Games PC DESKTOP DYNO 2000 User Manual

Motion Software, Inc.

535 West Lambert Road, Building “E” Brea, California 92821-3911

Voice: 714-255-2931, Fax: 714-255-7956 Web: www.motionsoftware.com

Email: support@motionsoftware.com

Dyno2000 Simulation v3.10, 5-/01 Release 5

MOTION SOFTWARE, INC. SOFTWARE LICENSE

PLEASE READ THIS LICENSE CAREFULLY BEFORE BREAKING THE SEAL ON THE DISKETTE ENVELOPE AND USING THE SOFTWARE. BY BREAKING THE SEAL ON THE DISKETTE ENVELOPE, YOU ARE AGREEING TO BE BOUND BY THE TERMS OF THIS LICENSE. IF YOU DO NOT AGREE TO THE TERMS OF THIS LICENSE, PROMPTLY RETURN THE SOFTWARE PACKAGE, COMPLETE, WITH THE SEAL ON THE DISKETTE ENVELOPE UNBROKEN, TO THE PLACE WHERE YOU OBTAINED IT AND YOUR MONEY WILL BE REFUNDED. IF THE PLACE OF PURCHASE WILL NOT REFUND YOUR MONEY, RETURN THE ENTIRE UNUSED SOFTWARE PACKAGE, ALONG WITH YOUR PURCHASE RECEIPT, TO MOTION SOFTWARE, INC. AT THE ADDRESS AT THE END OF THIS AGREEMENT. MOTION SOFTWARE, INC. WILL REFUND YOUR PURCHASE PRICE WITHIN 60 DAYS. NO REFUNDS WILL BE GIVEN IF THE DISKETTE ENVELOPE HAS BEEN OPENED.

Use of this package is governed by the following terms:

1.License. The application, demonstration, and other software accompanying this License, whether on disk or on any other media (the “Motion Software, Inc. Software”), and the related documentation are licensed to you by Motion Software, Inc. You own the disk on which the Motion Software, Inc. Software are recorded but Motion Software, Inc. and/or Motion Software, Inc.’s Licensor(s) retain title to the Motion Software, Inc. Software, and related documentation. This License allows you to use the Motion Software, Inc. Software on a single computer and make one copy of the Motion Software, Inc. Software in machine-readable form for backup purposes only. You must reproduce on such copy the Motion Software, Inc. copyright notice and any other proprietary legends that were on the original copy of the Motion Software, Inc. Software. You may also transfer all your license rights in the Motion Software, Inc. Software, the backup copy of the Motion Software, Inc. Software, the related documentation and a copy of this License to another party, provided the other party reads and agrees to accept the terms and conditions of this License.

2.Restrictions. The Motion Software, Inc. Software contains copyrighted material, trade secrets, and other proprietary material, and in order to protect them you may not decompile, reverse engineer, disassemble or otherwise reduce the Motion Software, Inc. Software to a human-perceivable form. You may not modify, network, rent, lease, loan, distribute, or create derivative works based upon the Motion Software, Inc. Software in whole or in part. You may not electronically transmit the Motion Software, Inc. Software from one computer to another or over a network.

3.Termination. This License is effective until terminated. You may terminate this License at any time by destroying the Motion Software, Inc. Software, related documentation, and all copies thereof. This License will terminate immediately without notice from Motion Software, Inc. if you fail to comply with any provision of this License. Upon termination you must destroy the Motion Software, Inc. Software, related documentation, and all copies thereof.

4.Export Law Assurances. You agree and certify that neither the Motion Software, Inc. Software nor any other technical data received from Motion Software, Inc., nor the direct product thereof, will be exported outside the United States except as authorized and permitted by United States Export Administration Act and any other laws and regulations of the United States.

5.Limited Warranty on Media. Motion Software, Inc. warrants the disks on which the Motion Software, Inc. Software are recorded to be free from defects in materials and workmanship under normal use for a period of ninety (90) days from the date of purchase as evidenced by a copy of the purchase receipt. Motion Software, Inc.’s entire liability and your exclusive remedy will be replacement of the disk not meeting Motion Software, Inc.’s limited warranty and which is returned to Motion Software, Inc. or a Motion Software, Inc. authorized representative with a copy of the purchase receipt. Motion Software, Inc. will have no responsibility to replace a disk damaged by accident, abuse or misapplication. If after this period, the disk fails to function or becomes damaged, you may obtain a replacement by returning the original disk, a copy of the purchase receipt, and a check or money order for $10.00 postage and handling charge to Motion Software, Inc. (address is at the bottom of this agreement).

6.Disclaimer of Warranty on Motion Software, Inc. Software. You expressly acknowledge and agree that use of the Motion Software, Inc. Software is at your sole risk. The Motion Software, Inc. Software and related documentation are provided “AS IS” and without warranty of any kind, and Motion Software, Inc. and Motion Software, Inc.’s Licensor(s) (for the purposes of provisions 6 and 7, Motion Software, Inc. and Motion Software, Inc.’s Licensor(s) shall be collectively referred to as “Motion Software, Inc.”) EXPRESSLY DISCLAIM ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. MOTION SOFTWARE, INC. DOES NOT WARRANT THAT THE FUNCTIONS CONTAINED IN THE MOTION SOFTWARE, INC. SOFTWARE WILL MEET YOUR REQUIREMENTS, OR THAT THE OPERATION OF THE MOTION SOFTWARE, INC. SOFTWARE WILL BE UNINTERRUPTED OR ERROR-FREE, OR THAT DEFECTS IN THE MOTION SOFTWARE, INC. SOFTWARE WILL BE CORRECTED. FURTHERMORE, MOTION SOFTWARE, INC. DOES NOT WARRANT OR MAKE ANY PRESENTATIONS REGARDING THE USE OR THE RESULTS OF THE USE OF THE MOTION SOFTWARE, INC. SOFTWARE OR RELATED DOCUMENTATION IN TERMS OF THEIR CORRECTNESS, ACCURACY, RELIABILITY, OR OTHERWISE. NO ORAL OR WRITTEN INFORMATION OR ADVICE GIVEN BY MOTION SOFTWARE, INC. OR A MOTION SOFTWARE, INC. AUTHORIZED REPRESENTATIVE SHALL CREATE A WARRANTY OR IN ANY WAY INCREASE THE SCOPE OF THIS WARRANTY. SHOULD THE MOTION SOFTWARE, INC. SOFTWARE PROVE DEFECTIVE, YOU (AND NOT MOTION SOFTWARE, INC. OR A MOTION SOFTWARE, INC. AUTHORIZED REPRESENTATIVE) ASSUME THE ENTIRE COST OF ALL NECESSARY SERVICING, REPAIR, OR CORRECTION. SOME JURISDICTIONS DO NOT ALLOW THE EXCLUSION OF IMPLIED WARRANTIES, SO THE ABOVE EXCLUSION MAY NOT APPLY TO YOU.

7.Limitation of Liability. UNDER NO CIRCUMSTANCES INCLUDING NEGLIGENCE, SHALL MOTION SOFTWARE, INC. BE LIABLE FOR ANY INCIDENT, SPECIAL, OR CONSEQUENTIAL DAMAGES THAT RESULT FROM THE USE, OR INABILITY TO USE, THE MOTION SOFTWARE, INC. SOFTWARE OR RELATED DOCUMENTATION, EVEN IF MOTION SOFTWARE, INC. OR A MOTION SOFTWARE, INC. AUTHORIZED REPRESENTATIVE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. SOME JURISDICTIONS DO NOT ALLOW THE LIMITATION OR EXCLUSION OF LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

In no event shall Motion Software, Inc.’s total liability to you for all damages, losses, and causes of action (whether in contract, tort (including negligence) or otherwise) exceed the amount paid by you for the Motion Software, Inc. Software.

8.Controlling Law and Severability. This License shall be governed by and construed in accordance with the laws of the United States and the State of California. If for any reason a court of competent jurisdiction finds any provision of this License, or portion thereof, to be unenforceable, that provision of the License shall be enforced to the maximum extent permissible so as to effect the intent of the parties, and the remainder of this License shall continue in full force and effect.

9.Complete Agreement. This License constitutes the entire agreement between the parties with respect to the use of the Motion Software, Inc. Software and related documentation, and supersedes all prior or contemporaneous understandings or agreements, written or oral. No amendment to or modification of this License will be binding unless in writing and signed by a duly authorized representative of Motion Software, Inc.

Motion Software, Inc.

535 West Lambert, Bldg. E

Brea, CA 92821-3911

714-255-2931; Fax 714-255-7956

© 1995, 2001 By Motion Software, Inc. All rights reserved. Motion Software, Inc., MS-DOS, DOS, Windows, and Windows95/98NT/2000 are trademarks of Microsoft Corporation. IBM is a trademark of the International Business Machines Corp. Motion-PC, DeskTop Dyno, Drag2000, DeskTop Dyno2000, DeskTop DragStrip, DeskTop Drag2000, DragStrip2000, Dyno Shop and other DeskTop and Motion-PC software products are trademarks of Motion Software, Inc.

All other trademarks, logos, or graphics are the property of their respective owners.

2—Dyno2000 Advanced Engine Simulation

MOTION SOFTWARE ACKNOWLEDGMENTS, ETC.

ACKNOWLEDGMENTS: Larry Atherton of Motion Software wishes to thank the many individuals who contributed to the development and marketing of this program:

Lance Noller, Lead Programmer. A special thanks for his dedication to the Dyno2000 project. His programming skills, tenacious troubleshooting and creative problem solving made the Dyno2000 possible.

