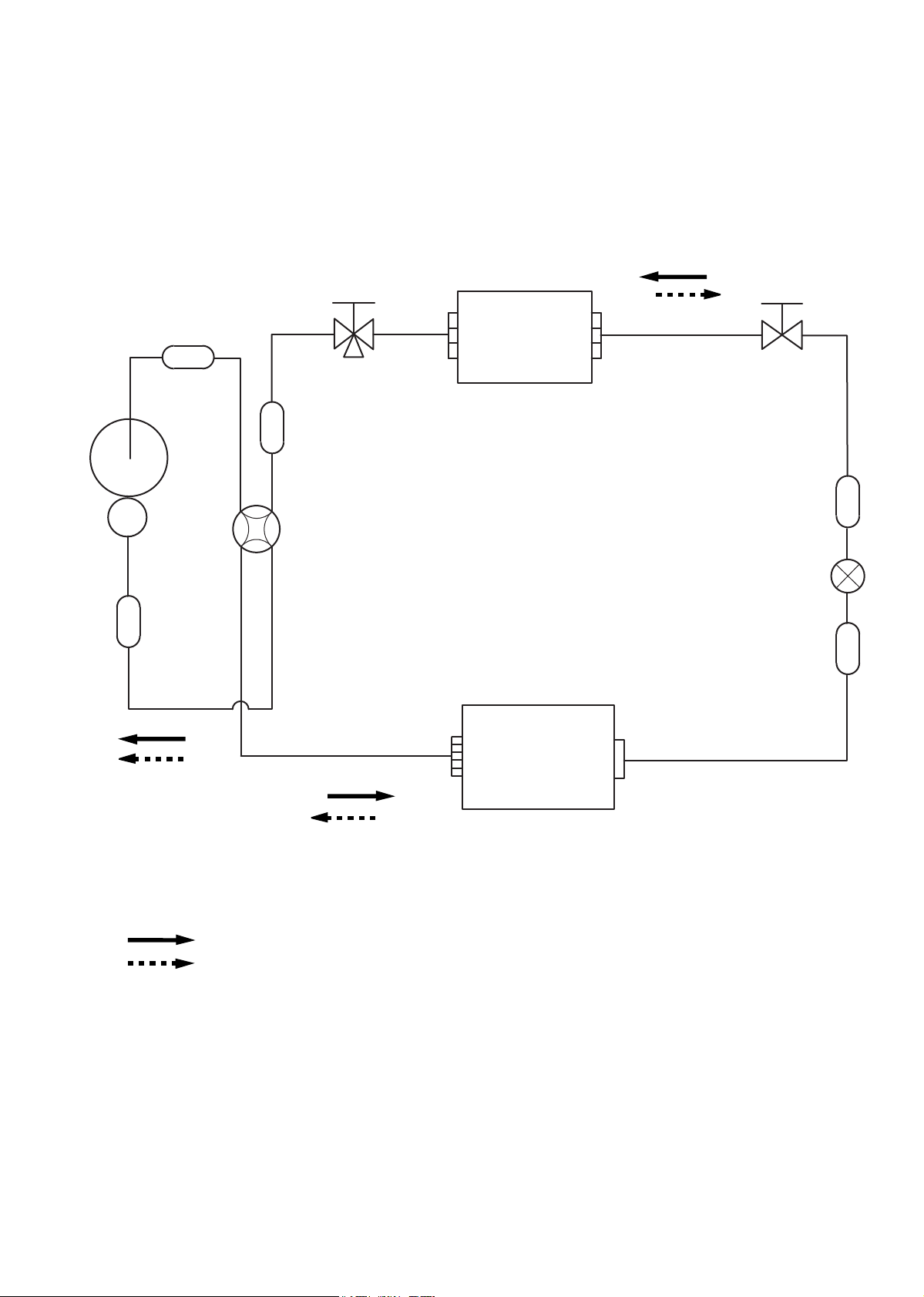

3 . REFRIGERANT SYSTEM DIAGRAM

REFRIGERANT SYSTEM DIAGRAM

3-Way

valve

Muffler

Muffler

Compressor

4-Way valve

Sub-accumulator

Heat exchanger

(Indoor unit)

2-Way

valve

Strainer

Expansion valve

Strainer

Heat exchanger

(Outdoor unit)

Refrigerant direction

Cooling

Heating

Refrigerant pipe diameter

Liquid : 1/4" (6.35 mm)

Gas : 1/2" (12.7 mm)

