Furuno SC-120 User Manual

SATELLITE COMPASS

SC-120

9-52 Ashihara-cho,

Nishinomiya, Japan

Telephone : 0798-65-2111

fax |

: 0798-65-4200 |

All rights reserved. |

Printed in Japan |

PUB.No. OME-72490

( KAMI ) SC-120

Your Local Agent/Dealer

FIRST EDITION : MAR. 2001 P1 : FEB. 26,2004

*00080919206*

*00080919206*

* 0 0 0 8 0 9 1 9 2 0 6 *

*OME72490P10*

*OME72490P10*

* O M E 7 2 4 9 0 P 1 0 *

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

Safety Instructions for the Operator

WARNING

WARNING

Do not open the equipment.

Only qualified personnel should work inside the equipment.

Do not disassemble or modify the equipment.

Fire, electrical shock or serious injury can result.

Immediately turn off the power at the switchboard if the equipment is emitting smoke or fire.

Continued use of the equipment can cause fire or electrical shock. Contact a FURUNO agent for service.

Do not place liquid-filled containers on the top of the processor unit.

Fire or electrical shock may result if the liquid enters the equipment.

CAUTION

CAUTION

No one navigation device should ever be solely replied upon for the navigation of a vessel.

Always confirm position against all available aids to navigation, for safety of vessel and crew.

Use the proper fuse.

Use of a wrong fuse can result in damage to the equipment.

Safety Instructions for the Installer

WARNING

WARNING

Do not open the cover unless totally familiar with electrical circuits and service manual.

Improper handling can result in electrical shock.

Turn off the power at the switchboard before beginning the installation.

Fire or electrical shock can result if the power is left on.

Do not install the equipment where it may get wet from rain or water splash.

Water in the equipment can cause fire, electrical shock or damage to the equipment.

NOTICE

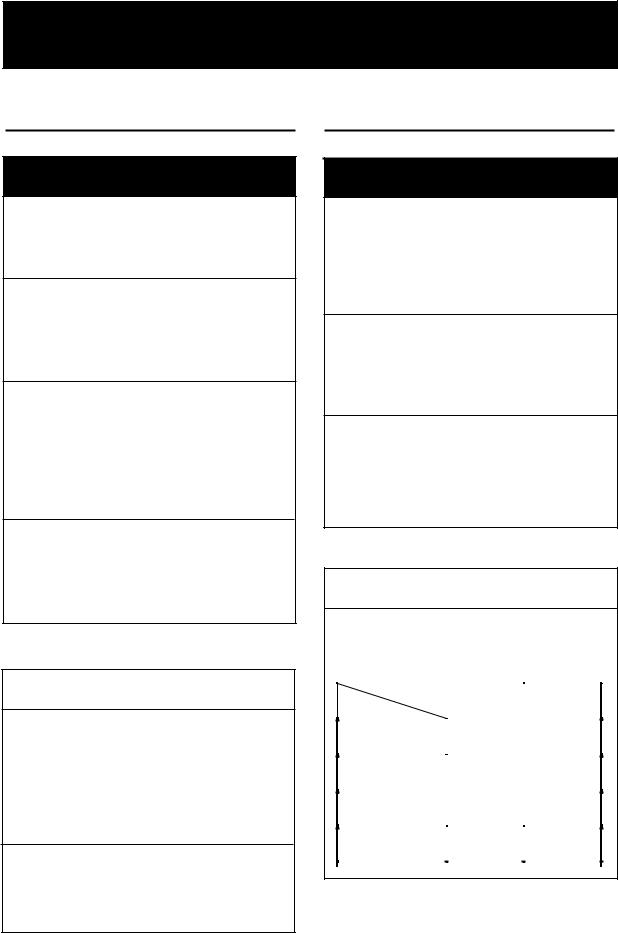

Observe the following compass safe distances to prevent interference to a magnetic compass:

|

Standard |

Steering |

|

|

Compass |

Compass |

|

Display unit |

0.5 m |

0.3 m |

|

SC-602 |

|||

|

|

||

Processor unit |

1.3 m |

0.8 m |

|

SC-1201/1201D |

|||

|

|

||

Antenna unit |

0.3 m |

0.3 m |

|

SC-1203F |

|||

|

|

||

DGPS beacon |

0.3 m |

0.3 m |

|

antenna GR-8 |

|||

|

|

||

|

|

|

i

TABLE OF CONTENTS

|

|

|

|

|

FOREWORD |

.................................................................................................................. |

iv |

||

SYSTEM CONFIGURATION ........................................................................................... |

v |

|||

EQUIPMENT LIST.......................................................................................................... |

vi |

|||

SOFTWARE VERSION LIST......................................................................................... |

vii |

|||

SPECIFICATIONS ..................................................................................................... |

SP-1 |

|||

1 |

PRINCIPLE OF OPERATION................................................................................. |

1-1 |

||

2 |

INSTALLATION...................................................................................................... |

2-1 |

||

|

2.1 |

Mounting Considerations..................................................................................................... |

2-1 |

|

|

|

2.1.1 |

SC - series antenna unit ............................................................................................. |

2-1 |

|

|

2.1.2 |

Display unit, processor unit ....................................................................................... |

2-3 |

|

2.2 |

Installing the Antenna Units................................................................................................. |

2-4 |

|

|

|

2.2.1 |

SC - series antenna unit ............................................................................................. |

2-4 |

|

|

2.2.2 |

DGPS antenna unit ................................................................................................... |

2-7 |

|

2.3 |

Installing the Processor Unit................................................................................................ |

2-9 |

|

|

|

2.3.1 |

Deck mount ............................................................................................................... |

2-9 |

|

|

2.3.2 |

Bulkhead mount ...................................................................................................... |

2-10 |

|

|

2.3.3 Installation on the underside of a desk................................................................... |

2-12 |

|

|

|

2.3.4 |

Adjusting for orientation error ................................................................................. |

2-14 |

|

2.4 |

Installing the Display Unit .................................................................................................. |

2-14 |

|

|

|

2.4.1 |

Desktop, overhead mounting .................................................................................. |

2-14 |

|

|

2.4.2 |

Flush mounting ....................................................................................................... |

2-15 |

|

2.5 |

Wiring |

................................................................................................................................. |

2-16 |

|

2.6 |

Initial Settings .................................................................................................................... |

2-19 |

|

|

|

2.6.1 .........................................Confirming satellite status; choosing mounting method |

2-19 |

|

|

|

2.6.2 ....................................................................................... |

Choosing heading source |

2-20 |

|

|

2.6.3 ............................................................................................... |

Heading data format |

2-21 |

|

2.7 |

Connection ....................................................................................of External Equipment |

2-22 |

|

|

2.8 |

Installing .........................................................................the DGPS Beacon Receiver Kit |