Curtis Leaverton, Simulation Designer. My friend and college, Curtis Leaverton is the “brains” behind the Dyno2000. His engine computer simulations have changed the way performance enthusiasts approach engine building.

Brent Erickson, Simulation Designer, Programmer. Developed new simulation models for the Dyno2000. A brilliant programmer, Brent’s positive “can-do” attitude is backed up by his ability to accomplish what many dismiss as impossible.

Trent Noller, Marketing/Sales Manager. Trent excels at problem solving and there

were more than a few problems that required his creative skills during the development and deployment of the Dyno2000. My friend for many years, Trent Noller can, simply, be credited with the success of the Dyno2000.

And special thanks are due to the marketing and management personnel of the Mr. Gasket Performance Group™:

Gary Gibson, His dedication to the DeskTop software line is more than greatly appreciated.

Bob Bruegging, President, CEO, Mr. Gasket Performance Group. Bob’s experience in performance marketing is vast. And so is his enthusiasm!

And thanks to the many other individuals at Mr. Gasket who have contributed to the success of the DeskTop line, including:

Don McGee, Kirk Tinney, Mike Roth and others too numerous to mention.

w |

|

|

|

|

|

® |

|

|

|

|

|

|

|

|

|

|

|

o |

|

w |

|

|

|

|

|

|

|

|

|

w |

|

|

|

|

|

|

|

c |

|

|

|

|

|

|

|

. |

|

||

. |

|

|

|

|

a |

e |

|

|

|

|

m |

|

|

|

|

|

|

|

|

|

|

o |

ti |

|

|

r |

|

|

|

|

|

|

w |

|

|

|

|||

|

|

|

t |

|

|

|

|

||

|

|

|

|

onsof |

|

|

|

|

|

m

This publication is the copyright property of Motion Software, Inc., Copyright © 1995, 2001 by Motion Software, Inc., 535 West Lambert, Bldg. E, Brea, CA 92821-3911. All rights reserved. All text and photographs in this publication are the copyright property of Motion Software, Inc. It is unlawful to reproduce—or copy in any way—resell, or redistribute this information without the expressed written permission of Motion Software, Inc. This PDF document may be downloaded by Dyno2000 users and prospective buyers for informational use only. No other uses are permitted.

The text, photographs, drawings, and other artwork (hereafter referred to as information) contained in this publication is provided without any warranty as to its usability or performance. Specific system configurations and the applicability of described procedures both in software and in real-world conditions—and the qualifications of individual readers—are beyond the control of the publisher, therefore the publisher disclaims all liability, either expressed or implied, for use of the information in this publication. All risk for its use is entirely assumed by the purchaser/user. In no event shall Motion Software, Inc. be liable for any indirect, special, or consequential damages, including but not limited to personal injury or any other damages, arising out of the use or misuse of any information in this publication. This book is an independent publication of Motion Software, Inc. All trademarks are the registered property of the trademark holders.

The publisher (Motion Software, Inc.) reserve the right to revise this publication or change its content from time to time without obligation to notify any persons of such revisions or changes.

Dyno2000 Advanced Engine Simulation— 3

CONTENTS

MOTION SOFTWARE LICENSE ......................... |

2 |

ACKNOWLEDGMENTS ...................................... |

3 |

INTRODUCTION ................................................. |

5 |

How It Works .............................................. |

5 |

What’s New In The Dyno2000 .................. |

6 |

Dyno2000 Requirements ........................... |

7 |

Requirements In Detail ............................. |

7 |

INSTALLATION ................................................. |

10 |

Helpful Installation Hints ......................... |

10 |

Installing The Dyno2000 ......................... |

10 |

Starting The Dyno2000 ........................... |

11 |

PROGRAM OVERVIEW .................................... |

13 |

Main Program Screen .............................. |

13 |

Using The Mouse Or Keyboard .............. |

16 |

Direct-Entry Menu Choices ..................... |

18 |

The Meaning Of Screen Colors ............... |

19 |

THE ENGINE COMPONENT MENUS ............... |

20 |

Bore, Stroke, Number Of Cylinders ........ |

20 |

What’s A Shortblock ........................ |

20 |

Bore, Stroke, & Compression ......... |

21 |

Cylinder Head And Valve Diameters ...... |

21 |

Basic Flow Theory ........................... |

22 |

Sorting Out Head Choices .............. |

23 |

Low-Performance ............................ |

24 |

Wedge Cylinder Heads .................... |

25 |

Canted-Valve Heads ........................ |

25 |

4-Valve Heads ................................... |

26 |

Custom Port Flow ............................ |

28 |

Valve Diameter Menu ............................... |

29 |

Compression Ratio Menu ........................ |

30 |

Compression Basics ....................... |

31 |

Changing Compression Ratio ........ |

33 |

Compression Ratio Calculator ....... |

34 |

Calculator With Flattops ................. |

35 |

Calculator With Domed Pistons ..... |

36 |

Induction Menu ........................................ |

38 |

Airflow And Pressure Drop ............. |

39 |

Airflow Assumptions ....................... |

40 |

Airflow Calculator ............................ |

40 |

Mode 1, Convert To 4-Bbl Flow ....... |

41 |

Mode 2, Convert To 2-Bbl Flow ....... |

42 |

Mode 3, Convert To Any Flow ......... |

43 |

Fuel Menu ................................................. |

44 |

Nitrous-Oxide Injection ................... |

44 |

Induction Manifold Menu ......................... |

46 |

Dual-Plane ........................................ |

46 |

Single-Plane ..................................... |

49 |

Tunnel-Ram ...................................... |

51 |

Individual Runner ............................ |

52 |

Tuned-Port Injection ........................ |

53 |

Sequential-Fire Injection ................. |

55 |

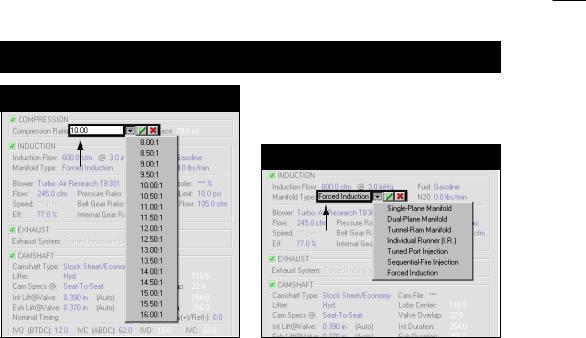

Forced Induction Menus ......................... |

55 |

Intercoolers .............................................. |

58 |

Exhaust Menu ........................................... |

60 |

Stock Manifolds/Mufflers ................ |

61 |

HP Manifolds/Mufflers ..................... |

61 |

Small Headers With Mufflers .......... |

62 |

Small Headers Open Exhaust ......... |

63 |

Large Headers With Mufflers .......... |

63 |

Large Headers Open Exhaust ......... |

63 |

Large Stepped Headers ................... |

64 |

Camshaft Menu ........................................ |

65 |

Cam Basics ...................................... |

66 |

Valve Events ..................................... |

67 |

Camshaft Menu Choices ................. |

68 |

Stock Street/Economy ..................... |

69 |

HP Street ........................................... |

70 |

Dual Purpose Street/Track .............. |

70 |

Drag Race/Circle Track .................... |

70 |

Drag Race High Speed .................... |

71 |

Lifter Menu ................................................ |

71 |

Hydraulic .......................................... |

72 |

Solid, Flat-Tappet ............................. |

72 |

Roller Or Roller Hydraulic ............... |

72 |

Making The Best Lifter Choice ....... |

72 |

Timing Method Menu ............................... |

74 |

Seat-To-Seat Method ....................... |

75 |

0.050-Inch Method ........................... |

75 |

Advance/Retard Menu ............................. |

76 |

Saving Cam Specs Menu ........................ |

77 |

The Cam Math Calculator ........................ |

78 |

THE GRAPHICS RESULTS DISPLAY .............. |

81 |

THE ITERATOR ................................................. |

87 |

Setting Up Iterative Testing ..................... |

89 |

Halting And Restarting Testing ............... |

93 |

Tips For Running Iterative Testing ......... |

93 |

OTHER FEATURES .......................................... |

95 |

DOS File Compatibility ............................ |

95 |

Printing Dyno Data And Power Curves .. |

96 |

General Simulation Assumptions .......... |

98 |

FREQUENTLY ASKED QUESTIONS ............. |

100 |

Basic Operation ..................................... |

100 |

Screen Display ....................................... |

101 |

Bore/Stroke/Shortblock ......................... |

101 |

Compression Ratio ................................ |

101 |

Induction/Fuels ...................................... |

101 |

Camshaft/Valvetrain ............................... |

103 |

Running A Simulation ............................ |

105 |

MINI GLOSSARY ............................................ |

106 |

DYNO TEST NOTES ....................................... |

111 |

MAIL/FAX SOFTWARE SUPPORT FORM ..... |

113 |

4— Dyno2000 Advanced Engine Simulation

INTRODUCTION

Note: If you can’t wait to start the Dyno2000™, feel free to jump ahead to INSTALLATION on page 10, but don’t forget to read the rest of this manual when you have time. Also, make sure you mail in your registration card—it entitles you to receive a FREE upgrade and other information and support.

Thank you for purchasing the Dyno2000™ for IBM® -compatible computers. This software is the result of several years of development and testing. It is just one of several quality software products developed by Motion Software, Inc., that can further your understanding and enjoyment of automobiles, performance, and racing technology.

HOW IT WORKS

The Dyno2000 is a Windows95/98 and WindowsNT/2000, 32-bit program based on the Filling-And-Emptying method of engine power simulation. We chose this family of mathematical models because of their

excellent power prediction accuracy and fast processing times. The Dyno2000 is a full-cycle simulation. This means that it calculates the complete fluid-dynamic, thermodynamic, and frictional conditions that exist inside each cylinder throughout the entire 720 degrees of the four-cycle process.