03-01

WALL MOUNTED type

R410A

INVERTER

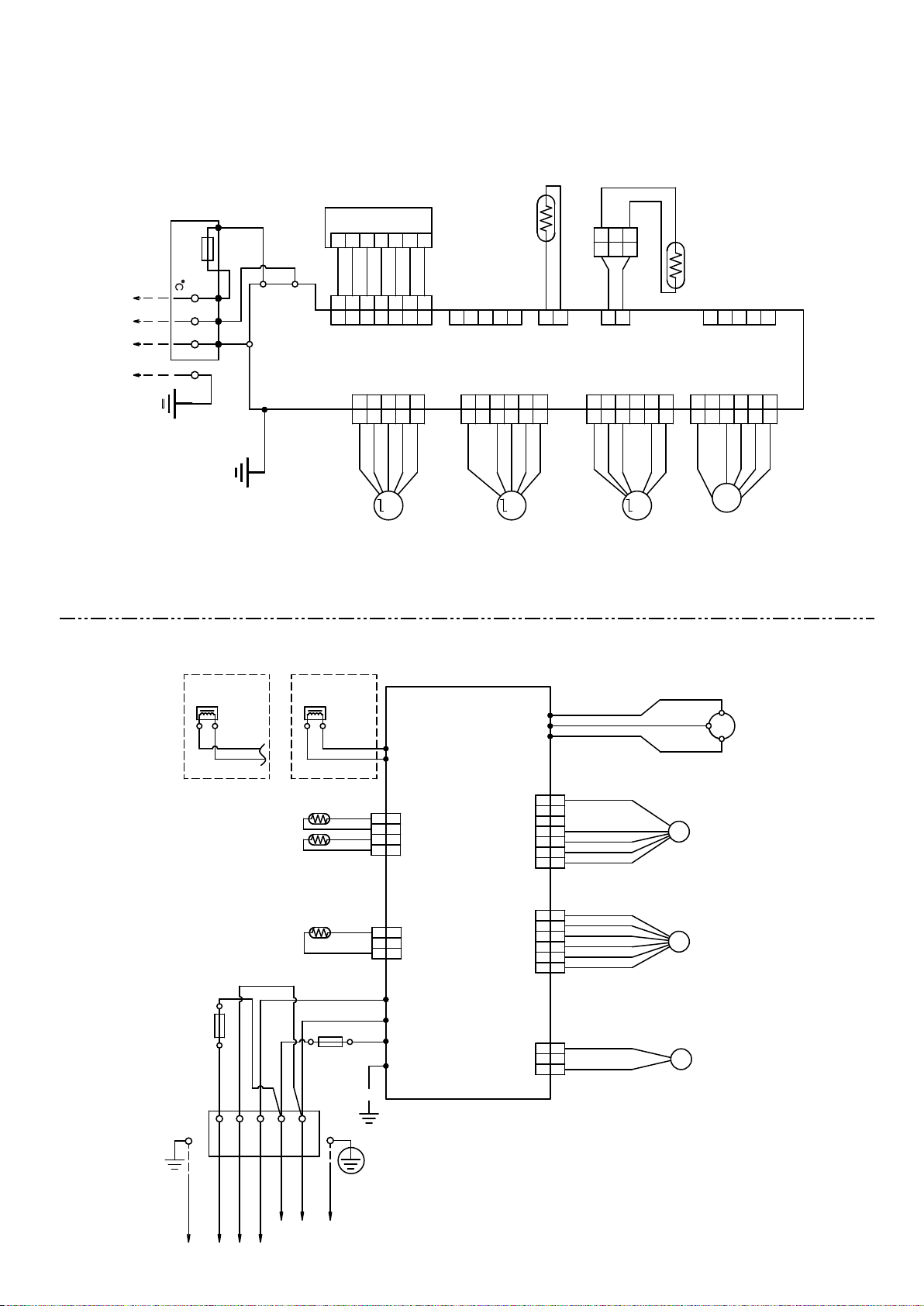

4 . CIRCUIT DIAGRAM

INDOOR UNIT

TERMINAL

THERMAL

FUSE 102

TO OUTDOOR UNIT

1 2 3

RED

CIRCUIT DIAGRAM

THERMISTOR

( ROOM TEMP. )

INDICATOR PCB ASSY

BLACK

WHITE

TM1

TM4

TM2

W5

GREEN

2

1

WHITE

RED

2

1

2

1

1

1

4

3

WHITE

WHITE

4

3

4

3

CN11

CN2

2

3

2

3

YELLOW

ORANGE

RED

CN201

5

6

7

WHITE

WHITE

WHITE

5

6

7

5

1

6

7

5

4

2

3

CN6

CN5

4

2

5

4

5

4

PINK

1

3

4

2

1

3

YELLOW

ORANGE

BLUE

RED

THERMISTOR

( PIPE TEMP. )

BLACK

BLACK

2

3

1

2

3

BLACK

1

CN1

5

6

5

6

BLUE

PINK

1

BLACK

2

WHITE

RED

1

2

CN3

CN8

5

4

2

1

3

6

5

4

2

1

3

RED

ORANGE

6

BLUE

PINK

YELLOW

TEST

1

5

4

2

3

CONTROLLER PCB ASSY

( MAIN PCB )

CN13

CN10

1

2

3

4

5

6

5

6

RED

1

2

3

4

BLUE

YELLOW

WHITE

BLACK

OUTDOOR UNIT

REACTOR

WHITE

RED

THERMISTOR ( PIPE TEMP. )

THERMISTOR ( DISCHARGE TEMP. )

THERMISTOR ( OUTDOOR TEMP. )

WHITE

FUSE

250V 5A

BLACK

BLACK

REACTOR

or

BLACK

( RIGHT / LEFT )

WHITE

BLACK

BLACK

BROWN

BROWN

BLACK

BLACK

WHITE

FUSE

250V 20A

STEP MOTOR

RED

RED

BLACK

GREEN

STEP MOTOR

M

W10

W11

( UP / DOWN )

CONTROLLER PCB ASSY

1

1

2

2

CN71

3

3

4

4

1

1

CN70

2

2

3

3

W4

W2

W1

W3

M

CN800

CN40

CN30

W7

W8

W9

STEP MOTOR

( DIFFUSER )

M

RED

WHITE

BLACK

RED

1

1

2

2

3

3

BLACK

4

4

WHITE

5

5

YELLOW

6

6

BROWN

7

7

RED

1

1

BROWN

2

2

BLUE

3

3

ORANGE

4

4

YELLOW

5

5

WHITE

6

6

BLACK

1

1

2

2

BLACK

3

3

FAN MOTOR

FM

EXPANSION VALVE

PMV

4-WAY VALVE

4WV

F M

FAN MOTOR

COMPRESSOR

R

CM

S

C

TERMINAL

1

TO INDOOR UNIT

3 L

2

(N)

