Garland CG-36, CG-48, CG-60, CG-72, CG-24 User Manual

SERVICE MANUAL

GARLAND GAS

“PRODUCTION GRIDDLES” MODELS: CG-24, CG-36, CG-48, CG-60 & CG-72

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY, OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

PLEASE READ ALL SECTIONS OF THIS MANUAL AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS COMMERCIAL COOKING EQUIPMENT AND MUST BE INSTALLED BY PROFESSIONAL PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS THIS PRODUCT MUST BE INSTALLED BY A LICENSED PLUMBER OR GAS FITTER. APPROVAL NUMBER: G-1-07-05- 8

For Your Safety:

Post in a prominent location, instructions to be followed in the event the user smells gas. This information shall be obtained by consulting your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com. The information contained herein, (including design and parts specifications), may be superseded and is subject to change without notice.

GARLAND COMMERCIAL INDUSTRIES |

GARLAND COMMERCIAL RANGES, LTD. |

Enodis UK LTD. |

185 East South Street |

1177 Kamato Road, Mississauga, Ontario L W 1X |

Swallowfield Way, Hayes, Middlesex UB3 1DQ ENGLAND |

Freeland, Pennsylvania 18 |

CANADA |

Telephone: 081-561-0 33 |

Phone: (570) 636-1000 |

Phone: 905-6 -0 60 |

Fax: 081-8 8-00 1 |

Fax: (570) 636-3903 |

Fax: 905-6 -5669 |

|

Part #GCGTRAINING06 (03/03/08) |

© 006 Garland Commercial Industries, Inc. |

Part #GCGTRAINING06 (03/03/08) |

Page 1 |

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects or other reproductive harm. Installation and servicing of this product could expose you to airborne particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers is known to the state of California to cause cancer. Operation of this product could expose you to carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of California to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Page |

Part #GCGTRAINING06 (03/03/08)) |

TABLE OF CONTENTS

IMPORTANT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 DIMENSIONS AND SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

WHAT IS A CHAIN GRIDDLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

How Does it work?.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mechanical.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Gas Supply .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Electrical Power, Lighting & Control.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Ventilation.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Start-Up.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

OPERATION & MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

SERVICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Have The Right Tools And Instruments.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Adjustments.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Pilot Flame Adjustment .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Burner Air .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Removing the Griddle Plate .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Thermostat.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Thermocouple.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

How To Replace A Thermocouple.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Incandescent Lamps.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Pilot Ignition Control (Control Module).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Gas Valve Regulator.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Power Switches.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Control Circuit.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

CONTROL PANEL SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 SERVICE BULLETIN #95-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Part #GCGTRAINING06 (03/03/08) |