You will find that many other simulation programs on the market (even a few that sell for several times the price of the Dyno2000) are not true engine simulations. Rather, they calculate the volumetric efficiency (VE) and then derive an estimate

The Dyno2000 is the most advanced engine simulation ever offered to the performance enthusiast. It combines ease of use, rapid calculation times,

powerful Iterative Testing™, and detailed graphics. The Dyno2000 is available from Mr. Gasket Perfor-

mance and Motion Software, Inc.

Dyno2000 Advanced Engine Simulation— 5

Introduction To The Dyno2000

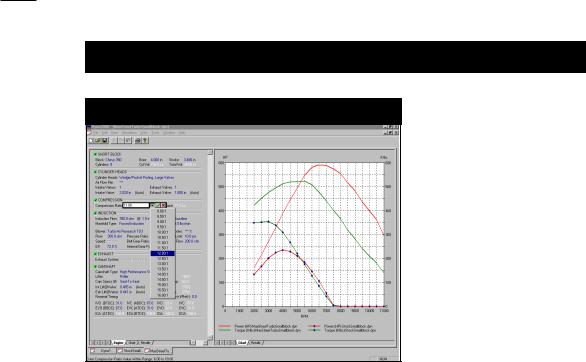

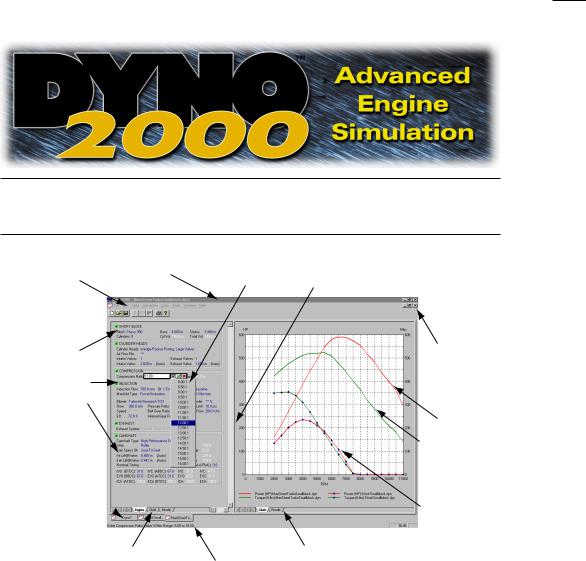

Dyno2000 Main Component Screen

The Dyno2000 incorporates a very clean, intuitive user interface. If you wish to change a component, simply click on the component name and select a new component from the dropdown list. A comprehensive data display is fully customizable. Multiple engine and/or data value comparisons are possible. All components and graphics displays can be printed in full color.

of torque and horsepower. There are many shortcomings to this technique. The two greatest drawbacks are: 1) since cylinder pressure is not determined, it is impossible to predict the pressure on the exhaust valve and the subsequent mass flow through the port when the exhaust valve opens, and 2) the inability to accurately determine the pumping horsepower (energy needed to move gasses into and out of the engine) from the predicted horsepower.

Since the Dyno2000 incorporates both filling-and-emptying and full-cycle modeling that includes frictional and pumping-loss calculations, extensive computation is required for each power point. In fact, the program performs several million calculations at each 500rpm test point on the power curve (a full power-curve simulation consists of 27 test points). This in-depth analysis offers unprecedented accuracy over a vast range of engines. The Dyno2000 has been successfully used to model single-cylinder “lawn mower” engines, light aircraft engines, automotive engines, modern Pro Stock drag-racing powerplants, and multi-thousand horsepower supercharged, nitrous-oxide injected “mountain motors.”

WHAT'S NEW IN THE DYNO2000

The Dyno2000 features a completely unique, easy-to use, point-and-click interface. Just click on any component, and drop-down menus offer alternative selections. Hundreds of components are available, including a wide selection of import engines. Instantly change between US and Metric measurements.

The Dyno2000 also models of forced induction systems, including turbocharging and roots/centrifugal supercharging. Set maximum boost, belt ratios, efficiencies, and more! Even model intercoolers.

Test engine power with alternate fuels, including Methanol, Ethanol, Propane,

6— Dyno2000 Advanced Engine Simulation

Introduction To The Dyno2000

LNG, and even Nitrous Oxide injection. Graph cylinder pressures, frictional losses, and other engine variables.

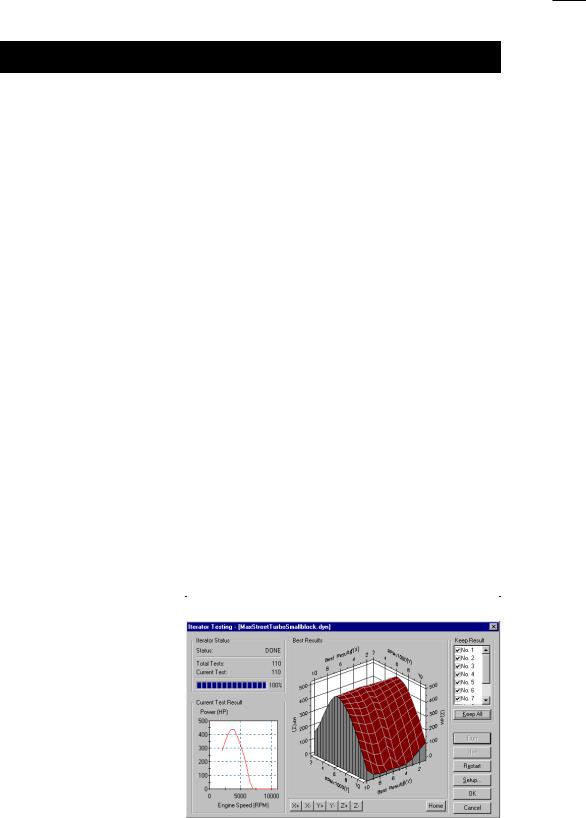

And the Dyno2000 is the only engine simulation with exclusive Iterative Testing™ that analyzes thousands of dyno tests, keep track of all the results, and displays the best setup for virtually any application, all automatically! Combine this power with uniquely versatile graphing capabilities, and the Dyno2000 is, simply, the best engine simulation you can buy. In fact, you will find no other software, even at many times the price, that offers so much capability and performance.

DYNO2000 REQUIREMENTS

The following list presents an overview of the basic hardware and software required to run the Dyno2000.

Minimum Requirements Overview:

•An IBM compatible “PC” computer with a CD-ROM drive

•At least 16MB of RAM (random access memory) for Windows95/98; 32MB for WindowsNT; 64MB for Windows2000

•Windows95/98 or Windows NT/2000 (recommend NT version 4.0 with SP4 or later)

•A video system capable of at least VGA (640 x 480 resolution). Recommend 800 x 600 or higher to optimize screen display and engine analysis

•A Pentium 200 or similar processor (Pentium II or III or faster processors will improve processing speeds; especially helpful for Iterative analysis)

•A mouse

•A printer (needed to obtain dyno-test printouts).

Iterative Testing™ is a |

Dyno2000 Iterative Testing™ Screen |

powerful feature of the |

|

Dyno2000. This screen |

|

illustrates a test that just |

|

evaluated a series of compo- |

|

nents (over 100 dyno tests |

|

were performed). Using this |

|

powerful tool it is possible to |

|

automatically run thousands |

|

or even hundreds of thou- |

|

sands of tests to find the |

|

best combinations. The |

|

Dyno2000 keeps track of all |

|

the results and displays the |

|

best matches to your test |

|

criterion. |

|

Dyno2000 Advanced Engine Simulation— 7

Introduction To The Dyno2000

REQUIREMENTS IN DETAIL

Computer: An IBM-compatible “PC” computer with a CD-ROM disk drive is required. The Dyno2000 will operate on any computer system with an Intel-compatible processor, however, a Pentium-class microprocessor is recommended to minimize calculation times (Pentium II or III 400+Mhz processors will improve processing speeds; especially helpful for Iterative analysis where hundreds or thousands of dyno tests can be performed in a continuous series).

Windows95/98 and NT/2000: The Dyno2000 is a full 32-bit program designed for Windows95, Windows98 and later versions of Windows using the Win95 kernel. The Dyno2000 is also compatible with WindowsNT versions 3.51 or later and Windows2000 (Motion recommends that if you use WindowsNT, use version 4.0 with service pack 4 or later; and if you use Windows2000, make sure to install the latest service pack for both Windows2000 and for Internet Explorer).

System Memory: Your system should have a minimum of 16Mbytes of physical RAM memory for Windows95/98, 32Mbytes for WindowsNT, and 64Mbytes for Windows2000. The Dyno2000 may not operate on systems with less installed memory. To optimize Windows and Dyno2000 performance, 64Mbytes or more is recommended.

Video Graphics Card And Monitor: Virtually any Windows compatible monitor and display card will work with the Dyno2000. Systems with SVGA or better graphics (800 x 600 resolution or higher) provide more screen “real estate.” This additional display space is very helpful in component selection and power-curve analysis.

Note1: See FAQ on page 100 for help in changing the screen resolution of your monitor.

Note2: Specialized graphics cards and ultra-high resolution “workstation” displays may not be compatible with Dyno2000. If you encounter display incompatibilities with the Dyno2000, please contact Motion Software Tech Support, 535 West Lambert, Bldg. E, Brea, CA 92821-3911, 714-255-2931, or visit our website: www.motionsoftware.com.