POWER SOURCE

N

04-01

WALL MOUNTED type

R410A

INVERTER

5 . DESCRIPTION OF EACH

CONTROL OPERATION

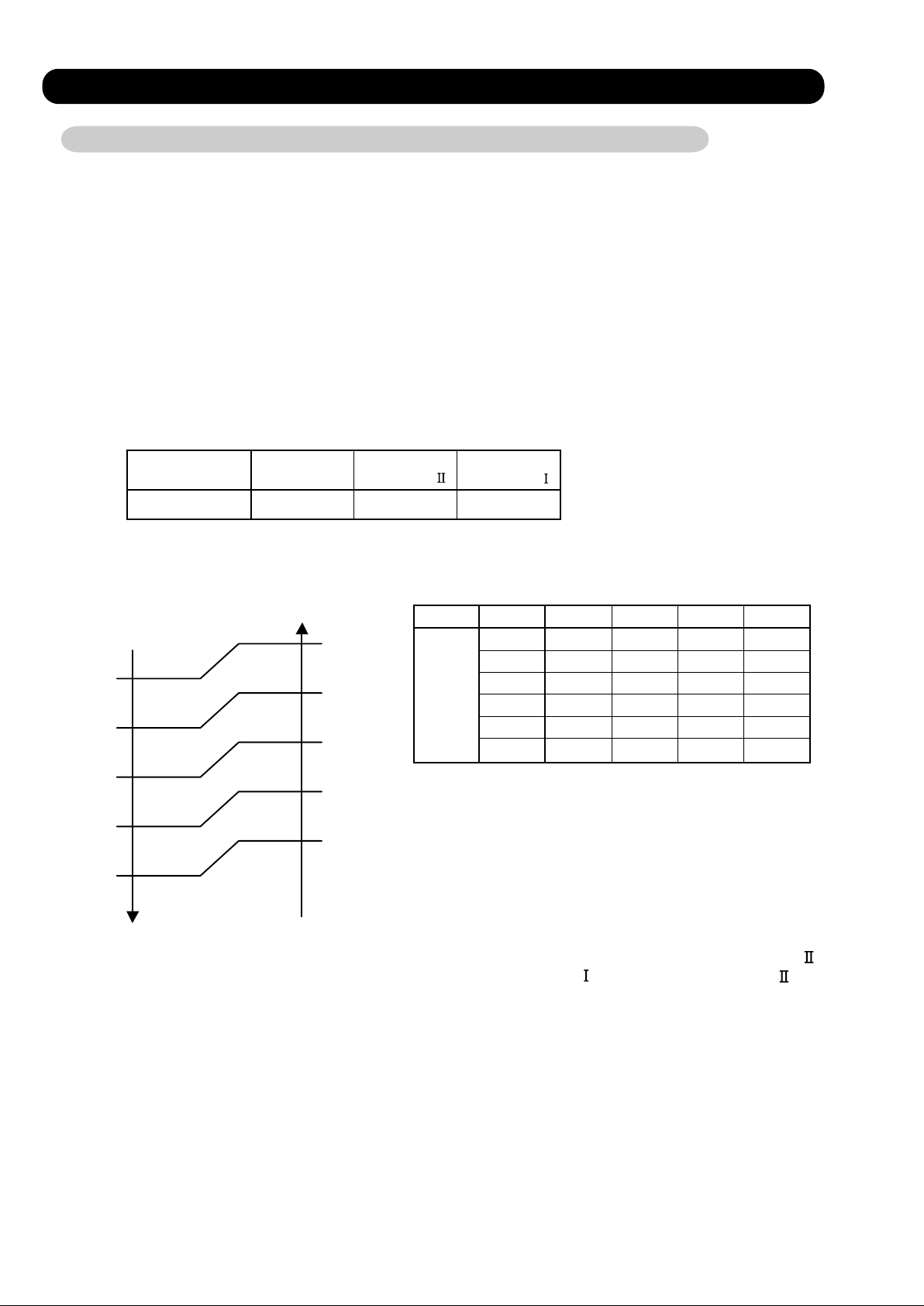

1. COOLING OPERATION

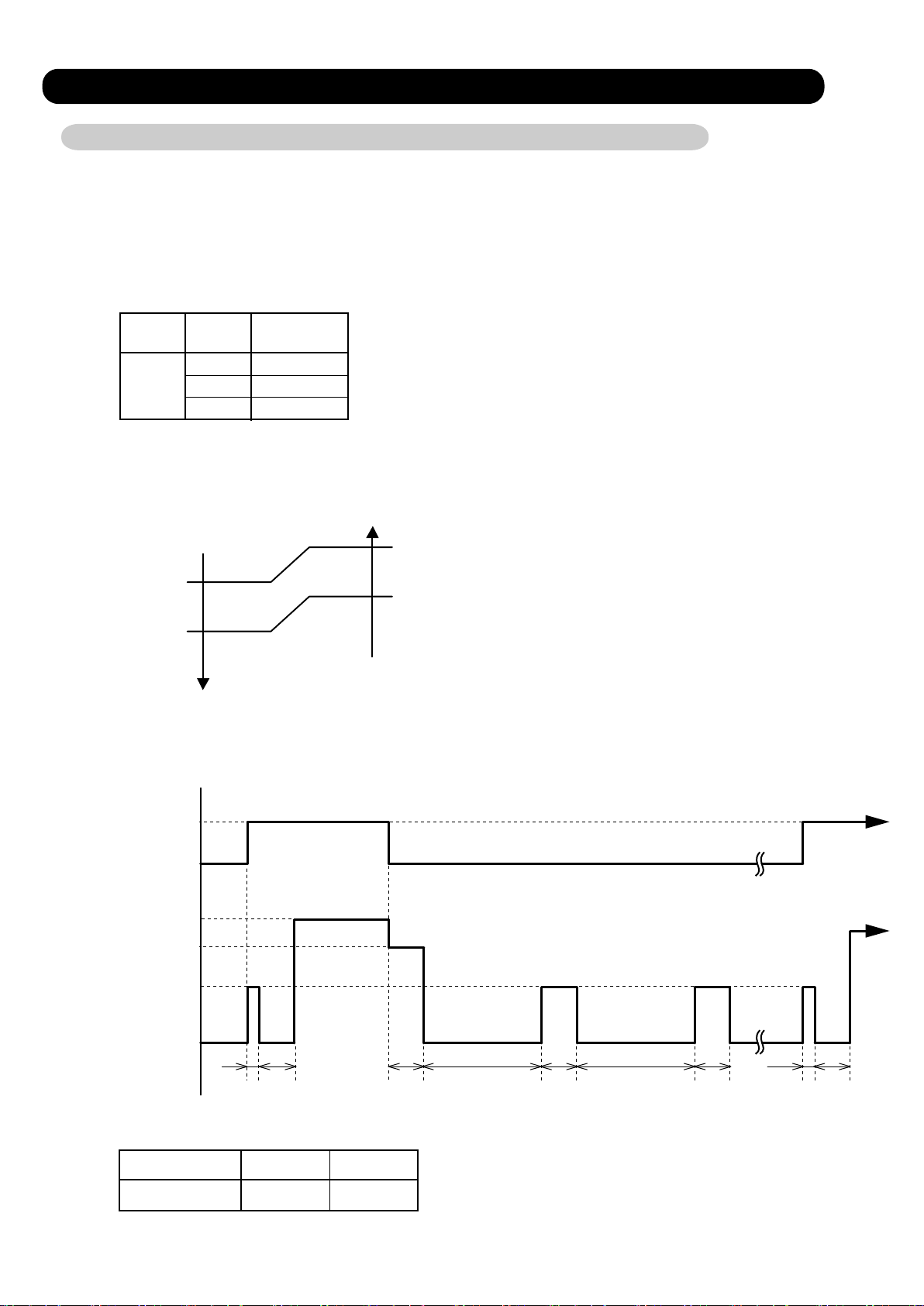

1-1 COOLING CAPACITY CONTROL

A sensor (room temperature thermistor) built in the indoor unit body will usually perceive

difference or variation between a set temperature and present room temperature, and

controls the operation frequency of the compressor.

* If the room temperature is 2°C higher than a set temperature, the compressor operation

frequency will attain to maximum performance.

* If the room temperature is 2.5°C lower than a set temperature, the compressor will be

stopped.

* When the room temperature is between +2°C to -2.5°C of the setting temperature,

the compressor frequency is controlled within the range shown in Table1.

However, the maximum frequency is limited in the range shown in Figure 1 based on the

fan speed mode and the outdoor temperature.

( Table 1 : Compressor Frequency Range )

minimum

frequency

AS*A18LEC 18Hz 70Hz 95Hz

maximum

frequency

maximum

frequency

( Fig. 1 : Limit of Maximum Frequency based on Outdoor Temperature )

Outside air Outside air

temperature temperature

A zone 95Hz 66Hz 54Hz 34Hz

B zone 95Hz 66Hz 54Hz 34Hz

C zone 95Hz 66Hz 54Hz 34Hz

D zone 58Hz 45Hz 30Hz 24Hz

E zone 58Hz 45Hz 30Hz 24Hz

F zone 58Hz 45Hz 30Hz 24Hz

34°C

30°C

19°C

10°C

0°C

A zone

B zone

C zone

D zone

E zone

36°C

32°C

21°C

12°C

2°C

18LEC

Hi Me Lo Quiet

F zone

When the compressor operates for 30 minutes continuously at over the maximum frequency ,

the maximum frequency is changed from Maximum Frequency to Maximum Frequency .