Page |

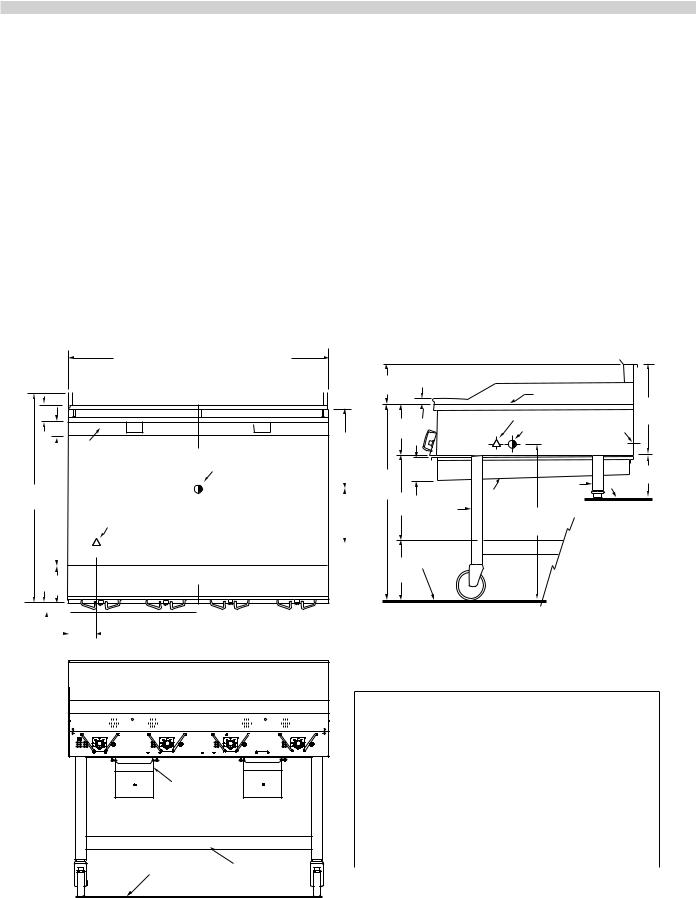

DIMENSIONS AND SPECIFICATIONS

INSTALLATION NOTES |

SPECIFY GAS TYPE |

ELECTRICAL CHARACTERISTICS |

|||

|

|

|

|

|

|

Combustible Wall Clearances |

Operating Pressure |

Specifications |

|||

|

|

|

|

|

|

Sides: |

Back: |

Natural: |

Propane: |

120 V, Single Phase, 60Hz, 1 amp |

|

6" (152mm) |

6" (152mm) |

7" W..C.. (17.4 mbar) |

11" W..C.. (24.4 mbar) |

6' (1829mm) power supply cord provided.. |

|

|

|

|

|

|

|

• IMPORTANT: Unit must be |

• Gas Input Ratings shown are for |

|

|||

installations up to 2,000 feet (610mm) |

• NOTE: No cord and plug on export units.. |

||||

installed on legs for proper air |

|||||

above sea level.. BTU input ratings must be |

Direct connection on junction box.. |

||||

circulation.. |

|

||||

|

derated for high altitude installations.. |

|

|||

|

|

|

|||

|

|

|

|||

ENTRY CLEARANCE |

VENTILATION |

EXPORT VOLTAGES |

|||

|

|

|

|

||

Crated |

Uncrated |

• Commercial cooking equipment requires |

• NOTE: Export voltages are available on |

||

|

|

an adequate ventilation system.. For |

request.. |

||

40" (1016mm) |

38" (965mm) |

||||

additional information, refer to the |

|

||||

|

|

• 220-240 volt, 50 Hz, 0.4 amps, single |

|||

• See illustration for further |

|||||

National Fire Protection Association’s |

|||||

phase.. |

|||||

specifications & size statistics |

|||||

standard NFPA96.. |

|

||||

|

|

||||

|

|

|

|

||

|

|

|

|

|

|

Available in 24, 36, 48, 60 & 72 Widths 610, 914, 1219, 1524 & 1829

3" [76mm] Extended Bumper

to Prevent Flue Vent Blockage

to Prevent Flue Vent Blockage

2.5

84

3.25

83

|

|

|

Grease Trough |

20 |

||||||||||

|

|

|

||||||||||||

|

|

|

|

|

|

|

Gas Connection Centered |

508 |

||||||

|

|

|

|

|

|

|

On Unit Width [Left to Right] |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24 |

|

|

|

|

|

|

|

|

|

|

|

|

||

38.75 610 |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||

984 |

|

|

|

|

Electric |

|

|

|

|

|||||

|

|

|

|

5.5 |

|

|||||||||

|

|

|

|

|

|

|||||||||

|

|

|

Cord/Connection |

|

|

140 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6

152

1.5 |

|

|

|

|

|

5 |

|

PLAN VIEW [Model CG-48R] |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|||

