GE Industrial Solutions MX150, MX250 User Manual

e GE Zenith Controls

MX150/MX250 (MX Version 6.0+ Only)

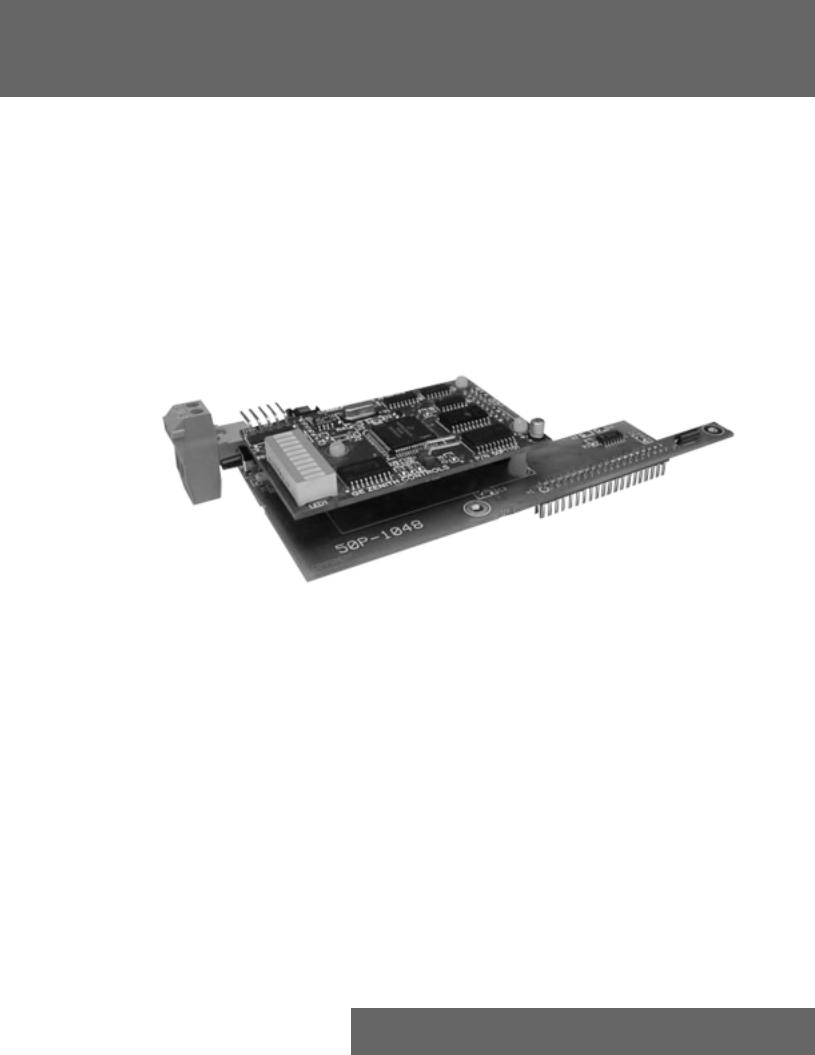

Modbus Network Card 50P-2035

71R-2200

10/04

Operation and Maintenance Manual

Table of Contents |

|

|

Page |

Overview .............................................................................................................................................................................................. |

01 |

LED Indicator .......................................................................................................................................................................... |

01 |

Installation .......................................................................................................................................................................................... |

02 |

Installation on the Controller ...................................................................................................................................... |

02 |

Termination Resistor .......................................................................................................................................................... |

02 |

Configuring a Modbus Network Card .................................................................................................................... |

02 |

Testing a Modbus Network.............................................................................................................................................. |

03 |

CDP Programmable Exercisers .................................................................................................................................... |

03 |

CDT Exercisers........................................................................................................................................................................ |

3 |

Operation ............................................................................................................................................................................................ |

04 |

Setting System Time ............................................................................................................................................................ |

04 |

Operation with In-Phase Monitor .............................................................................................................................. |

04 |

Operation Under Battery Backup .............................................................................................................................. |

04 |

Appendix A – Read Only Register List...................................................................................................................... |

05-12 |

Appendix B – Read/Write Register List ................................................................................................................ |

13-14 |

Appendix C – Modbus Network Card ............................................................................................................................ |

15 |

Appendix D – Connections for Configuring and Testing the Modbus Card ...................................... |