System Processor: The Dyno2000 is extremely calculation-intensive. Over 25 million mathematical operations are performed for each complete power-curve simulation. While the program has been written in fast C++ and hand-tuned assembler to optimize speed, a faster processor will improve data analysis capabilities. Furthermore, the Dyno2000 incorporates a powerful Iterative Tester that can perform an analysis of hundreds of thousands of dyno tests. To reduce these calculation times and extend the modeling capabilities of the program, use the fastest processor possible.

The following table gives an approximation of the time required to complete a

8— Dyno2000 Advanced Engine Simulation

Introduction To The Dyno2000

100 dyno-run Iterative test on various PC systems (this is a very short run; Iterative tests can consist of hundreds of thousands of simulated dyno runs or more):

Computer |

Coprocessor |

Calc. Time For 100-Test Run |

Pentium 400Mhz |

Built-In |

17 Seconds |

Pentium 200Mhz |

Built-In |

75 Seconds |

Pentium 133Mhz |

Built-In |

112 Seconds |

Pentium 60Mhz |

Built-In |

4.3 Minutes |

80486DX 33Mhz |

Built-In |

13.5 Minutes |

80386DX 25Mhz |

Yes (added) |

49 Minutes |

80486SX 25Mhz |

No |

6.4 Hours |

80386DX 33Mhz |

No |

9.4 Hours |

80286 at 10Mhz |

No |

24 Hours |

8088 at 8Mhz |

Yes (added) |

3.2 Hours |

Mouse: A mouse (trackball, or other pointer control) is required to use the Dyno2000. While most component selections can be performed with the keyboard, several operations within the Dyno2000 require the use of a mouse.

Printer: The Dyno2000 can print a comprehensive “dyno-test report” of a simulated dyno run with any Windows-compatible printer. If you use a color printer, the data curves and selected information will print in color (see page 81 for more information about Dyno2000 printing).

Dyno2000 Advanced Engine Simulation— 9

INSTALLATION

Helpful Installation Tips

Dyno2000 installation is a quick and easy on virtually all computers. To minimize the likelihood of problems, review the following tips before you begin:

1)The Dyno2000 requires Windows 95/98® or Windows NT/2000® and at least 16MB of installed memory (see pages 7-8 for more information about system requirements).

2)The entire installation of the Dyno2000 and DeskTop Videos requires 110MB of free disk space. If you do not wish to install the Software Videos, select the “Compact” option presented during the installation process.

3)If at all possible, install the software onto the (default) drive and directory suggested by the SETUP program. This will speed the process of installing Dyno2000 software updates in the future.

Installing The Dyno2000

The installation programs included with the Dyno2000 will copy the appropriate files to your hard drive. Please read and perform each of the following instructions carefully.

1)Start Windows95/98 (or Windows NT/2000), if necessary.

2)Insert the Dyno2000 CD-ROM into your CD drive.

3)An installation Welcome screen will appear on your desktop within 5 to 30 seconds (depending on the speed of your CD drive). Proceed to step 5.

4)If the Dyno2000 installation Welcome screen does not automatically display on your desktop after 30 to 60 seconds, run the Setup program included on the Dyno2000 CD-ROM. (Open the Windows Explorer, switch to your CD Drive, then double click on Setup. Alternatively, choose Settings from the Start menu,

10— Dyno2000 Advanced Engine Simulation

Installing & Starting The Dyno2000

select Control Panels, the double click on Add/Remove Programs, finally click on Install.)

5)Click Next to proceed to the second Installation screen. Click Next again to review the Motion Software License Agreement. Read the Agreement and if you agree with the terms, click Next to continue with the installation.

6)Enter your name and company name in the User Information screen (only enter your company name if the Dyno2000 is being registered to your company). Click Next again to continue the installation.

7)The Choose Destination Location window will suggest C:\Dyno2000 as the installation path. We recommend that you accept this default. However, if you prefer another location for the Dyno2000, click on Browse... to select a new path. When you are finished, click on Next to continue the installation.

8)The Setup Type window will present three installation options:

Typical— Installs Dyno2000, sample files, user manual, and software videos. Compact— Installs Dyno2000, sample files, and user manual only. Custom— Allows you to select the installed elements.

We recommend you select Typical, then press Next to continue the installation.

9)The Select Program Folder screen indicates that the Dyno2000 program folder will be added to the list of Windows Program choices displayed on the Start, Programs menu. You may change the name of the program folder. Press Next to continue.

10)The Start Copying Files screen gives you a chance to review all the installation choices that you’ve made. Press Back to make any changes; press Next to being copying files to your system.

11)When main installation is complete, the Setup Complete screen provides a checkbox option (defaults unchecked) that allows you to start the Dyno2000 immediately after installation. (Note: If you do not check this box and click Finish, you can start the Dyno2000 at any time by selecting Programs, Dyno2000 Engine Simulation from your Windows Start menu.) Click Finish to complete the installation.

Starting The Dyno 2000

12)To start the Dyno2000, open the Windows Start menu, select Programs, then choose Dyno2000 Engine Simulation, and finally click on the Dyno2000 Engine Simulation icon that opens from the folder.

Dyno2000 Advanced Engine Simulation— 11

Installing & Starting The Dyno2000

13)A video of the new DeskTop DragStrip2000, has been included with the Dyno2000. Start the demo by opening the Start menu, select Programs, then choose the Dyno2000 Engine Simulation folder, finally click on DragStrip2000 Demo NEW.

14)You can also access considerable additional information on the DeskTop software line and technical support by opening the Start menu, select Programs, then choose the Dyno2000 Engine Simulation folder, finally click on DeskTop Software Info.

15)Please review the remainder of this user guide for more information on menu selections, program functions, and simulation tips.

16)If you have installation problems with the Dyno2000, please review program requirements on pages 7-9, and take a few minutes and look over the following sources of information before you contact technical support:

•The FAQs starting on page 100 in this booklet contain detail installation and operational questions and answers.

•Visit the Tech Support section of the Motion Software website for additional tips and FAQs.

If you cannot find a solution to your problem, use the fax-back form in this manual. Fax or mail the completed form to:

Motion Software, Inc.

535 West Lambert, Bldg. E Brea, CA 92821-3911

Tech Fax: 714-255-7956, or visit our Web: www.motionsoftware.com Email: support@motionsoftware.com

Note: Tech support will only be provided to registered users. Please send in your registration card today. You may also register your software on-line at: www.motionsoftware.com. If you purchased your software directly from Motion Software, Inc., you are already registered.

12— Dyno2000 Advanced Engine Simulation

OVERVIEW

Program |

Title Bar |

Menu |

|

Bar |

|

Engine

Component

Categories

And

Status Boxes

Engine

Selection

Tabs

Left Pane

Display Tabs

Drop-Down |

Vertical Divider To |

Menu |

Resize Left/Right Panes |

Windows

Size

Buttons

Power

Curves For

Current

Engine

Comparison

Curves

Right Pane Display Tabs

Range Limits

And Status Box

THE MAIN PROGRAM SCREEN

The Main Program Screen allows you to select engine components, dimensions, and specifications. In addition, engine power curves and/or simulation data is displayed in graphical and chart form. The Main Program Screen is composed of the following elements:

1)The Title Bar displays the program name followed by the name of the currentlyselected engine.

2)The Program Menu Bar contains eight pull-down menus that control overall program function. Here is an overview of these control menus, from left to right

Dyno2000 Advanced Engine Simulation— 13

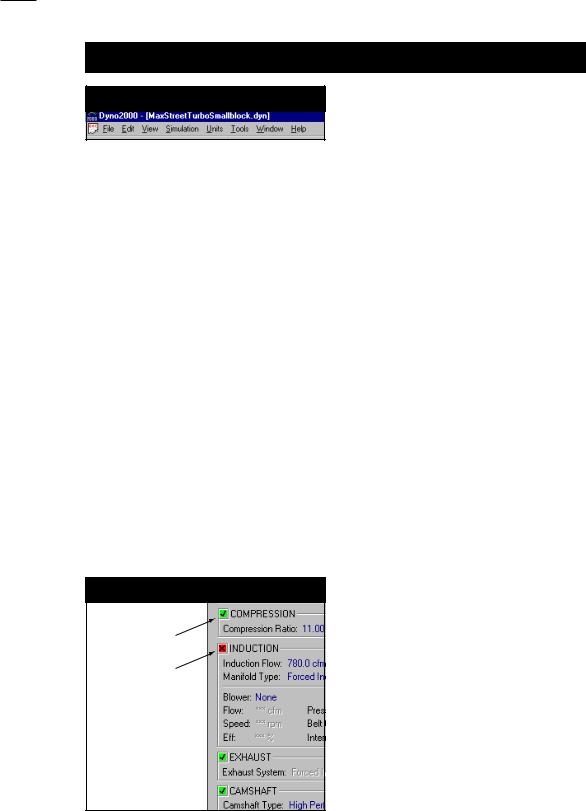

Program Overview

Program Menu Bar

Program Menu Bar contains eight pulldown menus that control overall program function.

(detailed information on menu functions is provided in the next section, beginning on page 20):

File— Opens and Saves dyno test files, exports DOS Dyno files to other DeskTop software, prints engine components and power curves, allows the quick selection of the most recently used Dyno files, and contains an exitprogram function.

Edit— Clears all component choices from the currently-selected engine (indicated by the Engine Selection Tab currently in the foreground; see Engine Selection Tabs, below).

View— Allows you to turn the Toolbar, Status Bar and Workbook layout on (default) or off.

Simulation— Run forces an update of the current simulation. Auto Run enables or disables (toggles) automatic simulation updates when any engine component is modified.

Units— Selects between US and Metric units.

Tools— Opens the Iterative Testing window or selects one of the build-in, engine-math calculators.