|

|

|

|

|

||||

38 |

|

|

|

|

|

|

Dimensions - All Models |

|

|

|

|

|

|

127 |

|

||

|

Grease Drawer(s) |

|

2' & 3' Units - One |

|

4', 5' & 6' Units - Two |

|

Finished Floor |

Optional Stand |

|

|

|

|

|

|

DIMENSIONS: |

Inches |

||

|

|

|

|

mm |

|||

5.75 |

|

0.625 |

|

|

|

|

|

|

16 |

|

|

|

|

|

|

146 |

|

|

|

Cooking Surface |

|

||

|

|

|

Electric Cord/Connection |

15.75 |

|||

|

10 |

|

400 |

||||

|

|

Gas Connection |

Rear |

|

|||

254 |

|

|

|

|

|

||

|

|

|

Gas Inlet |

|

|||

|

|

|

|

|

|

||

|

4.75 |

|

|

|

|

6 |

|

35 |

121 |

|

|

|

|

||

|

Counter |

|

Counter152 |

||||

|

|

|

|

||||

889 |

15 |

|

Removable |

Leg |

|

|

|

|

Optional |

Grease |

|

|

|

|

|

381 |

Stand |

Drawer 27 |

|

|

|

||

|

|

|

686 |

|

|

|

|

Finished 10 Floor

254

SIDE VIEW

INPUT CHART - Natural Or Propane Gas

Model |

BTU/ |

|

Gas |

Shipping |

Kw |

Weight |

|||

Number |

HOUR |

|

Inlet |

|

|

Lbs../Kgs.. |

|||

|

|

|

|

|

|

|

|

|

|

CG-24R |

60,000 |

17..60 |

3/4" |

335/152 |

|

|

|

|

|

CG-36R |

90,000 |

26.4 0 |

3/4" |

485/220 |

|

|

|

|

|

CG-48R |

120,000 |

35..00 |

3/4" |

625/284 |

|

|

|

|

|

CG-60R |

150,000 |

44..00 |

3/4" |

765/348 |

|

|

|

|

|

CG-72R |

180,000 |

52..70 |

1" |

995/411 |

|

|

|

|

|

FRONT VIEW [Model CG-48R]

Page |

Part #GCGTRAINING06 (03/03/08)) |

WHAT IS A CHAIN GRIDDLE

Commercial chain restaurants impose strict food procedures on franchise owners and operators to guarantee the quality and consistency of the product.. Beef burgers, hamburgers, french fries, onion rings, fried chicken and tortillas for example, must meet rigid standards of quality involving the ingredients used, the recipes followed, storage and, not least, the cooking temperature and time of cooking..

Accuracy of temperature control and the heating stability of the cooking surface are essential in maintaining consistent quality in the product.. Control and stability are the two primary features in the new chain griddle.. As compared with previous gas griddles of the same kind, temperature control of heating zones in the chain griddle is far tighter and more precise..

Two features provide precision control.. One feature is a burner for every foot of griddle surface.. The other is that each burner is electronically monitored for temperature control.. As a result, at 30,000 BTU using natural gas, there is excellent energy management and power recovery..

Temperature sensors are embedded in the griddle plate.. Each sensor is close to the plate surface where the load is.. The effect of this arrangement is to achieve an even temperature gradient across the plate.. Thanks to the electronic monitoring feature, a much faster response to changes in surface temperature is achievable in the chain griddle than in previous units..

The smoother temperature gradient per unit surface area and accurate temperature control has made the chain griddle an instant success.. This simple explanation of the two main features of the unit is what makes it so special.. Without fast response and a smooth gradient, the chain griddle would be just another design among many..

Explaining why the unit is special is one thing and understanding how it works in another.. Service technicians need to know this to have complete confidence when servicing the unit.. We describe how it works in the next part of this section..

Figure 1 -Front view of counter-top chain griddle

Burner ON amber |

|

|

|

|

||

indicator light |

|

|

Air vents |

|||

Securing |

Pilot ON green |

Flame |

||||

fasteners |

viewport |

|

|

|||

for removable |

indicator light |

|

Zone |

|

Removable top |

|

top |

|

thermostat |

|

access panel |

||

access panel |

|

|

|

|

|

|

Main power |

|

|

|

|

Hinged |

|

ON |

|

|

|

|

||

|

|

|

|

drop-down |

||

green |

|

|

|

|

||

|

|

|

|

bottom half |

||

indicator |

|

|

|

|

||

|

|

|

|

access |

||

light |

|

|

|

|

||

|

|

|

|

panel |

||

|

|

|

|

|

||

Main power |

Zone power |

|

Leg of counter-top |

|||

switch |

switch |

|

|

|||

Grease tray |

style griddle |

|||||

|

|

|

||||

How Does it work?

When the main power switch is turned on, the power indicating lamp is illuminated and power is applied to the thermostat input of the ignition modules.. This will initiate the pilot ignition sequence.. The ignition module supplies a spark ignition at the pilot burner and will energize the pilot solenoid valve for a maximum trail period of 50 seconds..