2-22 |

|

3 |

OPERATION........................................................................................................... |

3-1 |

||

|

3.1 |

Controls................................................................................................................................ |

3-1 |

|

|

3.2 |

Turning ....................................................................................................the Power On/Off |

3-2 |

|

|

3.3 |

Panel Illumination, ....................................................................................Display Contrast |

3-2 |

|

|

3.4 |

Choosing ..............................................................................................................a Display |

3-3 |

|

|

|

3.4.1 .............................................................................................. |

Description of displays |

3-3 |

|

3.5 |

Alarms.................................................................................................................................. |

3-5 |

|

|

3.6 |

Confirming ..................................................................................................Satellite Status |

3-6 |

|

|

3.7 |

GPS Setup........................................................................................................................... |

3-7 |

|

|

|

3.7.1 ...............................................................................Displaying the GPS setup menu |

3-7 |

|

|

|

3.7.2 .................................................................................GPS SETUP menu description |

3-7 |

|

ii

3.8 |

Output Data.......................................................................................................................... |

3-8 |

|

|

3.8.1 |

Heading ..................................................................................................................... |

3-8 |

|

3.8.2 |

Navigation data ......................................................................................................... |

3-9 |

|

3.8.3 |

Interface .................................................................................................................... |

3-9 |

|

3.8.4 |

Log pulse................................................................................................................. |

3-10 |

|

3.8.5 |

Talker identifier mnemonics .................................................................................... |

3-10 |

3.9 |

System Setup..................................................................................................................... |

3-11 |

|

|

3.9.1 |

Geodetic data.......................................................................................................... |

3-11 |

|

3.9.2 |

Units of measurement ............................................................................................. |

3-12 |

|

3.9.3 |

Using local time....................................................................................................... |

3-12 |

|

3.9.4 |

Time format ............................................................................................................. |

3-12 |

|

3.9.5 |

Demonstration mode............................................................................................... |

3-13 |

3.10 |

DGPS Setup....................................................................................................................... |

3-13 |

|

|

3.10.1 Manual DGPS setup ............................................................................................... |

3-13 |

|

|

3.10.2 Programming user beacon stations ........................................................................ |

3-15 |

|

|

3.10.3 Editing user beacon stations................................................................................... |

3-16 |

|

|

3.10.4 Erasing individual user stations .............................................................................. |

3-17 |

|

|

3.10.5 Erasing all user beacon stations ............................................................................. |

3-17 |

|

3.11 |

OTHERS Menu .................................................................................................................. |

3-18 |

|

3.12 |

TRIP Menu ......................................................................................................................... |

3-19 |

|

3.13 |

Resetting Distance Run ..................................................................................................... |

3-19 |

|

4 MAINTENANCE, TROUBLESHOOTING............................................................... |

4-1 |

|

4.1 |

Preventive Maintenance ...................................................................................................... |

4-1 |

4.2 |

Troubleshooting ................................................................................................................... |

4-2 |

4.3 |

Diagnostics........................................................................................................................... |

4-2 |

4.4 |

Program Number ................................................................................................................. |

4-5 |

4.5 |

Clearing Data ....................................................................................................................... |

4-5 |

4.6 |

Replacement of Battery ....................................................................................................... |

4-6 |

4.7 |

Replacement of Fuse........................................................................................................... |

4-7 |

4.8 |

Error Messages.................................................................................................................... |

4-7 |

APPENDIX .................................................................................................................. |

A-1 |

Menu Tree..................................................................................................................................... |

A-1 |

Geodetic Chart Codes .................................................................................................................. |

A-2 |

Digital Interface ............................................................................................................................. |

A-3 |

Input/Output Ports...................................................................................................................... |

A-10 |

Parts Location ............................................................................................................................. |

A-11 |

Parts List .................................................................................................................................... |

A-12 |

PACKING LISTS ......................................................................................................... |

A-1 |

OUTLINE DRAWINGS ................................................................................................ |

D-1 |

INTERCONNECTION DIAGRAMS.............................................................................. |

S-1 |

INDEX................................................................................................................... |

Index-1 |

Declaration of Conformity

iii

FOREWORD

A Word to the Owner of the SC-120

FURUNO Electric Company thanks you for purchasing the FURUNO SC-120 Satellite Compass. We are confident you will discover why the FURUNO name has become synonymous with quality and reliability.

For over 50 years FURUNO Electric Company has enjoyed an enviable reputation for quality and reliability throughout the world. This dedication to excellence is furthered by our extensive global network of agents and dealers.

Your satellite compass is designed and constructed to meet the rigorous demands of the marine environment. However, no machine can perform its intended function unless properly installed and maintained. Please carefully read and follow the operation and maintenance procedures set forth in this manual.

We would appreciate feedback from you, the end-user, about whether we are achieving our purposes.

Thank you for considering and purchasing FURUNO.

Features

The SC-120 is a new satellite compass designed with FURUNO’s advanced GPS kinematic technology. This compass finds a wide range of applications for any type of ships and mobile units at sea or on land.

The main features are

•Perfect for use as heading sensor for Radar/ARPA, AIS, ECDIS, scanning sonar, and video plotter

•There are no mechanical parts such as gimbals or rotating motor, thus the compass is free from routine maintenance

•The performance is not affected by geomagnetism thus it is suitable for use on any vessel

•No need for speed correction like a gyrocompass

•Short settling time - four minutes

•Provides all necessary functions as a GPS navigator.