05-01

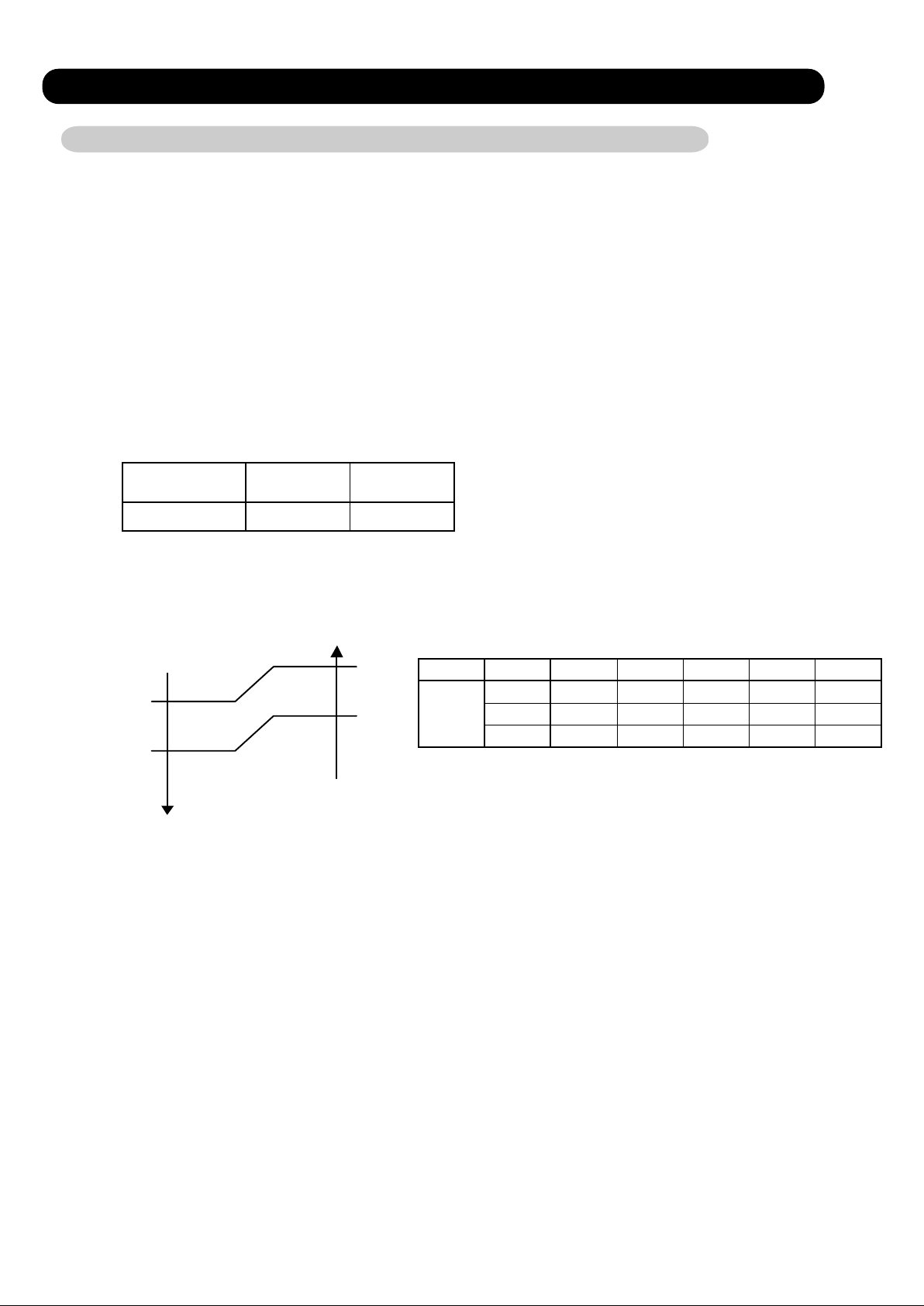

2. HEATING OPERATION

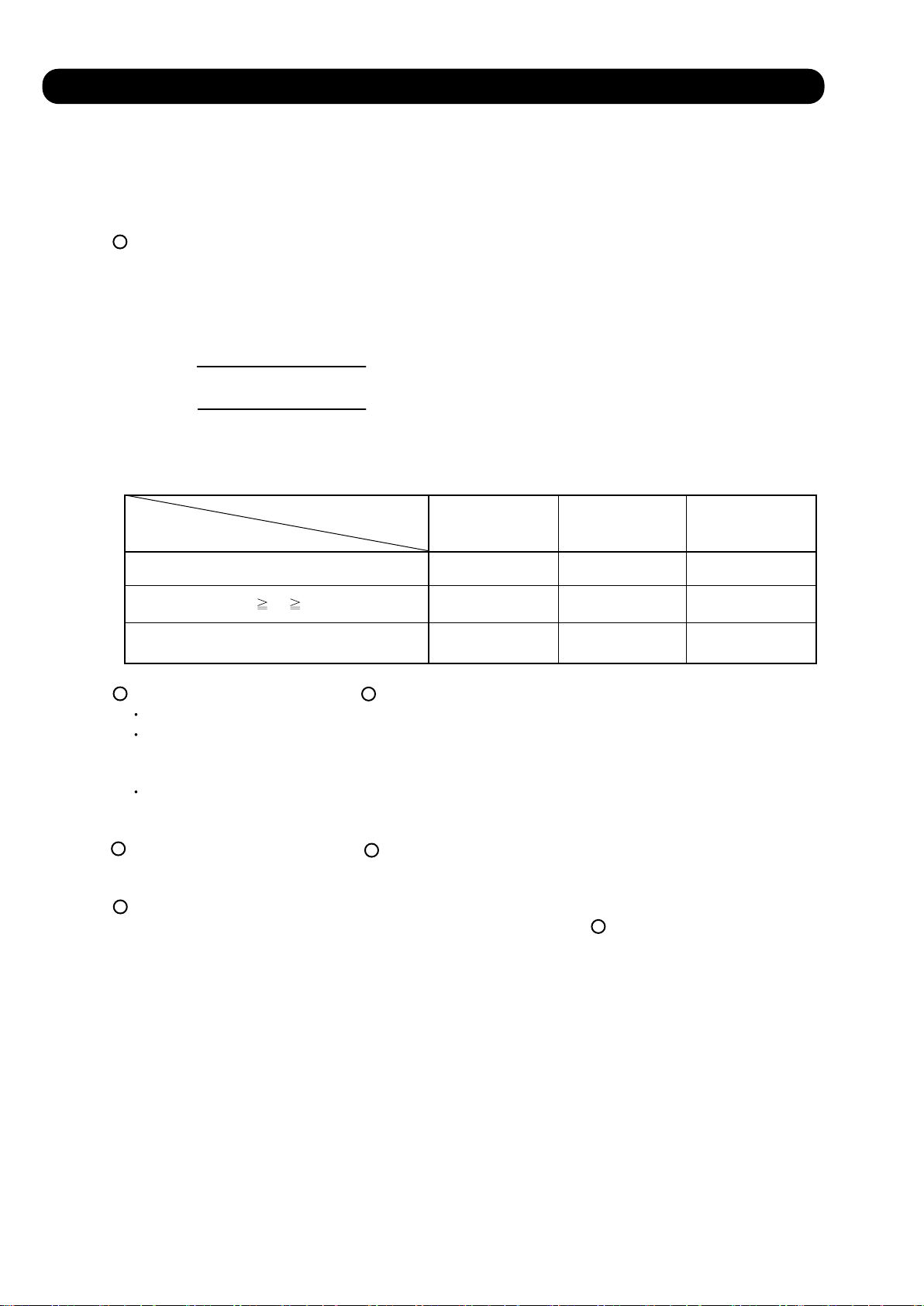

2-1 HEATING CAPACITY CONTROL

A sensor (room temperature thermistor) built in the indoor unit body will usually perceive

difference or variation between a set temperature and present room temperature, and

controls the operation frequency of the compressor.

* If the room temperature is lower by 3°C than a set temperature, the compressor operation

frequency will attain to maximum performance.

* If the room temperature is higher 2.5°C than a set temperatire, the compressor will be stopped.

* When the room temperature is between +2.5°C to -3°C of the setting temperature,

the compressor frequency is controlled within the range shown in Table2.

However, the maximum frequency is limited in the range shown in Figure 2 based on the

fan speed mode and the outdoor temperature.