16 |

Appendix E – RS485 Multi-Drop Connection .......................................................................................................... |

17 |

Appendix F – Installation of Modbus Card on Controller .............................................................................. |

18 |

Appendix G – Modbus Protocol Illustration ...................................................................................................... |

19-21 |

Appendix H – Configuring Controller for Modbus (MX150/250) .......................................................... |

22 |

Bill of Materials.............................................................................................................................................................................. |

23 |

Components for the Modbus Option (ZNET250M).................................................................................... |

23 |

Components for the Modbus Card Configuration ...................................................................................... |

23 |

Troubleshooting............................................................................................................................................................................ |

24 |

Disclaimer

GE Zenith Controls disclaims any and all liability for use of third-party application software that will be used to control the Automatic Transfer Switches.

WARNING

WARNING

AutomaticTransfer Switches are often used in critical applications. Failure of an ATS to operate properly could cause serious personal injury (including death) and property damage.Therefore, extreme caution must be used when designing or using programming software that will communicate with the ATS. Improper use of the Modbus network variables will cause the AutomaticTransfer Switch to malfunction. Always conduct a full test and debug of the programming software prior to installing and using it in the system.

Overview

The Modbus network card is designed for the MX150 and MX250 controllers, version 6.0 program and above. If the controller is ordered with the Modbus option, the Modbus card will reside on the back of the controller board and it will be part of the controller assembly. The purpose of this card is to allow the controller to be available on a Modbus network as a slave device. This allows a master device, such as a programmable logic controller (PLC), to obtain information from the controller and have that information available for control, data acquisition and monitoring.

Every Modbus network consists of one master device and at least one slave device. All devices on the network are daisy-chained using a twisted pair cable (see Appendix E). Each slave device is assigned a unique address from 1-247. Factory default for each Modbus card is Slave Address 1. This address enables the master to distinguish between the various slaves on the network. It also allows the master device to send a query command to the addressed slave. When the addressed slave receives this command it will send back an appropriate response to the master. Table 1 shows a list of Modbus commands which the Modbus network card supports. Reference Appendix G for a more detailed description of the Modbus commands.

Modbus Command |

Modbus Command Description |

01 |

Read Coil Status |

|

|

03 |

Read Holding Register |

|

|

05 |

Write Single Coil |

06 |

Write Single Holding Register |

15 |

Write Multiple Coils |

|

|

16 |

Write Multiple Holding Registers |

Table 1 – Supported Modbus Commands

The Modbus commands allow the master device to read data from, and write data to, specific memory locations in the controller. These memory locations, which are listed in Appendix A and B, make up the Modbus network variables. These variables allow the reading of controller status, configuration, etc. The variables which can be written to (reference Appendix B), include timer values, Fail/Restore settings, and control variables.

Both lists contain a parameter name column that displays the name of the memory locations. The non-indented names in that column are 16-bit registers while the indented ones are individual bits, which make up the 16-bit registers. For example, Status 0, a non-indented name, is a 16-bit register that consists of the following bits:

• |

S1 Available |

• |

Alarm |

• |

S2 Available |

• |

ATS Not in Auto Mode |

• |

Load, No Load, Fast |

• |

Automatic Transfer Relay |

|

Load Test Status |

|

|

• |

Load Test Running |

|

|

|

|

Most Significant Byte |

|

|

|

Least Significant Byte |

|

||||||

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

0 |

0 |

0 |

0 |

0 |

0 |

|||||||||||||

Normal Source Available

Emergency Source Available

Load, No Load, Fast Load Test Status

Load Test Running

Not Used

Alarm

ATS Not in Auto Mode

Automatic Transfer Relay

Figure 1 – Status 0 Register

These bits make up the least significant byte of the Status 0 register, while the most significant byte of the Status 0 register contains zeros. Figure 1 shows an example of what the Master device would see if it read back the entire Status 0 register. In this example, the Master device would read back the decimal value of 129 from the Status 0 register. When this value is decoded, the Master finds out that the S1 source is available and the Automatic Transfer Relay input is active. The Master also has the option of reading the individual bits, indented under Status 0. This allows the Master to know the status of each parameter without doing any decoding. The second column contains the actual addresses for the network variables. These addresses are used when the Master is reading a Holding Register (16-bit reg). The third column contains addresses that are used when the Master is reading a Coil (individual bit). The remaining columns show the values and ranges (only in Appendix B) for the

network variables.