iv

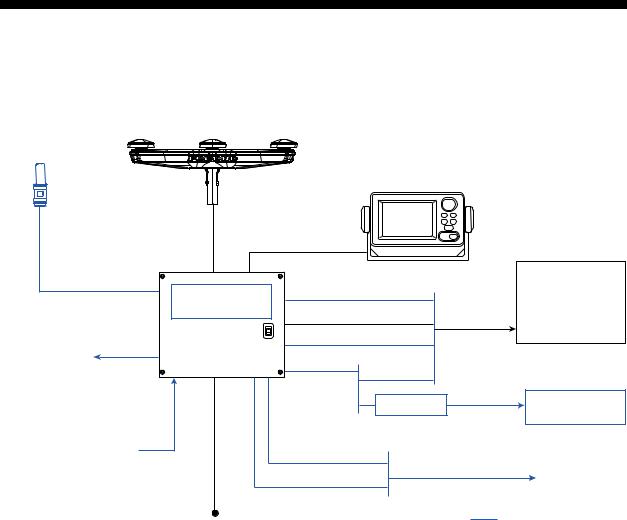

SYSTEM CONFIGURATION

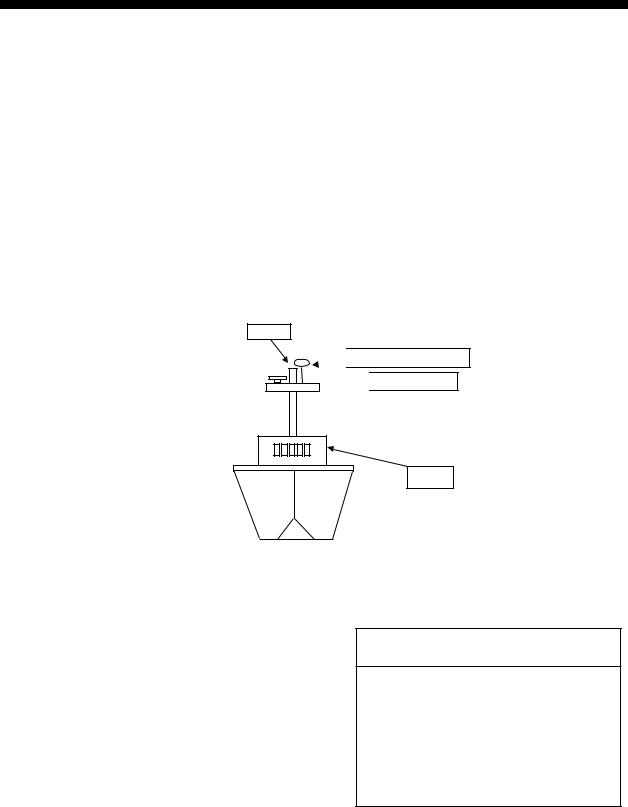

The SC-120 consists of three SC-series antennas, a display unit and a processor unit. The tri-antenna system helps reduce the influence of ship's motion (rolling).

|

Antenna Unit |

DGPS |

SC-1203 |

Beacon Antenna |

|

GR-800-1-S |

|

|

Beacon Receiver Kit |

|

GR-7001 |

Speed alarm/ |

Processor Unit |

SC-1201/SC-1201D |

|

Heading alarm |

|

(Contact) |

|

Gyro heading may be supplied through AD-100 Gyro Converter

(For primary gyrocompass and backup SC-120) or Doppler Speed Log

12-24 VDC

Display Unit

SC-602

Radar

Autopilot

VideoPlotter

Current Indicator

Heading Data Scanning Sonar

ECDIS

Repeater I/F |

Analog data |

Repeater Compass |

|

Autopilot |

|

|

|

GPS fix |

|

COG, SOG |

|

Time/Date |

|

Pitch/Roll |

Radar, |

2 ports |

Plotter, etc. |

|

|

|

|

Option |

|

System configuration

v

EQUIPMENT LIST

Standard supply

Name |

Type |

Code No. |

Qty |

Remarks |

||

Antenna Unit |

SC-1203F |

— |

1 |

|

|

|

DGPS |

GR-800-SC-1-S |

— |

1 |

No whip |

For |

|

Antenna |

antenna |

SC-1201-D |

||||

|

|

|

||||

Display Unit |

SC-602 |

— |

1 |

|

|

|

Processor Unit |

SC-1201 |

— |

1 |

|

|

|

SC-1201-D |

— |

With beacon receiver |

||||

|

|

|||||

|

CP20-02210 |

000-041-743 |

1 |

Accessories for Antenna Unit |

||

|

CP20-02241 |

|

||||

|

|

|

|

|

||

|

CP20-02203 |

— |

1 |

Accessories for Display Unit |

||

|

Tapping screw, 5X20, 4 pcs. |

|||||

Installation |

|

|

|

|||

|

|

|

Accessories for Processor Unit |

|||

Materials |

|

|

|

|||

|

|

|

MJ-A3SPF0013-035 |

|||

|

|

|

|

|||

|

CP20-02220 |

000-041-748 |

1 |

MJ-A6SPF0007-100 |

||

|

|

|

|

MJ-A7SPF0006-100 |

||

|

|

|

|

CP20-02221 |

|

|

Accessories |

FP14-02801 |

— |

1 |

Cover |

|

|

Spare Parts |

SP20-00901 |

004-377-600 |

1 |

Accessories for Processor Unit |

||

Optional equipment

Name |

Type |

Code No. |

Qty |

|

Remarks |

|

|

MJ-A6SPF0003-050 |

000-117-603 |

1 |

For AD-10 output, |

||

|

connector at one end, 5 m |

|||||

|

|

|

|

|||

|

MJ-A6SPF0007-100 |

000-125-237 |

1 |

For AD-10 output, |

||

|

connector at both ends, |

|||||

Cable Assy. |

|

|

|

10 m |

|

|

MJ-A6SPF0012-100 |

000-133-817 |

1 |

Cross for NMEA output, |

|||

|

||||||

|

10 m |

|

||||

|

|

|

|

|

||

|

|

|

|

For beacon/log/alarm |

||

|

MJ-A7SPF0003-050 |

000-136-730-01 |

1 |

signal output, connector at |

||

|

|

|

|

one end, 5 m |

||

Antenna |

CP20-01700 |

004-372-110 |

1 |

30 m |

3 pcs, for |

|

Cable Set |

CP20-01710 |

004-372-120 |

50 m |

SC-1203 |

||

|

||||||

DGPS Beacon |

GR-7001-K |

000-041-738 |

1 |

|

|

|

Receiver Kit |

|

|

|

|

|

|

Flush Mount F |

OP20-29 |

000-041-405 |

1 |

For display unit |

||

Flush Mount S |

OP20-17 |

000-040-720 |

1 |

For display unit |

||

Extension |

OP08-15-30 |

004-396-440 |

1 |

For DGPS, 30 m |

||

Cable |

OP08-15-60 |

004-396-450 |

For DGPS, 60 m |

|||

|

||||||

Antenna |

OP08-17 |

004-392-510 |

1 |

For DGPS antenna |

||

Cable Set |

||||||

|

|

|

|

|

||

Whip Antenna |

FAW-1.2 |

000-130-046 |

1 |

1.2 m |

|

|

Whip Antenna |

04S4176 |

000-112-845 |

1 |

2.6 m |

|

|

Flange |

OP20-31 |

004-378-230 |

1 |

|

|

|

vi

SOFTWARE VERSION LIST

|

|

DISPLAY UNIT: |

205-1312-009 |

PROCESSOR UNIT: |

205-1311-016 |

GPS1: |

205-1313-004 |

GPS2: |

205-1313-004 |

GPS3: |

205-1313-004 |

DGPS: |

085-0182-002 |

vii

This page is intentionally left blank.