( Table 2 : Compressor Frequency Range )

minimum

frequency

AS*A18LEC 18Hz 130Hz

maximum

frequency

( Fig.2 : Limit of Maximum Frequency based on Outdoor Temperature )

Outside air Outside air

temperature temperature

17°C

12°C

C zone

B zone

A zone

19°C

14°C

18LEC

A zone

B zone

C zone

Hi Me+ Lo Quiet

130Hz 130Hz 75Hz 62Hz

130Hz 130Hz 75Hz 62Hz

130Hz 130Hz

Me

95Hz

95Hz

95Hz 75Hz 62Hz

* The room temperature is controlled 2°C higher than the setting temperature for 60 minutes

after starting the operation.

After 60 minutes, it is controlled based on the normal setting temperature.

05-02

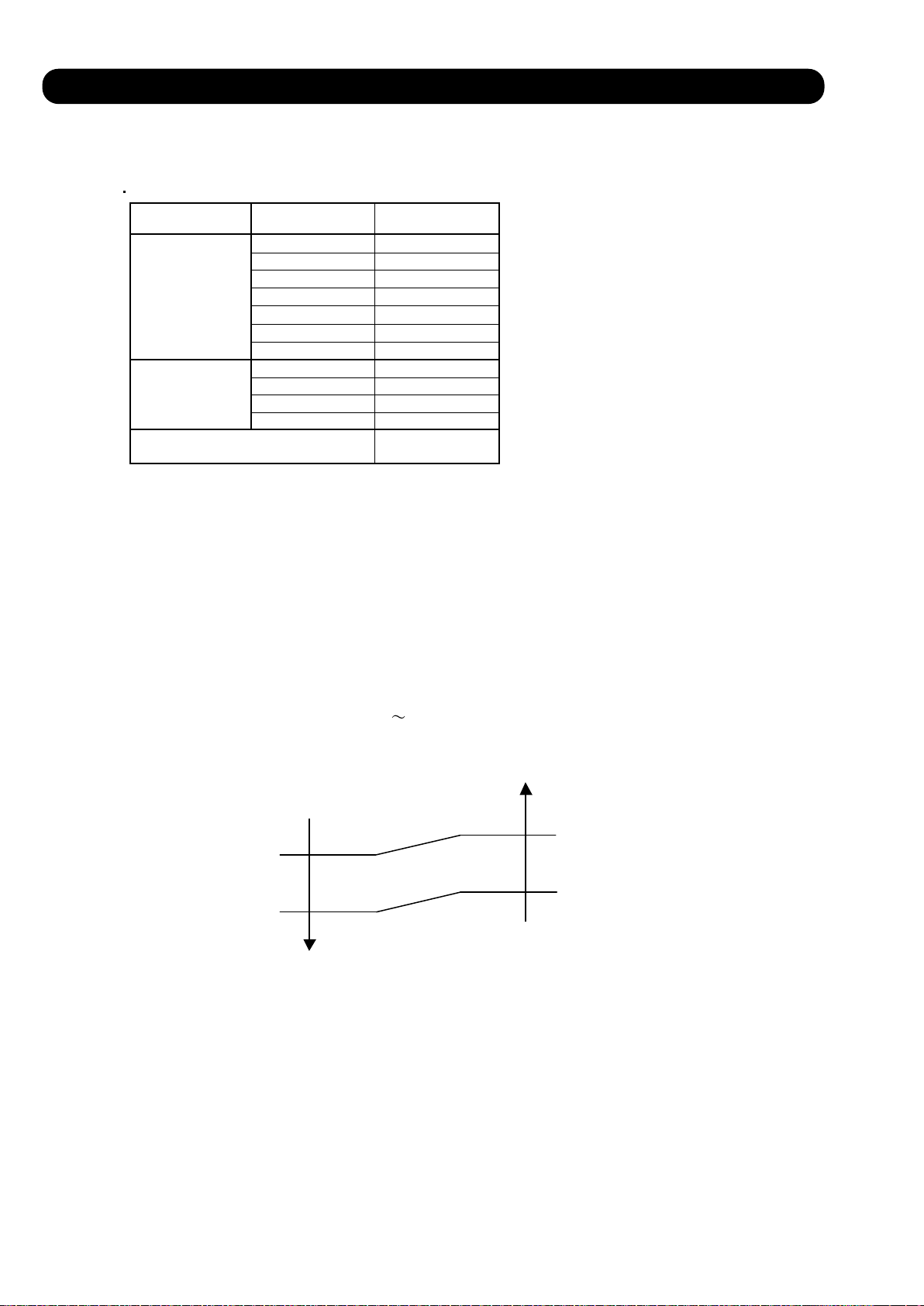

3. DRY OPERATION

3-1 INDOOR UNIT CONTROL

The compressor rotation frequency shall change according to the temperature, set temperature,

and room temperature variation which the room temperature sensor of the indoor unit body has

detected as shown in the Table 3.