LED Indicator |

|

LED 10 - 2 |

7 |

|

|

|

|||

The Modbus card has a |

|

|

||

|

|

|

|

|

|

LED 9 - 26 |

|

||

10-segment LED module |

|

|

||

(Refer to Appendix E |

|

LED 8 - 2 |

5 |

|

for location). These |

|

|

|

|

|

|

|

|

|

|

LED 7 - 24 |

|

||

LED’s display the slave |

|

|

||

address of the card as well |

|

LED 6 - 2 |

3 |

|

as transmit and receive |

|

|

|

|

|

LED 5 - 22 |

|

||

status. The first LED from |

|

|

||

the bottom indicates the |

|

LED 4 - 2 |

1 |

|

receive status, the second |

|

|

|

|

|

|

|

|

|

|

LED 3 - 20 |

|

||

LED indicates the transmit |

|

|

||

status. When a Modbus |

|

LED 2 - Transmit |

||

packet has been success- |

|

|||

|

|

|

|

|

|

LED 1 - Receive |

|||

fully transmitted or |

|

|||

received, the associated |

|

|

|

|

|

Figure 2 – LED Module |

|

|

|

LED will light for 100ms. If |

|

|

|

|

|

|

|

|

|

another packet is sent or received before the 100ms elapses, the LED on-time will be extended by another 100ms. LED’s 3-10 display the slave address of the controller as a binary number with each LED corresponding to a bit. Figure 2 shows the 10-segment LED module along with LED’s 3, 5, and 6 being lit. The lit LED’s correspond to slave address 13.

■ GE Zenith Controls |

MX150/MX250 Series Modbus Network Card (71R-2200) |

1 ■ |

Installation

Installation on the Controller

If the Modbus network card is not installed on the controller, do the following to install it:

1.Open the ATS cabinet. If the ATS has power going to it, be EXTREMELY cautious not to touch any energized parts.

2.Remove the two Engine Start wires from the P-Relay(s) if applicable (not applicable in Utility-Utility applications). Use electrical tape to tape over the exposed ends of both wires.

3.Obtain a grounding wrist strap and put the elastic end of the strap on your wrist. Attach the alligator clip end to the controller chassis or an equivalent earth ground.

4.Remove the J5 plug from the controller (located on bottom of board), this will remove power. If controller is equipped for external battery, also remove the J4 connector from the side of the controller. When power is removed from the controller, the ATS will not transfer.

5.Unscrew the black metal cover from the back of the controller. Be sure not to lose any screws.

6.Remove the three screws from the metal standoffs on the controller. Plug the Modbus network card into socket J3 and fasten it to the controller with the three screws (previously removed).

7.Screw the black metal cover back on.

8.Reconnect the J5 plug back into the controller.

(If controller is equipped for external battery, also reconnect the J4 connector on the side of the controller.)

9.Connect the two Engine Start wires to the P-Relay(s) if applicable.

10.Once the controller has power, the network option must be enabled by going into the CFG menu for the network option (Reference Appendix H).

11.When the network option is enabled, exit the CFG menu.

Termination Resistor

Located on the bottom of the Modbus card is jumper J6 (See Appendix C), which enables or disables a termination resistor on the board (Figure 3). Jumper J6 is disabled when it comes from the factory.

Disabled

(Factory Default)

Enabled

Figure 3 – Jumper J6

The only time that Jumper J6 should be enabled is when its corresponding Modbus card is the last device at the end of the chain.

Configuring a Modbus Network Card

The Modbus card can be configured in a variety of ways. The configuration of the card includes configuring the slave address, RTU or ASCII mode, baud rate, parity, and stop bits (the default settings are Slave Address 1, RTU mode, 9600 Baud, No Parity and 2 Stop Bits). These slave settings will be setup by the user and must match the master device settings for proper communications. The user configures these settings using the Modbus Configuration application (GE Zenith Part # 50P-1111). This application can also read the configuration of the card. The following is a procedure for configuring the Modbus Network card (See Appendix D for wiring connections).

To change configuration settings:

1.Disconnect the two Engine Start wires from the P- Relay(s), if applicable. Use electrical tape to tape over the exposed ends of both wires.