SPECIFICATIONS OF SATELLITE COMPASS

SC-120

1 |

GENERAL |

|

1.1 |

Receiver Type |

12 discrete channels GPS |

1.2 |

RX Frequency |

1575.42 MHz (L1) |

1.3 |

Class of Service |

Standard Positioning service (SPS) using the C/A code on the L1 |

|

|

frequency |

1.4 |

Processing |

All-in-view, 8-state Kalman filter |

1.5 |

Position Accuracy |

10 m (GPS), or 5 m (DGPS), 95% of the time |

1.6 |

Heading Accuracy |

±0.6° (95% static accuracy) |

1.7 |

Follow-up |

25°/s rate-of-turn |

1.8 |

Settling Time |

4 minutes |

2 |

DISPLAY |

|

2.1 |

Display Type |

4.5 inch monochrome LCD, 120 x 64 dots |

2.2 |

Effective Area |

95 mm (W) x 60 mm (H) |

2.3 |

Contrast |

64 steps |

2.4 |

Display Mode |

Heading, Nav data, Steering, Compass rose, Rate of turn and Speed |

|

|

modes |

3 |

INTERFACE |

|

3.1 |

Heading Output |

3 ports: AD-10 or IEC 61162-1 Ed.2 |

|

|

1 port: NMEA 0183 (Ver1.5/2.0) |

|

|

IEC 61162 Sentences: HDT, HDM, VTG, ZDA, GGA, ROT |

3.2 |

COG, SOG, L/L Output |

1 port: IEC 61162-1 Ed.2 |

|

|

1 port: RS-232C level |

|

|

IEC 61162 Sentences: VTG, GGA, ZDA, GLL, ROT, |

|

|

PFEC, Gpatt (FURUNO P-sentences) |

|

|

ATT (Proprietary): incl. pitch, roll and yaw data |

|

|

$PFEC,GPatt,xxx.x,+xx.x,+xx.x<CR><LF> (Ver. 1.5) |

|

|

$PFEC,GPatt,xxx.x,+xx.x,+xx.x*hh<CR><LF> (Ver. 2.0) |

3.3 |

Log Output |

1 port: 200/400 pulse/nm (closure signal) |

3.4 |

Alarm Output |

1 port: Alarm signal (closure signal) |

3.5 |

Heading Input |

1 port: Backup Heading (AD-10/IEC 61162 format) from external |

|

|

heading device |

|

|

Sentences: HDT, HDG, HDM |

|

|

(VBW, VHW, VLW for tide direction and speed) |

3.6 |

Beacon Data Input |

1 port: RTCM SC-104 format for RS-232C |

SP - 1 |

E7249S01H |

Sentences: MSK, GGA

5 POWER SUPPLY

12-24 VDC: 1.1-0.5 A

6 ENVIRONMENTAL CONDITION AND EMC

6.1Ambient Temperature

|

Display/Processor Unit |

-15°C to +55°C, Designed for protected area |

|

Antenna Unit |

-25°C to +70°C, Designed for exposed area |

6.2 |

Damp heat |

93%±3% at 40°C |

6.3 |

Waterproofing |

|

|

Antenna Unit |

IPX6 |

|

Display Unit |

IPX5 |

|

Processor Unit |

IPX0 |

6.4 |

Vibration |

IEC 60945 |

6.5 |

EMC |

IEC 60945 |

7 |

COATING COLOR |

|

7.1 |

Display/Processor Unit |

Panel: N3.0 Newtone No.5 (dark gray) |

|

|

Cover: 2.5GY5/1.5 (light gray) |

7.2 |

Antenna Unit |

N9.5 (white) |

8 STANDARDS APPLICABLE

IMO MSC.116(73) |

THD standards |

ISO 22090-3 |

Under development |

IMO A. 694(17) |

General requirements |

IEC 60945 version 4 |

General requirements (EMC tested to 2 GHz) |

IMO A.819 (19) |

Performance standard for shipborne GPS |

IEC 61108-1 |

Performance standard for shipborne GPS |

ITU-R M.1371 for AIS |

Rate of turn |

SP - 2 |

E7249S01H |

1 PRINCIPLE OF OPERATION

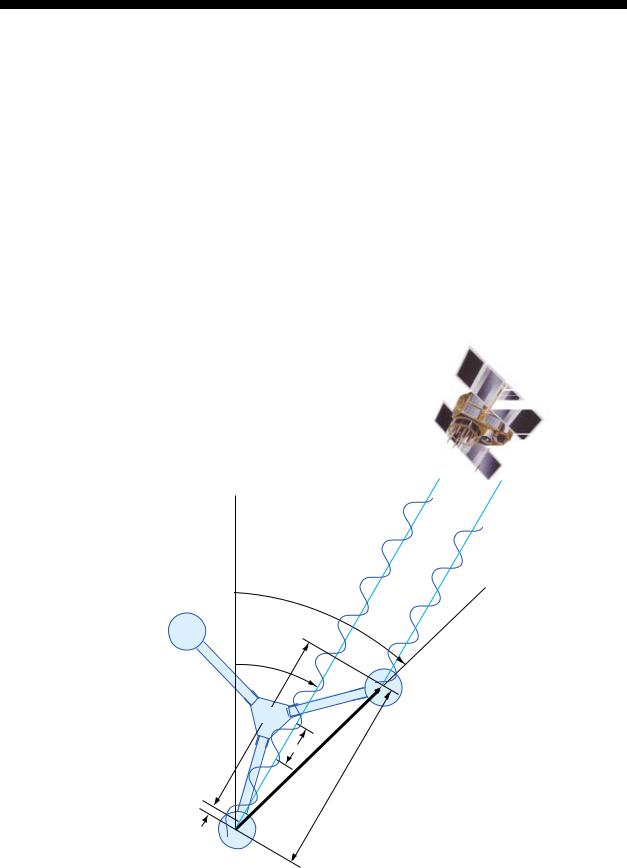

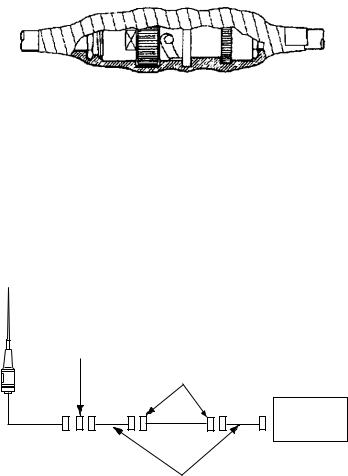

Own ship's heading can be determined by decoding the data in the carrier frequency in addition to ordinary GPS parameters. In principle, a pair of two antennas A1(ref) and A2(fore), each connected with an associated GPS engine and processor, are installed along the ship's fore-and-aft line. GPS systems at A1 and A2 calculate the range and azimuth to the satellite. Difference in range between A1 and A2 is ∆λ + nλ where λ is 19 cm. “n” is automatically found during the initialization stage by receiving three satellites. A fraction of a carrier wavelength, ∆λ , is processed by FURUNO’s advanced kinematic technology in geographical survey, thus determining a vector (range and orientation) A1 to A2.

In reality, a third antenna is used to reduce the influence of pitch, roll and yaw, and five satellites are processed to obtain 3D data. If the GPS signal is blocked by a tall building or the vessel is under a bridge, the 3-axis solid-state angular rate gyros in the processor unit take place of the satellite compass, maintaining the current heading continuously.