However, after the compressor is driven, the indoor unit shall run at operation frequency of

40Hz, for a minute.

( Table 3 : Compressor frequency )

Operating

frequency

18LEC

X zone

J zone

Y zone

( Fig.3 : Compressor Control based on Room Temperature )

Room Room

temperature temperature

34Hz

20Hz

0Hz

Ts+0.5°C

Ts -1.5°C

( Fig.4 : Indoor Fan Control )

Compressor

ON

OFF

Indoor fan

Setting air flow

Indoor fan

(as shown in Table 4)

Quiet

Ts+1.5°C

X zone

Ts -0.5°C

J zone

Y zone

OFF

10 30 60 180 60 180 60 10 30

( Table 4 : Indoor fan speed )

X zone J, Y zone

AS*A18LEC 710rpm 660rpm

(SEC)

05-03

4. AUTO CHANGEOVER OPERATION

When the air conditioner is set to the AUTO mode by remote control, operation starts in the optimum

mode from among the HEATING, COOLING, DRY and MONITORING modes. During operation, the

optimum mode is automatically switched in accordance with temperature changes. The temperature

can be set between 18°C and 30°C in 1°C steps.

When operation starts, only the indoor and outdoor fans are operated for 1 minute. After 1 minute,

1

the room temperature and outside air temperature are sensed and the operation mode is

selected in accordance with the table below.

( Fig.5 : Outside air temperature zone selection )

C zone

32°C

B zone

-10°C

A zone

( Table.5 Operation mode selection table)

Outside air temperature (TO)

Room temperature (TB)

TB > TS+2°C

TS+2°C TB TS - 2°C

<

TB TS- 2°C Heating Heating Monitoring

2

When COOING was selected at , the air conditioner operates as follow:

1

A zone B zone C zone

Monitoring

Monitoring Monitoring Monitoring

Cooling

(automatic dry)

Cooling

(automatic dry)

The same operation as COOLING OPERATION of item 1 above is performed.

When the room temperature has remained at (set temperature -1°C) for 8 minutes, operation is

automatically switched to DRY and the same operation as DRY OPERATION of item 3 above

is performed.

If the room temperature reaches (set temperature +2°C during DRY operation, operation returns to

COOLING operation.

3

When HEATING was selected at , the same operation as HEATING OPERATION of item 2

1

above is performed.

4

When the compressor was stopped for 6 consecutive minutes by the temperature control function

after the COOLING or HEATING operation mode was selected at above, operation is switched

1

to MONITORING and the operation mode is selected again.

05-04

5. INDOOR FAN CONTROL

1. Fan speed

( Table 6 : Indoor Fan Speed )

AS*A18LEC

Operation mode Air flow mode Speed (rpm)

Heating

Cooling

Dry

2. FAN OPERATION

Hi

Me+

Me

Lo

Quiet

Cool air prevention

S-Lo

Hi

Me

Lo

Quiet

1220

1120

1020

900

710

660

270

1220

1020

900

710

X zone: 710

J zone: 660

The airflow can be switched in 5 steps such as AUTO, QUIET, LOW, MED, HIGH,

while the indoor fan only runs.

When Fan mode is set at (Auto), it operates on (MED) Fan Speed.

3. COOLING OPERATION

Switch the airflow [AUTO], and the indoor fan motor will run according to a room temperature,

as shown in Figure 6.

On the other hand, if switched in [HIGH] [QUIET], the indoor motor will run at a constant airflow of [COOL]

operation modes QUIET, LOW, MED, HIGH,as shown in Table 6.

( Fig.6 : Airflow change - over ( Cooling : AUTO ) )

TR-Ts > 2.5 degC

=

2.5 degC > TR-Ts > 1.5 degC

1.5 degC > TR-Ts

=

TR-Ts > 2 degC

=

2 degC > TR-Ts > 1 degC

1 degC > TR-Ts

=

HIGH mode

MED mode

LOW mode

When the room

temperature drops

When the room

temperature rises

TR : Room temperature

Ts : Setting temperature

05-05

4. DRY OPERATION

Refer to the Table 6.

During the dry mode operation, the fan speed setting can not be changed.