2.Obtain a grounding wrist strap and put the elastic end of the strap on your wrist. Attach the alligator clip end to the controller chassis, or an equivalent earth ground.

3.Remove the J5 plug from the controller (located on bottom of board). This will remove power. (If controller is equipped for external battery, also remove the J4 connector from the side of the controller.)

4.Unscrew the black metal cover from the back of the controller.

5.Install the J4 jumper on the back of the Modbus Card (Refer to Appendix C for location).

6.Connect the RS232/485 converter (GE Zenith Part # 50W-1208) to the PC that has the Configuration Application Software Installed.

7.Connect a twisted pair cable between the RS485 connector of the Modbus Card and the RS485 connector of the RS232/485 converter. Verify correct polarity (Refer to Appendix D for connection).

8.Reconnect the J5 plug. This will restore power to the controller.

9.Start up the Configuration Application on the PC.

10.Click on the “READ” button to read the device's current configuration.

11.Click on the “MODIFY” button to enable parameter changing.

12.Make necessary changes to the communication settings.

13.Click on the “WRITE” button to send the new configuration to the Modbus Card.

14.Verify that the configuration was written by clicking the “READ” button, and verify the settings.

15.Remove the J5 plug from the controller.

16.Remove the J4 jumper from the Modbus Card.

17.Screw the black metal cover back on the controller.

18.Reconnect the J5 plug to the controller. (If controller is equipped for external battery, also reconnect the J4 connector on the side of the controller.)

19.Reconnect the two Engine Start wires to the P-Relay(s), if applicable.

■ 2 |

MX150/MX250 Series Modbus Network Card (71R-2200) |

GE Zenith Controls ■ |

Installation (cont’d)

Testing a Modbus Network

The Modbus network can be tested using the components in the Modbus Configuration package (GE Zenith Part # 50P-1124). Reference Appendix D for connections.

1.If testing a network consisting of more than one card, make sure that all of the cards are daisy chained as shown in Appendix E. Verify that all Modbus cards are in the run mode (jumper J4 on the Modbus card must not be installed). Termination jumper (J6) is only installed on the last card on the network daisy chain.

2.Connect the RS232/485 converter (GE Zenith Part

# 50W-1208) to the PC that contains the Configuration software (GE Zenith Part # 50P-1111). A cable needs to be connected to the RS485 connector of the Modbus card and the RS485 connector of the RS232/485 connector. Check to make sure that the polarity connections are correct. (See Appendix D)

3.Run the Configuration software on the PC.

4.Press the TEST button and then verify that the settings in the Communication Settings section match the settings of the Modbus network. If necessary, make changes to the settings and click the NEXT button.

5.The software will now scan the network and display the serial number of all controllers, which have the Modbus card attached. The user can select any of the listed serial numbers and execute a load test on a controller associated with the selected serial number, but only one controller can be tested at a time.

CDP Programmable Exercisers

CDP Programmable Exercisers are an option on the MX150 and MX250. They allow the controller to be programmed to automatically test the generator and Automatic Transfer Switch. Up to seven exercisers can be programmed to run on a daily, 7 day, 14 day, or 28 day basis; or up to 24 exercisers can be programmed to run on a yearly basis.

Configuration information regarding CDP Programmable Exercisers is available in the Exerciser Configuration Register (Holding Register 40063):

Bit 0 of the Exerciser Configuration Register (Coil 81) indicates whether the controller is configured for CDT or CDP Programmable Exercisers. A one means the controller is configured for CDP Programmable Exercisers.

Bit 2 of the Exerciser Configuration Register (Coil 82) indicates whether or not the CDP Programmable Exercisers can be configured to run under load (transfer the ATS to the generator). A zero indicates that exercisers can only run No-Load. A one indicates that exercisers can be programmed to run Load or No-Load.

Holding Registers 40101 through 40110 are provided to control and report the status of the CDP Exercisers. These registers contain valid data only if the controller is configured for CDP Exercisers. If the controller is configured for CDP Exercisers, then Holding Register 40063, Bit 0 (Coil 81) will be set to 1.