If the pilot flame ignites and is sensed within the 50 second period, the main burner output of the ignition module will be energized.. The pilot indicating lamp will illuminate.. The main burner solenoid valves are then controlled by the thermostats.. As a thermostat calls for heat, it will energize its output and the main burner valve along with the burner indicating lamp will energize.. The main burner will cycle with the thermostat..

There is only one trial for ignition.. If the pilot flame is not sensed during the trail period, the ignition module will lock out.. All ignition module outputs will be de-energized.. To reset the ignition module the main power switch must be turned off for a period of 30 seconds..

Part #GCGTRAINING06 (03/03/08) |

Page |

WHAT IS A CHAIN GRIDDLE continued

During normal operation, the pilot flame is continually monitored.. The flame current signal must maintain 0..15 microamps minimum.. Flame failure response time is 0..8 seconds maximum.. If at any time the ignition module does not detect a pilot flame, it will repeat the ignition process by allowing a 50 second trial of ignition..

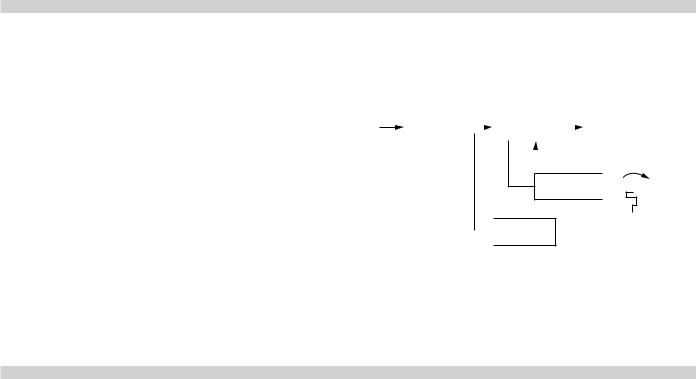

Figure 2 illustrates this sequence of operation..

Figure 2 – Sequence of Operation

Power |

|

|

|

Ignition |

|

Spark |

Flame |

||

|

|

|

|

||||||

|

|

|

|

|

|

|

o/p |

sensor |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pilot valve

Main valve

Main valve

INSTALLATION

The instructions given for installation form part of the delivery package.. Anyone installing a chain griddle should follow a strict procedure to make sure installation and commission are safe, efficient and complies with the applicable local codes.. Here is a check list of things to do in the order we recommend..

Mechanical

•Uncrate and check for shipping damage both obvious and hidden.. Write a damage report and report immediately to the carrier..

•Check the serial plate behind the front panel.. To do this, remove the front panel by unscrewing the two screws in the upper right and left corners.. Next unscrew the two fasteners securing the hinged lower font panel in place.. Note the burner inputs shown on the serial number plate.. It may be necessary to refer to these later.. You also need to be certain of the type of gas to which the unit is connected.. The serial plate also specifies the type of gas required for the unit.. Also, check that the electrical connections are in good order..

NOTE : The chain griddle is certified for installation on a combustible base with minimum clearance of 6”(152mm) back and 6”(152mm) sides from combustible walls..

•Every unit is fitted with a readily accessible shut-off valve at the main manifold.. Use a minimum of 3/4” NPT pipe to connect the incoming gas supply..

CAUTION : Check the pipe capacity tables given in the installation code.. When a long supply pipe run is necessary, you may have to install a supply line lager than 3/4”

•Have a qualified gas technician check the gas supply to make sure it will deliver the BTUs of gas the unit requires to operate with no more than 1/2” water pressure

drop.. Also when making this check be certain that all equipment on the gas line is turned to the ON position..

•If you are installing the unit using a new gas installation, make sure the supply lines have been cleaned and purged of piping compound, chips and other debris..

WARNING : Use soap solution if you have to check the gas lines for leaks..

•Place and install the unit on the legs or caters provided, and make sure there is a minimum of 4” (102mm) air space below the unit for adequate air flow to the burners..

CAUTION: Check for obstructions or objects that could restrict the air flow to the burners..

•Using a spirit level variously across the front, rear and sides of the unit, level it by adjusting the leveling legs..

Gas Supply

NOTE : For efficient operation, the griddle plate must be level..

Page |

Part #GCGTRAINING06 (03/03/08)) |

Loading...

Loading...