Antenna A3

∆λ

Heading |

|

line |

|

-aft |

|

|

|

|

|

-and |

|

θ |

Fore |

|

|

|

nλ

λ

Vector |

to |

|

decide

heading |

Antenna A2 |

|

Difference between the range from satellite to antenna 1 and the range to antenna 2.

Antenna A1

Principle of satellite compass operation

1-1

This page is intentionally left blank.

2 INSTALLATION

2.1Mounting Considerations

2.1.1SC-series antenna unit

General

•Keep the length of antenna cable in mind when selecting a mounting location. The cable comes in lengths of 15 meters (standard supply), or 30 m or 50 m (optional lengths).

•Select a location where vibration and shock are minimal.

Installing the antenna above superstructures

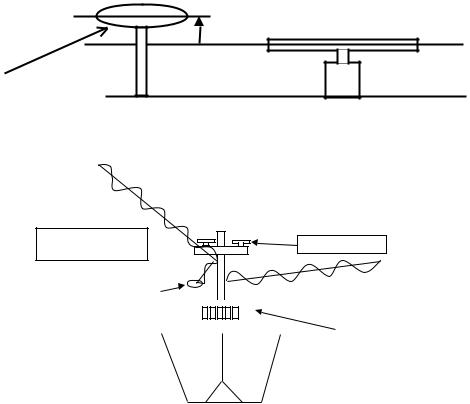

The antenna must be mounted above all other structures on the vessel to obtain an unobstructed view of the satellites regardless of vessel heading. Failure to do so will cause shadows and multipath reflection problems.

Mast

SC-series Antenna

SC-series Antenna

Radar

Radar Antenna

Antenna

Bridge

Example of proper installation

Installing the antenna below superstructures

If it is not possible to mount the antenna above all superstructures on the vessel, as shown in the illustration above, shading and multipath problems may occur on at least one heading, and possibly more. To possibly avoid those problems, observe the guidelines in this section.

NOTICE

If the antenna is installed below any superstructure, the installation must

be done over a two-day period, following the procedure in the service manual.

At least 12 hours are required to capture tracking data to measure multipath indexes and locate areas of shading.

2-1

2.INSTALLATION

•The horizontal separation between the antenna and masts must be as follows:

Mast diameter |

Separation distance (minimum) |

10 cm |

1.5 m |

30 cm |

3 m |

-80°  +80°

+80°

Separation degrees

•Keep the length of antenna cable in mind when selecting a mounting location. The cable comes in lengths of 15 meters (standard supply), or 30 m or 50 m (optional lengths).

•The field of view above the antenna should be as shown below, ±80° against zenith. To avoid reflections from masts and the like, locate the antenna well away from the shadows of the radar mast, etc.

Zenith

-80° +80°

SC-series antenna

SC-series antenna

SIDE VIEW

Antenna and field of view

•Referring to the figure below, locate the antenna away from objects which might block reception, such as a mast.

SC-series Antenna

Less than 10°

Mast, etc.

2-2

• Locate the antenna above the radar antenna, out of the radar beam.

Sc-series Antenna

Radar Antenna

Example of improper installation

Location influenced |

Radar Antenna |

|

by reflected wave. |

||

|

NO! UNSUITABLE LOCATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reception blocked by mast. |

||

SC-series |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

SC-series antenna located |

Antenna |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

below all other structures |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bridge |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Example of improper installation

2.1.2Display unit, processor unit

•Choose a location where vibration and shock are minimal.

•Install the units well away from locations subject to rain and water splash.

•Locate the units well away from air conditioner vents.

•Keep the units out of direct sunlight because of heat that can build up inside their cabinets.

•Choose a well-ventilated location.

•For the display unit, choose a location where it can be easily operated.

•Leave sufficient space around the units to permit access for maintenance. See the outline drawing for recommended maintenance space.

2-3

2. INSTALLATION

2.2Installing the Antenna Units

2.2.1SC-series antenna unit

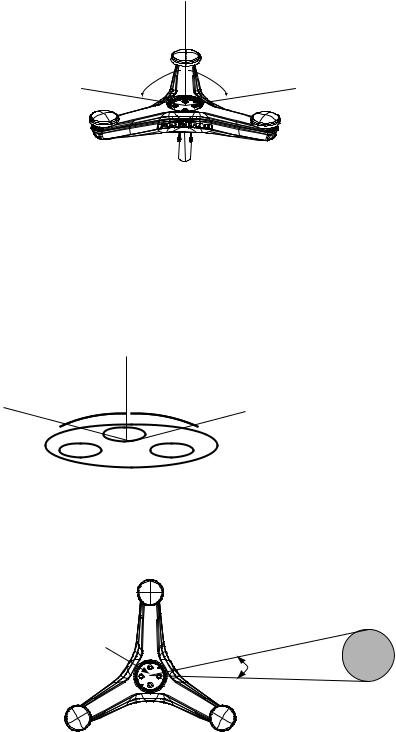

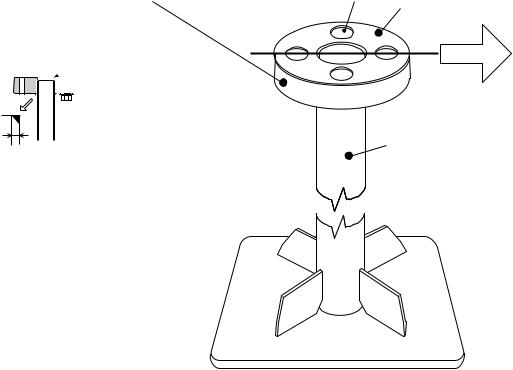

1.Prepare an installation post for the antenna in accordance with the illustration shown below.

Recommended Flange

(Option)

Name: Flange

Type: OP20-31

Code No.: 004-378-230

Weld all the way around.

Weld all the way around.