Reading the CDP Exerciser Holding Registers

The controller may be programmed for multiple exercisers, depending on the status of the Exerciser Schedule Selection. All data relevant to every exerciser is read out through Holding Registers 40101 through 40110. These registers will contain data describing one exerciser at a time. The value of Holding Register 40101, “Exerciser Record Pointer”, determines which exerciser is presently being displayed in Holding Registers 40102 through 40109.

To read the contents of a different exerciser, the Exerciser Record Pointer must be written. For example, in order to read data about CDP Exerciser #3, the Exerciser Record Pointer must be set to 3.

The controller will automatically place all exercisers in chronological order.

CDT Exercisers

CDT Exercisers are a standard feature of the MX150 and MX250 (unless replaced by CDP Programmable Exercisers). They allow the controller to be programmed to automatically test the generator and Automatic Transfer Switch. The exerciser will run at the same time of day on a daily, 7 day, 14 day, or 28 day basis. Programming of the CDT Exerciser can be done only at the HMI on the front panel of the MX150 or MX250.

Configuration information regarding CDT Exercisers is available in the Exerciser Configuration Register (Holding Register 40063):

Bit 0 of the Exerciser Configuration Register (Coil 81) indicates whether the controller is configured for CDT or CDP Programmable Exercisers. A zero means the controller is configured for CDT Exercisers. Conversely, bit 1 implies the controller is configured for the CDP Exerciser.

Bit 1 of the Exerciser Configuration Register (Coil 82) indicates whether or not the CDT is configured for Load Exercises. A one indicates the CDT will run a Load Exercise. A zero indicates the CDT will run a NoLoad Exercise.

The upper byte of the Exerciser Configuration Register (bits 15 through 8) indicates the CDT Exerciser Run Duration, in minutes.

■ GE Zenith Controls |

MX150/MX250 Series Modbus Network Card (71R-2200) |

3 ■ |

Operation

Setting System Time

Holding Registers 40094 through 40099 are provided to control and report the status of the controller’s System Time. Reading Holding Register 40094 through 40099 will report the current Hour, Minute, Day, Month, Year, and Day of Week to which controller’s internal clock is currently set.

Writing the System Time Holding Registers

Holding Registers 40094 through 40098 must be written using a Write Multiple Holding Register Command (Function Code 16). This is to ensure that the data contained in these registers is a complete ordered set. Any attempt to write Holding Registers 40094, 40095, 40096, 40097, or 40098 with a Write Single Holding Register Command (Function Code 6), or a Write Multiple Holding Register Command (Function Code 16) that does not include the entire range of 40094 - 40098, will result in an Illegal Data Address exception response from the Modbus Card.

Note: Holding Register 40099, “System Time-Day of Week” is Read Only. The value of this register is automatically computed and updated by the controller, based on the calendar date.

Operation with In-Phase Monitor

Special consideration is required if the controller is configured with the In-Phase Monitor. Most Modbus network data and control are unavailable while the In-Phase Monitor is waiting for phase synchronization. The Modbus Network Card will return a “Slave Device Busy” exception code (06h) to all Modbus queries, except for queries to the System Busy Status Register (Holding Register 40112) or the System Busy Control Register (Holding Register 40113).

If the Modbus Network Card returns a Slave Device Busy exception code, information about the source of the busy condition may be available in the System Busy Status Register (Holding Register 40112). If Bit 0 of the System Busy Status Register (Coil 105) is set to one, the controller is busy waiting for phase synchronization.

If the controller is busy waiting for phase synchronization, the In-Phase Monitor may be bypassed over the Modbus network by performing the following sequence:

Warning: EXTREME CAUTION must be used when bypassing the In-Phase Monitor! Transferring between sources that are not in phase synchronization may cause unexpected operation, resulting in damage to plant equipment and personnel.

1.Set Bit 0 of the System Busy Control Register (Coil 113) to one. This is a request by the Modbus user to bypass the In-Phase Monitor.

2.Once an In-Phase Monitor bypass has been requested, and the controller has been waiting for phase synchronization for more than one minute, the controller will request confirmation of the In-Phase Monitor bypass. This request is indicated by a one in Bit 1 of the System Busy Status Register (Coil 106).

3. To confirm the request to bypass, set Bit 1 of the System Busy Control Register (Coil 114) to one. The controller will bypass the In-Phase Monitor.