5. HEATING OPERATION

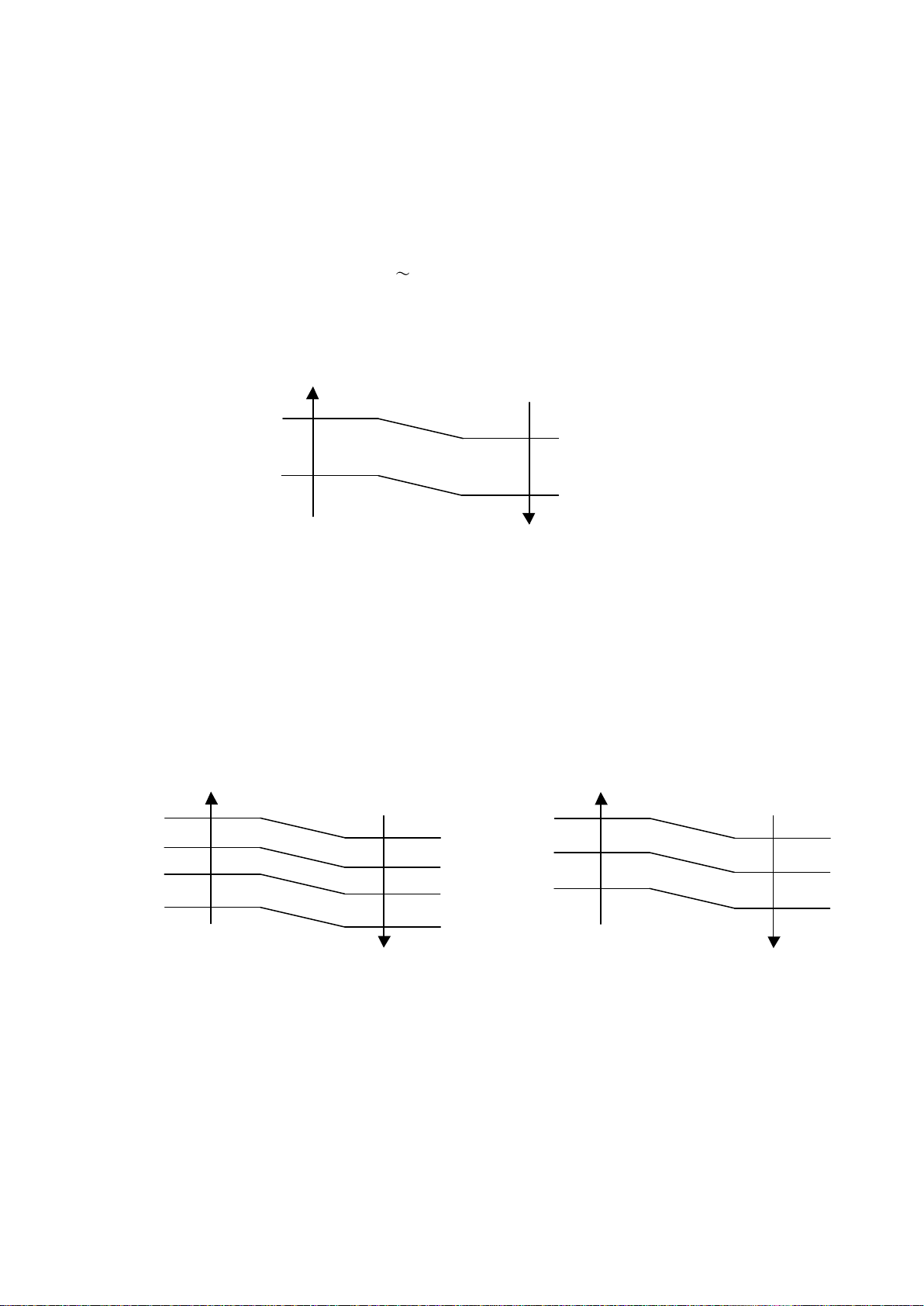

Switch the airflow [AUTO], and the indoor fan motor will run according to a room temperature,

as shown in Figure 7.

On the other hand, if switched in [HIGH] [QUIET], the indoor motor will run at a constant airflow

of [HEAT] operation modes QUIET, LOW, MED, HIGH, as shown in Table 6.

( Fig.7 : Airflow change - over ( Heating : AUTO ) )

When the room

temperature rises

TR-Ts > - 1 degC

=

- 1 degC > TR-Ts > - 2 degC

- 2 degC > TR-Ts

TR : Room temperature

Ts : Setting temperature

=

LOW mode

MED mode

MED+ mode

When the room

temperature drops

TR-Ts > - 1.5 degC

=

- 1.5 degC > TR-Ts > - 2.5 degC

- 2.5 degC > TR-Ts

=

6. COOL AIR PREVENTION CONTROL (Heating mode)

The maximum value of the indoor fan speed is set as shown in Figure 8, based on the detected

temperature by the indoor heat exchanger sensor on heating mode.

(Fig.8 : Cool Air Prevention Control)

Indoor heat exchanger

temperature

47°C

40°C

37°C

30°C

< [Hi] setting >

Hi

Me+

Lo

Cool air

prevention

S-Lo

Indoor heat exchanger

temperature

40°C

34°C

32°C

28°C

Indoor heat exchanger

temperature

40°C

37°C

30°C

< The other of [Hi] setting >

Setting

FAN mode

Lo (Qu)

Cool air

prevention

S-Lo

Indoor heat exchanger

temperature

34°C

32°C

28°C

05-06

6. OUTDOOR FAN CONTROL

1. Outdoor Fan Motor

Following table shows the type of the outdoor fan motor. The control method is different

between AC motor and DC motor.

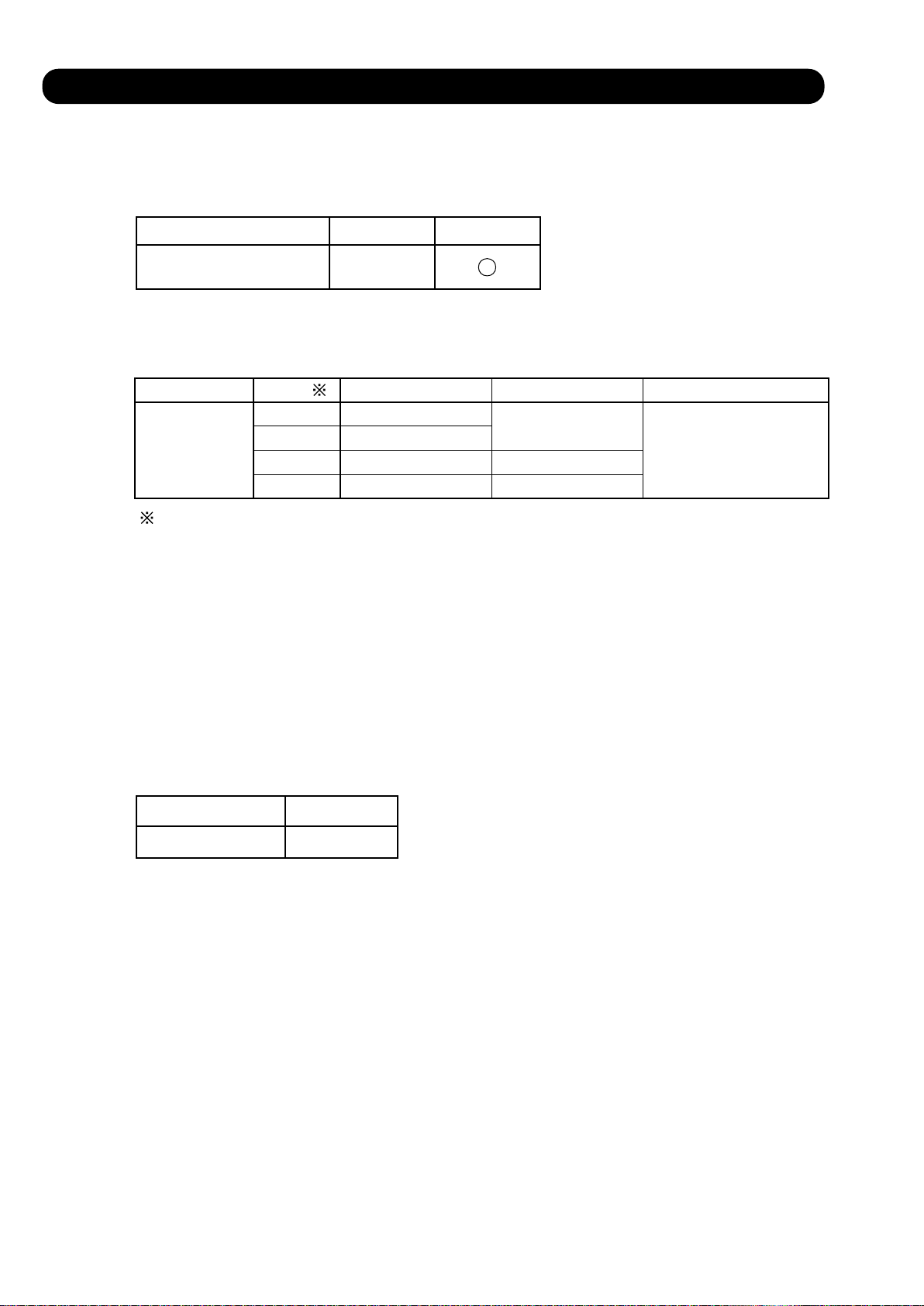

( Table 7 : Type of Motor )

AC Motor DC Motor

AS*A18LEC

2. Fan Speed

( Table 8 : Outdoor fan speed )

ZONE

AS*A18LEC 1050/ 870/ 720/ 530

Refer to Fig1.