Window— A standard Windows menu for arranging and selecting engine display windows.

Help— Gives access to this Users Guide, and other program help features.

3)The Engine Component Categories are made up of the following groups:

Component Status Boxes

All Components

Selected

Category

Incomplete

A Status Box is located in the upper left corner of each Component Category. These boxes either contain a red boxed X, indicating that the category is not complete (inhibiting a simulation run), or a green-boxed check-mark , indicating that all components in that category have been selected

14— Dyno2000 Advanced Engine Simulation

Program Overview

SHORTBLOCK— Select the bore, stroke, and number of cylinders in this category (see page 20).

CYLINDER HEADS— Select the cylinder head type, port configuration, and valve diameters. Direct entry of flow-bench data is also supported (see page 22).

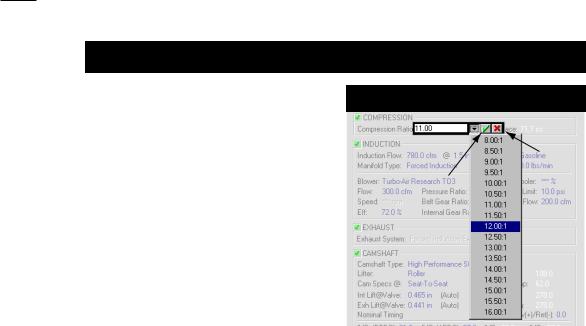

COMPRESSION— Select the compression ratio (see page 30). INDUCTION— Selects the airflow rate through the induction system, the type of fuel, nitrous flow rate, intake manifold, and a forced induction system (see page 38).

EXHAUST— Selects the exhaust-system configuration (see page 59). CAMSHAFT— Selects the camshaft type, lifter type, and allows direct entry of valve timing and lift data (see page 65).

Note: Each component category contains a Status Box located in the upper left corner. These boxes either contain a red boxed X, indicating that the category is not complete (inhibiting a simulation run), or a green-boxed check-mark , indicating that all components in that category have been selected. When all component categories have green checks, a simulation will be performed using the current data values and the results will be displayed in the graph on the right pane of the Main Program Screen (the simulation run and data plot will occur automatically providing Autorun is checked in the Simulation drop-down menu [default], see Simulation Menu described on the previous page).

4)The Drop-Down Component Menus contain components and specifications for each of the Component Category choices. Click on any component specification to open its menu. The menu will close when a selection is complete. If you wish to close the menu before making a new selection, click the red X next to the drop-down box or press the Escape key until the menu closes.

Component fields that do not yet |

Incomplete Component Fields |

|

contain valid entries are marked with a |

|

|

|

||

series of asteristics. This indicates that |

|

|

the field is empty and can accept data |

|

|

input. Most numeric fields accept direct |

Empty Component |

|

keyboard entry or selections from |

||

Fields |

||

provided drop-down menus. Text |

||

|

||

selection fields (like the Cylinder Head |

|

|

choice menu) only accept selections |

|

|

from the associated drop-down menu. |

|

|

When a valid selection has been made, |

|

|

it will replace the asteristics and be |

|

|

displayed next to the field names. |

|

|

|

|

Dyno2000 Advanced Engine Simulation— 15

Program Overview

Direct-Click™ Component Menus

|

Bounding |

|

The Direct-Click™ Component Menus |

Box |

Close |

contain components and specifications |

Accept |

Menu |

for each Component Category choice. |

|

|

Current |

|

|

Click on any component specification to |

|

|

Selection |

|

|

open its menu. The menu will close |

|

|

when a selection is complete (or accept |

|

|

the current selection by clicking on the |

|

|

green ). If you wish to close the menu |

|

|

before making a new selection, click the |

|

|

red X next to the drop-down box or |

|

|

press the Escape key until the menu |

|

|

closes. |

|

|

|

|

|

5)Several Component Category menus allow direct numeric entry. During this data entry, the range of acceptable values will be displayed in a Range Limit Line within the Status Box at the bottom of the screen.

6)The Dyno2000 can simulate several engines at once. Switch between “active” engines by selecting any Tab from the Engine Selection Tabs, just above the Status Box (see photo, page 13). The currently-selected engine is indicated on the foreground Tab. The name of the currently-selected engine is also displayed in the Title Bar.

7)The Main Program Screen window is divided into two panes (the width of these panes is adjustable; drag the vertical screen divider to resize). Each pane contains a Screen Display Tab group. Use these tabs to switch the display in each pane to component lists and other data displays.

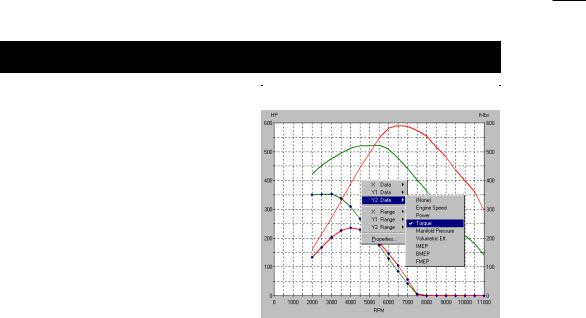

8)The Current Engine Power Curves window displays the horsepower and torque for the currently-selected engine. Horsepower and torque are the default curves, however, any graphic data display can be changed by right-clicking on the graph and reassigning each curve in the Graph Options Box. Use Properties... in the Options Box setup list to create comparisons between any “active” engines.

9)The Main Program Screen also incorporates Windows Size Buttons. These buttons provide standard maximizing, minimizing, and closing functions common to all windows. Refer to your Windows documentation for more information on the use of these buttons.

16— Dyno2000 Advanced Engine Simulation

Program Overview

The Right-Hand Power Curves Box |

Graph Options Box |

displays the horsepower and torque for |

|

the currently-selected engine. Horse- |

|

power and torque are the default curves, |

|

however, the data displayed can be |

|

modified by right-clicking on the graph |

|

and reassigning each curve in the Graph |

|

Options Box. In addition, you can use the |

|

Properties... choice available at the |

|

bottom of the Options Box to setup |

|

comparisons between any “active” |

|

engine. Note: A second, Left-Hand graph |

|

is available under the component |

|

selection screen (to activate this display, |

|

use the Left-Pane tabs at the bottom of |

|

the component screen). |

|

USING THE MOUSE OR KEYBOARD

TO BUILD A TEST ENGINE

Begin using the Dyno2000 by “assembling” a test engine from component parts. For example, select a bore and stroke by using the Block pull-down menu. Activate the menu by:

Mouse

1)Start the Dyno2000 or select New from the File menu. All component categories start off empty, indicated by strings of asterisks (****) next to each incomplete selection.

2)Move the mouse cursor into the SHORTBLOCK category and double click the left mouse button on the asterisks in the Block component category.

3)When the component-menu bounding box appears (see photo, page 16), click on the symbol to open the Shortblock selection menu.

4)Move the mouse pointer through the menu choices.

5)When a submenu opens, move the mouse cursor over your selected choice in the submenu.

6)Click the left mouse button on your selection. This loads the engine name, bore, stroke, and number of cylinders into the SHORTBLOCK category. Note that the red boxed X (Status Box) on the left of the SHORTBLOCK category changed to a green-boxed check-mark , indicating that all components in that category

Dyno2000 Advanced Engine Simulation— 17

Program Overview

have been selected.

7)Alternatively, to close the menu without making a selection, click the red X on the right of the bounding box or press the Escape key until the menu closes.

8)Continue making component selections until all the category Status Boxes have switched to green. At this point an engine simulation will be performed and the results will be displayed on the graph or chart on the right of the Main Program Screen.

Keyboard

1)Press and release the Alt key followed by the F key to highlight and open the File menu. Use the cursor-arrow keys to select New, then press Enter to create a new, blank component screen. All component categories start off empty, indicated by strings of asterisks (****) next to each incomplete component selection. Note: You can activate other menu choices— e.g., Edit, View, Simulation, etc., by pressing the Right-Arrow or Left-Arrow keys or by using the menu shortcuts (e.g., open the Edit menu by pressing Alt E).

2)A component menu bounding box is positioned around the Block choice in the SHORTBLOCK category.

3)Press Enter to activate the box. Then press Tab to move the highlight (focus) to the symbol. Then press the Spacebar to open the Block selection menu.

4)Use the Up-Arrow or Down-Arrow keys to scroll through the menu choices. When the menu selections include submenus (a small arrow points to the right at the end of the menu line), use the Right-Arrow key to open the submenu.

5)When you have highlighted your choice, press Enter to make the selection. This loads the engine name, bore, stroke, and number of cylinders into the SHORTBLOCK category. Note that the red boxed X (Status Box) on the left of the SHORTBLOCK category changed to a green-boxed check-mark , indicating that all components in that category have been selected.

Note: Alternatively, to close the menus without making a selection, press the

Escape key.

6)Use the TAB key to move the component-selection bounding box to the next blank field (Compression Ratio). Continue making component selections until all the main component category Status Boxes have changed to green. At this point an engine simulation will be performed and the results will be displayed on the graph or chart in the right pane of the Main Program Screen.

Note: The Shift Tab key combination will move the bounding box backwards to the previous component field.

18— Dyno2000 Advanced Engine Simulation

Program Overview

Fields Accepting Direct Input

Fields Not Accepting Direct Input

White Background:

Numeric input accepted. Enter value or make selection from

drop-down menu.

Gray Background:

No numeric input accepted. Make selection from drop-down menu.