Note: The In-Phase Monitor bypass feature is an interlocked command-and-confirm mechanism. The Modbus Card will not allow the Confirm Bypass control bit (Coil 114) to be set before the controller has set Ready

to Confirm Bypass status bit (Coil 106). If a write request is received to set Coil 114 before the controller has set Coil 106, an Illegal Data Value error code will be returned.

Bypass Pending Exerciser

Bit 0 (Coil 121) is the Bypass Pending Exerciser bit. The MX Platform performs a logic-OR with this bit and the BPASS EXER key on the HMI. A 1 in Bit 0 bypasses the pending exerciser; a 0 does nothing.

Cancel Bypass

Bit 1 (Coil 122) is the Cancel Bypass bit. The MX Platform performs a logic-OR this bit with the CANCL BPASS key on the HMI. A 1 in Bit 1 cancels the Bypass Pending Exerciser. A 0 in this bit position does nothing.

The Bypass Pending Exerciser Bit works different, between a Timer Exerciser and Clock Exerciser, depending on the state of Exerciser Type (Holding Register 40063, Bit 0, Coil 81). When Coil 81 = 0 (Timer Exerciser), if Coil 121 is set to 1, the Timer Exerciser will be bypassed until the Cancel Bypass Bit (Coil 122) is set to 1. When Coil 81 = 1 (Clock Exerciser), if Coil 121 is set to 1, only the exerciser that is pending at the time gets bypassed, and the exerciser only gets bypassed once. The Controller waits for Coil 121 to reset to a 0 before a subsequent bypass can be performed.

Operation Under Battery Backup

The controller can be powered from an external 12-volt battery in the event that neither S1 nor S2 are available. While the controller is on external battery backup, data will still be available over the Modbus Network

as noted below.

While the controller is running on external battery backup, data regarding ATS position and limit switch inputs may be invalid if both S1 and S2 sources are lost. Therefore, if Bits 6 and 7 of Holding Register 40001, or Coils 7 and 8, are both zero, the following Modbus network data may not be reliable:

•Automatic Transfer Relay –

Holding Register 40001, Bit 0 or Coil 1

•SN Limit Switch –

Holding Register 40002, Bit 0 or Coil 9

•SE Limit Switch –

Holding Register 40002, Bit 1 or Coil 10

•SNO Limit Switch –

Holding Register 40002, Bit 2 or Coil 11

•SEO Limit Switch –

Holding Register 40002, Bit 3 or Coil 12

•S1 Position Status –

Holding Register 40004, Bit 9 or Coil 34

•S2 Position Status –

Holding Register 40004, Bit 10 or Coil 35

■ 4 |

MX150/MX250 Series Modbus Network Card (71R-2200) |

GE Zenith Controls ■ |

Appendix A – Read Only Register List

Holding Reg. |

Bit Coil |

Description |

Value |

||

|

|

|

|

|

|

40001 |

|

|

MX Status 0 |

|

|

|

0 |

1 |

Automatic Transfer Relay |

1 |

= On, 0 = Off |

|

1 |

2 |

ATS Not in Auto Mode |

1 |

= Not in Auto |

|

2 |

3 |

General Purpose Alarm |

1 |

= Alarm Active |

|

3 |

4 |

Unused |

|

|

|

4 |

5 |

Load Test or Fast Load Test Running |

1 |

= Running |

|

5 |

6 |

Load, No Load, Fast Load Test Status |

1 |

= Running |

|

6 |

7 |

S2 Available |

1 |

= Available |

|

7 |

8 |

S1 Available |

1 |

= Available |

40002 |

|

|

MX Status 1 |

|

|

|

0 |

9 |

SN Limit Switch |

1 |

= On, 0 = Off |

|

1 |

10 |

SE Limit Switch |

1 |

= On, 0 = Off |

|

2 |

11 |

SNO Limit Switch |

1 |

= On, 0 = Off |

|

3 |

12 |

SEO Limit Switch |

1 |

= On, 0 = Off |

|

4 |

13 |

S2 Phase Rotation - Valid only if 3ph and S2 Avail |

1 |

= CW, 0 = CCW |

|

5 |

14 |

S1 Phase Rotation - Valid only if 3ph and S1 Avail |

1 |

= CW, 0 = CCW |

|

6 |

15 |

Number of Phases on S2 |

1 |

= Three, 0 = One |

|

7 |

16 |

Number of Phases on S1 |

1 |

= Three, 0 = One |

40003 |

|

|

MX Status 2 |

|

|

|

0 |

17 |

Unused |

|

|

|

1 |

18 |

S5 Active |

1 |

= On, 0 = Off |

|

2 |

19 |

S12 Active |

1 |

= On, 0 = Off |

|

3 |

20 |

Load Shed (LS) Active |

1 |

= On, 0 = Off |

|

4 |

21 |

Q7 Active |

1 |

= On, 0 = Off |

|

5 |

22 |

Q3 Active |

1 |

= On, 0 = Off |

|

6 |

23 |

Closed Transfer Relay (CTR) Active |

1 |

= On, 0 = Off |

|

7 |

24 |

Transfer Mode Select (TMS) Active |

1 |

= On, 0 = Off |

40004 |

|

|

Timer ID 0 |

|

|

|

0 |

25 |

Timer Bit 0 |

See Table 1 |

|

|

1 |

26 |

Timer Bit 1 |

See Table 1 |

|

|

2 |

27 |

Timer Bit 2 |

See Table 1 |

|

|

3 |

28 |

Unused |

|

|

|

4 |

29 |

Unused |

|

|

|

5 |

30 |

Unused |

|

|

|

6 |

31 |

Unused |

|

|

|

7 |

32 |

Unused |

|

|

|

8 |

33 |

Timer Active |

1 |

= Timer Running |

|

9 |

34 |

S1 Position Status |

1 |

= S1 Position |

|

10 |

35 |

S2 Position Status |

1 |

= S2 Position |

|

11 |

36 |

Unused |

|

|

|

12 |

37 |

Unused |

|

|

|

13 |

38 |

Unused |

|

|

|

14 |

39 |

Unused |

|

|

|

15 |

40 |

Unused |

|

|

■ GE Zenith Controls |

MX150/MX250 Series Modbus Network Card (71R-2200) |

5 ■ |

Appendix A (cont’d) Read Only Register List

Holding Reg. |

Bit Coil |

Description |

Value |

||

|

|

|

|

|

|

40005 |

|

|

Timer Countdown Value |

Seconds |

|

40006 |

|

|

S1 Voltage (Phase A-B) |

Volts |

|

40007 |

|

|

S1 Voltage (Phase B-C) |

Volts |

|

40008 |

|

|

S1 Voltage (Phase C-A) |

Volts |

|

40009 |

|

|

S2 Voltage (Phase A-B) |

Volts |

|

40010 |

|

|

S2 Voltage (Phase B-C) |

Volts |

|

40011 |

|

|

S2 Voltage (Phase C-A) |

Volts |

|

40012 |

|

|

Unused |

|

|

40013 |

|

|

S1 Frequency |

Freq Value = scaled value/10 |

|

40014 |

|

|

Unused |

|

|

40015 |

|

|

S2 Frequency |

Freq Value = scaled value/10 |

|

40016 |

|

|

Unused |

|

|

40017 |

|

|

Total Transfers to S1 |

|

|

40018 |

|

|

Unused |

|

|

40019 |

|

|

Serial Number (MSR) |

|

|

40020 |

|

|

Serial Number (LSR) |