Post should be constructed from stainless steel and measure

4mm or larger in thickness. 3 mm or less

The width of welding should be within 3 mm from the mast so that the welding does not touch the spring washer.

f15 |

Gasket |

|

|

|

(supplied in installation materials) |

|

BOW |

|

Bow direction is |

|

between antennas |

|

f60.5 mm #1 and #2. |

Installation post

2-4

2. INSTALLATION

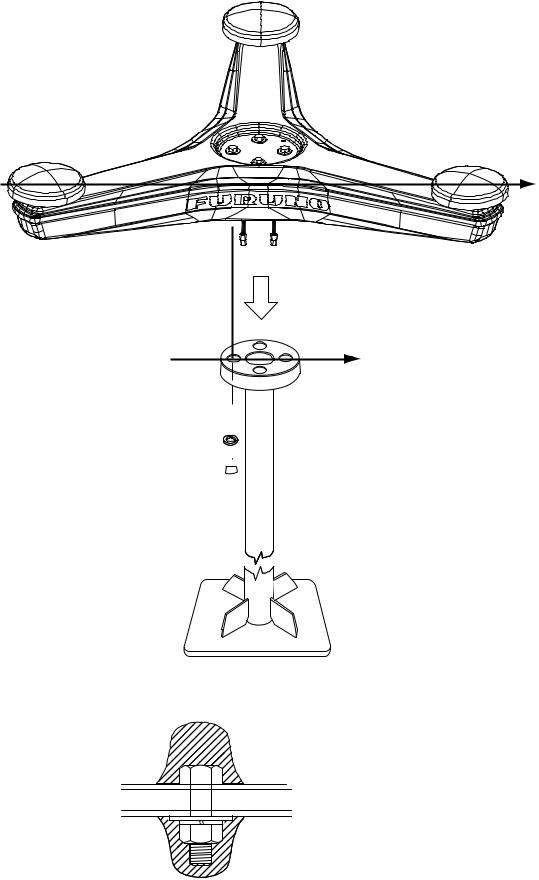

2. Fix the antenna unit to the post as shown below.

3

1 |

2 |

Set the antenna unit to the flange.

Flat washer

Spring washer

Nut

(Torque: 29.58 Nm)

Fix the antennas #1 and #2 on the fore-and-aft line of the ship, with the #2 a ntenna forward of the #1.

Fastening antenna unit to a post

3. Coat each nut, bolt and washer with silicone rubber for waterproofing.

Coat bolt, nut and washer completely with silicone rubber.

Coating bolt, nut and washer with silicone rubber

2-5

2.INSTALLATION

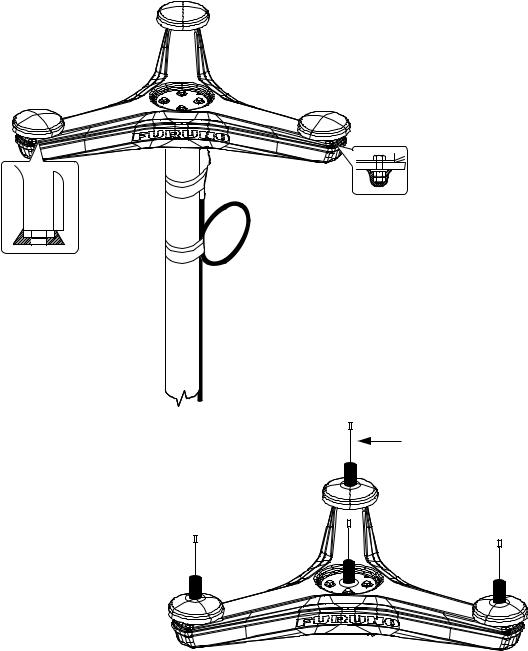

4.As shown below, make a loop in the antenna cable and fasten the antenna cable to the antenna post with two cable ties.

Coat bolt threads with Three Bond. Fasten bolt

with nuts and then coat nuts with Three Bond also.

Coat with Three Bond 1211 (supplied).

Fix antenna cable.

5. |

Coat bolt threads with |

|

|

Three Bond 1211. |

Bird-repellent fixture |

|

Fasten bolts with nuts. |

|

|

Coat nuts at the |

|

|

bottom of each |

|

|

antenna element with |

|

|

Three Bond 1211. |

|

6. |

Paint post and support |

|

|

plate with |

|

|

anti-corrosive paint. |

|

7. |

Attach “bird-repellent |

|

|

fixtures” (supplied) to |

|

|

each antenna element |

|

|

and center cover as shown right. |

Antenna element |

2-6

2. INSTALLATION

2.2.2DGPS antenna unit

Choose a mounting location for the DGPS antenna considering the points mentioned below. DPGS is not necessary for heading determination, however it can improve the accuracy of GPS position fixing

•Separate the DGPS antenna at least three meters from a radio antenna.

•Do not install the DGPS antenna within the radar beam.

1.Mount the DGPS antenna by one of the methods below.

•Screw it into a one-inch threaded pipe.

•Fasten it to a steel post (φ 35-φ 90) with stainless steel hose clamps (local supply).

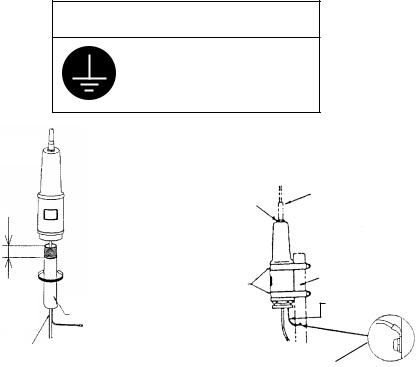

CAUTION

CAUTION

Ground the antenna to prevent receiving problems.

DGPS Antenna (preamp)

GR-800-SC-1-S

Whip Antenna

Spring Washer

50

Witt Threads (W25-14) Pitch: 1.8143 Qty: 14

Antenna cable

Hose

Clamp

Pipe f27.2

Ground to the ship’s body

as shown the right figure.

Post (f35-f90)

Ground Wire (0.3 m)

Note: Screw the pipe into the preamp BEFORE mounting the pipe.

Tap M4 threads in mast. Fasten ground wire with an M4 screw.

Mounting onto a threaded pipe |

Mounting with hose clamps |

Mounting the DGPS antenna

2.Set the spring washer to the whip antenna (local supply) and screw the whip antenna into the antenna housing. Coat the washer with silicone sealant to prevent loosening.

3.Drill a tapping hole in the post for an M4 screw and fasten the ground wire there.

2-7

2.INSTALLATION

4.The DGPS antenna is supplied with a 15 m cable. If extension is necessary use the extension cable (option). Cover the extension connectors with vulcanizing tape and vinyl tape, for waterproofing. Tie tape ends with a cable tie.

Extension Cable: Type: OP08-15-30, Code No.: 004-396-440 (30 m) Type: OP08-15-60, Code No.: 004-396-450 (60 m)

Name |

Type |

|

|

Code No. |

Qty |

Remarks |

||

Connector |

TNC-SA-JJ |

|

000-139-113 |

1 |

|

|||

|

TNC-PS-3D |

L30M |

000-139-078 |

|

30 m, connector at |

|||

Cable |

|

|

|

|

|

1 |

both ends |

|

TNC-PS-3D |

L60M |

000-139-080 |

60 m, connector at |

|||||

|

|

|||||||

|

|

|

|

|

|

|

both ends |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Waterproofing the extension connector

For coaxial cable RG-10UY (local supply, max. length 60 m), use the optional antenna cable set.