It runs at 500(A-D ZONE)/200(E,F ZONE) rpm for 20 seconds after starting up the outdoor fan.

*

The outdoor fan speed mentioned avobe depends on the compressor frequency.

*

A - C

D

E

F

Cooling Dry Heating

870/ 530/ 300

300

250/ 200

530

870/ 780/ 720/ 590/ 480

300

250/ 200

(rpm)

(When the compressor frequency increases, the outdoor fan speed also changes to the higher

speed. When the compressor frequescy decreases, the outdoor fan speed also changes to the

lower speed.)

Outdoor temperature falls, and if it becomes E and F zone(Refer to Fig1), rotations of fan speed

*

will fall.

After the defrost control is operated on the heating mode, the fan speed keeps at the higher speed

*

as table 9 without relating to the compressor frequency.

( Table 9 : Outdoor fan speed after the defrost )

AS*A18LEC

Min

1100rpm

05-07

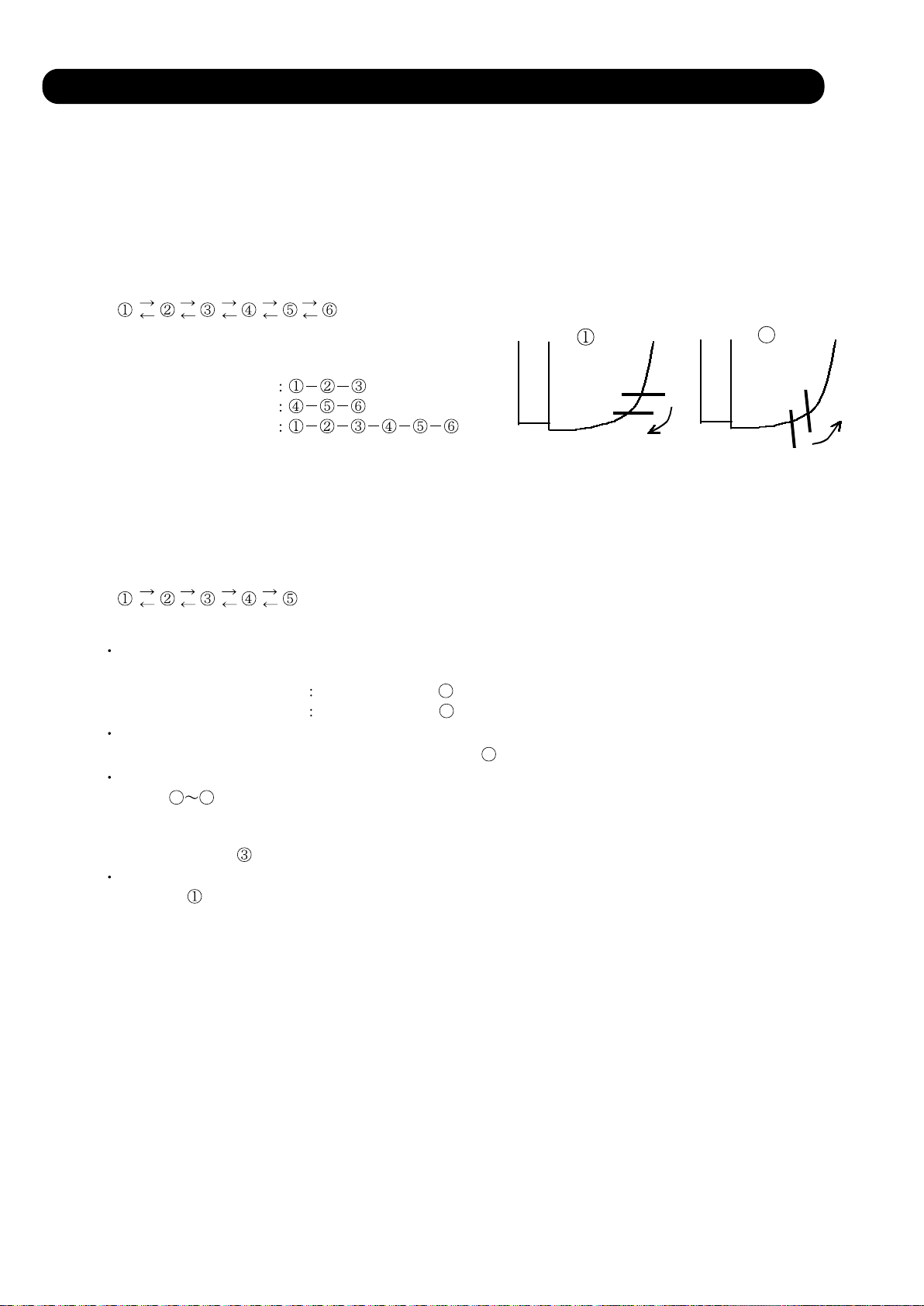

7. LOUVER CONTROL

1. LOUVER CONTROL

When the indoor control interface device receives a control signal light from the remote control,

it will actuate, the step motor according to the control signal, and set the louver to each position.

In addition, if the air conditioner is stopped, vertical louver will be closed automatically.

Vertical Air Direction Adjustment

(Function Range)

Each time the button is pressed, the air direction range will change as follow:

(Fig 9: Air Direction Range)

(Operation Range)

Cooling / Dry mode

Heating mode

Fan mode

Use the air direction adjustments within the ranges shown above.

Horizontal Air Direction Adjustment

(Function Range)

Each time the button is pressed, the air direction range will change as follow:

6

The vertical airflow direction is set automatically as shown, in accordance with the type of operation

selected.

Cooling / Dry mode Horizontal flow

Heating mode Downward flow

When the temperature of the air being blown out is low at the start of heating operation or during

defrosting, the airflow direction temporarily becomes to prevent cold air being blown onto the body.

During use of the Cooling and Dry modes, do not set the Air Flow Direction Louver in the Heating

4

range ( ) for long period of time, since water vapor many condense near the outlet louvers and

drop of water may drip from the air conditioner. During the Cooling and Dry modes, if the Air Flow

Direction Louvers are left in the hating range for more than 20minutes, they will automatically

return to position .

During Monitor operation in AUTO CHANGEOVER mode, the airflow direction automatically

becomes , the horizontal airflow direction does not cahnge, and it cannot be adjusted.

6

1

6

6

05-08

Loading...

Loading...