|

|

40021 |

|

|

Nominal Full-Scale Voltage |

|

|

40022 |

|

|

MX Network Configuration 0 |

|

|

|

0 |

41 |

Unused |

|

|

|

1 |

42 |

Unused |

|

|

|

2 |

43 |

Unused |

|

|

|

3 |

44 |

Unused |

|

|

|

4 |

45 |

Unused |

|

|

|

5 |

46 |

Closed Transition Configured |

1 |

= Configured |

|

6 |

47 |

In-Phase Monitor Configured |

1 |

= Configured |

|

7 |

48 |

ATS Type |

1 |

= Delay, 0 = Standard |

40023 |

|

|

MX Network Configuration 1 |

|

|

|

0 |

49 |

S12 Auto/Manual Option |

1 |

= Configured |

|

1 |

50 |

S5 Auto/Manual Bypass Option |

1 |

= Configured |

|

2 |

51 |

Phase Sequence Check Option |

1 |

= Configured |

|

3 |

52 |

S2 Overfrequency Option |

1 |

= Configured |

|

4 |

53 |

S2 Overvoltage Option |

1 |

= Configured |

|

5 |

54 |

S1 Overfrequency Option |

1 |

= Configured |

|

6 |

55 |

S1 Underfrequency Option |

1 |

= Configured |

|

7 |

56 |

S1 Overvoltage Option |

1 |

= Configured |

40024 |

|

|

MX Network Configuration 2 |

|

|

|

0 |

57 |

Phase Imbalance Configured |

1 |

= Configured |

|

1 |

58 |

Unused |

|

|

|

2 |

59 |

Closed Transition Configured |

1 |

= Configured |

|

3 |

60 |

Pre-Load Disconnect |

1 |

= Configured |

|

4 |

61 |

Post-Load Disconnect |

1 |

= Configured |

|

5 |

62 |

Open Loop Transfer Option |

1 |

= Configured |

|

6 |

63 |

Unused |

|

|

|

7 |

64 |

Controller Type |

1 |

= MX150/250, 0 = MX200 |

■ 6 |

MX150/MX250 Series Modbus Network Card (71R-2200) |

GE Zenith Controls ■ |

Appendix A (cont’d) Read Only Register List

Holding Reg. |

Bit Coil |

Description |

Value |

|

|

|

|

|

|

40025 |

|

|

S1 Voltage (Phase A-B), Raw A/D |

Raw A/D Value - See Note 1 |

40026 |

|

|

S1 Voltage (Phase B-C), Raw A/D |

Raw A/D Value - See Note 1 |

40027 |

|

|

S1 Voltage (Phase C-A), Raw A/D |

Raw A/D Value - See Note 1 |

40028 |

|

|

S2 Voltage (Phase A-B), Raw A/D |

Raw A/D Value - See Note 1 |

40029 |

|

|

S2 Voltage (Phase B-C), Raw A/D |

Raw A/D Value - See Note 1 |

40030 |

|

|

S2 Voltage (Phase C-A), Raw A/D |

Raw A/D Value - See Note 1 |

40031 |

|

|

S1 Period Count |

Raw Value - See Note 2 |

40032 |

|

|

S2 Period Count |

Raw Value - See Note 2 |

40049 |

|

|

Total S1 Fails |

|

40050 |

|

|

Total Transfers to S2 |

|

40051 |

|

|

Days Powered Up |

|

40052 |

|

|

Time S1 Available (MSR) |

Hours |

40053 |

|

|

Time S1 Available (LSR) |

Hours |

40054 |

|

|

Time S2 Available (MSR) |

Hours |

40055 |

|

|

Time S2 Available (LSR) |

Hours |

40056 |

|

|

Unused |

|

40057 |

|

|

Unused |

|

40058 |

|

|

Unused |

|

40059 |

|

|

Unused |

|

40060 |

|

|

Unused |

|

40061 |

|

|

Unused |

|

40062 |

|

|

Unused |

|

40063 |

|

|

Exerciser Schedule Status |

|

|

0 |

81 |

Exerciser Type |

1 = Clock, 0 = Timer |

|

1 |

82 |

Load/No Load Exerciser (Timer Exerciser Only) |

1 = Load |

|

2 |

83 |

User can set load exercises (Clock Exerciser Only) |

1 = Yes |

|

3 |

84 |

Unused |

|

|

4 |

85 |

Unused |

|

|

5 |

86 |

Unused |

|

|

6 |

87 |

Unused |

|

|

7 |

88 |

Unused |

|

|

[15:8] |

|

Timer Exerciser Run Duration |

Minutes |

40064 |

|

|

MX Status 3 |

|

|

0 |

89 |

Exerciser Pending |

1 = Exerciser Pending |

|

1 |

90 |

Exerciser Bypassed |

1 = Exerciser Bypassed |

|

2 |

91 |

Unused |

|

|

3 |

92 |

Unused |

|

|

4 |

93 |

Unused |

|

|

5 |

94 |

Unused |

|

|

6 |

95 |

Unused |

|

|

7 |

96 |

Unused |

|

40065 |

|

|

Unused |

|

40066 |

|

|

Unused |

|

40067 |

|

|

Unused |

|

■ GE Zenith Controls |

MX150/MX250 Series Modbus Network Card (71R-2200) |

7 ■ |

Loading...

Loading...