DIRECT-ENTRY MENU CHOICES

The Bore, Stroke, Number Of Cylinders, Valve Size, Compression Ratio, Induction Airflow, and several other menus permit direct numeric entry. When a component field supports direct entry, the bounding box will have a white interior. If the only entry possible is a choice from the drop-down menu, the bounding box will have a gray interior (see above photos). Choosing a new numeric value will replace the currently displayed value. When you press Enter the new value will be tested for acceptability, and if it passes, it will be used in the next simulation run. If you press Enter without entering a new value, the currently displayed value is left unchanged.

Data entry into any field in the component-selection screen is limited to values over which the Dyno2000 can accurately predict power. The range limits are displayed in the Range Limit Line within the Status Box at the bottom-left of the Main Program Screen. If you enter an invalid number, the Dyno2000 will play the Windows error sound and wait for new input.

THE MEANING OF SCREEN COLORS

The colors used on the component-selection screen provide information about various engine components and specifications. Here is a quick reference to screen color functionality:

White Numeric Values: White engine specifications indicate that they are automatically calculated by program and cannot be directly altered.

Dark Blue: All engine specifications that can be changed by the user through pulldown menus are displayed in dark blue.

Dyno2000 Advanced Engine Simulation— 19

COMPONENT MENUS

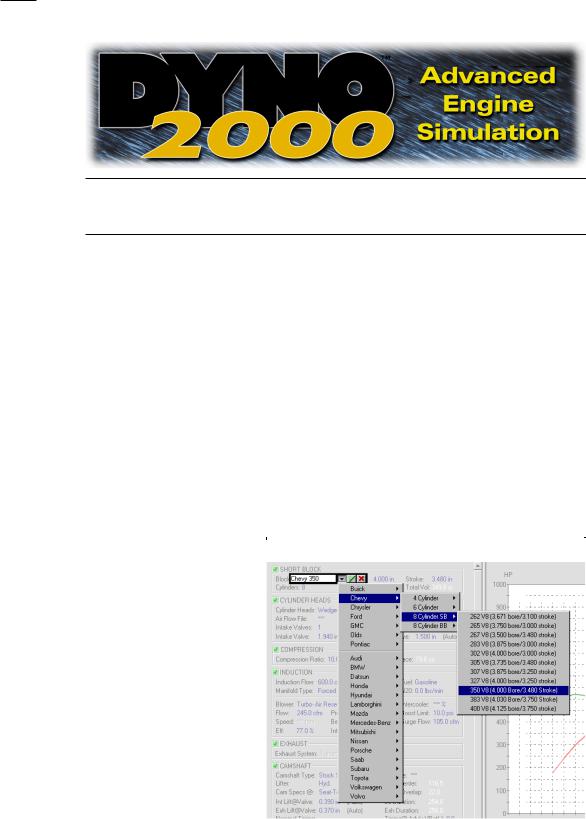

THE BORE, STROKE, AND NUMBER-OF-CYLINDER MENUS

The Block menu is located on the upper-left of the SHORTBLOCK component category on the Main Program Screen. By opening this menu, you are presented with a variety of domestic and import “pre-defined” engine shortblock configurations. If any one of these choices is selected, the appropriate bore, stroke, and number of cylinders will be loaded in the SHORTBLOCK category. In addition to selecting any predefined engine configuration, you can directly enter any Block name, Stroke, Bore, and Number Of Cylinder numeric values (within the acceptable range limits of the program indicated at the bottom of the screen in the Status Bar).

What’s A SHORTBLOCK

When a particular engine combination is selected from the Block menu, the bore, stroke, and the number of cylinders are “loaded” into the SHORTBLOCK category. These values are subsequently used in the simulation. The SHORTBLOCK menu

The Block component menu |

Block Component Menu |

contains over 200 bore and |

|

stroke combinations of |

|

popular domestic and import |

|

engines that you can in- |

|

stantly use in a simulation. |

|

|

|

20— Dyno2000 Advanced Engine Simulation

Block, Bore, and Stroke Menus

choices should be considered a “handy” list of common engine cylinder-bore and crankshaft-stroke values, not a description of engine configurations (e.g., V8, V6, straight 6, V4, etc.), material composition (aluminum vs. cast iron), the type of cylinder heads (hemi vs. wedge) or any other engine characteristics. The Bore/ Stroke menu only loads Bore, Stroke, and the Number Of Cylinders into the program database.

Bore And Stroke And Its Effects On Compression Ratio

After making a Bore, Stroke, and Number-Of-Cylinder selection, the swept cylinder volume and the total engine displacement will be calculated and displayed in the SHORTBLOCK component category. The swept cylinder volume measures the volume displaced by the movement of a single piston from TDC (top dead center) to BDC (bottom dead center). This “full-stroke” volume is one of the two essential values required in calculating compression ratio. We’ll discuss compression ratio in more detail later, but for now let’s take a quick look at how compression ratio is calculated:

Swept Cyl Vol + Combustion Space Vol Compression Ratio = ———————————————————

Combustion Space Vol

The total volume that exists in the cylinder when the piston is located at BDC (this volume includes the Swept Volume of the piston plus the Combustion Space Volume) is divided by the remaining volume that exists when the piston is positioned at Top Dead Center.

Bore and stroke dimensions greatly affect cylinder volumes and, therefore, compression ratio. When the stroke, and to a lessor degree the bore, is increased while maintaining a fixed combustion-space volume, the compression ratio will rapidly increase. And, as is the case in the Dyno2000 simulation, if the compression ratio is held constant— because it is a fixed component selected by you— the combustion space volume (not necessarily the same as the combustion-chamber volume, see page 31) must increase to maintain the desired compression ratio.

This may seem more understandable when you consider that if the combustionspace volume did not increase, a larger swept cylinder volume (due to the increase in engine displacement) would be compressed into the same final combustion space, resulting in an increase in compression ratio.

THE CYLINDER HEAD AND VALVE DIAMETER MENUS

The Cylinder Head pull-down menu is located in the CYLINDER HEAD category, and selection from this menu allows the Dyno2000 to simulate various cylinder head designs and a wide range of airflow characteristics. The menu lists general cylinder head characteristics, including restrictive low-performance ports, typical wedgeand

Dyno2000 Advanced Engine Simulation— 21

Cylinder Head Menu

Cylinder Head Menu

The Cylinder Head menu contains a wide range of head/port choices, from stock to all-out racing. In addition, Custom Port Flow allows the direct entry of flow bench data. This feature allows the simulation and testing of any cylinder head for which flow data is available.

canted-valve configurations, and 4-valve cylinder heads. Each type of head/port includes several stages of modifications from stock to all-out race configurations.

In addition, the Custom Port Flow choice at the bottom of the Cylinder Head menu allows the direct entry of flowbench data, allowing the Dyno2000 to model any cylinder head for which flow data is available. This option will be described in more detail later.

Basic Flow Theory

A selection from the Cylinder Head menu is the first part of a two-step process used by the simulation to accurately model cylinder head flow characteristics. The initial cylinder head selection determines the airflow restriction generated by the ports. That is, this choice establishes how much less air than the theoretical maximum peak flow will pass through each port. What determines peak flow? That’s selected from the remaining CYLINDER HEAD category menus: Intake and Exhaust Valve Diameter Menus. The valve-diameter menus allow the selection of valve sizes that fix the theoretical peak flow (called isentropic flow) of each port. Most cylinder heads flow only about 50% to 70% of this value.

Note: You can enable the Auto Calculate Valve Size feature to allow the Dyno2000 to automatically determine valve diameters based on bore size and the degree of cylinder head porting/modifications. The various Cylinder Head menu choices load airflow data into the simulation, but this flow data is not directly used to determine the airflow capacity of the cylinder heads.

There are several reasons for this. First of all, flow generated in the ports of a running engine is vastly different than the flow measured on a flow bench. Airflow on a flow bench is steady-state flow, measured at a fixed pressure drop (it’s also dry

22— Dyno2000 Advanced Engine Simulation

Cylinder Head Menu

flow, but a discussion of that feature is beyond the scope of this book). A running engine will generate rapidly and widely varying pressures in the ports. These pressure differences directly affect— in fact, they directly cause— the flow of fuel, air, and exhaust gasses within the engine. The Dyno2000 calculates these internal pressures at each degree of crank rotation throughout the four-cycle process. To determine mass flow into and out of the cylinders at any instant, the flow that occurs as a result of these changing pressure differences is also calculated. Since the variations in pressure, or pressure drops, within the engine are almost always different than the pressure drop used on a flow bench, flow bench data cannot directly predict flow within the engine.

While it is impractical to use cylinder head flow data directly in an engine simulation, measured cylinder head flow figures are, nonetheless, a good starting point. Flow-bench data can be used as a means to compare the measured flow of a particular port/valve configuration against the calculated isentropic (theoretical maximum) flow. The resulting “ratio,” called the discharge coefficient, has proven to be an effective link between flow-bench data and predicted mass flow moving into and out of the cylinders. Furthermore, the discharge coefficient also can be used to predict the changes in flow for larger or smaller valves and for various levels of port modifications. In other words, the discharge coefficient provides a practical method to simulate mass flow within a large range of engines under a wide range of operational conditions.

Sorting Out Cylinder Head Menu Choices

Now that some of the basic flow theory behind the choices in the CYLINDER HEAD category menus has been exposed, here’s some practical advice that may

Typical Low-Performance Cylinder Heads

The “Low Performance” cylinder head choices are intended to model cylinder heads that have unusually small ports and valves. Heads of this type were often designed for low-speed, economy applications, with little concern for high-speed performance. Early 260 and 289 smallblock Ford and to a lessor degree early smallblock Chevy castings fall into this category.