Antenna cable set |

Type: OP08-17, Code No.: 004-392-510 |

|||

|

|

|

|

|

Name |

Type |

Code No. |

Qty |

Remarks |

Converter Cable Assy. |

NJ-TP-3DXV-1 |

000-123-809 |

2 |

|

Connector |

TNC-SA-JJ |

000-139-113 |

1 |

|

Connector |

N-P-7 |

000-501-514 |

2 |

|

|

*TNC-SA-JJ |

|

|

*N-P-7 |

|

|

|

Processor |

15 m |

RG-10UY |

Unit |

|

* Converter cable assy. (supplied with antenna cable set)

Cable connection when using cable RG-10UY

2-8

2. INSTALLATION

2.3Installing the Processor Unit

The processor unit should be mounted aligned with the ship’s fore-and-aft line. It can be mounted on the deck, bulkhead, or on the underside of a desk. Choose a mounting location which allows you to easily view the power lamp on the top of the unit and which is within ± 2.5° of the ship’s fore-and-aft line.

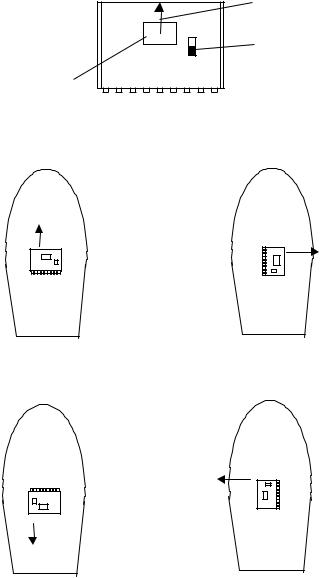

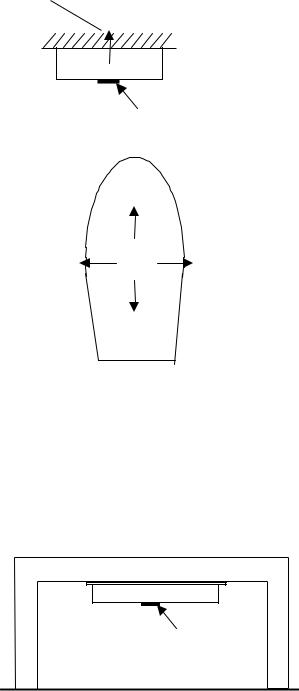

2.3.1Deck mount

1.The processor unit is factory adjusted for deck mounting. Fasten the processor unit to the mounting location with tapping screws (5 x 20, 4 pcs.). The unit can be oriented in one of the directions shown in the figure below. After the unit is installed you will specify the mounting method from the menu.

Mount processor unit |

|

Reference Direction |

|

so reference |

|

|

|

direction is within |

|

|

|

±2.5° of |

|

|

POWER switch |

fore-and-aft line. |

|

|

|

Name plate |

|

|

(power lamp) |

|

|

|

|

|

Connectors |

|

|

|

Processor Unit, top view |

||

Bow |

|

|

Bow |

|

|

|

|

|

Mounting Method: "Floor" |

Mounting Method: "Floor" |

|

|

|

(Deck) |

(Deck) |

|

Mounting Direction: A |

Mounting Direction: B |

|

Port |

Starboard |

Port |

Starboard |

|

|||

|

DIRECTION "A" |

DIRECTION "B" |

|

Stern |

|

|

Stern |

Bow |

|

|

Bow |

|

Mounting Method: "Floor" |

Mounting Method: "Floor" |

|

|

|

(Deck) |

(Deck) |

|

Mounting Direction: C |

Mounting Direction: D |

|

Port |

Starboard |

Port |

Starboard |

DIRECTION "C" |

DIRECTION "D" |

Stern |

Stern |

|

Processor unit orientation, deck mounting

2.Fasten the ground wire between the ground terminal on the processor unit and the ship’s superstructure.

2-9

2. INSTALLATION

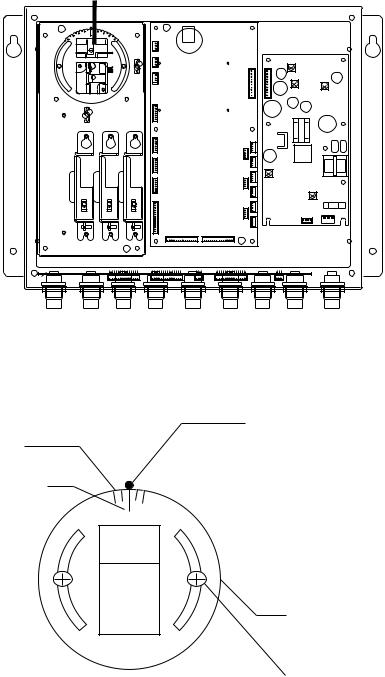

2.3.2Bulkhead mount

For mounting on a bulkhead, use the bulkhead mounting plate supplied with the installation materials.

1.Unfasten four screws from the top cover to open the front panel.

2.Unfasten two screws to dismount the angular rate sensor.

Angular Rate Sensor

BEACON

20P8171

Processor unit, top view

3.Fasten the bulkhead mounting plate to the angular rate sensor. Align the center graduation on the angular rate sensor with the hole of the bulkhead mounting plate and tighten fixing screws.

|

Hole of bulkhead |

Scale |

mounting plate |

|

|

Center Mark |

|

Angular Rate Sensor

Mounting Base

Fixing Screw

Angular rate sensor, top view

2-10

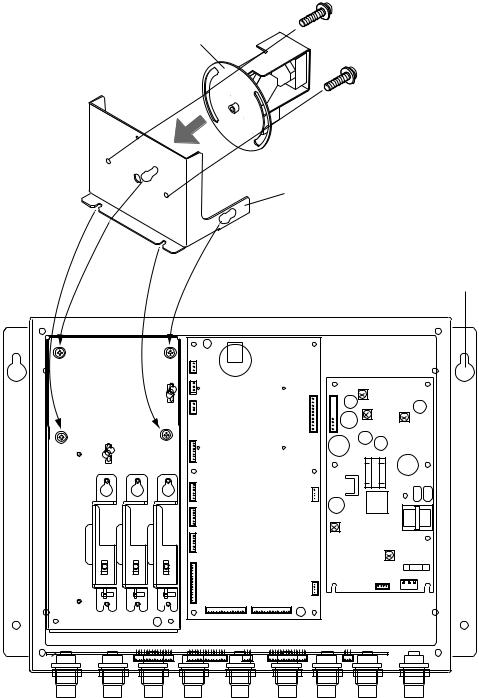

2. INSTALLATION

4.Loosen four screws on the angular rate sensor mounting base, and then fasten the bulkhead mounting plate to the angular rate sensor mounting base.

Angular Rate Sensor

Angular

Rate

Sensor

Mounting

Base

BEACON

20P8171

Bulkhead Mounting Plate

Top Fixing

Hole (x2)

HEAD3 HEAD2 HEAD1

HEAD3 HEAD2 HEAD1

Processor unit, top view

5.Close the top cover of the processor unit.