Dyno2000 Advanced Engine Simulation— 23

Cylinder Head Menu

Typical Wedge Cylinder Heads

The “Wedge Cylinder head” menu choices model cylinder heads that have ports and valves sized with performance in mind, like the heads on this LT1 smallblock Chevy.

help you determine the appropriate selections for your application.

Low Performance Cylinder Heads—There are three “Low Performance” cylinder head selections listed at the top of the Cylinder Head menu. Each of these choices is intended to model cylinder heads that have unusually small ports and valves relative to engine displacement. Heads of this type were often designed for lowspeed, economy applications, with little concern for high-speed performance. Early 260 and 289 smallblock Ford and to a lessor degree early smallblock Chevy castings fall into this category. These choices use the lowest discharge coefficient of all the head configurations listed in the menu. Minimum port cross-sectional areas are 85% of the valve areas or somewhat smaller and, if Auto Calculate Valve Size has been selected, relatively small (compared to the bore diameter) intake and exhaust valve diameters will be used.

The first low-performance choice models an unmodified production casting. The second “Low Performance/Pocket Porting” choice adds minor porting work performed below the valve seat and in the “bowl” area under the valve head. The port runners are not modified. The final choice “Low Performance/Ported, Large Valves” incorporates the same modifications plus slightly larger intake and exhaust valves and some modest work in the port runners. Auto-calculate valve size increases vary, but they are always scaled to a size that will install in production castings without extensive modifications.

The low-performance choices have some ability to model flathead (L-head & H- head) and hybrid (F-head) engines. While the ports in these engines are even more restrictive, by selecting Low-Performance and manually entering the exact valve sizes, the simulation will, at least, give you an approximate power output usable to evaluate changes in cam timing, induction flow, and other components.

24— Dyno2000 Advanced Engine Simulation

Cylinder Head Menu

Typical Canted-Valve Cylinder Heads

The “Canted-Valve Cylinder Head” selections have ports with generous cross-sectional areas and valves that angle toward the port mouths. The first three menu choices model oval-port designs. The final two selections simulate performance rectangular-port heads. This L29 big-block Chevy would be best modeled by the second or third menu choice—the fourth menu choice models a head with flow capacity beyond the capabilities of L29 castings.

Wedge Cylinder Heads—The wedge-chamber and canted-valve choices comprise the two main cylinder head categories. Choices from these two groups are applicable to 90% of all performance engine applications.

The first three basic wedge selections model heads that have ports and valves sized with performance in mind. Ports are not excessively restrictive for high-speed operation, and overall port and valve-pocket design offers a good compromise between low restriction and high flow velocity. The stock and pocket-ported choices are best for high-performance street to modest racing applications.

The fourth wedge head “Wedge/Fully Ported, Large Valves” moves away from street applications. This casting has improved discharge coefficients, greater port cross-sectional areas, and increased valve sizes. Consider this head to be an extensively modified, high-performance, factory-type casting that has additional modifications to provide optimum flow for racing applications. It does not incorporate “exotic” modifications, like raised and/or welded ports that require custom-fabricated manifolds.

The last choice in the wedge group is “Wedge/Pro-Stock Porting And Mods.” This selection is designed to model state-of-the-art, high-dollar, Pro-Stock drag-racing cylinder heads. These custom pieces are designed for one thing: Maximum power. They usually require hand-fabricated intake manifolds, have excellent valve discharge coefficients, and the ports have the largest cross-sectional areas in the smallblock group. This head develops sufficient airflow speeds for good cylinder filling only at high engine rpm.

Canted-Valve Cylinder Heads—All canted-valve selections are modeled after heads with “canted” valves. That is, the valve stems are tilted toward the outside of the cylinder heads to improve the discharge coefficient and overall airflow. All ports have

Dyno2000 Advanced Engine Simulation— 25

Cylinder Head Menu

generous cross-sectional areas for excellent high-speed performance.

The first three choices are based on an oval-port configuration. These smaller cross-sectional area ports provide a good compromise between low restriction and high flow velocity for larger displacement engines. The stock and pocket-ported choices are suitable for high-performance street to modest racing applications.

The final two selections simulate extensively modified rectangular-port heads. These choices model, primarily, all-out, big-block heads, however, they closely model other extremely aggressive high-performance racing designs, like the Chrysler Hemi head and all-out ProStock designs. As with the smallblock category, the “Canted/ Rectangular Ports/Fully Ported” heads are not suitable for most street applications. These castings have high discharge coefficients, large port cross-sectional areas, and increased valve sizes. This head is basically a factory-type casting but extensively improved. However, it does not incorporate “exotic” modifications, like raised and/or welded ports that require custom-fabricated manifolds.

The last choice in the canted-valve group is “Canted/Rectangular ProStock Ports/ Mods.” This selection is designed to model state-of-the-art, ProStock drag-racing cylinder heads. These custom pieces, like their wedge-design counterparts, are built from the ground-up for maximum power. They require hand-fabricated intake manifolds, have optimum valve discharge coefficients, and the ports have the largest cross-sectional areas in the entire Cylinder Head menu, except for 4-valve heads (discussed next). These specially fabricated cylinder heads only develop sufficient airflow for good cylinder filling with large displacement engines at very high engine speeds.

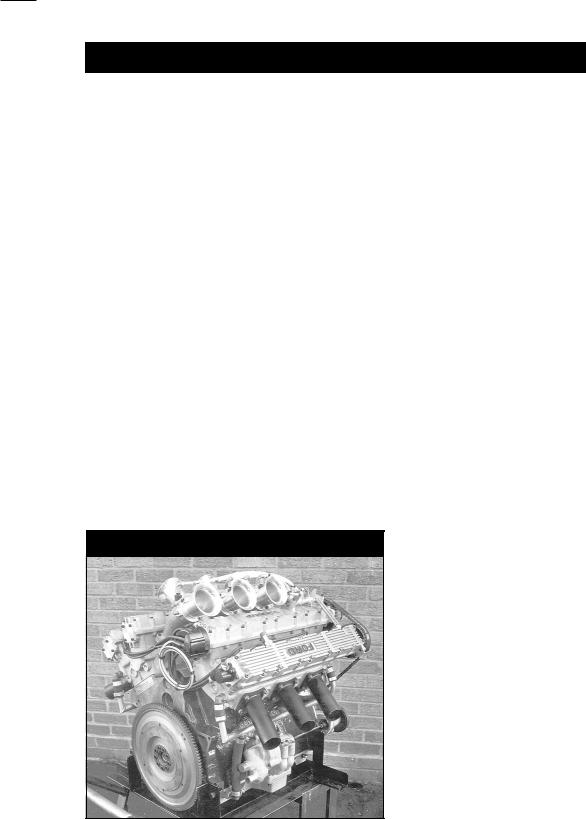

4-Valve Cylinder Heads—The next three selections in the Cylinder Head submenu

Typical 4-Valve Cylinder Heads

The “4-Valve Cylinder Head” selections model cylinder heads with 4-valves per cylinder. These heads can offer more than 1.5 times the curtain area of the largest 2-valve heads. This large valve area, combined with high-flow, lowrestriction ports greatly improves air and fuel flow into the cylinders at high engine speeds. These Cosworth heads were designed for the English Ford V6. When they were raced in England several years ago, they regularly beat V8s.

26— Dyno2000 Advanced Engine Simulation

Cylinder Head Menu

model 4-valve cylinder heads. These are very interesting choices since they simulate the effects of very low-restriction ports and valves used in many import stock and performance applications. The individual ports in 4-valve heads begin as single, large openings, then neck down to two Siamesed ports, each having a small (relatively) valve at the combustion chamber interface. Since there are two intake and two exhaust valves per cylinder, valve curtain area is considerably larger than with the largest single-valve-per-port designs. In fact, 4-valve heads can offer more than 1.5 times the curtain area of the largest 2-valve heads. This large area, combined with high-flow, low-restriction ports greatly improves air and fuel flow into the cylinders at low valve lifts and at high engine speeds. Unfortunately, the ports offer an equally low restriction to reverse flow (reversion) that occurs at low engine speeds when the piston moves up the cylinder from BDC to Intake Valve Closing (IVC) on the final portion of the intake stroke. For this reason, 4-valve heads, even when fitted with more conservative ports and valves, can be a poor choice for small-displace- ment, low-speed engines, unless camshaft timing is carefully designed to complement the low-lift flow capabilities of these cylinder heads. On the other hand, the outstanding flow characteristics of the 4-valve head put it in another “league” when it comes to horsepower potential on high-speed racing engines.

The first choice in the 4-valve group is “4-Valve Head/Stock Ports And Valves.” This simulates a 4-valve cylinder head that would be “standard equipment” on factory high-performance or “sports-car” engines. These heads offer power comparable to high-performance 2-valve castings equipped with large valves and pocket porting. However, because they still have relatively small ports, reasonably high port velocities, and good low-lift flow characteristics, they often show a boost in low-speed power over comparable 2-valve heads.