6.Partially screw in two tapping screws for the top fixing holes of the processor unit in the mounting location. Hang the processor unit on the tapping screws, using the top fixing holes. Screw in two tapping screws for the bottom fixing holes, and then tighten the top fixing holes.

2-11

2. INSTALLATION

The unit can be oriented as shown in the figure below. After the unit is installed you will specify the mounting method from the menu.

Reference Direction

Bulkhead

Mount processor unit so reference direction is within

±2.5° of fore-and-aft line.

Name Plate (other side)

|

Direction |

|

Mounting Method: "Wall" |

|||||

|

A |

|

(Bulkhead) |

|||||

|

|

|

|

|

|

|

|

Mounting Direction: A |

|

|

|

|

|

|

|

||

Direction D |

|

|

|

|

|

|

|

Direction B |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||

Mounting Method: "Wall" |

|

|

|

|

|

|

|

Mounting Method: "Wall" |

|

|

|

|

|

|

|

||

(Bulkhead) |

|

|

|

|

|

|

|

(Bulkhead) |

|

|

|

|

|

|

|||

Mounting Direction: D |

Direction |

|

Mounting Direction: B |

|||||

|

C |

|

Mounting Method: "Wall" |

|||||

|

|

|

|

|

|

|

|

(Bulkhead) |

|

|

|

|

|

|

|

|

Mounting Direction: C |

Processor unit orientation, bulkhead mounting

7.Fasten the ground wire between the ground terminal on the processor unit and the ship’s superstructure.

2.3.3Installation on the underside of a desk

The processor unit may be mounted on the underside of a desk as shown in the figure below. Do not install it on the overhead.

Desk

Name Plate

Installation of processor unit on the underside of a desk

2-12

2. INSTALLATION

The reference direction is as shown below. The mounting method is the same as that for mounting on the deck.

Reference Direction

Mount processor unit so reference direction is within ±2.5° of fore-and-aft line.

POWER switch |

|

Connectors |

|||

(power lamp) |

|

||||

Processor Unit, rear view |

|||||

|

|

||||

Bow |

|

|

|

Bow |

|

|

Mounting Method: Invert |

|

|||

|

Mounting Direction: A |

|

|||

Port |

Starboard |

|

Port |

||

Stern |

DIRECTION "A" |

Stern |

Bow |

Bow |

|

Mounting Method: Invert |

|

Mounting Direction: C |

Port |

Starboard |

Port |

DIRECTION "C"

Stern |

Stern |

Name plate (other side)

Mounting Method: Invert

Mounting Direction: B

Starboard

Starboard

DIRECTION "B"

Mounting Method: Invert

Mounting Direction: D

Starboard

DIRECTION "D"

Processor unit orientation, installation on the underside of a desk

Mount the processor unit on a level surface with its name plate facing the bow, stern, port or starboard.

2-13

2. INSTALLATION

2.3.4Adjusting for orientation error

It may be impossible to perfectly align the processor unit on the fore-and-aft or port-and-starboard line. Open the top cover, loosen the two fixing screws on the angular rate sensor and turn. For example, if the orientation error is 2.5° to port, rotate the sensor 2.5° starboard. The range of adjustment is -45° to +45°. Close the top cover after completing the adjustment.

Fore-aft line or Port-starboard direction

Reference

Processor Unit

Direction

Alignment hole on processor unit

Scale, every 2.5°

Bulkhead Mounting

Plate

Fixing Screw

Angular rate sensor, top view

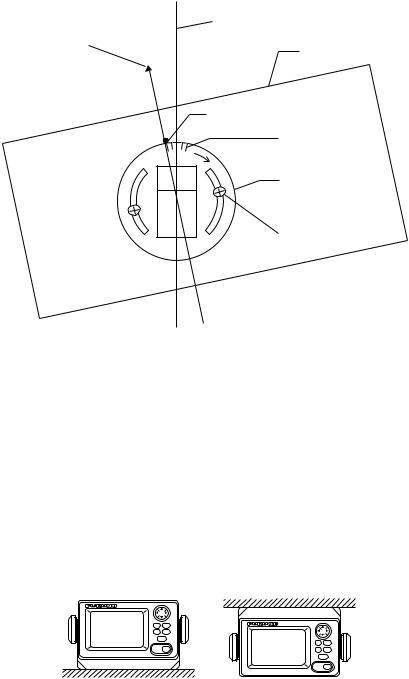

2.4Installing the Display Unit

2.4.1Desktop, overhead mounting

1.Fasten the hanger to the mounting location with four tapping screws (supplied). See the outline drawing for mounting dimensions.

2.Screw the knobs into the display unit.

3.Set display unit to the hanger and tighten the knobs.

4.Run the ground wire between the ground terminal on the display unit and the ship’s superstructure.

Desktop |

Overhead |

Display unit mounting methods

2-14

2. INSTALLATION

2.4.2Flush mounting

Two types of flush mounts are available. See the outline drawing at the back of the manual for details.

Flush mount “F” |

|

|

|

|

|

Flush mount “F” kit |

Type: OP20-29, Code No: 000-041-405) |

||||

|

|

|

|

|

|

|

Name |

|

Type |

Code No. |

Qty |

|

Cosmetic Panel |

|

20-016-1051 |

100-251-370 |

1 |

|

Tapping Screw |

|

5X20 |

000-802-840 |

4 |

|

Hex Bolt |

|

M6X12 |

000-862-127 |

2 |

|

Spring Washer |

|

M6 |

000-864-260 |

2 |

1.Make a cutout in mounting location. The dimensions are 183(W) x 92(H) mm.

2.Fasten the cosmetic panel to the display unit with hex bolts and flat washers.

3.Fasten the display unit to the mounting location with tapping screws.

Flush mount “S” |

|

|

|

|

Flush mount “S” kit |

Type: OP20-17, Code No.: 000-040-720) |

|||

|

|

|

|

|

Name |

|

Type |

Code No. |

Qty |

Flush Mount Fixture |

|

20-007-2401 |

100-183-190 |

2 |

Wing Bolt |

|

M4X30 |

000-804-799 |

4 |

Wing Nut |

|

M4 |

000-863-306 |

4 |

Hex Bolt |

|

M6X12 |

000-862-127 |

2 |

Spring Washer |

|

M6 |

000-864-260 |

2 |

1.Make a cutout in the mounting location. The dimensions are 167(W) x 92(H) mm.

2.Place the display unit in the cutout.

3.Fix the display unit to the two flush mount fixtures with hex bolts and spring washers.

4.Screw the wing nut on the wing bolt.

5.Fix the display unit with the wing bolt and then tighten the wing nut.

Flush mount “S”

2-15

Loading...

Loading...