The next choice, “4-Valve Head/Ported With Large Valves” incorporates mild performance modifications. Larger valves have been installed and both intake and

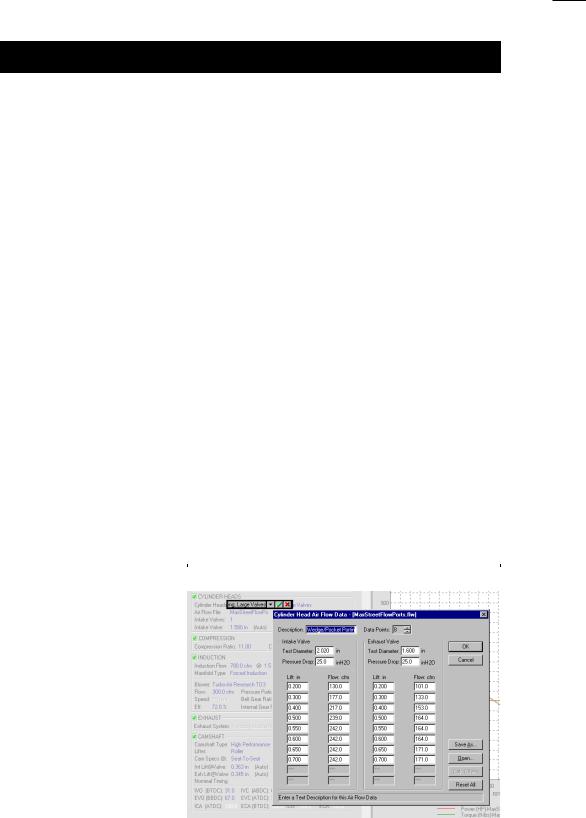

The Custom Port Flow |

Custom Port Flow Dialog |

|

dialog box allows the direct |

||

|

||

entry of flow bench data. |

|

|

From 4 to 10 data points for |

|

|

each port can be entered. |

|

|

Virtually any test valve |

|

|

diameter and pressure drop |

|

|

can be used. |

|

|

|

|

Dyno2000 Advanced Engine Simulation— 27

Custom Port Flow Dialog

exhaust flow has been improved by pocket porting. However, care has been taken not to increase the minimum cross-sectional area of the ports. These changes provide a significant increase in power with only slightly slower port velocities. Reversion has increased, but overall, these heads should show a power increase throughout the rpm range on most engines.

The final choice, “4-Valve Head/Race Porting And Mods,” like the other “Race Porting And Mod” choices in the Cylinder Head menu, models an all-out racing cylinder head. This selection has the greatest power potential of all. The ports are considerably larger than the other choices, the valves are larger, and the discharge coefficients are the highest possible. These heads suffer from the greatest reversion effects, especially with late IVC timing on low-speed, small-displacement engines. Note: These heads, like all choices provided in the Cylinder Head menu, are “scaled” to engine size, so that smaller engines automatically use appropriately smaller valves— providing the Auto Calculate Valve Size option is selected— and smaller ports.

Tip: If you would like to know what “hidden” power is possible using any particular engine combination, try this cylinder head choice. It is safe to say that the only way to find more power, with everything else being equal, would be to add forced induction, nitrous-oxide injection, or use exotic fuels.

Custom Port Flow—The Dyno2000 will accept flowbench data, taken from measuring virtually any port, with any valve size, at any pressure drop. Selecting Custom Port Flow opens the airflow-bench dialog box (see photo on previous page). If you open this dialog after you have selected one of the other cylinder head menu choices, the Custom Port Flow dialog will display the flow data for that head configuration.

To enter flow-bench data, first provide a short description of the flow-bench/ cylinder head test in the Description field. Then select the number of data points

Custom Port Flow Description And Filename

Custom Port Flow

Saved Flow Data

When Custom Port Flow is used, the port Description name (entered in the PortFlow Dialog Box) is displayed in the CYLINDER HEAD category. In addition, if the flow data was saved to disk, the filename is also displayed. You can doubleclick on the filename (or asteristics in that field) and load and save airflow data.

28— Dyno2000 Advanced Engine Simulation

Valve Size Menus

in your flowbench test into the Data Points field (click up to increase, down to decrease). Then enter the test-valve diameters and the pressure drop (in inches of H20) at which the tests were performed. Finally enter flow and valve-lift test data. Note 1: You may press the Calc Others button at any time to fill in the remaining lift fields with the same “step” value that was established in the previous fields. The Calc Others button is smart enough to change step values at higher valve lifts.

Note 2: If you have fewer data points for one of the valves, simply repeat the highest measured flow value to “flush out” the remaining data points. This technique has been shown to produce accurate simulations.

You can save the flow data to your hard drive at any time by pressing the Save As button. Recall previously saved flow data with the Open button.

Pressing OK will load the new test data into the engine database and display the custom flow Description in the CYLINDER HEAD category.

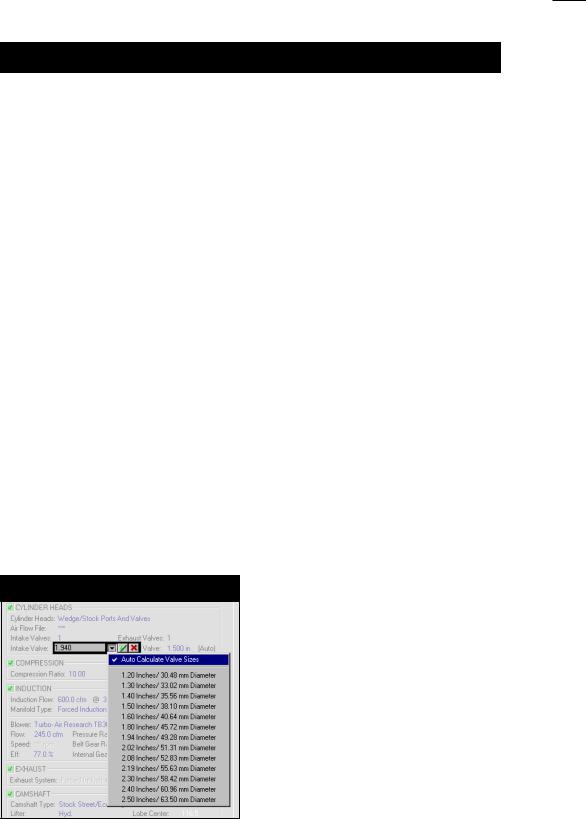

Valve Diameters

The Valve Diameter menus are located in the lower portion of the CYLINDER HEAD category. The first selection is Auto Calculate Valve Size. This feature instructs the simulation software to determine the most likely valve sizes to be used with the current engine based on an assessment of the current bore diameter and the Cylinder Head selection. When the Auto Calculate function is activated Auto will be displayed next to the calculated sizes, and it remains active on the current engine until turned off (by selecting it a second time). Auto Calculation is turned off by default when the Dyno2000 is started and whenever Clear Components is chosen from the Edit menu.

Auto Calculate Valve Size is especially helpful if you are experimenting with several different bore and stroke combinations or comparing different engine configurations. Auto Calculate will always select valves of appropriate diameter for the

Intake And Exhaust Valve Sizes

Select valve sizes for the intake and exhaust valves from drop-down menus. If you choose Auto Calculate Valve Size from either the intake or the exhaust menu, the Dyno2000 will size all valves appropriately, based on the cylinderhead type and the bore diameter. Deselecting

Auto Calculate Valve Size on either the intake or the exhaust valve-size menus will disable this feature on all valves.

Dyno2000 Advanced Engine Simulation— 29

Compression Ratio Menu

Selecting a specific valve size will |

Manually Selecting Valve Sizes |

disable Auto Calculate Valve Size. You |

|

can select from the provided sizes |

|

(displayed in both US and Metric mea- |

|

surements), or you can directly enter |

|

any valve dimension within the range |

|

limits of the Dyno2000. |

|

|

|

cylinder heads under test and it will never use valve sizes that are too large for the current bore diameter (also, see page 69 for information on the related Auto Calculate Valve Lift feature).

While the Auto Calculate Valve Size is helpful during fast back-to-back testing, it may not “guess” the precise valve sizes used, and therefore, not simulate power levels as accurately as possible. In these situations refer to the lower choices on the Valve Diameter menus. Here you will find a list of exact valve sizes consisting of common intake and exhaust dimensions. In addition, you can directly enter any valve diameters within the acceptable range limits of the program.

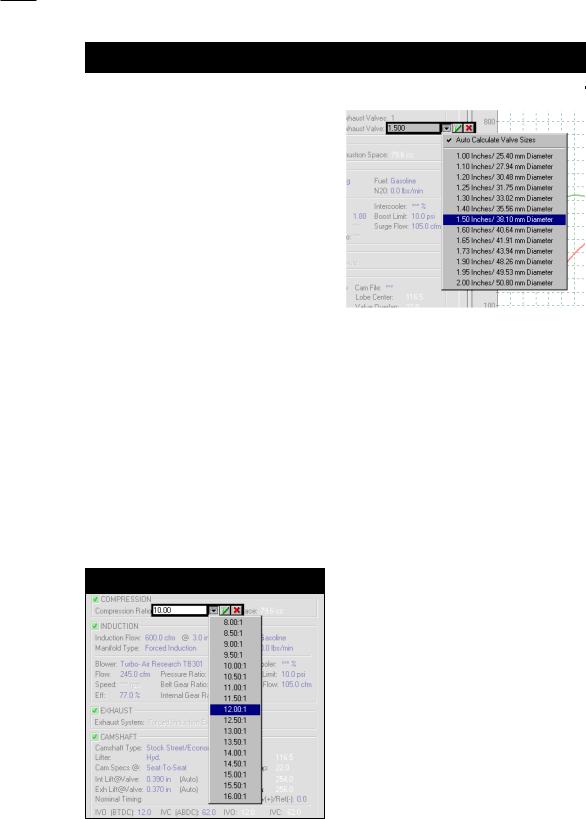

THE COMPRESSION RATIO MENU

The Compression Ratio

Compression Ratio Menu

menu is located in the COMPRESSION category. A

The Compression Ratio of the engine is a comparison of the geometric volume that exists in the cylinder when the piston is located at BDC (bottom dead center) to the “compressed” volume when the piston reaches TDC (top dead center). Passenger car engines often have 8 to 10:1. While racing engines can have as high as 18:1 compression ratio.

30— Dyno2000 Advanced Engine Simulation

Loading...

Loading...